Patents

Literature

295results about How to "Efficient manufacturing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

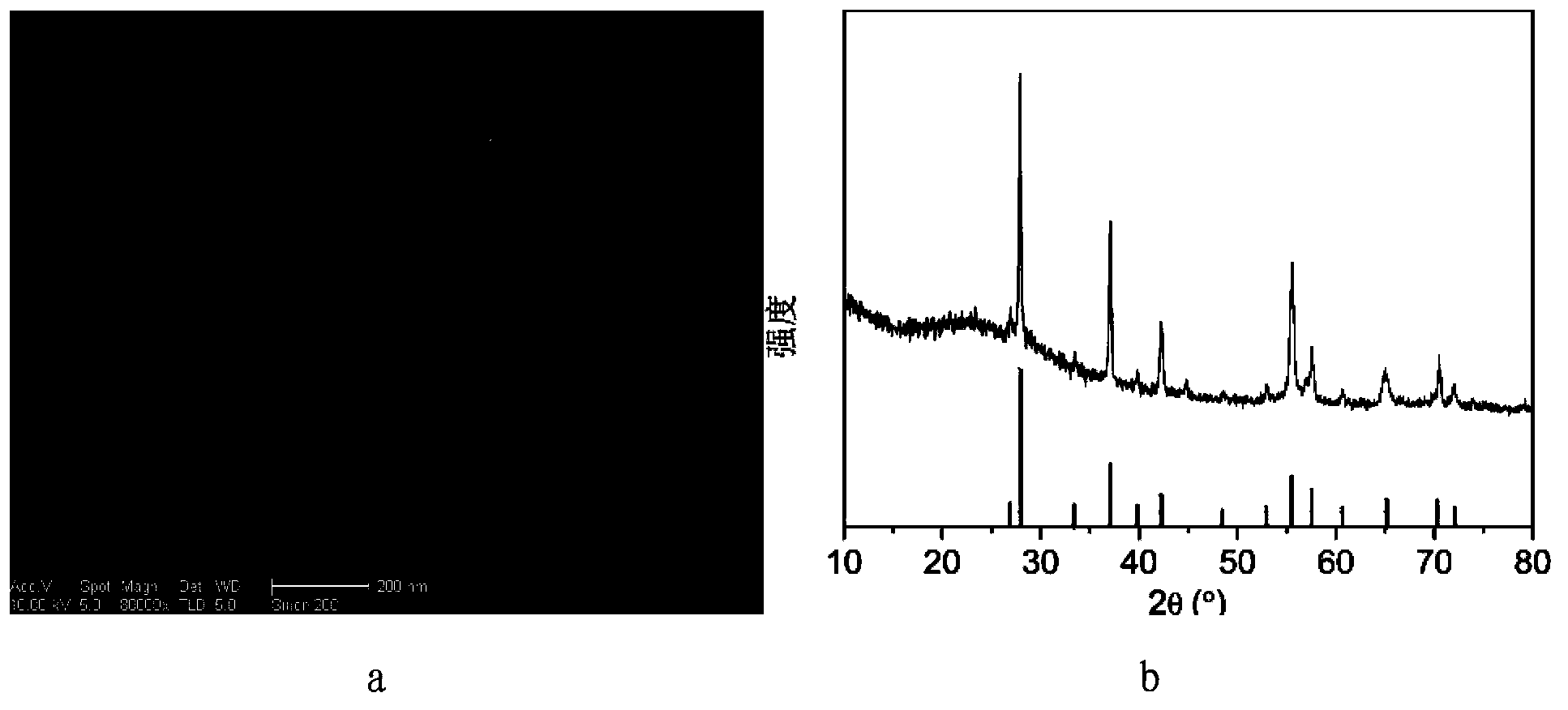

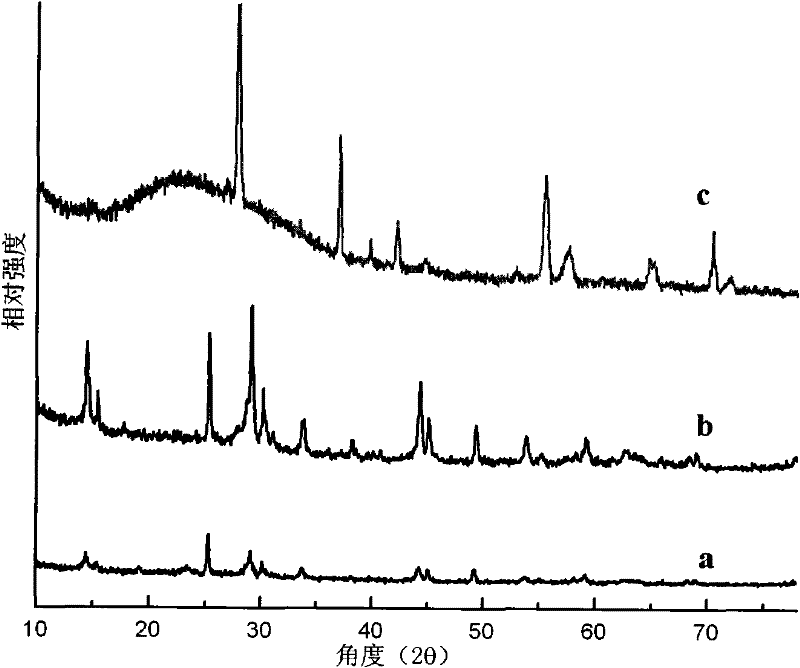

Preparation method of monodispersed M-phase vanadium dioxide nanoparticles

InactiveCN104071843AGood phase change propertiesExcellent infrared control performanceMaterial nanotechnologyVanadium oxidesVanadium dioxideDispersity

The invention discloses a preparation method of monodispersed M-phase vanadium dioxide nanoparticles. The preparation method comprises the following steps: mixing vanadium pentoxide, oxalate dihydrate and water according to a molar ratio of (1-2.5) : 1 : (500-800) to obtain mixed liquid, adding 4%-6% of a surfactant based on the volume of the mixed liquid into the mixed liquid, and stirring for at least 2 hours to obtain a precursor solution; reacting the precursor solution in a sealed state at 200-260 DEG C for at least 1 day to obtain reaction liquid; performing solid-liquid separation and washing on the reaction liquid in sequence to obtain orthogonal vanadium dioxide powder; annealing the orthogonal vanadium dioxide powder in a nitrogen atmosphere at 300-600 DEG C for 0.5 hour to obtain the monodispersed M-phase vanadium dioxide nanoparticles with particle sizes of 60nm-80nm. The preparation method has the advantages of environmental protection and no temperature gradient control during annealing, and can be widely used for preparing the M-phase vanadium dioxide nanoparticles with very good dispersity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

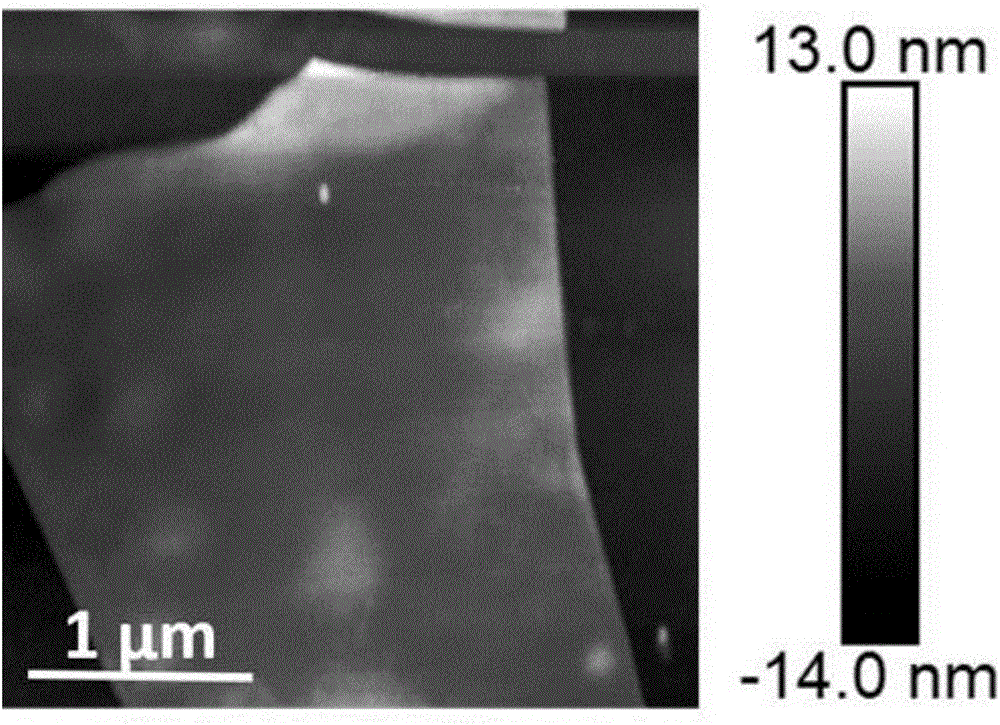

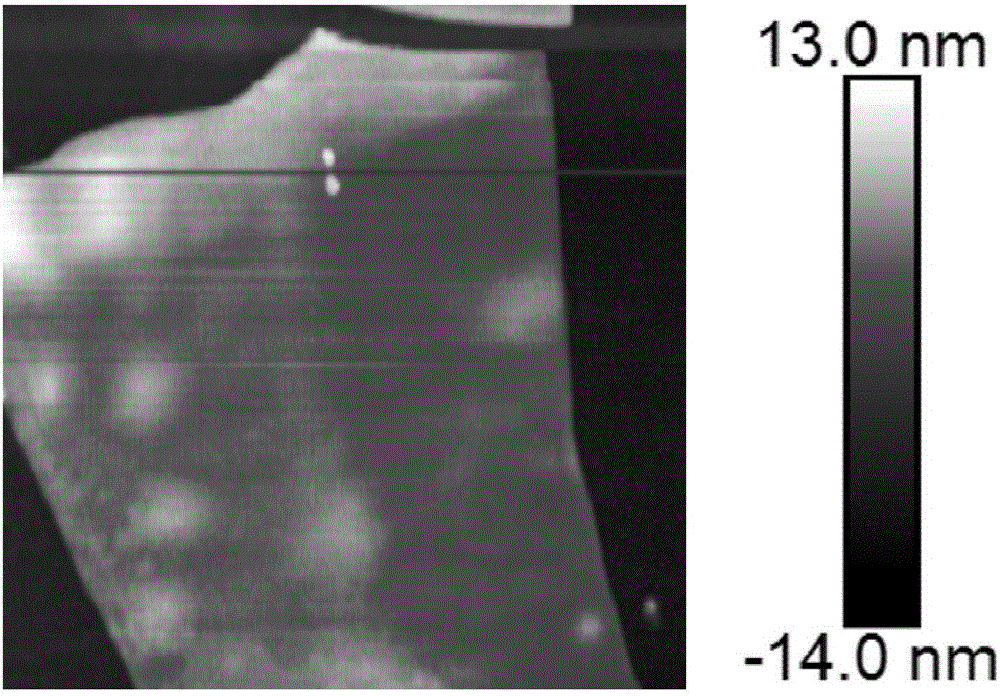

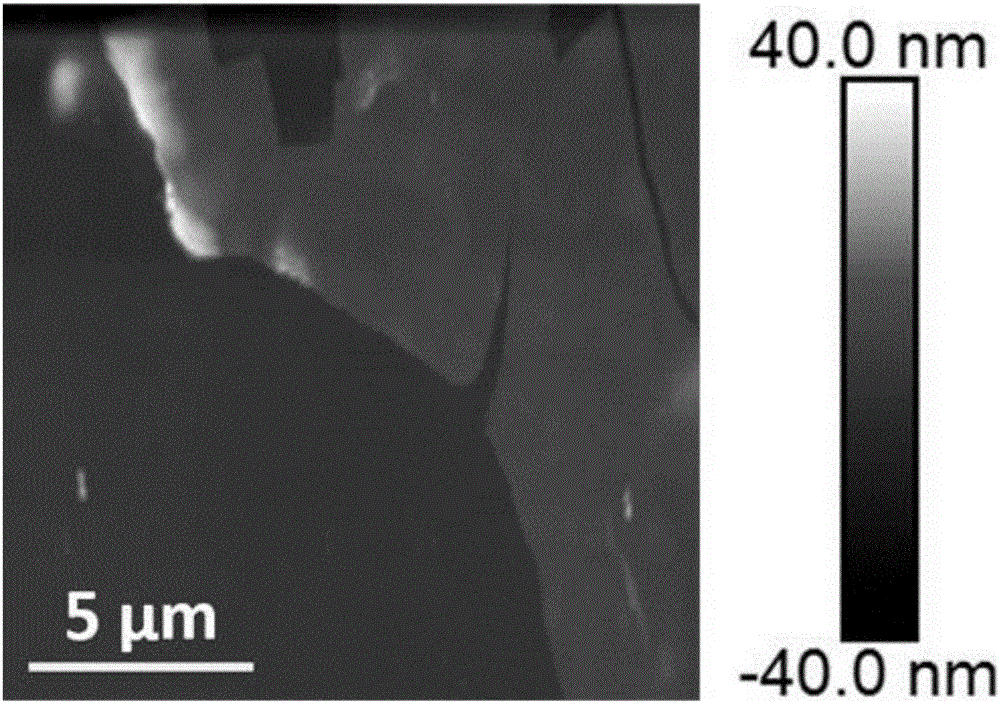

Metal ion modified black phosphorus as well as preparation method and application of metal ion modified black phosphorus

ActiveCN106185848AImprove antioxidant capacityStable structureMaterial nanotechnologyPhosphorusShielding gasStructural stability

The invention provides metal ion modified black phosphorus as well as a preparation method and an application of the metal ion modified black phosphorus. The preparation method comprises the following steps of placing black phosphorus raw materials in a metal ion organic solution, performing impregnating under the temperature of 0-50 DEG C for 5min to 2h, and then performing blow-drying under protective gas so as to prepare the metal ion modified black phosphorus. The invention further provides the metal ion modified black phosphorus prepared by the preparation method, and the application of the metal ion modified black phosphorus in thin-film transistor materials, battery negative electrode materials, flexible display materials, light emitting diode materials, optical switch materials and biosensor materials. The metal ion modified black phosphorus provided by the invention can utilize the metal ions to improve the structural stability and the property stability of the black phosphorus in the existence of water and oxygen gas under the condition of being not changing the intrinsic attributes of the black phosphorus, so that the antioxidant ability of the black phosphorus is improved.

Owner:SHENZHEN INST OF ADVANCED TECH

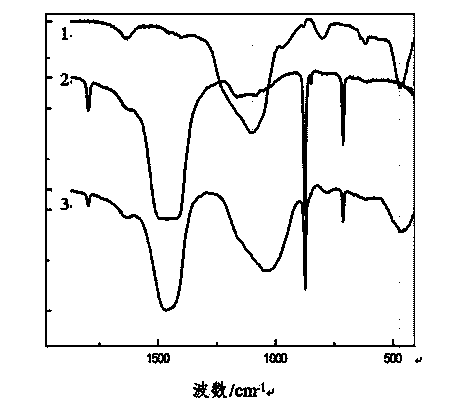

Nanometer fire retardant coating and preparation method thereof

The invention discloses a nanometer fire retardant coating and a preparation method thereof. The coating comprises inorganic filler, a film-forming agent, a firm-forming aid, a plasticizer, a cross-linking agent and a drier, wherein the inorganic filler is a modified nanometer composite particle of an inorganic nanometer particle of which the surface is covered with silicon dioxide particles. The preparation method comprises the following steps of: adding the inorganic nanometer particle to a sodium silicate aqueous solution; agitating; adjusting with acid; ageing to obtain mixed sol; performing suction filtration and washing for the mixed sol; drying to obtain the composite particle; sequentially adding the composite particle and a silane coupling agent to ethanol while stirring to perform reflux reaction so as to obtain reaction liquid; alternately centrifugally washing and separating the reaction liquid with ethanol to obtain the modified nanometer composite particle; and then mixing the modified nanometer composite particle, the firm-forming agent, the firm-forming aid, the plasticizer, the cross-linking agent and the drier and performing ball milling, so as to obtain the target product. The nanometer fire retardant coating can perform endothermic reaction to produce a ceramic heat insulating layer in different stages of a fire, and can be widely applied to various situations requiring fire resistance and inflaming retarding performance.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Polypropylene/ organic montmorillonite nano composite material and preparation method thereof

ActiveCN101880421AImprove melt strengthRaise the crystallization temperatureMontmorilloniteCrystallization temperature

The invention discloses a polypropylene / organic montmorillonite nano composite material which is prepared by the components in part by weight: 80-100 parts of polypropylene, 1-15 parts of organic montmorillonite, 0.02-0.10 part of organic peroxide initiator, 2.0-5.0 parts of cross-linking agent and 5-15 parts of compatilizer. The invention also discloses a preparation method of the polypropylene / organic montmorillonite nano composite material. The polypropylene / organic montmorillonite nano composite material has higher crystallization temperature, toughness and modulus as well as better strength, realizes low cost and high performance of polypropylene foam material, and improves the application competitiveness of polypropylene plastic.

Owner:CHINA PETROLEUM & CHEM CORP

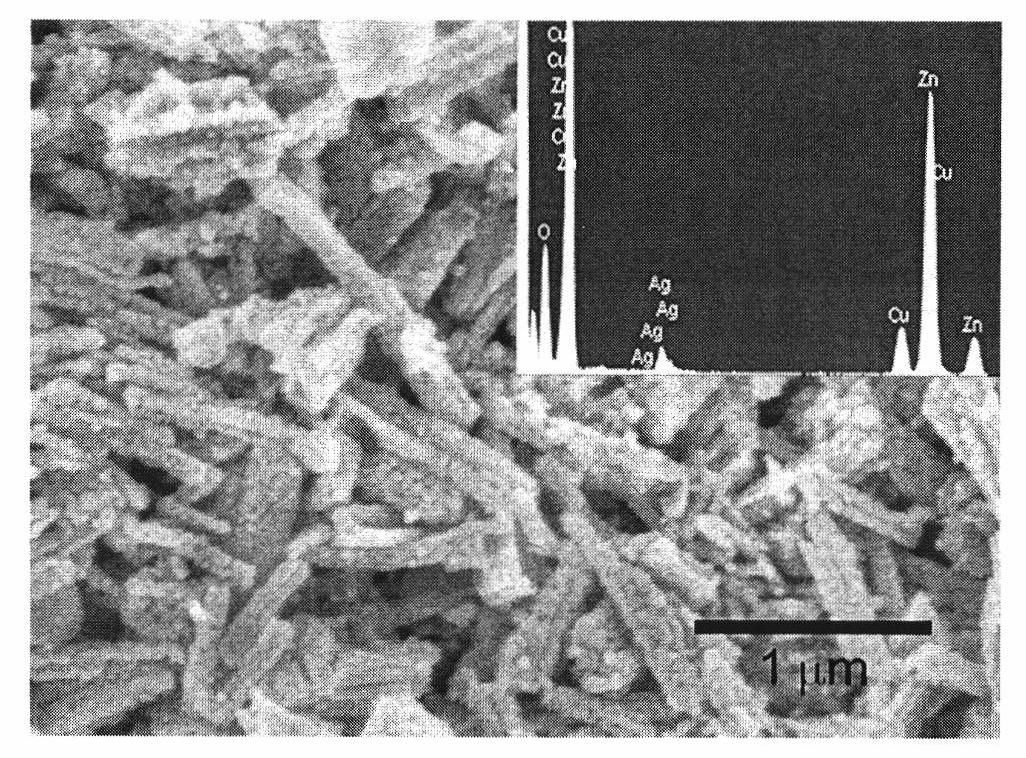

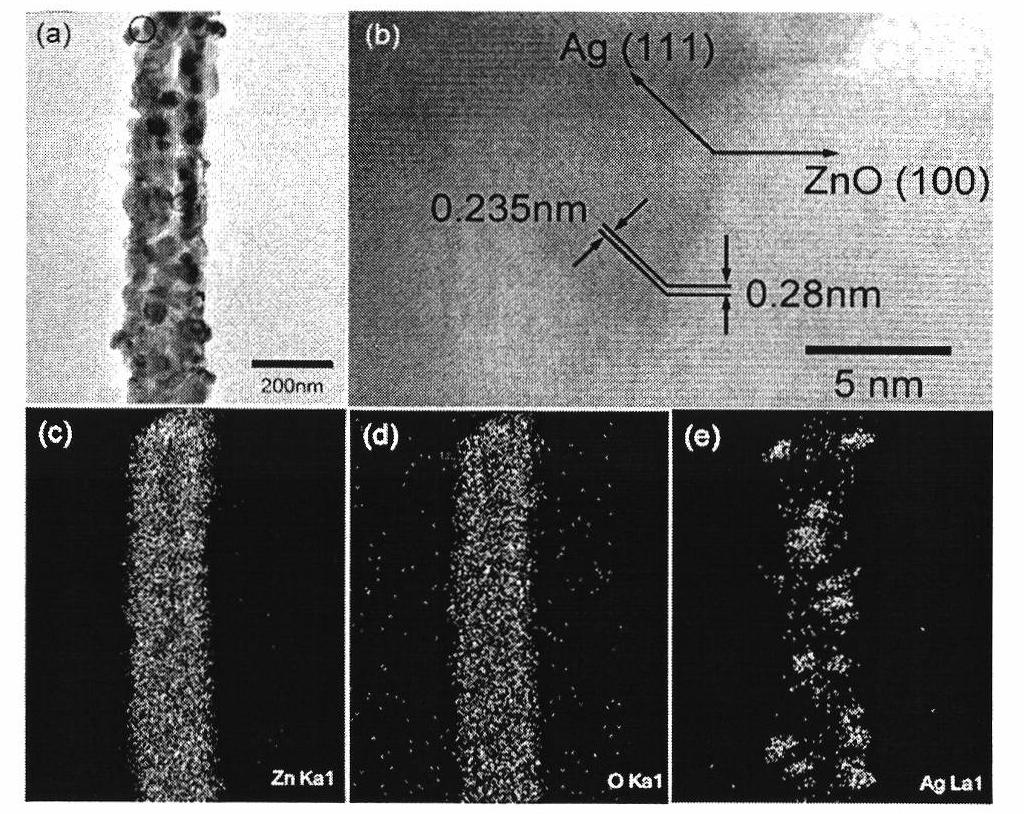

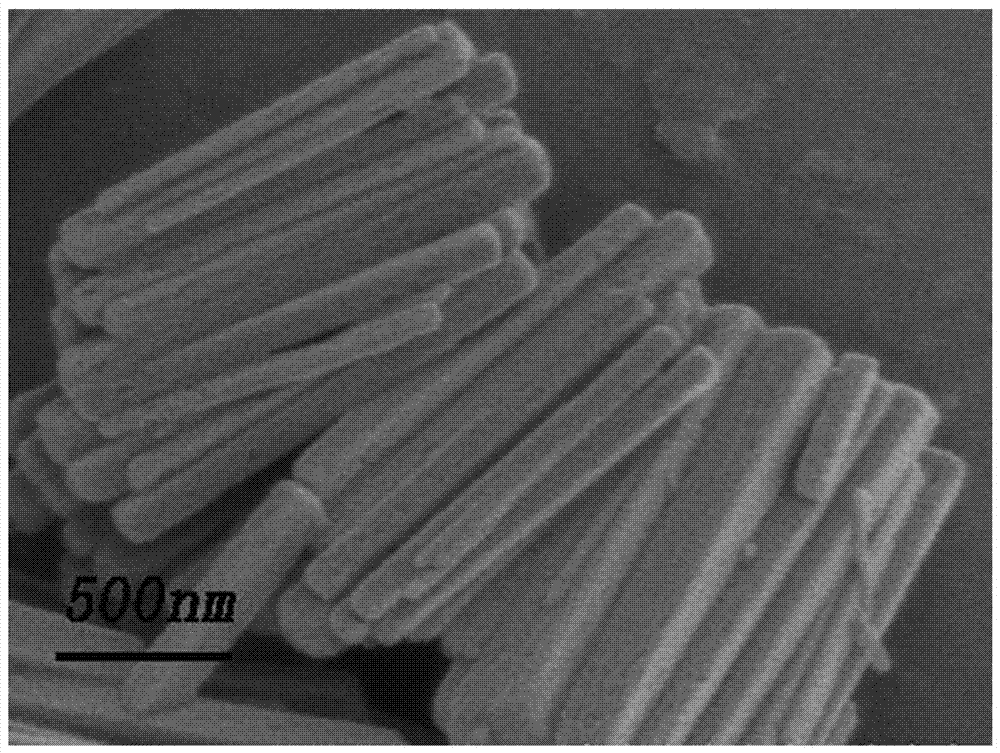

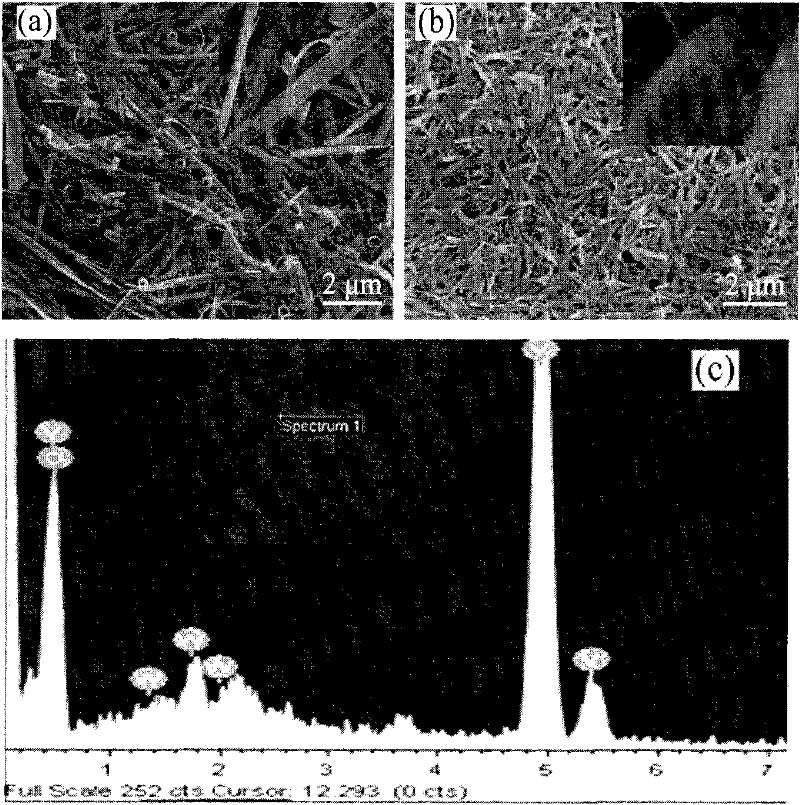

Porous zinc oxide-silver composite nanorod, as well as preparation method and application thereof

