Patents

Literature

240results about How to "Fully mixed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

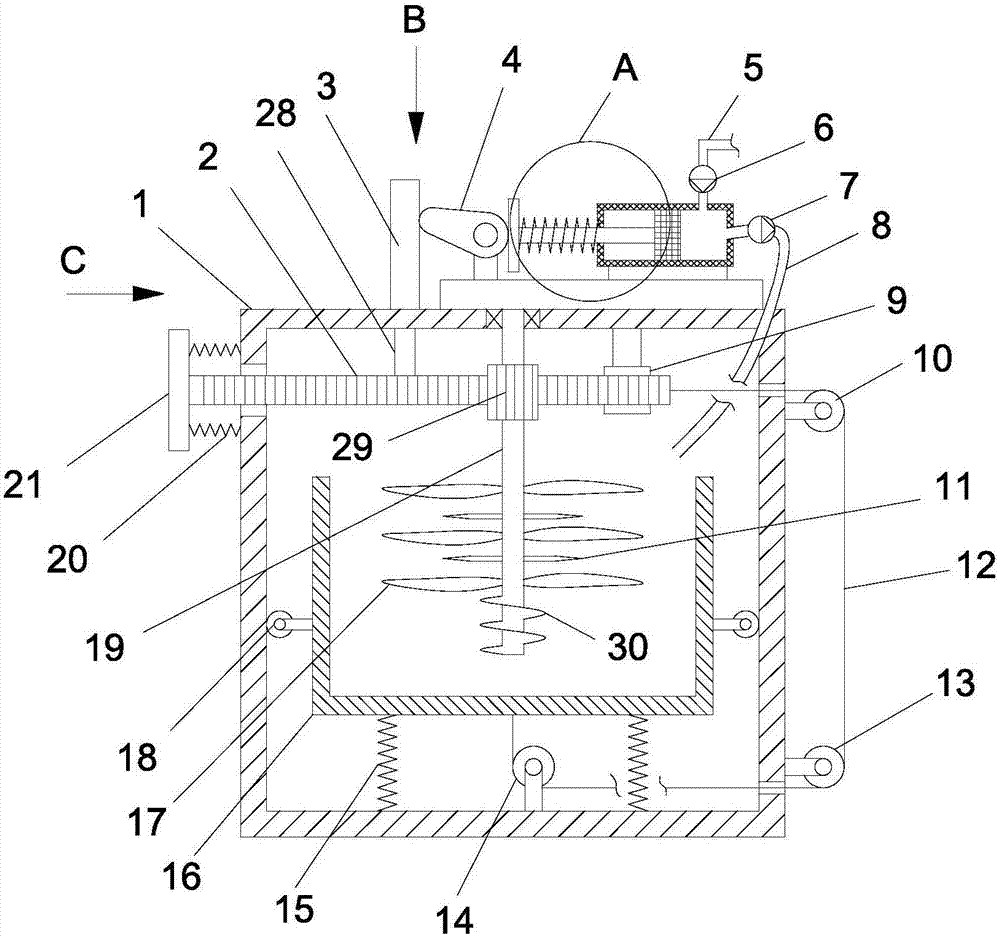

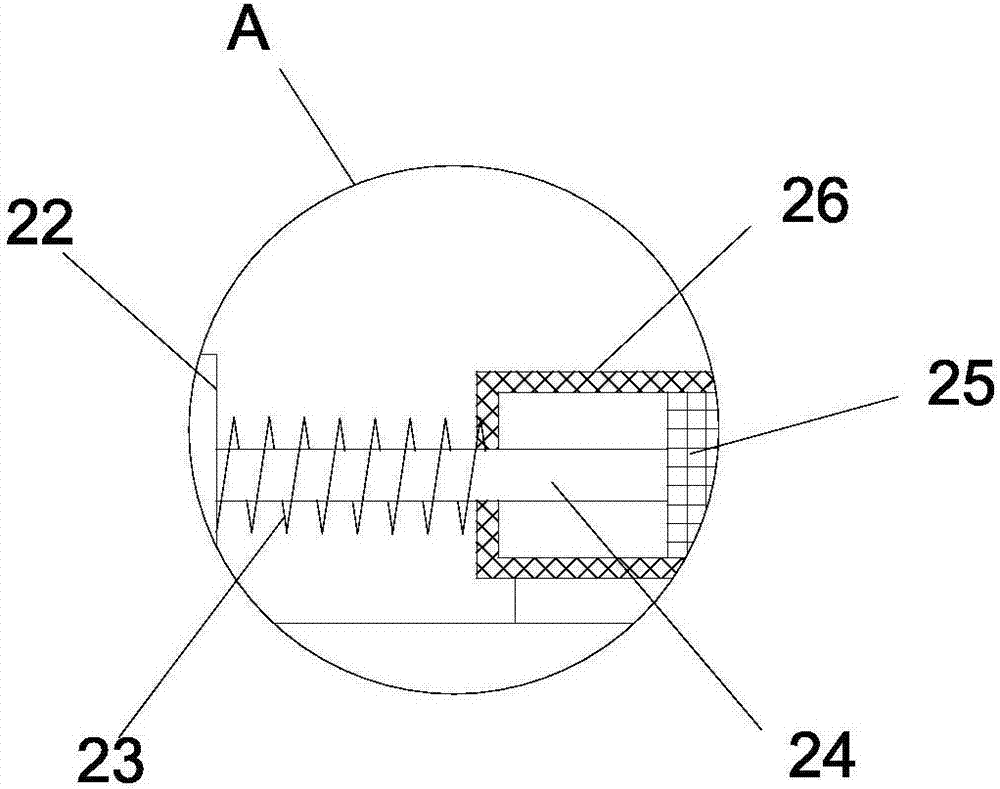

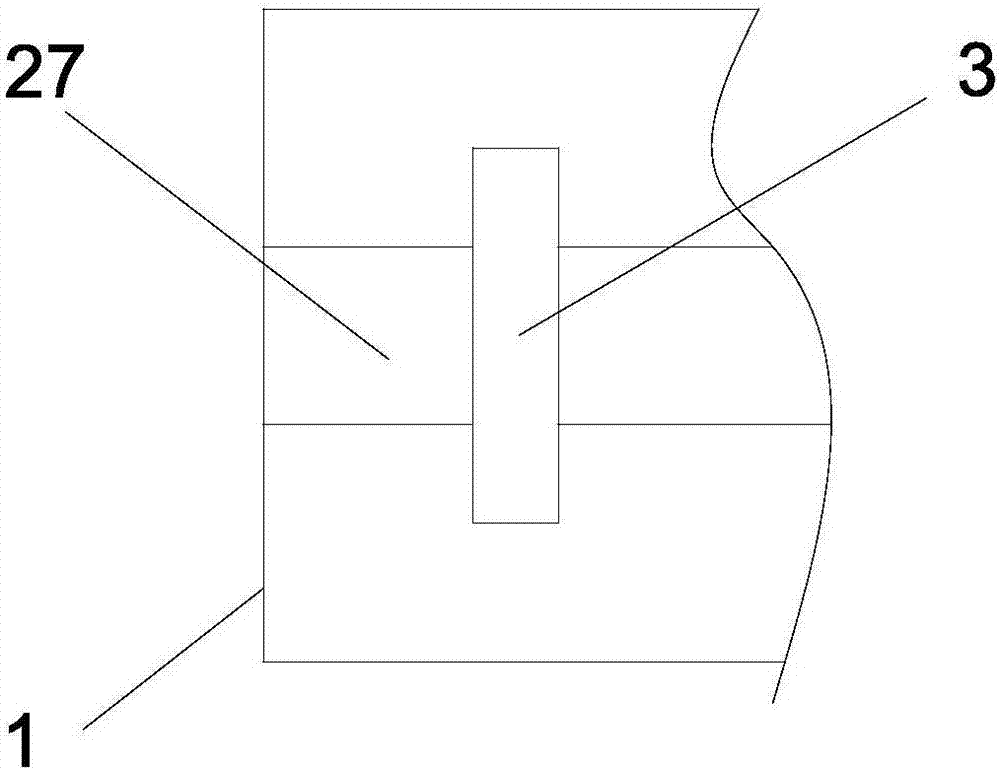

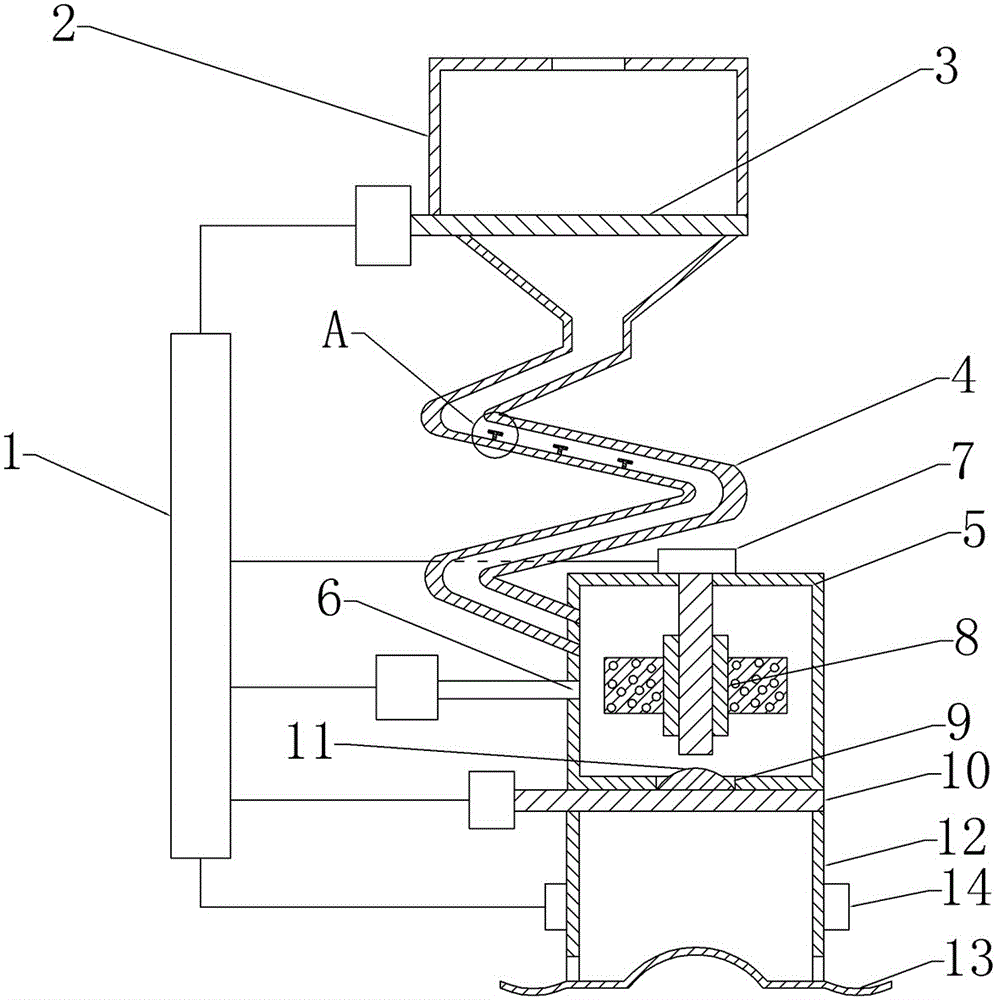

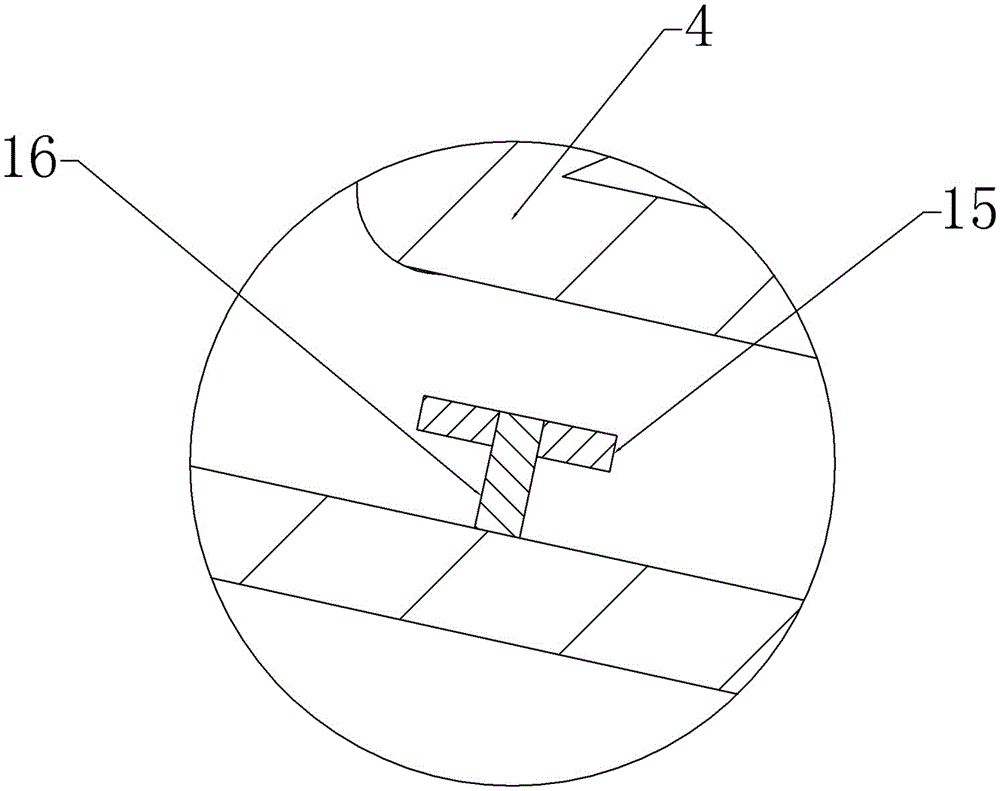

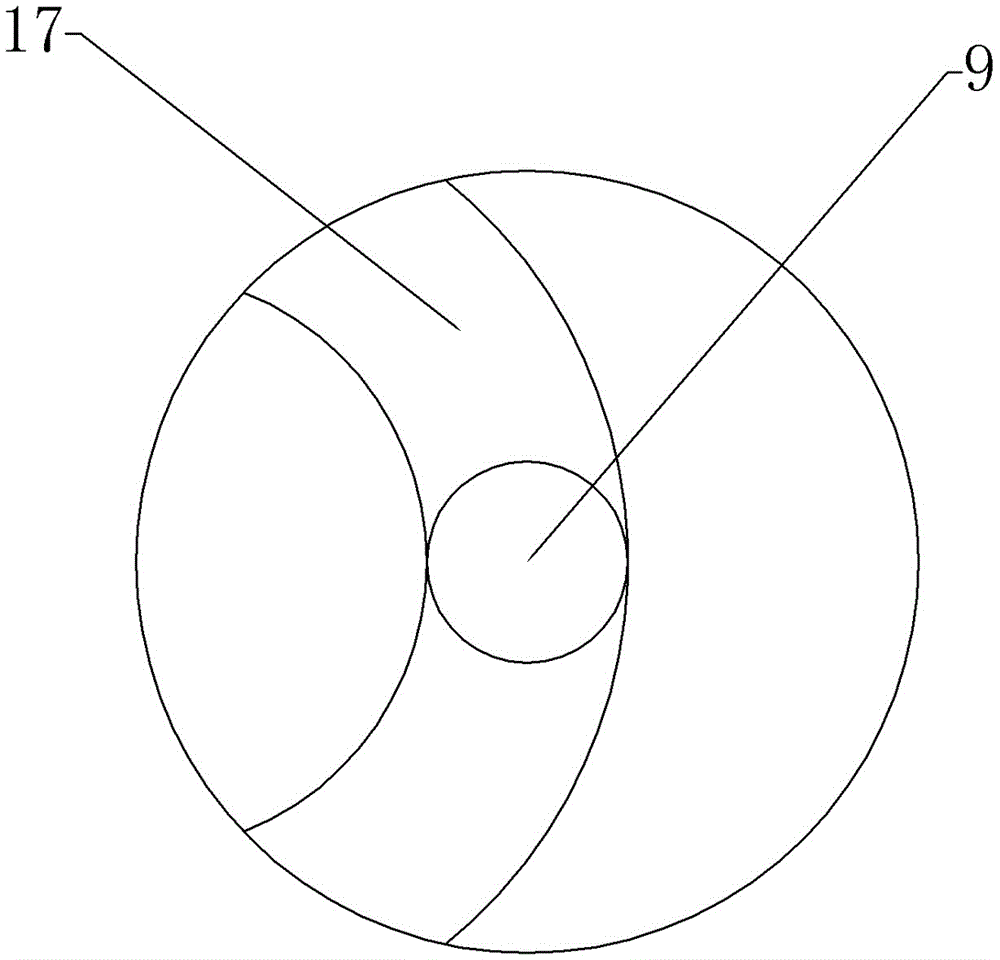

Concrete mortar stirring and mixing device for building construction

InactiveCN107053480AImprove the mixing effectImprove stirring efficiencyCement mixing apparatusLiquid ingredients supply apparatusHelical bladeArchitectural engineering

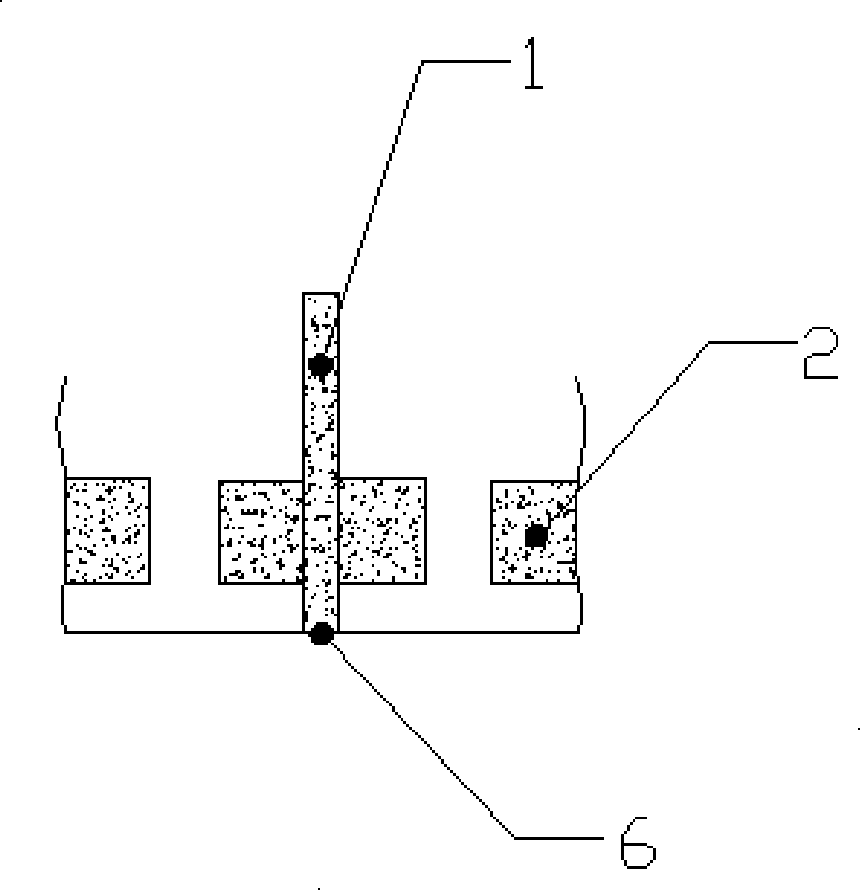

A concrete mortar mixing device for building construction, including a main body, a mixing bucket is arranged inside the main body, a limit spring is arranged between the mixing bucket and the main body, a number of auxiliary mixing blades and a number of auxiliary mixing blades and a number of Auxiliary cutting blade, the spur rack slides through the body, the left end of the spur rack is fixed with a limit plate, the limit plate is located outside the body, a first return spring is arranged between the limit plate and the body, and a piston is fixedly installed on the body The water-drawing sleeve, the left end of the piston rod is vertically fixed with a piston top plate, the cam is in contact with the right side of the transmission plate, and the cam is in contact with the left side of the piston top plate; the spiral blade arranged at the bottom of the stirring shaft in the present invention will move the bottom of the mixing tank The concrete mortar is turned upwards to make the mixing more complete. Driven by the wire rope, the mixing bucket vibrates up and down, making the concrete mortar shake up and down in the mixing bucket, which promotes the mixing effect of the concrete mortar.

