Patents

Literature

2265 results about "Tungstate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a tungstate is a compound that contains an oxoanion of tungsten or is a mixed oxide containing tungsten. The simplest tungstate ion is WO²⁻₄, "orthotungstate". Many other tungstates belong to a large group of polyatomic ions that are termed polyoxometalates, ("POMs"), and specifically termed isopolyoxometalates as they contain, along with oxygen and maybe hydrogen, only one other element. Almost all useful tungsten ores are tungstates.

Electroless deposition processes and compositions for forming interconnects

InactiveUS20060252252A1Material nanotechnologySemiconductor/solid-state device detailsHydrogen fluorideTungstate

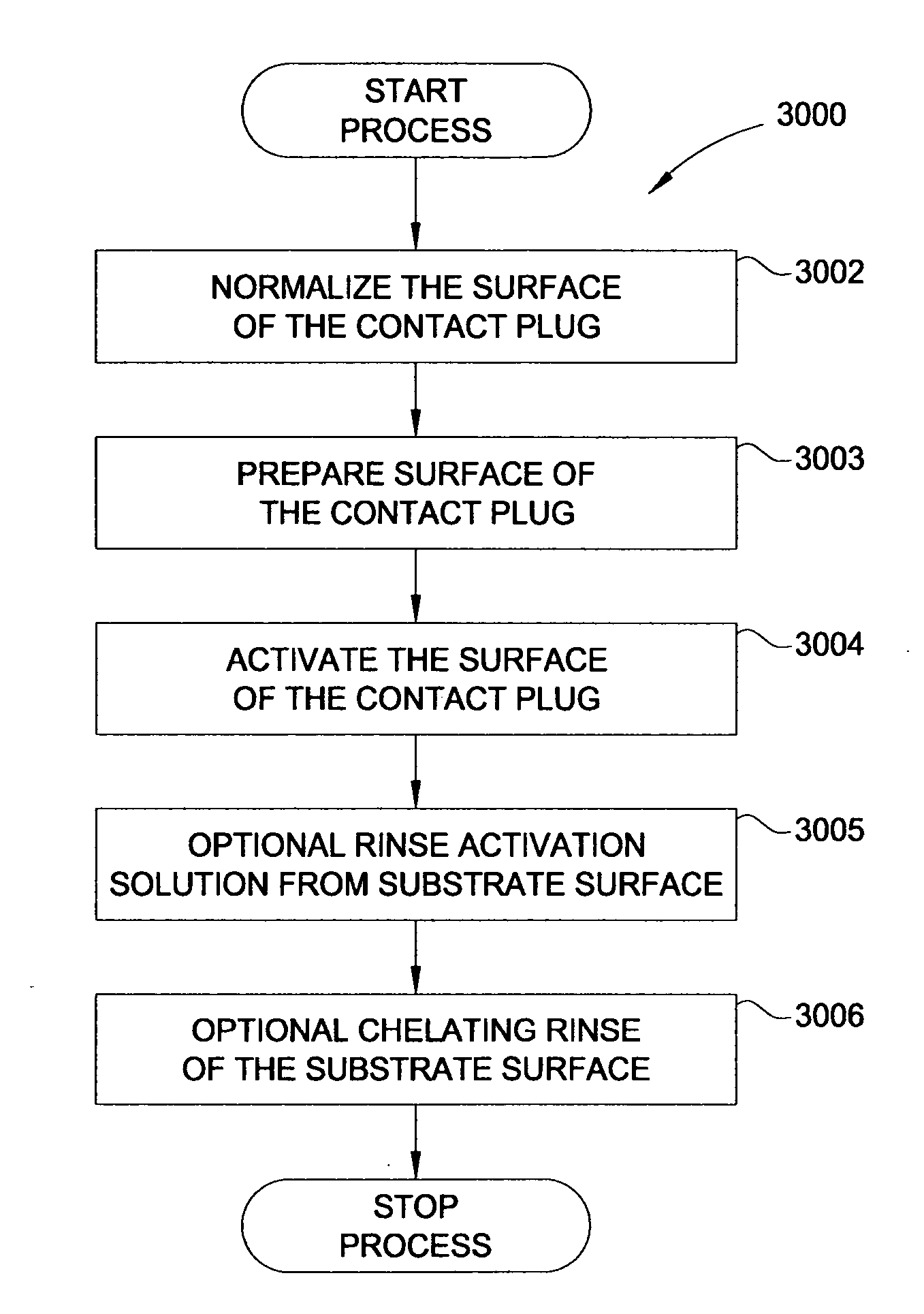

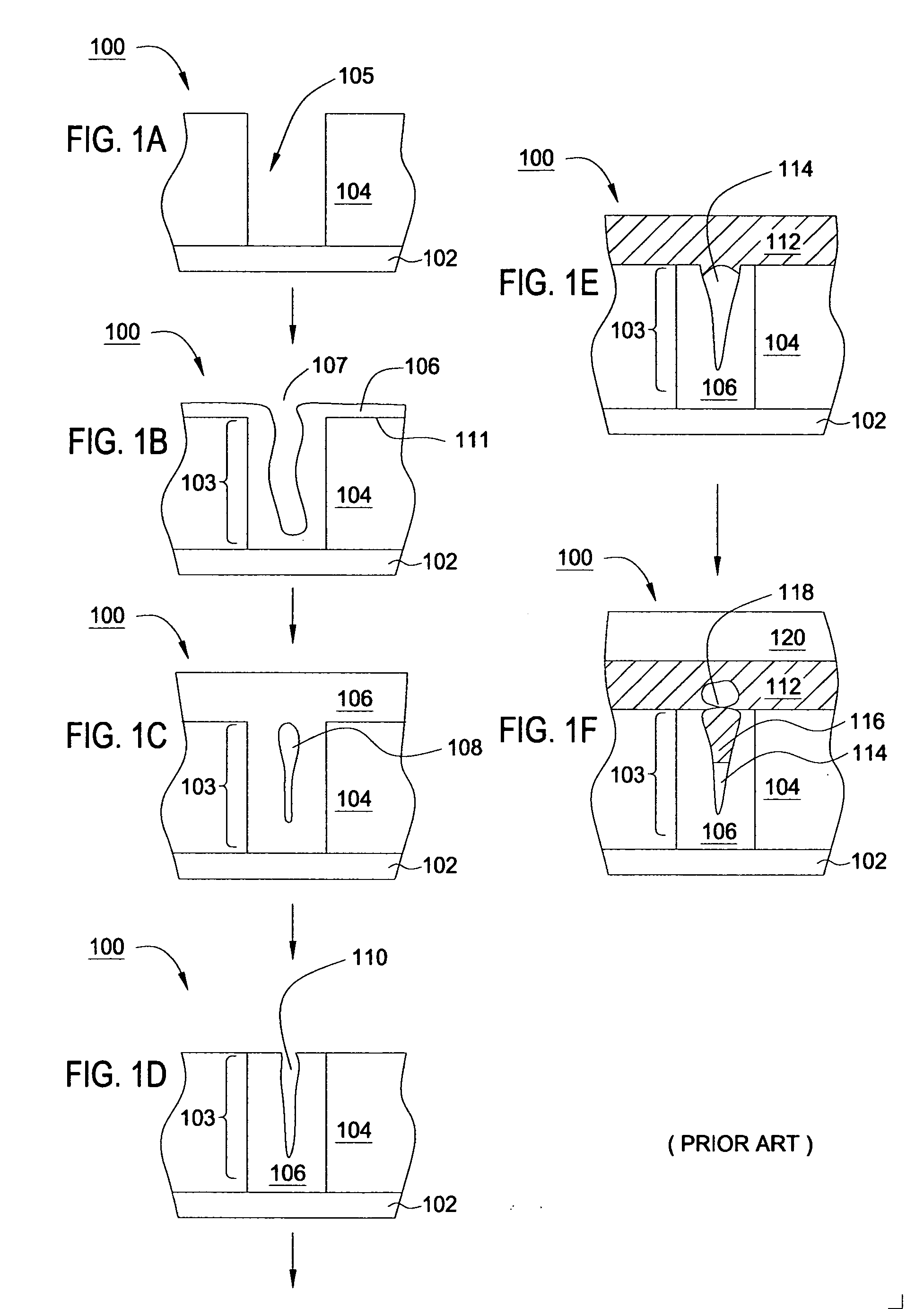

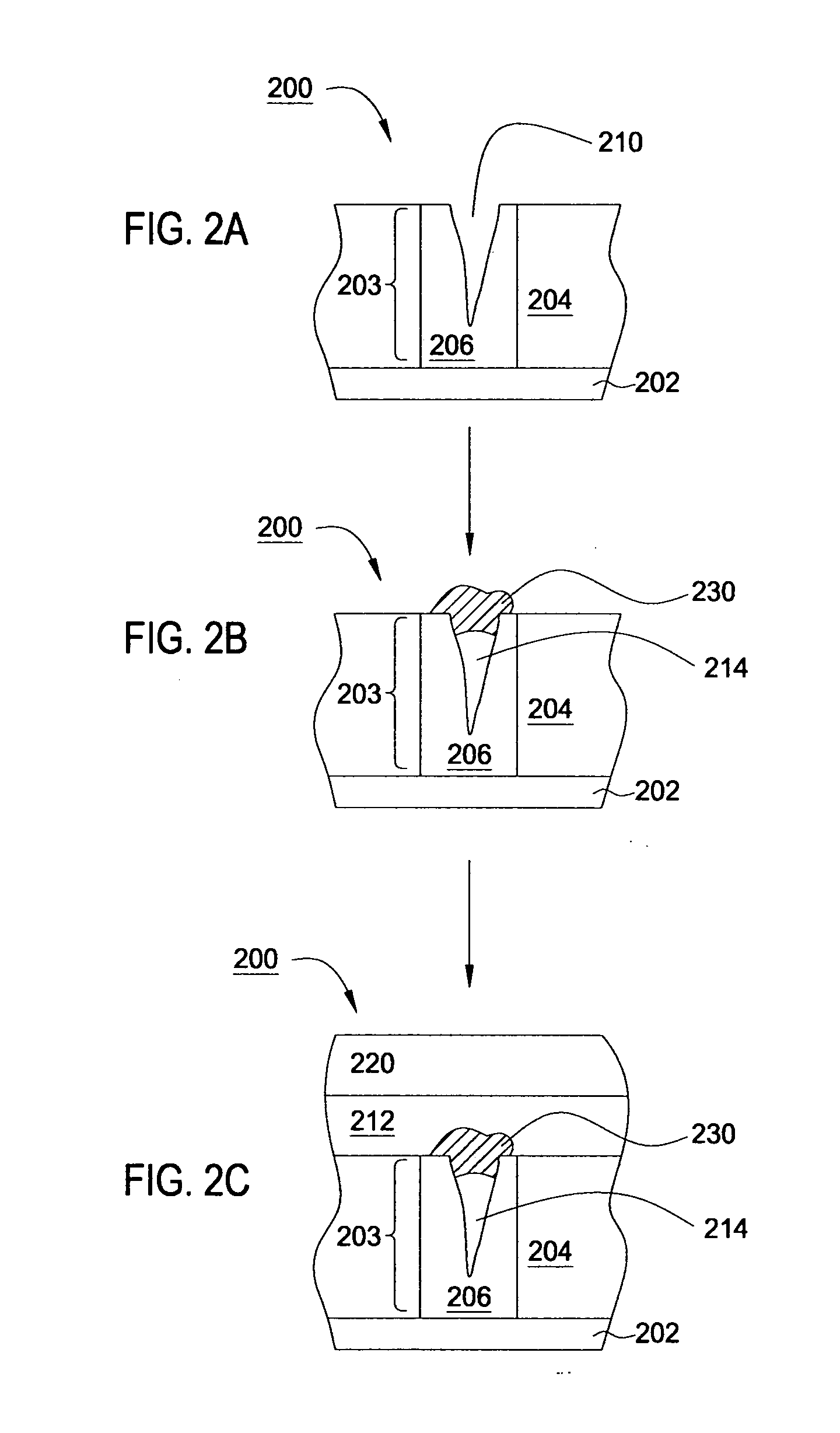

In one embodiment, a method for depositing a material on a substrate is provided which includes positioning a substrate containing a contact within a process chamber, exposing the substrate to at least one pretreatment step and depositing a fill the contact vias by an electroless deposition process. The pretreatment step contains multiple processes for exposing the substrate to a wet-clean solution, a hydrogen fluoride solution, a tungstate solution, a palladium activation solution, an acidic rinse solution, a complexing agent solution or combinations thereof. Generally, the HARC via contains a tungsten oxide surface and the shallow contact via may contain a tungsten silicide surface. In some example, the substrate is pretreated such that both vias are filled at substantially the same time by a nickel-containing material through an electroless deposition process.

