Flexible composite laminate used for secondary cryogenic sealing barrier and adhered with lower laminate and its assembling method

A technology for sealing partitions, flexible layers, applied in adhesive heating bonding methods, lamination devices, household packaging, etc., to achieve the effect of avoiding surface contamination

Active Publication Date: 2010-08-18

HUTCHINSON SA

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Also, small leaks of liquid gas are very likely to propagate at the glass cloth yarns at the ply / adhesive interface where the applied glue forms the outer surface of the flexible ply and / or the underlying ply and may eventually do so through the secondary stage containment diaphragms, with potentially serious consequences as described above

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

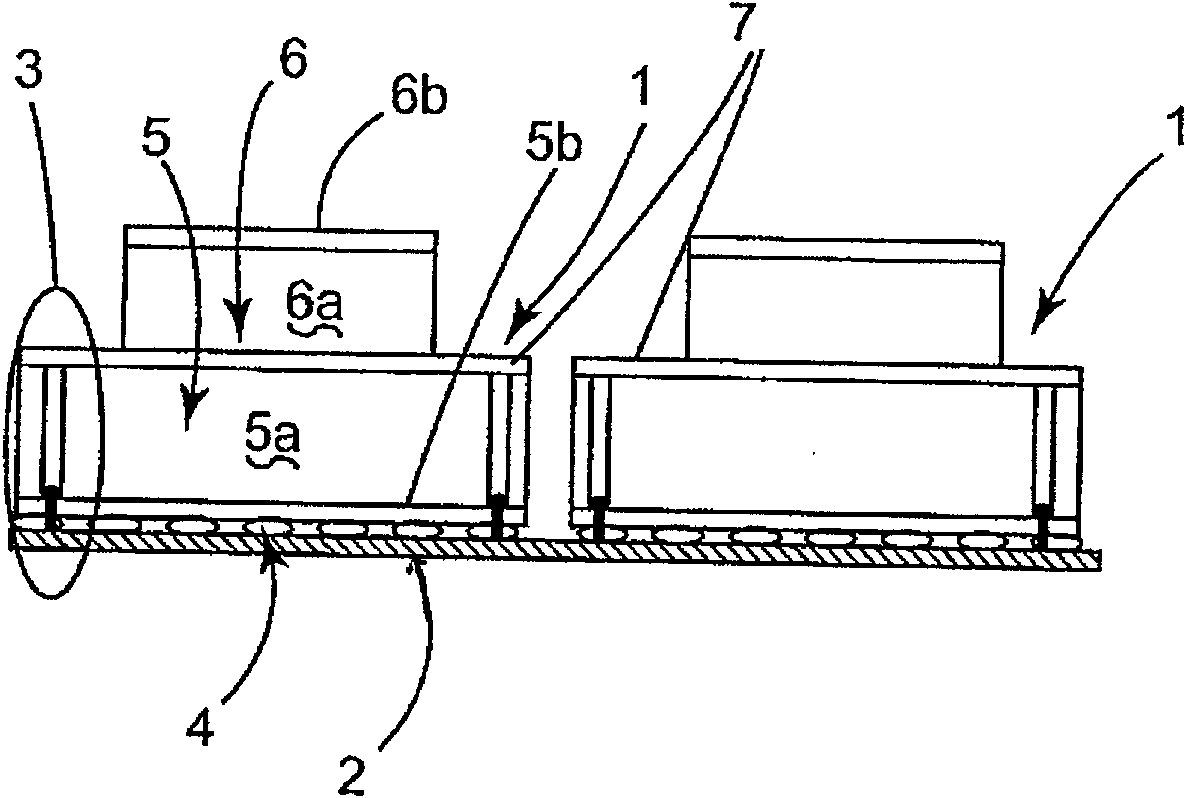

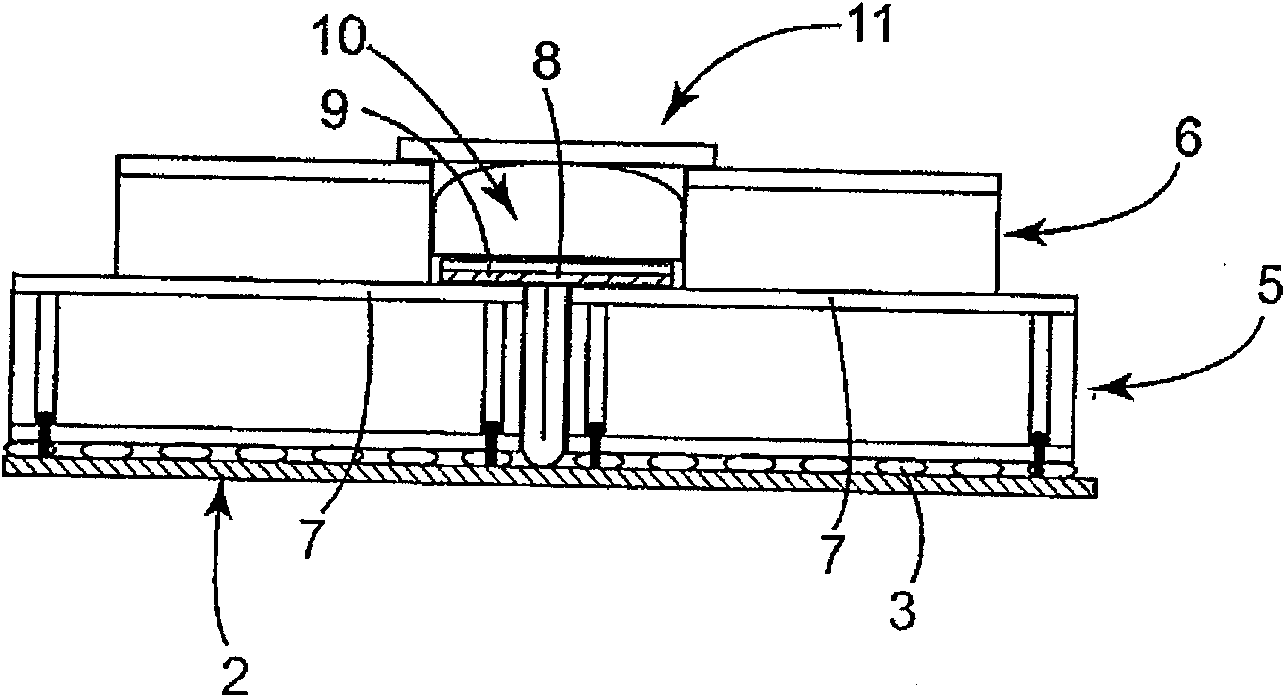

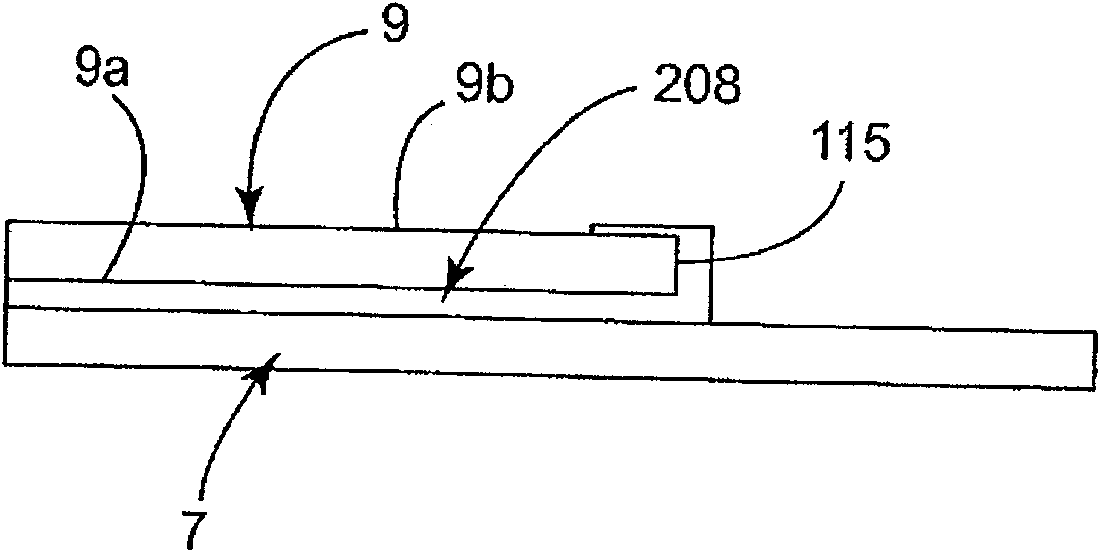

The invention relates to a flexible composite laminate (9) forming covering strip of a secondary cryogenic sealing barrier for container containing liquid methane, the secondary cryogenic sealing barrier comprises a flexible laminate belt adhered with a seam of a synthesis plate covered by another lower composite laminate. The invention also relates to a method for assembling the secondary barrier by adhering. The flexible composite laminate (9) is adhered to the seam of the adjacent synthesis plate covered by the lower laminate (7), the laminates comprise a metal foil dipped with an adhesion inserted between two fabrics. According to the invention, The flexible composite laminate is precoated with an adhesive by using a hot melt adhesive (208) cured by heat input, the hot melt adhesive is applied to tissues (9a) at a softening temperature to cover the external tissue of each lower laminate, and a peripheral edge (115) of the flexible laminate, the adhered assembly obtained by curing the adhesive contacted with the lower laminate by heating under the pressure condition, especially has improved mechanical strength and prevent the micro leakage of the low temperature liquid.