Owner:长沙鼎成新材料科技有限公司

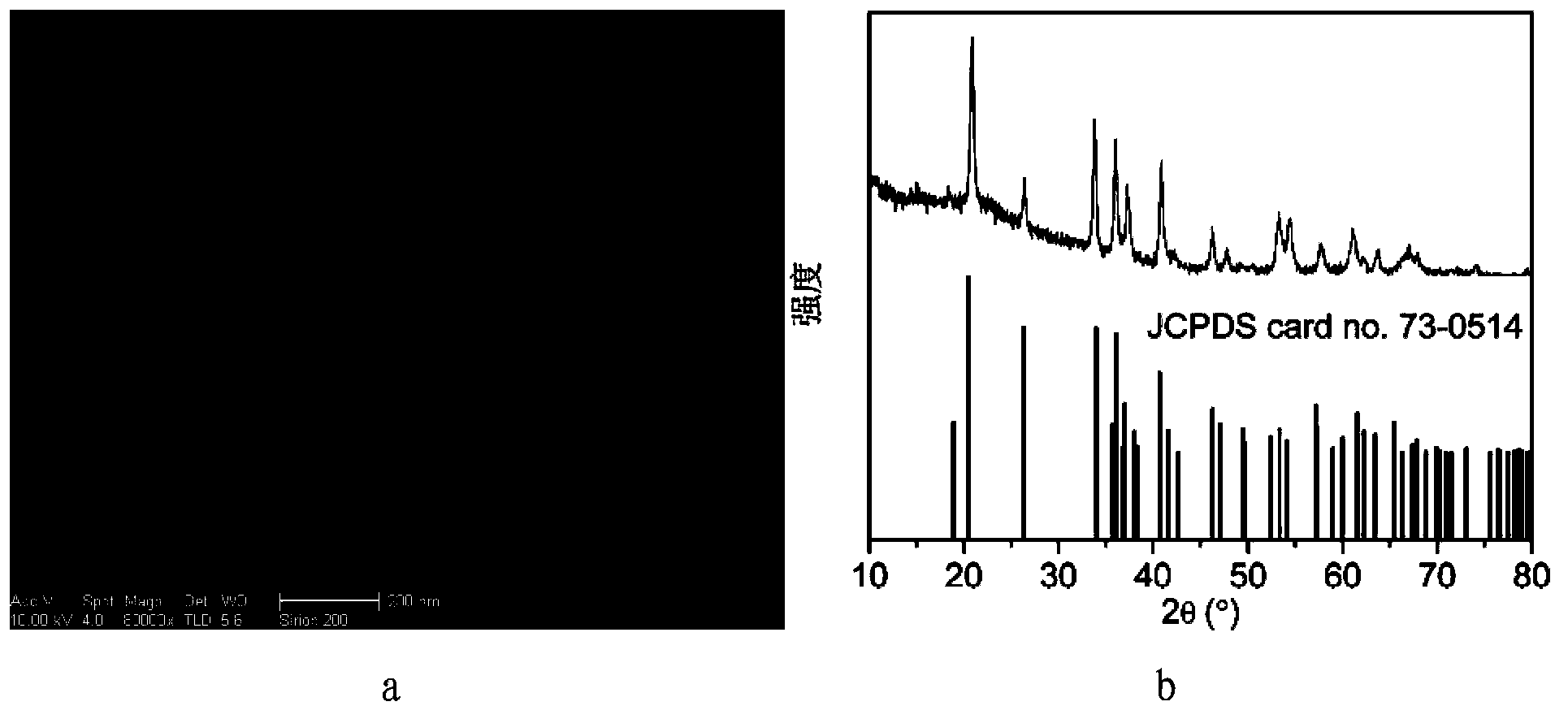

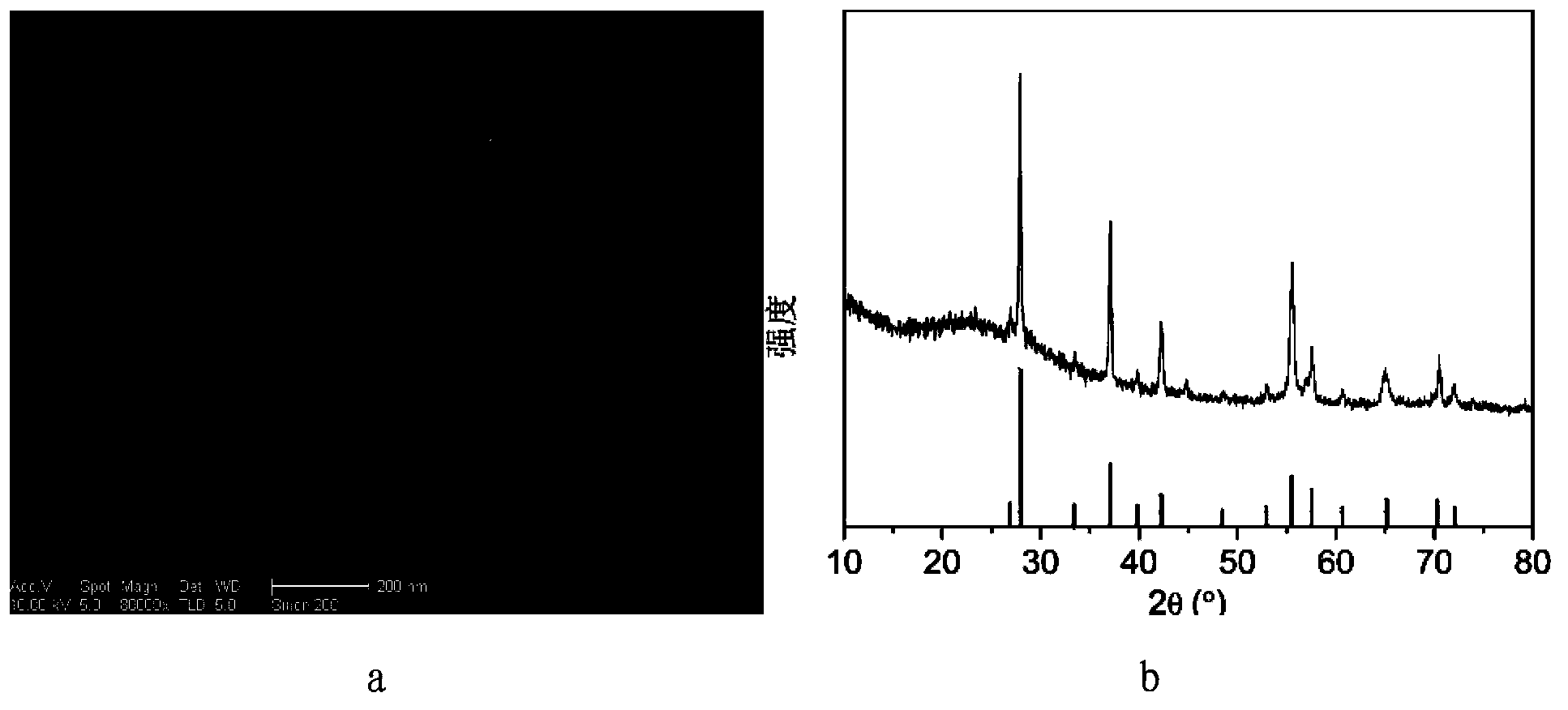

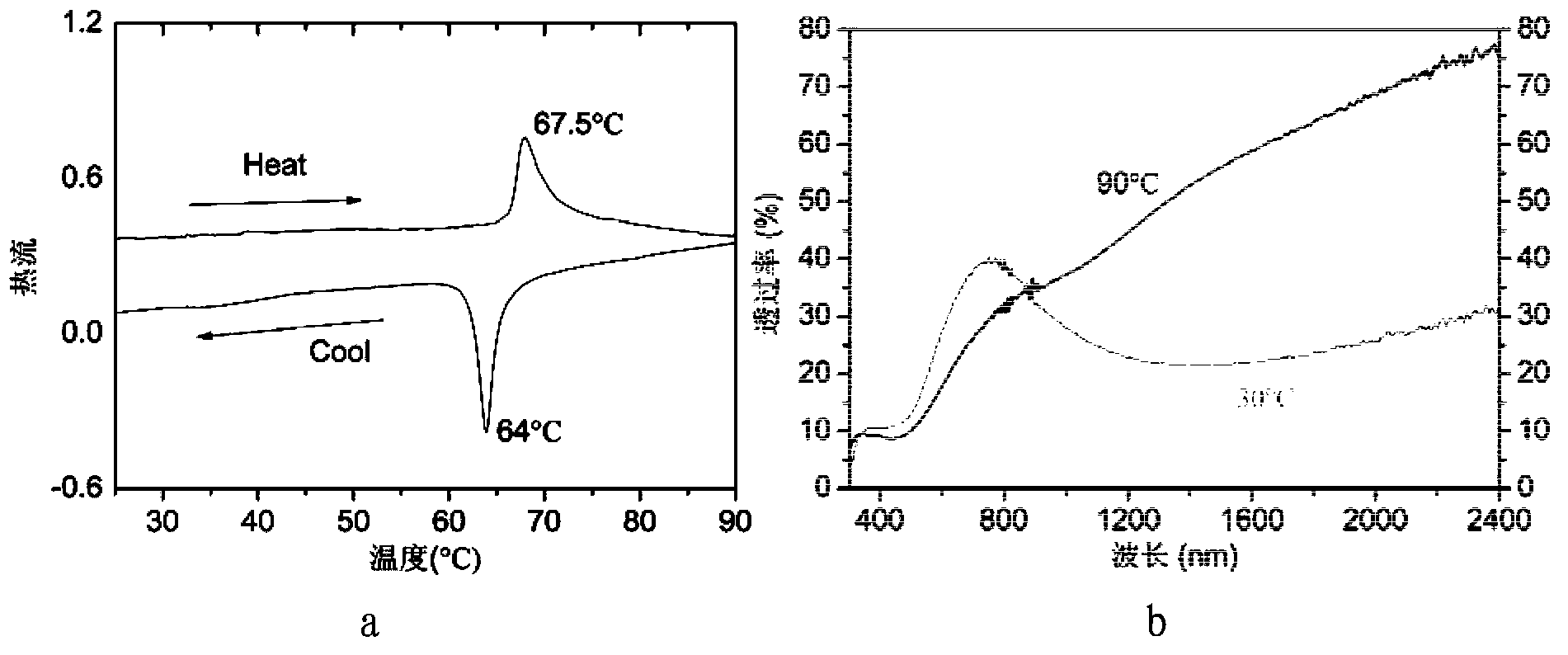

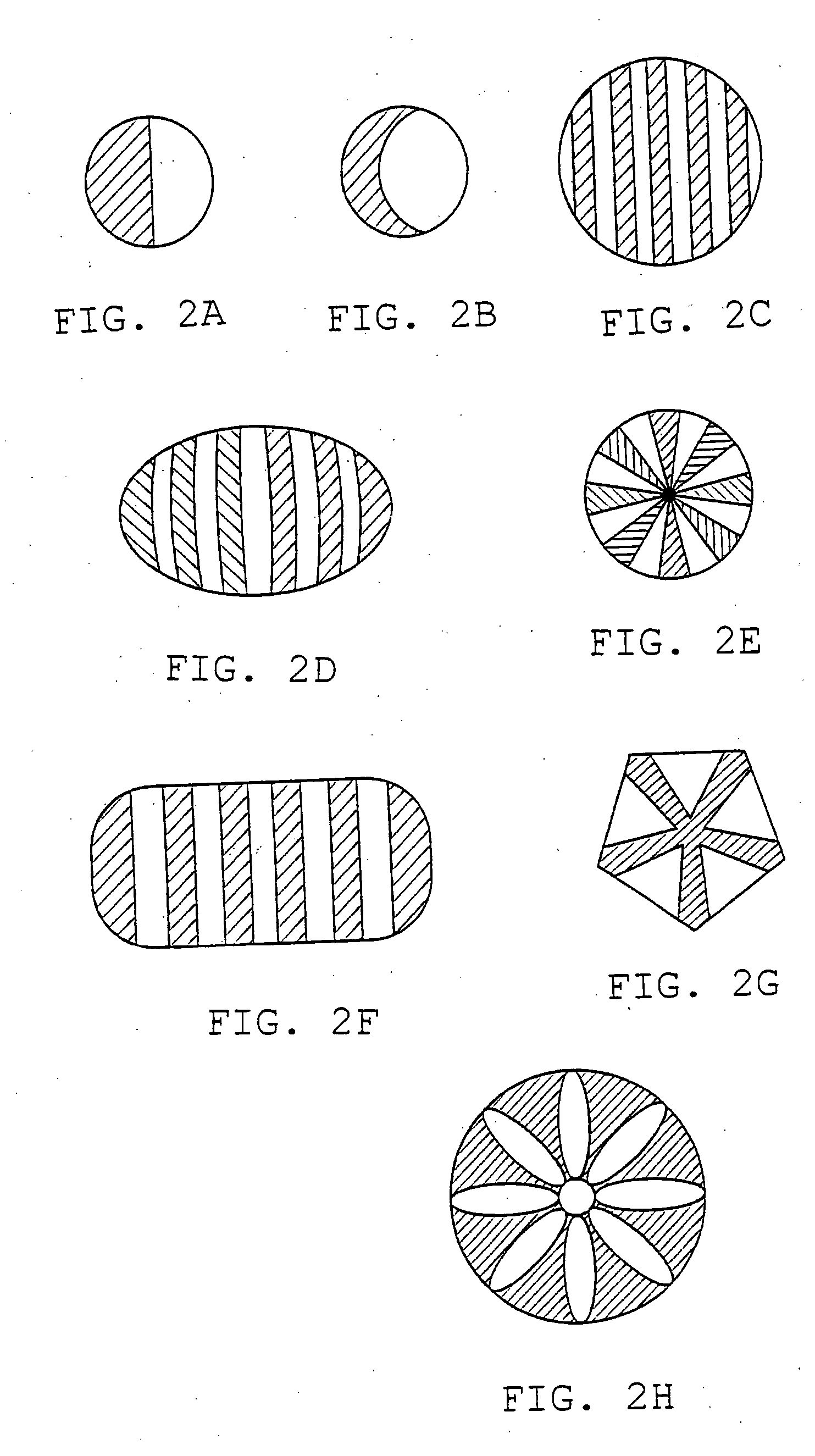

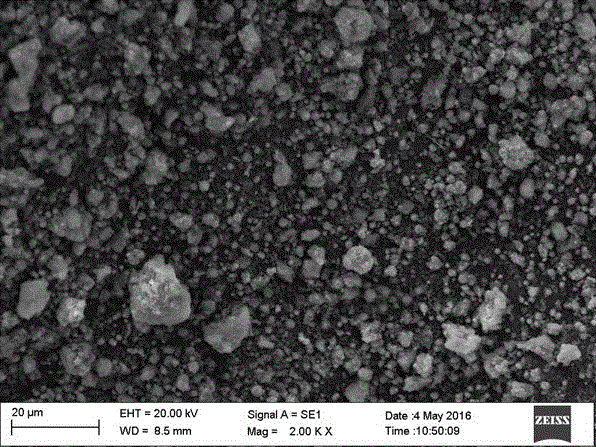

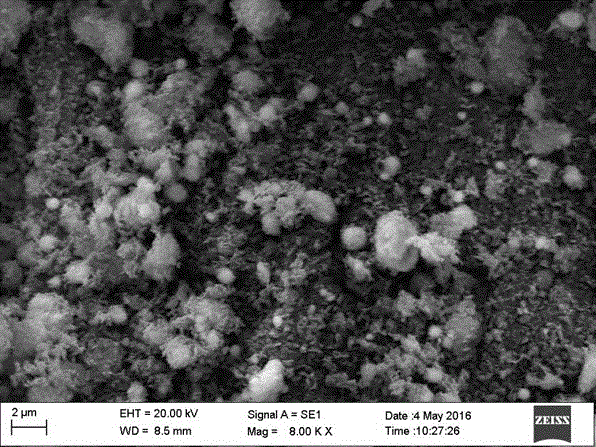

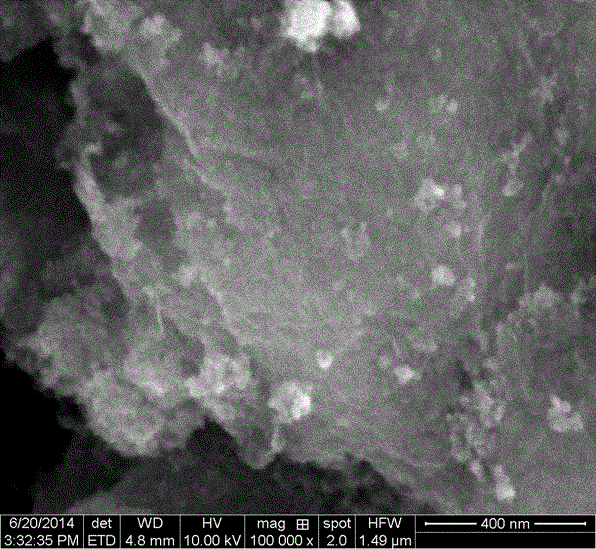

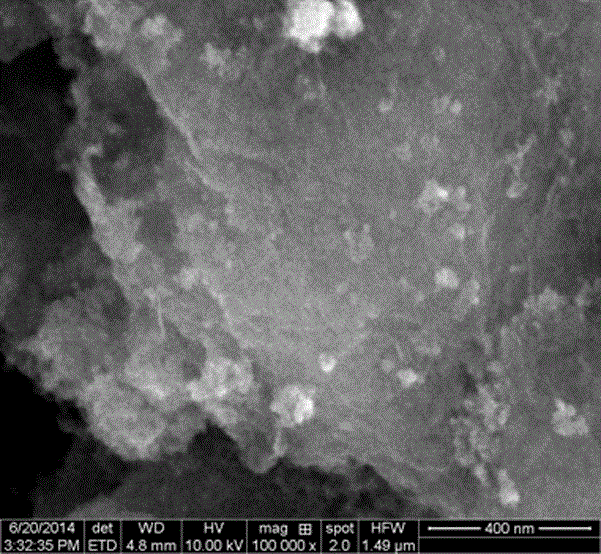

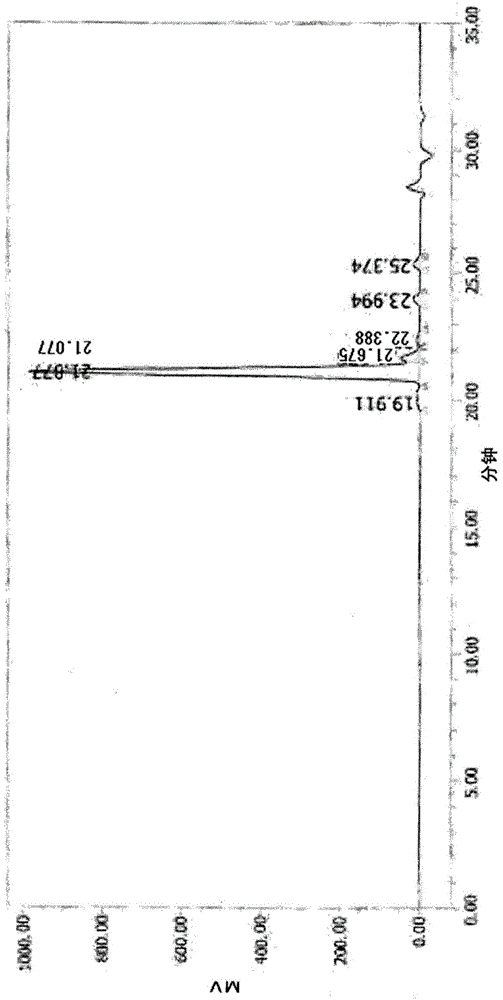

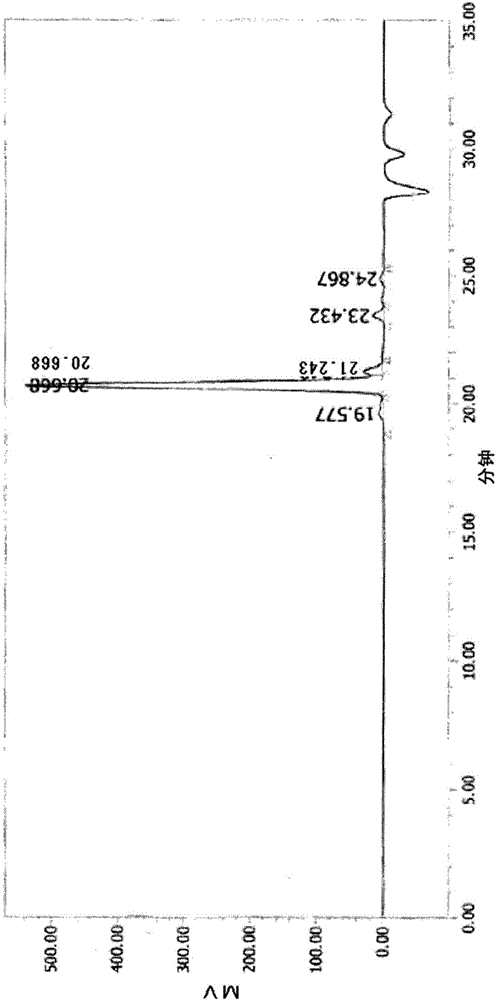

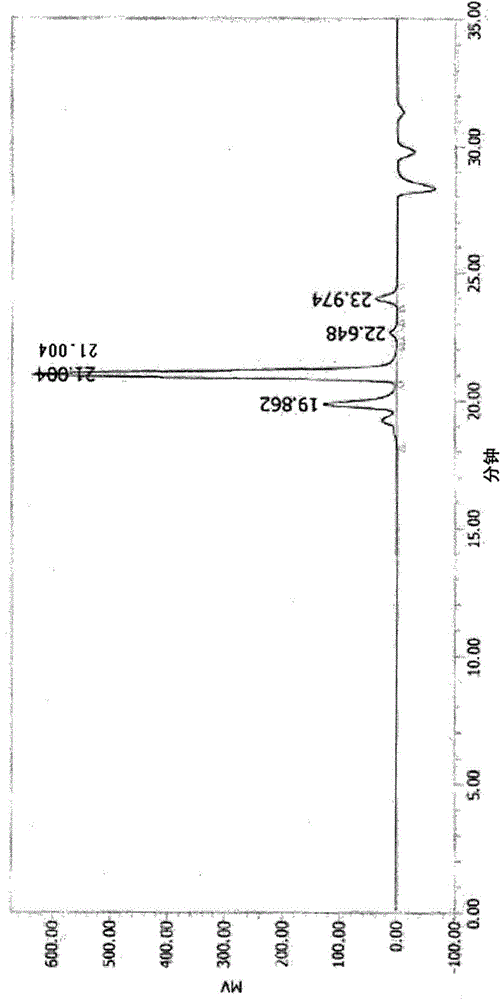

Preparation method of monodispersed M-phase vanadium dioxide nanoparticles

InactiveCN104071843AGood phase change propertiesExcellent infrared control performanceMaterial nanotechnologyVanadium oxidesVanadium dioxideDispersity

The invention discloses a preparation method of monodispersed M-phase vanadium dioxide nanoparticles. The preparation method comprises the following steps: mixing vanadium pentoxide, oxalate dihydrate and water according to a molar ratio of (1-2.5) : 1 : (500-800) to obtain mixed liquid, adding 4%-6% of a surfactant based on the volume of the mixed liquid into the mixed liquid, and stirring for at least 2 hours to obtain a precursor solution; reacting the precursor solution in a sealed state at 200-260 DEG C for at least 1 day to obtain reaction liquid; performing solid-liquid separation and washing on the reaction liquid in sequence to obtain orthogonal vanadium dioxide powder; annealing the orthogonal vanadium dioxide powder in a nitrogen atmosphere at 300-600 DEG C for 0.5 hour to obtain the monodispersed M-phase vanadium dioxide nanoparticles with particle sizes of 60nm-80nm. The preparation method has the advantages of environmental protection and no temperature gradient control during annealing, and can be widely used for preparing the M-phase vanadium dioxide nanoparticles with very good dispersity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

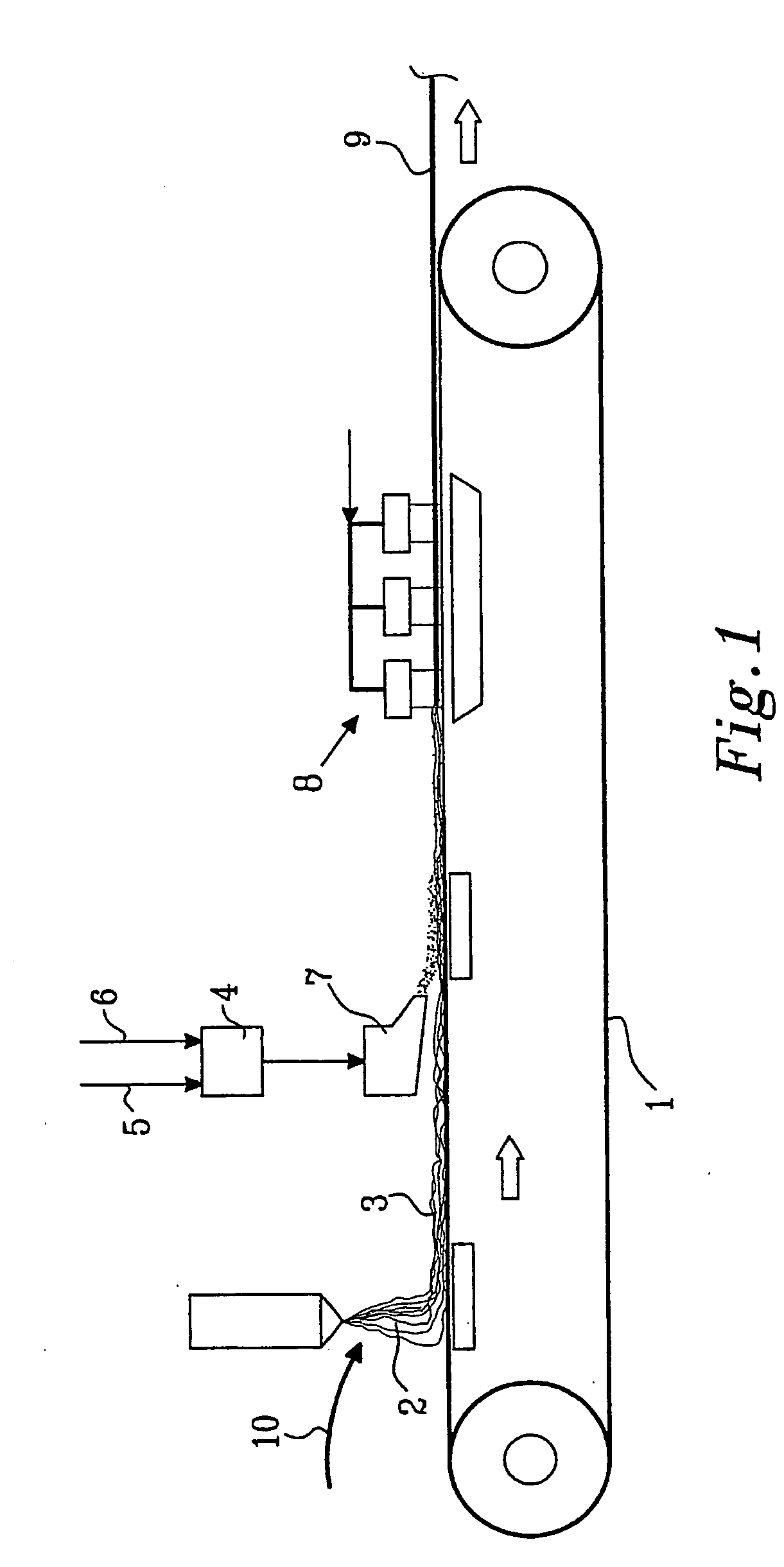

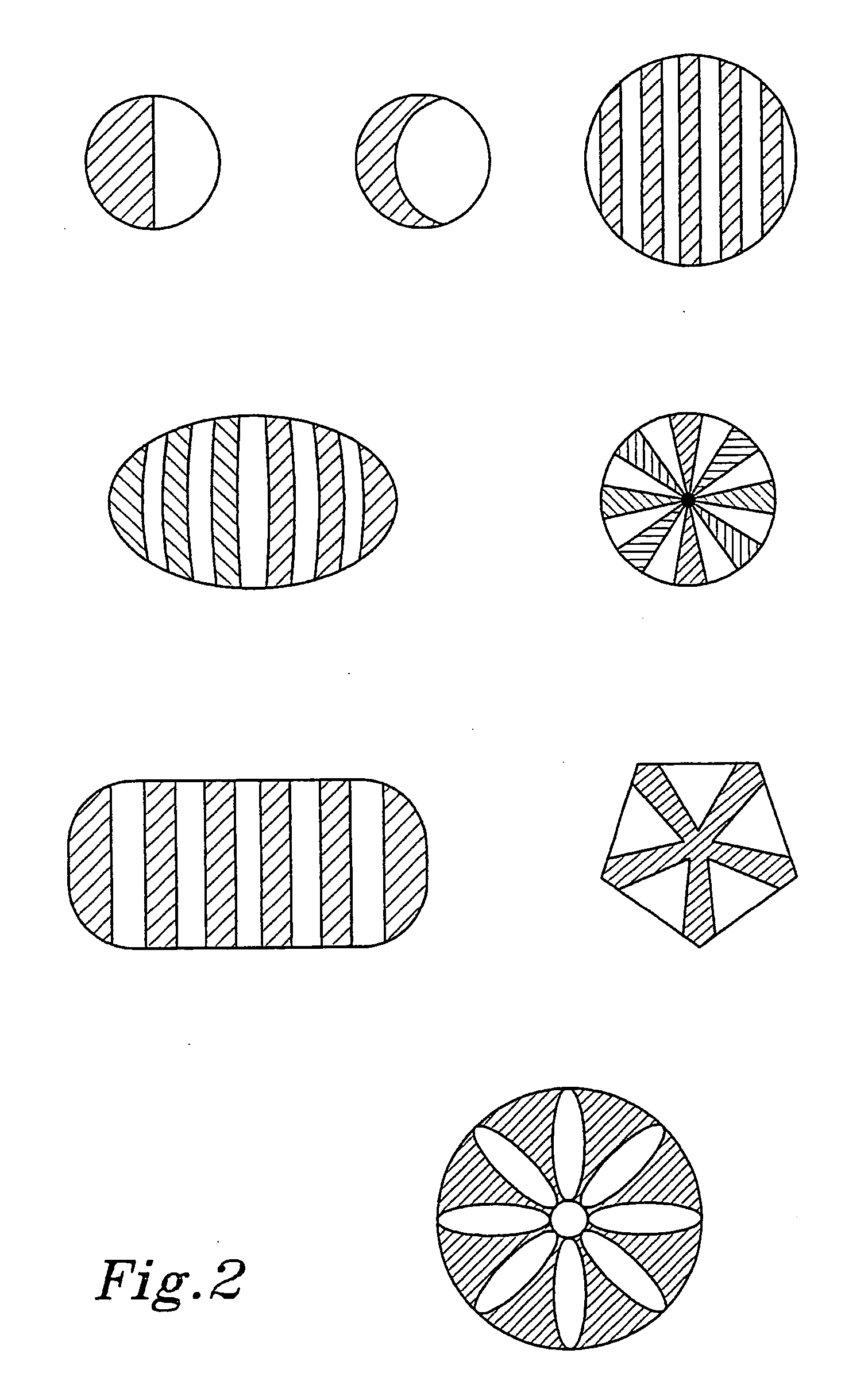

Hydroentangled split-fibre nonwoven material

InactiveUS20070178795A1Reduce two-sidednessImprove textile feelingLaminationLamination apparatusThermal bondingFiber

A hydroentangled integrated composite nonwoven material, includes a mixture of randomized continuous filaments, splittable shortcut staple fibres, and optionally non-splittable staple fibres. The splittable fibres should be 3-16 mm long bicomponent fibres. Preferably there should be no thermal bonding points between the filaments. The nonwoven material has improved textile feeling and reduced two-sidedness. The continuous filaments should preferably be spunlaid filaments. Some of the staple fibres can be coloured. A process of producing such a nonwoven material is disclosed.

