Process for preparing high-purity ammonium paratungstate

A technology of ammonium paratungstate and ammonium tungstate, which is applied in the technical field of producing high-purity ammonium paratungstate, can solve the problems of not being able to satisfy tungsten deep-processing products, and achieve the effect of improving technical content and product added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

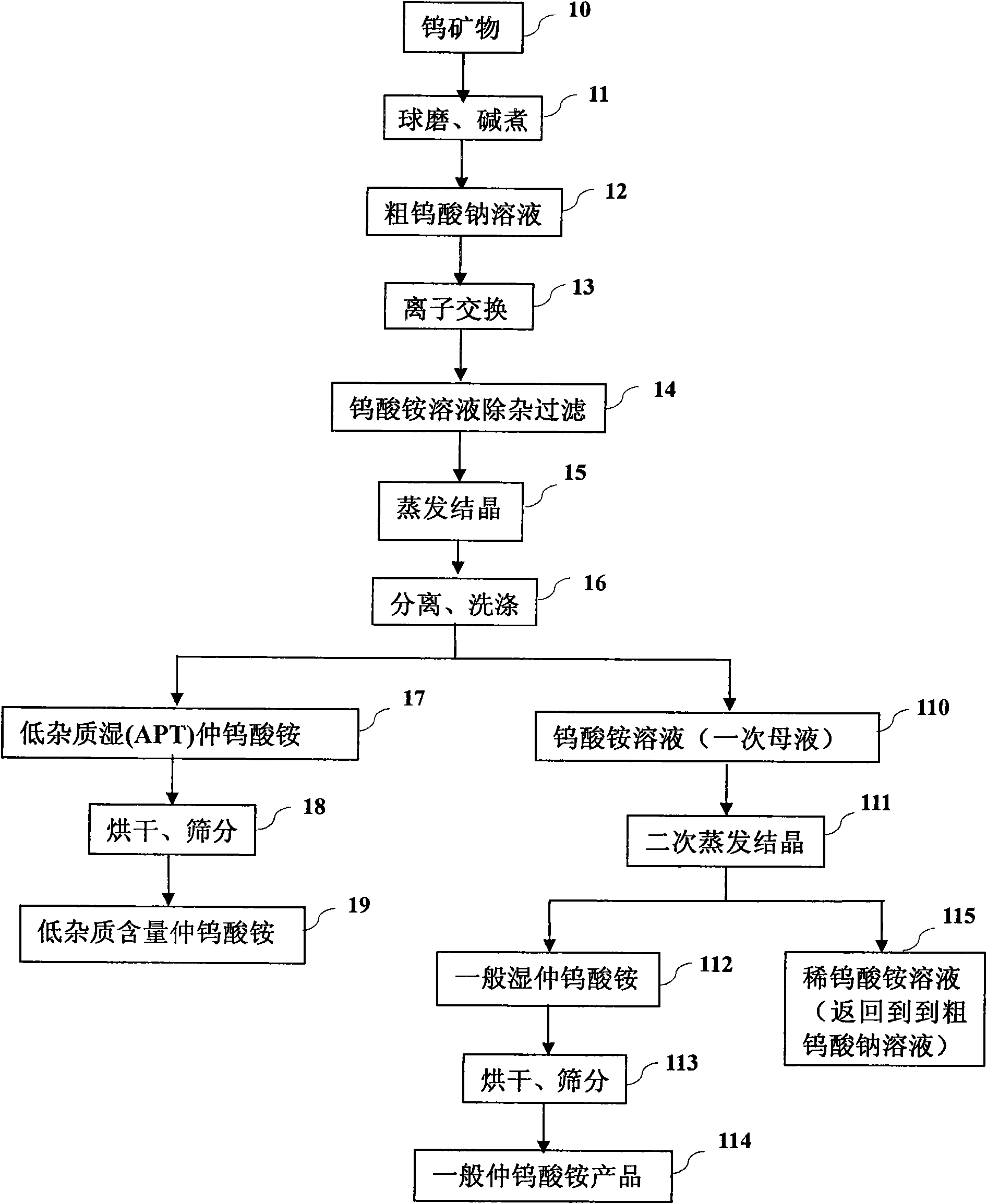

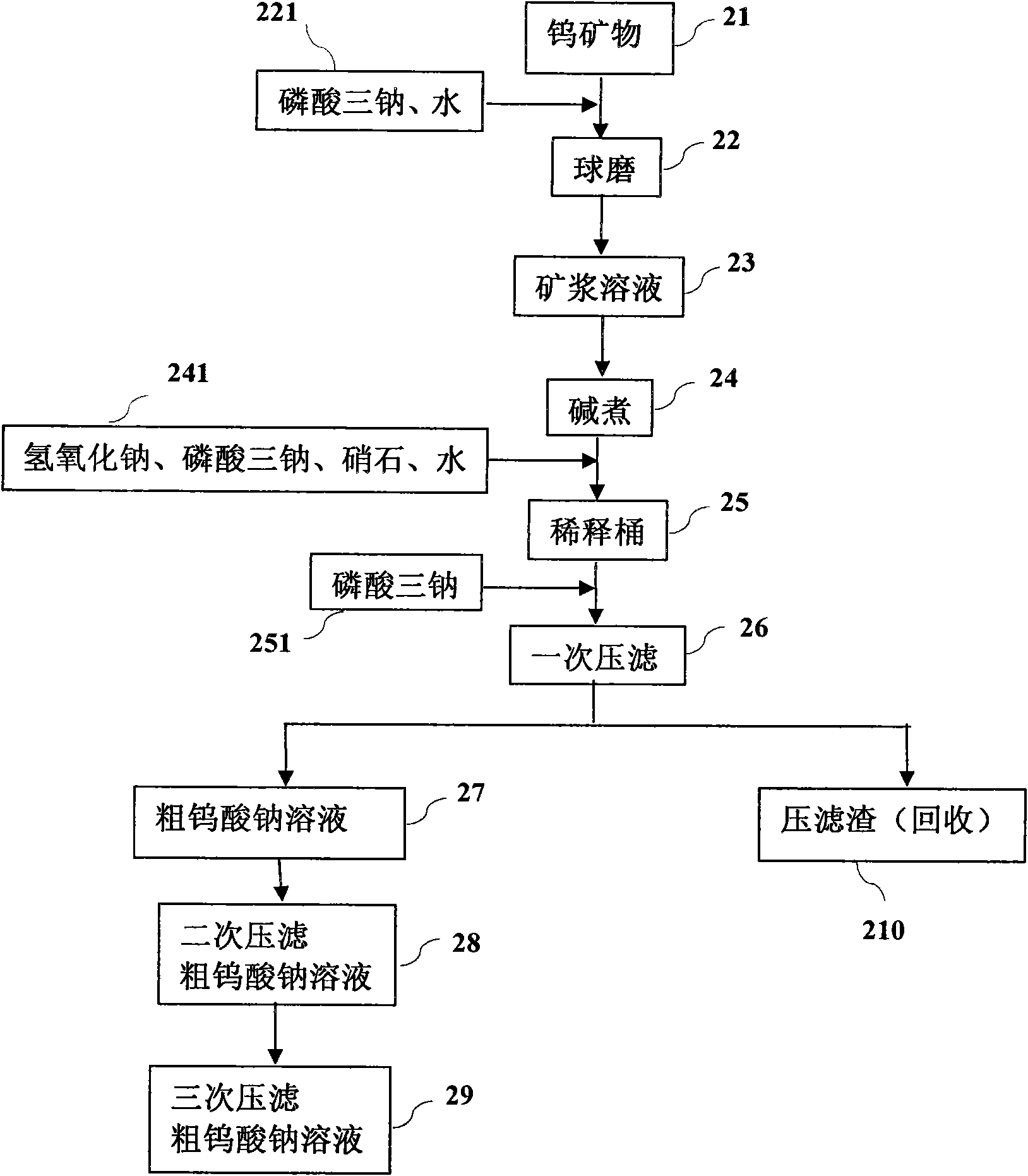

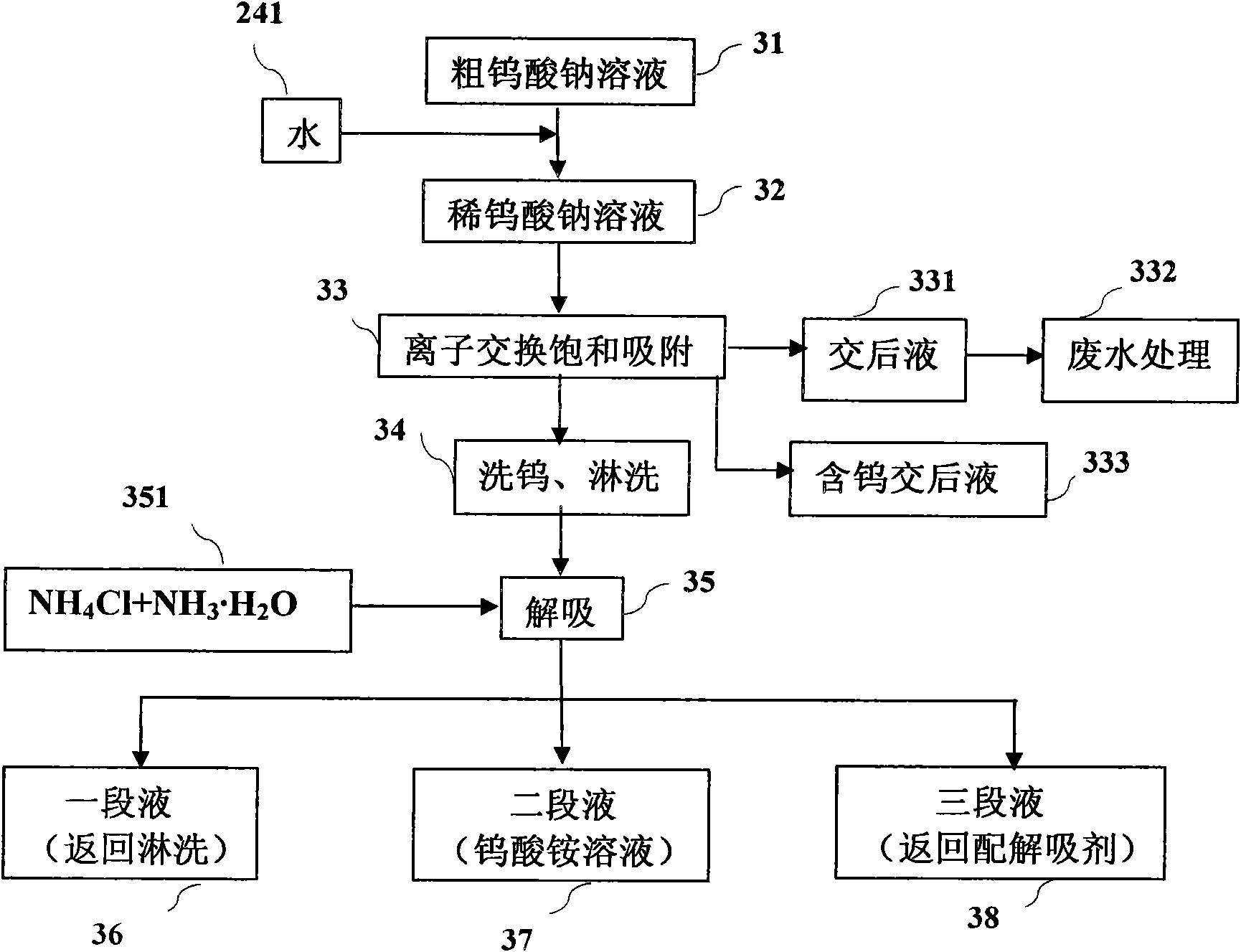

[0032] Such as Figure 1-5 Shown, according to the technique for producing parahigh-purity ammonium tungstate of the present invention, be with black tungsten concentrate (Fe, Mn) WO 4 , scheelite (CaWO 4 ), or tungsten ore as raw material, the main steps include:

[0033] 1. Process of preparing crude sodium tungstate solution

[0034] (1) Put the tungsten minerals 10 and 21 into the hopper of the ball mill, send the tungsten minerals into the vibrating ball mill at a quantitative and uniform speed through the screw feeder, and add an appropriate amount of phosphorus salt and water 221 at the same time, and carry out the fine grinding of the ball mill 11 and 22, Make the sieving particle size of the tungsten mineral after the ball milling reach -320 mesh ≥ 95%, add the slurry solution 23 after the ball milling: caustic soda (NaOH) 241, the amount of alkali is not less than 1.8 times of the theoretical amount, preferably 2.1 times; 3 PO 4 ) 241, phosphorus salt (Na 3 PO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com