Patents

Literature

130 results about "Liquid methane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

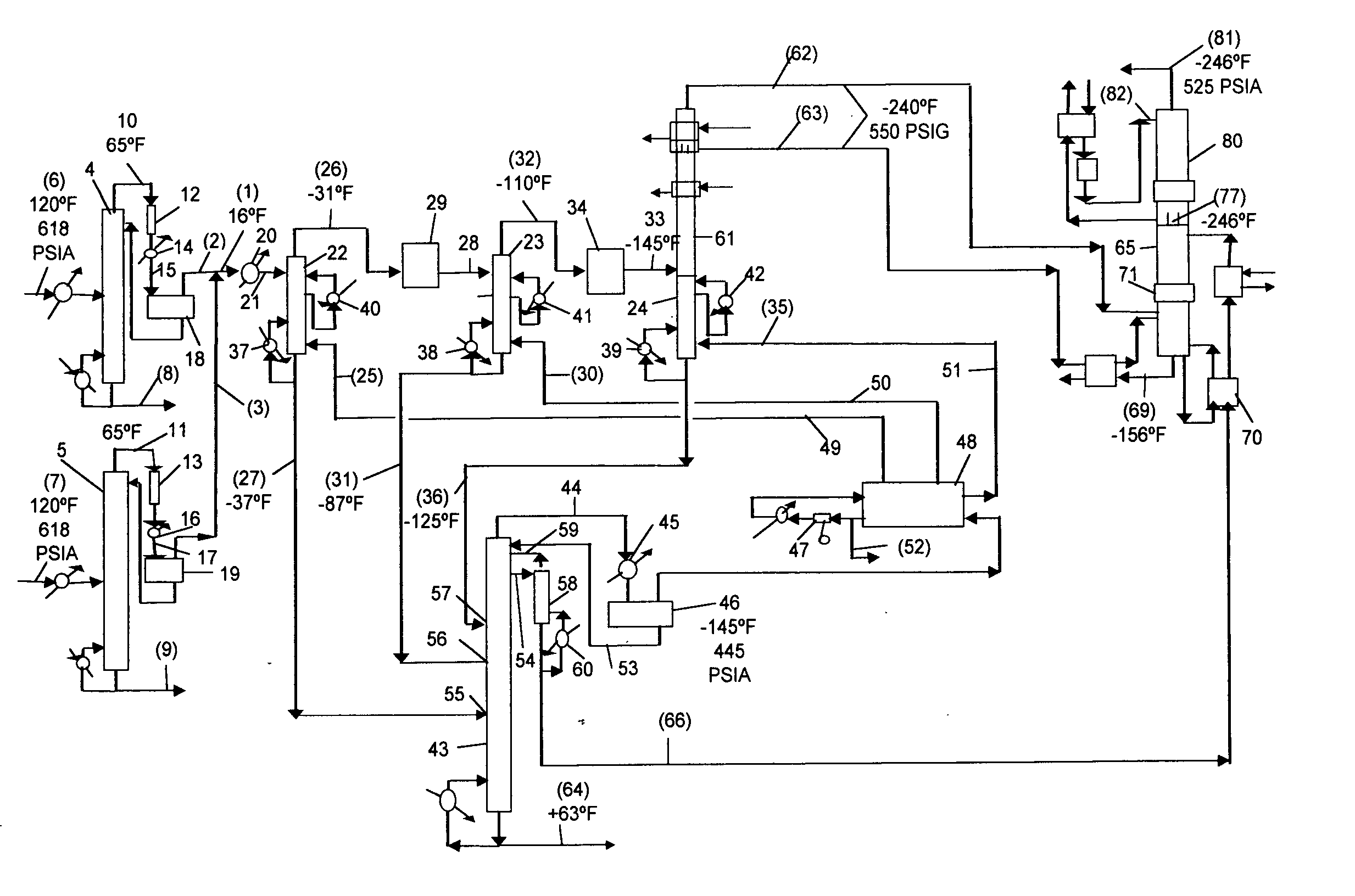

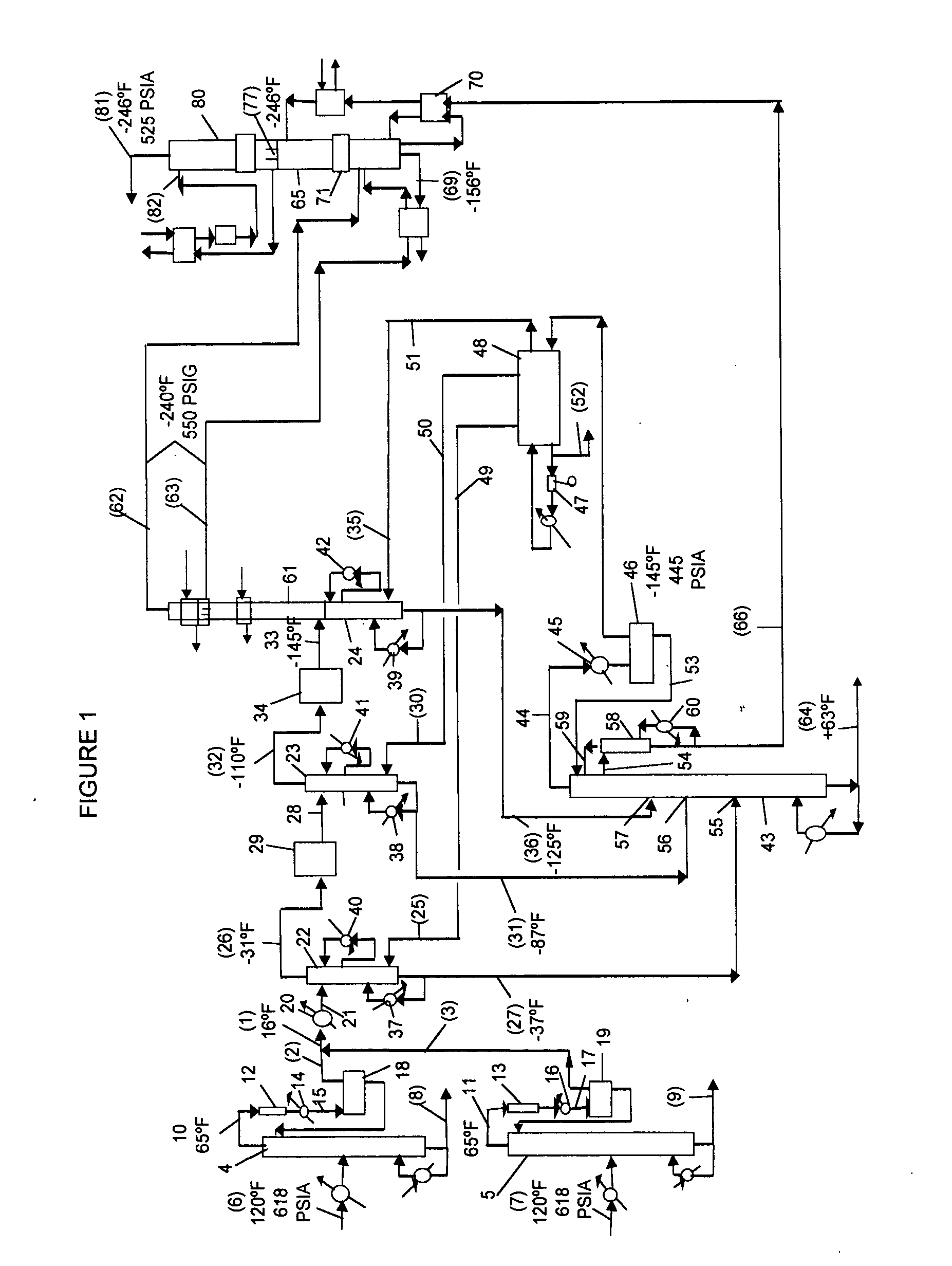

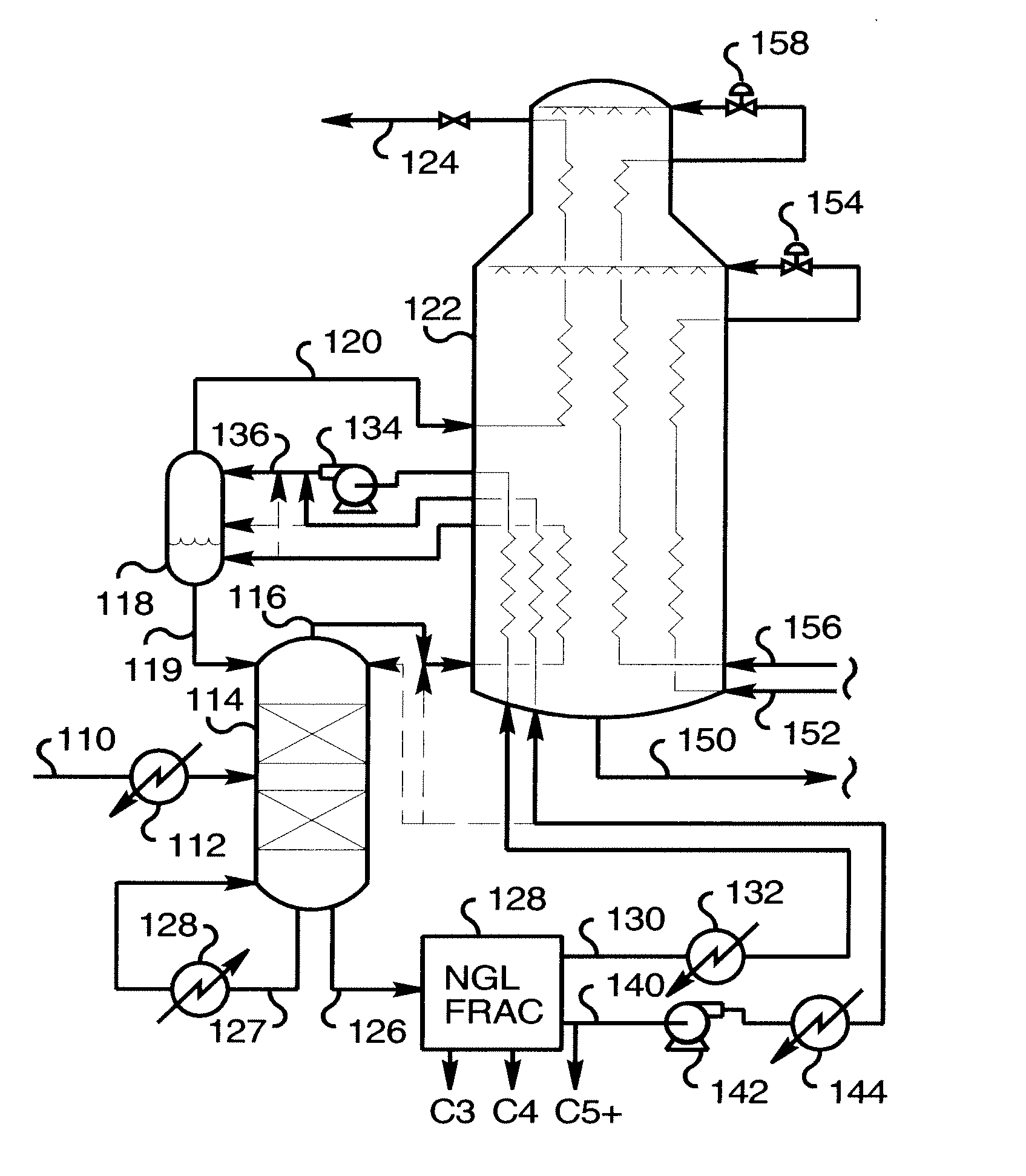

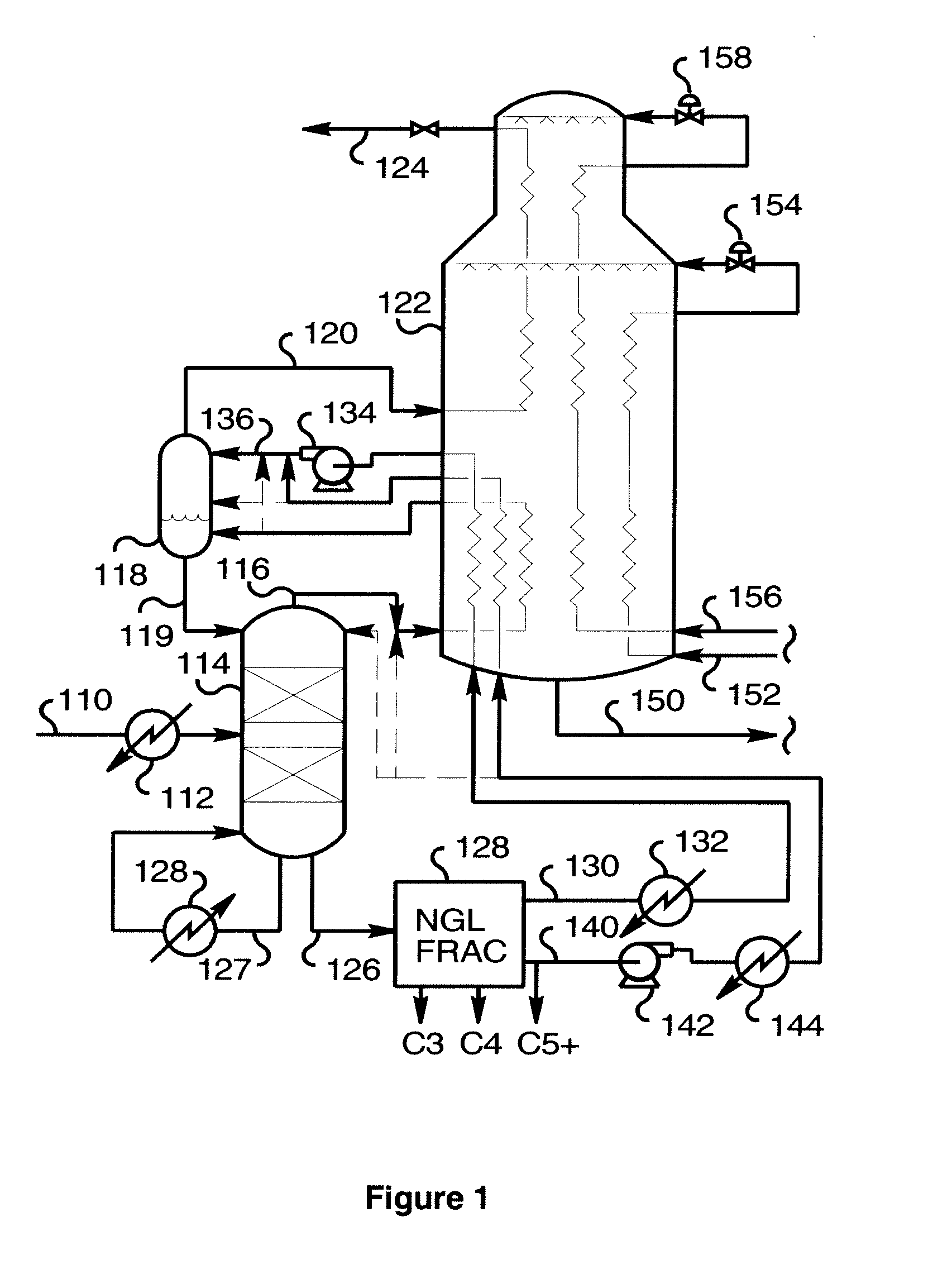

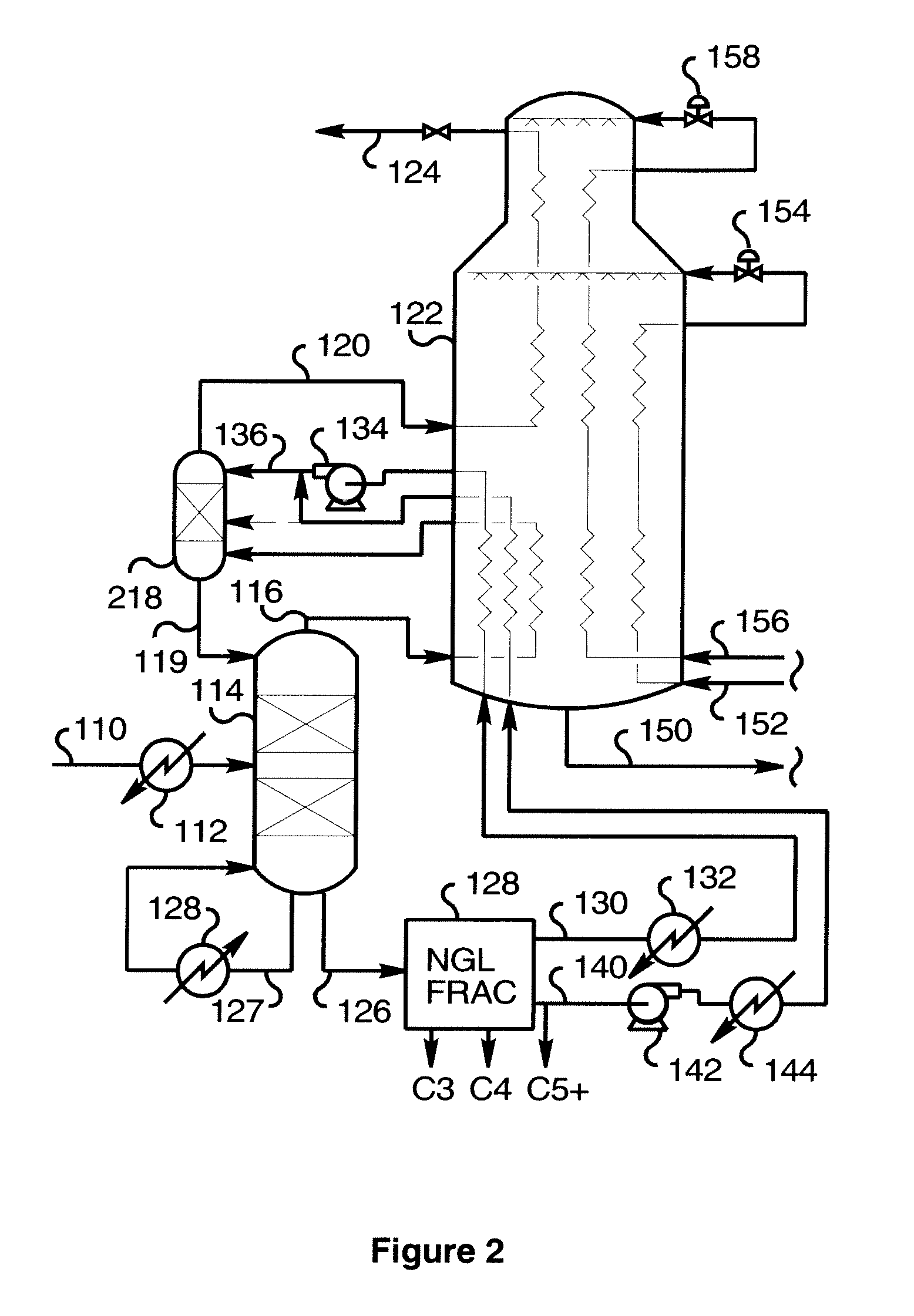

Integrated NGL recovery and liquefied natural gas production

InactiveUS20060260355A1Improves ethane-propane separationMaximize the benefitsSolidificationLiquefactionHydrocotyle bowlesioidesFractionation

