Patents

Literature

39results about How to "Reduce recirculation air volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

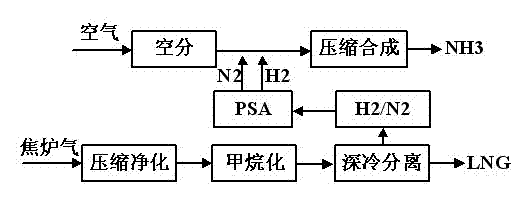

Technology for preparing liquefied natural gas and liquid ammonia by using coke oven gas

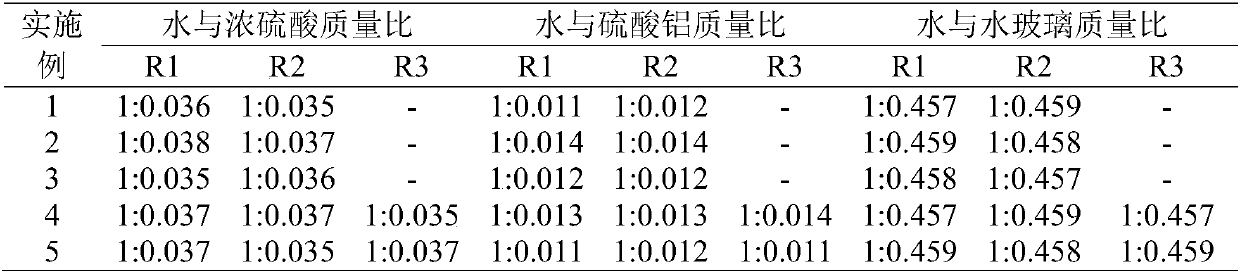

InactiveCN102517108AIncrease added valueReduce in quantityGaseous fuelsBulk chemical productionMethanationCoke oven

The invention discloses a technology for preparing liquefied natural gas and liquid ammonia by using coke oven gas. The coke oven gas is subjected to the steps of compression, purification, methanation, cryogenic separation and liquefaction of synthetic natural gas, variable pressure adsorptive separation and liquid ammonia preparation with hydrogen rich gas, so that the liquefied natural gas (LNG) of which methane purity is more than 99 percent and the liquid ammonia reaching national first level standard are obtained. By the technology, the hydrogen byproduct of the coke oven gas for preparing the LNG is fully utilized; effective ingredients of the coke oven gas such as H2, N2, CH4, CO and CO2 are furthest utilized; the CO and the CO2 are methanated, so that the yield of the CH4 is improved by about 1 / 3; the liquefied CH4 is used as the LNG and sold; and the rest nitrogen-containing hydrogen-rich gas is used as a raw material for synthesizing ammonia, so that the additional value of the coke oven gas is improved, and reliable raw material guarantee is provided for developing downstream products with high additional values and prolonging the product chain.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

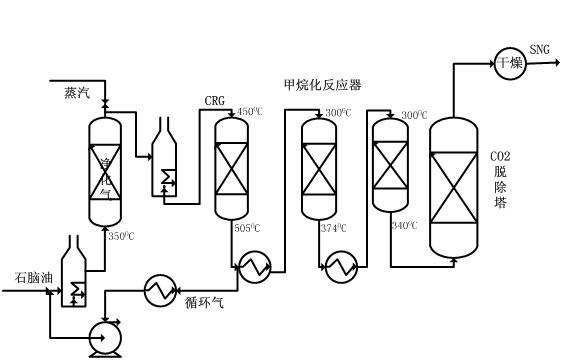

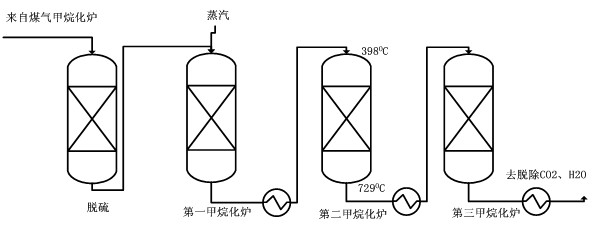

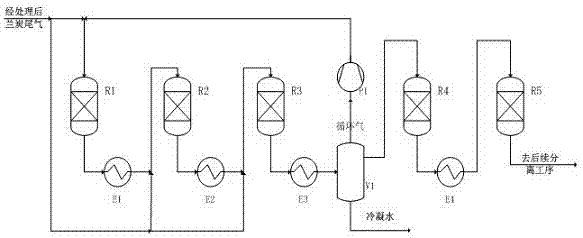

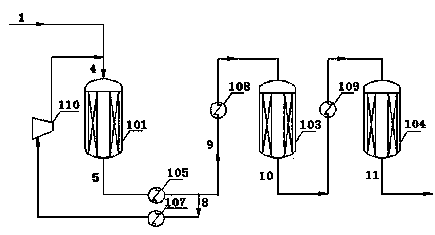

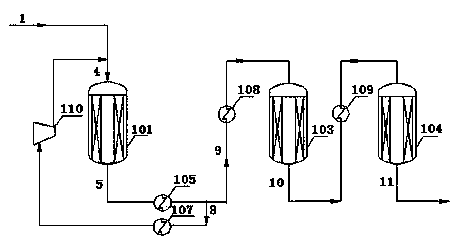

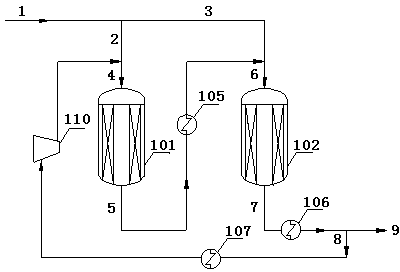

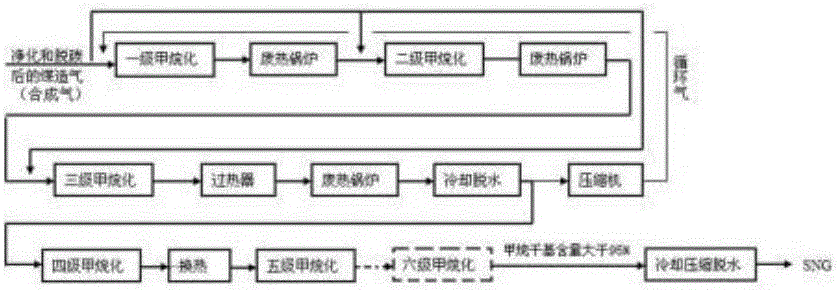

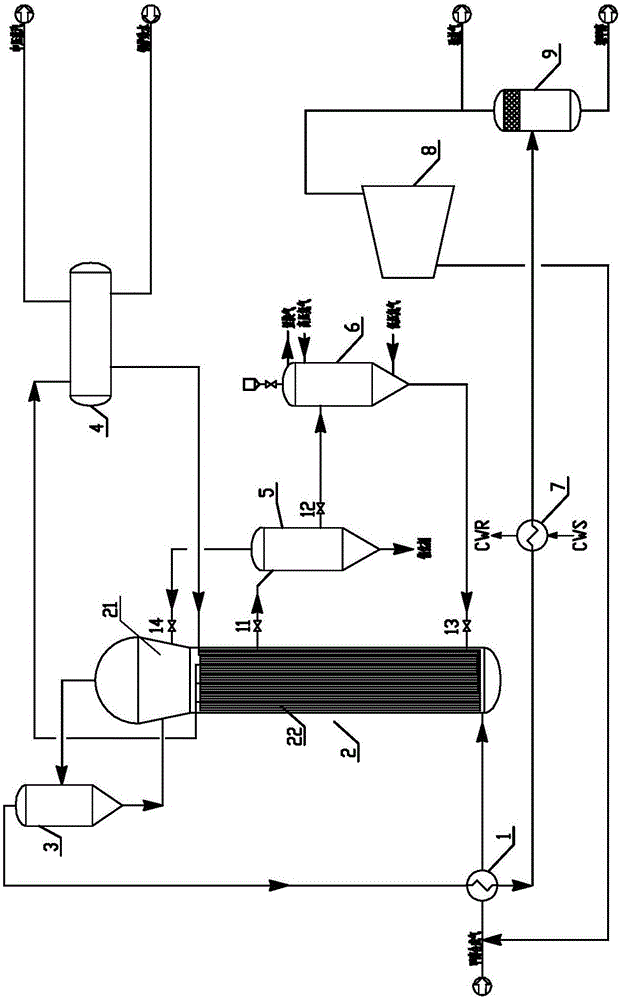

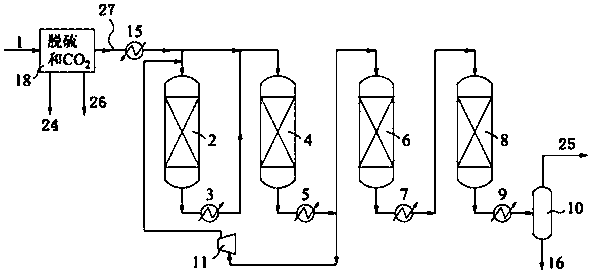

New process for synthesizing natural gas by methanation of coke oven gas

InactiveCN102021054AControl concentrationControl outlet gas temperatureGaseous fuelsMethanationEngineering

The invention belongs to the technical field of coke oven gas application, and particularly relates to a new process for synthesizing natural gas by methanation of coke oven gas. After the coke oven gas diluted by recycle gas passes through a methanation reactor bed, the coke oven gas and the recycle gas in a certain ratio enter a methanation reactor, the gas at the inlet of the methanation reactor of each stage consists of CO and CO2 which are less than 7 percent, the temperature of the inlet of the methanation reactor of each stage is controlled to be between 220 and 400 DEG C, and heat exchange is performed in the reactor of the last stage through a heat exchanger. The process can protect the environment and save energy; on technology, the methanation reaction process can sharply reduce the number of the heat exchangers and make full use of heat generated in the reaction; the process can well control the composition of the raw material gases entering the methanation reactor of each stage; and meanwhile, the process effectively controls the temperature of the gas at the outlet of the methanation reactor. The process is favorable for selection of reactor materials, reduces the quantity of the recycle gas, and reduces energy consumption so as to reduce the cost.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

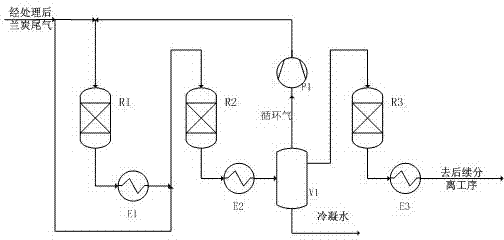

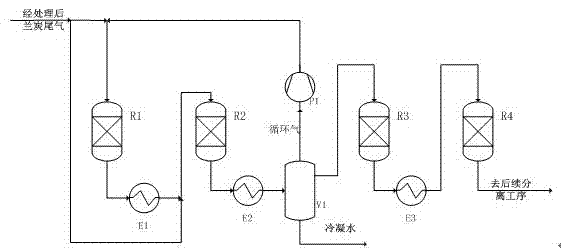

Circulating method for preparing natural gas by multi-stage methanation of semi-coke tail gas

ActiveCN102776043AReduce heat resistance requirementsExtended service lifeGaseous fuelsPtru catalystMethanation

The invention discloses a circulating method for producing a natural gas by multi-stage methanation of semi-coke tail gas, and belongs to the field of preparation methods of natural gas. The preparation method comprises the following steps that: the purified semi-coke tail gas the hydrogen to carbon ratio of which is adjusted is used as a raw material, and the multi-stage methanation reaction is adopted to obtain a methane-rich gas; a front-end methanation part and a back-section methanation part are comprised, wherein the front-end methanation part is formed by connecting at least two methanation furnaces in series, and the back-section methanation part is formed by connecting more than one methanation furnace in series; and the obtained methane-rich gas is separated to obtain a product natural gas. The methanation process has strong controllability, the temperature of the methanation reaction can be controlled by adjusting the recycle gas, the raw material inlet temperature and the steam addition amount and other ways, and the temperature of the methanation reaction is controlled below 500 DEG C. The lower methanation operating temperature is not only favorable for performing the methanation reaction, reduces the requirements of the process on a material of a reactor and heat resistance of a catalyst, but also is favorable for prolonging the service life of the methanation reactor and the catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

