Patents

Literature

567 results about "Ammonium paratungstate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium paratungstate (or APT) is a white crystalline salt with the chemical formula (NH₄)₁₀(H₂W₁₂O₄₂)·4H₂O. It is described as "the most important raw material for all other tungsten products."

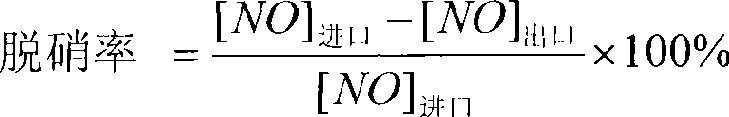

Regeneration fluid for SCR denitration catalyst

InactiveCN101574671AHigh activityEasy to cleanDispersed particle separationCatalyst regeneration/reactivationAdditive ingredientAmmonium paratungstate

The invention discloses a regeneration fluid for an SCR denitration catalyst, which comprises the following components: 0.001 to 1 weight percent of penetration enhancer JFC, 0.001 to 1 weight percent of surfactant OP-10, 0 to 1 weight percent of peregal, 0.6 to 4 weight percent of ammonium metavanadate, 5.5 to 12.5 weight percent of ammonium paratungstate, 0 to 6.5 weight percent of ammonium paramolybdate, and the balance of deionized water and acid. The regeneration fluid has the advantages that the regeneration fluid can also supplement active ingredients during the washing, and the activity recovery of the catalyst after the regeneration is up to between 90 and 105 percent; a nonionic surfactant is added into the regeneration fluid, so that the regeneration fluid improves the cleaning capability on the catalyst and cannot cause the damage to a catalyst carrier and other effective ingredients; and the regenerated catalyst fully can continue to be normally used, and the service life can reach more than 95 percent of that of a new catalyst.

Owner:COUNTRY JIANGSU CATALYST REGENERATION TECH

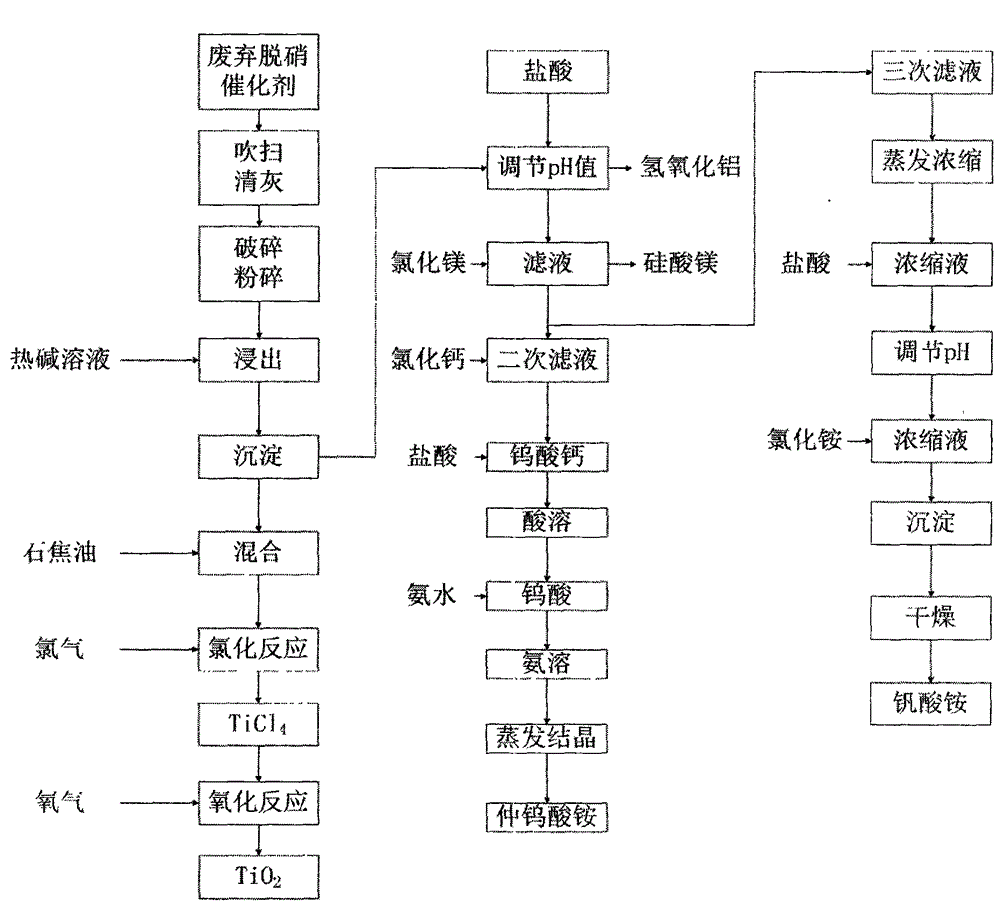

Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

InactiveCN102936039AHigh purityHigh recovery rateTitanium dioxideVanadium compoundsHigh concentrationAmmonium paratungstate

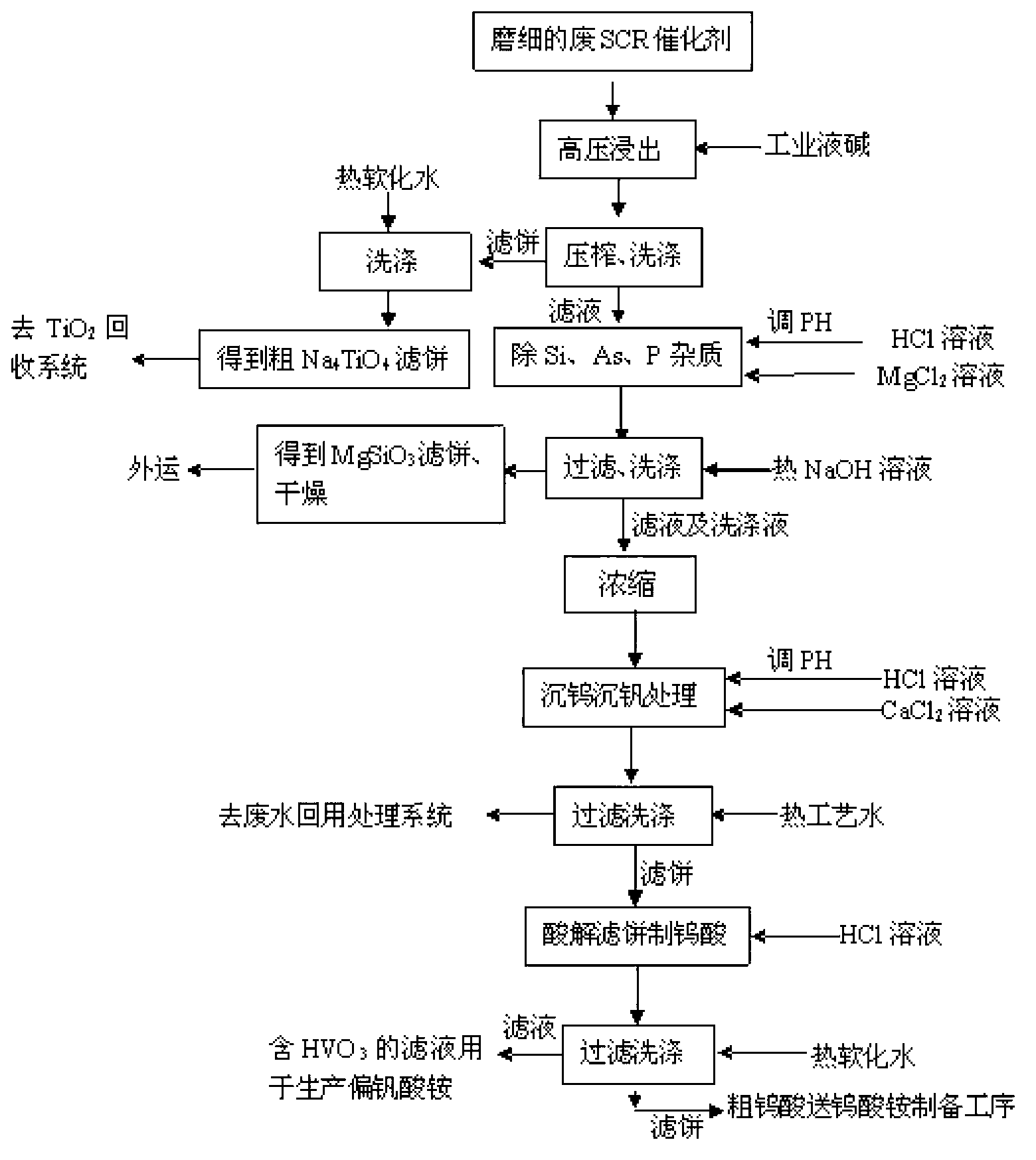

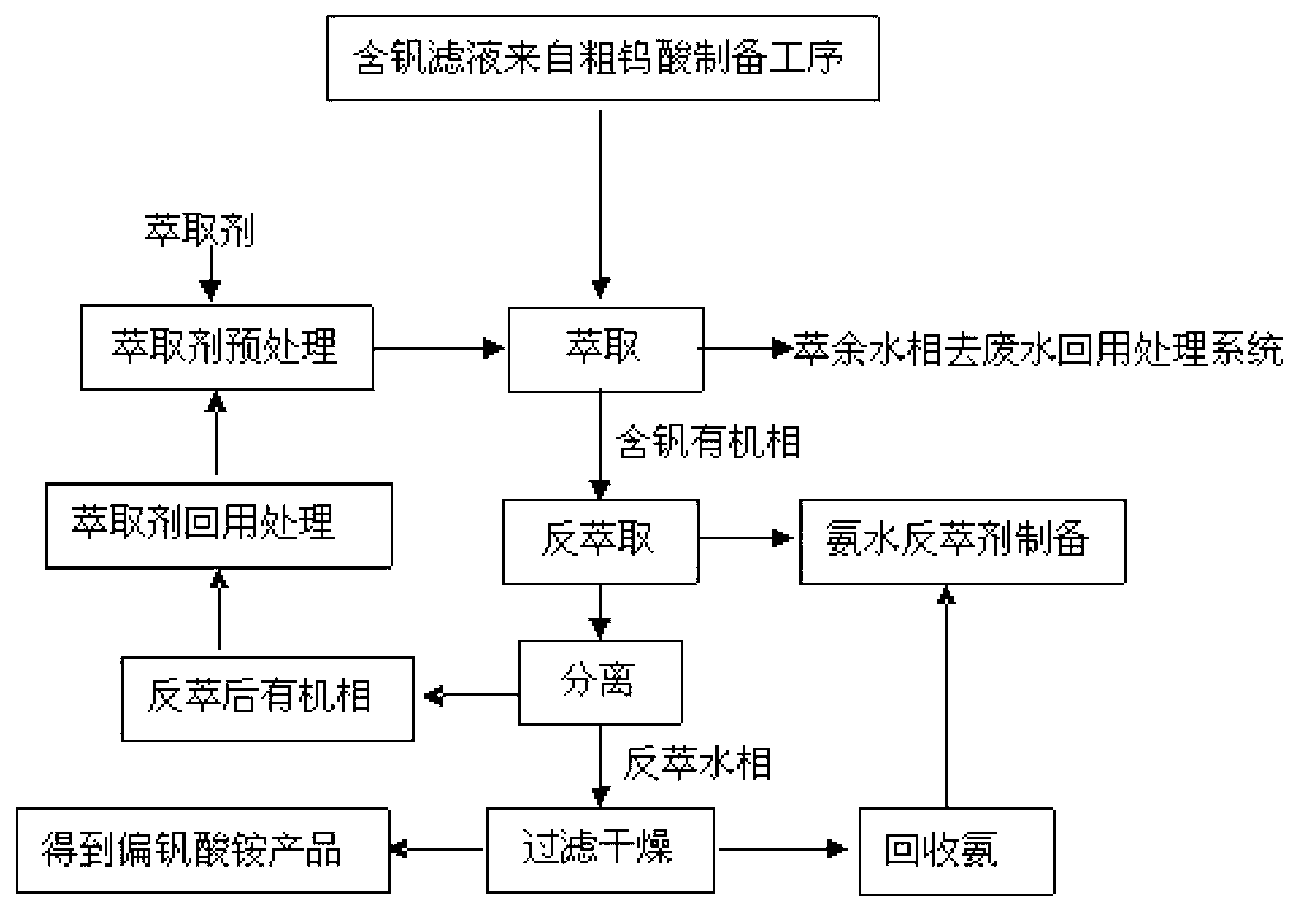

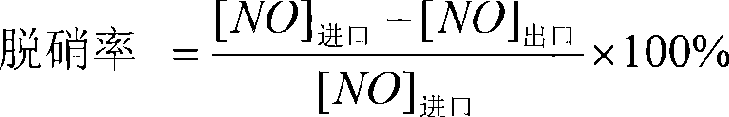

The invention discloses recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst. The process includes the following steps: a, preprocessing the SCR waste catalyst and leaching at the high temperature and under high pressure; b, adding hydrochloric acid into leaching liquid, adjusting pH, and removing impurities; c, adding hydrochloric acid into the leaching liquid, reacting, calcining and preparing rutile titanium dioxide; d, preparing ammonium paratungstate; e, preparing ammonium metavanadate; and f, recycling and treating waste water. Main products of ammonium paratungstate, ammonium metavanadate and rutile titanium dioxide obtained in the process are high in purity and recovery rate. By-products of silicon magnesium slags, salty mud, high-concentration sodium chloride liquid and barium sulfate dregs are high-purity harmless useful goods. The process is free of harmful secondary pollutant emission, environment-friendly and capable of circulating, has high economical and social benefit and is practicable.

Owner:曾瑞

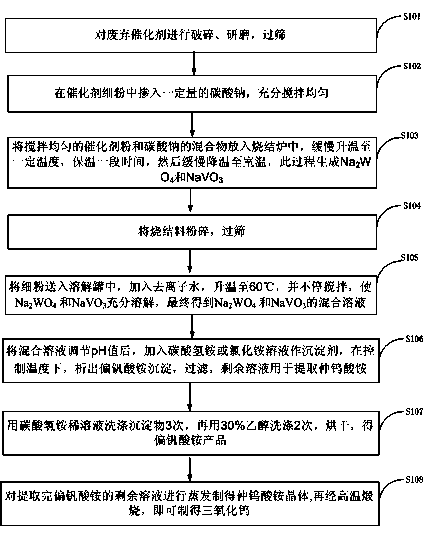

Method for recovering tungsten trioxide and ammonium metavanadate from selective catalytic reduction (SCR) denitration catalyst

ActiveCN102557142AEmission reductionTungsten oxides/hydroxidesDispersed particle separationWarm waterAmmonium paratungstate

The invention relates to a method for recovering tungsten trioxide and ammonium metavanadate from a selective catalytic reduction (SCR) denitration catalyst. The method comprises the following steps of: crushing the SCR denitration catalyst, sieving to obtain catalyst powder, mixing with sodium carbonate, and stirring fully and uniformly; putting the mixed powder into a sintering furnace, and sintering to obtain a sintered material; keeping temperature for 1 hour, and sieving to obtain sintered material powder; pouring warm water, so that Na2WO4 and NaVO3 in the sintered material powder are dissolved fully, filtering, and removing precipitates to obtain a mixed solution of Na2WO4 and NaVO3; regulating the pH value to be 6.5-7.5, adding an ammonium bicarbonate solution or an ammonium chloride solution, and precipitating ammonium metavanadate precipitate; filtering, washing by using a diluted ammonium bicarbonate solution for 2 to 3 times, washing by using 30 percent ethanol for 1 to 2 times, and drying to obtain an ammonium metavanadate finished product; and converting the Na2WO4 in the residual solution into ammonium paratungstate, evaporating the residual solution to obtain ammonium paratungstate crystals, and calcining to obtain the tungsten trioxide. By the method, the ammonium metavanadate and the tungsten trioxide can be recovered, and the discharge of pollutants is reduced.