Owner:SCA HYGIENE PROD AB

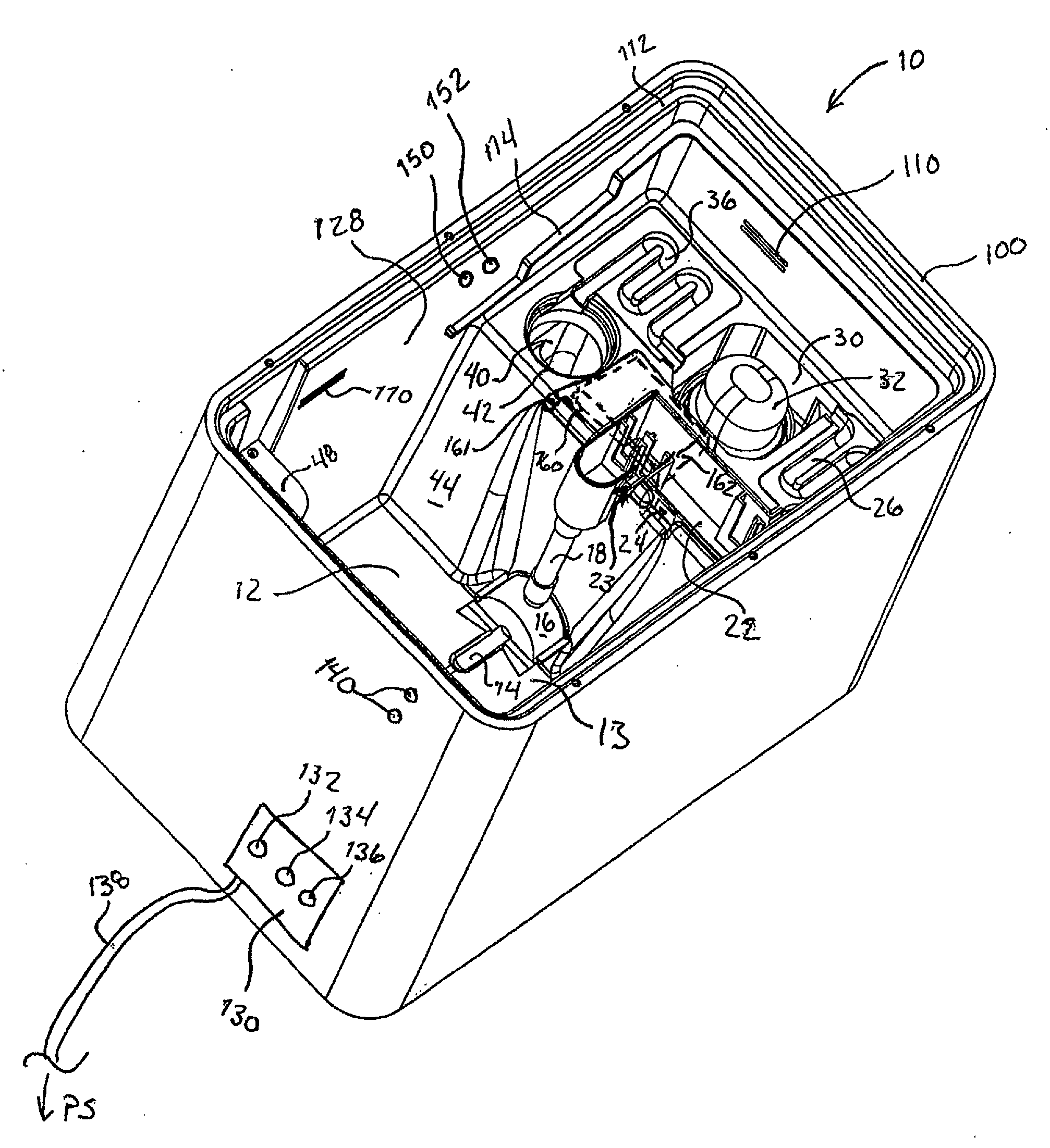

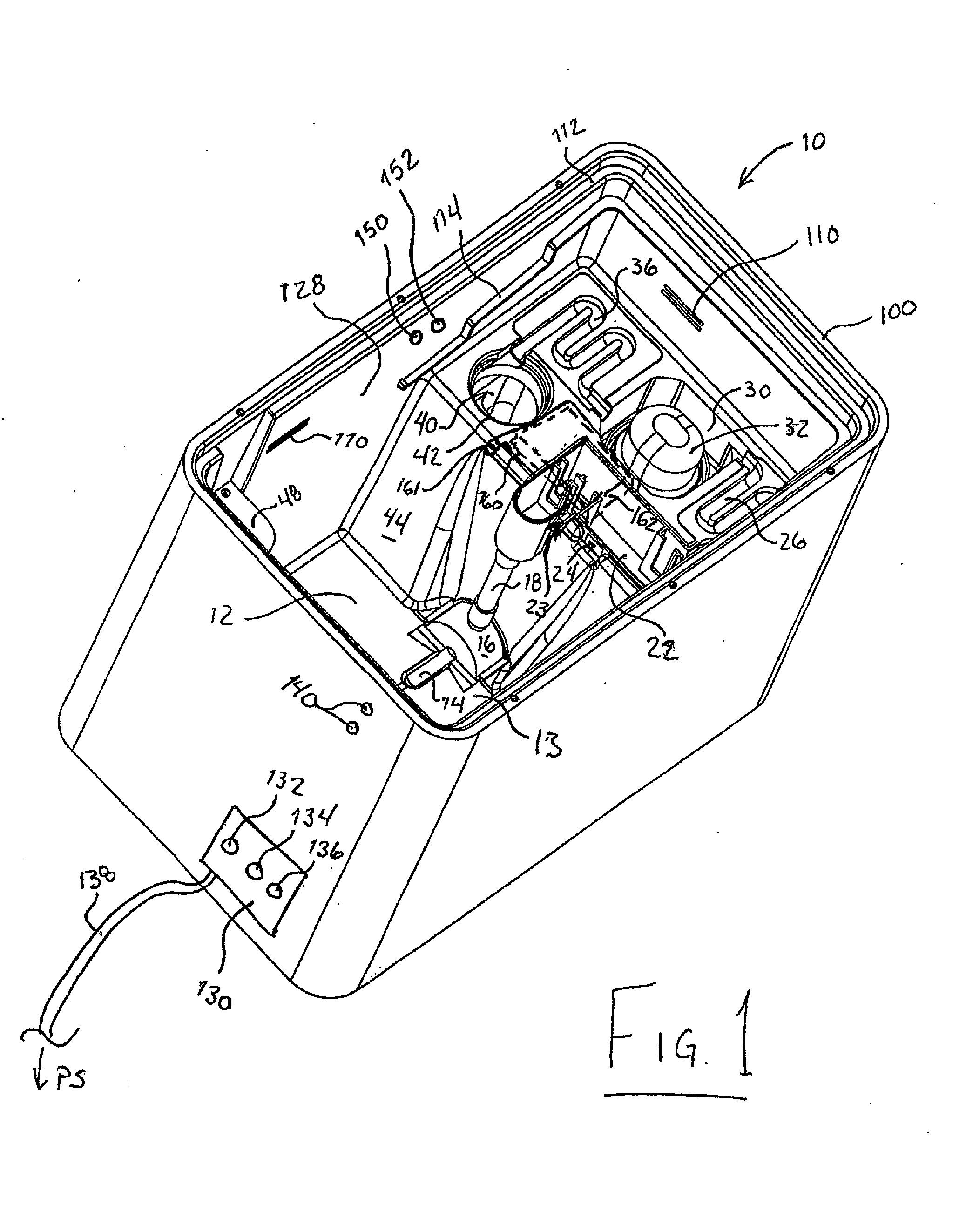

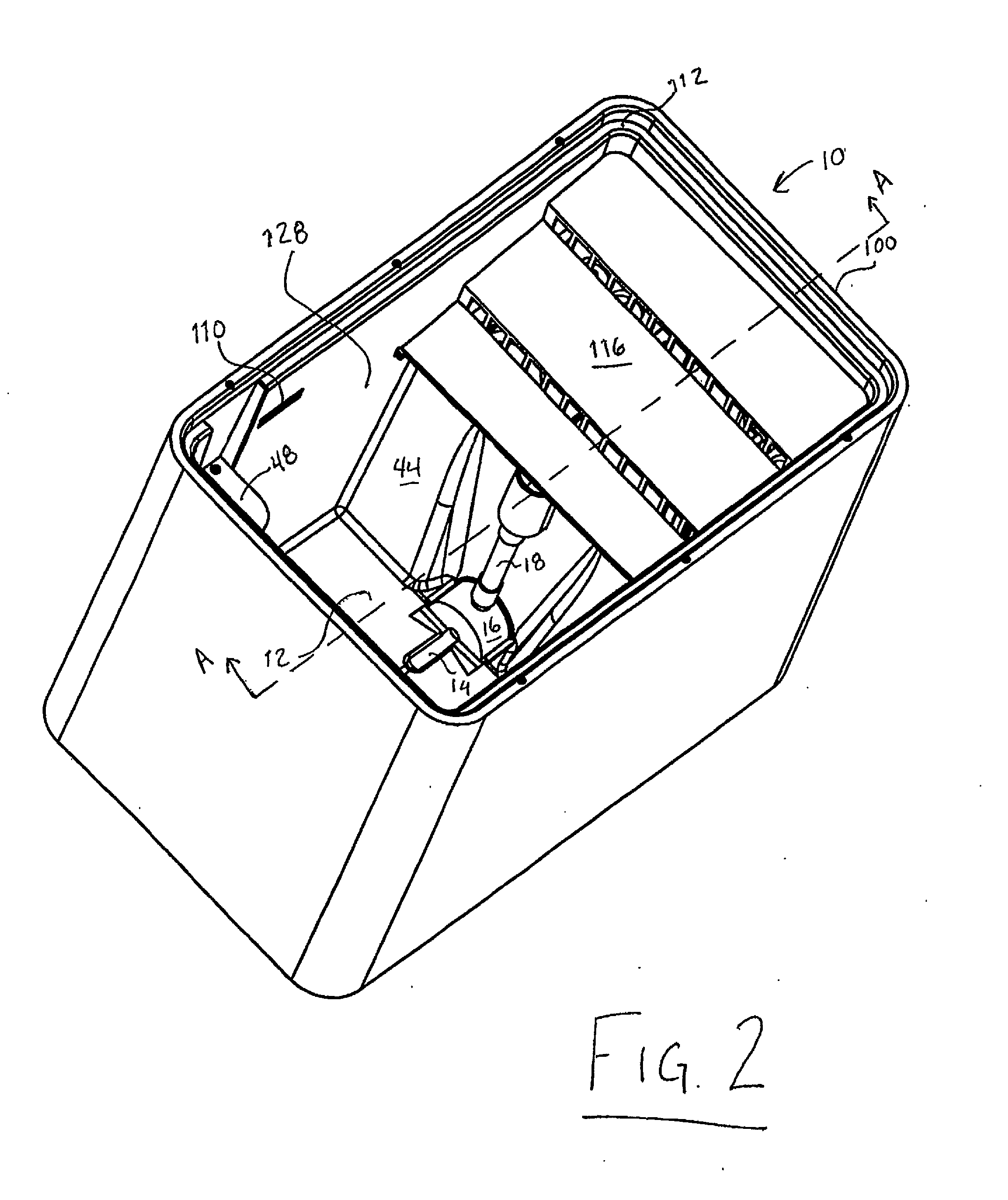

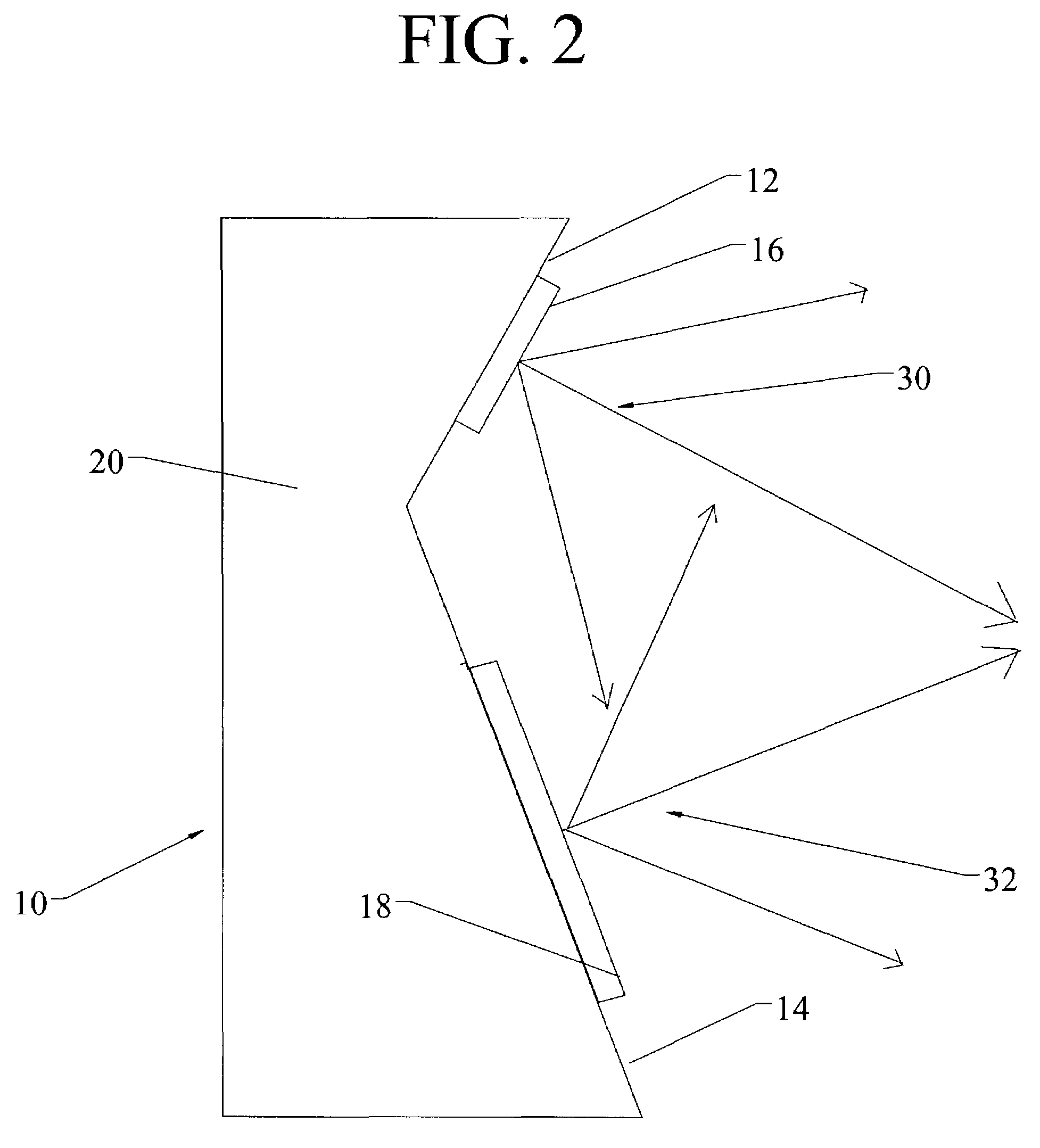

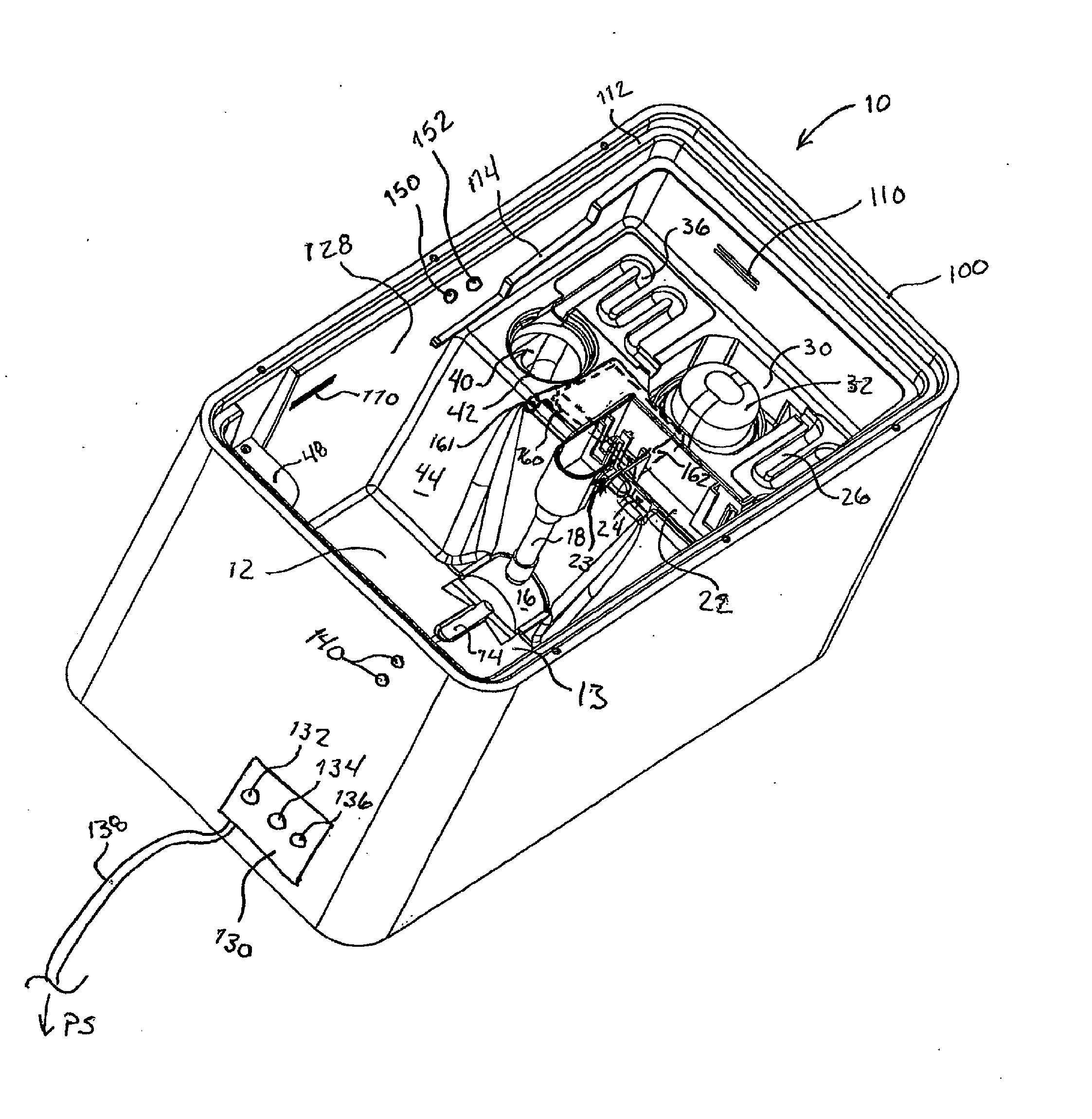

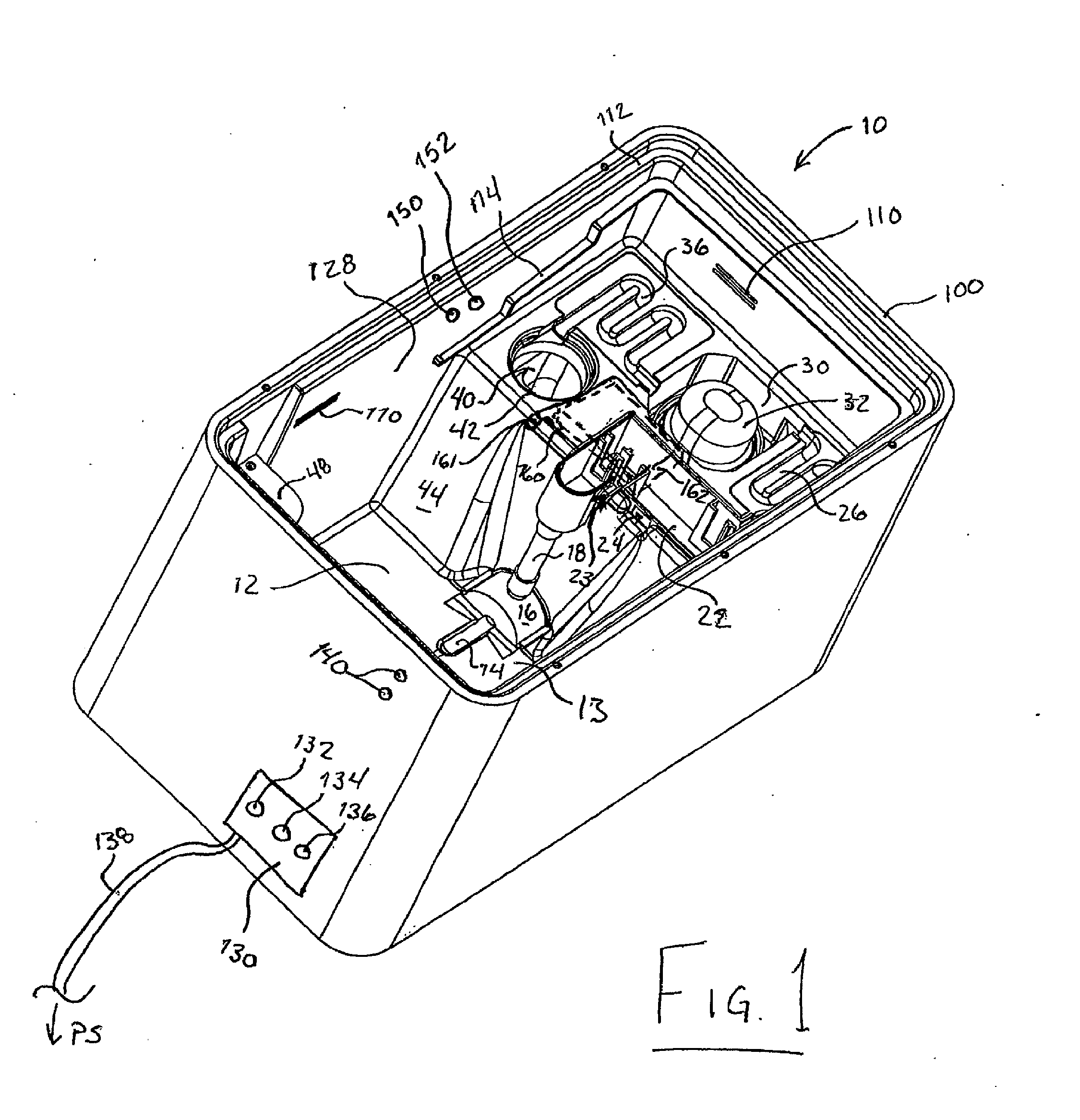

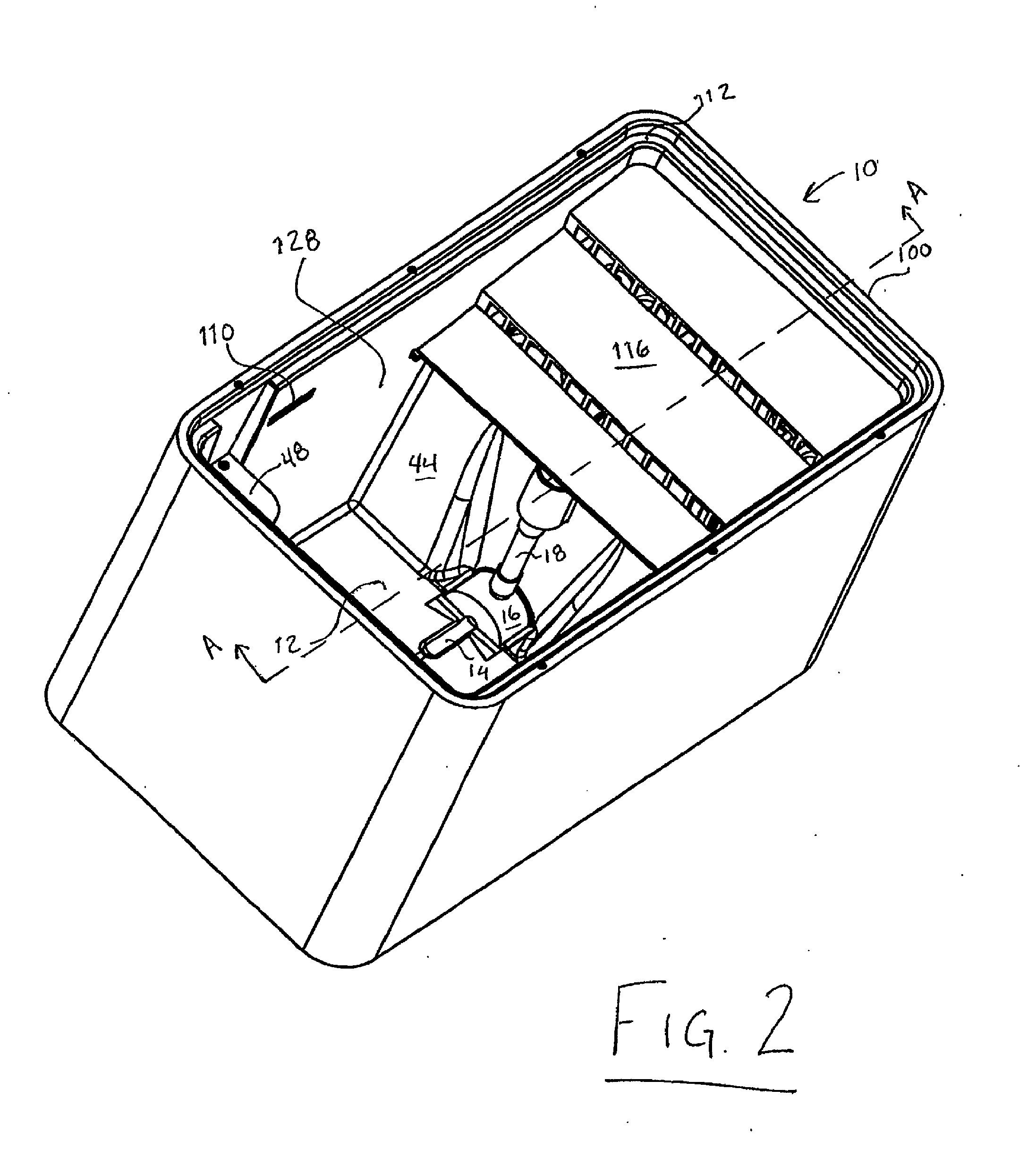

Combination warm and cool mist humidifier

ActiveUS20120112371A1Increase efficiency and outputHigh outputLighting and heating apparatusUsing liquid separation agentWater reservoirEngineering

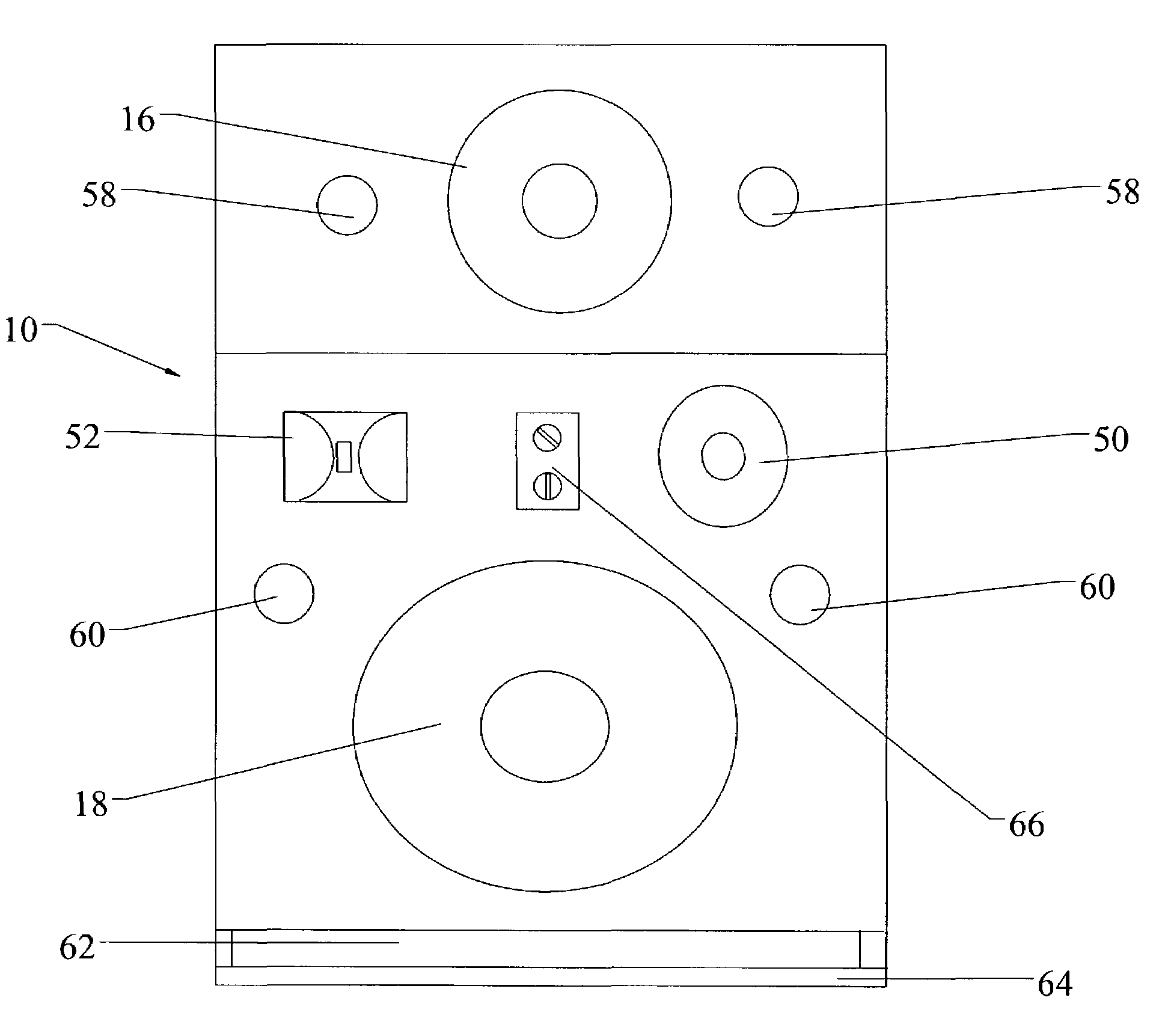

A humidifier includes a housing with a substantially open top portion. Water can be added to the humidifier by pouring the water into a water reservoir through an open top. The water is pumped from the water reservoir to an upper portion of the humidifier where it is dispersed into the environment by a flow of air. The humidifier may include both an ultrasonic nebulizer and a heater to provide a warm mix of cool mist and hot vapor. Alternatively, a warm mist can be provided by dispersed water from an ultrasonic nebulizer in combination with warm air. The humidifier may also solely provide a cool mist from an ultrasonic element, or the water can be dispersed using a wicking filter.

