Low-temperature sealing glass frit and method for preparing composite filler in glass frit

a technology of glass frit and composite filler, which is applied in the field of low-temperature sealing glass frit and the preparation of composite filler in glass frit, can solve the problems of degrading the strength of the sealing material as a whole, low and difficult control of the thermal expansion coefficient, so as to improve the yield of the packaged oled device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

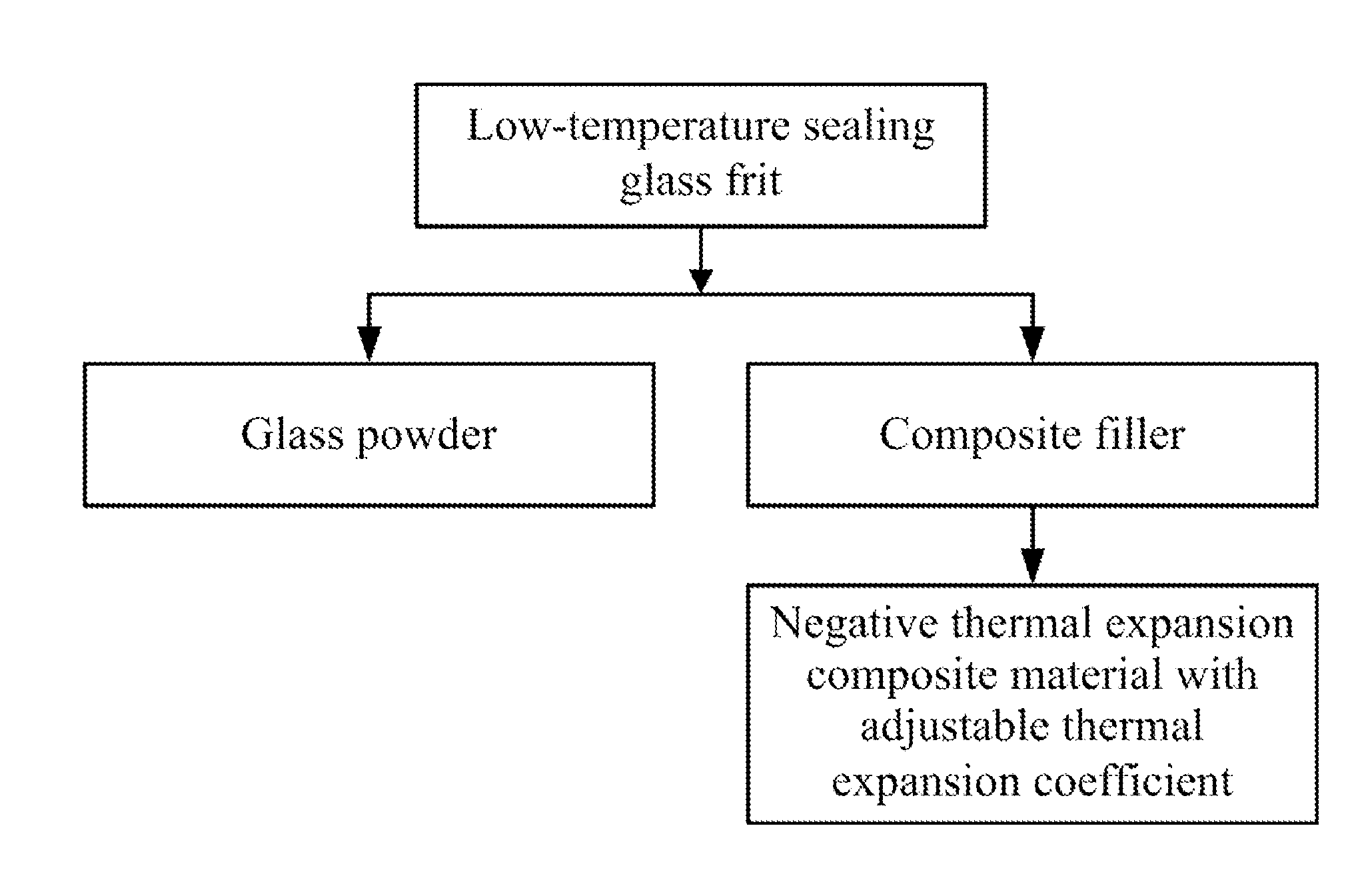

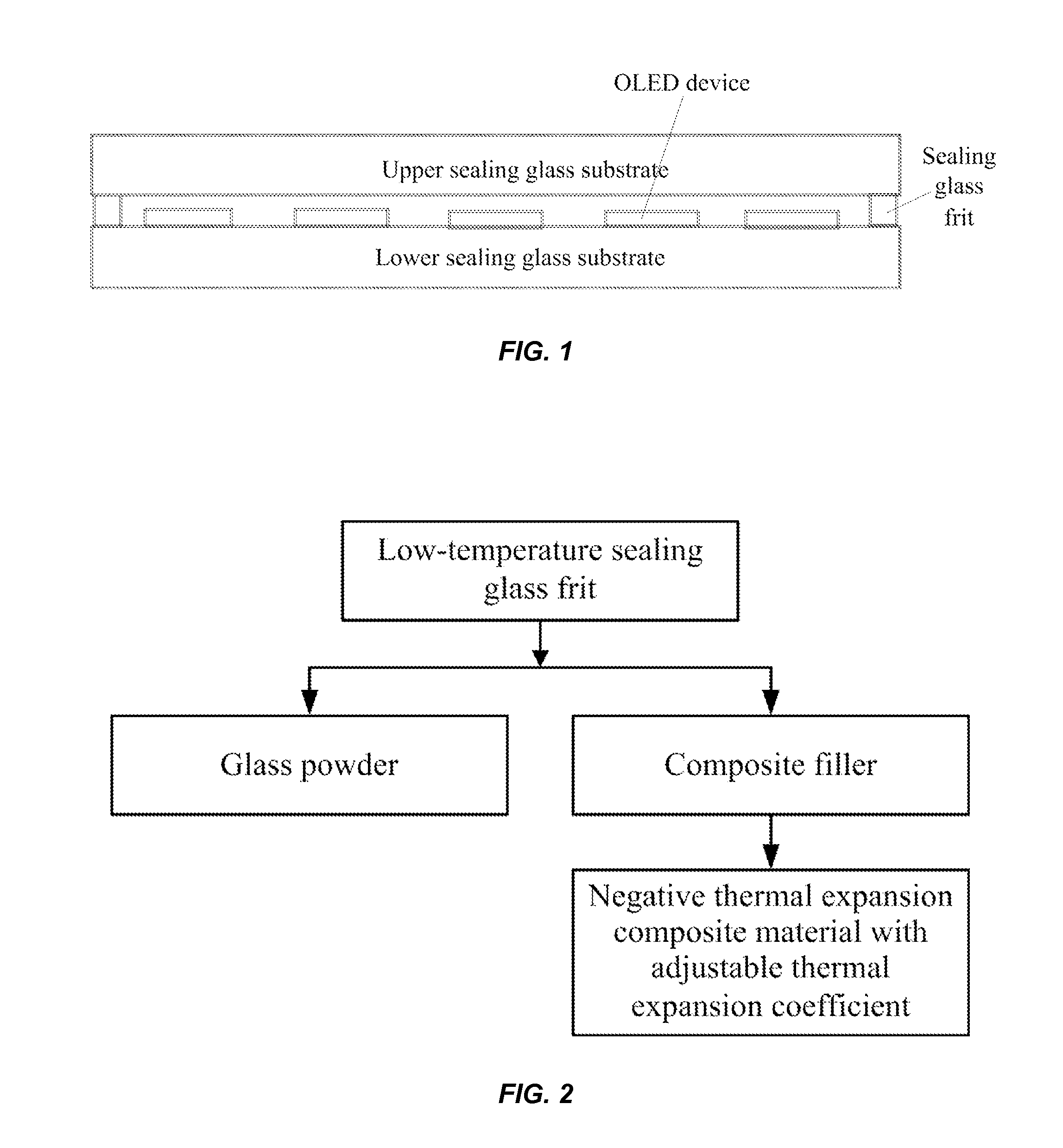

[0026]A low-temperature sealing glass frit according to an embodiment of the invention as illustrated in FIG. 2 includes a glass powder and a composite filler. The composite filler is a negative thermal expansion composite filler with an adjustable thermal expansion coefficient. The glass powder is typically made of one or more of V2O5, TeO2, Fe2O3, Co2O3, TiO2, ZrO2, ZnO and K2O.

