Patents

Literature

192results about How to "Reduce the number of units" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

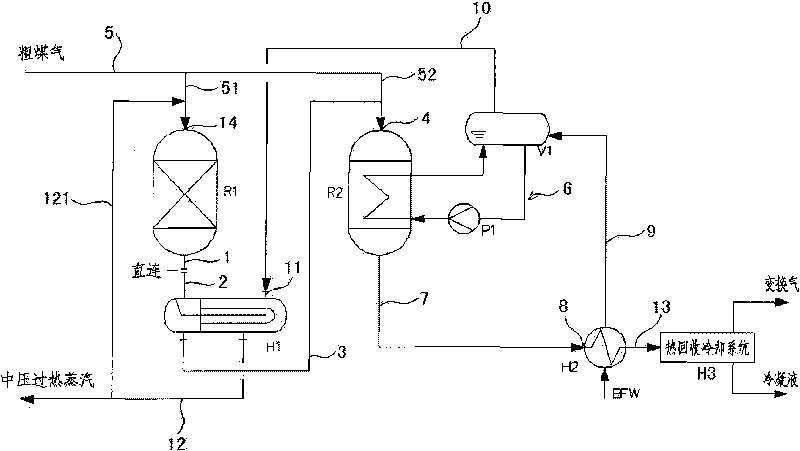

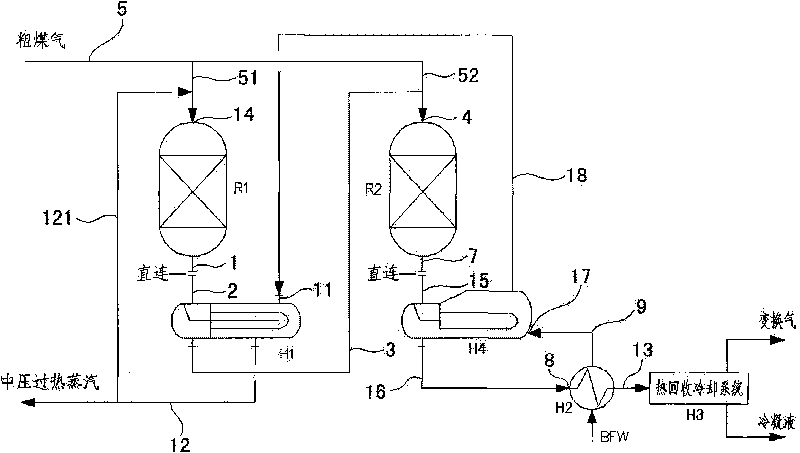

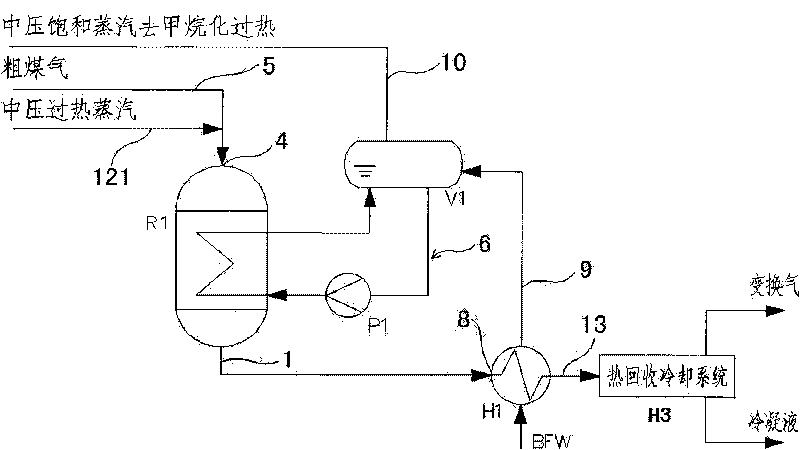

Shunting-type isothermal sulfur-tolerant conversion process and equipment thereof

ActiveCN101704513ASatisfy conversion rate requirementsMeet the requirements of adiabatic conversion control temperature riseHydrogenChemical industryShunt typesSulfur

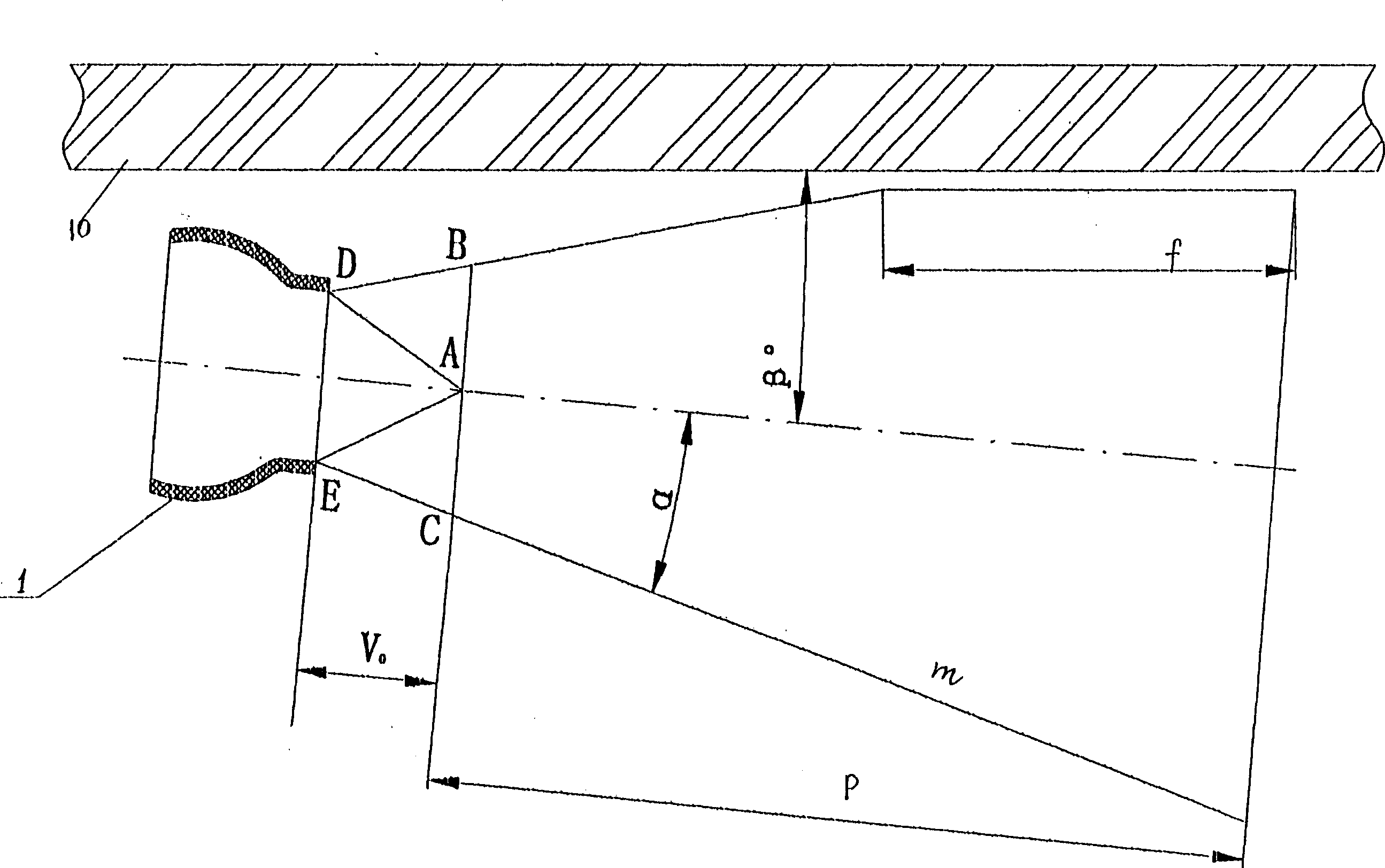

The invention discloses a shunting-type isothermal sulfur-tolerant conversion process. The process comprises the following steps: shunting raw coal gas from exterior into at least two parts; leading overheat stream in the first part of the raw coal gas to increase the temperature to 200-300 DEG C; and then entering a first-stage conversion reaction step to carry out a conversion reaction and generate first conversion gas; and conveying the other part of the raw coal gas to next-stage conversion reaction step to carry out a conversion reaction. The catalyst bed of a shift converter has the advantages of stable temperature, simple control, convenient operation and low output CO content. The invention has the advantages of short conversion flows, few equipment, reduced resistance, great byproduct stream amount, high overheat temperature, stream pressure and heat recovery rate, and the like, thereby achieving the aims of reducing conversion stages, equipment number and resistance fall, decreasing investment, having great byproduct stream amount and high overheat temperature, stream pressure and heat recovery rate, reducing conversion stream consumption and outward wastewater discharge, protecting the environment and easily maximizing the device equipment. The invention also discloses shunting-type isothermal sulfur-tolerant conversion equipment used by the process.

Owner:SHANGHAI INT ENG CONSULTING

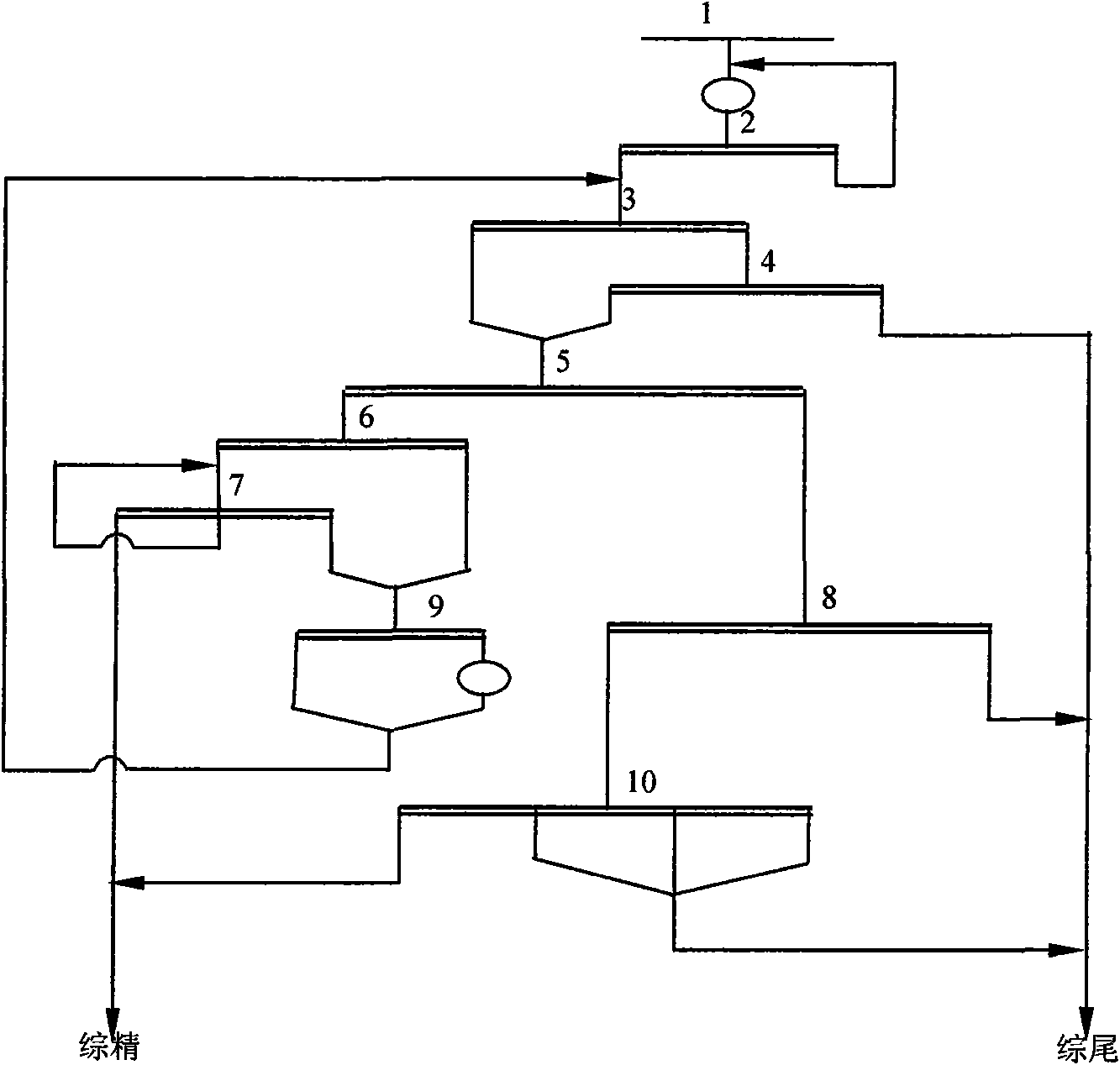

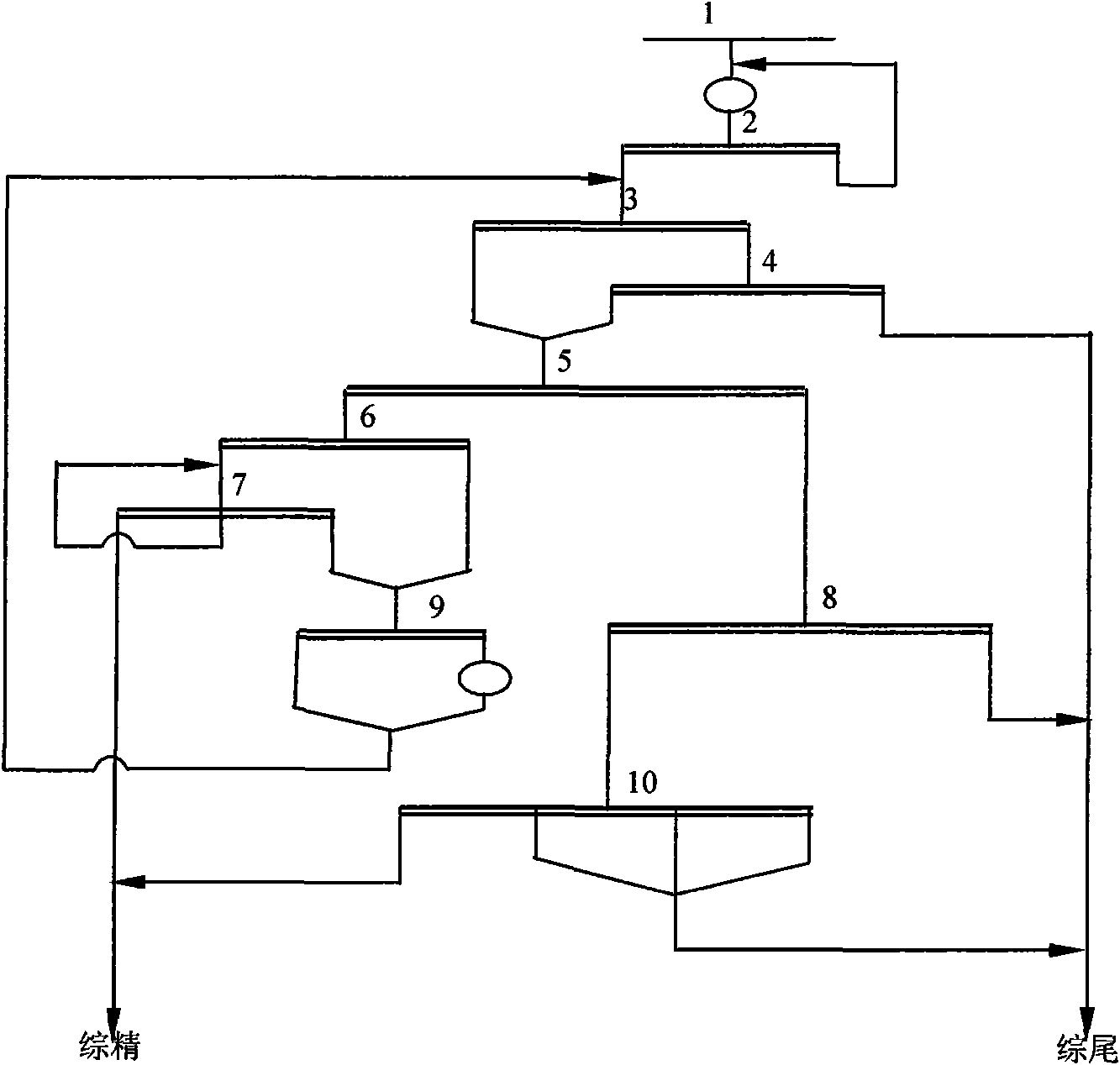

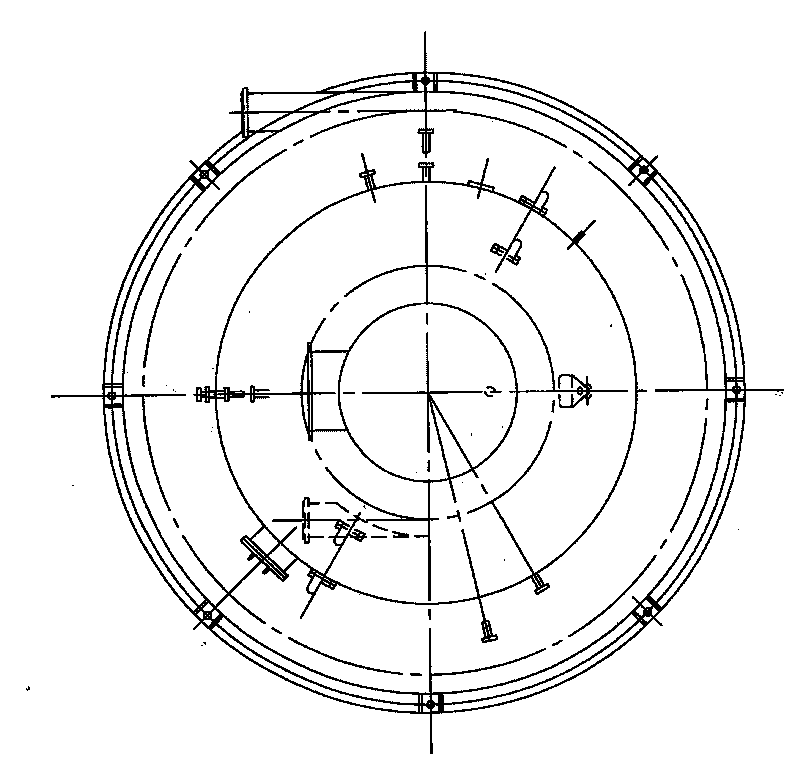

Benefication technology of extra poor hematite

ActiveCN101927209AReduce the amount of regrindReduce overgrindingWet separationOre concentrateBall mill

The invention relates to a benefication technology of extra poor hematite, which is characterized by comprising the following steps: feeding a raw ore in a closed circuit grinding system composed of a primary ball mill and a spiral classifying mechanism, feeding in a weak magnetic machine for benefication after primary classification and overflow, feeding the weak magnetic tailing in a strong magnetic machine, feeding a mixed magnetic concentrate composed of a weak magnetic concentrate and a strong magnetic concentrate in a spiral chute, obtaining a selected spiral concentrate as a coarse grain concentrate after the coarse grains are subjected to two-stage spiral chute benefication, performing self-circulation on the middling in the selected spiral chute, forming the middling by a roughly selected spiral tailing and a selected spiral tailing, feeding the middling in an open circuit grinding system composed of secondary classifying and secondary grinding for re-grinding, returning to the weak magnetic machine after re-grinding, feeding the overflow of a swirler after benefication of a centrifuge into a table for benefication, merging a table middling, table slurry and a table tailing into a table tailing, merging the strong magnetic tailing, a centrifugal tailing and a table tailing as a final tailing, and merging the selected spiral chute concentrate and the table concentrate into a final concentrate. The invention can improve the milling grade of follow-up operations of the extra poor hematite, reduce the re-grinding amount of the middlings, and is favor of acquiring better beneficiation indexes.