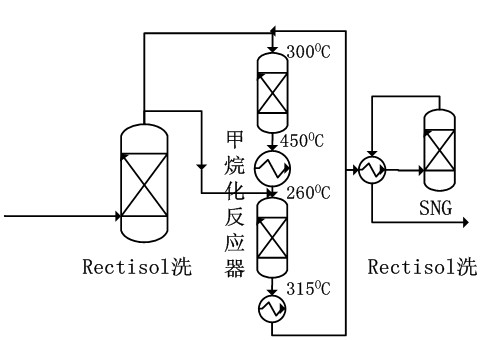

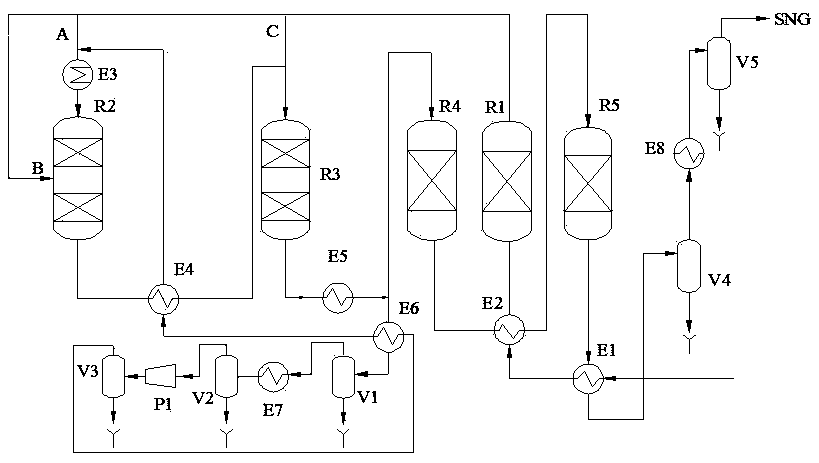

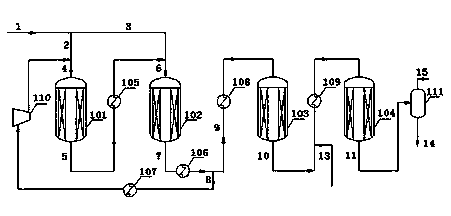

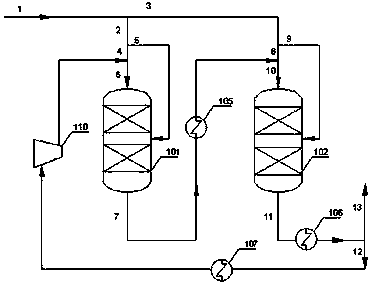

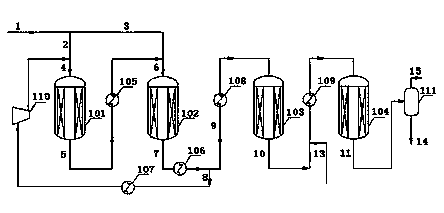

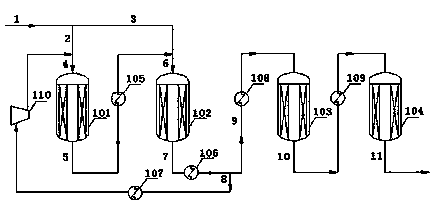

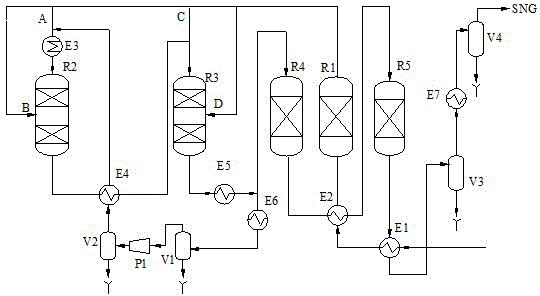

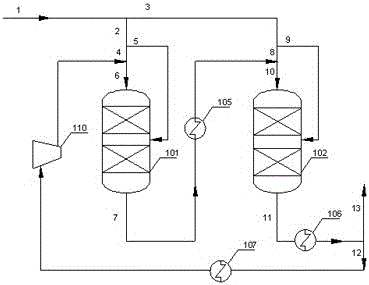

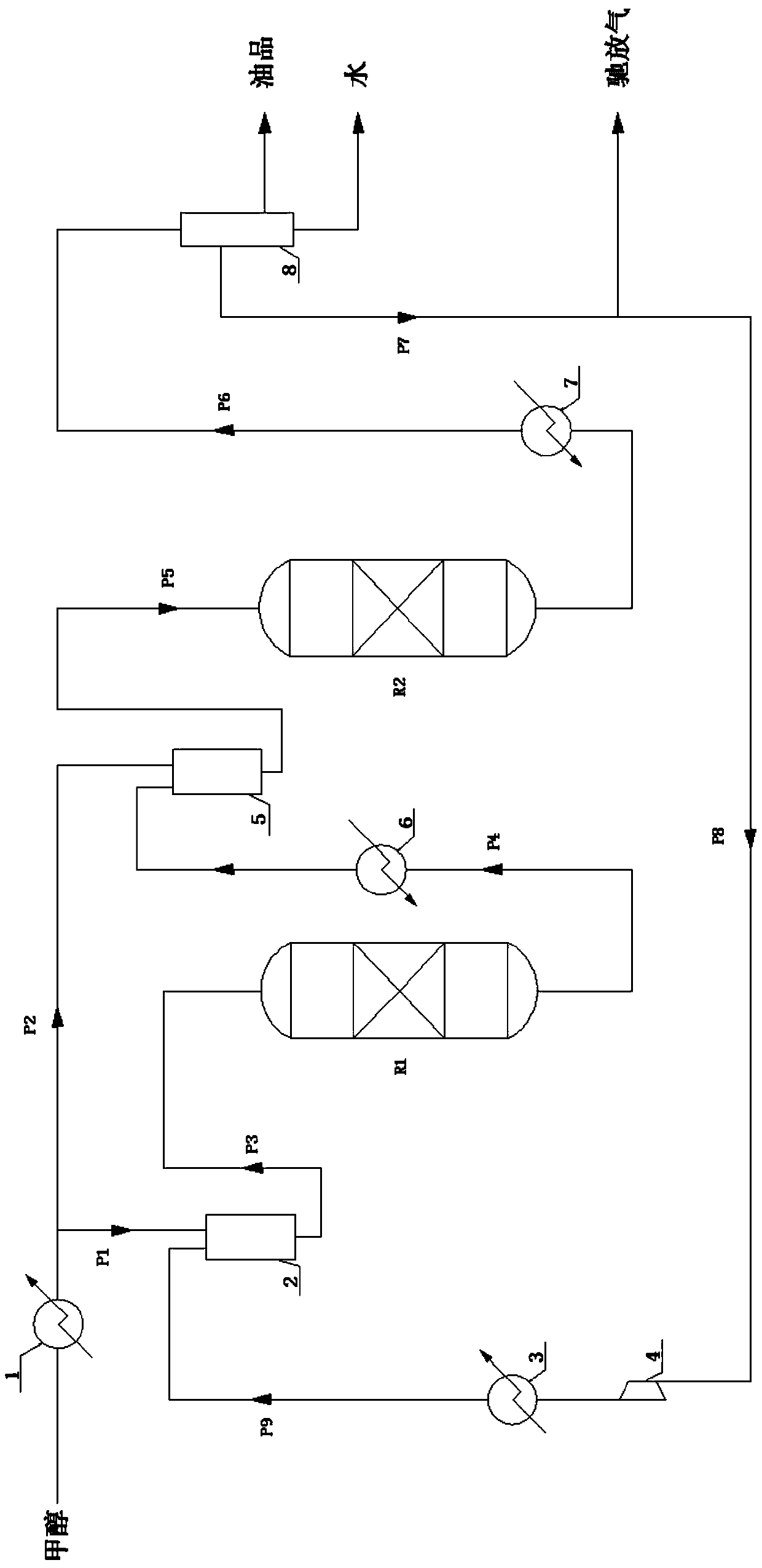

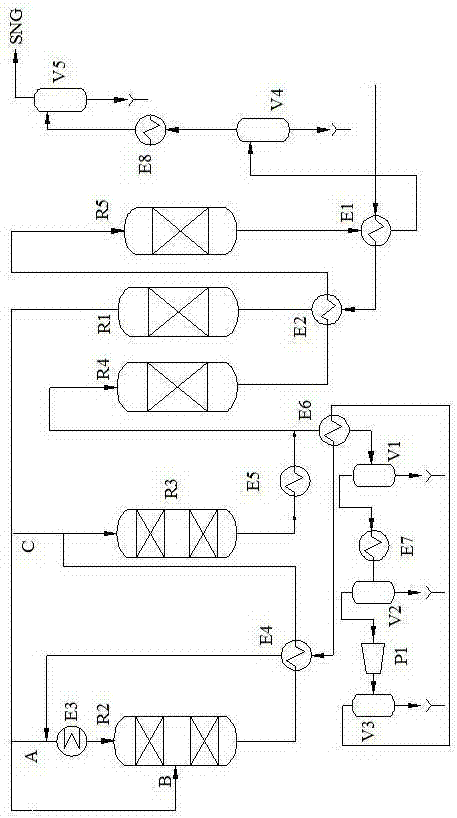

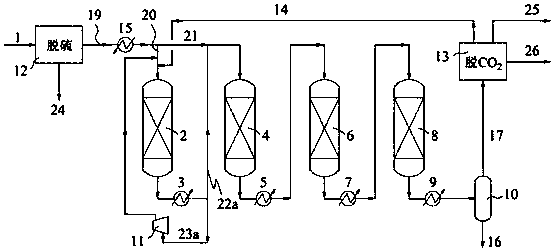

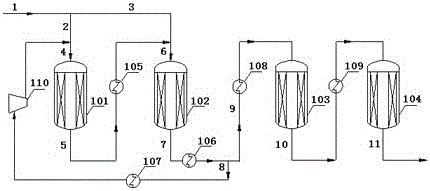

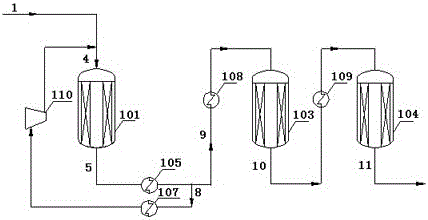

Methanation technique for preparing synthetic natural gas from coal-based synthetic gas

ActiveCN103509618AReduce recirculation air volumeImprove energy utilizationGaseous fuelsSyngasChemical industry

The invention belongs to the field of energy chemical industry, and discloses a methanation technique for preparing synthetic natural gas from coal-base synthetic gas, which comprises the following steps: synthetic gas, which is obtained by carrying out fine desulfurization on methane synthetic gas from a gas purification section, is divided into three fresh gas streams A, B and C; first-section inlet gas formed by mixing the fresh gas A and circulation gas enters a first section of a methane synthesis reactor, second-section inlet gas formed by mixing first-section outlet gas and fresh gas B enters a second section of the first methane synthesis reactor, and second-section outlet gas of the first methane synthesis reactor and fresh gas C are mixed and enter a second methane synthesis reactor; after outlet gas of the second methane synthesis reactor is cooled, part of gas enters a circulating compressor to be pressurized and returns to the inlet of the first section of the first methane synthesis reactor as circulating gas, and the rest of gas sequentially enters a third methane synthesis reactor and a fourth methane synthesis reactor to be subjected to methane synthetic reaction; and outlet gas of the fourth methane synthesis reactor, in which the methane content is higher than 94% on dry basis, is cooled and dehydrated to obtain satisfactory synthetic natural gas SNG.

