Kneading disc segment and twin-screw extruder

A technology of kneading discs and sections, which is applied to mixers, mixers with rotating stirring devices, transportation and packaging, etc. It can solve the problems that the mixing degree cannot fully meet the mixing degree, and achieve the effect of high mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

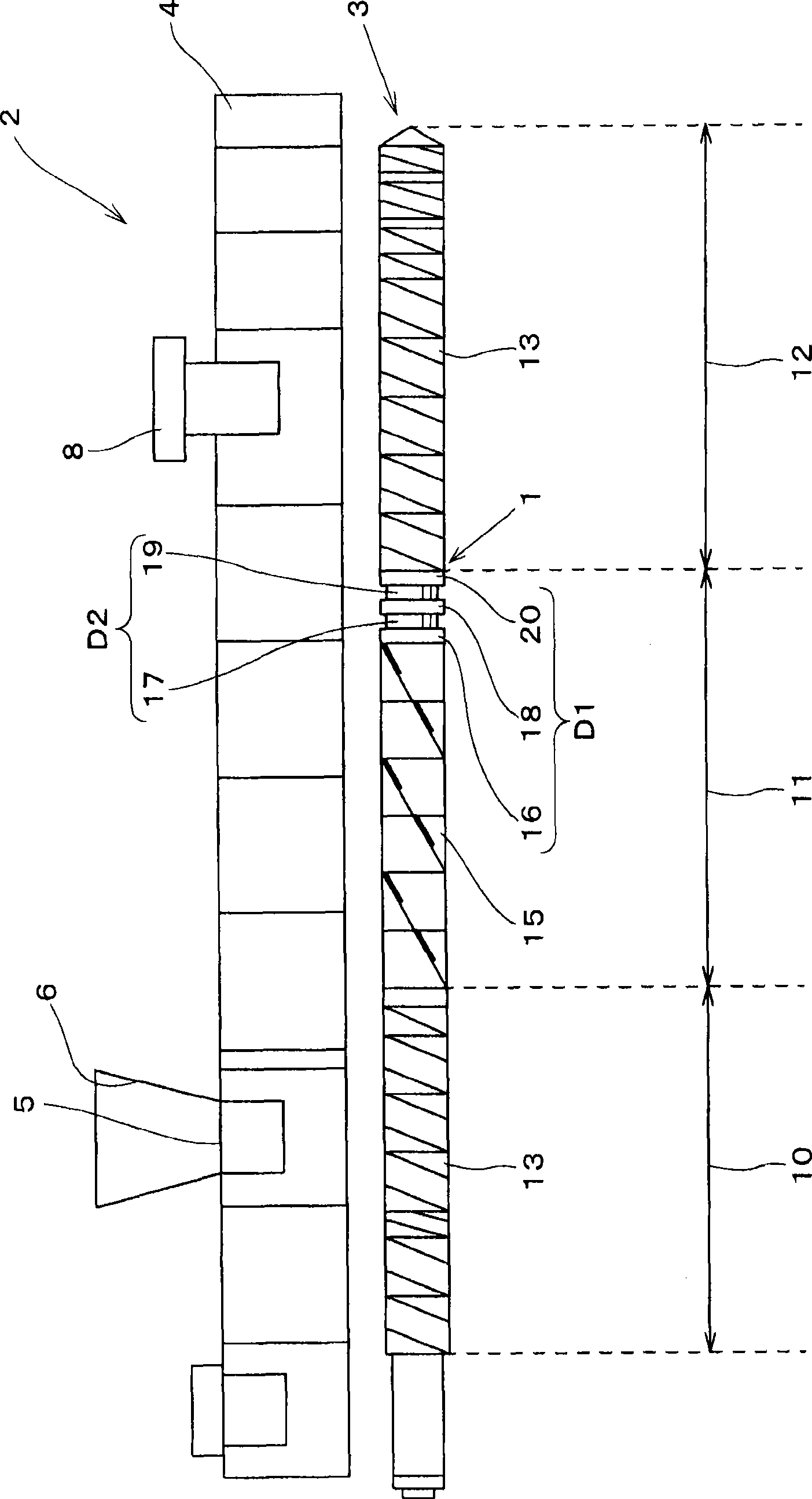

[0026] like figure 1 As shown in the schematic diagram of FIG. 1 , the kneading disc section 1 of the first embodiment is set on the kneading screw 3 of the co-rotating intermeshing twin-screw extruder 2 (hereinafter sometimes simply referred to as the extruder 2.). The twin-screw extruder 2 includes a hollow drum 4 and a kneading screw 3 provided so as to penetrate the inside of the drum 4 in the axial direction. Therefore, in the extruder 2, by supplying the material into the drum 4 and rotating the kneading screw 3, the material in the drum 4 is kneaded and sent to the downstream side.