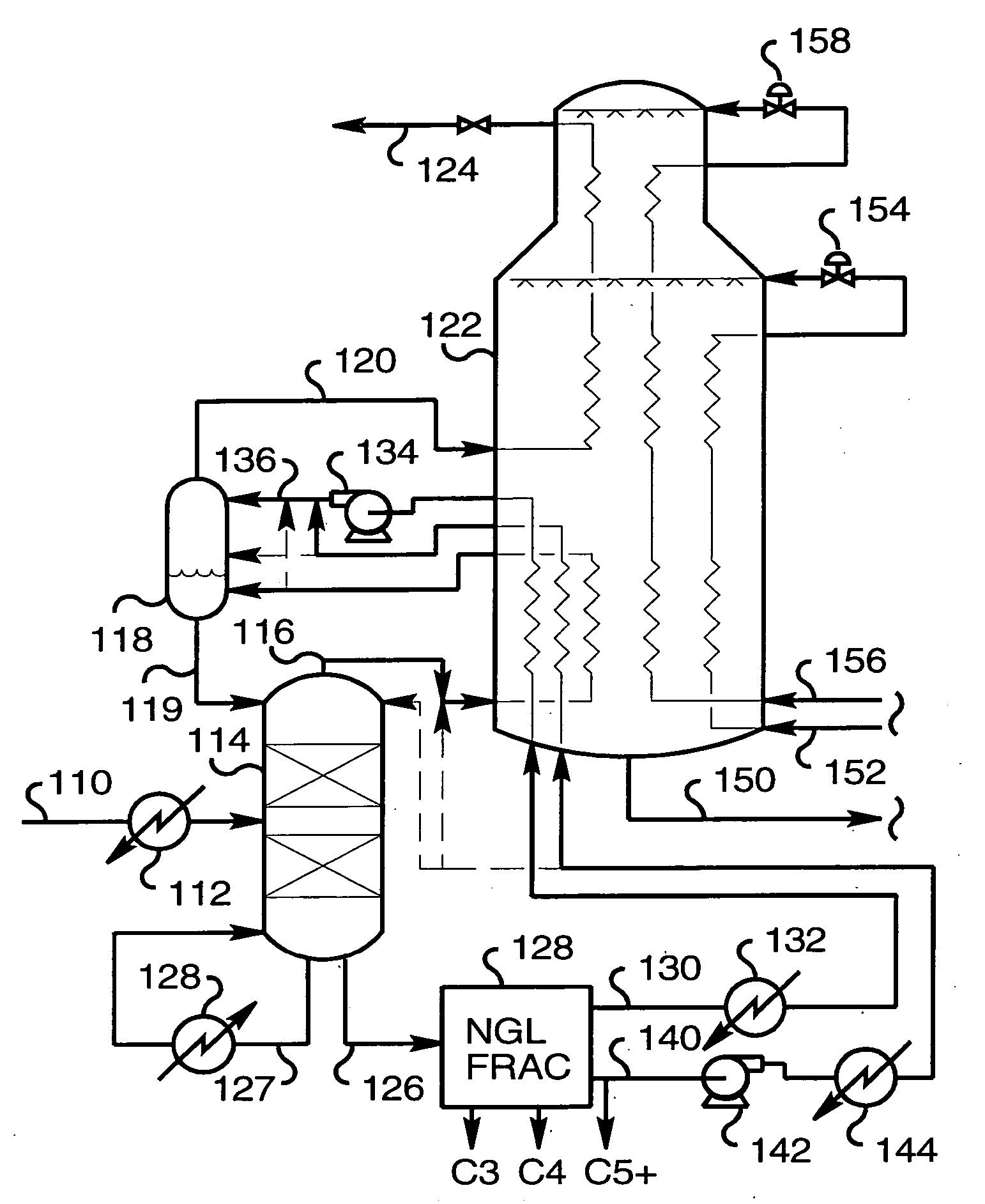

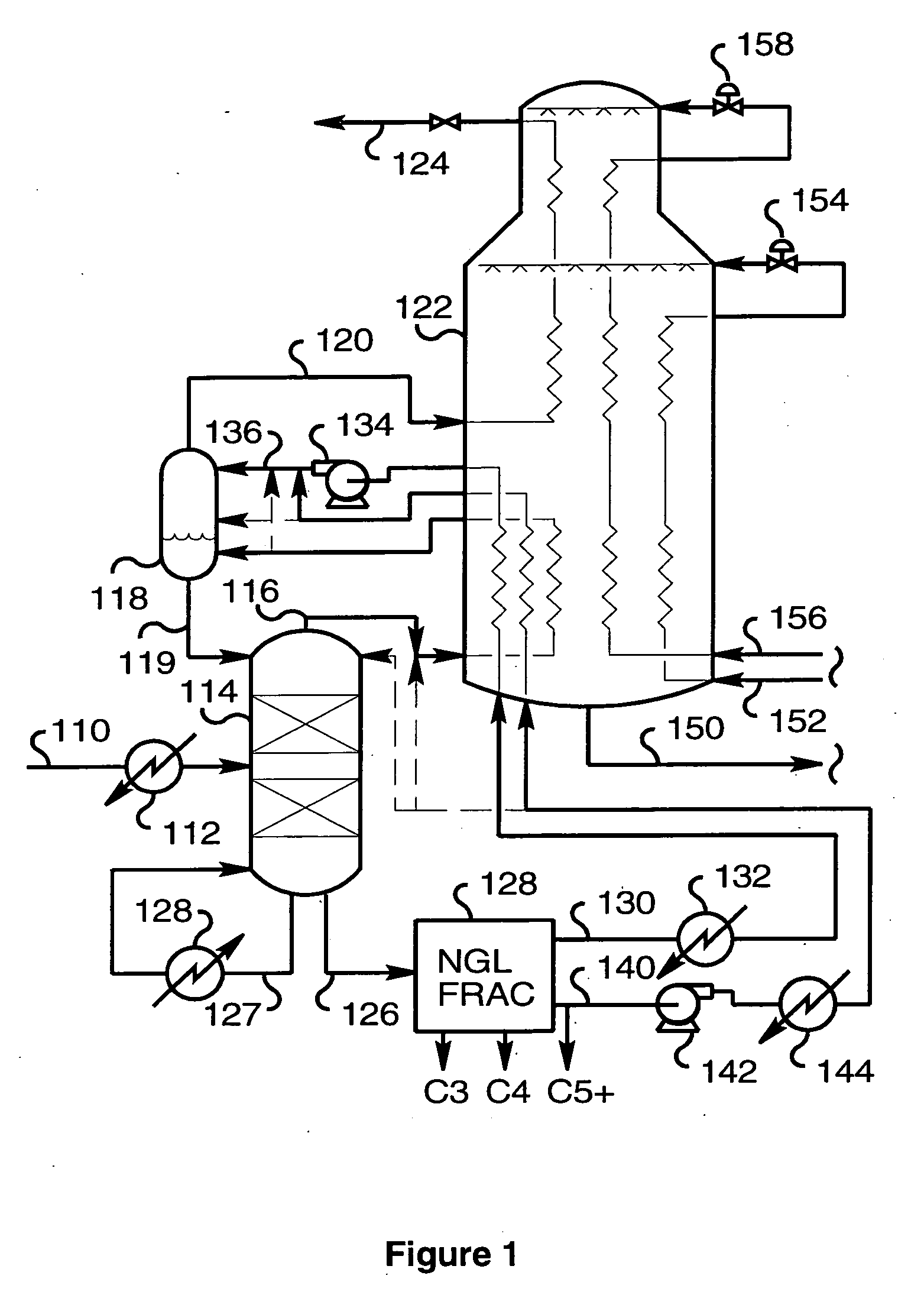

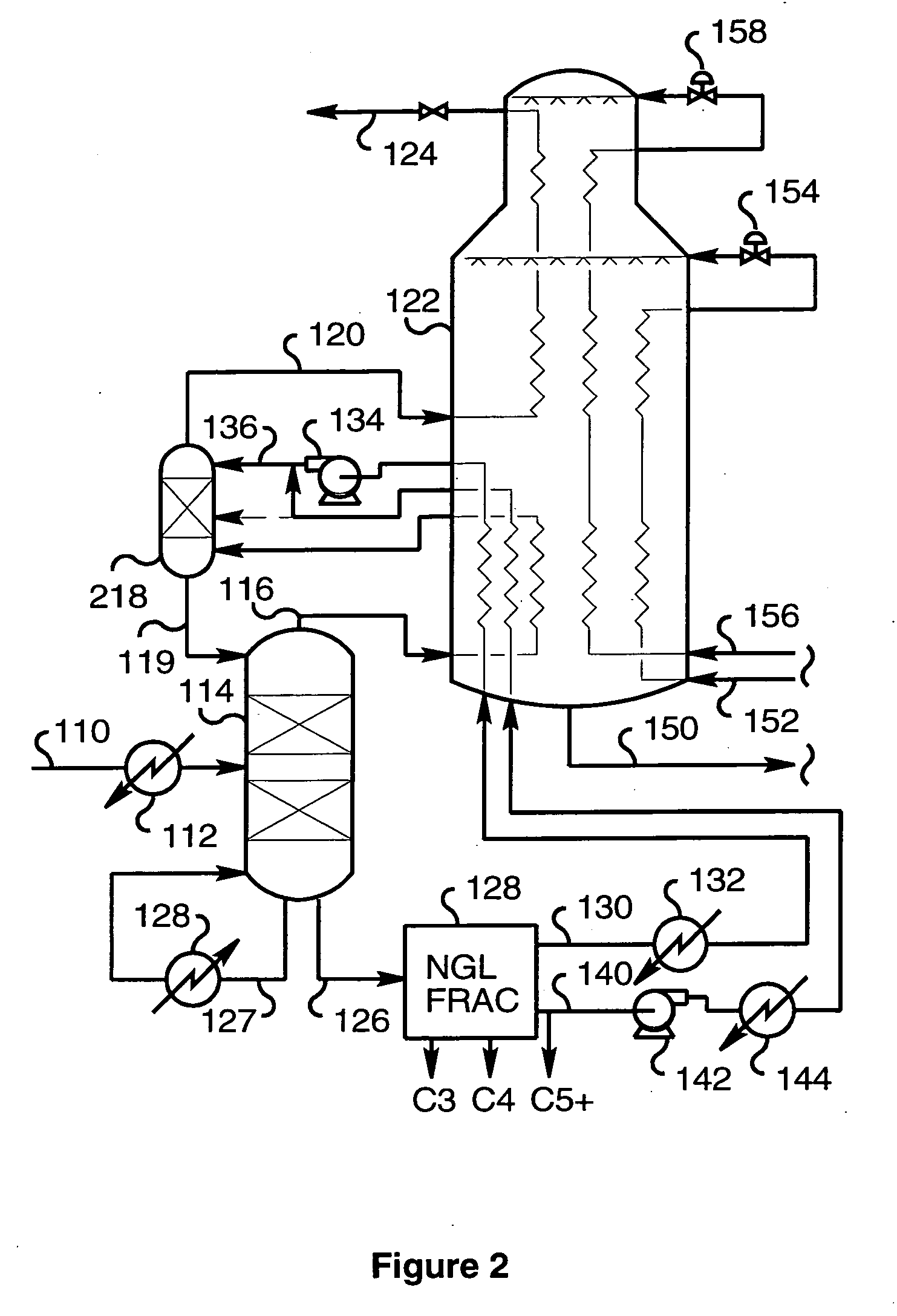

The separation of methane from an admixture (110) with ethane and higher hydrocarbons, especially natural gas, using a scrub column (114), in which the admixture is separated into a methane-rich overhead (116) that is partially condensed (122) to provide reflux to the column (114) and liquid methane-depleted bottoms liquid (126), is improved by providing additional reflux (136) derived from an ethane enriched stream (130) from fractionation (128) of the bottoms liquid. Preferably, absorber liquid (140) from the fractionation (128) also is introduced into the scrub column. The vapor fraction (120) remaining after partial condensation can be liquefied (122) to provide LNG product (124).

Owner:AIR PROD & CHEM INC

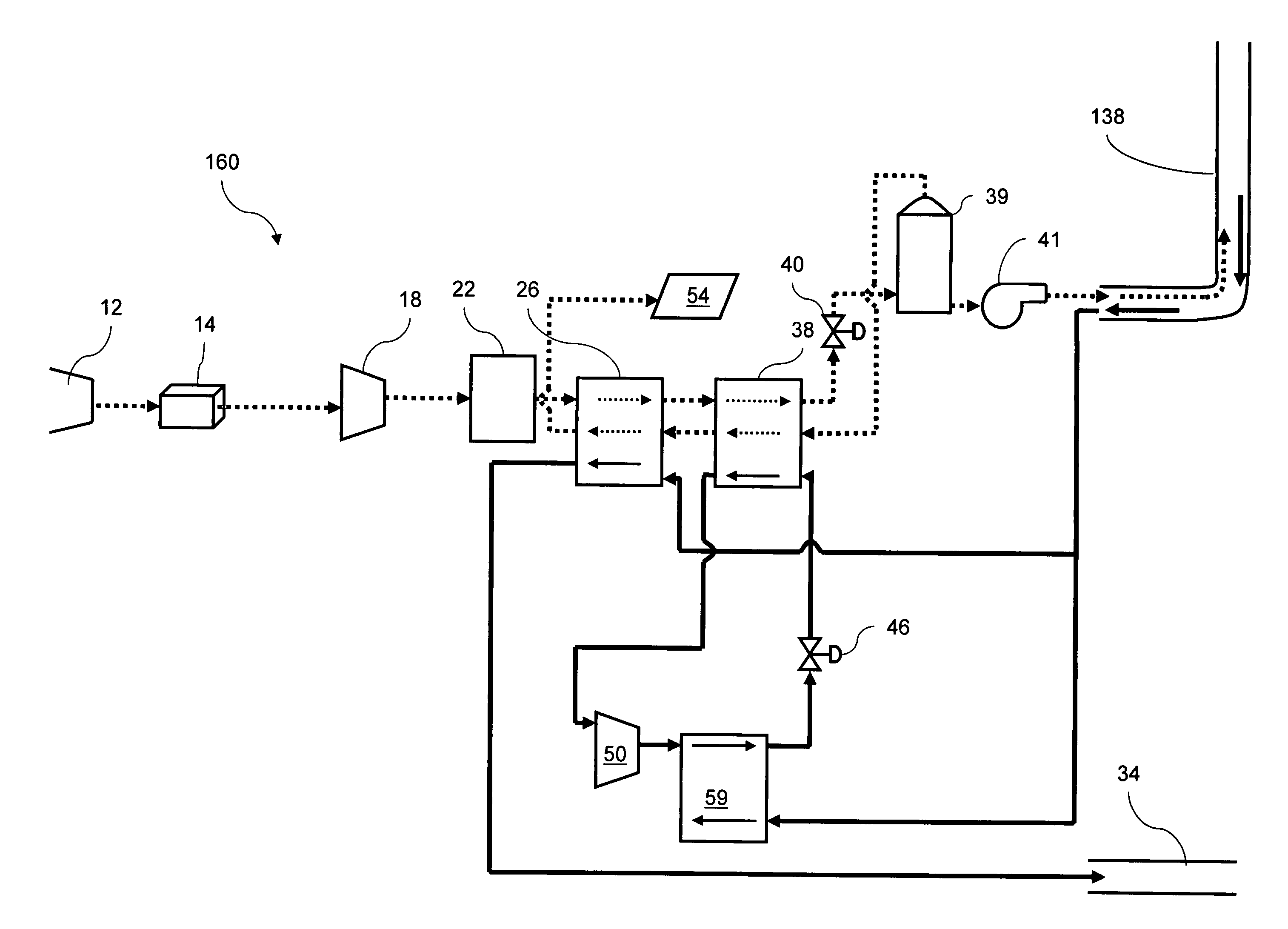

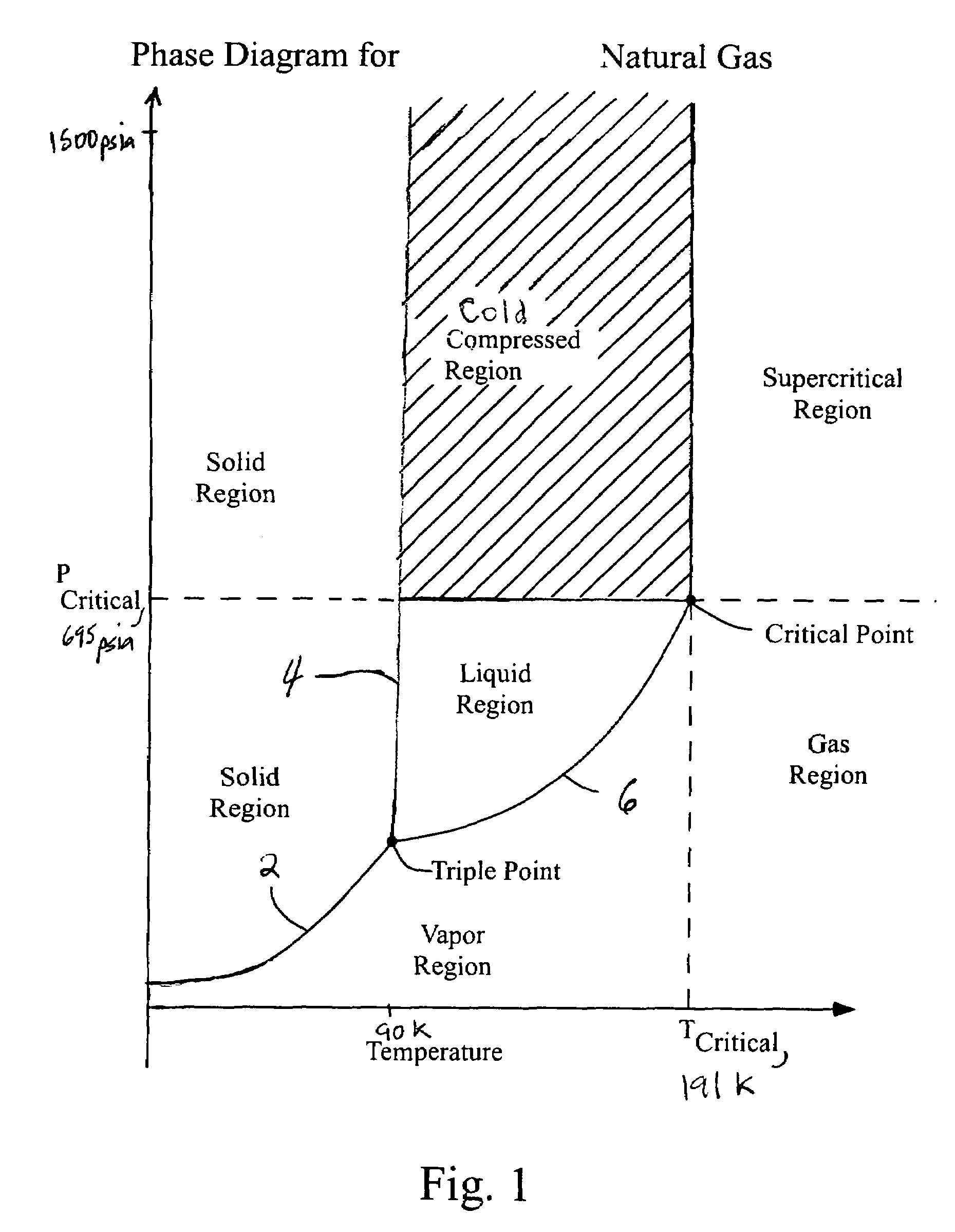

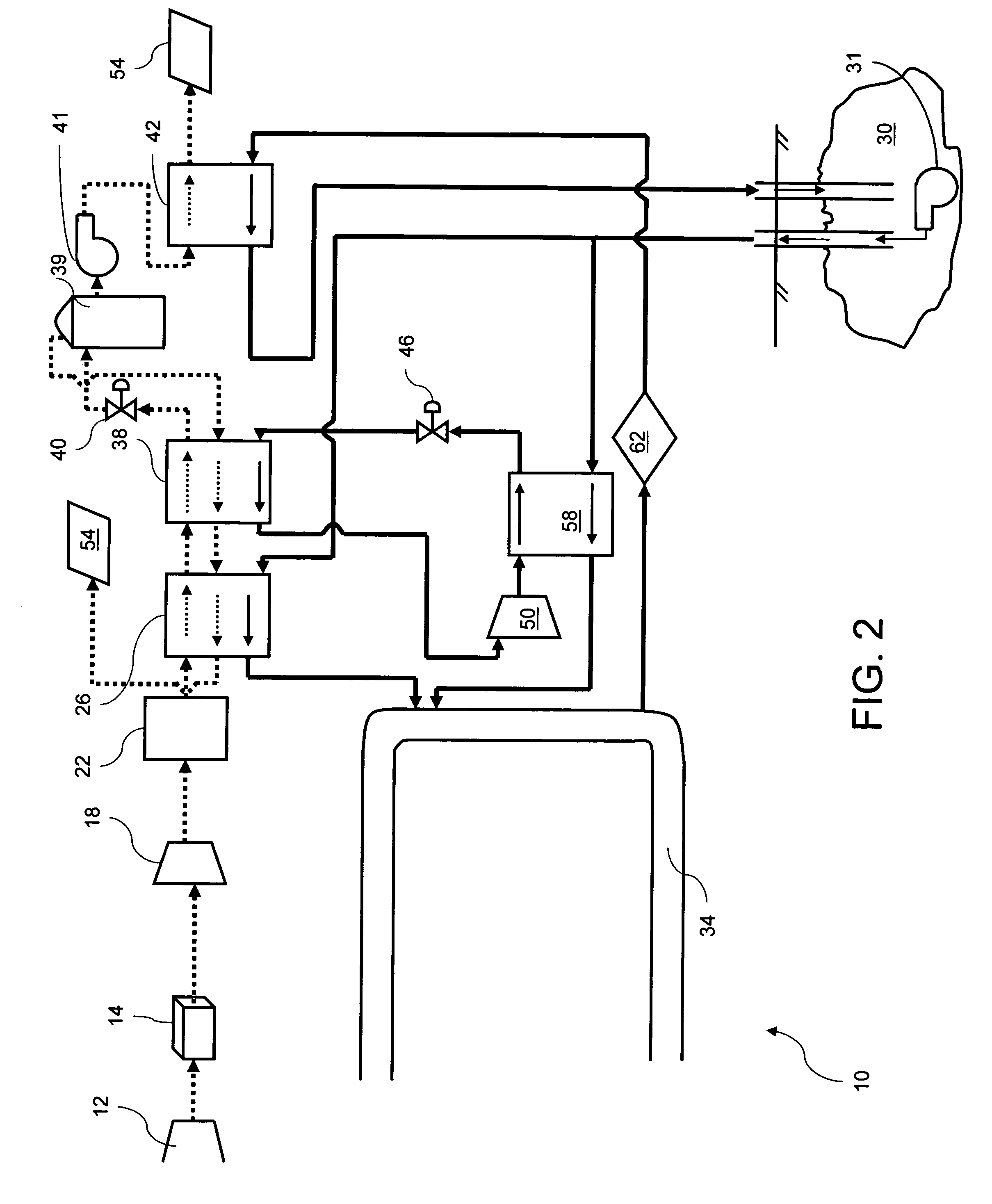

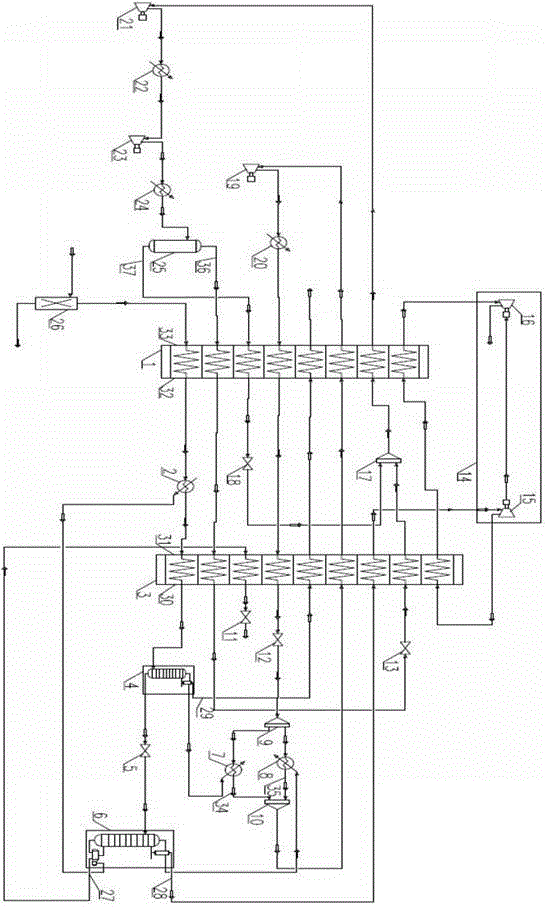

System and method for cold recovery

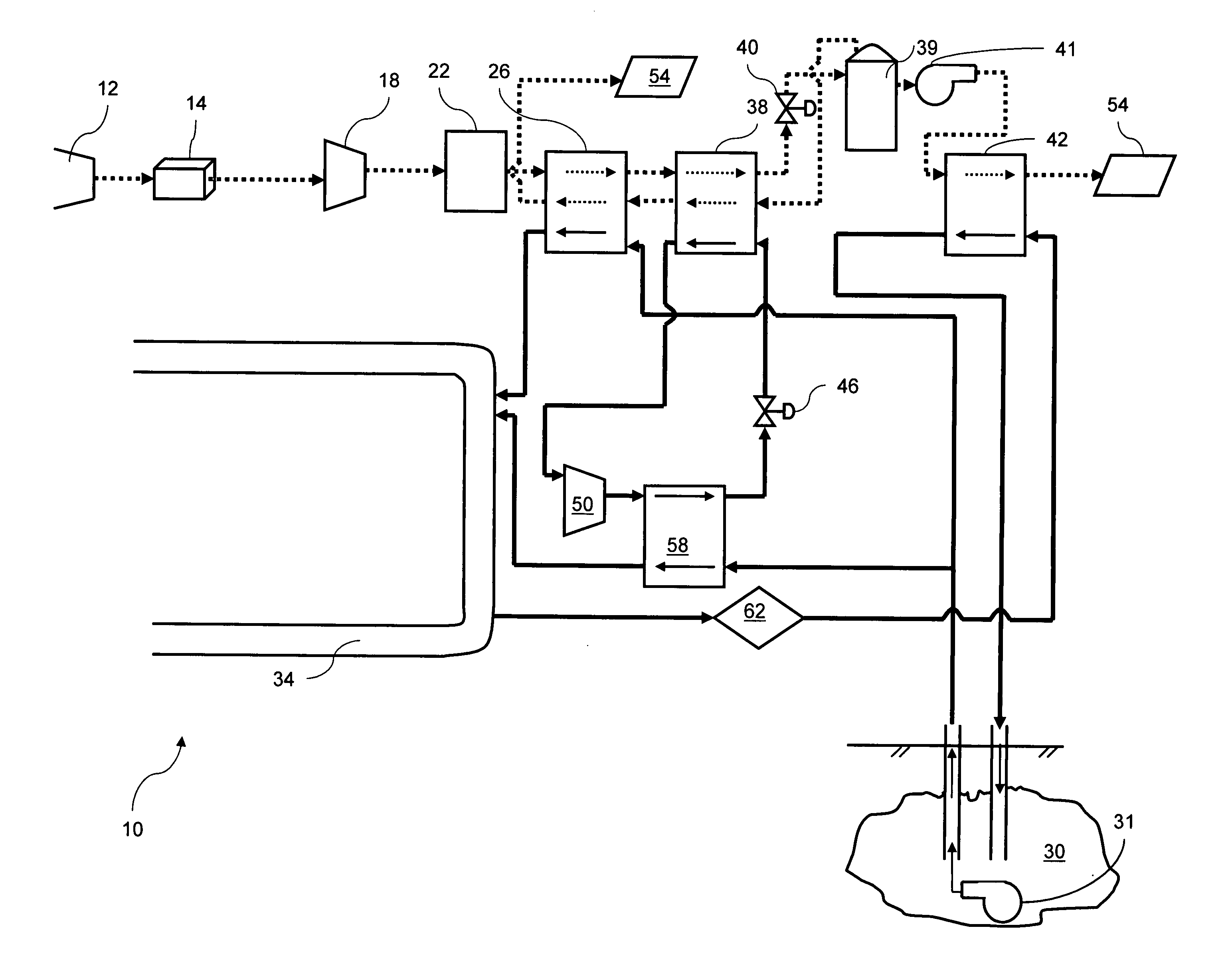

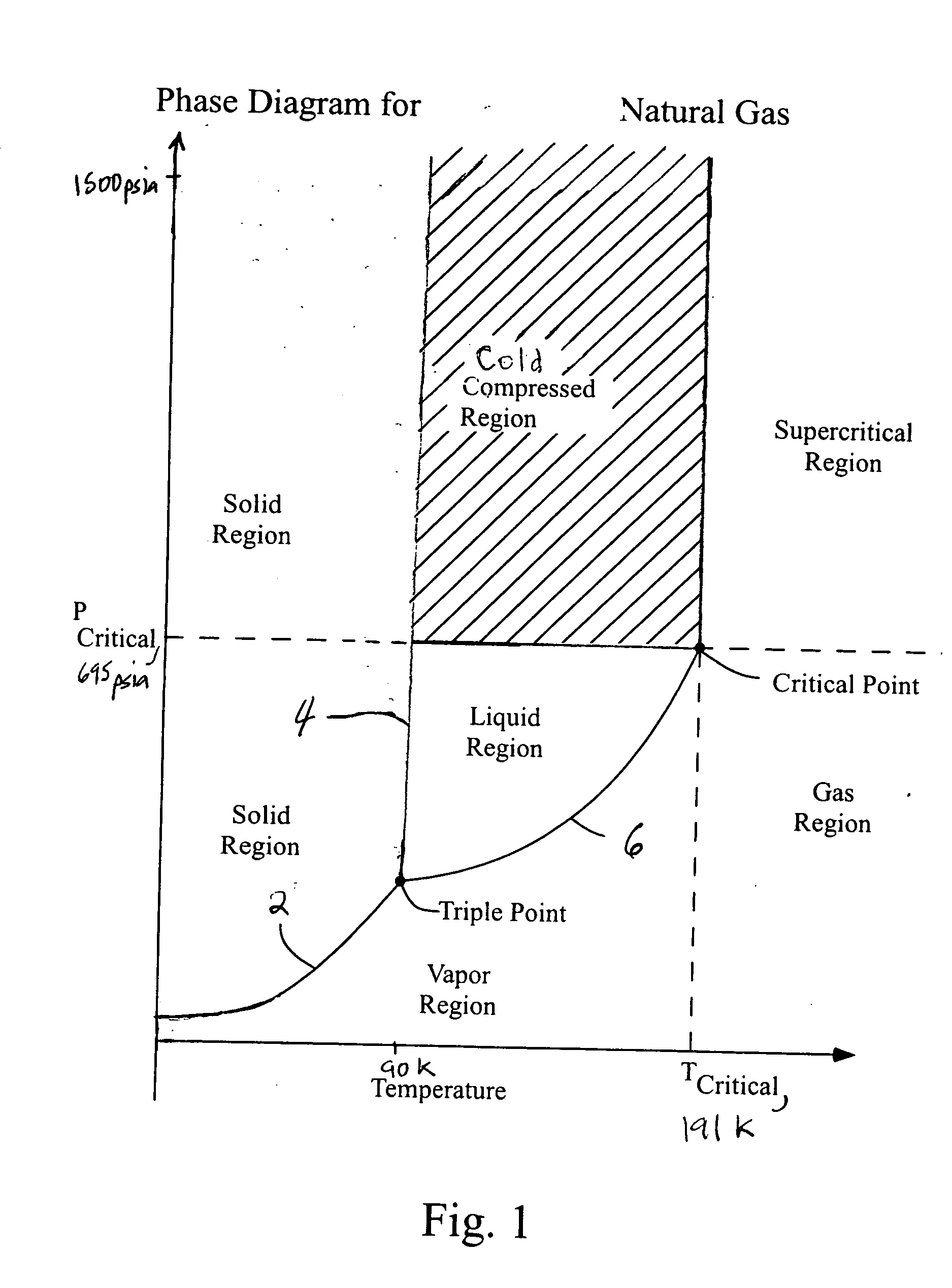

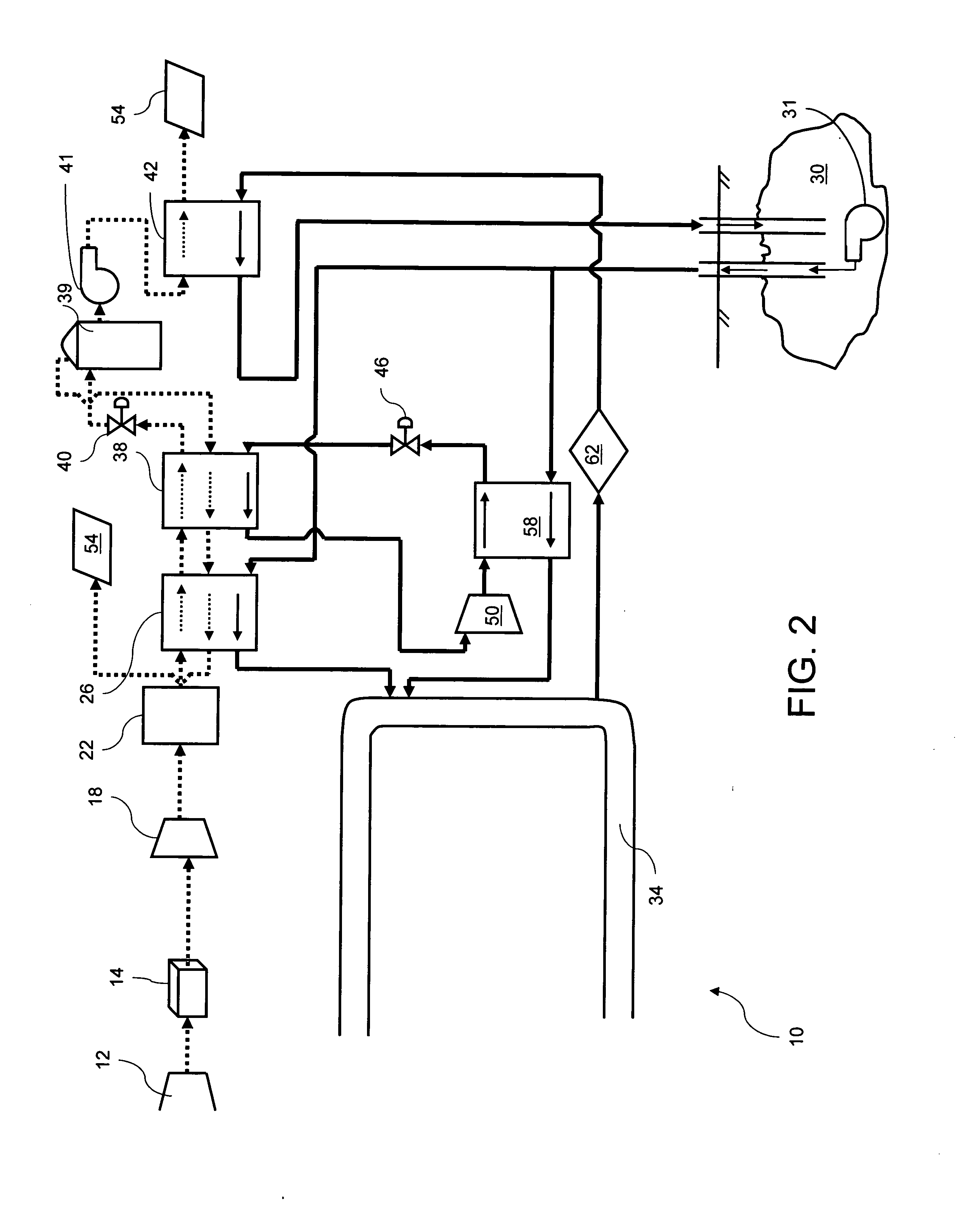

A method of cold recovery in a cold compressed natural gas cycle, the method comprising: compressing air; drying air; heat exchanging air with cold compressed natural gas from a storage vessel, in a first heat exchanger, thereby forming cooled air; heat exchanging the cooled air with liquid methane, in a second heat exchanger, such that the cooled air becomes liquid air and the liquid methane becomes methane; heat exchanging the liquid air with natural gas from a pipeline, in a third heat exchanger, such that the natural gas cools to a cold compressed natural gas and the liquid air becomes air in a gaseous state; discharging the air in a gaseous state. A system of cold recovery comprising: an air dryer; an air compressor in fluid communication with the air dryer; a first heat exchanger in fluid communication with the air compressor; a second heat exchanger in fluid communication with the first heat exchanger; a third heat exchanger in fluid communication with the second heat exchanger; a methane expander valve in fluid communication with the second heat exchanger; a fourth heat exchanger in fluid communication with the methane expansion valve; a methane compressor in fluid communication with the second heat exchanger and with the fourth heat exchanger; a natural gas scrubber in fluid communication with a third heat exchanger; a natural gas pipeline in fluid communication with the first heat exchanger; the fourth heat exchanger, and the natural gas scrubber; and a storage vessel in fluid communication with the first heat exchanger, the third heat exchanger, and the fourth heat exchanger.