Owner:APPLIED MATERIALS INC

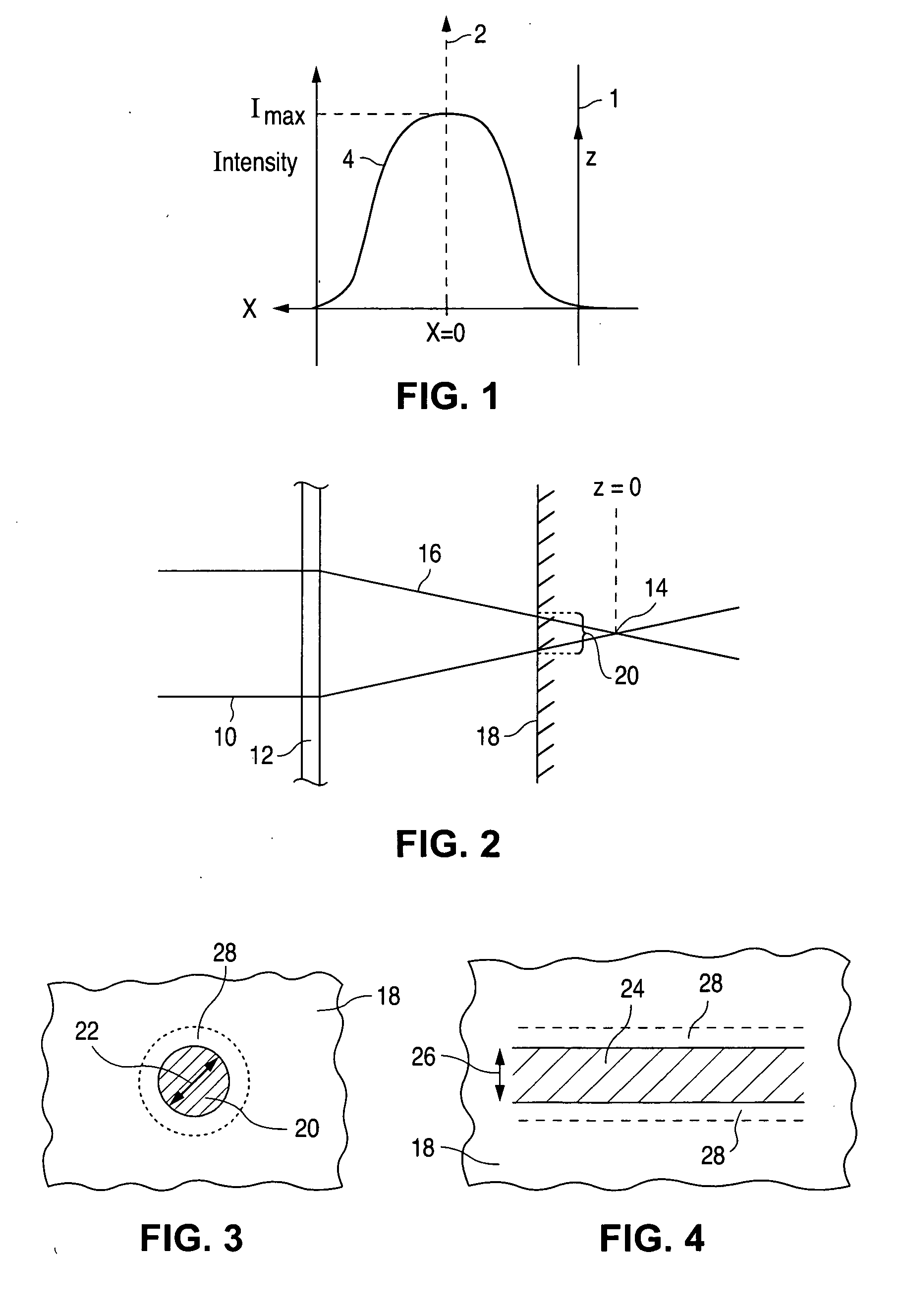

Fabricating medical devices with an ytterbium tungstate laser

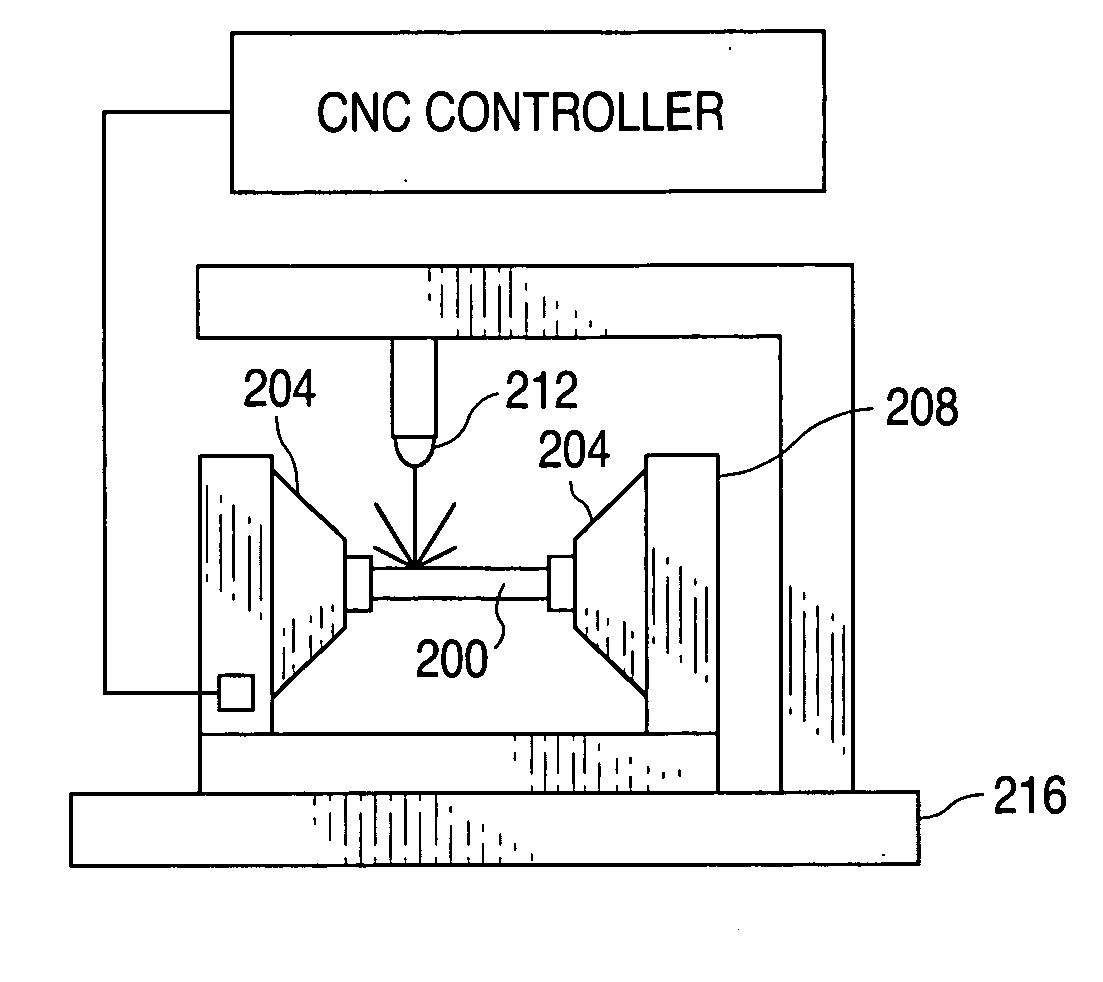

Methods for fabricating a stent using a femtosecond laser with an Ytterbium Tungstate active medium are disclosed. In some embodiments, a method includes forming a pattern in the substrate with the laser, the pattern including a plurality of structural elements.

Owner:ABBOTT CARDIOVASCULAR

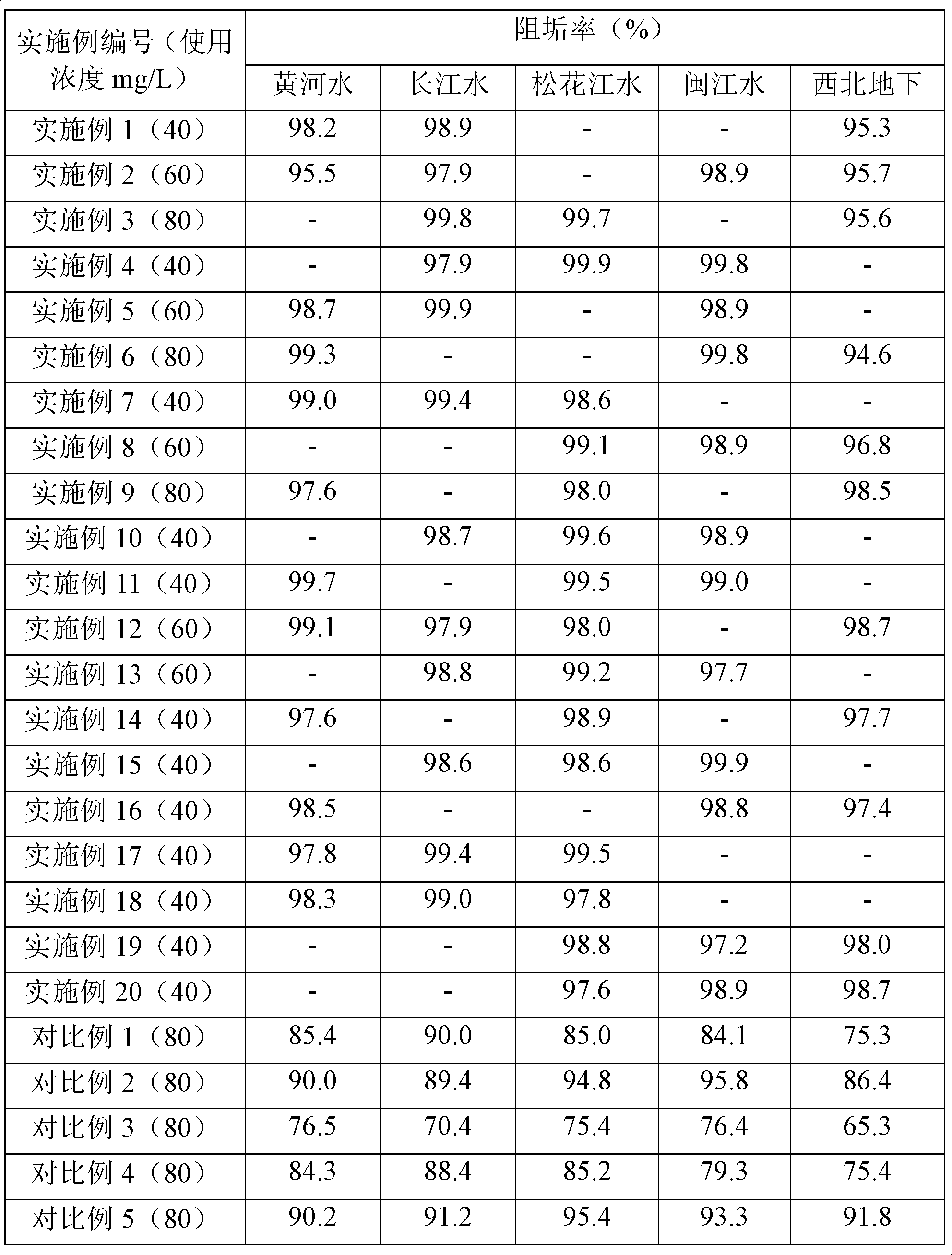

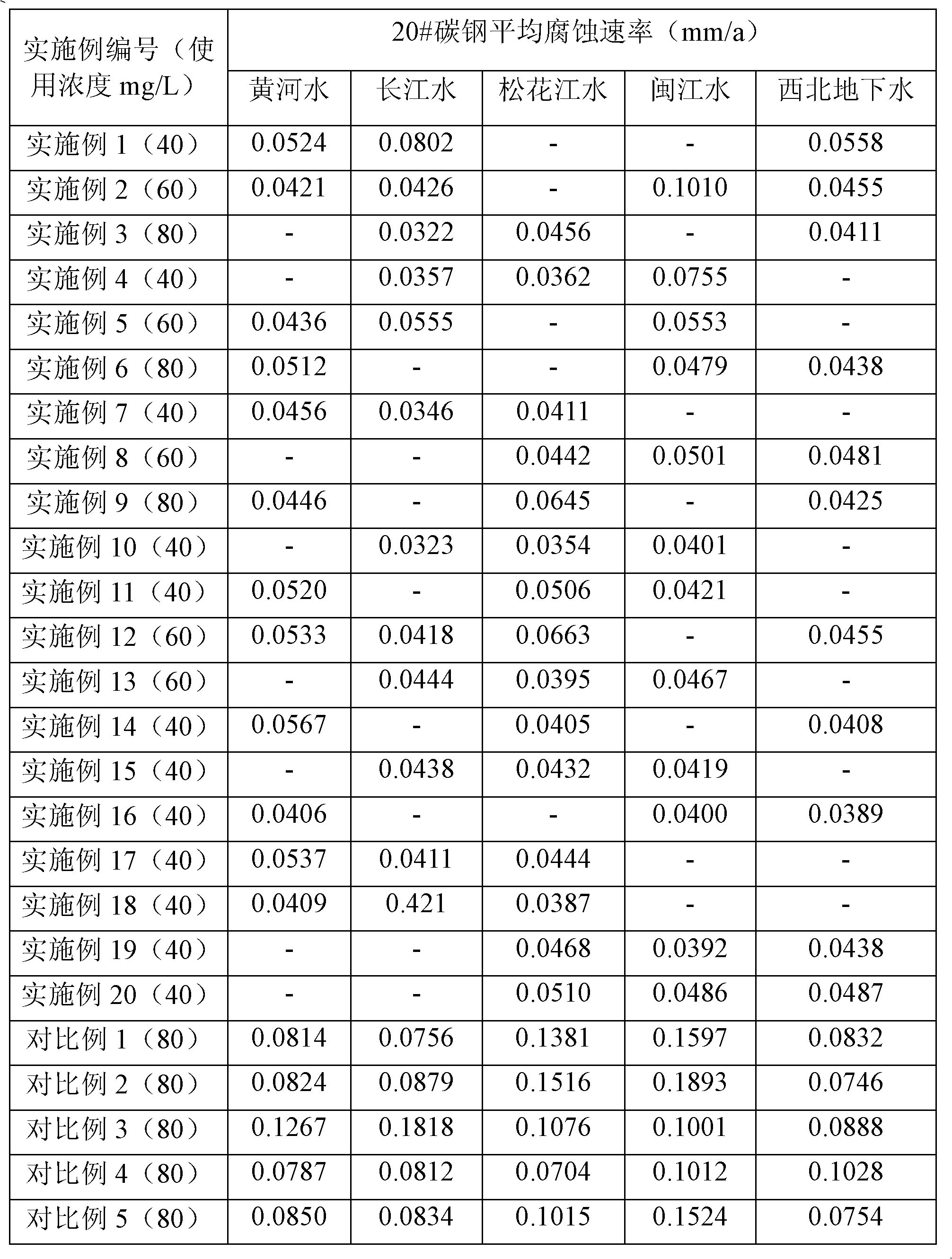

Non-phosphorus compound scale and corrosion inhibitor for treatment of circulating cooling water

ActiveCN1621362AEasy to useIncrease the concentration factorScale removal and water softeningPhosphateTungstate

The composite phosphate-free scale inhibiting corrosion inhibitor for treating circular cooling water consists of scale inhibitor and corrosion inhibitor. The scale inhibitor consists of one or several of PASP, PVA, oxidized starch, polyacrylic acid, acrylic acid / acrylate copolymer and acrylic acid / acrylate copolymer with sulfo radical. The corrosion inhibitor consists of one or several of sodium salt / potassium salt / ammonium salt of organic salt, sodium / potassium / ammonium borate, nitrous organic matter, soluble molybdenate, soluble tungstate, soluble nitrate, soluble nitrite and soluble zinc salt. The composite scale inhibiting corrosion inhibitor has excellent scale inhibiting and corrosion inhibiting performance, is environment friendly, and is especially the treatment of hard circulation water with high calcium and high alkali content.

Owner:BEIJING YANHUA XINGYE TECH DEV +1

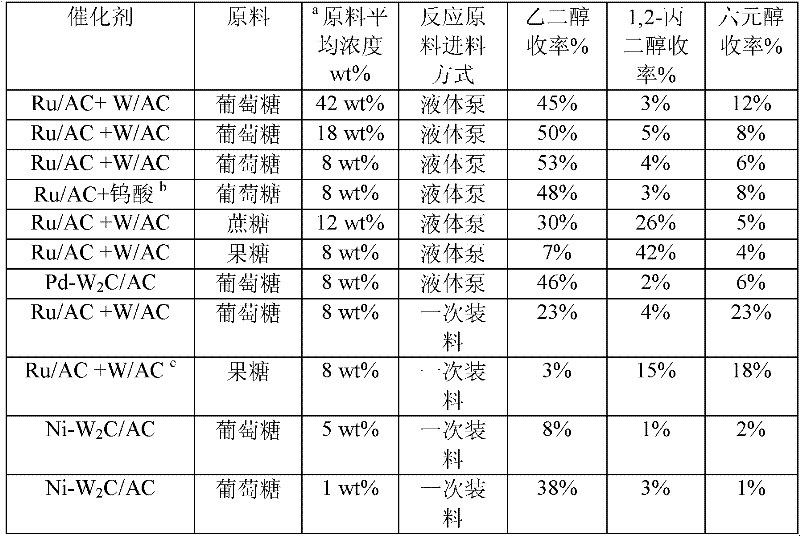

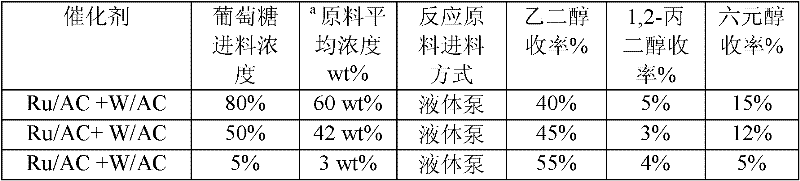

Method for preparing ethylene glycol and 1,2-propylene glycol by using saccharide solution

ActiveCN102675045AIncrease concentrationReduce distillation energy consumptionOrganic compound preparationHydroxy compound preparationHydrogen pressurePolyethylene glycol

The invention provides a method for preparing ethylene glycol and 1,2-propylene glycol by using a high-concentration saccharide solution. Reaction raw materials comprise cane sugar, glucose, fructose, fructosan, xylose, soluble lower polyxylose and soluble starch. According to the method, high-concentration saccharide is used as a reaction raw material, and a high-pressure pump feeding mode is used in a reaction process which is performed in a high-pressure reaction kettle; iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum which serve as transition metal in eighth, ninth and tenth groups are used as hydrogenation active ingredients; the hydrogenation active ingredients form a composite catalyst together with metal tungsten, tungsten carbide, tungsten nitride, tungsten phosphide, tungsten oxide, tungsten sulfide, tungsten chloride, tungsten hydroxide, tungsten bronze, tungstic acid, tungstate, metatungstic acid, metatungstate, paratungstic acid, paratungstate, peroxotungstic acid, peroxotungstate and tungsten-containing heteropolyacid which serve as catalytic active ingredients; and the high-concentration saccharide solution can be efficiently prepared into the ethylene glycol and the propylene glycol at high selectivity and high yield in a one-step catalytic conversion process under the hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13MPa. By the method, the problem of coking of the high-concentration saccharide in the catalytic conversion process can be effectively solved, and high-concentration ethylene glycol and propylene glycol can be prepared by the high-concentration saccharide.

Owner:中科柏易金(郑州)新能源科技有限责任公司

Free radical-forming activator attached to solid and used to enhance CMP formulations

ActiveUS20060117667A1Increased substrate removal rateImprove efficiencyPigmenting treatmentOther chemical processesAluminateOrganic acid

A CMP composition having: a fluid comprising water and at least one oxidizing compound that produces free radicals when contacted with an activator; and a plurality of particles having a surface and comprising at least one activator selected from ions or compounds of Cu, Fe, Mn, Ti, or mixtures thereof disposed on said surface, wherein at least a portion of said surface comprises a stabilizer. Preferred activators are selected from inorganic oxygen-containing compounds of B, W, Al, and P, for example borate, tungstate, aluminate, and phosphate. The activators are preferably ions of Cu or Fe. Surprisingly, as little as 0.2 ppm and 12 ppm of activator is useful, if the activator-containing particles are suspended in the fluid as a slurry. Advantageously, certain organic acids, and especially dihydroxy enolic acids, are included in an amount less than about 4000 ppm. Advantageously, activator is coated onto abrasive particles after the particles have been coated with stabilizer.