Owner:CHINA PETROLEUM & CHEM CORP +1

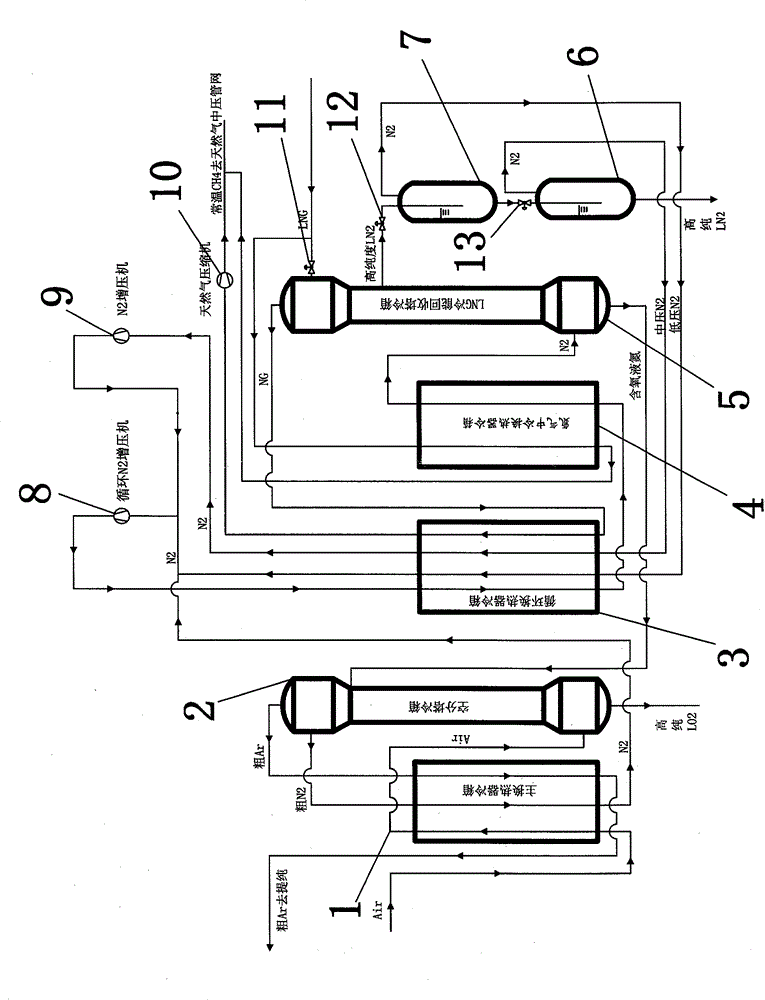

Method for air separation production on liquid oxygen and liquid nitrogen through LNG (Liquefied Natural Gas) cold energy

InactiveCN104807289AFull and efficient useLow stress levelSolidificationLiquefactionEnergy recoveryHigh pressure

The invention provides a method for air separation production on the liquid oxygen and the liquid nitrogen through the LNG (Liquefied Natural Gas) cold energy. According to the all-liquid air separation method, the investment is less, the energy-saving rate is high, the energy consumption is low, the cold loss is small, the output of the liquid nitrogen and the liquid oxygen is large, and the production cost can be greatly reduced. According to the technical scheme, the implementation steps of the method includes that the raw nitrogen from an air separation tower cold box is reheated through a main heat exchanger cold box to join the medium-pressure and low-temperature nitrogen separated through a gas and liquid separation tank to be reheated through a circulating heat exchanger cold box, the reheated low-pressure and low-temperature nitrogen is reheated through the circulating heat exchanger cold box, and the medium-pressure and normal-temperature nitrogen boosted through a nitrogen booster enters a circulating nitrogen booster to be boosted into the high-pressure nitrogen; the high-pressure nitrogen is precooled through the circulating heat exchanger cold box; the precooled high-pressure nitrogen is fed into the air separation tower cold box to serve as an air separation cold source, the high-purity and high-pressure liquid nitrogen is obtained at the bottom of an upper tower of an LNG cold energy recovery tower cold box, the high-pressure liquid nitrogen is throttled through a throttling valve to obtain the medium-pressure liquid nitrogen and the medium-pressure nitrogen, and the medium-pressure liquid nitrogen and the medium-pressure nitrogen are throttled through the throttling valve to obtain a low-pressure liquid nitrogen product and the low-pressure nitrogen.

Owner:刘继福

Method of producing substitute natural gas by methanation of synthesis gas

The invention relates to a method of producing substitute natural gas by methanation of synthesis gas, mainly solving problems, namely large using amount of recycle gas and high energy consumption of compressors, of high-temperature methanation reactions in the prior art. According to the technical scheme adopted by the method, the method comprises: a) a step of providing a high-temperature methanation reaction zone including n-stage series-connected reactors, with the n being not less than 2; b) a step of dividing the synthesis gas raw materials containing H2, CO, CO2 and H2O into n sections and respectively feeding the n sections of the synthesis gas raw materials into inlets of the reactors at all stages in the high-temperature methanation reaction zone, wherein a stream flowing out of an outlet of each of the reactors except the reactor at the final stage enters the inlet of the reactor at the next stage, the stream Vn flowing out from the reactor at the final stage is divided into Vn' and Vn'', and the stream Vn' is condensed and circulated to the inlet of the reactor at the first stage; c) a step of providing a low-temperature methanation reaction zone including m-stage series-connected reactors, with the m being not less than 2; and d) a step of feeding the stream Vn'' into the low-temperature methanation reaction zone, and substitute natural gas is obtained after the reaction. By the technical scheme, the problems are solved well and the method can be used in industrial production of the substitute natural gas from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

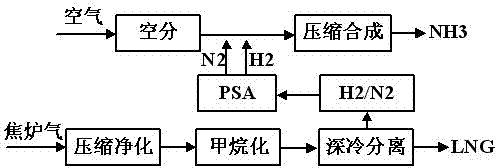

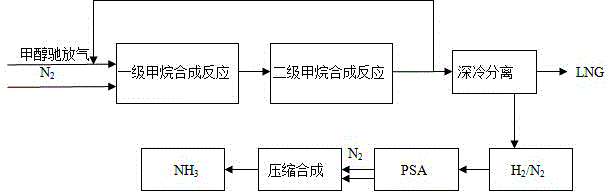

Process for synthesizing LNG (Liquefied Natural Gas) and coproducing liquid ammonia by using methanol purge gas

InactiveCN105733715ANo impuritiesHigh methane contentGaseous fuelsAmmonia preparation/separationChemical industryNitrogen

The invention belongs to the field of energy and chemical industry, and discloses a process for synthesizing LNG and co-producing liquid ammonia by utilizing methanol purge gas. Under the action of a methane synthesis catalyst, the methanol purge gas produced from methanol synthesis is directly preheated to 250°C~350°C and enters the The methane synthesis unit performs a methane synthesis reaction. The obtained methane gas enters the cryogenic separation and liquefaction process after being cooled and dehydrated. Liquefied natural gas (LNG) is obtained in the bottom of the rectification tower. The yield of LNG is 95%~100%. Hydrogen gas and hydrogen-rich gas enter the pressure swing adsorption separation process after recovery of cooling capacity. The hydrogen-rich gas is separated from hydrogen, nitrogen and methane in the pressure swing adsorption separation device to obtain hydrogen, nitrogen and methane respectively, and then the nitrogen is pressurized and mixed with hydrogen to enter the ammonia synthesis process according to the hydrogen-nitrogen ratio of 2.9~3.1 , hydrogen and nitrogen that meet the conditions are mixed and then pressurized to 12.0MPa~30.0MPa to enter the ammonia synthesis tower to produce liquid ammonia.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of producing substitute natural gas by methanation of synthesis gas

The invention relates to a method of producing substitute natural gas by methanation of synthesis gas, mainly solving problems, namely large using amount of recycle gas, high energy consumption of compressors, and excess of the H2 component or the CO2 component in substitute natural gas products, of high-temperature methanation reactions in the prior art. According to the technical scheme adopted by the method, the method comprises: a) a step of providing a high-temperature methanation reaction zone including n-stage series-connected reactors; b) a step of dividing the synthesis gas raw materials into n sections and respectively feeding the n sections of the synthesis gas raw materials into inlets of the reactors at all stages in the high-temperature methanation reaction zone, wherein the stream Vn flowing out from the reactor at the final stage is divided into Vn' and Vn'' and the stream Vn' is condensed and circulated to the inlet of the reactor at the first stage; c) a step of providing a low-temperature methanation reaction zone including m-stage series-connected reactors; and d) a step of supplementing a stream I containing CO2 to a reactor at any stage in the low-temperature methanation reaction zone, and a substitute natural gas product is obtained after the reaction. By the technical scheme, the problems are solved well and the method can be used in industrial production of the substitute natural gas from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

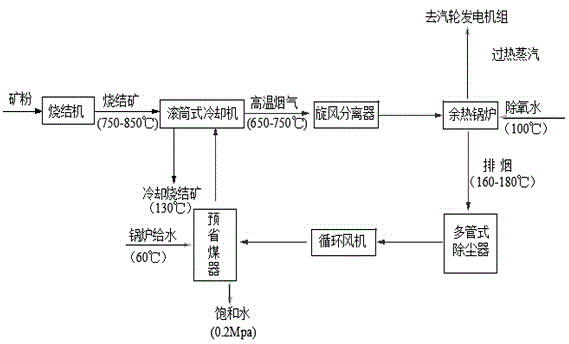

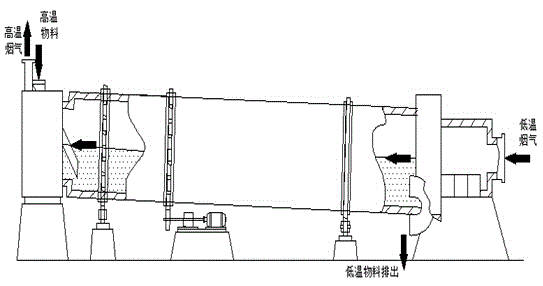

Novel efficient sinter sensible heat recovery technology

InactiveCN104990421ASolve serious air leakageImprove utilization efficiencyEnergy industryIncreasing energy efficiencyPulp and paper industrySuperheated steam

The invention discloses a novel efficient sinter sensible heat recovery technology. The novel efficient sinter sensible heat recovery technology comprises a roller type cooler, a waste heat boiler, a cyclone dust remover, a multi-pipe type dust remover and a pre-economizer. After high-temperature sinter with the temperature of 750 DEG C to 850 DEG C enters the roller type cooler, high-temperature smoke with the temperature of 650 DEG C to 750 DEG C enters the waste heat boiler after passing the cyclone dust remover; the waste heat boiler absorbs the sensible heat of the high-temperature smoke and generates overheat steam of 4.5 MPa and 450 DEG C; the temperature of the smoke at the outlet of the boiler is reduced to 160 DEG C to 180 DEG C, secondary dust removing is carried out through the multi-pipe type dust remover, and then the smoke enters the roller type cooler. The high-temperature sinter is cooled in the roller type cooler, the high-temperature hot air is generated and conveyed to the waste heat boiler, and the overheat steam is generated for power generation. Meanwhile, a full-closed form is adopted in a cooling circulation system, and the quality of recycled waste heat is improved. The two-level dust removing technology mode is adopted, the recycling rate of mineral powder is increased, and the environment is protected.