Owner:江苏万德环保科技有限公司

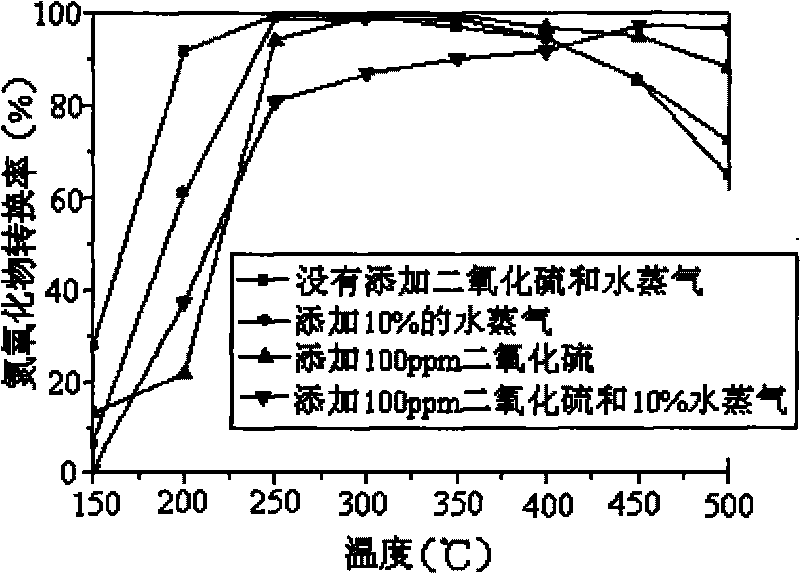

Titanium-base multi-component catalyst for power plant flue-gas SCR denitration and preparation method thereof

InactiveCN101396655AHigh activityActivity has no effectDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAmmonium paratungstateManganese

The invention belongs to the chemical material field, in particular to a titanium-base multicomponent catalyst used for the denitrification of power plant flue gas SCR and a preparation method thereof. The catalyst comprises a catalyst carrier TiO2 accounting for 80-99wt percent of the total content, and the active components of 1-5wt percent of V2O5, 5-15wt percent of WO3 and 1-5wt percent of oxide of molybdenum or cerium or manganese according to the total content. The catalyst also comprises the other components of 0-5wt percent of MoO3, 0-5wt percent of CeO2 and 0-5wt percent of MnO3. The preparation process is: ammonium metananadate, ammonium paratungstate and titanium dioxide are mixed in water solution and are dried, calcined and sieved to obtain the catalyst. The catalyst has the advantages of active temperature region of 240-480 DEG C, high denitration efficiency, and good SO3 poisoning resistance. Added SO2 has almost no influence on the activity of the catalyst.

Owner:TSINGHUA UNIV +1

SCR denitration catalyst and preparation method thereof

ActiveCN101185886AImprove structural stabilityImprove mechanical stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSilanesAmmonium paratungstate

The invention relates to a preparation method of an SCR denitration catalyst, which comprises the following steps: (1) Al2O3 sol is prepared, which comprises the steps that hot ammonia, the Al2O3 is added in drops into the ammonia and then HCI is added and the mixture is stirred; (2) Al2O3-SiO2-TiO2 composite sol is prepared, which comprises the steps that tetratethoxy-silane, butyl titanate, deionized water are sequentially put into ethanol to be aging and then the sol prepared by step (1) is adding to be stirred and aging; (3) vector is coated, which comprises the steps that cordierite honeycomb immersed into the sol of step (2) and the raffinate in a channel is cleaned, dried and roasted after being taken out; (4) active component impregnating solution is prepared, which comprises the steps that lanthanum nitrate, ammonium metavanadate and ammonium paratungstate are dissolved into the deionized water after being mixed together and oxalate acid is added to be aging; (5) the active component is loaded, which comprises the steps that the vector of the step (3) is immersed into the impregnating solution of the step (4) and then the raffinate in the channel is cleaned to be dried and roasted. The invention also relates to the denitration catalyst which is prepared by the method.

Owner:山西蒲洲博奇环保科技有限公司

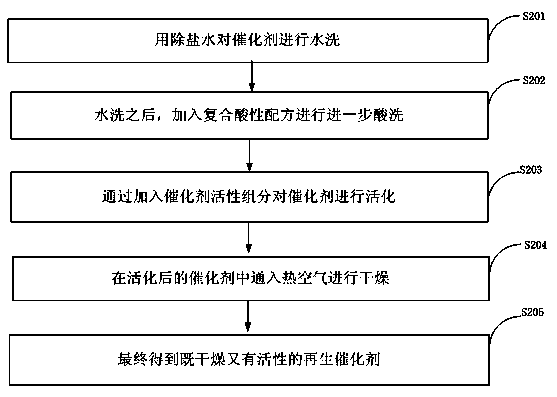

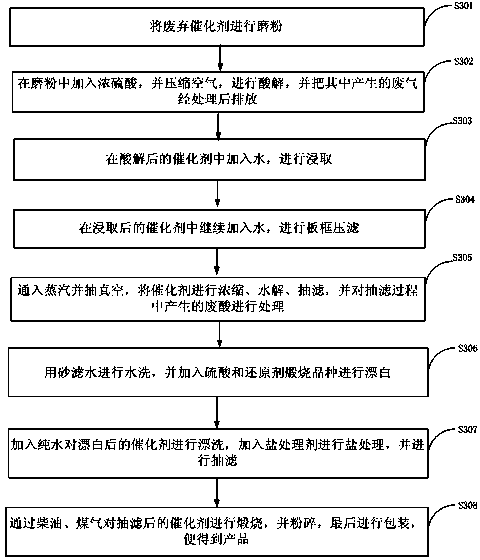

Method for regeneration and resource utilization of waste honeycombed denitrification catalyst

InactiveCN103508491ALow costRestore activityTungsten oxides/hydroxidesDispersed particle separationResource utilizationAmmonium paratungstate

The invention discloses a method for regeneration and resource utilization of a waste honeycombed denitrification catalyst. The method comprises the following steps of: crushing, grinding and sieving the waste catalyst; loading a mixture of the powdered catalyst and sodium carbonate into a sintering furnace to produce Na2WO4 and NaVO3, dissolving completely, adjusting the pH value to separate ammonium metavanadate precipitates, filtering, applying the remaining liquid to ammonium paratungstate extraction, washing the precipitates and oven-drying to obtain ammonium metavanadate, and making ammonium paratungstate crystals and tungsten trioxide. The regeneration method of the SCR catalyst comprises the following steps of: performing water-washing, pickling, activation and drying on the catalyst. The method for producing titanium pigment from the waste catalyst as raw material comprises the following steps of: performing pulverization, acidolysis and extraction on the waste catalyst, performing plate-frame pressure filtration; performing concentration, hydrolysis and suction-filtration on the catalyst, washing and blanching with sand leaching water, calcining, grinding and packaging. The method disclosed by the invention can effectively restore the activity of a deactivated catalyst and prolong the service life of the deactivated catalyst, which not only reduce the operating cost of a thermal power plant but also save the valuable rare earth resources.

