Patents

Literature

75 results about "Cryogenic seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cryogenic seals provide a mechanical containment mechanism for materials held at cryogenic temperatures, such as cryogenic fluids. Various techniques, including soldering and welding are available for creating seals; however, specialized materials and processes are necessary to hermetically entrap cryogenic constituents under vacuum-tight conditions. Most commonly used are liquid helium and liquid nitrogen, which boil at very low temperatures, below −153 °C (120 K), as well as hydrocarbons with low freezing points and refrigerating mixtures. Pure indium wire or solder preform washers are accepted as the most reliable low temperature sealing materials. When correctly formed, indium will afford leak rates of less than 4.0x10 -9 mbar- liter/sec. Alternative cryogenic seal materials include silicone grease conical seals, and Pb/Sn (lead-tin) wire seals.

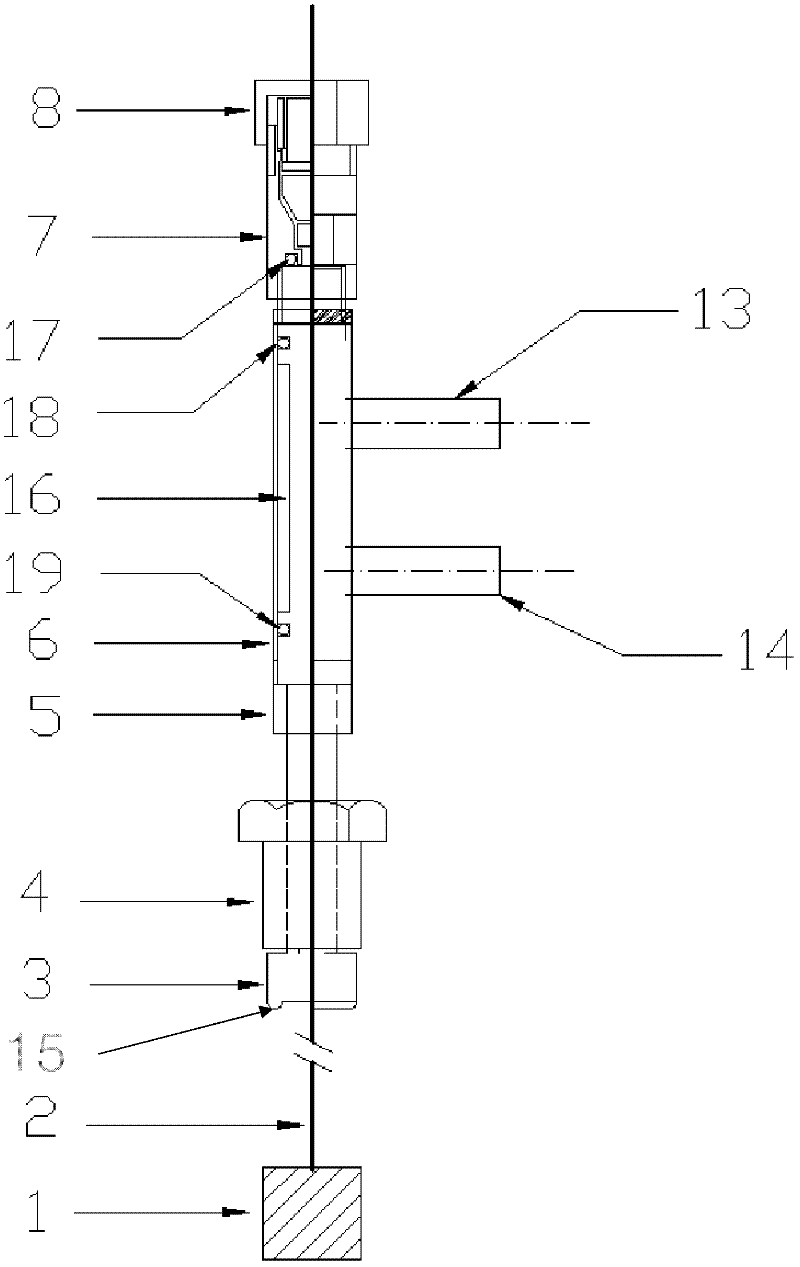

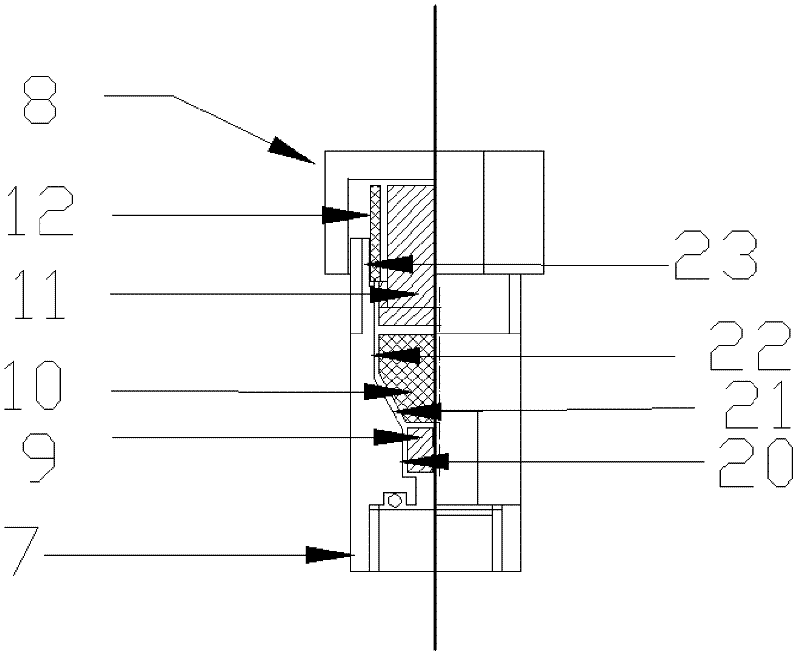

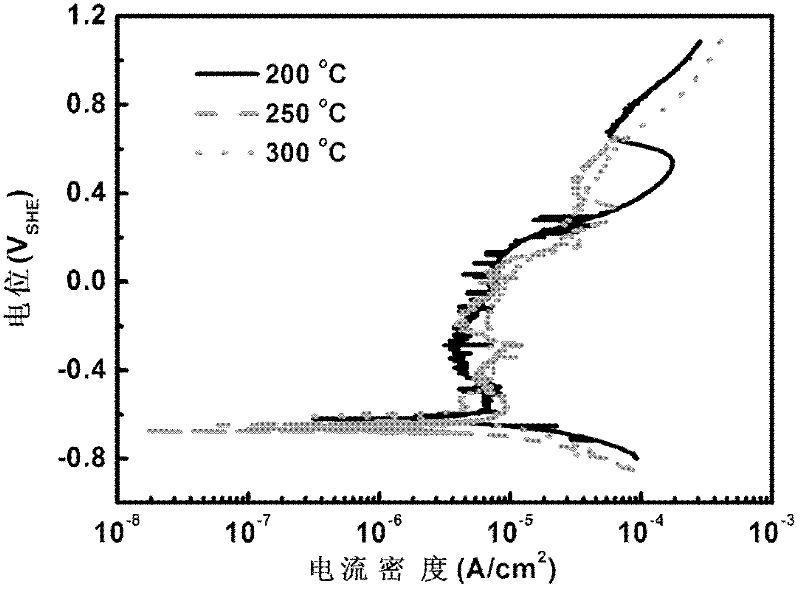

Working electrode for realizing electrochemical test of high-temperature high-pressure water system

ActiveCN102445478AReduce the difficulty of sealingImproves sealing reliabilityMaterial electrochemical variablesRoom temperatureHigh pressure water

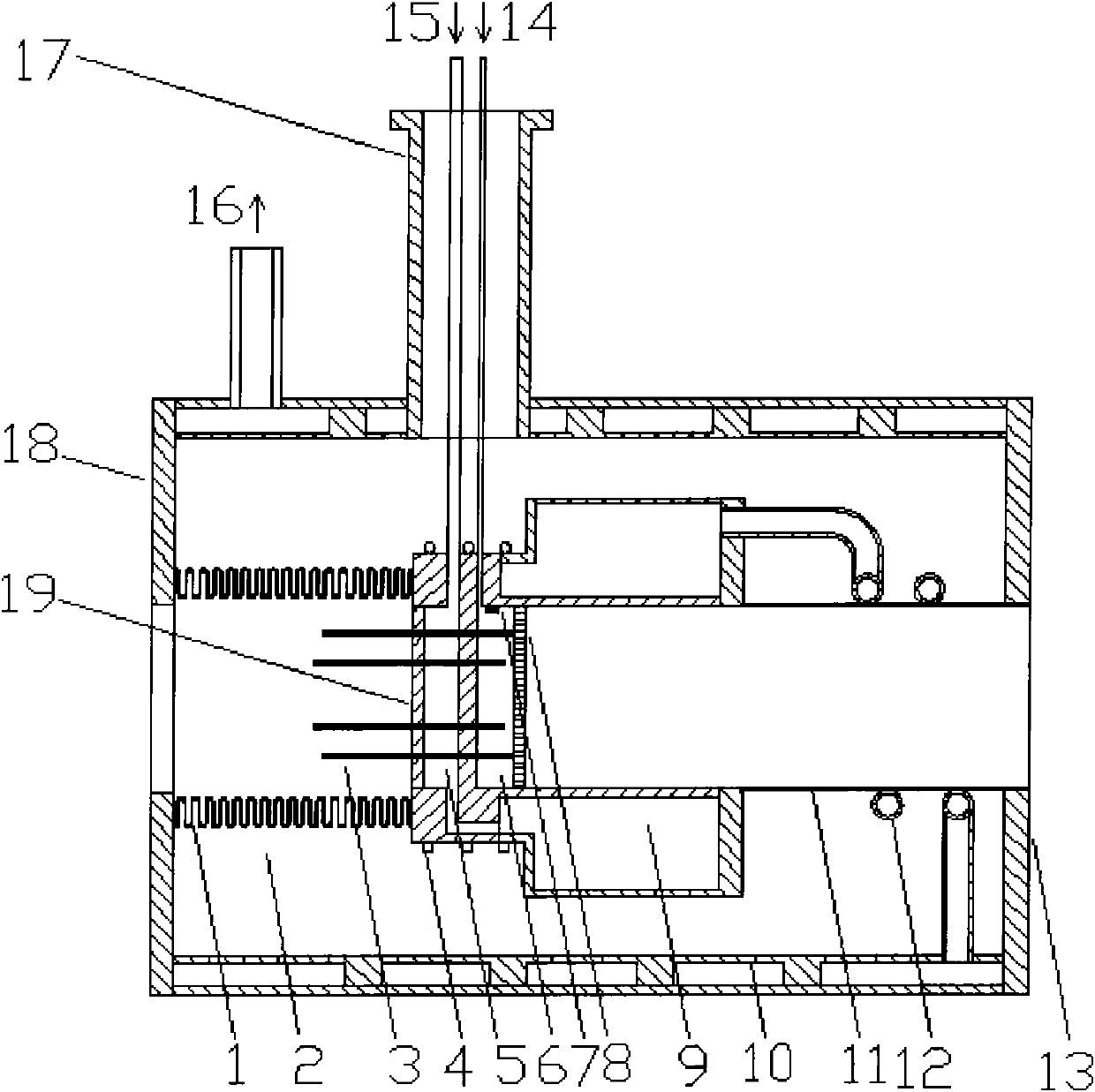

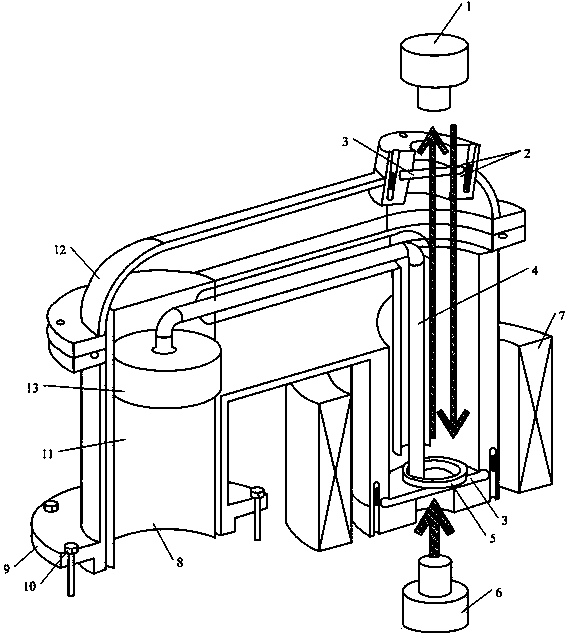

The invention relates to the field of an electrochemical test of a high-temperature high-pressure water system, in particular to a working electrode for realizing the electrochemical test of the high-temperature high-pressure water system. The working electrode comprises a metal electrode, a high-temperature sealing piece, a water cooling device and a low-temperature sealing piece, wherein an electrode lead of the metal electrode is used for wrapping a heat-shrink tube; metal hard sealing is existed between the high-temperature sealing piece and a high-pressure kettle cover; the water coolingdevice is arranged on the high-temperature sealing piece; the low-temperature sealing piece is sealed with the water cooling device through an O-shaped ring; the electrode lead of the metal electrodesequentially penetrates through central holes of the high-temperature sealing piece, the water cooling device and the low-temperature sealing piece; and the low-temperature sealing piece is sealed with the electrode lead through a rubber sealing plug. The working electrode is simple to manufacture, has good sealability, can realize the electrochemical test of the high-temperature high-pressure water system of metal materials under the temperature being between normal temperature and 350 DEG C, and the pressure being between normal pressure and 20MPa, and solves the problems of higher preparation process requirement and difficulty in realization of experimental facilities and the working electrode due to harsh environment of a high-temperature high-pressure water.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

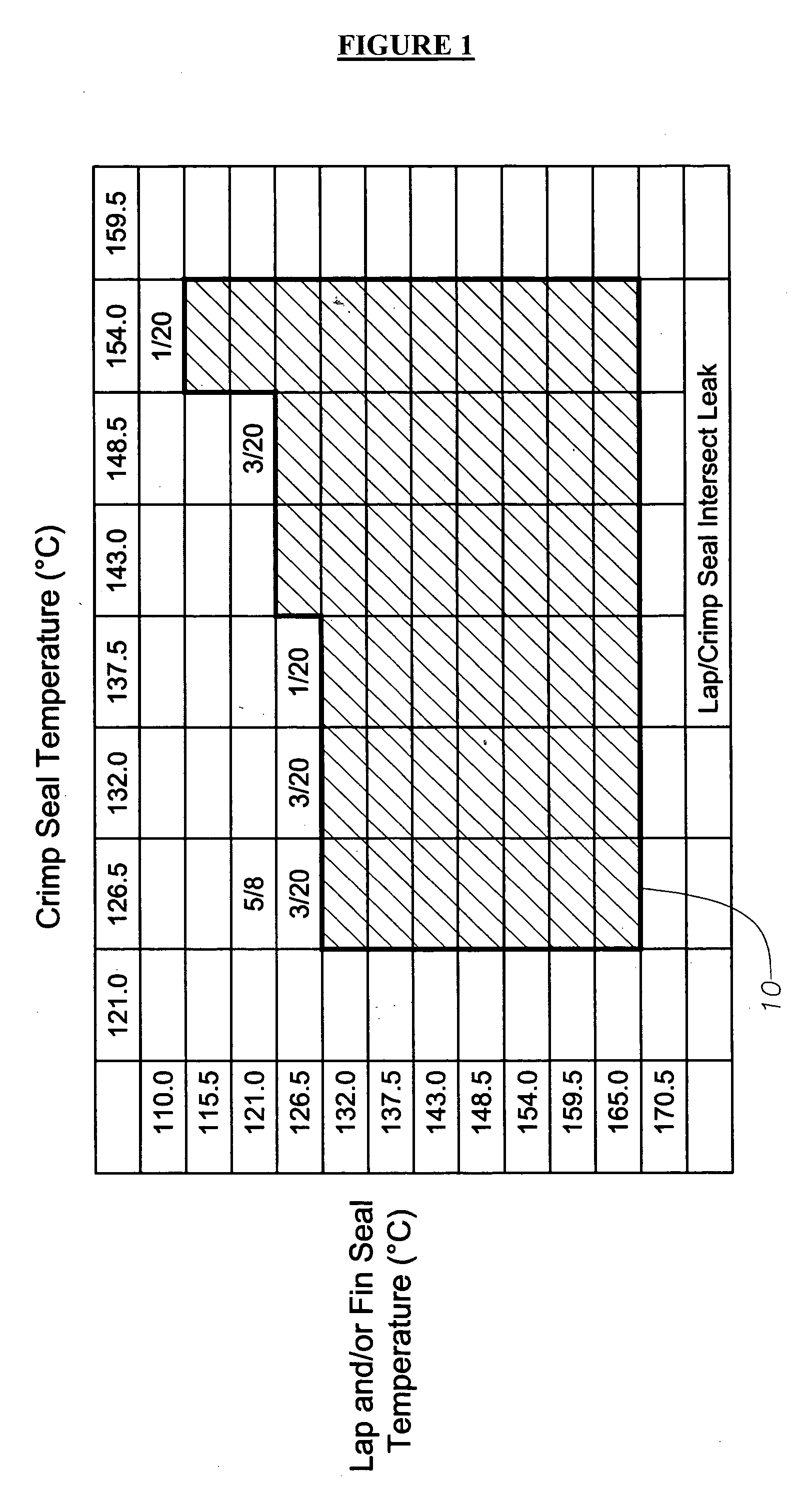

Polymer films and methods of producing and using such films

InactiveUS20070082155A1Function increaseImprove seal strengthDomestic sealsSynthetic resin layered productsHermetic sealEngineering

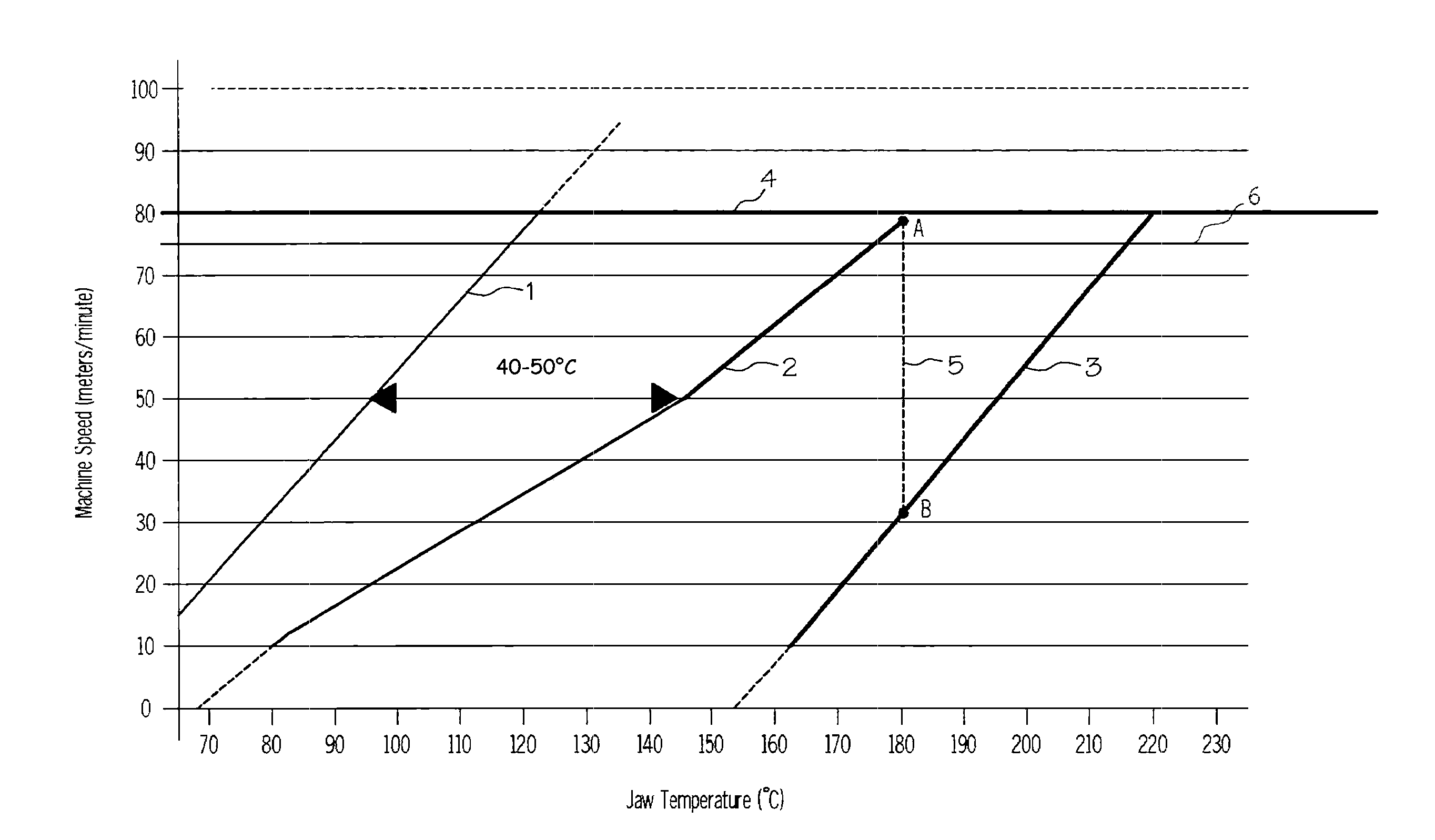

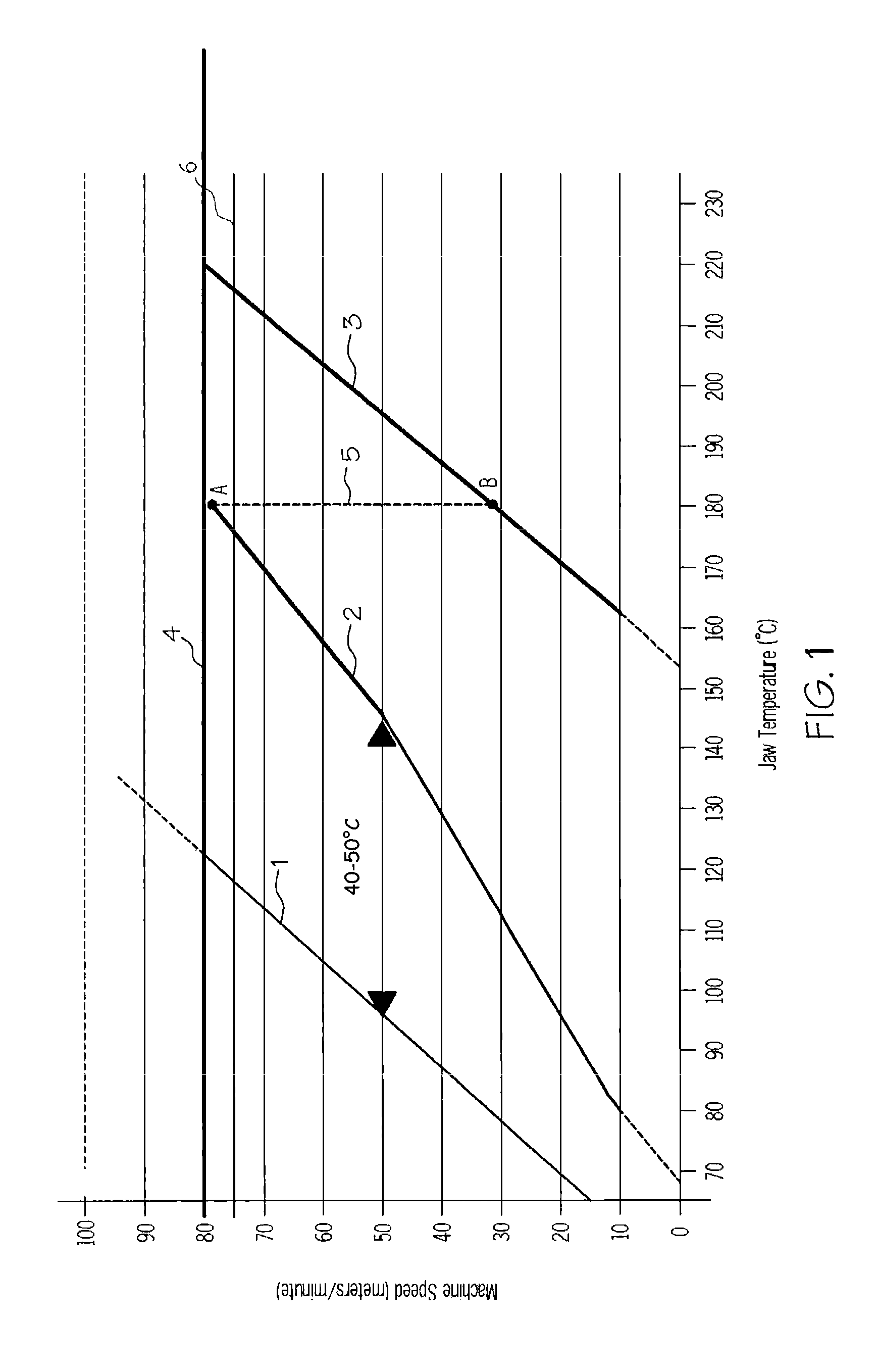

Multi-layer films particularly suited for packaging applications, including a core layer, a tie layer made from at least 10 wt % of a first polymer and a service layer, wherein the tie layer is a sealable layer and may provide a hermetic seal when sealed to itself. The films of this invention may be suitable for use in preparing hermetically sealed packages. Optionally, the multi-layer film may have a skin layer and / or a second skin layer. Embodiments may have the advantage of improved seal strength, hermeticity, hot tack, reduced-temperature sealability, and improved packaging machine operating speed.