Owner:鞍钢集团矿业设计研究院有限公司

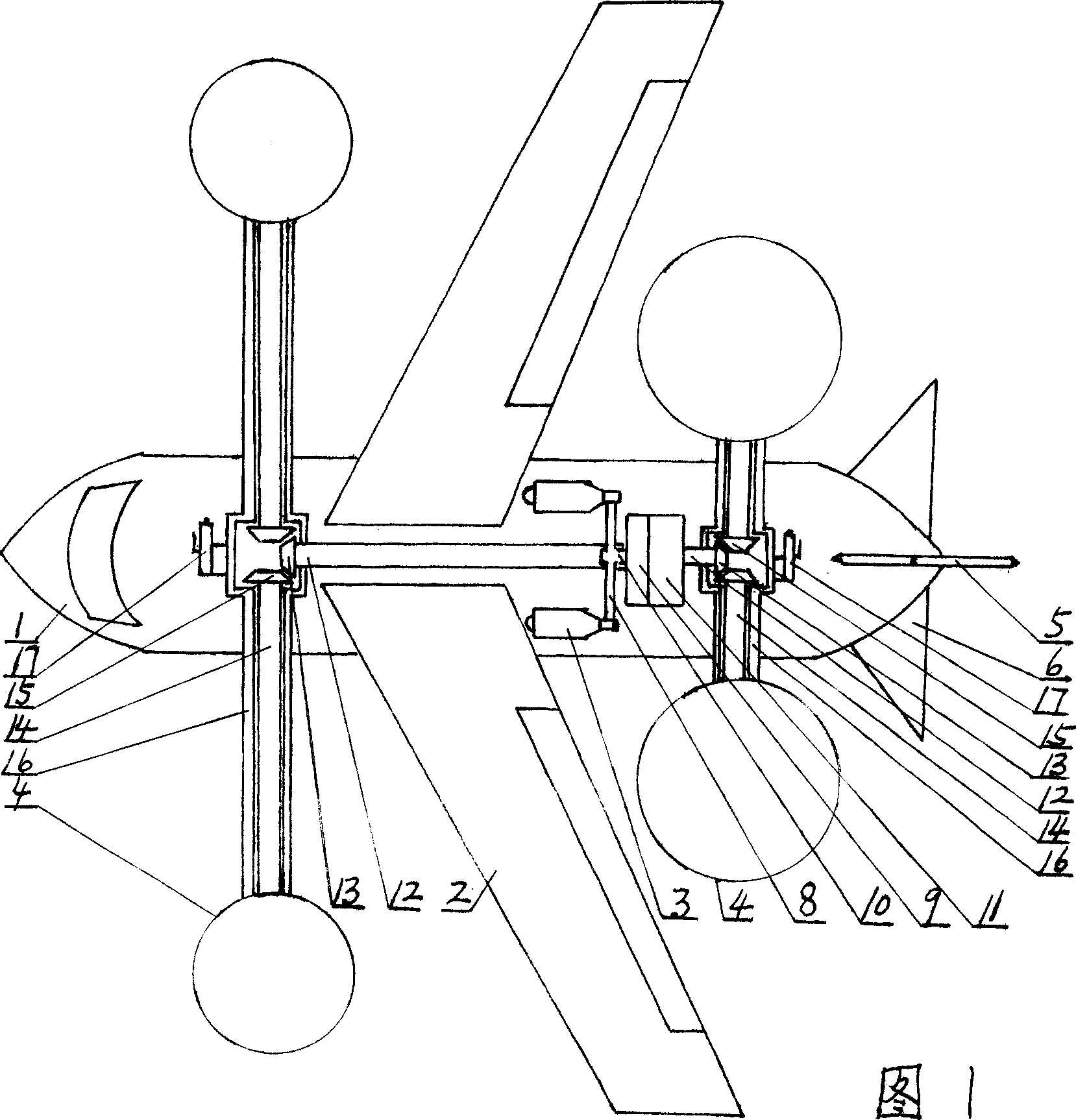

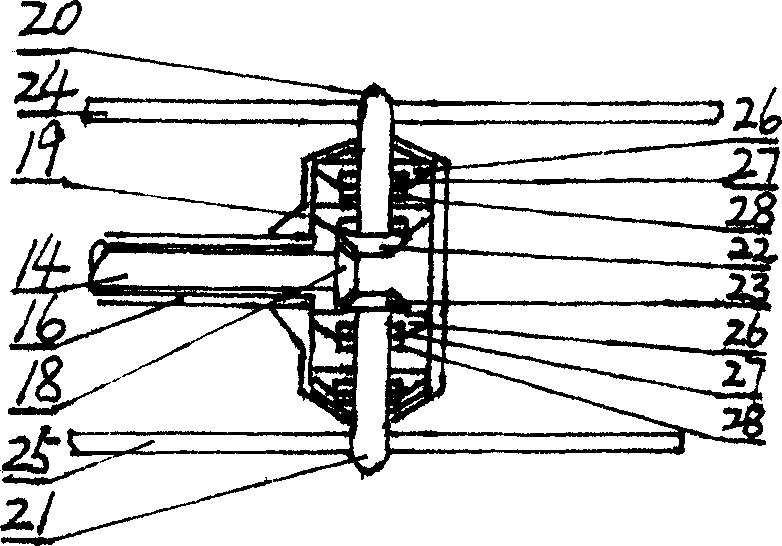

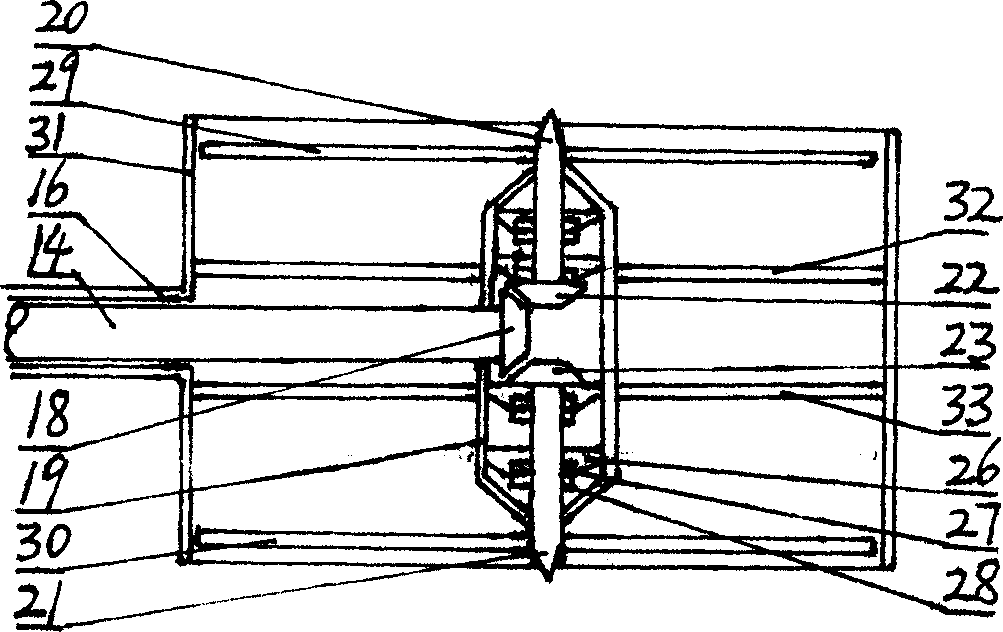

Vertical take-off and landing aircraft

InactiveCN1754777AReduce the number of enginesOil shortVertical landing/take-off aircraftsFlight vehicleAirplane

This invention discloses one vertical lift plane, which relates to one aviator and to one inclined rotation fan or inclined channel fan pusher vertical plane, which comprises plane body, main wing, motor, pusher, vertical tail wing, level tail wing, lift rack and other device. The invention is characterized by the following: power from at least one motor is concentrated through central gear or decelerator through drive power system to distribute on machien gravity or main wing front and back. The left and right inclined axis end can pass level and vertical rotation to seaprte pusher front projection.

Owner:李环

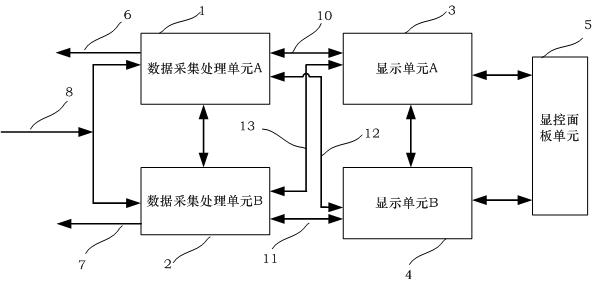

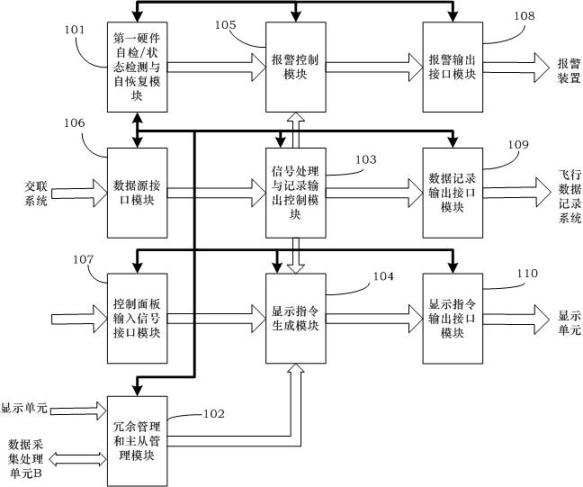

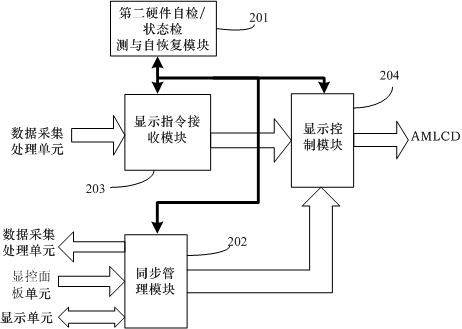

Integrated display system for aircraft engine parameters and air service information and construction method thereof

InactiveCN101923739ARelieve congestionFlexible and diverse display formsRegistering/indicating working of vehiclesData switching networksFlight vehicleDriver/operator

The invention provides an integrated display system for aircraft engine parameters and air service information and a construction method thereof, wherein, the integrated display system processes and displays the aircraft engine parameters and air service information data. The integrated display system mainly comprises two data acquisition and processing units, two display units and a display control panel unit, wherein, the data acquisition and processing units process the data and output the processed data to the display units, and a user controls the display units to display through the display control panel unit. The construction method of the integrated display system comprises the following steps: carrying out functional requirement analysis on the system, dividing target tasks, constructing a system architecture using a SMART structure, and finally judging whether various indexes meet the requirement. The integrated display system and the construction method thereof of the invention adopts an integrated architecture, thus improving man-machine efficacy, reducing workload of a driver, improving working efficiency, enhancing system reliability and lowering cost; and by adopting main and auxiliary hot backup redundant strategies, the system reliability is improved.

Owner:BEIHANG UNIV

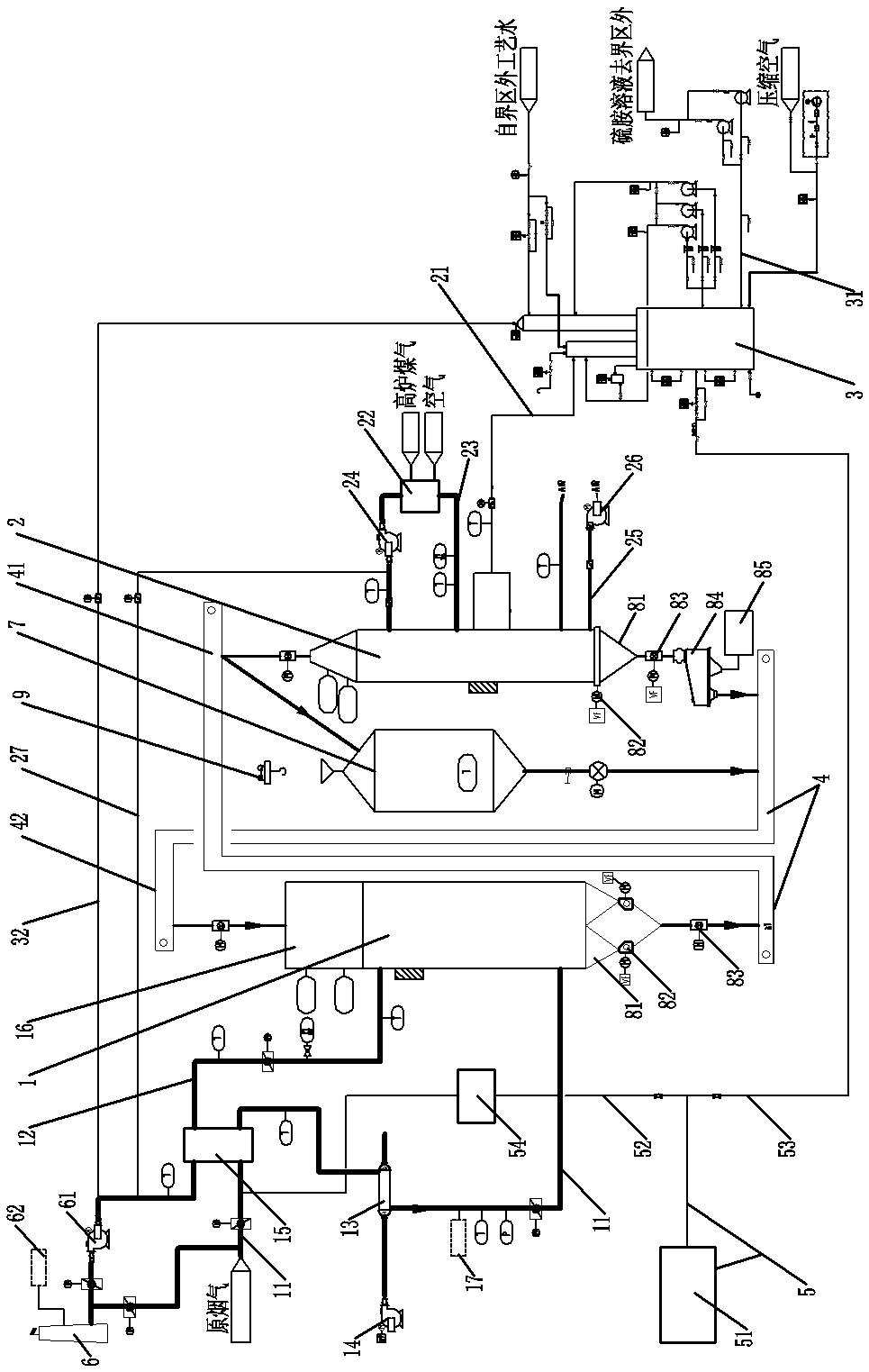

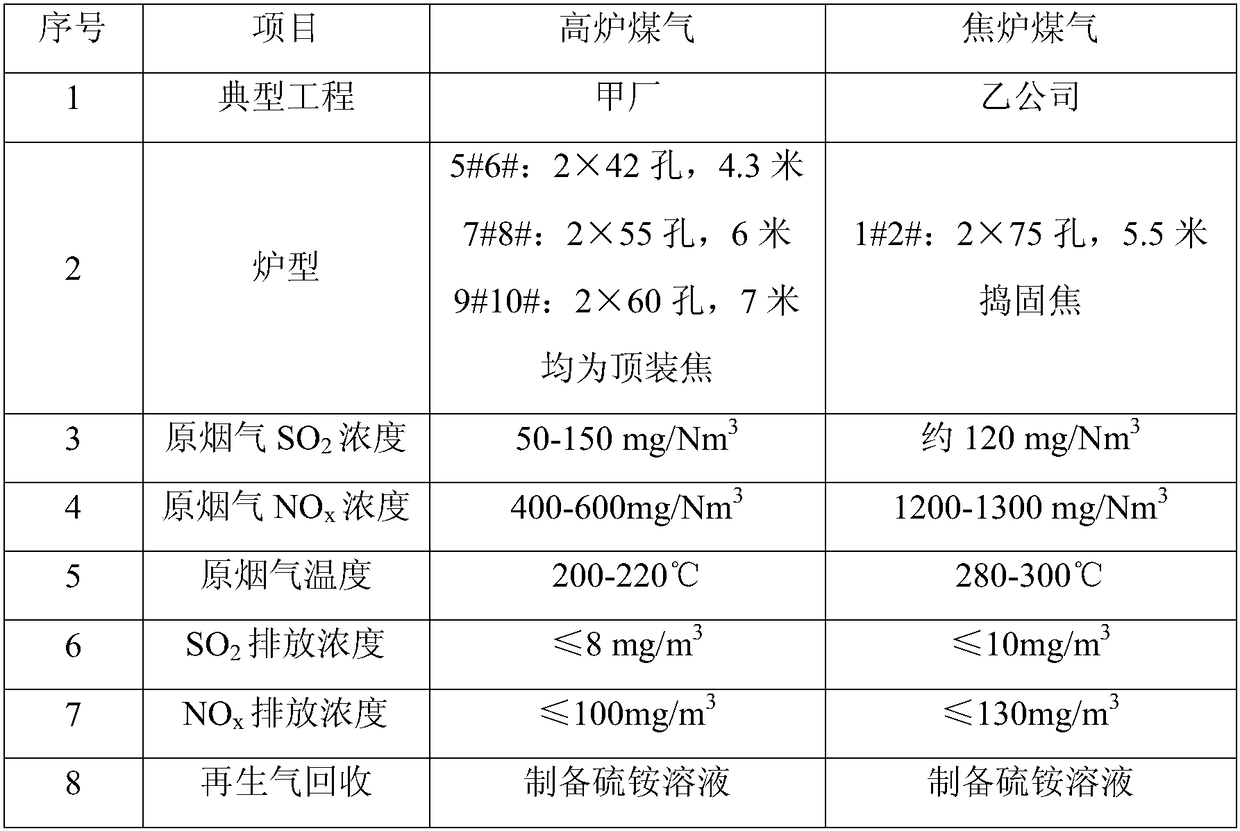

Activated carbon/coke-based coke oven flue gas desulfurization and denitration system and activated carbon/coke-based coke oven flue gas desulfurization and denitration method

PendingCN108380041AReduce escapeWell mixedGas treatmentDispersed particle separationEngineeringAmmonium sulfate

The invention discloses an activated carbon / coke-based coke oven flue gas desulfurization and denitration system and an activated carbon / coke-based coke oven flue gas desulfurization and denitration method. The flue gas desulfurization and denitration system comprises an activated carbon / coke flue gas purification tower, an activated carbon / coke regeneration tower, a chimney, an ammonia water injection system and an absorption tower, wherein an activated carbon / coke conveyor is arranged between the purification tower and the regeneration tower; the regeneration tower is connected with a high temperature heating system and a regenerated gas pipeline; the ammonia water injection system comprises an ammonia water container; the ammonia water container is connected with a first ammonia water pipeline and a second ammonia water pipeline which are arranged in parallel; the first ammonia water pipeline and the second ammonia water pipeline are respectively communicated with the interiors of aflue gas inlet pipeline and the absorption tower; the bottom of the absorption tower is connected with an ammonium sulfate solution pipeline, and the top of the absorption tower is connected with a waste gas exhaust pipeline; the regenerated gas pipeline is communicated with the interior of the absorption tower; a purified gas exhaust pipeline and the waste gas exhaust pipeline are communicated with the chimney; the activated carbon / coke conveyor comprises an old material conveyor used for conveying activated carbon / coke at the bottom of the purification tower onto the top of the regenerationtower, and a new material conveyor used for conveying activated carbon / coke at the bottom of the regeneration tower onto the top of the purification tower.