Owner:WUXI YIEN TECH

Method of producing substitute natural gas from synthesis gas

The invention relates to a method of producing substitute natural gas from synthesis gas, mainly solving problems, namely large using amount of recycle gas, high energy consumption of compressors and short service lifetime of catalysts, of high-temperature methanation reactions in the prior art. According to the technical scheme adopted by the method, the method comprises: a) a step of providing a high-temperature methanation reaction zone including n-stage series-connected reactors, wherein the n is not less than 2, each reactor is divided into m sections of catalyst layers and the m is not less than 2; b) a step of dividing the synthesis gas raw materials into n sections and respectively feeding the n sections of the synthesis gas raw materials into inlets of the reactors at all stages in the high-temperature methanation reaction zone, wherein each section of the synthesis gas raw materials that enters a reactor is then divided into m streams and the m streams respectively enter the corresponding catalyst layers; c) a step of allowing a stream flowing out of an outlet of each of the reactors except the reactor at the final stage to enter the first section of catalyst layer in the reactor at the next stage; and d) a step of shunting the stream Vn flowing out from the reactor at the final stage to obtain a part Vn', and circulating the stream Vn' after the Vn' is condensed to the inlet of the reactor at the first stage. By the technical scheme, the problems are solved well and the method can be used in industrial production of substitute natural gas from synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing substitute natural gas

The invention relates to a method for producing substitute natural gas. The problems of large using amount of high-temperature methanation reaction circulating gas, high energy consumption of a compressor and excess of an H2 or CO2 component in a substitute natural gas product in the prior art are mainly solved. According to the technical scheme, the method comprises the following steps: (a) proving a high-temperature methanation reaction area, wherein the high-temperature methanation reaction area comprises an n stages of cascaded reactors; (b) dividing synthesis gas raw materials into n sections, causing the n sections of synthesis gas raw materials to enter an inlet of a reactor in each stage in the high-temperature methanation reaction area, dividing a material flow Vn flowing out of an outlet of the reactor in a final stage into Vn' and Vn', and compressing and circulating the material flow Vn to an inlet of the reactor in the first stage; (c) providing a low-temperature methanation reaction area, wherein the low-temperature methanation reaction area comprises m stages of reactors which are connected in series; (d) supplementing an H2-containing material flow I into the reactor in any stage of a low-temperature methanation unit, and performing reaction to obtain the substitute natural gas product. According to the method, the problems are well solved; the method can be used for industrial production of preparing the substitute natural gas with synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

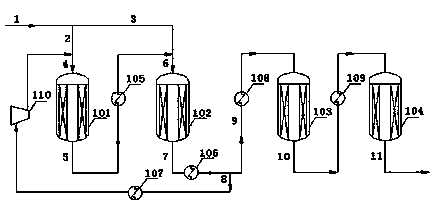

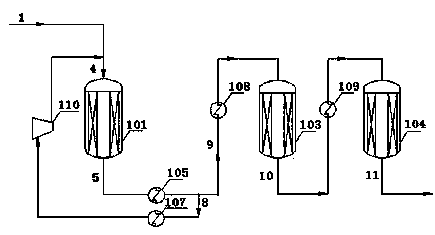

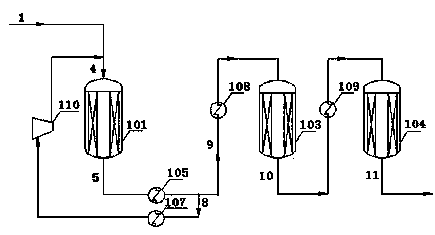

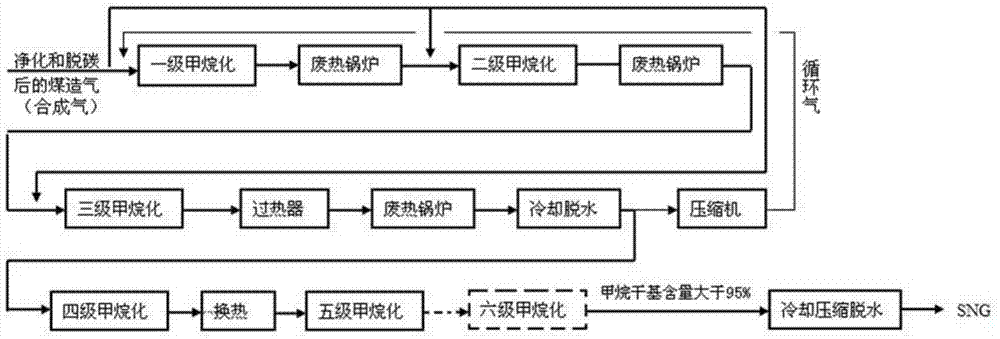

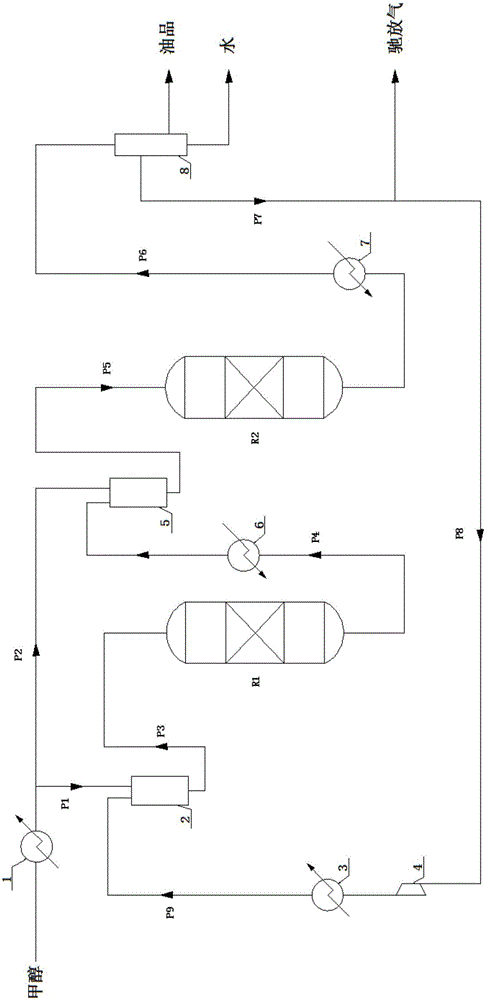

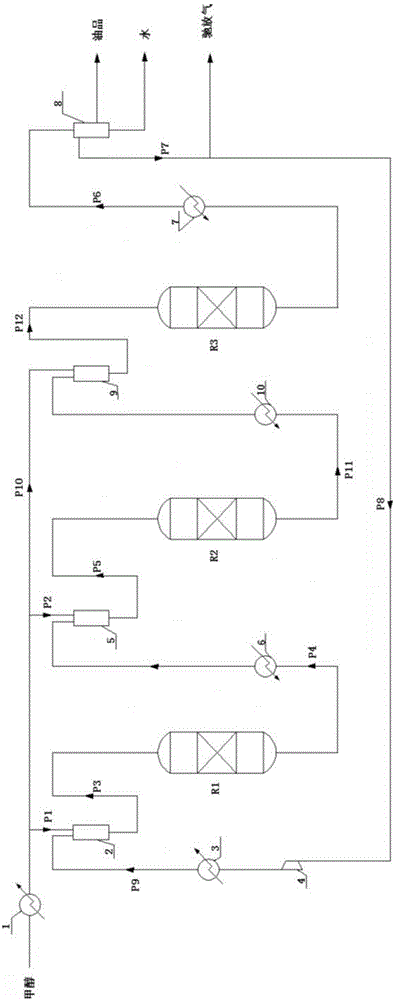

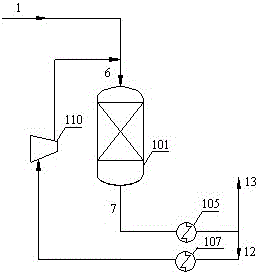

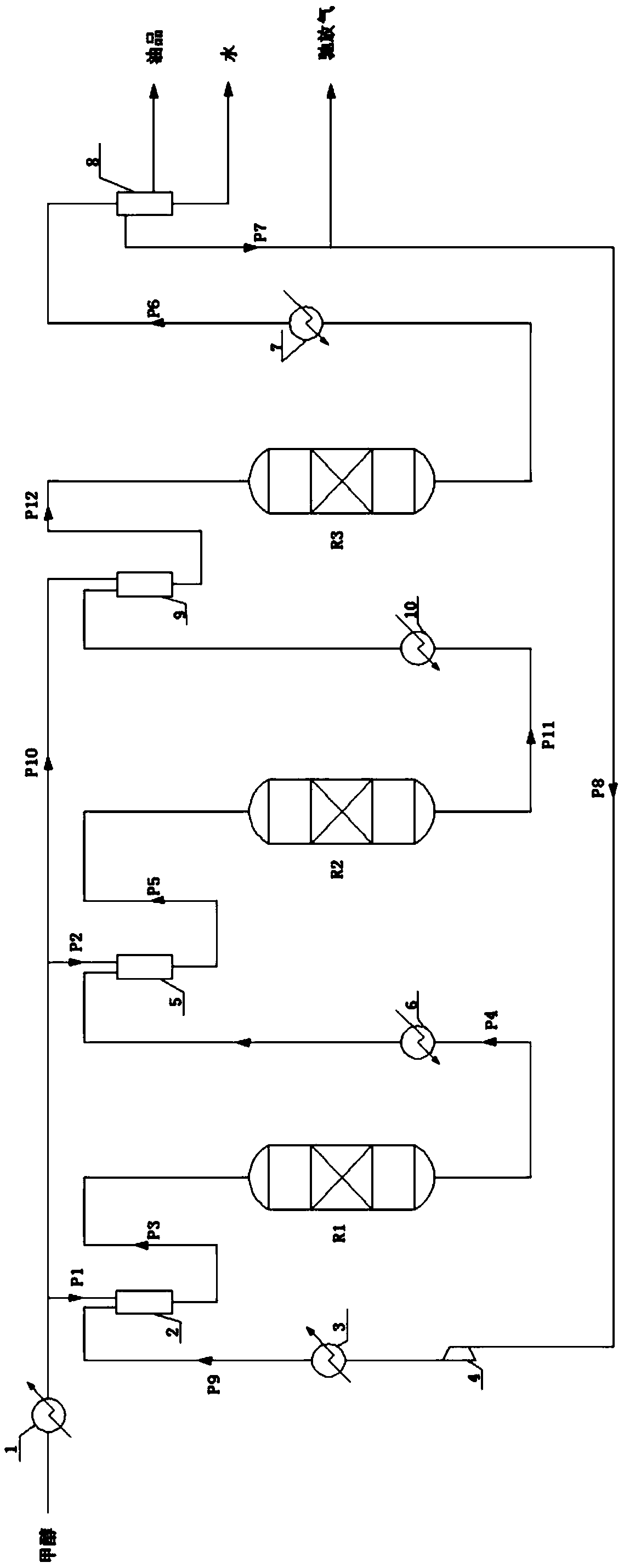

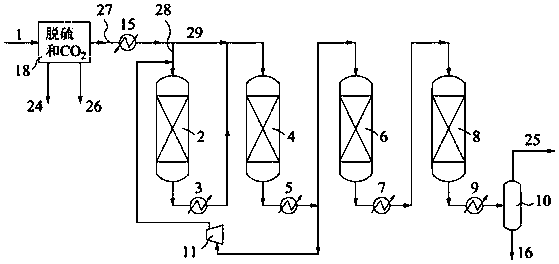

A methanation process of synthetic natural gas prepared from coal

InactiveCN104762115AImprove energy utilizationReduce recirculation air volumeGaseous fuelsSyngasThermodynamics

The invention discloses a methanation process of synthetic natural gas (SNG) prepared from coal. Purified and decarbonized synthetic gas prepared from coal is divided into three parts, wherein the first part of synthetic gas enters into a first methanation reactor after being mixed with recycle air, gas at the outlet of the first methanation reactor enters into a second methanation reactor after being mixed with the second part of synthetic gas, the gas at the outlet of the second methanation reactor enters in to a third methanation reactor after being mixed with the third part of synthetic gas, after the gas is cooled in the third methanation reactor, part of the gas enters into a cyclic compressor to be boosted to be used as the recycle gas, other gases sequentially enter into a fourth methanation reactor, a fifth methanation reactor and a sixth methanation reactor to be subjected to methanation reaction, the dry basis content of methane in the gas at the outlet of the final methanation reactor is larger than 95%, and then the SNG meeting the requirement is obtained through cooling, compressing and dehydrating. The invention has the advantages of small recycle gas quantity, high energy utilization ratio and small investment.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND +1