InactiveCN102649060ALarge specific surface areaImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsZinc Acetate DihydrateMaterials science

The invention discloses a porous zinc oxide-silver composite nanorod, as well as a preparation method and application thereof. The composite nanorod is formed by zinc oxide particles; sliver particles are loaded on the surface of the in porous rodlike zinc oxide, meso pores are formed between zinc oxide and / or silver particles, the rod length of the porous rodlike zinc oxide is 0.6-3 mum, the rod diameter is 90-150 nm, the specific surface area is 18-22m<2> / g, the particle size of the zinc oxide is 10-30nm, the size of the silver particles is 20-30nm, and the meso pore diameter is 3-30nm. The method comprises the following steps of: firstly mixing zinc acetate ethanol solution and ethanol oxalate dehydrate solution; putting the mixture in a seal state; insulating for at least 5h at the temperature of 70-90 DEG C; centrifuging, washing and drying; annealing the obtained zinc oxalate for at least 2h at the temperature of 430-470 DEG C; adding the zinc oxalate into silver nitrate ethylene glycol solution; stirring for at least 15min under visible light; and centrifuging, washing and drying, thereby preparing a target product. The porous zinc oxide-silver composite nanorod can be used for carrying out visible light catalytic degradation in water polluted by organic matters.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

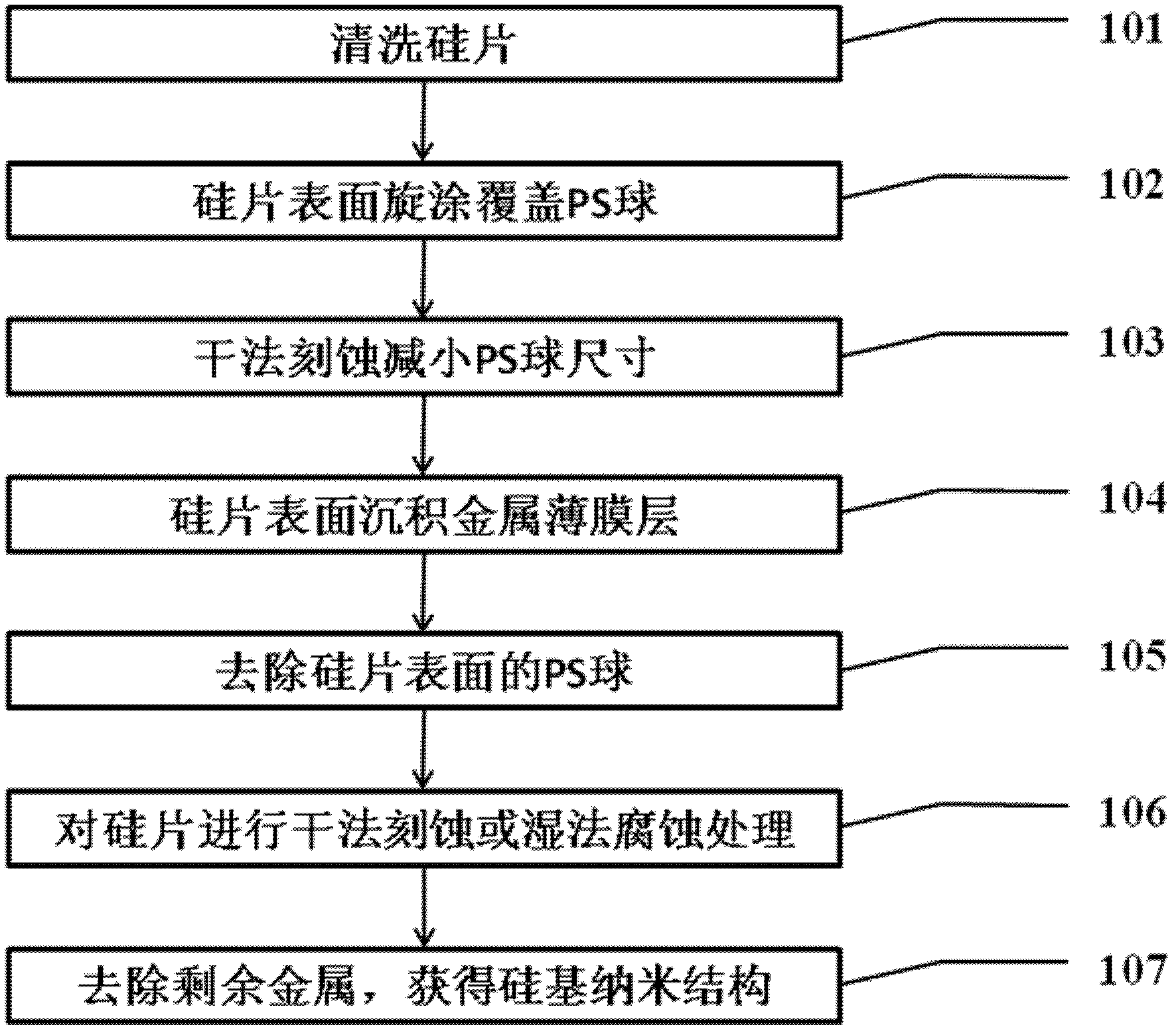

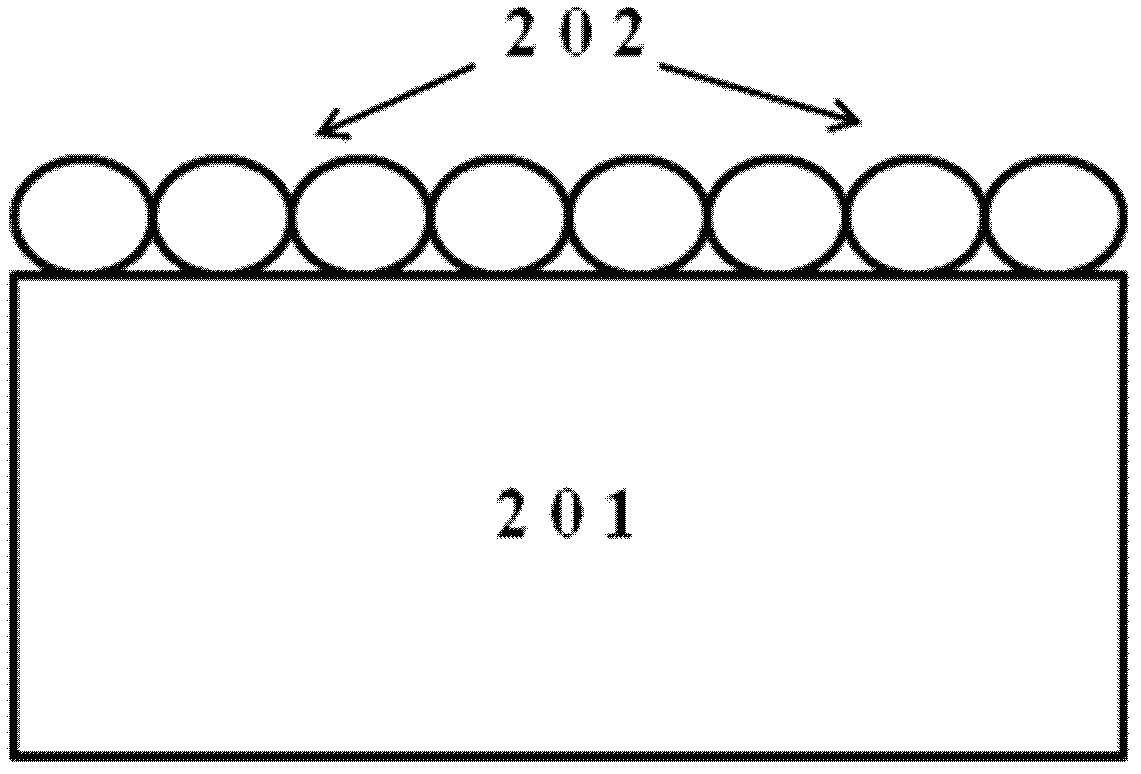

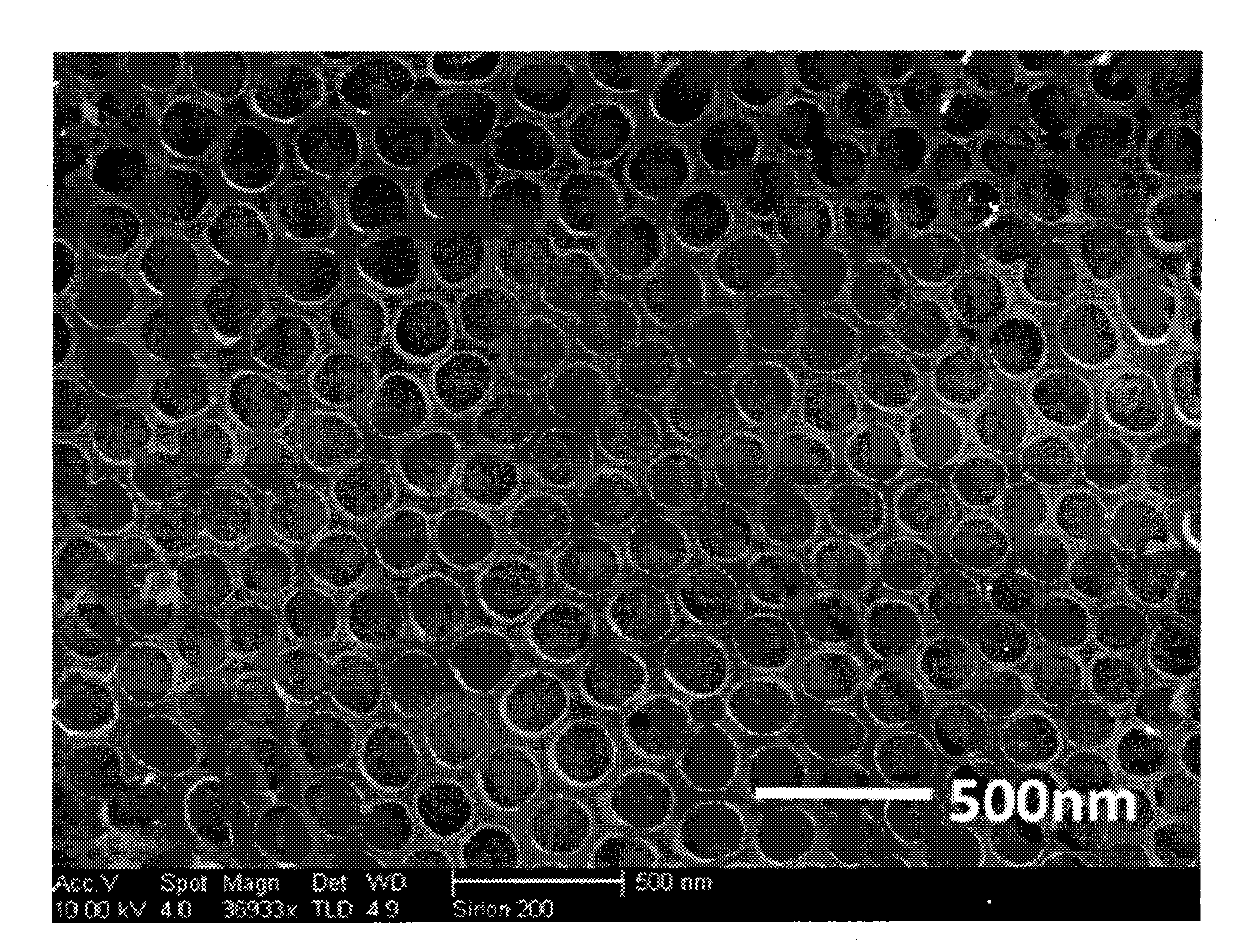

Silicon substrate nano-structure for solar cell and preparing method thereof

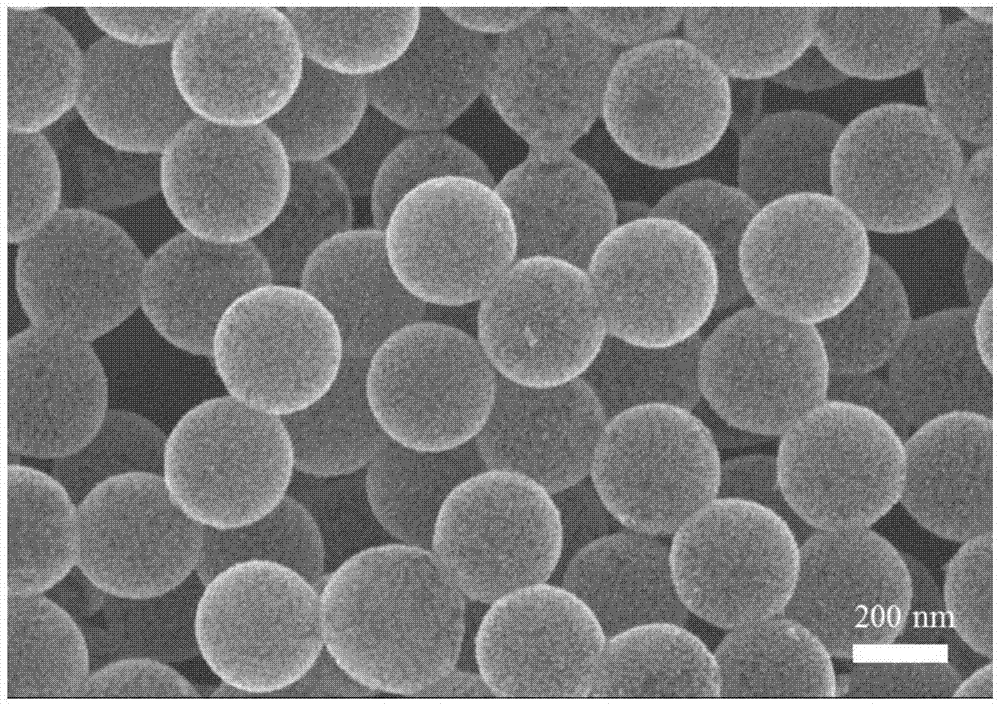

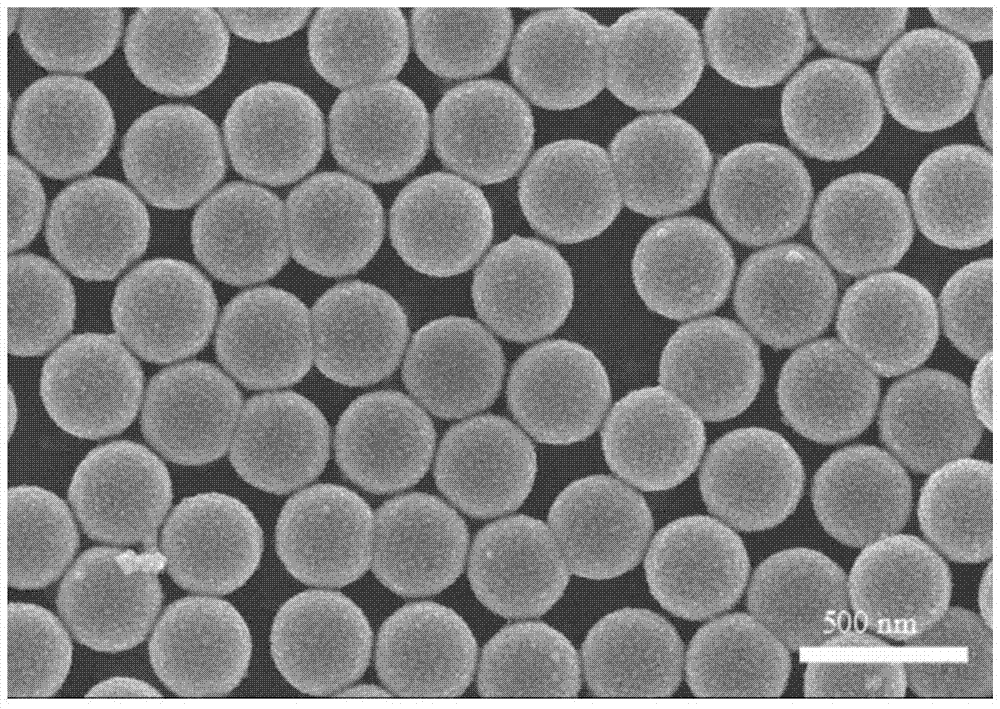

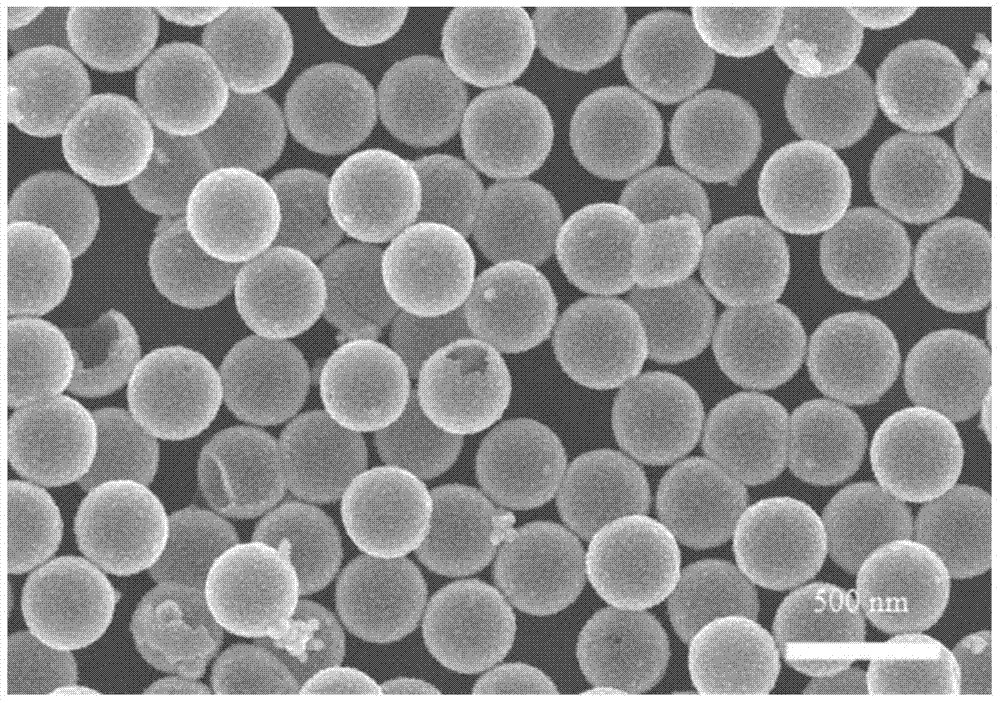

InactiveCN102593261AImprove conversion efficiencyUniform sizeFinal product manufactureNanoinformaticsPolystyreneSolar cell

The invention discloses a silicon substrate nano-structure for a solar cell and a preparing method thereof, and the method includes: cleaning silicon chips; spin-coating and covering single layer polystyrene (PS) spheres on the surface of the silicon chips; etching the PS spheres and reducing the sizes of the PS spheres; depositing a metal film layer on the surface of the silicon chip surface and forming metal mask; removing residual PS spheres on the silicon chip surface and remaining for the left metal masking layer; forming the silicon substrate nano-structure by using a dry etching or wet etching method; treating the silicon chips by heated concentrated acid and removing the residual metal and finishing the preparation of the silicon substrate nano-structure. According to the silicon substrate nano-structure for the solar cell and the preparing method thereof, PS spheres masking and metal film growth are utilized and the dry etching method and the wet etching method are combined so that a preparing method of silicon substrate nano-structure for the solar cell is provided. According to the silicon substrate nano-structure, the reflectivity is low, the light trapping ability is of high efficient, the light absorption of the solar cell is enhanced and the efficiency of the solar cell is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