Owner:HELEN OF TROY LIMITED

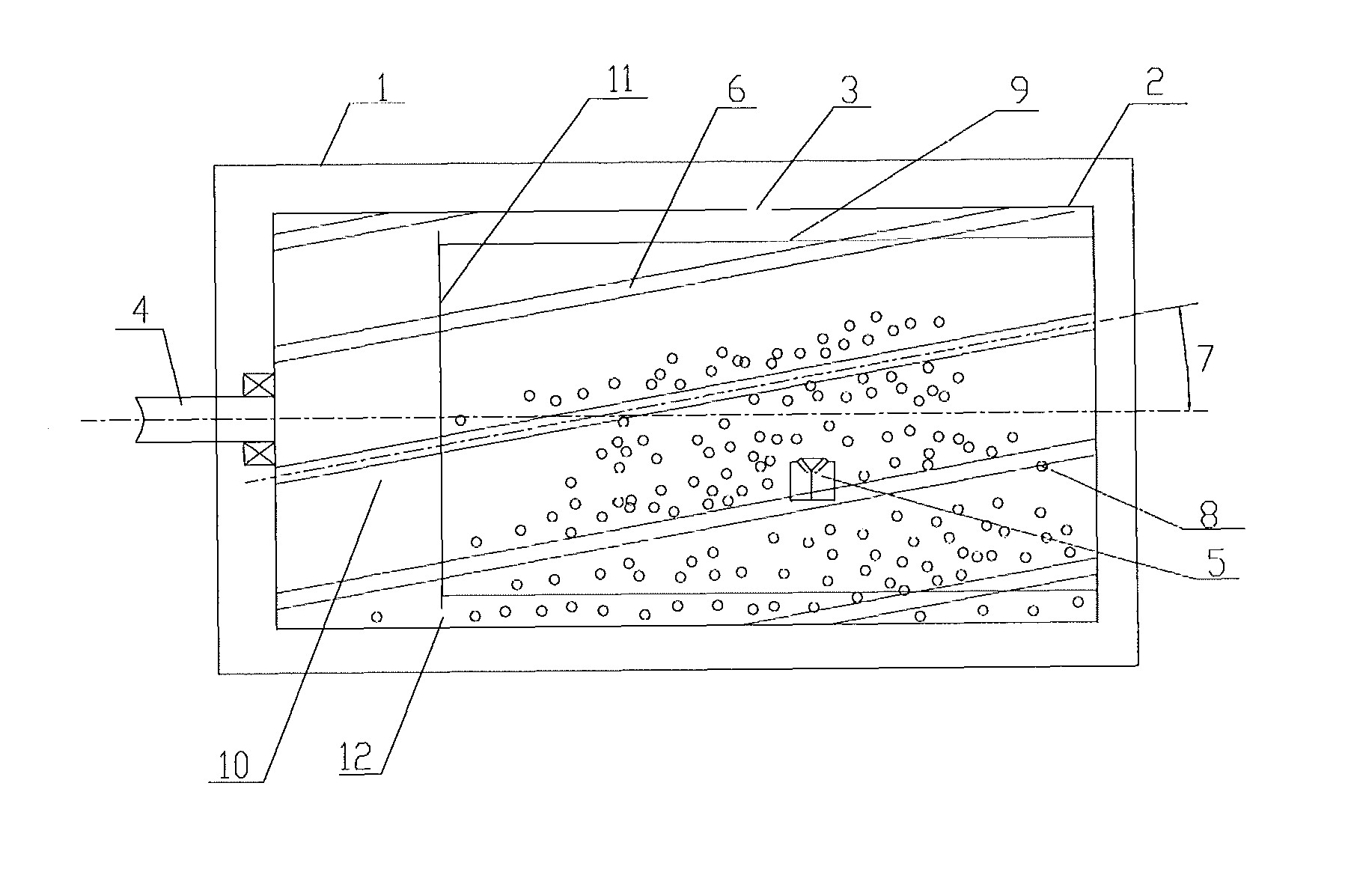

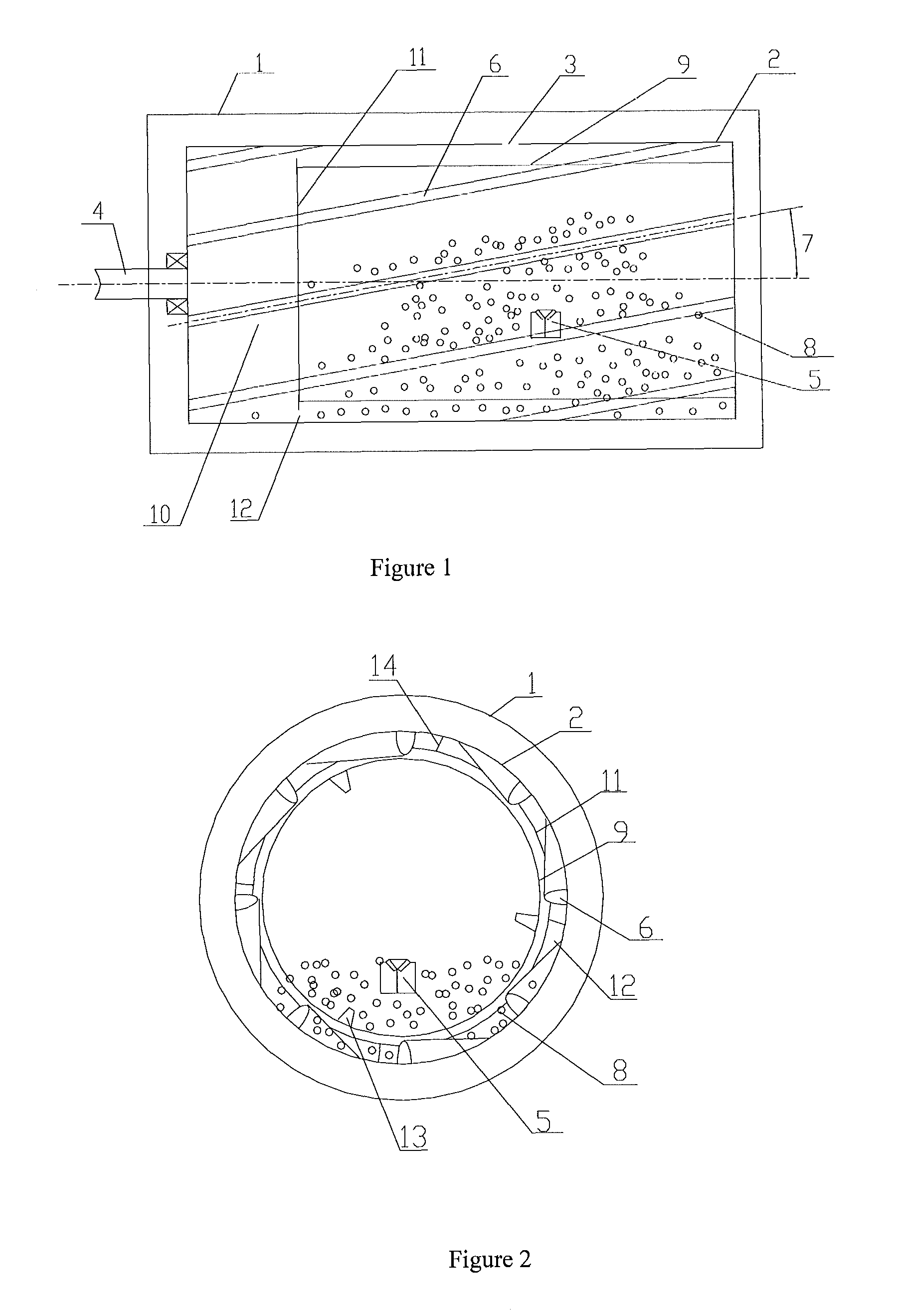

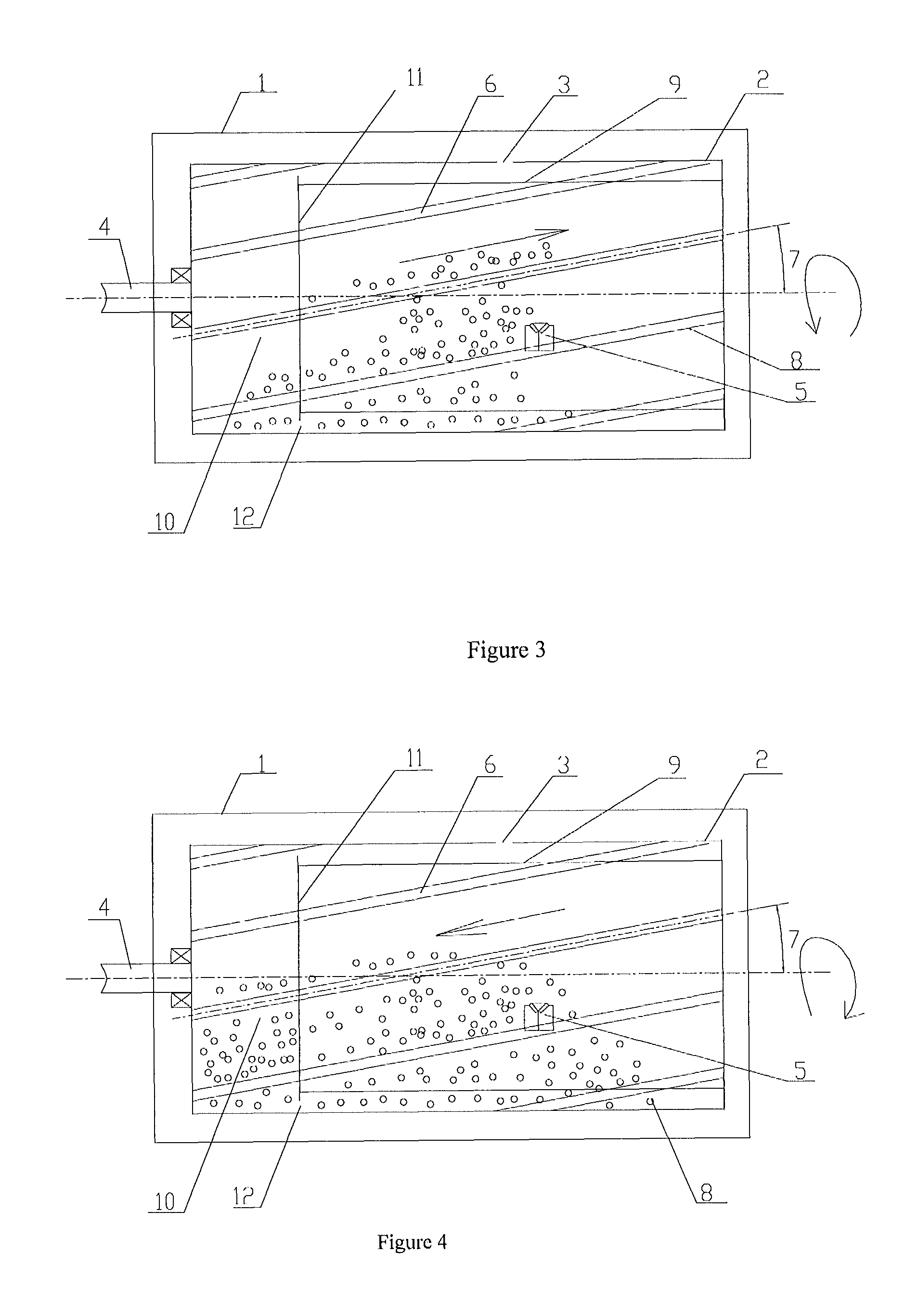

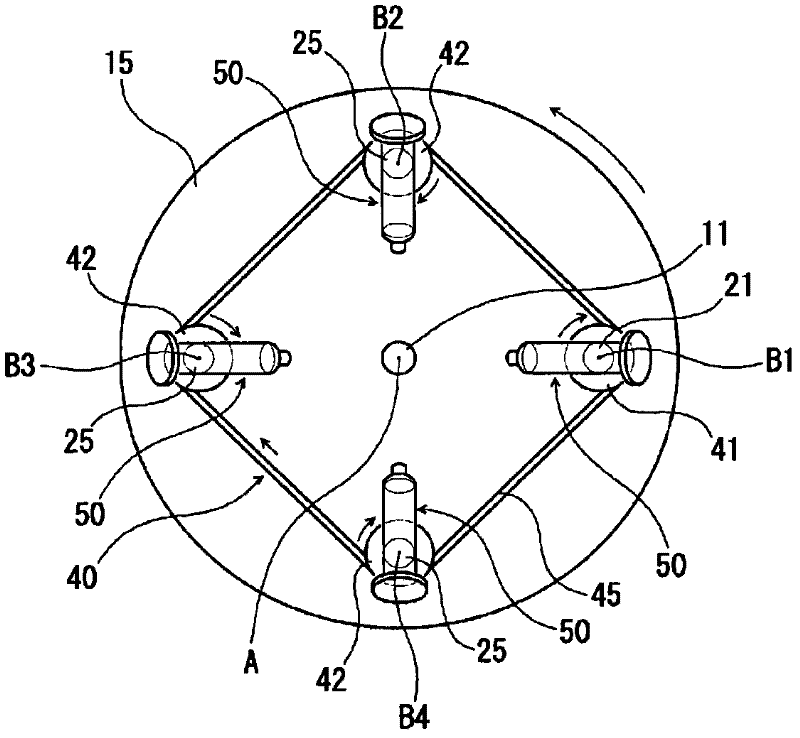

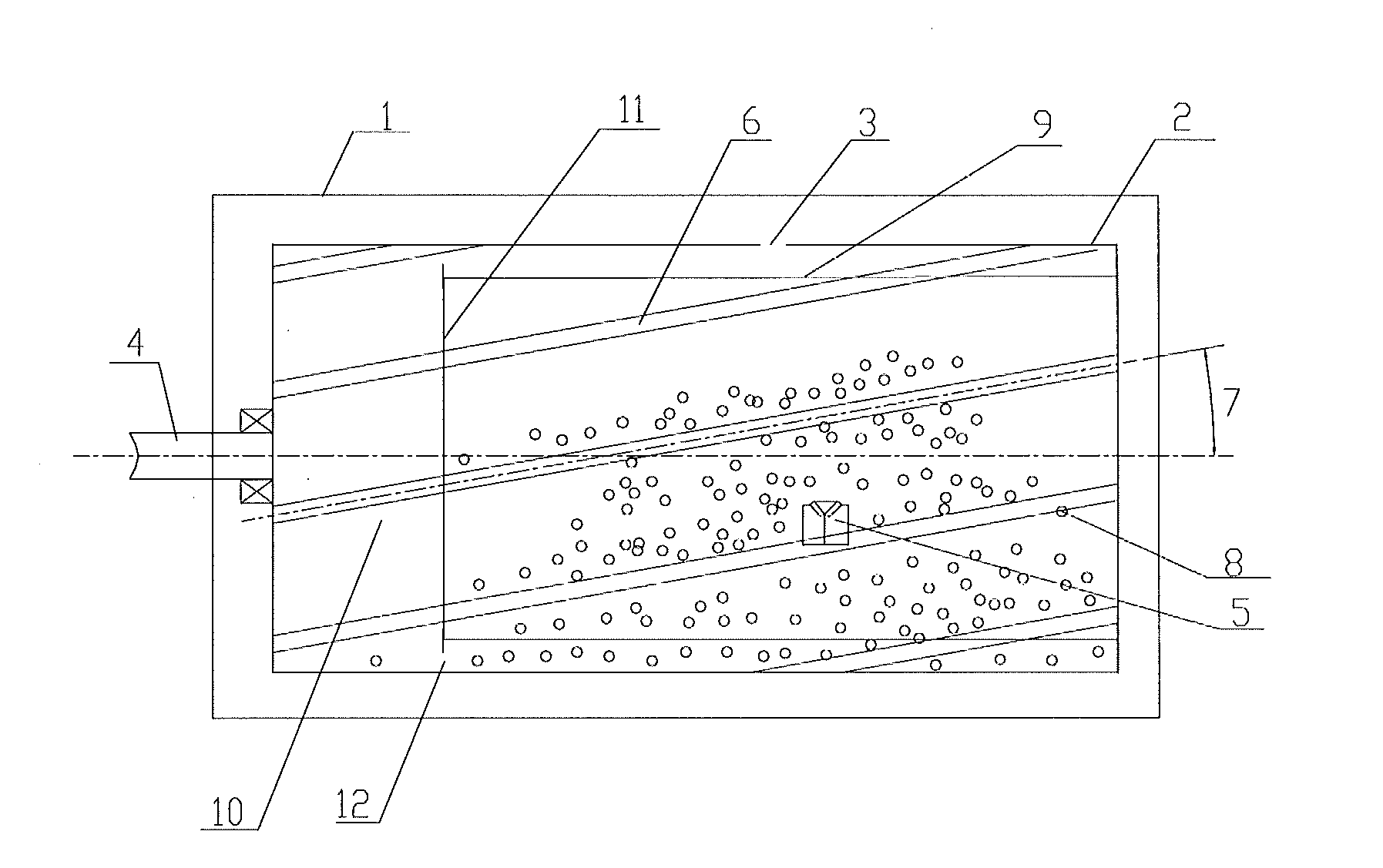

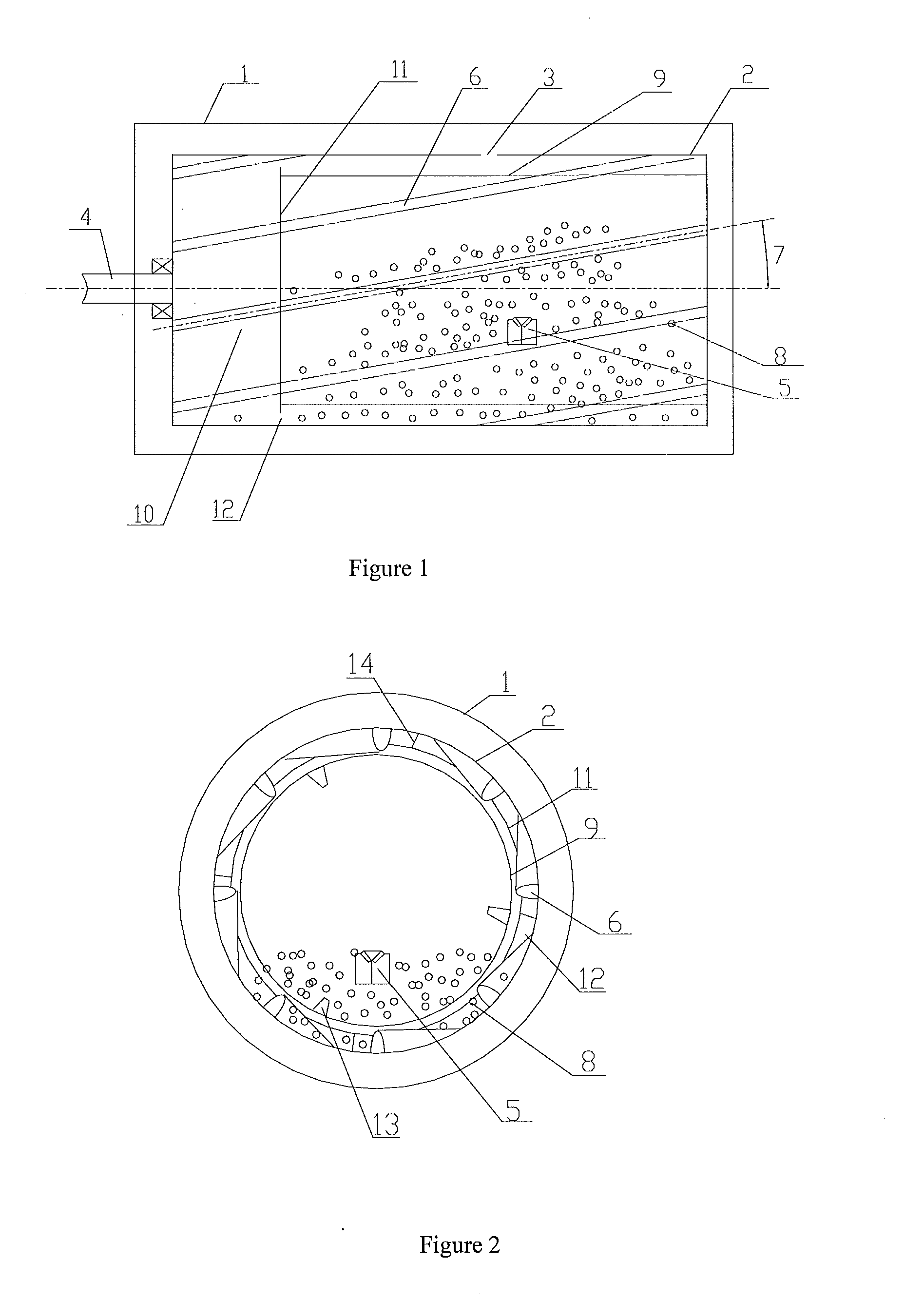

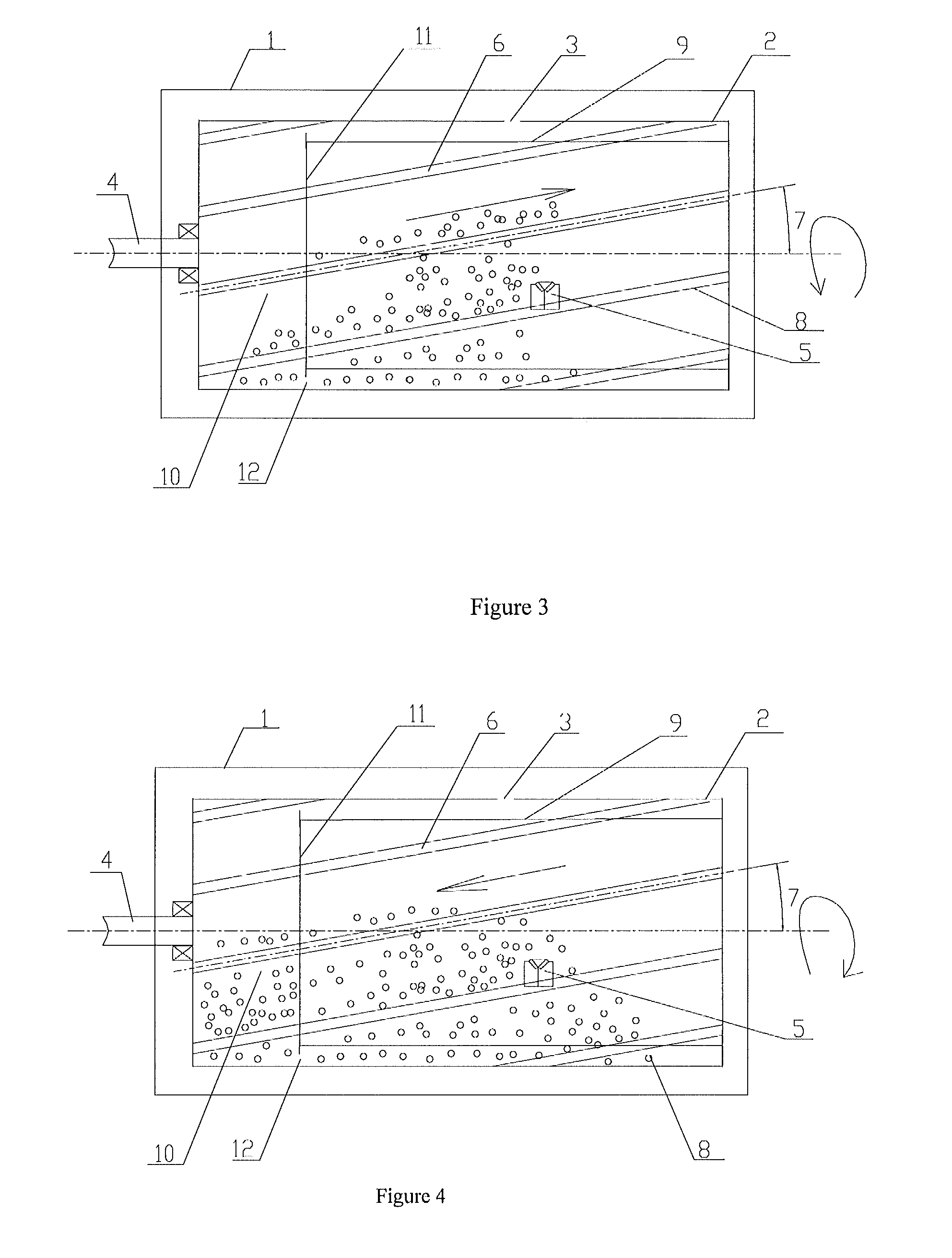

Washing machine and washing method

ActiveUS9410278B2Simple structureSimplify the washing processOther washing machinesTextiles and paperEngineeringSolid particle

A washing machine and a washing method, comprises an inner cylinder, an outer cylinder, and solid particles as washing medium. The inner cylinder is driven into rotation by a driver device. The inner cylinder has arranged on the inner wall thereof scraper blades that protrude inwards and are bent along the wall of the inner cylinder. The scraper blades drives the particles into obliquely upward or obliquely downward movements and flipping, thus allowing for more fully mixing clothes with the particles, for simplified washing process, while also for improved cleaning rate, and for facilitated recycling of the particles.