Owner:南京泽众环保科技有限公司

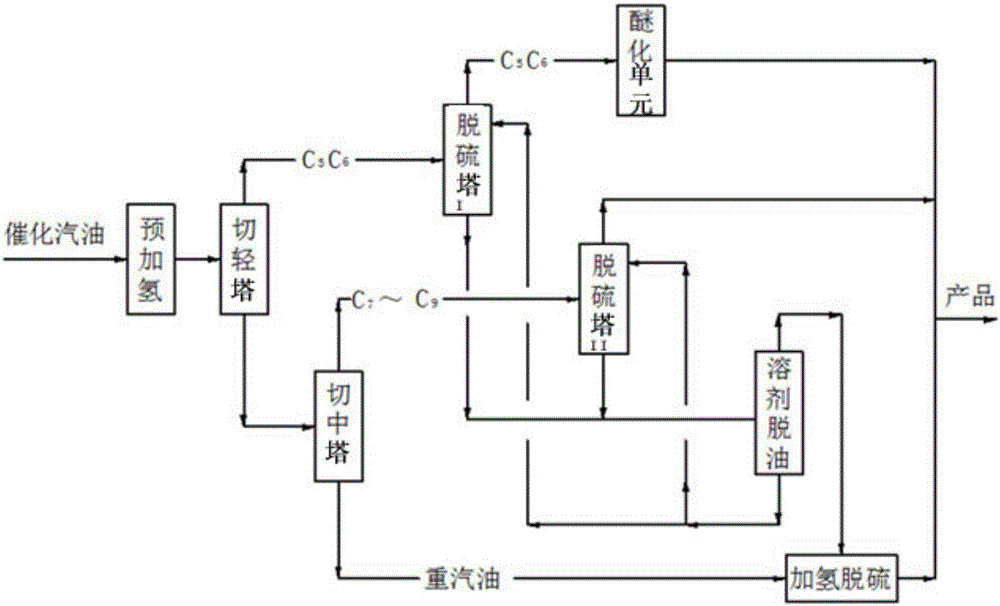

Catalytic gasoline desulfurization method capable of satisfying maximum light gasoline etherification olefin reduction demands

ActiveCN106381168AGood energy saving effectAvoid condensationTreatment with hydrotreatment processesHydrocarbon oils treatment productsGas phaseExtractive distillation

The invention provides a catalytic gasoline desulfurization method capable of satisfying maximum light gasoline etherification olefin reduction demands. The method comprises the following steps: after carrying out prehydrogenation treatment on catalytic gasoline, cutting into gasoline light fractions mainly composed of C5 and C6, gasoline middle fractions mainly composed of C7-C8 or C7-C9 fractions and gasoline heavy fractions; directly carrying out adsorption distillation desulfurization treatment on the light fractions in the gas state, cooling, and carrying out etherification olefin reduction for later use; carrying out extractive distillation desulfurization treatment on the gasoline middle fractions in the saturated gas phase or gas-liquid mixed phase for later use; and carrying out selective hydrotreating desulfurization on the gasoline heavy fractions, and finally, mixing with the treated light and middle fractions to obtain the deep-desulfurized catalytic gasoline. The method satisfies the requirements of the gasoline maximum etherification process, and lowers the olefins and prevents the catalytic gasoline octane number from reduction in the catalytic gasoline desulfurization process. The technique has the advantages of fewer devices and simple process. The light and middle fraction desulfurization adopt gas-phase or gas-liquid mixed phase feeding, thereby avoiding the secondary vaporization and condensation in the process from distillation cutting to distillation desulfurization, and having obvious energy-saving effects.

Owner:洋浦中溢化工有限公司

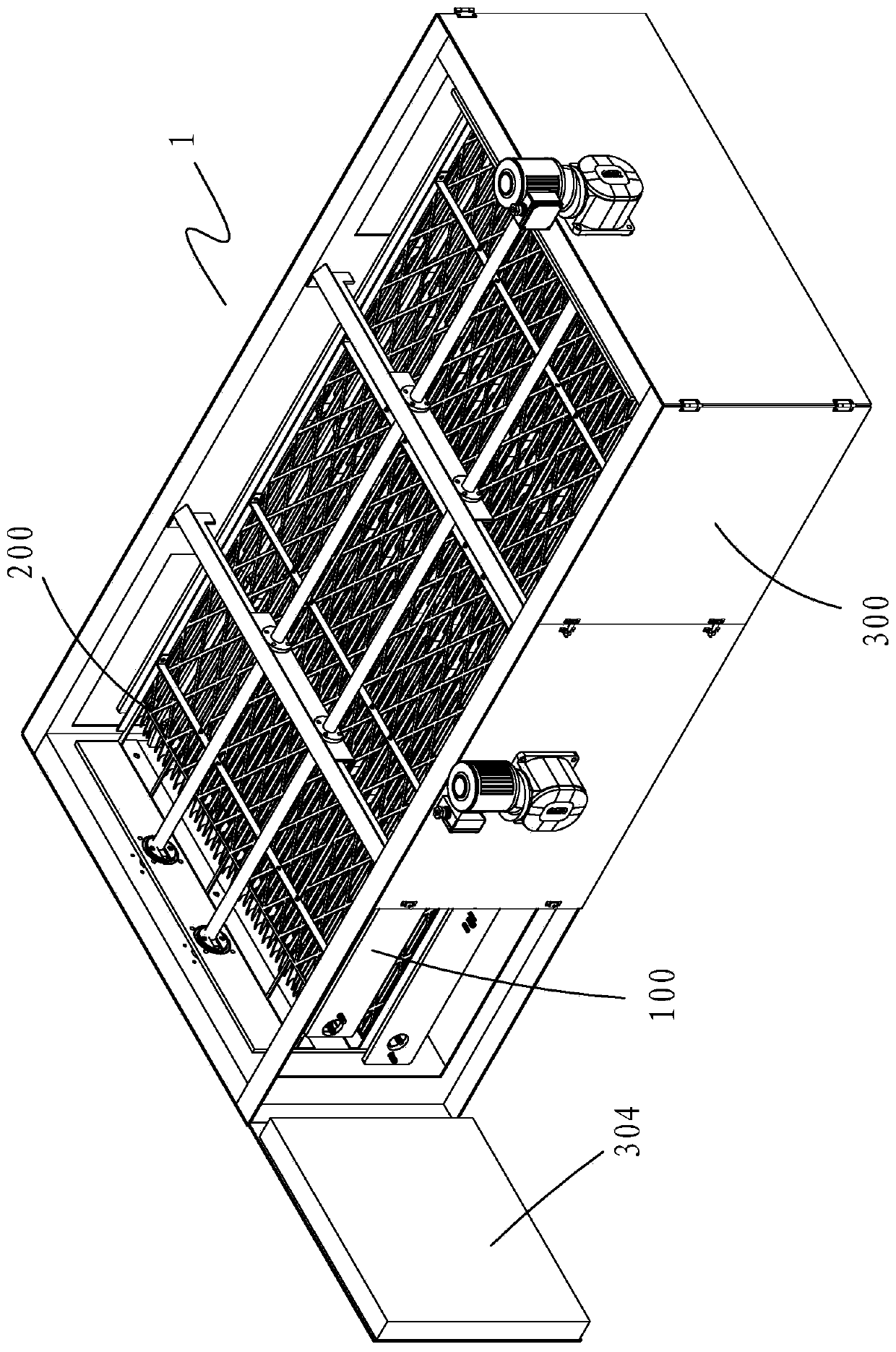

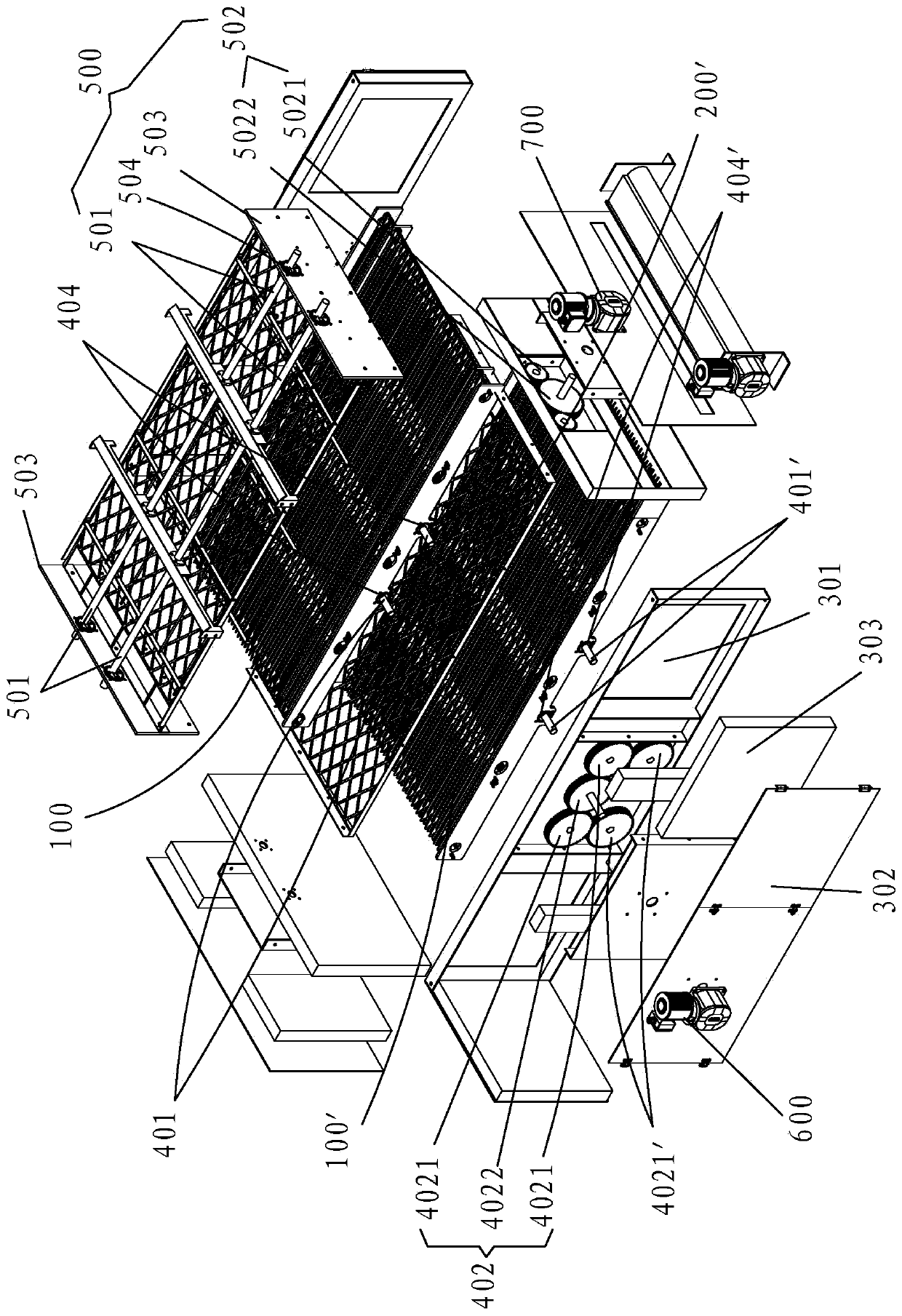

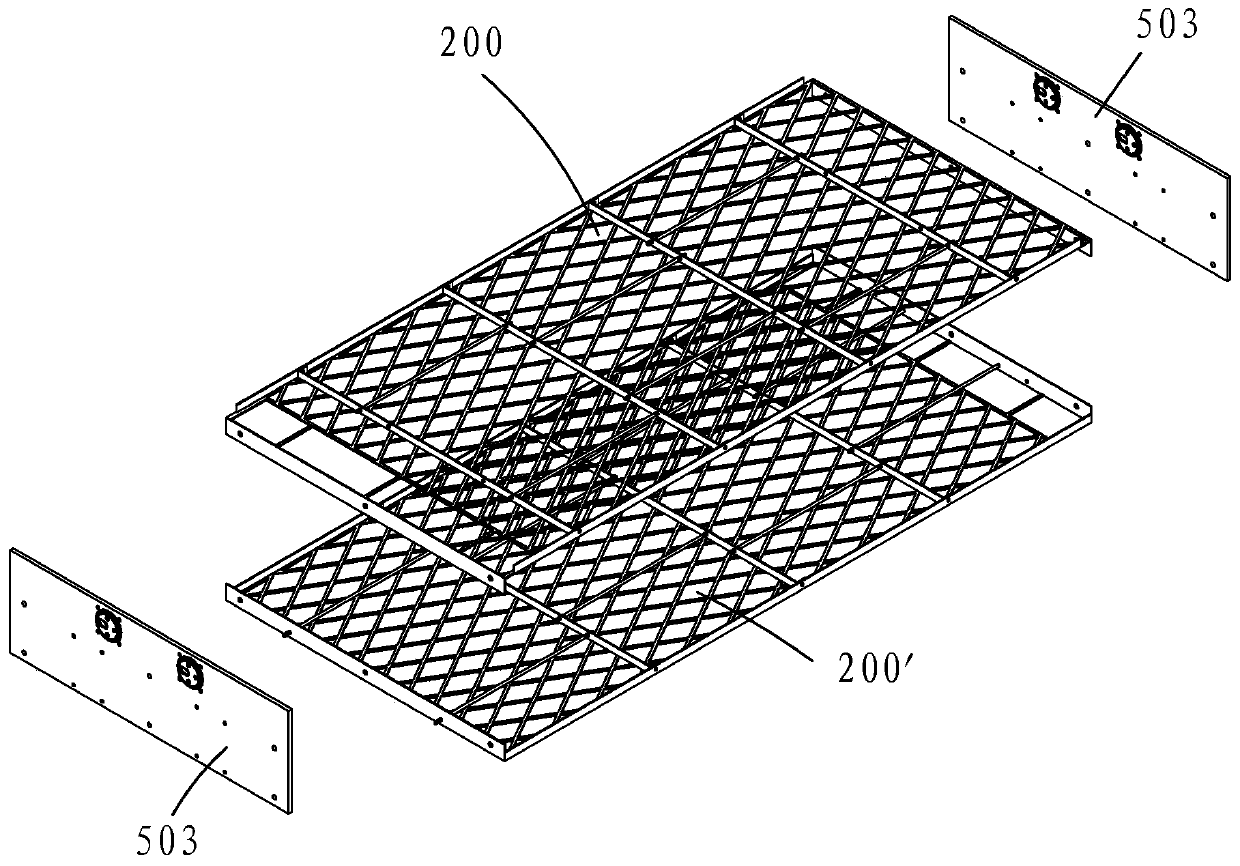

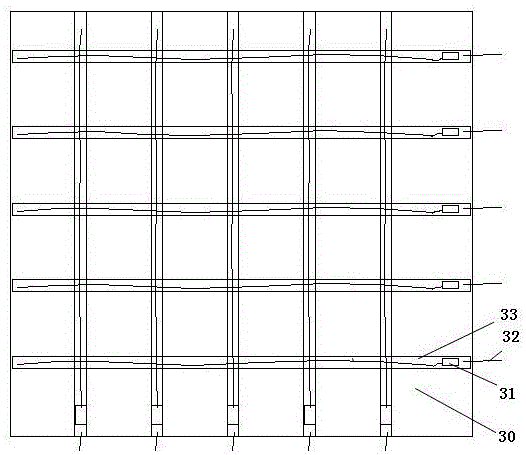

Material grinding and conveying module and drying chamber thereof

PendingCN111377588AFully rolledEvenly distributedSludge treatment by de-watering/drying/thickeningElectric machineEngineering

A material grinding and conveying module comprises a conveying platform composed of grid bar assemblies, a grinding device arranged above the conveying platform and a supporting frame. A first motor drives a first driving mechanism to drive the conveying platform to do reciprocating synchronous circular motion to bear and propel materials to advance; the grinding device comprises a grinding platform and a second driving mechanism; a second motor drives the second driving mechanism to drive the grinding platform to do reciprocating type synchronous circular motion perpendicular to the pushing direction of the materials to grind and scrape the materials; the second motor alternately performs forward rotation and reverse rotation, and the forward rotation time is equal to the reverse rotationtime. A drying chamber comprises a material grinding and conveying module, and the number of the material grinding and conveying module is one or more than one which are stacked. The grinding platform conducts grinding in the forward direction and the reverse direction, materials can be more evenly distributed on the conveying platform, the evaporation area is increased, and the drying efficiencyis improved.