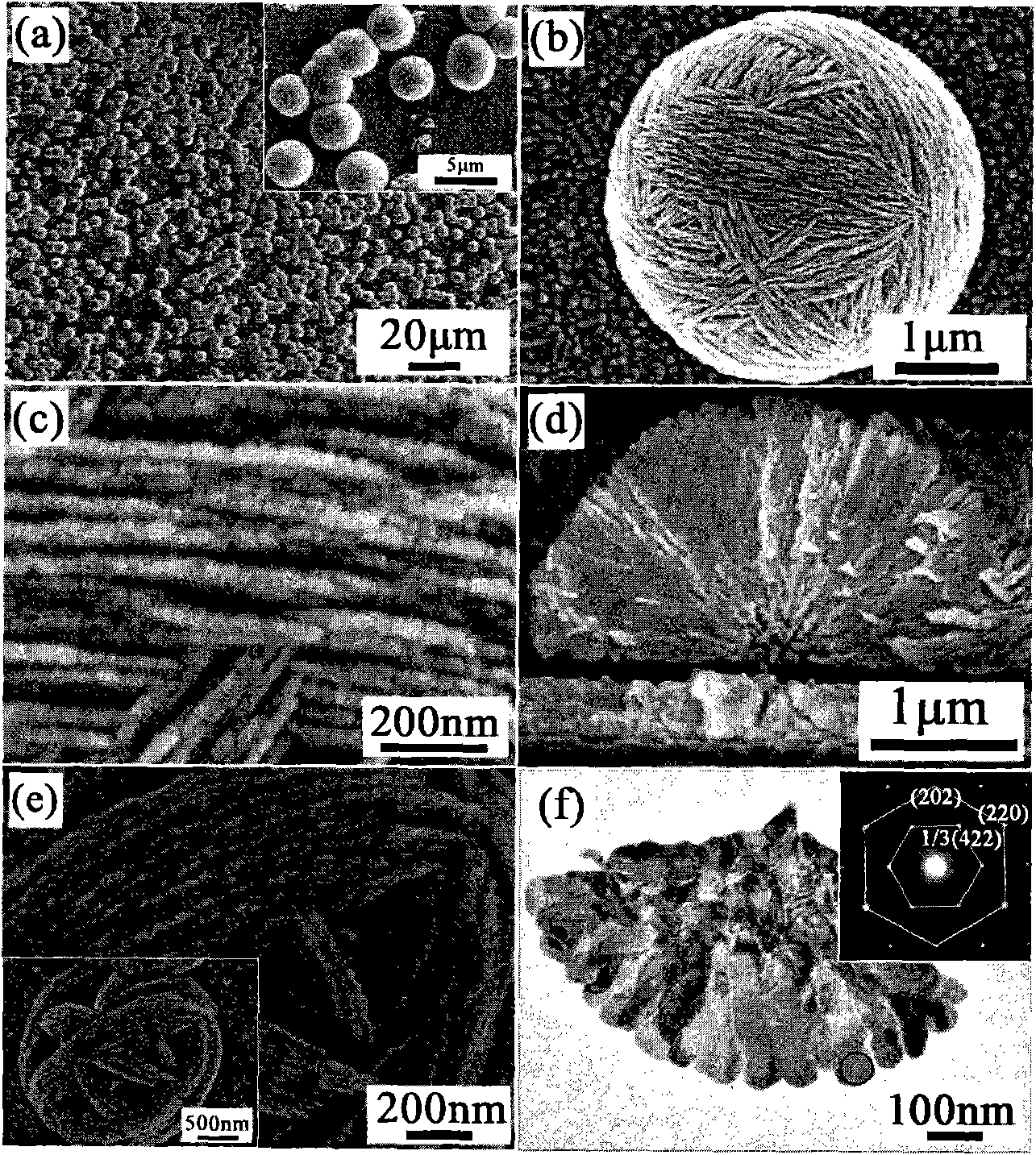

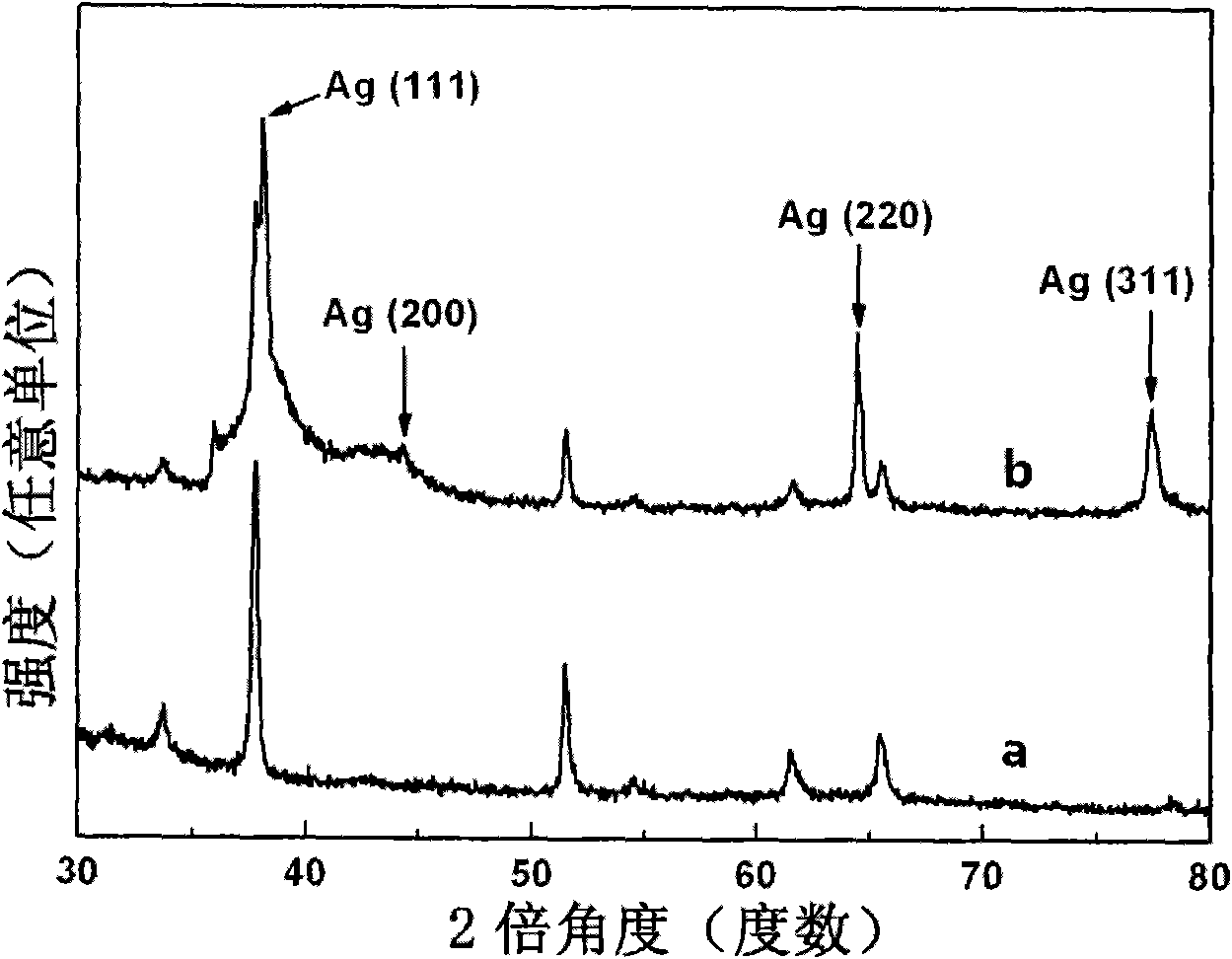

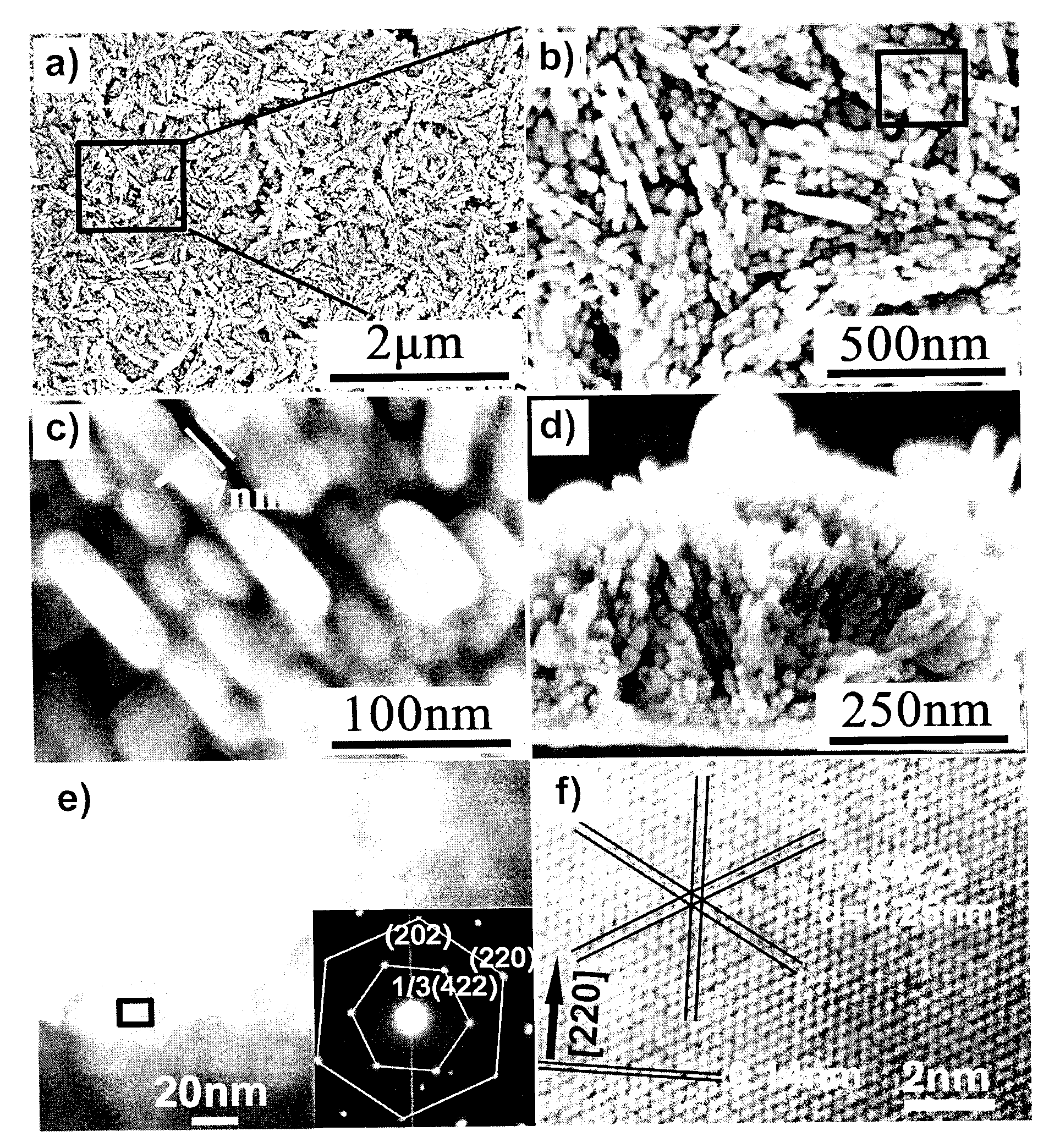

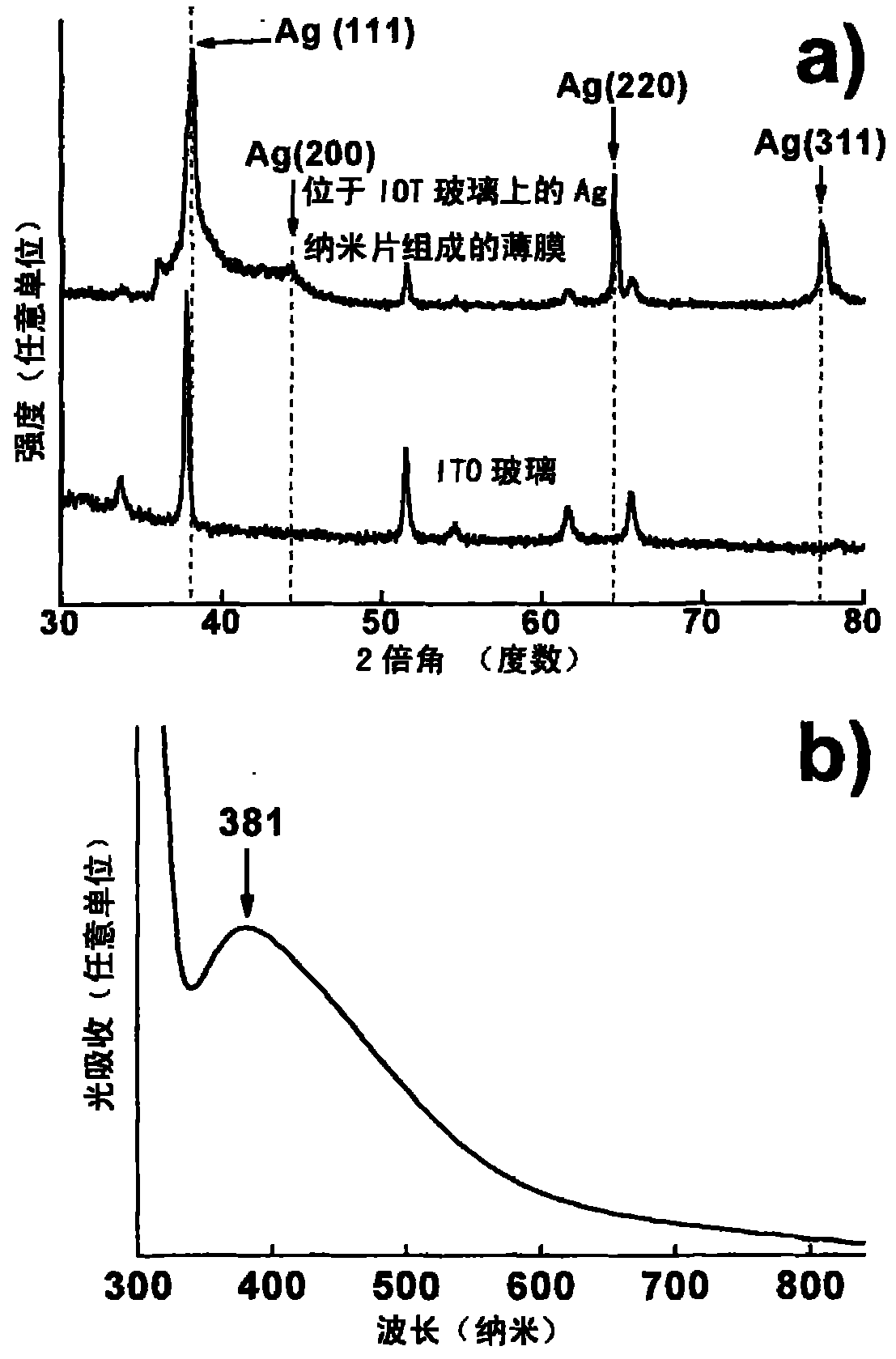

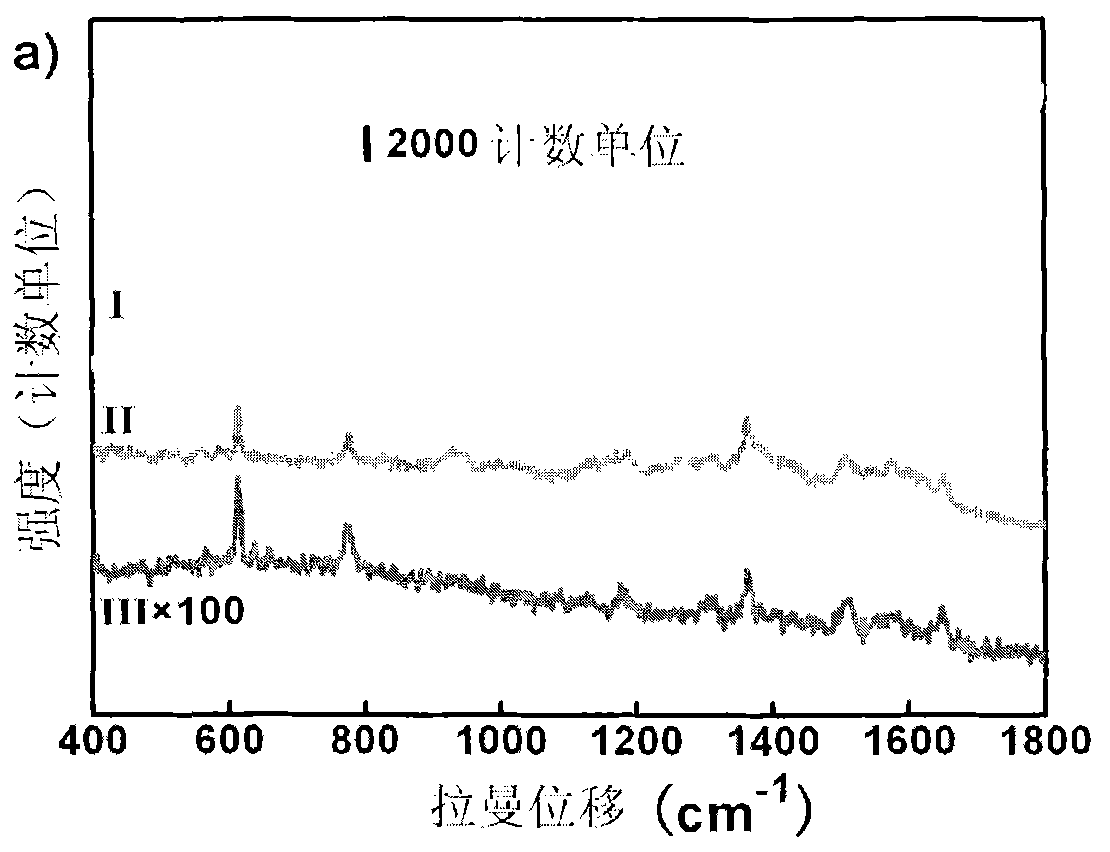

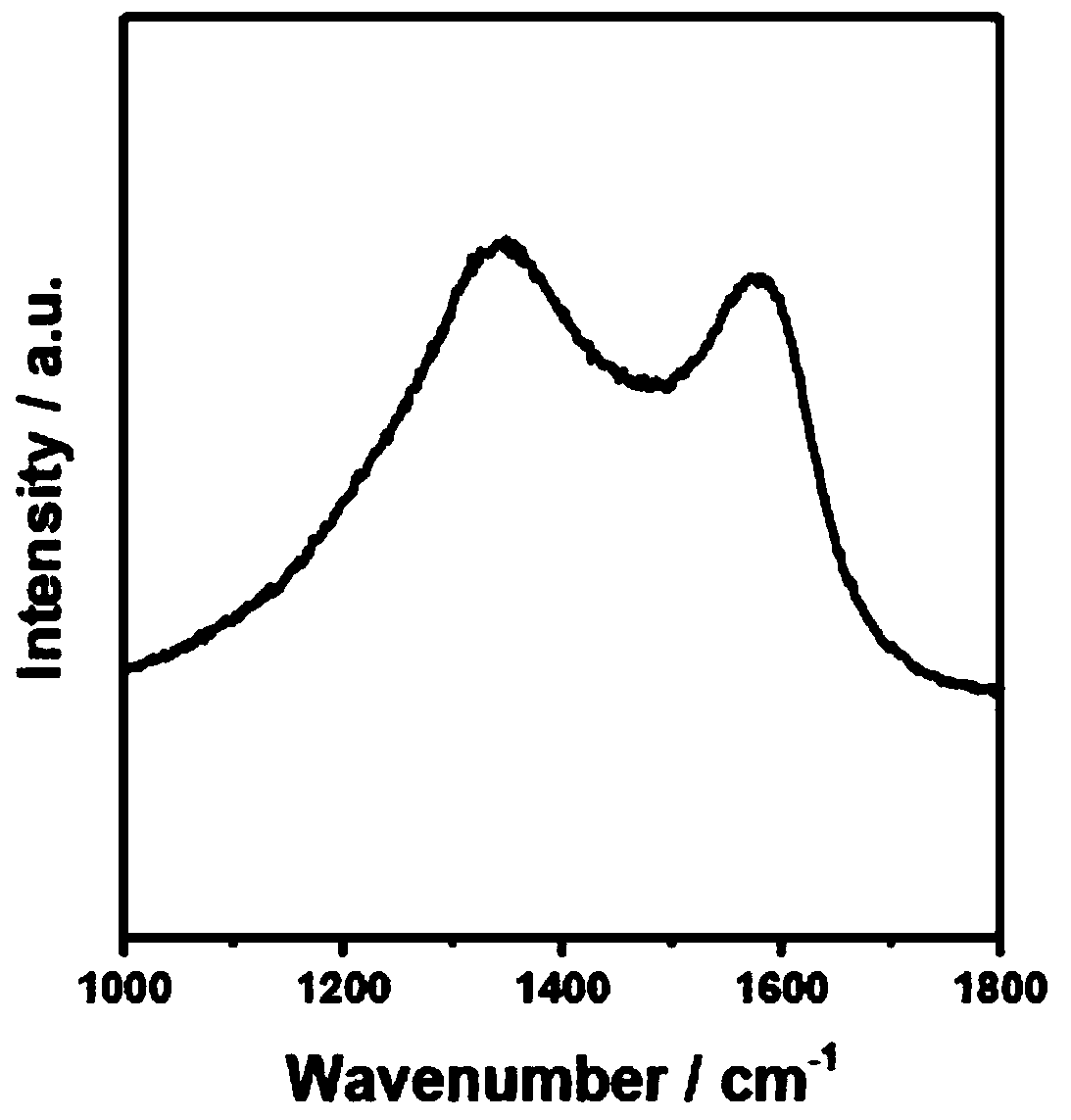

Micron semisphere composed of silver nano-flakes as well as preparation method and use thereof

InactiveCN102233433AQuick checkPreparation method sciencePolycrystalline material growthSingle crystal growth detailsSingle crystalSpectrometer

The invention discloses a micron semisphere composed of silver nano-flakes as well as a preparation method and a use thereof. The micron semisphere with the diameter of 1-30mu m is formed by stacking the silver nano-flakes adhered to a conducting substrate into a sector plate, wherein, the plane of the sector plate is vertical to the center of the semisphere; and the nano-flakes forming the sector plate are of a single crystal structure of silver, the length is 0.5-15mu m, the width is 20nm-1mu m and the thickness is 20-50nm. The preparation method comprises the following steps: firstly evenly mixing a silver nitrate aqueous solution with the concentration of 2-32g / L and a citric acid aqueous solution with the concentration of 8-144g / L based on the volume ratio of (0.8-1.2): (0.8-1.2) to obtain an electrolyte; and taking the conducting substrate as a cathode and a graphite flake as an anode to be placed in the electrolyte, and carrying out electro-deposition under constant current with the density of 0.1-1mA / cm<2> for 10-180 minutes to finally obtain the micron semisphere composed of the silver nano-flakes. The obtained micron semisphere can be utilized as a surface enhanced Ramanscattering (SERS) active substrate so as to measure content of rhodamine or polychlorinated biphenyls (PCBs) or p-methyl benzenethiol adhered thereon by utilizing a confocal Raman spectrometer.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

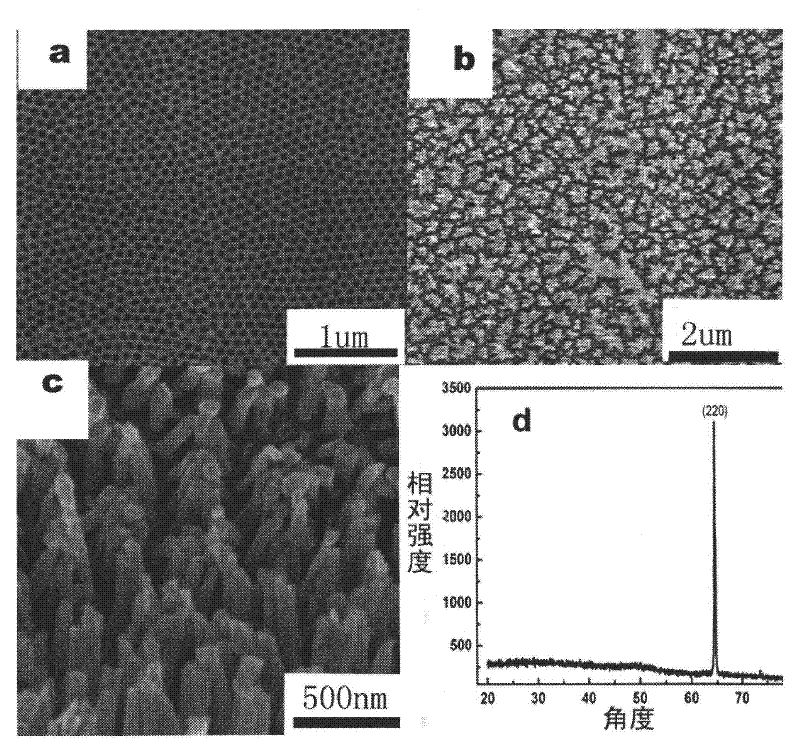

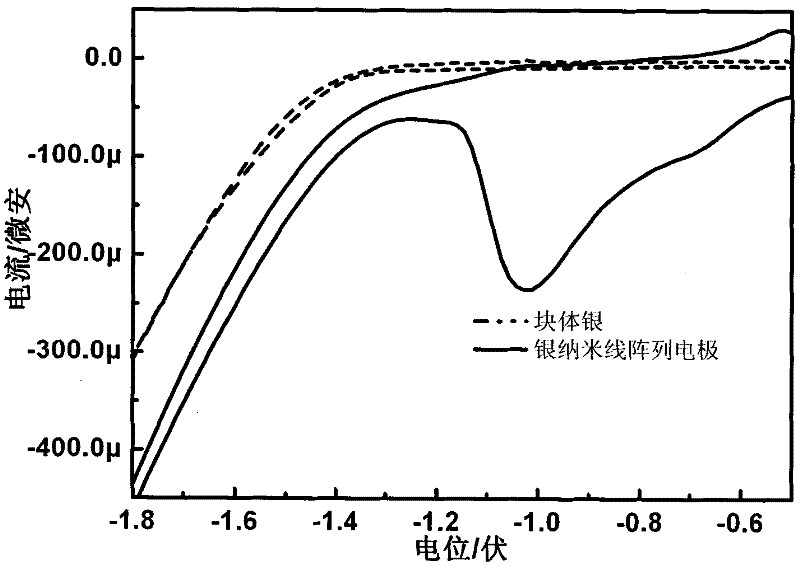

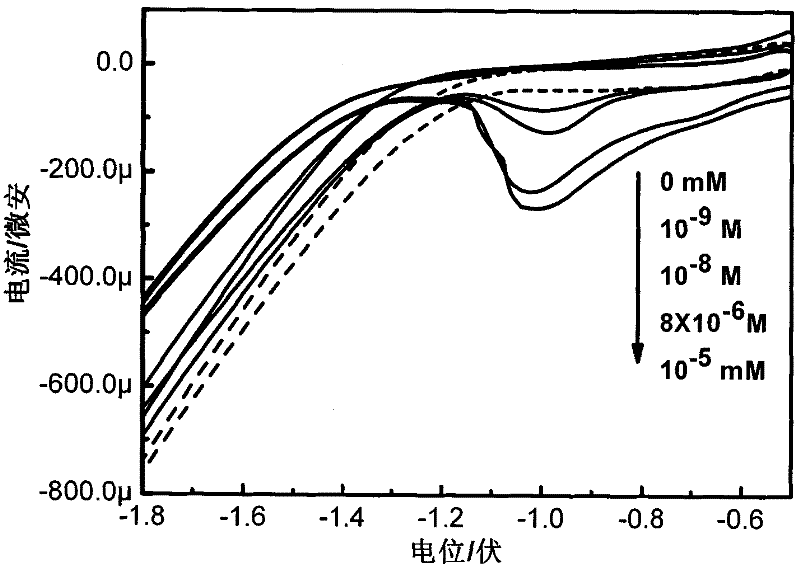

Silver nanowire array electrode and its preparation method and application

InactiveCN102267682AGood arrayUnbreakableIndividual molecule manipulationVacuum evaporation coatingElectrolysisSilver nanowires

