Sealing device used for cryogenic ball valve

A technology for sealing devices and ball valves, applied to valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as leakage of low-temperature ball valves, and achieve the effects of preventing leakage, good low-temperature sealing, and increasing contact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

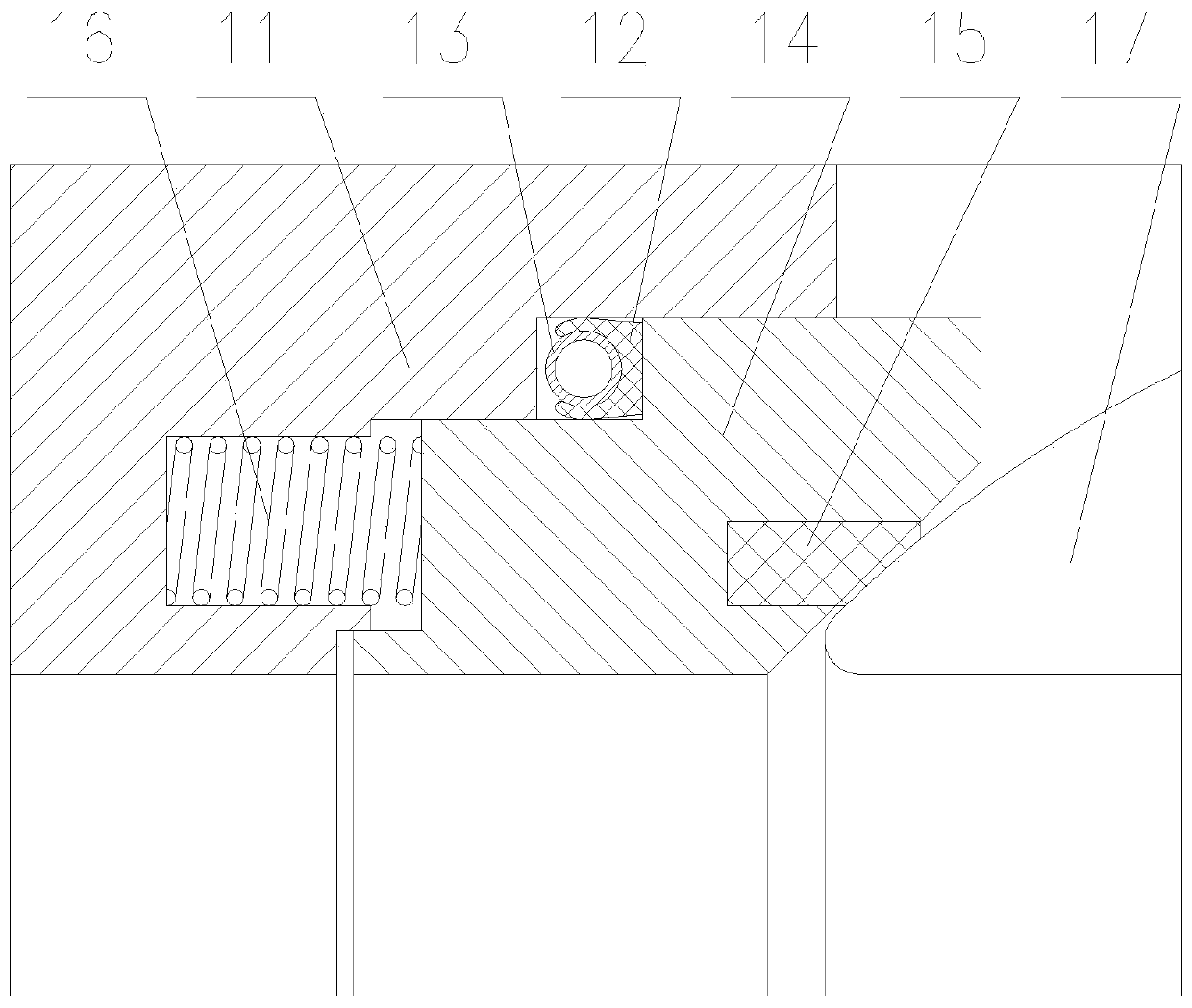

Embodiment 1

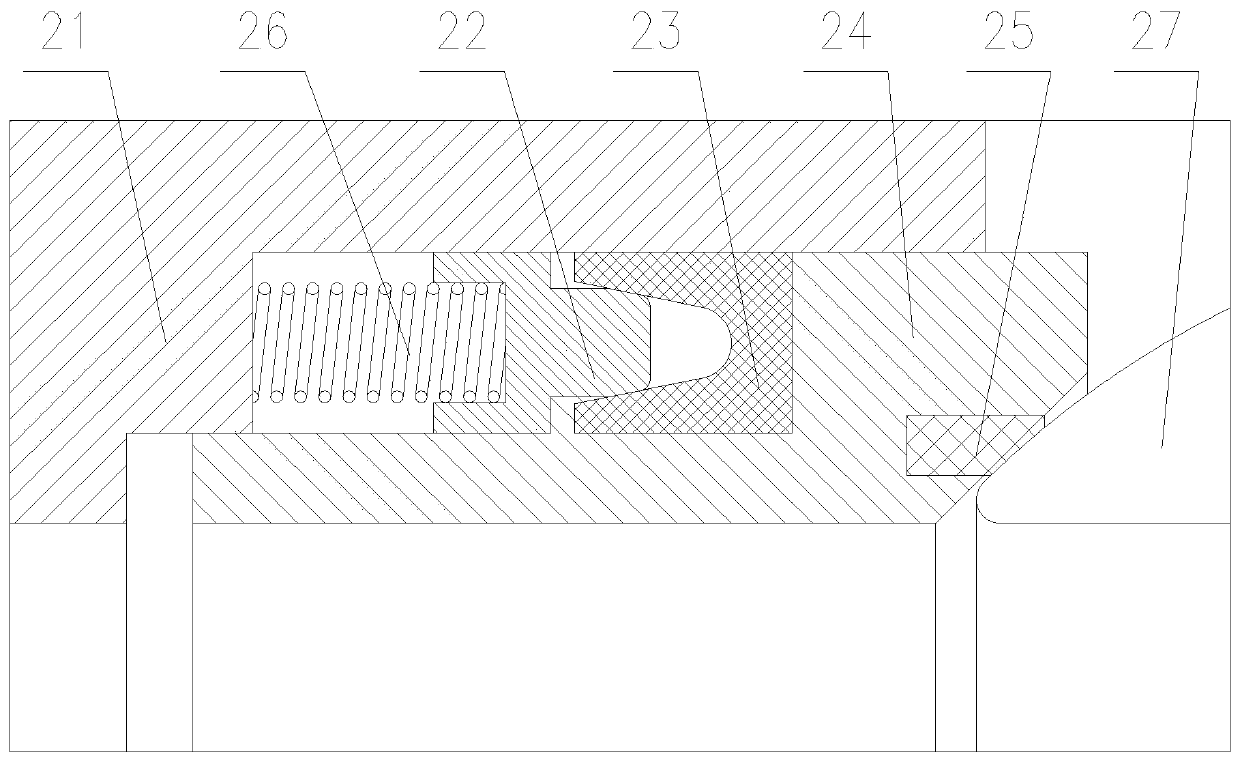

[0032] A sealing device for cryogenic ball valves, see figure 2 , including a valve body 21, a metal valve seat 24 and a ball 27, an annular metal support ring 22 and an annular first lip seal 23 are installed in the space between the valve body 21 and the metal valve seat 24, and the first lip seal The ring 23 includes two first lips, and there is an annular groove between the first lips. The outside of the first lip seal 23 is pressed against the valve body 21, and the inside of the first lip seal 23 is in contact with the metal valve seat. 24 against pressure. One end of the metal support ring 22 is a protruding head, and the other end of the metal support ring 22 is a set of round holes, the protruding head abuts against the annular groove of the first lip seal 23 . A thrust spring 26 is arranged in a group of circular holes of the metal support ring 22 , and the other end of the thrust spring 26 is against the valve body 21 .

[0033]The thrust spring 26 pushes the met...