Owner:EXPANSION ENERGY

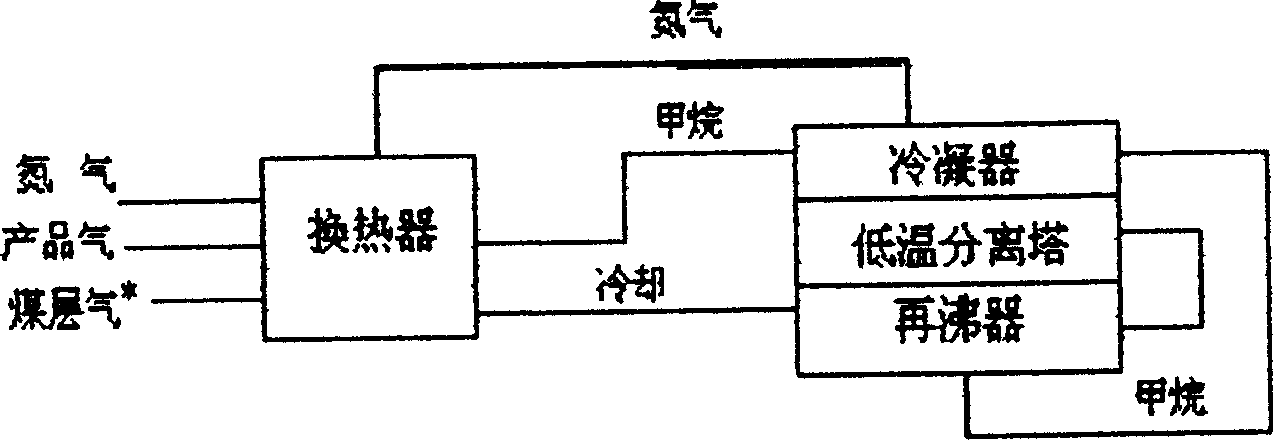

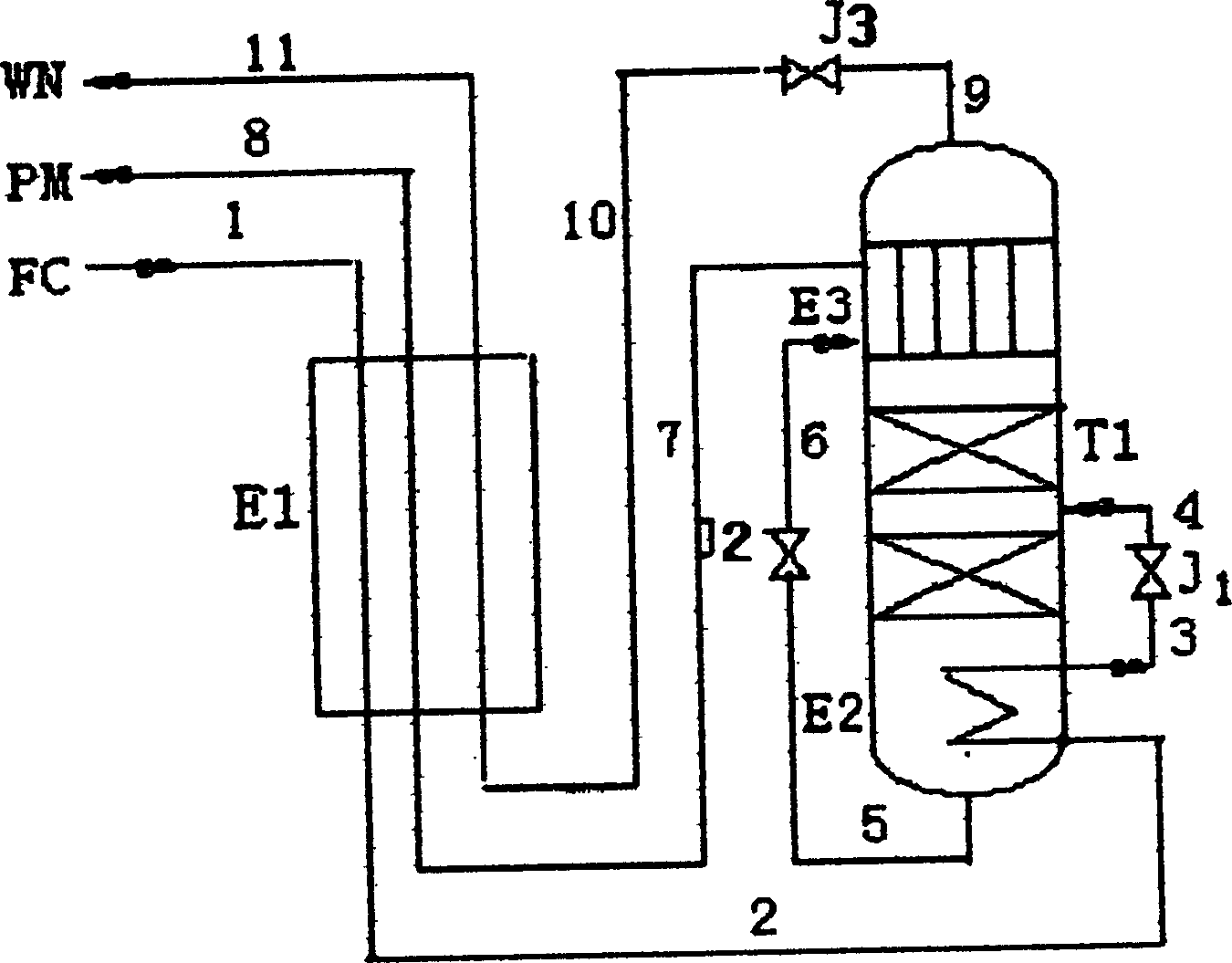

Technology of low temperature separation and concentration coal layer gas to produce methane

A process for low-temp separation of methane from coal seam gas and concentrating it includes such steps as removing O2, pressurizing, desulfurizing, decarbonizing, drying. Low-temp separation to obtain liquid methane, flowing in the condenser on the tower top for using it as the cold source of condensing reflux, and flowing the evaporated methane through heat exchanger to obtain product. Its purity is 95-99%. Its recovery rate is 95-99%.

Owner:HAO HUA CHENGDU TECH

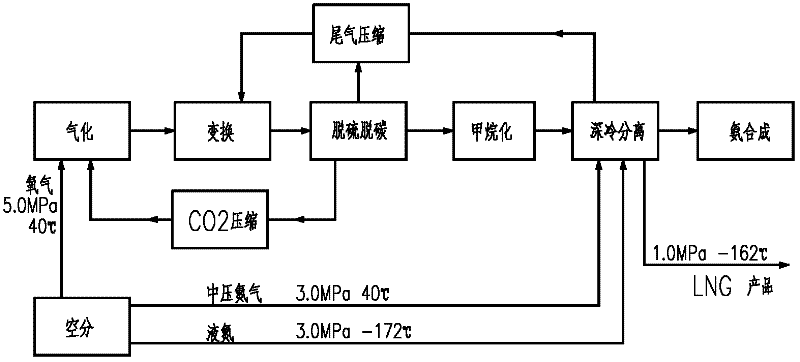

Process for coproducing liquefied natural gas (LNG) and synthetic ammonia

ActiveCN102533365ATake advantage ofOmit the step of separating nitrogenSolidificationLiquefactionMethanationNitrogen

The invention belongs to the technical field of coal chemical industry and particularly relates to a process for coproducing gasified synthetic ammonia and liquefied natural gas (LNG). The invention provides a method and equipment for coproducing the LNG and the synthetic ammonia by using raw coal gas generated by a high-temperature entrained bed; the desulphurization and the decarbonization are carried out by using a mature and advanced physical and chemical absorption process, methane is obtained by using an advanced methanation conversion technology, then, a deep cooling technology is adopted to produce liquid methane and hydrogen through staged cooling and washing separation, the produced liquid methane is outputted as a product, i.e. the LNG, meanwhile, the produced hydrogen is mixed with nitrogen to form a synthetic gas, and the synthetic gas is conveyed to an ammonia synthesizer for the production of the synthetic ammonia after the cold energy is recovered. The coproduction of natural gas and liquid ammonia is achieved, the equipment has corresponding capability for load adjustment, and the emission of vent gas in synthesis is not needed, so that the raw coal gas is maximally used in the production of products.

Owner:CHANGZHENG ENG

Method And Apparatus for High Purity Liquefied Natural Gas

InactiveUS20140130542A1Eliminate requirementsEnvironment safetySolidificationLiquefactionMolecular sieveDistillation

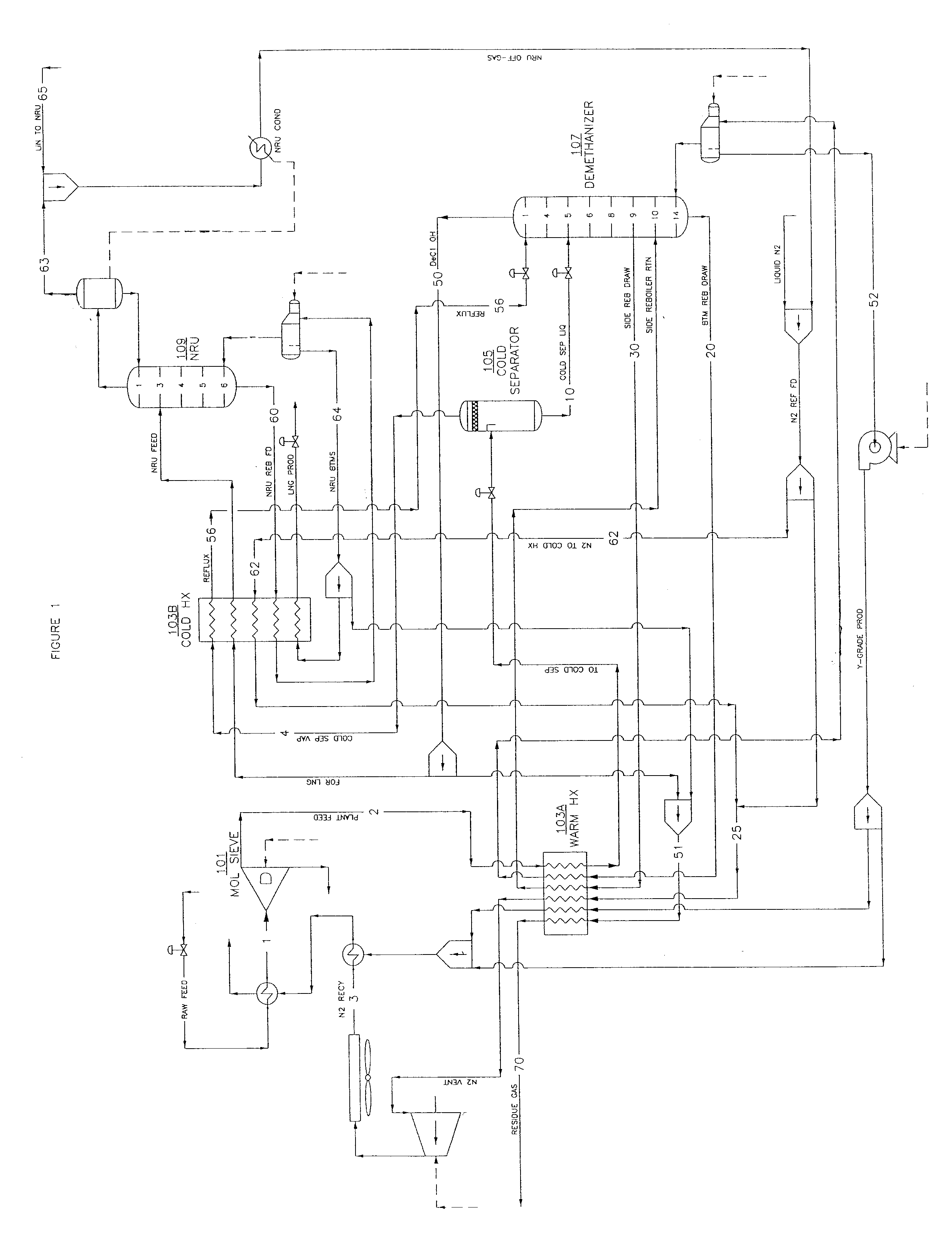

A novel method and system for liquefying and distilling natural gas into high purity liquid methane (LNG) and NGL product streams. Heat exchangers and distillation towers are configured to produce high purity liquefied natural gas (LNG) and NGL product streams, while also rejecting excess nitrogen contained in the inlet gas stream, utilizing liquid nitrogen as the process refrigerant. A molecular sieve pretreatment system is configured to utilize the vaporized nitrogen stream for regeneration of the molecular sieve beds which are designed for removing water and carbon dioxide from the inlet gas stream