Owner:VERSUM MATERIALS US LLC

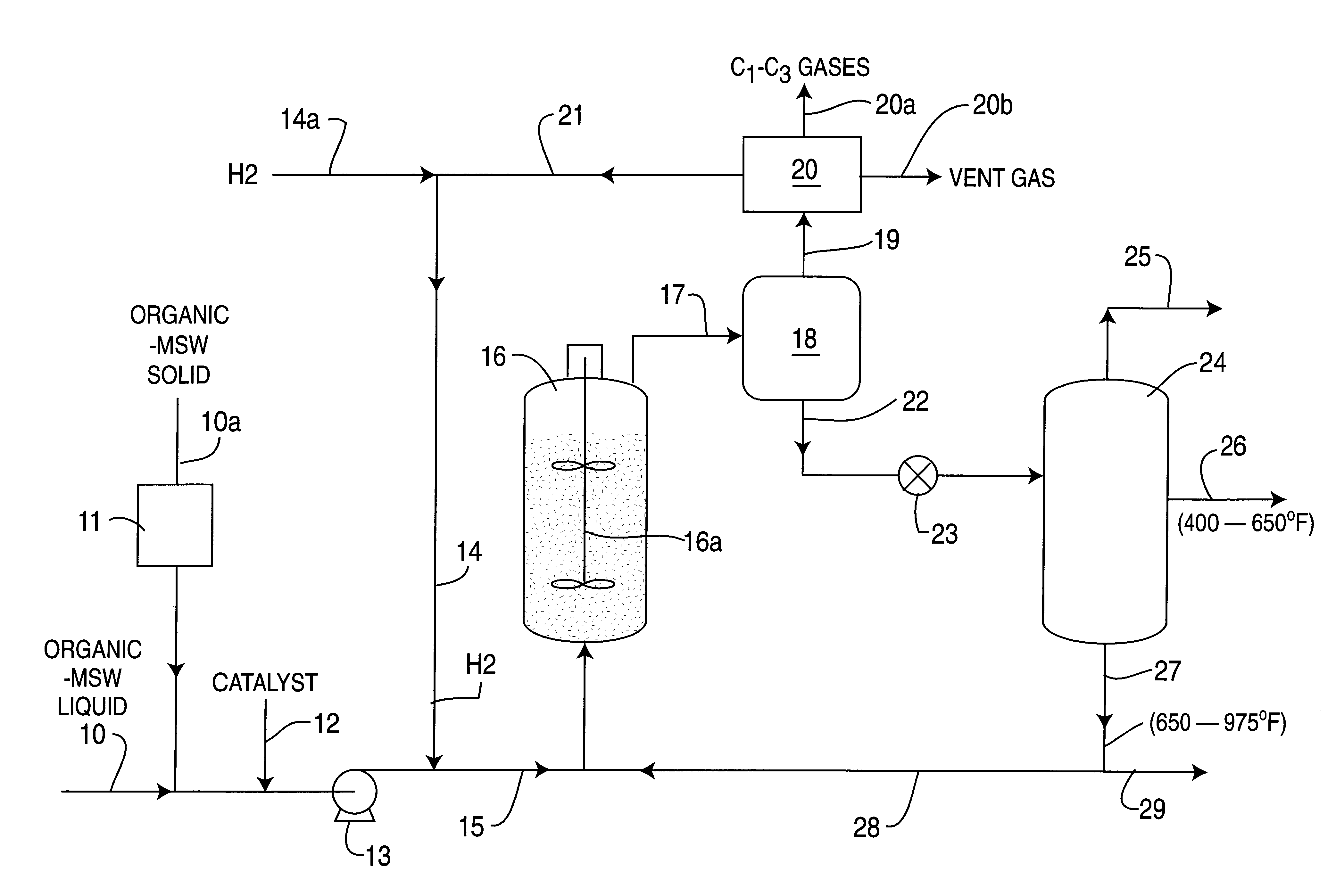

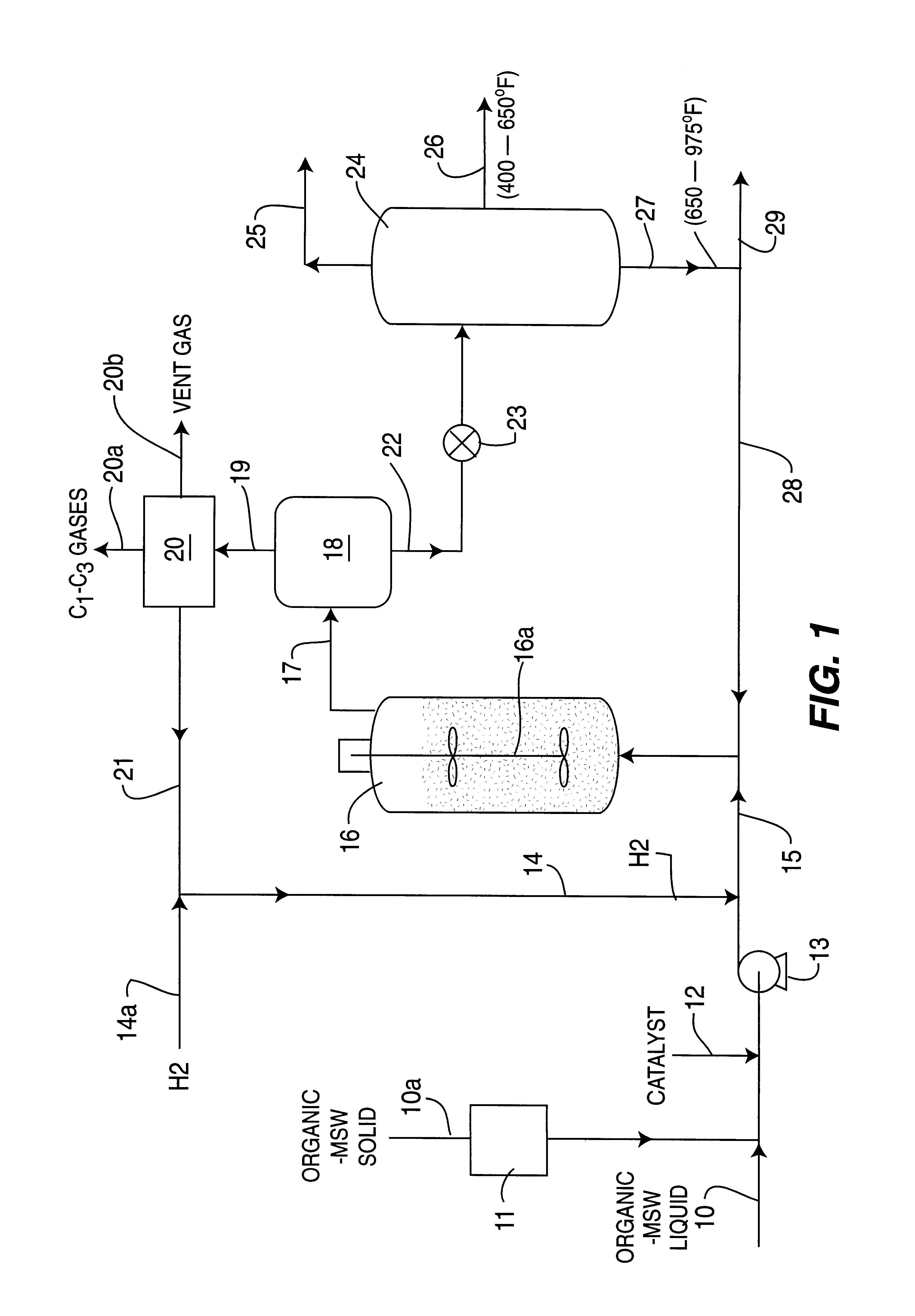

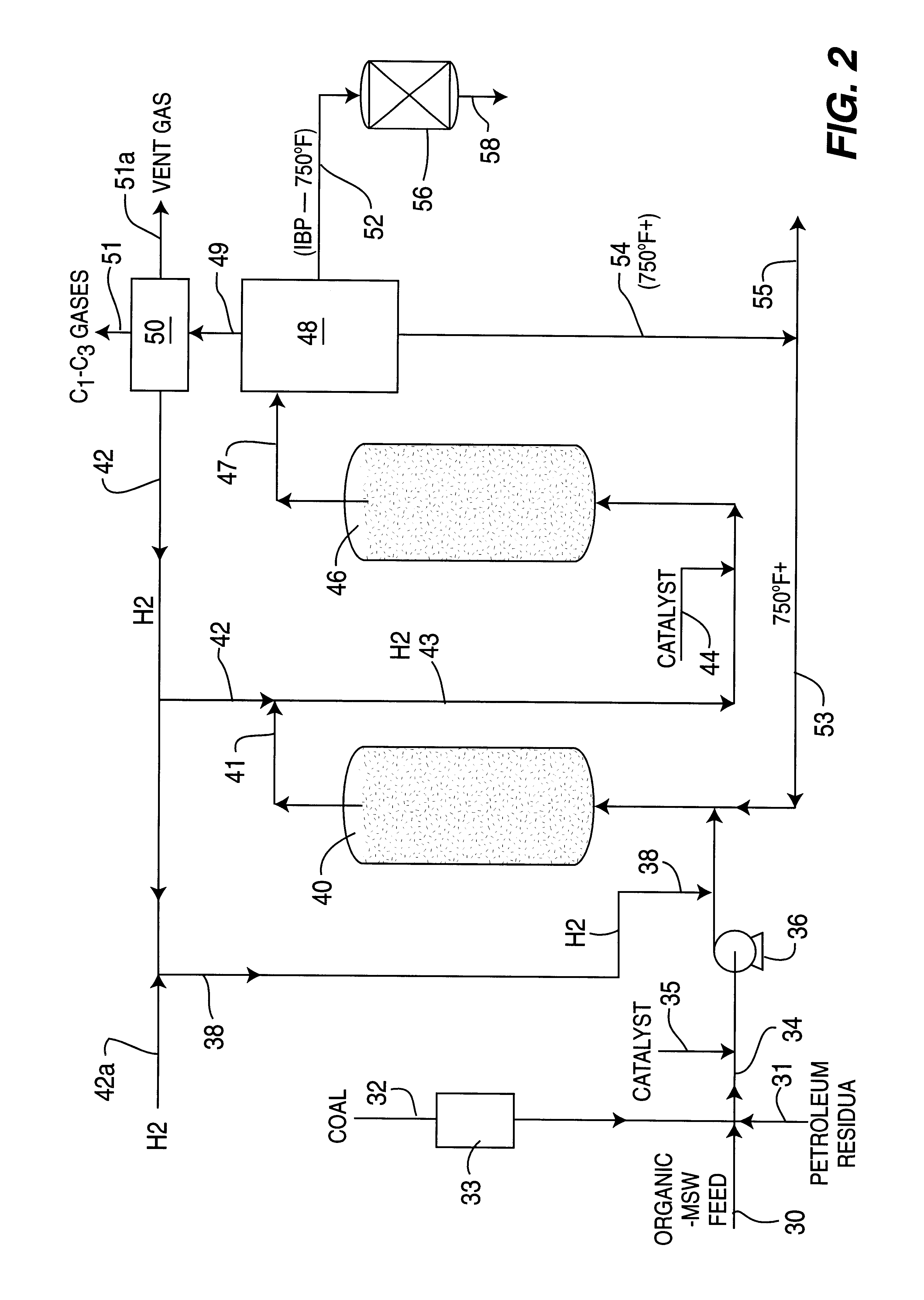

Catalytic hydroconversion of chemically digested organic municipal solid waste materials

InactiveUS6270655B1Increase surface areaReduce total nitrogenLiquid hydrocarbon mixture productionHydrocarbon oil crackingParticulatesLiquid product

A hydrocarbon liquid feedstock containing at least 50 wt. % chemically digested organic-MSW material is catalytically hydroconverted utilizing either a single stage or two-stage catalytic reaction process to produce desirable lower-boiling hydrocarbon liquid products. The catalyst can be either a particulate supported type catalyst such as containing cobalt and / or molybdenum and / or nickel on alumina support, or a dispersed slurry type catalyst containing mainly iron oxide with anions of molybdate, phosphate, sulfate or tungstate, and combinations thereof. Broad useful reaction conditions are 600-860° F. (315-460° C.) temperature, 1000-3000 psi hydrogen partial pressure, and fresh feed rate of 20-60 pounds / hr / ft3 reactor volume. Effluent material from the final stage catalytic reactor is phase separated and the resulting liquid portion is fractionated to produce the desired low-boiling hydrocarbon liquid products particularly useful as transportation fuels. If desired, the chemically digested organic-MSW feedstock can be blended with petroleum residua and / or particulate coal and / or mixed waste plastics and the blended feed material processed in catalytic two-stage reactors to produce similar desirable low-boiling hydrocarbon liquid products.

Owner:HYDROCARBON TECH

Preparation of hydrogenation catalyst

ActiveCN101439289AOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsMolybdateActive component

The invention discloses a preparation method for a hydrogenation catalyst. The metal components of the catalyst comprise one or two metals from Co and Ni as well as one or two metals from Mo and W; carbamide or ammonia is used as a reaction addition agent; a method of reaction in-situ in the hole of a carrier is adopted to lead the metal active components to generate nickel molybdate (cobalt) or nickel tungstate (cobalt) compounds, thereby being capable of avoiding the reaction between the metals and the carrier, simultaneously leading the metal active components to be easier to be sulfurized and being capable of improving the activity of the hydrogenation catalyst.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Non-Phosphorus composite anti incrustation eorrosion snhibiter and its application in water treatment

ActiveCN1785853AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt performanceScale removal and water softeningMolybdatePolyaspartic acid

The present invention relates to a phosphorus-free composite antiincrustation corrosion inhibitor. It includes polyaspartic acid and / or polyepoxysuccinic acid and at least one kind of scale inhibition and dispersion agent, in which the scale inbibition and dispersion agent is polymer containing carboxylic acid group, or it includes polyaspartic acid and / or polyepoxysuccinic acid, zinc salt, molybdate or tungstate and polymer containing carboxylic acid group. Said invention is applicable to treatment of circulating cooling water.

Owner:BEIJING YANHUA PETRO CHEM

Composition used in scale-inhibition corrosion inhibitor, scale-inhibition corrosion inhibitor, and application thereof

ActiveCN103253777AHigh calcium and alkali toleranceGood scale and corrosion inhibitionScale removal and water softeningHigh concentrationTungstate

The invention discloses a composition used in a scale-inhibition corrosion inhibitor, a scale-inhibition corrosion inhibitor, and an application thereof. The composition used in the scale-inhibition corrosion inhibitor comprises cyclodextrin and / or a cyclodextrin derivative, a carboxylic-acid-group-containing homopolymer, a sulfonic-acid-group-containing copolymer, and selectively hydroxycarboxylic acid with a weight ratio of 1:0.2-20:0.04-15:0.2-30:0-20. The scale-inhibition corrosion inhibitor provided by the invention is environment-friendly. According to the invention, the application of phosphorus-containing compound or non-renewable molybdate or tungstate is prevented, such that the scale-inhibition corrosion inhibitor is phosphorus-free and nitrogen-free. The scale-inhibition corrosion inhibitor has high tolerance to calcium and alkali, resistance to corrosion of high-concentration chloride ion and sulfate ion, and wide applicability to water quality. Therefore, technical condition is provided for operation of circulation water under high concentration multiple and for reducing sewage discharge. The scale-inhibition corrosion inhibitor provided by the invention has excellent scale inhibition and corrosion inhibition performances in circulation water system application. With the scale-inhibition corrosion inhibitor, a dose is low, scale-inhibition treatment process is simple and substantial effect is provided. The scale-inhibition corrosion inhibitor is suitable for popularization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for recovering vanadium, tungsten and titanium from waste vanadium-tungsten-titanium-based denitration catalyst

ActiveCN103484678ASimultaneous recoveryLow recovery rateTitanium compoundsVanadium compoundsTungstateAmmonium metavanadate

The invention relates to a method for recovering non-ferrous metals from waste denitration catalysts, particularly relates to a method for recovering vanadium, tungsten and titanium from a waste vanadium-tungsten-titanium-based denitration catalyst, belonging to the field of non-ferrous metal recovery technologies. The method mainly comprises the steps of preparing the catalyst into powder with the grain size being smaller than 100 meshes, and adding concentrated alkali liquor; heating to react vanadium, tungsten and titanium with alkali, so as to produce slightly-soluble titanate, water-soluble vanadate and tungstate; filtrating to obtain a titanate filter cake, wherein titanate or titanic acid can be prepared from the filter cake; adding ammonium salt into a filtrate so as to precipitate ammonium metavanadate, and filtrating to obtain ammonium metavanadate and a new filtrate; adding concentrated acid into the new filtrate, thereby preparing solid tungstic acid. The method has the advantages of simple process, low energy consumption, good solid-liquid reaction contact, high vanadium, tungsten and titanium recovery rate, and the like.