Embodiment 2

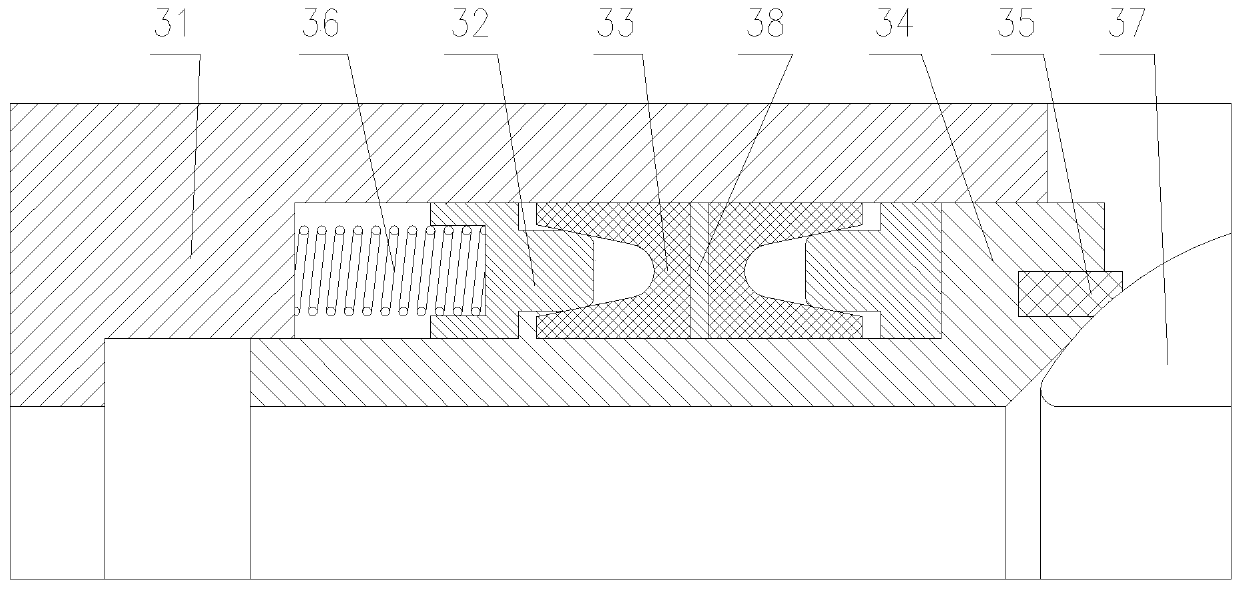

[0035] A sealing device for cryogenic ball valves, which is a double-piston effect sealing structure, see image 3 , including a valve body 31, a metal valve seat 34 and a ball 37, an annular metal support ring 32 and an annular first lip seal 33 are installed in the space between the valve body 31 and the metal valve seat 34, the first lip seal The ring 33 includes two first lips, and there is an annular groove between the first lips. The outside of the first lip seal 33 is pressed against the valve body 31, and the inside of the first lip seal 33 is in contact with the metal valve seat. 34 against pressure. One end of the metal support ring 32 is a protruding head, and the other end of the metal support ring 32 is a set of round holes, the protruding head abuts against the annular groove of the first lip seal 33 . A thrust spring 36 is arranged in a group of round holes of the metal support ring 32 , and the other end of the thrust spring 36 is against the valve body 31 , a...

Embodiment 3

[0038] A sealing device for a cryogenic ball valve is a secondary sealing structure, including a first lip seal ring 43 with a first toe heel 411, providing a secondary sealing structure of axial sealing and plane sealing. see Figure 4 , including a valve body 41, a ball 47, a metal valve seat 44, a first lip seal 43 with a first toe heel 411 in the annular cavity of the valve body 41 and the metal valve seat 44, a metal support ring 42, and a protruding head part against the annular groove of the first lip seal ring 43 with the first toe heel 411, pushed by a group of thrust springs 46 on the back, and the outer side of the first lip tightly pushes against the inner cylinder surface inside the valve body 41, There is a notch on the valve body 41, the first toe heel 411 is pressed on the notch, the lip seal seat 43 with the first toe heel 411 is pressed by a pressing plate 49, and the pressing plate 49 is pressed on the valve body 41 with a screw 48 On the front end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com