Owner:EXXONMOBIL CORP (US) +1

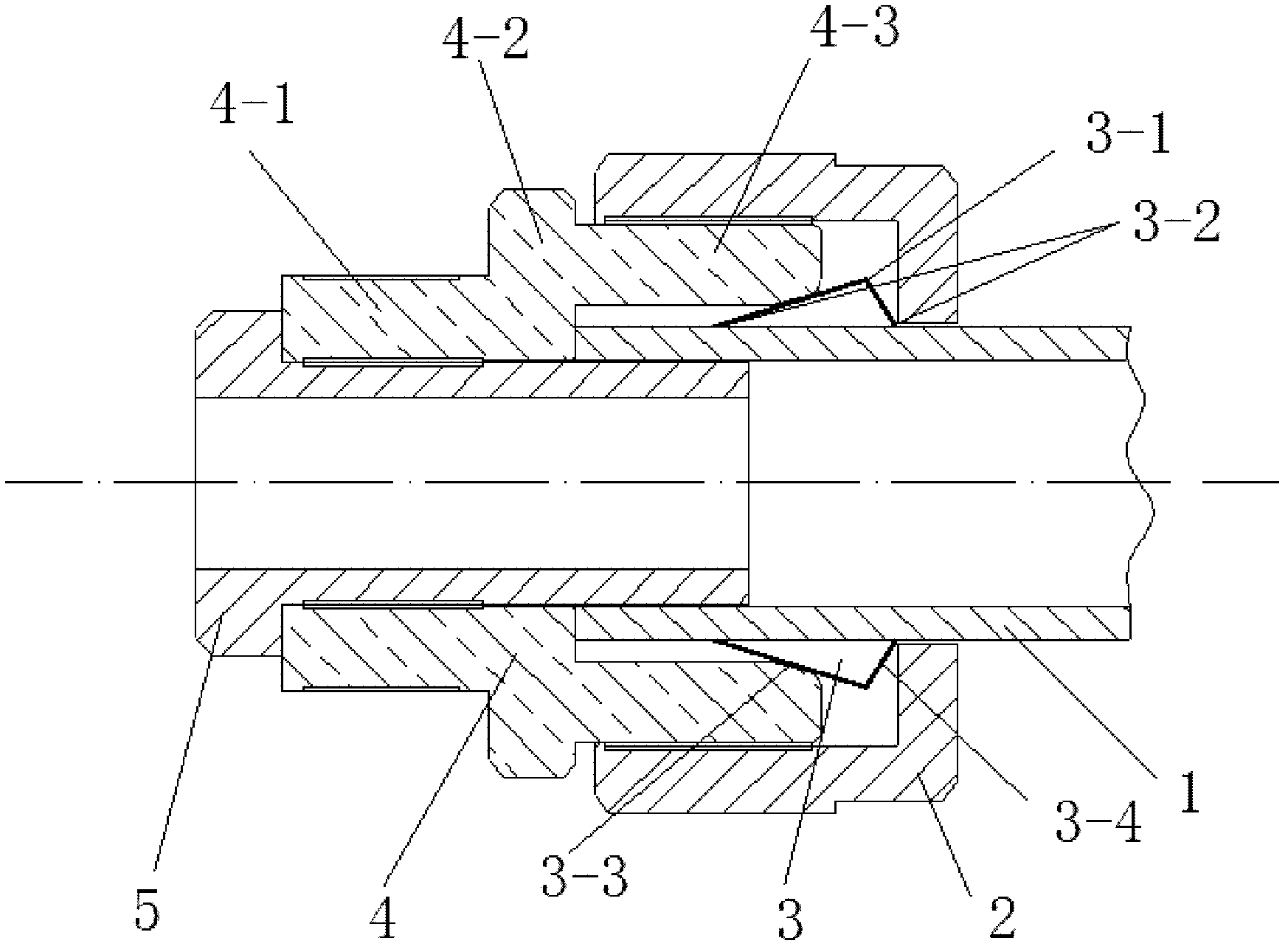

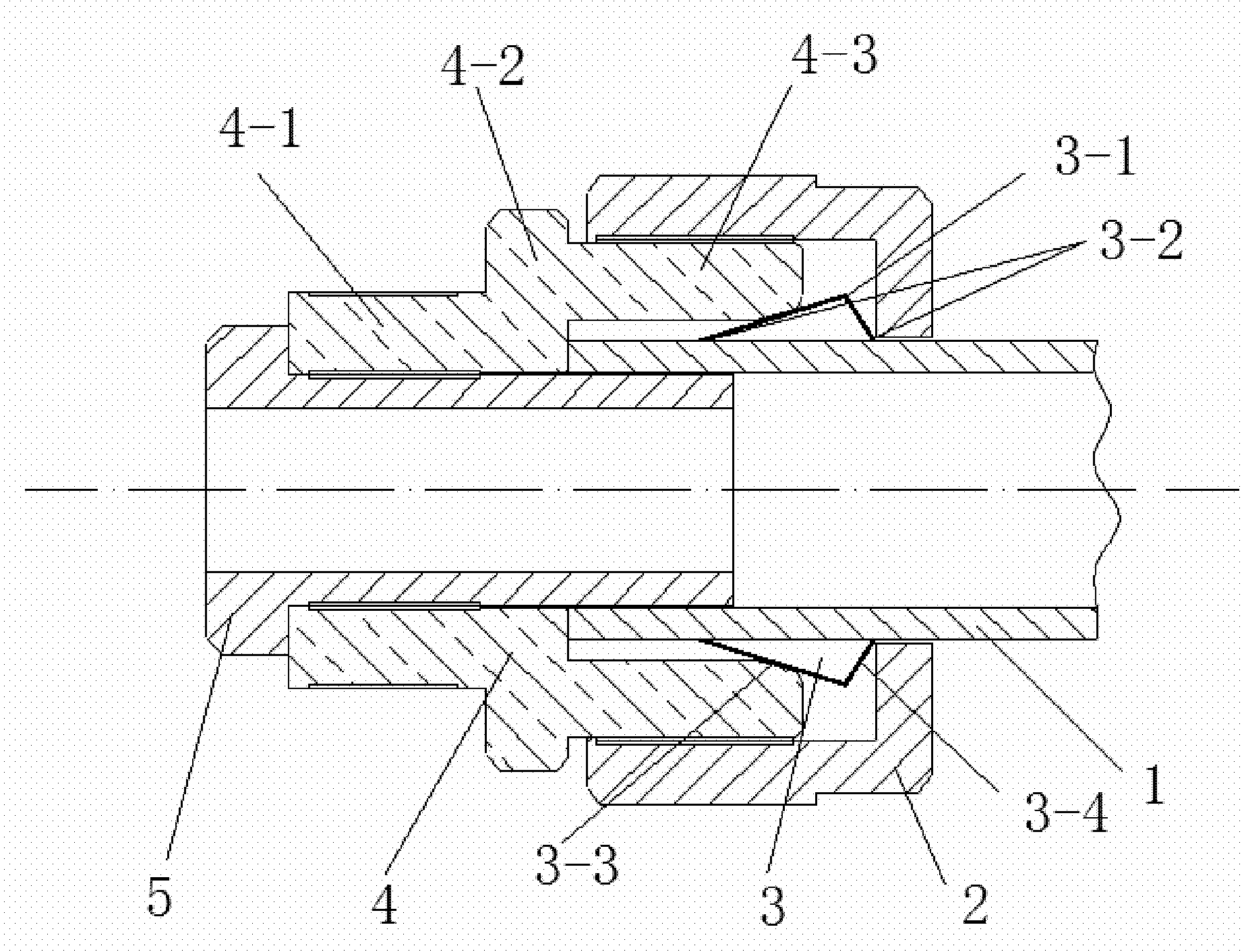

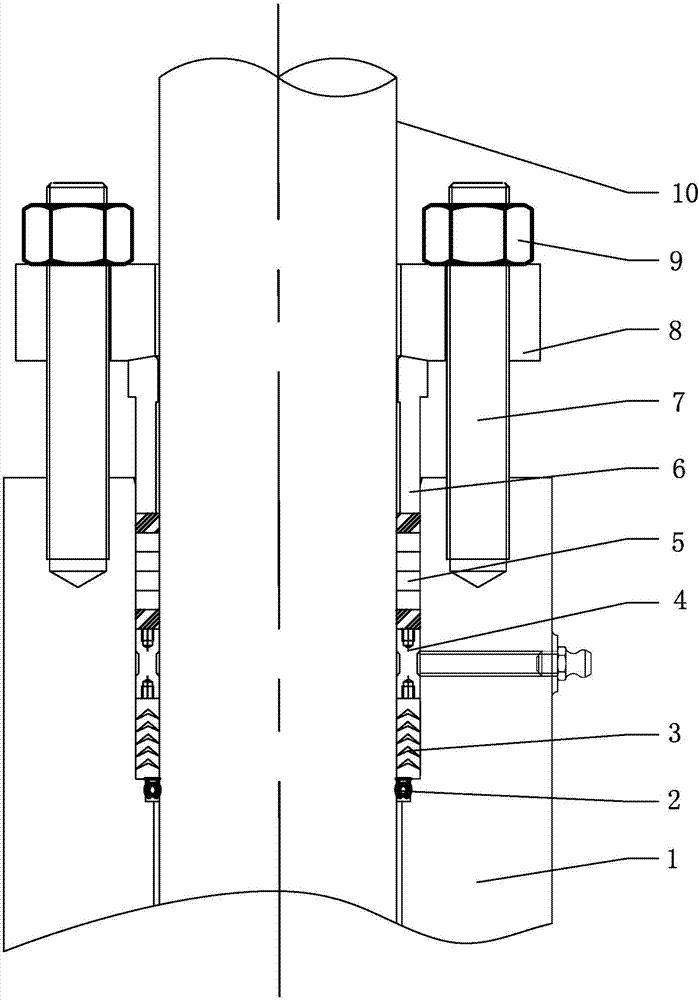

Seal joint of deep low-temperature nonmetal pipeline

The invention discloses a seal joint of a deep low-temperature nonmetal pipeline for rapidly connecting nonmetal pipelines and metal pipelines which are used for transmitting deep low-temperature fluid, and keeping seal. The seal joint comprises a nut, a metal seal ring, a metal connecting stud, a metal inner stud and a nonmetal connecting pipeline; the seal structure comprises external seal and internal seal; at the room temperature, the radial force which is generated jointly by the nut, the metal seal ring, the connecting stud and the outer surface of the connecting pipeline deforms the conical metal seal ring so that the metal seal ring and the outer surface of the connecting pipeline contact tightly, thereby achieving the seal effect; when the temperature drops to deep low temperature, such as the temperature of liquid nitrogen (78K), because the heat expansion coefficient of the nonmetal material is greater than that of a metal material, the clearance fit between the nonmetal connecting pipeline and the metal pipeline which is inserted into a pipe at the room temperature is changed into tight fit, thereby achieving the aim of low temperature sealing. The seal joint has the following characteristics that the structure is simple, and can be connected and dismounted rapidly; the seal joint is suitable for a greater range from the room temperature to the deep low temperature, and the temperature fluctuation can not influence the seal effect; the seal effect is good under pressure; and the seal property can not be reduced when the seal joint is used repeatedly.

Owner:ZHEJIANG UNIV

Low temperature hermetic sealing via laser

A method and apparatus for low temperature laser sealing of bonded articles is disclosed. Hermetic sealing of glass substrates using low temperature sealing techniques that do not adversely affect bulk strength of glass substrates, the environment created between the substrates and / or any components housed within the sealed glass substrates is disclosed. Such low temperature sealing techniques include use of localized laser heating of sealing materials to form a hermetic seal between glass substrates that does not involve heating the entire article to be sealed.

Owner:GUARDIAN IND CORP

Polytetrafluoroethylene reactivating material high and low temperature resistant sealing member

InactiveCN101108959AReasonable structureLow production costOther chemical processesGlass fiberTetrafluoroethylene

The invention relates to a sealing member manufactured by the modified high low temperature resistance polyfluortetraethylene recycled materials, which is manufactured in the method that the polyfluortetraethylene recycled waste is crushed to fine powders by a high-speed crusher through washing to manufacture the polyfluortetraethylene recycled fine powders after conventional heating and drying; the graphite or glass fiber are added as fillers to manufacture the sealing member through pressing and heating after mixing uniformly. The invention has the advantages of reasonable structure, scientific technology, reasonable production cost, high low temperature resistance range of minus 100 DEG C. to 350 DEG C., convenient maintenance, continuously recycled resources and environment protection without pollution.

Owner:陈秉杞

Special modified high and low temperature resistant sealing part material produced by polytetrafluoroethylene regeneration method, sealing part and preparation method thereof

ActiveCN101608043AEfficient removalDecomposition and purification treatment effect is goodAlkali freeMaterials processing

The invention provides a special modified high and low temperature resistant sealing part material produced by a polytetrafluoroethylene regeneration method, which consists of regenerative polytetrafluoroethylene powder processed by special step, high-temperature magnesium oxide and alkali-free glass fiber powder. A sealing part formed by processing the material has good high and low temperature resistant performance and can keep good using performance within the range of -220 DEG C-+350 DEG C, thereby not only keeping the unique chemical stability of the polytetrafluoroethylene, but also keeping the toughness and the broad operatability of a high temperature resistant and micro-fibrous internal unchanged structure of the material; furthermore, the sealing part also has the advantage of super-strong sealing property, wear resistance and lubricity, so that the range of applications is wider. The material can not only be used in the sealing field, but also be used in matching energy conservation and emission reduction of solar energy manufacturing industry, as well as equipment of military industry.

Owner:义乌市秉杞氟塑科技有限公司

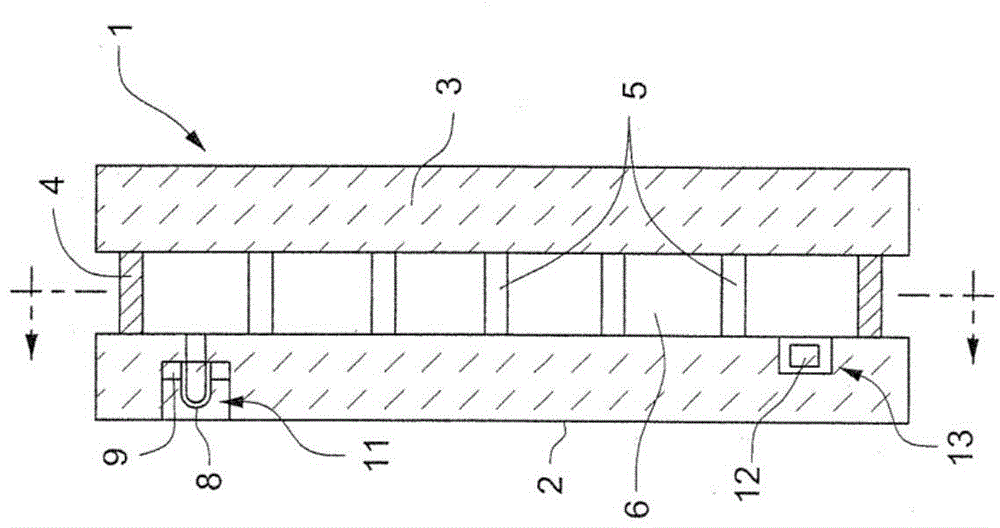

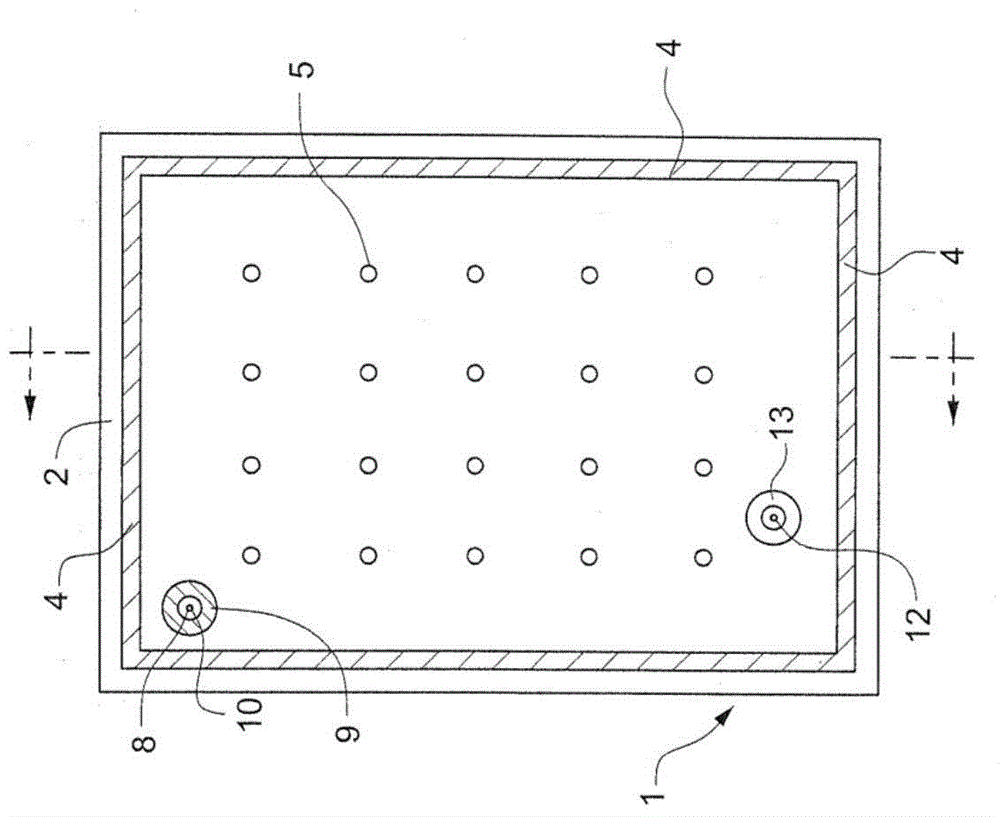

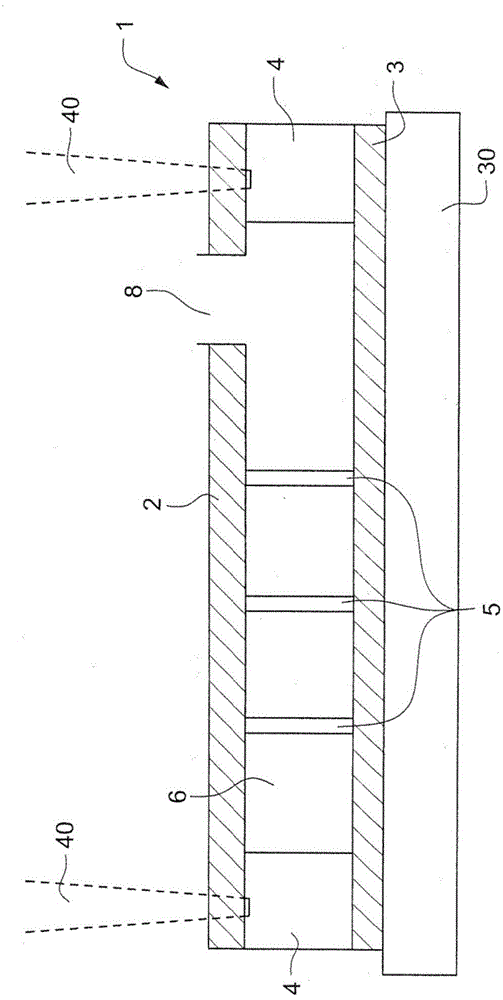

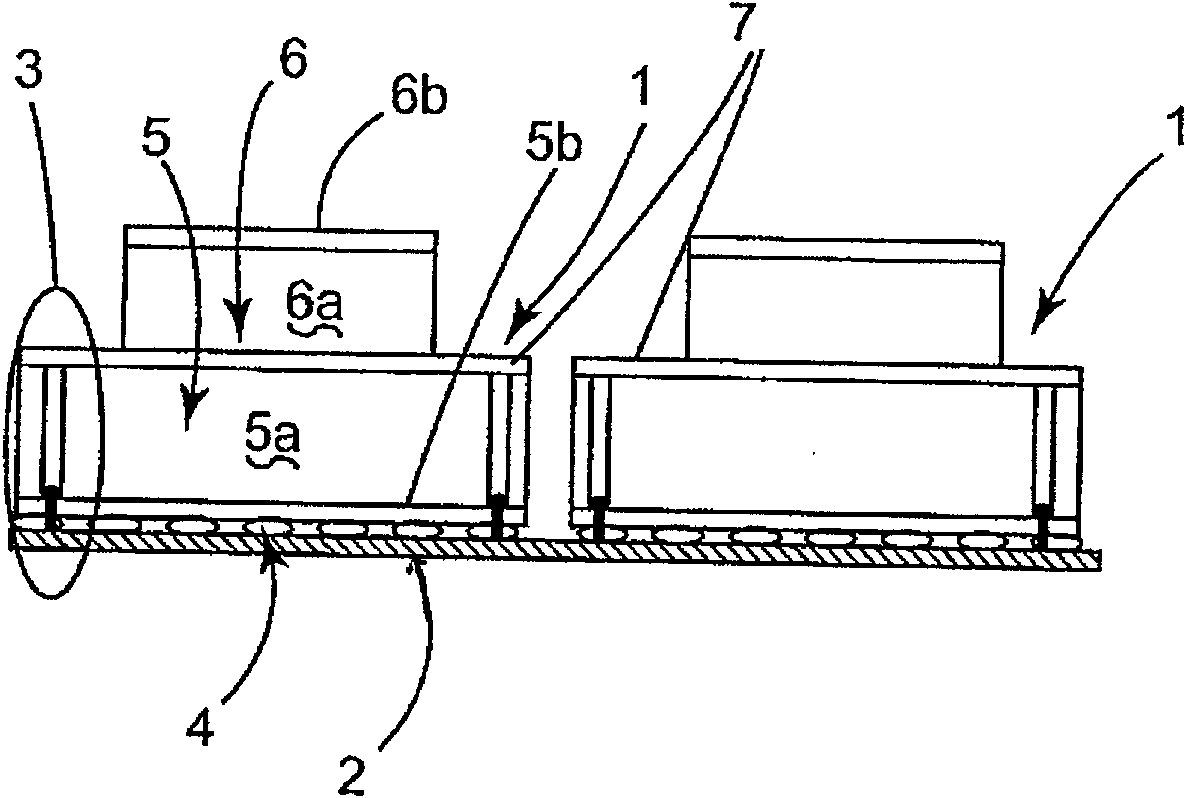

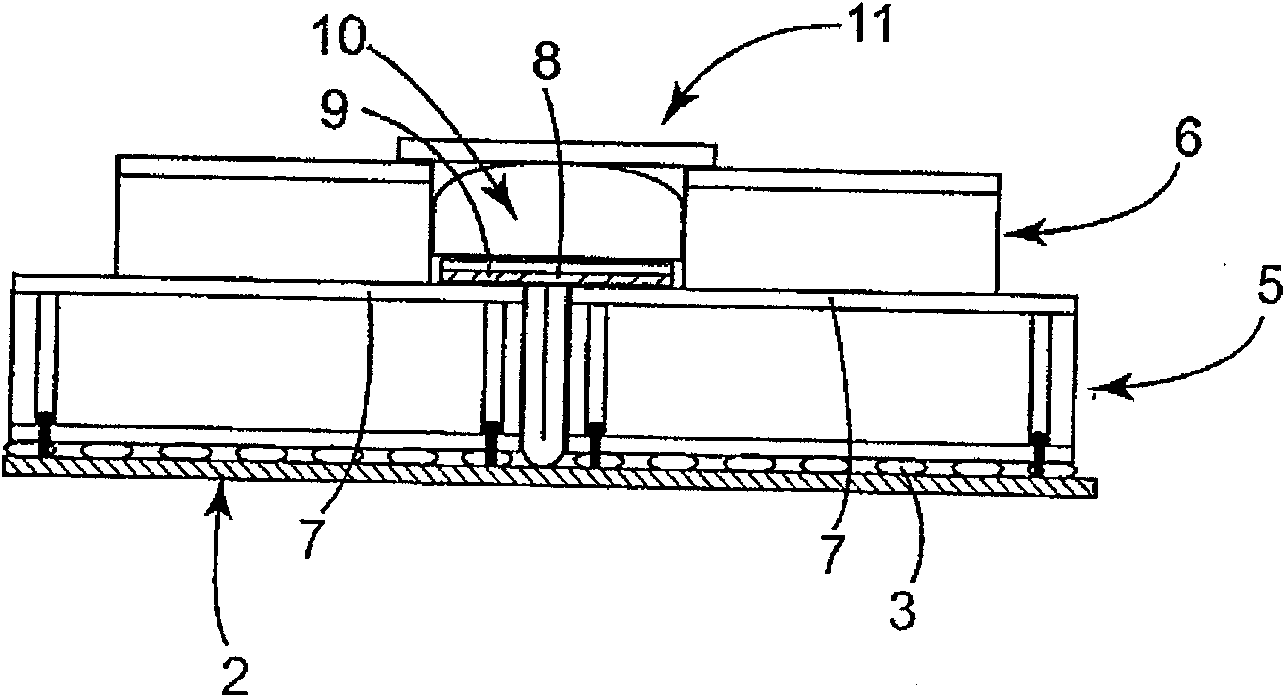

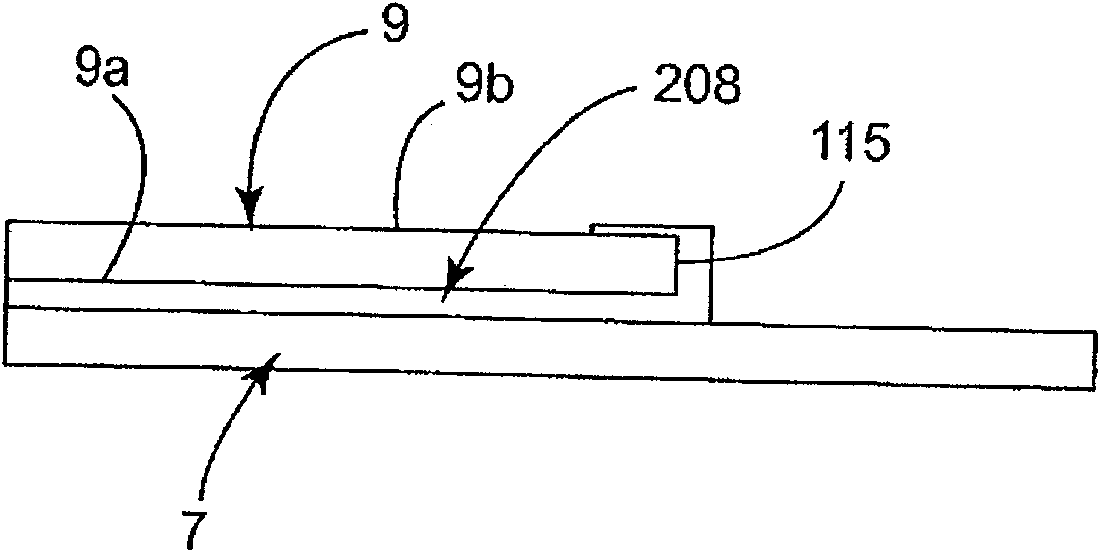

Flexible composite laminate used for secondary cryogenic sealing barrier and adhered with lower laminate and its assembling method

ActiveCN101804707AEasy to avoid surface contaminationAvoid surface contaminationVessel manufacturingWaterborne vesselsMetal foilComposite laminates

The invention relates to a flexible composite laminate (9) forming covering strip of a secondary cryogenic sealing barrier for container containing liquid methane, the secondary cryogenic sealing barrier comprises a flexible laminate belt adhered with a seam of a synthesis plate covered by another lower composite laminate. The invention also relates to a method for assembling the secondary barrier by adhering. The flexible composite laminate (9) is adhered to the seam of the adjacent synthesis plate covered by the lower laminate (7), the laminates comprise a metal foil dipped with an adhesion inserted between two fabrics. According to the invention, The flexible composite laminate is precoated with an adhesive by using a hot melt adhesive (208) cured by heat input, the hot melt adhesive is applied to tissues (9a) at a softening temperature to cover the external tissue of each lower laminate, and a peripheral edge (115) of the flexible laminate, the adhered assembly obtained by curing the adhesive contacted with the lower laminate by heating under the pressure condition, especially has improved mechanical strength and prevent the micro leakage of the low temperature liquid.

