Preparation method of nano yttrium oxide dispersion strengthening tungsten alloy

A technology of nano-yttrium oxide and dispersion strengthening, which is applied in the field of powder manufacturing, can solve the problems of grain boundary segregation, large dispersed phase of tungsten alloy grains, uneven mixing of yttrium oxide, etc., and achieve high hardness and high density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

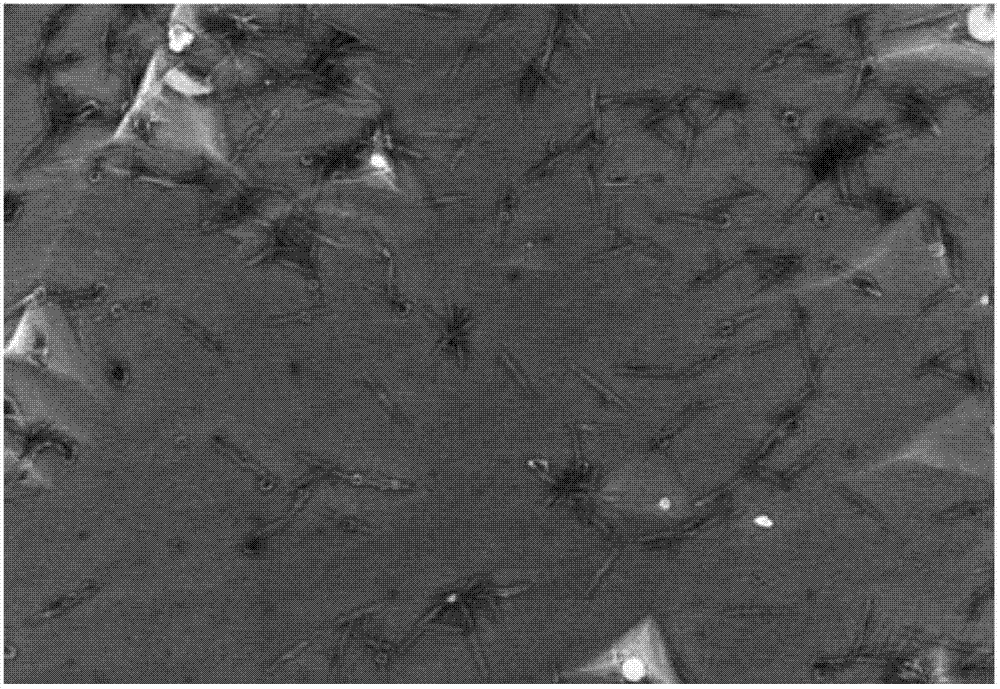

Image

Examples

Embodiment 1

[0019] In the process of preparing sintered tungsten alloy with nanometer Y2O3 content of 0.05%, the specific preparation process is as follows:

[0020] Step 1. Dissolve 1.42g of yttrium nitrate in 100ml of alcohol, ball mill and mix with 270g of ammonium paratungstate. The mass ratio of yttrium nitrate to ammonium paratungstate is 1:1000. The mixing process is that the ball milling speed is 120r / min, and the ball milling time is 2 hours ;

[0021] Step 2. Put the mixed wet powder into a vacuum drying oven, dry at 50°C, and dry for 20 hours;

[0022] Step 3: put the dried raw material powder into a muffle furnace for calcination, the calcination temperature is 700°C, and the calcination time is 1 hour, to obtain nano-yttrium oxide dispersion-strengthened tungsten oxide powder;

[0023] Step 4: Prepare nano-yttrium oxide dispersion-strengthened tungsten powder by subjecting the nano-yttrium oxide dispersion-strengthened tungsten oxide powder to hydrogen reduction at 900°C for...

Embodiment 2

[0027] Preparation of sintered tungsten alloy with nanometer Y2O3 content of 2.5% In this implementation process, the specific preparation process is:

[0028] Step 1. Dissolve 19.15g of yttrium nitrate in 150ml of alcohol, and ball mill and mix it with 270g of ammonium paratungstate. The mass ratio of yttrium nitrate and ammonium paratungstate is 1:40. The mixing process is that the ball milling speed is 150r / min, and the ball milling time is 8 hours ;

[0029] Step 2. Put the mixed wet powder into a vacuum drying oven, and dry at 65°C for 12 hours;

[0030] Step 3, put the dried raw material powder into a muffle furnace for calcination, the calcination temperature is 500°C, and the calcination time is 3 hours, to obtain nano-yttrium oxide dispersion-strengthened tungsten oxide powder;

[0031] Step 4. The nano-yttrium oxide dispersion-strengthened tungsten oxide powder is subjected to hydrogen reduction at 700°C for 60 minutes to prepare nano-yttrium oxide dispersion-streng...

Embodiment 3

[0035] Preparation of sintered tungsten alloy with nanometer Y2O3 content of 5% In this implementation process, the specific preparation process is:

[0036] Step 1. Dissolve 38.3g of yttrium nitrate in 500ml of alcohol, and mix it with 270g of ammonium paratungstate by ball milling. The mixing process is that the ball milling speed is 150r / min, the mass ratio of yttrium nitrate to ammonium paratungstate is 1:20, and the ball milling time is 12 hours ;

[0037] Step 2. Put the mixed wet powder into a vacuum drying oven and dry at 75°C for 36 hours;

[0038] Step 3: putting the dried raw material powder into a muffle furnace for calcination at a calcination temperature of 900° C. and a calcination time of 1 hour to obtain nano-yttrium oxide dispersion-strengthened tungsten oxide powder.

[0039] Step 4: The nano-yttrium oxide dispersion-strengthened tungsten oxide powder is subjected to hydrogen reduction at 1000° C. for 30 minutes to prepare the nano-yttrium oxide dispersion-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com