Owner:YIXING YIGANG ENVIRONMENTAL PROTECTION ENG & MATERIALS

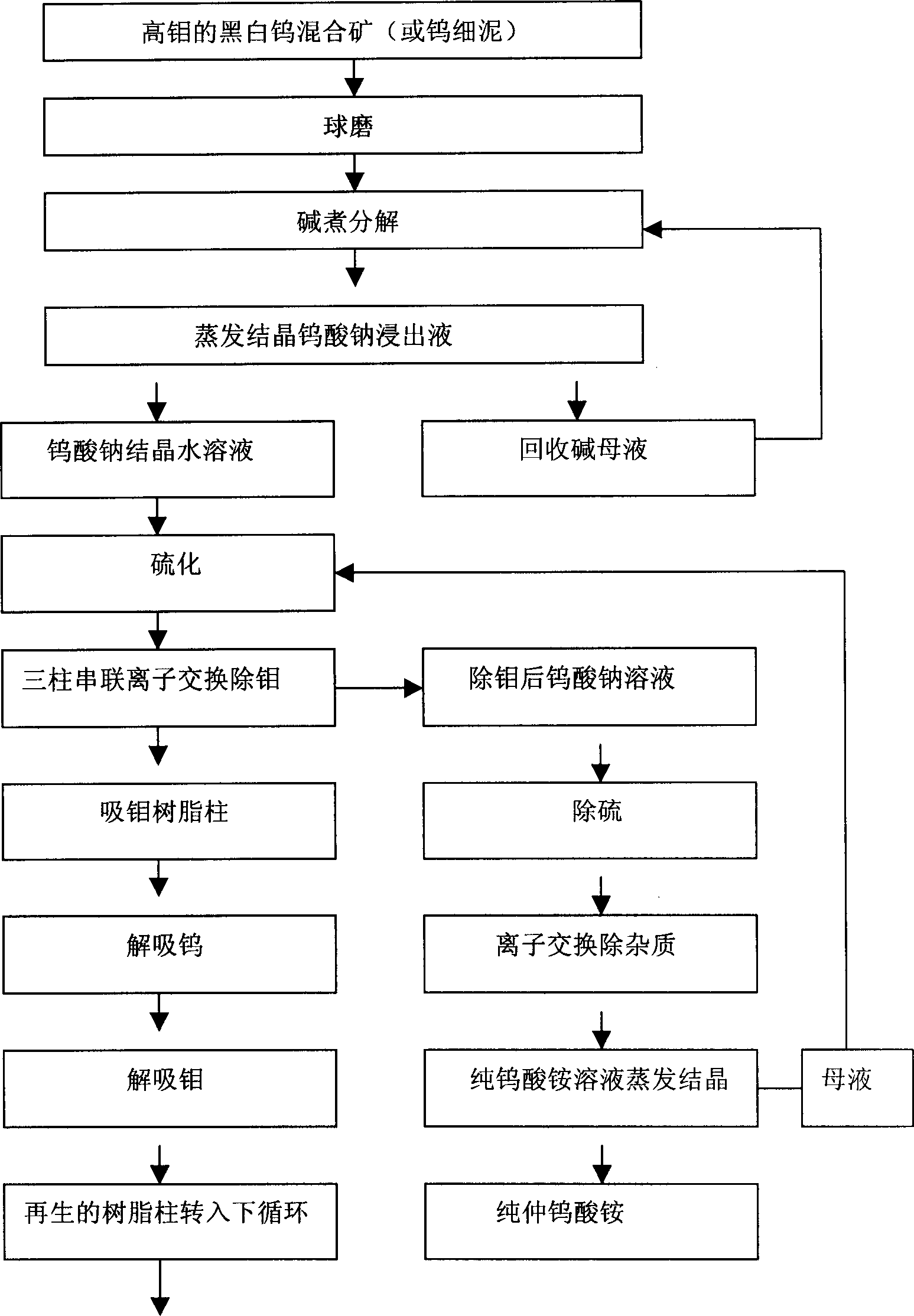

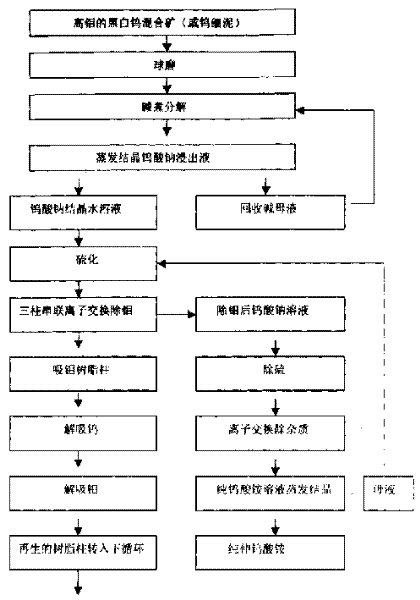

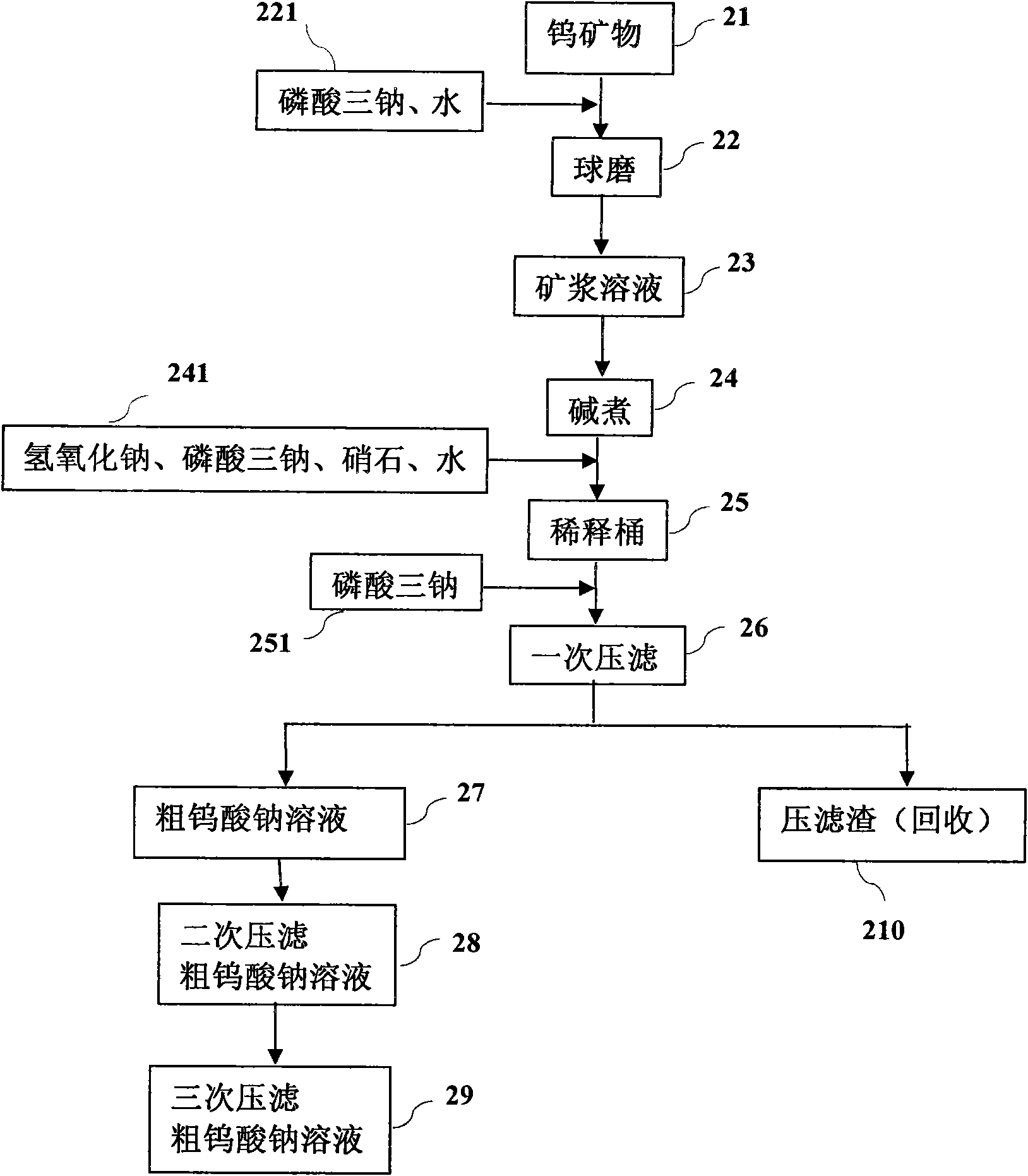

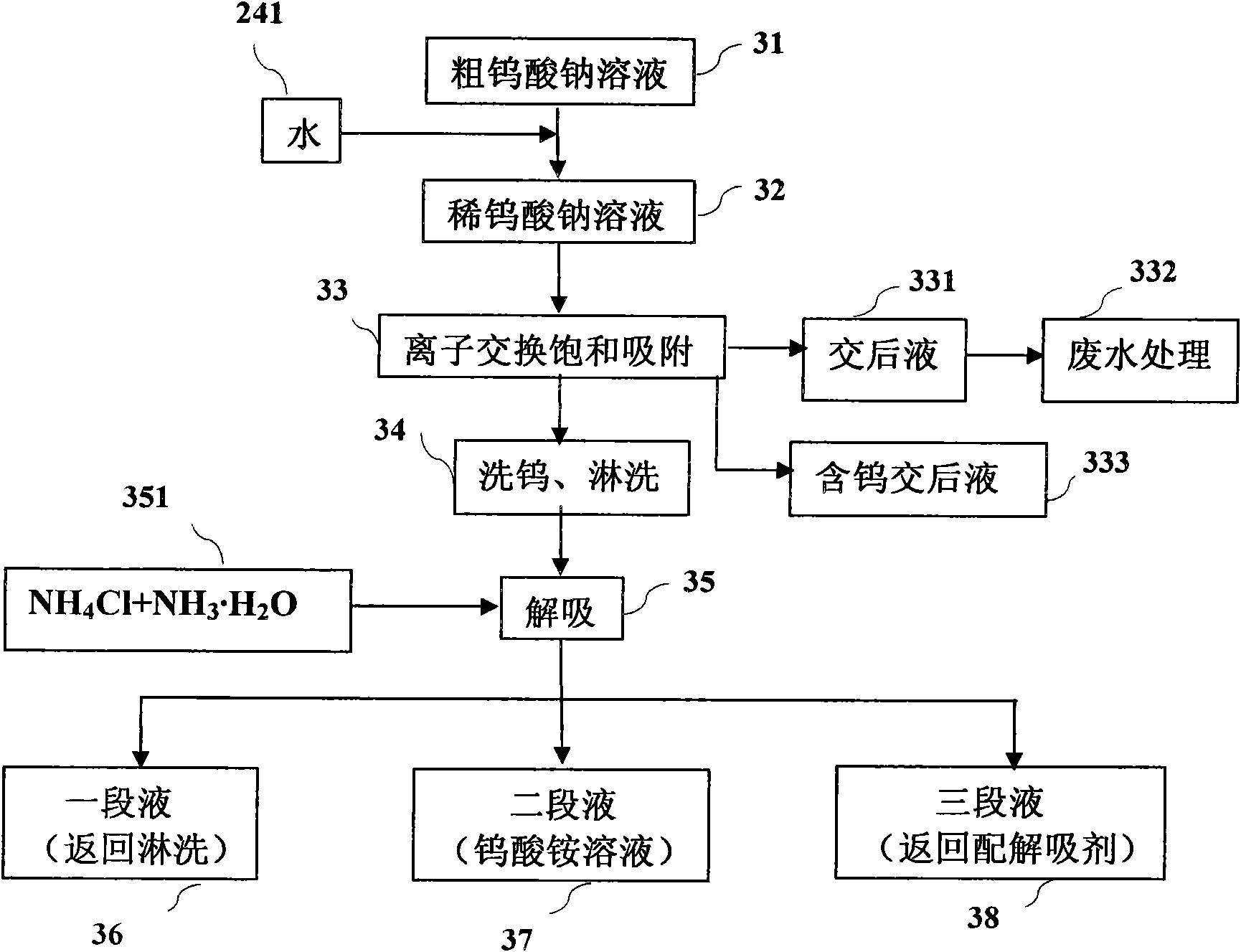

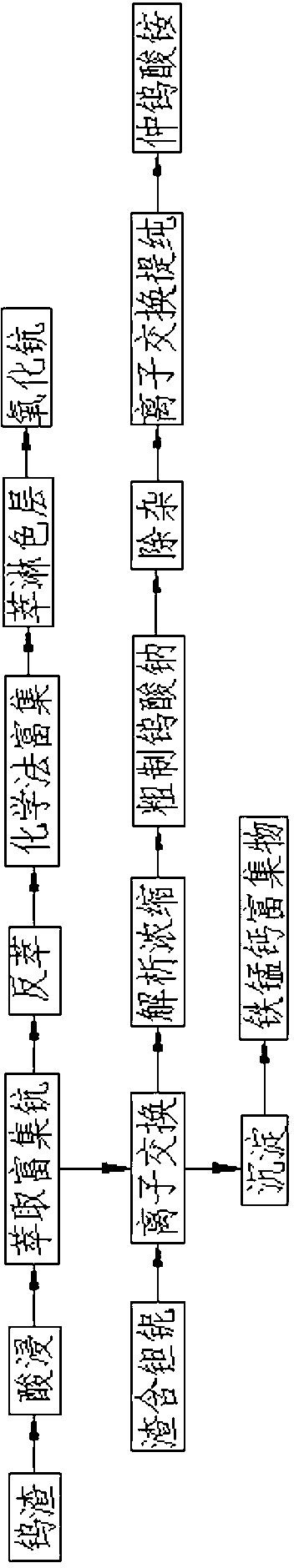

Process for preparing high purity ammonium para-tungstate using hihg-molybdenum tungsten ore

The present invention provides a method of treating high-molybdenum tungsten mineral or tungsten slime by means of three-ion column exchange molybdenum-eliminating technology so as to obtain ammoniumpara-tungstate with high purity at low cost. The treating process includes grinding, alkali leaching, filtering and concentration to obtain sodium tungstate crystal; water dissolving, filtering and sulfurizing sodium tungstate; ion exchange to eliminate molybdenum; desulfurizing sodium tungstate liquid; ion exchange to elimiante impurity and desorbing tungsten with ammonia water and ammonium chloride solution to prepare ammonium tungstate solution; and evaporation to obtain ammonium para-tungstate crystal. The present invention has low cost.

Owner:王旭升 +1

Denitration catalyst and preparation method thereof

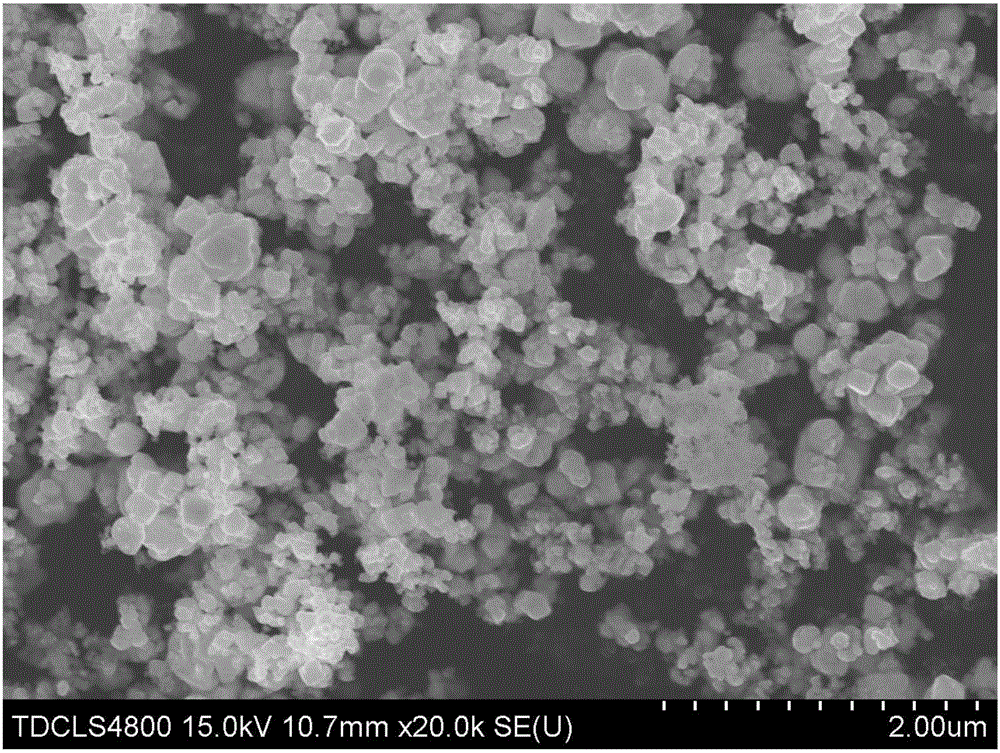

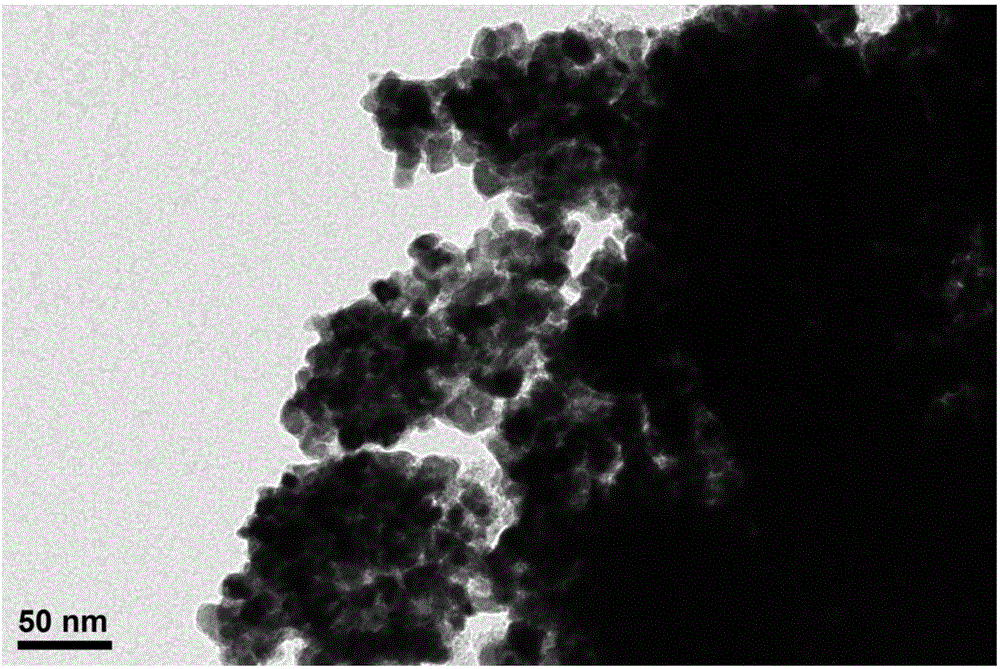

ActiveCN102225333AImprove mechanical propertiesHigh strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAmmonium paratungstate

The invention provides a denitration catalyst and a preparation method thereof. The denitration catalyst comprises: by weight, 40 to 45 parts of nano-titanium dioxide, 6 to 8 parts of nano-silica, 0.5 to 4 parts of ammonium metavanadate, 0.5 to 4 parts of ammonium paratungstate, 0.5 to 2 parts of Acesulfame K (A.K) sugar, and 3 to 5 parts of one or two moulding auxiliary agents. In the invention,trough the introduction of A.K sugar, the denitration catalyst has an excellent denitration performance and through the introduction of rare earth elements, an anti-poisoning performance of the denitration catalyst is improved greatly; the A.K sugar in the denitration catalyst has a binding effect and can improve effectively a mechanical property and a strength of the denitration catalyst thus ananti-crushing property of the denitration catalyst is improved and the problem that a denitration catalyst adopted by the prior art can be crushed frequently in use is solved.

Owner:上海瀚昱环保材料有限公司

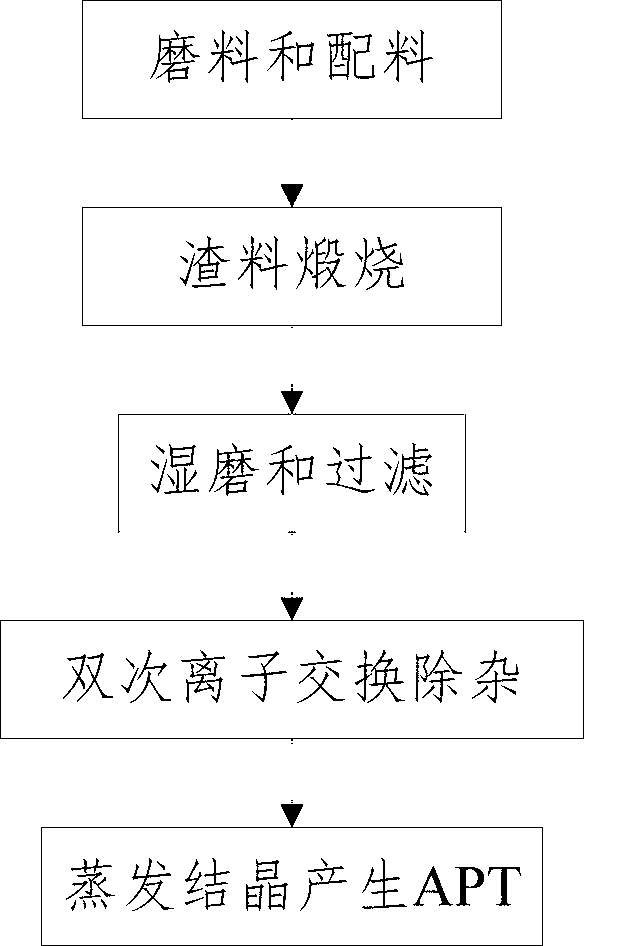

Method for regenerating APT (ammonium paratungstate) by use of APT waste low-grade tungsten slag

InactiveCN103103359AHigh recovery rateEasy to useProcess efficiency improvementAmmonium paratungstateSlag

The invention belongs to the field of tungsten resource recycling, and particularly relates to a method for regenerating APT (ammonium paratungstate) by the use of waste low-grade tungsten slag in an APT production process. The invention discloses a method for regenerating APT by use of APT waste low-grade tungsten slag, which is realized by improving the technological parameters of the traditional soda sintering method and comprises the following steps of: (a) grinding and dosing; (b) slag calcining; (c) wet grinding and filtering; (d) two-secondary ion exchange and impurity removal; and (e) evaporating and crystallizing to generate APT. The method provided by the invention can reduce resource waste, improve the utilization rate of resources, and can increase the economic benefits of an enterprise by recycling the APT waste low-grade tungsten slag; the method is suitable for treating the waste low-grade tungsten slag of which the WO3 grade is 2-10%, overcomes the shortcomings of the technology matching the waste and the tungsten concentrate raw material, and can effectively improve the recovery rate of tungsten and reduce environmental pollution; and through the invention, the service life of the tungsten resource of the country can be prolonged, the current situation of shortage in tungsten resource is relieved, the emission of waste can be effectively reduced, and environmental pollution is reduced.