Owner:HUTCHINSON SA

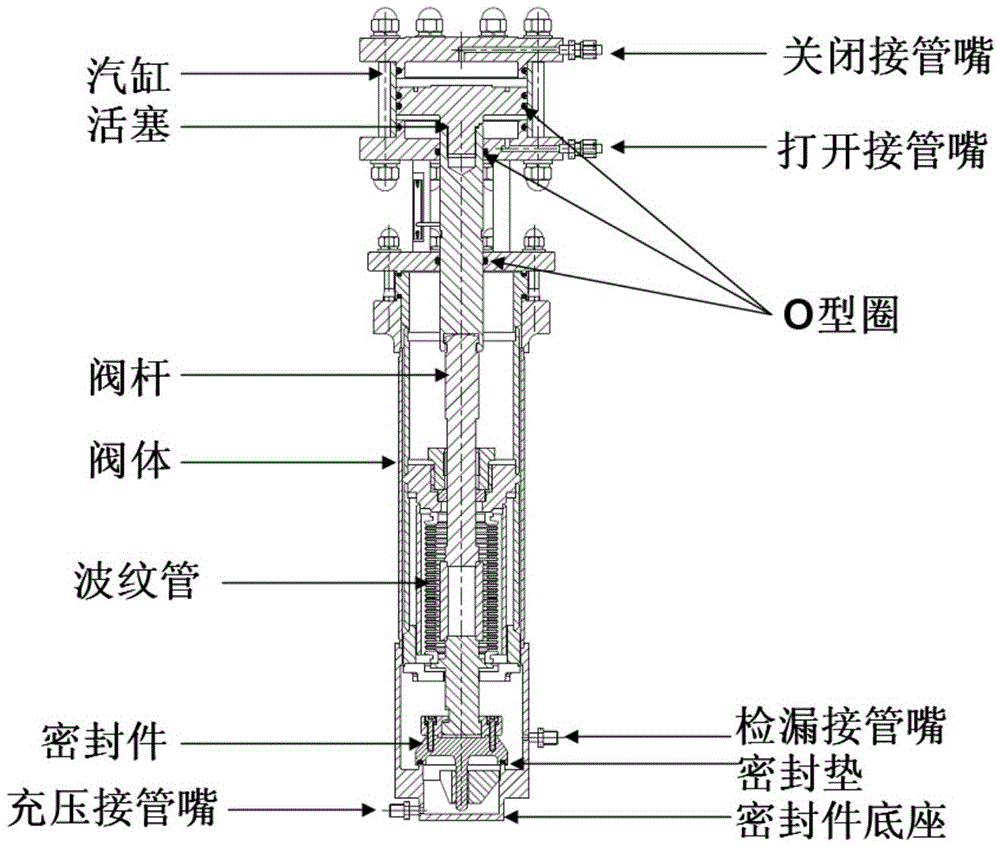

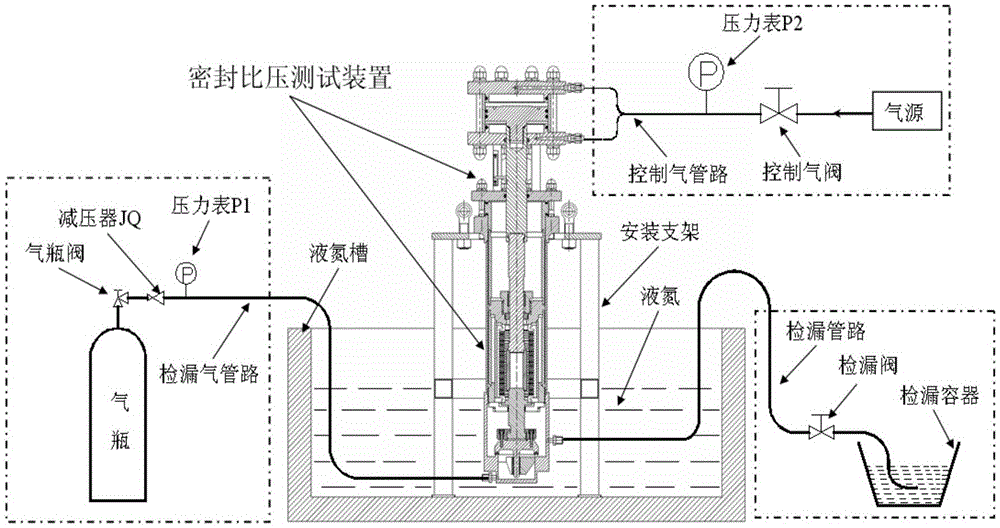

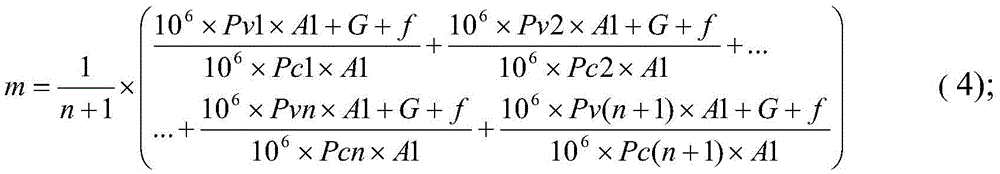

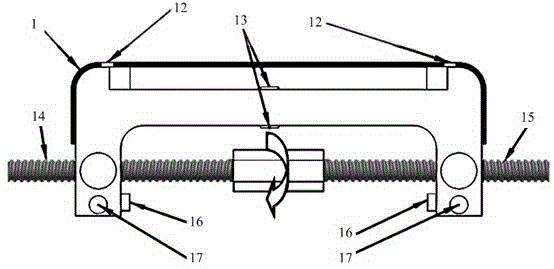

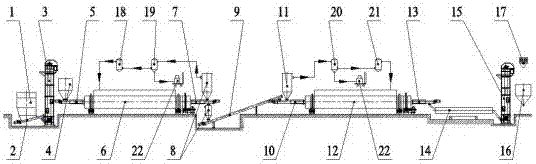

System and method for measuring low-temperature sealing specific pressure performance parameters of sealing material

ActiveCN105675221AAccurate measurementFunction increaseDetection of fluid at leakage pointCryogenic sealLiquid nitrogen

The invention discloses a system and a method for measuring the low-temperature sealing specific pressure performance parameters of the sealing material. The system for measuring the low-temperature sealing specific pressure consists of a sealing specific pressure testing device, a liquid nitrogen tank, a mounting bracket, a control module, a pipeline, a gas supply and leak detection device and the like. Through controlling the pressure of the gas source and detecting the pressure of the gas leakage, the minimum compressive stress or the specific pressure y of the sealing gasket material, and the gasket factor m of the sealing gasket material in low-temperature working conditions can be calculated in combination with the structure parameters of a piston., a valve stem, a sealing part, a sealing gasket and other parts. Meanwhile, sealing gaskets of different specifications are replaced during the testing process, so that the sealing specific pressure performance parameters of the sealing gaskets of different specifications in the low-temperature state can be determined. According to the technical scheme of the invention, the liquid-nitrogen environment at a temperature of -196 DEG C is adopted as the testing environment for testing the low-temperature sealing specific pressure performance parameters of the sealing material. In this way, the real working condition for the sealing state of a sealing gasket in a low-temperature medium pipeline can be really reproduced. The system and the method provide a reference for the parameter selection of the sealing part in the low-temperature medium pipeline, and are better in pertinence and objectivity.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Coating compositions, coated substrates and hermetic seals made therefrom having improved low temperature sealing and hot tack properties

InactiveUS8129032B2Improve propertiesIncrease temperatureLiquid surface applicatorsPaper coatingHermetic sealAlpha-olefin

Novel coated substrates are disclosed wherein a substrate is coated with a coating composition that forms good hermetic seals at very low temperatures and exhibits good blocking and slip characteristics. Such coating composition is comprised of an aqueous dispersion of a substantially non-polar copolymer of ethylene and an alpha-olefin having less than 20 carbon atoms, and an additive selected from the group consisting of an anti-blocking and slip agent, a coalescent and wetting agent, and mixtures thereof.

Owner:JINDAL FILMS AMERICAS LLC

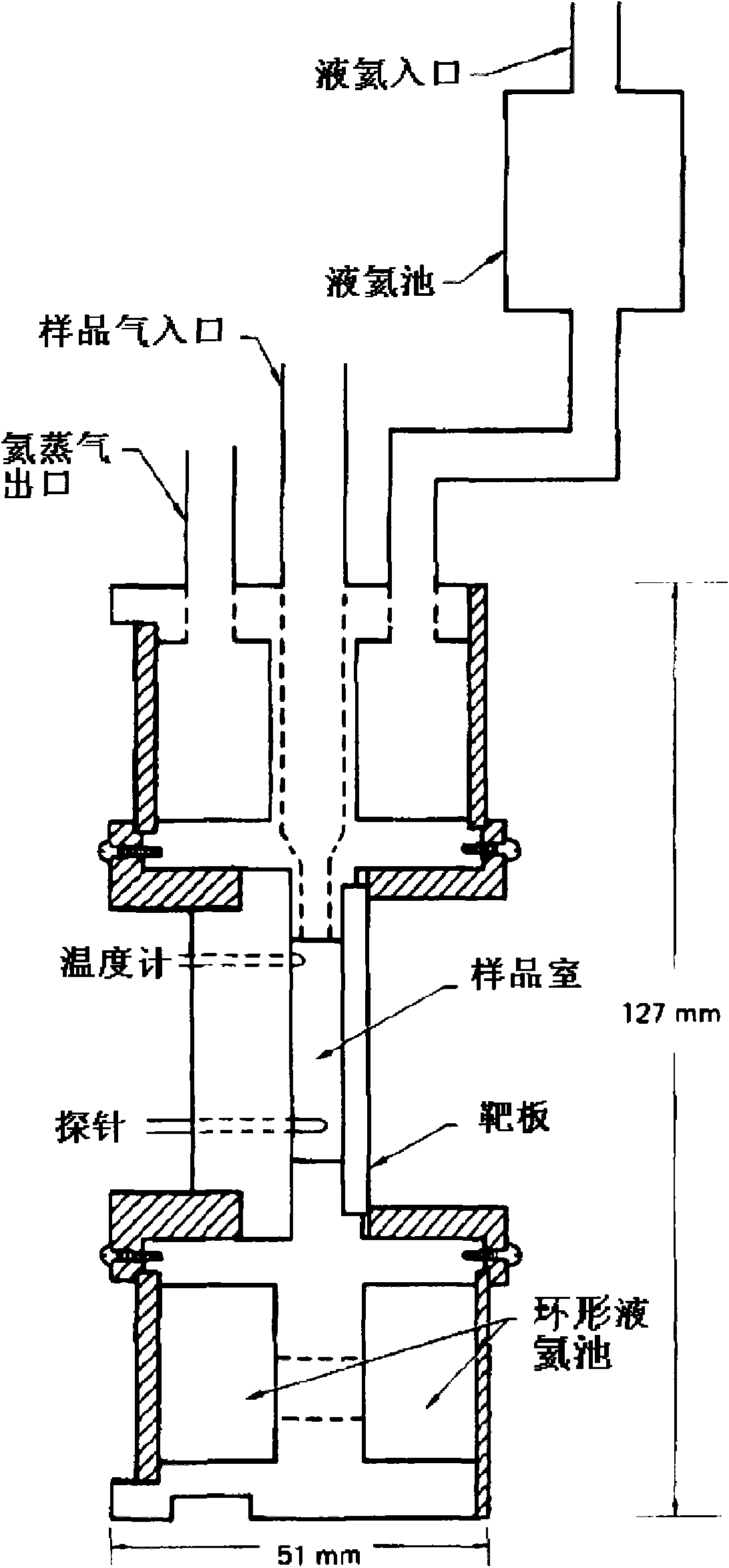

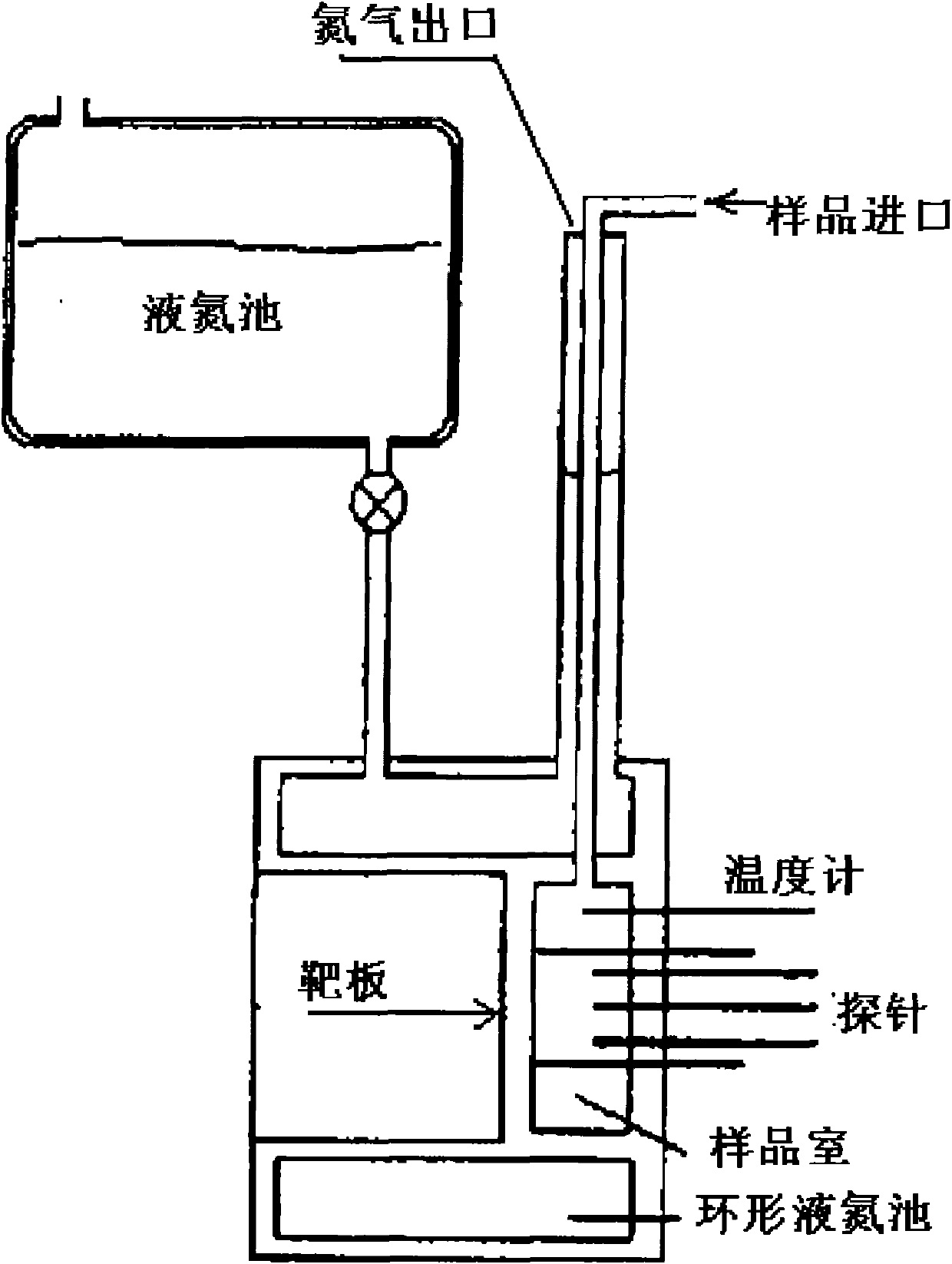

Liquid helium temperature cryogenic target for impact compression test

ActiveCN102023113AAvoid lostShorten the liquefaction timePreparing sample for investigationEngineeringLow vacuum

The invention relates to a liquid helium temperature cryogenic target for impact compression test, which comprises an air-cooled screen cavity formed by an air-cooled screen inner barrel, an air-cooled screen outer barrel and a spiral groove on the wall of the inner barrel. The air-cooled screen inner barrel is provided with a front baffle plate, a neck pipe, an assembly, a corrugated pipe and a rear baffle plate in turn from front to back; and the assembly is provided with a liquid helium side tank, a liquid helium tank, a sample chamber, a probe, a thermometer, a return gas winding pipe, a sample gas inlet pipe, a liquid helium inlet pipe, a helium steam outlet, a joint and the like. Based on continuous liquid helium delivery and reduced pressure cooling, heat leakage of an environment on the sample chamber and the liquid helium tank is reduced by using combination of helium steam sensible heat and high-vacuum heat insulation; through a reasonable sealed structure, difficulties of low vacuum, low liquid helium latent heat, small liquid helium tank volume, small cryogenic target size and low-temperature seal on storage of liquid helium in the liquid helium tank and sample helium liquefaction are overcome; and the purpose of obtaining a stable liquid sample at any temperature of between 3.6 and 80K is fulfilled by controlling the power of a heating wire.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

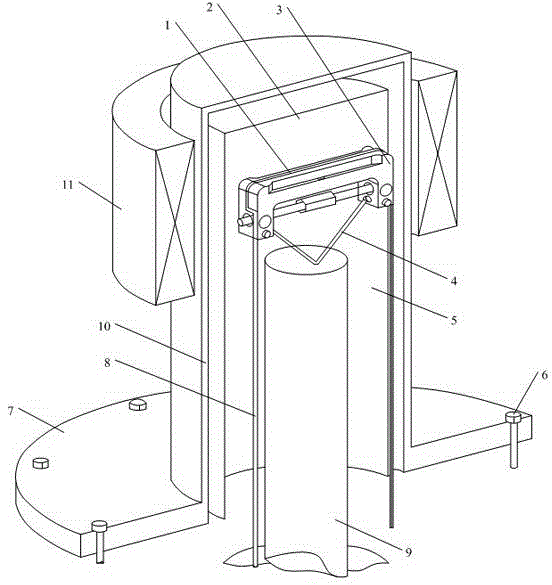

Performance test system of low temperature superconducting stranded wire

InactiveCN103336212ASimple structureImprove practicalityElectrical testingHeat transmissionHigh energy

The invention discloses a performance test system of a low temperature superconducting stranded wire, which comprises a low temperature sealing container internally provided with a vacuum chamber, a GM (Gifford-Mcmahon) refrigerator sealed and mounted with the low temperature sealing container, a magnet coating the periphery of the low temperature sealing container, a stress loading device arranged in the vacuum chamber in the low temperature sealing container and located above a secondary refrigeration head of the GM refrigerator, and a heat transmission component arranged between the stress loading device and the GM refrigerator, wherein a test sample is placed on the stress loading device. The performance test system of the low temperature superconducting stranded wire can overcome defects of high energy consumption, complicated structure, poor practicability and the like in the prior art, and has the advantages of low energy consumption, concise structure and good practicability.

Owner:LANZHOU UNIVERSITY

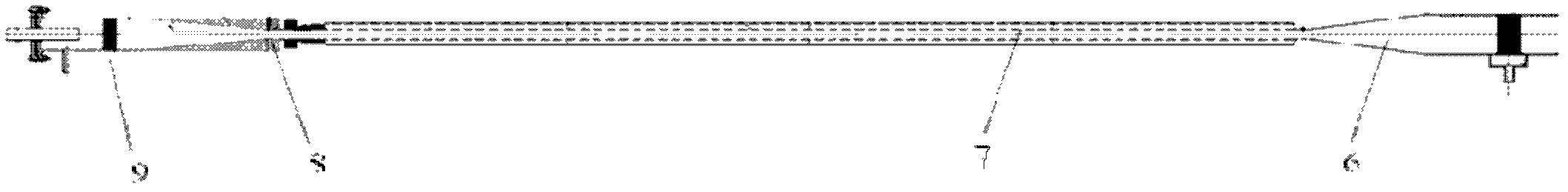

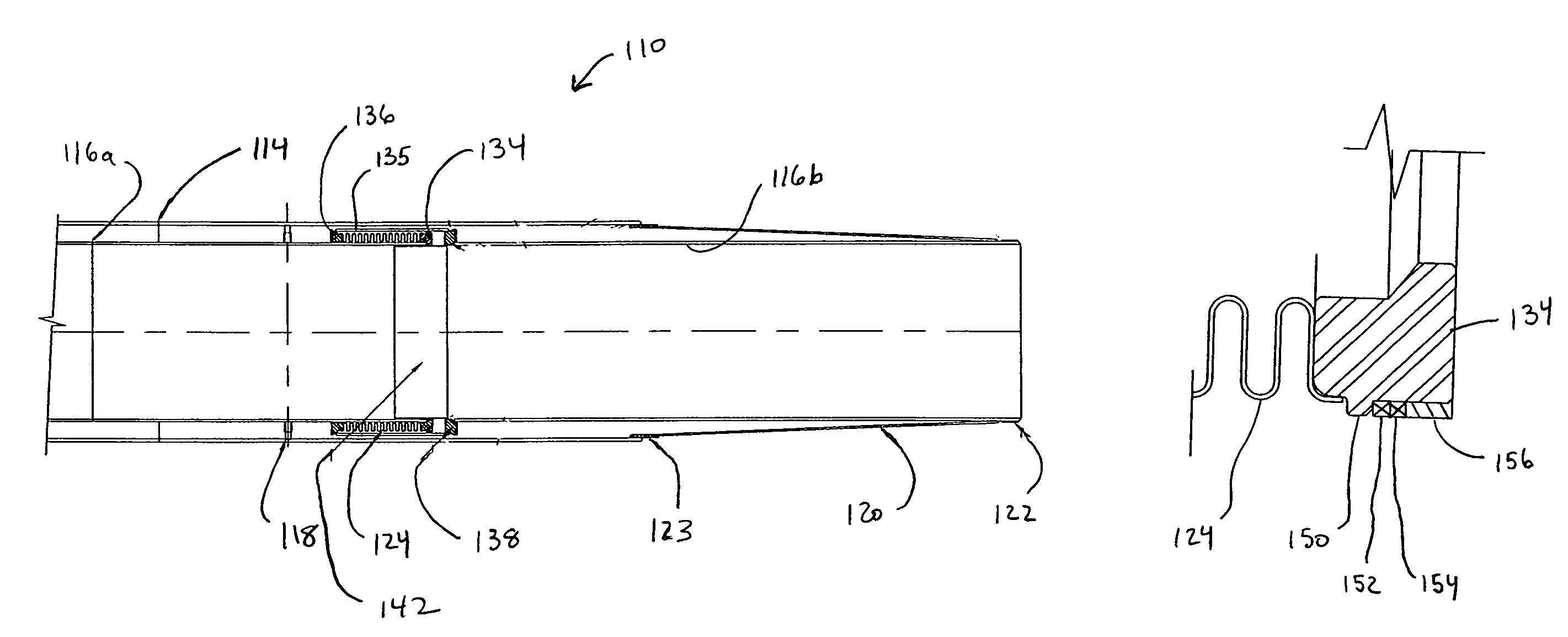

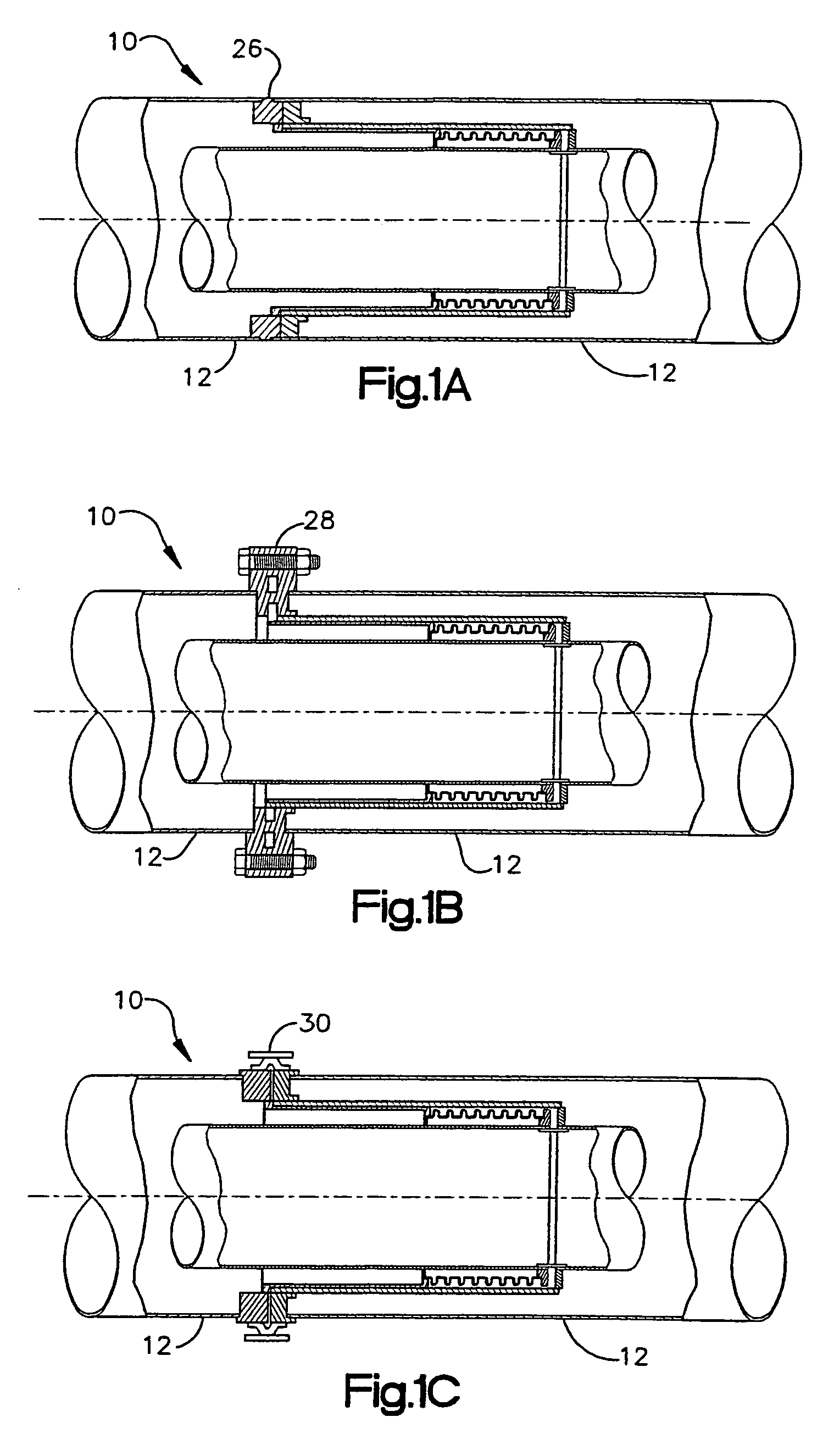

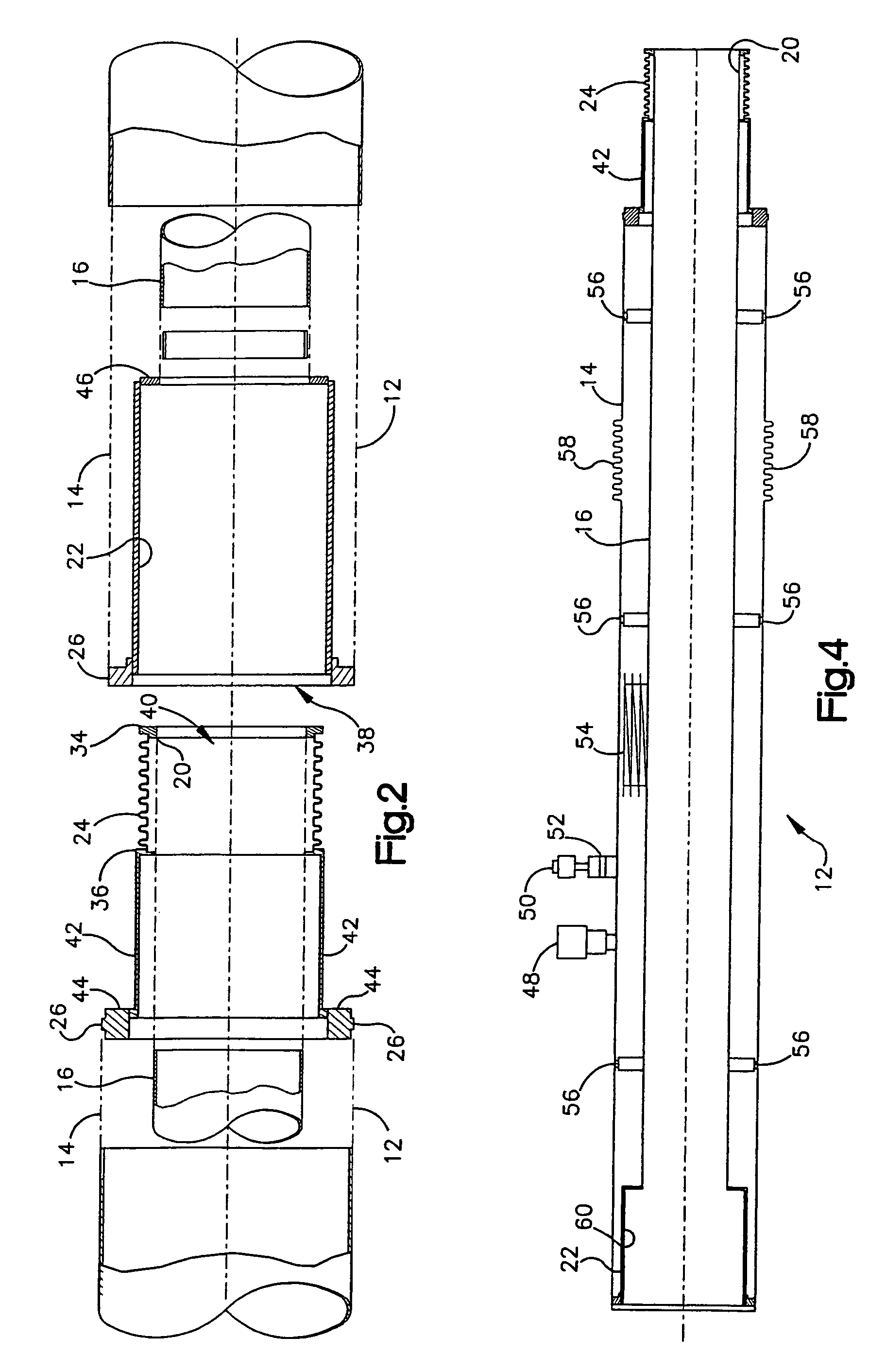

Cryogenic seal for vacuum-insulated pipe expansion bellows

A cryogenic seal for vacuum-insulated pipe systems where the pipe system includes an inner pipe connected to an outer pipe by a bellows. The seal prevents cryogenic liquid from leaking from the inner pipe into the annular vacuum space between the inner and outer pipes in the event of bellows failure. One end of the bellows is connected to the inner pipe by a movable bellows ring and the other end of the bellows is attached to the outer pipe by a fixed bellows ring. A bellows guide is attached to the fixed bellows ring and receives the movable bellows ring in a sliding fashion. The seal may be positioned between the movable bellows ring and the bellows guide or between the fixed bellows ring and the outer surface of the inner pipe. The seal may also be positioned between the bellows shield and the movable bellows ring. The seal may be a leak control ring or the packed gland type.