The invention discloses a silver nanowire array electrode, a preparation method and application thereof. The electrodes are silver nanowires forming an array with a diameter of 50-70nm and a wire length of 250-350nm. The bottom of the array is a silver film of 130-170nm and a copper film of 0.5-1mm; the method is to use a secondary anode on the aluminum sheet first Oxidation method to obtain a through-hole alumina template with a pore diameter of 50-70nm, and then use the ion sputtering method to vapor-deposit a silver film on one side of the alumina template, and then place the alumina template with a silver film on one side in a silver electrolysis solution, use the electrodeposition method to electrodeposit at a constant voltage of 0.08 to 0.12V for 1 to 5 minutes, then place it in the copper electrolyte, use the electrodeposition method to electrodeposit 2.5 to 3.5 at a current of 8 to 12mA / cm2 h, after that, put the aluminum oxide template with silver nanowires in the hole, one side covered with silver film and copper film in sequence, in acid solution or strong alkali solution to corrode the aluminum oxide template, and make silver nanowire array electrode. Array electrodes can be used as sensitive elements for trace detection or reduction of halogenated organic compounds.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Composite material with negative ion releasing function and preparation method thereof

InactiveCN103360657AHigh tensile strengthHigh elongation at breakPolymethyl methacrylatePolyvinyl chloride

The invention discloses a composite material with a negative ion releasing function and a preparation method thereof. The composite material comprises tourmaline powder, an auxiliary agent(s) and a macromolecule matrix(es) which are in a weight ratio of 5-20:2-10:70-93, wherein the grain size of the tourmaline powder ranges from 500 nanometers to 3 microns, the auxiliary agent is one or more than two of polyethylene glycol, polypropylene glycol, polytetramethylene glycol, cetyl sodium sulfate, cetyl sodium sulfonate, octaphenyl polyoxyethyiene and cetyl trimethyl ammonium bromide, and the macromolecule matrix is one or more than two of polyethylene, polystyrene, polymethyl methacrylate, polyurethane, polyvinyl chloride and polyacrylate. The preparation method comprises the following steps of: firstly, ball milling the tourmaline powder, the auxiliary agent and water in a ball mill or stirring and shearing in an emulsifying machine; then, drying; adding the mixture into a macromolecule reaction monomer for in-situ synthesis, or mixing the mixture with the macromolecule matrix(es) and then carrying out melt blending after mixing the mixture, so as to prepare a target product. The composite material can automatically release a large quantity of negative ions.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

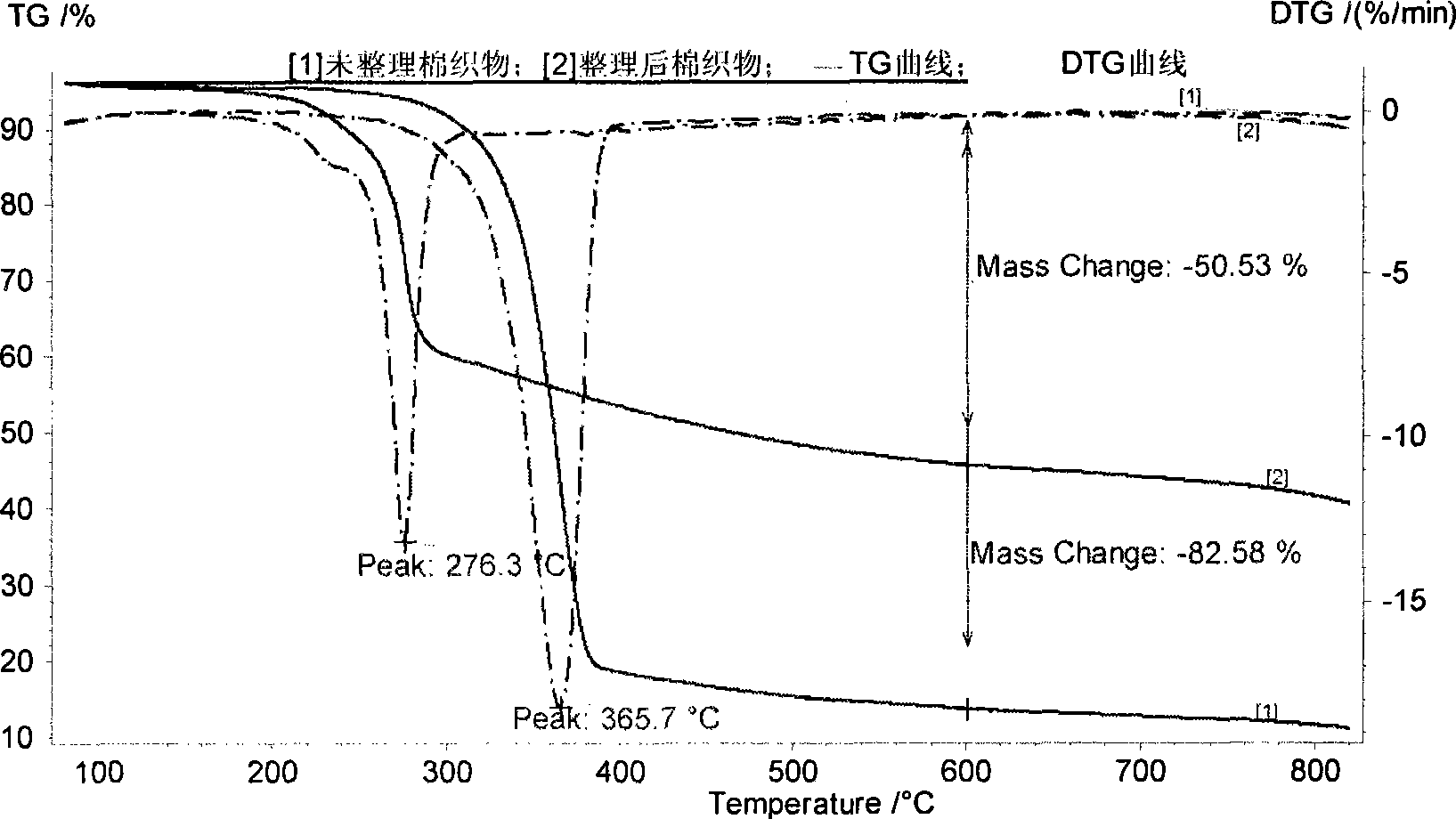

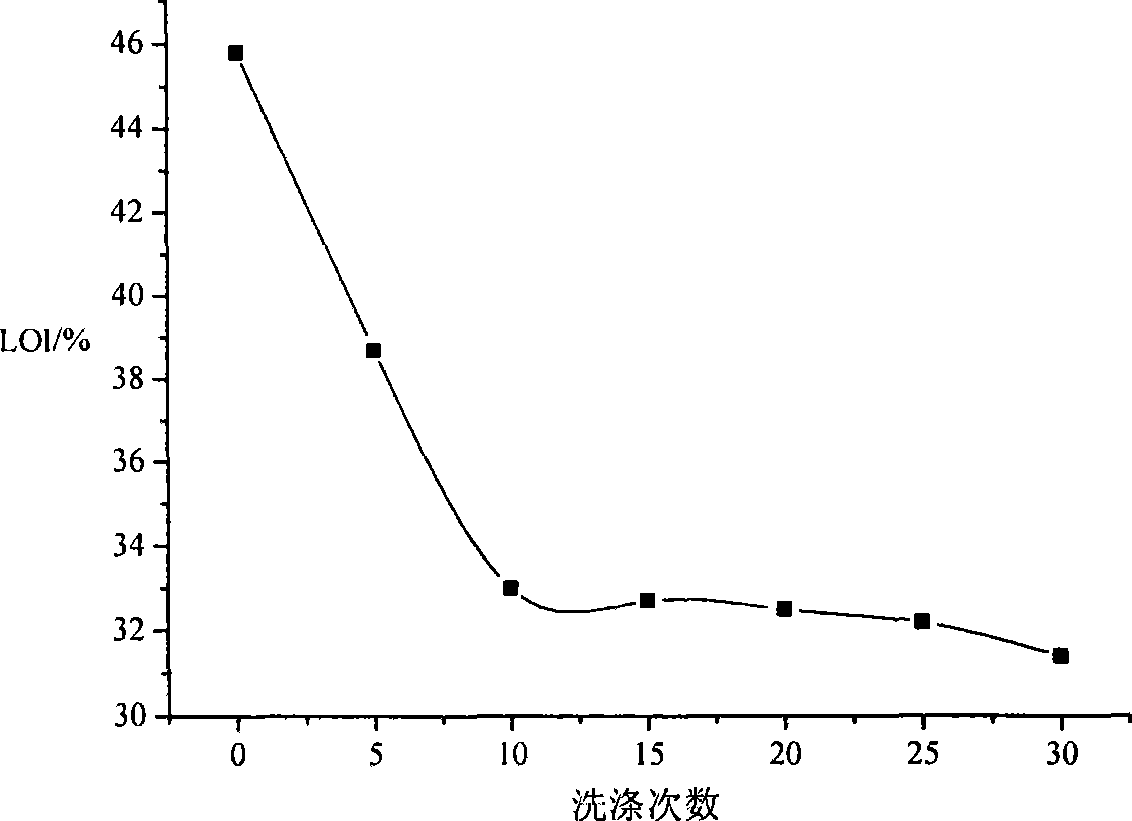

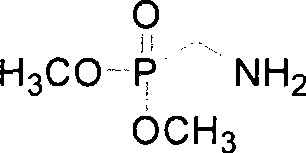

Method for preparing durable flame-proof cotton fabric

InactiveCN101413214AGood flame retardant effectWide variety of sourcesVegetal fibresChemistrySilane coupling

The invention relates to a method for preparing durable flame retardant cotton fabrics, which comprises the following steps: firstly, preparation of a finishing liquid, namely amino-methylphosphonate DAMP, a silane coupling agent gamma-glycidyl oxyl propyl trimethyl silicane and running water are uniformly mixed, and the pH value of the mixture is adjusted to between 3 and 7 by a finishing liquid pH regulator to obtain the finishing liquid; secondly, flame retardant finishing of the cotton fabrics, namely the cotton fabrics are immersed into the finishing liquid for 20 minutes at a temperature of 40 DEG C, padded until the liquid rate is between 75 and 80 percent, dried for 3 minutes at a temperature of between 80 and 100 DEG C, and roasted for 3 minutes at a temperature of between 150 and 180 DEG C; and thirdly, testing of the flame retardant property and the durability of the cotton fabrics after finishing. The method for preparing the flame retardant cotton fabrics has the advantages that raw materials have wide sources; the prepared cotton fabrics have good durability and flame retardant property; and the method has small influence on physical and mechanical properties of the cotton fabrics.

Owner:DONGHUA UNIV

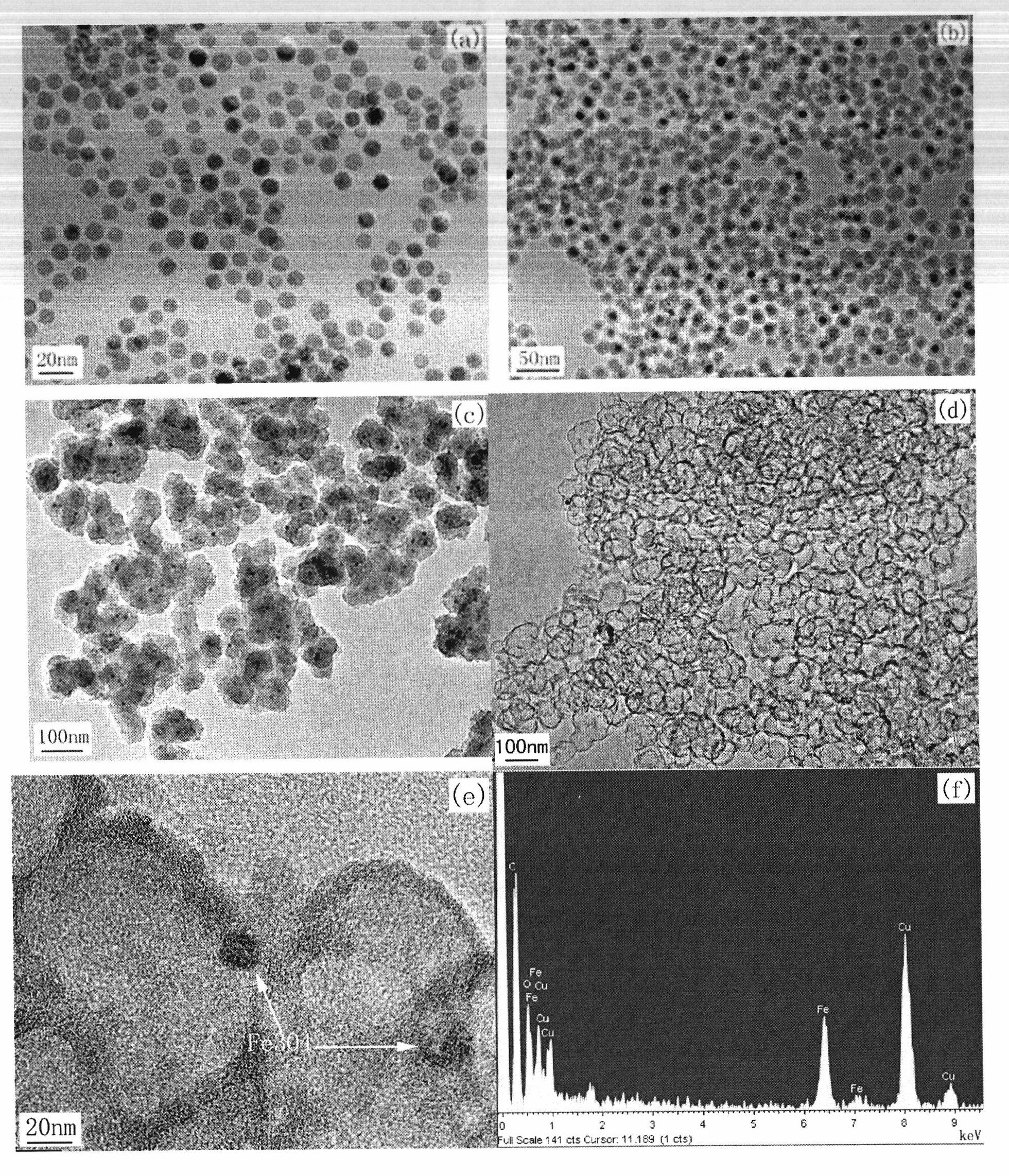

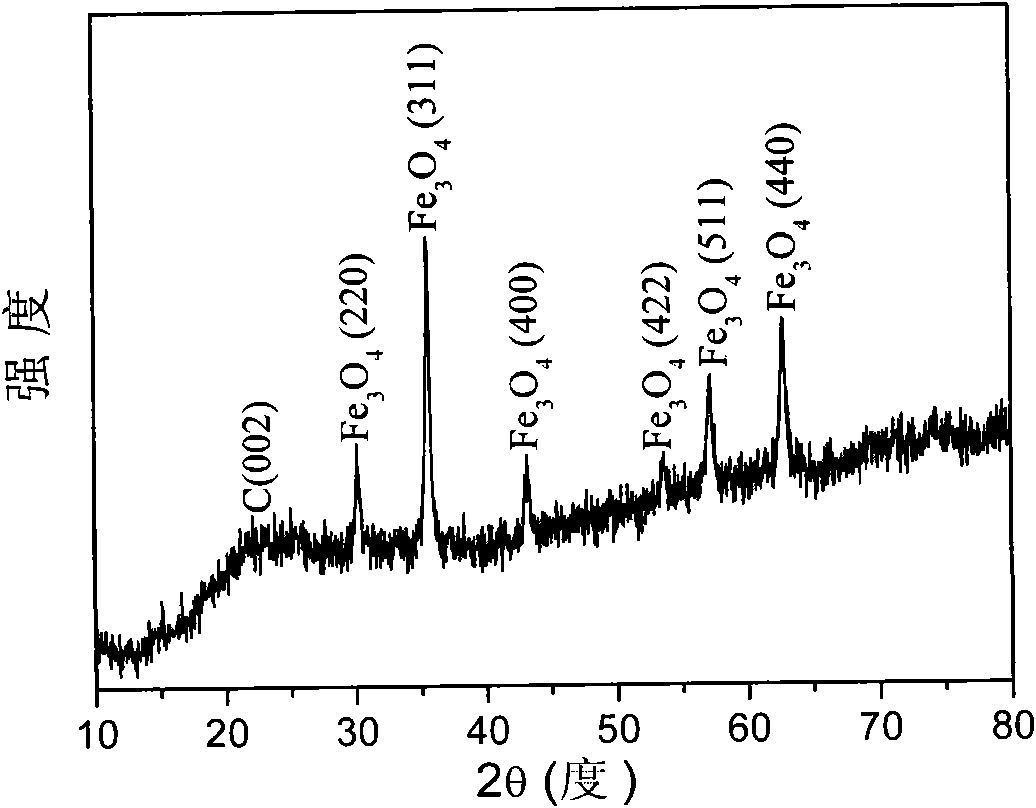

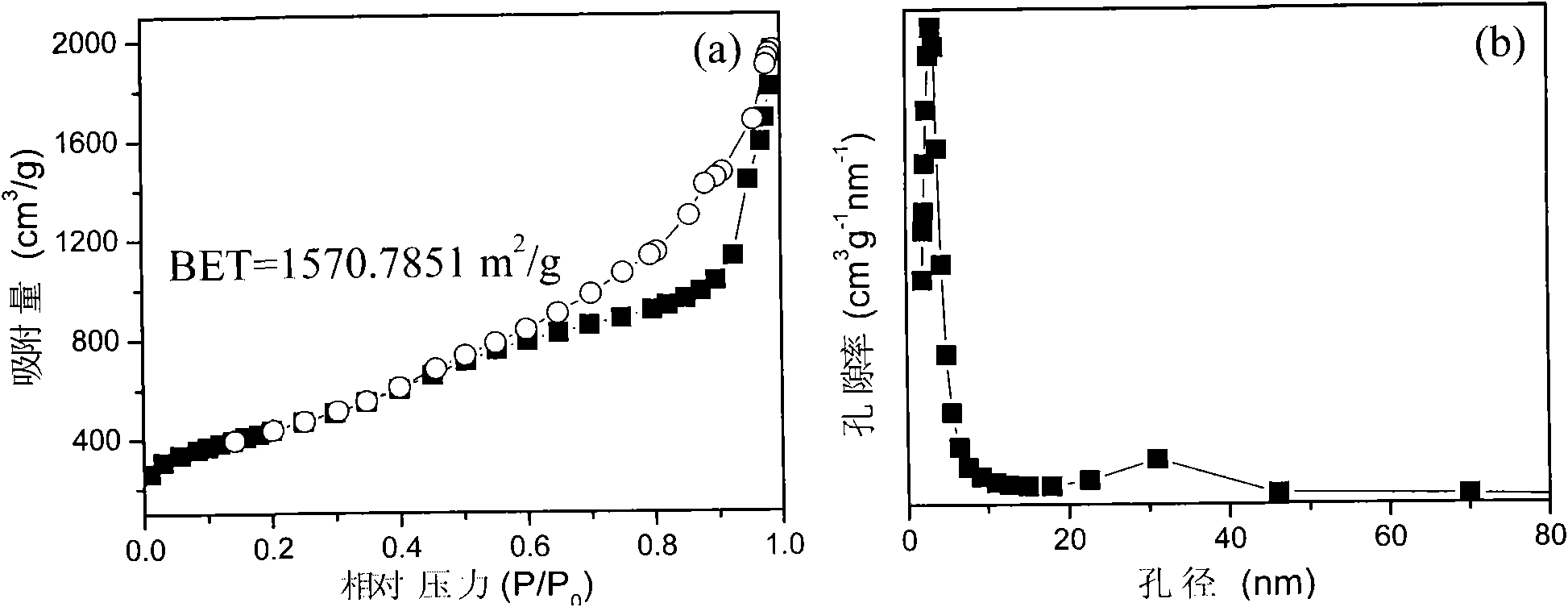

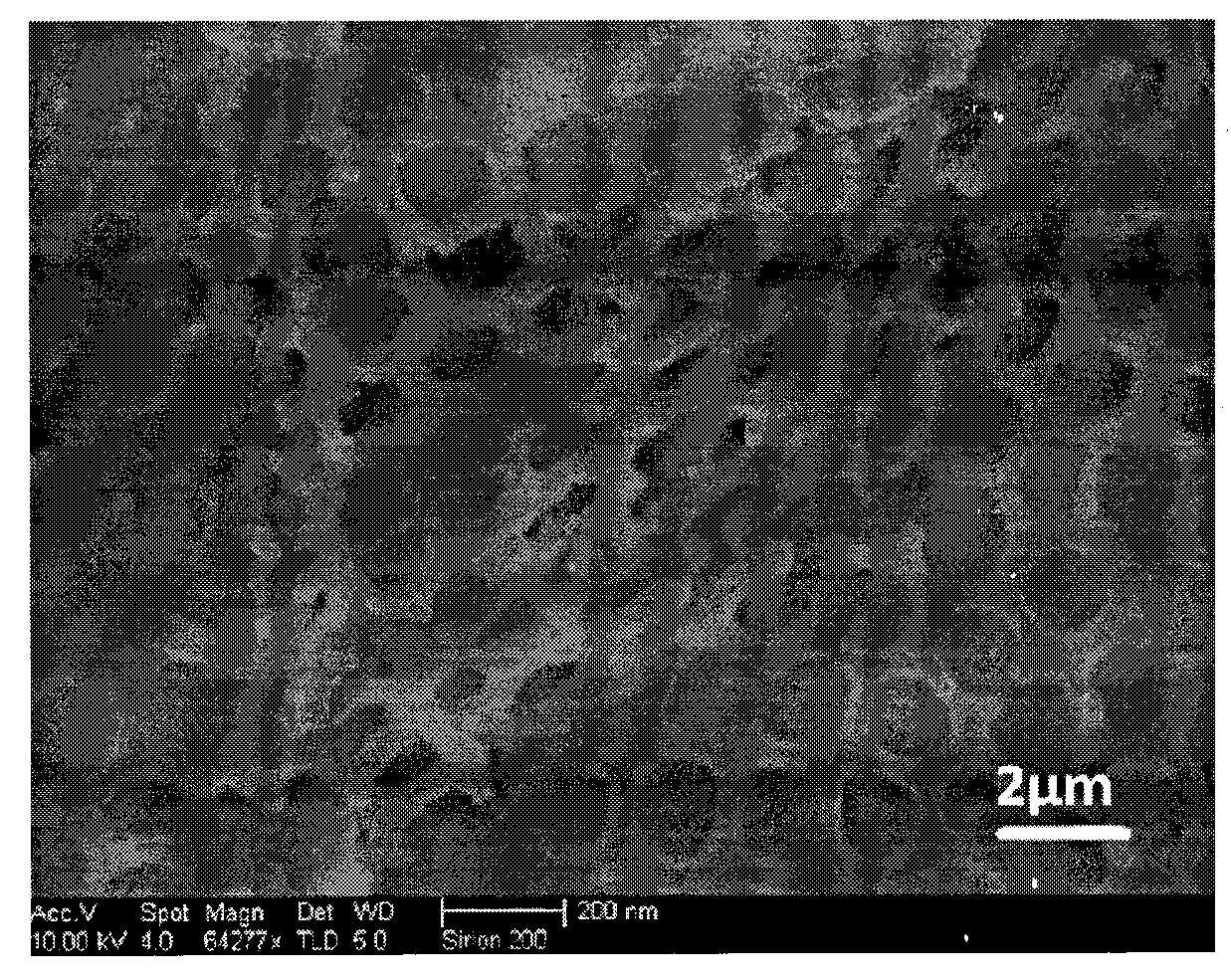

Nanometer ferroferric oxide core-carbon meso pore hollow shell complex, as well as preparation method and application thereof

InactiveCN102649046AIncrease the areaHigh porosityOther chemical processesAlkali metal oxides/hydroxidesCongo redMesoporous silica