Owner:XEROS LTD

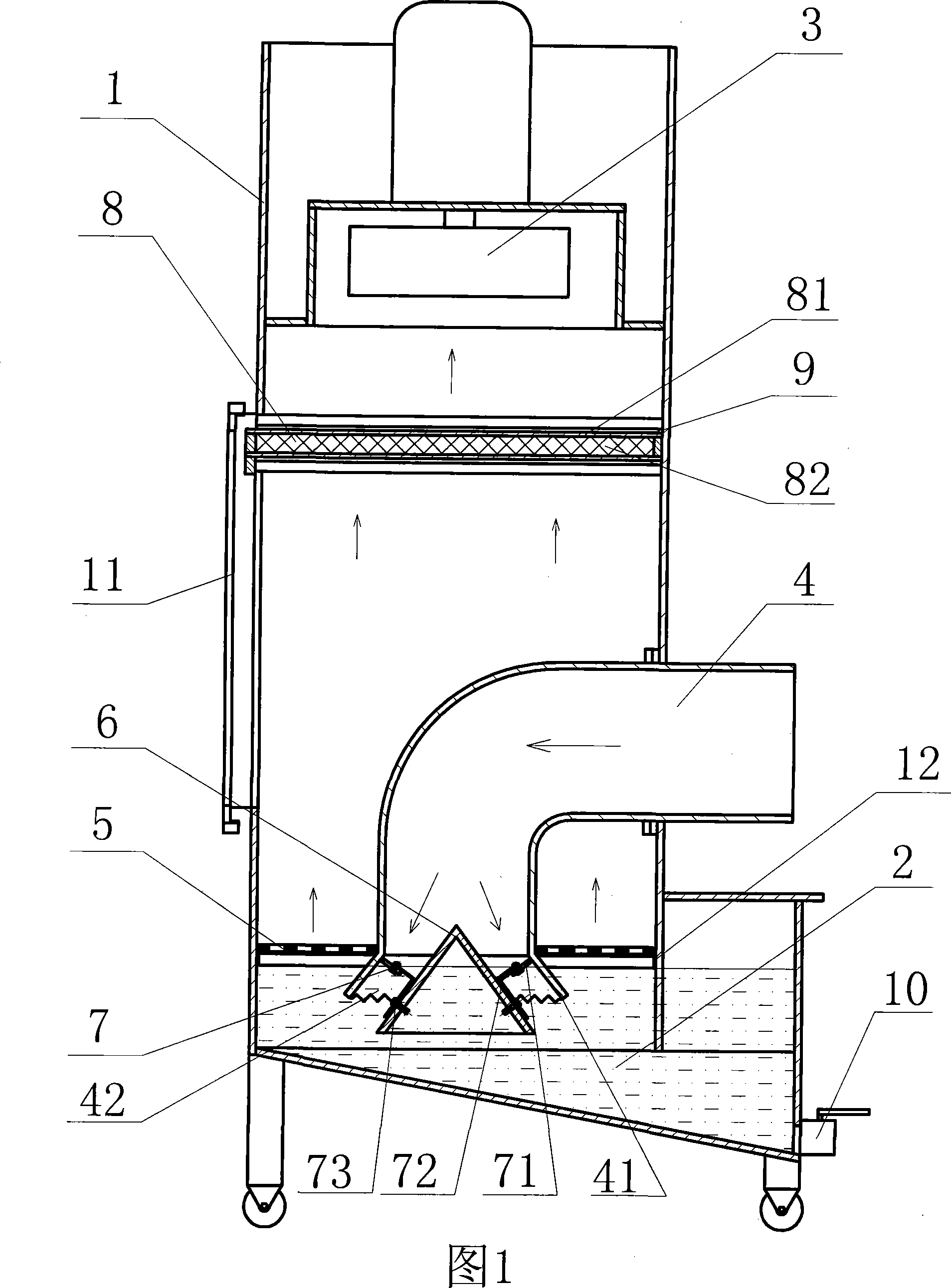

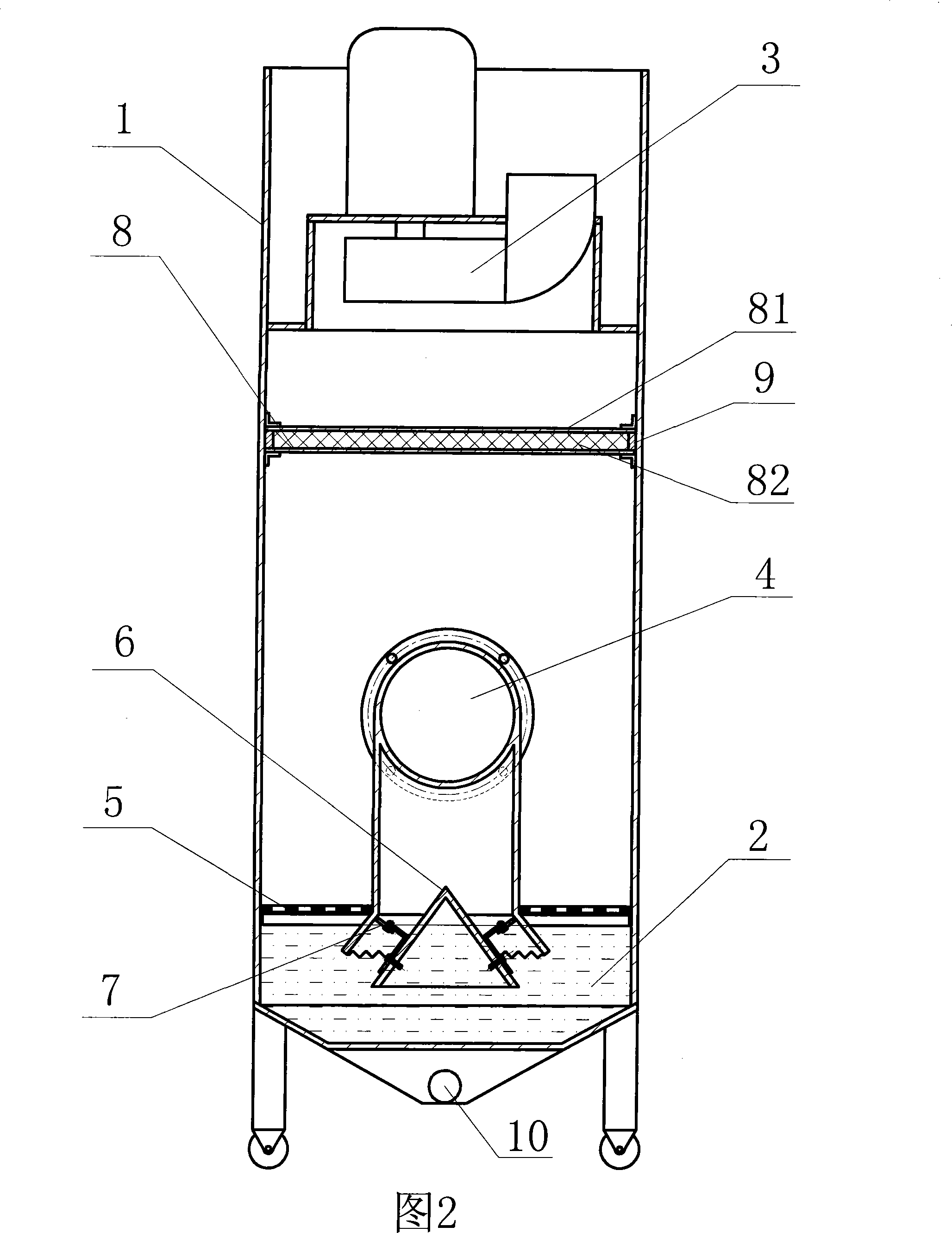

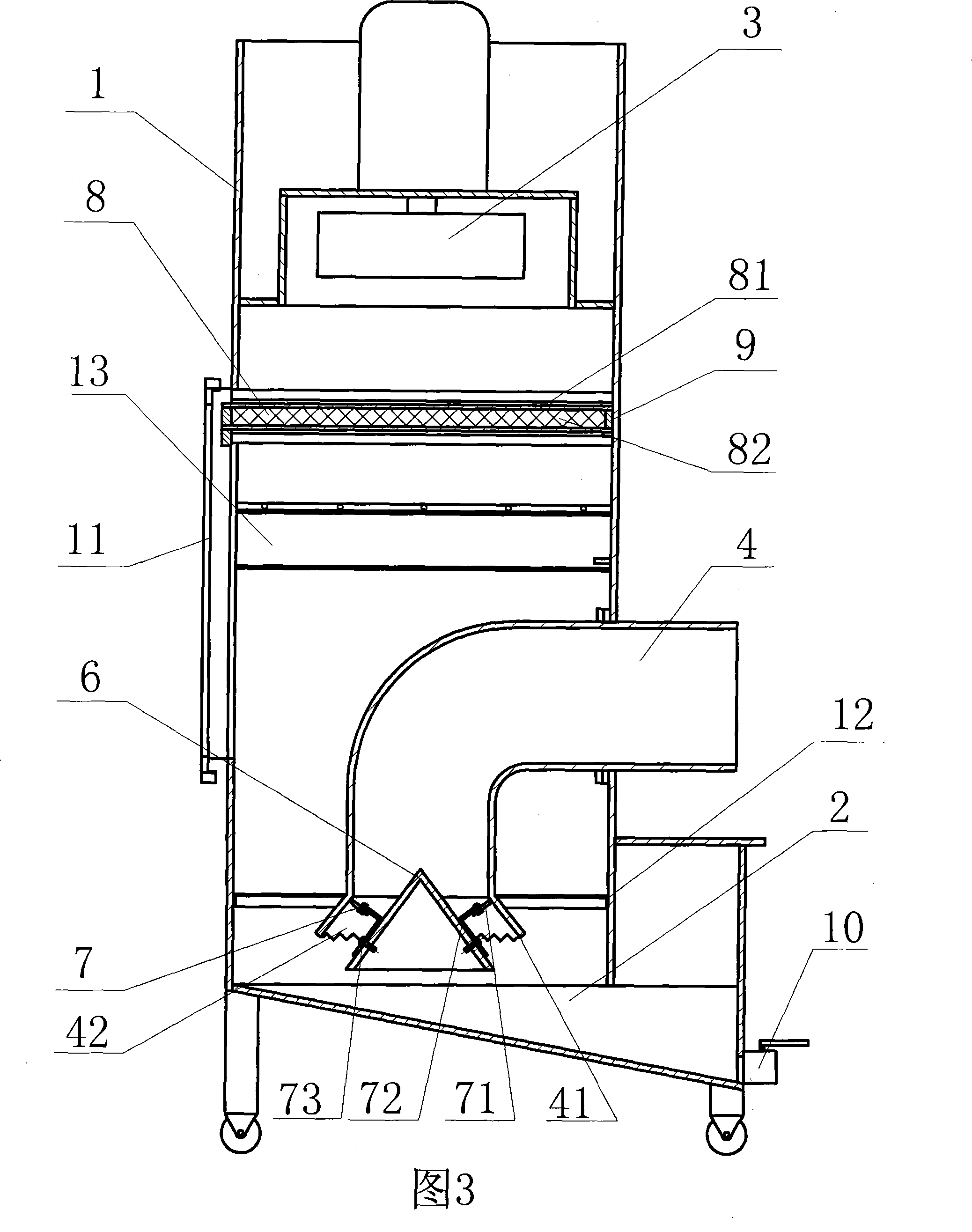

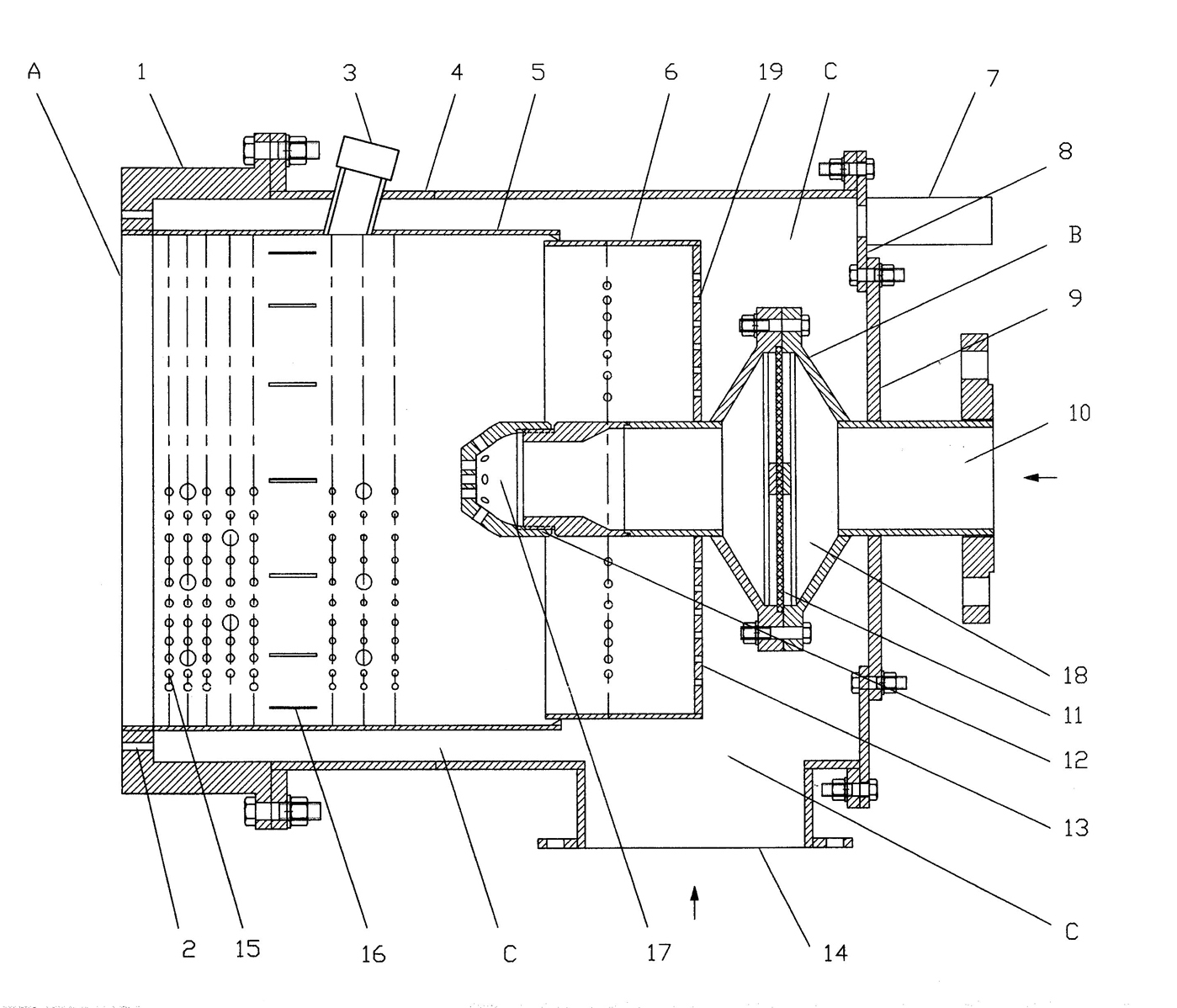

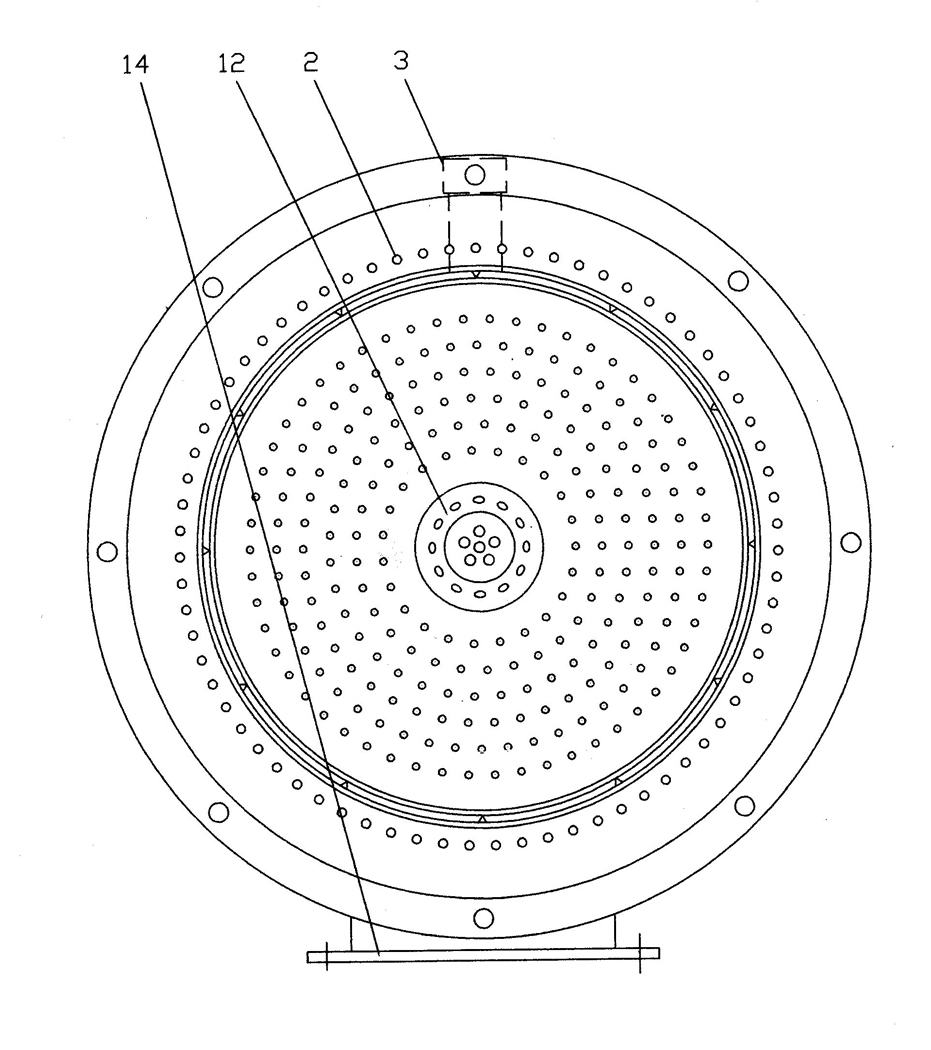

Bubble wet processing dust container

InactiveCN101229465AExtended stayFully mixedCombination devicesUsing liquid separation agentProduct gasPerforated metal

The invention discloses a water medium filtering and dust removing bubble wet dust collector, which comprises a tank body (1), a water tank (2) arranged under the tank body (1), an ejector positioned over the tank body, a drain pipe (10) positioned below the water tank, a door (11) arranged at the side of the tank body, a filter plate (8) in the tank body, a pumping elbow (4) fixed on the water tank, a bell mouth (41) at the outlet end thereof, a layer of perforated metal sheet (5) arranged close to the working water surface and supported by a bar bearer (12) in the tank body. The bell mouth (41) enters into the water through the perforated metal sheet (5); the middle most of the lower part of the bell mouth (41) is provided with a pyramidal guide wind bucket (6) which is suspended at the inner side of the bell mouth (41) through a duct regulating thread slipping (7), thereby ensuring the outer side of the guide wind bucket (6) and the inner side of the bell mouth form an annular exhaust passage (42), size of which can be adjusted. The invention has simple structure and generates bubble through the guide wind bucket, thereby ensuring the pumped dust gas can fully enter into the water to be filtered and saving energy.

Owner:江门市蓬江区永兴盛五金设备有限公司

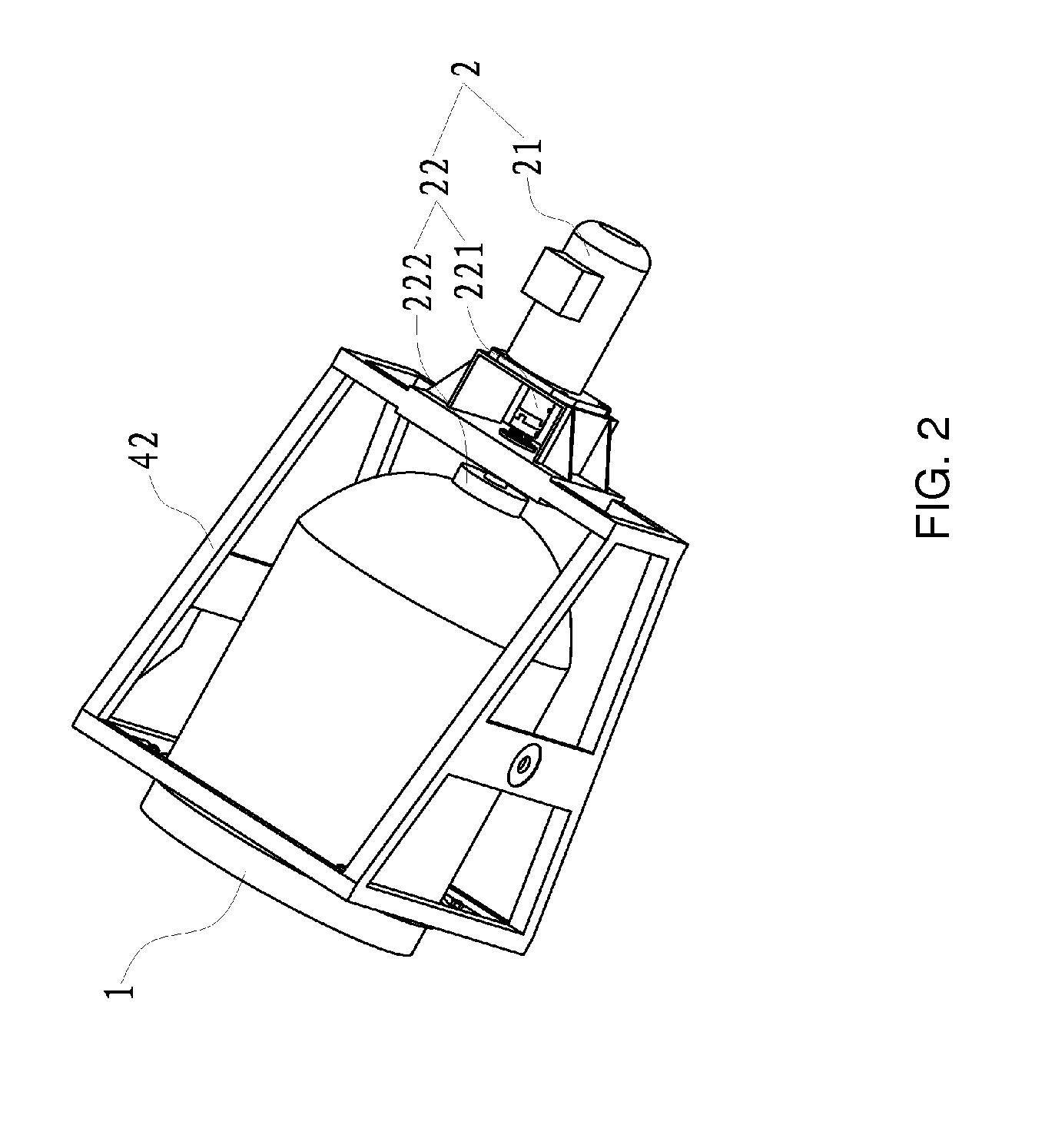

Cooking equipment

InactiveUS20110297008A1Easily control cooking durationStir wellBaking-tinsCooking vessel constructionsRotational axisEngineering

The present invention provides a cooking equipment comprising a pot, a body bracket, a rotation mechanism and a turning-over mechanism in which the pot is in shape of a barrel, a hemisphere or the like with an opening at its end, the rotation mechanism is connected to the pot to drive the pot to rotate around a rotation axis of the pot, the turning-over mechanism is connected to the pot to drive the pot to turn around a turning-over axis together with the body bracket, and when the cooking equipment is in its operating state, the angle between the rotation axis of the pot and horizontal plane is in the range of 0° to 90°.

Owner:LIU XINYU

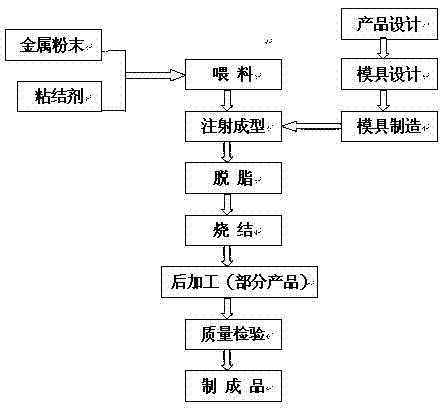

Powder metallurgy injection molding process

InactiveCN102962455ASolve liquidity problemsAddressing the Weakness of Mixed PoorMetallurgyInjection molding process

The invention provides a powder metallurgy injection molding process, belonging to the technical field of powder metallurgy. The powder metallurgy injection molding process comprises the following steps of: 1), mixing metal powder and a bonding agent according to a ratio; 2), feeding: putting a mixture of the metal powder and the bonding agent into a pre-designed and manufactured mould cavity; heating to 120-140 DEG C under the protection of ammonia gas to carry out warm pressing molding; and in a molding process, vibrating the mould cavity; 3), degreasing: after de-molding, heating a molded product to 250-300 DEG C; and 4), sintering: sintering at a vacuum state, wherein the sintering temperature is 850-1000 DEG C and the heat-preservation time is 1-2.5 hours. The invention provides a pulse periodic vibration mixing method aiming to solve the technical problems of defects of the prior art that the agitation is not uniform and the product stability is poor; and the disadvantages of poor mobility and mixing performance of raw materials in an injection molding process are overcome, the product density is high and the distribution is uniform.

Owner:LANZHOU JINHAO MACHINERY MFG

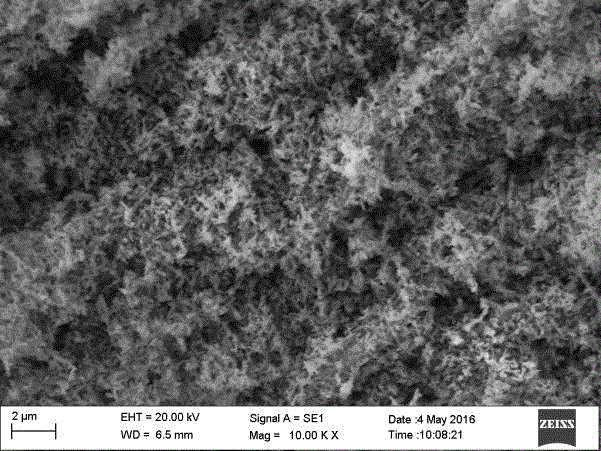

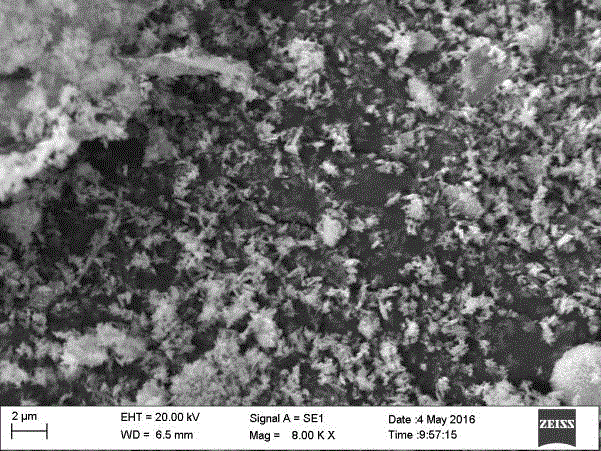

CuO-NiO/rGO composite material with efficient electro-catalysis oxygen reduction performance

The invention relates to a CuO-NiO / rGO composite material with efficient electro-catalysis oxygen reduction performance, and belonging to the technical field of electro-catalysis materials. In the CuO-NiO / rGO composite material provided by the invention, CuO-NiO nanoparticles are attached to a reduction-oxidized graphene sheet layer, a mass ratio of the CuO-NiO nanoparticles to the rGO is 100:3-5, the sizes of the CuO-NiO nanoparticles are 6-10nm, and the reduction-oxidized graphene sheet layer is a single sheet layer; and the electro-catalysis oxygen reduction performance is provided. Compared with existing oxygen reduction reaction catalysts, the CuO-NiO / rGO composite material provided by the invention is significantly reduced in cost, and is the oxygen reduction reaction catalyst with low price and excellent electro-catalysis oxygen reduction performance. The CuO-NiO / rGO composite material provided by the invention adopts copper salts, nickel salts, hydroxides and oxidized graphene as materials, deionized water and absolute ethyl alcohol as solvents, and glycol as a dispersing agent and a reducing agent, and is synthesized by using a one-pot hydrothermal method. The CuO-NiO / rGO composite material provided by the invention is low in material price, prone to get materials, simple and easy in preparation operation, simple in aftertreatment process, prone to control reaction parameters, short in flow and low in energy consumption.

Owner:UNIV OF JINAN

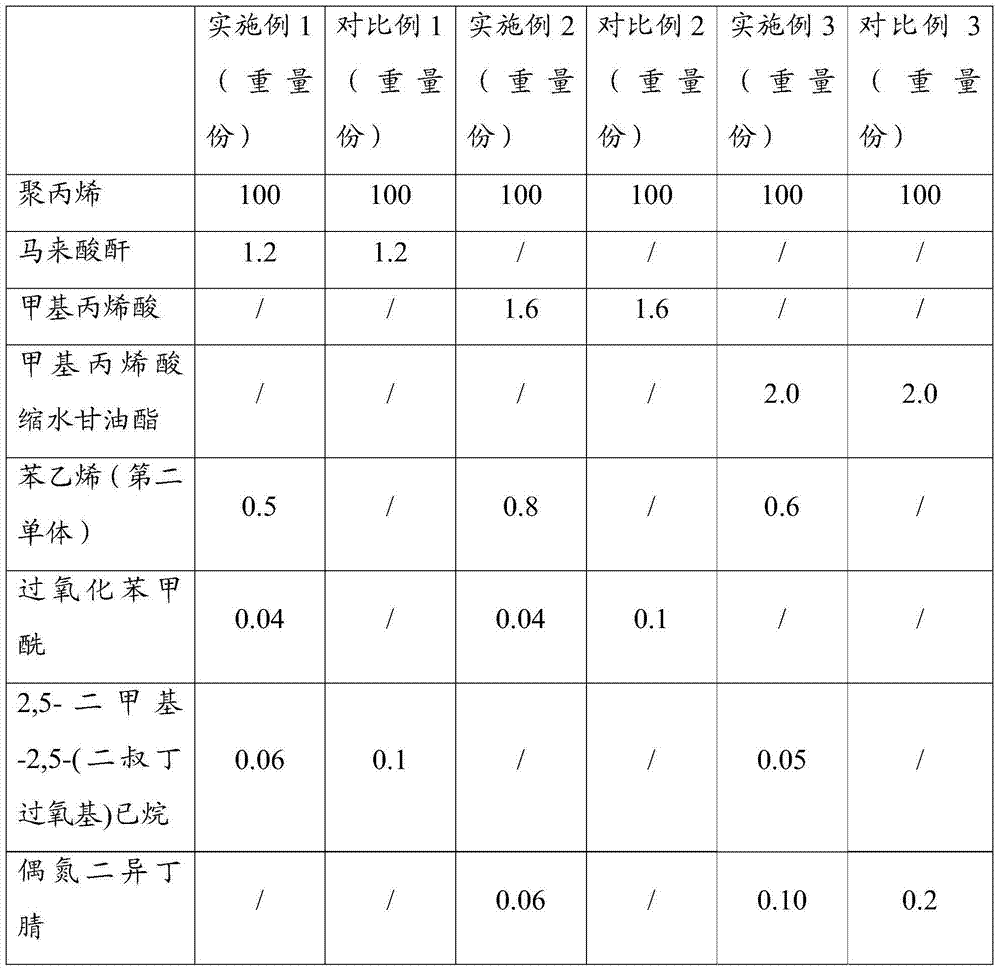

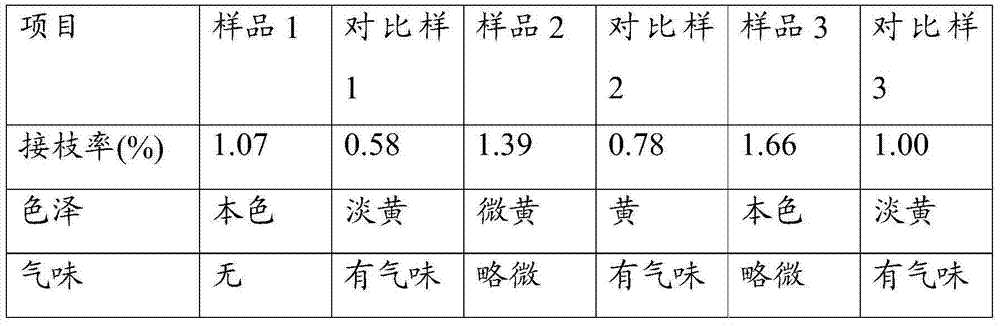

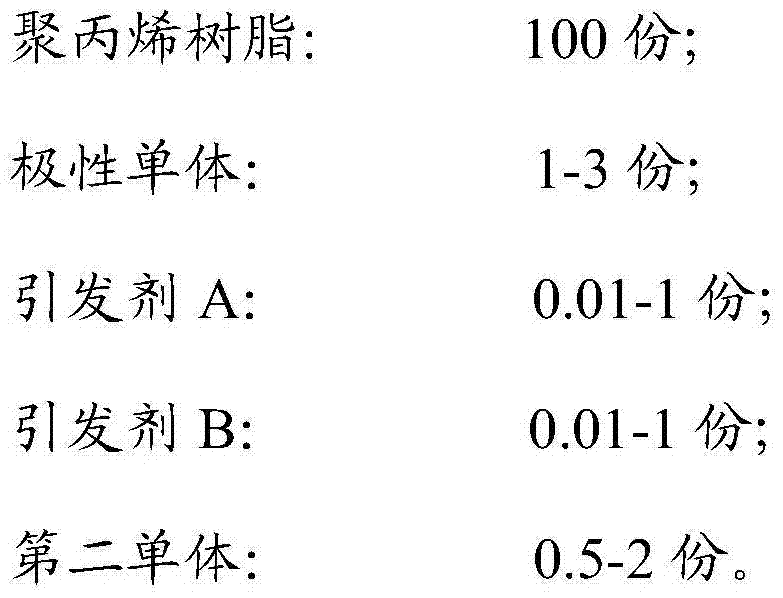

High-grating-rate and low-odor polypropylene resin composition and preparation method thereof

The invention provides a high-grating-rate and low-odor polypropylene resin composition and a preparation method thereof. The polypropylene resin composition consists of the following components in parts by weight: 100 parts of polypropylene resin, 1-3 parts of a polar monomer, 0.01-1 part of an initiator A, 0.01-1 part of an initiator B and 0.5-2 parts of a second monomer. The preparation method comprises the steps of weighing raw materials according to the weight part, mixing the raw materials in a high-speed mixer for 2-5min and discharging materials; and implementing reactive extrusion grafting on the mixed raw materials through a dual-screw extruder. The polypropylene resin composition disclosed by the invention, through selecting initiator and comonomer, reduces pungent odor of materials and improves grafting efficiency. The prepared polypropylene disclosed by the invention has the advantages of light product odor, high grating rate and low gel rate, and is applicable to a flexibilizer and a compatilizer of polar monomer and non-polar polymer alloy; the polypropylene resin composition is used for filling or strengthening polypropylene, and is capable of improving the mechanical performance and the heat resistance of the material.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

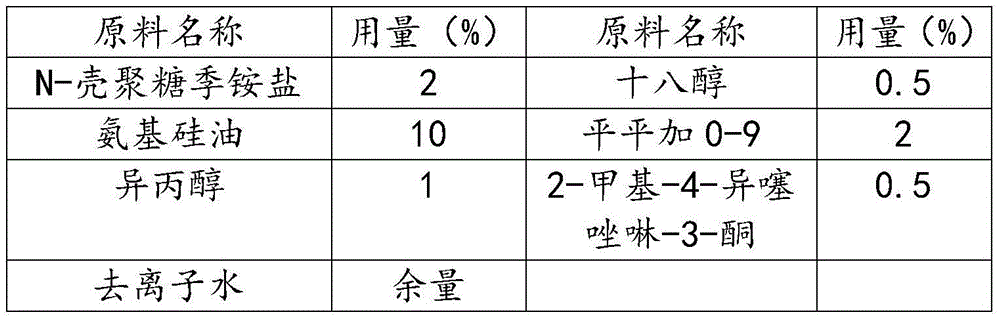

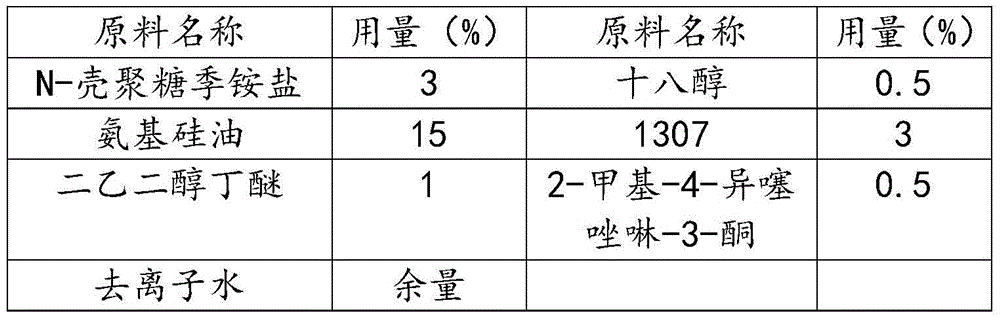

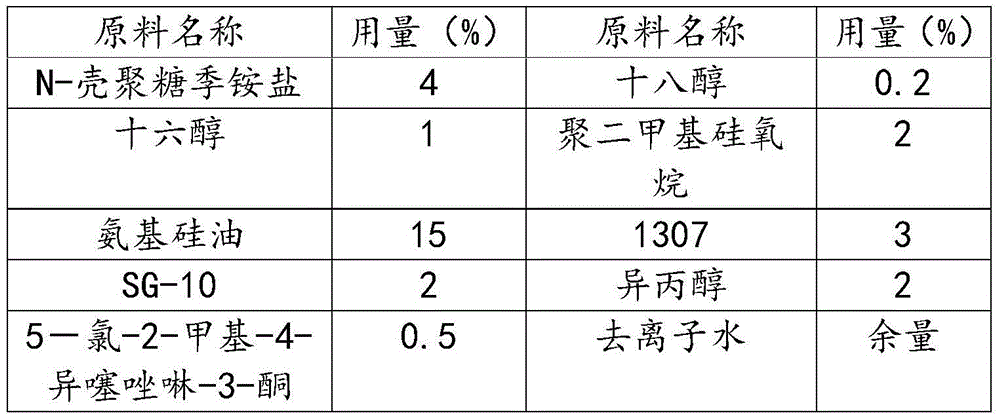

Environment-friendly antibacterial fur after-finishing agent and preparation method thereof

InactiveCN105648127AImproves antimicrobial cleansingGood dispersionLeather surface finishingStatic performanceSolvent

The invention provides an environment-friendly antibacterial fur after-finishing agent and a preparation method thereof. The environment-friendly antibacterial fur after-finishing agent is mainly prepared from quaternary ammonium salt, organic silicon, fatty alcohol, surfactants, preservatives, solubilizer and solvents. The environment-friendly antibacterial fur after-finishing agent can enhance the antibacterial cleanness of fur and improve the brightness, softness, smoothness and anti-static performance of the fur, and has excellent scientificity and environmental protection performance. The environment-friendly antibacterial fur after-finishing agent and the preparation method thereof are simple in process and suitable for mass production; the prepared environment-friendly antibacterial fur after-finishing agent can achieve the effects of antibacterial performance, fur glossiness, softness and fluffiness, electrostatic resistance and the like, and can keep a system stable for a long term.