Owner:CHART INDS

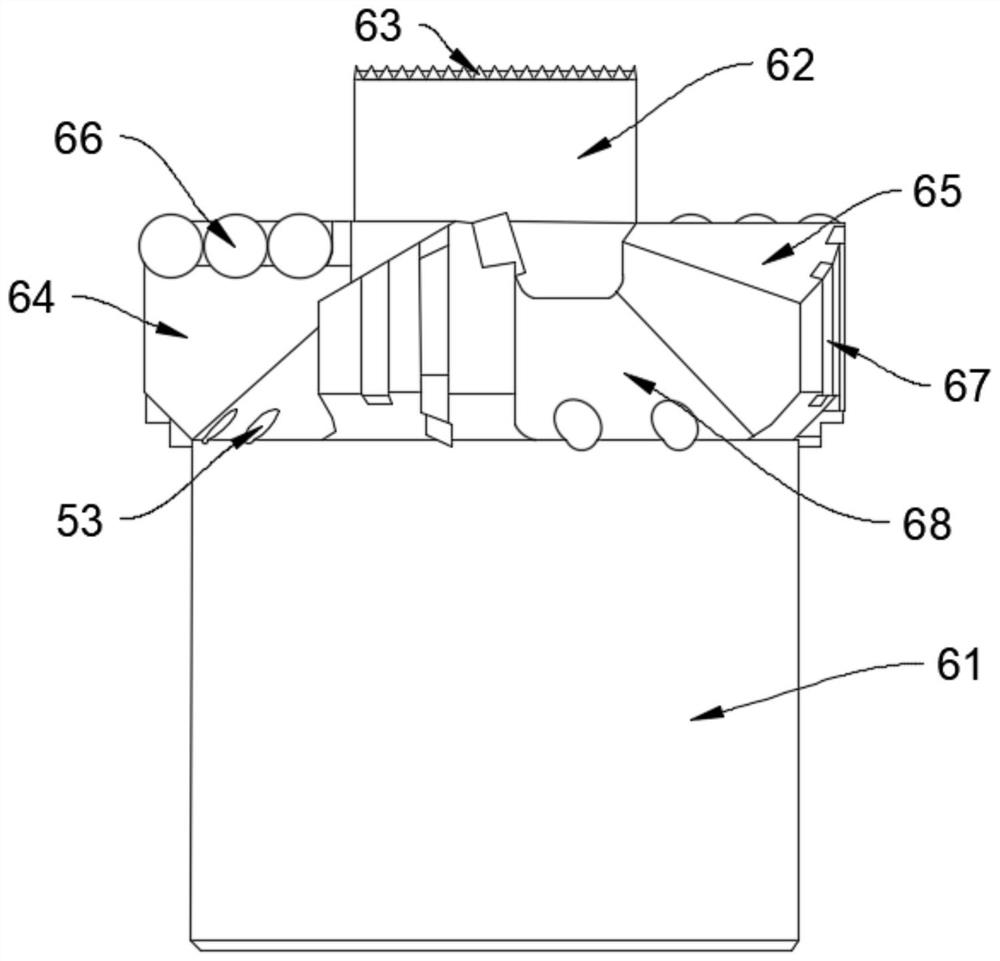

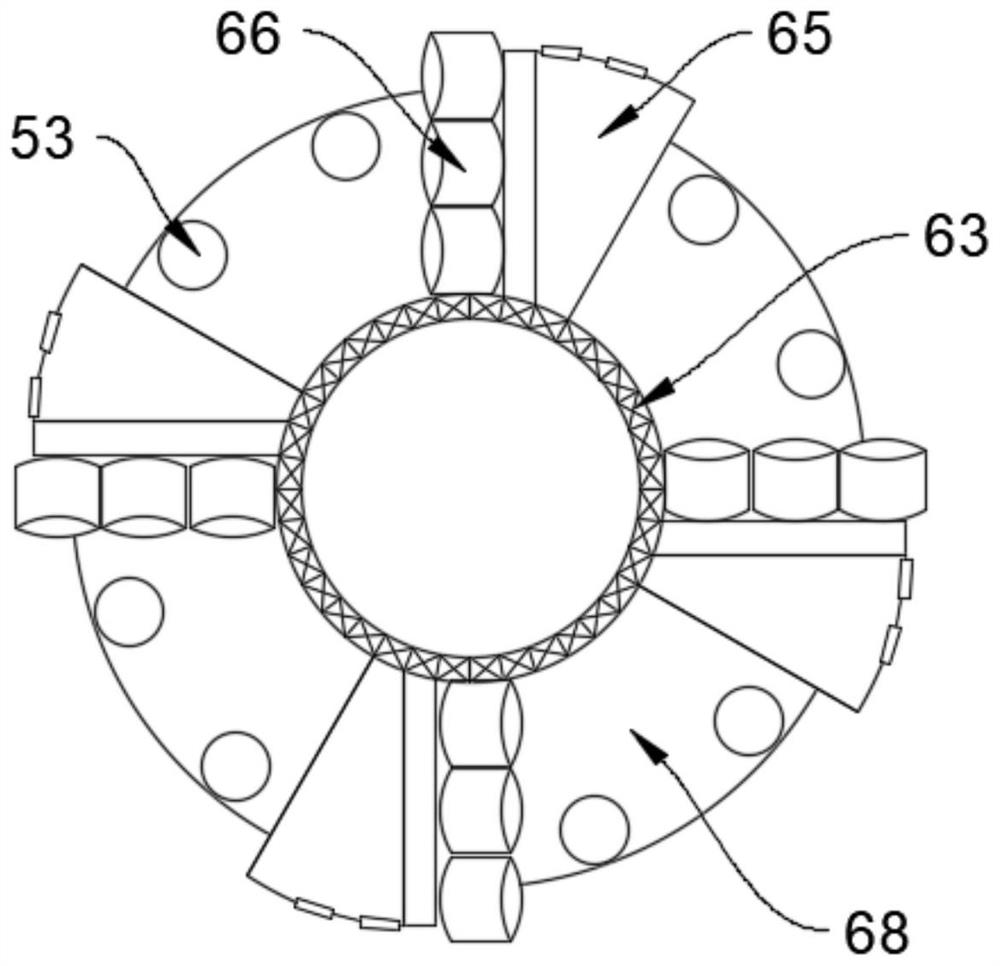

Spent bleaching clay non-pollution treatment process and equipment

ActiveCN107189863ANo pollution in the processSimple processFatty oils/acids recovery from wasteFatty substance recoveryProcess engineeringEnvironmental engineering

The invention discloses a spent bleaching clay non-pollution treatment process and equipment. The spent bleaching clay non-pollution treatment process comprises the following steps: drying and dehydrating spent blenching clay by adopting a low-temperature thermal-distilling method; treating and recycling moisture and volatile matters generated in a dehydrating process; separating an oil product from the dehydrated spent leaching clay by a high-temperature calcining method; treating and recycling the generated oil product to obtain non-pollution spent bleaching clay. The spent bleaching clay non-pollution treatment equipment comprises a low-temperature rotary heating furnace and a high-temperature rotary heating furnace, wherein a discharging end of the low-temperature rotary heating furnace communicates with a low-temperature sealing cabin through a low-temperature discharging spiral conveyer; the low-temperature sealing cabin is divided into an upper part and a lower part; an inlet end of the high-temperature rotary heating furnace is connected with a high-temperature sealing cabin; an outlet end of the high-temperature rotary heating furnace communicates with a cooling machine through a high-temperature discharging spiral conveyer. The treatment equipment has the advantages of high oil recycling rate, high automation degree, easiness in operation, low investment cost and environmental friendliness.

Owner:江苏恒茂再生能源有限公司

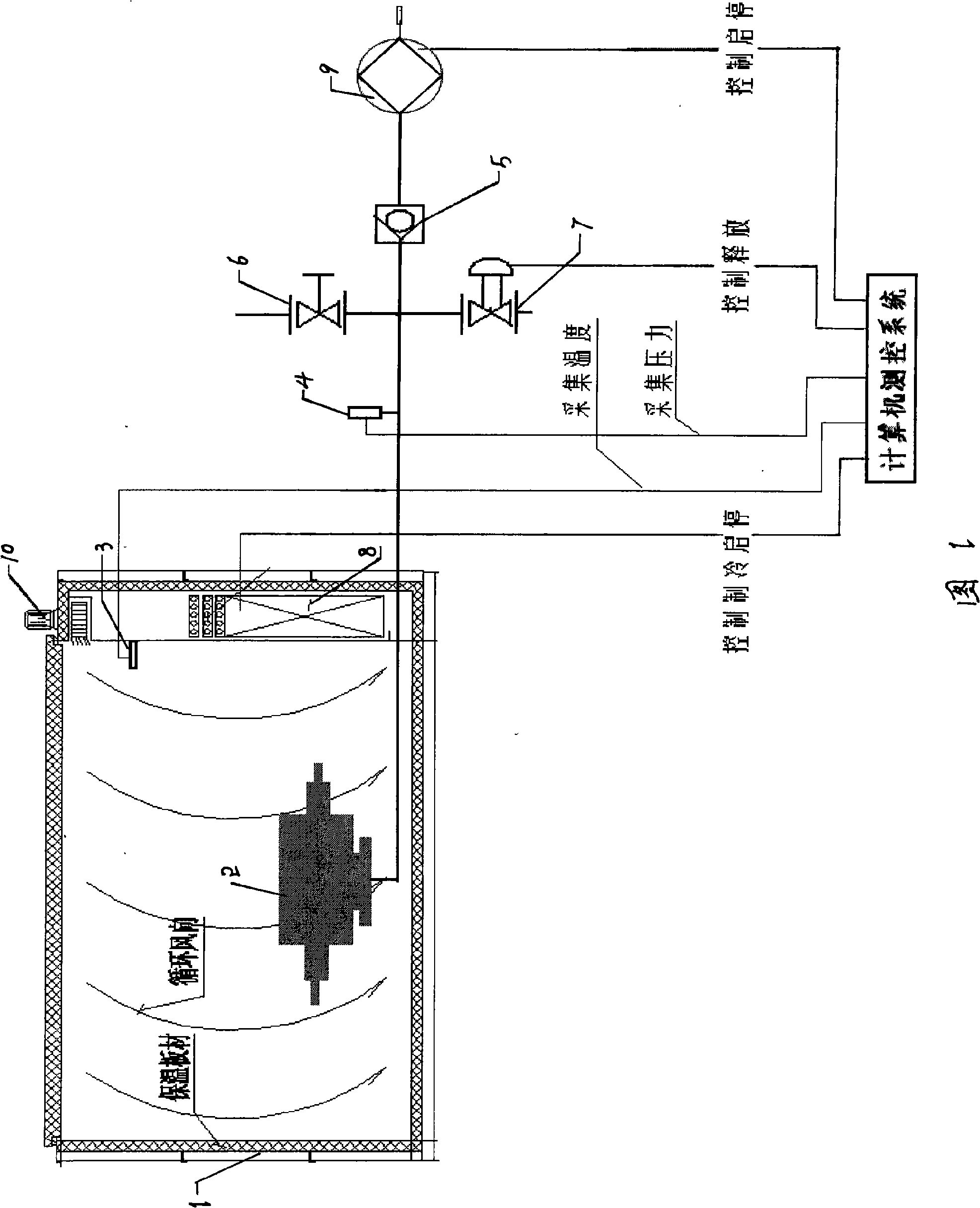

Performance detecting process of well control product and well head apparatus under low temperature state

ActiveCN101281081ASimulated tightnessSimulate low temperature sealing performanceMeasurement of fluid loss/gain rateStrength propertiesComputer monitoringMetallic materials

The invention discloses a performance detection technology for well control products and wellhead devices in conditions with low surrounding temperature, comprising steps as follows: opening a low environment temperature box, reducing and stabilizing temperature to a rated temperature of subzero 69 DEG to subzero 29 DEG; then opening a pressure device, pressurizing a measured object to a rated working pressure of 1 to 140 MPa; stabilizing the pressure for 0.5 to 2 hours, then reducing the pressure to 0 MPa after a computer monitoring and control system deciding whether the quality and performance of the measured object is qualified according to fluctuations of the temperature and pressure values, increasing temperature to the normal value, then completing the detection. Through pressure testing in low temperature condition, reducing the temperature of the measured object and simulating the practical working condition to decide whether the quality and performance of the measured object meets the requirements of the site use, the invention can detect the low-temperature-resistant sealing performance of well control products and wellhead devices and the low-temperature-resistant performance of non-metallic and metal materials.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

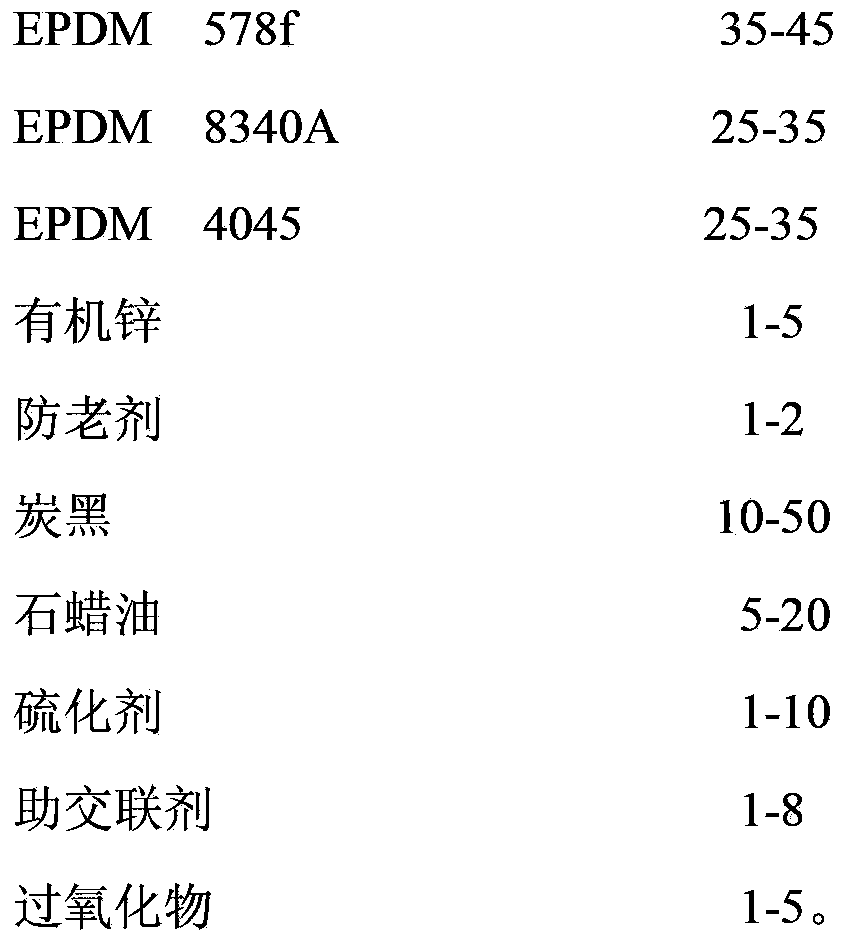

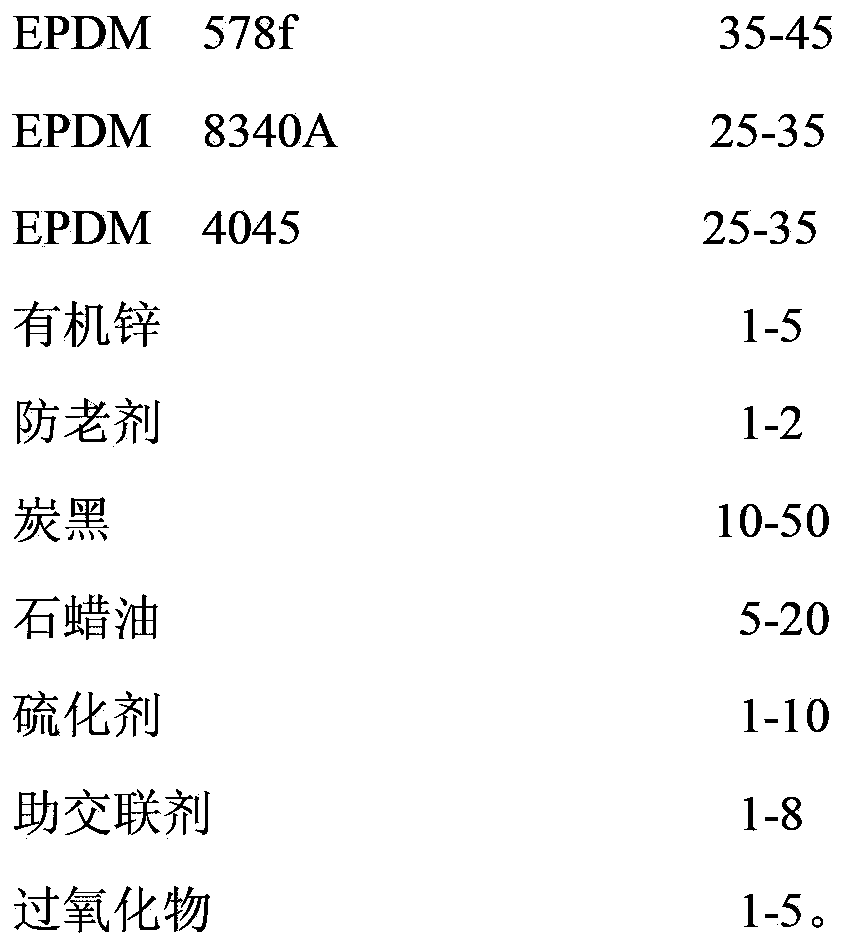

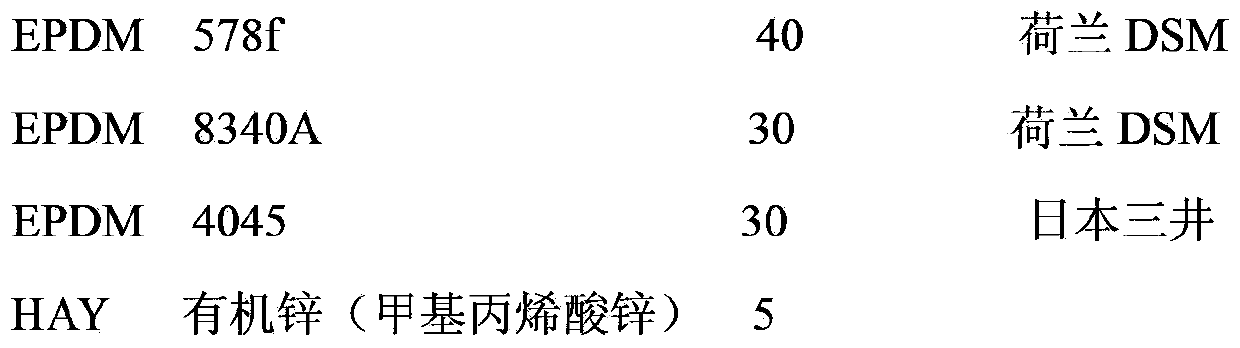

Ethylene-propylene-diene monomer (EPDM) material for super high and low temperature resistant sealing element and preparation method of EPDM material

The invention relates to an ethylene-propylene-diene monomer (EPDM) material for a super high and low temperature resistant sealing element and a preparation method of the EPDM material. The EPDM material comprises the following components in parts by weight: 40 parts of EPDM 578f, 30 parts of EPDM 8340A, 30 parts of EPDM 4045, 1-5 parts of HAY organic zinc, 10-50 parts of carbon black N330, 5-20 parts of paraffin oil, 1-10 parts of vulcanizing agent, 1-8 parts of assistant crosslinker and 1-5 parts of peroxide. By adopting different matching technologies and special auxiliaries, the characters of the EPDM material can be improved and optimized, the obtained EPDM material can be used within the temperature range from 50 DEG C below zero to 150 DEG C for a long term, and a sealing product made of the EPDM material can keep an excellent sealing effect within the temperature range from 50 DEG C below zero to 150 DEG C.

Owner:HEBEI XIANGYI MEDICAL TECH

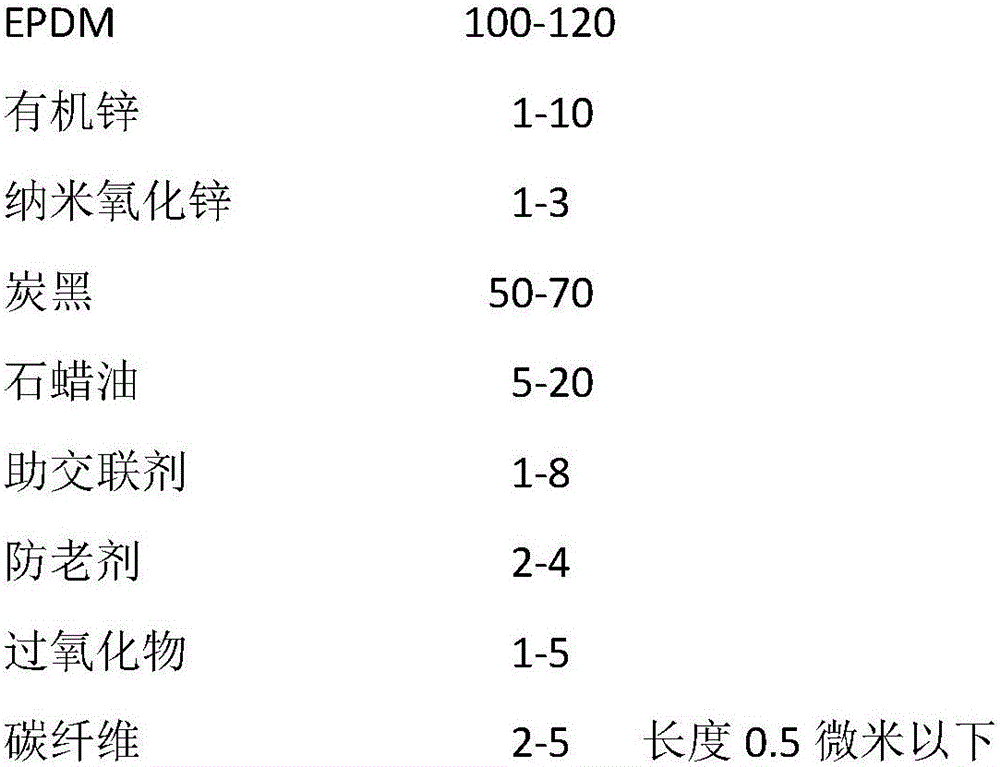

High-impact-resistant anti-shearing ethylene propylene diene monomer material

The invention relates to an ethylene propylene diene monomer material for a high-low-temperature-resistant sealing part. The ethylene propylene diene monomer material is prepared from the following steps: 100 to 120 parts of EPDM, 1 to 10 parts of organic zinc, 1 to 3 parts of nano zinc oxide, 50 to 70 parts of carbon black, 5 to 20 parts of paraffin oil, 1 to 8 parts of assistant cross-linking agent, 2 to 4 parts of anti-aging agent, 1 to 5 parts of peroxide, 2 to 5 parts of carbon fibers and other additives. The ethylene propylene diene monomer material can be used in a severe engineering environment, for example, used in a reamer shaft of a dredging vessel in a sealing manner, in the working environment of the dredging vessel, the content of minerals and sand in the water is high, so that the wear resistance and torsion resistance are needed, and in particular the wear resistance is needed in the twisting process; by adding the carbon fiber, the wear resistance of the rubber is effectively improved, and the wear resistance of the adhesive is provided under certain torque.