Owner:BROWN WILLIAM GEORGE +2

System and method for cold recovery

Owner:EXPANSION ENERGY

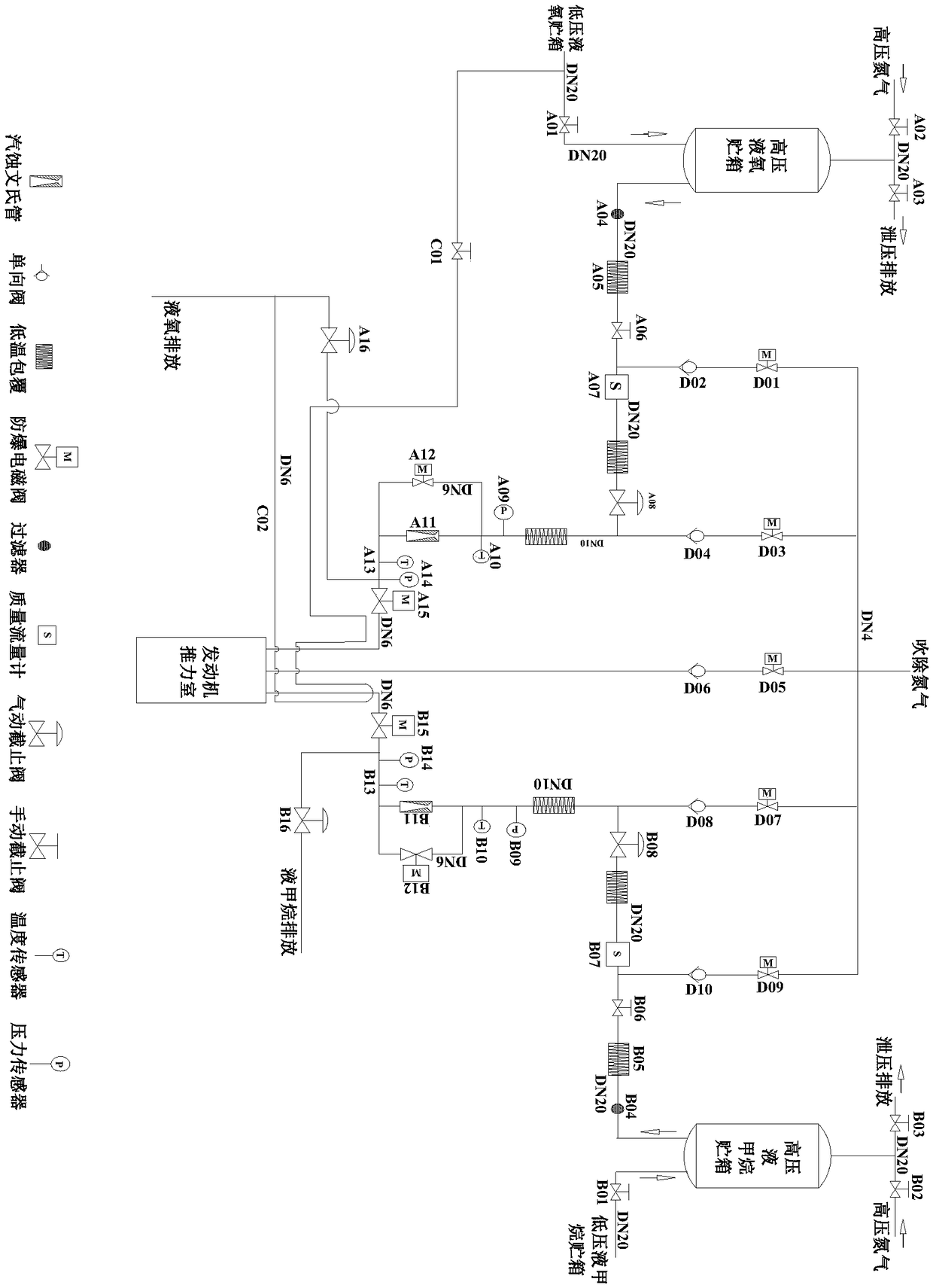

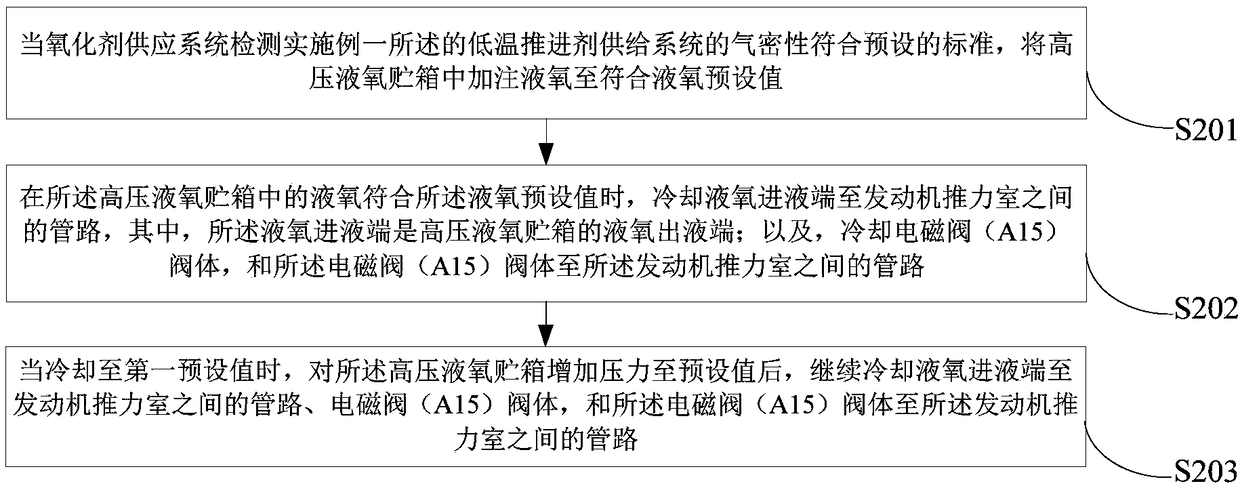

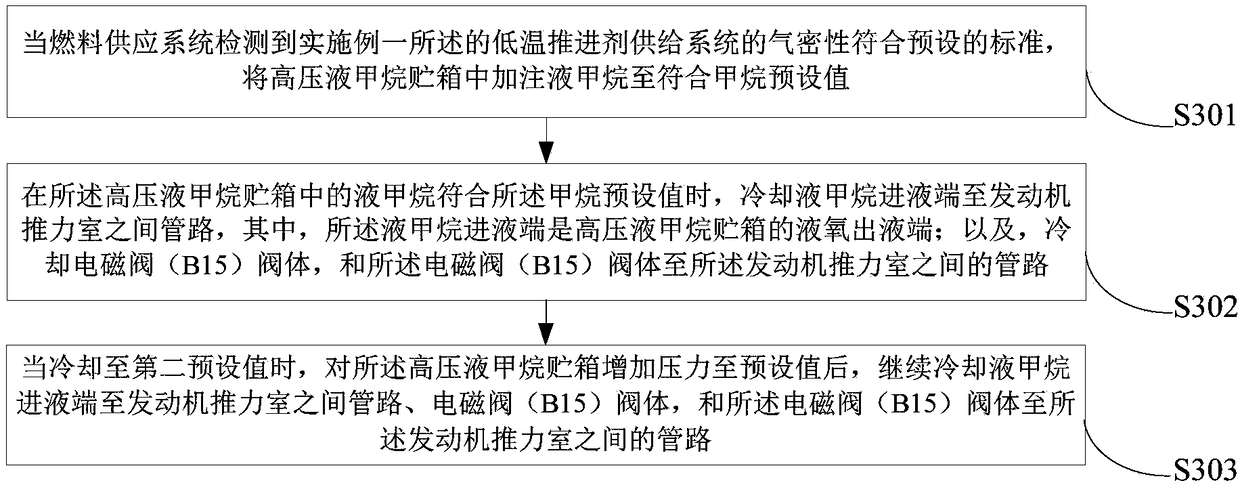

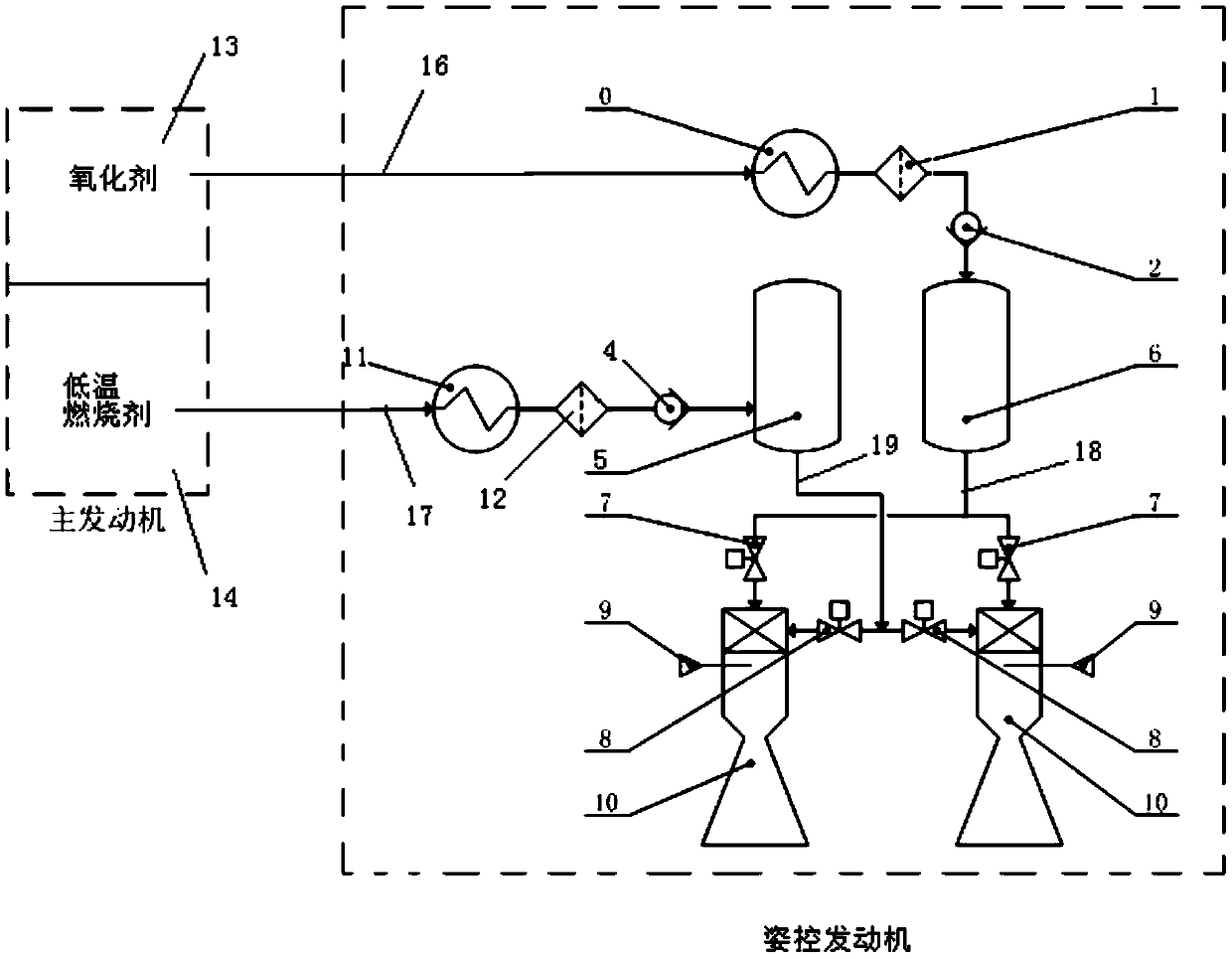

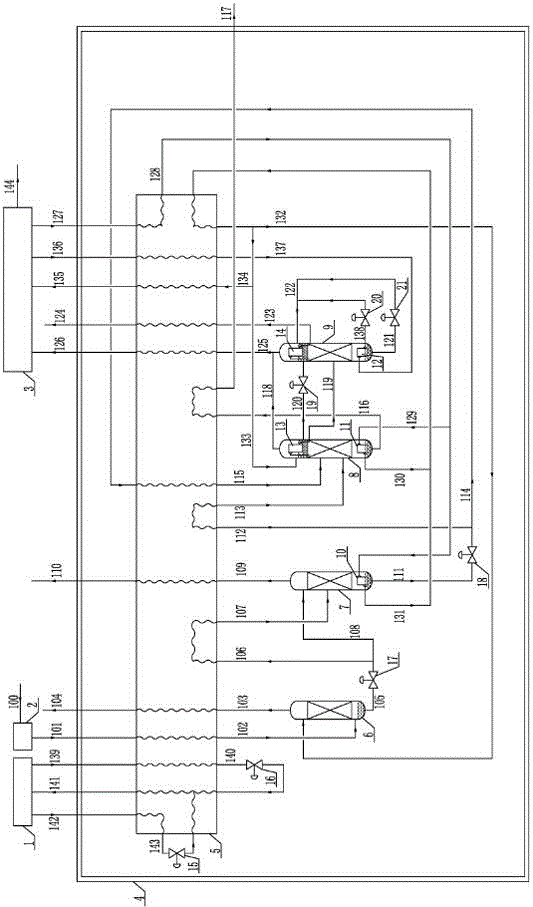

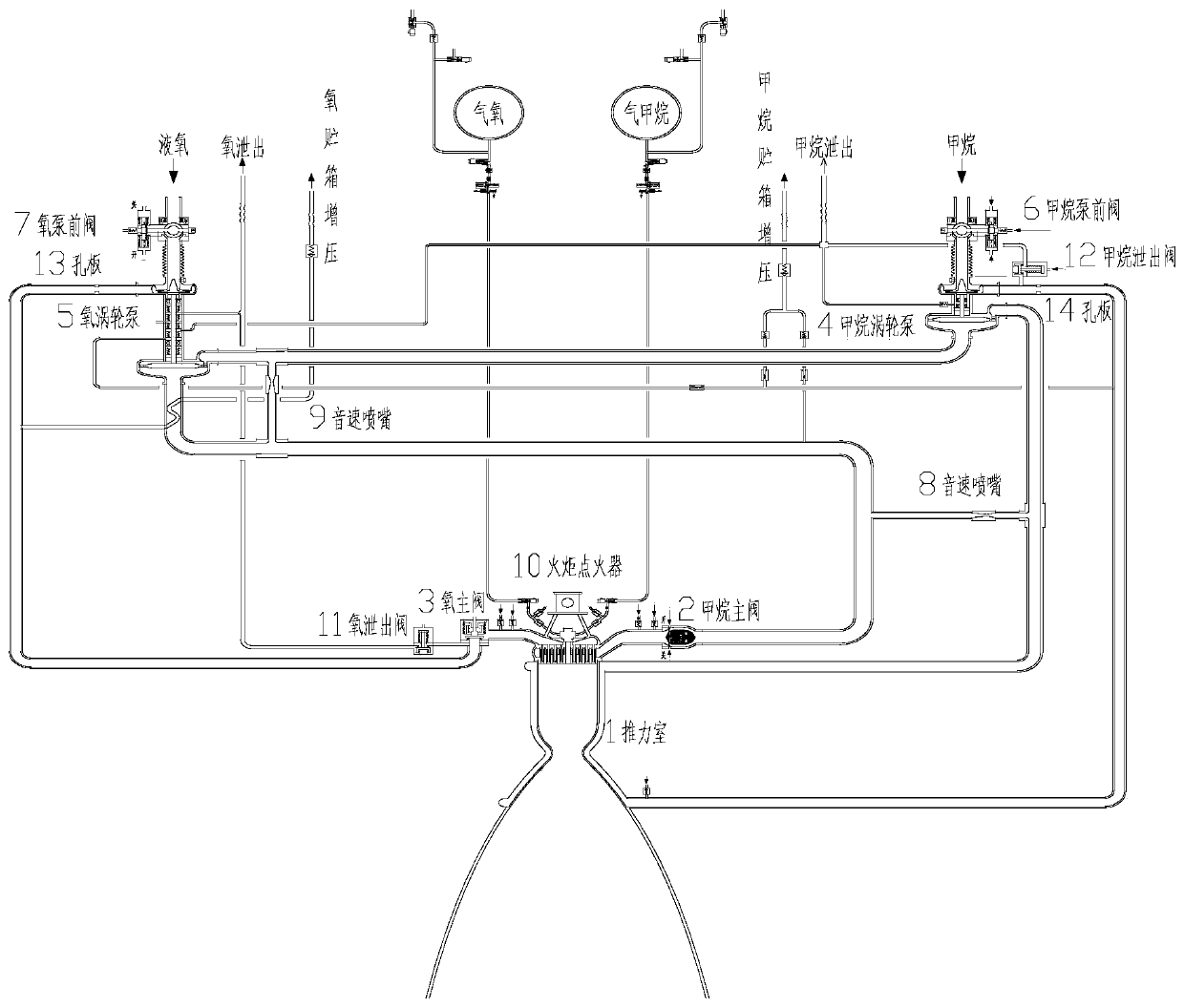

Low-temperature propellant supplying system, method and device

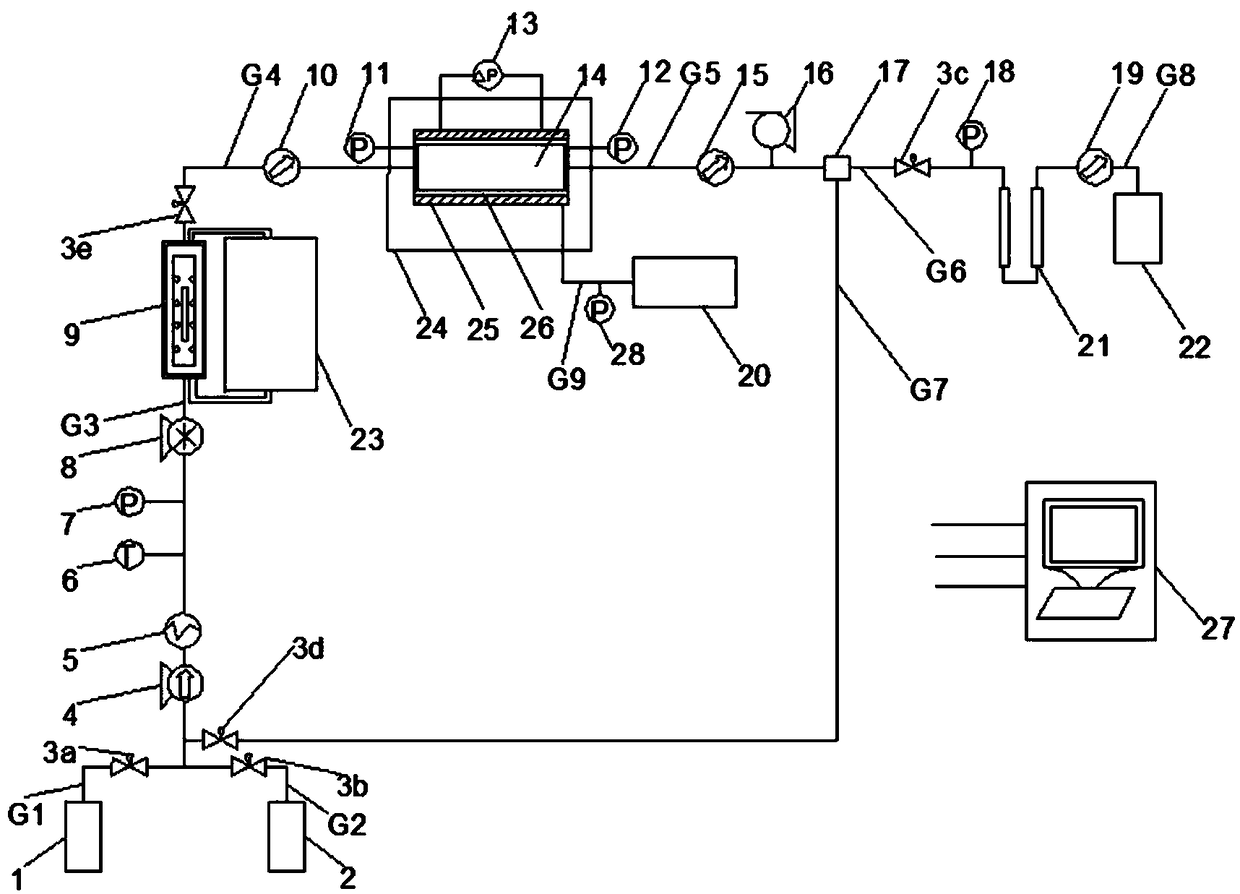

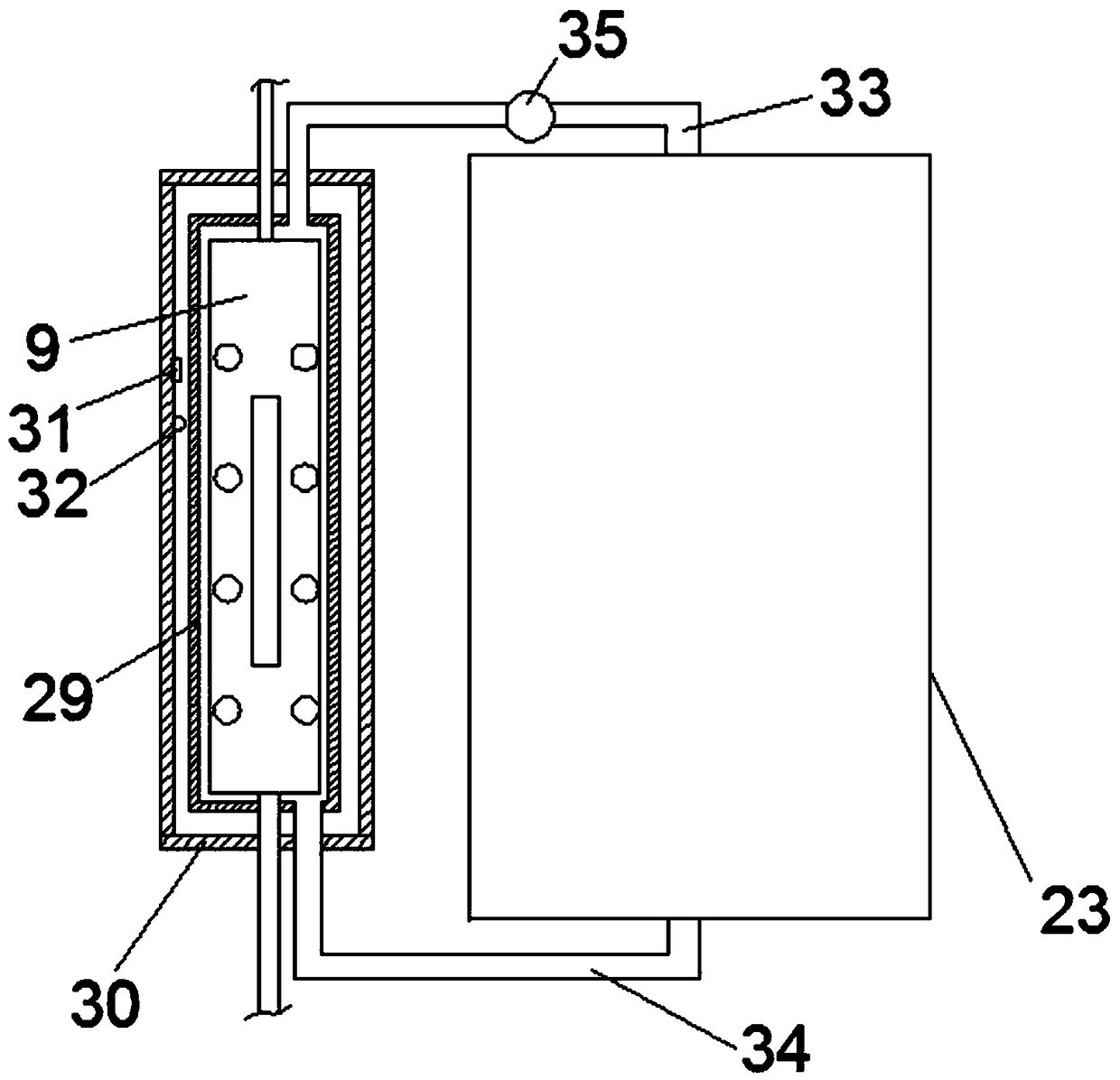

ActiveCN109469558AStable adjustment of delivery volumeControl flowGas-turbine engine testingRocket engine plantsThrust chamberNitrogen

The invention provides a low-temperature propellant supplying system, a method and a device. The low-temperature propellant supplying system comprises a nitrogen blowing away system, an oxidant supplying system, a fuel supplying system and a low-pressure liquid oxygen cooling system; the nitrogen blowing away system is used for carrying out purging operation on a system pipeline before and after an experiment and detecting the air tightness of the low-temperature propellant supplying system; under the condition that the air tightness of the low-temperature propellant supplying system is qualified, the oxidant supplying system is used for conveying liquid oxygen to an engine thrust chamber; the fuel supplying system is used for conveying liquid methane to the engine thrust chamber; the low-pressure liquid oxygen cooling system is used for cooling a pipeline, wherein partial pipeline is located between an electromagnetic valve (A15) and the engine thrust chamber and partial pipeline is located between an electromagnetic valve (B15) and the engine thrust chamber. According to the embodiment of the supplying system, the method and the device, the required preset temperature can be achieved before the test, the low-pressure liquid oxygen cooling system adopts low-pressure liquid oxygen to cool the environment so as to ensure the safety, the propellant conveying amount can be stablyadjusted, and simplicity and reliability are achieved.

Owner:BEIHANG UNIV

Pressure synthesis and refining process of methane chloride

InactiveCN1515528AAvoid quenchingAvoid sudden heatHalogenated hydrocarbon preparationCatalytic methodLiquid methane

The present invention relates to a new process for producing methane chloride by using liquid-phase catalytic method and pressurization process. The hydrogen chloride and methyl alcohol are mixed according to a certain ratio, then placed in a tank reactor with catalyst, and under the condition of a certain temp. and pressure the invented methane chloride can be synthesized. It adopts acid / water washing and alkali-washing processes to remove unreacted methyl alcohol and hydrogen chloride, and adopts concentrated sulfuric acid washing process to remove residual water content and reaction by-product dimethyl ether, then the purified and dried methane chloride gas is undergone the processes of compression and condensation so as to obtain high-purity liquid methane chloride product.

Owner:蓝星安迪苏股份有限公司

Recovery of hydrogen from refinery and petrochemical light ends streams

A process for recovering hydrogen from a stream comprised of hydrogen, non-condensable gases, and propane and lighter hydrocarbons, wherein the process comprises the steps of stripping hydrogen and non condensable gases out of the feed light ends stream with methane vapor, washing the stripped hydrogen stream with liquid methane to absorb the non condensable gases, and washing the hydrogen stream with a hydrocarbon lean oil such as liquid ethane to absorb methane, to produce the product hydrogen stream.

Owner:WYLIE

Methane-producing composite microbial inoculum and preparation method thereof

InactiveCN101705199AReasonable designBreed fastBacteriaMicroorganism based processesBiogas productionLiquid methane

The invention relates to a methane-producing composite microbial inoculum and a preparation method thereof, which can solve the long-standing difficult problems that the existing biogas digester is lack of high-efficient methane-producing bacteria, thereby resulting in long initial start-up time of biogas production and poor stability of the biogas production. Methanosarcina acetoacidophilum DSM-N0.2834, methanobacterium formicicum DSM-No.1535, methanobrevibacter arboriphilicus DSM-No.1125, methanolobus tindarius DSM-No.2278 and methanothrix concilii DSM-No.6752 collected in German collection of microorganisms and cell cultures are adopted and inoculated in a liquid methane bacterial culture medium under the anaerobic condition, the independent enlarged culture is carried out grade by grade respectively, and bacterial liquid after the cultured methane bacteria is mixed together according to the volume ratio, thereby preparing a liquid methane-producing composite microbial inoculum; and the liquid methane-producing composite microbial inoculum can also be prepared into a solid methane-producing composite microbial inoculum. The method has reasonable design and adopts the high-efficient strains with the optimal combination and the rapid propagation technology, and the developed high-efficient methane-producing composite microbial inoculum can significantly accelerate the start-up time of the biogas production when in new construction of the biogas digester and large material change, and improve the efficiency and the stability of the biogas production of the biogas digester.

Owner:北京合百意可再生能源技术有限公司 +1

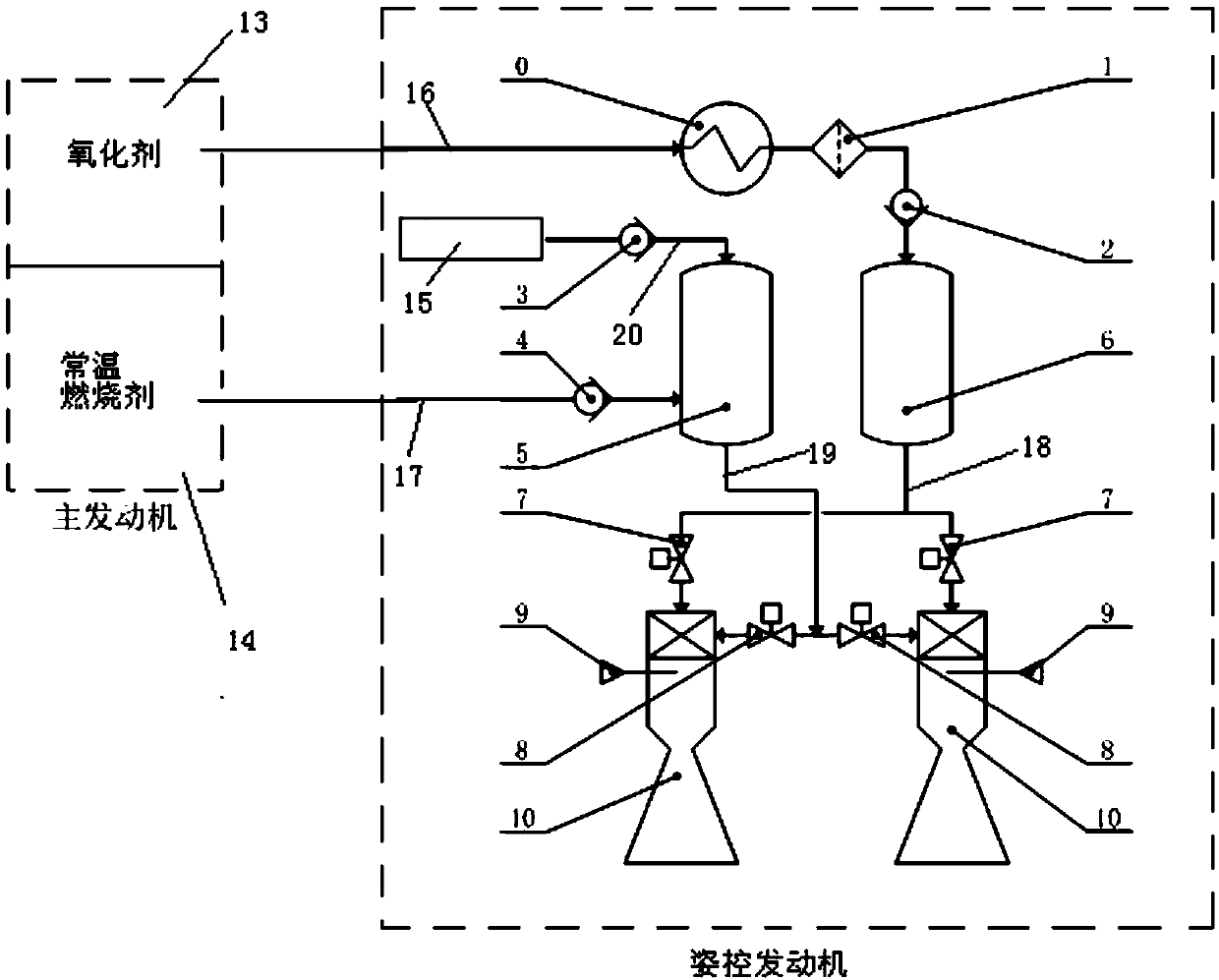

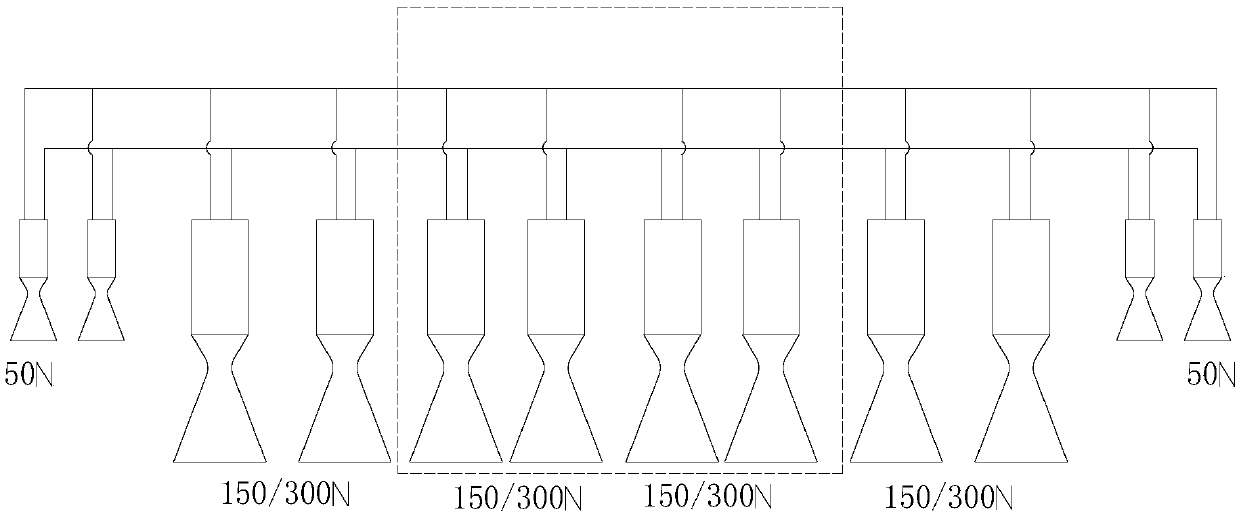

Power system for carrier rocket upper stage and orbit transfer vehicle

The invention discloses a power system for a carrier rocket upper stage and an orbit transfer vehicle. The power system for the carrier rocket upper stage and the orbit transfer vehicle solves the existing problems that a main engine and an attitude control engine are relatively independent, the carrying burden is relatively heavy,a propellant used in the attitude control engine is rather toxic,and the environment and safety of a human body are seriously threatened. The power system for the carrier rocket upper stage and the orbit transfer vehicle comprises the main engine and the attitude control engine; a propellant tank of the main engine can simultaneously deliver a propellant to a thrust chamber of the main engine and a thrust chamber of the attitude control engine under the action ofa propellant supply system of the propellant tank, and liquid oxygen is used as an oxidant of the propellant; kerosene, or liquid hydrogen or liquid methane is used as an incendiary agent; the detoxication of the attitude control engine is achieved, and integration of the homologous propellant of the main engine and the attitude control engine is achieved; a propellant tank of the attitude control engine can be supplemented after operation through the main engine; and the propellant dosage carried by the attitude control engine during flight can be reduced, thus the weight of the overall system is lowered, and the payload of a carrier is greatly increased.

Owner:XIAN AEROSPACE PROPULSION INST

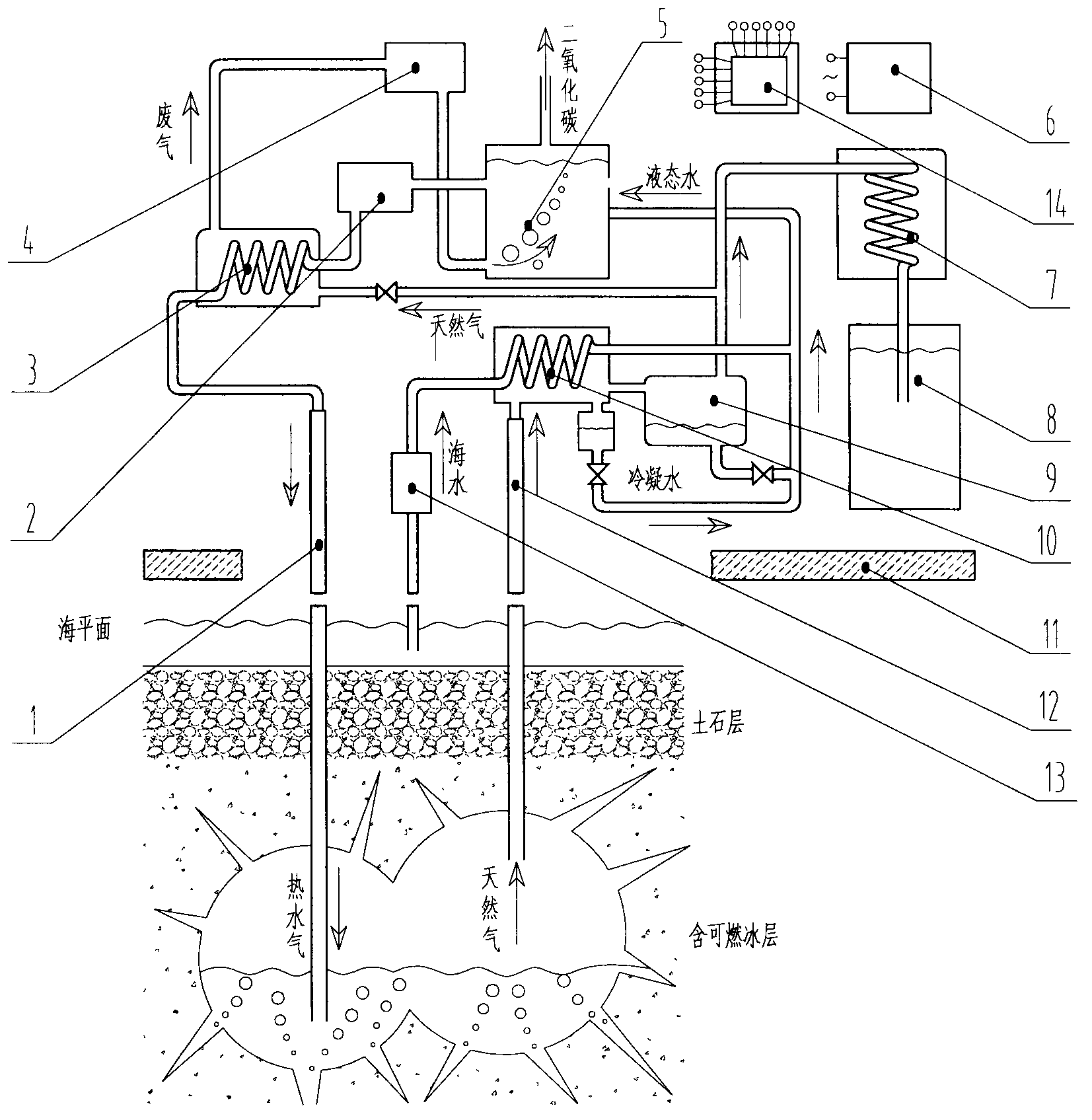

Method and system for exploiting seabed flammable ice

ActiveCN103510926AWill not cause collapseWon't leakOther gas emission reduction technologiesFluid removalOcean bottomDecomposition

The invention provides a method and system for exploiting seabed flammable ice. The method comprises the steps that two shafts are drilled through a drilling platform and reach a seabed flammable ice layer, the depths of the two shafts are different, the distance between the two shafts is small, two cavities are formed in the bottom of the shafts through explosives in an exploded mode, the two cavities are communicated, high-temperature sea water is constantly poured into the bottom of the deeper shaft, so that methane is changed into the gaseous state from the solid state, gaseous methane is jetted from the other shaft, moistures are eliminated through pressurization and cooling, the temperature is lowered to minus 162 DEG C in a refrigerating mode through a nitrogen compressor, so that liquid methane is formed, or the methane is made into flammable ice again to be stored, and part of methane is used as fuel for heating sea water. The method and system for exploiting the seabed flammable ice has the advantages that as long as pouring of the high-temperature sea water is stopped, the flammable ice can stop decomposition, insulation measures are applied to pipes and containing tanks, and therefore waste of heat energy cannot be generated; power is supplied by a diesel generator, the manufacturing cost is low, and operation is reliable; the method for exploiting the seabed flammable ice belongs to the gap permeation substitution method, and seabed collapse cannot be caused; emission only comprises carbon dioxide, and other waste is used for seabed backfilling and recycled.