[0027] Furthermore, in the following description, the figure 1 In the drawing, the left side of the paper is taken as the upstream side when describing the extruder 2, and the right side of the paper is taken as the downstream side. Additionally, the figure 1 The left-right direction of the paper surface in the figure is used as the axial direction when explaining the extruder 2 . Furth...

Embodiment

[0047] The present invention will be described below using Examples and Comparative Examples.

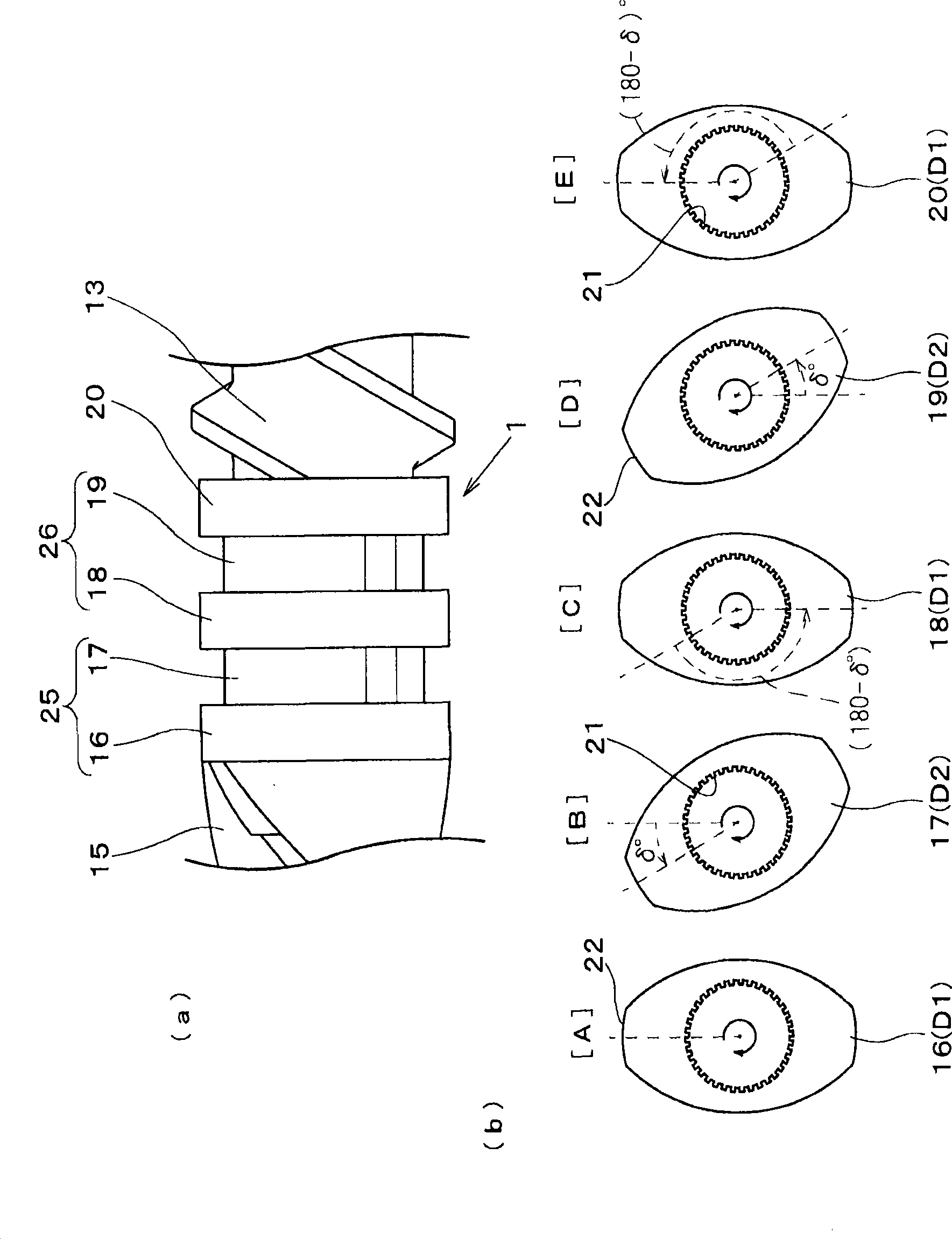

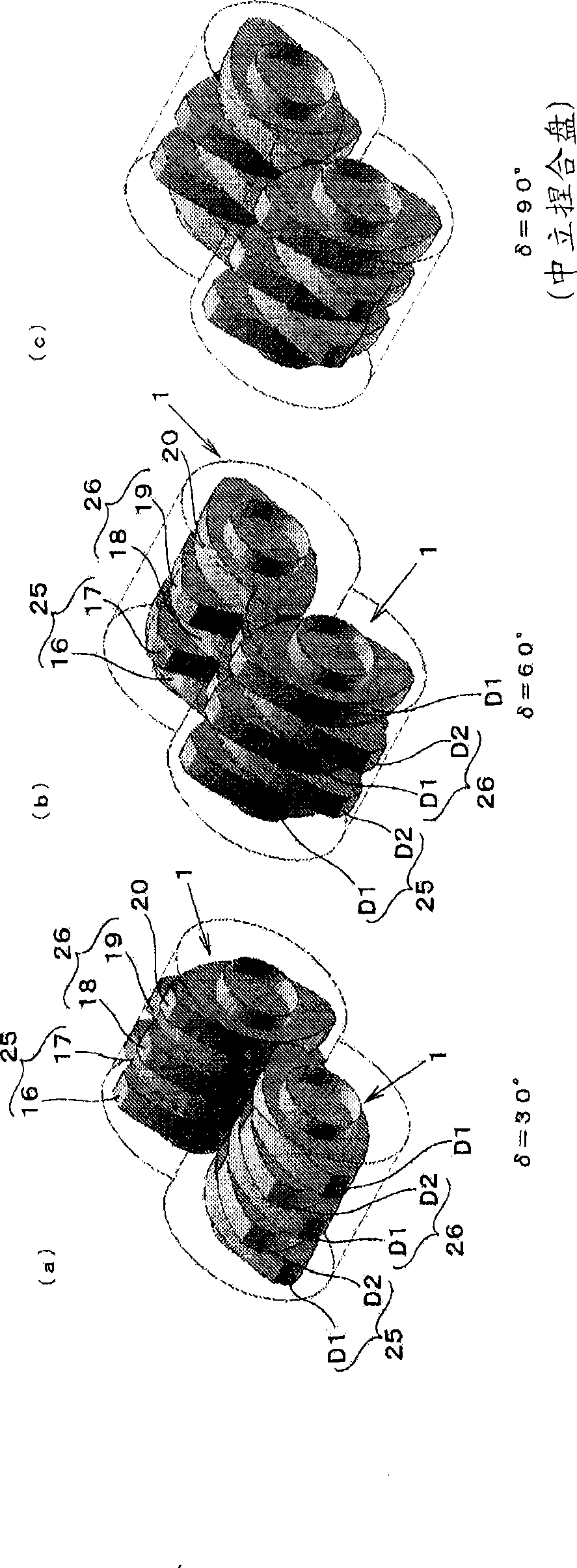

[0048] like image 3 As shown, the influence of the phase difference δ of the first kneading disk D1 and the second kneading disk D2 in the kneading disk section 1 on the degree of kneading was calculated by computer simulation in Examples and Comparative Examples.

[0049] The kneading disk segment 1 used in the simulation has a spline shaft with a shaft diameter of 20 mm in the axial direction, and five kneading disks 16 to 20 are continuously provided on the spline shaft at an initial length of 5 mm from the upstream side. These five kneading disks 16 to 20 are arranged such that, from the upstream side, they are the first kneading disk D1, the second kneading disk D2, the first kneading disk D1, the second kneading disk D2, and the first kneading disk D1. The axis centers of the shafts have a phase difference in the reverse direction of the kneading screw 3 , respectively. lik...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com