Owner:TIANJIN BAOBOTE SEALING TECH

Disperse combined stuffing structure of low-temperature ball valve

The invention provides a disperse combined stuffing structure of a low-temperature ball valve. The disperse combined stuffing structure comprises a low-temperature spring energy-accumulating sealing ring, V-shaped stuffing and a flexible graphite group from inside to outside, wherein an opening of the low-temperature spring energy-accumulating sealing ring is inward; the V-shaped stuffing is madeof a PTFE material; and the flexible graphite group is a low-leakage forming flexible graphite group which consists of upper and lower knitting end rings and a plurality of graphite rings in the middle. The low-temperature spring energy-accumulating sealing ring can provide a beneficial primary low-temperature sealing environment, so that low-temperature medium entering is reduced; a wear-resisting and anti-scratch V-shaped stuffing group made of the PTFE material is used, so that the integral service life of a stuffing box can be prolonged; and the low-leakage forming flexible graphite groupis used, so that a fireproof function is achieved while sealing performances are guaranteed. Therefore, the disperse combined stuffing structure has triple independent sealing structural design, meetssafe operation, under various extremely dangerous working conditions, of the valve, and improves safety performances of the valve.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

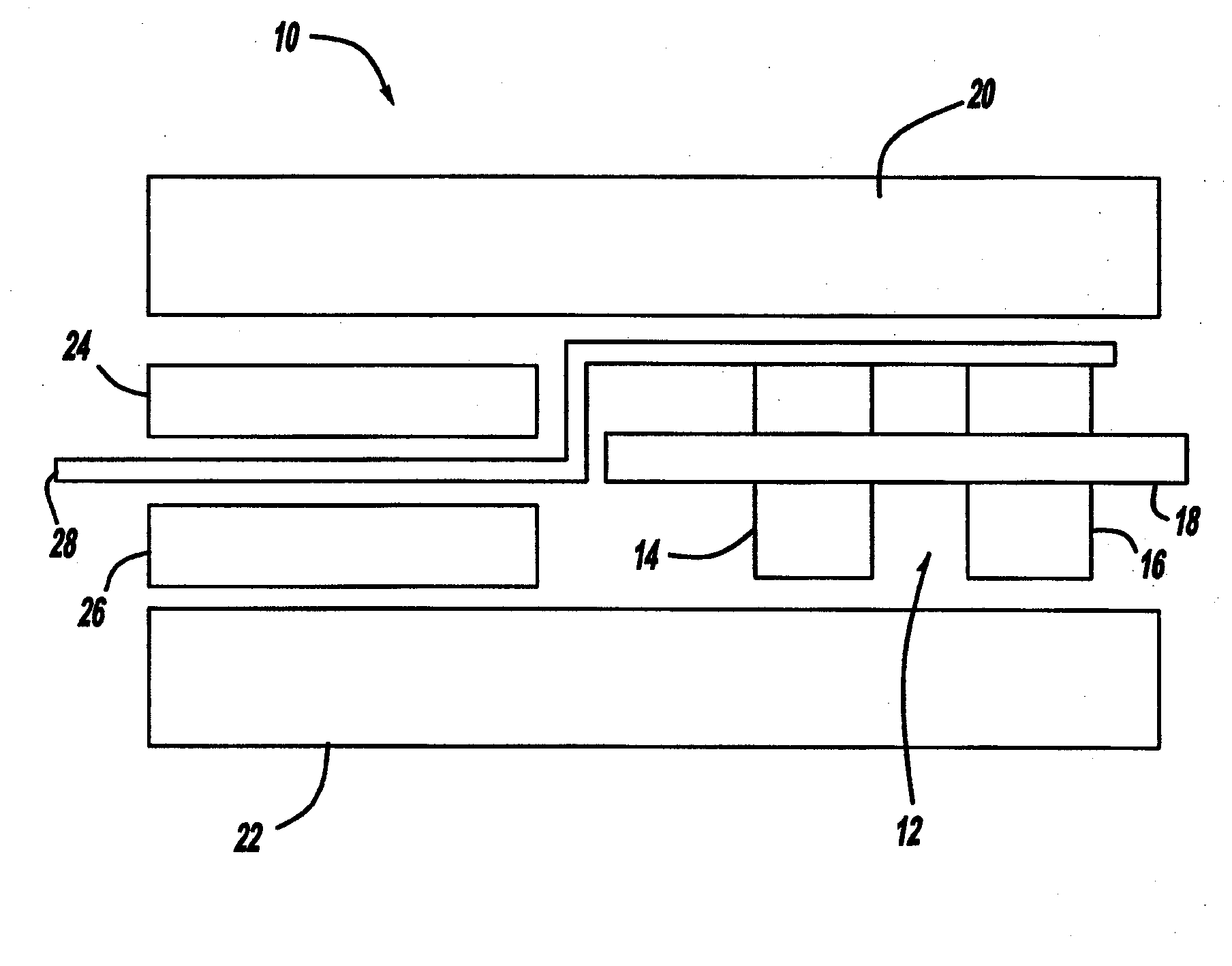

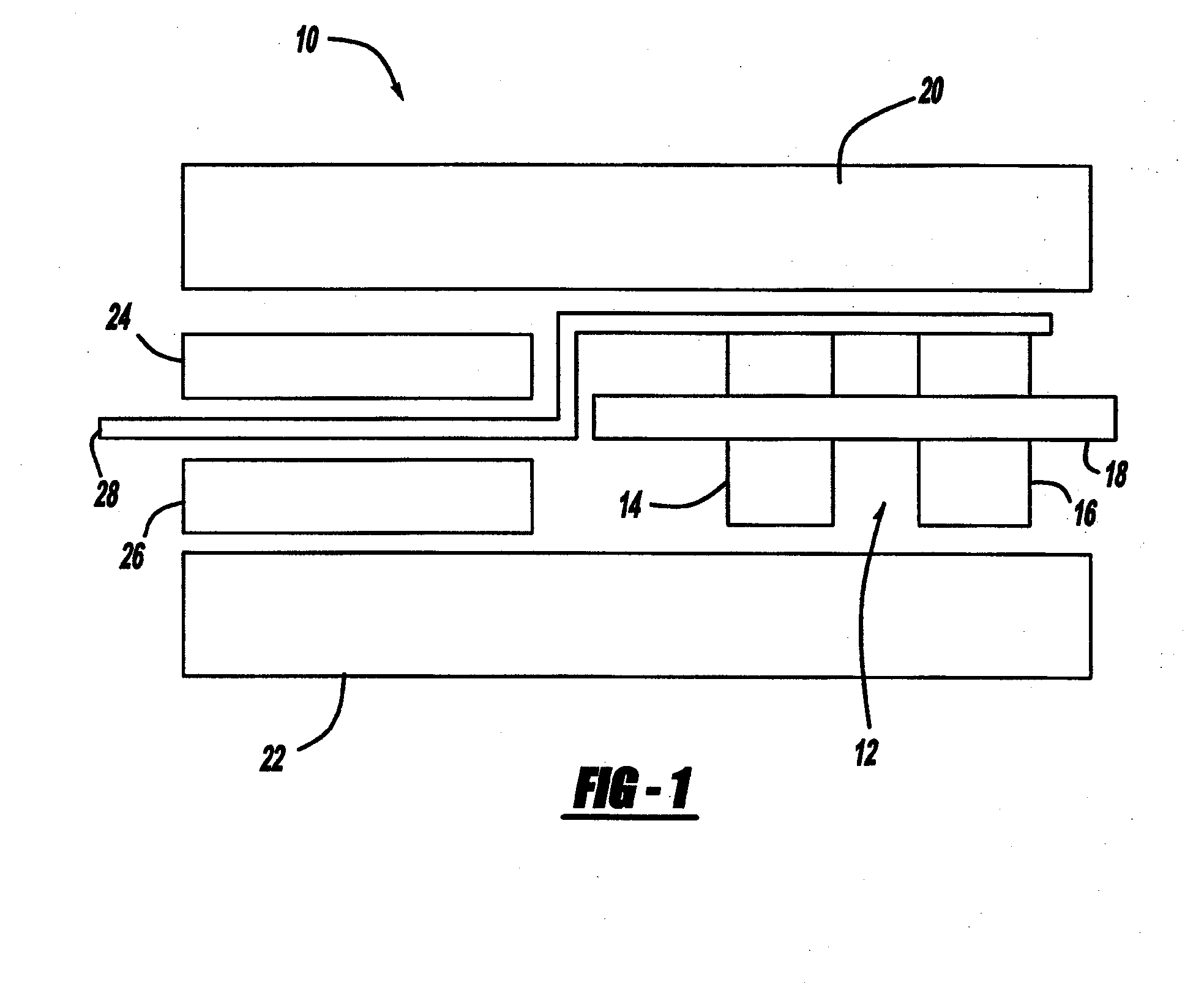

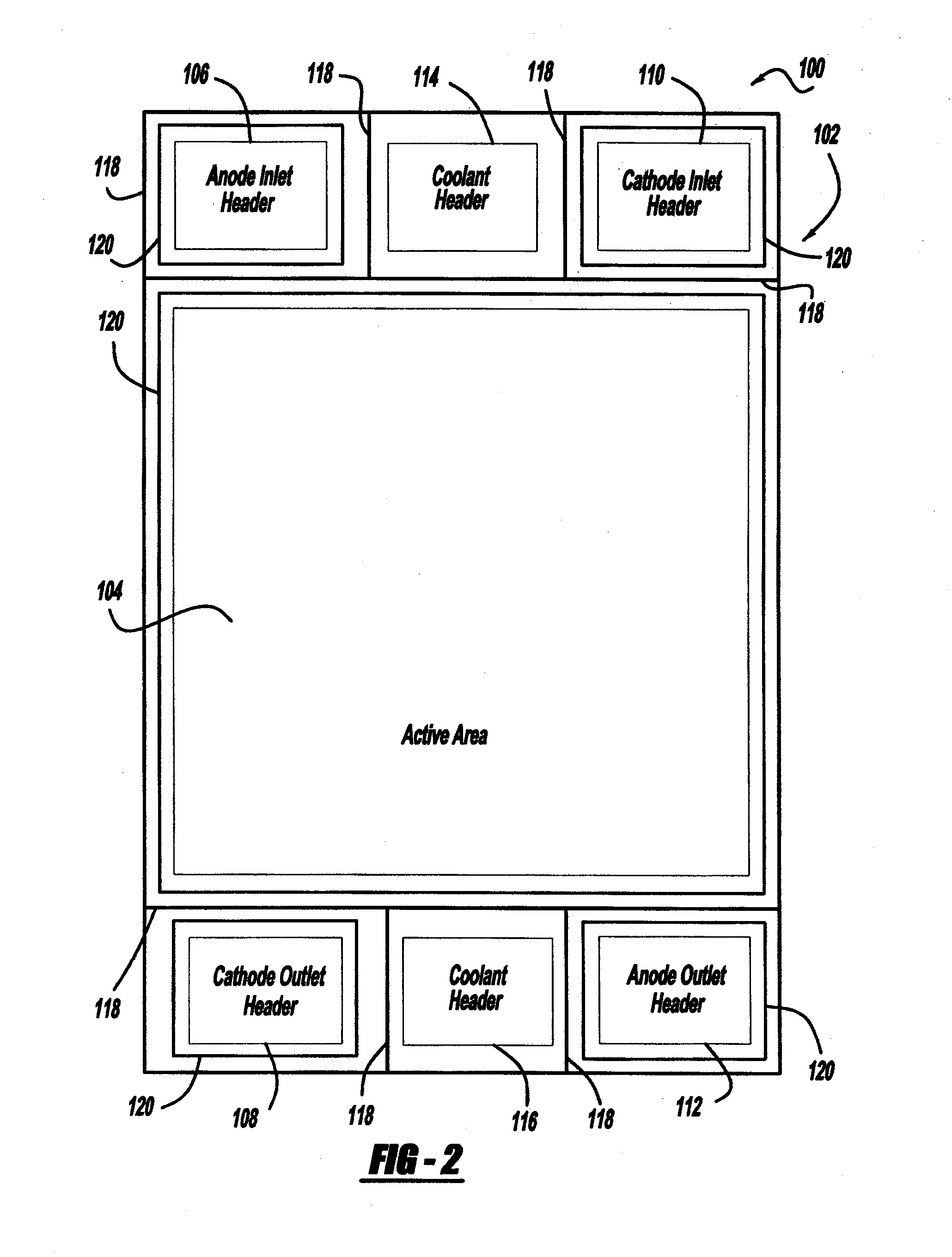

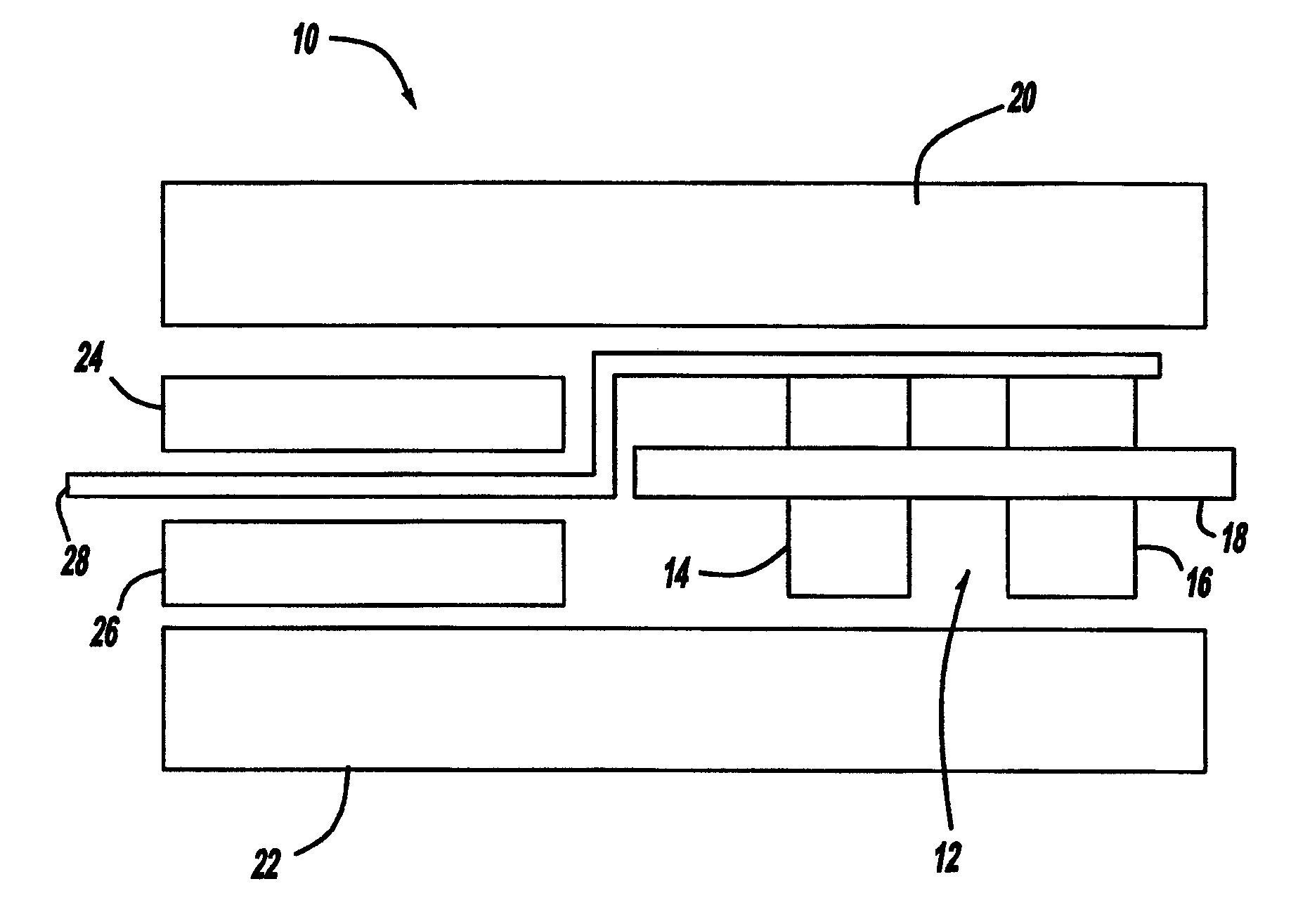

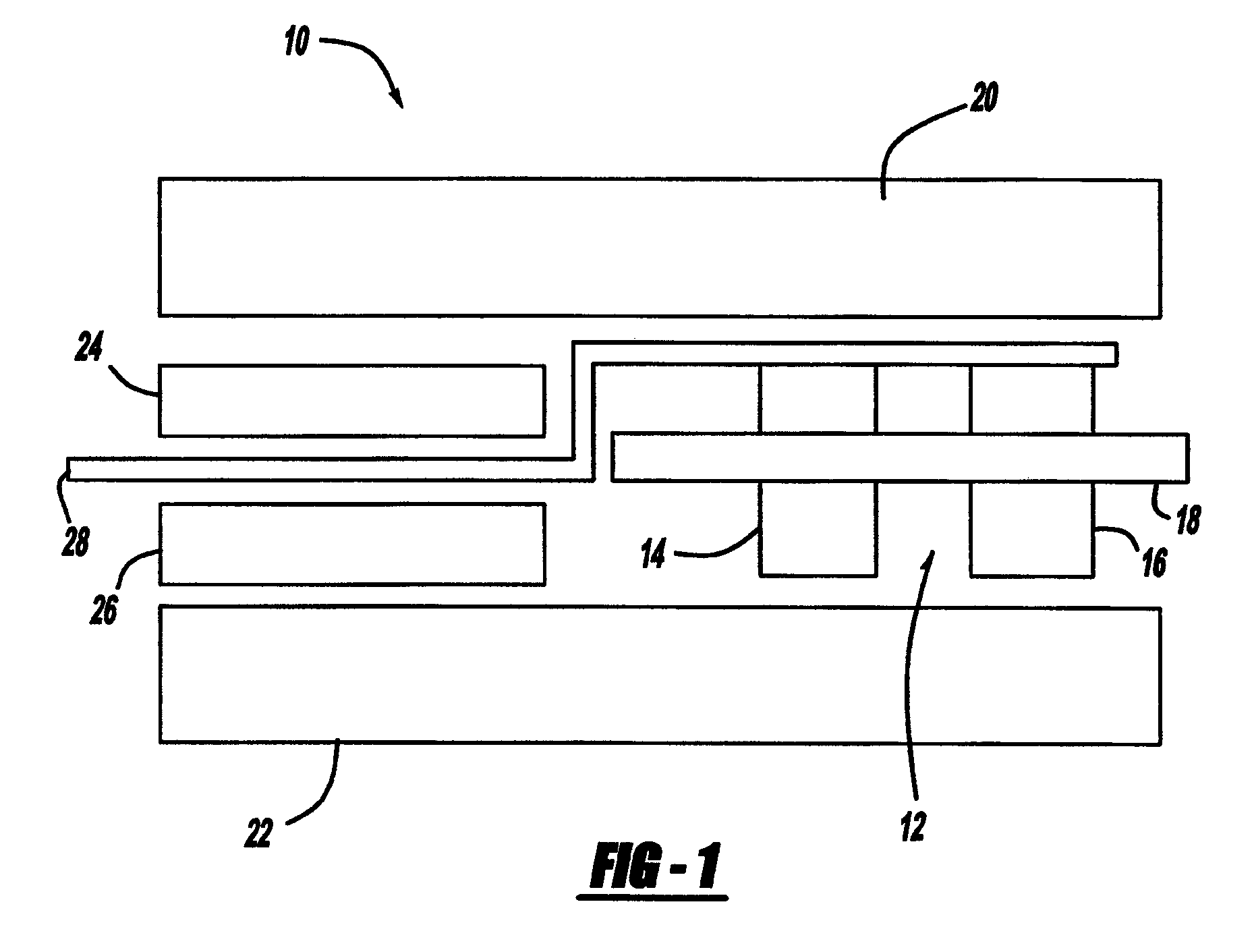

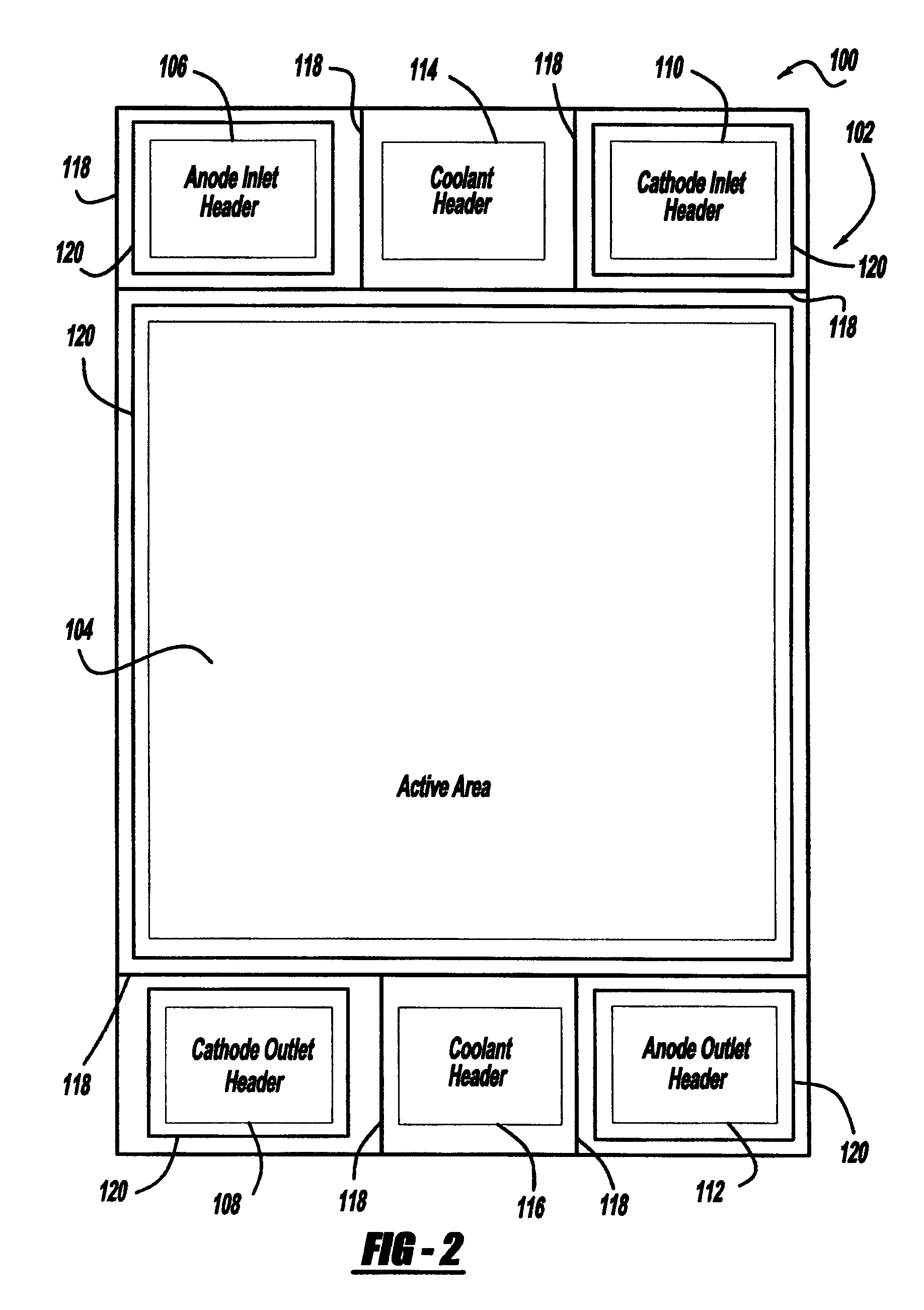

Multi-Component Fuel Cell Gasket For Low Temperature Sealing And Minimal Membrane Contamination

InactiveUS20080026280A1Electrode carriers/collectorsCell component detailsFuel cellsEthylene-propylene-diene-monomer

A gasket for a fuel cell, wherein the gasket includes the use of two or more different materials as the gasket. For example, ethylene propylene diene monomer (EPDM) and / or the like, or another more chemically inert gasket material, is located inside or on an inboard position and is the wetted material that is exposed to the fuel cell operating environment. Silicone and / or the like, or another potentially contaminating material with better cold temperature sealability, is located outside or on an outboard position and does not come in contact with the fuel cell internal environment. One method of constructing such a gasket would be two include two parallel bead traces of the gasket materials on a polyimide (e.g., KAPTON®) carrier, or the like.

