High-efficiency preparation method of lithium ion battery slurry

A lithium-ion battery and preparation process technology, applied in the field of lithium-ion batteries, can solve the problems of long time for preparing slurry, high vacuum stirring cost, short stirring time, etc., and achieve the effects of shortening dissolution time, avoiding high cost and accelerating dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

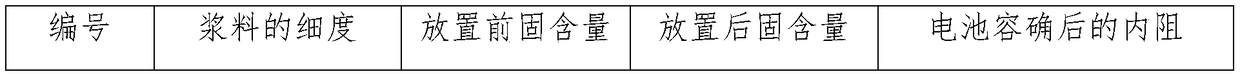

Embodiment 1

[0017] This example is used to illustrate the preparation method of the high-efficiency lithium-ion battery slurry provided by the present invention.

[0018] The positive electrode active material NCM111 (D50=8 μm), the binder PVDF, and the conductive agent HS100 were dry-mixed in a mass percentage of 95%:3%:2% by using a V-type mixer. The powder after dry mixing is added into the solvent under stirring by means of oscillation, the solvent temperature is 60°C, the revolution speed of stirring is 18rmp, the high-speed dispersion speed is 500rmp, and the way of adding into the solvent under stirring by stirring for 6min is as follows: The original design, the test found that it can shorten the stirring time and at the same time, it does not need vacuum defoaming, which greatly reduces the process, saves time and cost.

[0019] The temperature of the stirred tank is kept at 60±5°C, the solid content of the powder in the first step is 68% after being added to the solvent, the rev...

Embodiment 2

[0026] The graphite (D50=9 μm) negative electrode active material, the binder CMC, and the conductive agent SPC were dry-mixed in a mass percentage of 96%:2%:2% dry powder using a V-type blender. The powder after dry mixing was added into the solvent under stirring by means of vibration, the temperature of the solvent was 55°C, the revolution speed of stirring was 17 rpm, the high speed dispersion speed was 450 rpm, and the stirring was carried out for 8 minutes.

[0027] The temperature of the stirred tank is kept at 55±5°C, the solid content of the powder in the first step is 67% after being added to the solvent, the revolution speed is 37rmp, and the high-speed dispersion speed is 1600rmp, stirring for 8min. In the second step, a solvent is added until the solid content is 65%, the revolution speed is 37 rpm, and the high-speed dispersion speed is 1600 rpm, and the mixture is stirred for 8 minutes. In the third step, a solvent is added until the solid content is 63%, the re...

Embodiment 3

[0031] The positive electrode active material NCM111 (D50=6 μm), the binder PVDF, and the conductive agent HS100 were dry mixed in a mass percentage of 94%:3%:3% by using a V-type mixer. The powder after dry mixing was directly added into the solvent, the temperature of the solvent was 58°C, the stirring revolution speed was 16rmp, the high speed dispersion speed was 700rmp, and the stirring was carried out for 8 minutes.

[0032]The temperature of the stirred tank is kept at 58±5°C, the solid content of the powder in the first step is 67% after being added to the solvent, the revolution speed is 38rmp, and the high-speed dispersion speed is 1600rmp, stirring for 9min. In the second step, a solvent is added until the solid content is 65%, under the conditions of a revolution speed of 38 rpm and a high-speed dispersion speed of 1600 rpm, and stirring for 9 minutes. In the third step, a solvent is added until the solid content is 63%, under the conditions of a revolution speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com