Owner:ZIBO HIGH TECH ZONE CHENGDA MACHINERY DESIGN INST

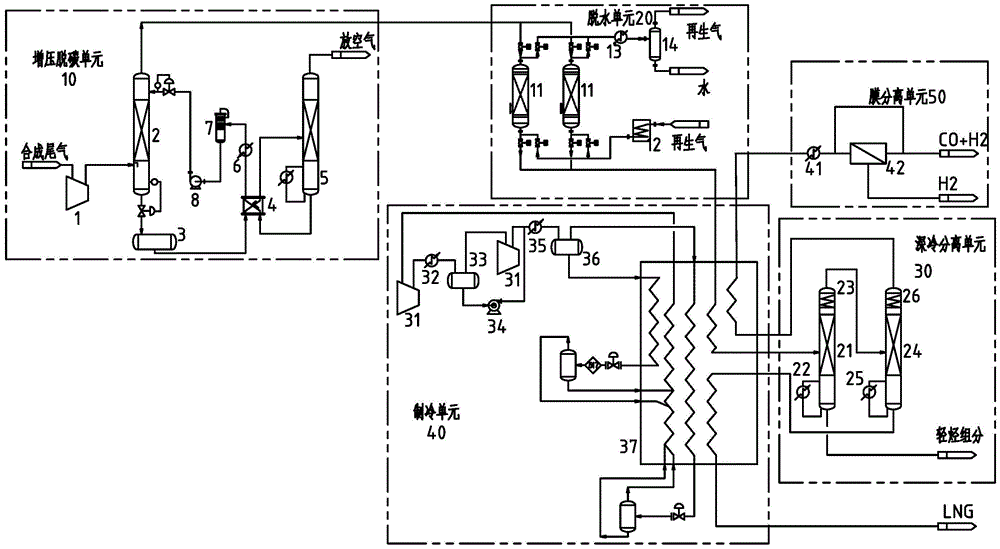

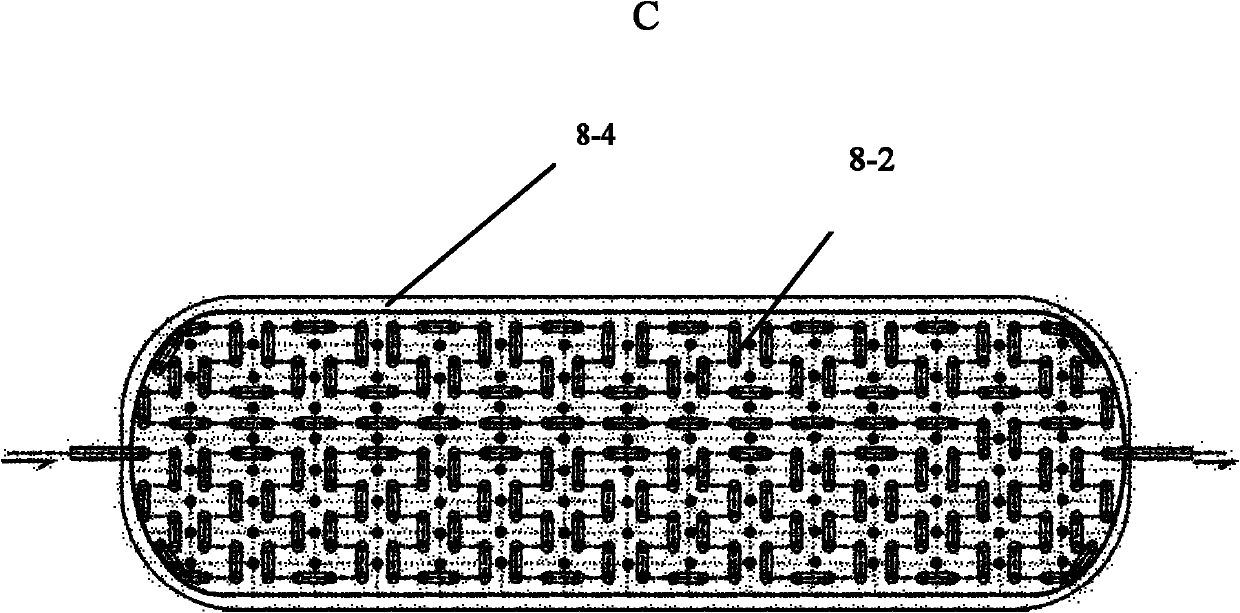

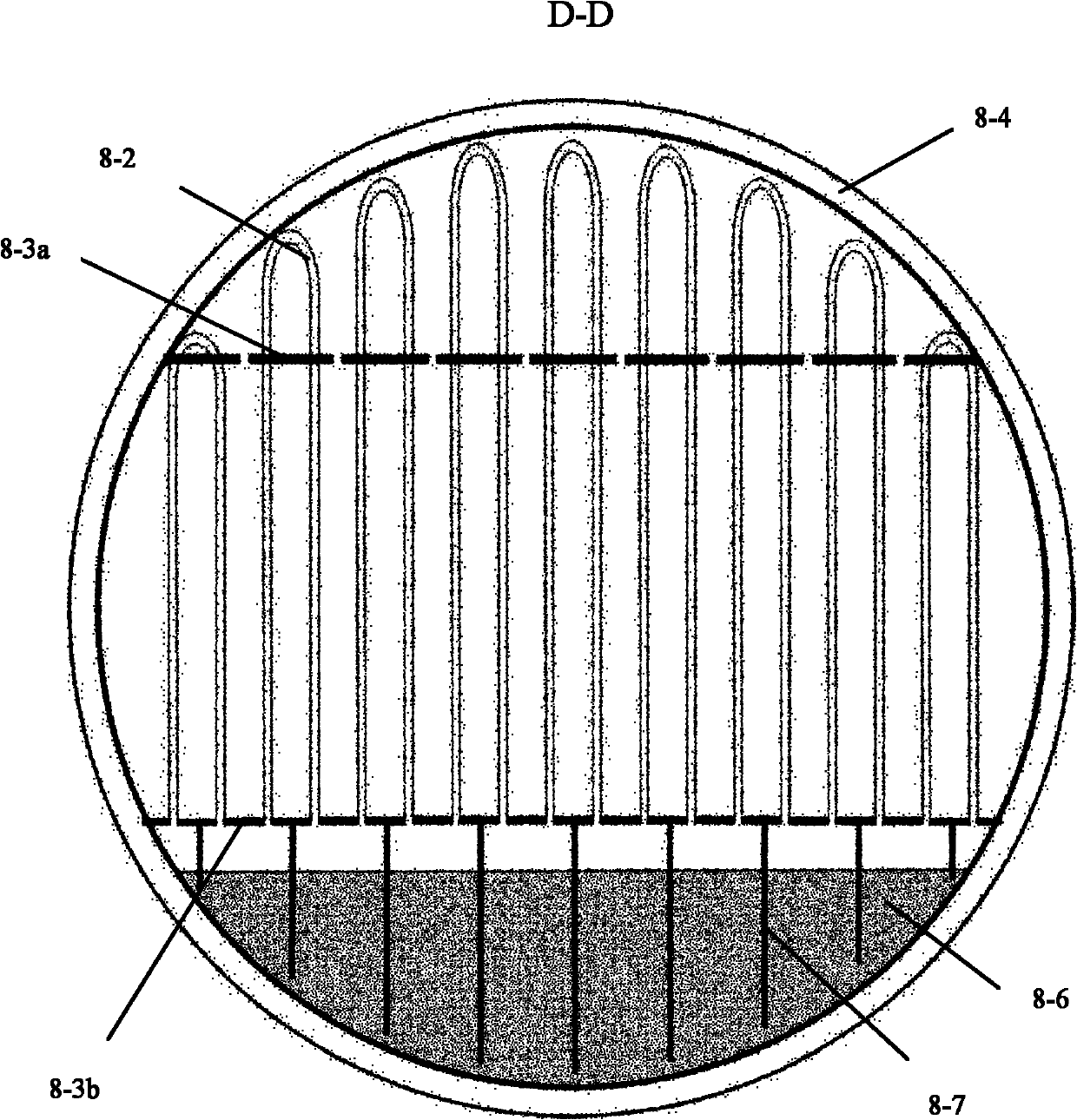

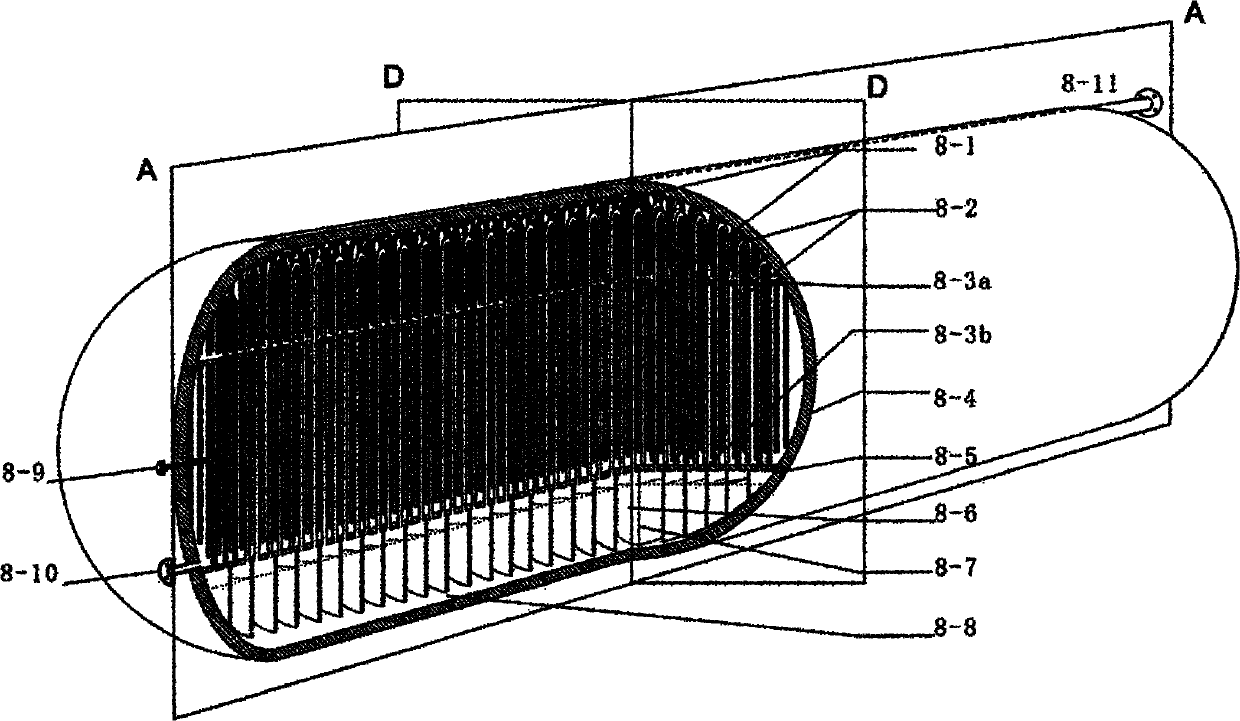

System and method for preparing high purity carbon monoxide and hydrogen-enriched co-production liquid methane

InactiveCN105865147AHigh purityHigh recovery rateSolidificationLiquefactionDehydrogenationLiquid methane

The invention relates to the field of low-temperature gas separation, in particular to a system and method for preparing high purity carbon monoxide and hydrogen-enriched co-production liquid methane. The system mainly comprises a raw material gas purification unit, a low-temperature liquefying separation unit, a CO product compressor and a mixed refrigerant compressor. The low-temperature liquefying separation unit comprises a main heat exchanger, a methane washing tower, a dehydrogenation tower, a demethanization tower and a denitrification tower. A first evaporator is arranged at the bottom of the dehydrogenation tower; a second evaporator is arranged at the bottom of the demethanization tower; a first condenser is arranged on the top of the demethanization tower; a third evaporator is arranged at the bottom of the denitrification tower; and a second condenser is arranged on the top of the denitrification tower. According to the system and method, while high purity products rich in H2 and CO are obtained through four-tower process flow, high purity liquid methane can be obtained; the adaptability of a device to raw material gas is high; the requirement for raw material gas purities of the device is lowered; and part of CO is extracted from the tail stage or the middle stage of the CO product compressor to be used as a cold source and a heat source of a rectifying tower circularly according to the pressure of CO product gas, a nitrogen compressor and an expander are omitted, the number of devices is small, and the investment is small.

Owner:KAIFENG AIR SEPARATION GROUP

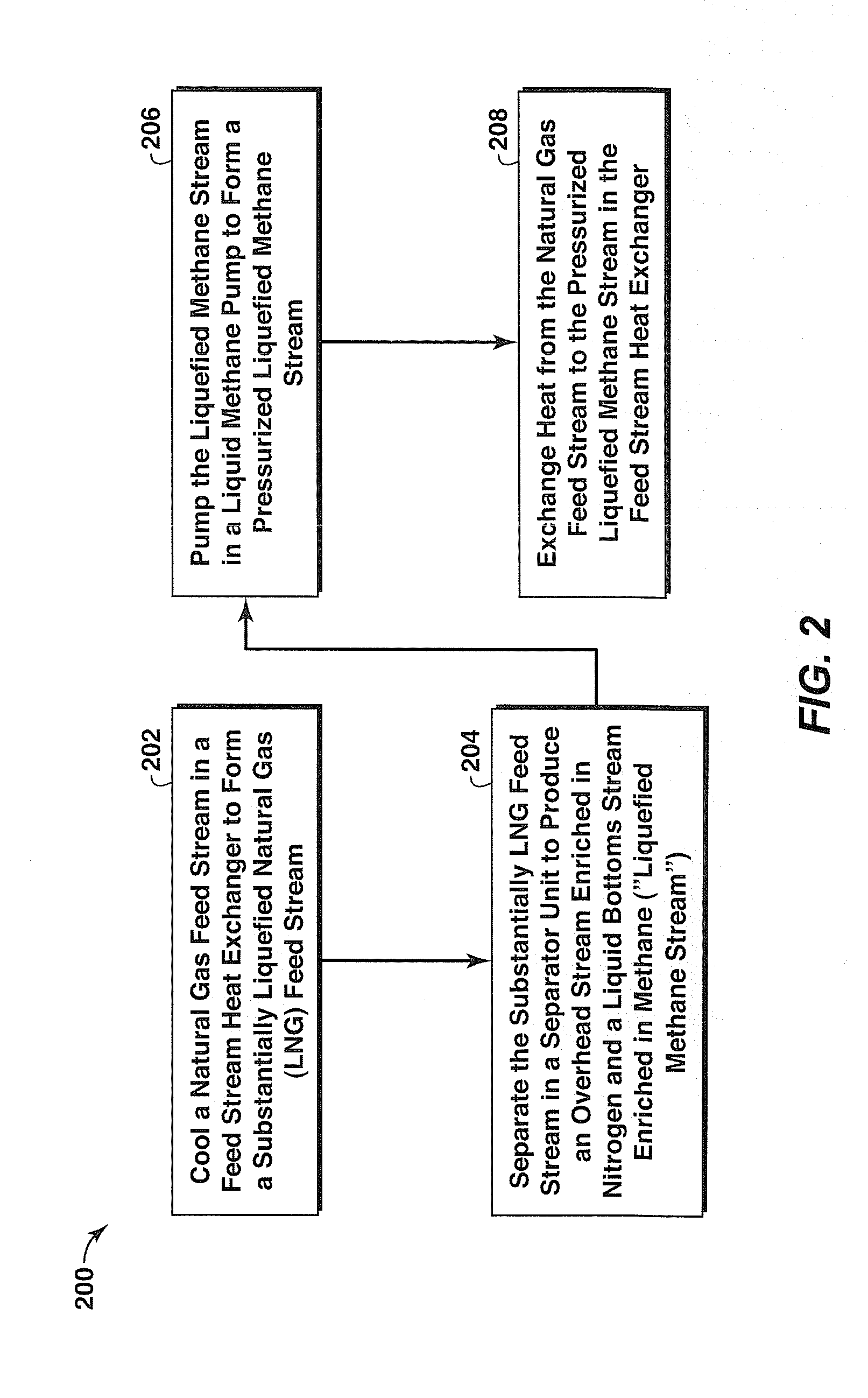

Nitrogen rejection methods and systems

Methods and systems for removing nitrogen from a natural gas feed stream. The systems and methods generally include a heat exchange unit, a separation unit, and a liquid methane pump unit, where the separation unit produces a liquid methane bottoms stream and a gaseous overhead stream enriched in nitrogen and the liquid methane pump unit compresses the liquid methane bottoms stream and then pumps the stream through the heat exchange unit to cool a natural gas feed stream. In some embodiments the liquid methane pump unit is a sleeve bearing type unit. Beneficially, the disclosed systems and methods incorporate high head pumps for liquid methane compression instead of vaporizing the liquid methane and compressing it in a gaseous compression units that are typically used for this purpose, saving space, materials, and power.

Owner:EXXONMOBIL UPSTREAM RES CO

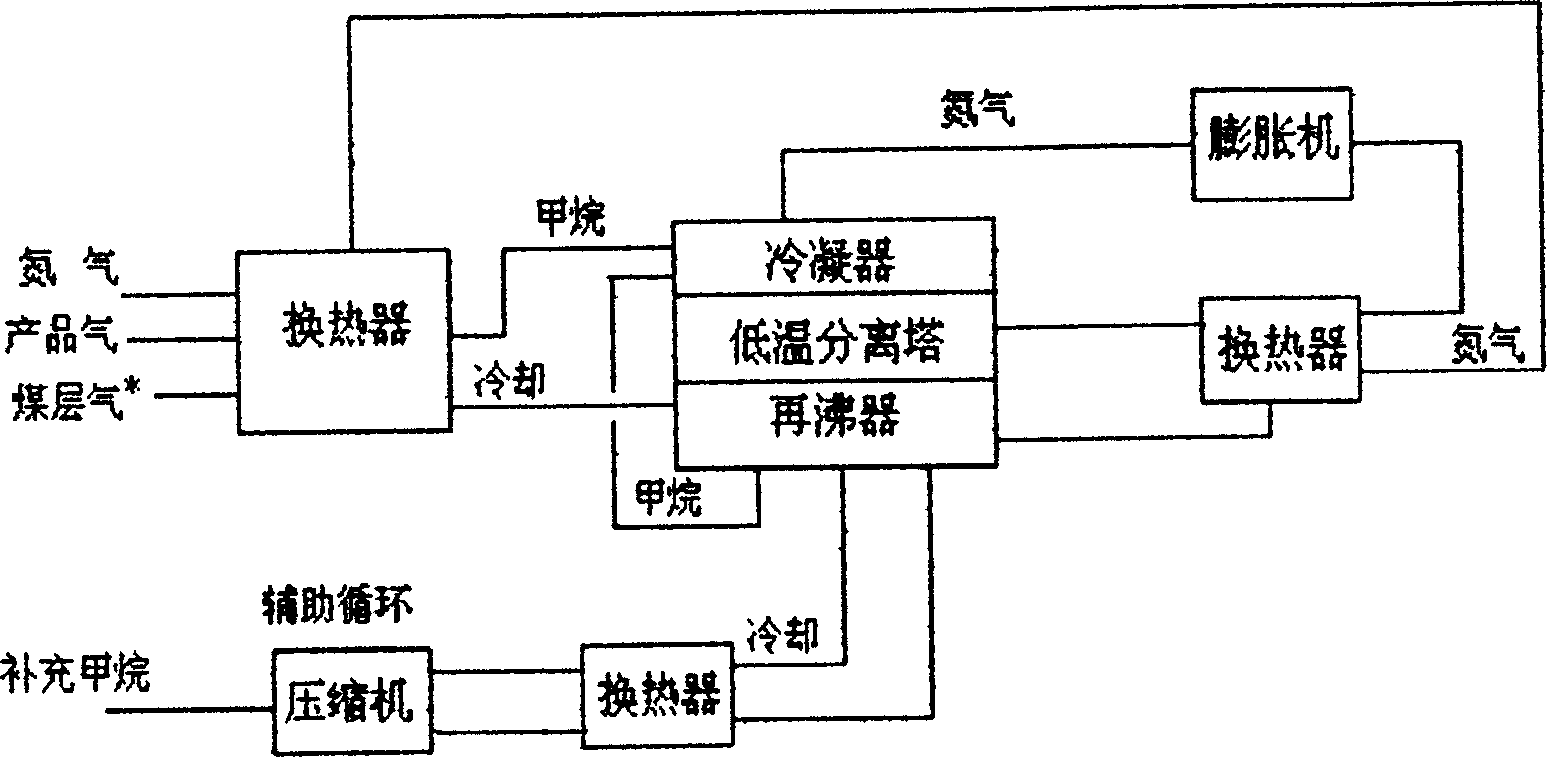

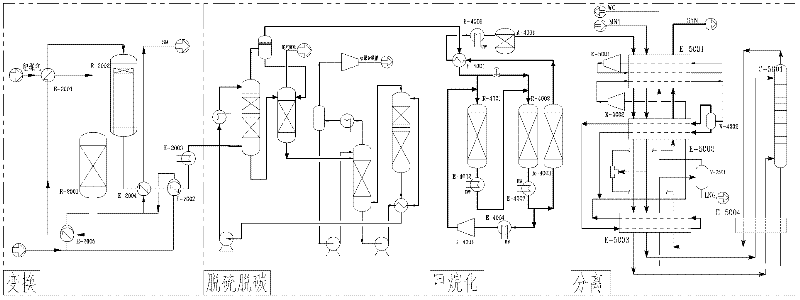

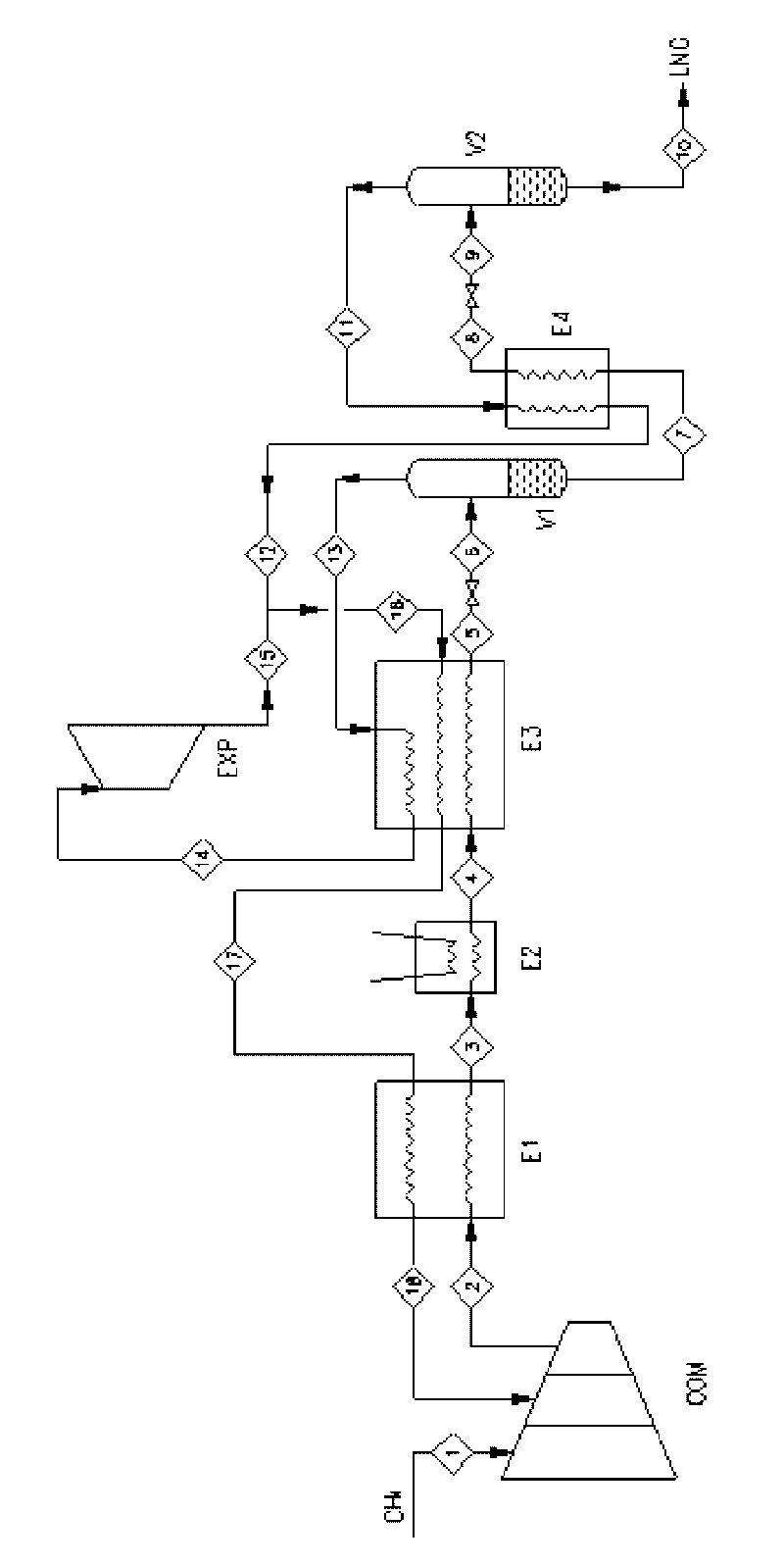

Method for preparing liquefied natural gas by using coke-oven gas

The invention discloses a method for preparing liquefied natural gas by using coke-oven gas, which mainly comprises the steps of methanation reaction, rectification separation and liquefaction, wherein the methanated gas first enters a rectification column after heat exchange and cooling; a tower kettle reboiler is heated by the methanated gas; liquid methane flows to an overhead condenser to evaporate to provide cold; under the rectification action of the rectification tower, methane with a purity of over 99.5 percent is obtained and a mixture of H2, N2 and a small amount of methane is obtained in the tower top; and the methane is heated again and delivered to a liquefying device to be liquefied. The method has the advantages that: the separation and liquefaction are separate, so the operation is smooth and flexible; LNG and methane gas can be output; the refrigerant is derived from the product methane rather than external supply, so investment is reduced and the cost for other refrigerants is saved; and in addition, according to an preferred scheme, a rear methane expander is adopted, the amount of methane entering the methane expander is increased and the refrigerating capacity is increased, so a circulation ratio is reduced to 4.0 to 4.5.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Expansion cycle liquid oxygen and methane upper-stage engine system

ActiveCN111005821ANo pollution in the processEasy to storeRocket engine plantsThrust chamberControl system

An expansion cycle liquid oxygen and methane upper-stage engine system comprises a propellant supply system, an ignition system and a thrust chamber. The propellant supply system comprises a methane supply system and a liquid oxygen supply system, the methane supply system pressurizes low-temperature liquid methane from an external storage tank and then supplies the low-temperature liquid methaneto the thrust chamber; the liquid oxygen supply system pressurizes the low-temperature liquid oxygen from the external storage tank and then supplies the low-temperature liquid oxygen to the thrust chamber; and the ignition system is located at the head of the thrust chamber and ignites under the control of a control system, liquid oxygen and methane entering the thrust chamber are ignited, and generated high-temperature gas is sprayed out of the nozzle of the thrust chamber to generate thrust force. The liquid oxygen and liquid methane are used as a propellant combination, and a closed expansion circulation system scheme is adopted, so the system is simple, the inherent reliability is high, the specific impulse performance is high, and repeated starting is easy to achieve.

