Reaction device for preparing mixed aromatics from methanol

A technology for mixing aromatic hydrocarbons and reaction devices, which can be used in feeding devices, hydrocarbon production from oxygen-containing organic compounds, lighting and heating equipment, etc., and can solve the problems of high technical difficulty, unrecoverable heat, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

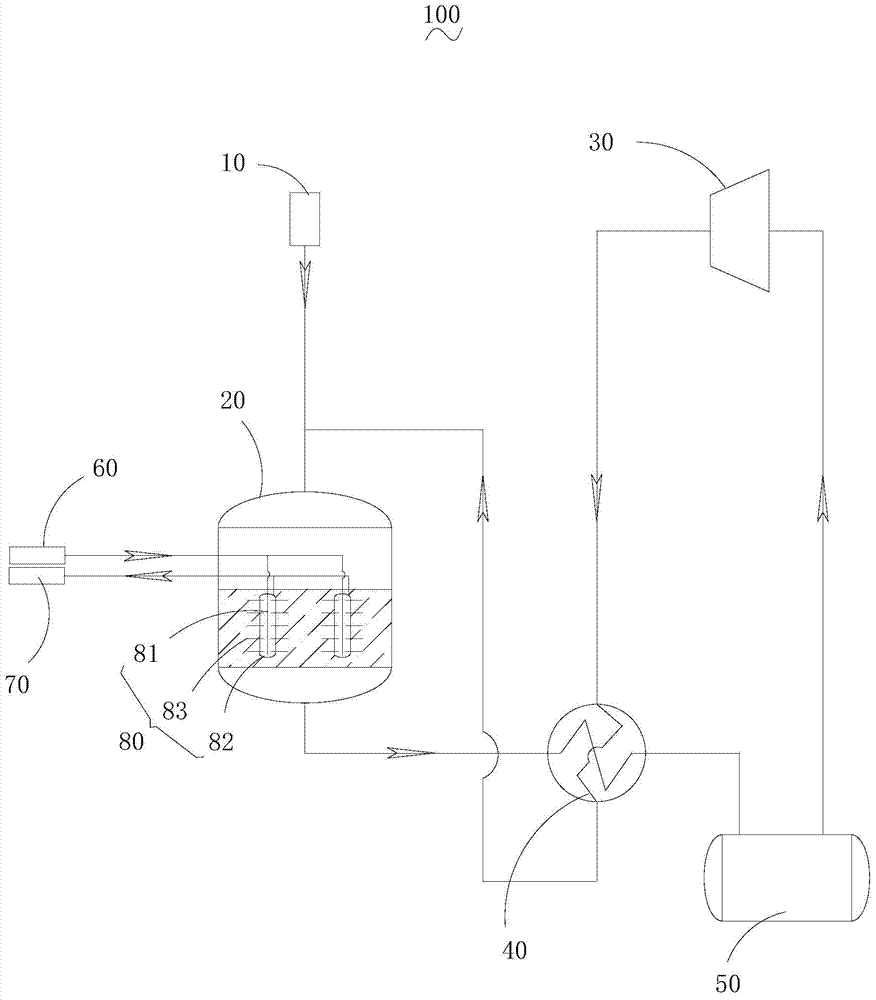

[0019] Such as figure 1 As shown, it is a schematic structural diagram of a reaction device 100 for preparing mixed aromatics from methanol according to an embodiment, including: a methanol evaporator 10 , a reactor body 20 , a compressor 30 , a gas heat exchanger 40 and a gas-liquid separator 50 . The methanol evaporator 10 is connected to the inlet of the reactor body 20 through a pipeline, the gas outlet of the reactor body 20 is connected to the first inlet of the gas heat exchanger 40 through a pipeline, and the first outlet of the gas heat exchanger 40 is connected th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com