Owner:GM GLOBAL TECH OPERATIONS LLC

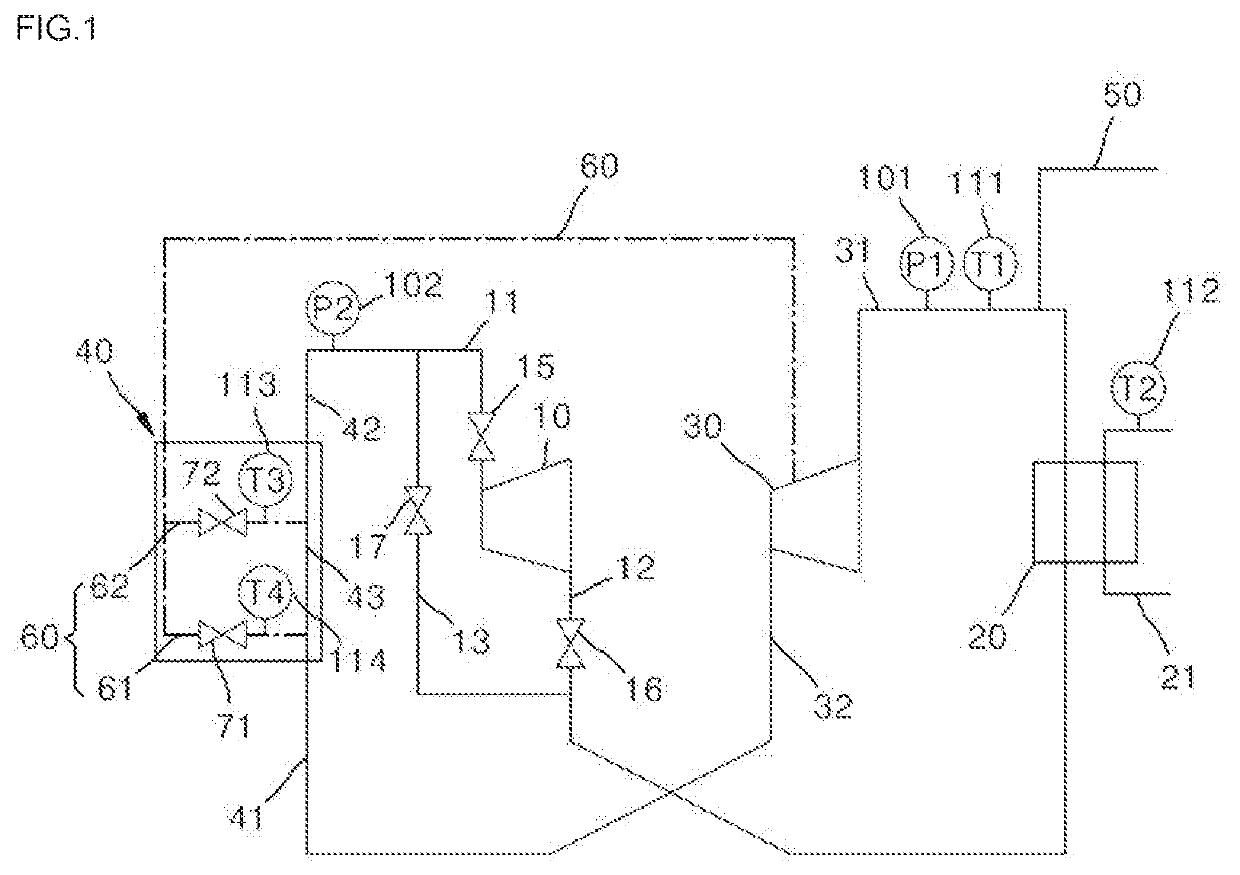

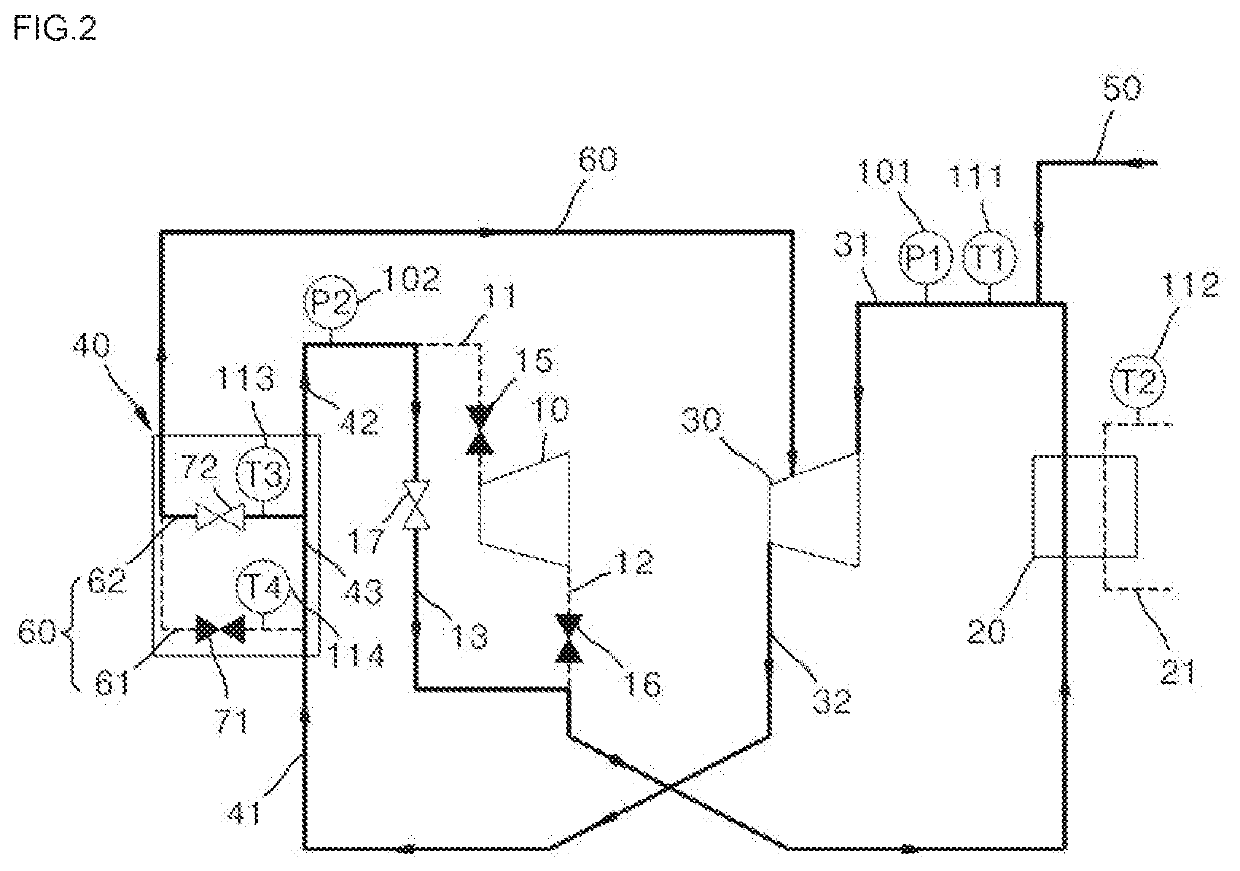

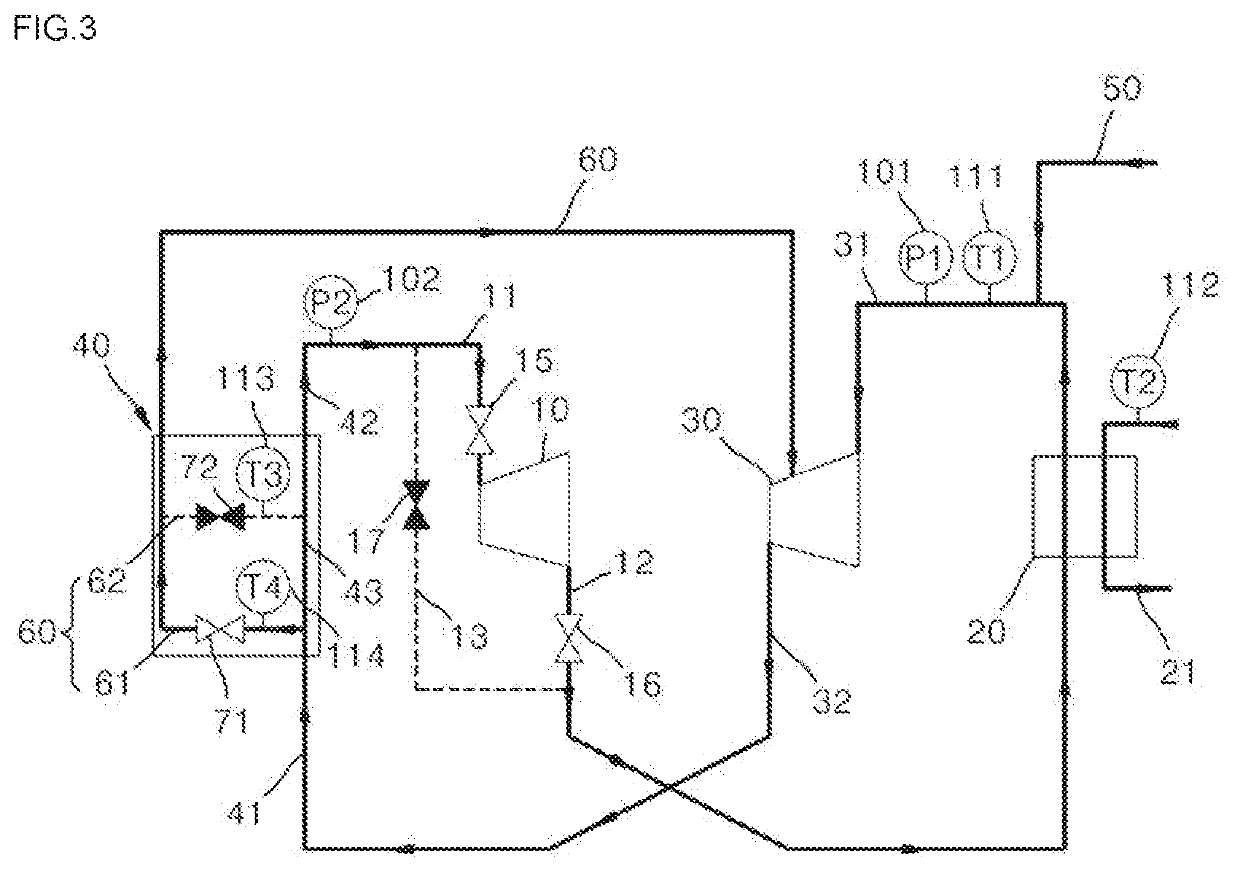

Supercritical carbon dioxide power generation system including dry gas seal and method of operating the same

ActiveUS20200131920A1Easy injectionLow costEngine sealsWorking fluid for enginesDry gas sealProcess engineering

According to the present invention, part of carbon dioxide heated by a heater is supplied to a dry gas seal portion of a compressor so that a device for pressurizing and heating a seal gas is not additionally required, configuration can be simplified and cost can be reduced. In addition, a seal gas flow path includes a low-temperature seal gas flow path and a high-temperature seal gas flow path so that, in an initial driving mode, carbon dioxide heated by a high-temperature portion of the heater is used as a seal gas and in a turbine-driving mode, carbon dioxide heated by a low-temperature portion of the heater is used as a seal gas and thus a more efficient operation can be performed.

Owner:KOREA INST OF ENERGY RES

Chloroprene rubber composition for ultra low temperature sealing arrangement

ActiveCN101412824AMeet the requirementsExcellent thermal adhesionOther chemical processesPolymer scienceNeoprene

The invention provides a neoprene composition for an ultra low temperature sealing device, wherein neoprene, carbon black, ZnO and accelerant are evenly mixed and placed in a rubber mixing machine for mixing. The neoprene composition has good process performance and metal heat bonding performance; and at an ultra low temperature of 196 DEG C below zero, the neoprene composition has good medium compatibility and reliable sealing performance, and the pressure resisting range reaches between 0.1 below zero to 35MPa.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Low temperature sealing glass

InactiveUS6248679B1Excellent devitrified sealGood processing characteristicsCryogenic sealVitreous state

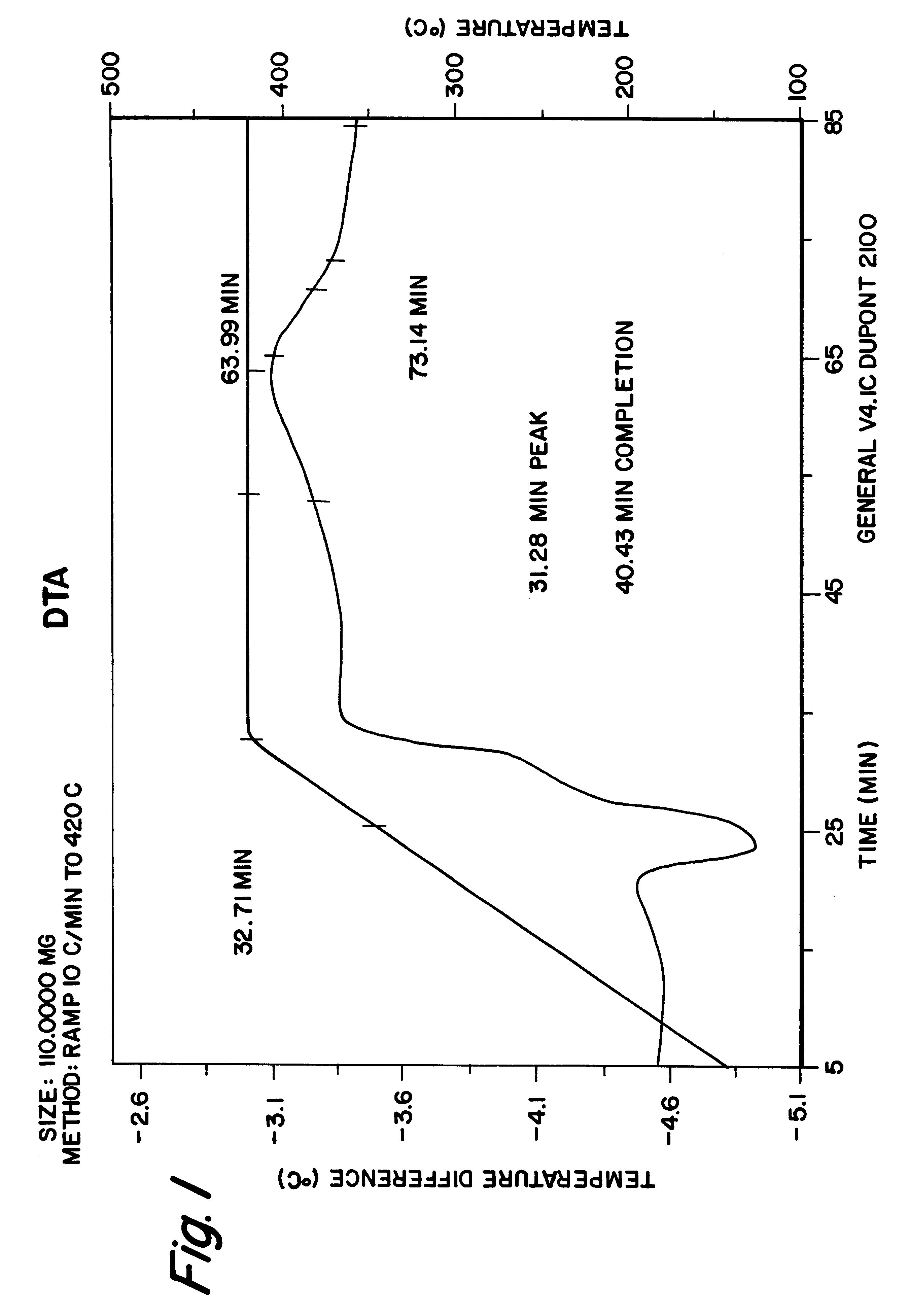

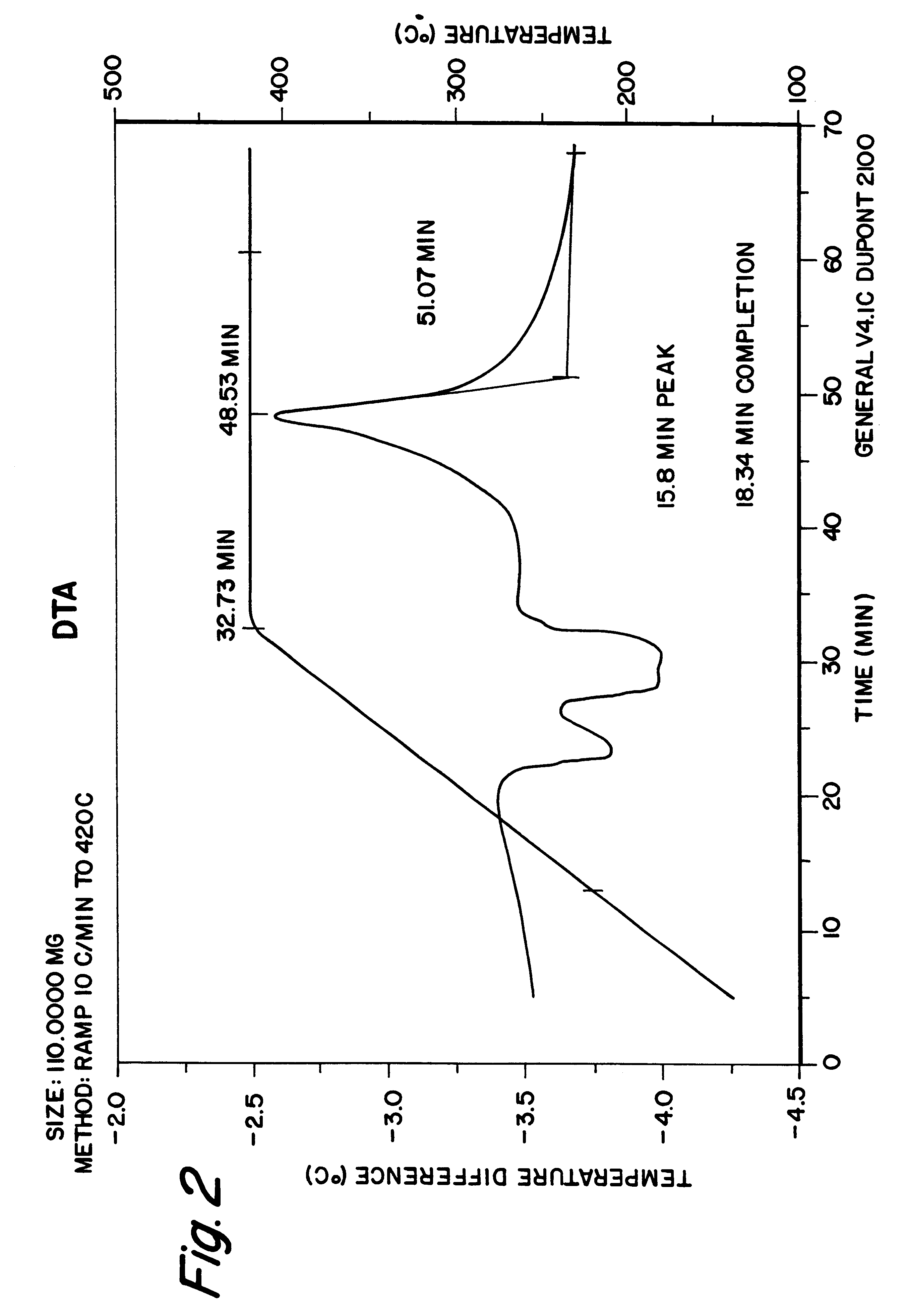

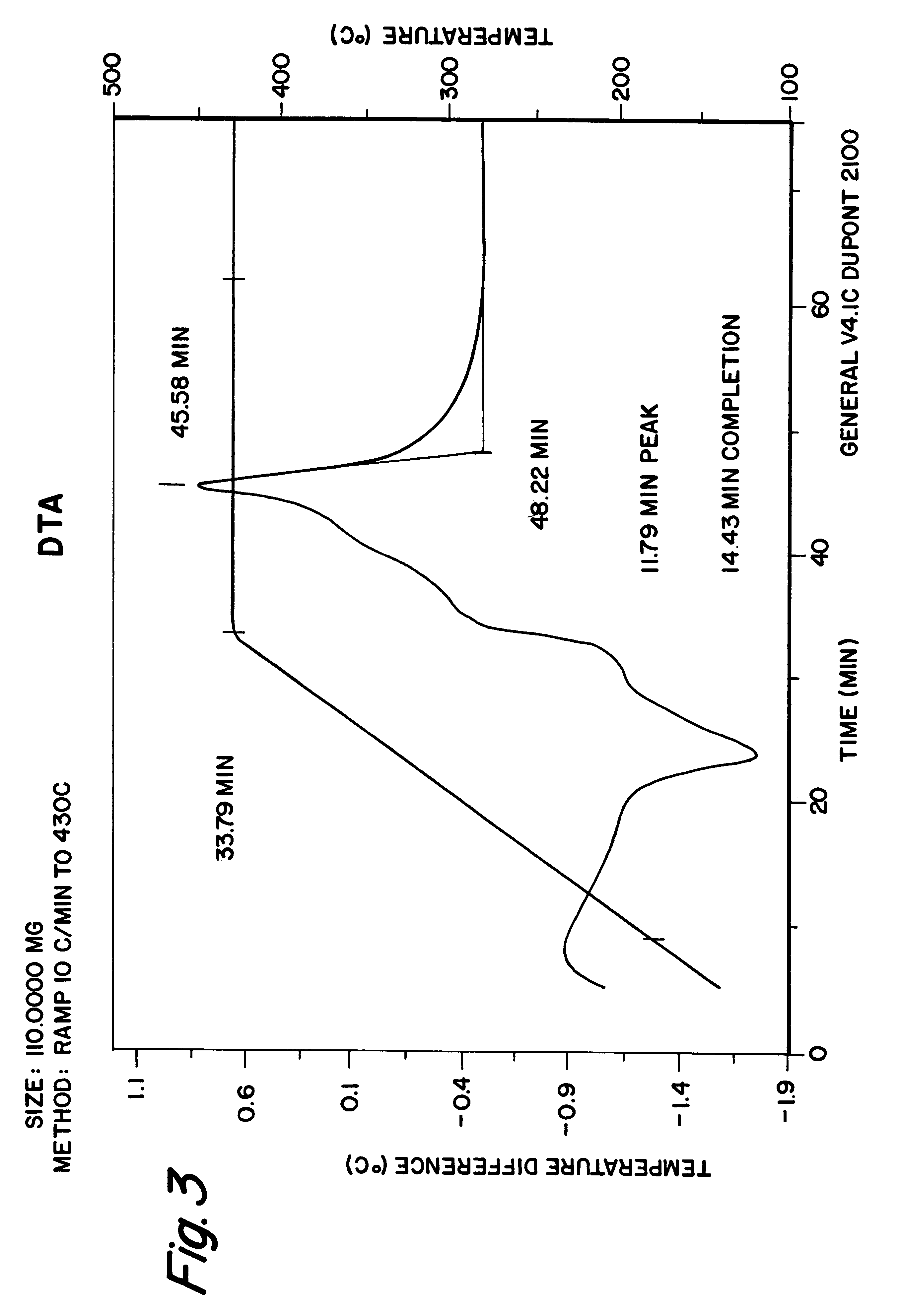

A sealing glass composition in powdered form comprising a crystallizable PbO / ZnO / B2O3 / SiO2 glass in the vitreous state, an effective amount of a nucleating agent, and an optional filler. The glass composition can be used to seal television picture tubes with excellent results when heated to a hold range of about 420° C. to about 435° C.

Owner:TECHNEGLAS

Visual low-temperature Dewar system for superconducting film magnetic-thermal characteristic tests

InactiveCN103364743AOvercome usabilityOvercoming the defects of poor application prospectsMagnetic property measurementsMaterial thermal analysisOptical testHeat transmission

The invention discloses a visual low-temperature Dewar system for superconducting film magnetic-thermal characteristic tests. The visual low-temperature Dewar system comprises a low-temperature sealed container and a Gifford-Mcmahon (GM) refrigerating machine which are in sealed fit installation with each other, a vacuum chamber which is in fit installation in the low-temperature sealed container, a GM refrigerating machine connector which is positioned above the vacuum chamber, a sample shelf for putting superconducting film samples to be tested, a heat transmission component which is connected between the GM refrigerating machine connector and the sample shelf, an external optical testing system and a laser pulse device which are respectively fit with and installed at the upper and lower ends of the low-temperature sealed container, and magnets which wrap the periphery of the low-temperature sealed container. The visual low-temperature Dewar system for superconducting film magnetic heat characteristic tests can be used for overcoming the defects such as inconvenience in use and poor application prospect in the prior art, so that the advantages of convenience in use and good application prospect are achieved.

Owner:LANZHOU UNIVERSITY

Multi-component fuel cell gasket for low temperature sealing and minimal membrane contamination

InactiveUS7569299B2Electrode carriers/collectorsCell component detailsFuel cellsEthylene-propylene-diene-monomer

A gasket for a fuel cell, wherein the gasket includes the use of two or more different materials as the gasket. For example, ethylene propylene diene monomer (EPDM) and / or the like, or another more chemically inert gasket material, is located inside or on an inboard position and is the wetted material that is exposed to the fuel cell operating environment. Silicone and / or the like, or another potentially contaminating material with better cold temperature sealability, is located outside or on an outboard position and does not come in contact with the fuel cell internal environment. One method of constructing such a gasket would be two include two parallel bead traces of the gasket materials on a polyimide (e.g., KAPTON®) carrier, or the like.