Owner:BEIJING UNIV OF CHEM TECH

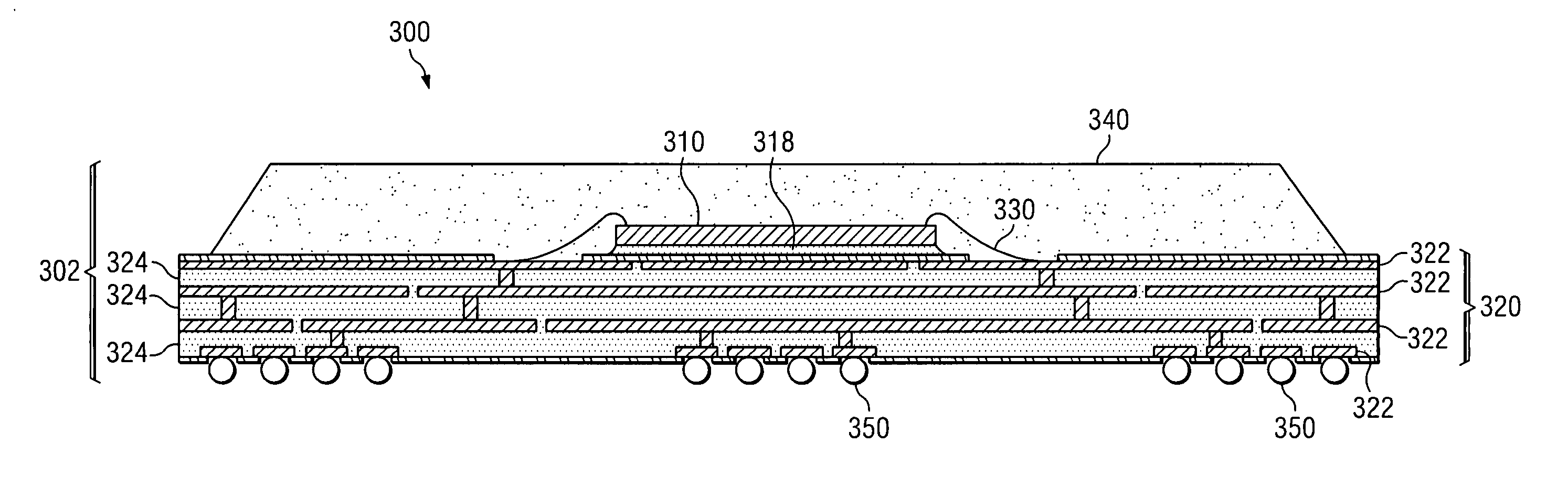

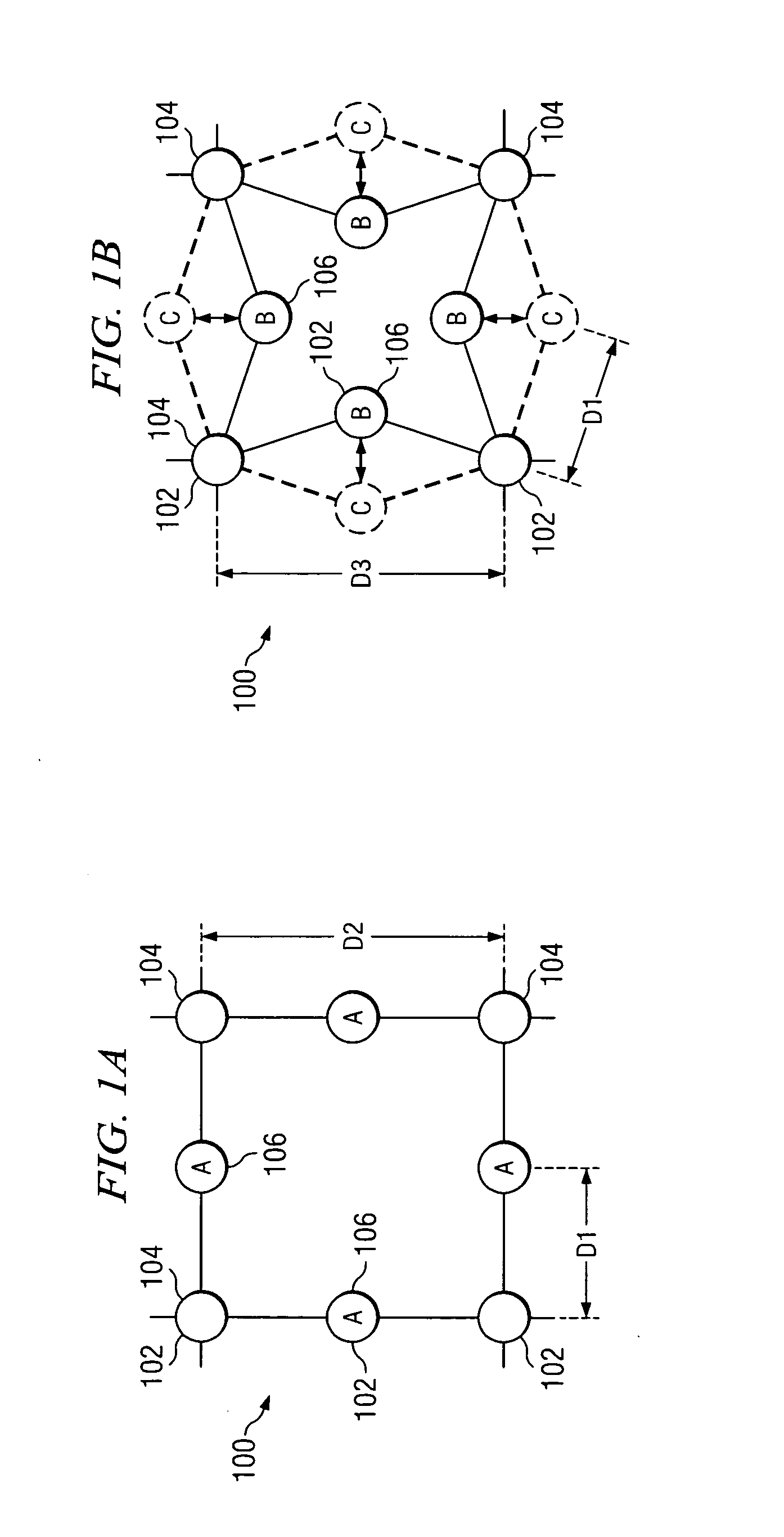

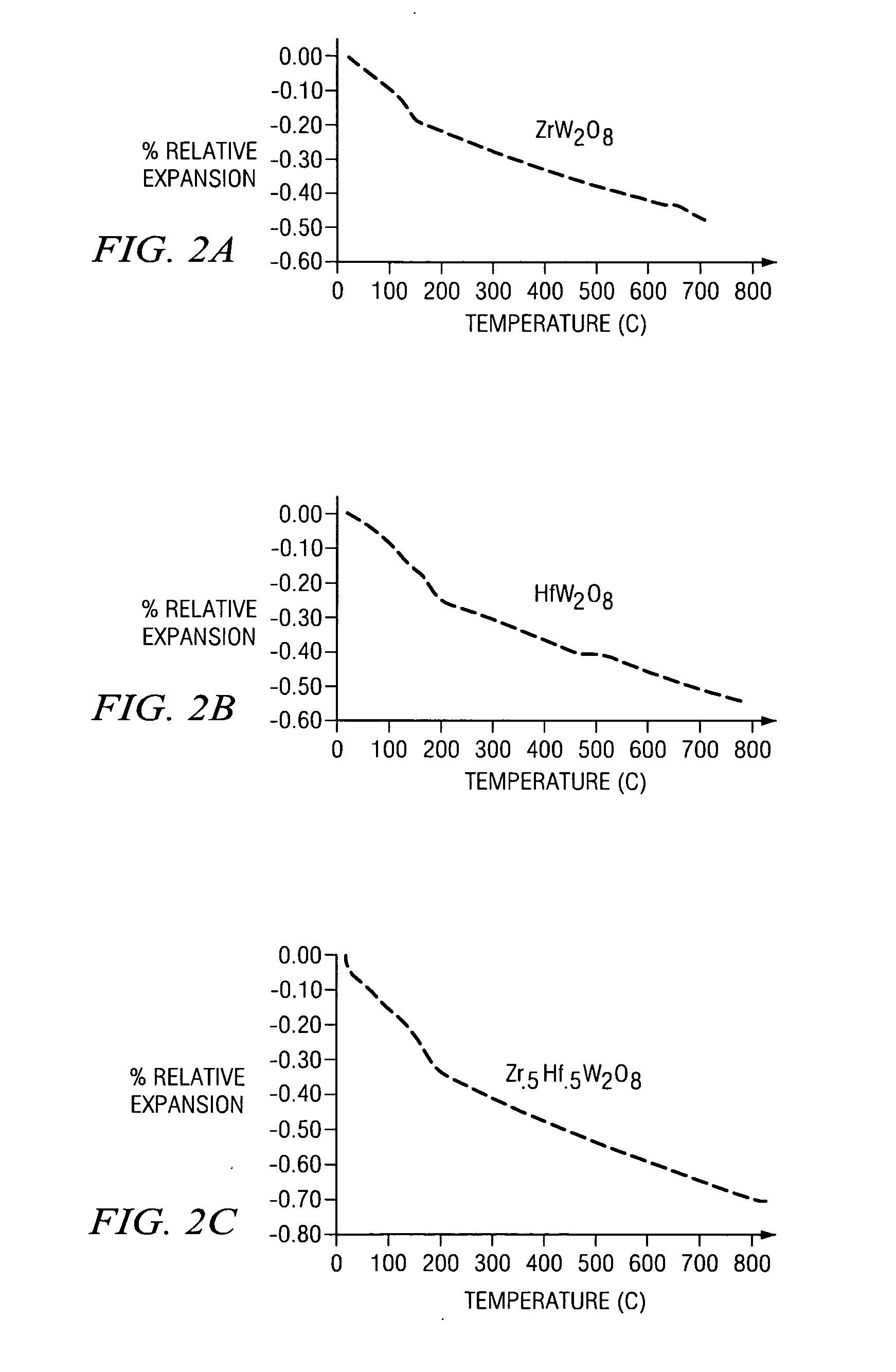

Low coefficient of thermal expansion (CTE) semiconductor packaging materials

InactiveUS20050110168A1Semiconductor/solid-state device detailsSolid-state devicesTungstateSemiconductor package

A low-CTE packaging material for assembling a semiconductor die into a package and a method for assembling a semiconductor die into a package, in which the packaging material comprises a negative-CTE material. The low-CTE packaging material in accordance with the embodiments of the invention may be a die attach material, a lid attach material, or an encapsulant, such as a mold compound or glob-top material. Preferably, the negative-CTE material is a tungstate compound, such as zirconium tungstate, halfnium tungstate or a solution of zirconium and halfnium tungstate.

Owner:TEXAS INSTR INC

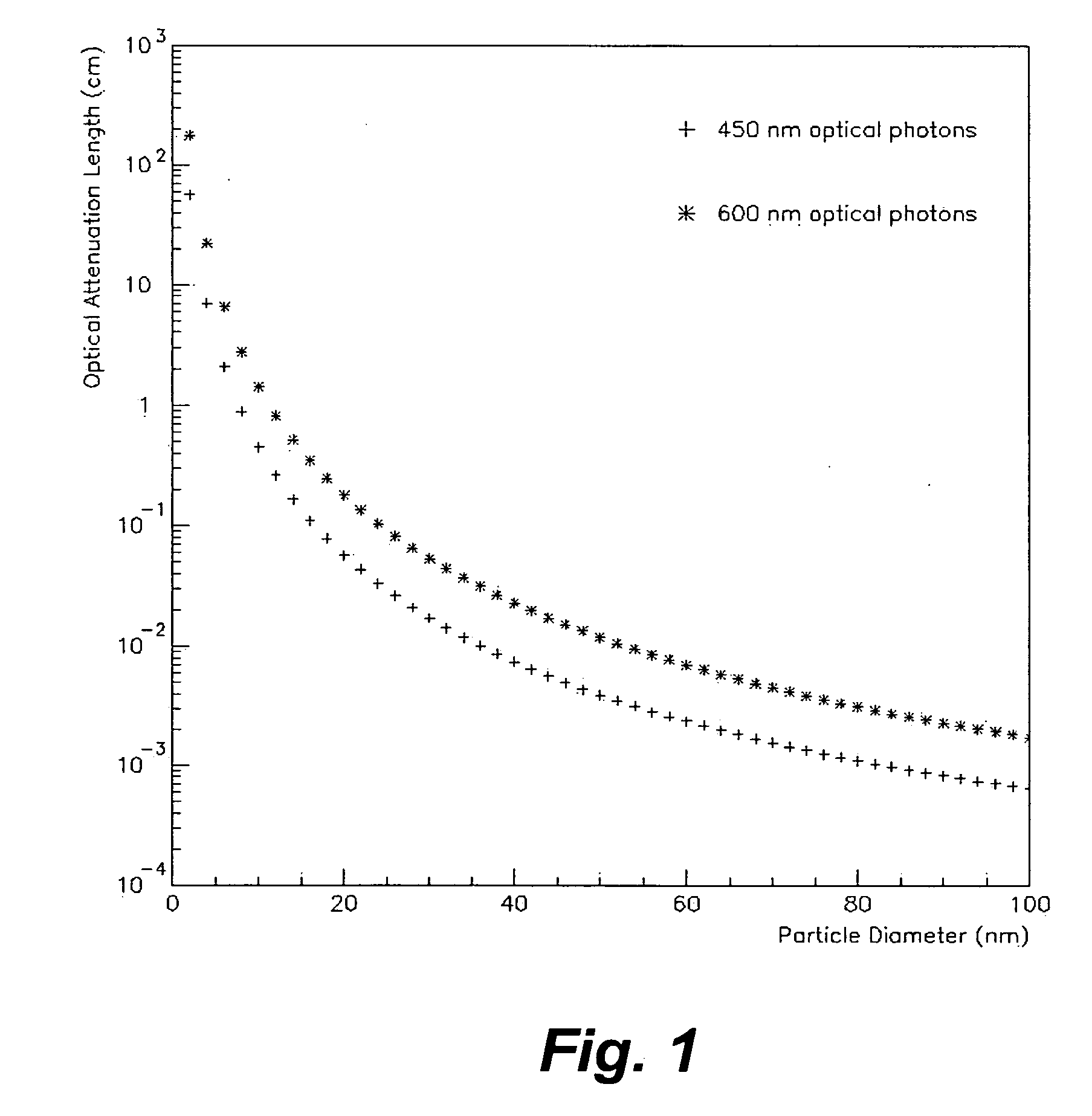

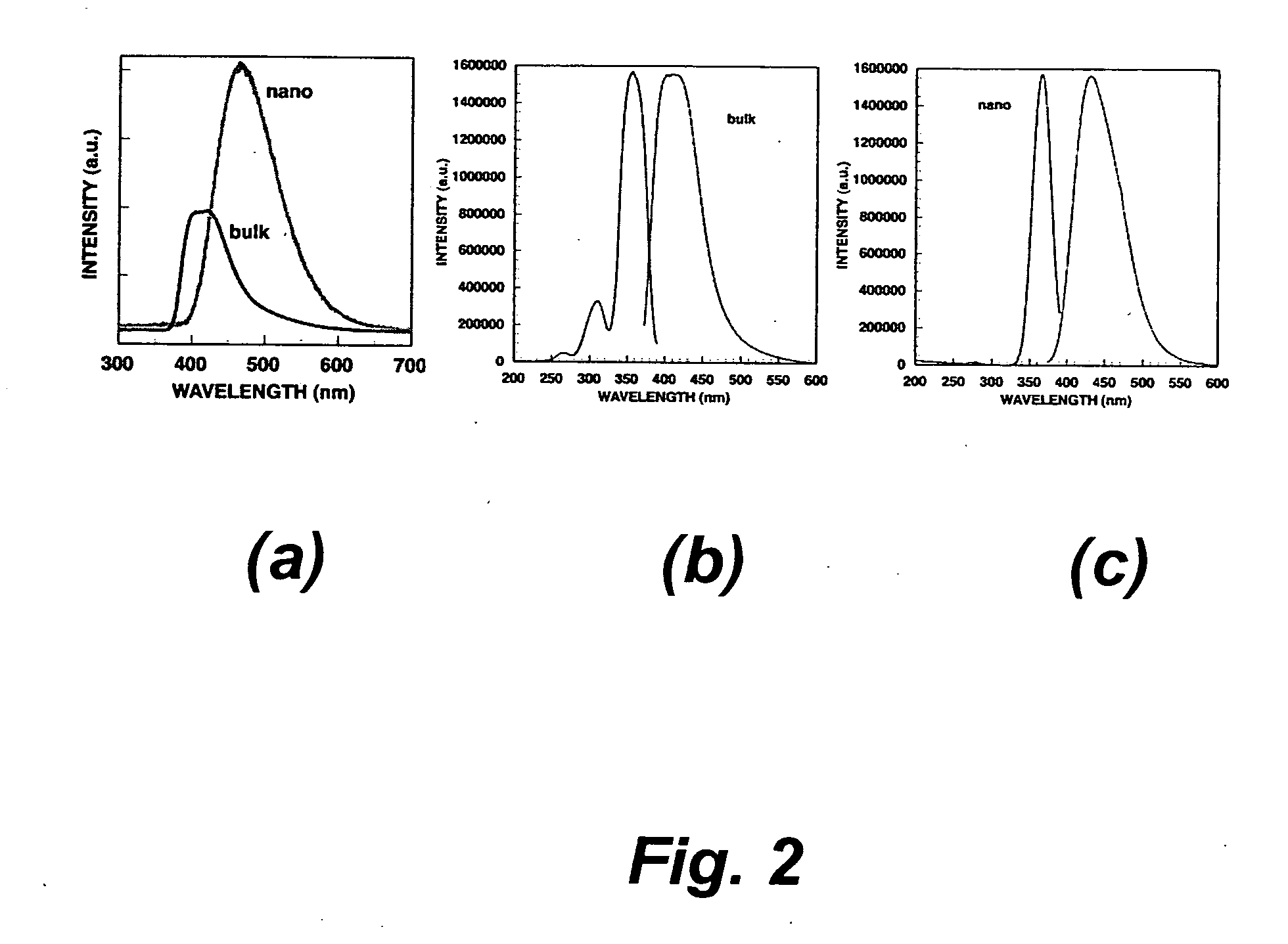

Nanocomposite scintillator, detector, and method

InactiveUS20080093557A1Material analysis by optical meansLuminescent compositionsSodium iodideTungstate

A compact includes a mixture of a solid binder and at least one nanopowder phosphor chosen from yttrium oxide, yttrium tantalate, barium fluoride, cesium fluoride, bismuth germanate, zinc gallate, calcium magnesium pyrosilicate, calcium molybdate, calcium chlorovanadate, barium titanium pyrophosphate, a metal tungstate, a cerium doped nanophosphor, a bismuth doped nanophosphor, a lead doped nanophosphor, a thallium doped sodium iodide, a doped cesium iodide, a rare earth doped pyrosilicate, or a lanthanide halide. The compact can be used in a radiation detector for detecting ionizing radiation.

