New process for synthesizing natural gas by methanation of coke oven gas

A technology for synthesizing natural gas and gas methane, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of low heat recovery rate and high temperature, and achieve the effect of small gas circulation volume, cost reduction, and circulating gas volume reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

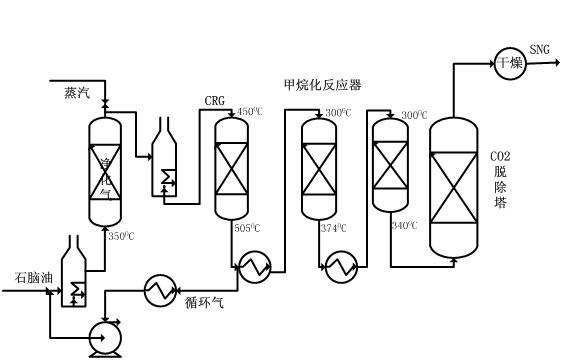

[0037] Such as Figure 4 Shown: coke oven gas composition (vol%) is: H 2 57.6,CH 4 26.9, CO 7.2, CO 2 2.1,N 2 4.1,C 2 h 6 2.1, the purified raw gas volume is 1000 kmol / h (22400 Nm 3 / h).

[0038] 404 kmol / h (9049.6 Nm 3 / h) The coke oven gas is passed into the methanation reactor-R1, and the circulation ratio is 2.1. At this time, CO+CO 2 The concentration of the gas is 3.0%, the inlet temperature is 280°C, and the reactor outlet temperature is 456°C. After passing through the methanation reactor-R1, the outlet gas is 848.4 kmol / h (19004.2 Nm 3 / h) coke oven gas mixture, at this time the CO+CO participating in the reaction 2 The concentration of the gas is 3.4%, and the inlet temperature of the second methanation reactor R2 is about 300°C. After the reaction gas comes out, heat exchanger 1, heat exchanger 2 B1, and heat exchanger 3 E2 are used for centralized heat exchange. Part of it is preheated by compressor P to a certain temperature so that it is mixed with...

Embodiment 2

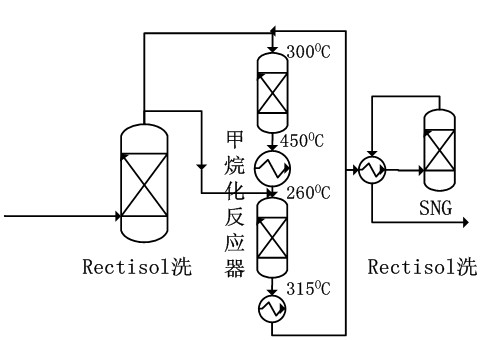

[0040] In this example, the methanation reaction process of synthesizing natural gas from coke oven gas is as follows: Figure 5 Shown:

[0041] The composition of the purified coke oven gas (vol%) is: H 2 57.6,CH 4 26.9, CO 7.2, CO 2 2.1,N 2 4.1,C 2 h 6 2.1. The purified raw gas volume is 1000 kmol / h (22400 Nm3 / h).

[0042] 208.33 kmol / h (4446.60 Nm 3 / h) The coke oven gas is passed into the methanation reactor-R1, and the circulation ratio is 1.325. At this time, CO+CO2 The concentration is 4.0%, the inlet temperature is 250°C, the reactor outlet temperature is 485°C, after passing through the methanation reactor-R1, the outlet gas is 64.58 kmol / h (1446.60 Nm 3 / h) cycle gas, 343.75 kmol / h (7730.98 Nm 3 / h) coke oven gas mixed, at this time the concentration of CO+CO2 participating in the reaction is 4%, the inlet temperature of R2 into the methanation reactor 2 is about 250°C, and the outlet temperature of the reactor is about 485°C. The outlet gas from metha...

Embodiment 3

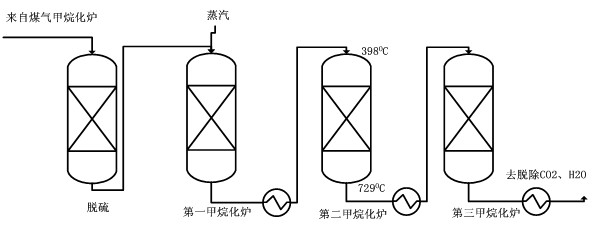

[0044] In this example, the methanation reaction process of synthesizing natural gas from coke oven gas is as follows: Figure 6 Shown:

[0045] The composition of the purified coke oven gas (vol%) is: H 2 57.6, CH 4 26.9, CO 7.2, CO 2 2.1,N 2 4.1,C 2 h 6 2.1. The purified raw gas volume is 1000 kmol / h (22400 Nm 3 / h).

[0046] 135.87 kmol / h (3043.49 Nm 3 / h) The coke oven gas is passed into the methanation reactor-R1, and the circulation ratio is 1.657. At this time, CO+CO 2 The concentration is 3.5%, the inlet temperature is 280°C, the reactor outlet temperature is 485°C, after passing through the methanation reactor-R1, the outlet gas is 38.72 kmol / h (867.33 Nm 3 / h) cycle gas, 201.09 kmol / h (4504.42Nm 3 / h) coke oven gas is mixed, at this time, the inlet temperature of R2 into the methanation reactor 2 is about 280°C, and the CO+CO participating in the reaction 2 The concentration is 3.5%, the reactor outlet temperature is about 485°C, and the outlet gas a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com