Owner:陈泉兴

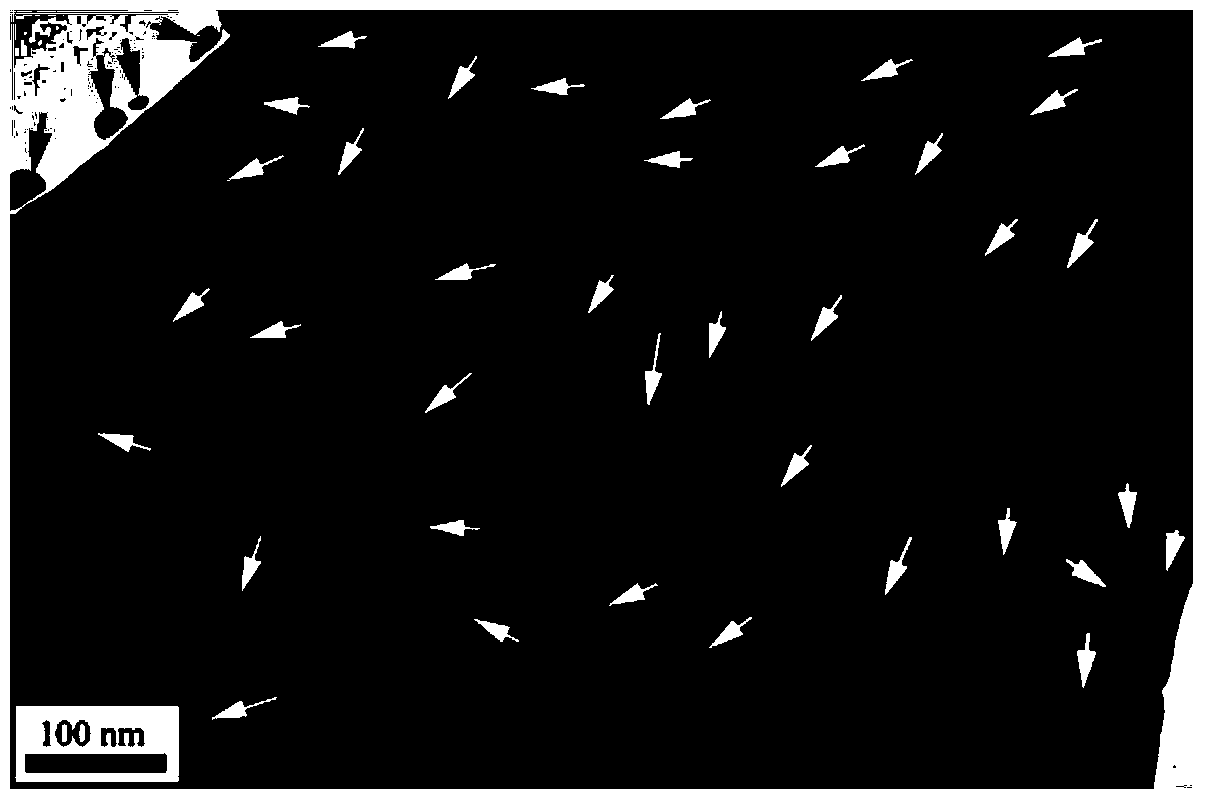

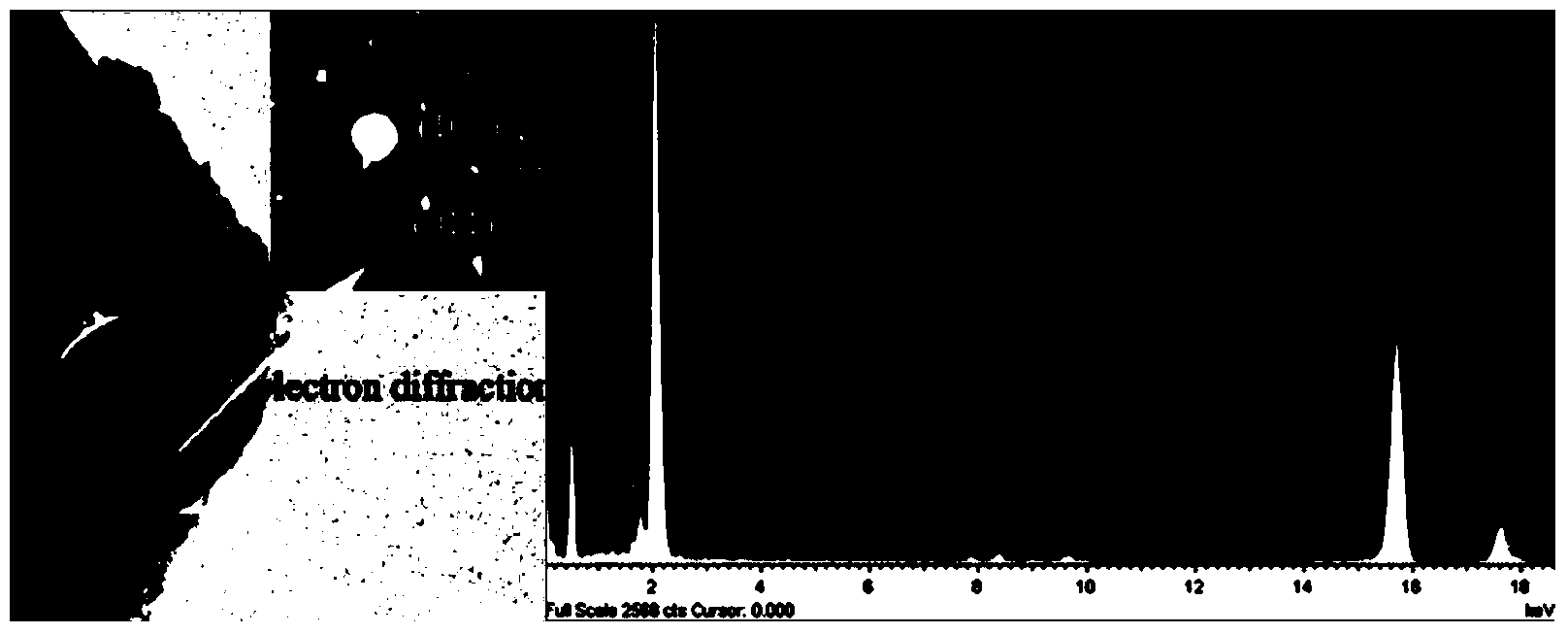

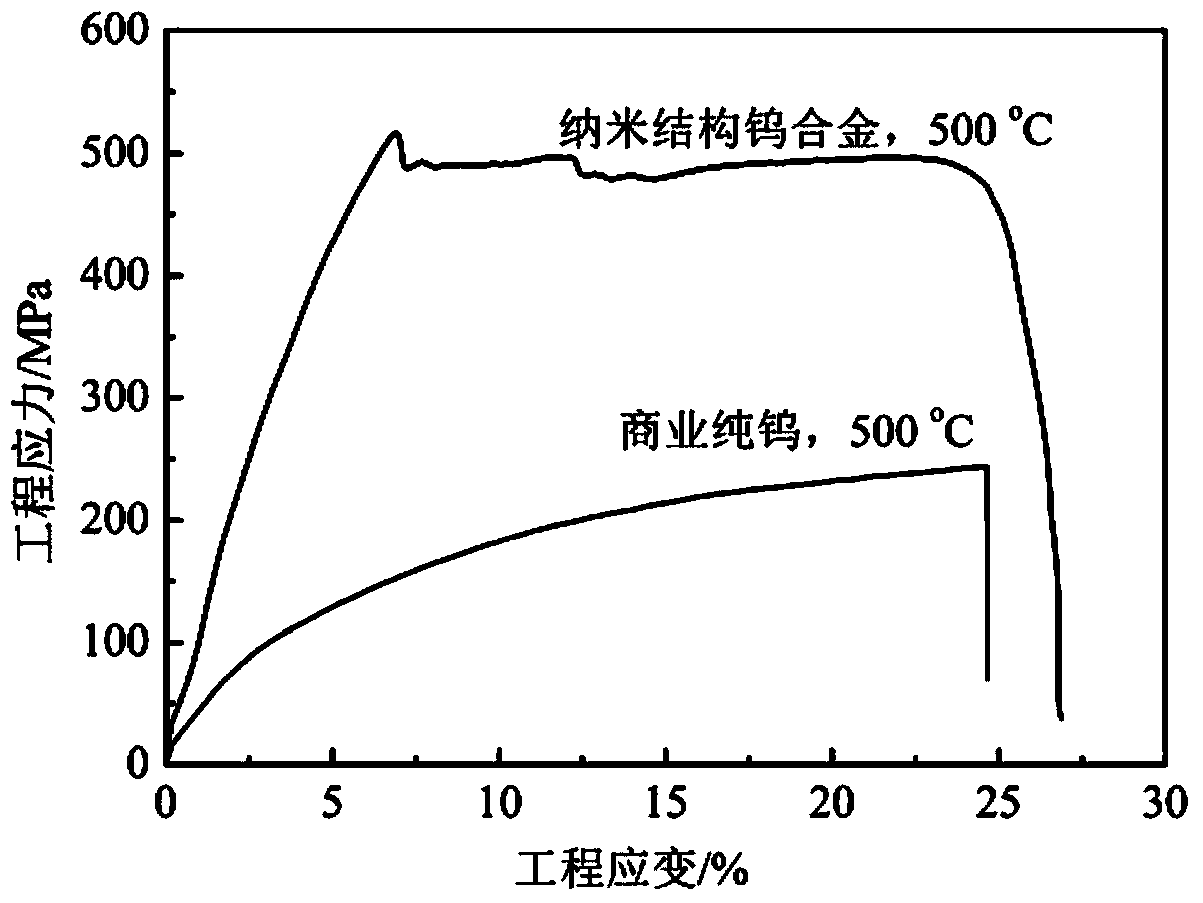

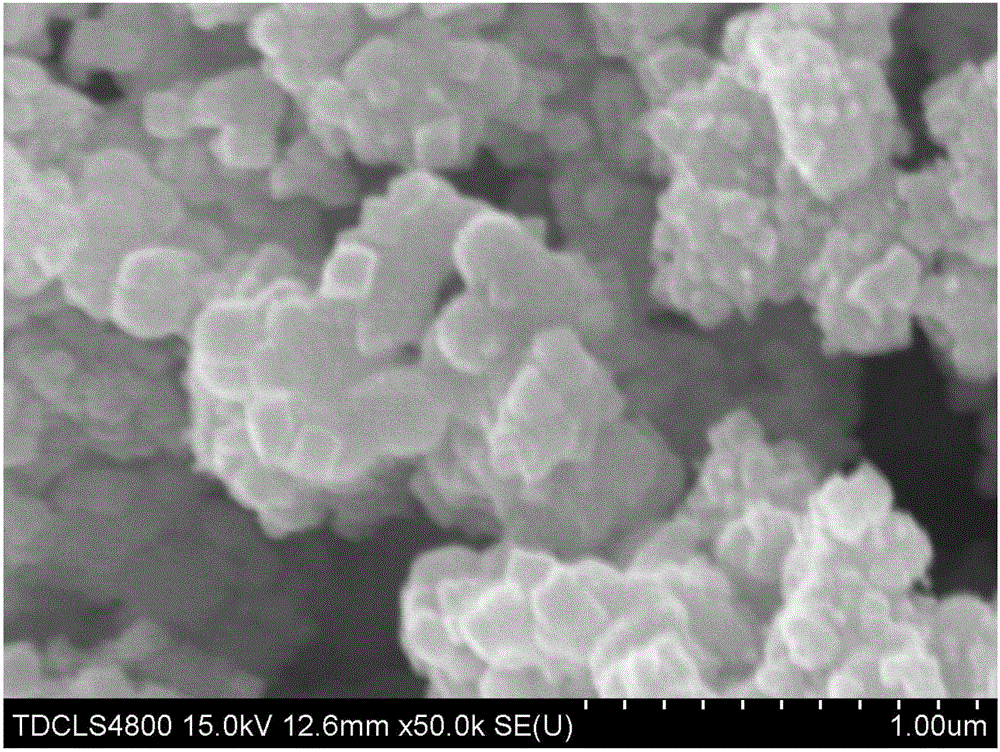

Preparation method of nano yttrium oxide dispersion strengthening tungsten alloy

The invention provides a preparation method of a nano yttrium oxide dispersion strengthening tungsten alloy and belongs to the field of the manufacturing of powder used for powder metallurgy. The preparation method mainly comprises the following steps of: dissolving yttrium nitrite (Y(NO3)3.6H2O) in ethyl alcohol, and carrying out ball milling and mixing on yttrium nitrite and ammonium paratungstate (APT); after wet powder is dried by distillation, calcining for 20-150 minutes at the temperature of 400-900 DEG C to obtain nano yttrium oxide dispersion strengthening tungsten powder; then reducing by H2 for 30-150 minutes at the temperature of 600-1000 DEG C to prepare the nano yttrium oxide dispersion strengthening tungsten powder; and mixing 0.1-1% of Ni as an activated sintering agent, and carrying out compression moulding and H2 gas shield sintering or vacuum or HIP (hot isostatic pressing) sintering, so that the nano yttrium oxide dispersion strengthening tungsten alloy can be prepared. The preparation method provided by the invention has the advantages that the density can be 18.28-19.2g / cm<3>, and a yttrium oxide dispersed phase is fine and is uniformly distributed in tungsten crystal particles.

