Circulating method for preparing natural gas by multi-stage methanation of semi-coke tail gas

A technology of semi-coke tail gas and methanation, which is applied in the field of using semi-coke tail gas to produce natural gas, can solve the problem of low balance conversion rate, achieve the effect of reducing heat resistance requirements and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

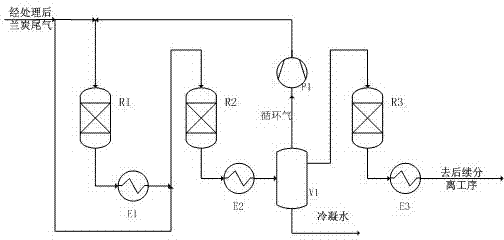

[0036] like figure 1 As shown, the main composition (volume percentage) of semi-coke tail gas after purification and adjustment of hydrogen-carbon ratio is as follows: H 2 : 38.22, CH 4 : 7.87, CO: 8.61, CO 2 : 3.86, C n h m : 0.53, N 2: 40.91, gas volume 1000kmol, pressure 2.1MPa, temperature 40°C.

[0037] Front-end methanation part: first and second methanation furnaces R1, R2; back-stage methanation part: third methanation furnace R3. The feed gas is preheated to 250-300°C and then divided into two streams. The first stream has a volume of 450 kmol. It is mixed with steam and recycled reaction gas and enters the first methanation furnace R1 for reaction. Among them, the volume ratio of water vapor to reaction gas is 0.18, the circulation ratio (i.e. the ratio of circulation gas to total inlet gas volume, the same below) is 0.5, the temperature of raw material gas entering the first methanation furnace R1 is not lower than 260°C, and the outlet temperature is about ...

Embodiment 2

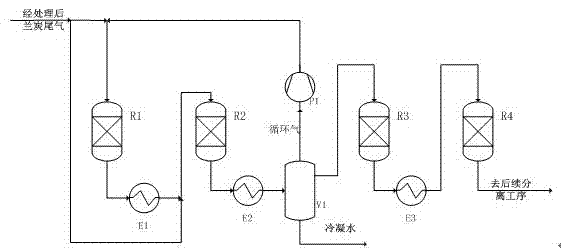

[0040] like figure 2 As shown, the main composition (volume percentage) of semi-coke tail gas after purification and adjustment of hydrogen-carbon ratio is as follows: H 2 : 38.22, CH 4 : 7.87, CO: 8.61, CO 2 : 3.86, C n h m : 0.53, N 2 : 40.91, gas volume 1000kmol, pressure 2.1MPa, temperature 40°C.

[0041] Front-end methanation part: first and second methanation furnaces R1 and R2; back-stage methanation part: third and fourth methanation furnaces R3 and R4. The feed gas is preheated to 250-300°C and then divided into two streams. The first stream has a volume of 420 kmol. It is mixed with steam and recycled reaction gas and enters the first methanation furnace R1 for reaction. The volume ratio of water vapor to reaction gas is 0.05, the circulation ratio of circulating gas is 0.65, the temperature of raw material gas entering the first methanation furnace R1 is not lower than 260°C, and the outlet temperature is about 463°C. The gas at the outlet of the first metha...

Embodiment 3

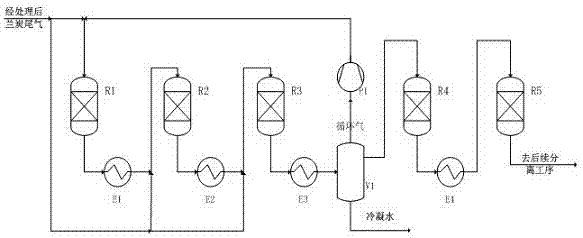

[0045] like image 3 As shown, the main composition (volume percentage) of semi-coke tail gas after purification and adjustment of hydrogen-carbon ratio is as follows: H 2 : 38.22, CH 4 : 7.87, CO: 8.61, CO 2 : 3.86, C n h m : 0.53, N 2 : 40.91, gas volume 1000kmol, pressure 2.1MPa, temperature 40°C.

[0046] Front-end methanation part: first, second and third methanation furnaces R1, R2, R3; back-stage methanation part: fourth and fifth methanation furnaces R4 and R5. The feed gas is preheated to 250-300°C and divided into three streams. The first stream has a volume of 250 kmol. It is mixed with steam and recycled reaction gas and enters the first methanation furnace R1 for reaction. The volume ratio of water vapor to reaction gas is 0.13, the circulation ratio of circulating gas is 0.6, the temperature of raw material gas entering the first methanation furnace R1 is not lower than 260°C, and the outlet temperature is about 469°C. The gas at the outlet of the first me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com