Method for preparing substitutive natural gas by synthesis gas methanation

The invention relates to a method for preparing substitutive natural gas by synthesis gas methanation. The method mainly solves the problems that the consumption of high-temperature methanation reaction recycle gas is great and the energy consumption of a compressor is high in the prior art. The method comprises the following steps that a) a high-temperature methanation reaction area is provided; the high-temperature methanation reaction area comprises n reactors connected in series, wherein n is greater than or equal to 2; b) raw synthesis gas containing H2, CO, CO2 and H20 is divided into n sections to enter inlets of the reactors in the high-temperature methanation reaction area respectively; flows flowing out of outlets of the reactors except the last reactor flow into inlets of the next reactors respectively; a flow Vn flowing out of an outlet of the last reactor is divided into Vn' and Vn''; the flow Vn' is compressed and then circulates to the inlet of the first reactor; c) a low-temperature methanation reaction area is provided; the low-temperature methanation reaction area comprises m reactors connected in series, wherein m is greater than or equal to 2; and d) the flow Vn'' enters the low-temperature methanation reaction area to react; and then the substitutive natural gas is obtained. With the adoption of the technical scheme, the problems are solved better, so that the method can be used in industrial production of substitutive natural gas preparation by the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methanation technology for preparing SNG from coal-based synthetic gas

A methanation technology or preparing SNG from coal-based synthetic gas comprises the following steps: methane synthetic gas from a coal gas purifying workshop section is finely desulphurized, and the desulphurized synthetic gas is divided into four virgin gases A, B, C and D; the virgin gas A and circulation gas simultaneously enter the first segment of a first methane synthesis reactor, first segment outlet gas and the virgin gas B simultaneously enter the second segment of the first methane synthesis reactor, the outlet gas of the second segment of the first methane synthesis reactor and the virgin gas C simultaneously enter the first segment of a second methane synthesis reactor, the outlet gas of the first segment of the second methane synthesis reactor and the virgin gas B are mixed to form second segment gas, and the second segment gas enters the second segment of the second methane synthesis reactor; and the outlet gas of the second methane synthesis reactor is cooled, parts of the cooled gas is pressurized without water separation, the pressurized gas returns to the inlet of the first segment of the first methane synthesis reactor as circulation gas, the remaining gas sequentially enters a third methane synthesis reactor and a fourth methane synthesis reactor and undergoes a methane synthesis reaction, the methane dry base content of the outlet gas of the fourth methane synthesis reactor is greater than 95%, and the outlet gas of the fourth methane synthesis reactor is cooled and dehydrated to obtain the SNG.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing aromatic hydrocarbon from methanol by virtue of fixed bed

ActiveCN106542947AReduce gas volume ratioReduce operating energy consumptionMolecular sieve catalystCatalystsThree levelFixed bed

The invention relates to a process for preparing aromatic hydrocarbon from methanol by virtue of a fixed bed. Methanol raw material gas is divided into two or three parts and is respectively processed by virtue of a two-level reactor or a three-level reactor in a serial-parallel combination manner, so that the flow ratio of circulating gas to raw material gas is decreased, and the total equipment investment and corresponding energy consumption in the reaction process are greatly reduced.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

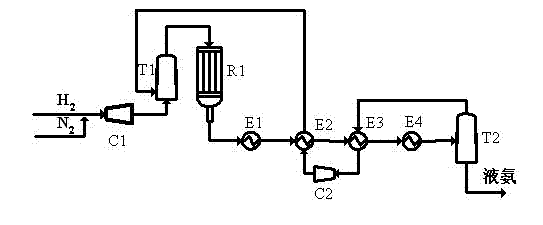

Method for preparing synthetic ammonia from low-H2/N2-ratio synthesis gas

InactiveCN105731493AReduce hydrogen contentMaintain structureBulk chemical productionAmmonia preparation/separationSyngasTemperature control

The invention discloses a method for low H 2 / N 2 A method for producing synthetic ammonia from synthetic gas, comprising: Step 1: converting H below the stoichiometric ratio 2 -N 2 The synthesis gas is mixed with the circulating synthesis gas, pressurized by the compressor and preheated by the heat exchanger; step 2: the preheated mixed gas in step 1 first passes through an iron-based catalyst synthesis ammonia reactor, so that the outlet ammonia concentration reaches or exceeds 10 %, mixed gas H 2 / N 2 The ratio drops to or lower than 2.8; step 3: the mixed gas in step 2 passes through four alternately arranged heat exchangers and ruthenium-based catalyst synthesis ammonia reactors in turn, and the final outlet ammonia concentration reaches more than 25%; H 2 / N 2 The ratio is 1.00 to 2.50. This structure is beneficial to control the temperature of the catalyst bed, to ensure that the catalyst does not overheat, and to exert the high activity of the ruthenium-based catalyst under relatively low temperature and low pressure conditions, while maintaining the structure and stability of the ruthenium-based ammonia synthesis catalyst. Effectively improve the final outlet ammonia concentration of synthetic ammonia under the premise of high efficiency, which can reach more than 25%.

Owner:PETROCHINA CO LTD

Synthesis gas production method to replace natural gas

Owner:CHINA PETROLEUM & CHEM CORP +1

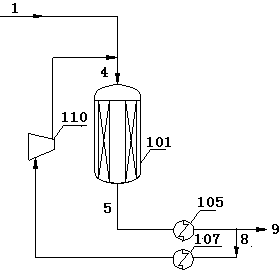

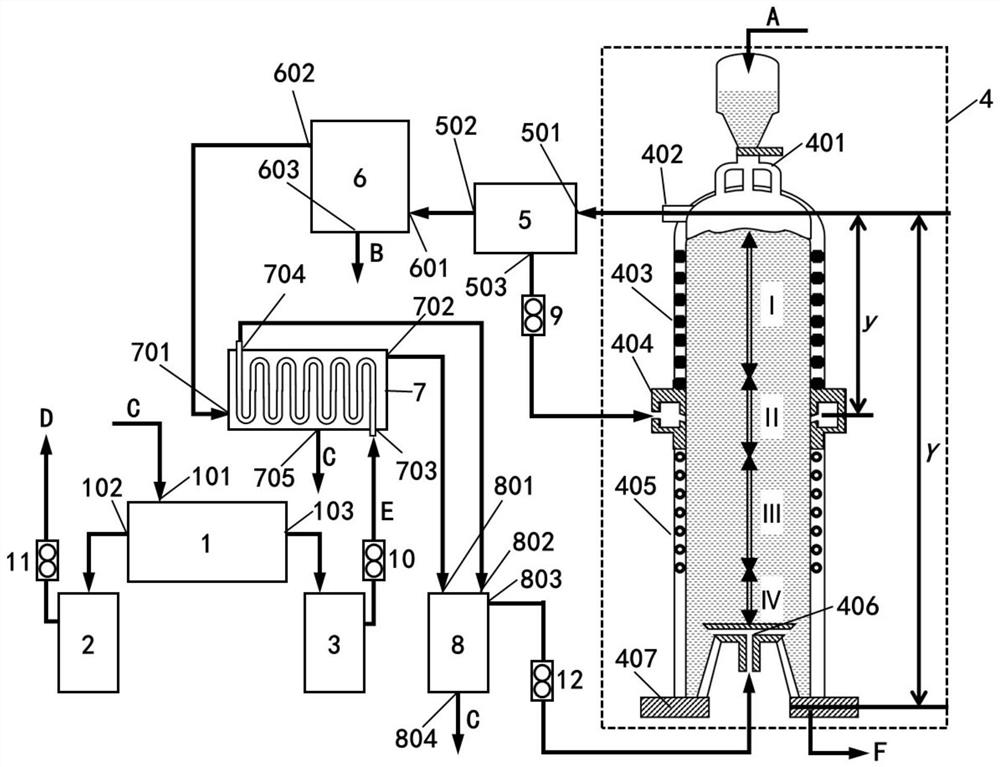

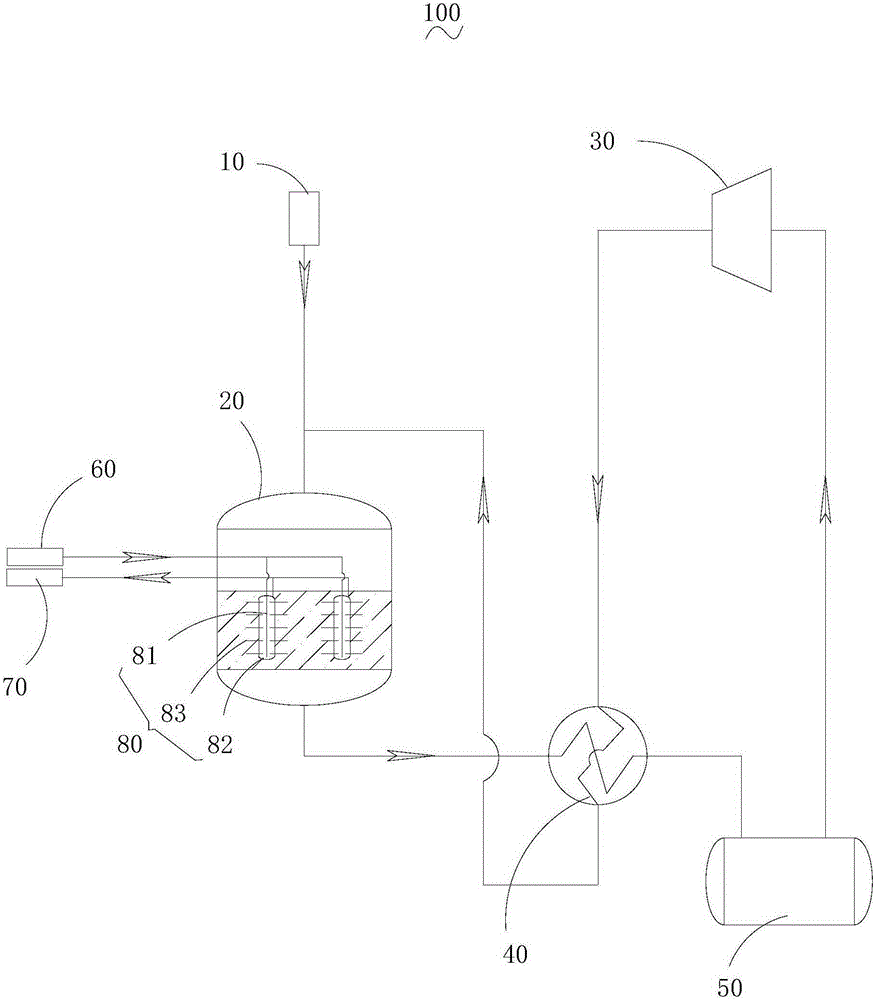

Reaction device for preparing mixed aromatics from methanol

InactiveCN103877920AReduce workloadExtended service lifeChemical industryHydrocarbon from oxygen organic compoundsVapor–liquid separatorProcess engineering

The invention discloses a reaction device for preparing mixed aromatics from methanol. The reaction device comprises a methanol evaporator, a reactor body, a compressor, a gas heat exchanger and a gas-liquid separator, wherein the methanol evaporator is connected to the reactor body through a pipeline; the reactor body is connected to an inlet of the gas heat exchanger through a pipeline; an outlet of the gas heat exchanger is connected to an inlet of the gas-liquid separator through a pipeline; an outlet of the gas-liquid separator is connected to an inlet of the compressor; an outlet of the compressor is connected to the methanol evaporator; a heating unit is arranged in the reactor body and is a heat pipe type heat exchanger. According to the reaction device, the structure is simple, the cost is lowered, and the heat energy is recovered; the low-power compressor is adopted for bringing out heat in the reactor body, so that the electrical energy is saved and the service life of the compressor is prolonged.