Owner:AMCON FUJIAN ENVIRONMENT PROTECTION EQUIP CO LTD

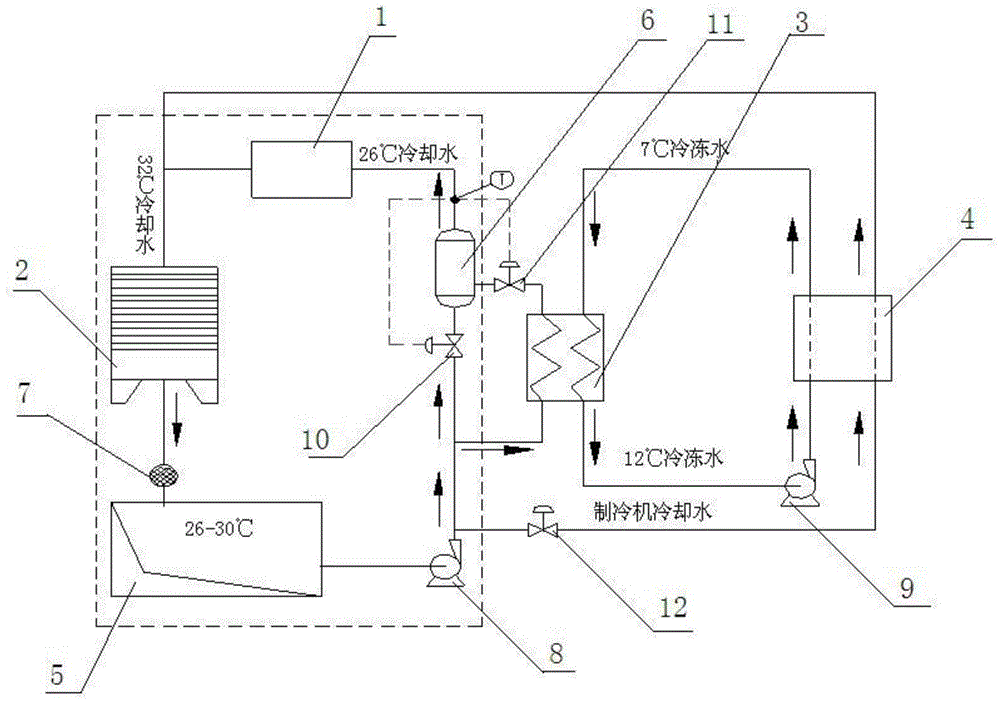

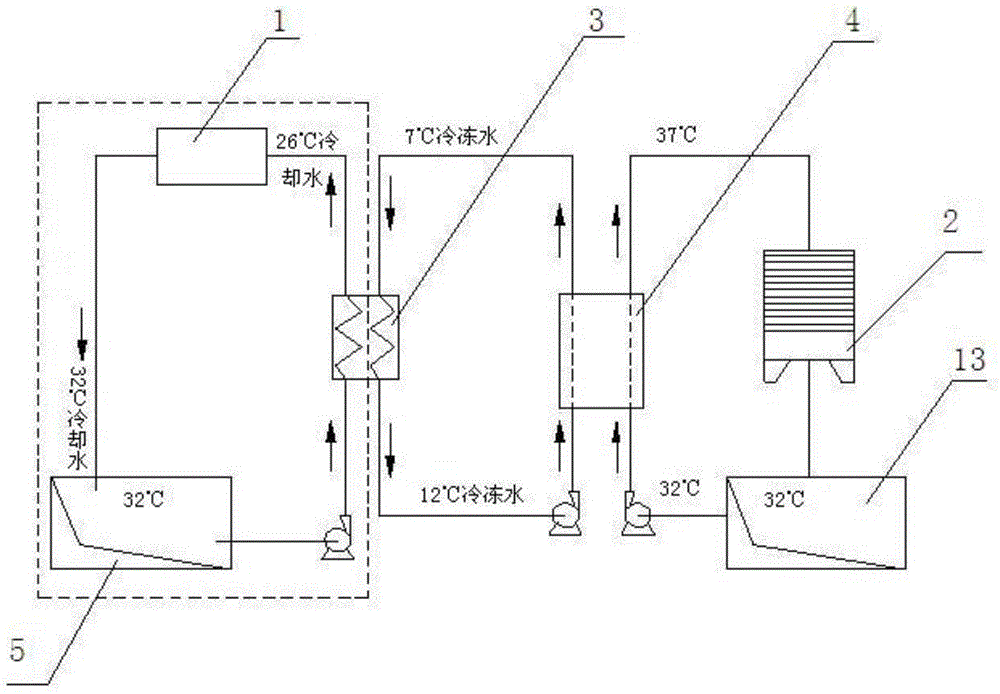

Circulating cooling water system and cooling water circulation method thereof

ActiveCN104990337AReduce in quantityHigh control precisionLighting and heating apparatusCooling fluid circulationCooling towerChilled water

The invention discloses a circulating cooling water system and a cooling water circulation method using the same. The system comprises a cooling device which is connected with a workshop appliance to form a circulating loop. The cooling device comprises a cooling tower, a circulating cooling water supply pool and a mixer which are sequentially connected, wherein the circulating cooling water supply pool is connected with the mixer through at least two pipelines connected in parallel; one pipeline is directly connected with the mixer; the other pipeline is connected with the mixer through a heat exchanger; each pipeline is provided with an adjusting valve. Only a little cooling water is subjected to heat exchange and cooling through the heat exchanger, the number of refrigerators for providing chilled water to the heat exchanger is reduced indirectly, and the operation expenses are greatly reduced. Meanwhile, by the adoption of the circulating cooling water system and the cooling water circulation method using the same, cooling water of the refrigerators can be from the circulating cooling water supply pool for providing cooling water to the workshop appliance, the number of water supply pools and the number of corresponding water supply pumps are reduced, and therefore the technological requirements are met, the purpose of energy conservation is also achieved, and the water temperature control precision is improved.

Owner:QINGDAO HUAKONG ENERGY TECH

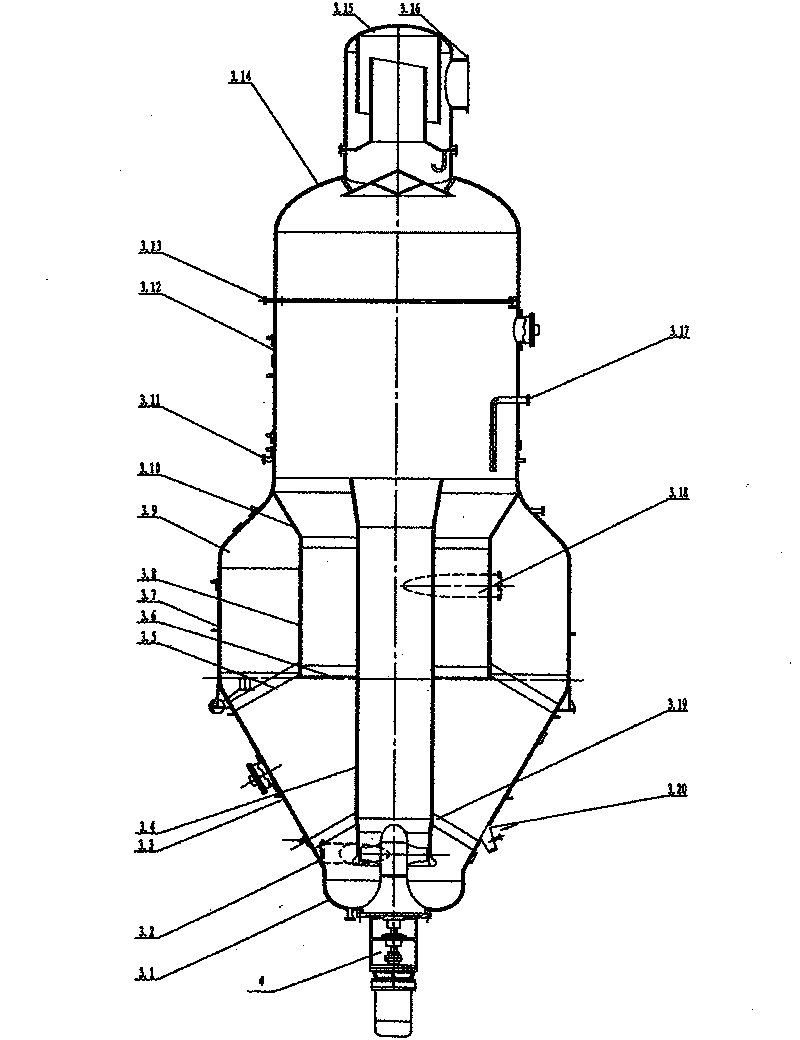

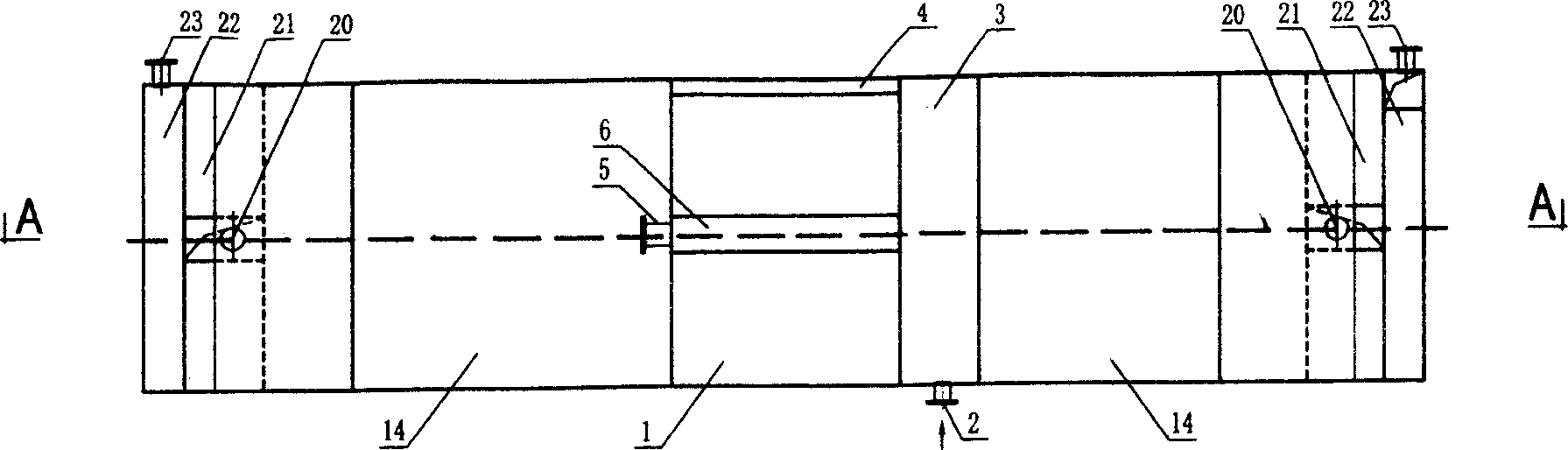

Continuous crystallizer

InactiveCN101732885AIncrease production capacityContinuous operationSolution crystallizationCirculating pumpMixing tank

The invention relates to a continuous crystallizer mainly used for concentrative crystallization in monosidum glutamate production of food industry, which comprises a crystallizer (3), a raw liquid and mother liquid mixing tank (1), a feeding pump (2), a plate type heater (14), an outer circulating pump (11), a heater (5), an inner circulating pump (4) and a discharging pump (10), wherein the raw liquid and mother liquid mixing tank (1) is connected with the feeding pump (2) connected with the plate type heater (14) which is communicated with the outer circulating pump (11), the outer circulating pump (11) is connected with the heater (5) communicated with a circulated flow returning port (3.2) of the crystallizer (3), and an circulated discharging port (3.18) of the crystallizer (3) is communicated with the outer circulating pump (11); the inner circulating pump (4) is arranged at the bottom of the crystallizer (3); and an outlet of the discharging pump (10) is respectively connected with a crystal paste circulating port (3.11) of the crystallizer (3) and a crystallization-assistant slot (8). The continuous crystallizer has the characteristics of low steam consumption, high equipment yield, high degree of the automation and the like.

Owner:江阴丰力生化工程装备有限公司

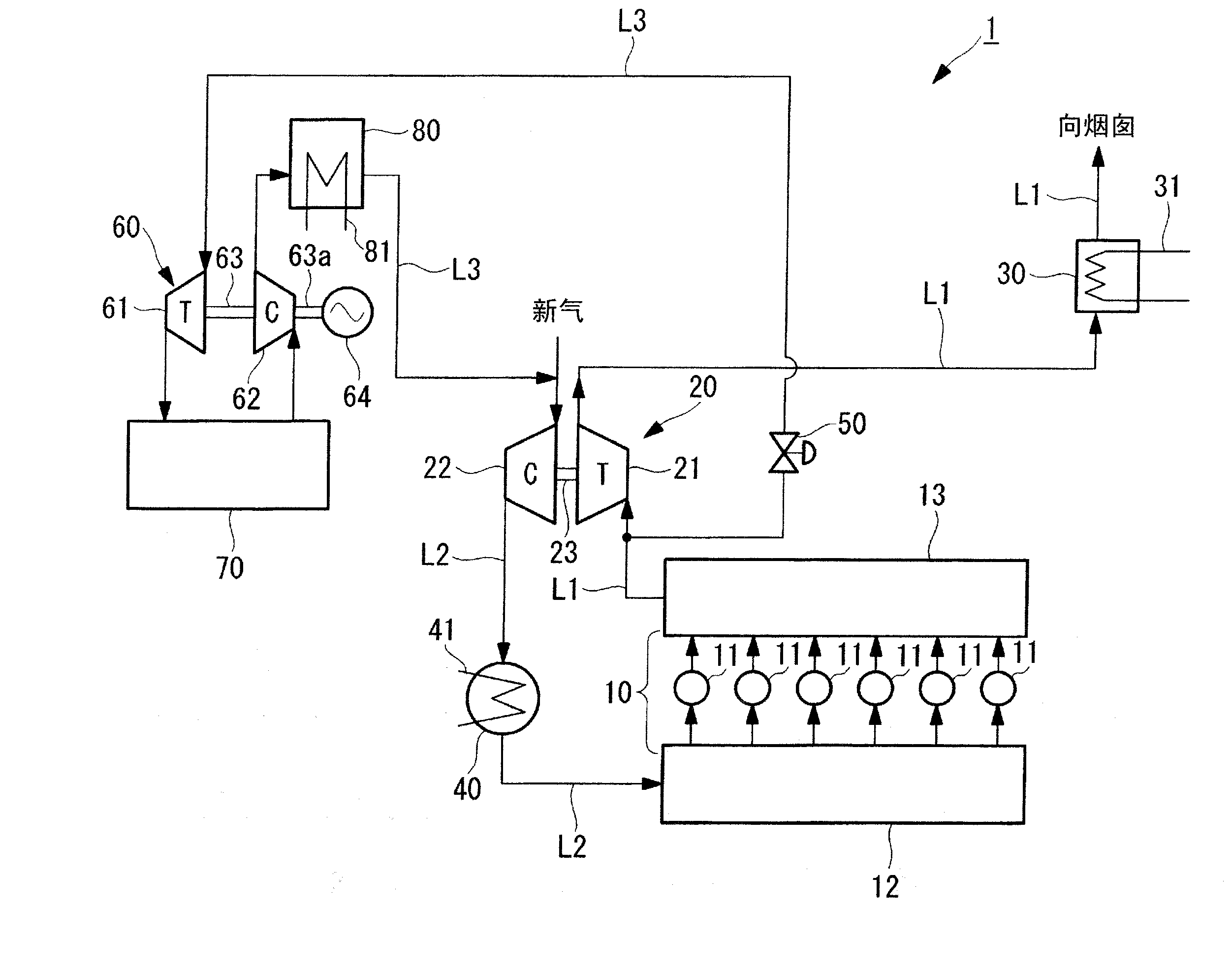

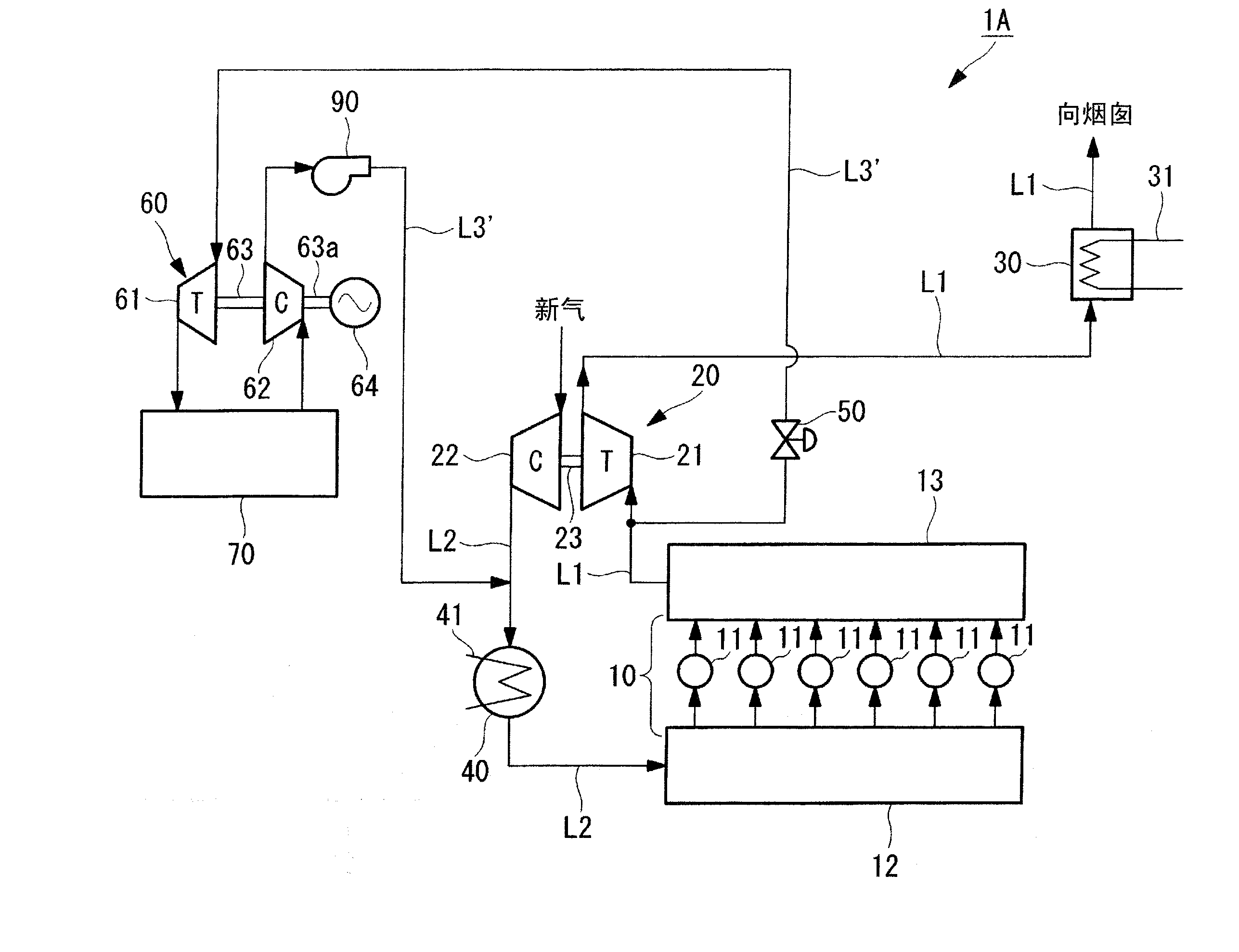

Engine exhaust gas purification device

ActiveCN103210201AImprove reliabilityIncreased durabilityNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerAir pollutants

Provided is an engine exhaust gas purification device which reduces or eliminates the need for electric power required to raise the pressure of EGR gas, which is extracted from the upstream side from an exhaust turbosupercharger in order to be used for exhaust gas recirculation (EGR), after cleaning treatment by an exhaust gas cleaning unit. An engine exhaust gas purification device (1) for reducing or eliminating air pollutants in exhaust gas emitted from a main engine (10) provided with an exhaust turbosupercharger (20) is provided with an exhaust gas cleaning unit (70) for subjecting part of exhaust gas introduced as EGR gas from an exhaust system (L1) on the upstream side from a turbine part (21) of the exhaust turbosupercharger (20) to cleaning treatment, and a recirculation exhaust turbosupercharger (60) for raising the pressure of the EGR gas which has passed through the exhaust gas cleaning unit (70) by a recirculation compressor part (62) coaxial with a recirculation turbine part (61) disposed on the upstream side from the exhaust gas cleaning unit (70) and driven using the EGR gas.