Owner:UNIV OF SCI & TECH BEIJING

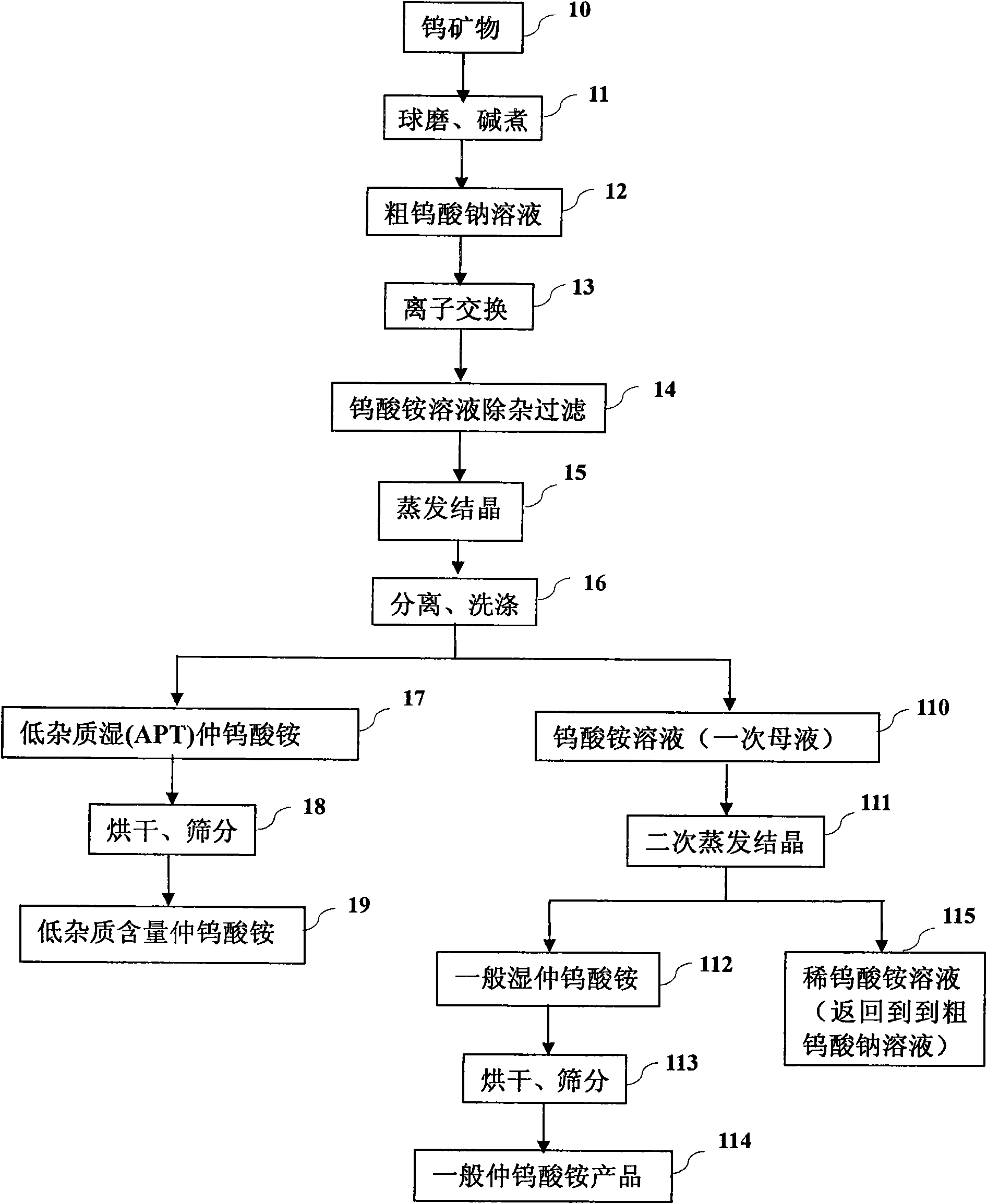

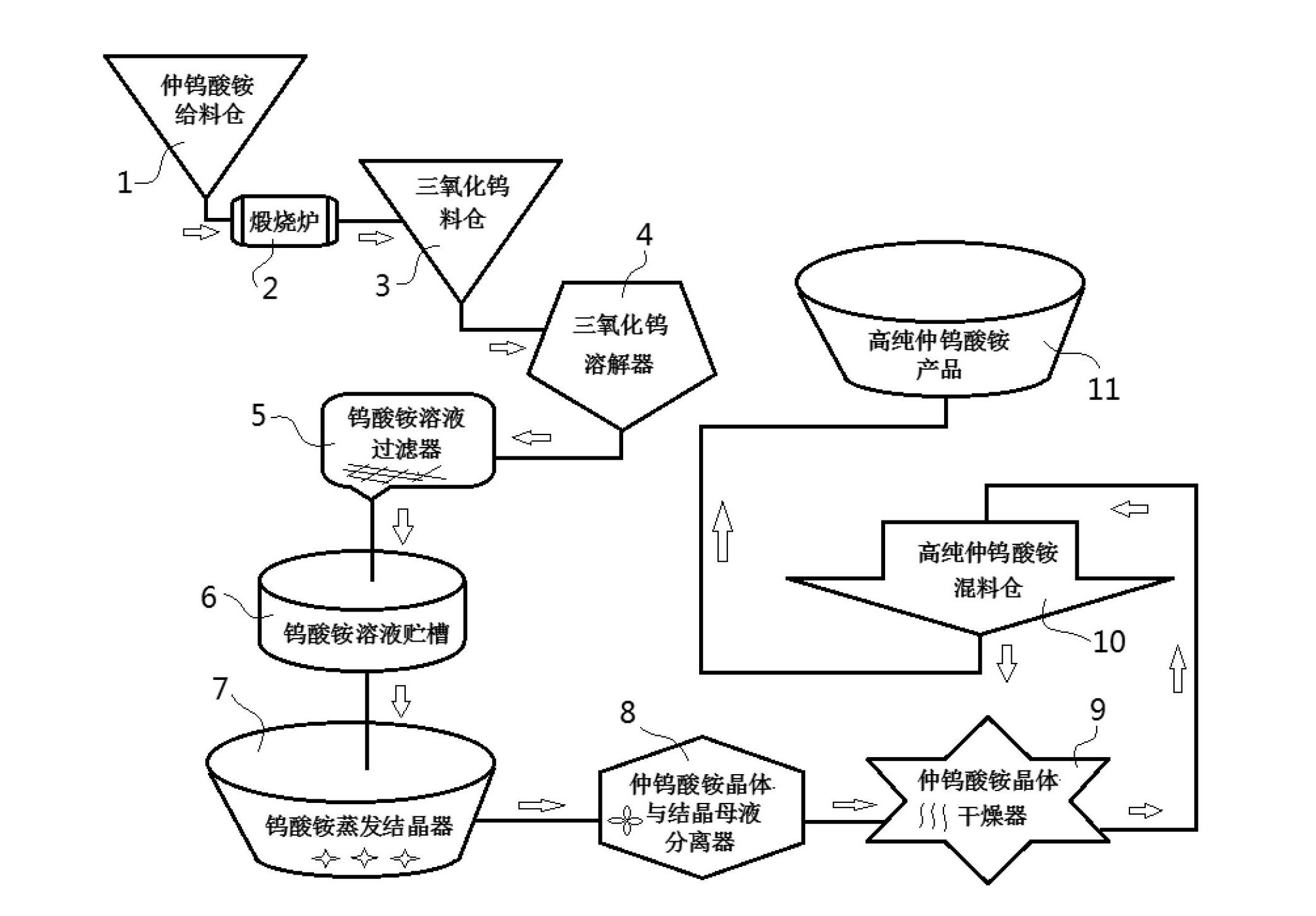

Process for preparing high-purity ammonium paratungstate

The invention relates to a process for preparing high-purity ammonium paratungstate, which can obtain a non-ferrous metal product, namely the ammonium paratungstate with low impurity content, whereinthe impurity content of the ammonium paratungstate is low and is lower than 70 ppm, and the ammonium paratungstate can be directly used for preparing deep processed products of tungsten, such as tungsten powder with low impurity content and the like. The process comprises the following four process steps: (1) a process step of preparing a sodium tungstate solution by using a tungsten concentrate (Fe, Mn)WO4, white tungsten (CaWO4) or a tungsten middling product as a raw material; (2) a process step of performing ion exchange on the sodium tungstate solution; (3) a process step of performing impurity removal and filtration by using an ammonium tungstate solution; and (4) a process step of performing crystallization, washing, drying and screening. The process for preparing the high-purity ammonium paratungstate optimizes the technological processes, improves the quality of a product, and reduces the preparation cost of the product.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

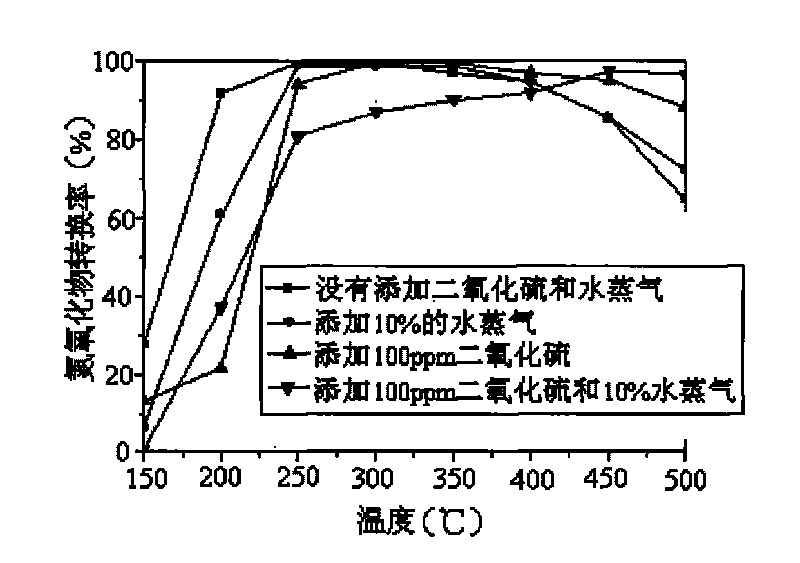

Power plant flue-gas SCR denitration catalyst capable of preventing sulfur trioxide poisoning and preparation method thereof

InactiveCN101396656ASimple preparation processEasy to operateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAmmonium paratungstateSlurry

The invention belongs to the chemical material field, in particular to an SO3 poisoning resisting power plant flue gas SCR denitrification catalyst and a preparation method thereof. Tungsten doped titanium pigment which is synthesized from domestic metatitanic acid slurry and ammonium paratungstate oxalic acid solution is adopted by the catalyst as a carrier. Vanadium is used as a main catalyst, and oxide of germanium or zinc is added as additive for lowering the oxidization of the vanadium on SO2. Through drying, calcining and sieving, the catalyst is obtained. The catalyst comprises 80-95wt percent of TiO2, 3-15wt percent of WO3, 1-8wt percent of V2O5 and 1-8wt percent of GeO2 or ZnO2. The preparation method has the advantages of simple preparation process, easy operation, low cost and good denitrification effect. The SCR catalyst prepared by the method is tested to prove high denitrification efficiency and good SO3 poisoning resistance. Added SO2 has almost no influence on the activity of the catalyst.

Owner:TSINGHUA UNIV +1

Recycling method for waste denitration catalyst

InactiveCN104099476AEmission reductionShort production processProcess efficiency improvementMagnesium saltAmmonium paratungstate

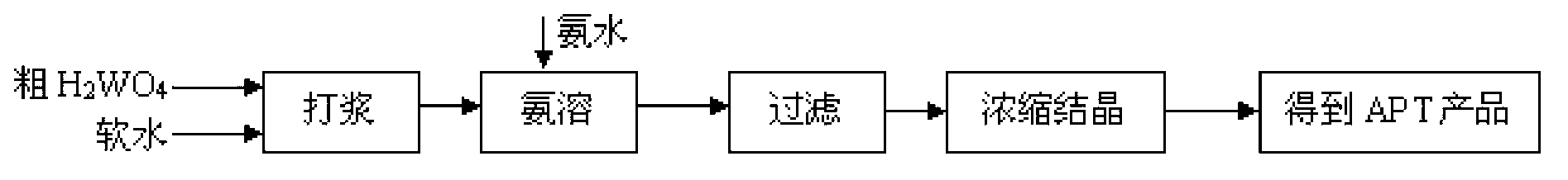

A recycling method for waste denitration catalyst is characterized by comprising the following steps: (1) the waste denitration catalyst is smashed into powder of 100 to 200 meshes; (2) the powder reacts with an alkali solution under a heating and stirring condition to obtain a titanium-rich material and a solution containing elements such as vanadium, tungsten, silicon and aluminum; (3) the titanium-rich material reacts with chlorine gas to generate titanium tetrachloride, then the titanium tetrachloride is condensed and reacts with oxygen to generate titanium dioxide, and the titanium dioxide is treated with surface finish and drying to obtain a titanium dioxide finished product; (4) the pH value of the solution obtained in the step (2) is adjusted; a magnesium salt is added into the solution to remove silicate ions and obtain a solution containing vanadium and tungsten; calcium chloride powder is added into the solution containing vanadium and tungsten to generate calcium tungstate; the calcium tungstate reacts with hydrochloric acid to generate tungstic acid; the tungstic acid is treated with ammonia dissolution and evaporative crystallization to obtain ammonium paratungstate crystals; (5) a precipitant ammonium chloride is added, and centrifugal drying is carried out to obtain solid ammonium vanadate. The method has the advantages that the operation is easy; three wastes are reduced; the economic efficiency is improved; the waste denitration catalyst is recycled.