Owner:东莞市九丰化工有限公司

Method of producing substitute natural gas from synthesis gas

The invention relates to a method of producing substitute natural gas from synthesis gas, mainly solving problems, namely large using amount of recycle gas and high energy consumption of compressors, of high-temperature methanation reactions in the prior art. According to the technical scheme adopted by the method, the method comprises: a) a step of providing a high-temperature methanation reaction zone including n-stage series-connected reactors, with the n being not less than 2; b) a step of dividing the synthesis gas raw materials containing H2, CO, CO2 and H2O into n sections and respectively feeding the n sections of the synthesis gas raw materials into inlets of the reactors at all stages in the high-temperature methanation reaction zone; c) a step of allowing a stream flowing out of an outlet of each of the reactors except the reactor at the final stage to enter the inlet of the reactor at the next stage; and d) a step of shunting the stream Vn flowing out from the reactor at the final stage to obtain a part Vn', circulating the stream Vn' after the Vn' is condensed to the inlet of the reactor at the first stage, and feeding the rest of the stream into subsequent processes. By the technical scheme, the problems are solved well and the method can be used in industrial production of substitute natural gas from synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

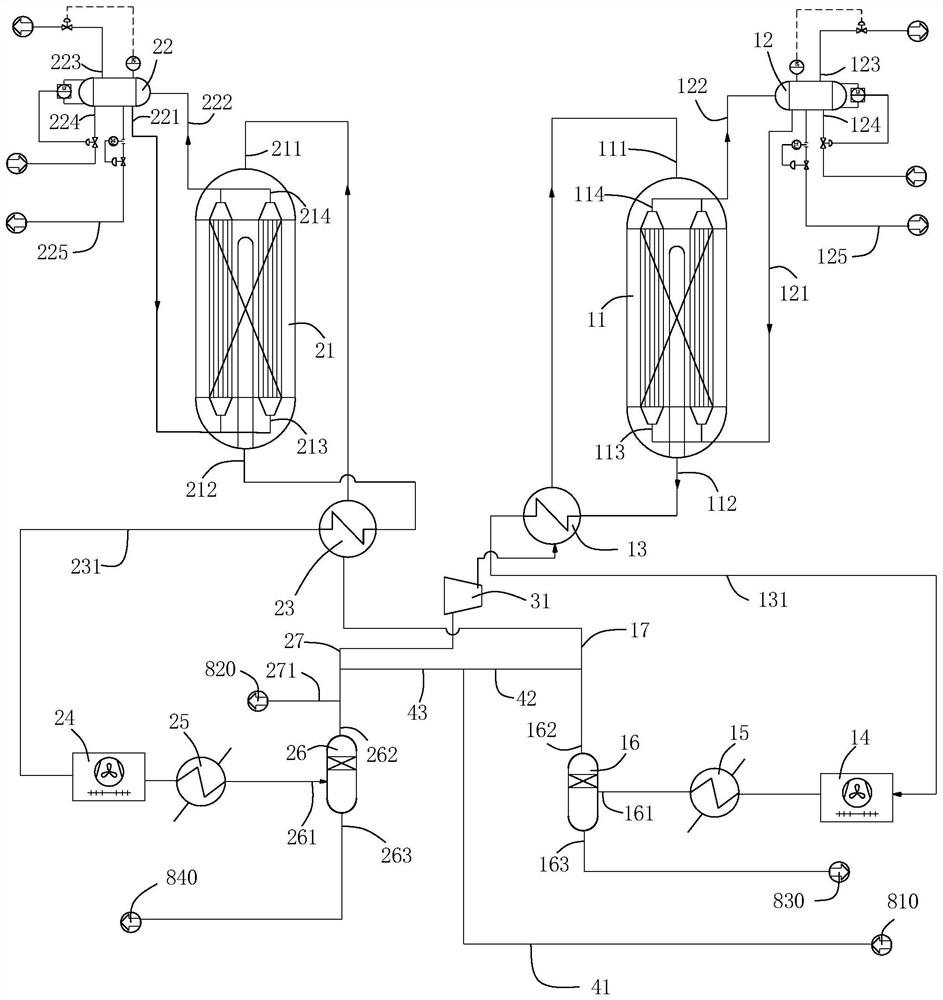

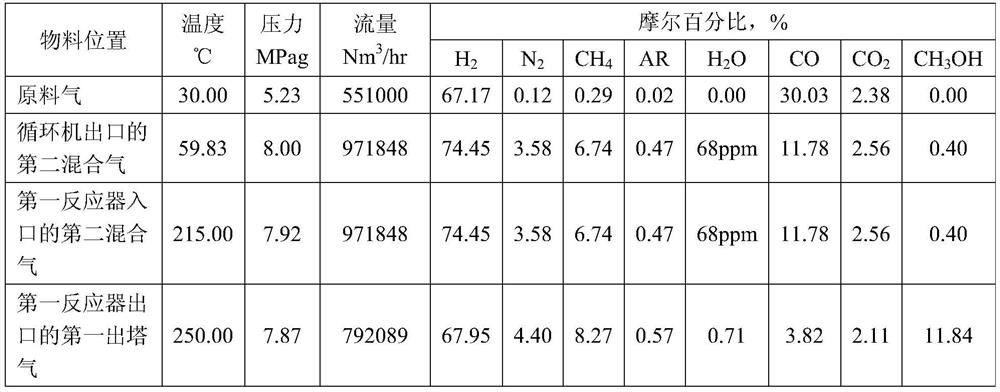

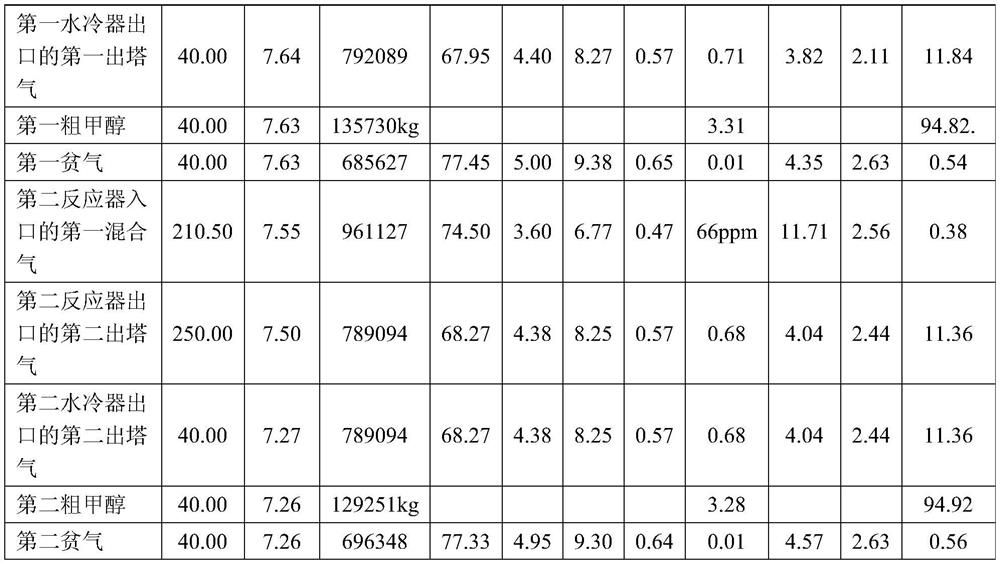

Two-stage double-separation methanol production method

PendingCN112125779AImprove stabilityUniform temperatureOrganic compound preparationEnergy inputProcess engineeringMixed gas

The invention discloses a two-stage double-separation methanol production method which comprises the following steps of: (1) compressing a second mixed gas containing a second complementary gas and asecond lean gas by a circulator, feeding the compressed second mixed gas into a first reactor for reaction, and discharging a first tower outlet gas; (2) recovering methanol from the first tower outlet gas to form a first lean gas; (3) mixing the first lean gas and the first complementary gas to form a first mixed gas, enabling the first mixed gas to enter a second reactor for reaction, and discharging a second tower outlet gas; and (4) recovering methanol from the second tower outlet gas to form a second lean gas, heating the second mixed gas by the first tower outlet gas through a first heatexchanger, and heating the first mixed gas by the second tower outlet gas through a second heat exchanger. In the application, the material circularly flows between the two reactors, so that the volume ratio of the first complementary gas to the second complementary gas is approximately the same, the reaction parameters of the two reactors are also approximately the same, the reaction of the tworeactors can be controlled in the same manner, and the production stability is improved.

Owner:NANJING JUTUO CHEM TECH

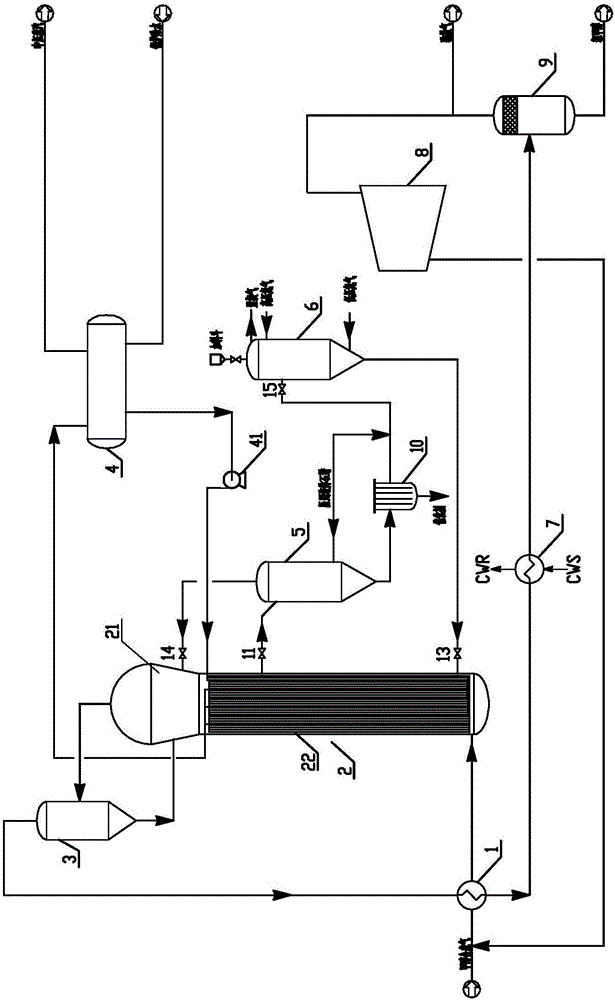

Methanation technology for coal to synthetic natural gas

InactiveCN106047429AImprove energy utilizationReduce recirculation air volumeGaseous fuelsSyngasMethanation

The invention discloses a methanation technology for coal to synthetic natural gas. The technology comprises the following steps: coal gas is divided into three flows by purified and decarburized synthetic gas, the first synthetic gas flow and circulating gas are mixed and then enter a first methanation reactor, gas from the outlet of the first methanation reactor and the second synthetic gas flow are mixed and then enter a second methanation reactor, gas from the outlet of the second methanation reactor and the third synthetic gas flow are mixed, then enter a third methanation reactor and are cooled in the third methanation reactor, one part of the gas in the third methanation reactor enters a circulating compressor and is boosted to be used as circulating gas, the remaining gas in the third methanation reactor sequentially enter a fourth methanation reactor, a fifth methanation reactor or a sixth methanation reactor to carry out a methanation reaction until the dry methane content in gas at the outlet of the last methanation reactor is greater than 95%, and the gas from the outlet of the last methanation reactor is cooled, compressed and dehydrated to obtain the required synthetic natural gas (SNG). The method has the advantages of small circulating gas volume, high energy utilization rate and investment saving.

Owner:天津佳晟染料贸易有限公司

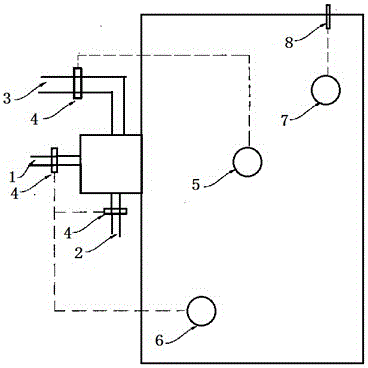

Control device used for coal dry distillation process and control method thereof

InactiveCN105938378AAchieve self-controlIncrease the circulating air volumeSimultaneous control of multiple variablesTemperature controlCombustion

The invention relates to a control device used for the coal dry distillation process and a control method thereof, and is used for a coal dry distiller having a pipeline for transporting gas, air and recycle gas. The control device has a heat carrier temperature control part and a material terminal temperature control part. According to the control device used for the coal dry distillation process, the heat carrier temperature control part is realized by the mode of gas distribution, i.e. two gases enter into a mixing chamber simultaneously, wherein one is high temperature flue gas generated by gas and air through combustion, and the other is recycle gas (the drying section is flue gas and the dry distillation section is raw gas) through heat exchange. A temperature sensor and a pressure sensor are arranged in the mixing chamber for providing feedback signals. The amount of recycle gas is increased if temperature is high and the amount of recycle gas is decreased if temperature is low so that operation is convenient and flexible, the control device can be rapidly adapt to the change of temperature and realization of automatic control is facilitated.