Owner:GM GLOBAL TECH OPERATIONS LLC

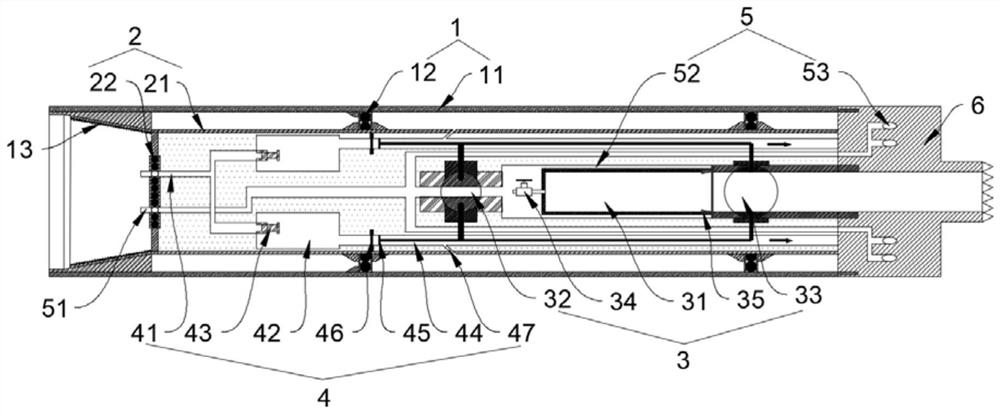

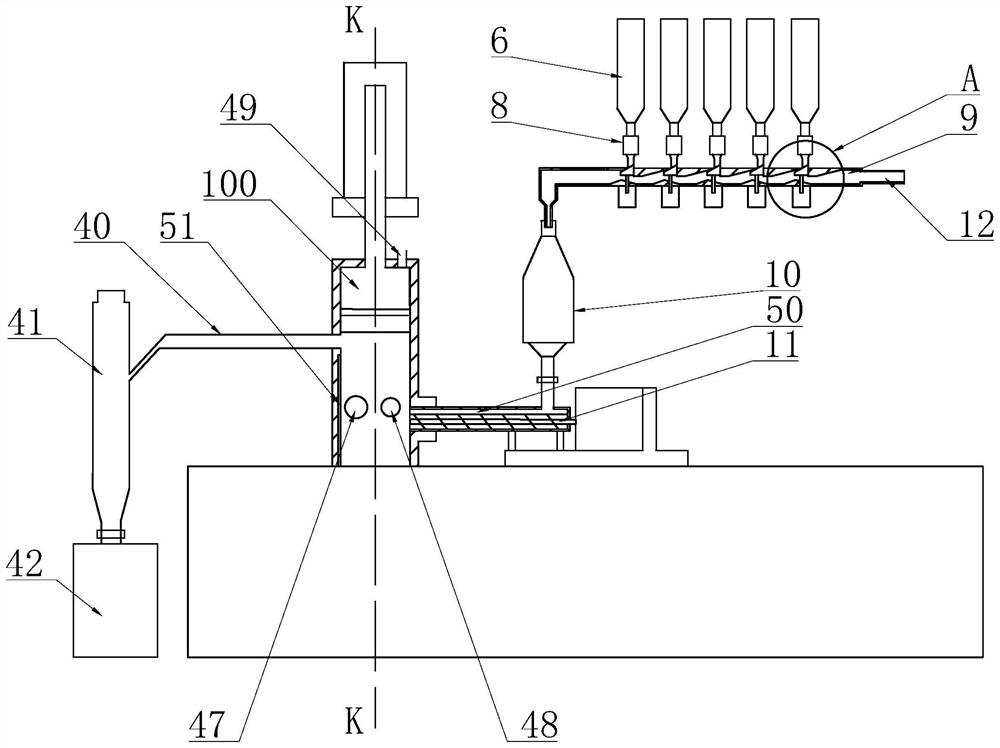

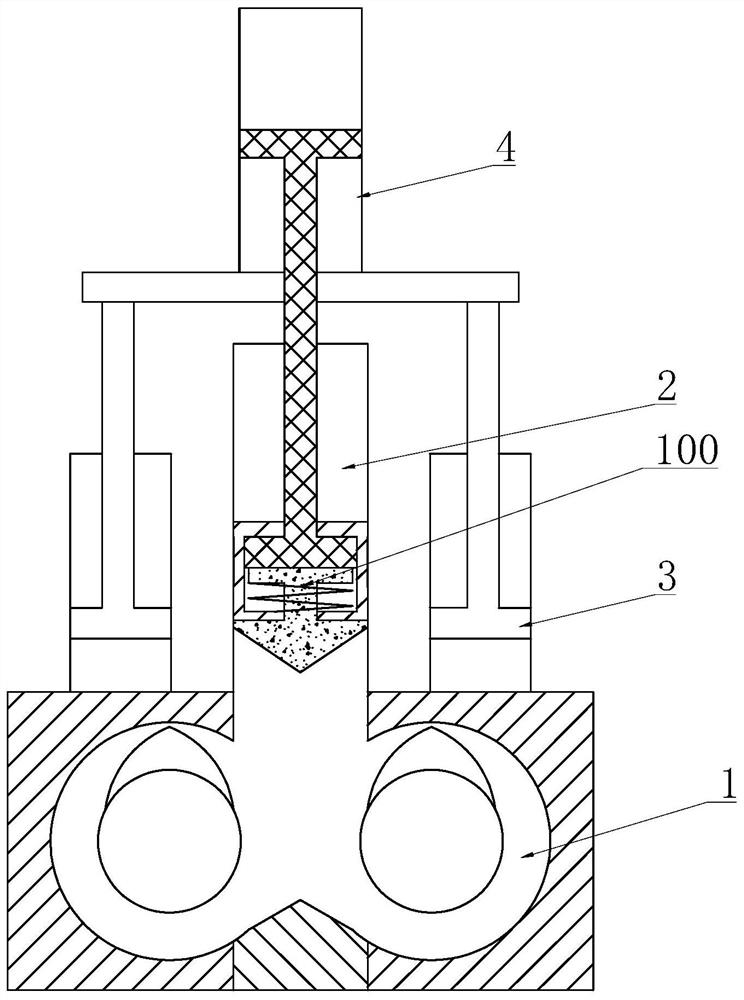

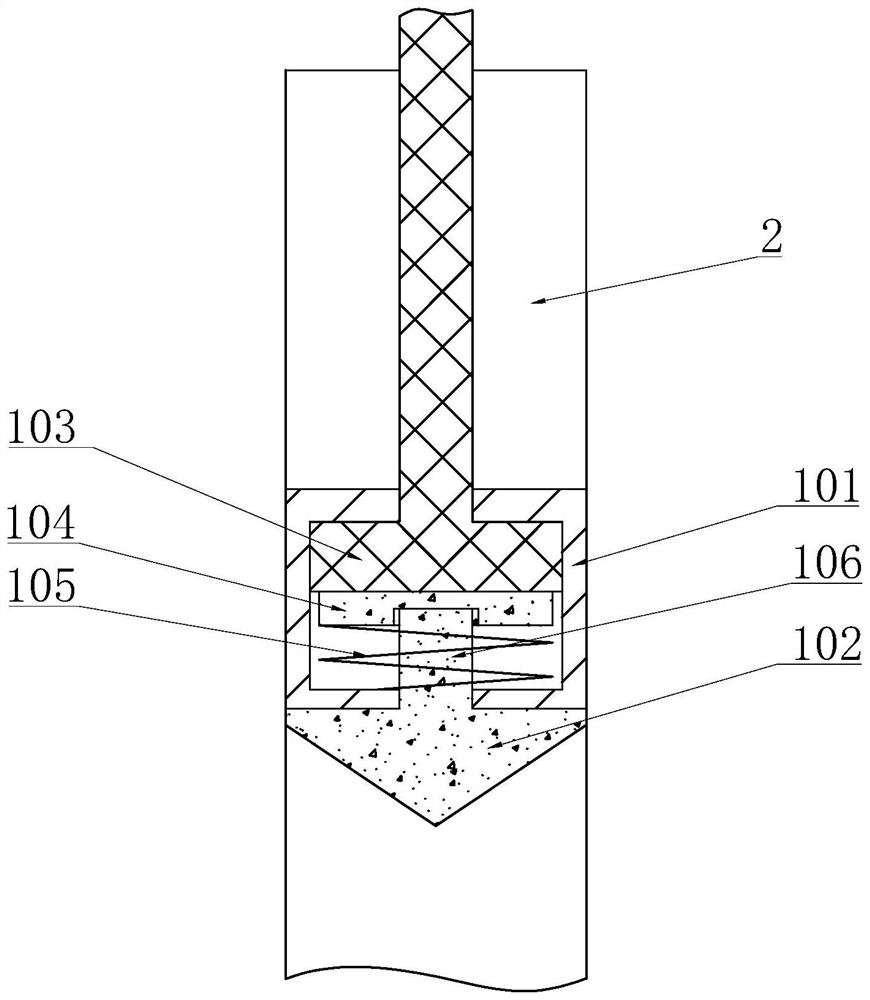

Coal mine underground low-temperature closed coal core drilling device and method

ActiveCN114396240AReduce spill effectGeothermal energy generationCore removalMining engineeringCoal mine methane

The invention discloses an underground coal mine low-temperature closed coal core drilling device and method, and belongs to the technical field of coal core drilling.The underground coal mine low-temperature closed coal core drilling device comprises an outer cylinder assembly, an inner cylinder assembly is rotationally installed in the outer cylinder assembly, a collecting assembly is fixedly installed at one end of the inner cylinder assembly, and a water supply assembly is rotationally installed at one end of the inner cylinder assembly; a cold supply assembly is rotatably mounted at one end of the inner cylinder assembly, a drill bit assembly is fixedly mounted at one end of the outer cylinder assembly, a coal seam is cooled through a liquid nitrogen nozzle during use, after cooling, the coal seam is cut through the drill bit assembly, and a coal sample enters a collection chamber through a small-diameter drill bit; the upper end ball valve and the core cutting ball valve are pushed through the water supply assembly, then low-temperature sealing is carried out on a coal sample, the gas overflowing effect is reduced, field desorption is carried out, and accurate basic data can be conveniently obtained for coal mine gas content measurement, gas disaster control, coal bed gas resource exploration and development and the like.

Owner:GUIZHOU INST OF COAL SCI

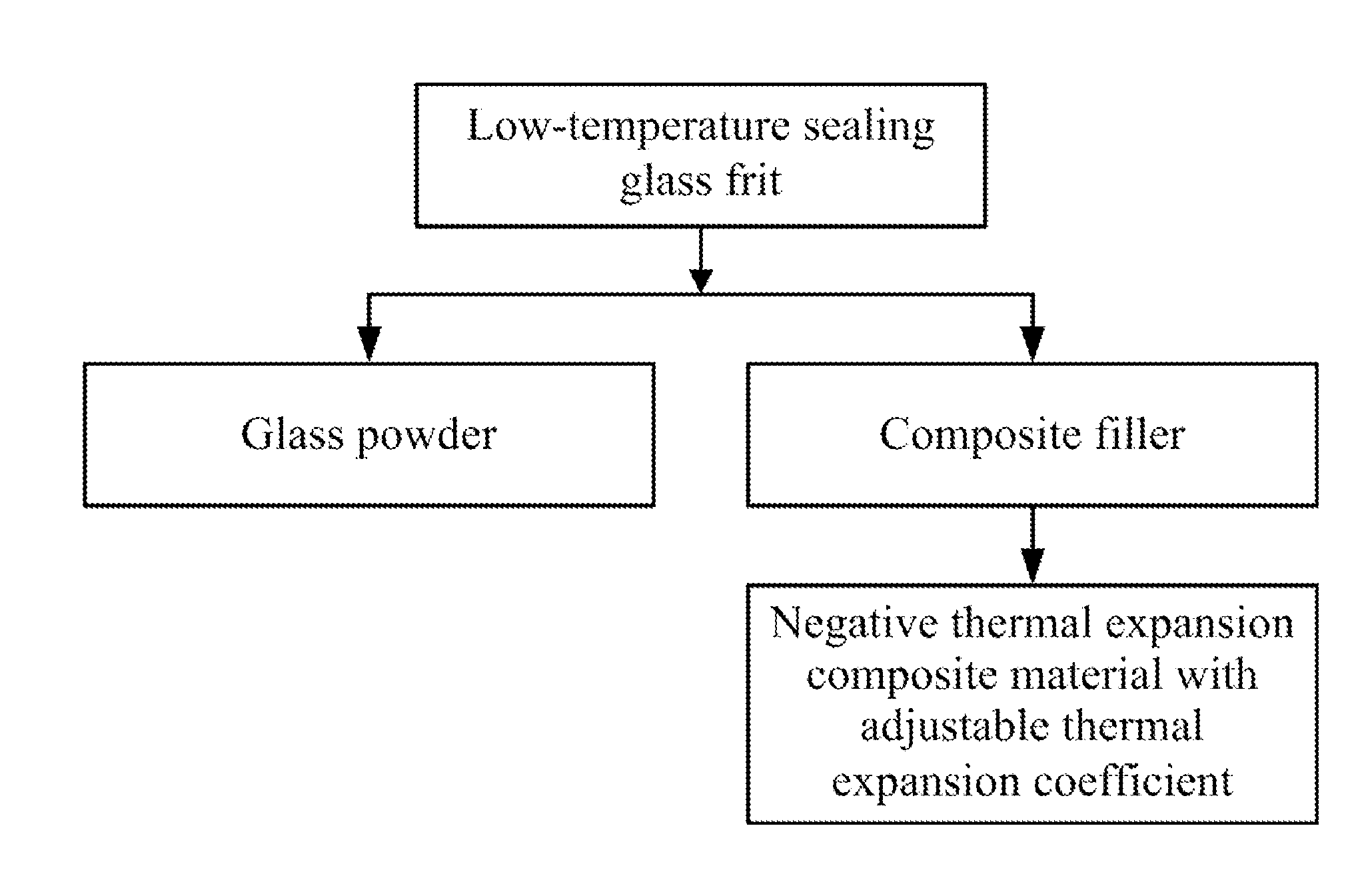

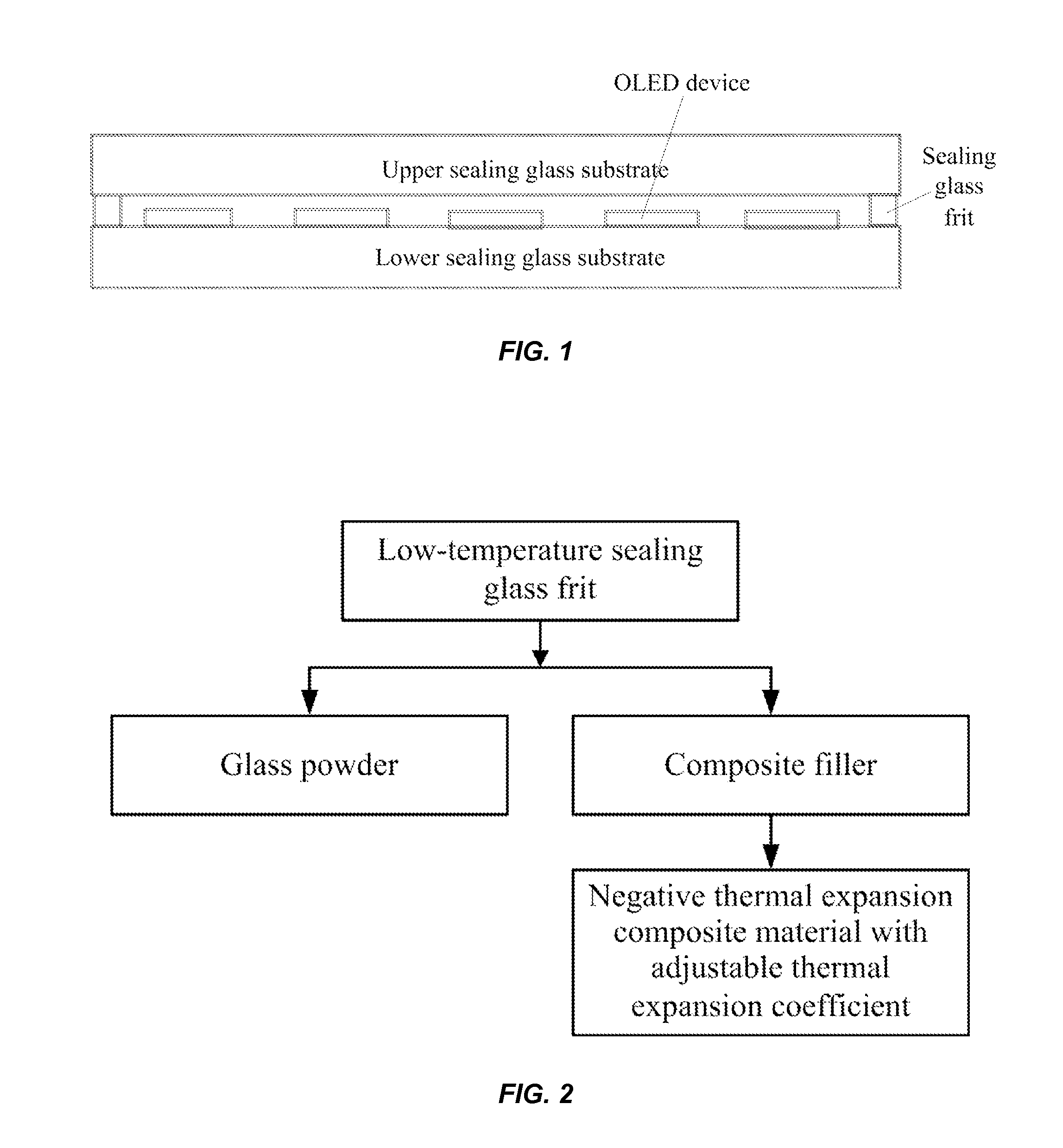

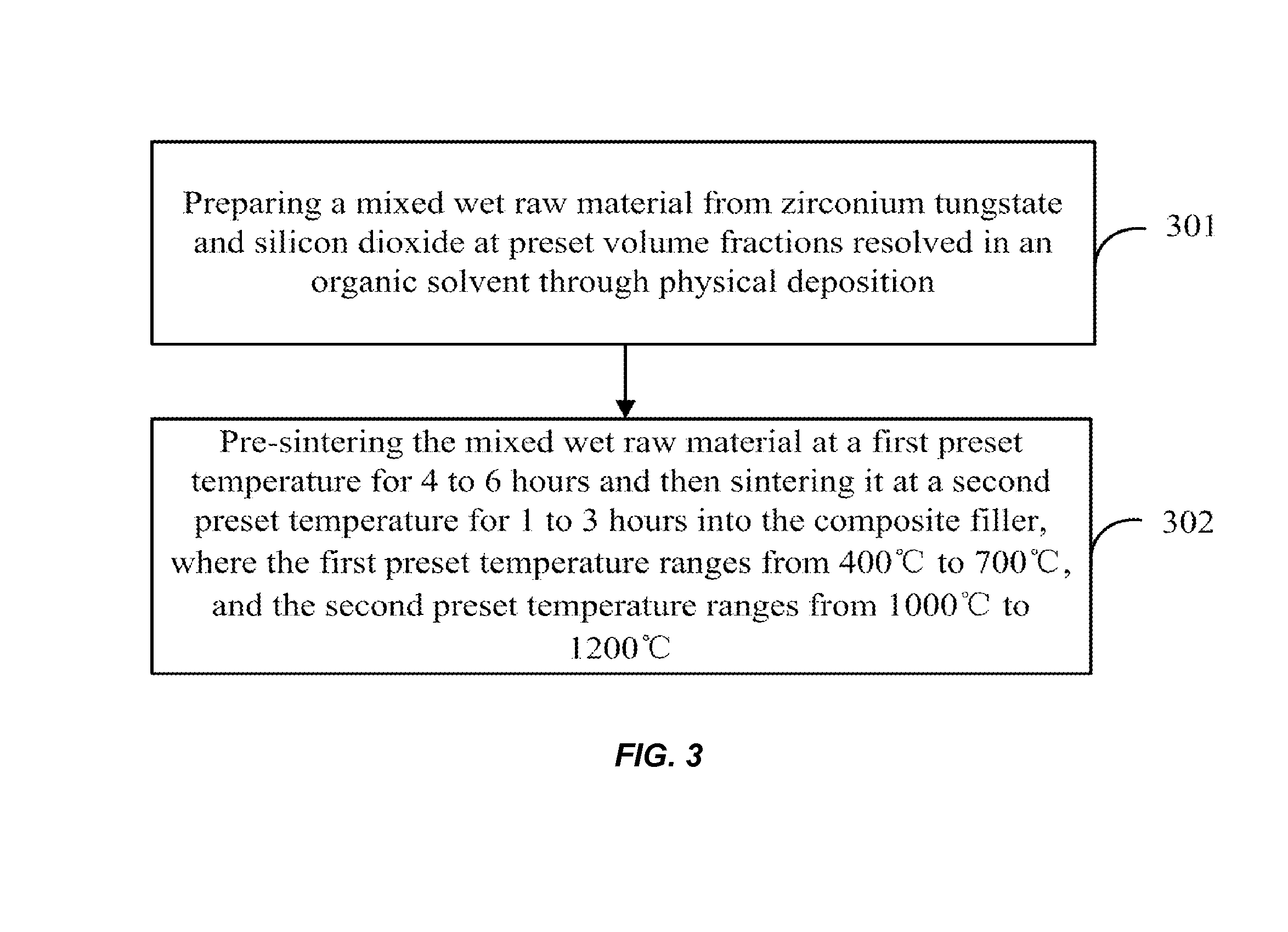

Low-temperature sealing glass frit and method for preparing composite filler in glass frit

The invention discloses a lower-temperature sealing glass frit and a method for preparing a composite filler in the glass frit. The lower-temperature sealing glass frit includes a glass powder and a negative thermal expansion composite filler with an adjustable thermal expansion coefficient. The thermal expansion coefficient of the low-temperature sealing glass frit into which the composite material and the glass powder is mixed can be adjustable so that the thermal expansion coefficient of the low-temperature sealing glass frit can match the thermal expansion coefficient of glass substrates packaging an OLED device to thereby improve the yield of the packaged OLED device.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

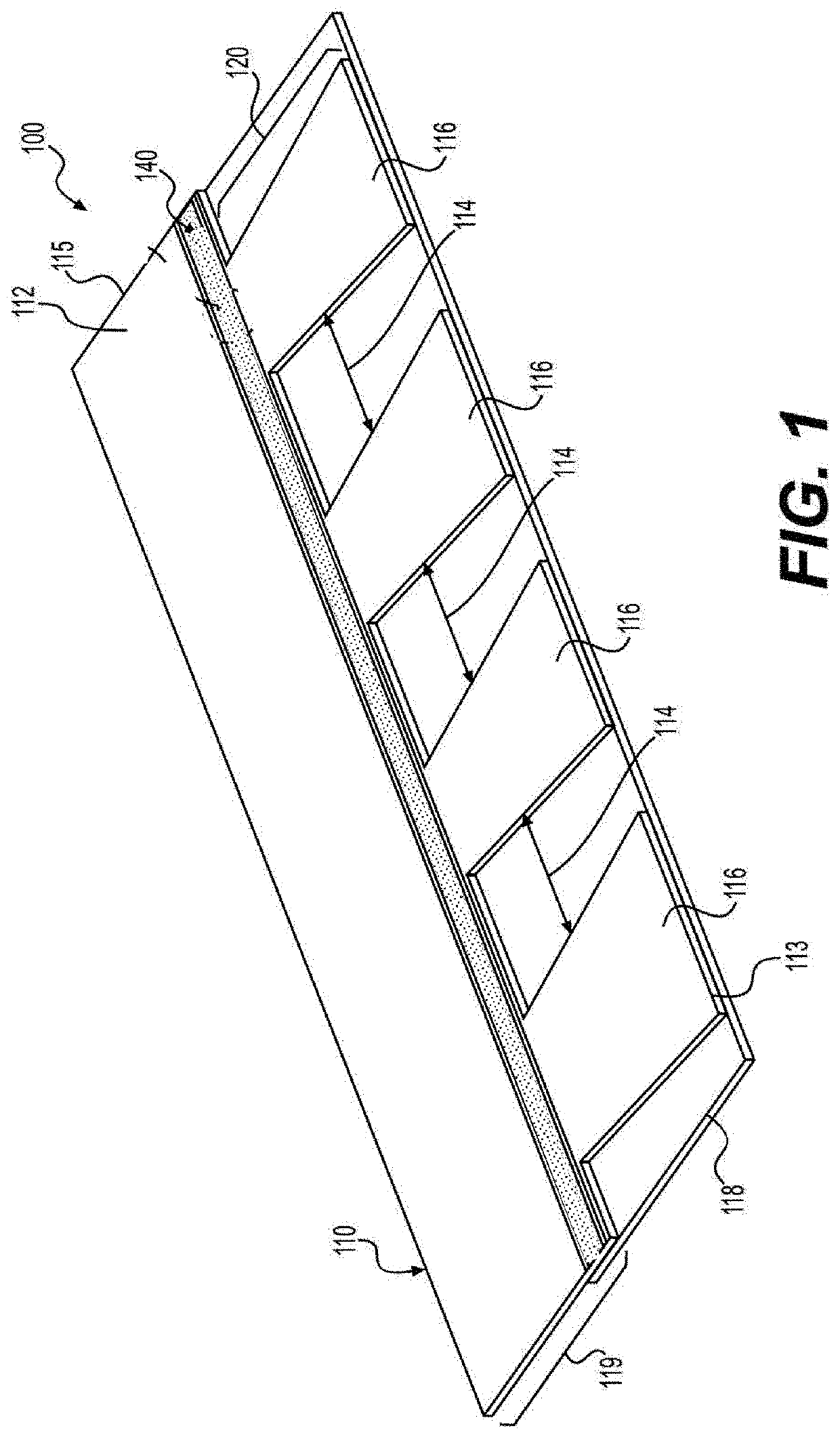

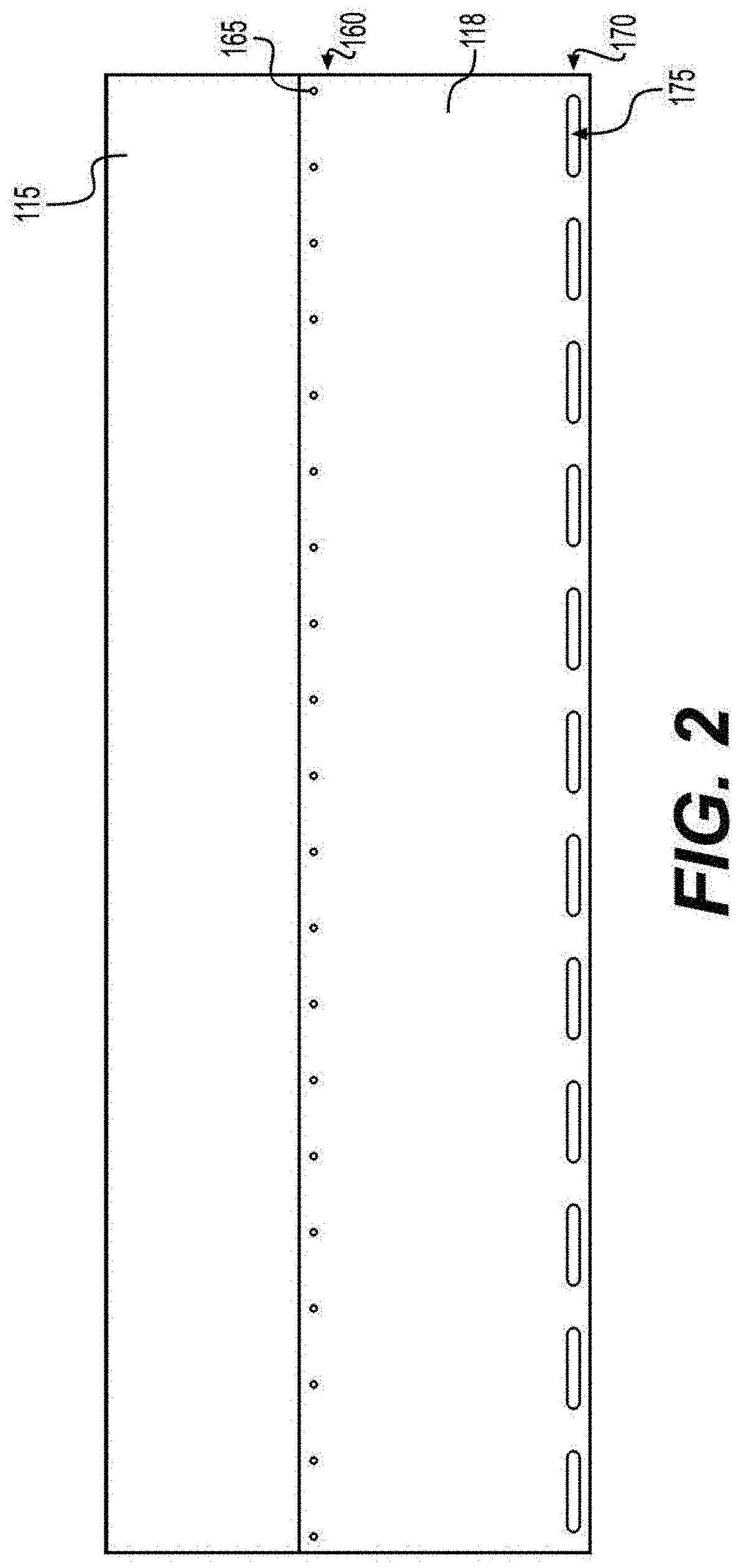

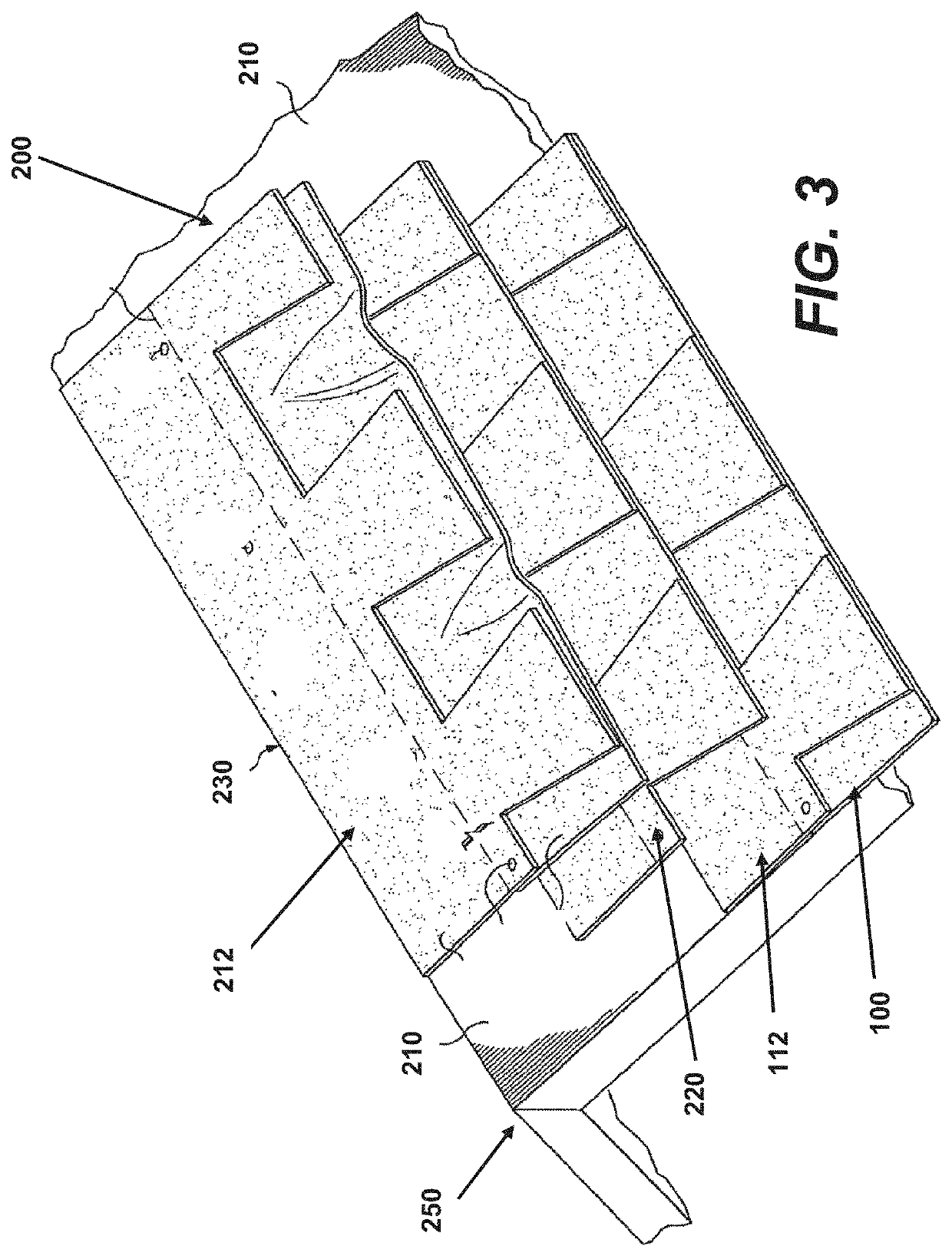

Roofing materials with improved low temperature sealant performance and methods of making thereof

PendingUS20220056695A1Roof covering using tiles/slatesConstructions elementsPolymer scienceCryogenic seal

This invention, in embodiments, relates to a roofing material comprising (a) a coated or covered substrate and (b) a single sealant applied to a surface of the coated or covered substrate, with the single sealant being free of asphalt. The single sealant exhibits a minimum activation temperature (° C.) (tan δ>1) from −10° C. to 0° C. The single sealant is configured to adhere the roofing material to at least one of (i) an underlying roofing material, (ii) an overlying roofing material, and (iii) a roofing deck substrate.