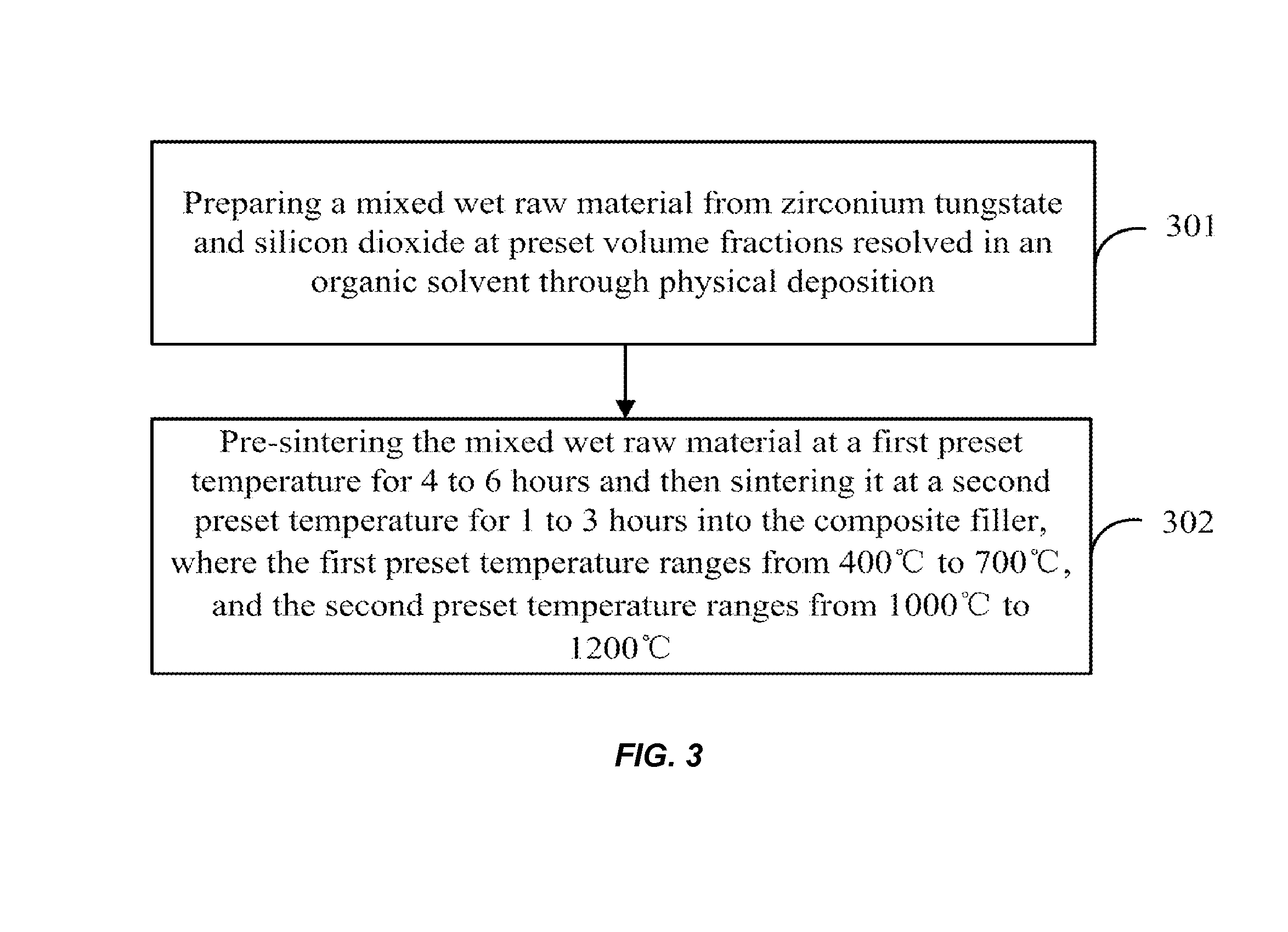

[0027]The composite filler according to this embodiment is a composite material prepared from a chemical reaction of a mixture of zirconium tungstate and silicon dioxide at high temperature, where zirconium tungstate is an isotropic negative thermal expansion material, and silicon dioxide is an amorphous silicon dioxide powder material which is a zero thermal expansion material. The isotropic negative thermal expansion material being heated will shrink with cubic symmetry in all of the three crystal axles at the same shrinkage coefficient which can be adjustable uniformly as a whole in respective directions...

second embodiment

[0039]The components of the composite filler according to the first embodiment described above can be extended resulting in some other negative thermal expansion composite materials with an adjustable thermal expansion coefficient and low-temperature sealing glass frits with an adjustable thermal expansion coefficient, where the composite filler can be extended according to the components thereof at least as follows:

[0040]In a first supplementary embodiment, the composite filler is a composite filler resulting from a chemical reaction of a mixture of zirconium tungstate, silicon dioxide and cordierite at high temperature, and composite phases of the composite filler includes a zirconium tungstate and silicon dioxide composite phase, and a zirconium tungstate and cordierite composite phase.

[0041]In a second supplementary embodiment, the composite filler is a composite filler resulting from a chemical reaction of a mixture of zirconium tungstate, silicon dioxide and eucryptite at high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass fraction | aaaaa | aaaaa |

| mass fraction | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com