Nanostructure tungsten alloy and preparation method thereof

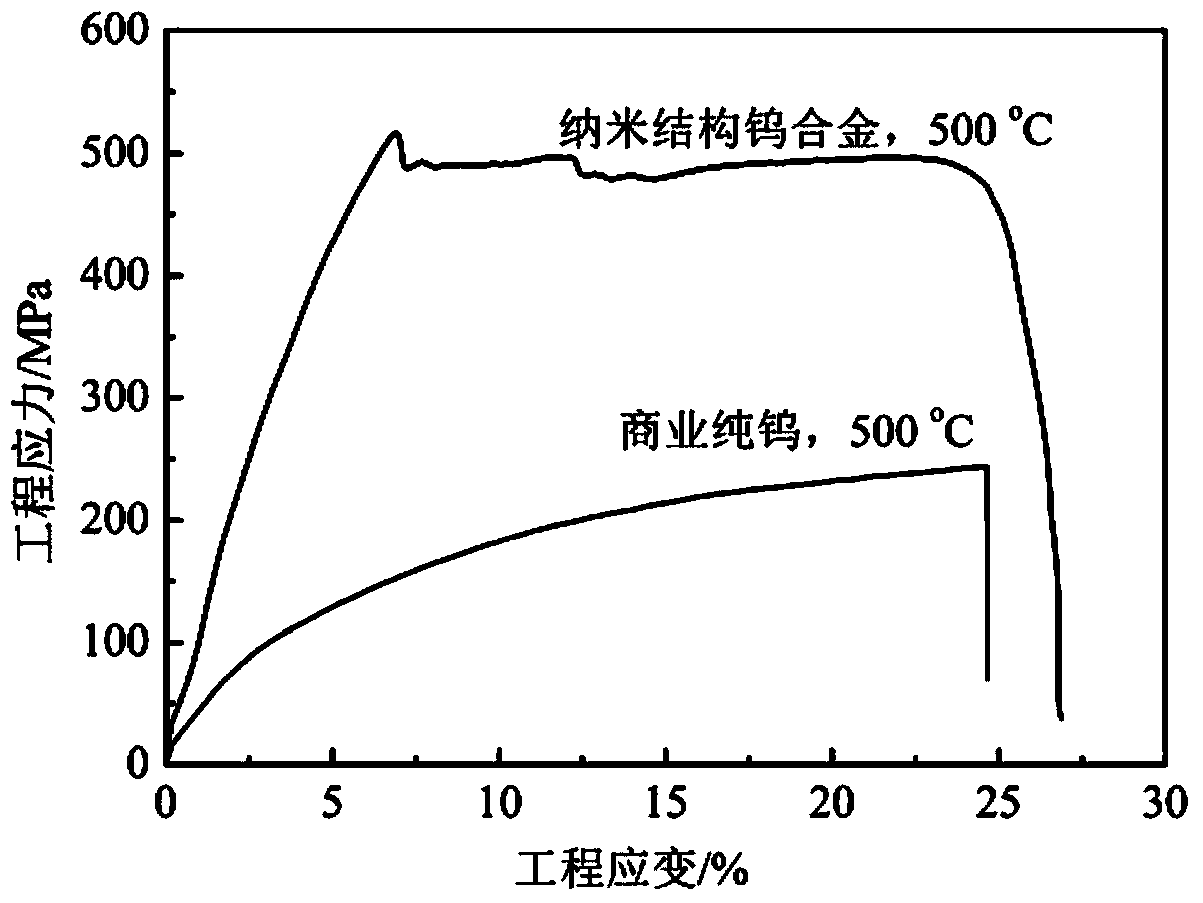

A nanostructure and tungsten alloy technology, which is applied in the field of nanostructure tungsten alloy and its preparation, can solve the problems of improving toughness, inability to obtain high temperature strength and toughness, etc., and achieve the effect of improving strength, small size, and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The concrete steps of preparation are:

[0035] Step 1, first prepare ammonium paratungstate, rare earth metal nitrate, citric acid and deionized water into a transparent mixed solution, and then place it at 50°C to stir and react to obtain a gel; wherein, the ammonium paratungstate, rare earth metal nitrate in the mixed solution The molar ratio with citric acid is 1:0.08:24, and the rare earth metal nitrate is yttrium nitrate. Then the gel is heated and dried and then calcined at 400°C for 3 hours; wherein, the temperature of the gel is heated and dried at 100°C for 20 hours to obtain a mixed powder of tungsten oxide and rare earth metal oxide.

