Nitrogen rejection methods and systems

a technology of nitrogen and nitrogen, applied in the direction of refrigeration and liquidation, lighting and heating apparatus, solidification, etc., can solve the problems of increasing the area footprint and weight of the facilities involved, the nitrogen content of produced natural gas streams is one of the toughest energy challenges in the world, and the separation of nitrogen from methane is technically challenging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

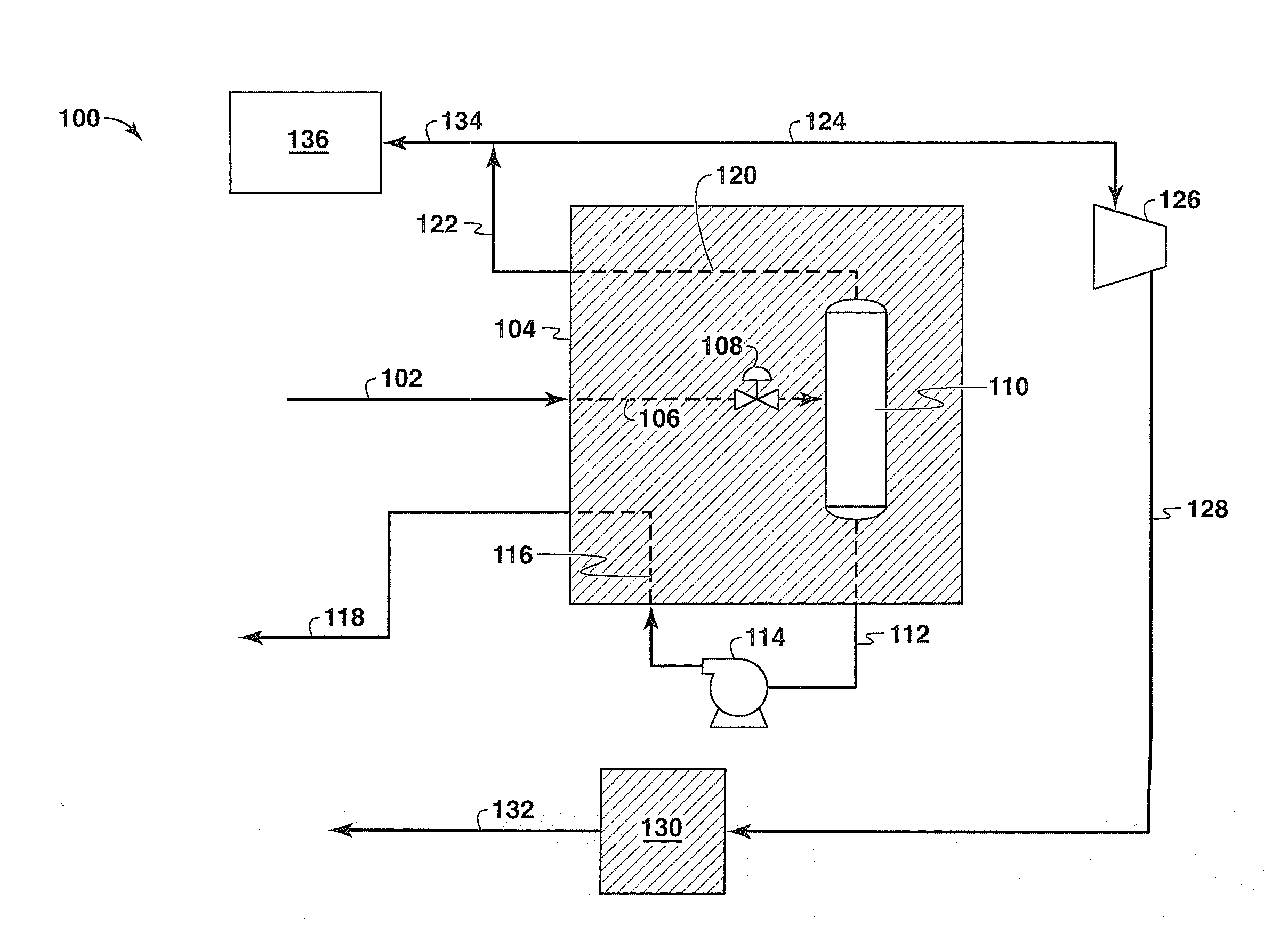

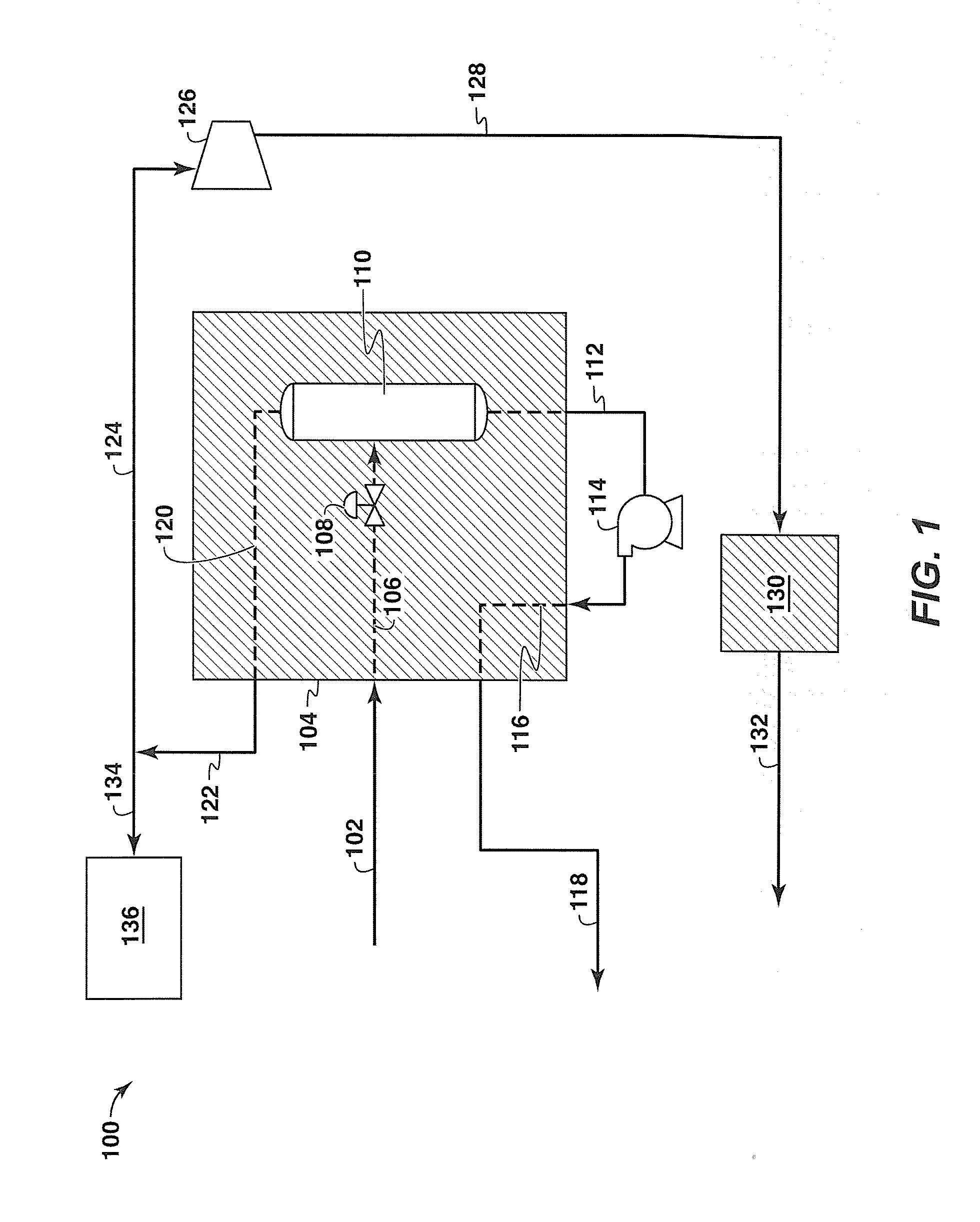

[0076]In one exemplary case, a natural gas feed stream having an assumed temperature, flow rate, pressure, and composition was provided. Table 1 below shows the temperature, flow rate, pressure, and composition of the relevant streams as shown in FIGS. 1 and 3A.

TABLE 1StreamStreamStreamStreamStreamStreamStreamStreamComponent102122118106306112120312methane0.9040.7750.9770.9040.9040.9650.7810.773nitrogen0.0930.2240.0200.0930.0930.0320.2190.227ethane0.0030.0010.0030.0030.0030.0030.0000.000Total1.0001.0001.0001.0001.0001.0001.0001.000Pressure915275770905902285280300(psia)Temperature136130130−131−150−170−176−174(deg F.)Mscfd9534619595771618

[0077]In particular, the exemplary flow rates illustrate the relative size of warmed nitrogen rich stream 122 as compared with the natural gas feed stream 102. Beneficially, this results in a smaller volume of fluids going to the NRU 130 for further treatment, lowering the energy consumption, footprint, materials, and capital costs of such systems and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com