Owner:JIANGSU YINGFENG INTELLIGENT ENG TECH CO LTD

A process for preparing aromatics from methanol in a fixed bed

ActiveCN106542947BReduce gas volume ratioReduce operating energy consumptionMolecular sieve catalystCatalystsThree levelAromatic hydrocarbon

The invention relates to a process for preparing aromatic hydrocarbon from methanol by virtue of a fixed bed. Methanol raw material gas is divided into two or three parts and is respectively processed by virtue of a two-level reactor or a three-level reactor in a serial-parallel combination manner, so that the flow ratio of circulating gas to raw material gas is decreased, and the total equipment investment and corresponding energy consumption in the reaction process are greatly reduced.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A methanation process for producing synthetic natural gas from coal-based syngas

ActiveCN103509618BReduce recirculation air volumeImprove energy utilizationGaseous fuelsChemical industrySyngas

The invention belongs to the field of energy chemical industry, and discloses a methanation technique for preparing synthetic natural gas from coal-base synthetic gas, which comprises the following steps: synthetic gas, which is obtained by carrying out fine desulfurization on methane synthetic gas from a gas purification section, is divided into three fresh gas streams A, B and C; first-section inlet gas formed by mixing the fresh gas A and circulation gas enters a first section of a methane synthesis reactor, second-section inlet gas formed by mixing first-section outlet gas and fresh gas B enters a second section of the first methane synthesis reactor, and second-section outlet gas of the first methane synthesis reactor and fresh gas C are mixed and enter a second methane synthesis reactor; after outlet gas of the second methane synthesis reactor is cooled, part of gas enters a circulating compressor to be pressurized and returns to the inlet of the first section of the first methane synthesis reactor as circulating gas, and the rest of gas sequentially enters a third methane synthesis reactor and a fourth methane synthesis reactor to be subjected to methane synthetic reaction; and outlet gas of the fourth methane synthesis reactor, in which the methane content is higher than 94% on dry basis, is cooled and dehydrated to obtain satisfactory synthetic natural gas SNG.

Owner:CHINA PETROLEUM & CHEM CORP +1

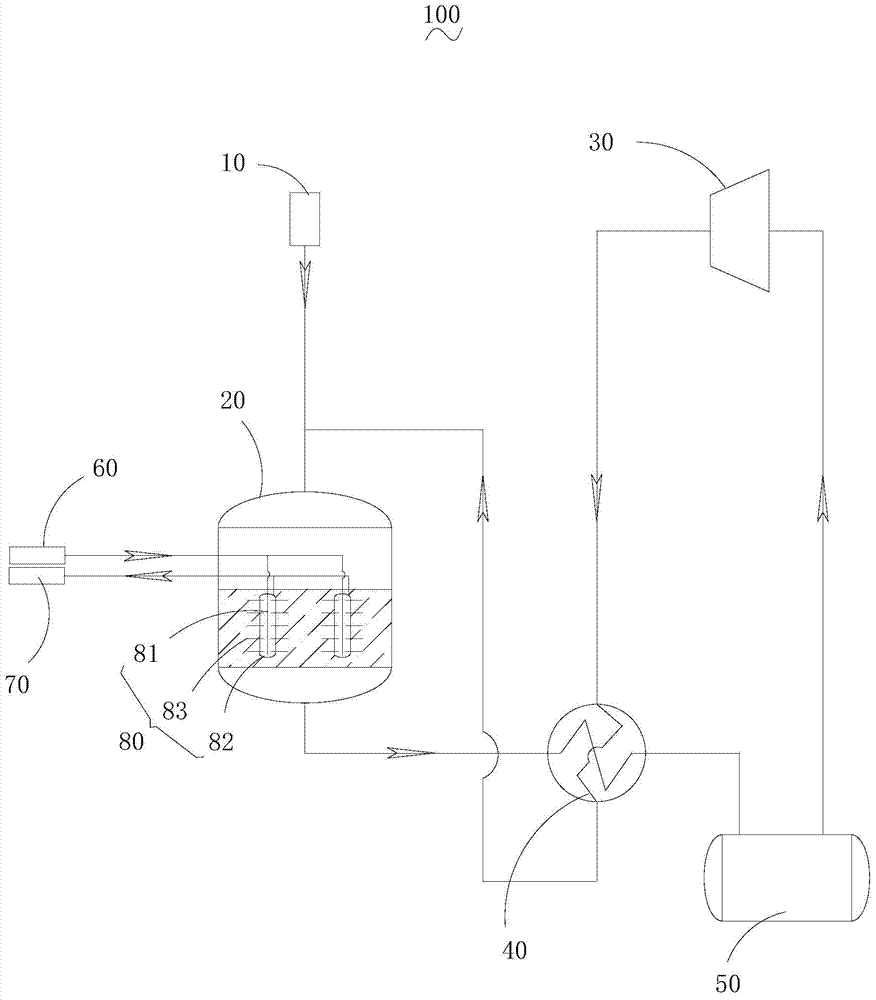

Slurry reactor methanol synthesis process

ActiveCN106588574AImprove heat transfer performanceEasy temperature controlOrganic compound preparationHydroxy compound separation/purificationSyngasVapor–liquid separator

The invention relates to a slurry reactor methanol synthesis process. The slurry reactor methanol synthesis process is characterized by comprising the following steps: mixing raw material gas from upstream with circulating gas to form mixed gas, enabling the mixed gas to enter a shell side of the reactor from the bottom after heat exchange to be in contact with a catalyst in the shell side to perform reaction; enabling bubble point boiler water to enter a tube side of the reactor; discharging the reaction gas generated by the reaction out of the top of the reactor and enabling the reaction gas to enter a separator to perform separation; enabling the separated non-gas phase to return to the reactor from the gas phase space at the upper part of the reactor, enabling the separated gas phase, namely crude methanol synthesis gas, to enter a gas liquid separator after heat exchange, pressurizing the separated gas phase to serve as circulating gas, wherein the separated liquid phase is crude methanol; when catalyst abrasion reaches to a set value, extracting catalyst slurry from the reactor; supplementing fresh catalyst slurry into the shell side of the reactor. According to the slurry reactor methanol synthesis process, the catalyst can be changed timely without shutdown.