Owner:CECEP L&T ENVIRONMENTAL TECH

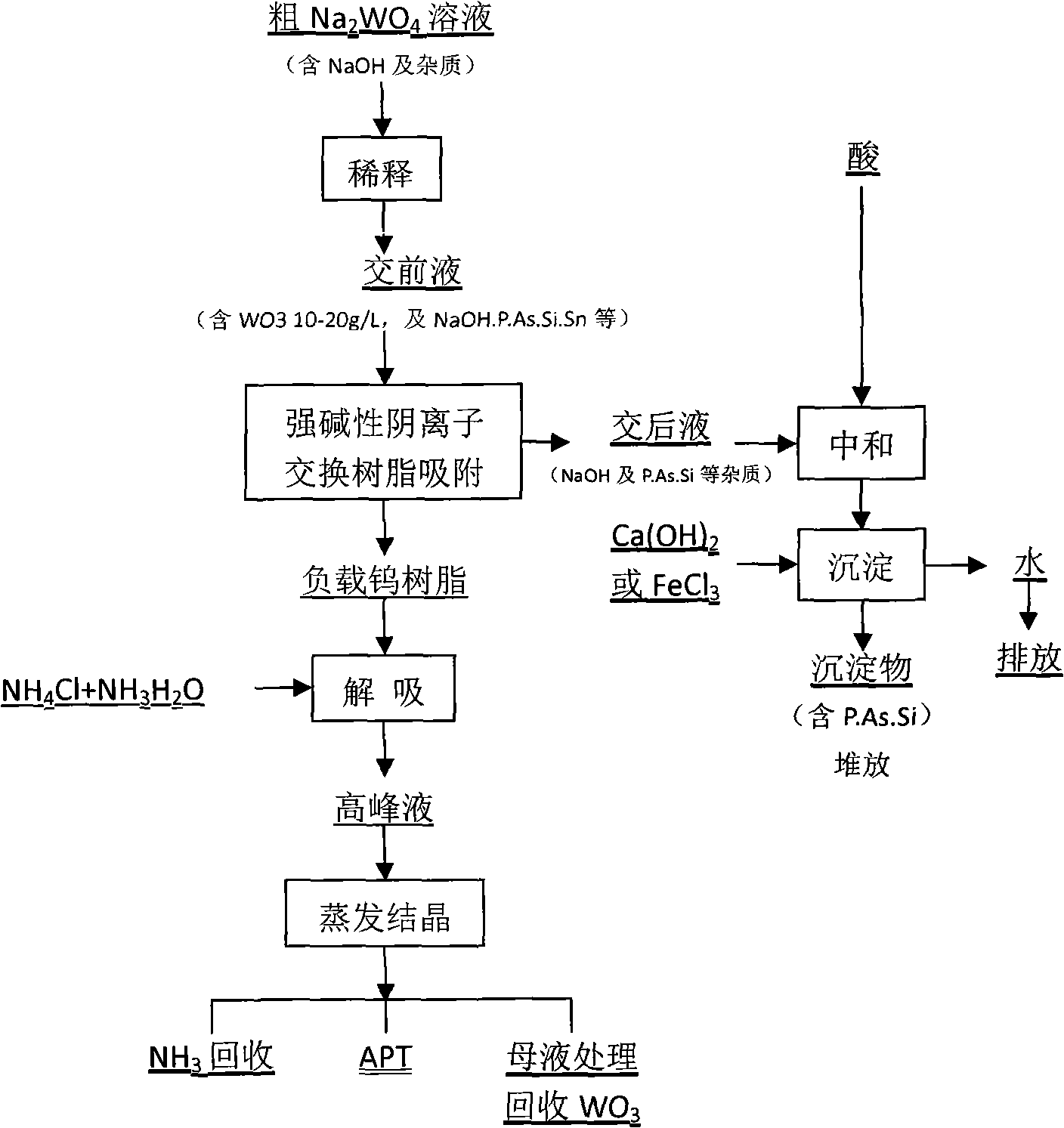

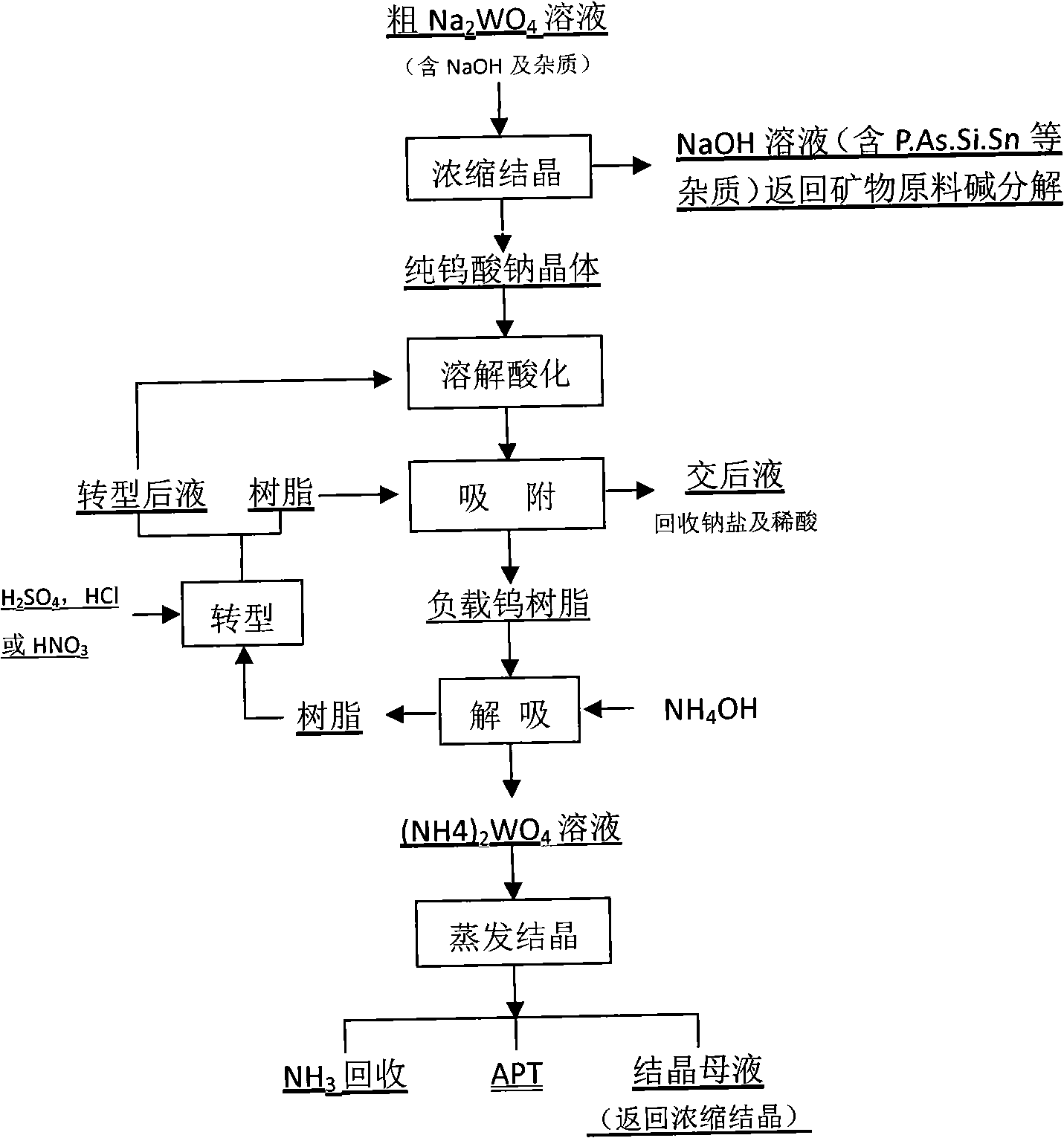

Method for preparing ammonium paratungstate from sodium tungstate solution

InactiveCN101570346AIncrease concentrationEmission reductionTungsten compoundsAmmonium paratungstateEvaporation

The invention provides a method for preparing pure ammonium paratungstate (APT) from crude Na2WO4 solution containing NaOH, P, As, Si, Sn and other impurities. The method comprises the following steps of crystallizing tungsten into Na2WO4 crystals through concentration, separating NaOH from impurities, redissolving and acidifying the Na2WO4 crystals till the pH of the crystals is between 2.0 and 6.0, adsorbing the crystals by use of macroporous weak alkaline anion exchange resin, desorbing the crystals by use of NH4OH, obtaining (NH4)2WO4 solution, performing evaporation crystallization and obtaining the APT. Under the condition that the crystallization rate is between 88 and 90 percent, the P, the As and the Si contained in the APT are all less than 10*10. The method has the outstanding advantage of small amount of discharged wastewater (mainly liquid after exchange), namely the volume of the discharged liquid after the exchange is one third to one twenty-fifth of that of liquid before the exchange; in addition, the discharged liquid after the exchange contains no detrimental impurities and is easy to control.

Owner:CENT SOUTH UNIV

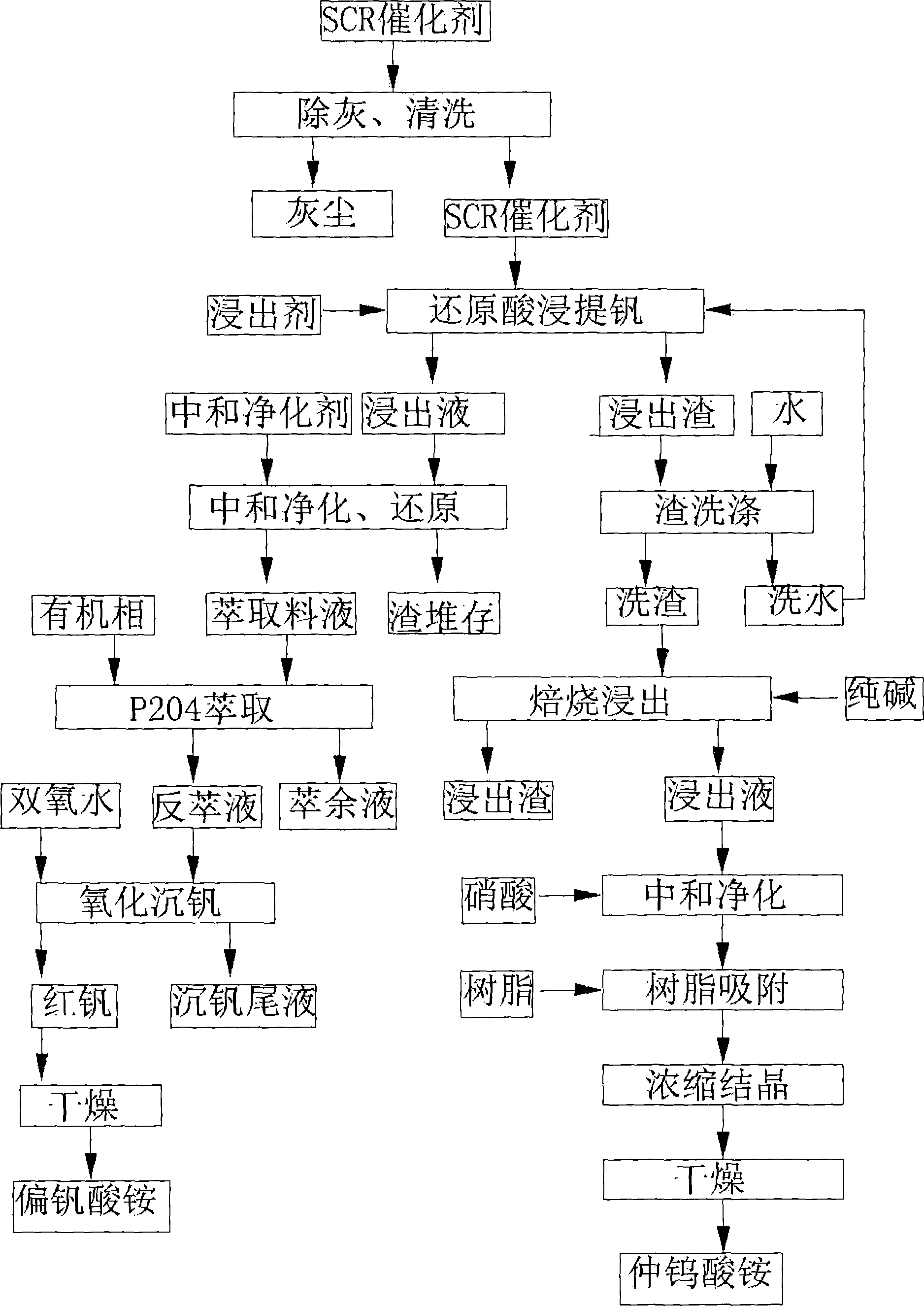

Comprehensive recycling method for waste titanium based vanadium SCR catalyst

ActiveCN104384167ARealize resource utilizationReduce processing costsSolid waste disposalPregnant leach solutionAmmonium paratungstate

The invention relates to a comprehensive recycling method for a waste titanium based vanadium SCR (selective catalytic reduction) catalyst. The method comprises the steps of: removing dust from the waste SCR catalyst; crushing the treated SCR catalyst; subjecting the crushed powder material to acid leaching vanadium extraction in an acid leaching tank, conducting neutralization, reduction and purification on the leachate, then employing P204 to conduct organic extraction, and performing drying to obtain the product ammonium metavanadate; washing the leaching residue generated by vanadium extraction to be close to neutral, adding sodium carbonate to conduct roasting so as to obtain a roasted material, levigating the roasted material and then conducting water leaching, adjusting the obtained leachate with acid to a pH value of 6-9, adsorbing tungsten with weakly basic anions, resolving the loaded resin with a mixed solution of ammonia water and ammonium chloride; heating the resolved solution to boiling and volatilizing ammonia in the solution until the pH value of the ammonia solution is reduced to 7.0-7.7, performing cooling to obtain wet ammonium paratungstate, and finally carrying out drying to obtain the product ammonium paratungstate. The method provided by the invention can effectively recover valuable metals in the waste catalyst.

Owner:HUADIAN HIGH TECH GAOBEIDIAN ENVIRONMENTAL TECH +1

Catalyst for denitration by SCR method with low cost and preparation method thereof

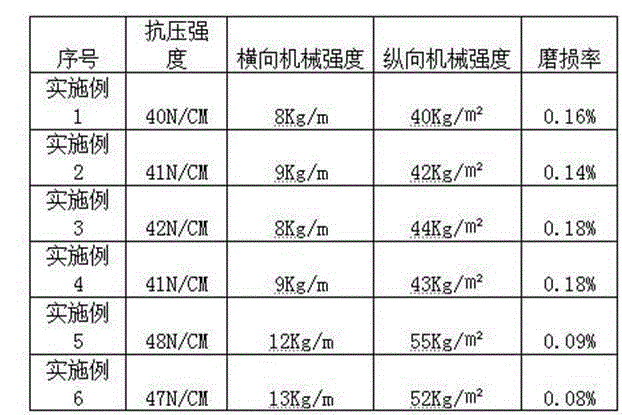

ActiveCN101347722AHigh activityImprove abrasion resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiberPolyethylene oxide

The invention provides a low-cost SCR method denitration catalyst and a preparation method thereof. The weight percentage of the components of the catalyst is as follows: 52-55% of slag micropowder, 2.7-2.9% of plaster, 1.3-1.5% of ammonium metavanadate, 5.5-5.7% of ammonium paratungstate, 2.6-2.8% of silica sol, 1.6-1.8% of clay, 2.5-3.0% of fiber glass filament, 2.7-2.9 % of methylcellulose, 1.3-1.5% of polyethylene oxide, 2.7-3.0% of monoethanolamine and 20-23 % of distilled water. Firstly, the slag and the plaster are pulverized and activated in high-temperature water vapor to prepare carrier; secondly, the carrier is evenly blended with other components to prepare slurry; the slurry is prepared into the semi-finished product of the catalyst according to the shape requirements of the catalyst, and then the semi-finished product is dried and calcined to prepare the finished product of the catalyst. The invention has simple production technique, and the catalyst has good activity and anti-abrasion performance and long service life, thus effectively lowering the production cost of the catalyst and operation expense of denitration treatment.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