Owner:北京泛博清洁技术研究院有限公司

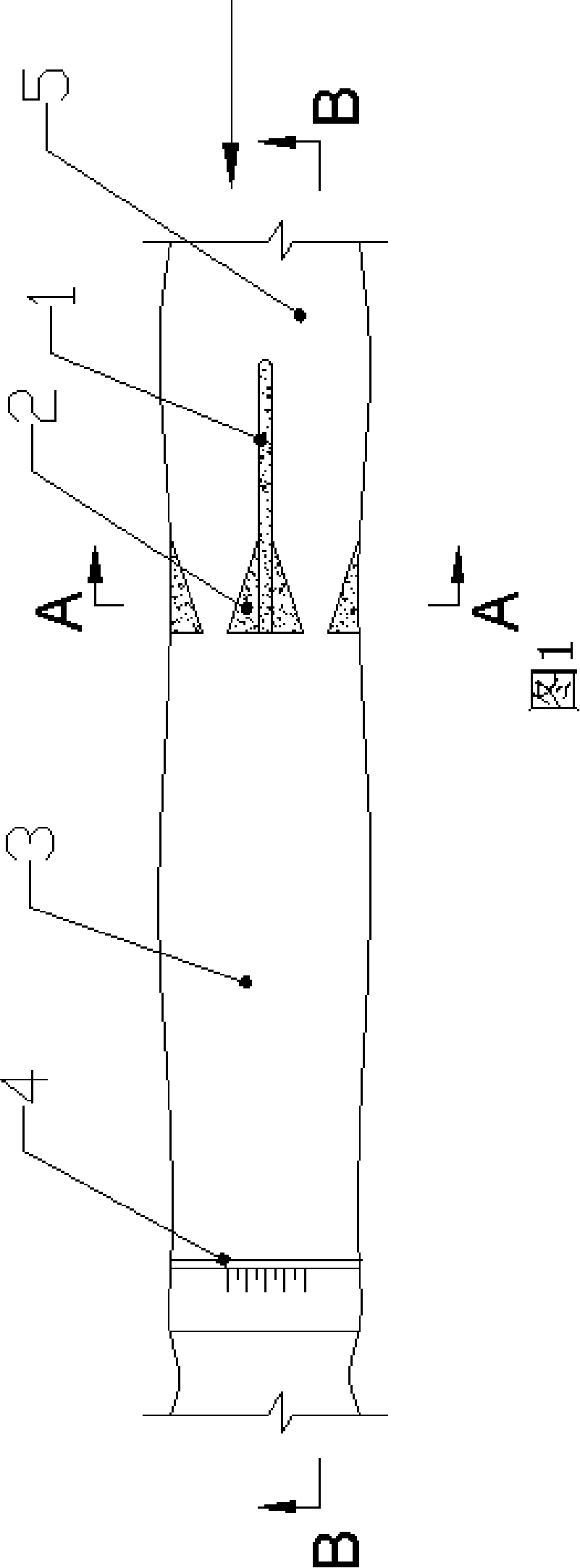

Flood discharging and energy dissipating device

InactiveCN101182707AFully mixedImprove energy dissipation efficiencyBarrages/weirsWater flowEngineering

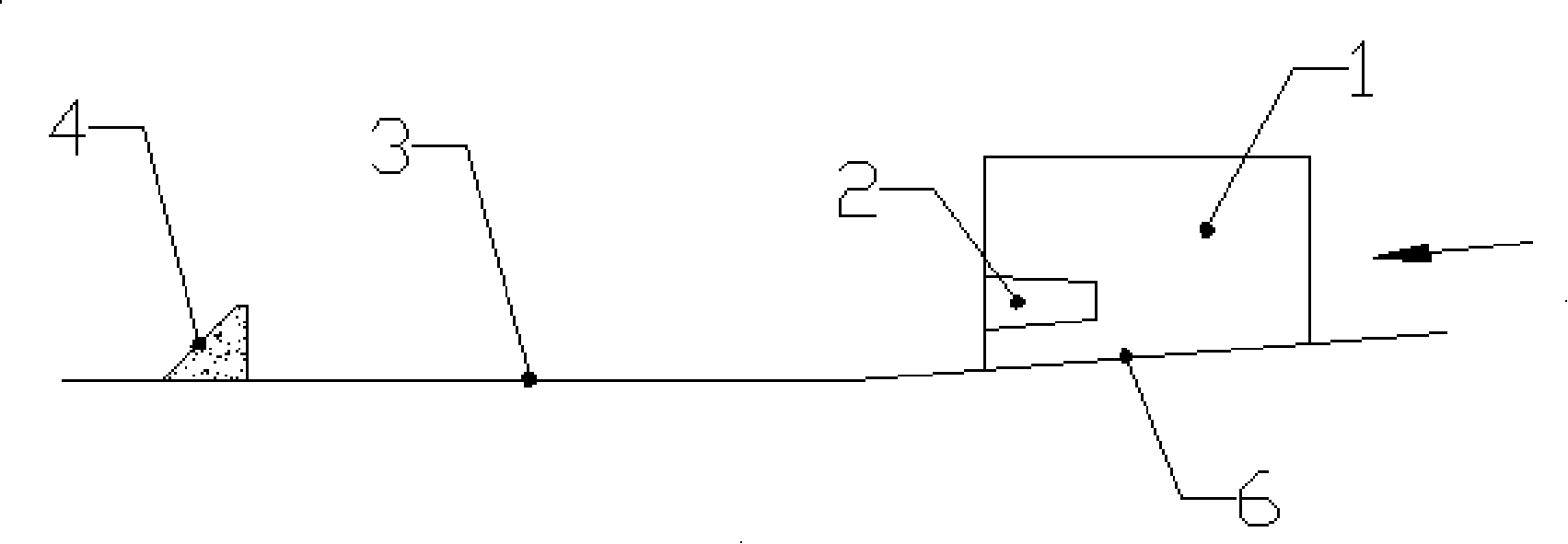

The invention discloses a flood discharge energy dissipater in a flood discharge channel and can promote the flood discharge energy dissipation efficiency of a water conservancy dam or a hydropower dam. The flood discharge energy dissipater comprises a flood discharge channel equipped with separation piers. The separation piers are equipped with wide-tail energy dissipation piers, the width of which gets bigger along the water flow direction. The bottom of the wide-tail energy piers and the channel surface of the flood discharge channel are separated with a certain distance. The top of the wide-tail energy dissipation piers is equipped with a bevel of minus 10 to 15 degrees, so the top acts as a water passing area and a water tongue jetting from the top jets freely and then flows out of the dam. Thus, the water flow forms an energy dissipation model of the free water jetting plus the longitudinally stretched water flowing plus the bottom flowing, so the water flows are fully mixed outside the dam to promote the energy dissipation efficiency to over 50 percent. The invention is applicable in all large, medium and small water-flow water-conservancy dams and hydropower dams.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Preparation method of high-quality wool heavy-twist and anti-wrinkle fabric

ActiveCN104397910AAvoid damageUniform dyeingLiquid/gas/vapor removalDyeing processEngineeringDesign methods

The invention provides a preparation method of high-quality wool heavy-twist and anti-wrinkle fabric. The high-quality wool heavy-twist and anti-wrinkle fabric is prepared by interweaving warps and wefts, wherein the warps and the wefts are respectively prepared by blending raw materials by weight percent, and the raw materials comprise 75% of 16.0 mu m Australasian wool and 25% of mulberry silk. The preparation method adopts an innovative easily-caring and anti-wrinkle fabric design method and an after-finishing technology; the prepared fabric is smooth in hand feeling, good in elasticity, excellent in draping property and good in wearability, and reaches the requirement of easy care, thus being very suitable for making a high-quality non-lining or semi-lining business and casual suit.

Owner:江苏纺谷科技有限公司

Speaker system

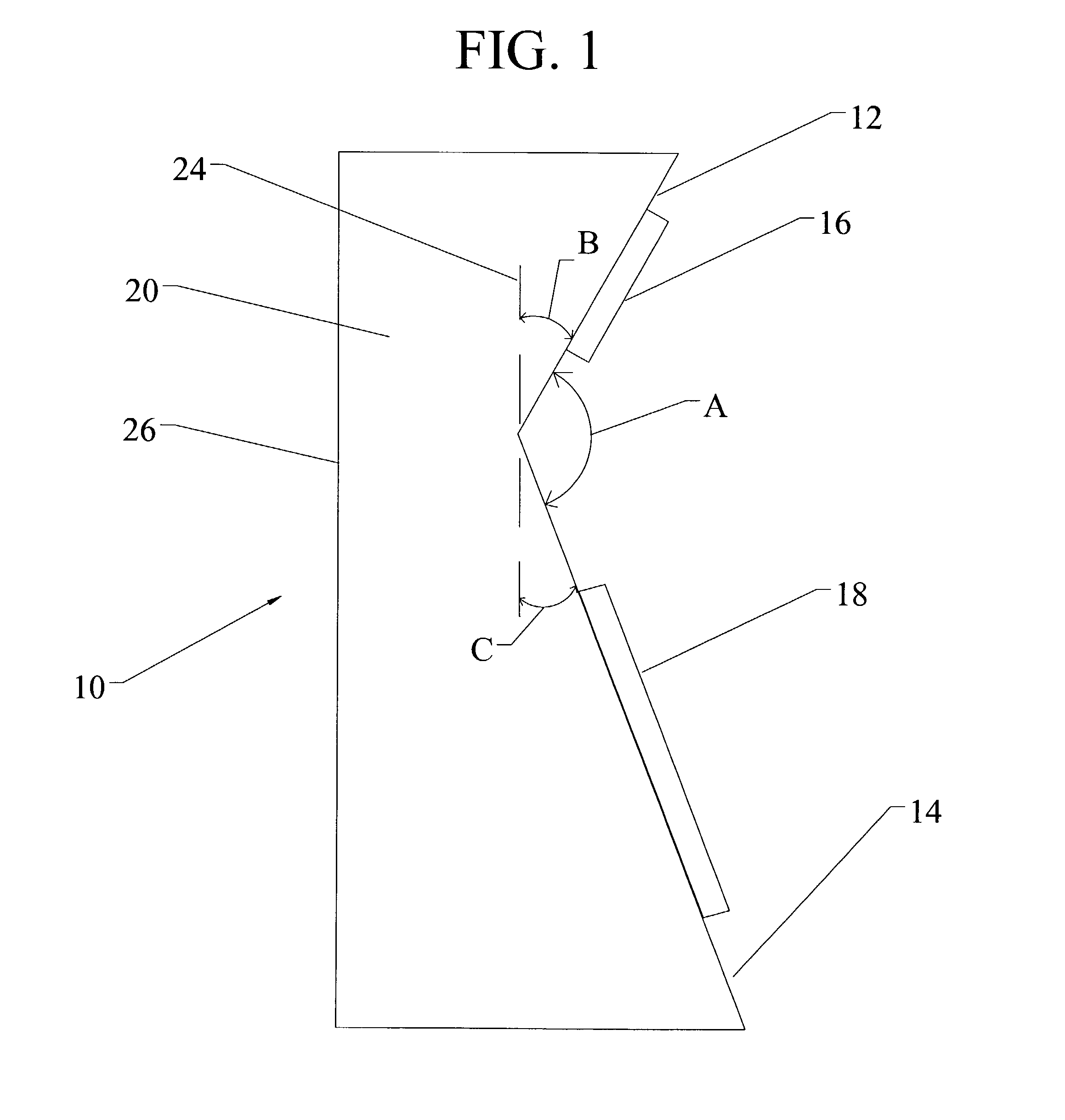

A speaker system having a first speaker, a second speaker, and a housing having a first mounting surface to which the first speaker is mounted and a second mounting surface to which the second speaker is mounted. The first mounting surface and the second mounting surface are substantially planar and abut one another to form an included angle of between 120 degrees and 140 degrees. By so arranging the mounting surfaces, the sound produced by each speaker is allowed to mix to provide a full sound.

Owner:SPINALE ROBERT G

CuO/rGO composite material having efficient electrocatalysis oxygen reducing performance

InactiveCN106654304ALow priceEfficient electrocatalytic oxygen reduction performanceMaterial nanotechnologyCell electrodesSolventOxygen

The invention relates to a CuO / rGO composite material having efficient electrocatalysis oxygen reducing performance and belongs to the technical field of electrocatalysis materials. Nano CuO particles are attached onto a reduced-oxidized graphene sheet layer, a mass ratio of nano CuO and rGO is 100:3-5, size of the nano CuO particles is 6-10nm, the reduced-oxidized graphene sheet layer is a single sheet layer, and the CuO / rGO composite material has electrocatalysis oxygen reducing performance. Compared with existing oxygen reducing reaction catalysts, the CuO / rGO composite material has the advantage that cost is lowered obviously; the CuO / rGO composite material is an oxygen reducing reaction catalyst low in cost and excellent in electrocatalysis oxygen reducing performance. The CuO / rGO composite material is synthesized by taking copper salt, hydroxide and graphene oxide as raw materials, deionized water and anhydrous alcohol as solvents and ethylene glycol as a dispersant and reductant and adopting a hydrothermal one-pot process. The raw materials are low in cost and easy to obtain, preparation operation is simple and easy to implement, aftertreatment process is simple, reaction parameters are easy to control, process is short, and energy consumption is low.

Owner:UNIV OF JINAN

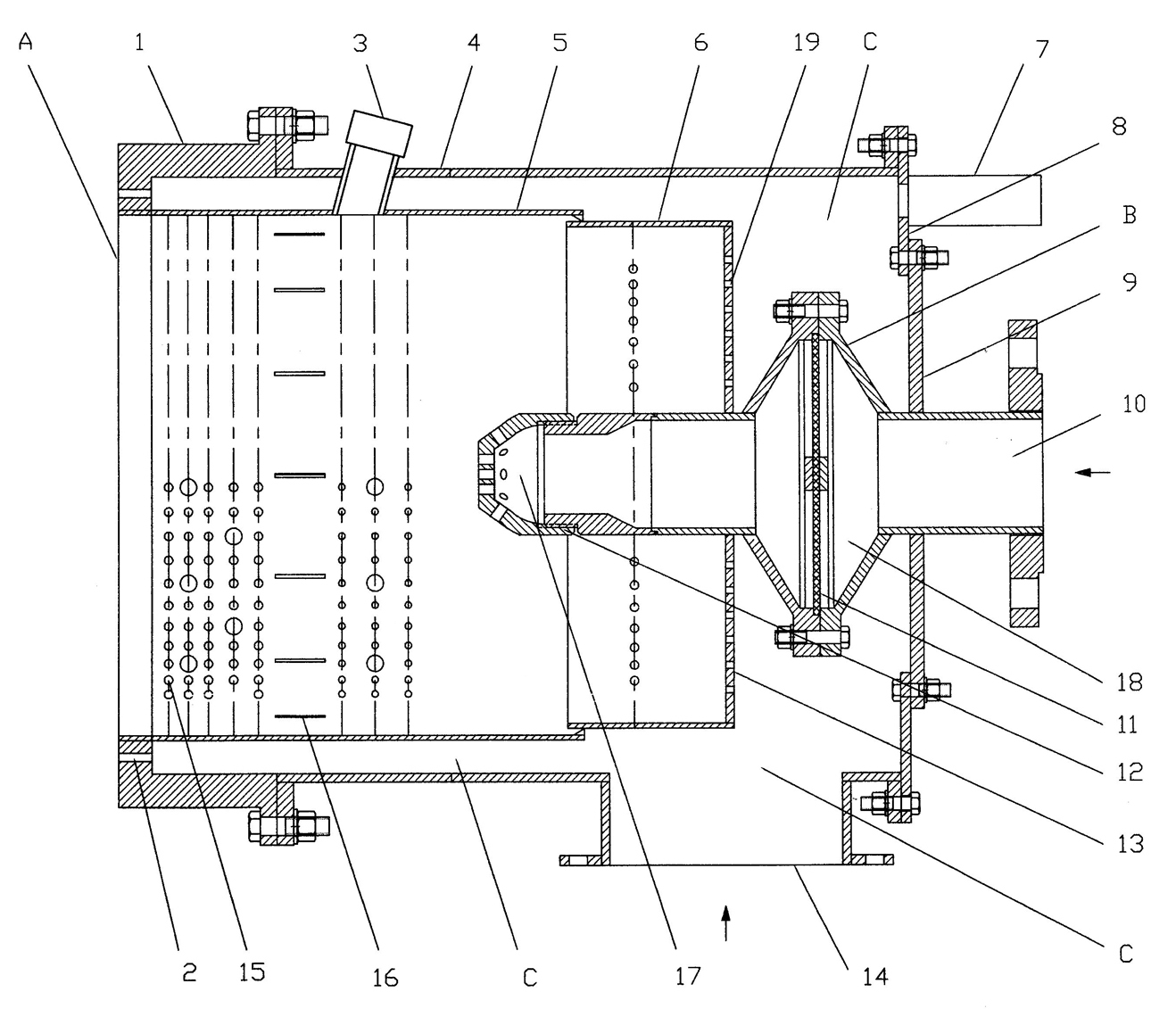

Anti-backfire gas combustor

ActiveCN101975398AImprove securityExtended service lifeGaseous fuel burnerCombustorCombustion chamber

The invention relates to an anti-backfire gas combustor, in particular to a combustor comprising a combustion chamber and an adjustable nozzle assembly. The combustion chamber comprises a high-temperature combustion head, an outer shell, an outer shell end plate, a flame tube and a flame tube end plate, wherein the high-temperature combustion head, the outer shell and the outer shell end plate are arranged outsides, the flame tube and the flame tube end plate are arranged insides, the adjustable nozzle assembly comprises a nozzle, a fire-retardant mesh, a gas inlet and a rear end cover and is arranged in the middle of the flame tube end plate, the nozzle of the adjustable nozzle assembly penetrates into the flame tube, the rear end cover of the adjustable nozzle assembly is fastened with the outer shell end plate through bolts, the high-temperature combustion head, the outer shell and the outer shell end plate are connected into a whole through bolts to form an interlayer hollow cavity together with the flame tube in the combustion chamber and the adjustable nozzle assembly, the flame tube is uniformly provided with radial hybrid air distribution holes and tangential air inlet grooves, the flame tube end plate is uniformly provided with axial air inlets, and combustion air inlets arranged on the outer shell are communicated with the interlayer hollow cavity and the air distribution holes or the air inlet grooves. The invention has high safety performance and long service life and is more energy-saving and environment-friendly.

Owner:游述怀

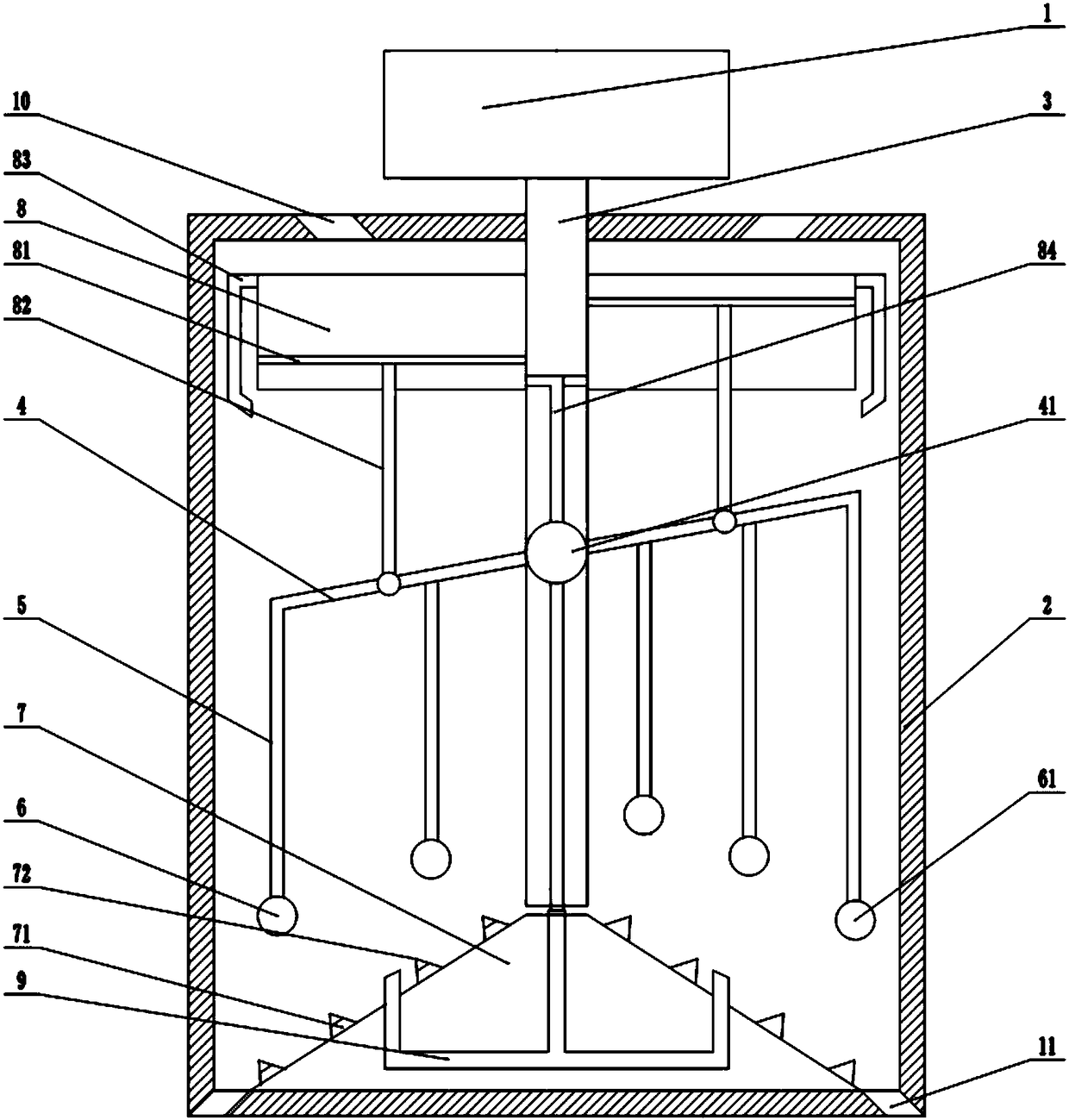

Pet feed mixing device

ActiveCN108211957AAchieve circumferential stirring and mixingRealize up and down stirring and mixingFeeding-stuffTransportation and packagingMagnetic polesCircular cone

The invention discloses a pet feed mixing device. The pet feed mixing device comprises a motor, a material mixing barrel, a circular cone table and a spindle, wherein a feeding inlet is formed in thetop surface of the material mixing barrel and the center of the top surface of the material mixing barrel is rotationally sealed with the spindle, the spindle is hollow and cylinders are arranged at the upper side part of the spindle, and a cross rod is in ball joint with the middle part of the spindle; a plurality of stirring rods are connected onto the cross rod on both sides of the spindle, a first magnet and a gravity block are respectively arranged at the end parts of the stirring rods on both sides, piston rods are hinged to the cross rod and connected with pistons in the cylinders, first guide pipes are arranged at the upper ends of the cylinders, and second guide pipes which extend into a cavity inside the spindle are arranged at the lower ends of the cylinders; the circular cone table is fixed at the bottom of the material mixing barrel, a plurality of protrusions are arranged on the circular cone table, second magnets are mounted on the protrusions on one side, the magnetic poles of the second magnets are the same as those of adjacent ends of first magnets, the second guide pipes extend out of the bottom of the spindle, and tee pipes are arranged inside the circular conetable, and rotationally connected with the second guide pipes, wherein two bifurcated pipes of the tee pipes respectively protrude from an inclined surface of the circular cone table. By adopting thedevice disclosed by the invention, granules and powdered pet feed can be uniformly mixed.