Owner:BEIJING AEROSPACE PROPULSION INST

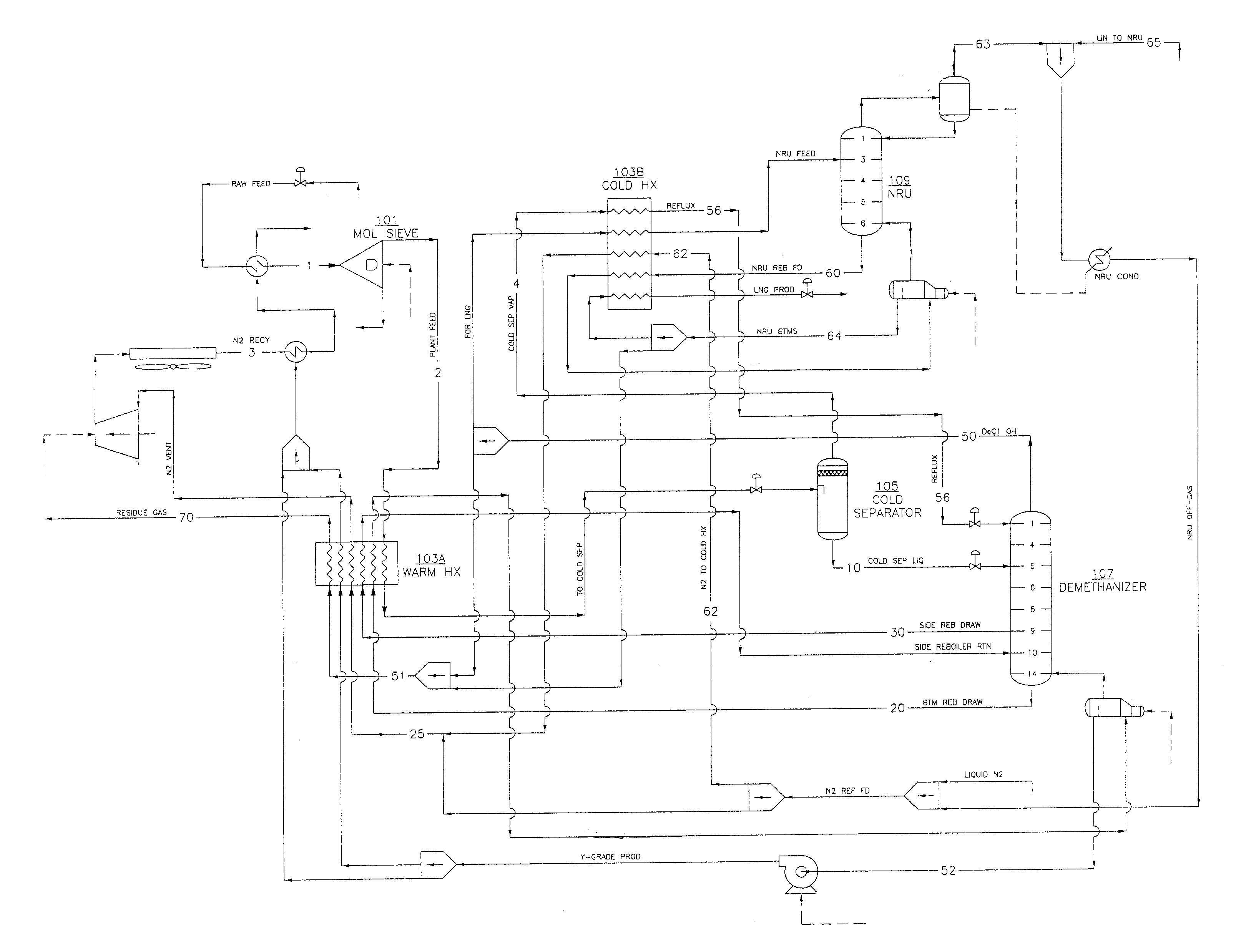

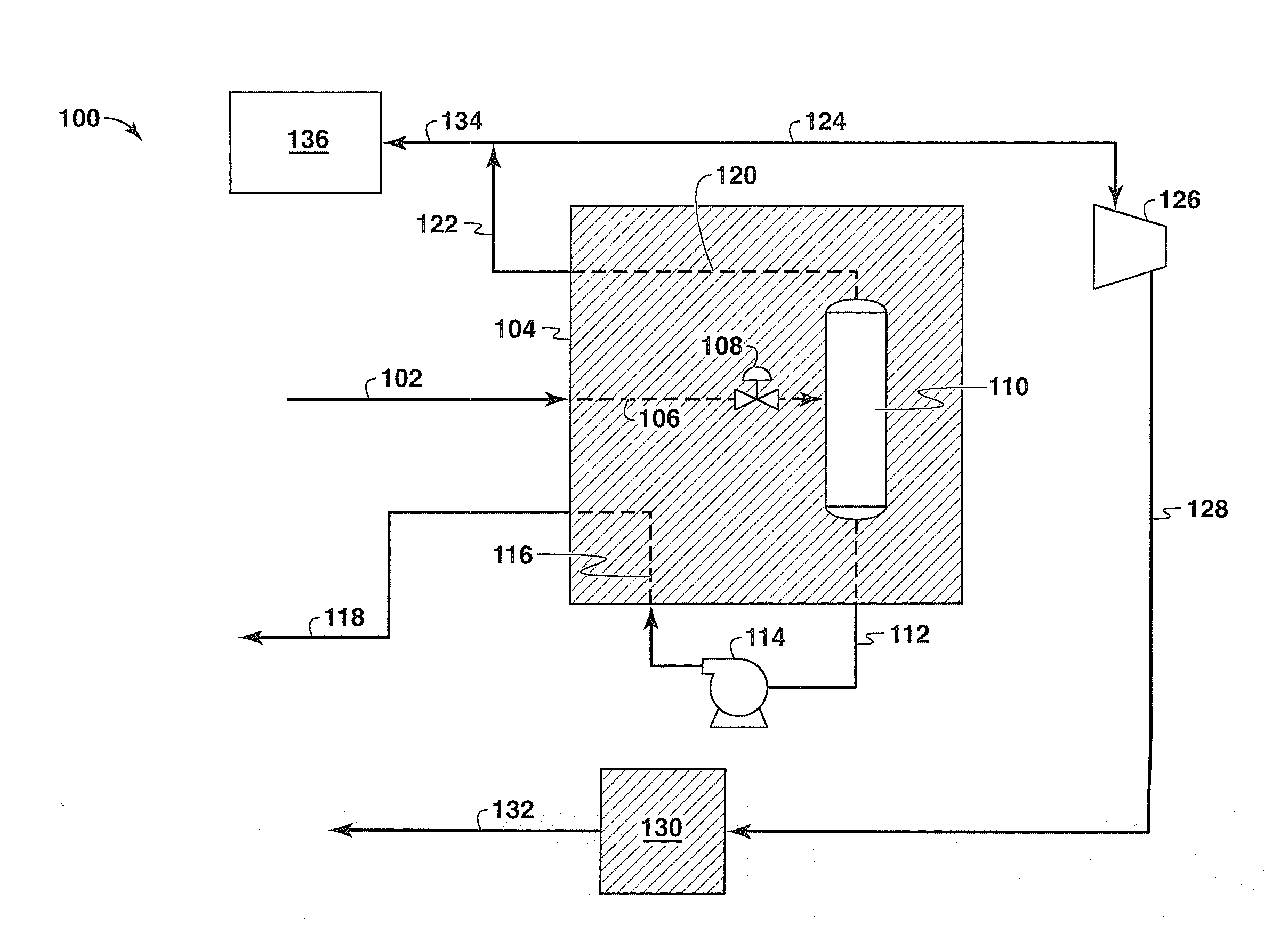

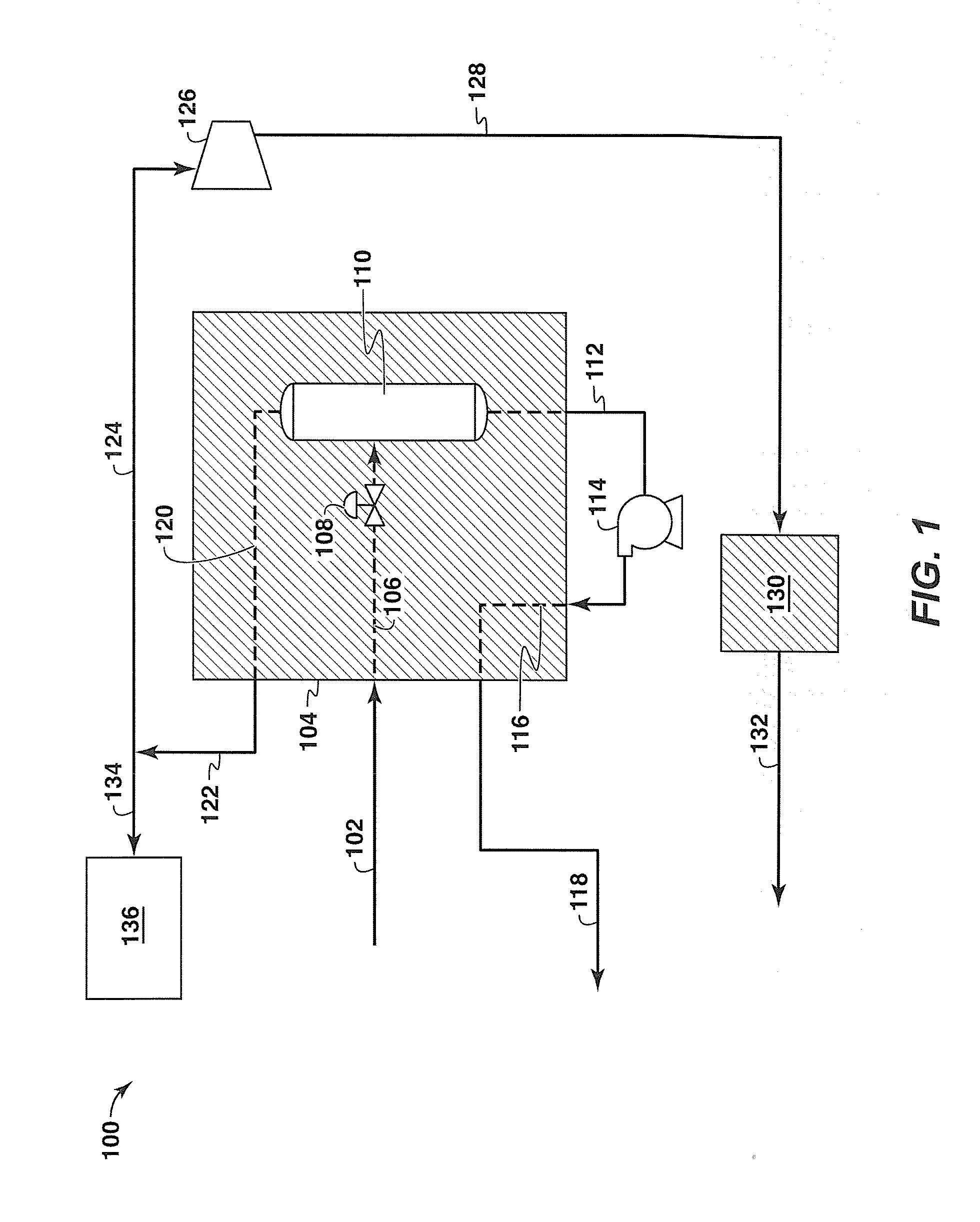

Integrated NGL Recovery And Liquefied Natural Gas Production

InactiveUS20100024477A1Easy to separateMaximize the benefitsSolidificationLiquefactionFractionationLiquid methane

The separation of methane from an admixture (110) with ethane and higher hydrocarbons, especially natural gas, using a scrub column (114), in which the admixture is separated into a methane-rich overhead (116) that is partially condensed (122) to provide reflux to the column (114) and liquid methane-depleted bottoms liquid (126), is improved by providing additional reflux (136) derived from an ethane enriched stream (130) from fractionation (128) of the bottoms liquid. Preferably, absorber liquid (140) from the fractionation (128) also is introduced into the scrub column. The vapor fraction (120) remaining after partial condensation can be liquefied (122) to provide LNG product (124).

Owner:AIR PROD & CHEM INC

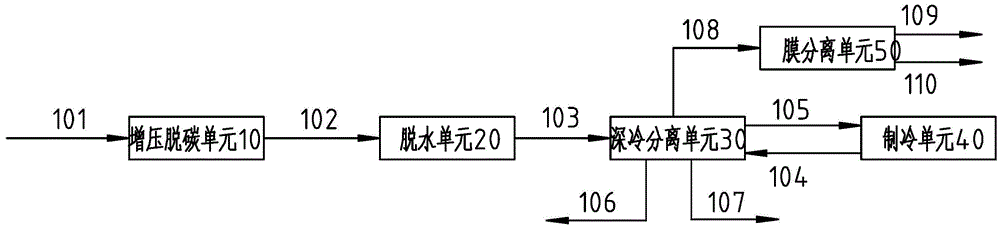

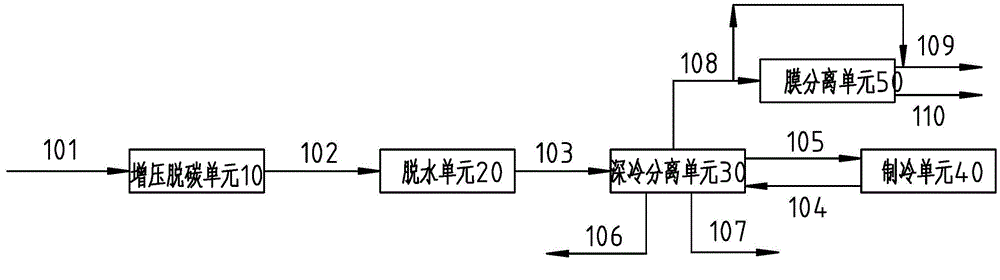

Device for recovery of light hydrocarbons and co-production of LNG from tail gas of Fischer-Tropsch synthesis and method thereof

ActiveCN103980930AHigh yieldGood economic benefitsHydrogen separationHydrocarbon purification/separationEconomic benefitsCryogenic treatment

The invention discloses a method for recovery of light hydrocarbons and co-production of LNG from tail gas of Fischer-Tropsch synthesis. The method comprises the following steps: tail gas from a Fischer-Tropsch synthesis unit passes through a supercharging decarburization unit to remove a CO2 component and then remove H2O therein; the purified tail gas is cooled and then enters a dethanizer; light hydrocarbons are removed from the tail gas in the dethanizer, cooled at the bottom of the dethanizer and then enters a downstream process unit; the tail gas at the top of the dethanizer enters a demethanizer; liquid methane flows out of the demethanizer and cryogenic treatment is continuously carried out to obtain LNG which enters an LNG storage tank; after the tail gas at the top of the demethanizer is reheated, H2, CO and N2 therein are separated; a separated permeate gas with an appropriate H2 / CO ratio returns the Fischer-Tropsch synthesis unit or a PSA hydrogen production device; and the N2-containing tail gas is emptied or used as a fuel gas. By the use of the method for recovering light hydrocarbons from the tail gas, operating cost of the device can be reduced effectively, yield of hydrocarbon products is raised, and LNG is coproduced. Then, good economic benefit can be obtained.

Owner:天津市振津石油天然气工程有限公司

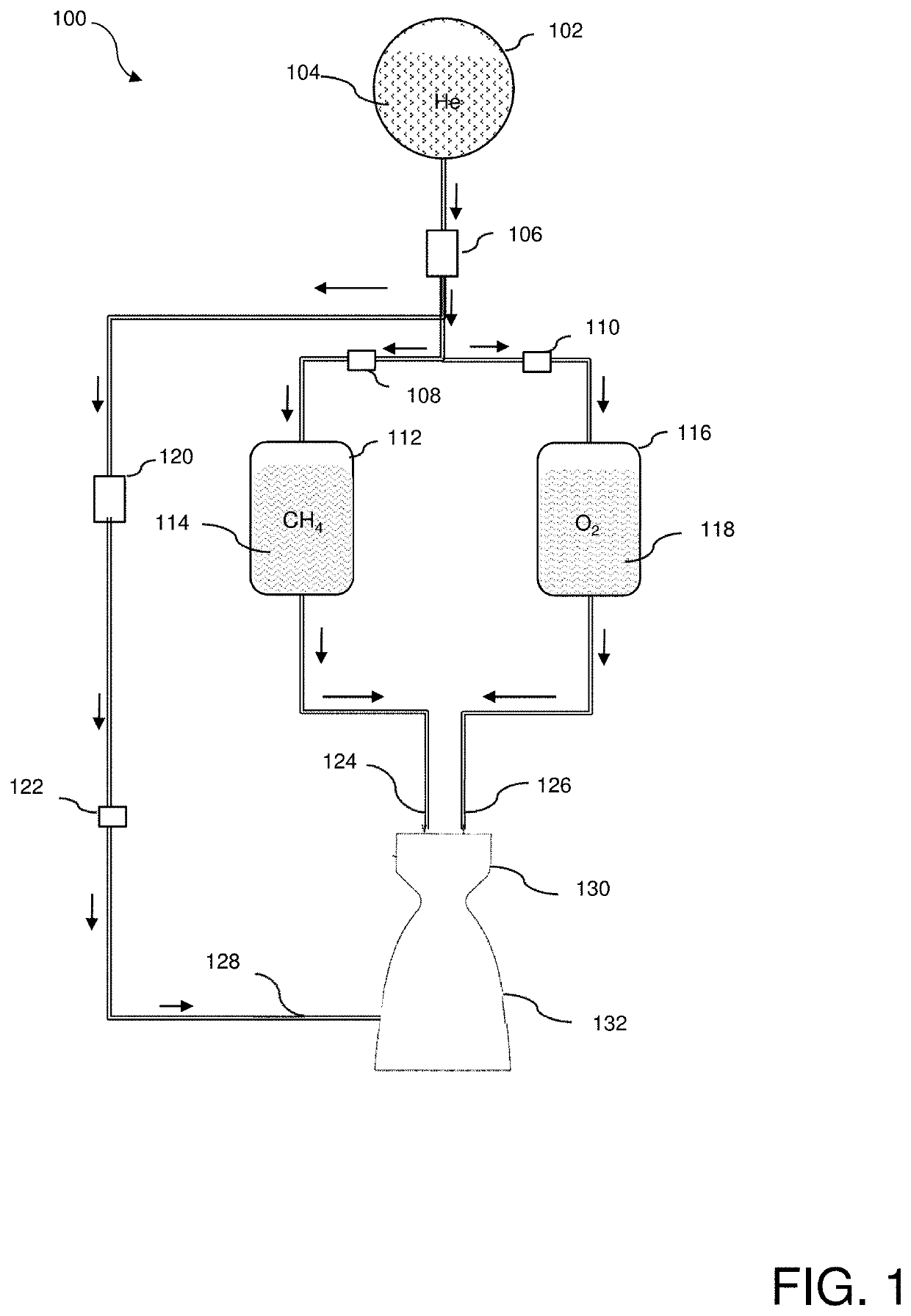

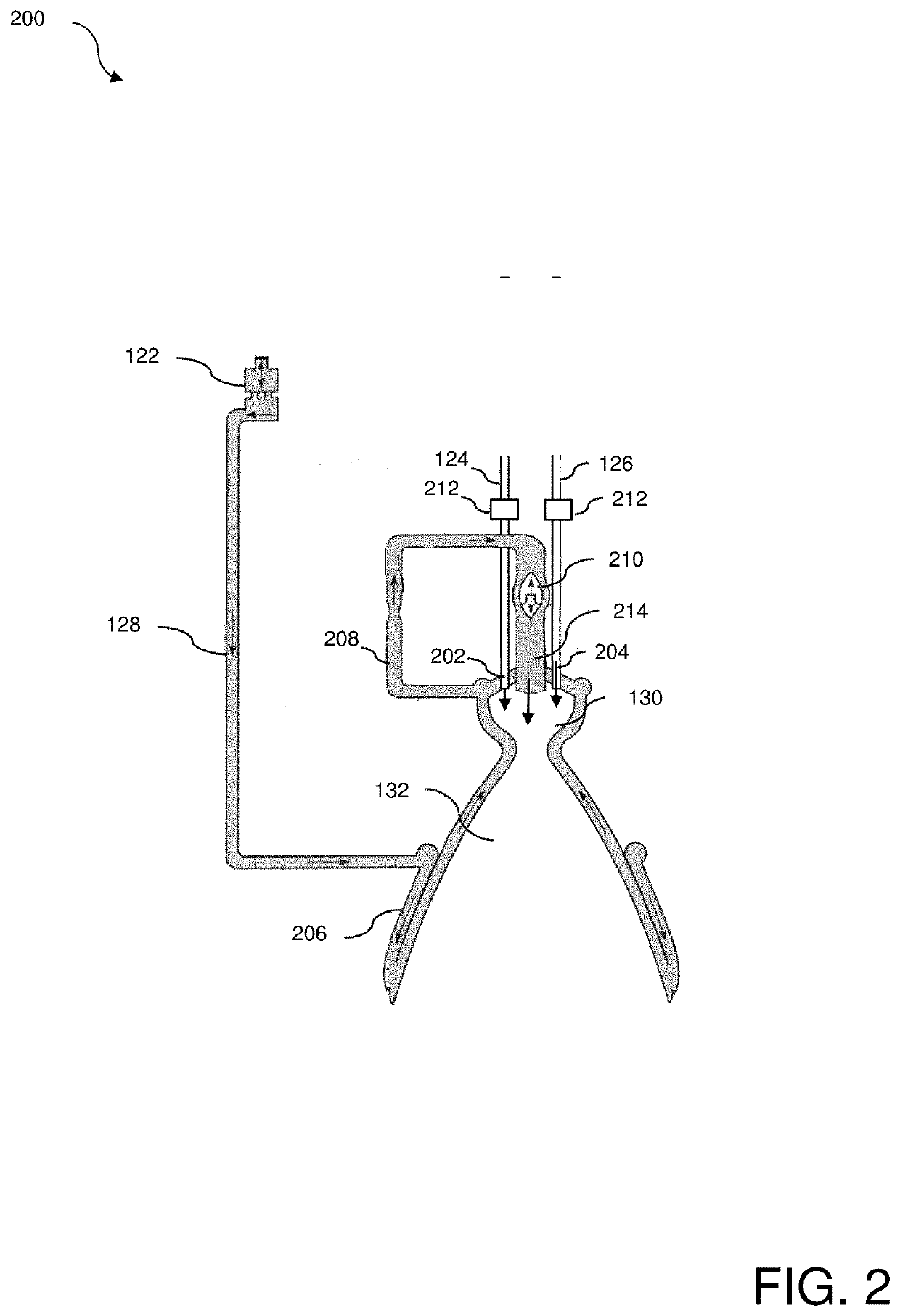

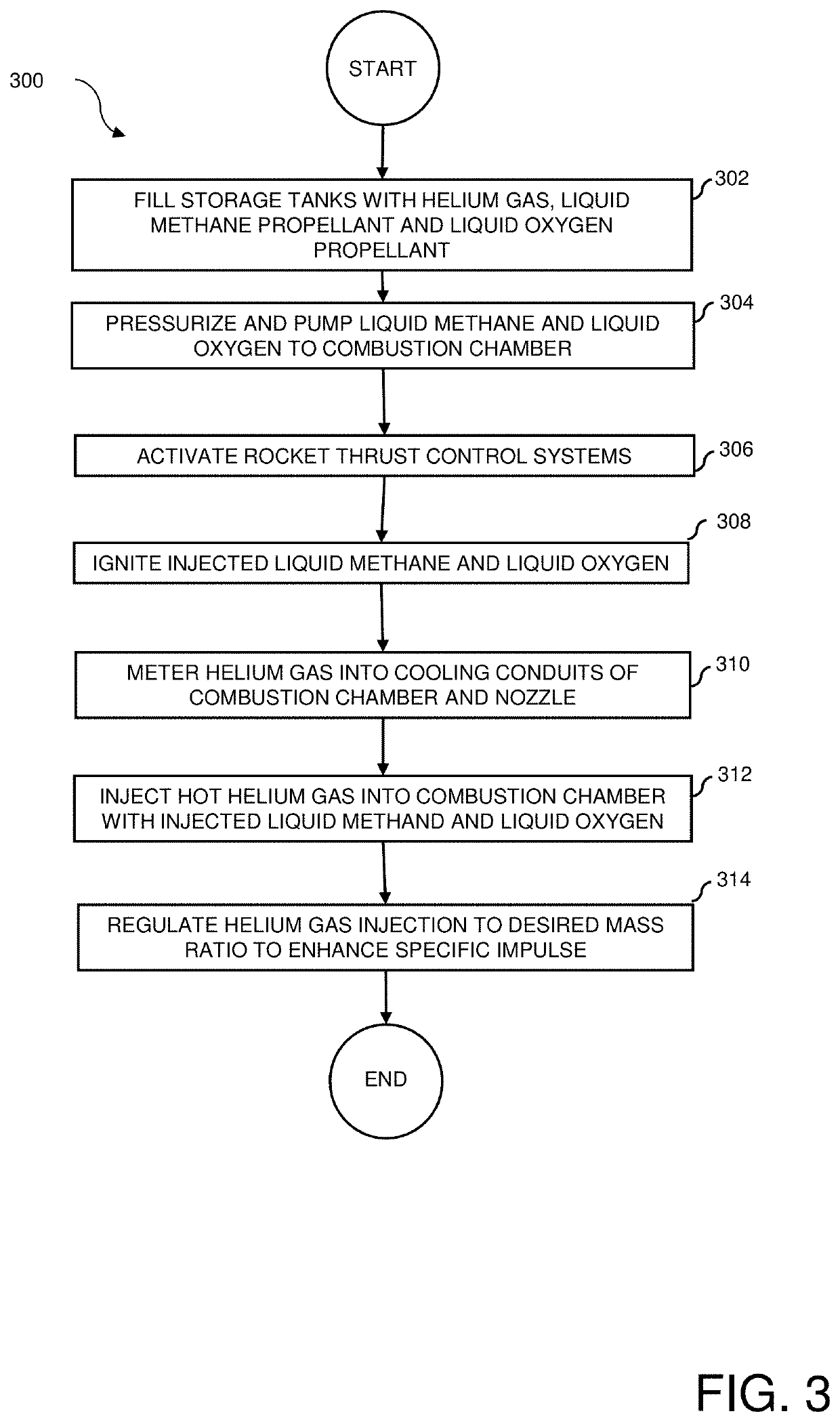

Methane/Oxygen Rocket Engine with Specific Impulse Enhancement by Hot Helium Infusion