Owner:SINOPEC NINGBO ENG +2

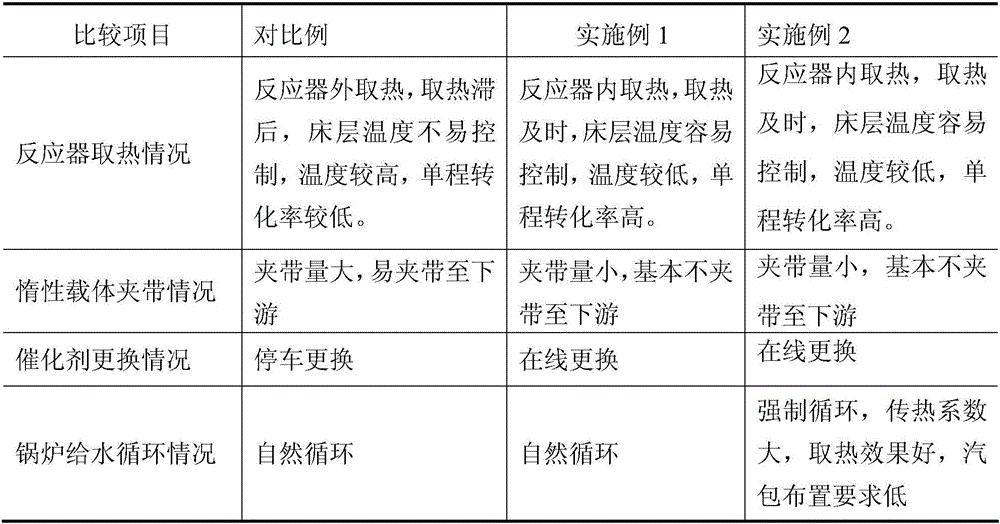

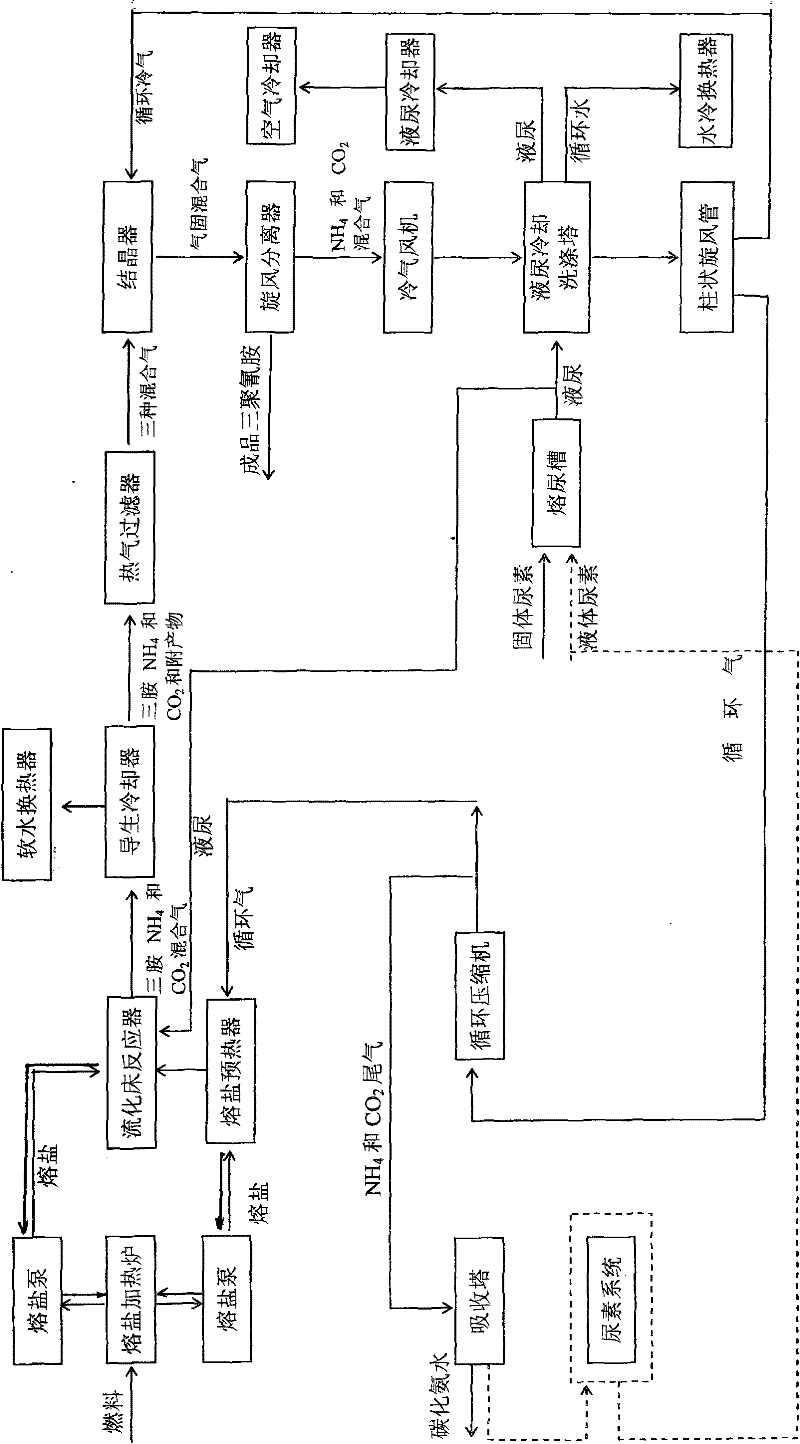

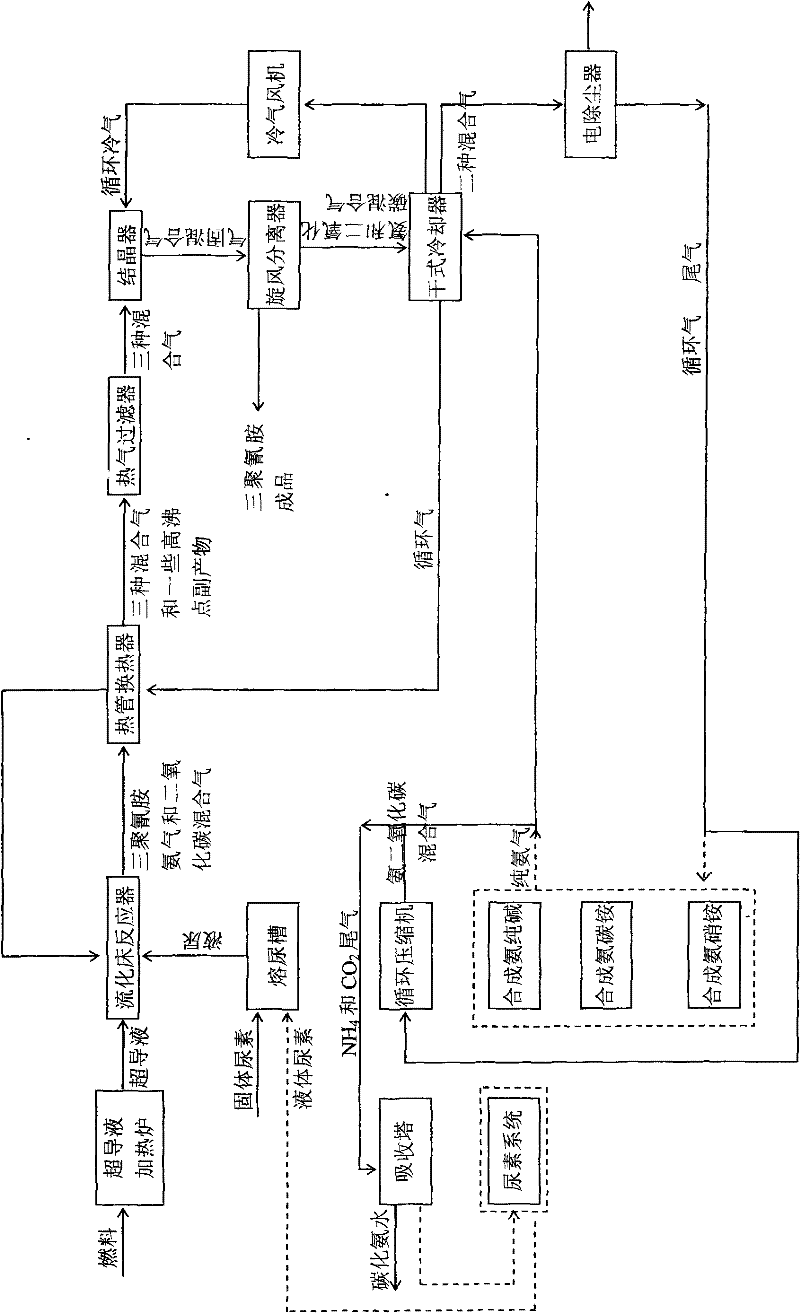

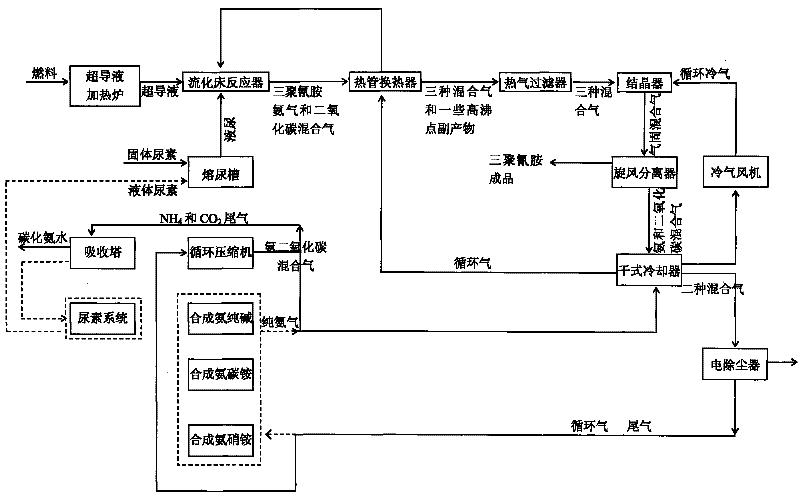

Energy-saving technology for producing melamine by one-step method

InactiveCN101671311BReduce consumptionReduce lossesOrganic chemistryChemical industryFluidized bedHeating furnace

The invention discloses an energy-saving technology for producing melamine by a one-step method, mainly comprising the following steps: supplying heat to a fluidized bed reactor by a superconducting liquid heating furnace or a heat pipe heating furnace; cooling produced gas-state melamine and a high-temperature mixed gas of ammonia and carbon dioxide by a heat pipe exchanger; and then filtering, crystallizing and separating to obtain a finished product solid melamine, wherein the rest mixed gas of the ammonia and the carbon dioxide can be circularly used for supplying a working gas for a system after being purified and can also enter a synthesis ammonia soda ash device or a synthesis ammonia ammonium carbonate device or a synthesis ammonia nitramine device to be used for supplying a raw material for the system. Compared with the traditional one-step method, the energy-saving technology can reduce the fuel consumption by 40 percent and the electric power consumption by 30 percent.

Owner:徐建华

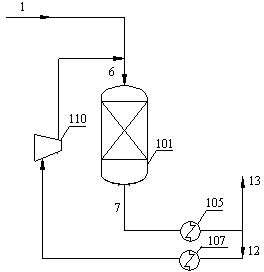

Technology for preparing natural gas from synthesis gas

ActiveCN108102750AReduce recirculation air volumeLess investmentGaseous fuelsMethanationGas compressor

The invention relates to a technology for preparing natural gas from synthesis gas. Sulfur-containing components in raw synthesis gas are removed firstly, desulfurized gas containing CO2 enters a methanation device and is subjected to a methanation reaction, and coarse SNG (synthetic natural gas) product gas is obtained; CO2 in the coarse SNG product gas is removed, a qualified SNG product is prepared, and methane-rich gas obtained in the CO2 removing process returns to the methanation reactor and is utilized as diluent gas to control the reaction temperature rise of the methanation reactor. Compared with the prior art, not only is the reaction temperature rise of the methanation reactor controlled, but also circulating gas flow rate of a circulating gas compressor can be greatly reduced,so that system energy consumption and equipment investment are remarkably reduced.

Owner:WISON ENG +1

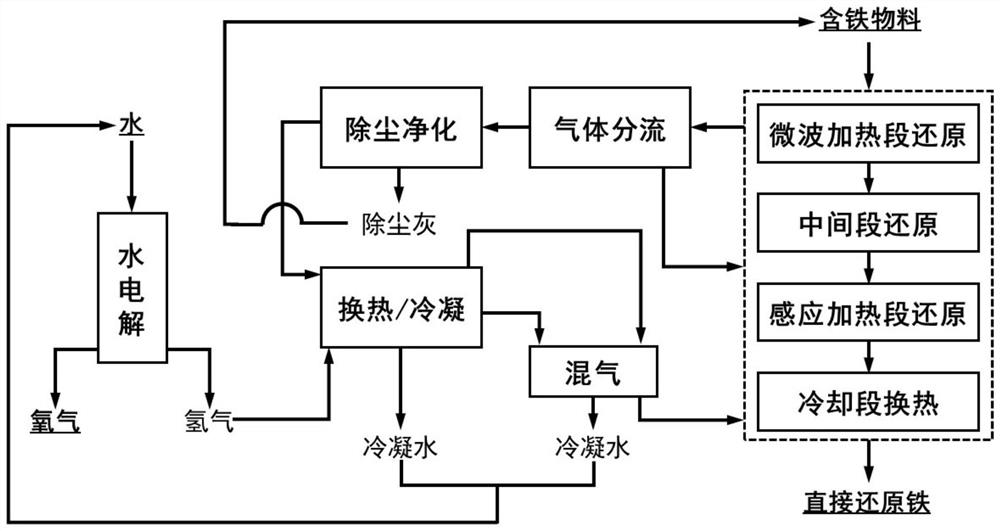

A hydrogen shaft furnace ironmaking system and method using electric energy heating

ActiveCN112899427BGuaranteed temperatureReduce recirculation air volumeExhaust gas handlingShaft furnaceElectrolysisShaft furnace

A hydrogen shaft furnace ironmaking system and method using electric energy heating, the system includes a water electrolyzer, a hydrogen storage tank, an electric energy heating hydrogen shaft furnace, a heat exchanger, and a gas mixing tank; the furnace body is provided with a microwave heating section, a middle section, The induction heating section, the cooling section and the screw discharger, the air inlet pier is below the cooling section, and the water electrolyzer, hydrogen storage tank, heat exchanger, gas mixing tank are connected with the air inlet of the air inlet pier in sequence. The method is as follows: (1) The hydrogen gas generated by the electrolysis of the water electrolyzer is passed into the hydrogen storage tank; (2) The hydrogen gas is passed into the coil in the heat exchanger, discharged into the gas mixing tank, and passed into the furnace body through the air inlet pier; (3) Turn on the microwave radiation source and the induction coil; (4) Put the iron-containing material into the furnace body to exchange heat with the gas and undergo a reduction reaction; (5) After the iron-containing material passes through each section of the furnace body, it will generate direct reduced iron and discharge it. The method of the present invention avoids oxygen blowing at the upper part, can realize the direct recovery and utilization of part of the high-temperature tail gas on the top of the furnace, reduces energy consumption and operation cost, and can avoid pipeline material failure and other related safety accidents caused by hydrogen diffusion.

Owner:NORTHEASTERN UNIV LIAONING

Reaction device for preparing mixed aromatics from methanol

InactiveCN103877920BReduce workloadExtended service lifeChemical industryHydrocarbon from oxygen organic compoundsVapor–liquid separatorPlate heat exchanger

The invention discloses a reaction device for preparing mixed aromatics from methanol. The reaction device comprises a methanol evaporator, a reactor body, a compressor, a gas heat exchanger and a gas-liquid separator, wherein the methanol evaporator is connected to the reactor body through a pipeline; the reactor body is connected to an inlet of the gas heat exchanger through a pipeline; an outlet of the gas heat exchanger is connected to an inlet of the gas-liquid separator through a pipeline; an outlet of the gas-liquid separator is connected to an inlet of the compressor; an outlet of the compressor is connected to the methanol evaporator; a heating unit is arranged in the reactor body and is a heat pipe type heat exchanger. According to the reaction device, the structure is simple, the cost is lowered, and the heat energy is recovered; the low-power compressor is adopted for bringing out heat in the reactor body, so that the electrical energy is saved and the service life of the compressor is prolonged.

Owner:东莞市九丰化工有限公司

Synthesis gas methanation method to replace natural gas

The invention relates to a method of producing substitute natural gas by methanation of synthesis gas, mainly solving problems, namely large using amount of recycle gas and high energy consumption of compressors, of high-temperature methanation reactions in the prior art. According to the technical scheme adopted by the method, the method comprises: a) a step of providing a high-temperature methanation reaction zone including n-stage series-connected reactors, with the n being not less than 2; b) a step of dividing the synthesis gas raw materials containing H2, CO, CO2 and H2O into n sections and respectively feeding the n sections of the synthesis gas raw materials into inlets of the reactors at all stages in the high-temperature methanation reaction zone, wherein a stream flowing out of an outlet of each of the reactors except the reactor at the final stage enters the inlet of the reactor at the next stage, the stream Vn flowing out from the reactor at the final stage is divided into Vn' and Vn'', and the stream Vn' is condensed and circulated to the inlet of the reactor at the first stage; c) a step of providing a low-temperature methanation reaction zone including m-stage series-connected reactors, with the m being not less than 2; and d) a step of feeding the stream Vn'' into the low-temperature methanation reaction zone, and substitute natural gas is obtained after the reaction. By the technical scheme, the problems are solved well and the method can be used in industrial production of the substitute natural gas from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com