The invention discloses a nanometer ferroferric oxide core-carbon meso pore hollow shell complex, as well as a preparation method and application thereof. The complex is formed by ferroferric oxide particles and a carbon shell sleeved and sealed outside, wherein the carbon sheel is of a mesoporous structure with the hole diameter being 1-5nm; the grain size of the ferroferric oxide particles is 8-12nm; the external diameter of a carbon mesoporous shell is 80-100nm; the thickness of the shell is 10-20nm; and the diameter of a hollow part between the ferroferric oxide and the carbon mesoporous shell is 30-60nm. The preparation method comprises the following steps of: synthetizing ferroferric oxide nanometer nanometers through a high-temperature reflux method, using a microemulsion method to obtain a ferroferric oxide core silicon dioxide shell powder body; then depositing a layer of mesoporous silicon dioxide on the surface of a silicon dioxide shell through a chemical method to obtain a three-layer core shell structure; taking the three-layer core shell structure as a hard template, and depositing carbon in clearances of the mesoporous silicon dioxide; and finally, etching the silicon dioxide by utilizing strong alkali solution, thereby obtaining a target product. The nanometer ferroferric oxide core-carbon meso pore hollow shell complex can be used for carrying out adsorption processing in solution polluted by methylthionine chloride, congo red or phenol.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Preparation method of titanium dioxide nanopore array film

ActiveCN102888645APreparation method scienceEfficient manufacturing methodMaterial nanotechnologySurface reaction electrolytic coatingElectrolytic agentGlycol synthesis

The invention discloses a preparation method of a titanium dioxide nanopore array film. The preparation method comprises the steps of: mixing ammonium fluoride, water and ethylene glycol to obtain an electrolyte, oxidizing a two-electrode system by using a titanium sheet as a positive electrode and graphite as a negative electrode to obtain an electrolyte 1 and an electrolyte 2; then sequentially placing the titanium sheet in the electrolyte 1, the electrolyte 2 and the electrolyte to be oxidized to obtain a titanium oxide sheet; placing the titanium oxide sheet in a hydrofluoric acid to be corroded, blowing the hydrofluoric acid solution by air in a bypass to obtain a titanium oxide film stripped from the titanium oxide sheet; and finally, sequentially respectively placing the titanium oxide film into hydrofluoric acid solutions with different concentrations for being corroded, gradually diluting the hydrofluoric acid solutions until the concentrations reach 0.004-0.006wt percent, and finally preparing the titanium dioxide nanopore array film with thickness of 10-50nm. A target product prepared by adopting the preparation method can be used as a mask for preparing a quantum dot, and can be used as a micro gate to be applied to a sample support of a transmission electron microscope, and is a good filter bacterium film material further.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

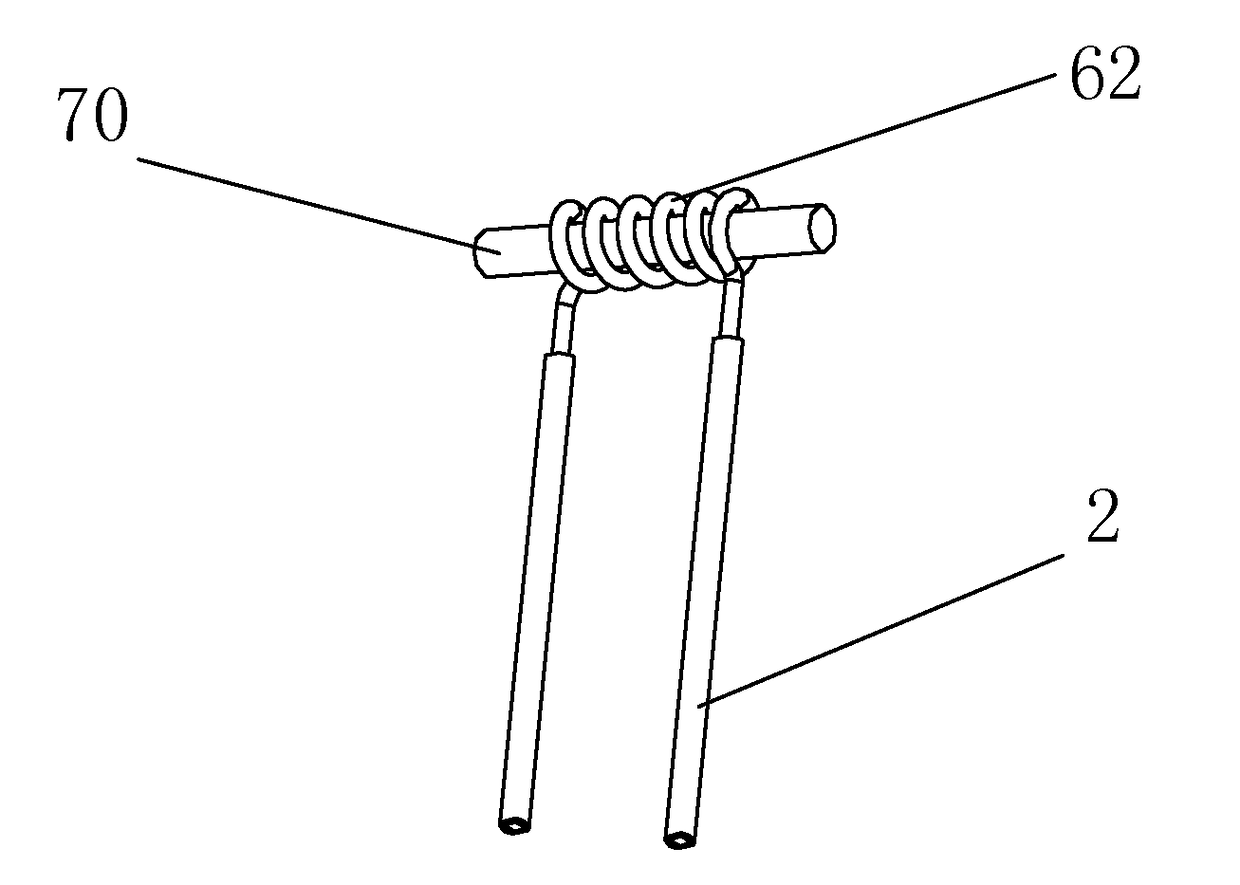

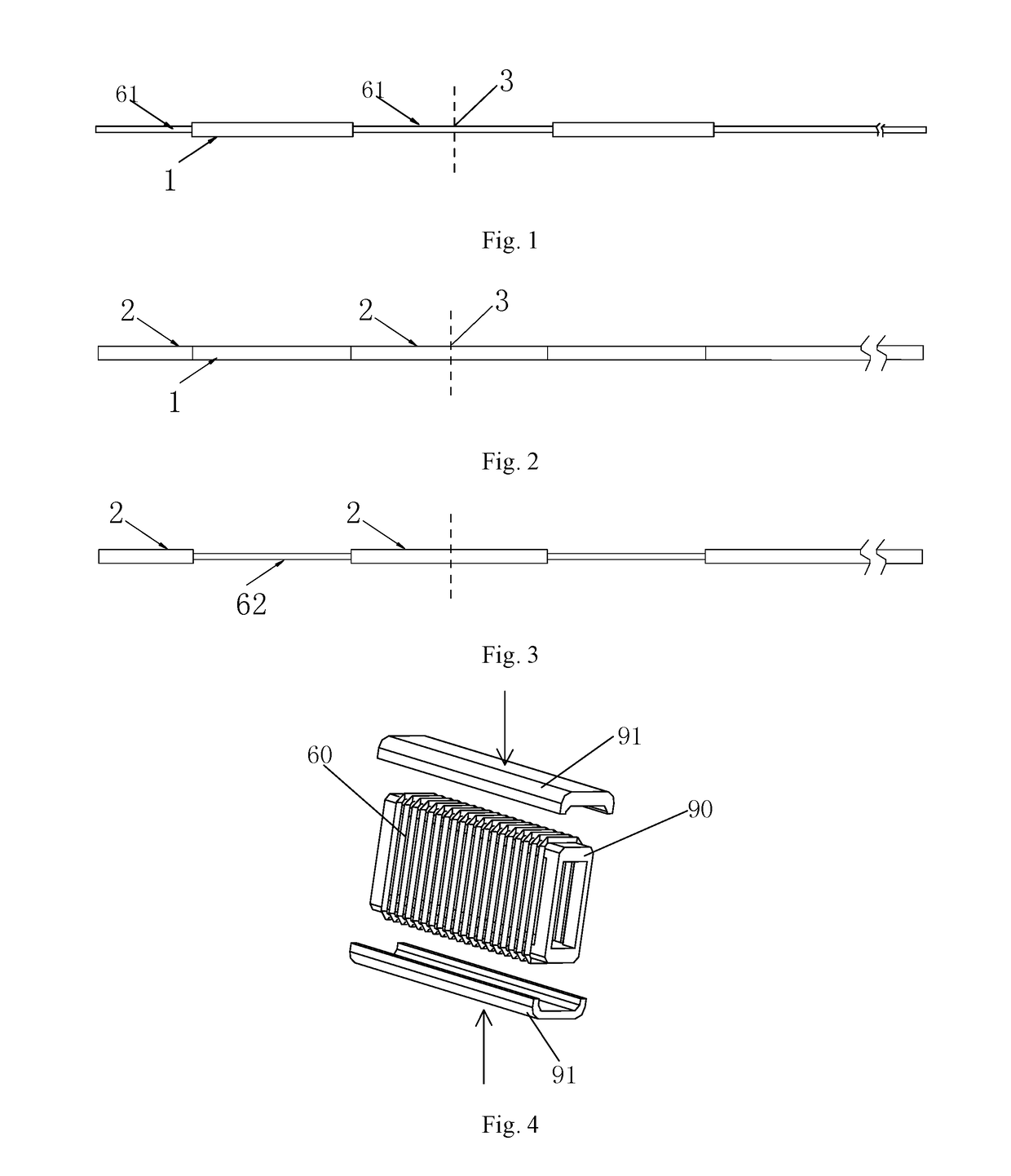

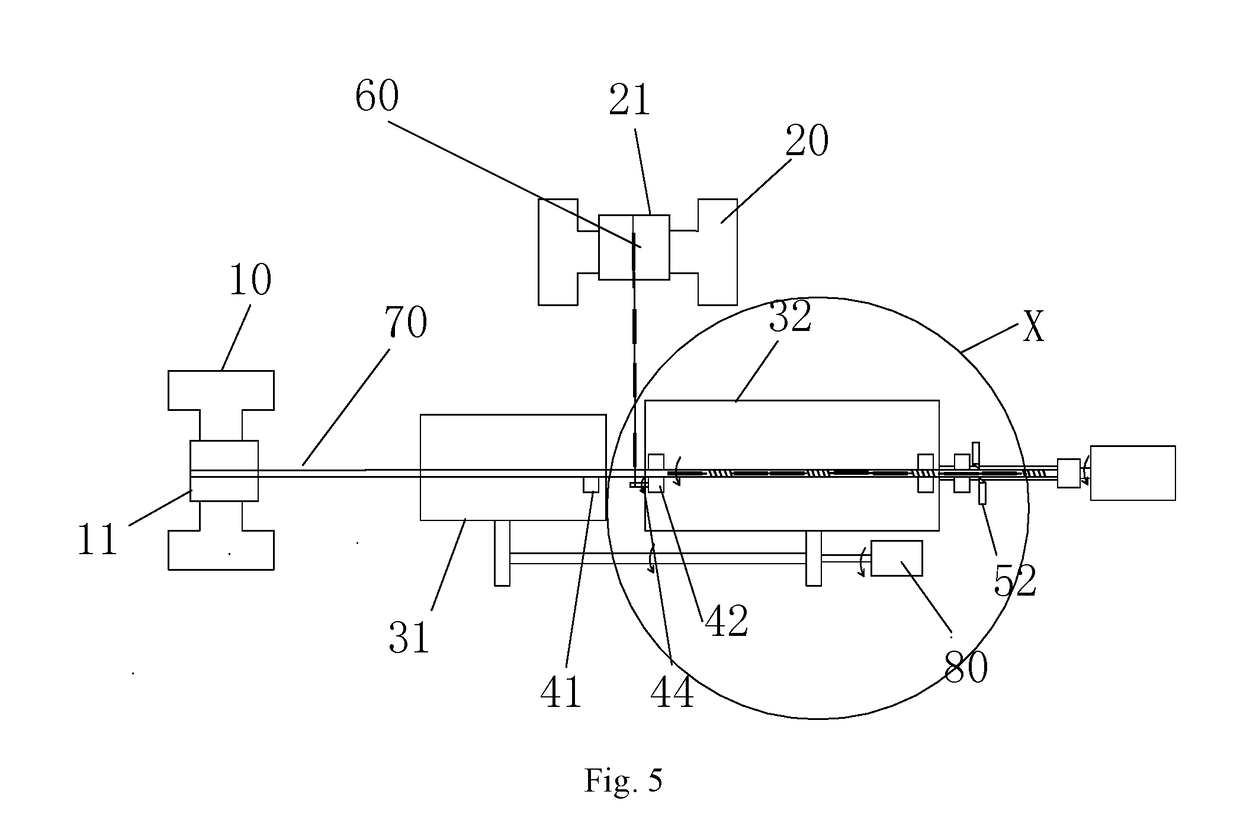

Forming method for heating element of electronic cigarette and manufacturing method for atomization assembly

InactiveUS20170224021A1Efficient manufacturing methodIncrease productivityTobacco devicesHeating element shapesElectrical resistance and conductanceEngineering

A forming method for a heating element of an electronic cigarette and a manufacturing method for an atomization assembly are provided, the forming method comprises coiling a heating wire into a heating coil, dividing the heating coil into sections including a plurality of heating sections and connecting sections; providing a deposition preventing layer on an external surface of the heating section; electroplating the heating coil, coating outer peripheral faces of all of the connecting sections of the heating coil with coatings having an electrical resistivity lower than that of the heating wire; removing the deposition preventing layer; and cutting the heating coil electroplated. The present application makes the manufacturing process of the heating element and the atomization assembly continues automatically, the production efficiency is improved, the resistance of the heating element or atomization assembly manufactured is more stable, and the product quality is higher.

Owner:HUIZHOU KIMREE TECH

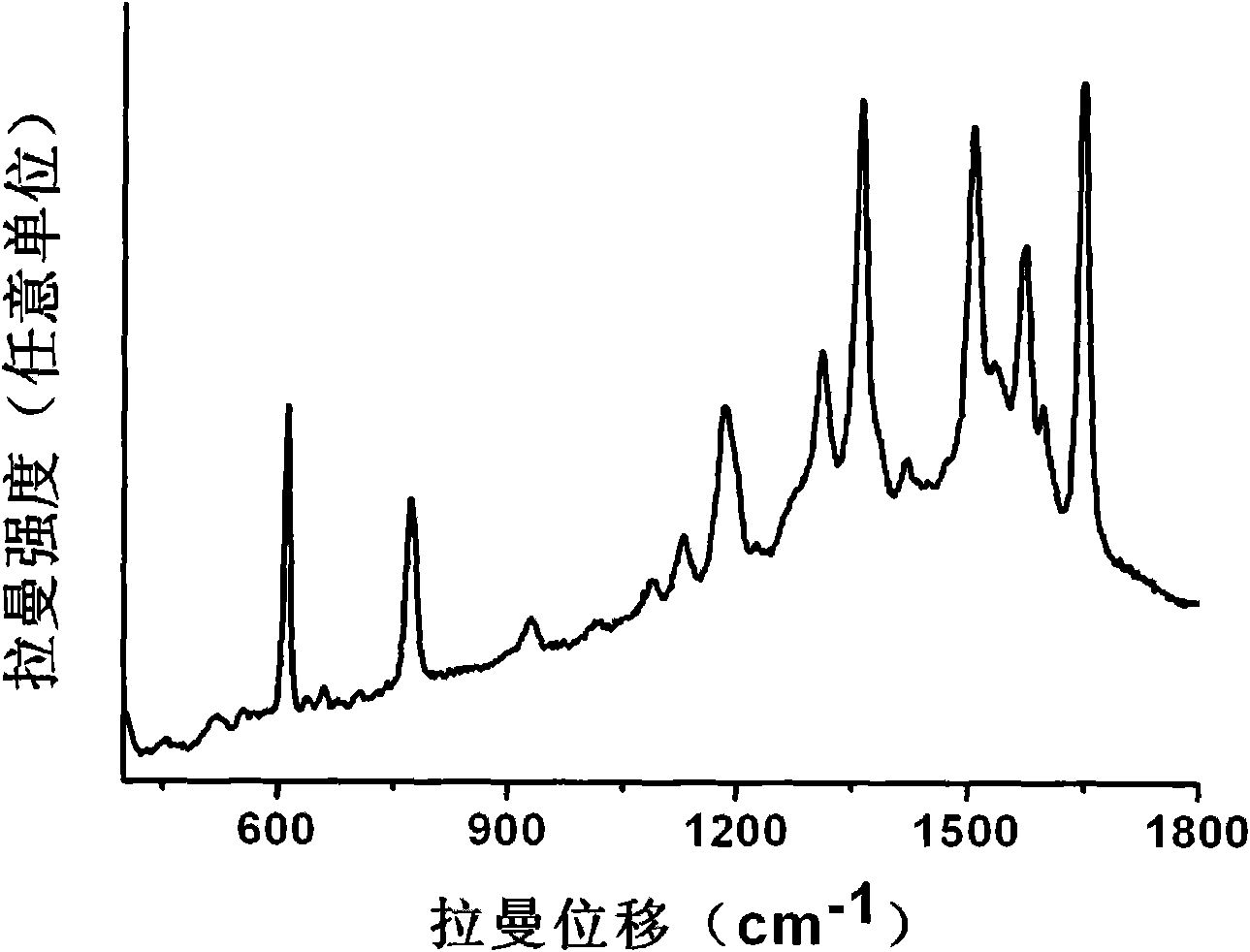

Film formed by silver nanosheets and preparation method and application of film

InactiveCN103103608AStrong SERS active substrate structurePreparation method scienceMaterial nanotechnologyPolycrystalline material growthSeed crystalElectrolyte

The invention discloses a film formed by silver nanosheets and a preparation method and application of the film. The film is 200-500nm in thickness and is formed by covering a nanometer flat branch cluster on a conductive substrate, wherein a gap between every two nanometer flat branches in the cluster is 1-15nm; and the film is formed by connecting nanosheets with arc-shaped edges in series, wherein the thickness of each nanosheet is 10-50nm, width is 30-300nm and length is 90-150nm. The preparation method comprises the following steps of: mixing and stirring a silver nitrate water solution, a citric acid water solution and water to obtain a mixed solution, and injecting a sodium borohydride water solution into the mixed solution and stirring and aging to obtain a silver seed crystal solution; then coating the silver seed crystal solution onto the conductive substrate and then airing the conductive substrate; and then putting the conductive substrate which is coated with silver seed crystals and is used as a cathode in electrolyte consisting of the silver nitrate water solution and the citric acid water solution, and carrying out electro-deposition for 5-120 minutes under the constant current of which the current density is 0.1-1mA / cm<2> to obtain the target product. The film disclosed by the invention can be used as an SERS (Surface Enhanced Raman Scattering) active substrate to rapidly detect the content of trace rhodamine 6G or tetrachlorobiphenyl-77 attached onto the SERS active substrate.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

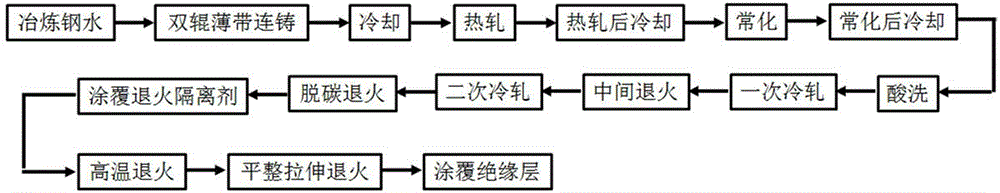

Ultrathin oriented silicon steel sheet and short-process manufacturing method thereof

ActiveCN104962816AQuantity is easy to controlEasy to control distributionProcess manufacturingMolten steel

The invention relates to an ultrathin oriented silicon steel sheet and a short-process manufacturing method thereof. The steel sheet comprises the following components in percentage by mass: 0.002-0.08% of C, 2.8-3.4% of Si, 0.05-0.30% of Mn, 0.015-0.04% of S, 0.005-0.05% of Als, 0.003-0.010% of N, 0-0.6% of Cu, 0-0.2% of Sn, less than 0.004% of O, less than 0.01% of P and the balance of Fe. The thickness of the product is 0.05-0.15mm. The manufacturing method comprises the following steps: (1) smelting molten steel; (2) carrying out continuous casting to obtain a casting band; (3) cooling, carrying out hot rolling and coiling; (4) carrying out normalizing treatment and controlled cooling; (5) pickling, and carrying out primary cold rolling; carrying out interannealing; (6) pickling, and carrying out secondary cold rolling; carrying out decarburizing annealing; (7) coating an annealing separant; and (8) carrying out high-temperature annealing and purification annealing. The method greatly simplifies the ultrathin oriented silicon steel sheet production process, is simple and effective, and has the characteristics of short process, high controllability and low energy consumption.