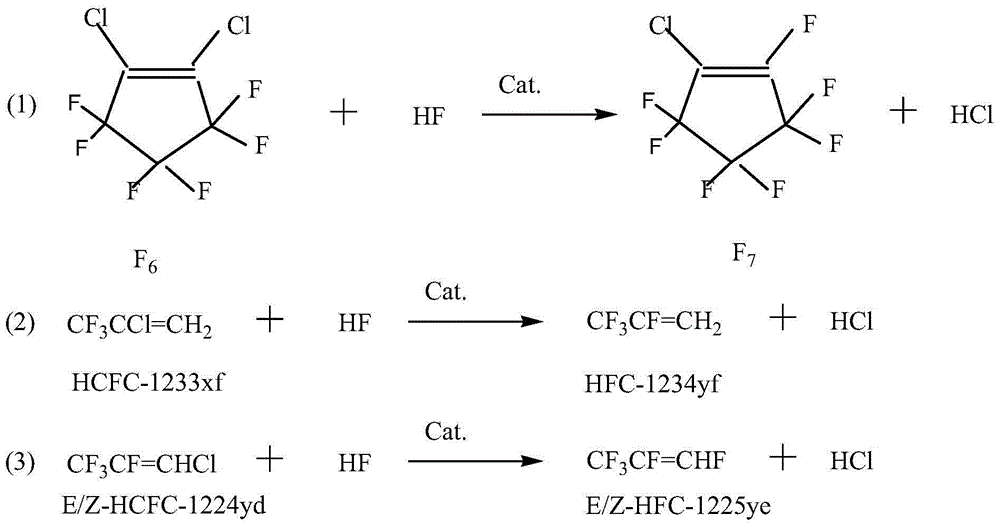

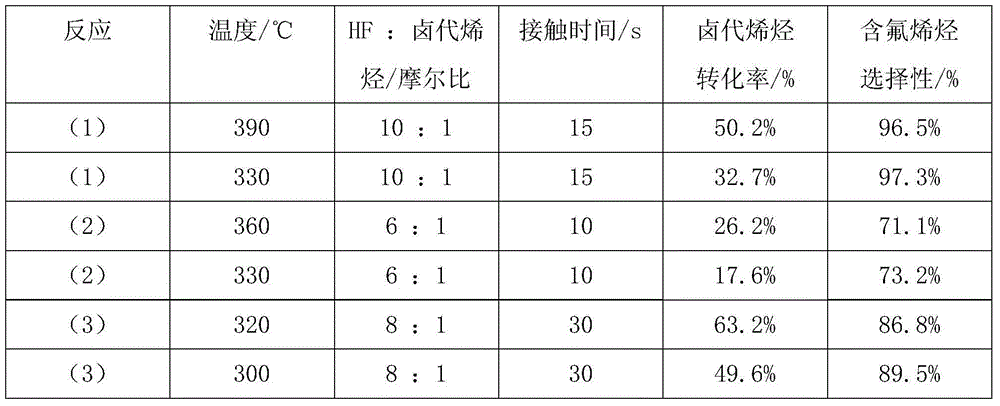

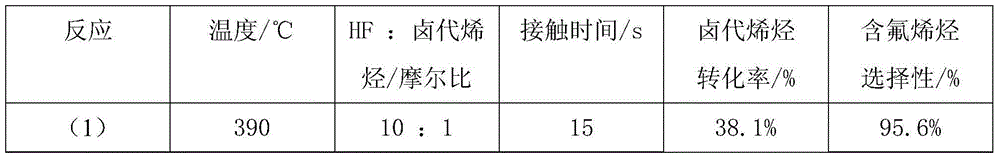

Fluorination catalyst, and preparation method and use thereof

ActiveCN104907065AIncrease the areaHigh pore volumePreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsChromium CompoundsChemical synthesis

The invention discloses a fluorination catalyst, and a preparation method and a use thereof, and belongs to the field of chemical synthesis. The precursor of the catalyst is formed by blending 40-95mass% of a trivalent chromium compound with 5-60mass% of tungstate, wherein the trivalent chromium compound can be chromic oxide or chromium hydroxide, and the tungstate can be zinc tungstate, nickel tungstate, magnesium tungstate, aluminum tungstate, silicotungstic acid, ammonium tungstate, ammonium paratungstate or ammonium metatungstate. The fluorination catalyst has the advantages of high use temperature, high catalysis activity and long service life, and can be mainly used in reactions for preparing fluorinated alkenes through gas phase catalysis of fluorination of alkenyl halides at a high temperature.

Owner:泉州宇极新材料科技有限公司

Nanostructure tungsten alloy and preparation method thereof

The invention discloses nanostructure tungsten alloy and a preparation method thereof. The alloy mainly comprises tungsten, and also comprises 0.05 to 1.0wt percent of zirconium and 0.2 to 2.0wt percent of rare-earth metal oxide particles, wherein the rare-earth metal oxide particle adopts yttrium oxide particles, lanthanum oxide particles or cerium oxide particles distributed in tungsten crystal particle. The method comprises the steps of firstly preparing ammonium paratungstate, rare-earth metal nitrate, citric acid and deionized water into transparent mixed liquor, stirring the transparent mixed liquor, obtaining gel after reaction, heating and drying the gel, then calcining the gel, so as to obtain a mixed powder of tungsten oxide and rare-earth metal oxide, putting the mixed powder into hydrogen atmosphere, so as to obtaining a mixed powder of tungsten and rare-earth metal oxide after reduction reaction, mixing the mixed powder with zirconium and zirconium hydride powder, so as to obtain a mixed powder of tungsten, zirconium, or zirconium hydride, and rare-earth metal oxide, and finally performing compaction and sintering to the mixed powder, so as to obtain the nanostructure tungsten alloy. The nanostructure tungsten alloy can be applied to fields of lighting, high-temperature components, aerospace devices, high temperature resistance containers and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Ceria-based denitration catalyst and preparation method thereof

InactiveCN101721992AReduce pollutionLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater bathsAmmonium paratungstate

The invention relates to a ceria-based denitration catalyst and a preparation method thereof. The catalyst takes anatase titanium dioxide as a carrier, cerium oxide as a main active component and tungsten trioxide as an auxiliary agent having the synergistic effect, and the catalyst is expressed as CeO2-WO3 / TiO2. The preparation method comprises the steps of: dissolving oxalate into deionized water to prepare oxalate solution; adding ammonium paratungstate into the oxalate solution for heating in a water bath to prepare transparent solution; dissolving cerous nitrate into the oxalate solution to prepare mixed solution; dripping the mixed solution into the transparent solution to prepare solution with flocculent precipitates; adding titanium dioxide powder into the solution with the flocculent precipitates for stirring and heating in a water bath to prepare slurry; and performing ultrasonic immersing, drying and calcination on the slurry to prepare the CeO2-WO3 / TiO2 catalyst. The catalyst can purify oxynitride under the high-sulfur, high-dust and high-temperature environment, and can reduce cost and improve use safety.

Owner:TSINGHUA UNIV

Method for preparing denitration catalyst carrier TiO2-WO3 composite powder

InactiveCN102327783AImprove performanceEasy to processCatalyst carriersDispersed particle separationPtru catalystAmmonium paratungstate

The invention discloses a method for preparing denitration catalyst carrier TiO2-WO3 composite powder, which comprises the following steps of: pulping and dispersing a metatitanic acid raw material; adjusting until the concentration of the slurry, calculated in terms of the titanium dioxide TiO2, is 15-25% by mass; adding ammonium paratungstate to the slurry according to a proportion, wherein calculated by the mass of tungsten trioxide WO3, the additive proportion of the ammonium paratungstate is 4.0%-10.0% of the sum of the TiO2 and the WO3; adding ammonia water to the slurry to adjust the pH to 6.5-9.0; filtering and dewatering to obtain a blocky filter cake; crushing the filter cake mechanically; drying and roasting the crushed filter cake at 200 DEG C to 580 DEG C for 6 hours; and crushing the roasted material falling in the kiln to obtain a TiO2-WO3 composite powder product serving as the denitration catalyst carrier. The method disclosed by the invention is low in manufacturing cost and simple in process; and the prepared product has the advantages of high specific surface area, high surface chemical activity, high catalytic efficiency and good processability.

Owner:四川华铁钒钛科技股份有限公司

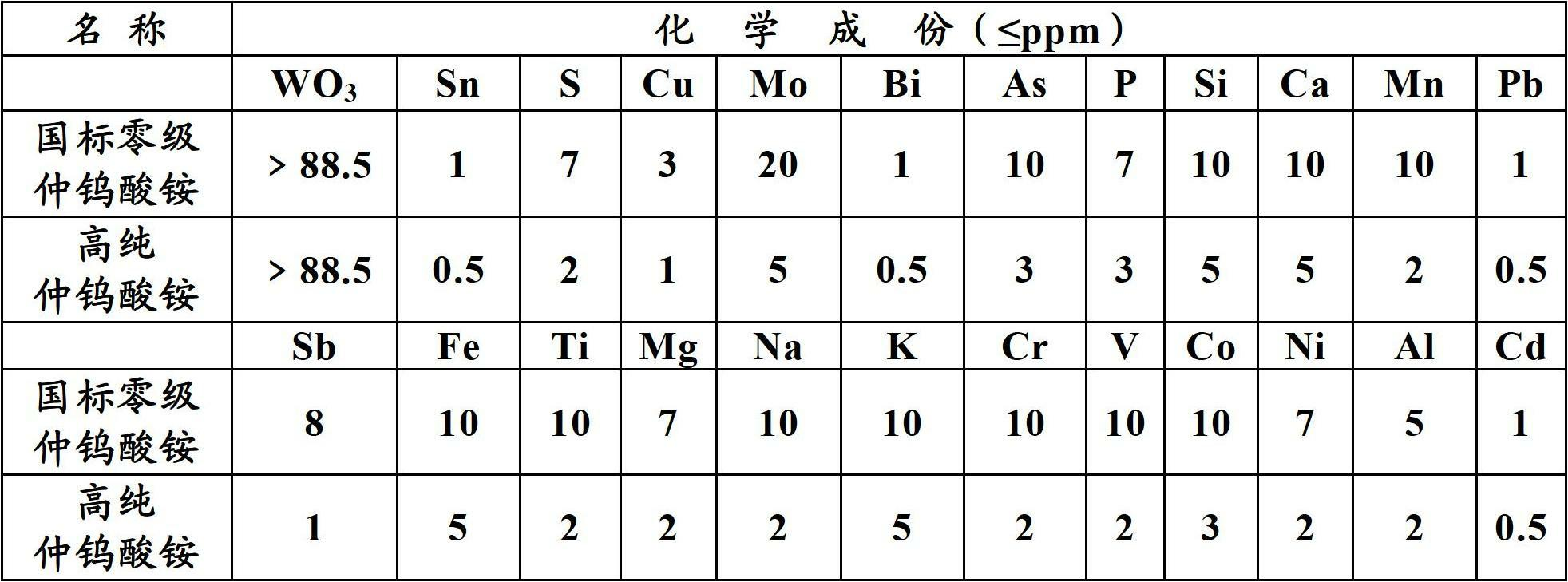

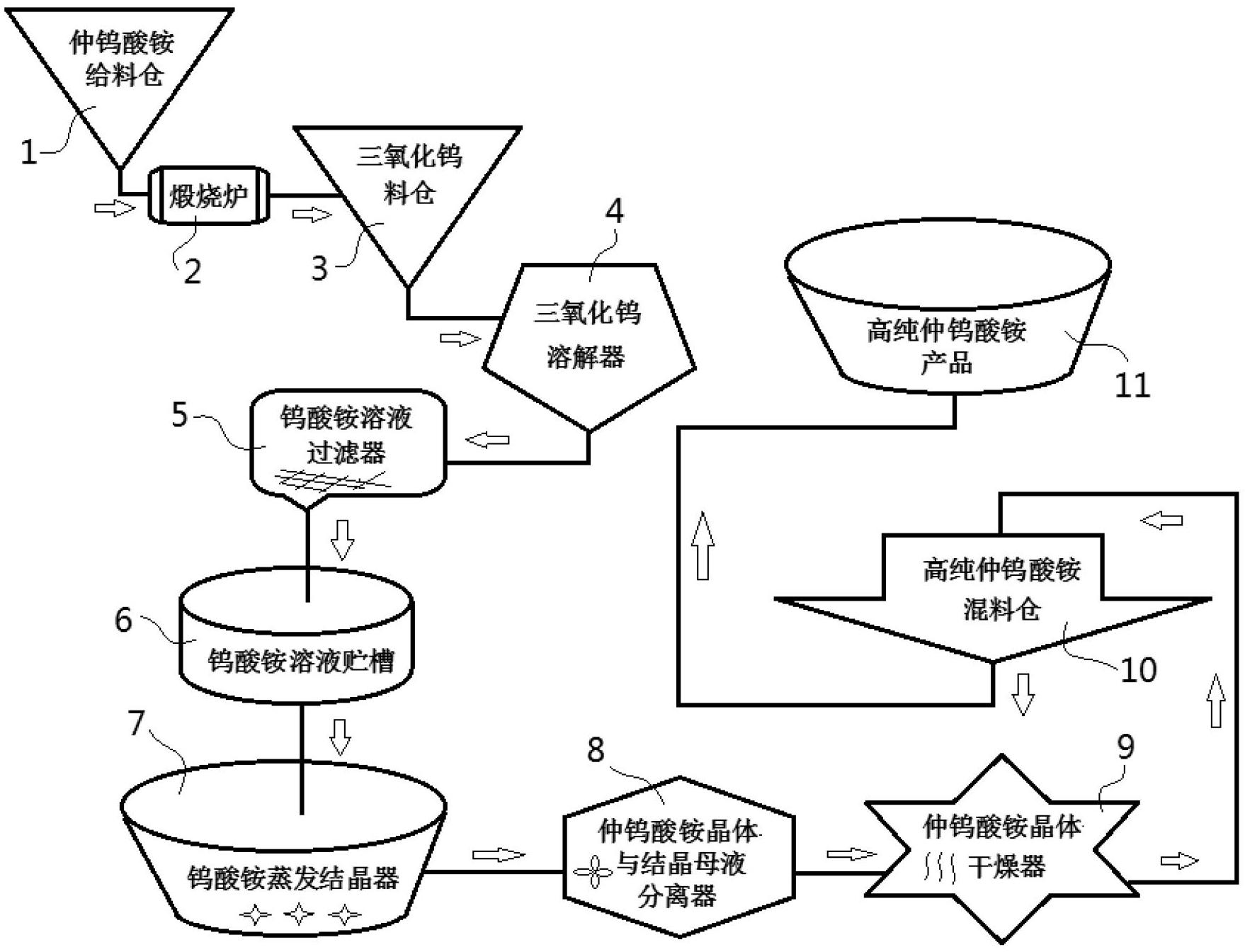

Preparation method for high-purity ammonium paratungstate

ActiveCN102674460ASolve the problem of poor dissolution effectEfficient removalTungsten compoundsAmmonium paratungstateTungstate

The invention relates to a preparation method for high-purity ammonium paratungstate. The preparation method is characterized in that: raw materials are prepared, namely APT (ammonium paratungstate) which is produced by an ion exchange method or an extraction method, has the impurity total content less than or equal to 177.5 ppm and confirms to national standard of 0 level or unqualified APT which is produced in the production process and has the impurity total content more than or equal 177.5 ppm are prepared. The method comprises the following steps of: calcining the prepared raw materials to produce tungsten trioxide; dissolving the produced tungsten trioxide by using ammonia to produce ammonium tungstate solution; performing evaporative crystallization on the produced ammonium tungstate solution to obtain wet ammonium paratungstate crystals; and drying and screening the wet ammonium paratungstate crystals so as to obtain the high-purity ammonium paratungstate of which the impurity total content is less than or equal to 65 ppm. According to the extraction method, a production process of the high-purity APT is optimized, the product quality is improved, and the production cost of the high-purity APT products is reduced.