Owner:BMIC LLC

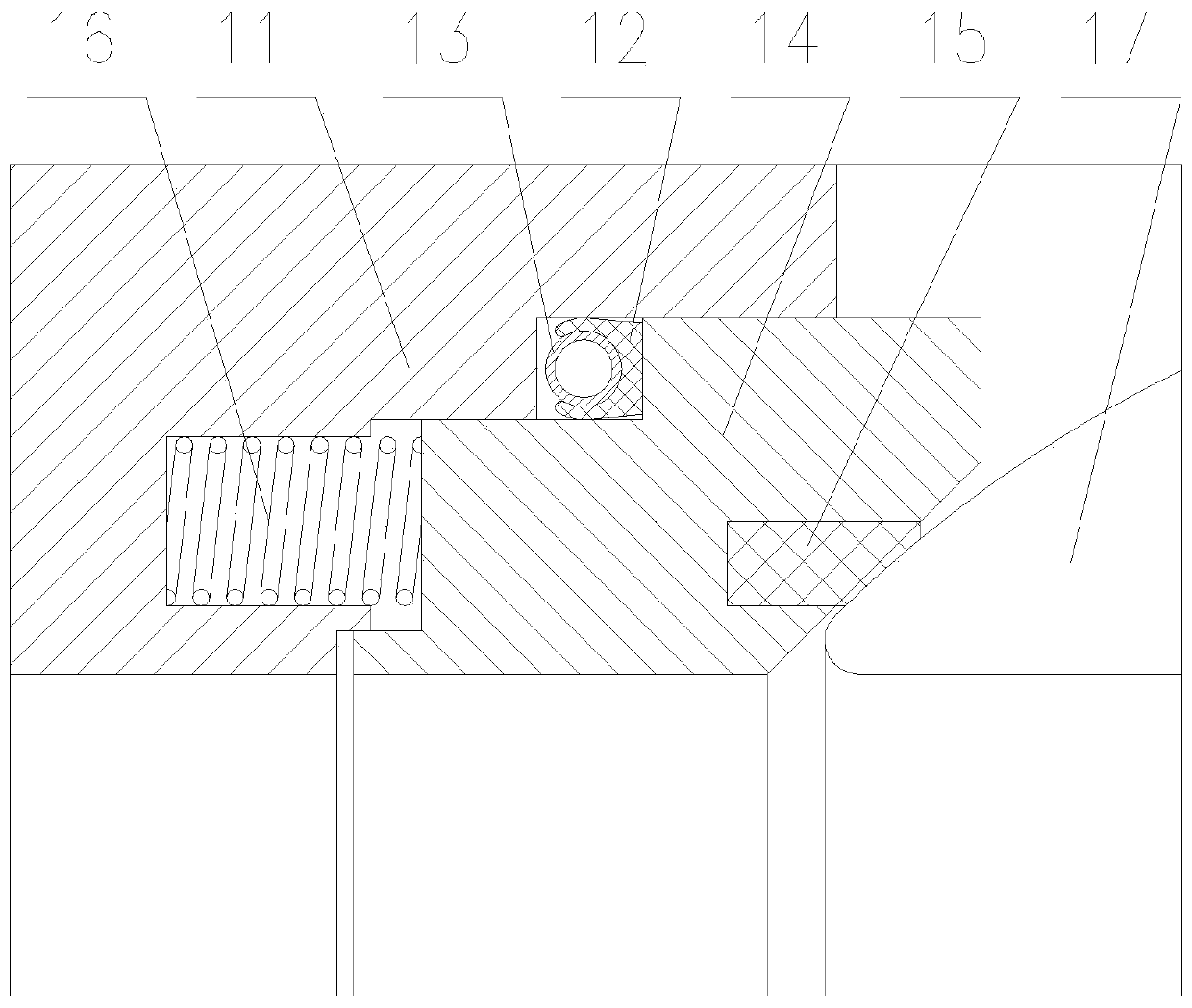

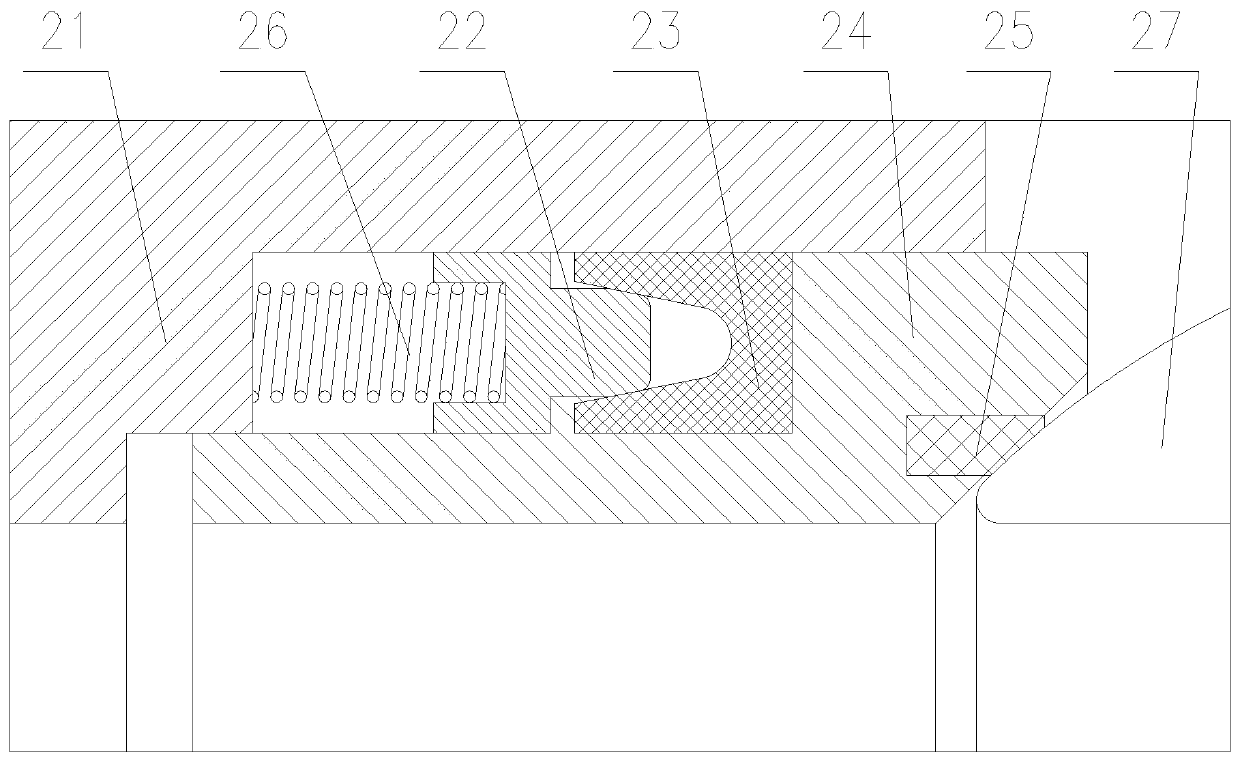

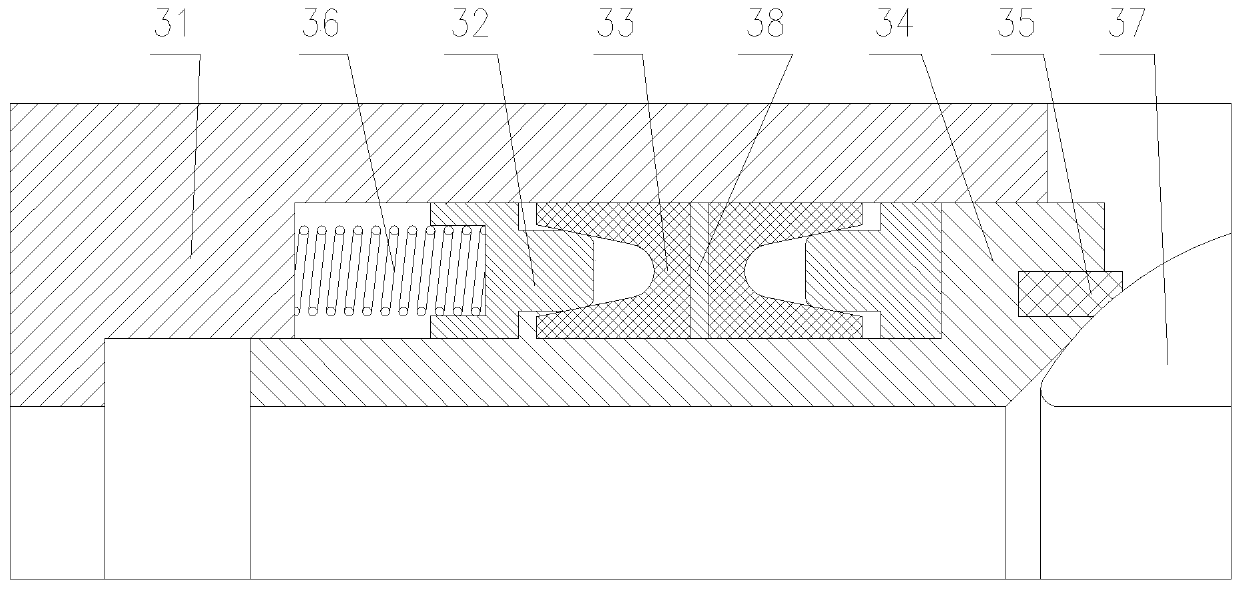

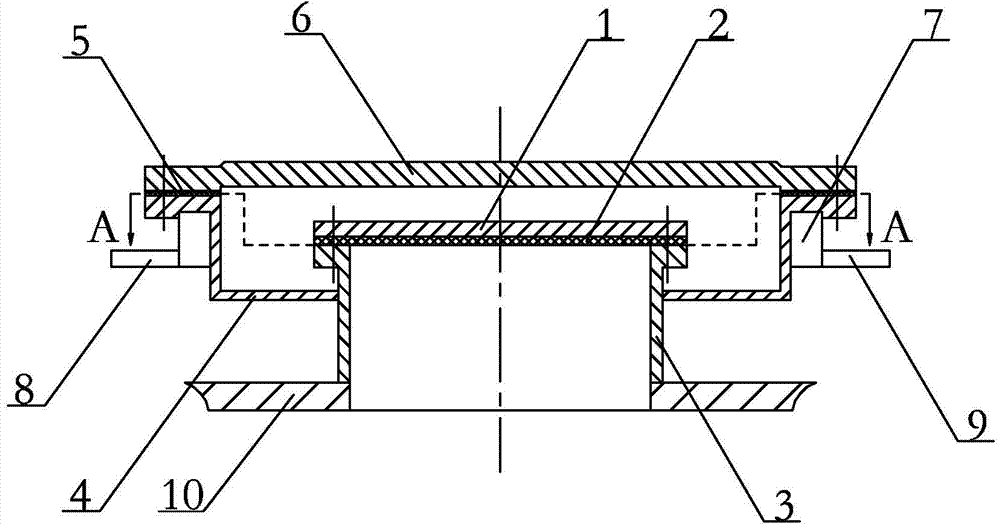

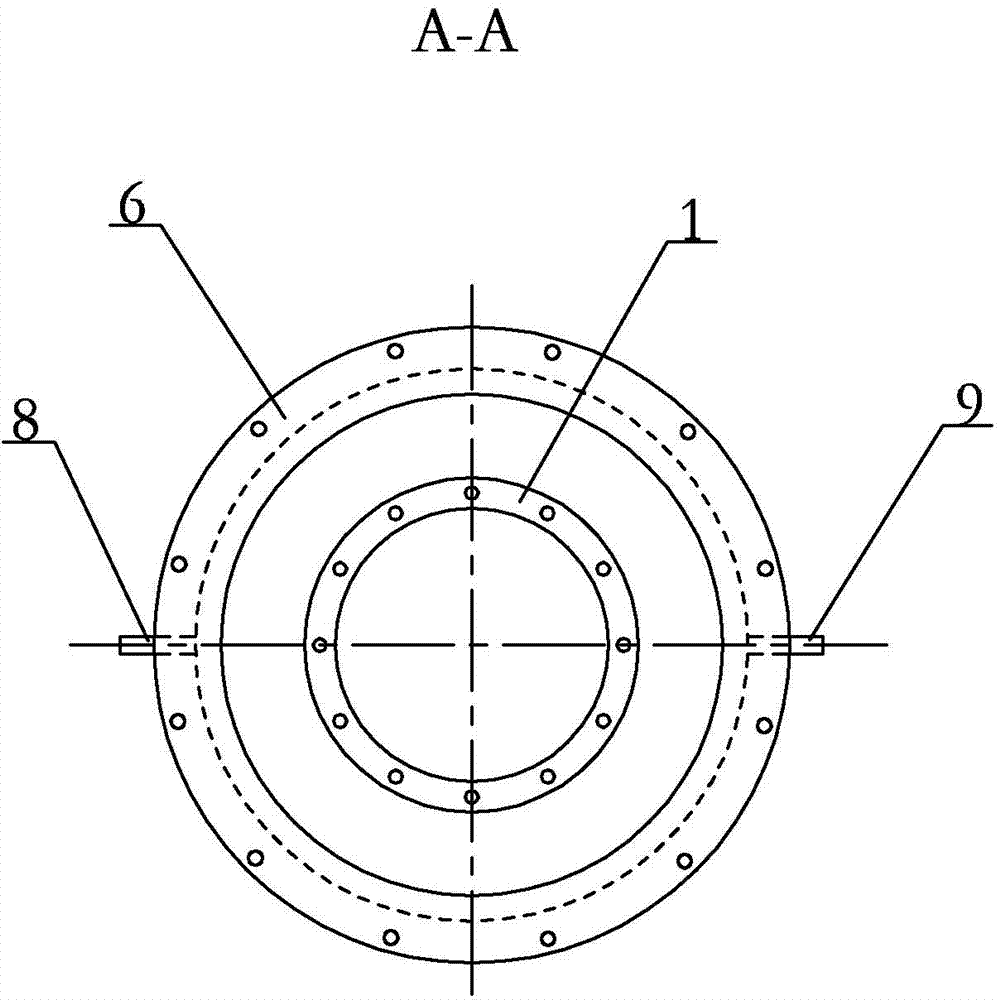

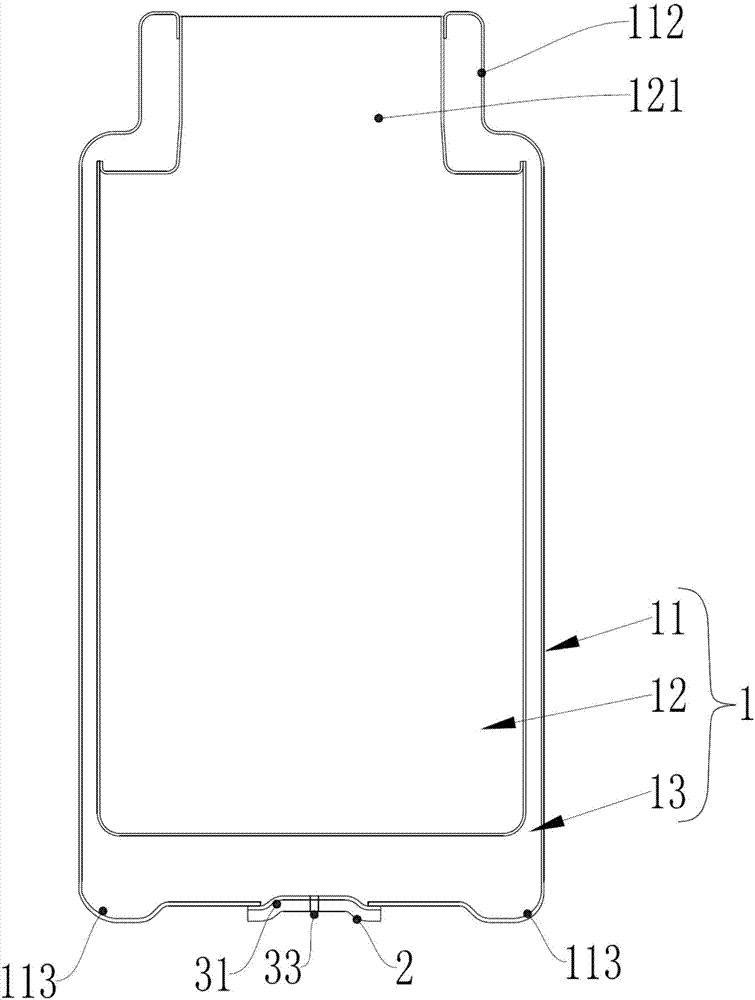

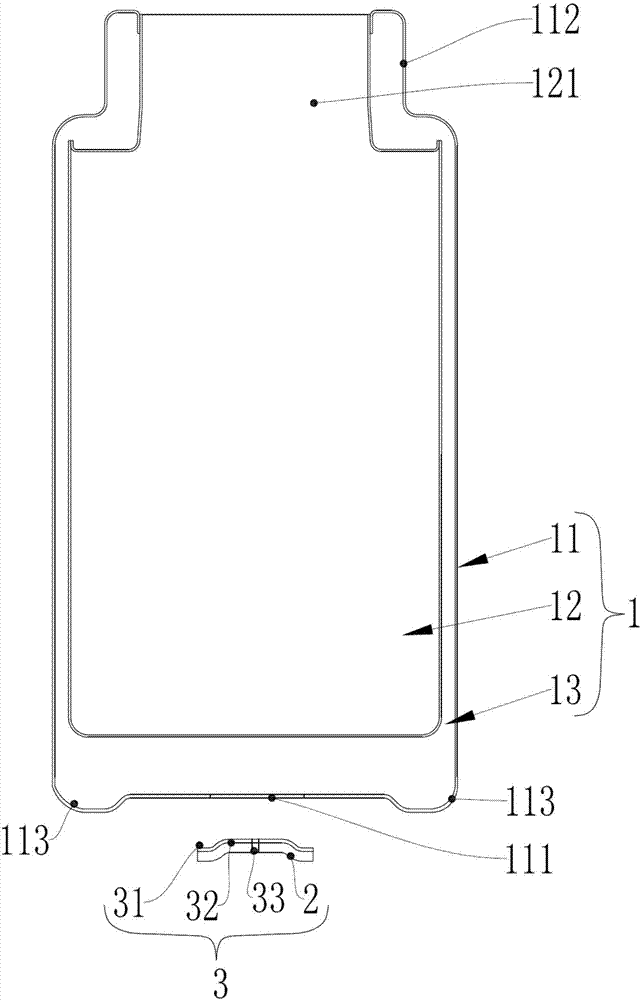

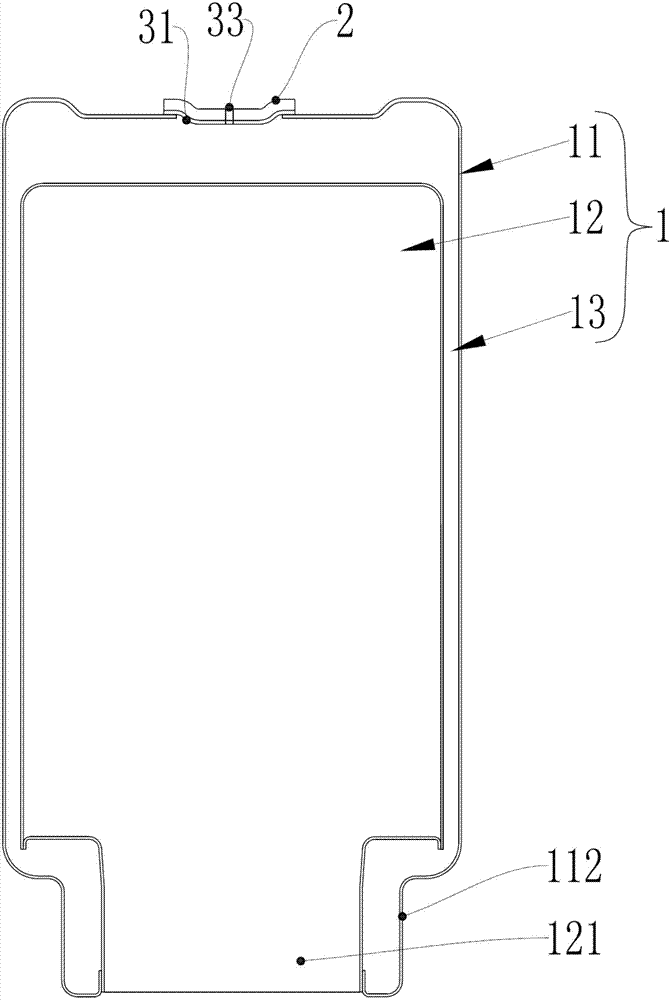

Sealing device used for cryogenic ball valve

PendingCN111412302AGood low temperature sealingIncrease contact forcePlug valvesCryogenic sealLip seal

The invention provides a sealing device for a cryogenic ball valve. The sealing device comprises a valve body, a metal valve seat and a sphere; an annular metal support ring and an annular first lip sealing ring are installed in a space between the valve body and the metal valve seat; the first lip sealing ring includes two first lip edges; an annular groove is formed between the first lip edges;the outer side of the first lip sealing ring butts against the valve body; the inner side of the first lip sealing ring is butts against the metal valve seat; one end of the metal support ring is a protruding head part; the other end of the metal support ring is a circular hole; the protruding head part butts against the interior of the annular groove of the first lip sealing ring; a thrust springis arranged in the circular hole of the metal support ring; and the other end of the thrust spring butts against the valve body. The sealing device for the cryogenic ball valve provided by the invention has very good low-temperature sealing performance.

Owner:上海华托阀门自动化有限公司

Heat-resistant sealing structure for high-temperature gas container

InactiveCN103775826AImprove sealingReduce the temperature of the sealed structureContainer filling methodsContainer discharging methodsEngineeringProduct gas

The invention discloses a heat-resistant sealing structure for a high-temperature gas container, relates to a heat-resistant sealing structure, and aims at solving the problem that an existing sealing gasket at a high temperature is relatively poor in sealing effect in comparison with a low-temperature sealing gasket universally. The heat-resistant sealing structure comprises an inner layer sealing structure and an outer layer sealing structure; the inner layer sealing structure comprises an inner layer sealing end cover, an inner layer high-temperature sealing gasket and an inner layer sealing support; the inner layer sealing end cover is arranged on the inner layer sealing support through an inner layer high-temperature sealing gasket sealing cover; the outer layer sealing structure comprises an outer layer sealing support, a normal-temperature sealing gasket, an outer layer sealing end cover and a water cooling jacket; the outer layer sealing support is fixedly arranged on the inner layer sealing support; the upper end face of the outer layer sealing support is higher than the upper end face of the inner layer sealing end cover; the outer layer sealing end cover is tightly arranged on the outer layer sealing support through a normal-temperature sealing gasket; and the water cooling jacket is arranged on the outer lateral wall of the outer layer sealing support in a sleeved mode. The heat-resistant sealing structure is applied to heat-resistant sealing of the high-temperature gas container.

Owner:HARBIN INST OF TECH

Internal mixing device for low-temperature-resistant sealing material and control method of internal mixing device

The invention discloses an internal mixing device for a low-temperature-resistant sealing material and a control method of the internal mixing device. The internal mixing device has the characteristics of high production efficiency and high forming quality. According to the key point of the technical scheme, the internal mixing device comprises an internal mixer and a PLC control unit, wherein the PLC control unit is used for controlling the operation state of the internal mixer; the internal mixer comprises an internal mixing chamber; a screw is arranged in the internal mixing chamber; a feeding cavity and a top bolt assembly are arranged at the top of the internal mixing chamber; the top comprises two first oil cylinders installed above the internal mixing chamber; piston rods of the two first oil cylinders are connected through a cross beam; a second oil cylinder is arranged on the cross beam, and the lower end of a piston rod of the second oil cylinder is connected with a material pressing mechanism; and the material pressing mechanism comprises a main box body connected with the inner wall of the feeding cavity in a sliding manner and a pressing weight arranged at the bottom of the main box body; and a floating assembly used for controlling the pressing weight to float up and down is arranged in the main box body. The internal mixing device is suitable for the technical field of internal mixing devices.

Owner:黄春方

Efficient manufacturing method of insulated container and manufactured insulated container

ActiveCN107380740AIncreased renovation costsLow retrofit costDomestic cooling apparatusLighting and heating apparatusProduction lineMetallic materials

The invention discloses an efficient manufacturing method of an insulated container and the manufactured insulated container. The efficient manufacturing method comprises the following steps that A, an inner shell is mounted in an outer shell to form a container body, the container body forms an insulated cavity between the outer shell and the inner shell, and meanwhile a low-temperature sealing layer and a substrate layer are welded to each other to form a sealing piece; B, an exhaust groove is formed in the sealing piece, an exhaust hole is formed in the exhaust groove, and meanwhile an installing hole is formed in the bottom of the outer shell. The sealing piece and the bottom of the outer shell are welded to seal the installing hole, so that machining is more convenient, splicing of the container body and the preparation of the sealing piece are achieved synchronously, and the production efficiency is improved. The improvement cost of a production line is low. The low-temperature sealing layer and the substrate layer are both made of metal materials, so that compared with glass cement, the fusion degree is better; and the metal low-temperature sealing layer is not prone to breakage, and air can be effectively prevented from entering the insulated cavity through the exhaust hole.

Owner:FOSHAN KEITH TITANIUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com