Owner:NORTHEASTERN UNIV

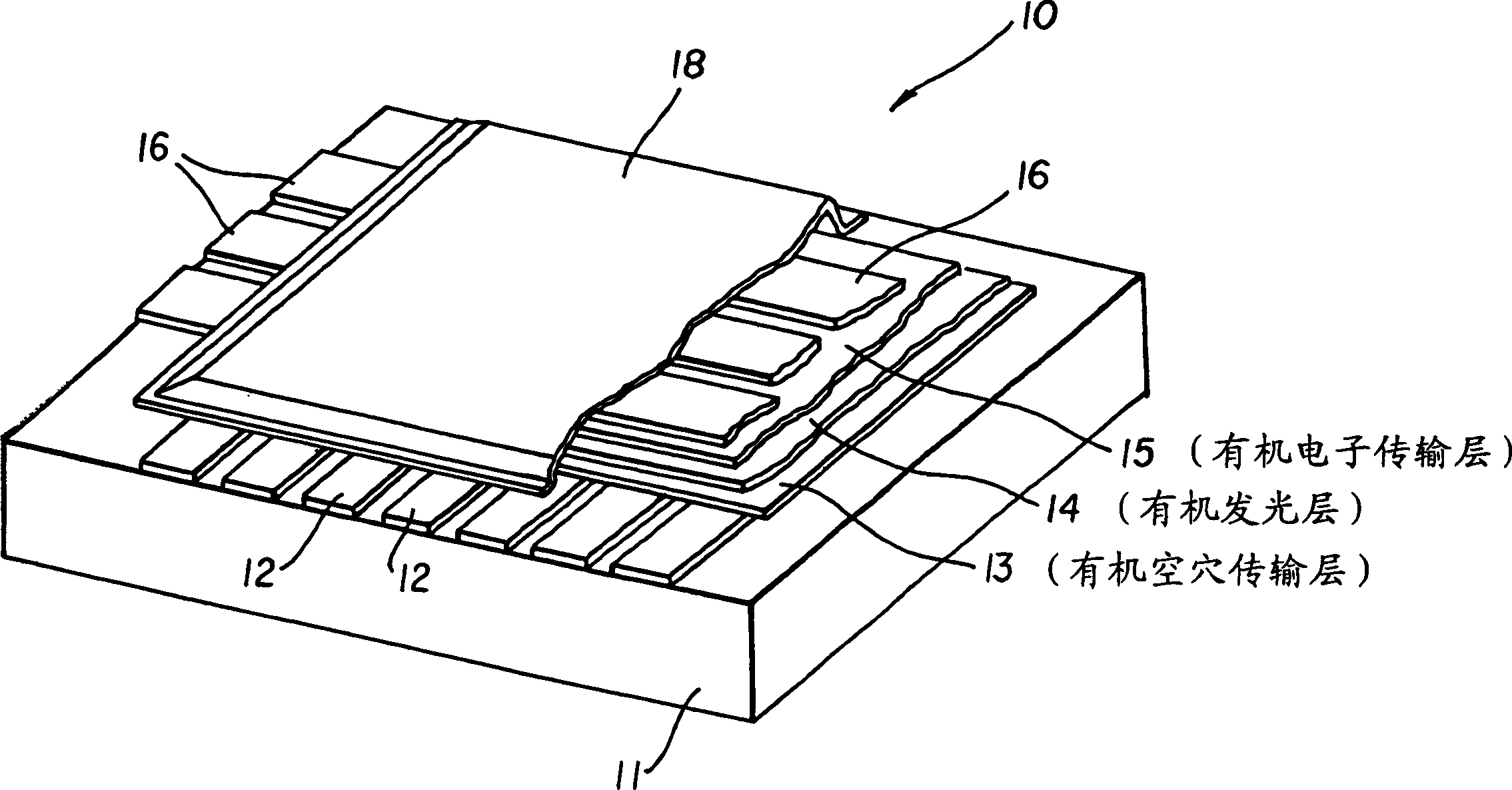

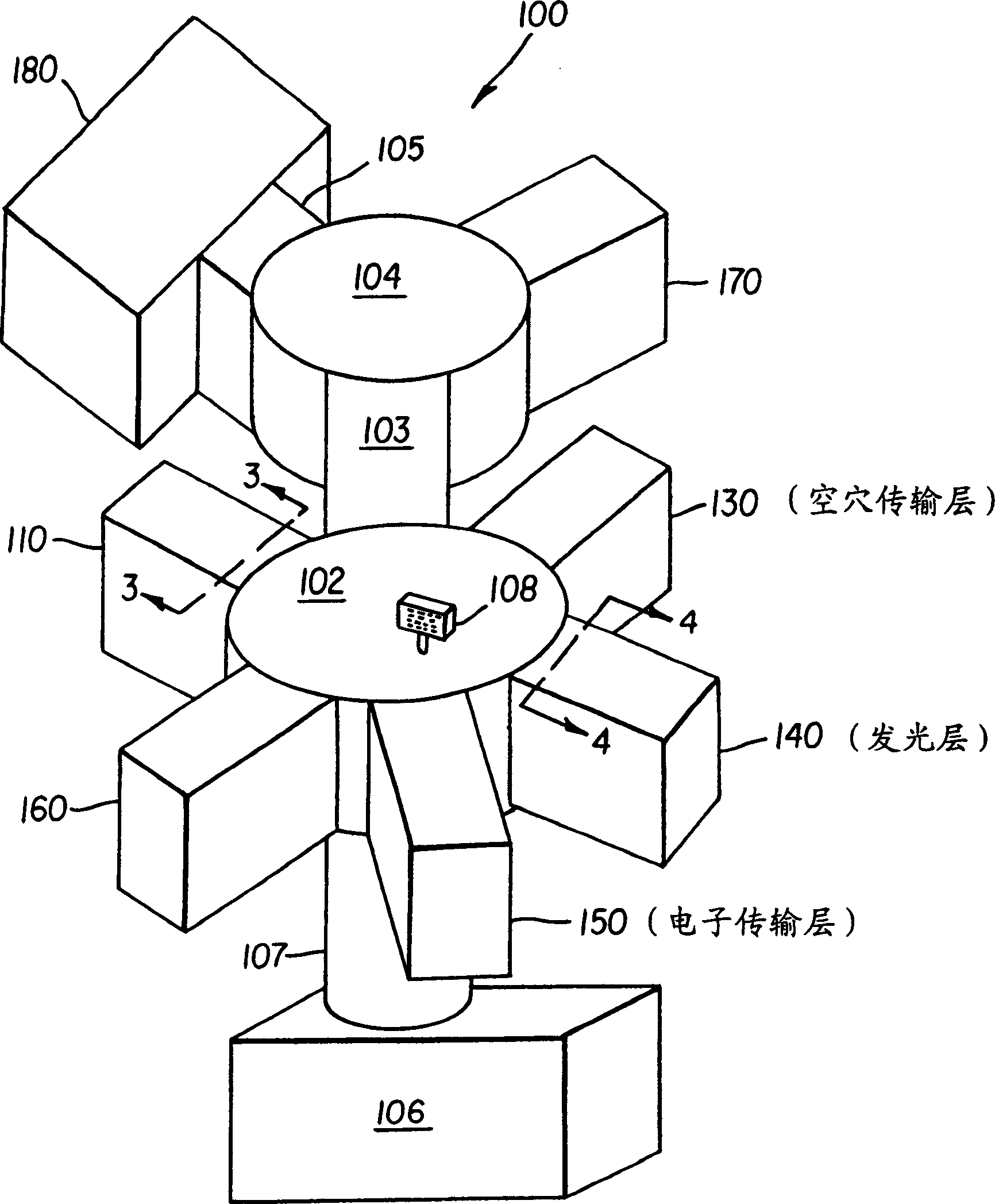

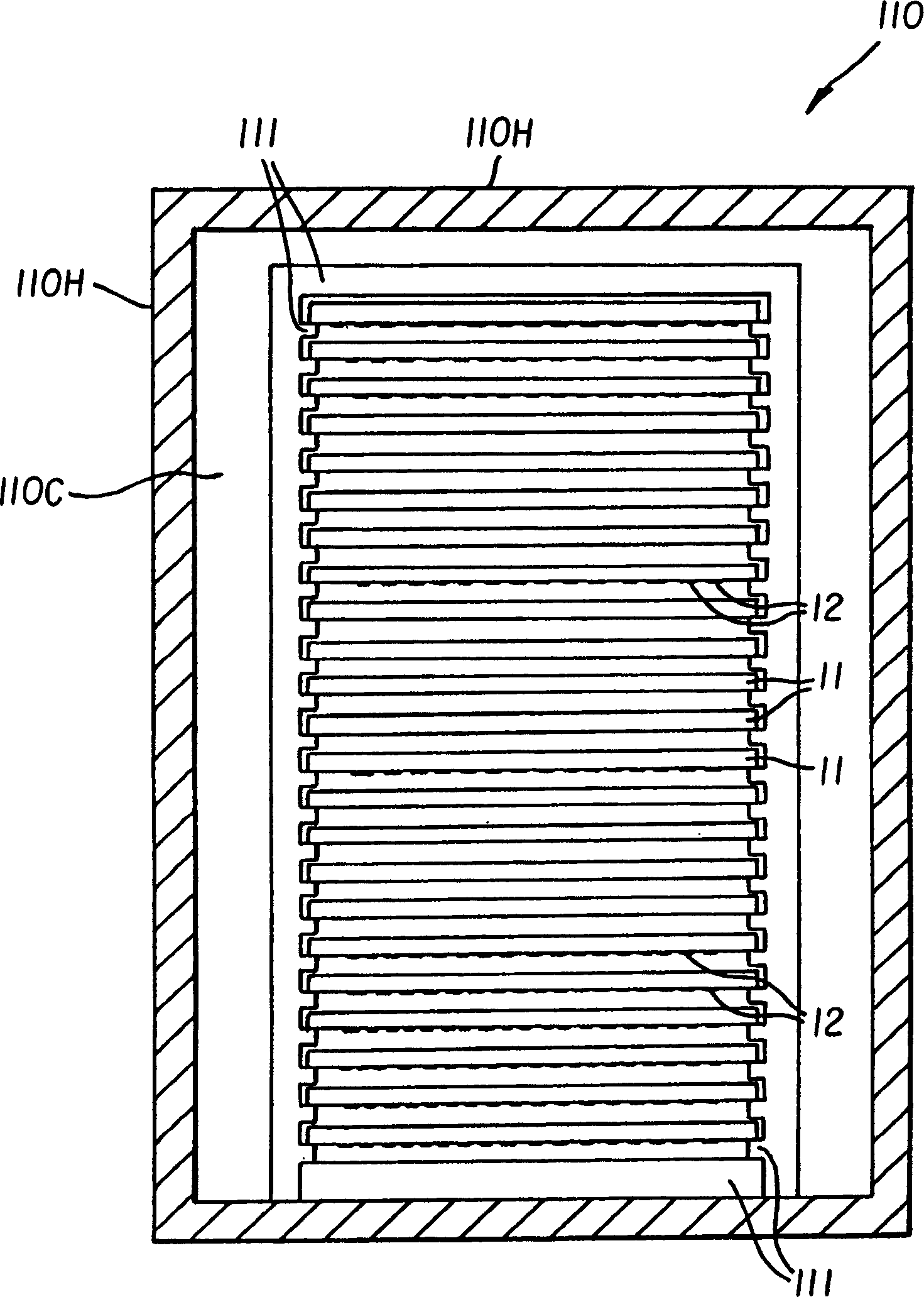

Reusable substance amount sensor in prodn. of organic luminous device

InactiveCN1382827AEfficient manufacturing methodElectroluminescent light sourcesVacuum evaporation coatingControl signalOrganic light emitting device

The present invention relates to a method for controlling the deposition of organic materials in the manufacture of an organic light-emitting device, the method comprising: depositing an organic material in a deposition area to form a layer of an organic light-emitting device; setting a movable sensor, when the sensor moves to A signal indicative of the deposition rate and thickness of the organic material forming the layer is provided in the deposition zone and when covered during the deposition step. The method further includes: controlling the deposition of the organic material based on the signal to control the deposition rate and thickness of the organic material forming the layer; moving the movable sensor from the deposition area to a cleaning position; and removing the sensor from the movable sensor. Organic materials enable removable sensors that can be reused.

Owner:GLOBAL OLED TECH

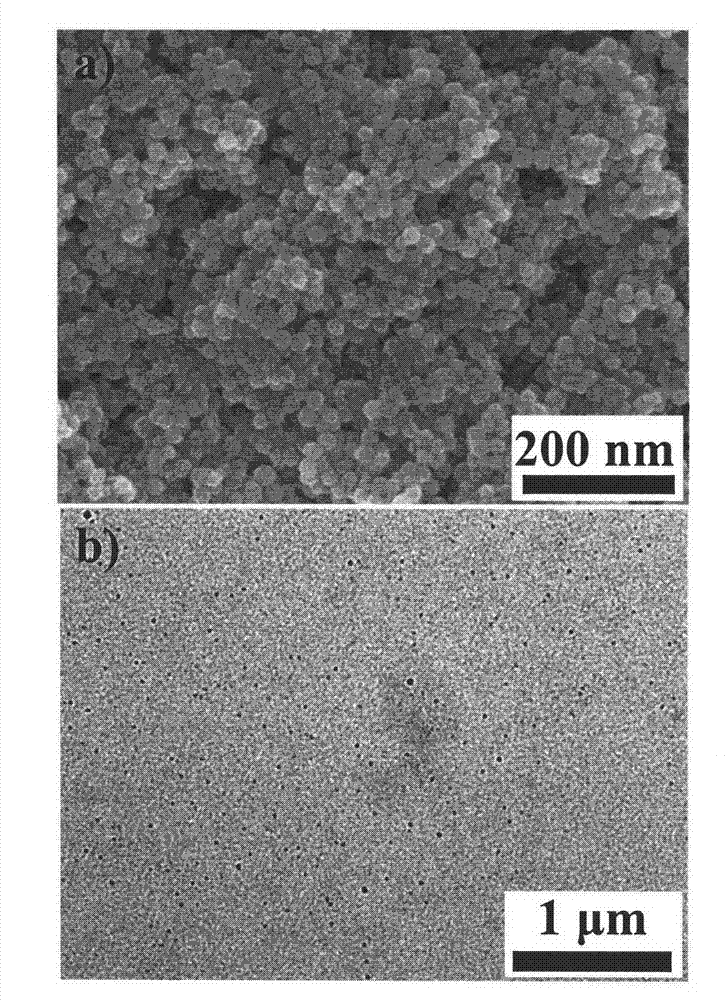

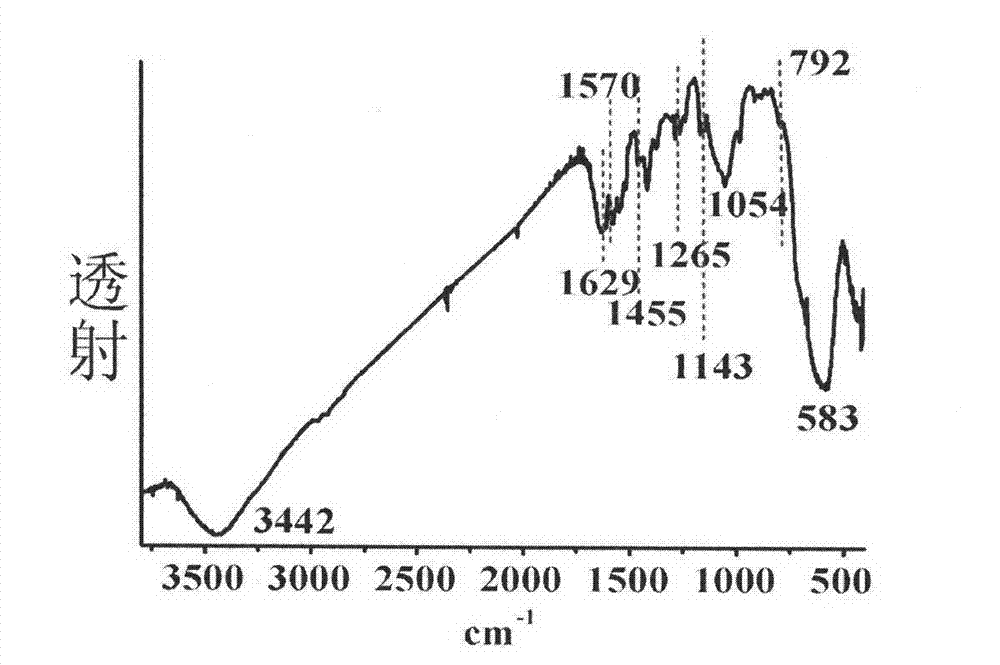

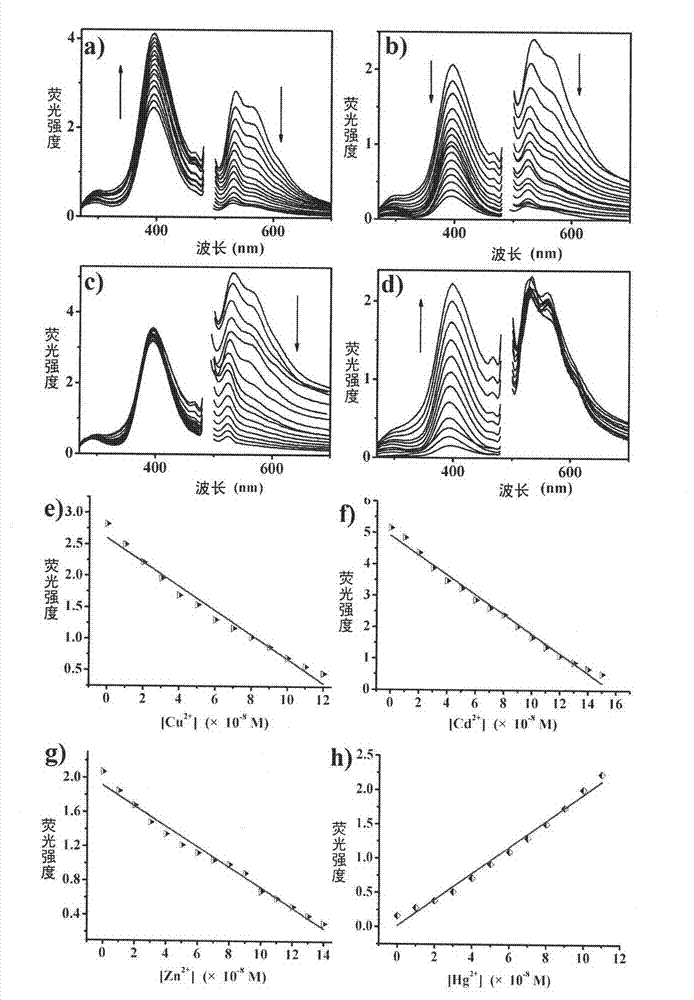

Ferroferric oxide nano-composite particle and preparation method and applications thereof

InactiveCN103241776AGood dispersionEfficient detectionFerroso-ferric oxidesNanotechnologySodium acetateN dimethylformamide

The invention discloses a ferroferric oxide nano-composite particle and a preparation method and applications thereof. The composite particle is a ferroferric oxide nano-composite particle with the particle size of 10-30nm, and 1,4-dihydroxy anthraquinone and fluorenylmethoxycarbonyl are modified on the surface of the ferroferric oxide nano-composite particle. The preparation method comprises the steps of: firstly, carrying out a hydrothermal method on ferric trichloride hexahydrate, sodium acetate, 1,6-hexanediamine and ethanediol to obtain the ferroferric oxide nano-composite particle, then producing 1,4-dihydroxy anthraquinone, chloroacetyl chloride, and N,N-dimethylformamide into dyes, then adding the ferroferric oxide nano-composite particle, sodium carbonate and the dyes into acetonitrile to carry out a reflux reaction, carrying out solid-liquid separation, washing and drying on the obtained reaction liquor to obtain an intermediate product, then dispersing the intermediate product into the N,N-dimethylformamide, adding dispersion liquid into the fluorenylmethoxycarbonyl, stirring for 2 hours, and carrying out solid-liquid separation, washing and drying to obtain a target product. The ferroferric oxide nano-composite particle can be used for fast detecting four heavy metal ions, namely copper, zinc, cadmium and mercury in an aqueous solution.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Hollow spherical mesoporous PtAu nanomaterial and preparation method and application thereof

ActiveCN106935871AStructurally precise regulationGood catalytic propertiesCell electrodesPlatinumMethanol fuel

The invention discloses a hollow spherical mesoporous PtAu dual-metal methanol fuel cell catalyst nanomaterial and a preparation method thereof. The hollow spherical nanometer comprises hollow spheres formed by a shell layer; the inner surface of the shell layer is formed by gold while the outer surface of the shell layer is formed by platinum; the shell layer adopts a continuous porous structure; the shell layer is 5-200nm in thickness; the holes are 1-15nm in diameter; the hollow spherical nanometer is 50-2,000nm in grain diameter; and the atomic ratio of gold to platinum in the shell layer is (0.1-9.9) to 1. A dual-metal shell layer is formed on a temperate through a template method via a seed growth method to prepare the core-shell structure; and then the template is removed by adopting a solvent to form the hollow dual-metal shell layer. According to the method disclosed by the invention, the catalyst structure can be realized by controlling preparation conditions in each step, so that accurate regulation and control on appearance and compositions, and simple and easy implementation of the operation are achieved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

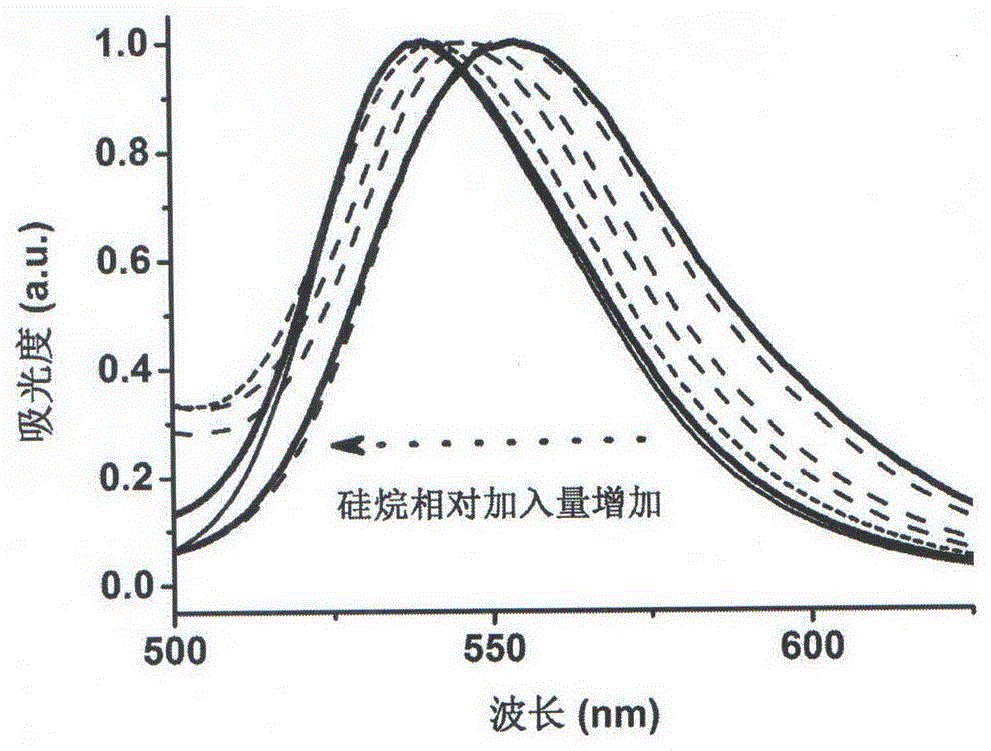

Preparation method and application of gold nanocluster with adjustable fluorescence and size

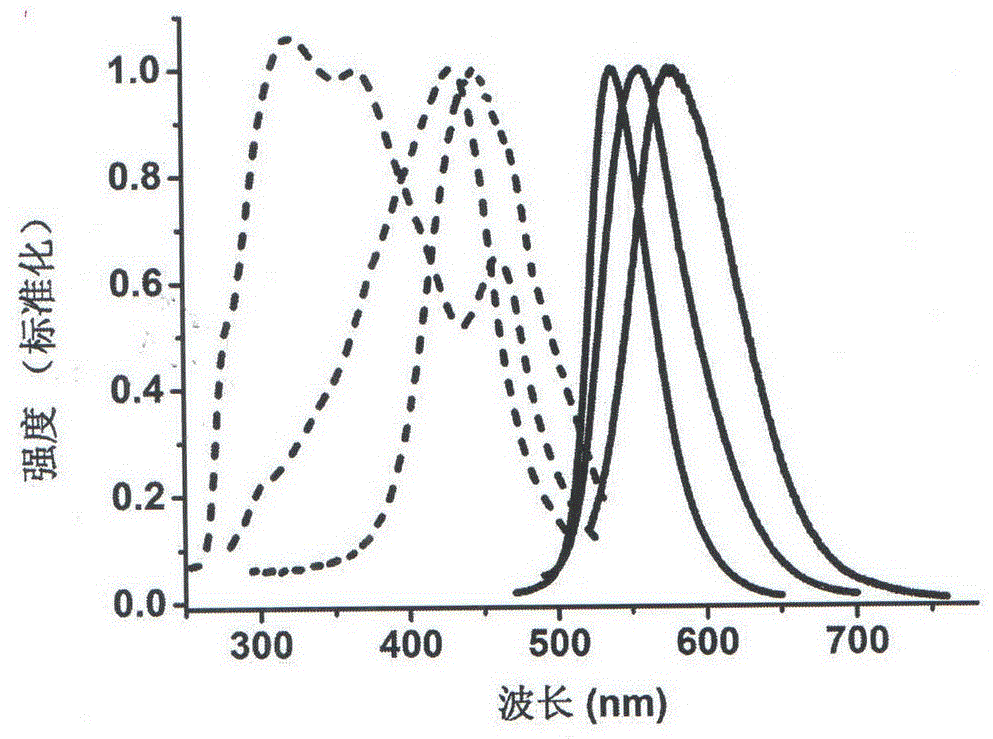

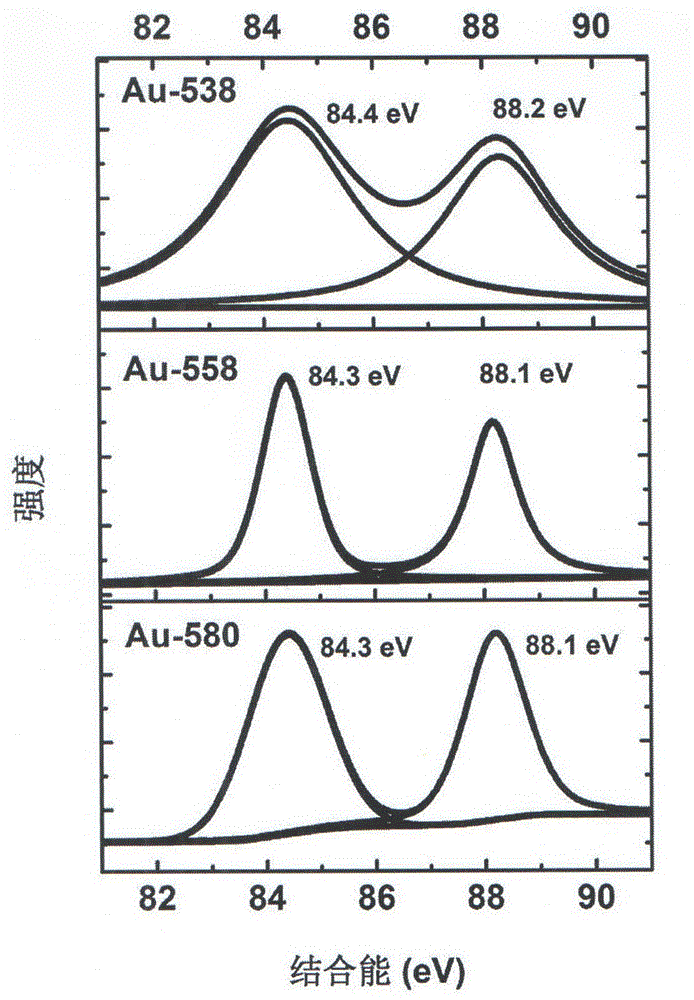

InactiveCN105689735AEvenly dispersedFast preparation methodTransportation and packagingMetal-working apparatusGold clusterPhotoluminescence

The invention relates to a preparation method and an application of a gold nanocluster with adjustable fluorescence and size. The method adopts mercaptosilane commonly used in the industry as a stabilizer and a reductant, and prepares the gold nanocluster in a way of chloroauric acid photochemical reduction. The method is quick, effective and simple in preparation program, no extra reductant is added, and no reaction produces in a multi-phase environment. The gold nanocluster prepared with the method can be uniformly dispersed in an organic solvent and water, and has excellent photoluminescent performance. The maximum excitation wavelength of the fluorescence of the gold nanocluster is positioned in a visible light region (400-460nm) and the position of an emission peak can be adjusted and controlled in a range of 530-580nm. The gold nanocluster has the characteristics of visible light excitation, large Stokes shift and adjustable fluorescence-emission color and size, thereby having potential application prospects in the fields of fluorescence imaging, marking and catalysis.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