Owner:JIANGXI XINSHENG TUNGSTEN IND

TiO2-WO3-SiO2 composite powder used as catalyst carrier and preparation method thereof

InactiveCN102553655AHigh catalytic efficiencyHigh strengthCatalyst carriersDispersed particle separationPtru catalystAmmonium paratungstate

The invention discloses and provides a preparation method of TiO2-WO3-SiO2 composite powder used as a catalyst carrier. The method sequentially comprises the following steps: dispersing a metatitanic acid raw material into the slurry through beating, and regulating the concentration of the slurry having the mass fraction of 10 percent to 20 percent and counted with titanium dioxide; respectively adding ammonium paratungstate and white carbon black into the slurry; adding ammonia water and regulating the pH value to be within the range of 5.5 to 8.5; filtering and dehydrating the slurry to obtain a blocky filter cake; mechanically grinding the blocky filter cake obtained after filtering and dehydrating, drying the ground filter cake for 2.5 hours at a temperature of 200 DEG C to 380 DEG C and calcining the dried filter cake for 4.5 hours at a temperature of 380 DEG C to 680 DEG C; and obtaining the TiO2-WO3-SiO2 composite powder after grinding calcined falling materials. The method disclosed by the invention has the advantages of low manufacturing cost, simple process, high specific surface area of a product, high surface chemical activity, and good processing performance. A denitration catalyst prepared from the product has the advantages of high strength, long service life, high catalytic efficiency and the like.

Owner:四川华铁钒钛科技股份有限公司

Recovery process for valuable metals in tungsten residues

ActiveCN103290224AReduce recycling costsLow costProcess efficiency improvementAmmonium paratungstateFiltration

The invention provides a recovery process for valuable metals in tungsten residues. The tungsten residue treatment method comprises the following steps of: boiling tungsten residues and 15%-25% of hydrochloric acid for acid dissolution, further adding NaF and sodium nitrate, and filtering to obtain filtrate after the end of the reaction; then extracting tungsten from the filtrate by adopting N235, and evaporating, crystallizing and drying a stripping solution to obtain APT (ammonium paratungstate); and performing alkali dissolution on filtration residues, and performing pressure filtration to directly recover Ta, Nb and Sn valuable metals. Tungsten, scandium, iron, manganese, tin, copper, tantalum and niobium valuable elements and the like in the tungsten residues can be comprehensively recovered, thus the recovery cost is reduced. The recovery process disclosed by the invention further has the advantages of good environmental benefits and low cost. According to the recovery process disclosed by the invention, the acid is adopted for dissolving the tungsten residues, the tungsten and the scandium are recovered under acid conditions, the other elements are simultaneously recovered, and the process is simple.

Owner:北京恒泰岩磊科技有限公司

Preparation method of superfine yttrium oxide doped tungsten composite precursor powder

ActiveCN106564927AImprove uniformityGuaranteed purityRare earth metal oxides/hydroxidesNanotechnologyAmmonium paratungstateDissolution

The invention relates to a preparation method of superfine yttrium oxide doped tungsten composite precursor powder. The preparation method comprises the steps: dissolving ammonium paratungstate, yttrium nitrate hexahydrate and a surfactant into water, and carrying out sufficient dispersion and dissolution through mechanical stirring and ultrasonic treatment to prepare a solution; adding concentrated HNO3 into the solution under stirring and ultrasonics to carry out precipitation reaction to form a suspension liquid; adding absolute ethyl alcohol into the suspension liquid to further react, filtering the reacted suspension liquid, and cleaning a precipitate by using absolute ethyl alcohol or distilled water; after drying the precipitate, grinding the precipitate to obtain composite powder, then, placing the composite powder into a tube furnace, and calcining the composite powder in a nitrogen or argon flow to obtain W-Y2O3 composite oxide powder; and carrying out two-step reduction in the tube furnace by using pure hydrogen to obtain the superfine yttrium oxide doped tungsten composite precursor powder. The average grain size of the powder reaches about 10nm, and the uniformity of the grain size is good. Meanwhile, Y2O3 is also uniformly doped, which provides a good basis for subsequent calcination for obtaining fine-grain compact tungsten-based alloy.

Owner:TIANJIN UNIV

Formula for coal-fired flue gas denitrification catalyst activity regeneration

InactiveCN102764675ADispersed particle separationCatalyst regeneration/reactivationPtru catalystAmmonium paratungstate

Provided is a formula for coal-fired flue gas denitrification catalyst activity regeneration, belonging to the technical field of air pollution control. The formula of the invention mainly makes use of a composite regeneration solution mainly including (NH4)2SO4, ethylene diamine tetraacetic acid (EDTA), alkylphenol ethoxylates (OP-(n), n=10), high-carbon fatty alcohol polyoxyethylene ether (penetrantfor JFC and nylon leveling agent O), ammonium metavanadate and ammonium paratungstate to recover the activity of a deactivated catalyst. The formula of the invention selects the inexpensive and operationally safe (NH4)2SO4 as the main ingredient of a regenerant, adds the EDTA component, and effectively removes heavy metal elements on the surface of the catalyst. The formula can maximally recover the catalyst activity on the basis of no influence on the mechanical properties of the catalyst.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Regenerating method of invalid SCR denitration catalyst

ActiveCN104475174AHigh out-of-stock activityActivate Active IngredientsDispersed particle separationCatalyst regeneration/reactivationHydrofluoric acidActive component

The invention discloses a regenerating method of an invalid SCR denitration catalyst. The regenerating method comprises the following steps: (1) purging; (2) carrying out thermal treatment; (3) washing; (4) carrying out acid pickling, namely, putting the SCR denitration catalyst after washing into a mixed solution of 10wt% sulfuric acid and 5wt% hydrofluoric acid, and carrying out ultrasonic dispersion for 2 hours; and (5) carrying out activity regeneration, namely, soaking the SCR denitration catalyst after acid pickling into an active mixed solution containing 5wt% ammonium paratungstate and 1wt% ammonium metavanadate for 2 hours, taking out, and drying. The regenerating method has the beneficial effects that a catalyst which is invalid because of multiple reasons can be comprehensively treated in practical production, so that not only can the surface deposition of the catalyst be removed, but also can the poisoned catalyst be restored, and the active components of the catalyst can be activated; the regenerated catalyst is high in denitration activity and cannot generate pollution in the use process.

Owner:安徽迪诺环保新材料科技有限公司

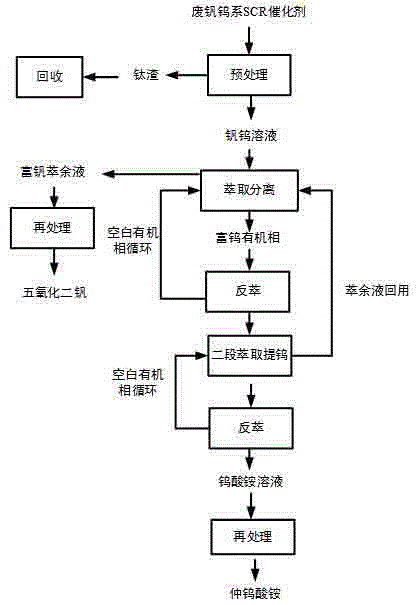

Vanadium and tungsten separating and purifying method for spent vanadium and tungsten SCR (selective catalytic reduction) catalysts

ActiveCN104862485ARealize separation and recoveryRealize recycling of resourcesProcess efficiency improvementPtru catalystAmmonium paratungstate

The invention discloses a vanadium and tungsten separating and purifying method for spent vanadium and tungsten SCR (selective catalytic reduction) catalysts. The method comprises the following steps: a spent catalyst is pretreated to obtain titanium slag and a vanadium and tungsten solution; the vanadium and tungsten solution is extracted for separation, and an obtained vanadium-rich raffinate is treated again to obtain vanadium pentoxide; a tungsten-rich organic phase obtained through separation is subjected to two-stage extraction for tungsten extraction after back extraction, a product is subjected to back extraction again to obtain an ammonium tungstate solution, and the ammonium tungstate solution is treated to prepare ammonium paratungstate. The blank of lack of a vanadium and tungsten separating, purifying and recovering technology for the spent vanadium and tungsten SCR catalysts in the denitration industry is filled up completely, the recovery rates of vanadium and tungsten both exceed 95%, the obtained vanadium pentoxide and ammonium paratungstate products all meet the high-purity standard, and the purity is higher than 99%.

Owner:BOTREE CYCLING SCI &TECH CO LTD

Denitrification catalyst regeneration method

InactiveCN102974404AImprove structural areaIncrease surface areaDispersed particle separationCatalyst regeneration/reactivationAmmonium paratungstateAmmonium metavanadate

The invention relates to a denitrification catalyst regeneration method. The denitrification catalyst regeneration method comprises the following steps of: cleaning solution soaking, deionized water soaking, active steeping liquor soaking, and drying to obtain a regenerated catalyst. The technological process of the denitrification catalyst regeneration method is technically characterized by comprising the following steps: (1) preparing a cleaning solution of certain concentration; (2) still steeping the catalyst in a washing pool for 30 to 60 minutes, and transferring the catalyst into a rinsing pool; (3) washing the catalyst with deionized water or a sulfuric acid solution (lower than 1%), and steeping for 30 to 60 minutes; (4) preparing an active steeping liquor of certain concentration, transferring the catalyst into an active steeping pool and steeping for 30 to 60 minutes; (5) and transferring the catalyst into an oven, drying for 1-3 hours at the temperature of 240-320 DEGC, and cooling the catalyst to obtain a regenerated catalyst, wherein the cleaning solution contains one or more of ammonium carbonate, ammonium bicarbonate, ammonium phosphate or ammonium hydrogen phosphate of certain concentration, and the active steeping liquor comprises the following main components: ammonium metavanadate, ammonium paratungstate and oxalate. The denitrification catalyst regeneration method has the characteristics that the washing process adopts chemical process standing operation, so that the loss of effective components in the catalyst can not be caused, and the hardness of the catalyst and the service life of the catalyst can be ensured to the maximum extent.

Owner:CECEP L&T ENVIRONMENTAL TECH

Process for preparing multicomponent composite rare-earth-tungsten electrode material

ActiveCN1586797AEasy to processImprove yieldWelding/cutting media/materialsSoldering mediaAmmonium paratungstateEvaporation

The present invention belongs to the field of refractory RE functional material. The improved multicomponent composite RE-W electrode material contains three kinds of RE oxides in 2.0-2.2 wt%, including La2O3, Y2O3 and CeO2 in 0.4-1.4 wt% each, except W. The preparation process of the multicomponent composite RE-W electrode material includes compounding mixed RE oxide solution with La2O3, Y2O3 and CeO2; preparing suspension of ammonium paratungstate in deionized water; mixing the solution and the suspension via stirring, evaporation and drying; the first hydrogen reduction at 550-700 deg.c, and the second hydrogen reduction at 850-1000 deg.c to prepare powder of average granularity of 1.2-1.4 micron. The preparation process has no ammonium paratungstate calcinating step, simplified process, low power consumption, raised finished product rate and stability.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Method for recovering metal by use of APT (ammonium paratungstate) waste slag

InactiveCN103103358AReduce wasteIncrease profitProcess efficiency improvementDecompositionAmmonium paratungstate

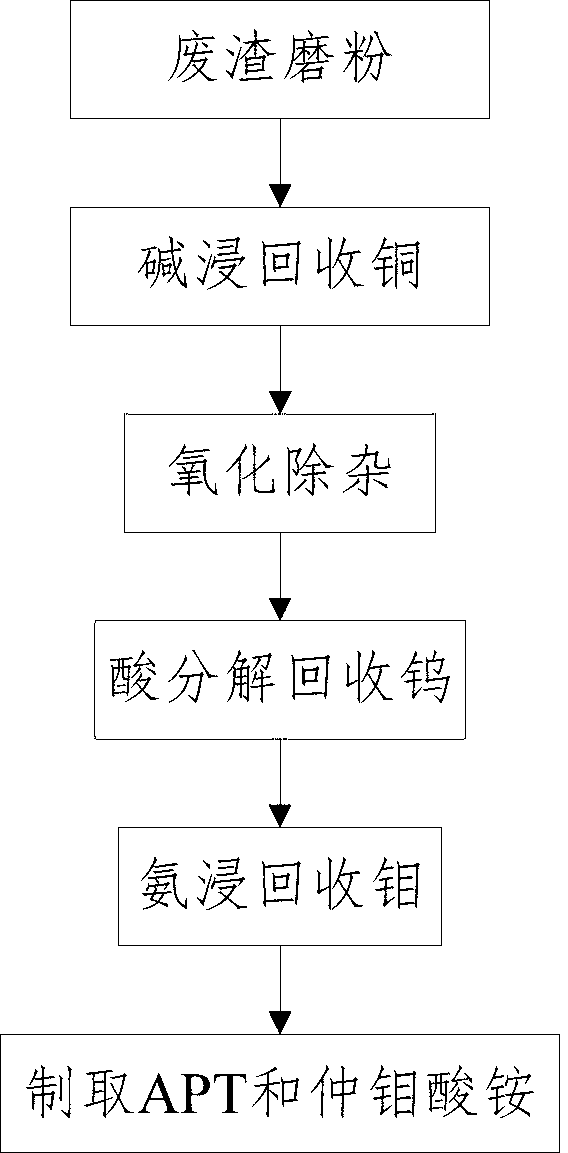

The invention belongs to the field of resource recycling, and particularly relates to a method for recovering metal by the use of APT (ammonium paratungstate) waste slag. The invention discloses a method for recovering metal by the use of APT waste slag, and comprises the following steps of: (a) waste slag grinding: grinding the waste slag containing copper, tungsten and molybdenum generated in an ammonium paratungstate production process until the particles of -325 meshes account for at least 90%; (b) alkaline leaching and copper recovery; (c) oxidation and impurity removal; (d) acid decomposition and tungsten recovery; (e) ammonia leaching and molybdenum recovery; and (f) preparation of APT and ammonium paramolybdate: preparing APT and ammonium paramolybdate from the tungstic acid and ammonium molybdate obtained in step d and step e respectively by subsequent traditional process. The method provided by the invention can recover copper, tungsten and molybdenum in the APT waste slag so as to effectively reduce resource waste and improve the utilization rate of resources; the recovery rate of copper, tungsten and molybdenum is as high as about 95%; by recovering the elements copper, tungsten and molybdenum in waste slag, the economic benefits of an enterprise can be increased; and a major part of the solution generated by the method is treated in subsequent processes, causing little environmental pollution.

Owner:陈泉兴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com