ActiveUS20200011275A1Enhance the specific impulse of the rocket engineRocket engine plantsCombustion chamberEngineering

An apparatus and method to enhance the performance of rockets engines which utilize liquid methane / oxygen propellants by injecting optimized amounts of pressurized hot helium gas into the combustion chamber with the propellants. In one embodiment, the pressurized helium gas is stored at low temperatures near those of the cryogenic propellants and is used for regenerative cooling of the combustion chamber and nozzle during rocket operation in order to raise the temperature of the helium gas before being injected into the combustion chamber.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

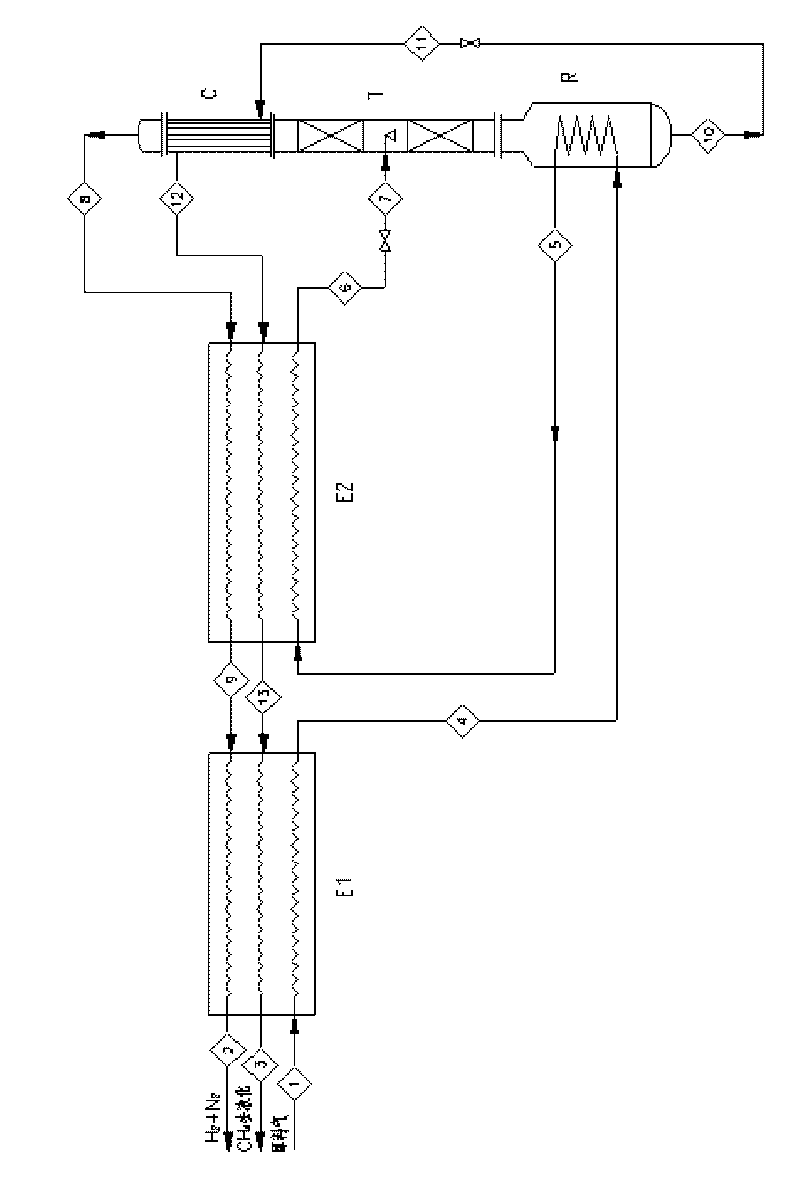

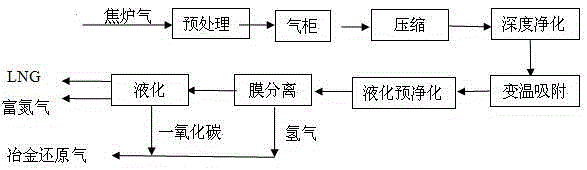

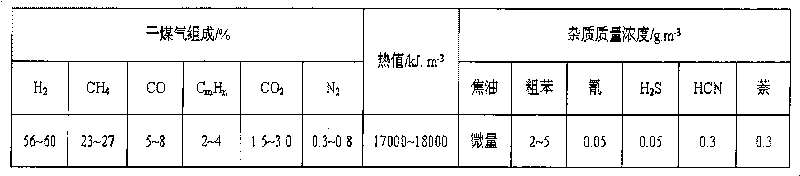

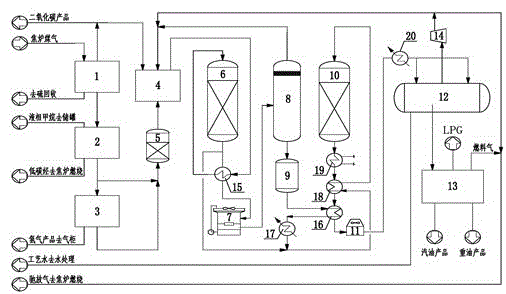

Process for preparation of metallurgical reduction gas and co-production of liquefied natural gas through coke gas

ActiveCN105293436AMake full use of resourcesRemove completelySolidificationLiquefactionMethane gasLiquid methane

The invention belongs to the technical field of preparation of metallurgical reduction gas, and relates to a method for preparing high methane gas through industrial exhaust gas containing carbon and hydrogen, in particular to a process for preparation of metallurgical reduction gas and co-production of liquefied natural gas through coke gas. According to the process, coke gas serving as a raw material is subjected to pre-purification to roughly remove impurities such as tar and naphthalene, then the processed coke gas is introduced into a gas tank for buffering, the buffered coke gas is introduced into a compressor for pressurizing, deep purification is conducted on the pressurized coke gas to remove tar and naphthalene, benzene and ammonia in the processed coke gas are removed via a TSA procedure, CO2, H2S and water are removed through liquefied pre-purification, then high H2 is obtained through membrane separation, residual gas enters a liquefaction unit, and separation is carried out to obtain carbon monoxide gas and byproduct liquid methane. Through the process, coke oven gas resources are fully utilized, and byproduct liquefied natural gas (LNG) is obtained while the metallurgical reduction gas is obtained, so that the economic benefits are obvious.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method and device for purifying ammonia synthesis virgin gas and co-generating SNG (synthetic natural gas) or/and LNG (liquefied natural gas) via liquid nitrogen washing

The invention discloses a method and a device for purifying ammonia synthesis virgin gas and co-generating SNG (synthetic natural gas) or / and LNG (liquefied natural gas) via liquid nitrogen washing, wherein by the addition of a methane rectification tower and a liquid methane pump in a conventional liquid nitrogen washing device, and a reasonable line configuration, a methane-rich fraction can be re-heated and then used as a city gas and output; the methane-rich fraction can also be cyclically refrigerated via Claude and used for producing the LNG product; simultaneously, a product adjustment can be performed on SNG and LNG according to different used loads.

Owner:SHANGHAI INT ENG CONSULTING

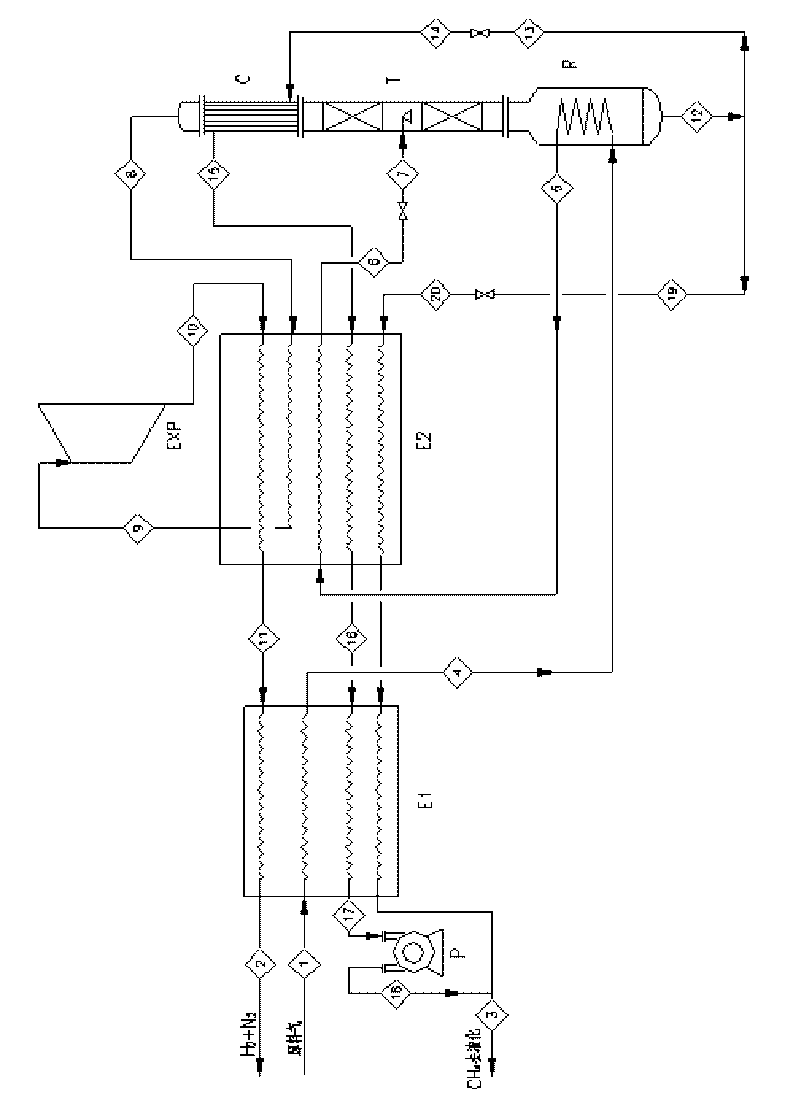

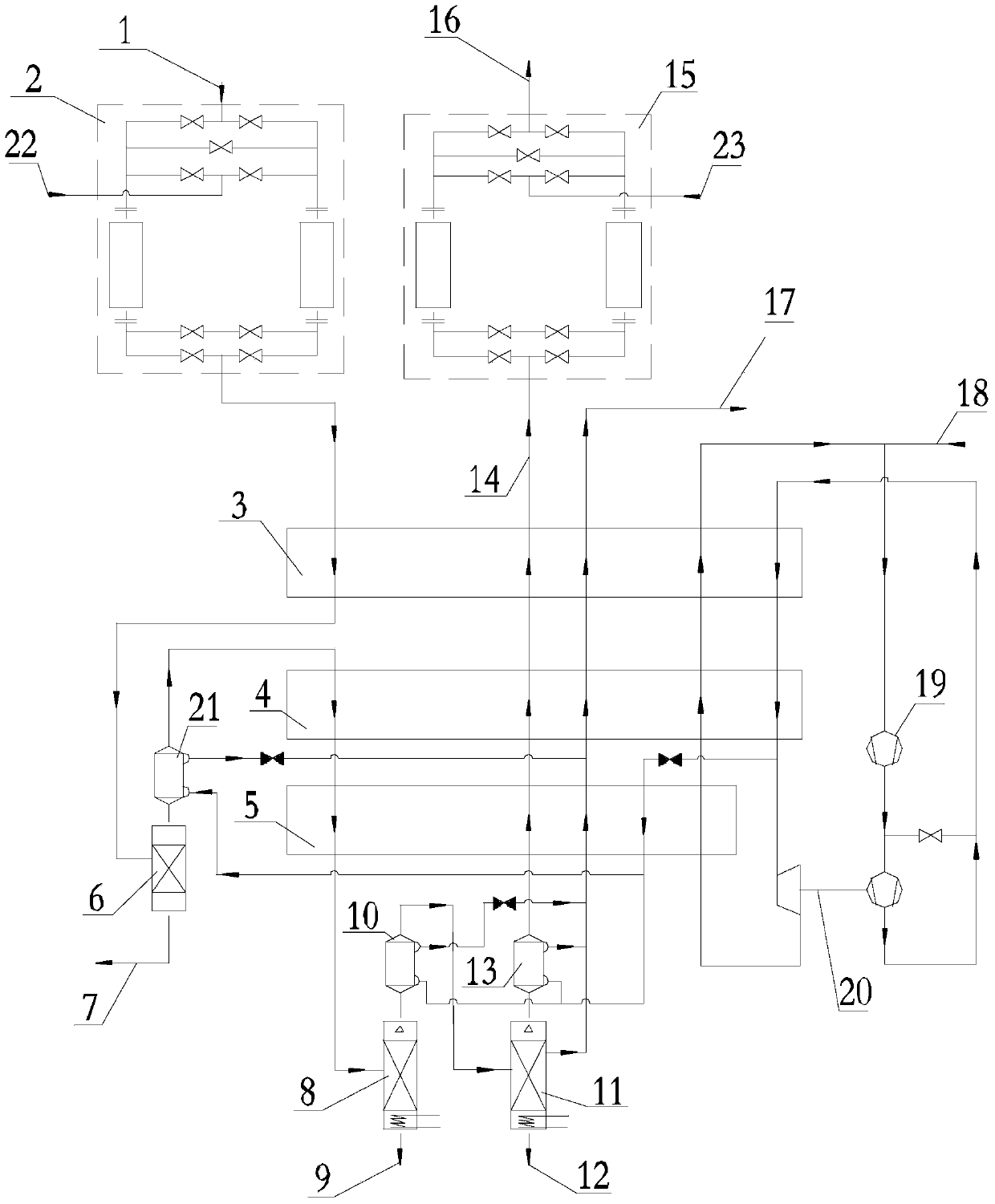

System and method for preparing hydrogen rich gas and liquid methane

InactiveCN105180595AReduce circulationReduce power consumptionSolidificationLiquefactionExhaust fumesProcess engineering

The invention relates to a system and method for preparing hydrogen rich gas and liquid methane. The system mainly comprises a purge gas purification unit and a low-temperature liquidation and separation unit. By means of mixed refrigerant compression circulating refrigeration, nitrogen circulation compression refrigeration and waste gas expansion refrigeration, hydrogen rich gas and liquid methane are obtained by conducting rectification and separation on synthesis ammonia or methyl alcohol purge gas in an efficient rectifying tower, the flow is simple, the energy consumption is low, and the recovery rate is high. The system and method for preparing hydrogen rich gas and liquid methane are high in reliability, low in running cost and high in product purity.

Owner:KAIFENG AIR SEPARATION GROUP

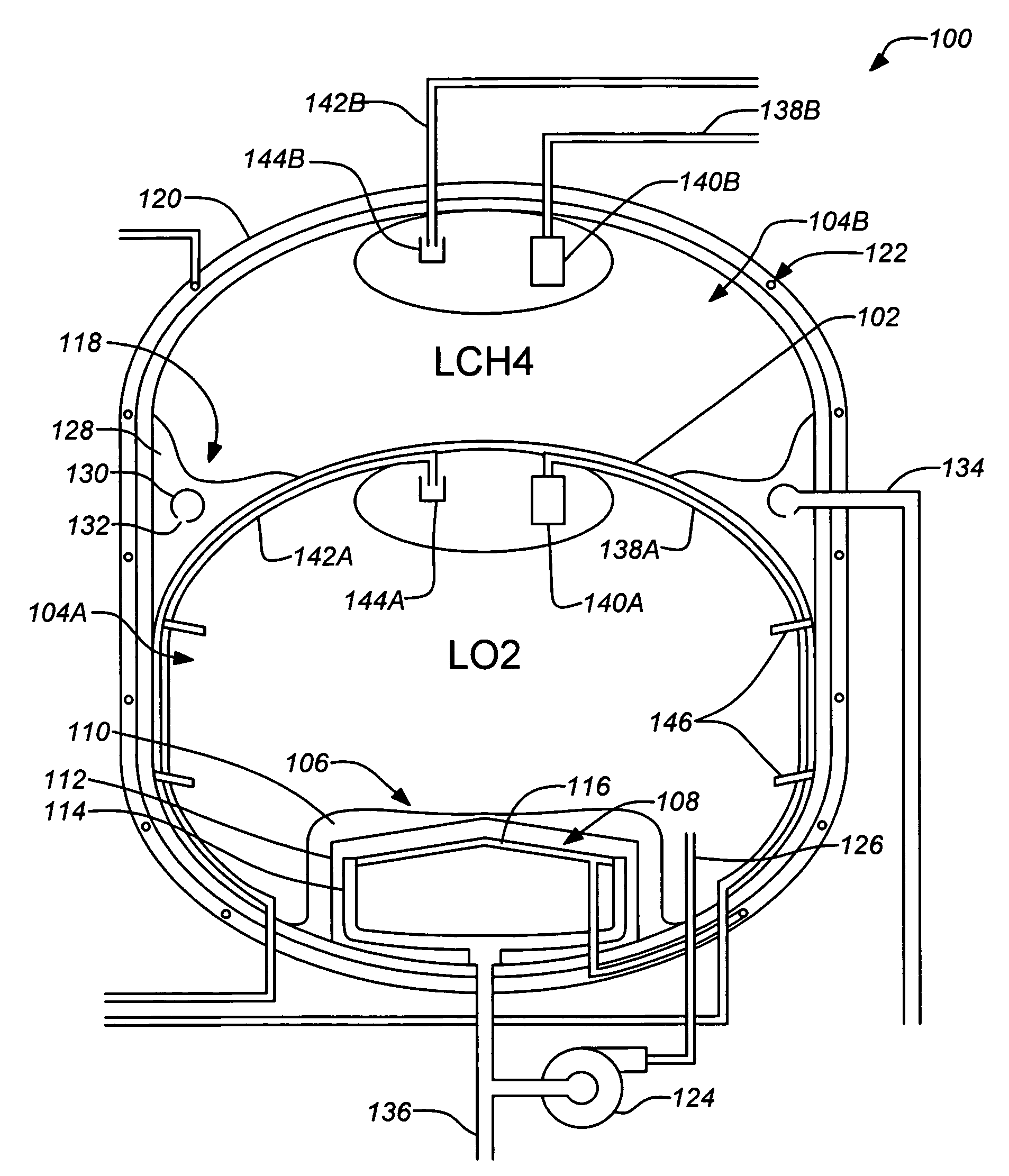

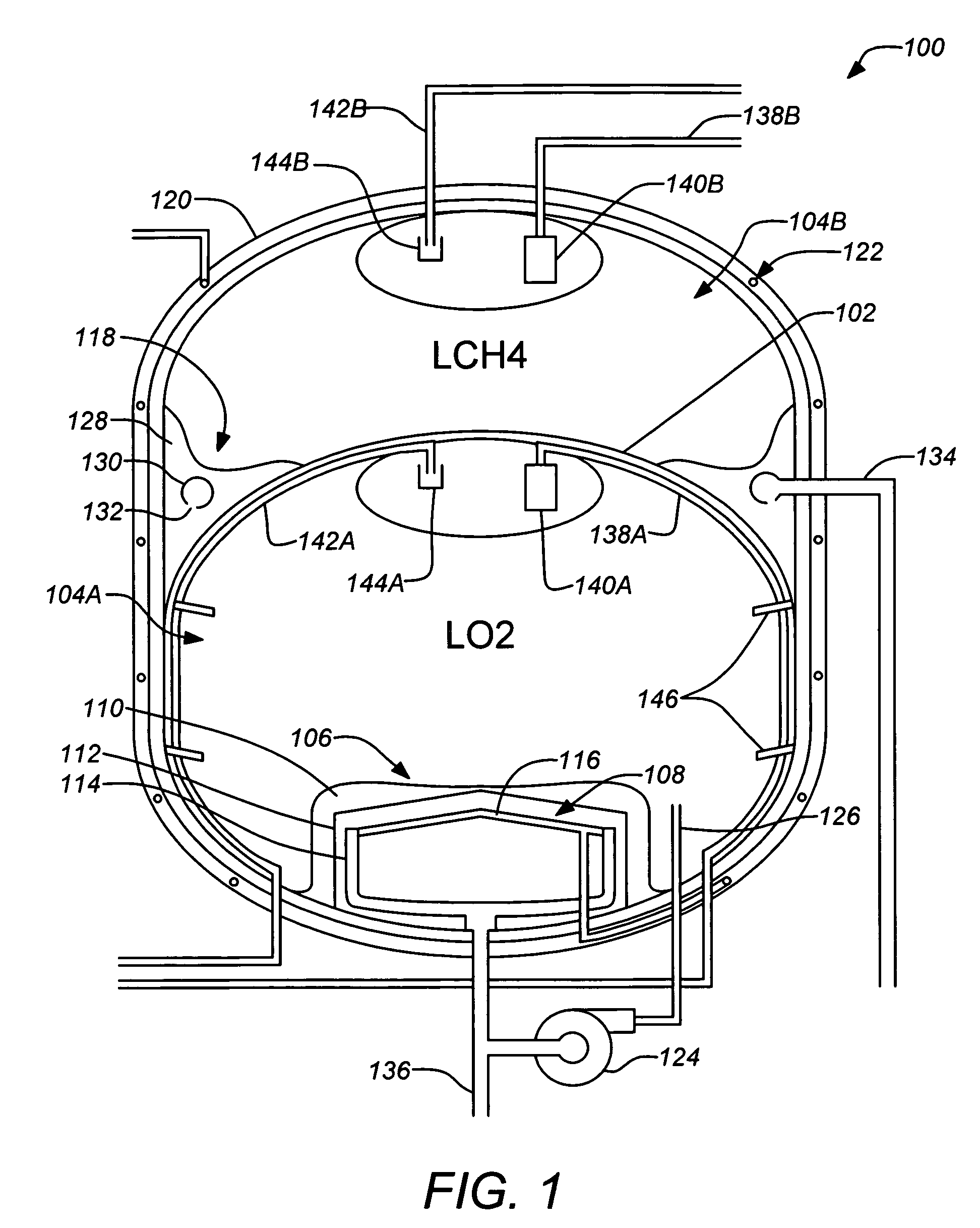

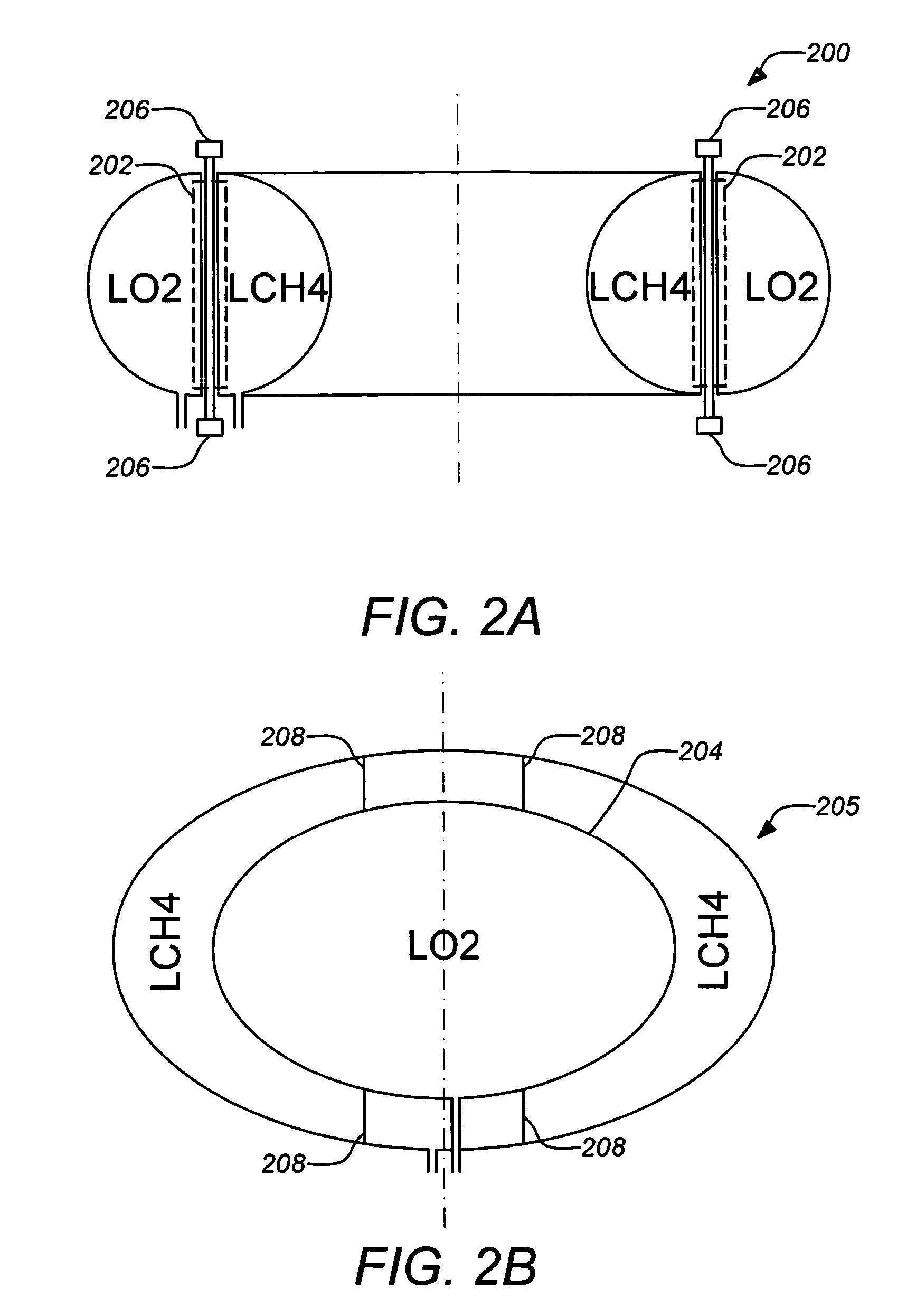

Thermally coupled liquid oxygen and liquid methane storage vessel

A cryogenic propellant storage tank system and method are disclosed that thermally couple LO2 and LCH4 tanks together by using either a single tank compartmentalized by a common tank wall or two separate tanks that are coupled together with one or more thermal couplers having high thermal conductivity. Cryogenic cooling equipment may be located only in the LO2 tank while the LCH4 is cooled by the LO2 tank interface. Embodiments of the invention may employ both LO2 and LCH4 liquid acquisition devices (LADs) for low-gravity use. In further embodiments, only the LO2 LADs may be integrated with thermal cooling equipment.