Owner:RGT UNIV OF CALIFORNIA

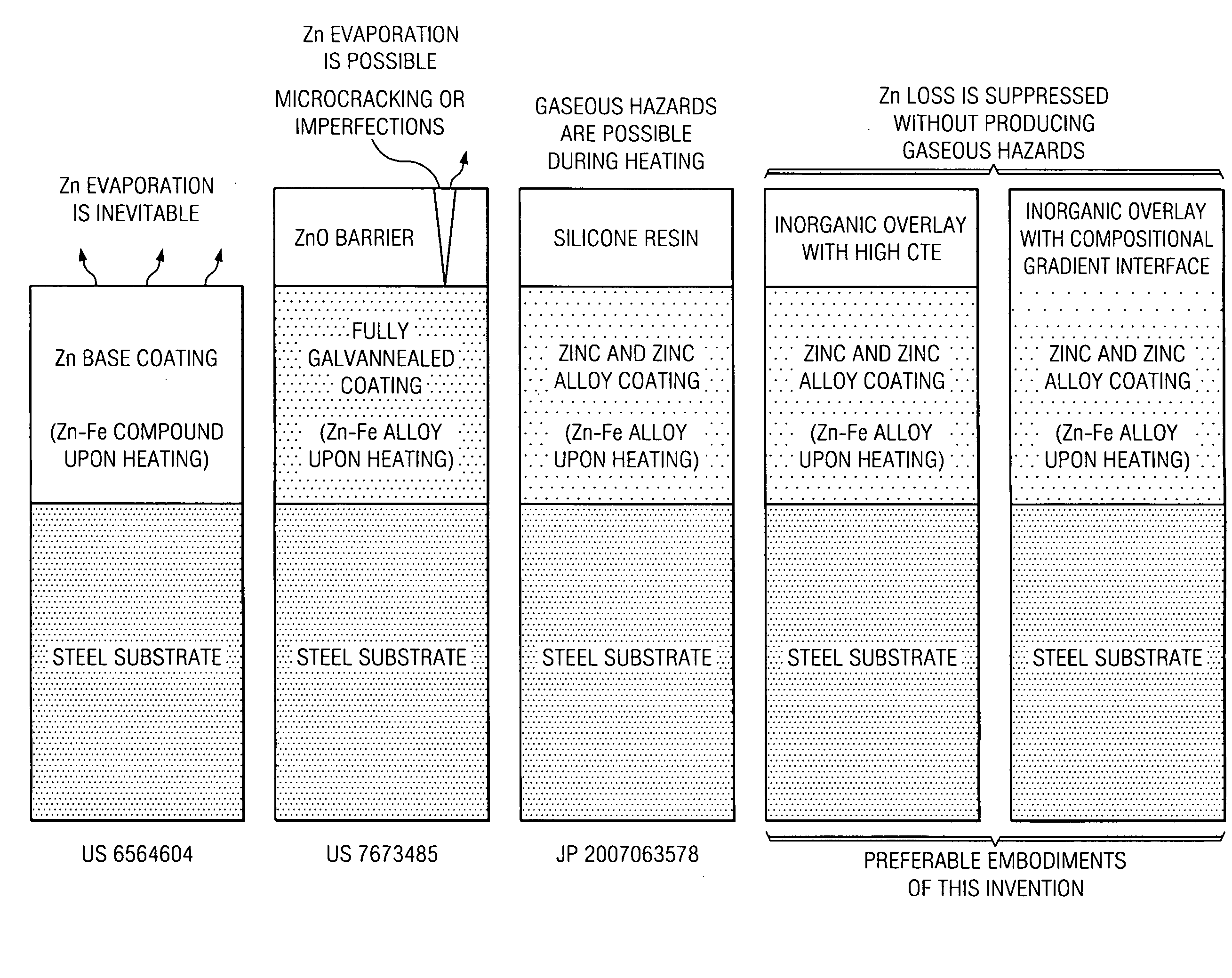

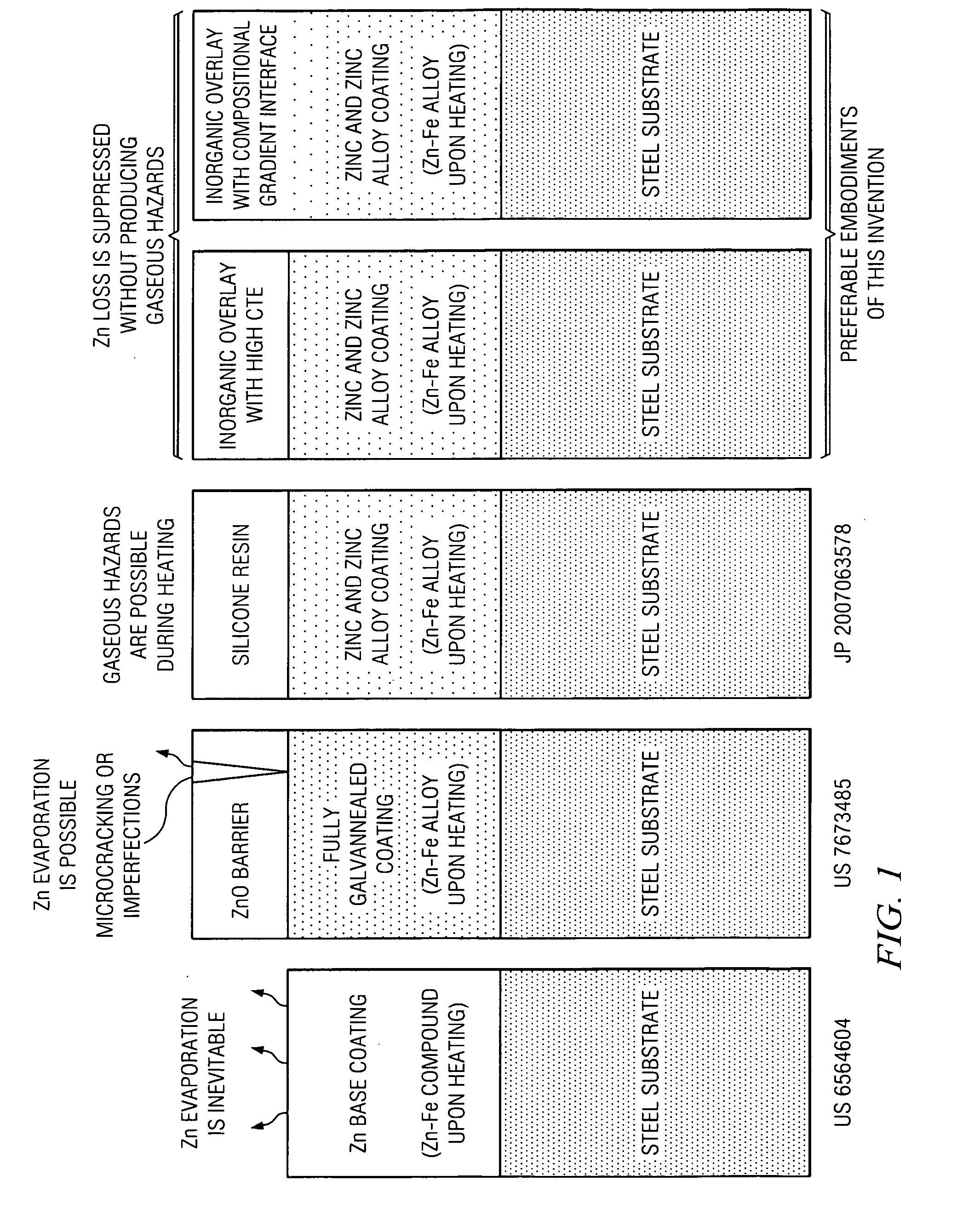

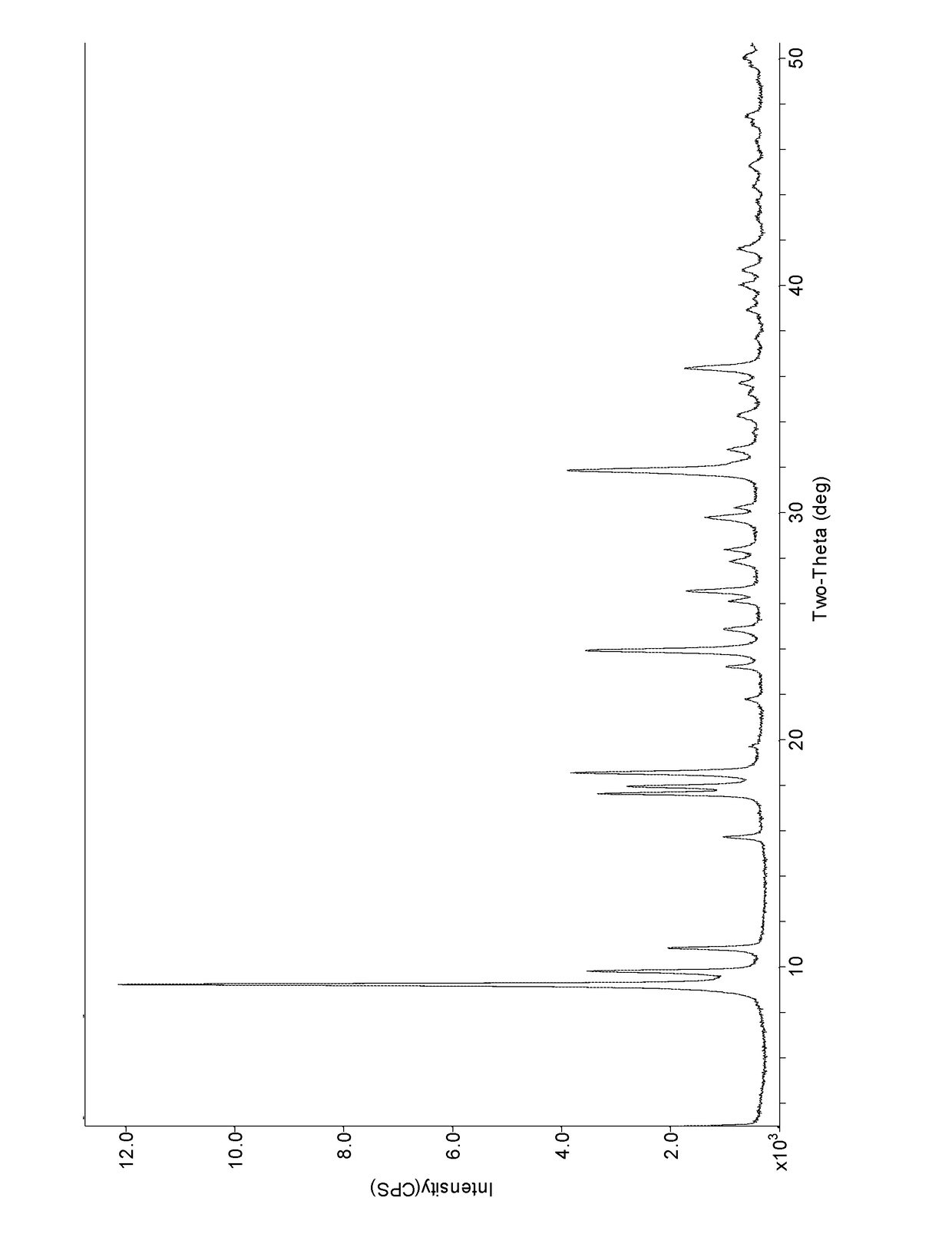

Zinc coated steel with inorganic overlay for hot forming

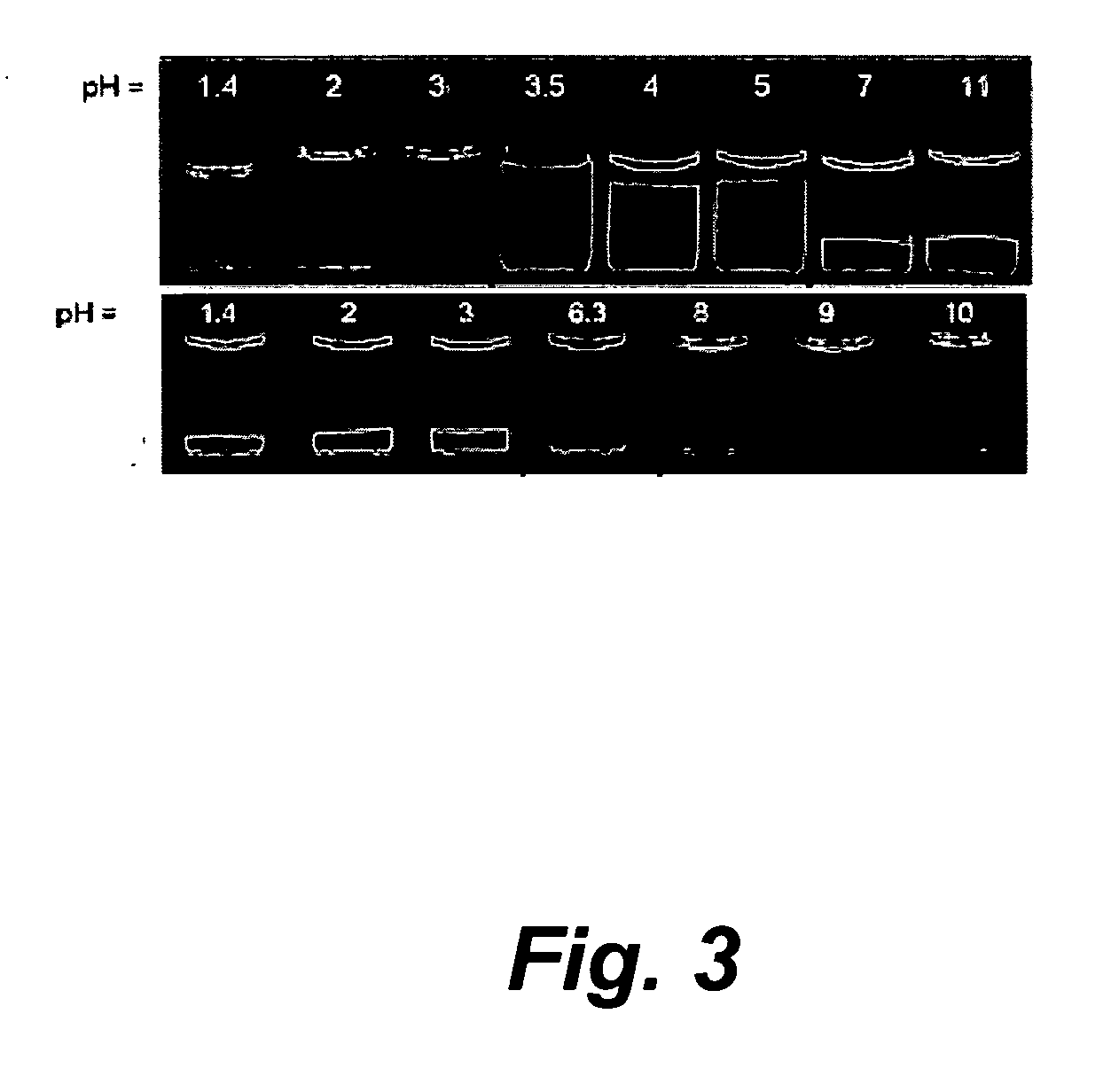

InactiveUS20120118437A1Retard and restrict lossReduce hardnessHot-dipping/immersion processesPretreated surfacesTungstatePhosphate

The present invention is of zinc or zinc alloy coated steel for hot forming having an inorganic overlay covering the zinc or zinc alloy coating to prevent loss of zinc during heating and hot forming. In one embodiment, the inorganic overlay has a coefficient of thermal expansion greater than the coefficient of thermal expansion of zinc oxide. In another embodiment, the inorganic overlay has a compositional gradient interface with the zinc or zinc alloy coating. Preferably the inorganic overlay may be comprised of material selected from phosphates, oxides, nitrates, carbonates, silicate, chromate, molybdate, tungstate, vanadate, titanate, borate, fluoride and mixtures thereof. A method of preparing the steel for hot forming and a method for hot forming the steel are provided.

Owner:WANG JIAN +1

Crystalline transition metal tungstate

ActiveUS20170165650A1Catalyst activation/preparationHydrocarbon oil crackingTungstateHydrodesulfurization

A hydroprocessing catalyst has been developed. The catalyst is a unique transition metal tungstate material. The hydroprocessing using the crystalline ammonia transition metal dimolybdotungstate material may include hydrodenitrification, hydrodesulfurization, hydrodemetallation, hydrodesilication, hydrodearomatization, hydroisomerization, hydrotreating, hydrofining, and hydrocracking.

Owner:UOP LLC

Preparation method of structured flue gas denitration catalyst, prepared catalyst and application of catalyst

ActiveCN102166514AReduce oxidation rateHigh mechanical strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTungstateNitric oxide

The invention relates to a preparation method of structured flue gas denitration catalyst, a prepared catalyst and application of the catalyst. The method comprises the following steps of: pre-mixing TiO2 powder and ammonium meta-tungstate-containing oxalic acid solution to prepare WO3-containing TiO2 powder; mixing the prepared TiO2 powder, an inorganic binder, a plasticizer, glass fibers and sesbania powder in a special mass ratio; adding oxalic acid solution of ammonium metavanadate and aqueous solution of cerous nitrate; mixing the materials; adding ammonia water to adjust the pH value tobetween 9 and 10; ageing the mixture for 5 to 10 days; coating the aged mud material onto a stainless steel net; after rolling the aged mud, forming, and drying and roasting the prepared plate type structural V2O5 / TiO2-based denitration catalyst. The plate type structural V2O5 / TiO2-based denitration catalyst has high mechanical strength and catalytic activity and low SO2 oxidation rate, so the catalyst can be widely applied to the removal of nitric oxide in coal / oil / gas boilers and nitric acid industry.