Owner:MITSUBISHI HEAVY IND LTD +1

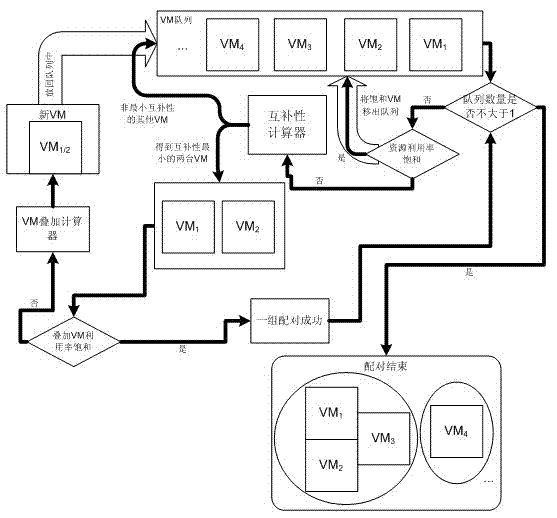

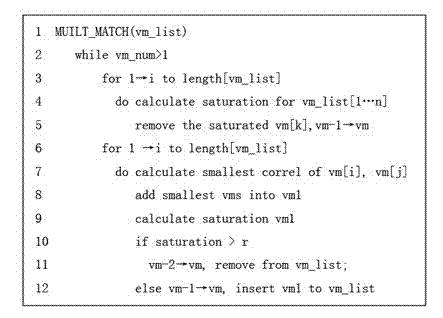

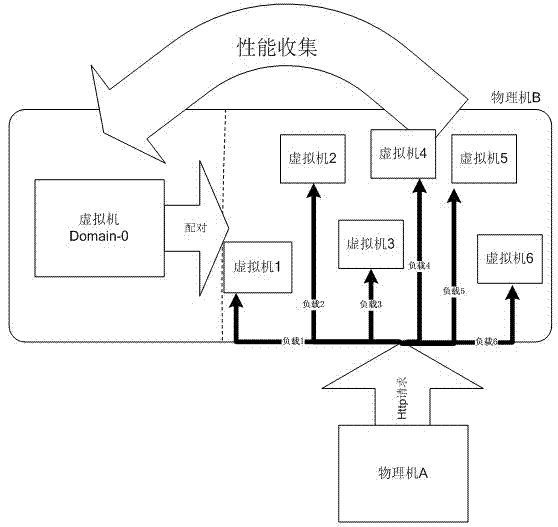

Method for placing load-related virtual machine

ActiveCN102541622AImprove resource utilizationNo reduction in service qualityResource allocationSoftware simulation/interpretation/emulationVirtualizationQuality of service

The invention relates to a method for placing a load-related virtual machine. In a currently common virtualized environment, in order to ensure performance, resources are often excessively allocated, leading to a low resource utilization level and resulting in increase of the cost and resource waste. By utilizing a multi-iteration complementary pairing method provided by the invention, the problems of a low resource utilization ratio as well as unreasonable pairing caused by random pairing or one-time pairing can be solved; and the iteration degree is controlled by setting a saturation of the resource utilization ratio, so that the performance of the system and the service quality of a user are controlled within an acceptable range. By a multi-iteration virtual machine method, by utilizing the time complementarity of the resources, the resource utilization ratio of the virtual machine can be improved in a relatively deep level on the premise of not reducing the service quality of the user.

Owner:HANGZHOU DIANZI UNIV

Intelligent indoor air replacement and purifying device and method

InactiveCN106152288AAvoid cloggingSolution to short lifeMechanical apparatusSpace heating and ventilation safety systemsGas detectorCarbonization

The invention discloses an intelligent indoor air replacement and purifying device and method and belongs to the field of indoor and outdoor fresh air purifying devices. The indoor air replacement and purifying device is internally provided with a plurality of filters comprising the heating carbonization ceramic filter, the bilateral rotation draught fan and the conical ceramic filter; the heating carbonization ceramic filter and the conical ceramic filter are spongy micropore ceramic filters; the upper portion of the heating carbonization ceramic filter inclines towards the outer side; the periphery of the intelligent indoor air replacement and purifying device is provided with an automatic sample connection communicating with the interior of a room; the automatic sample connection is provided with a gas detector; the intelligent indoor air replacement and purifying device is internally provided with an electric current detector and further configured with an intelligent controller; the acquisition cost of an air purifying device, the consumable investment and the installation and maintenance cost can be reduced through the intelligent indoor air replacement and purifying device; the air purifying effect of the intelligent indoor air replacement and purifying device is improved; the device manufacturing cost is reduced; and intelligent operation of the air purifying device is achieved.

Owner:ANYANG HENGAN MOTOR

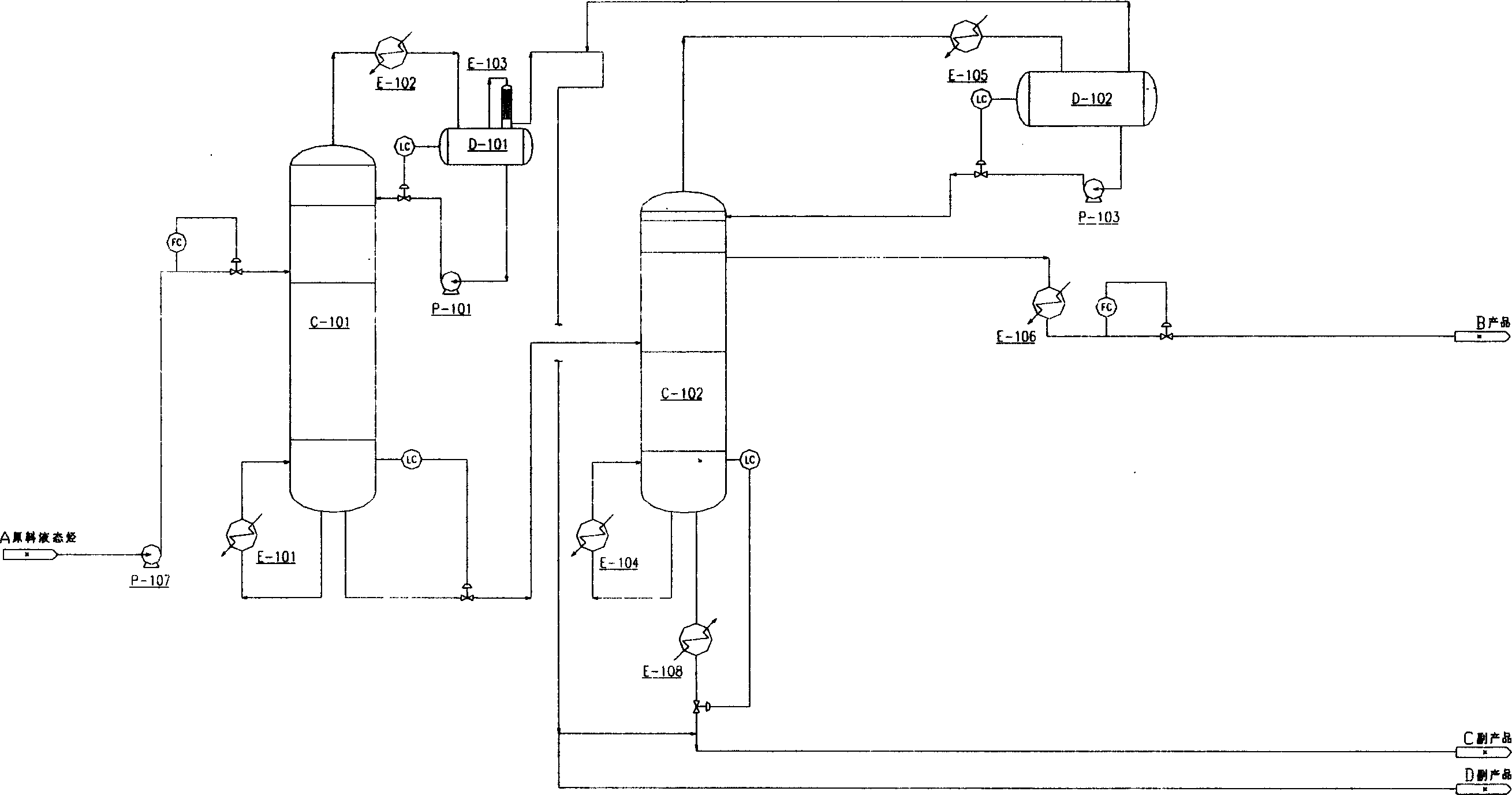

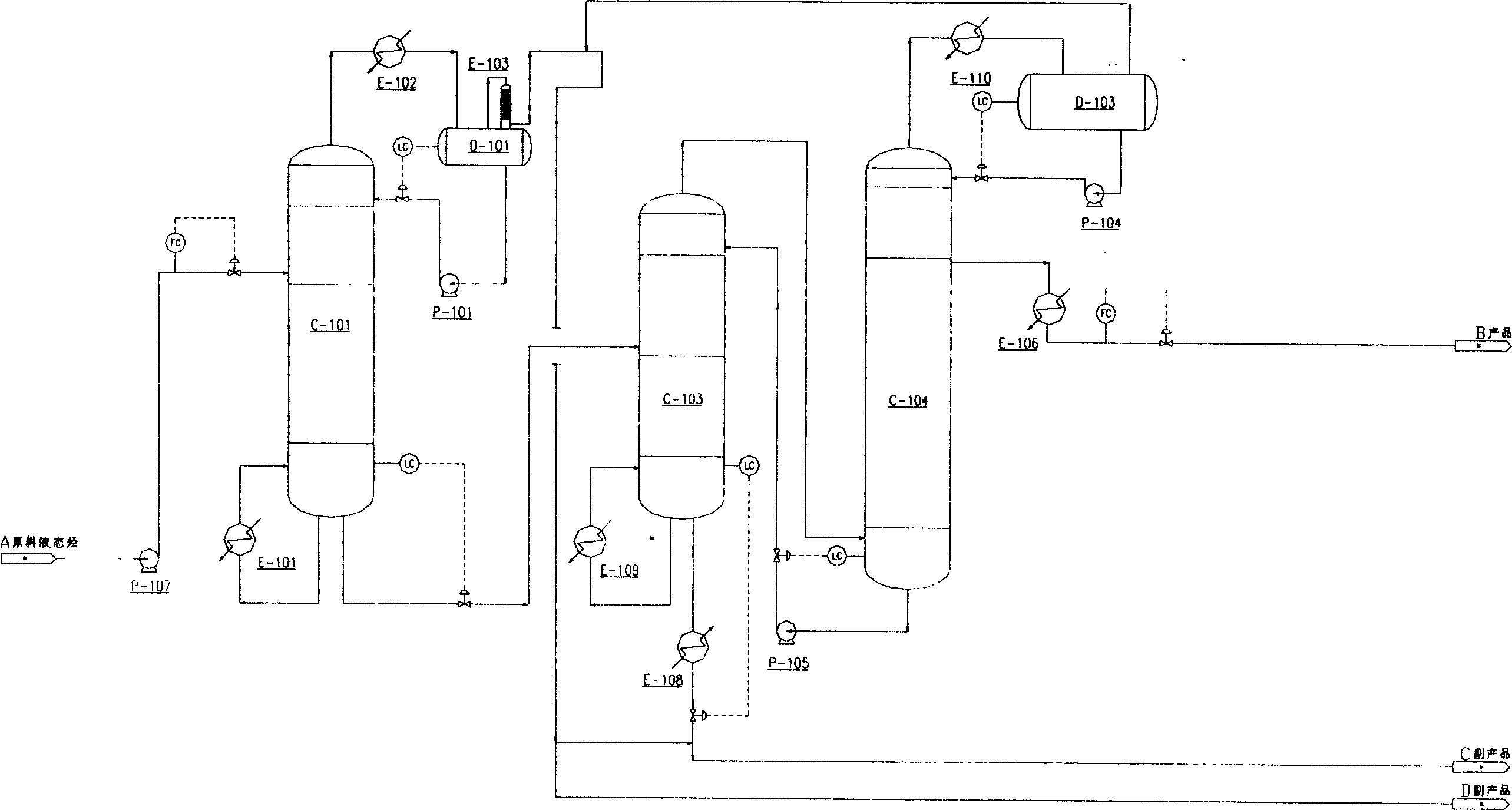

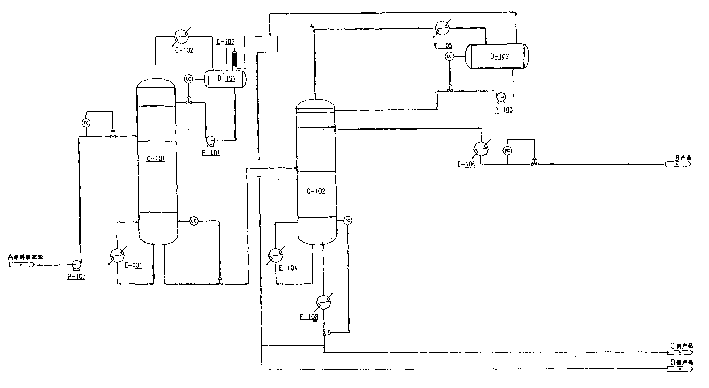

Fractionating method for separating liquid hydrocarbon mixture

InactiveCN1583971AAchieve separationSolving problems that would cost a lot to solveTreatment with plural serial refining stagesHydrocarbon mixturesLiquid state

The invention is a fractionation method to separate hydrocarbon compound in liquid state. It contains light hydrocarbon removing and heavy hydrocarbon removing processes, and fractionation by using light hydrocarbon separating tower and heavy hydrocarbon separating tower. And separate the liquid-state hydrocarbon compound from lightness to heaviness. The invention has a host of advantages involving high production quality, low cost, high security, wide range of application, and low cost of operation and source consumption.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

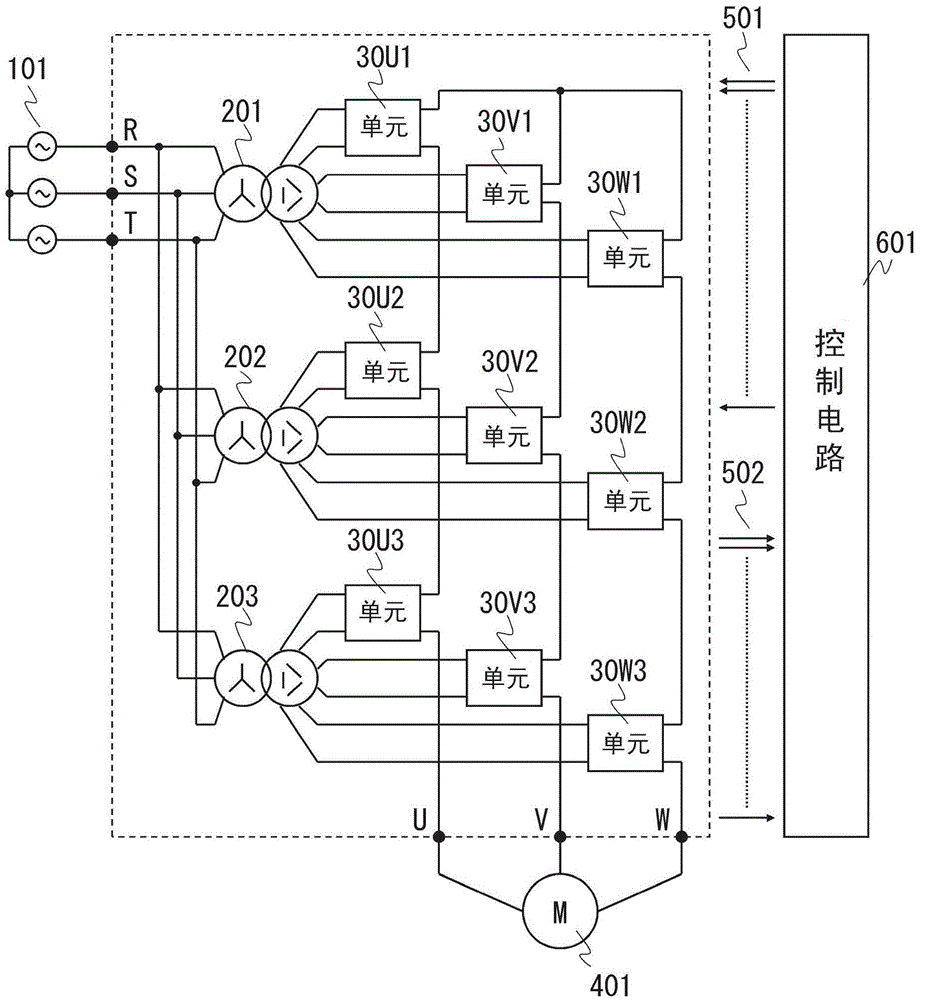

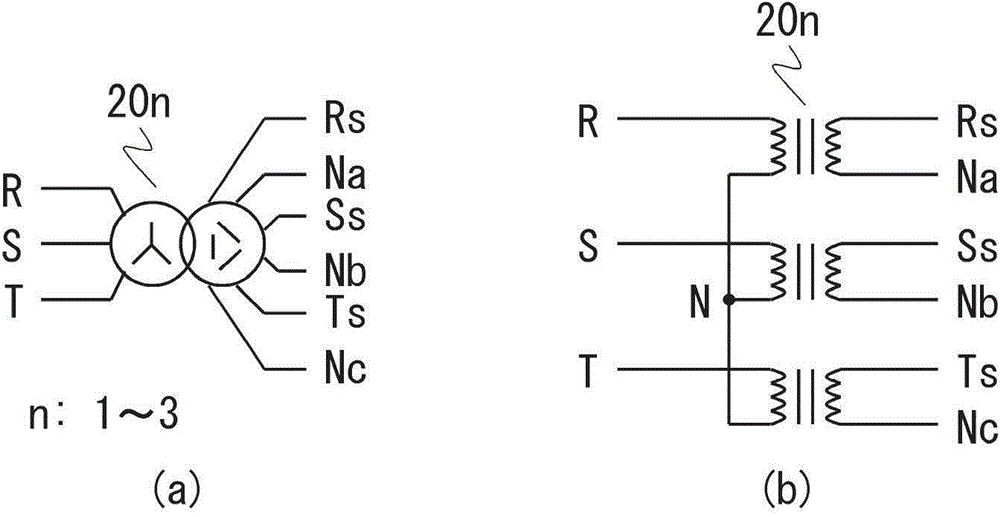

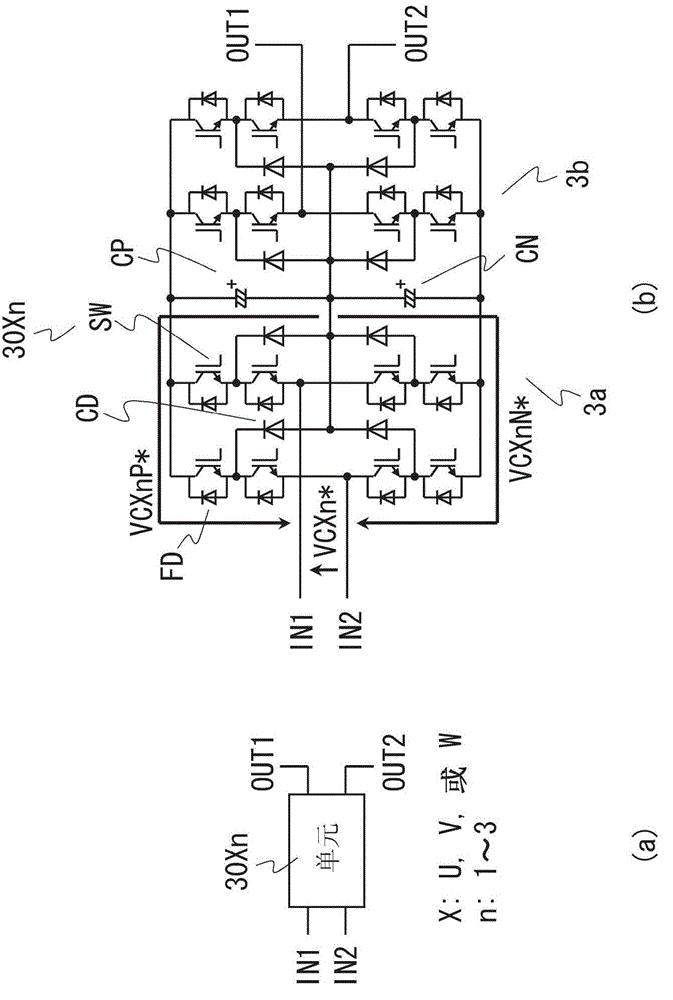

Power conversion device

ActiveCN104380586ALow costImprove voltage waveformAc-ac conversionDc-ac conversion without reversalTransformerEngineering