Description

Flexible laminate bonded to an underlying laminate and method of assembly thereof for a cryogenically sealed diaphragm technical field The present invention relates to flexible composite laminates forming a tape-like covering for a cryogenically sealed partition of a vessel containing, for example, liquid methane at -162°C, and to such a secondary partition, It consists of a strip of the flexible ply glued to the seam of a composite panel covered by another ply, the invention also relates to a method of assembling the secondary membrane by gluing. Background technique The design of the secondary containment partitions of the vessels in the methane transporter is based on the "Mark III" or "CS1" technology developed by the French company GTT, currently based on a laminate called a "Triplex" laminate, as leaked The partition of liquid methane is in direct contact with the cryogenic liquid if the primary partition parallel to the vessel wall is damaged or ruptured. This seco...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B32B7/12B32B15/14B32B37/12B32B37/10

CPCF17C2223/0161F17C2203/0329B32B15/08F17C2209/227C09J2463/006F17C2209/232F17C2203/0354F17C2260/036C09J2475/00B32B7/12C09J2463/00F17C2203/0636F17C2270/0107F17C2221/033F17C2203/0646F17C2203/0604C09J5/06B32B3/04B32B3/08B32B3/18B32B5/02B32B5/18B32B5/22B32B5/245B32B15/20B32B27/12B32B27/30B32B27/40B32B2250/44B32B2260/021B32B2260/046B32B2262/101B32B2307/30B32B2307/402B32B2307/50B32B2307/546B32B2439/00B32B2439/40

Inventor 法比恩·莱洛伊迪迪埃·拉瓦所特

Owner HUTCHINSON SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com