Catalytic cracking method for producing propylene

A catalytic cracking and propylene technology, applied in catalytic cracking, cracking, hydrocarbon cracking and hydrocarbon production, etc., to achieve the effects of high high-value product yield, high heavy oil conversion depth, high propylene yield and butene yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

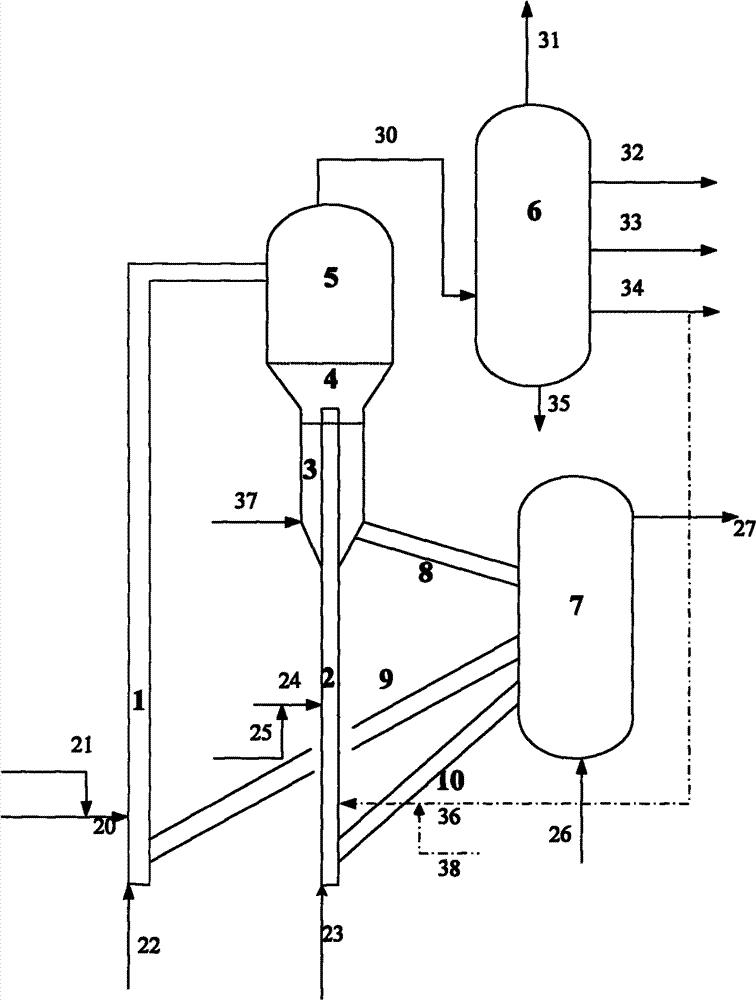

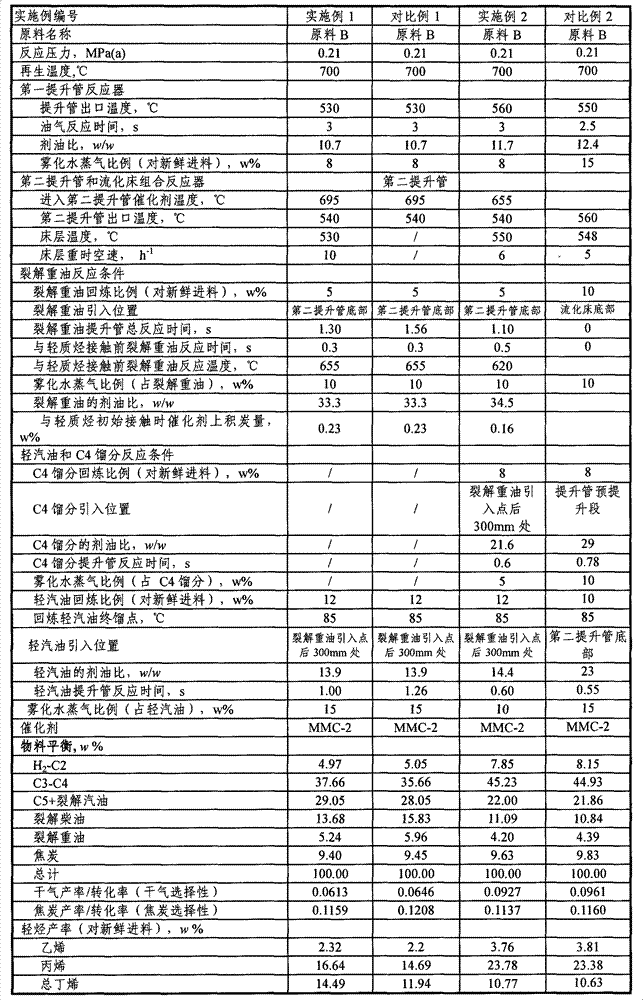

[0043] The experiment was carried out in a medium-sized riser catalytic cracking unit. The inner diameter of the first riser reactor of this medium-sized device is 16 mm, and the length is 3800 mm. The inner diameter of the second riser reactor is 16 mm, and the length is 3200 mm. The outlet of the second riser reactor is connected to the fluidized bed reactor. The inner diameter of the fluidized bed reactor is 64 mm and the height is 600 mm, and its configuration is as follows figure 1 As shown, the test was operated in the way of back refining. A stream of high-temperature regenerated catalyst is introduced into the riser reactor 1 through the regenerated inclined pipe 9, and flows upward under the action of the pre-lift medium (steam); the feed oil B is preheated and mixed with atomized water vapor, and then passes through the feed nozzle Enter the riser reactor 1, contact with the hot regenerant to carry out the catalytic conversion reaction, the reacted oil gas and catal...

Embodiment 2

[0047] Experiments were carried out with reference to the method of Example 1, and the refractory C4 fraction from the product separation system 6 was added to enter the second riser to participate in the reaction, and the reaction operating parameters were adjusted. The reaction conditions and reaction results are shown in Table 3

Embodiment 3

[0049] This example is performed on a medium-sized device, such as figure 1 As shown, in this medium-sized device for continuous reaction-regeneration operation, the internal diameter of riser 1 is 16 mm, and the length is 3800 mm; the internal diameter of riser 2 is 16 mm, and the length is 3200 mm; Bed 3, fluidized bed 3 has an inner diameter of 64 mm and a height of 600 mm. The raw material is atmospheric heavy oil B, and the catalyst is MMC-2. The first stream of high-temperature regenerated catalyst is introduced into the bottom of riser reactor 1 from regenerator 7 through regenerated catalyst delivery pipe 9, and flows upward under the action of steam pre-lifting medium, and then is introduced into riser reactor 1 through pipeline 20. B contact reaction, then enter the settler 5 for oil agent separation, the separated oil and gas are introduced into the product separation system 6, and the catalyst enters the fluidized bed reactor 4; the second regenerated catalytic cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com