A power conversion device includes transformers (20n) provided with primary windings connected to input terminals (R,S,T) and secondary windings including pluralities of single-phase open windings that are insulated from each other; a plurality of converter cells (30Xn) connected to the secondary windings of the transformers (20n); and a control circuit (601) for controlling ON / OFF of switching elements. The converter cells (30Xn) each include a converter (3a) and the inverter (3b) that are provided with the switching elements, in which their input ends are connected to the respective single-phase open windings, so that the input ends are connected in mutually parallel fashion, through the transformers (20n), to the input terminal (R,S,T) of each phase, and in which their output ends are connected in mutually serial fashion to an output terminal (U,V,W) of each phase, to thereby perform three or more-level power conversion.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

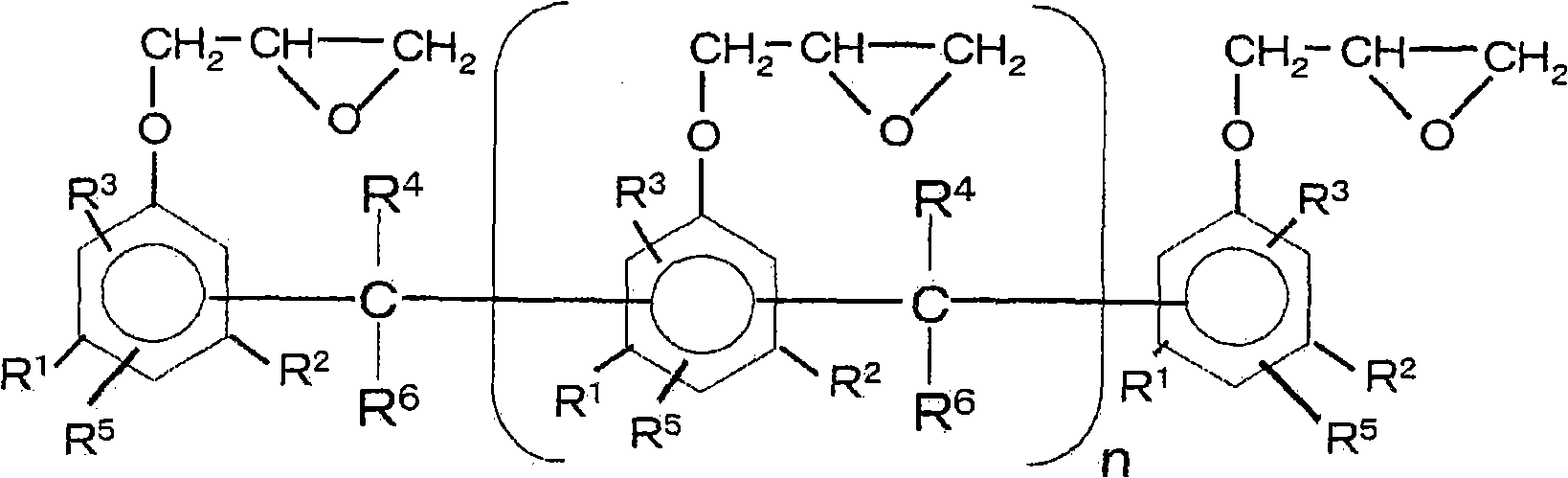

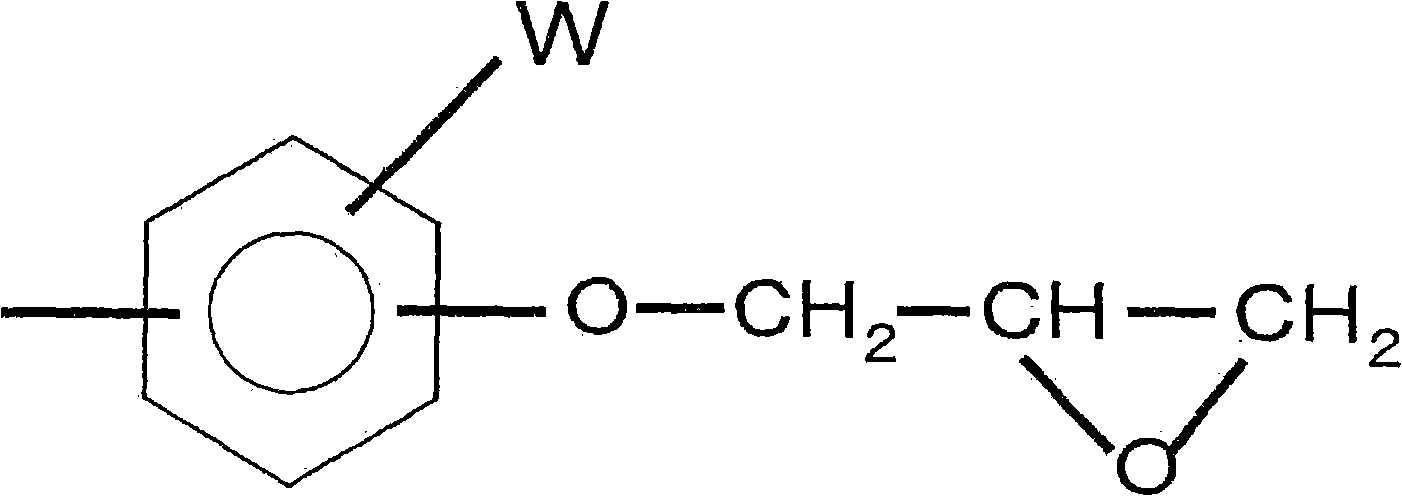

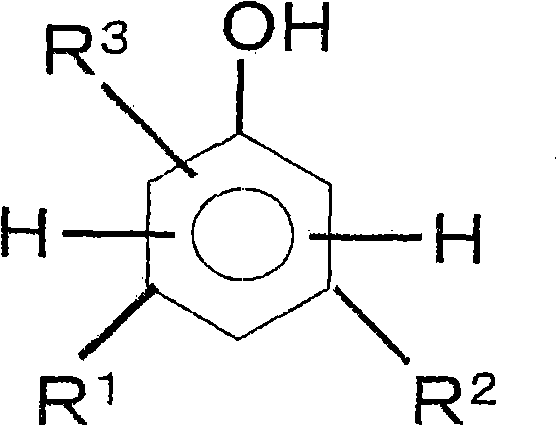

Pigment disperse sizing agent and electrophoretic paint

ActiveCN101353501AGood redispersibilityGood storage stabilityPaints for electrolytic applicationsEpoxy resin coatingsCelluloseSolid component

The purpose of the invention is to provide a pigment dispersing paste capable of saving energy of coating apparatus and saving redispersibility of dye of the apparatus and electrophoretic paint. Specifically, the invention relates to a pigment dispersing paste for electrophoretic paint, containing pigment dispersing resin (A), tinting color (B), color filler (C) and cellulose composition (D); responding to the solid component 100 weight parts of the resin (A), the paste is characterized by containing: (1) 60 to 800 weight parts of (b1) titanium dioxide coated by 0.1 to 10.0 weight parts of Al2O3 without SiO2 on 100 weight parts of titanium dioxide as matrix; and / or (b2) ferric oxide as the of tinting color (B); (2) 2 to 200 weight parts of micro barium sulfate with the mean grain size of linear particle being 0.01 to 0.1 micron as the color filler (C); and (3) 1 to 50 weight parts of cellulose composition (D).

Owner:KANSAI PAINT CO LTD

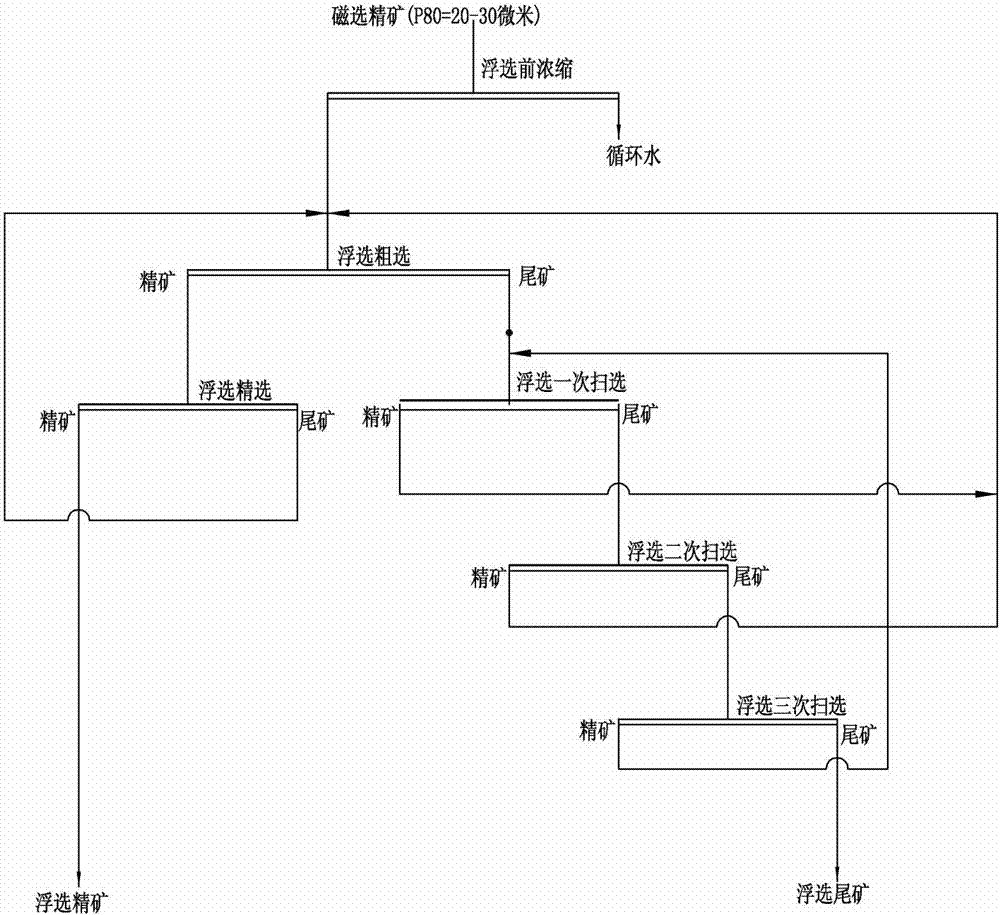

Micro-fine particle hematite greater circulation mine returning negative ion reverse flotation technology

The invention relates to a micro-fine fine particle hematite greater circulation mine returning negative ion reverse flotation technology. The technology is characterized in that magnetic concentrate with the Fe-grade being 40-41% and the granularity being P80=20-30 micrometers is fed into a thickener to be subjected to concentration after magnetic separation, then is fed to a negative ion reverse flotation operating system in an underflow mode and then is fed into circulating water in an overflow mode. Firstly, the magnetic concentrate is fed into flotation rough concentration operation, underflow concentrate of the flotation rough concentration operation is fed into flotation fine concentration operation, foam tailings of the flotation rough concentration operation is fed into scavenging operation, and the scavenging operation is divided into three times of scavenging operation; foam tailings of the first time scavenging is fed into the second time scavenging, foam tailings of the second time scavenging is fed into the third time scavenging, underflows of the first time scavenging and the second time scavenging both return to the flotation rough concentration operation, and the underflow concentrate of the third time scavenging operation returns to the first time scavenging. The foam tailings scavenged by the third time scavenging operation are the final flotation tailings, the underflow concentrate of the flotation fine concentration operation is the final concentrate, the grade of the final concentrate is 65.9%, and the iron recovery rate is 88.5%.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Control method for high-efficiency operation of multi-compressor energy-step-utilization water-heating unit of water-to-water heat pump

ActiveCN105042968AGuaranteed uptimeGood matching load changeRefrigeration safety arrangementEngineeringThermal water

The invention relates to a control method for high-efficiency operation of a multi-compressor energy-step-utilization water-heating unit of a water-to-water heat pump. The control method is characterized in that water temperatures of total inlet water and outlet water at a hot water side of the unit are set to be t1 and t2; inlet water and outlet water temperatures at the hot water side corresponding to each compressor are designed to be tn1 and tn2; n presents the tandem n-th compressor; the inlet and outlet water temperatures at the hot water side of the first compressor are t11 and t12; practical inlet and outlet water temperatures of the unit are t1 and t2; when the practical inlet water temperature t1 is lower than or equal to t12, all compressors are started; when the practical inlet water temperature t1 is greater than t12 but lower than or equal to t22, the first compressor is stopped, and only the (2-n)-th compressor is started; when the practical inlet water temperature t1 is greater than t22 but lower than or equal to t32, the first and the second compressors are stopped, and only the (3-n)-th compressor is started; when the practical inlet water temperature t1 is greater than t(n-1)2 but lower than or equal to t2, the n-th compressor is started, and when the water temperature changes with the range, load changes are matched by adding and subtracting through the unit; and when the inlet water temperature reaches (t2+1) DEG C, all compressors are spotted. The control method has the beneficial effects of enabling the unit to efficiently operate, saving energy resources, and the like.

Owner:广州市设计院集团有限公司

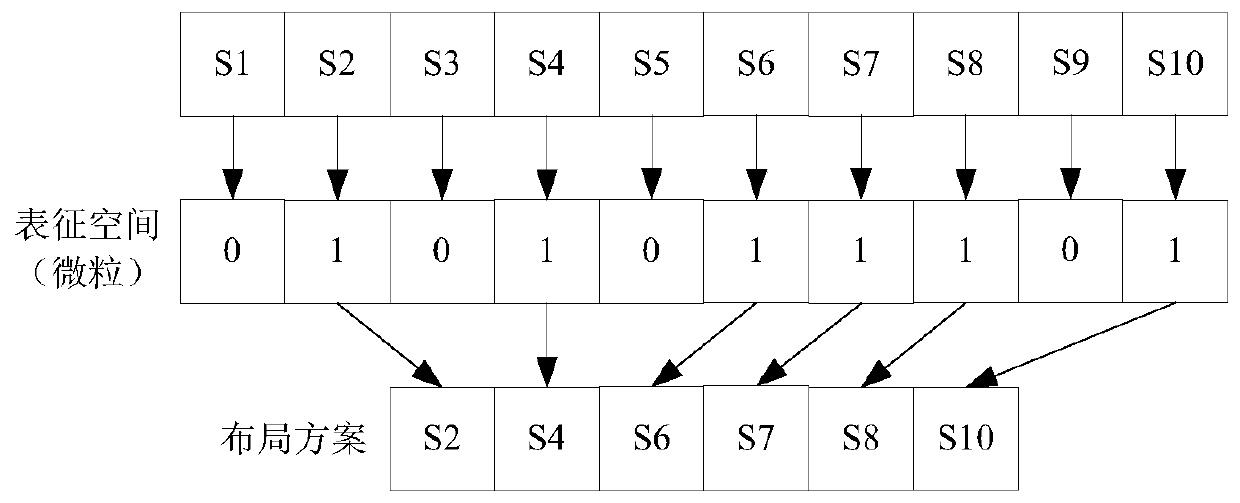

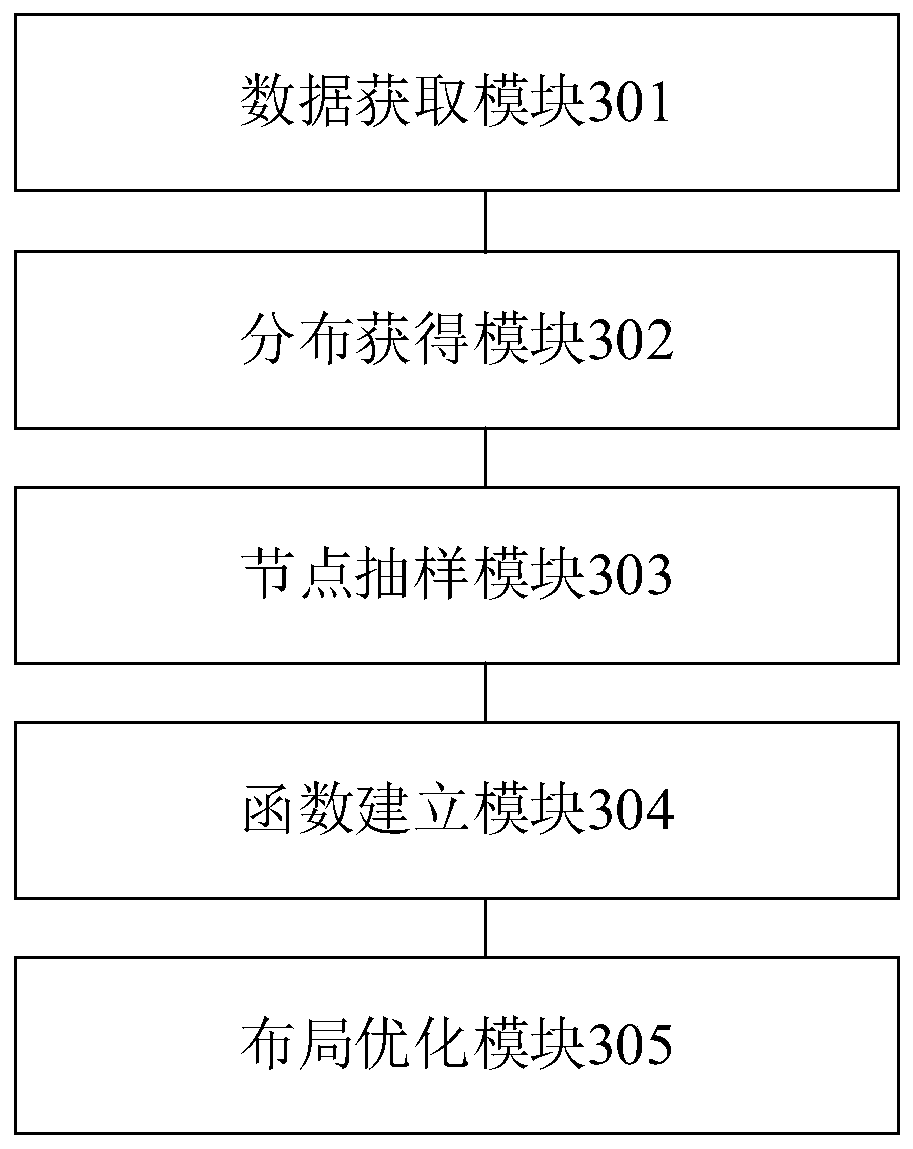

Rainfall sensor network node layout optimization method and device

ActiveCN110232471AMake up for uncertaintyHigh precisionForecastingArtificial lifeDiscretizationParticle swarm algorithm

The invention provides a rainfall sensor network node layout optimization method and device. The rainfall sensor network node layout optimization method and device can obtain high-precision rainfall space distribution through simulation by taking satellite remote sensing rainfall data as a background field and combining the ground monitoring data, so as to convert discretized ground monitoring data into high-precision and continuous ground data, and furthermore, can discretize the ground area through the Thiessen polygon, to reduce the number of traversing units, and improve the calculation efficiency. According to rainfall spatial distribution, the rainfall sensor network node layout optimization method and device can establish a multi-objective function and constraint conditions of nodelayout optimization to obtain a rainfall station layout optimization model, and can solve the model to obtain an optimal rainfall sensor network node layout by adopting a multi-objective microscopic neighborhood particle swarm algorithm, so as to provide a theoretical basis for reasonable layout of a ground monitoring station. In the solving process, the rainfall sensor network node layout optimization method and device transform the multi-target microscopic neighborhood particle swarm algorithm to be suitable for a parallel computing architecture, so as to accelerate the solving efficiency.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

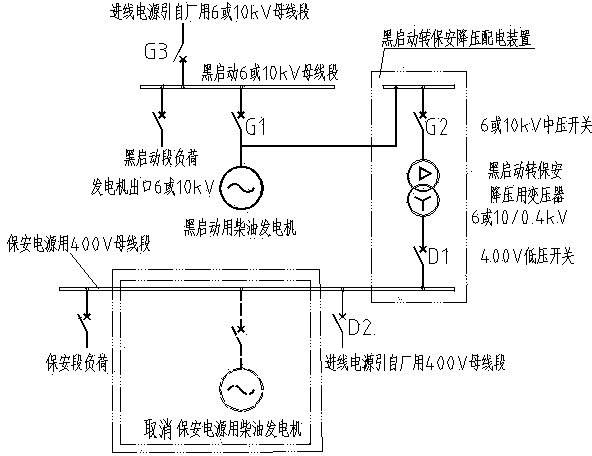

Method for utilizing black-start diesel generator to be doubled as safety source diesel generator

ActiveCN104065065AAvoid duplicate settingsReduce in quantityAc network circuit arrangementsPower stationDiesel generator

The invention relates to the switch-over and sharing technology of diesel generators in a power station, in particular to a method for utilizing a black-start diesel generator to be doubled as a safety source diesel generator. According to the method, the safety source diesel generator is removed, a black-start conversion safety step-down power distribution unit is set to step down the voltage of an outlet of the black-start diesel generator so as to be supplied to a safety source load for use, and therefore the black-start diesel generator can be doubled as the safety source diesel generator; when the safety source is needed, the safety source diesel generator is changed to be the black-start diesel generator for starting, the 400V power distribution segment with the safety source is operated, and after functions for the safety source are completed, black-start is performed according to the subsequent instructions. The method has the advantages that repeated setting of the diesel generator of the black-start power station can be avoided, the number and volume of the diesel generators are reduced, the utilization rate of the diesel generator is improved, the number of generators and the running cost are greatly reduced, cost is effectively reduced, the area occupied by the power station is reduced, and running maintenance caused by decreasing of the number of the diesel generators in the future is reduced.