Owner:CHONGQING SIWEITE PET SUPPLIES CO LTD

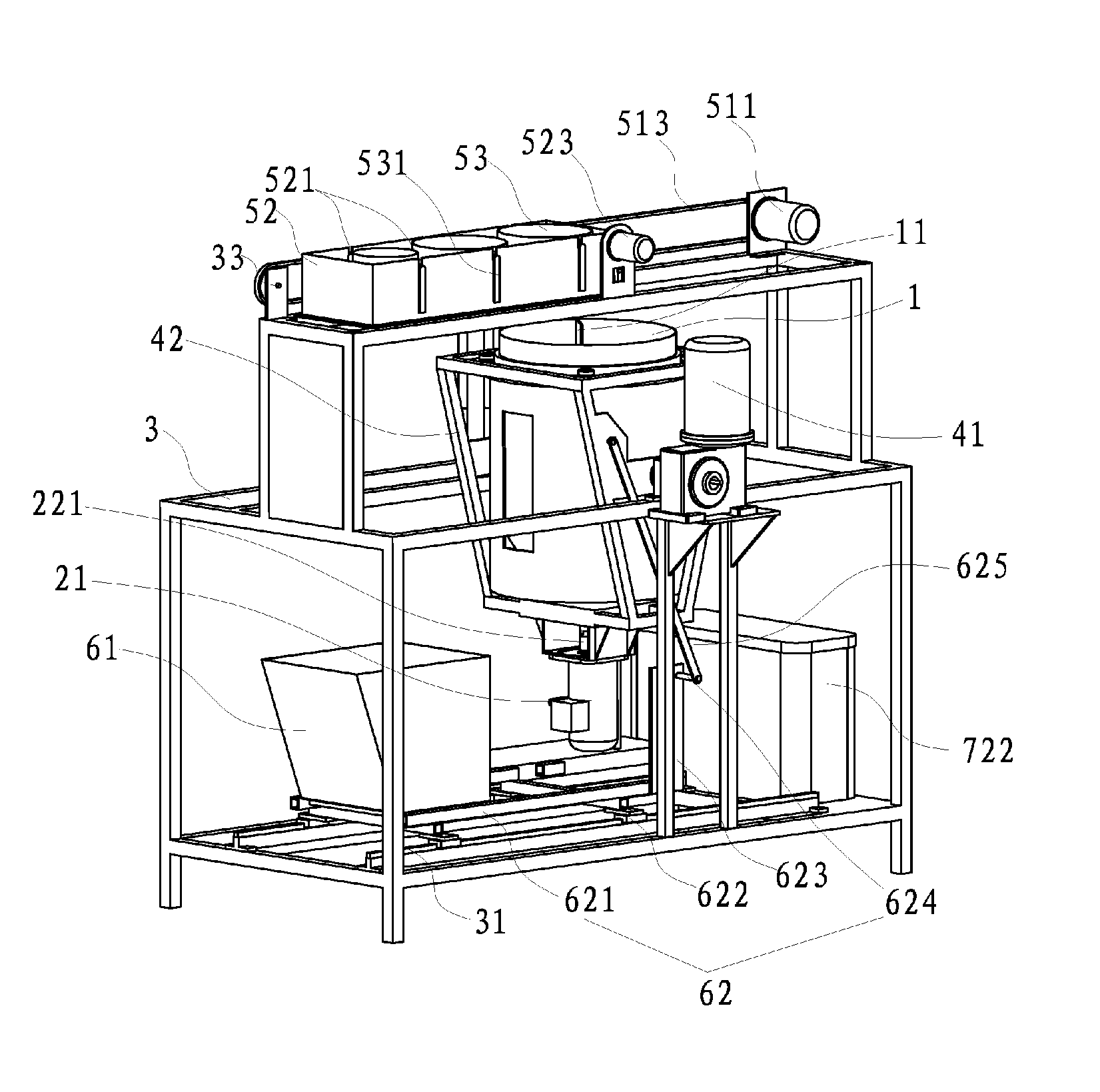

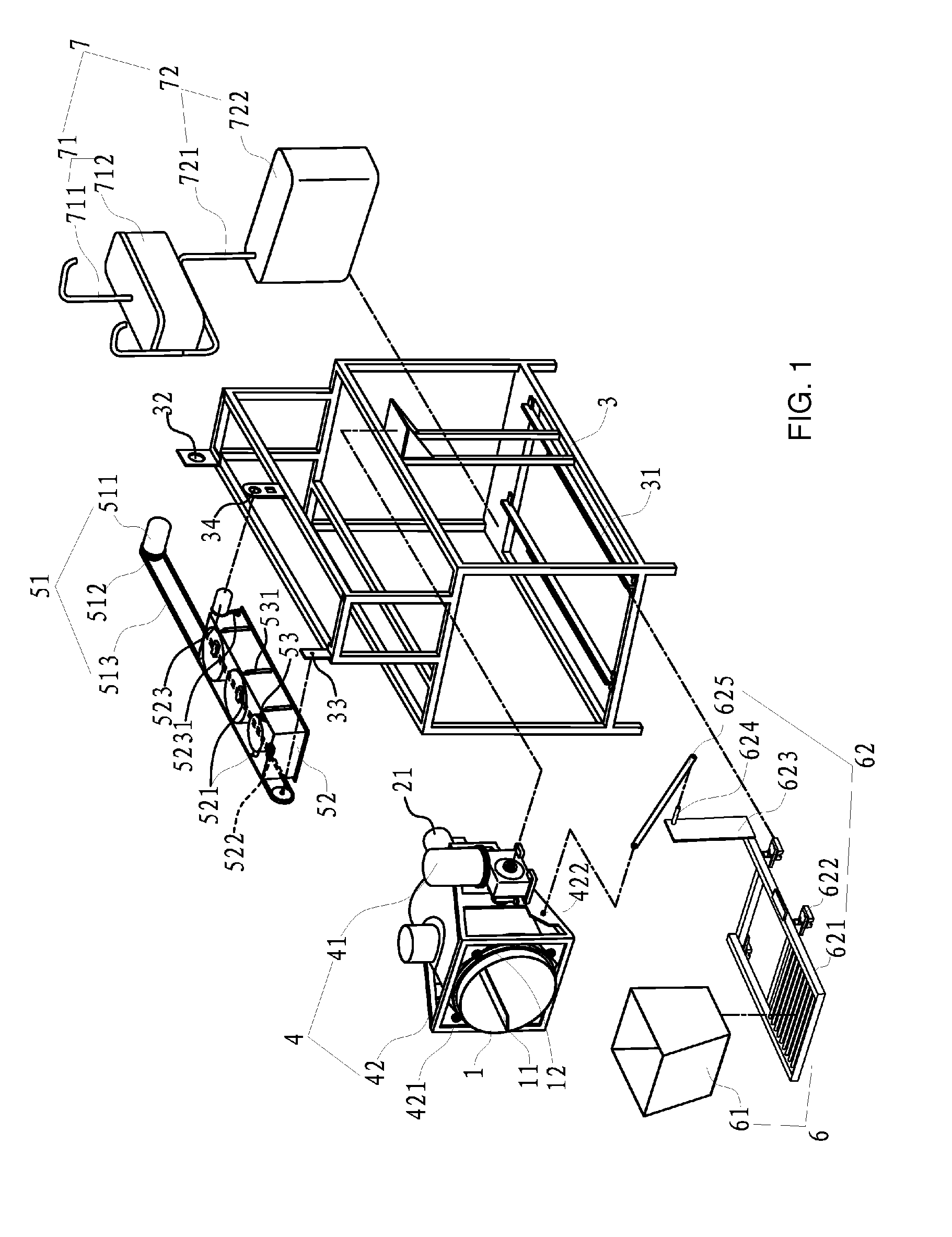

Feed feeder

Owner:CHONGQING FENGXINGYUAN ECOLOGICAL AGRI DEV

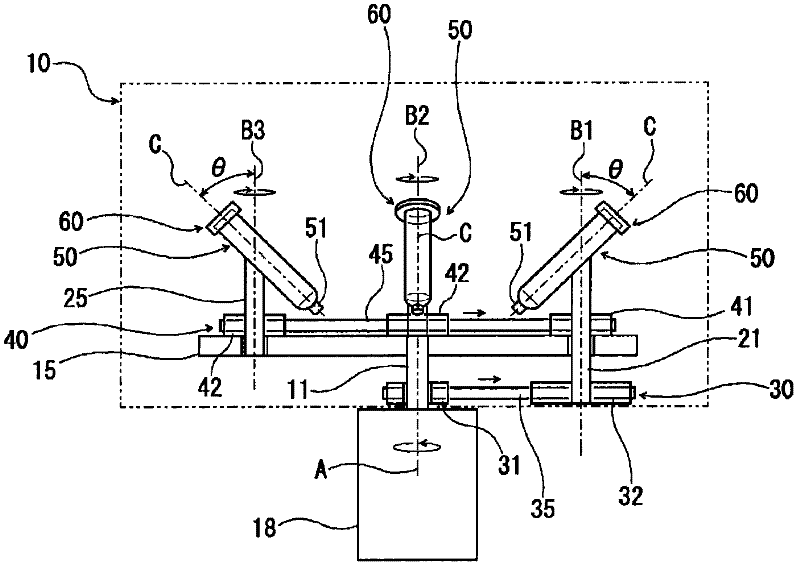

Vacuum kneading-and-defoaming device

ActiveCN102470288AFully defoamedUniform and sufficient defoamingRotating receptacle mixersTransportation and packagingRotational axisInterior space

Provided is a vacuum kneading-and-defoaming device that can subject a paste material contained in a cylindrical paste container to uniform and sufficient kneading and to sufficient and highly efficient defoaming. The disclosed vacuum kneading-and-defoaming device includes: a revolution-purpose rotary element that is provided inside a chamber to be brought into a decompressed state, and that rotates within a horizontal plane about a reference drive rotation axis; a container retaining means that is provided on the orbiting edge of the revolution-purpose rotary element in a manner so as to be spinnable about an operation rotation axis which is parallel to the reference drive rotation axis, and that detachably retains a paste container in a state such that the central axis of the paste container obliquely intersects with the operation rotation axis; and a drive mechanism that rotates the revolution-purpose rotary element and the container retaining means. An opening provided in the paste container for the introduction of a paste material has: a degassing valve that opens the interior space of the paste container to the interior space of the chamber by the action of centrifugal force caused by the revolution and the spinning of the paste container; or a gas-permeable membrane that is impermeable to the paste material.

Owner:马康

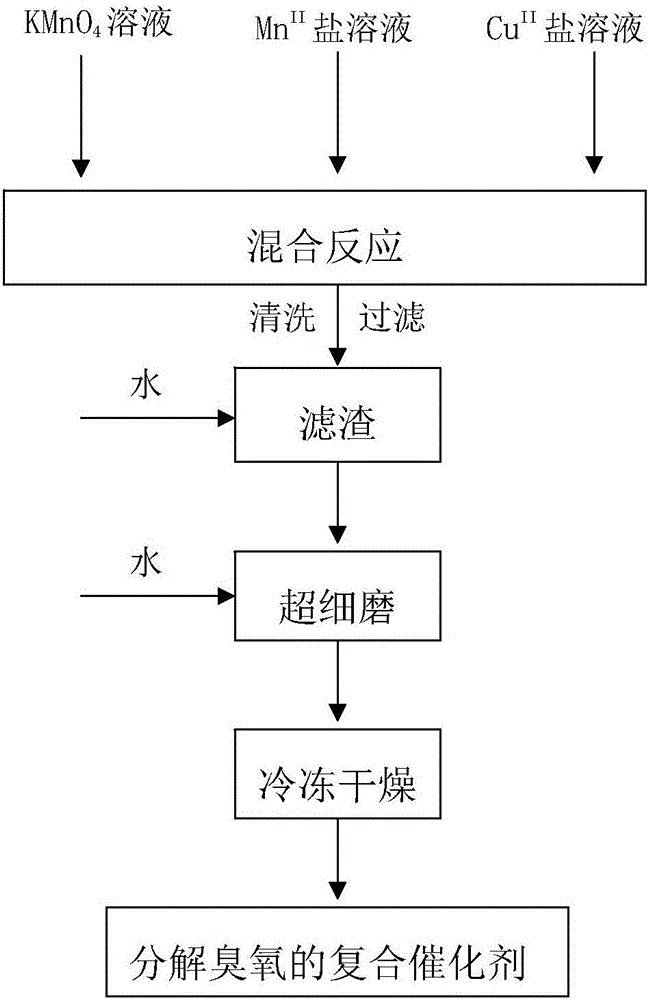

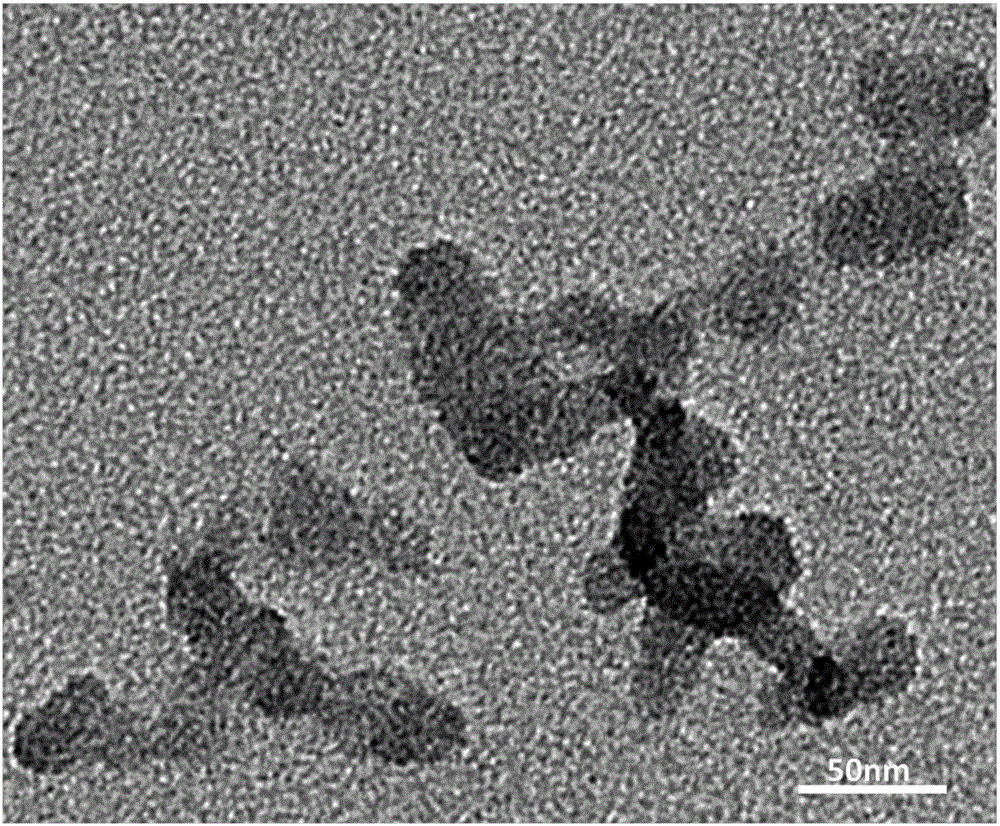

Composite catalyst for decomposing ozone and preparation method of composite catalyst

ActiveCN106179396AFew synthetic stepsAchieve compositeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFreeze-dryingRedox

The invention relates to a method for preparing a composite catalyst for decomposing ozone. The method comprises the following steps: separately dissolving permanganate, an Mn<II> salt and a Cu<II> salt, so as to obtain three kinds of salt solutions; rapidly mixing the three kinds of salt solutions, stirring, carrying out an oxidation-reduction reaction, and then, carrying out filtrating and washing, so as to obtain filtrated residue of a composite oxide; adding the filtrated residue into water, carrying out mixing so as to form a suspension of the filtrated residue and the water, carrying out extra-fine grinding treatment on the suspension so as to thoroughly grind the suspension, and then, carrying out a freeze-drying process, thereby obtaining the composite catalyst for decomposing the ozone. According to the method provided by the invention, the number of synthesis steps is small, the synthesis conditions are simple, the process of extra-fine grinding treatment is simple, the dispersion effect is good, and various substances in the prepared composite catalyst are thoroughly mixed and doped, so that the catalysis effect is improved remarkably.

Owner:NINGBO TAIAN NEW MATERIAL TECH CO LTD

Washing machine and washing method

ActiveUS20140230160A1Simple structureSimplify the washing processOther washing machinesDetergent compounding agentsSolid particleMechanical engineering

A washing machine and a washing method, comprises an inner cylinder, an outer cylinder, and solid particles as washing medium. The inner cylinder is driven into rotation by a driver device. The inner cylinder has arranged on the inner wall thereof scraper blades that protrude inwards and are bent along the wall of the inner cylinder. The scraper blades drives the particles into obliquely upward or obliquely downward movements and flipping, thus allowing for more fully mixing clothes with the particles, for simplified washing process, while also for improved cleaning rate, and for facilitated recycling of the particles.

Owner:XEROS LTD

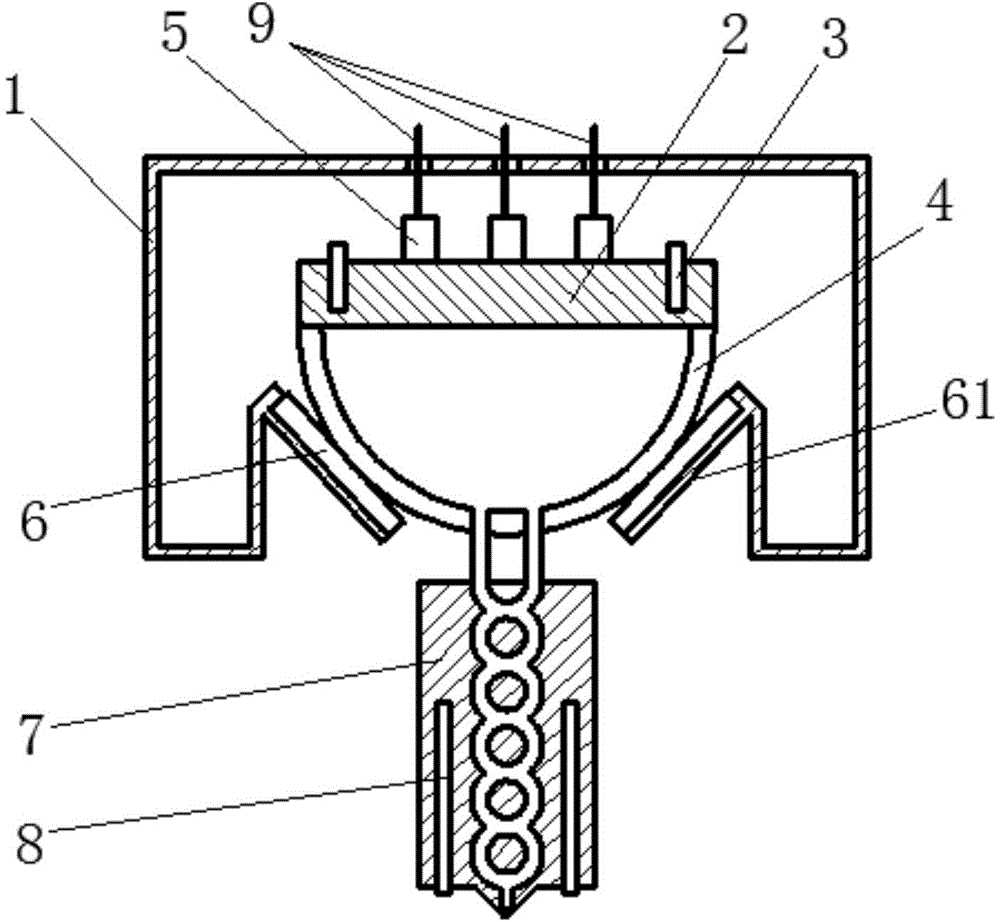

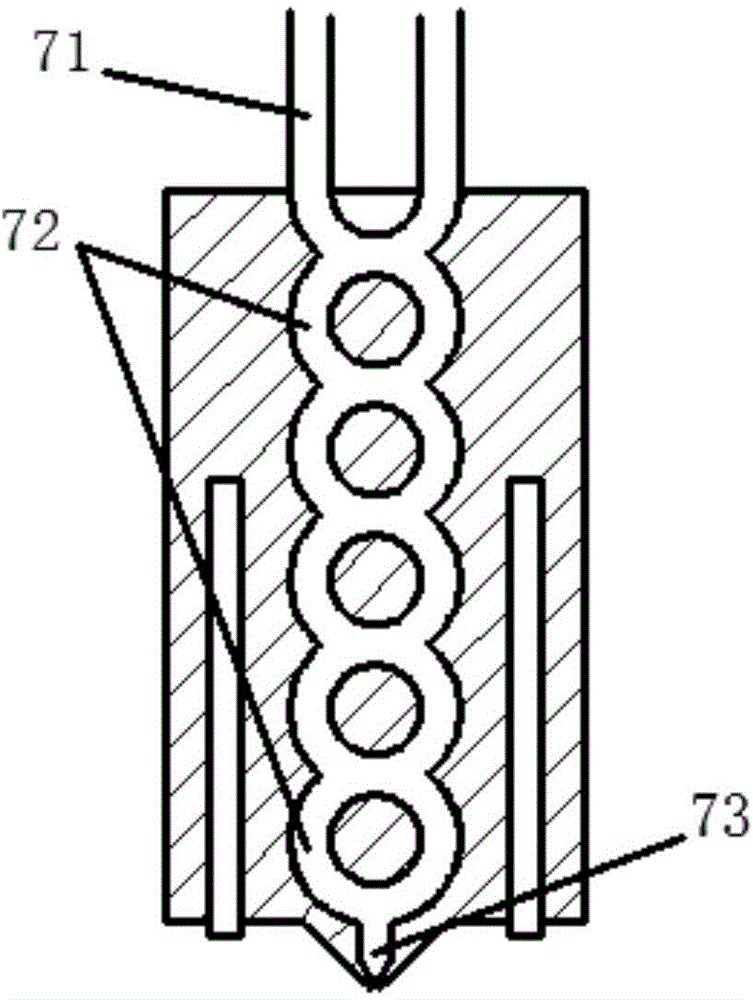

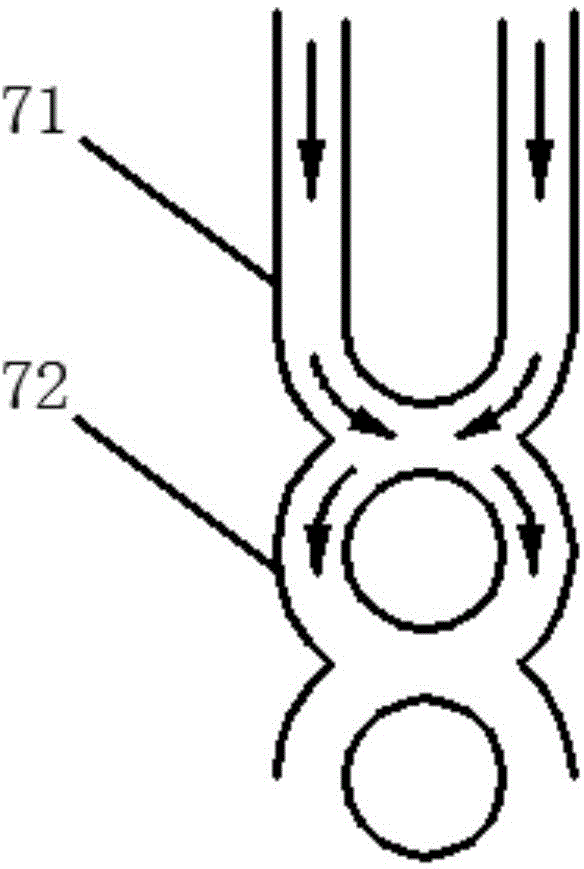

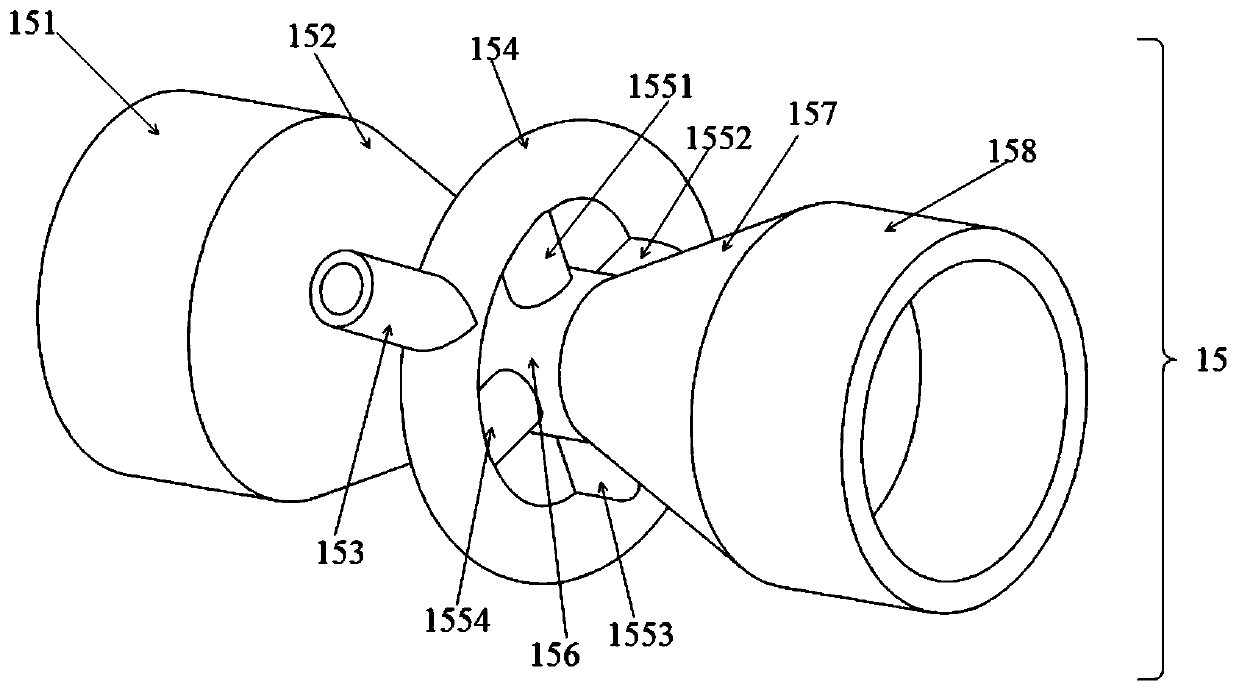

Blender of melt extrusion type color 3D (three-dimensional) printing head

ActiveCN104890247ASolve the problem of impure colorFully mixedAdditive manufacturing apparatus3d printPulp and paper industry

The invention discloses a blender of a melt extrusion type color 3D (three-dimensional) printing head. The blender comprises a blending support, a heating block arranged in the blending support, heating rods inserted into the heating block, a primary blending chamber fixed to the bottom of the heating block, a secondary blending chamber disposed at the bottom of the primary blending chamber and heat insulation rods inserted into the secondary blending chamber, symmetrical inclined planes are arranged on the blending support, and piezoelectric bimorphs are fixed to the symmetrical inclined planes. The secondary blending chamber comprises two vibration reduction feed pipes, an array blending ring and a discharge opening, the upper ends of the vibration reduction feed pipes are communicated with the bottom of the primary blending chamber, the lower ends of the same are connected with the upper portion of the array blending ring, and the bottom of the array blending ring is connected with the discharge opening. Molten materials of three primary colors can be blended fully so as to blend pure material colors, and printing resolution is unaffected in the blending process.

Owner:江苏鸿邦彩印包装有限公司

Air purification composition capable of releasing negative oxygen ions and preparation method and application of composition

ActiveCN105778859AImprove living environmentPromote human healthBiocideOther chemical processesGypsumActivated carbon

The invention relates to an air purification composition capable of releasing negative oxygen ions and a preparation method and application of the composition.The method comprises the steps of 1, material obtaining, wherein 50%-85% by volume of expanded vermiculite, 0.1%-10% by volume of tourmaline and 5%-50% by volume of activated carbon are weighed and serve as the raw materials; 2, material mixing, wherein all the raw materials are mixed through a stirrer and stirred to be uniform, and the air purification composition is obtained.Corresponding air purification products can be prepared by adding the air purification composition to raw material formulas of calcium silicate boards, gypsum boards, cement boards, plywood, coatings, putty and textiles.Compared with the prior art, the air purification composition has the advantages of being capable of releasing the negative oxygen ions, environmentally friendly, high in practicability and the like.