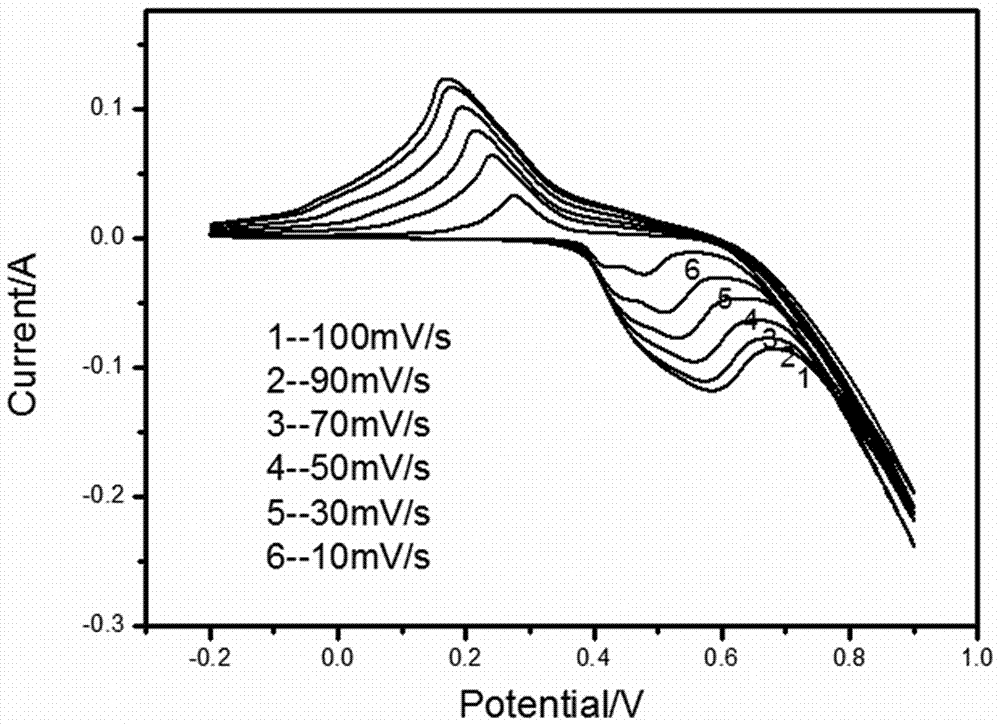

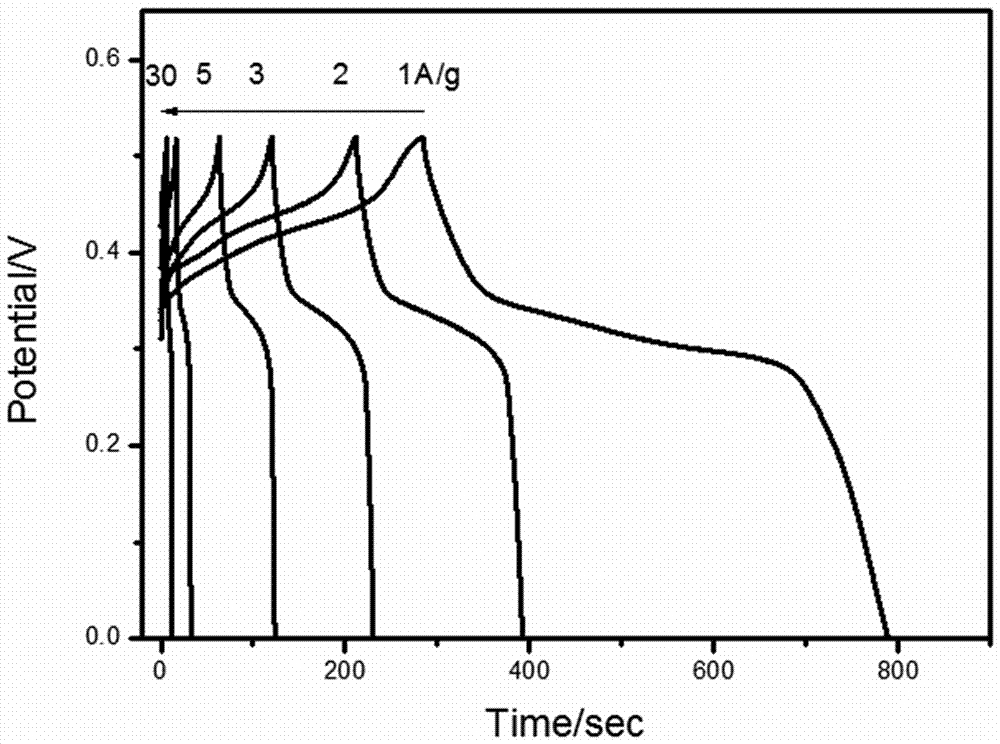

Preparation method for nickel ferrite supercapacitor electrode material taking foamed nickel as substrate

InactiveCN106935418AEasy to operateComplete structureHybrid capacitor electrodesHybrid/EDL manufactureIonAir atmosphere

The invention discloses a preparation method for a nickel ferrite supercapacitor electrode material taking foamed nickel as a substrate. The preparation method comprises the following steps of (1) preparing nickel nitrate hexahydrate, ferric chloride, hexadecyl trimethyl ammonium bromide, urea and deionized water to obtain a precursor solution; (2) adding the precursor solution obtained in the step (1) into an inner container of a reaction kettle, performing stirring for 30-40 minutes so that the mixture is uniformly mixed; (3) placing the foamed nickel after being processed in the inner container of the reaction kettle in the step (2), and performing hydrothermal reaction after sealing; (4) naturally cooling after completion of hydrothermal reaction, taking out the foamed nickel, and performing washing and drying; and (5) performing thermal processing in a tubular furnace in an air atmosphere to obtain the nickel ferrite supercapacitor electrode material. The preparation method is simple, is low in cost and high in yield, and the prepared electrode material has relatively high specific capacity and favorable stability, is long in service lifetime, and simultaneously also has good electrochemical activity.

Owner:XINYANG NORMAL UNIVERSITY

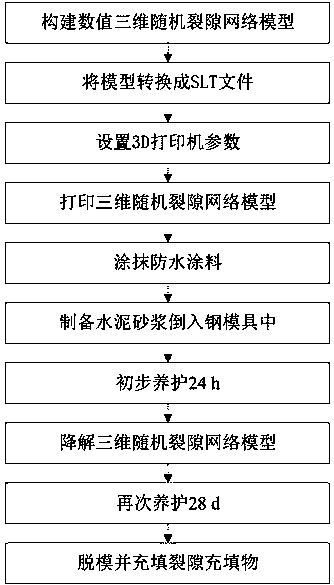

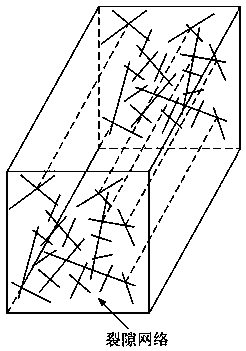

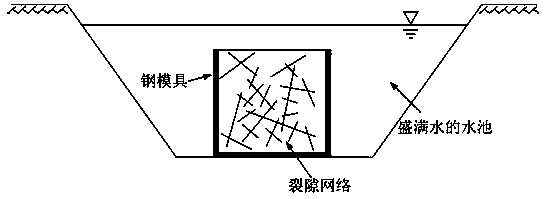

Filling type fracture network rock test piece preparing method based on 3D printing technology

InactiveCN109648693AEfficient manufacturing methodEffective WaysAdditive manufacturing apparatusPreparing sample for investigationType fractureEngineering

The invention relates to a filling type fracture network rock test piece preparing method based on the 3D printing technology, and belongs to the related technical field of construction, hydraulic engineering, mining and other underground project tests. According to the filling type fracture network rock test piece preparing method based on the 3D printing technology, firstly, a three-dimensionalrandom fracture network model is constructed; the obtained model is converted into an SLT file; the SLT file is guided into a 3D printer; the 3D printer is used for printing the three-dimensional random fracture network model; the outer surface of the model is coated with a waterproof coating; the three-dimensional random fracture network model is placed in a steel die, cement mortar is poured into the steel die containing the three-dimensional random fracture network model, and uniform vibration is conducted; and a cement mortar test piece and the steel die are placed in a standard curing boxtogether; then the three-dimensional random fracture network model is degraded; and the degraded test piece is placed in the standard curing box again to be cured, the cured test piece three-dimensional random fracture is filled with needed materials, and finally a filling type fracture network rock test piece is obtained.

Owner:KUNMING UNIV OF SCI & TECH

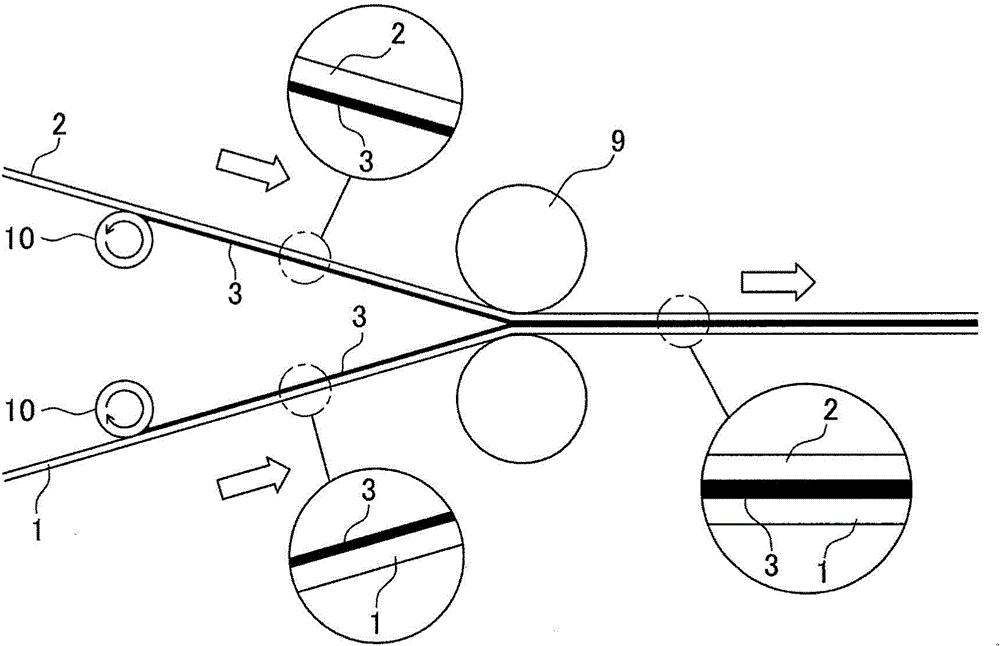

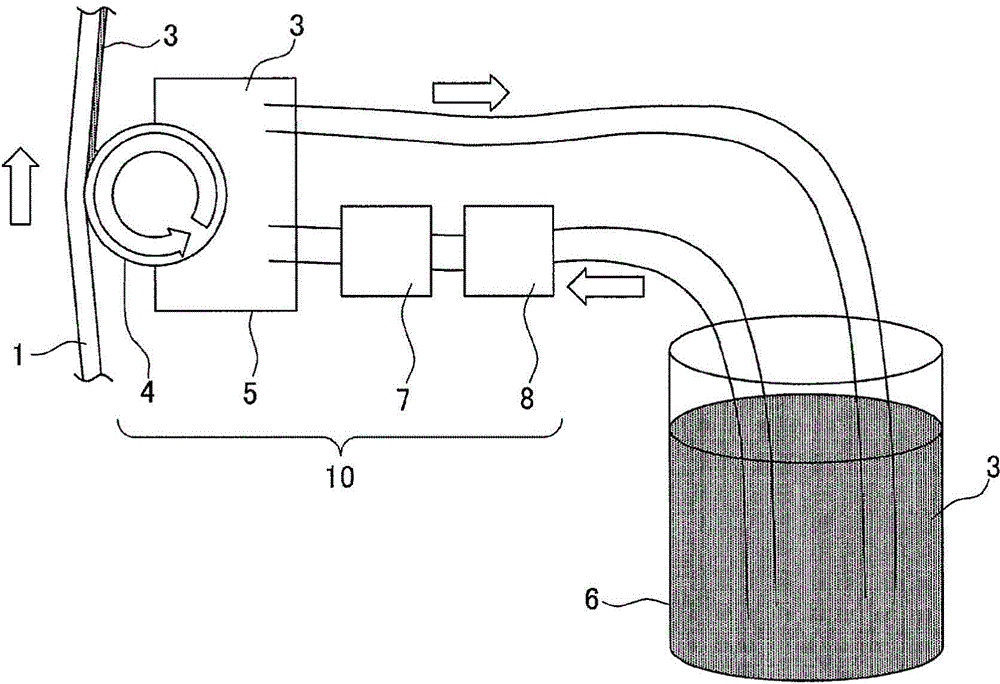

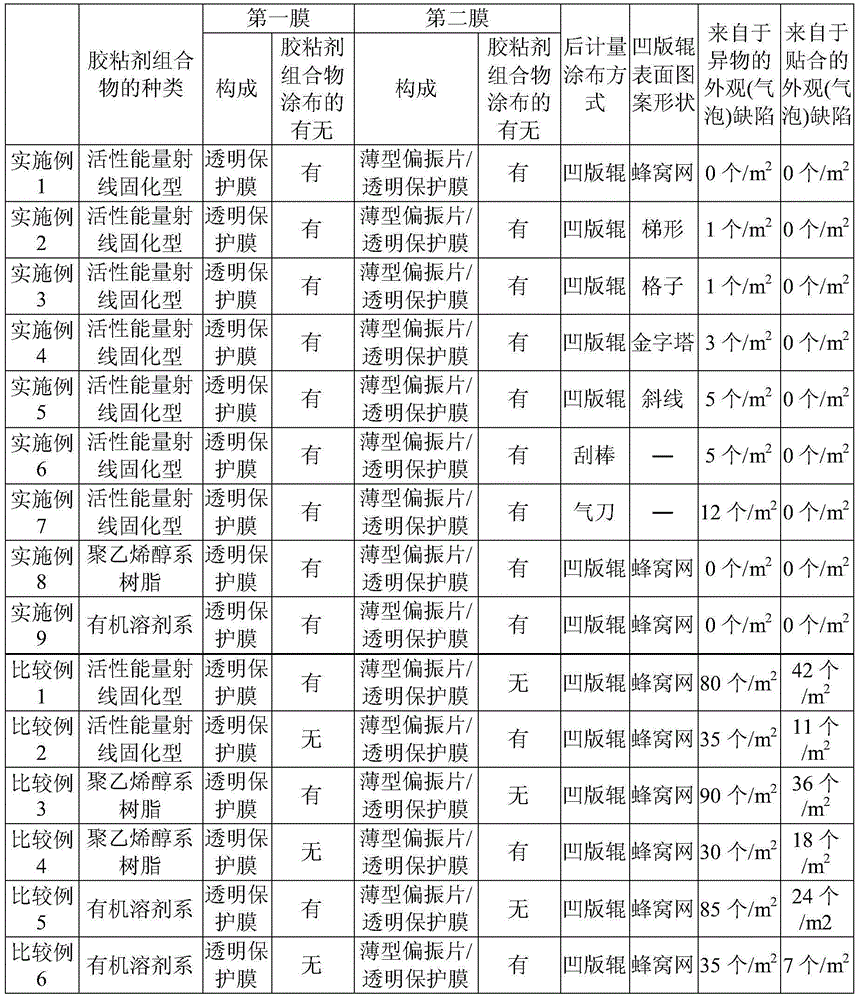

Method for producing optical film, optical film and image display device

InactiveCN104884258AAvoid mixingEfficient manufacturing methodAdhesive processesLamination ancillary operationsDisplay deviceAir bubble

A method for producing an optical film which comprises a multilayer structure wherein at least a first film and a second film are bonded with each other with an adhesive layer or bonding agent layer being interposed therebetween, said adhesive layer or bonding agent layer being composed of a layer of a cured product of an adhesive composition or bonding agent composition. This method for producing an optical film comprises a coating step wherein foreign materials and / or air bubbles are removed by applying the adhesive composition or bonding agent composition to both the bonding surface of the first film and the bonding surface of the second film using a post-measurement coating method.

Owner:NITTO DENKO CORP

Carbon composite material for secondary battery, preparation method thereof and application thereof

InactiveCN109950548AImprove performanceIncrease energy densityElectrode carriers/collectorsCarbon compositesElectrical battery

The invention provides a carbon composite material, a preparation method thereof and an application thereof. The carbon composite material is composed of soft carbon and hard carbon. When the carbon composite material provided by the invention is used as a negative electrode current collector of a secondary battery, the advantages of the soft carbon and the hard carbon can be complemented, electrochemically active substances can be uniformly embedded, adsorbed or deposited in the carbon composite material, the destruction of the structures of the carbon material and the short circuit of the battery do not occur, and at the same time, the performance of a metal secondary battery can be improved. The carbon composite material not only provides space for metal deposition but also provides a space or passage for metal ion insertion, adsorption and extraction, and the storage capacity and cycle life of the secondary battery are improved. When the carbon composite material provided by the present invention is used as the negative electrode current collector of the secondary battery, the change of the original assembly process of the battery is not needed.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