Owner:POWERCHINA FUJIAN ELECTRIC POWER SURVEY & DESIGN INST CO LTD

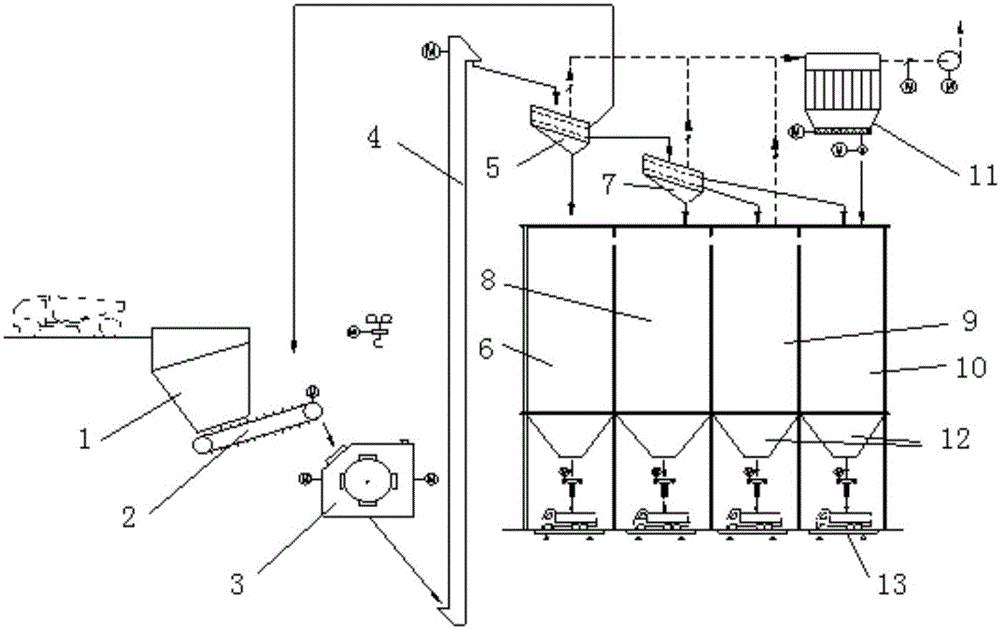

Efficient energy-saving concrete aggregate production line and method

ActiveCN105107571ASimple processReduce the number of equipmentGrain treatmentsProduction lineAutomatic control

The invention relates to an efficient energy-saving concrete aggregate production line. A feed inlet of a crusher, a plate type feeding machine, a hammer impact crusher, an elevator and a primary vibrating screen are sequentially connected. A primary coarse material outlet, a primary medium material outlet and a primary fine material outlet are formed in the primary vibrating screen and connected with the crusher, a first stock bin and a secondary vibrating screen respectively. A secondary coarse material outlet, a secondary medium material outlet and a secondary fine material outlet are formed in the secondary vibrating screen and connected with a second stock bin, a third stock bin and a fourth stock bin respectively. According to the efficient energy-saving concrete aggregate production line, the optimized scheme that the efficient crusher is used, the elevator is used for conveying and screening machines are arranged at the tops of the stock bins is adopted, in this way, the procedure is greatly simplified, the number of pieces of equipment is greatly reduced, and the number of dust raising points is also greatly reduced; a distributed control system (DCS) centralized full-automatic control scheme is adopted, and thus the efficient energy-saving concrete aggregate production line has the advantages that the number of required workers is small, the occupied area is small, investment is low, and energy consumption is low.

Owner:坚构建材科技集团有限公司

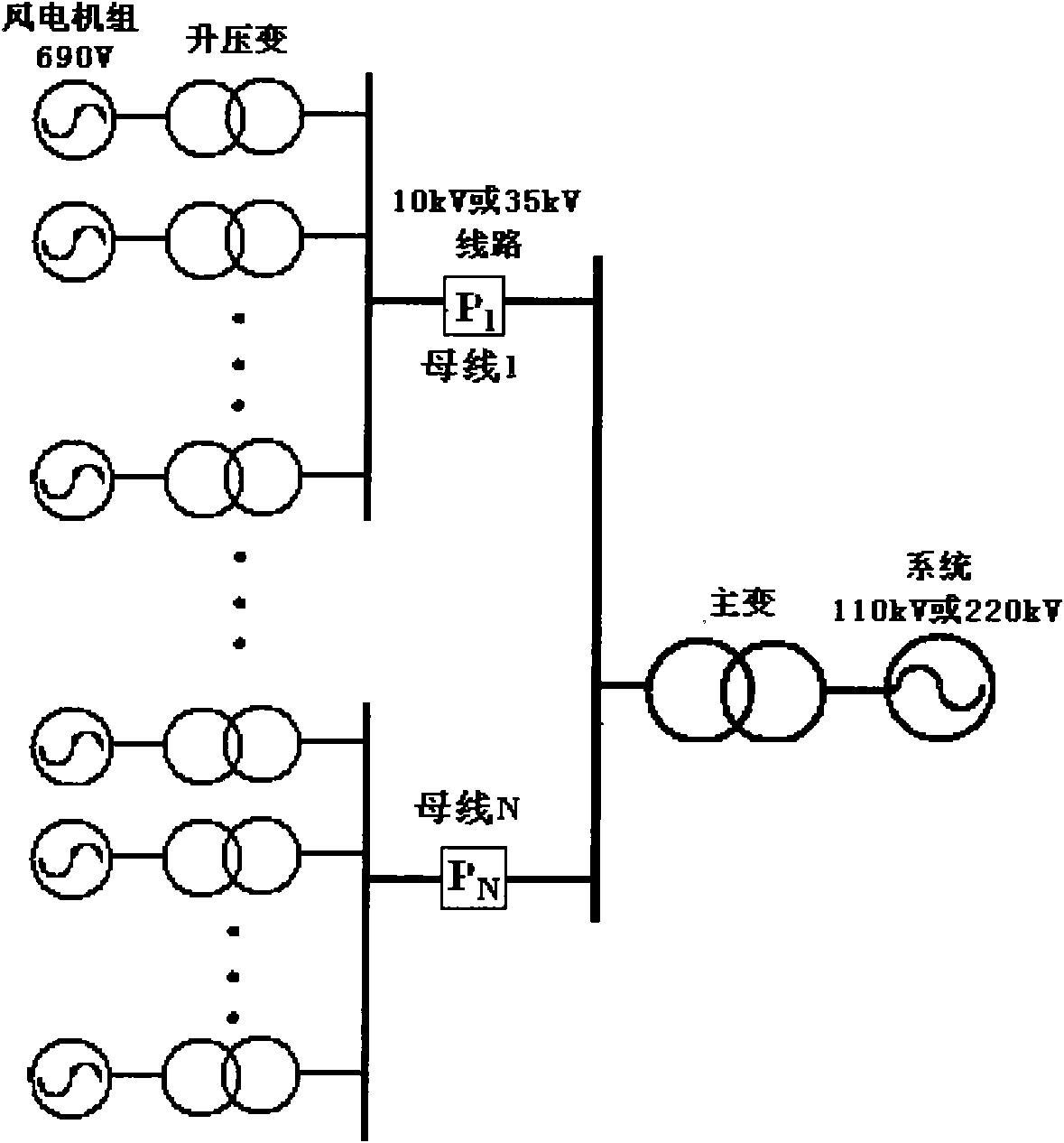

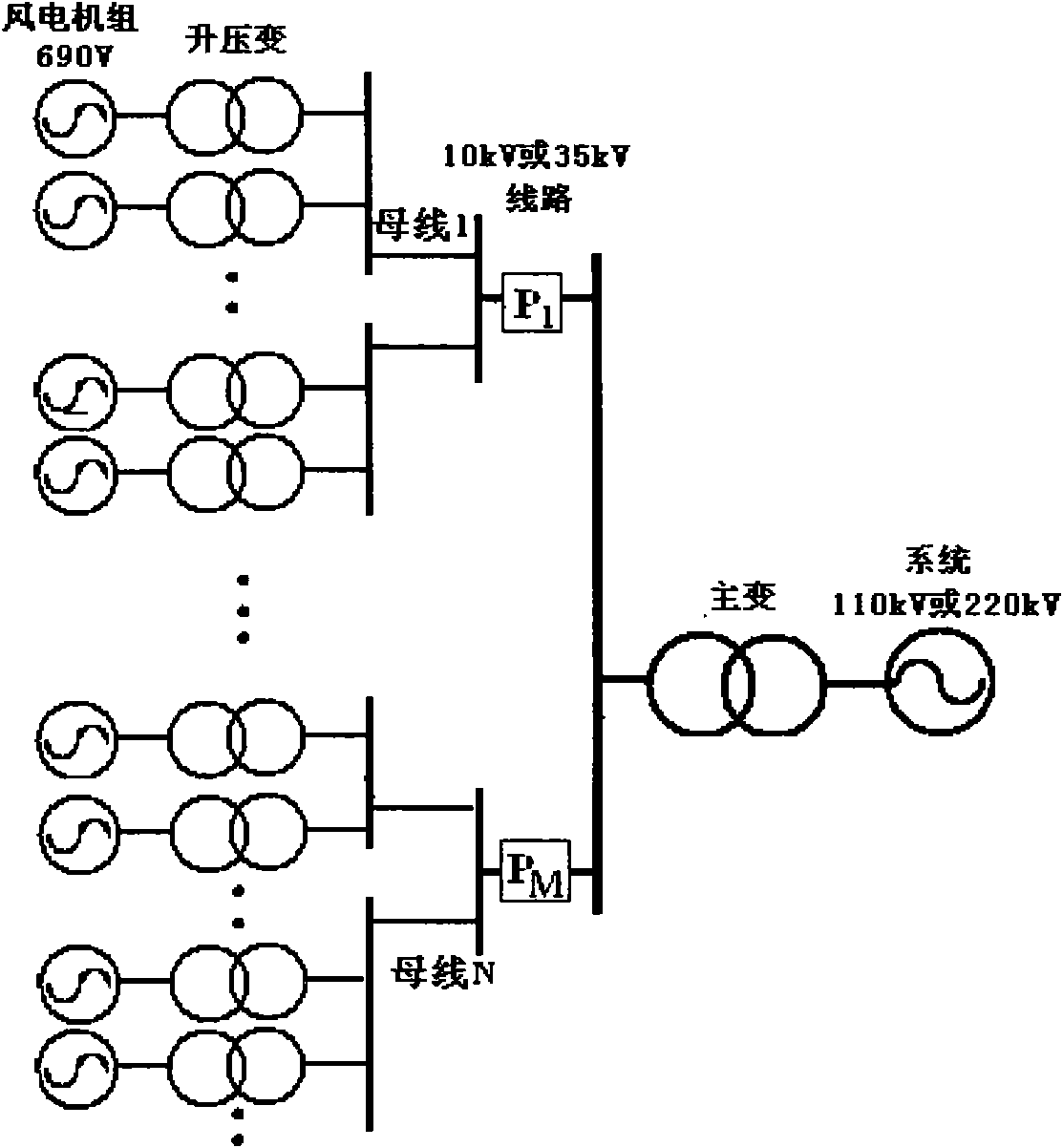

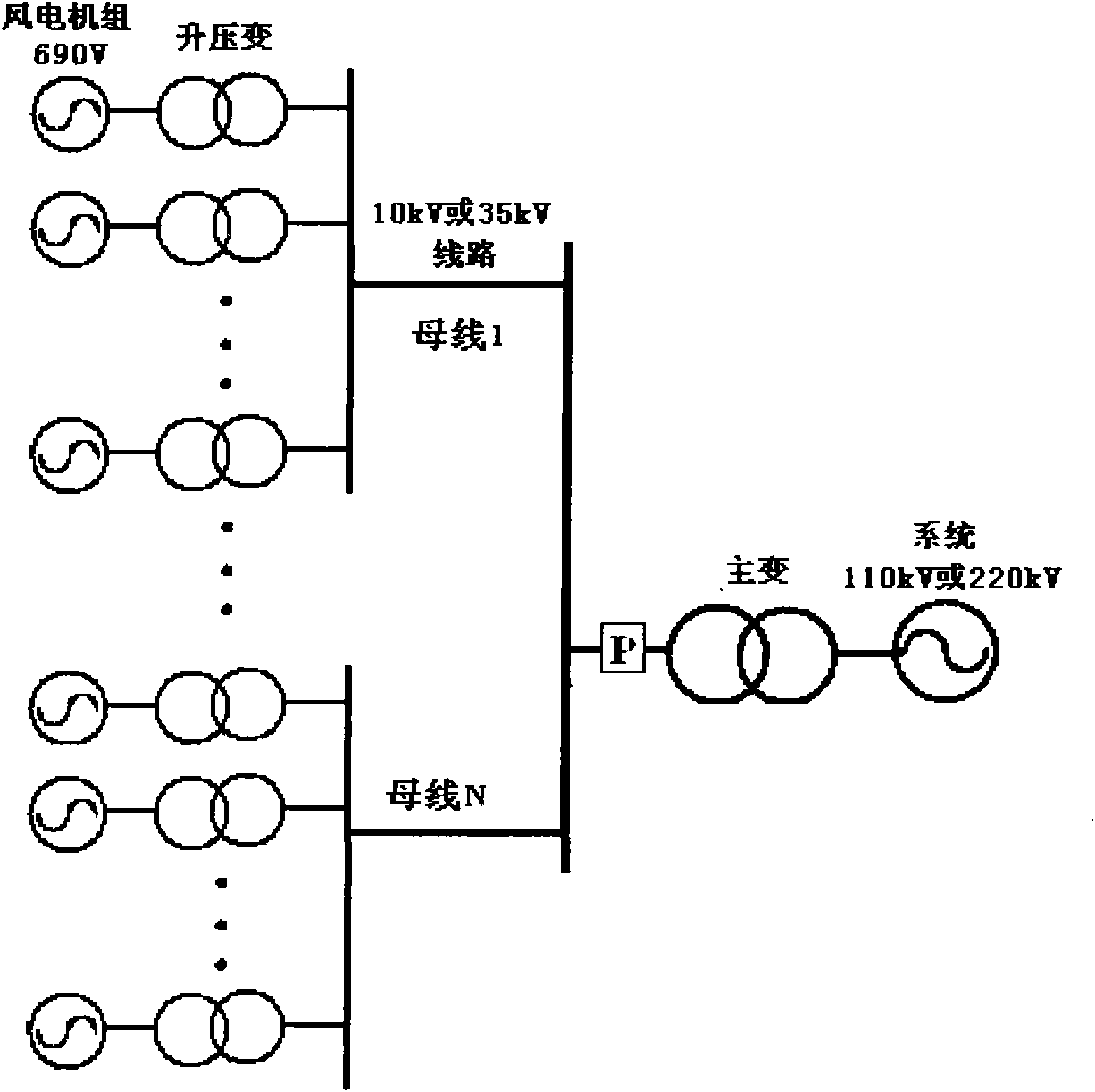

Wind power station whole low voltage ride through (LVRT) system

InactiveCN101902052AObvious advantagesDoes not take up spaceSingle network parallel feeding arrangementsWind energy generationElectricityPower station

The invention provides a wind power station whole low voltage ride through (LVRT) system. The system comprises at least one wind turbine and at least one wind turbine set-up transformer which are connected in series at a wind power station side and at least one main step-up transformer at a power grid side. The system further comprises a plurality of current collection busses and a power grid bus, wherein each current collection bus accesses at least one wind turbine and at least one wind turbine step-up transformer which are connected in series; the current collection busses are divided into at least one group, and each group comprises at least one current collection bus; the power grid bus is used for accessing the main step-up transformer at the power grid side; and each group of the current collection busses are respectively connected to the power grid bus through an LVRT device. The invention can achieve the wind power station whole LVRT by using fewer LVRT devices.