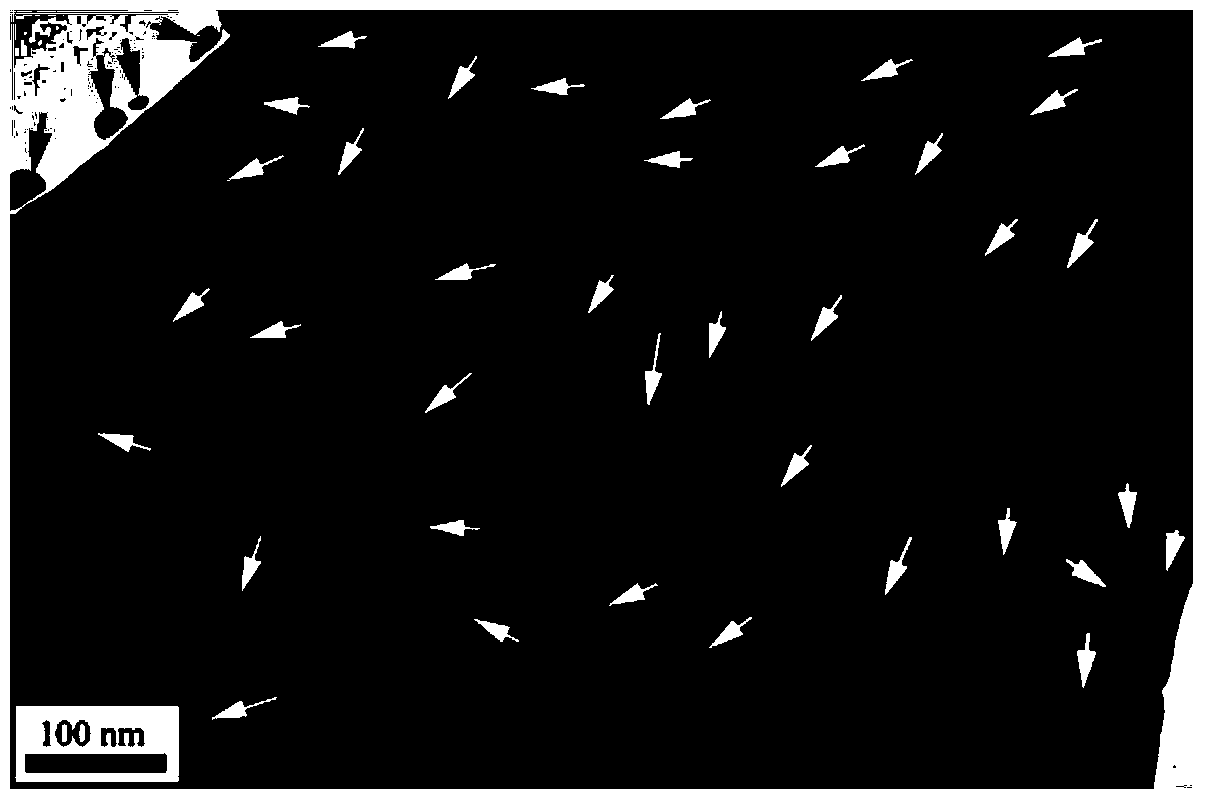

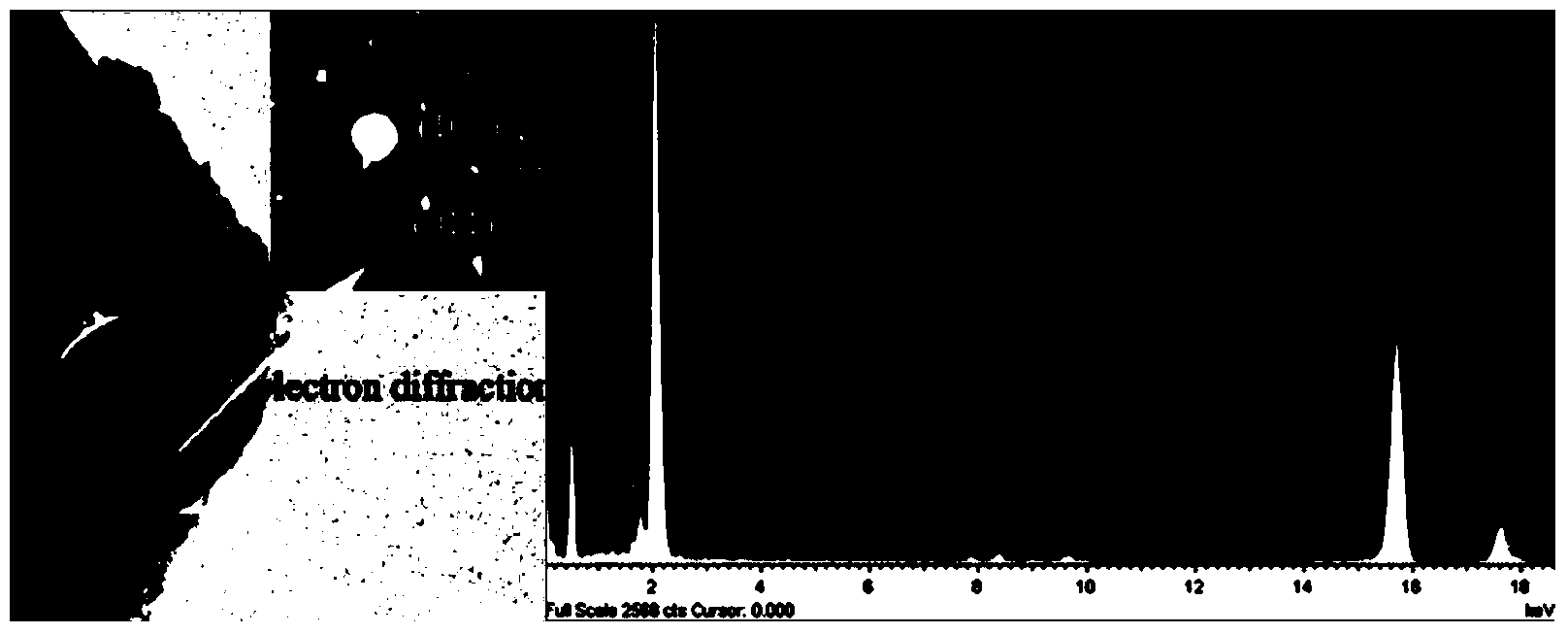

[0036]Step 2, first place the mixed powder of tungsten oxide and rare earth metal oxide in a hydrogen atmosphere, and conduct a reduction reaction at a temperature of 500° C. for 3 hours to obtain a mixed powder of nanometer-sized metal tungsten and rare earth metal oxide. Then mix nano-sized metal tungsten and rare earth met...

Embodiment 2

[0042] The concrete steps of preparation are:

[0043] Step 1, first prepare ammonium paratungstate, rare earth metal nitrate, citric acid and deionized water into a transparent mixed solution, then place it at 61°C to stir and react to obtain a gel; wherein, the ammonium paratungstate, rare earth metal nitrate in the mixed solution The molar ratio with citric acid is 1:0.12:18, and the rare earth metal nitrate is yttrium nitrate. Then heat and dry the gel and place it at 500° C. for 2.5 hours for calcination; wherein, the temperature of the gel is heated and dried at 138° C. for 15 hours to obtain a mixed powder of tungsten oxide and rare earth metal oxide.