Owner:CHINA DATANG TECH & ENG

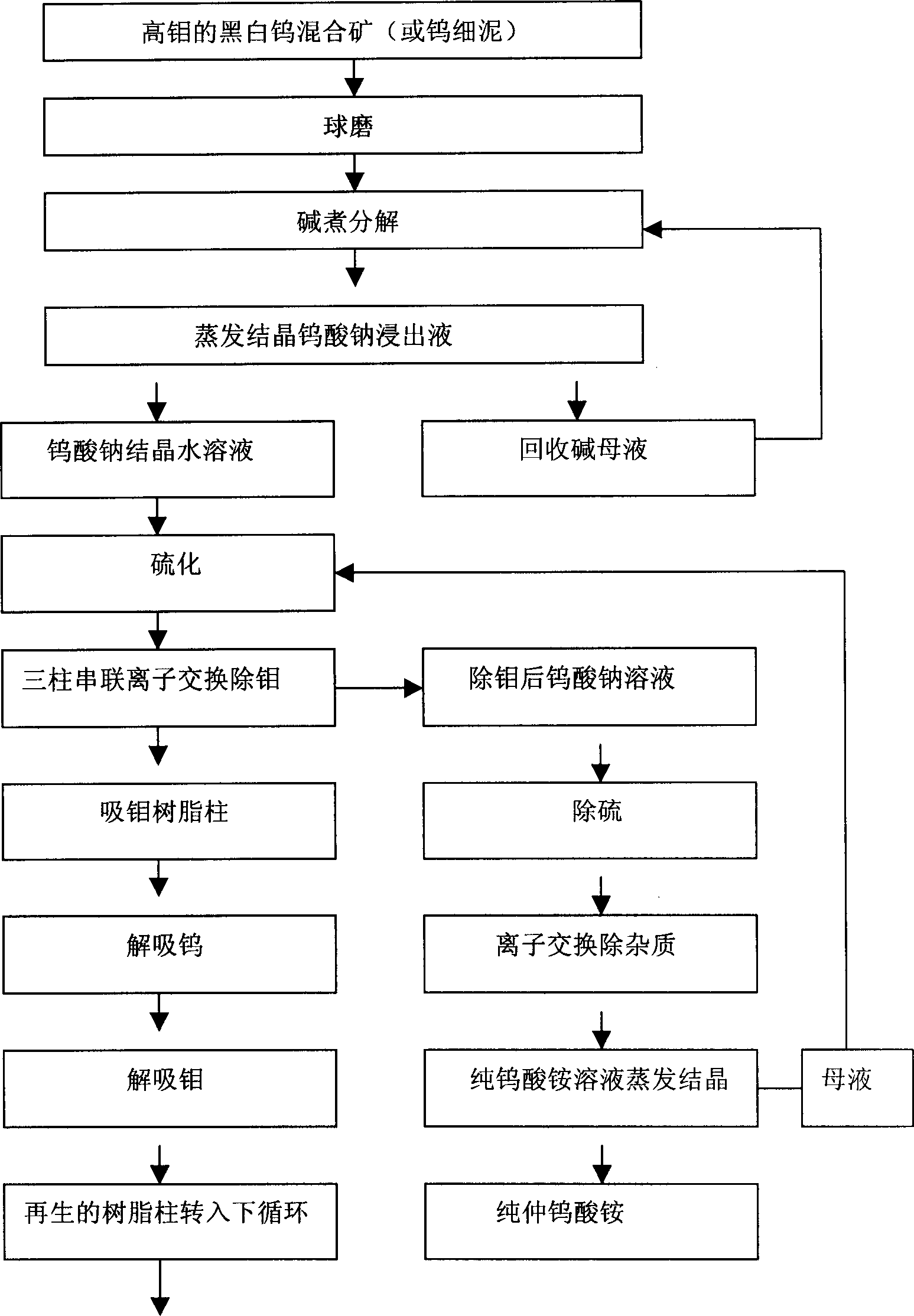

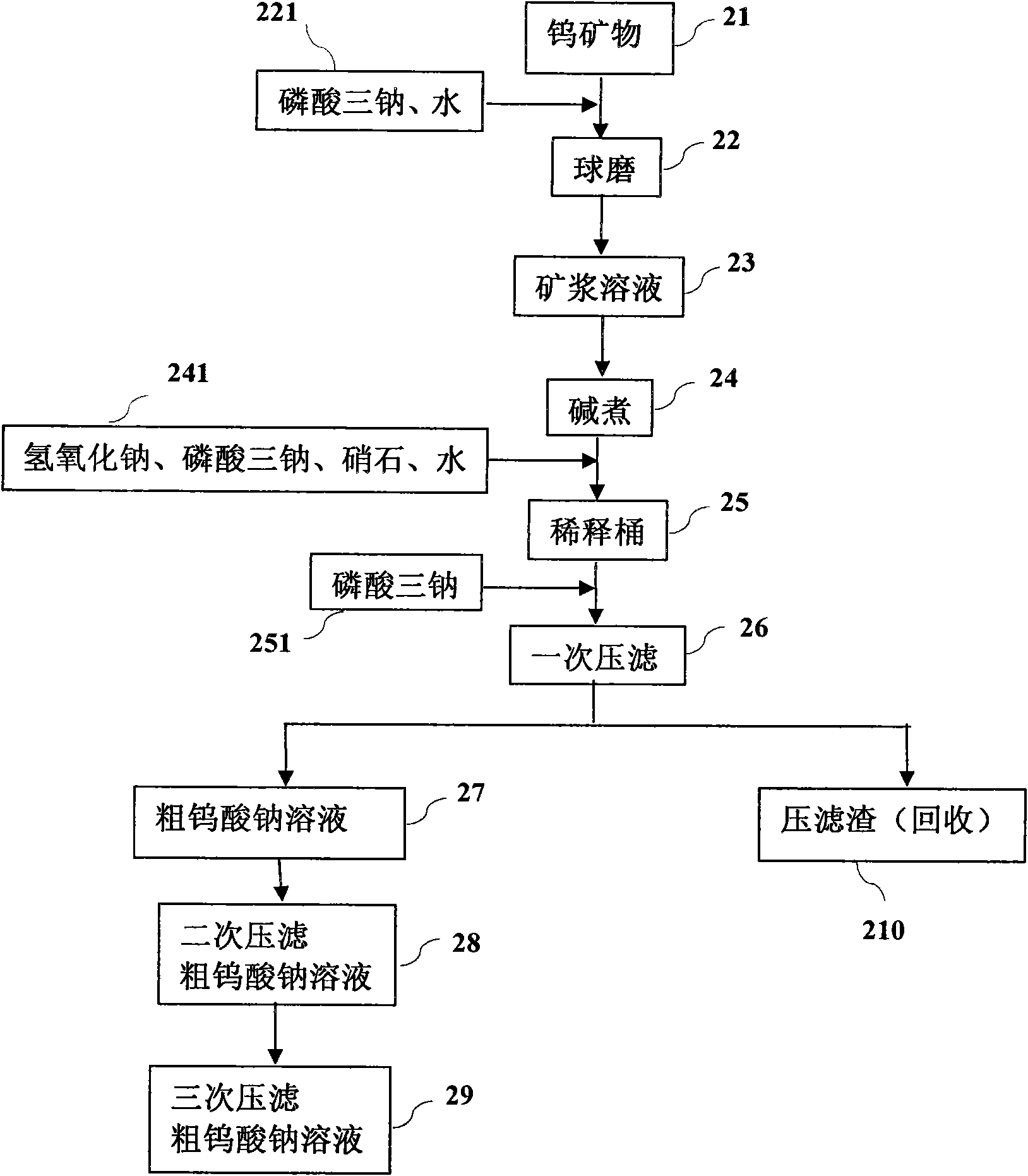

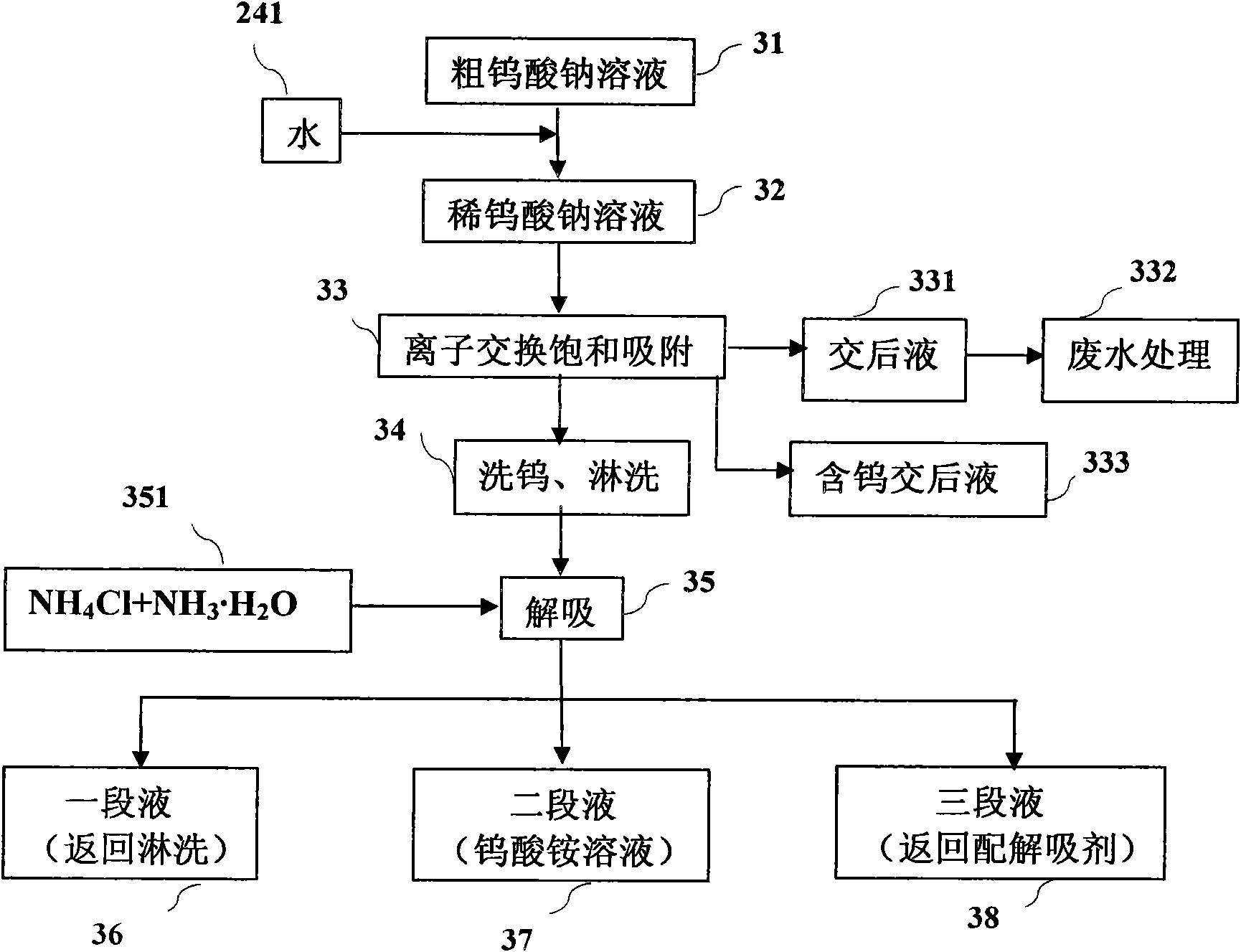

Process for preparing high purity ammonium para-tungstate using hihg-molybdenum tungsten ore

The present invention provides a method of treating high-molybdenum tungsten mineral or tungsten slime by means of three-ion column exchange molybdenum-eliminating technology so as to obtain ammoniumpara-tungstate with high purity at low cost. The treating process includes grinding, alkali leaching, filtering and concentration to obtain sodium tungstate crystal; water dissolving, filtering and sulfurizing sodium tungstate; ion exchange to eliminate molybdenum; desulfurizing sodium tungstate liquid; ion exchange to elimiante impurity and desorbing tungsten with ammonia water and ammonium chloride solution to prepare ammonium tungstate solution; and evaporation to obtain ammonium para-tungstate crystal. The present invention has low cost.

Owner:王旭升 +1

Method for separating and extracting tungsten-molybdenum from mixed solution of tungstate-molybdate

InactiveCN101880780AEfficient separationRealize recyclingProcess efficiency improvementMagnesium saltDecomposition

Owner:CENT SOUTH UNIV

Method for treating low-grade tungsten concentrate and tungsten slag

ActiveCN103614545AImprove resource utilization efficiencyAchieve selective separationMagnetic separationProcess efficiency improvementNiobiumSlag

The invention discloses a method for treating low-grade tungsten concentrate and tungsten slag. The method comprises the steps of mixing low-grade tungsten concentrate or tungsten slag and coal powder with a reduction roasting enhancer, and then performing reduction roasting; grinding the product obtained through the reduction roasting, then performing neutral leaching to obtain a tungstate solution and leaching residues, and performing magnetic separation on the leaching residues by adopting a magnetic field so as to obtain iron concentrate and valuable metal tailings; removing silicon from the valuable metal tailings by using dilute hydrochloric acid and leaching out manganese from the valuable metal tailings by using concentrated hydrochloric acid in sequence, and then leaching out tantalum and niobium by using hydrofluoric acid to prepare tantalum and niobium products. By adopting the method, valuable elements including tungsten, iron, copper, manganese, bismuth, cobalt, tantalum, niobium and the like which are difficult to extract in the low-grade tungsten concentrate and tungsten slag can be efficiently enriched, separated and recovered effectively, so that the resource comprehensive utilization of the valuable elements in the low-grade tungsten concentrate or tungsten slag is realized; moreover, the method is simple in equipment, short in flow, simple and convenient in operation, is economical and reliable, and is favorable for industrial production.

Owner:CENT SOUTH UNIV

Crystalline transition metal molybdotungstate

ActiveUS20170165652A1Heterogenous catalyst chemical elementsCatalyst activation/preparationTungstateHydrodesulfurization

A hydroprocessing catalyst has been developed. The catalyst is a unique transition metal tungstate material. The hydroprocessing using the crystalline transition metal molybdotungstate material may include hydrodenitrification, hydrodesulfurization, hydrodemetallation, hydrodesilication, hydrodearomatization, hydroisomerization, hydrotreating, hydrofining, and hydrocracking.

Owner:UOP LLC

Method for preparing rare-earth oxide dispersion strengthened fine-grained tungsten material

ActiveCN105518169AGood compatibilityEvenly distributedTransportation and packagingMetal-working apparatusRare-earth elementTungstate

A method for preparing a rare-earth oxide dispersion strengthened fine-grained tungsten material, comprising: according to a condition that a mass percentage of rare-earth oxide is 0.1-2%, and the remaining composition is W, weighing soluble rare-earth salt and tungstic acid salt, and respectively preparing 50-100 g / L of rare-earth saline solution and 150-300 g / L of tungstic acid saline solution; adding a minor amount of alkali into the rare-earth salt to control the pH to be 7-8, adding an organic dispersing agent, and stirring to enable the rare-earth salt to form uniformly suspending R(OH)3 colloidal particles (R represents a rare-earth element); adding the tungstic acid saline solution into the R(OH)3 colloidal particles, adding a minor amount of acid to control the pH to be 6-7, adding the organic dispersing agent, stirring to enable the tungstic acid salt to form tungstic acid micro-particles, precipitating and coating the R(OH)3 colloidal particles with the R(OH)3 colloidal particles as a core, and forming coprecipitated coated colloidal particles; conducting spray drying on the coprecipitated coated colloidal particles to obtain a composite precursor powder of tungsten and rare-earth oxide; calcining, conducting thermal reduction via hydrogen, and preparing superfine nanometer tungsten powder having a particle size of 50-500 nm; and conducting normal high-temperature sintering after a general pressing forming. The high-performance fine-grained tungsten material dispersed and strengthened by a minor amount of rare-earth oxide prepared by the above method has a density approximate to full density (>=98.5%), and uniform and small tungsten grains having an average size of 5-10 [mu]m; in addition, rare-earth oxide particles having a particle size of 100 nm - 500 nm are uniformly distributed in a tungsten crystal or a crystal boundary.

Owner:长沙微纳坤宸新材料有限公司

Method for separating tungsten and molybdenum

ActiveCN105200246AEasy to separateThe operation process is easy to controlProcess efficiency improvementTungstateIon-exchange resin

The invention relates to a method for separating tungsten and molybdenum. The method comprises the following steps: (1) adding acid into a tungsten-molybdenum mixed solution and adjusting pH value to obtain mixed sediment of tungsten acid and molybdenum acid; (2) adding hydrogen peroxide and acid into the mixed sediment to form peroxide tungsten acid and peroxide molybdenum acid; (3) heating an obtained mixed solution, adding tungsten powder, reacting and filtering to obtain tungsten acid sediment and a molybdenum-containing acid solution; (4) calcining the prepared tungsten acid to prepare tungsten trioxide or dissolving by using ammonium hydroxide to obtain an ammonium tungstate solution and then evaporating and crystallizing to prepare APT; (5) extracting the molybdenum in the obtained molybdenum-containing acid solution by using an extraction agent / ion exchange resin; and (6) reversely extracting molybdenum-containing organic phase / resin by using ammonium hydroxide to obtain the ammonium molybdate solution, and carrying out acid precipitation to obtain ammonium tetramolybdate. The production process of tungsten-molybdenum products is taken into account in the method, so that the separated tungsten acid or molybdenum can be directly used for preparing the products thereof; the separation effect is excellent; the operation process is simple and is liable to control; the industrial popularization and application are liable to implement.

