Motor-operated compressor

a motor-operated compressor and compressor technology, which is applied in the direction of machines/engines, rotary/oscillating piston pump components, liquid fuel engines, etc., can solve the problems of increasing friction loss, difficult to quickly secure back pressure, and difficulty in maintaining back pressure. , to achieve the effect of suppressing friction loss, suppressing compression loss, and maintaining required back pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]Description will now be given in detail of a motor-operated compressor according to exemplary embodiments disclosed herein, with reference to the accompanying drawings.

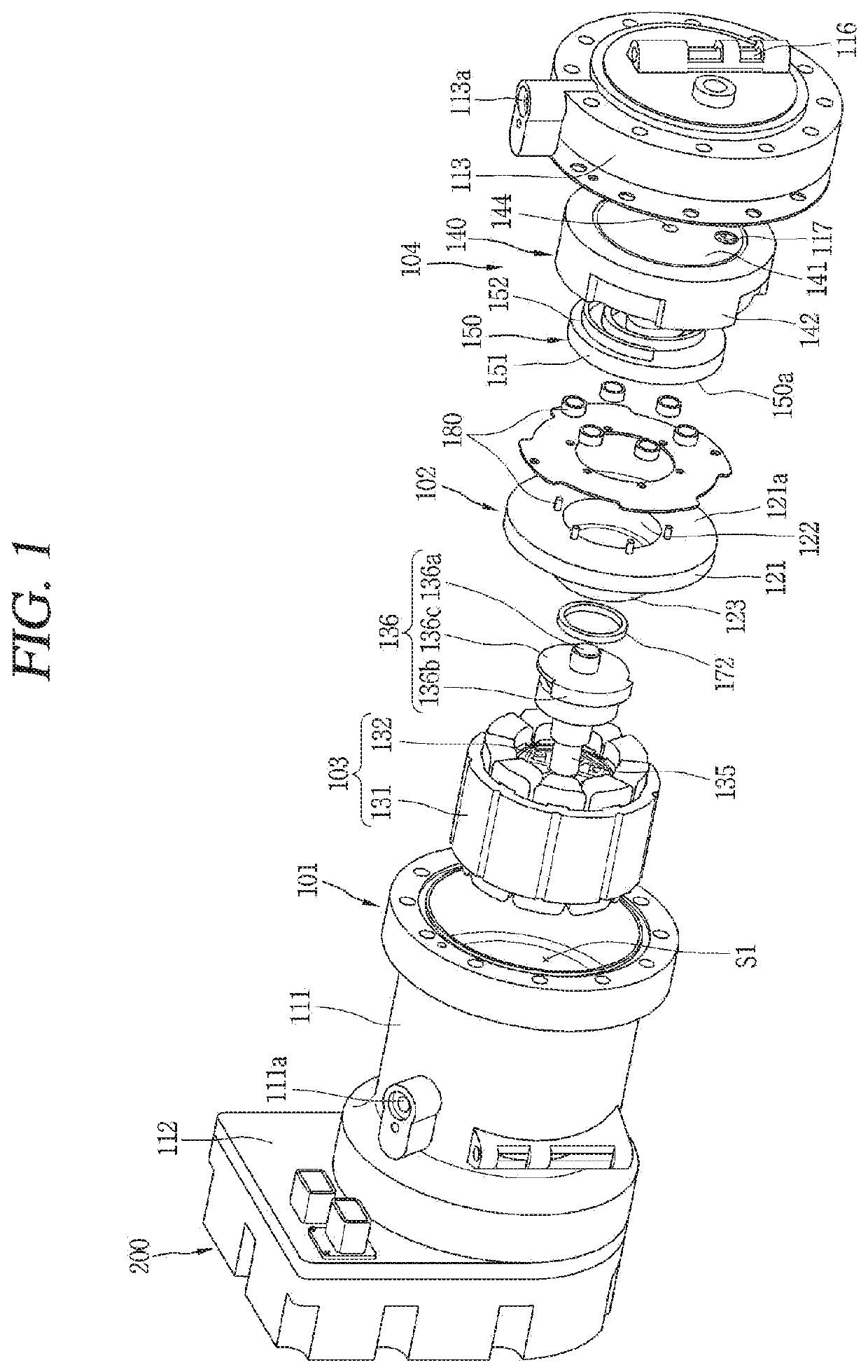

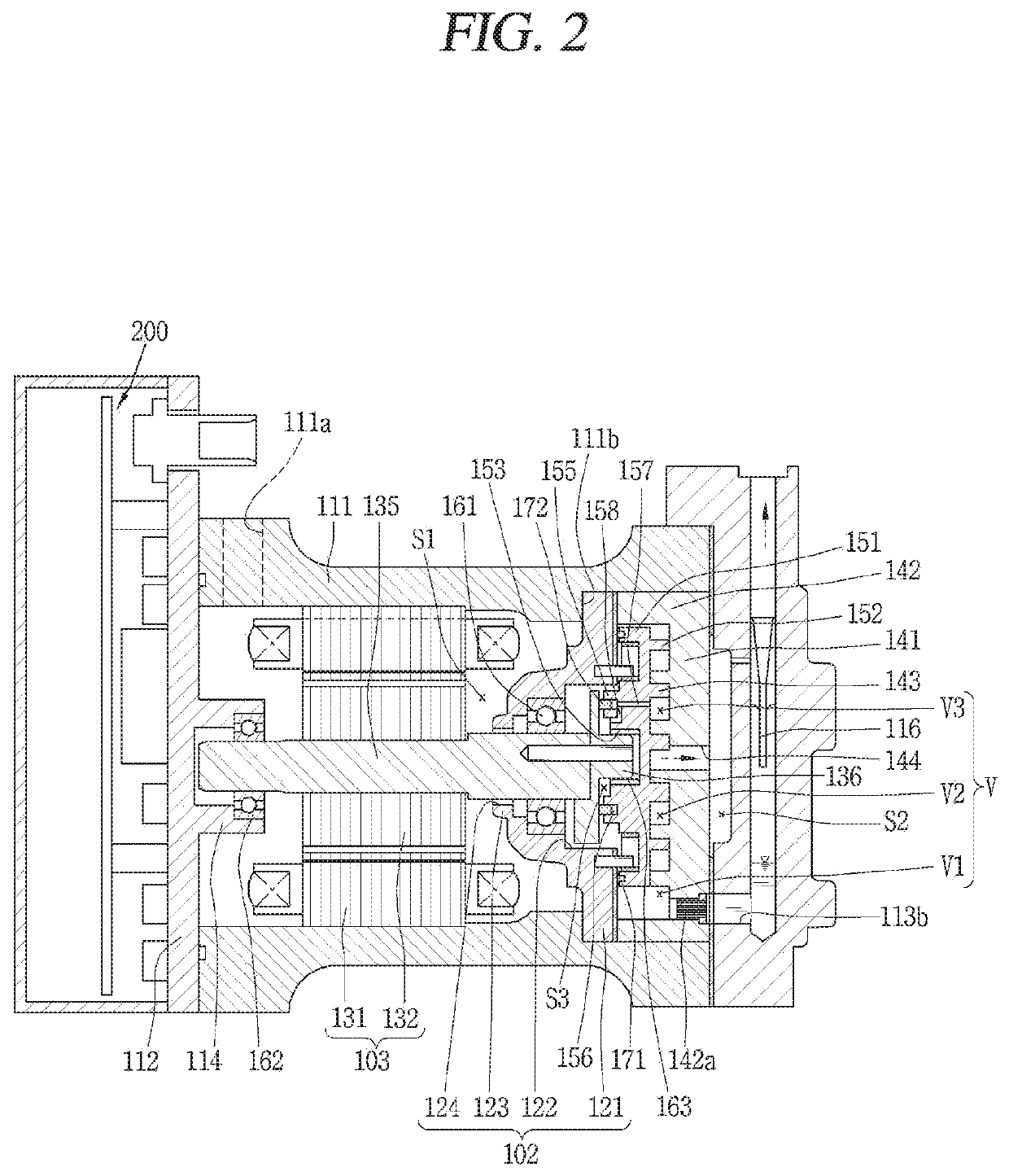

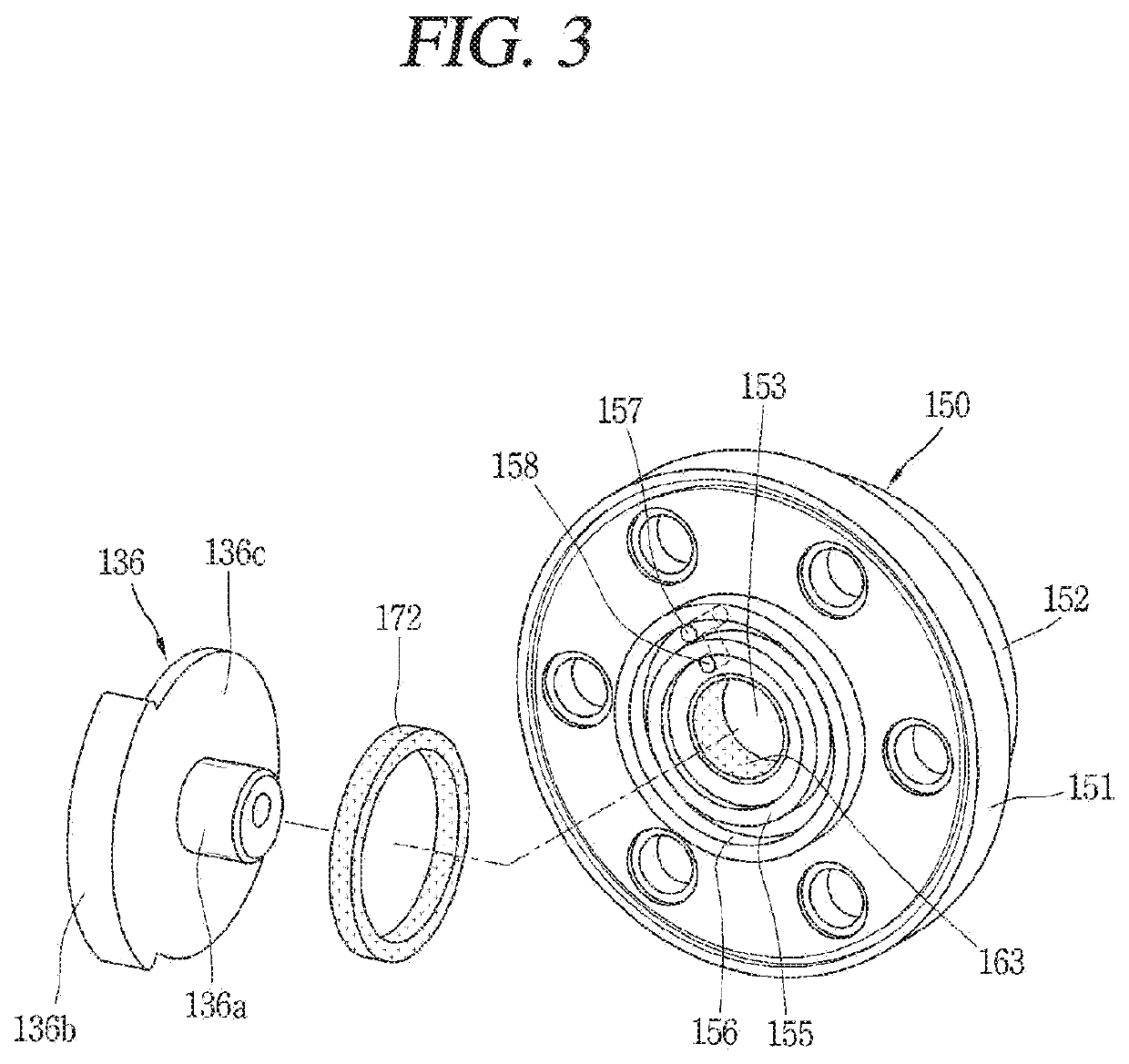

[0049]A motor-operated compressor according to the present invention is a part of a refrigeration cycle apparatus which sucks and compresses a refrigerant, namely, a scroll compressor, in which two scrolls are engaged with each other to compress a refrigerant. This embodiment of the present invention illustrates a high-temperature and high-pressure motor-operated scroll compressor that uses a carbon dioxide (CO2) refrigerant having discharge pressure of 100 bar, more precisely, of about 130 bar and a discharge temperature of about 170° C. FIGS. 1 and 2 are an exploded perspective view and an assembled sectional view of a motor-operated compressor according to the present invention.

[0050]Referring to FIGS. 1 and 2, a motor-operated compressor according to this embodiment may include a casing 101, a main frame 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com