[0044] Step 2, first place the mixed powder of tungsten oxide and rare earth metal oxide in a hydrogen atmosphere, and conduct a reduction reaction at a temperature of 600° C. for 2.5 hours to obtain a mixed powder of nanometer-sized metal tungsten and rare earth metal oxide. Then mix nano-sized metal tungsten and rare ...

Embodiment 3

[0050] The concrete steps of preparation are:

[0051] Step 1, first prepare ammonium paratungstate, rare earth metal nitrate, citric acid and deionized water into a transparent mixed solution, then place it at 73°C to stir and react to obtain a gel; among them, the ammonium paratungstate, rare earth metal nitrate in the mixed solution The molar ratio with citric acid is 1:0.04:13, and the rare earth metal nitrate is yttrium nitrate. Then heat and dry the gel and place it at 600° C. for 2 hours for calcination; wherein, the temperature of the gel is heated and dried at 175° C. for 10 hours to obtain a mixed powder of tungsten oxide and rare earth metal oxide.

[0052] Step 2, first place the mixed powder of tungsten oxide and rare earth metal oxide in a hydrogen atmosphere, and conduct a reduction reaction at a temperature of 700° C. for 2 hours to obtain a mixed powder of nanometer-sized metal tungsten and rare earth metal oxide. Then, the mixed powder of nano-sized metal tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com