Owner:CENT SOUTH UNIV

Method for extraction and separation of tungsten and molybdenum from tungsten and molybdenum mixed solution

ActiveCN102876906AOvercoming Difficult Phase Splitting ProblemsOvercoming the problem of large loss in tungsten co-extractionProcess efficiency improvementTungstateDiluent

The invention provides a method for extraction and separation of tungsten and molybdenum. Hydrogen peroxide is filled in the tungsten and molybdenum mixed solution, the pH value is regulated to be acidic, and the acid tungsten mixed solution is taken as a water phase feed liquid to carry out extraction and separation with an organic phase. The organic phase comprises trialkylphosphine oxide, tributyl phosphate and a diluting agent; the organic phase conducts the multi-stage extraction with the water phase feed liquid, molybdenum is extracted into the organic phase, and tungsten is left in a raffinate, so that the separation of tungsten and molybdenum is achieved. The load-bearing organic phase adopts an alkaline back-extraction agent to carry out back-extraction to obtain a molybdenum-contained solution, and the organic phase subjected to the back-extraction returns to the extraction process. Tungsten and molybdenum are extracted and separated in the tungsten and molybdenum mixed solution containing H2O2 by adopting a novel binary mixture extracting agent, the method has the advantages that extraction and the back-extraction are high in split-phase speed, the separation effect of tungsten and molybdenum is good, the tungsten co-extraction loss is low, the loss of the organic phase as well as the environmental pollution is low, the industrialization is easy to realize, and the method is especially suitable for separating tungsten and molybdenum in the tungstate solution with high molybdenum content.

Owner:CENT SOUTH UNIV +1

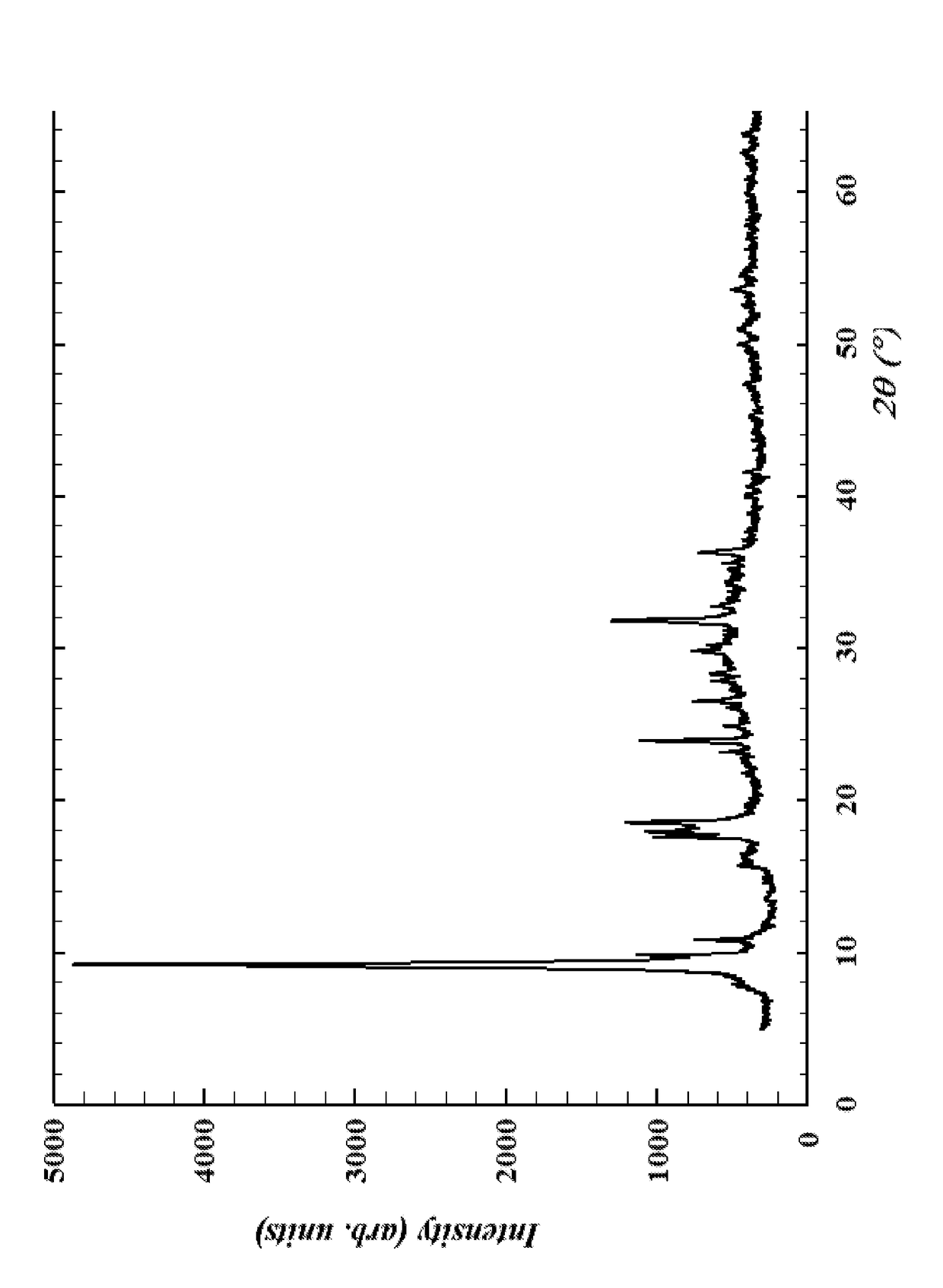

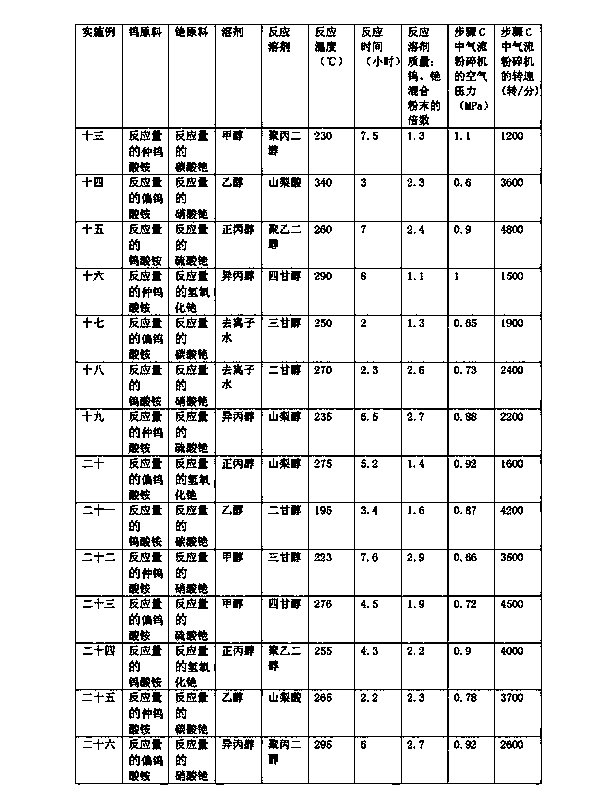

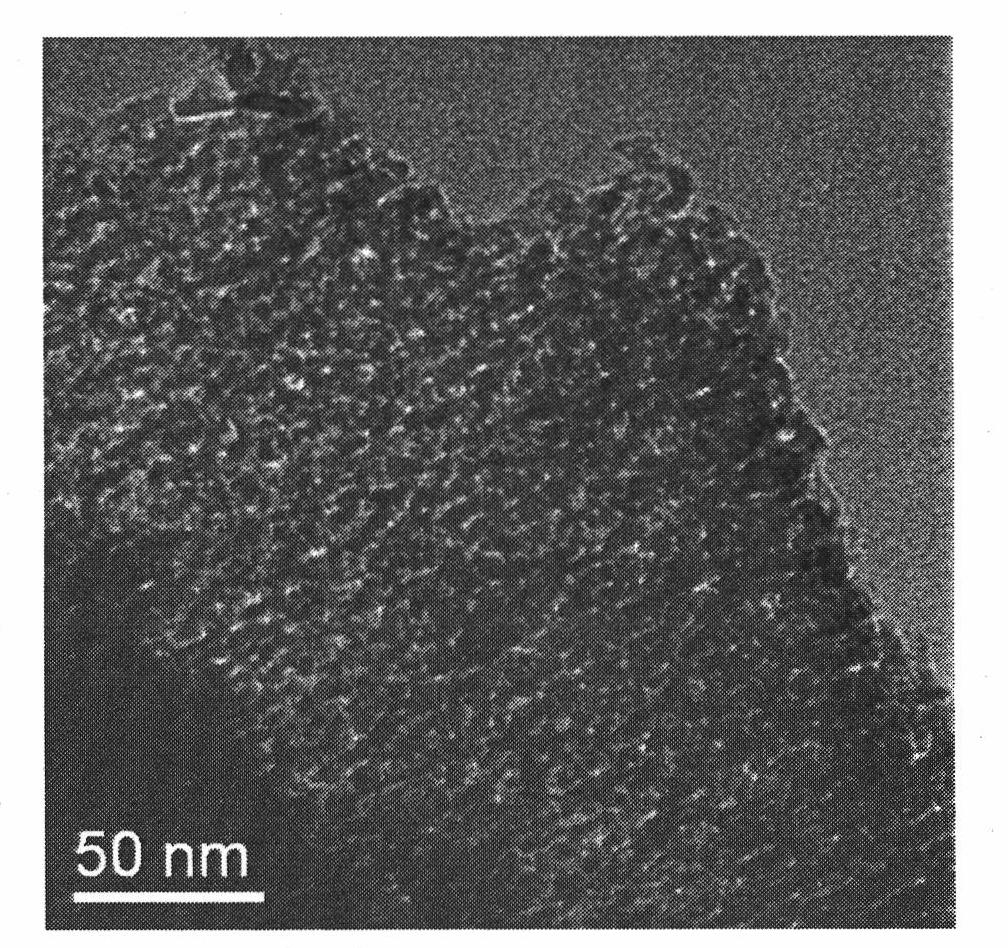

Preparation method of cesium tungstate nanopowder

ActiveCN104192910ALow degree of reunionIncrease productivityMaterial nanotechnologyTungsten compoundsTungstatePhysical chemistry

The invention discloses a preparation method of cesium tungstate nanopowder. The preparation method comprises the following steps of A, dissolving reacting doses of tungsten raw materials and cesium carbonate raw materials into a solvent, drying the solution to obtain particles, and further smashing the obtained particles to obtain tungsten and cesium mixed powder; B, placing the tungsten and cesium mixed powder into a sealed reaction kettle with a stirring function, adding a reaction solvent in the sealed reaction kettle, and reacting at the temperature of 180-350 DEG C for 2-8h while stirring, wherein the mass of the reaction solvent is 1-3 times as mush as that of the tungsten and cesium mixed powder; and C, separating the reaction product obtained in the step B, washing by using deionized water or ethanol, then, drying, and milling by using a jet mill to obtain a target product, namely the cesium tungstate nanopowder. The cesium tungstate nanopowder prepared by using the preparation method is low in agglomeration degree; and the preparation method is high in production efficiency and low in cost.

Owner:宁波今心新材料科技有限公司

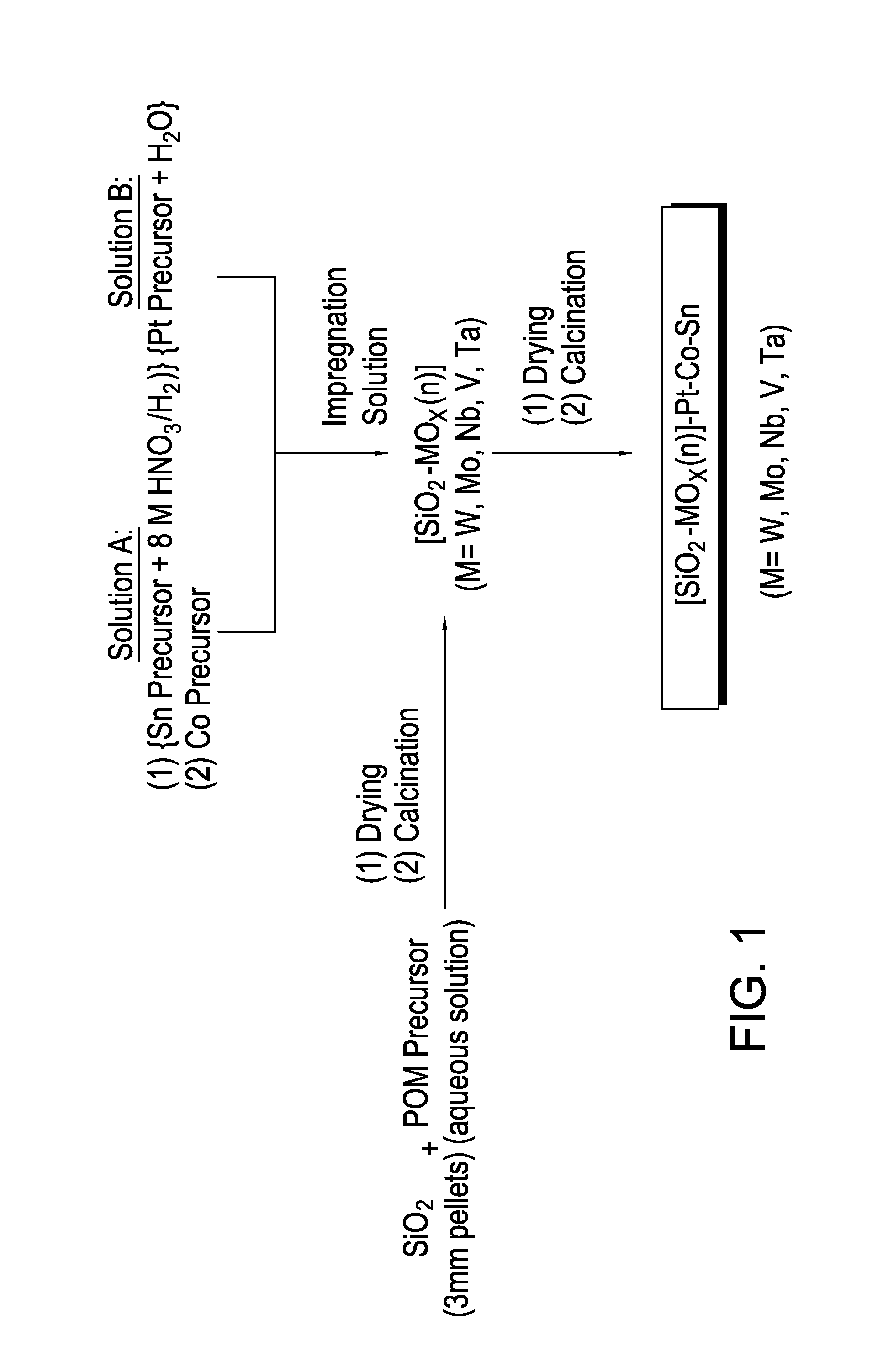

Method for preparing denitration catalyst

InactiveCN102357359AImprove conversion rateGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystTungstate

The invention discloses a preparation method of a denitration catalyst. The method comprises the following steps: (1) with an intermediate product of metatitanic acid from a titanium dioxide factory as a raw material, washing with dilute nitric acid, weak aqua ammonia, deionized water respectively to remove impurity ions so as to prepare metatitanic acid slurry; (2) orderly adding ammonium tungstate, ammonium molybdate and ammonium metavanadate into the metatitanic acid slurry, beating the mixture by ultrasonic wave, adjusting the pH of the slurry to 4.0-6.5 by an acid; (3) allowing the mixed slurry to stand, drying to obtain the catalyst powder; (4) compacting and molding the catalyst powder into honeycomb by a mold, performing heat treatment at 200-600 DEG C for 4-10 hours to obtain the denitration catalyst of the invention. The method for preparing the denitration catalyst of the invention has low cost and simple process, and the denitration catalyst can increase the conversion rate of NO. The denitration catalyst of the invention can realize a conversion rate of NO in power plant flue gas flue gas components of up to above 97% at a reaction temperature of 350 DEG C.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

