Method for producing methanol synthetic gas with hydrocarbon gas and coal as raw materials

A technology for methanol synthesis gas and gaseous hydrocarbons, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve problems such as high content, less hydrogen and more carbon in synthesis gas, more hydrogen and less carbon in synthesis gas, etc. Achieve the effects of increasing methanol content, reasonable hydrogen-carbon ratio, and reducing conversion load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

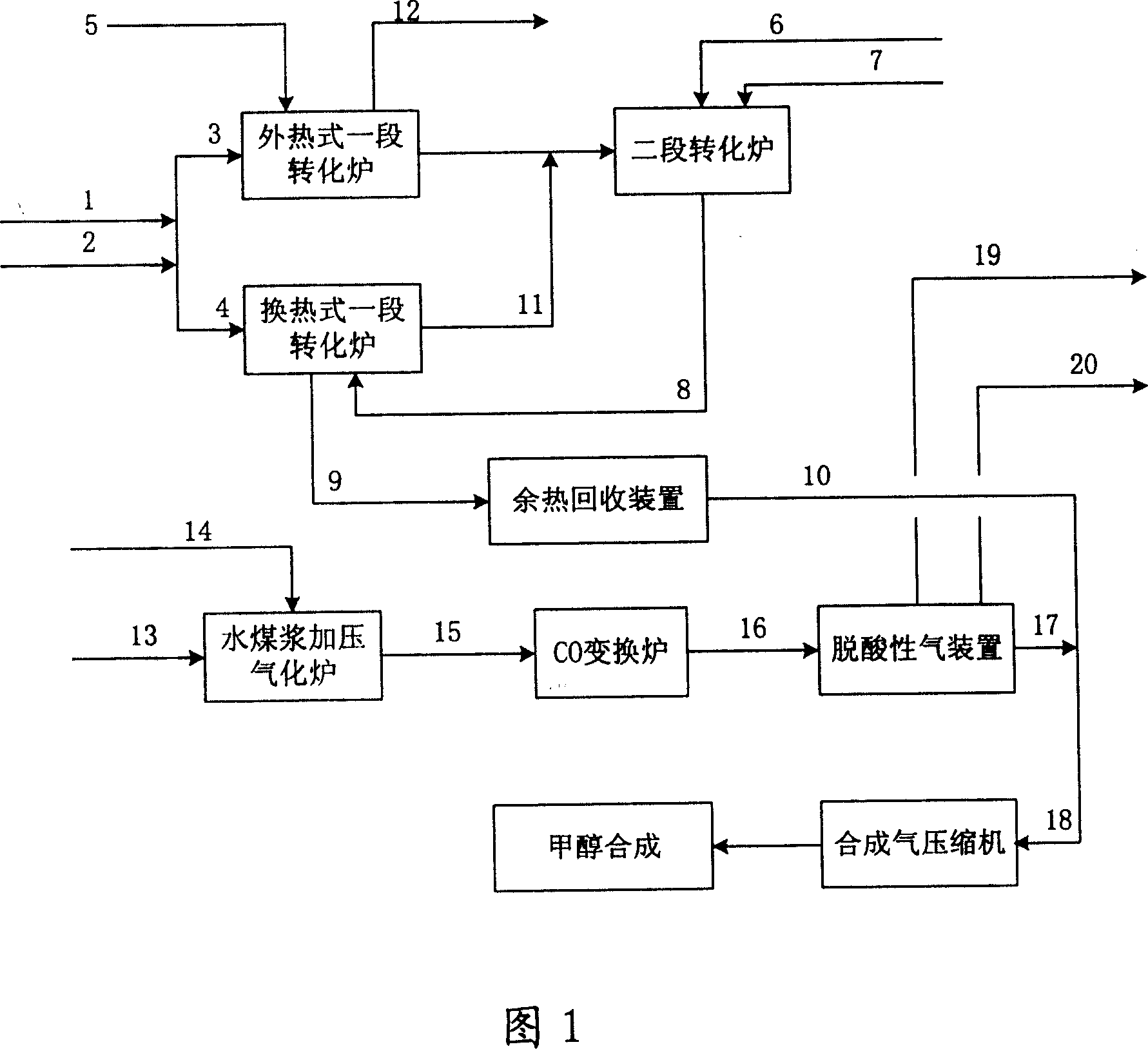

[0046] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0047] As shown in Figure 1, it is a schematic diagram of the structural relationship of the process system of the present invention and the flow of various reactants. As can be seen from Fig. 1, this method provided by the present invention takes gaseous hydrocarbon and coal as raw material production methanol synthesis gas is such:

[0048] Raw material natural gas 1 with a flow rate of 13.8Kmol / h, a pressure of 3.8MPa, and a temperature of 350°C that has been refined and desulfurized to a sulfur content of 4 The conversion reaction with water vapor, the first-stage reforming gas exiting the externally heated first-stage reformer has a pressure of 3.5MPa and a temperature of 800°C, and the residual CH 4 Content 6%. Another stream of mixed gas 4, accounting for about 45% of the total, goes to the reforming tube of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com