Owner:THE BOEING CO

Supercritical carbon dioxide high-temperature and high-pressure PVT testing and methane displacement integrated experimental device and method

PendingCN109269962AHigh simulationEasy to observeSpecific gravity by measuring pressure differencesSpecific gravity using flow propertiesPressure differenceHigh pressure

The invention relates to a supercritical carbon dioxide high-temperature and high-pressure PVT testing and methane displacement integrated experimental device and method. The device comprises a liquidcarbon dioxide storage tank, a liquid methane storage tank, a displacement pump, a core holding unit, a constant-temperature oil bath system, a PVT barrel, a ring pressure generation device, a pressure difference sensor, a flow sensor, a pressure sensor, a temperature sensor, a sodium hydroxide absorption storage tank and a gas storage tank, wherein the liquid carbon dioxide storage tank and theliquid methane storage tank are separately connected to an inlet of the PVT barrel via a first pipeline, a second pipeline and a third pipeline; an outlet of the PVT barrel is connected with an inletof the core holding unit through a fourth pipeline; a manifold tee is separately connected with the outlet of the core holding unit, the inlet of the sodium hydroxide storage tank and the third pipeline through a fifth pipeline, a sixth pipeline and a seventh pipeline; and the outlet of the sodium hydroxide storage tank is connected with the gas storage tank through an eighth pipeline. By the supercritical carbon dioxide high-temperature and high-pressure PVT testing and methane displacement integrated experimental device and method, the changing law of the phase state, viscosity and displacement efficiency of supercritical carbon dioxide at a high temperature and under high pressure along with the temperature and pressure can be researched.

Owner:ZHENGZHOU UNIV

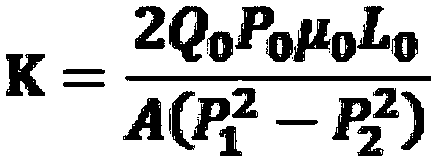

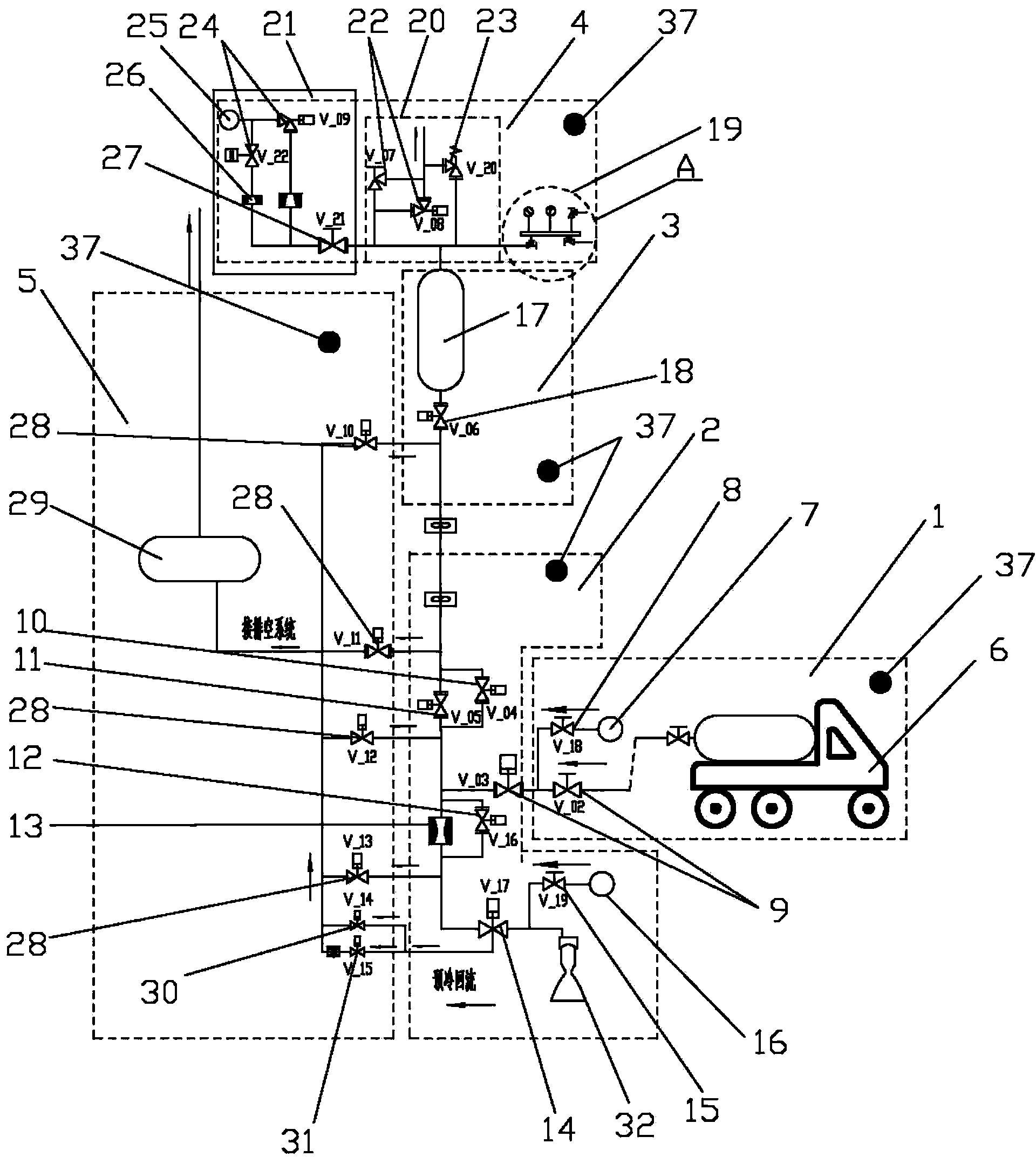

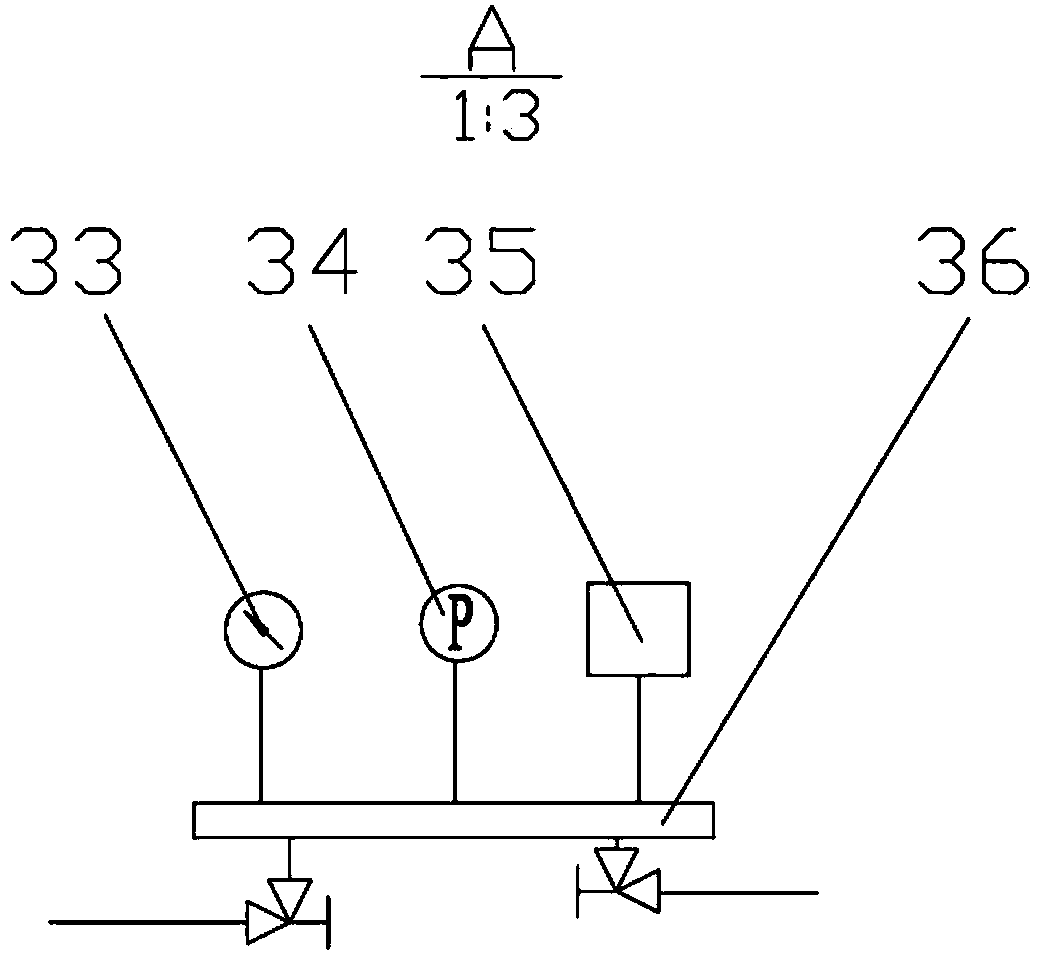

Liquid methane filling-up system

ActiveCN103867885AImprove reliabilityImprove securityContainer discharging methodsContainer filling under pressureProcess engineeringHigh pressure

The invention relates to a liquid methane filling-up system which is suitable for a filling-up system of flammable and combustible fuels such as methane. The liquid methane filling-up system comprises a filling unit, a front testing unit, a container unit, a pressurizing and exhausting unit and a recycling and discharging unit, which are communicated with one another and are cooperated to achieve the operations of nitrogen gas blowing of the system, filling of a methane container, low-pressure precooling of the system, high-pressure precooling of the system and the like, and particularly, each unit is also provided with a methane concentration real-time alarm device. According to the liquid methane filling-up system, the safety and the reliability for liquid methane filling operation are greatly improved.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

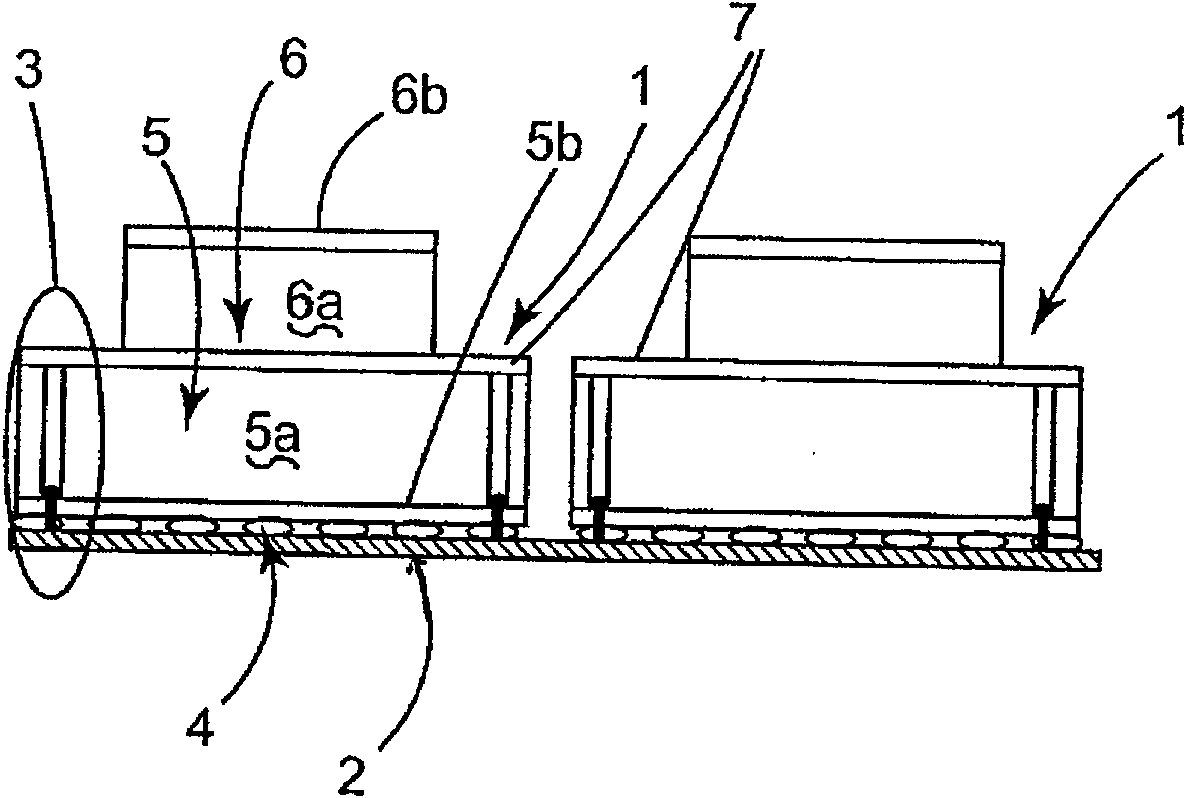

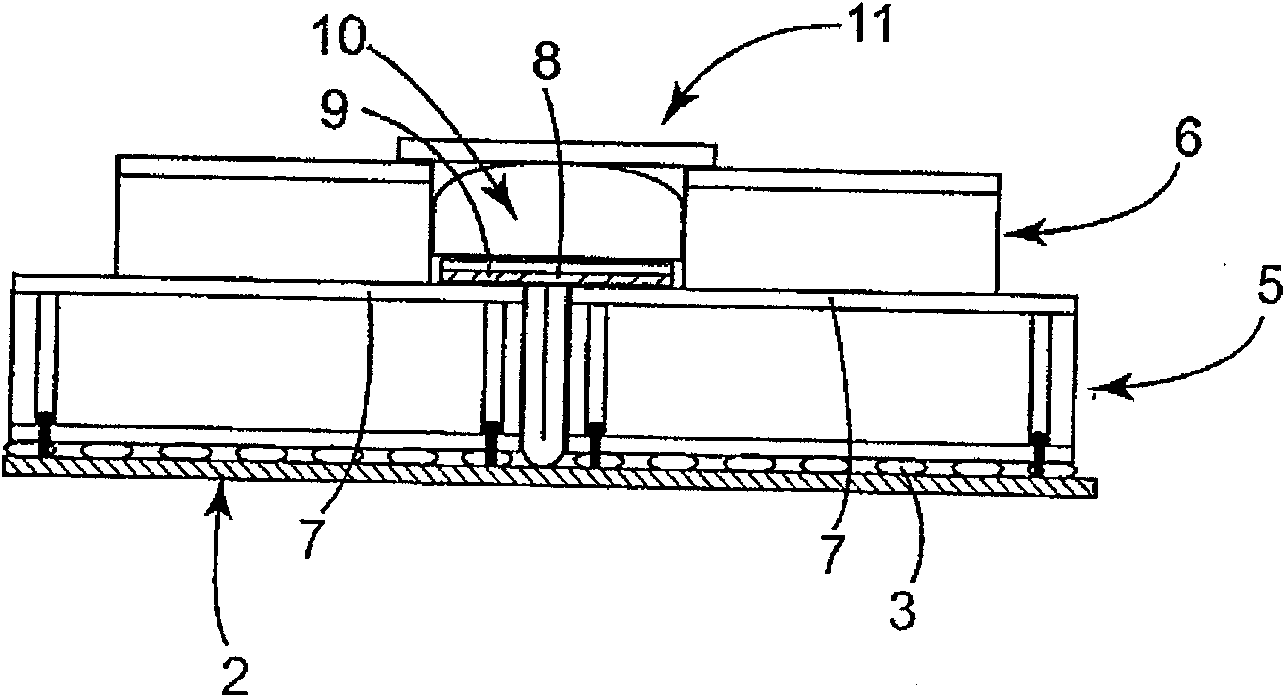

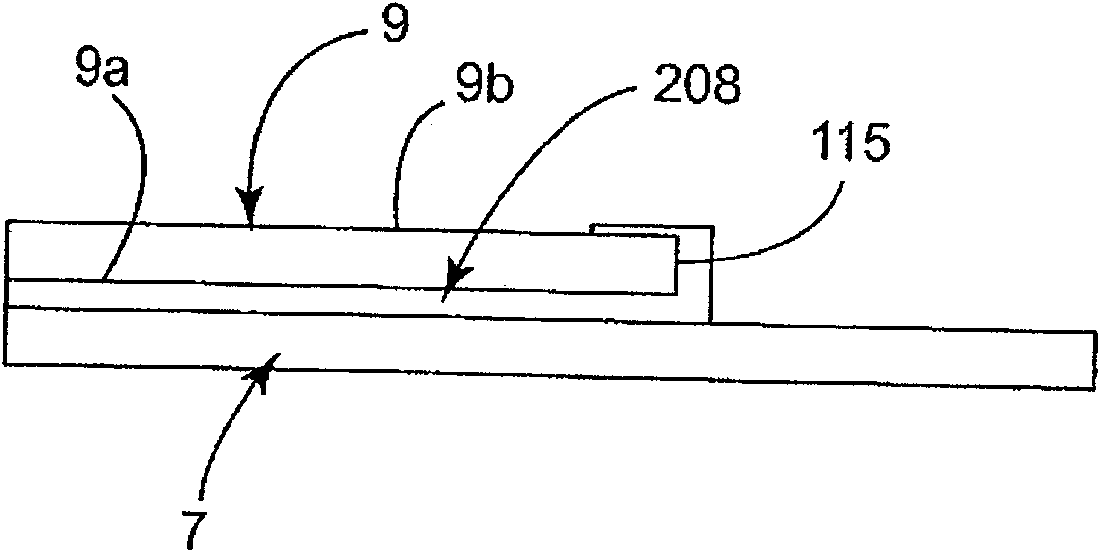

Flexible composite laminate used for secondary cryogenic sealing barrier and adhered with lower laminate and its assembling method

ActiveCN101804707AEasy to avoid surface contaminationAvoid surface contaminationVessel manufacturingWaterborne vesselsMetal foilComposite laminates

The invention relates to a flexible composite laminate (9) forming covering strip of a secondary cryogenic sealing barrier for container containing liquid methane, the secondary cryogenic sealing barrier comprises a flexible laminate belt adhered with a seam of a synthesis plate covered by another lower composite laminate. The invention also relates to a method for assembling the secondary barrier by adhering. The flexible composite laminate (9) is adhered to the seam of the adjacent synthesis plate covered by the lower laminate (7), the laminates comprise a metal foil dipped with an adhesion inserted between two fabrics. According to the invention, The flexible composite laminate is precoated with an adhesive by using a hot melt adhesive (208) cured by heat input, the hot melt adhesive is applied to tissues (9a) at a softening temperature to cover the external tissue of each lower laminate, and a peripheral edge (115) of the flexible laminate, the adhered assembly obtained by curing the adhesive contacted with the lower laminate by heating under the pressure condition, especially has improved mechanical strength and prevent the micro leakage of the low temperature liquid.

Owner:HUTCHINSON SA

Method for extracting hydrogen and methane from coke oven gas by utilizing membrane separation and low-temperature rectification

InactiveCN101747131AAccelerating the Hydrogen EraHydrogen separationFractional condensation purification/separationLiquid hydrogenSulfide

The invention relates to a method for extracting hydrogen and methane from coke oven gas by utilizing membrane separation and low-temperature rectification, comprising: the coke oven gas is compressed to be 0.12-0.15MPa, after the temperature is cooled to 20-40 DEG C, sulphur, benzene and tar are removed; the coke oven gas is compressed to be 2.2-4.0MPa, H2S is removed by hydrolysis; CO2 is removed by a N-methyldiethanolamine wet process, sulfide, mercury, moisture and compounds with more than five carbons are removed by an adsorptive process; and then the coke oven gas enters in a membrane separation device under 1.5-4.0MPa at 20-60 DEG C, hydrogen is separated from CH4, N2 and CO, and the separated hydrogen is compressed to be 2.0-5.0MPa and enters in a liquid hydrogen device to obtain the liquid hydrogen; the coke oven gas enters into a changing-over plate heat exchanger and the residual substances with above -50 DEG C of boiling point in the coke oven gas are removed by reducing the temperature; the coke oven gas enters in a low-temperature rectification tower, and liquid methane containing C1, C2 and C3 is extracted from the tower bottom, the purity can reach 98 percent, the content of the carbon monoxide is less than 05 percent, and the liquid methane is heated to be gaseous methane.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Vehicle-mounted methane freezing, liquefying and separating device

ActiveCN101949633ALower the altitudeIncrease the number ofSolidificationLiquefactionCompression deviceNitrogen gas

The invention relates to a vehicle-mounted methane freezing, liquefying and separating device which comprises a nitrogen compressor, a condenser, a compressed nitrogen storage pot and a nitrogen swelling, freezing and separating cabin. The device is characterized in that the nitrogen compressor, the condenser, the compressed nitrogen storage pot and the nitrogen swelling, freezing and separating cabin are uniformly arranged on a truck, wherein the nitrogen swelling, freezing and separating cabin is respectively provided with a methane inlet and a water outlet and respectively communicated with a normal pressure nitrogen storage bag, the compressed nitrogen storage pot, a liquefied and vulcanized hydrogen storage pot, a liquid methane storage pot and a liquid carbon dioxide storage pot; the normal pressure nitrogen storage bag is communicated with the compressed nitrogen storage pot through a nitrogen compression device via a cooler; and the nitrogen compressor is connected with a methane generator through a gear box. The device has the advantages of flexibility, light weight, convenience, movability and convenient running, reduces the transportation cost and the power cost of straw raw materials and methane dreg waste and can be used for recovering carbon dioxide and realizing low-carbon agricultural development. Moreover, the device increases the side product income of methane processing and also has the advantages of income increase, energy saving and environmental protection.

Owner:张永北

Ammonia synthesis waste gas recycling device

ActiveCN104190200AIncrease profitHigh economic valueHydrogen separationDispersed particle separationLiquid argonHydrogen

The invention discloses an ammonia synthesis waste gas recycling device. The device comprises a decarbonization adsorber, a first heat exchanger, a second heat exchanger, a third heat exchanger, a liquid ammonia rectifying tower, a liquid ammonia rectifying tower condenser, a methane rectifying tower, a methane rectifying tower condenser, an argon rectifying tower and an argon rectifying tower condenser, wherein the decarbonization adsorber is provided with a gas inlet and a first regenerated gas inlet, the liquid ammonia rectifying tower is provided with a liquid ammonia outlet, the methane rectifying tower is provided with a liquid methane outlet, the argon rectifying tower is provided with a liquid argon outlet and a waste gas outlet; the ammonia synthesis waste gas separating device further comprises a hydrogen pipeline with one end connected with the argon rectifying tower, a hydrogen purifying device connected with the hydrogen pipeline, a nitrogen circulating compressor, a nitrogen expander and a nitrogen supplementing port connected with the nitrogen circulating compressor; the hydrogen purifying device is provided with a hydrogen outlet and a second regenerated gas inlet; the recycling device can be used for extracting liquid ammonia, liquid methane, liquid argon, and high-pure hydrogen with relatively high purity from the waste gas.

Owner:SUZHOU XINGLU AIR SEPARATION PLANT SCI & TECH DEV CO LTD

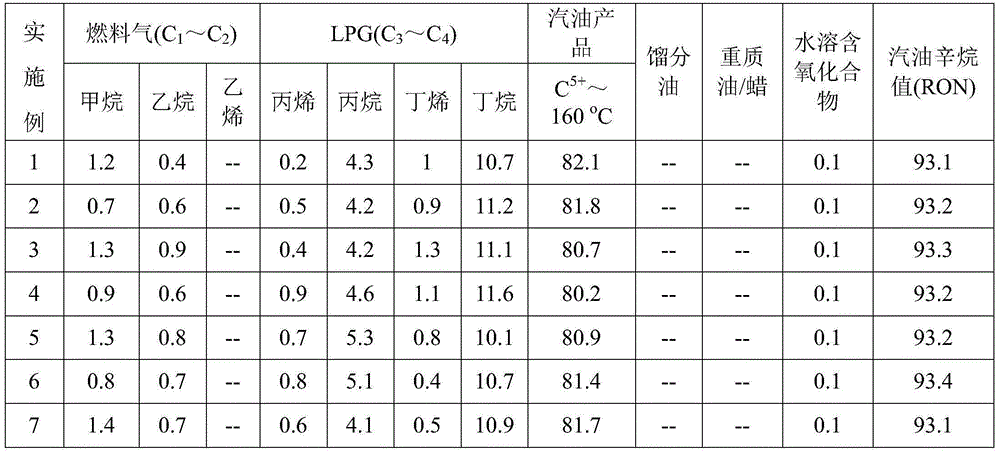

Technology for production of gasoline and combined production of natural gas and hydrogen through methanol synthesis of coke oven gas

ActiveCN105062591AWith characteristicsHave made significant progressGaseous fuelsLiquid hydrocarbon mixture productionGas compressorLiquid methane

Owner:SEDIN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com