Owner:上海爱迪技术发展有限公司

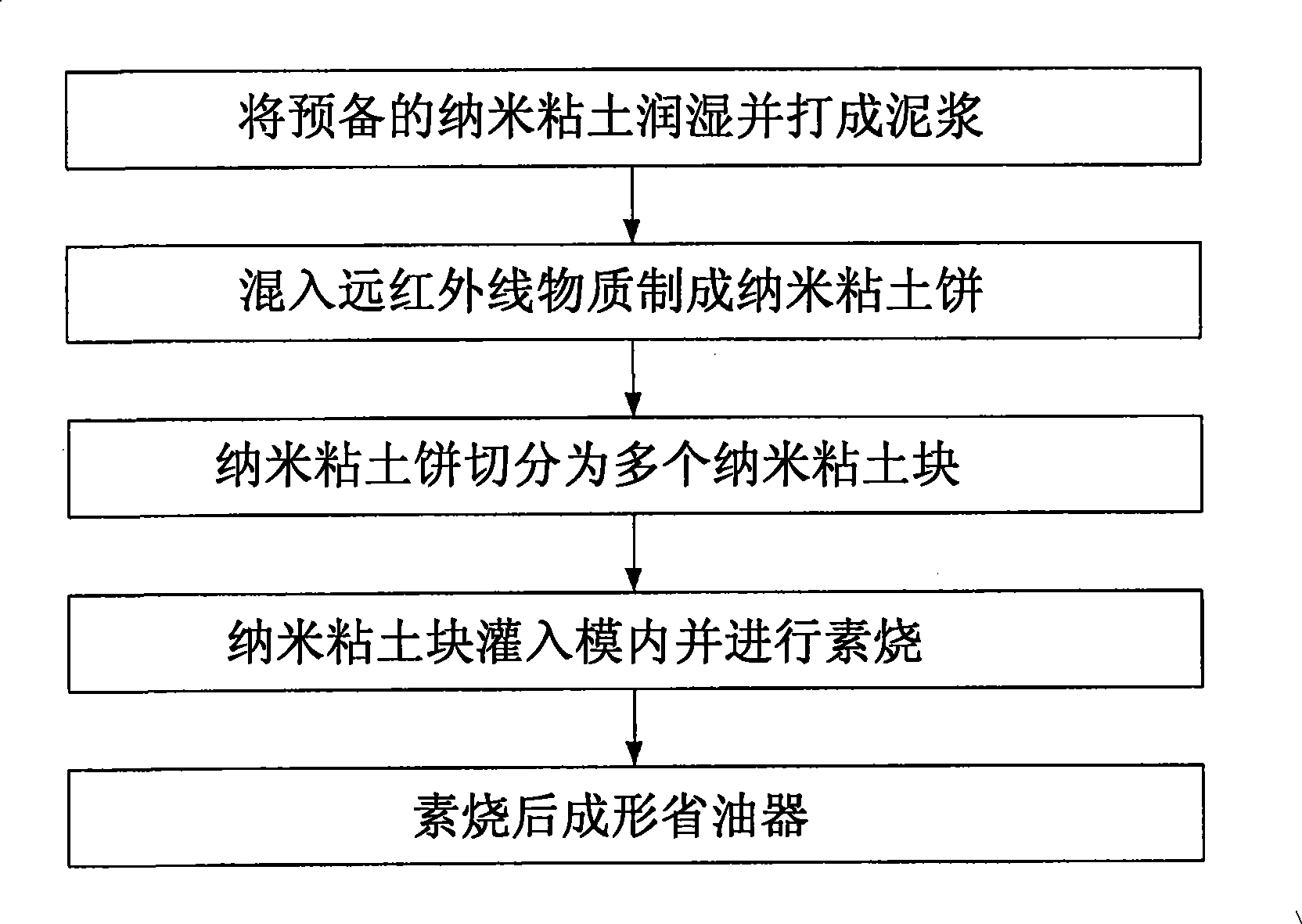

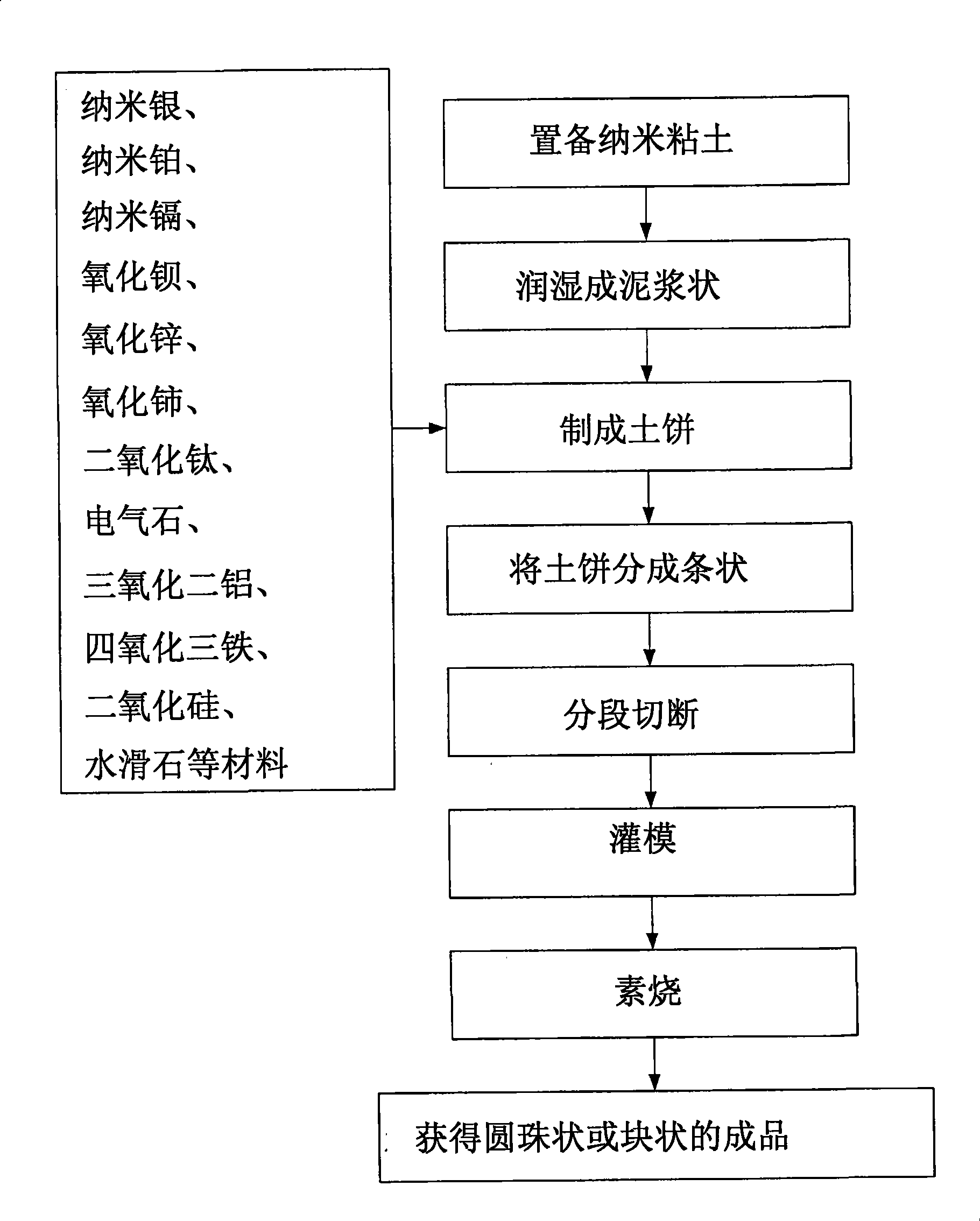

Method for making combined economizer made of ceramic material

InactiveCN101382101AImprove mechanical propertiesImprove heat resistanceCombustion-air/fuel-air treatmentMachines/enginesCombustionComposite ceramic

The invention relates to a method for manufacturing an oil economizer made of composite ceramic materials, wherein the oil economizer is manufactured by means of biscuiting of a nano-clay mixed with far-infrared substances, and is mainly characterized in that the wet nano-clay is pulped into slurry and mixed with the far-infrared substances into a nano-clay pie, and the pie is cut into a plurality of nano-clay blocks which are poured into a die to undergo the biscuiting so as to form the oil economizer. Therefore, after being put into an oil tank, the oil economizer can improve the combustion efficiency of the combustion engine, and improve the durability of the oil economizer at the same time.

Owner:ABA NANO TECH

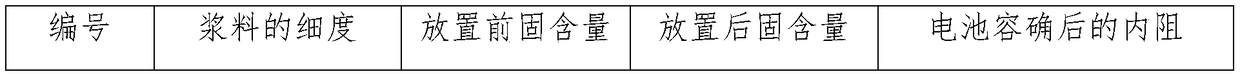

High-efficiency preparation method of lithium ion battery slurry

ActiveCN108923025AShorten the dissolution timePromote decentralizationCell electrodesSecondary cellsSolventElectrochemistry

The invention discloses a high-efficiency preparation method of lithium ion battery slurry. The high-efficiency preparation method of positive electrode slurry and negative electrode slurry of a lithium ion battery comprises: dry-mixing active materials, a binder and a conductive agent, gradually adding the dry mixed powder into a solvent in a stirring state through an oscillation method, and carrying out stirring under the conditions of a certain temperature, revolution and high-speed dispersion without vacuuming conditions to obtain slurry for coating. Through the preparation method, powderis uniformly and rapidly wetted so that stirring time is significantly shortened to only 1h, the production efficiency is significantly improved, the equipment energy consumption and equipment dependency are reduced and the labor cost is saved. The slurry has good consistency and stability. The prepared battery has good electrochemical performances. The method has high efficiency and is especiallysuitable for mass production.

Owner:北京英耐时新能源科技有限公司 +1

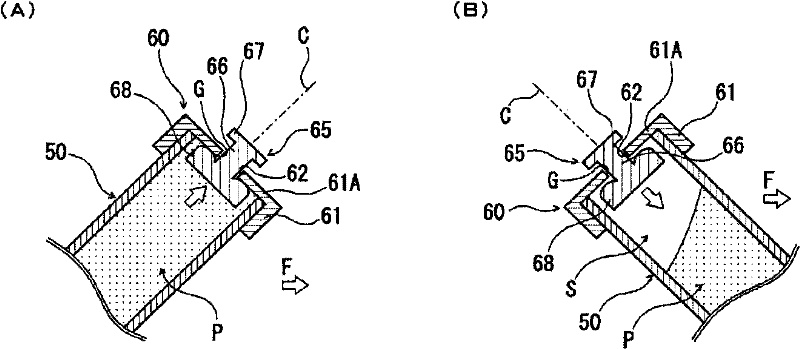

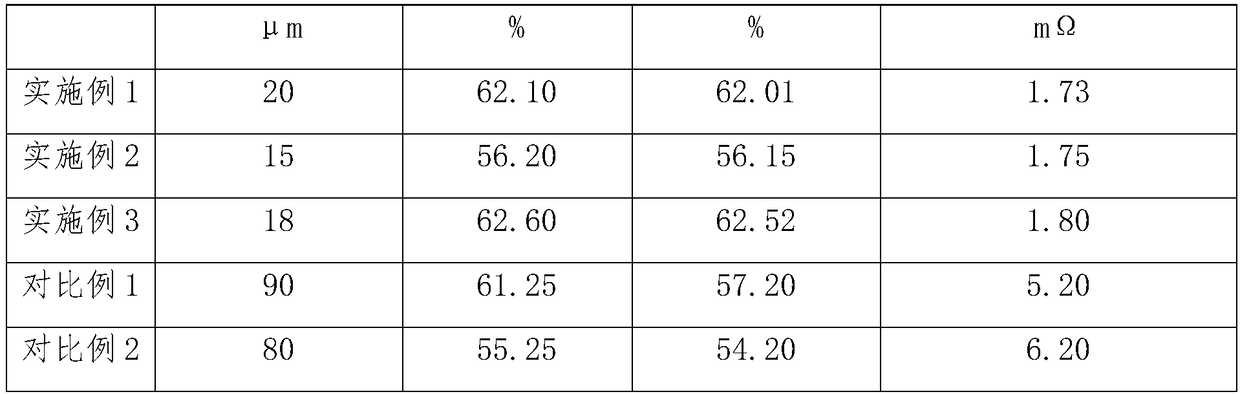

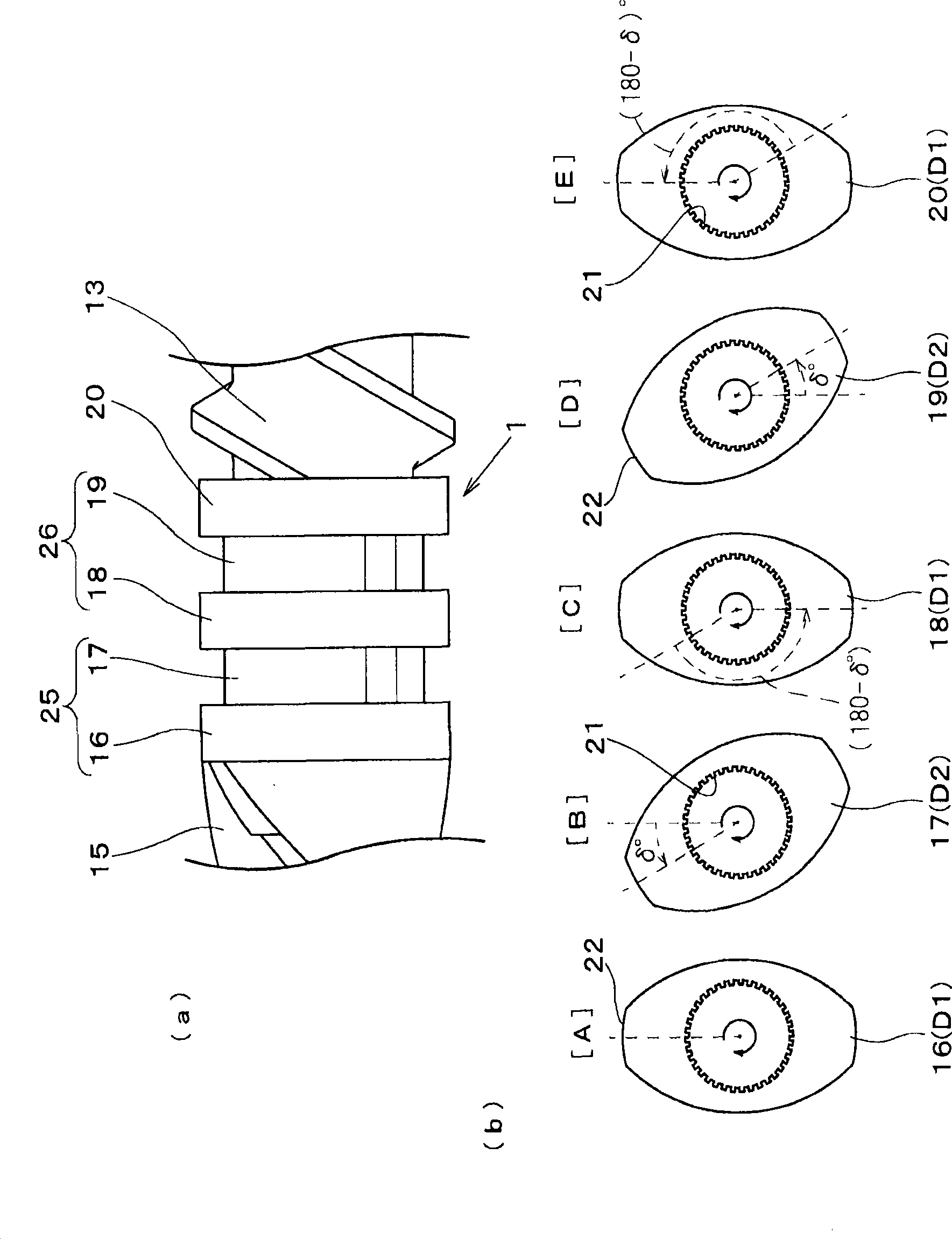

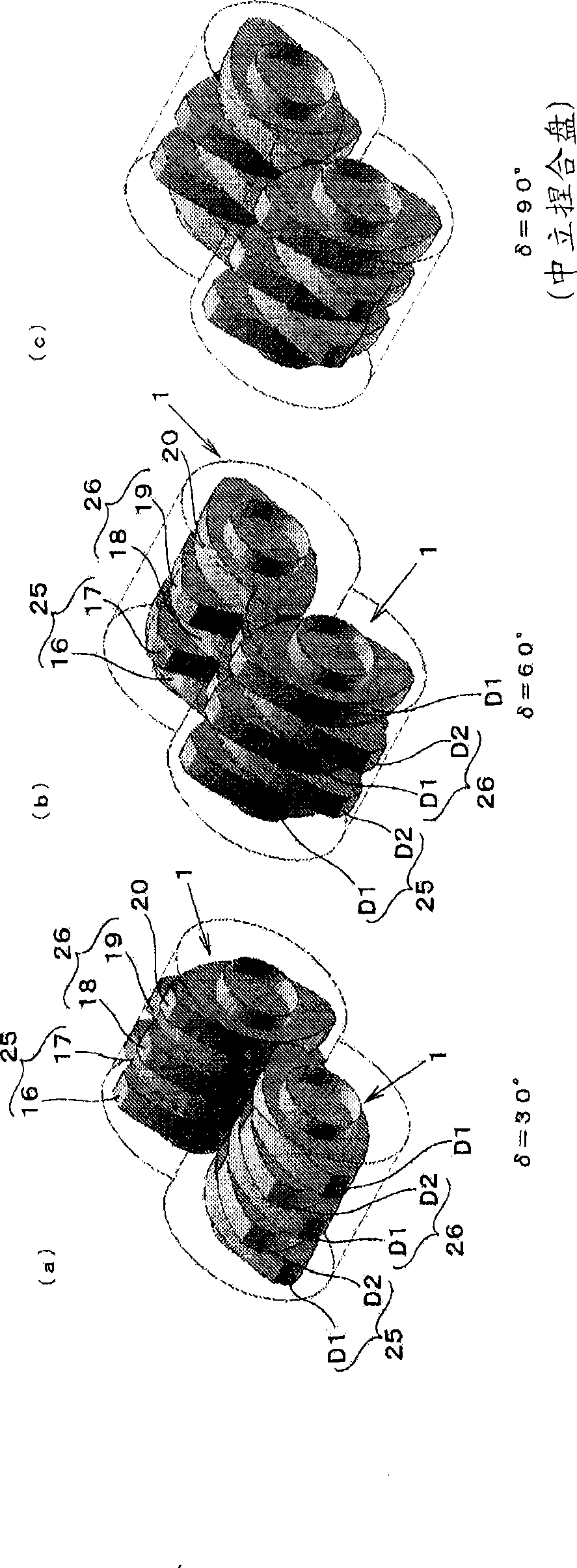

Kneading disc segment and twin-screw extruder

ActiveCN101518926AFully mixedIncrease the degree of mixingTransportation and packagingRotary stirring mixersPhase differenceAcute angle

The kneading disc segment according to the present invention comprises plural disc sets each comprising two kneading discs and mounted on a kneading screw (3) which is for kneading a material while feeding the material to a downstream side. Disc sets each comprising a first kneading disc positioned on an upstream side and a second kneading disc, the second kneading disc being mounted continuously with and downstream of the first kneading disc so as to have a phase difference delta of an acute angle relative to the first kneading disc, are disposed continuously in the axial direction of the kneading screw. The first kneading discs in two continuous disc sets have a phase difference of 180 DEG. With the construction, a higher degree of kneading than in the conventional neutral kneading disc segment can be obtained.

Owner:KOBE STEEL LTD

Composite phase change material for microwave heating energy storage, as well as preparation method and application thereof

InactiveCN110283573ASafe and non-toxicIncentivize cross-developmentHeat-exchange elementsDrinking vesselsMicrowaveMass ratio

The invention discloses a composite phase change material for microwave heating energy storage, as well as a preparation method and application thereof. The composite phase change material comprises a phase change material and graphene, wherein the mass ratio of the phase change material to the graphene is 1:(0.01-0.05); the phase change temperature of the composite phase change material is 54-62 DEG C; the heat of fusion is 200-220 J / g; the density is 0.9 g / cm<3>. According to the composite phase change material for the microwave heating energy storage, as well as the preparation method and application thereof, the design is simple; no harsh environment such as vacuum in the production process is needed; the cost can be reduced; a safer effect is realized; mass production on a large scale can be realized; microwaves are utilized to rapidly heat a vacuum cup and a large amount of heat energy is stored; the daily heat preservation demand for beverages is met; the heat preservation time is long; the cost is saved; no additional device is used.

Owner:XI AN JIAOTONG UNIV

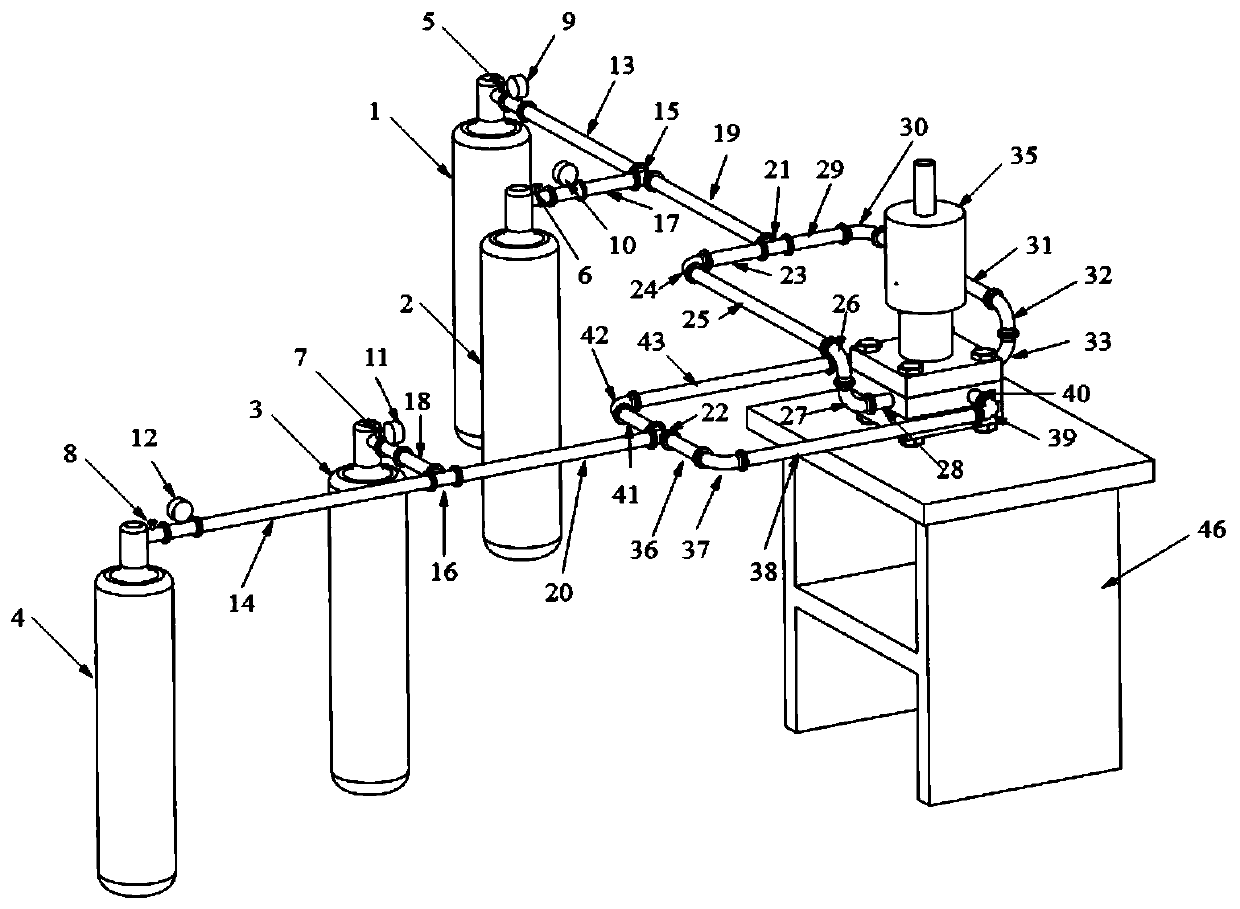

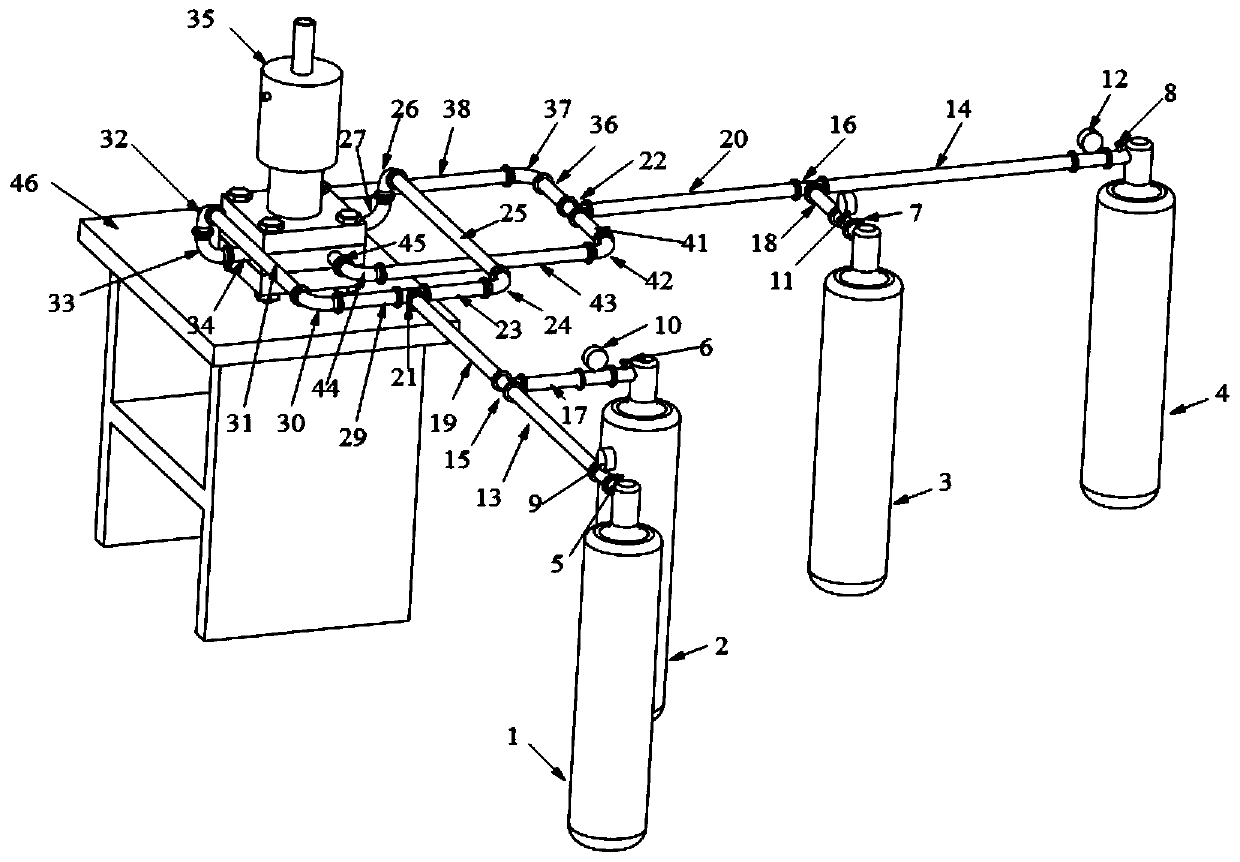

Venturi premixed swirl combustion experiment table

PendingCN110780024AObserve the combustionFully mixedChemical analysis using combustionLaboratory benches/tablesCombustion chamberGas cylinder

The invention discloses a venture premixed swirl combustion experiment table. The experiment table comprises a nitrogen gas cylinder, a methane gas cylinder, an oxygen gas cylinder, valves, flow meters, connecting pipes, venturi tubes, three-way pipes, elbows, a swirl frame outer connecting pipe, a swirl combustor, an igniter and an experiment table body; the swirl combustor comprises a combustionchamber, a combustor front cover, a middle swirl frame, a combustor rear cover, a screw and a nut; the combustion chamber comprises a combustion chamber front section, a combustion chamber rear section, a flue, the igniter, an observation hole and a safety valve. Methane and nitrogen are evenly mixed through the venturi tube, oxygen and nitrogen are evenly mixed through the venturi tube, and thena mixture tangentially enters the swirl combustor to be fully combusted. By adjusting the opening degrees of the valves of different gas cylinders, the flow of gases can be adjusted, and the mixing ratio of the gases is changed. According to the invention, gases with different mixing ratios can be uniformly mixed.

Owner:XI AN JIAOTONG UNIV +1

Polycarboxylic acid and polycarboxylic acid composition containing same, epoxy resin composition, thermosetting resin composition, and cured material of same, and optical semiconductor device

InactiveCN106795125AHigh transparencyHigh hardnessOrganic chemistrySemiconductor/solid-state device detailsEpoxyVitrification

The purpose of the present invention is to provide: a polycarboxylic acid and polycarboxylic acid composition containing the same, an epoxy resin composition, and a thermosetting resin composition having minimal volatility when cured and excellent curing properties, whereby a cured material thereof has excellent transparency and hardness, the glass transition temperature of the cured material can be adequately increased, and excellent moldability and minimal coloring of the cured material are obtained; a cured material of the aforementioned compositions; and a semiconductor device. This polycarboxylic acid is represented by formula (1). (In formula (1), R1 represents a C1-6 alkylene group, and R6 represents a hydrogen atom or a C1-10 organic group containing a carboxyl group. In formula (1), the plurality of R1 and R6 may each be the same or different, but 50 mol% or more of the plurality of R6 are C1-10 organic groups containing a carboxyl group.)

Owner:NIPPON KAYAKU CO LTD

Combination warm and cool mist humidifier

ActiveUS20140151907A1Easy to useImprove efficiencyLighting and heating apparatusEfficient regulation technologiesUltrasonic nebulizersEngineering

A humidifier includes a housing with a substantially open top portion. Water can be added to the humidifier by pouring the water into a water reservoir through an open top. The water is pumped from the water reservoir to an upper portion of the humidifier where it is dispersed into the environment by a flow of air. The humidifier may include both an ultrasonic nebulizer and a heater to provide a warm mix of cool mist and hot vapor. Alternatively, a warm mist can be provided by dispersed water from an ultrasonic nebulizer in combination with warm air. The humidifier may also solely provide a cool mist from an ultrasonic element, or the water can be dispersed using a wicking filter.

Owner:HELEN OF TROY LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com