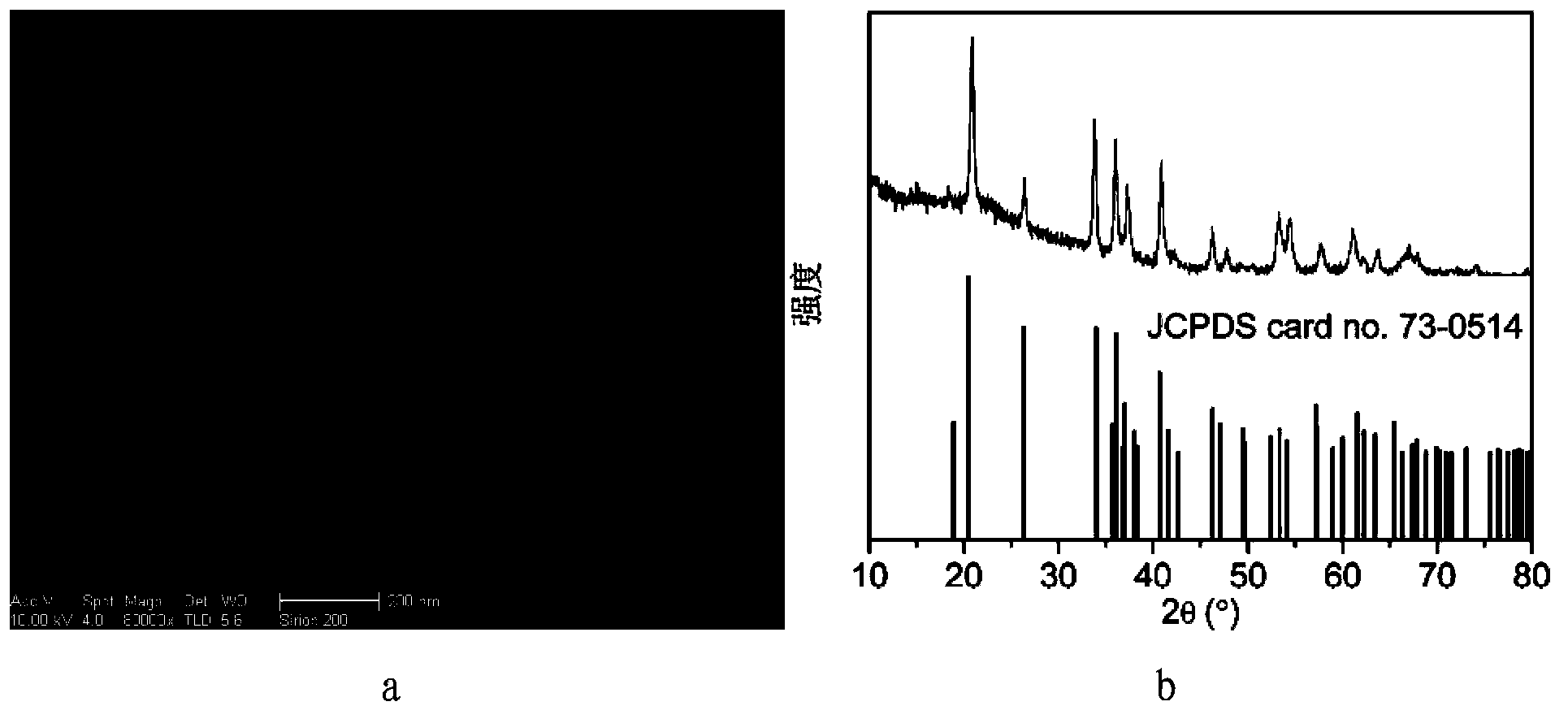

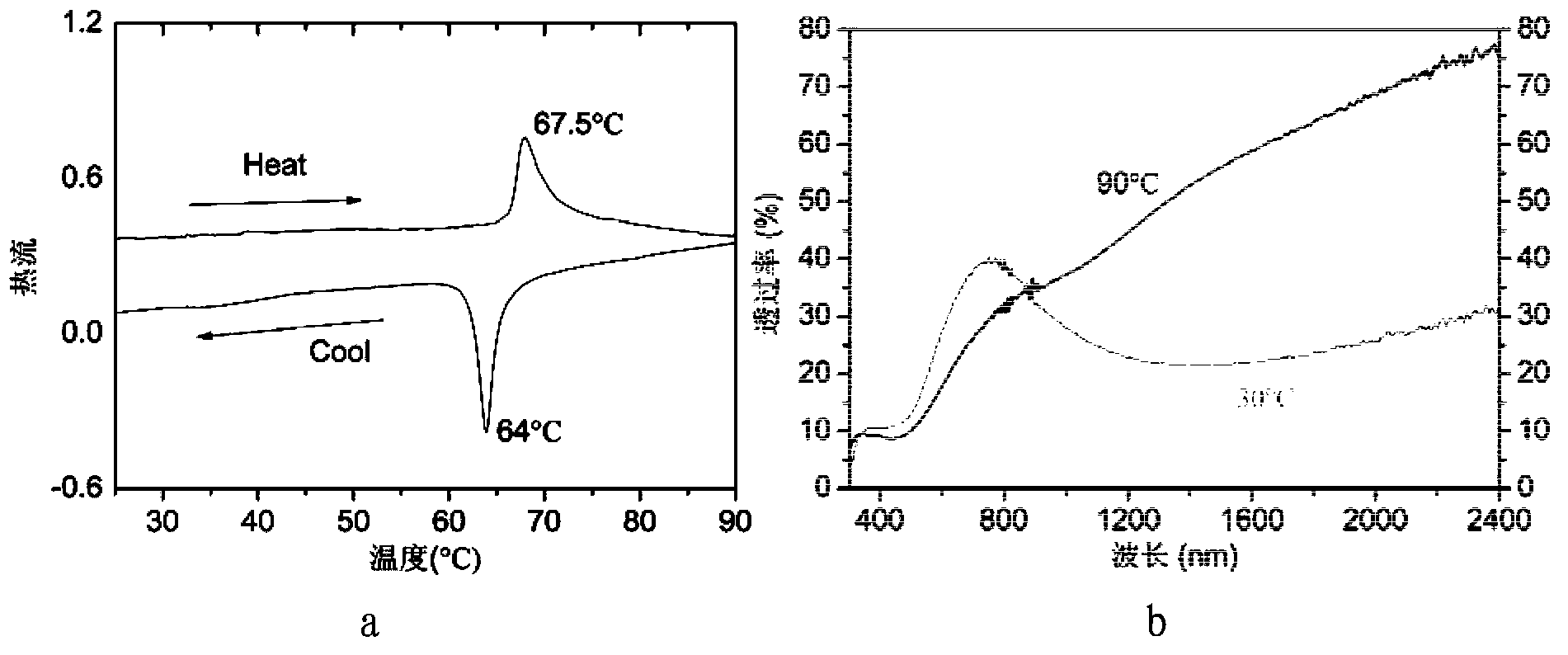

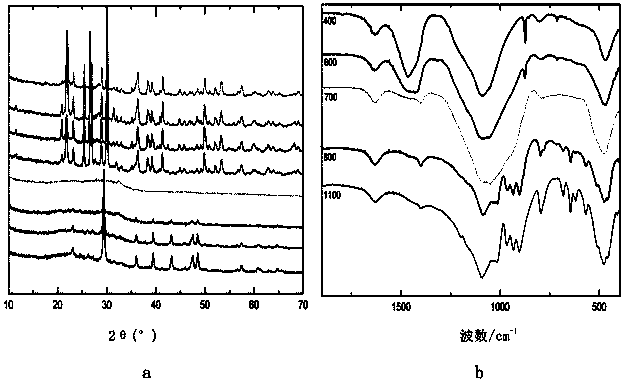

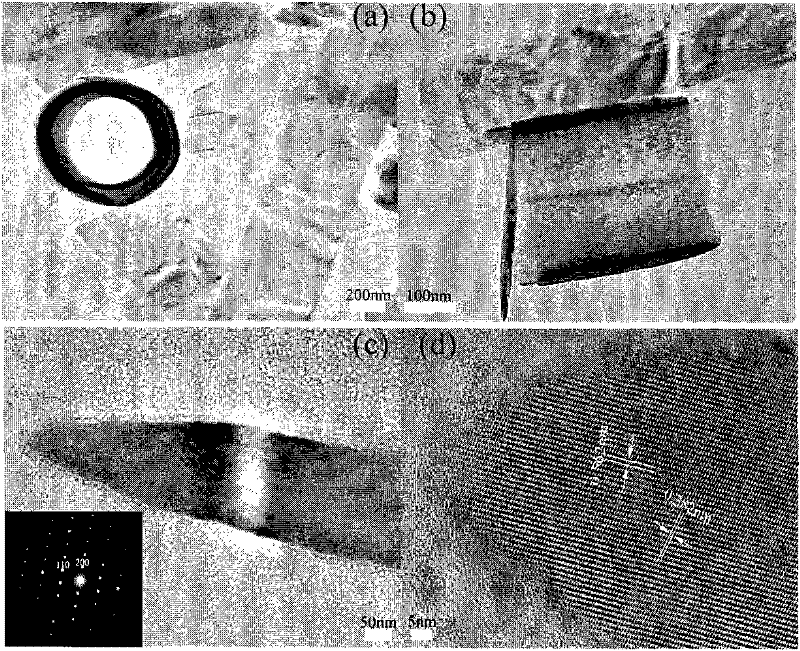

Tungsten-doped vanadium dioxide nanopowder and preparation method thereof

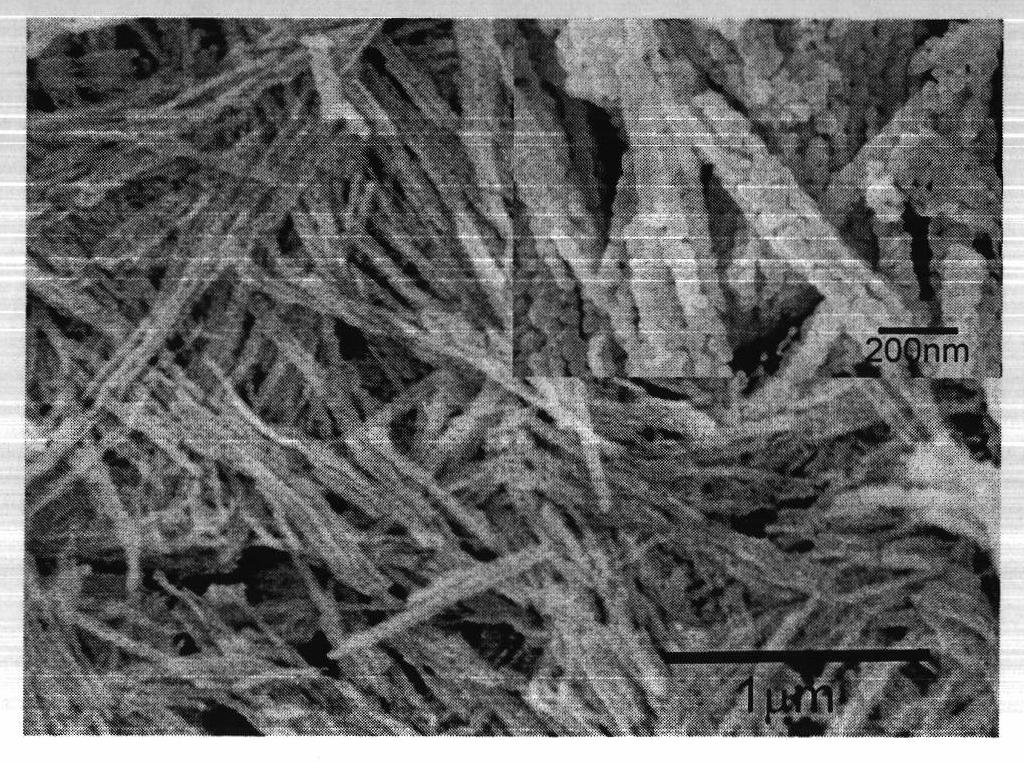

ActiveCN102295312ADoping achievedGood dispersionNanostructure manufactureVanadium oxidesVanadium dioxideTungstate

The invention discloses a tungsten-doped vanadium dioxide nanopowder and a preparation method for the nanopowder. The powder is flaky or conic rod-shaped tungsten-doped B-phase vanadium dioxide of which the chemical formula is V1-xWxO2; the flaky V1-xWxO2 is 1-10 nm thick, 350-450 nm wide and 3-5 mum long, and the conic tip diameter of the conic rod-shaped V1-xWxO2 is 15-25 nm, the cone length is110-150 nm, the rod diameter is 130-150 nm and the rod length is 1-2 mum; the preparation method comprises the following steps of: firstly, weighting vanadium pentoxide and ammonium tungstate according to a component ratio of the V1-xWxO2, melting the weighted vanadium pentoxide and ammonium tungstate and preserving heat for at least 20 minutes, then, dipping the molten mass in a quenching media and stirring for at least 12 hours, standing and aging for at least 10 days to obtain a doped sol, afterwards, adding polyethylene glycol aqueous solution into the doped sol, stirring for at least 8 hours to obtain mixed solution, and setting the mixed solution to be airtight for reaction for 2-6 days at the temperature of 180-220 DEG C so as to prepare the tungsten-doped B-phase vanadium dioxide powder. The tungsten-doped B-phase vanadium dioxide powder can be used as electrode material for lithium ion batteries; and after being annealed, the tungsten-doped B-phase vanadium dioxide powder canbe prepared into a phase-change metallic oxide material with wider application, namely, a tungsten-doped M-phase VO2.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

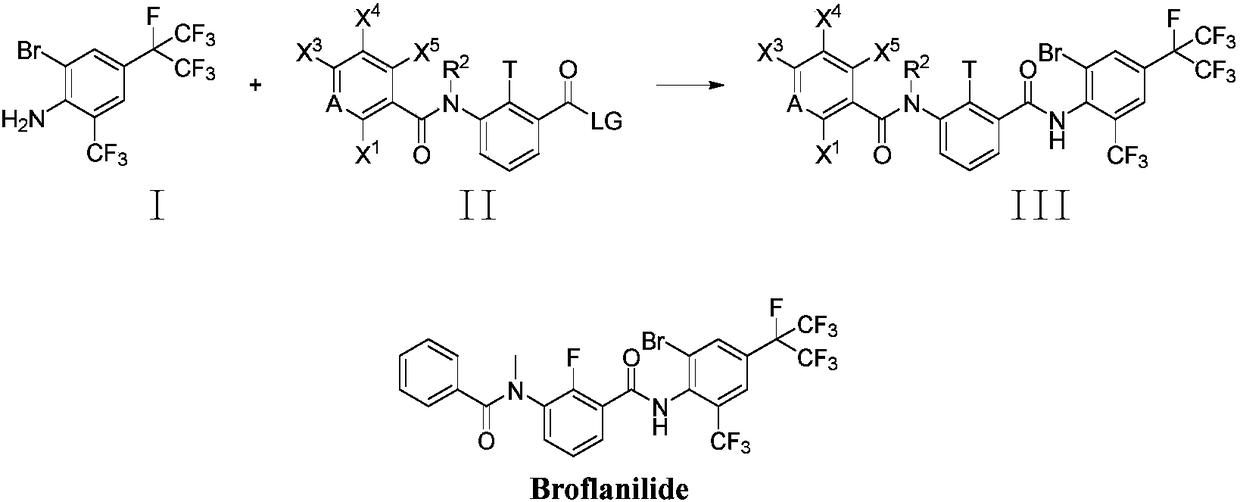

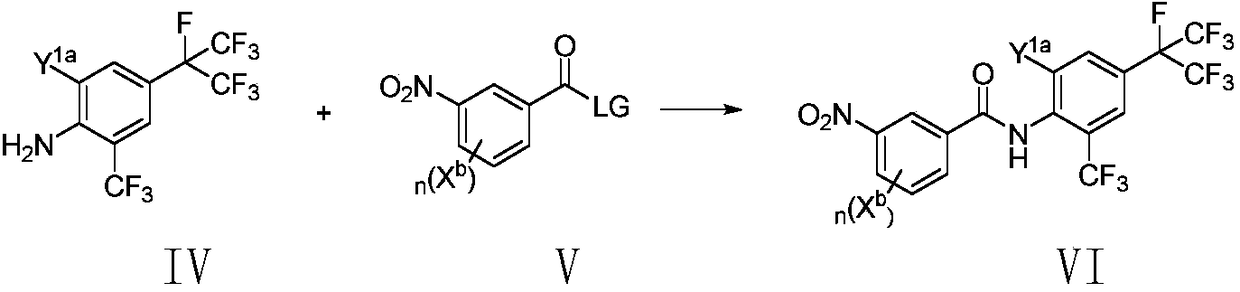

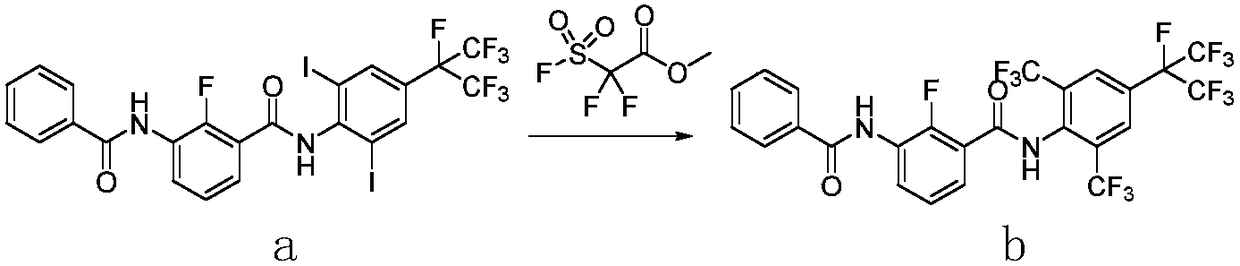

Method for preparing o-trifluoromethylaniline compound and intermediate thereof

ActiveCN109206335AMild reaction conditionsHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationTrifluoromethylationOrganic synthesis

The invention belongs to the field of organic synthesis, and specifically relates to a method for preparing an o-trifluoromethylaniline compound and an intermediate thereof. The reaction formula is asshown in the specification. In the formula, each substituent group is described in the specification. Specifically, a compound VII and a compound VIII react in a suitable reaction solvent under the action of a suitable catalyst to prepare a compound IX, and the compound IX further reacts with a suitable trifluoromethylating reagent under suitable reaction conditions to prepare a compound X. The invention provides an effective preparation method for the industrial development of the insecticidal compounds.

Owner:SHENYANG SINOCHEM AGROCHEMICALS R&D CO LTD

Nano-composite coating with low surface energy and preparation method thereof

The invention discloses a nano-composite coating with low surface energy and a preparation method thereof. The nano-composite coating consists of a transition layer and a surface layer, wherein the thickness of the transition layer is between 2 and 200 mu m, and the transition layer consists of more than one layer of mixture of bulbs, clubs and flakes; and the thickness of the surface layer is between 2 and 40 mu m, and the surface layer consists of a reticulated silica glassy substance. The method comprises the steps of: performing cleaning and roughing treatment on the surface of a substrate first, then mixing the bulbs, the clubs, the flakes, a slurry forming agent and a solvent to obtain slurry of the transition layer, using the slurry of the transition layer to coat the substrate, placing the coated substrate at a temperature of between 180 and 250 DEG C to obtain the transition layer, then mixing organosiloxane water solution and alcohol solution of ethyl orthosilicate to obtain hydrolytic polycondensation reaction solution first, then dripping acid into the hydrolytic polycondensation reaction solution to obtain coating solution of the surface layer, coating the substrate coated with the transition layer by the coating solution of the surface layer, and then placing the substrate at a temperature of between 180 and 250 DEG C to obtain the nano-composite coating with low surface energy. The coating has the characteristics of low surface energy, high density, adjustable hardness, good flexibility and strong adhesion force.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

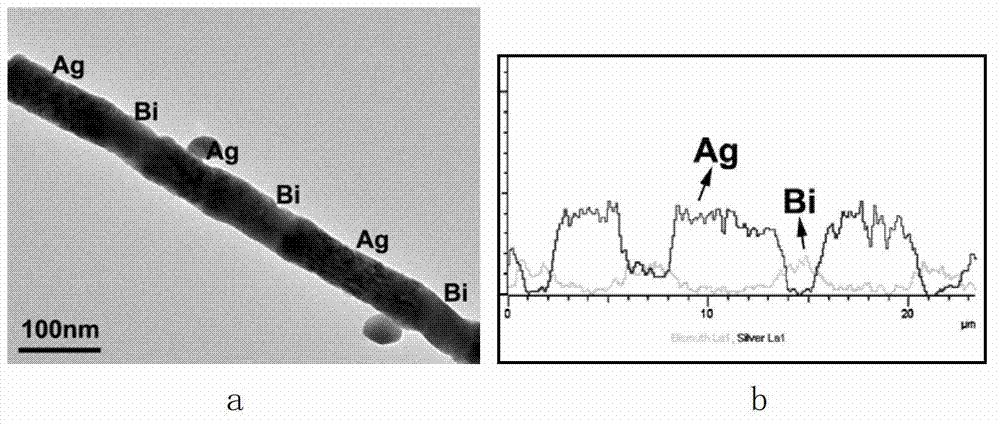

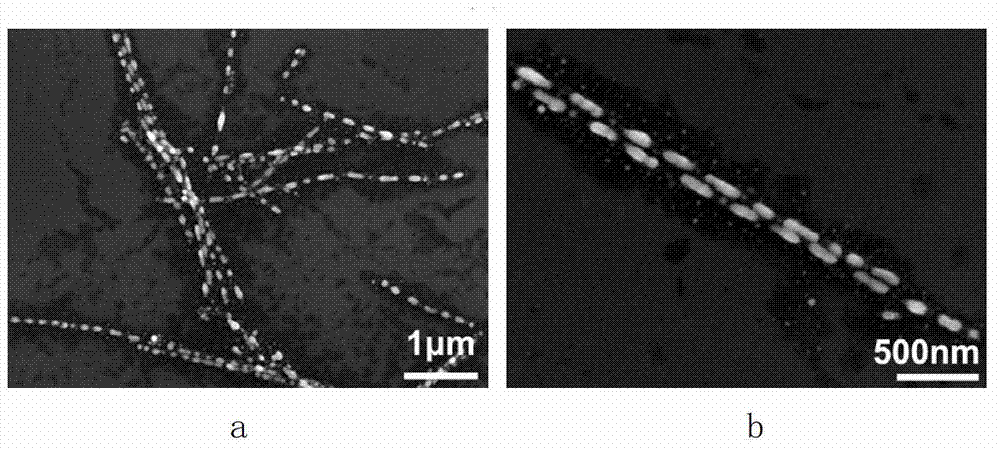

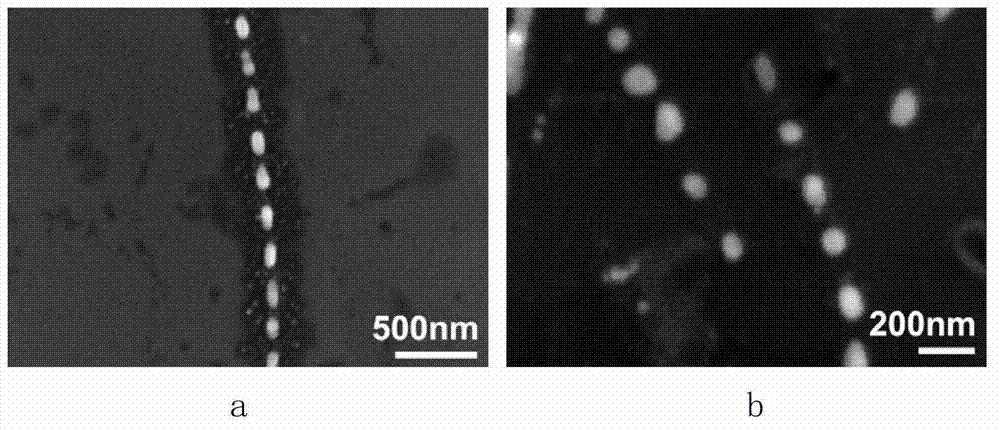

Preparation method for silver nanoparticle chain

ActiveCN103111621APreparation method scienceEfficient manufacturing methodNanotechnologyElectrolytic agentMetallic materials

The invention discloses a preparation method for a silver nanoparticle chain. At first, an aluminum sheet is processed through an anodic oxidation method so that a through-hole alumina template is obtained; a gold film is plated on one side of the through-hole alumina template in an evaporated mode and then the through-hole alumina template is used as a negative pole and placed in silver electrolyte and bismuth electrolyte respectively for multiple times of alternative electrolytic depositions, so that the alumina template is obtained, wherein the through holes of the through-hole alumina template are placed with the silver cylinders and the bismuth cylinders, the silver cylinders and the bismuth cylinders are connected alternatively and one side of the alumina template is plated with the gold film; then the alumina template is soaked in aqueous alkali, so that a nanowire array which is formed by the alternative connection of the silver cylinders and the bismuth cylinders is obtained; and then the nanowire array is placed in ethylalcohol for ultrasonic dispersion, so that a nanowire which is formed by the alternative connection of the silver cylinders and the bismuth cylinders is obtained; and the nanowire which is formed by the alternative connection of the silver cylinders and the bismuth cylinders is placed in an environment with a vacuum degree<=10 Pa to 3 Pa and a temperature 450 DEG C to 500 DEG C to be annealed for 2 hours to 6 hours, so that a target product is obtained. The preparation method for the silver nanoparticle chain has the advantages of being simple in process, low in cost, high in practical value, and capable of being widely used in the preparation of one-dimensional nanoparticle chains of various metal materials.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

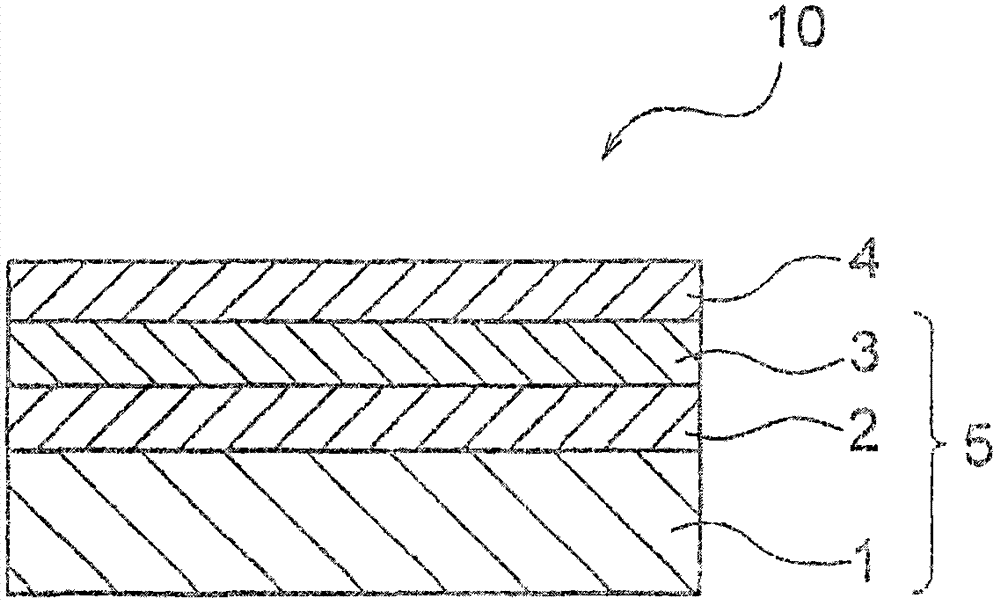

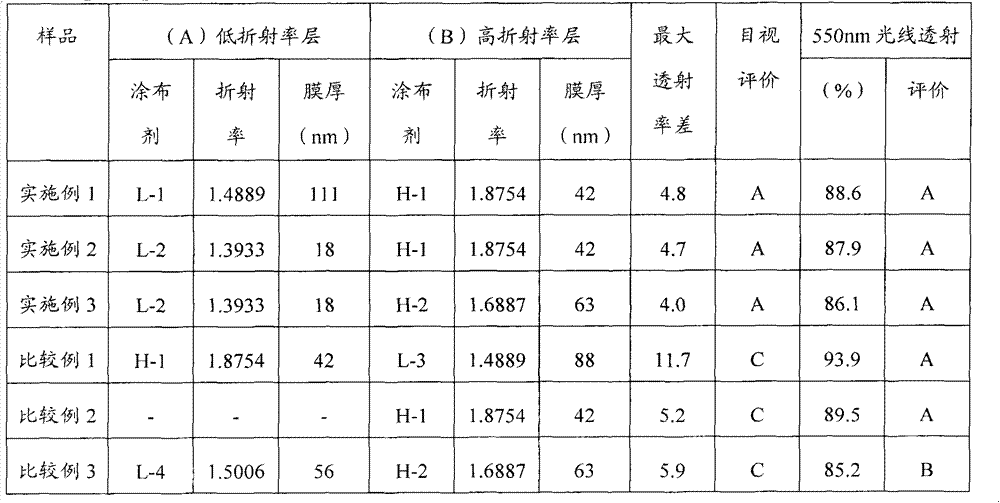

Film for laminating transparent conductive coatings, method of producing the same, and transparent conductive film

ActiveCN103302913AImprove transmittanceEfficient manufacturing methodConductive layers on insulating-supportsLamination ancillary operationsConductive coatingTransmittance

The utility model provides a transparent conducting membrane for laminating, comprising a transparent basis material, (A) low-refractive index layer (B) and a high-refractive index layer. The conducting membrane for laminating is characterized in that the (A) low-refractive index layer is laminated on at least one surface of the transparent basis material, that the high-refractive index layer (B) is further laminated on the low-refractive index layer (A), and that the refractive index of the high-refractive index layer (B) is higher than that of the low-refractive index layer for more than 0.2. The transparent conducting membrane for stacking provides a transparent conducting membrane for a touch panel, and the transparent conducting membrane for the touch panel has an unobvious overlapping part and high transmissivity in short wavelength area of visible light. In particular, the transparent conducting membrane for laminating is used as the transparent conducting membrane of an electrostatic capacity touch panel and used for providing a transparent conducting membrane for laminating of the transparent conductive membrane.

Owner:LINTEC CORP

Wood fiber biomass loaded nano hydrated titanium dioxide composite material, and preparation method and application thereof

ActiveCN110813383AReduce manufacturing costEnable recyclingWater/sewage treatment by irradiationWater treatment compoundsFiberPhoto catalysis

The invention discloses a wood fiber biomass loaded nano hydrated titanium dioxide composite material, and a preparation method and an application thereof, and belongs to the technical field of titanium dioxide composite materials. The preparation method comprises the steps: soaking wood fiber biomass into a mixed solution of butyl titanate and absolute ethyl alcohol, treating with an alkaline solution, washing the wood fiber biomass material with water, and drying to obtain the wood fiber biomass loaded nano hydrated titanium dioxide composite material. The wood fiber biomass is selected as acarrier, the good photocatalyst titanium dioxide and the wood fiber biomass are combined, the composite material is low in preparation cost and environmentally friendly, recycling of resources is achieved, and the preparation process is simple, convenient and environmentally friendly. The composite material not only can adsorb and remove heavy metal ions in water, but also can catalytically degrade organic pollutant methylene blue under the excitation of sunlight and visible light.

Owner:NANJING FORESTRY UNIV

Expanded graphite modified injection molding grade ultra-high molecular weight polyethylene and preparation method thereof

The invention discloses an expanded graphite modified injection molding grade ultra-high molecular weight polyethylene and a preparation method thereof. The polyethylene comprises ultra-high molecular weight polyethylene, high density polyethylene and expanded graphite with the weight ratio of (60-100):(5-50):(1-10). The preparation method comprises steps of adding the ultra-high molecular weight polyethylene, high density polyethylene and expanded graphite into a rubber and plastic internal mixer for internal mixing, then crushing by a crusher, finally extruding and pelletizing. As the expanded graphite is stripped at high load and high shearing speed, nano dispersing expanded graphite can be obtained and can form a continuous, uniform and stable lubricant membrane with a matrix, so as to play a lubricant role in ultra-high molecular weight polyethylene composite, energy transfer between polyethylene chains can be improved, the ultra-high molecular weight polyethylene chains relatively slide easily, and the fluidity of the ultra-high molecular weight polyethylene is improved. Furthermore, the expanded graphite is beneficial to lowering the friction coefficient and improving the abrasive resistance of the composite.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com