Microfoaming functional masterbatch, door seal, preparation method of door seal and refrigeration equipment

A functional masterbatch and micro-foaming technology, applied in the field of refrigeration equipment and micro-foaming functional masterbatch, can solve the problem of high risk of plasticizer migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

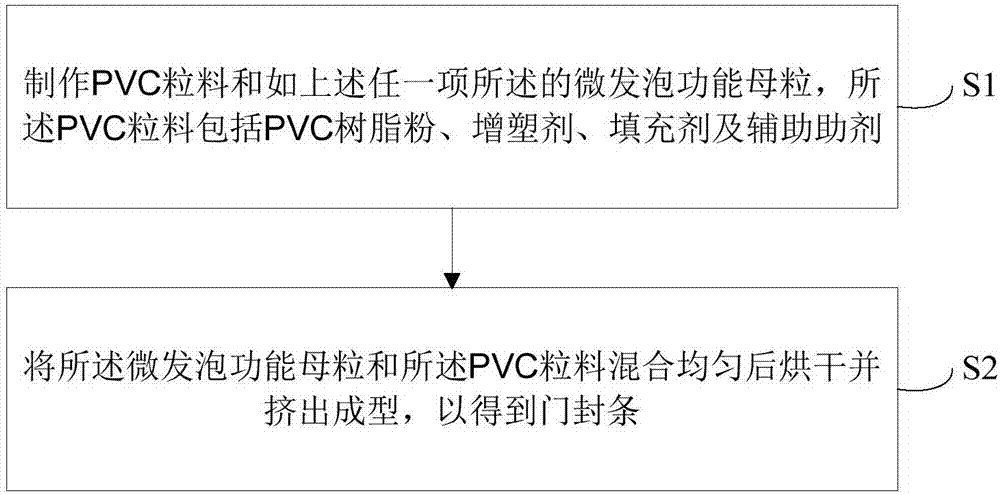

[0043] see figure 2 , the present invention also provides a kind of preparation method of door seal, the preparation method of described door seal comprises the following steps:

[0044] S1, making PVC pellets and the micro-foaming functional masterbatch as described above, the PVC pellets include PVC resin powder, plasticizer, filler and auxiliary additives;

[0045] S2, mixing the micro-foaming functional masterbatch and the PVC pellets evenly, drying and extruding to obtain a door seal.

[0046] For the components of the micro-foaming functional masterbatch, please refer to the foregoing examples. Since this micro-foaming functional masterbatch adopts all the technical solutions of all the above-mentioned embodiments, it at least has all the benefits brought by the technical solutions of the above-mentioned embodiments. effects, which will not be repeated here.

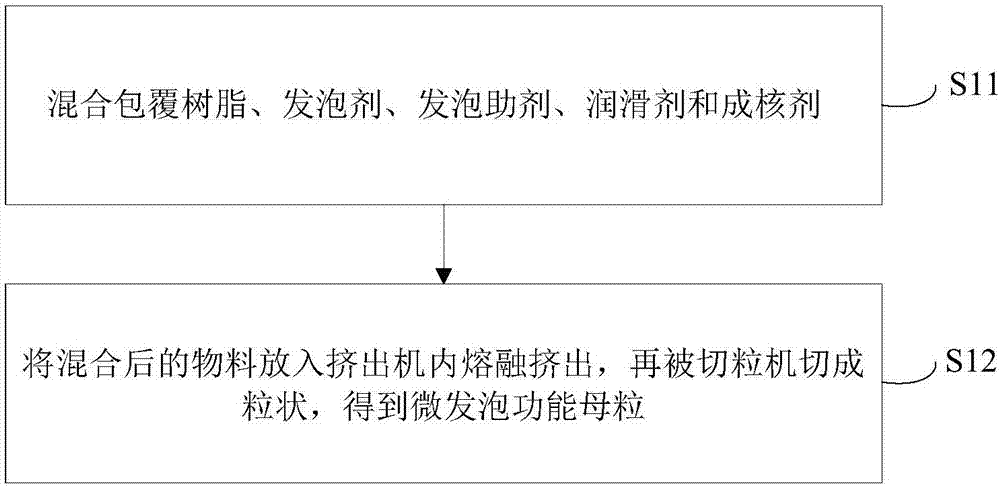

[0047] Specifically, after the PVC material granules are produced, the PVC resin powder and the micro-foaming...

Embodiment 1

[0060] A door seal, which includes PVC pellets and micro-foaming functional master batches. The PVC granules include by weight: 100 parts of PVC resin powder, 42 parts of plasticizer, 50 parts of filler, 5 parts of heat stabilizer, 1 part of antioxidant, 0.5 part of lubricant and 1 part of color masterbatch, The parts by weight of the micro-foaming functional masterbatch is 5 parts. The micro-foaming functional master batch includes by weight: 100 parts of coating resin EVA, 30 parts of foaming agent AIBN, 7 parts of foaming aid zinc oxide, 1.5 parts of lubricant PE wax and 3 parts of nucleating agent talcum powder.

[0061] The preparation method of this door seal comprises the following steps:

[0062] S1, making PVC pellets and micro-foaming functional masterbatches;

[0063] S2, mixing the micro-foaming functional masterbatch and the PVC pellets according to the weight ratio of the micro-foaming functional masterbatch and PVC resin powder is 5:100, then drying and extrus...

Embodiment 2

[0072] A door seal, which includes PVC pellets and micro-foaming functional master batches. The PVC granules include by weight: 100 parts of PVC resin powder, 36 parts of plasticizer, 50 parts of filler, 5 parts of heat stabilizer, 1 part of antioxidant, 0.5 part of lubricant and 1 part of color masterbatch, The parts by weight of the micro-foaming functional masterbatch is 10 parts. The micro-foaming functional master batch includes by weight: 100 parts of coating resin EVA, 30 parts of foaming agent AIBN, 7 parts of foaming aid zinc oxide, 1.5 parts of lubricant PE wax and 3 parts of nucleating agent talcum powder.

[0073] The preparation method of this door seal comprises the following steps:

[0074] S1, making PVC pellets and micro-foaming functional masterbatches;

[0075] S2, mixing the micro-foaming functional masterbatch and the PVC pellets according to the ratio of micro-foaming functional masterbatch and PVC resin powder to a ratio of 10:100 by weight, drying and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com