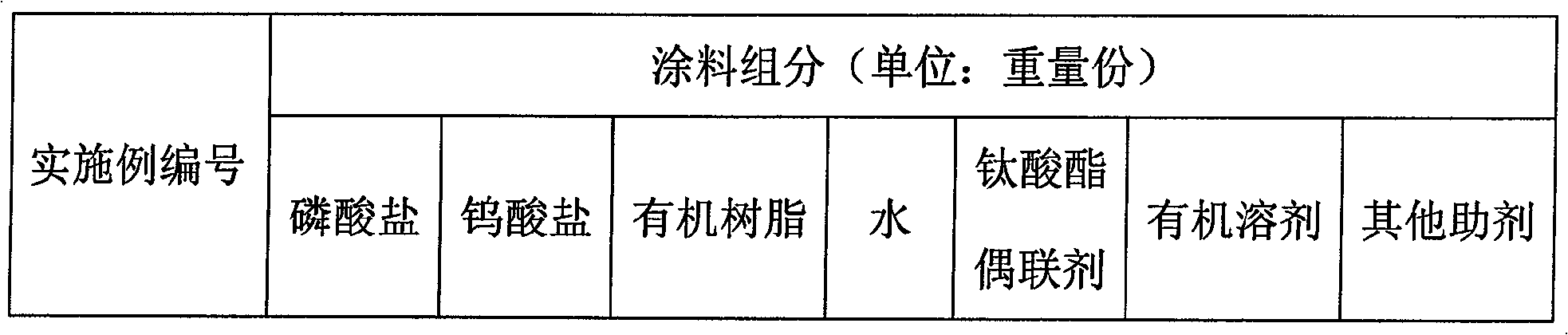

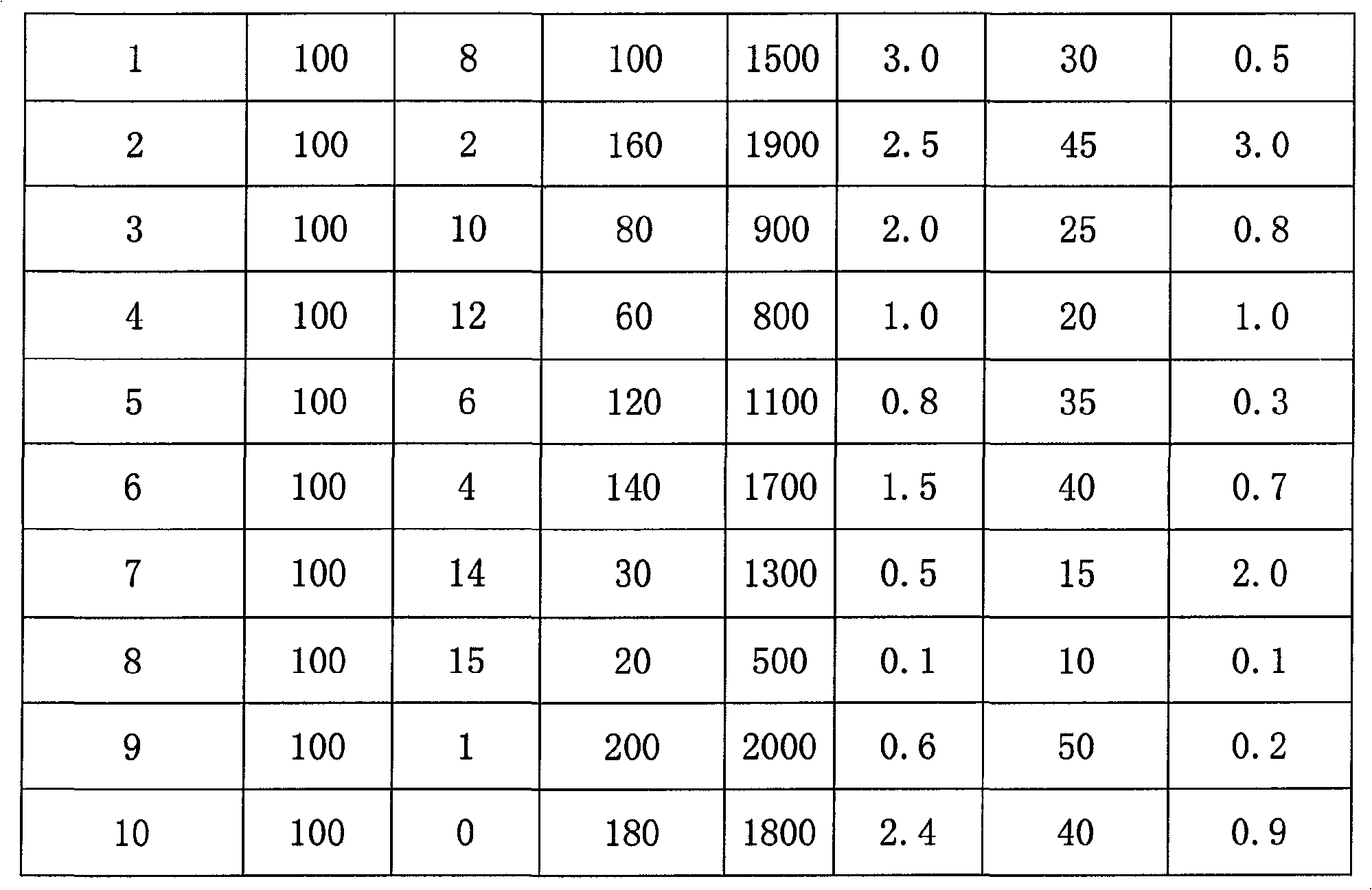

Non-oriented electric steel semi-organic phosphate insulating paint with good corrosion resistance

ActiveCN101560342AImprove corrosion resistanceImprove coating appearanceAnti-corrosive paintsPolyurea/polyurethane coatingsTungstateOrganic phosphates

The invention discloses a non-oriented electric steel semi-organic phosphate insulating paint with good corrosion resistance. The semi-organic phosphate insulating paint comprises the following main components: water-soluble phosphate, tungstate, organic resin, water, a titanate coupling agent, an organic solvent and the like; and contents of the components of the insulating paint (parts by weight) based on 100 parts of the water-soluble phosphate by weight are as follows: 1-15 parts of the tungstate, 20-200 parts of the organic resin, 500-2000 parts of the water, 0.1-3 parts of the titanate coupling agent, 10-50 parts of the organic solvent and 0.1-3 parts of other paint addictives. The semi-organic phosphate insulating paint contains no harmful ingredients restricted by an EU directive RoHS, which can meet the requirements for environmental protection; and compared with the common phosphate coating, the coating of the semi-organic phosphate insulating paint has better corrosion resistance, good insulating property, good adhesiveness, good blanking property, good welding property, good heat resistance and the like, which can meet the requirements of electric motor and transformermanufacturers for application to the electric steel coating.

Owner:MAANSHAN IRON & STEEL CO LTD

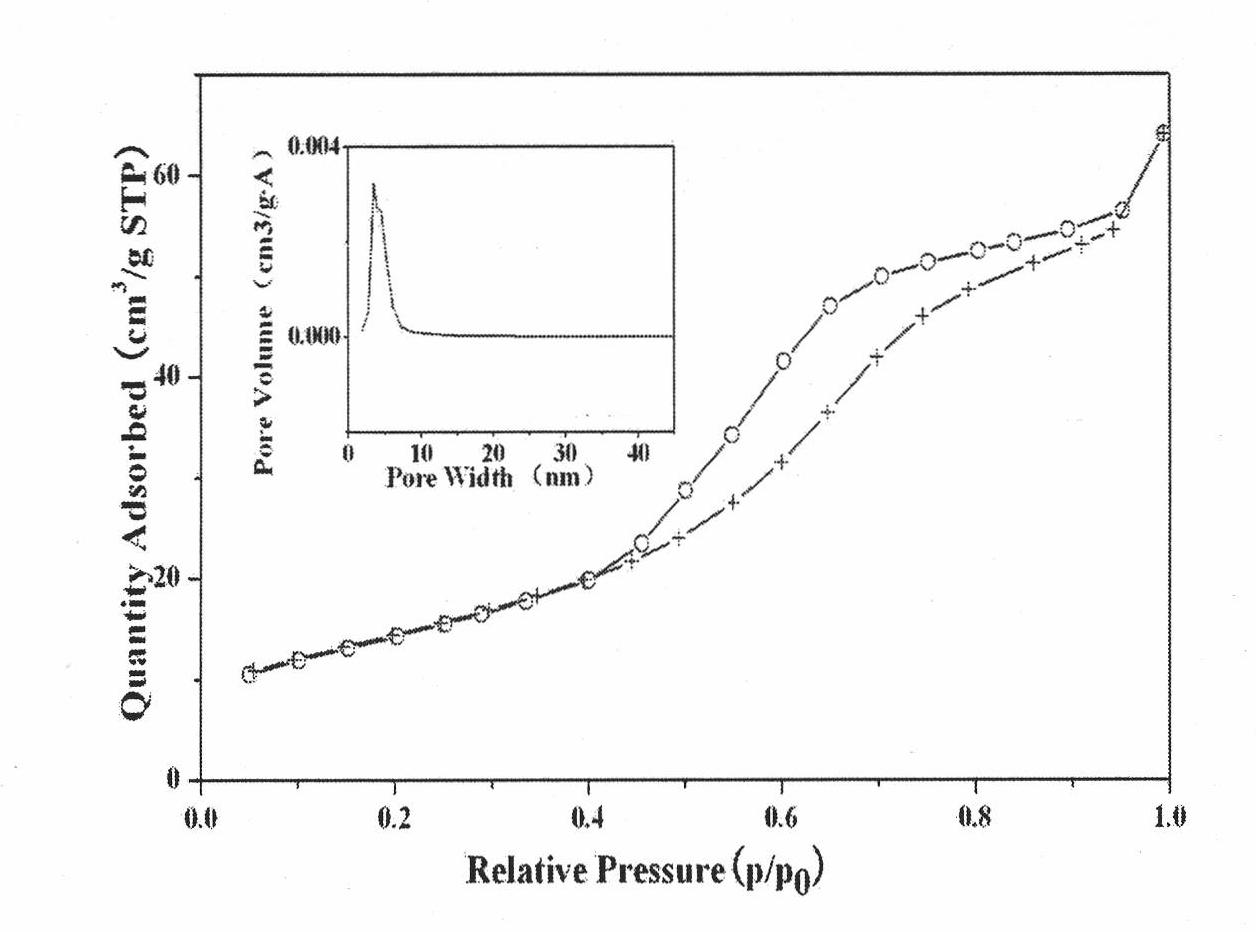

Mesoporous tungstate photocatalysis material and preparation method thereof

InactiveCN102372305AAvoid fusion growthImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsTungsten compoundsInorganic saltsTungstate

The invention provides a mesoporous tungstate photocatalysis material and a preparation method thereof. According to the invention, metal inorganic salt and alkoxide are used as precursors, and molecular level mixing of metallic elements in a precursor solution is realized through addition of a chelating agent so as to avoid phase separation during evaporation of solvents; the method of an inorganic pore forming agent is used to allow a certain metallic element to be excessive in the process of synthesis and to exceed stoichiometric proportion, a part of the excessive metallic element participates in a reaction in the process of roasting to produce tungstate, and the rest part of the excessive metallic element is precipitated to form metal oxide or salt, functioning as a pore forming agent and stabilizing a meso-structure; the inorganic pore forming agent is removed by using treating methods of acid, alkali, dissolving and the like to obtain the mesoporous tungstate material. The invention has the advantages of a simple synthesis process, no harsh conditions and practicable operation. When applied in indoor air purification, the mesoporous tungstate photocatalysis material obtained in the invention has an obvious effect in removing formaldehyde, with a removal rate up to 92%.

Owner:范晓星

Low-phosphorus antiincrustation corrosion inhibitor and its use

ActiveCN1743281AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt functionScale removal and water softeningAlkalinityPhosphor

This invention relates to a sort of low-phosphor scale-corrosion inhibitor which comprises 2-phospinobutane-1, 2, 4-tricarboylic acid (PBTCA) (or / and 2-hydroxyphonoacetic acid (HPAA)), zinc salts, molyadate or tungstate and carboxyl-containing copolymer, copper corrosion inhibitor (needed or not conditionally). This low-phosphor scale-corrosion inhibitor can be used to treat recirculated cooling-water in ways such as adjusting pH of high-hardness and high-alkalinity water or treating low-alkalinity and low-hardness water. Its phosphor concentration in recirculated water is no more than 1mg / L, reducing the hazard of phosphor discharge to environment.

Owner:BEIJING YANHUA PETRO CHEM +1

Non-phosphorus composite anti- incrustation corrosion inhibiter and its application in water treatment

ActiveCN102730847AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt performanceScale removal and water softeningMolybdateTungstate

The invention relates to a non-phosphorus composite anti-incrustation corrosion inhibiter, the non-phosphorus composite anti-incrustation corrosion inhibiter comprises a) water-soluble molybdate and / or water-soluble tungstate; b) two different salts in water-soluble borate, water-soluble gluconate and water-soluble silicate; and c) at least an anti-incrustation dispersant, wherein the anti-incrustation dispersant is a non-phosphorus polymer containing carboxylic acid groups. The non-phosphorus composite anti-incrustation corrosion inhibiter of the present invention has the advantages of good combination property, possesses excellent function to block CaCO3 incrustation, has good capability for stabilizing Zn<2+> in water and corrosion slowing performance, can be used for circulating cooling water process and solves the environmental hazard caused by the drainage of phosphorus.

Owner:CHINA PETROLEUM & CHEM CORP +1

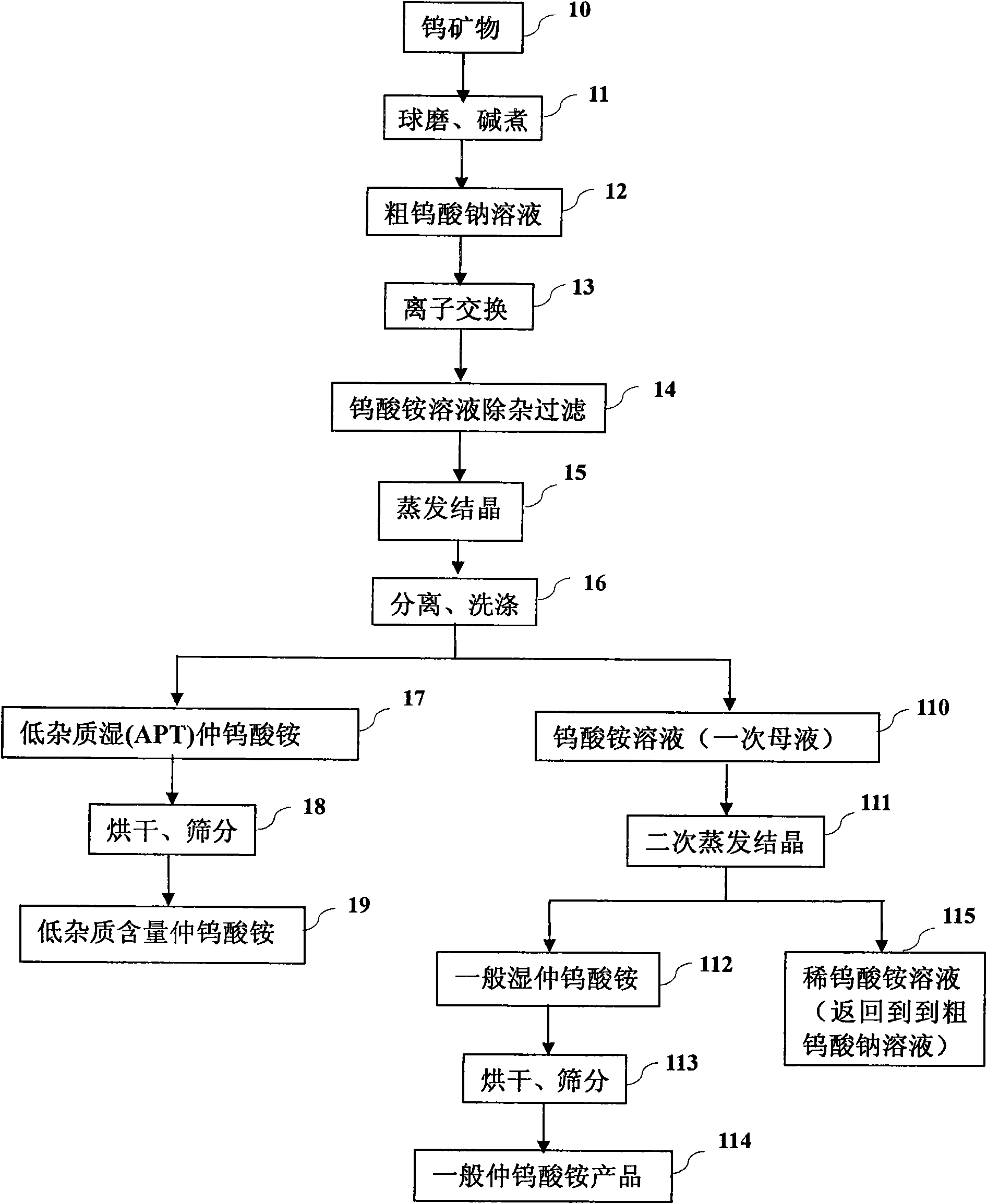

Process for preparing high-purity ammonium paratungstate

The invention relates to a process for preparing high-purity ammonium paratungstate, which can obtain a non-ferrous metal product, namely the ammonium paratungstate with low impurity content, whereinthe impurity content of the ammonium paratungstate is low and is lower than 70 ppm, and the ammonium paratungstate can be directly used for preparing deep processed products of tungsten, such as tungsten powder with low impurity content and the like. The process comprises the following four process steps: (1) a process step of preparing a sodium tungstate solution by using a tungsten concentrate (Fe, Mn)WO4, white tungsten (CaWO4) or a tungsten middling product as a raw material; (2) a process step of performing ion exchange on the sodium tungstate solution; (3) a process step of performing impurity removal and filtration by using an ammonium tungstate solution; and (4) a process step of performing crystallization, washing, drying and screening. The process for preparing the high-purity ammonium paratungstate optimizes the technological processes, improves the quality of a product, and reduces the preparation cost of the product.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

Hydrogenation Catalysts

InactiveUS20130178664A1Degree of stabilityOrganic compound preparationHeterogenous catalyst chemical elementsAcetic acidTungstate

The present invention relates to catalysts, to processes for making catalysts and to chemical processes employing such catalysts. The catalysts are preferably used for converting acetic acid to ethanol. The catalyst comprises a precious metal and one or more active metals on a modified support. The modified support may comprise cobalt tungstate.

Owner:CELANESE INT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com