Owner:龙源电力集团股份有限公司

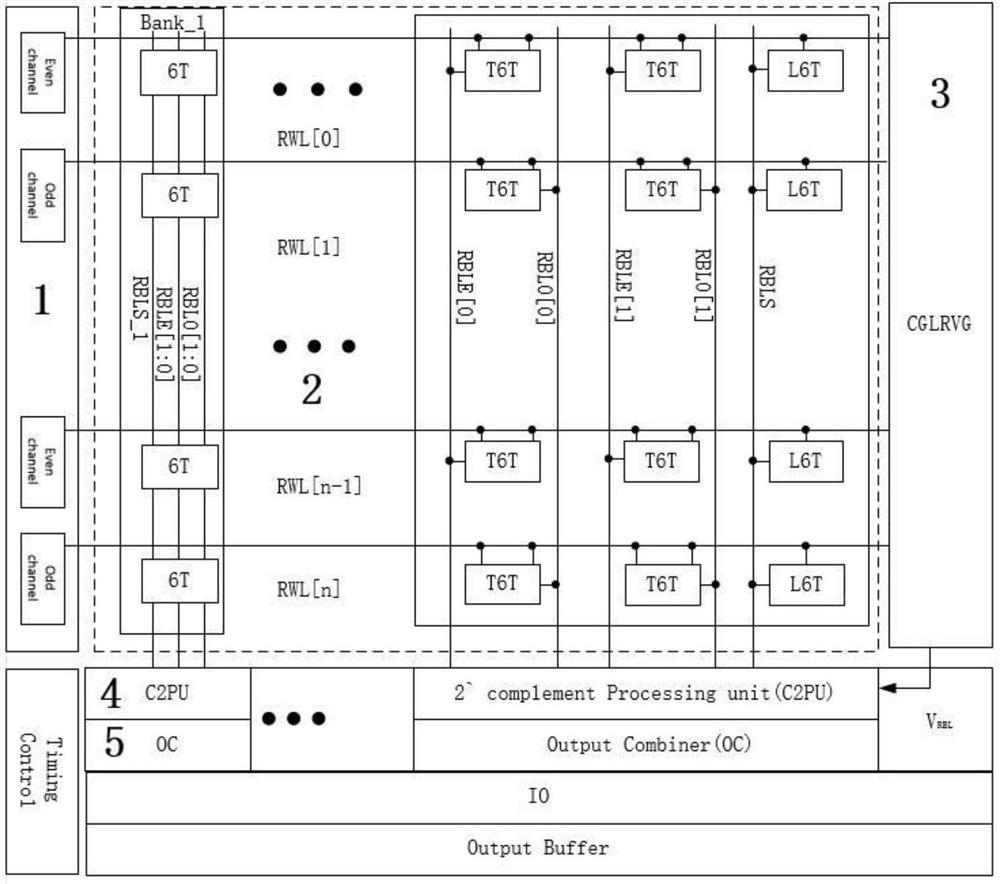

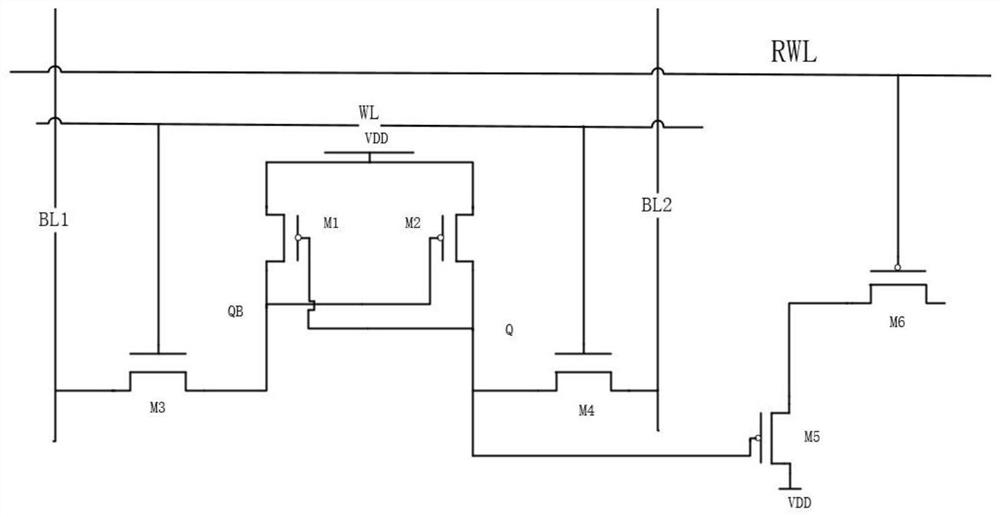

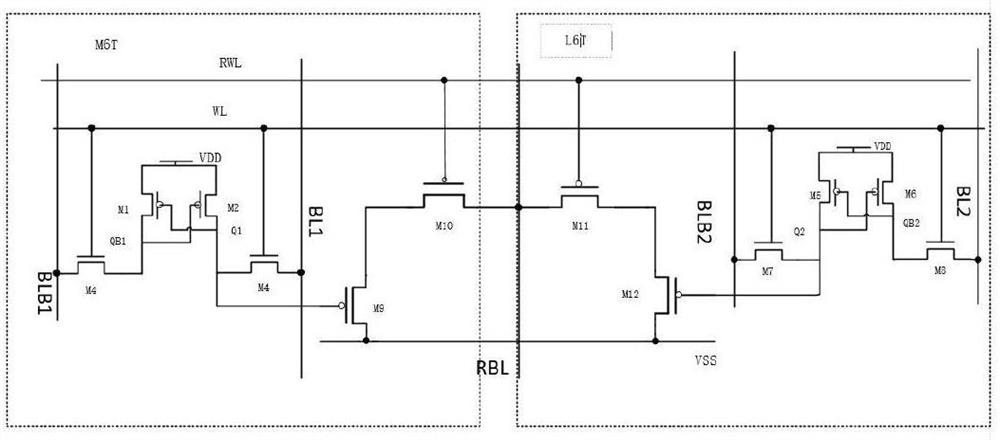

In-memory computing device of double-6T SRAM structure

ActiveCN111816231AReduce areaIncrease the areaDigital storageEnergy efficient computingComputer architectureEngineering

The invention relates to an in-memory computing device of a double-6T SRAM structure. The device comprises an odd-even dual-channel array, a T6T SRAM unit array, a global-local reference voltage generation module, a two-bit complement processing module and an output combiner; the odd-even dual-channel array is used for inputting input data into the T6T SRAM unit array by utilizing odd channels andeven channels respectively; the T6T SRAM unit array is used for storing and calculating the input data; the T6T SRAM unit array is connected with the global-local reference voltage generation module;the global-local reference voltage generation module is connected with the two-bit complement processing module; the two-bit complement processing module is used for performing complement operation on data calculated by the T6T SRAM unit array; the output combiner is connected with the two-bit complement processing module; and the output combiner is used for accumulating and combining the data which has been subjected to complement operation to obtain final output data. With the in-memory computing device adopted, the generation of intermediate data can be reduced, and power consumption is reduced.

Owner:中科南京智能技术研究院

Double-action double-angle lateral shaping mechanism

The invention relates to a double-action double-angle lateral shaping mechanism which comprises a drive part and a movable male die working part. The drive part is an upper die of a punching device. The upper die is provided with a drive face, an insertion type guide plate is disposed at the front end of the drive face, a vertical face is disposed on the rear side of the upper die, and a mounting face and a mounting guide plate are disposed on the vertical face. When an upper die lateral shaping insert completes work, two upper die wedge drive blocks mounted on the upper die lateral shaping insert starts to work at two different angles. Advance and retreat sequence of wedges is important, the upper die lateral shaping insert starts to work when a movable male die slider and a lower die auxiliary pressing plate are in place, and when the upper die lateral shaping insert completes work, the upper die wedge drive blocks mounted on the upper die lateral shaping insert starts to work. Wedges of different angles are mounted on the wedges, and two working directions are provided. The movable die working part comprises various drive blocks, a nitrogen cylinder, a pressing plate, a balance cushion block, an insertion type guide plate and a wear-resistant plate.

Owner:SHANGHAI HUAZHUANG MOLD

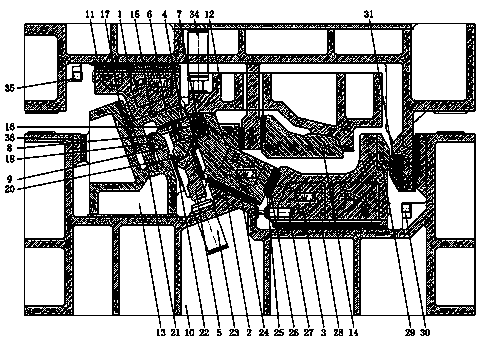

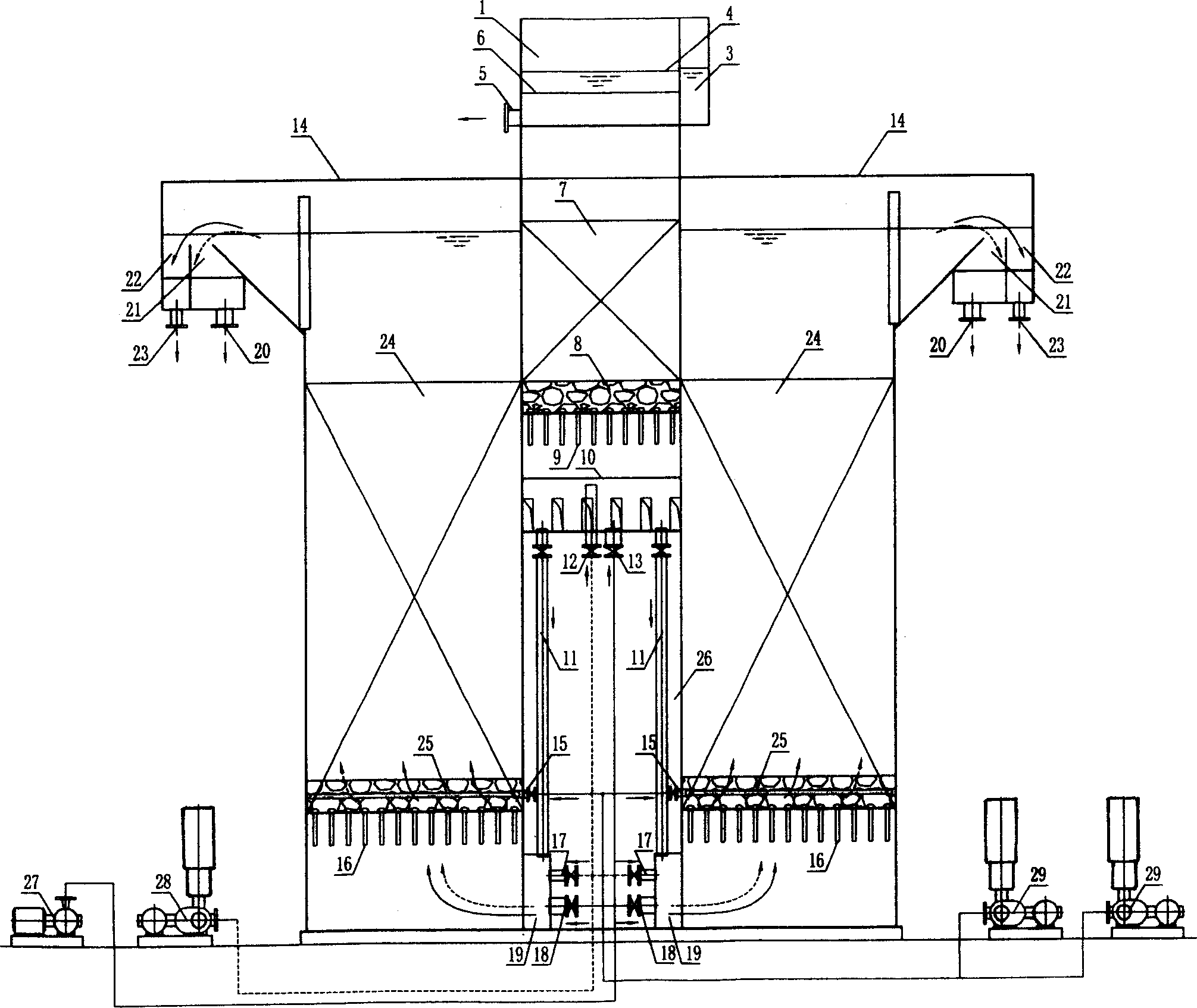

Laminated aerator biological filter pool and its method for pretreat light-pollution primary water

InactiveCN1896013AImprove purification efficiencyImprove water qualityTreatment using aerobic processesSustainable biological treatmentAmmoniacal nitrogenBiofilm

A laminated aeration biological filter pool and its treatment for pre-treatment micro-pollution primary water are disclosed. The laminated aeration biological filter pool consists of settlement pre-aeration biological filter pool and two ascending aeration biological filter pools, pipe corridor with height 3.5-4m and the same cross section area is arranged at bottom of settlement pre-aeration biological filter pool and two ascending aeration biological filter pools are located at both sides of pipe corridor and settlement pre-aeration biological filter pool. The process is carried out by filtering suspended substance, shellfish and algae in primary water by large-particular filter material of settlement pre-aeration biological filter pool and removing ammonia-nitrogen, organic substance, algae and split biological membrane under double-action of biological membrane and small-particular filter material in ascending aeration biological filter pool. It is cheap, has better space utilization ratio and purification efficiency and saves energy source. It can be used for micro-pollution water supply biological pre-treatment.

Owner:SOUTH CHINA UNIV OF TECH

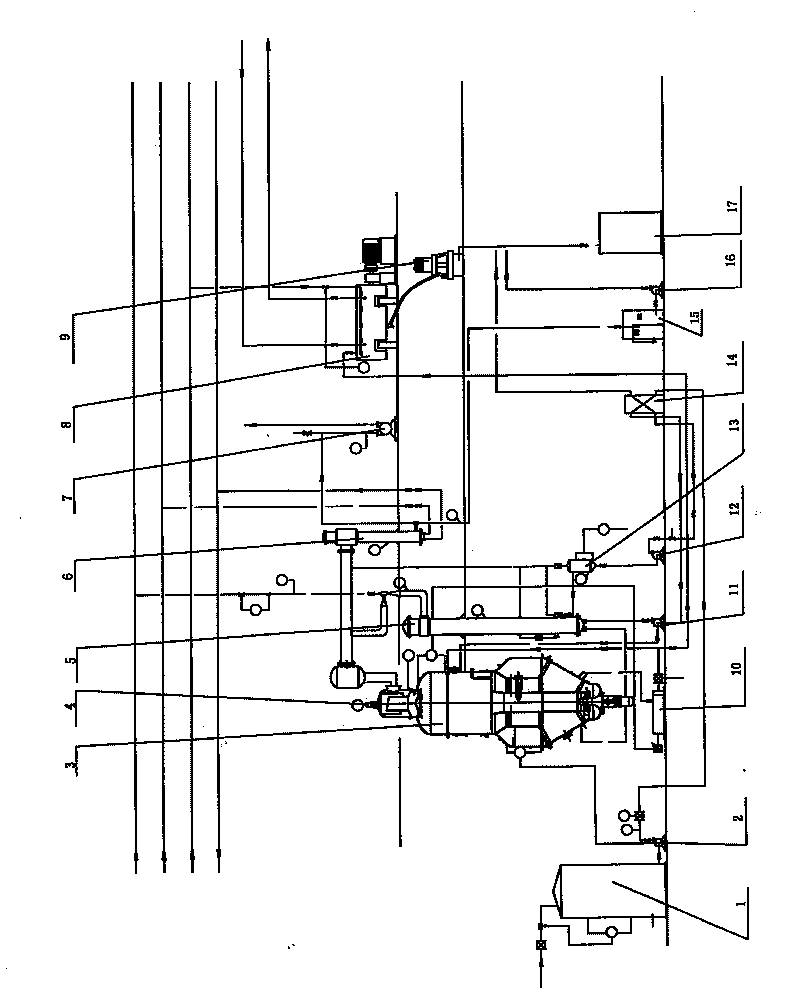

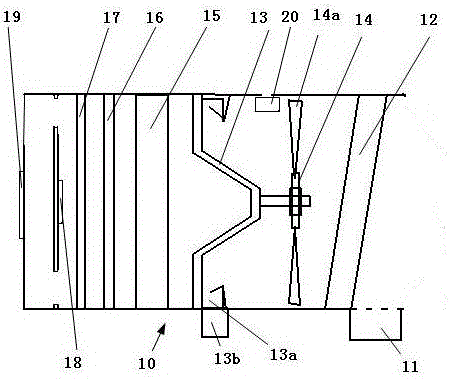

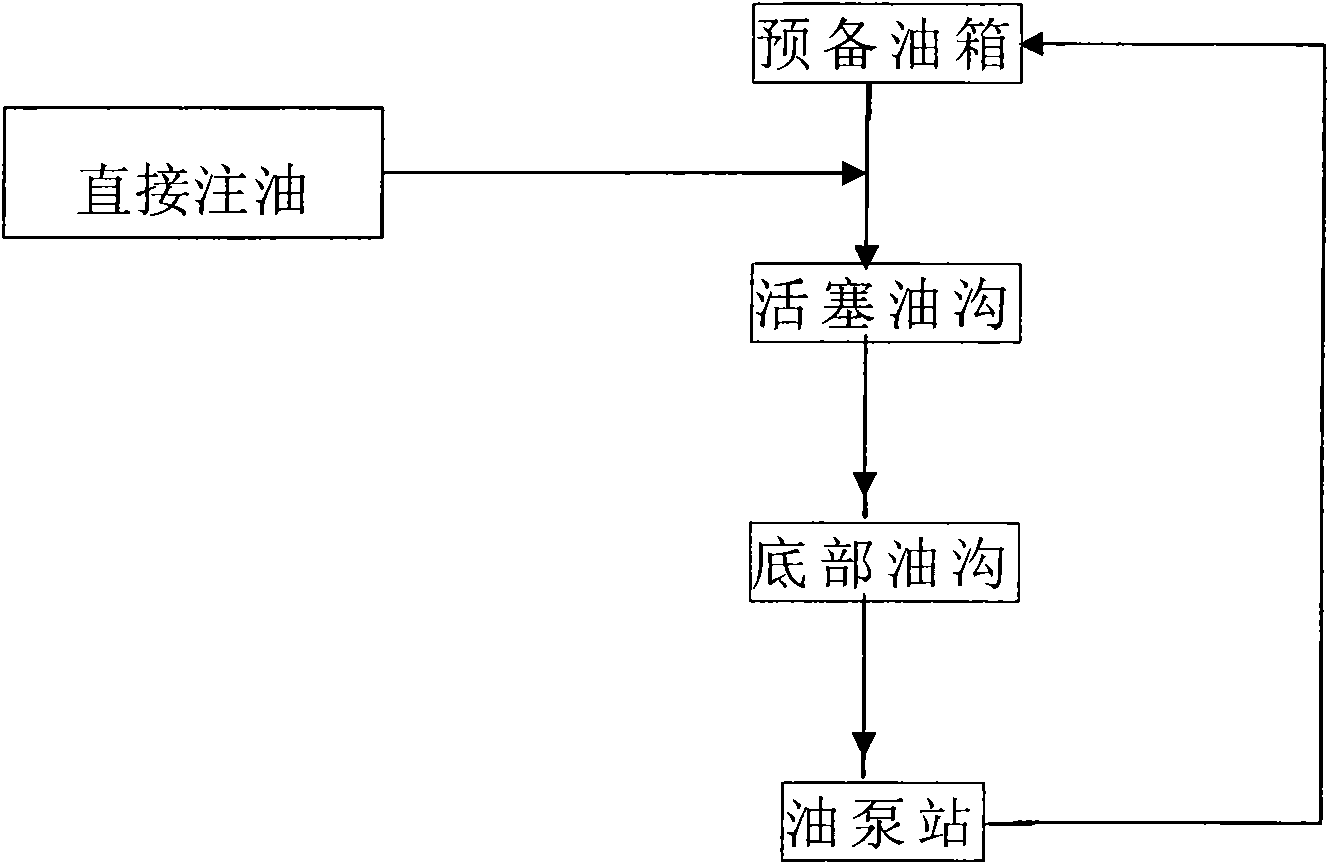

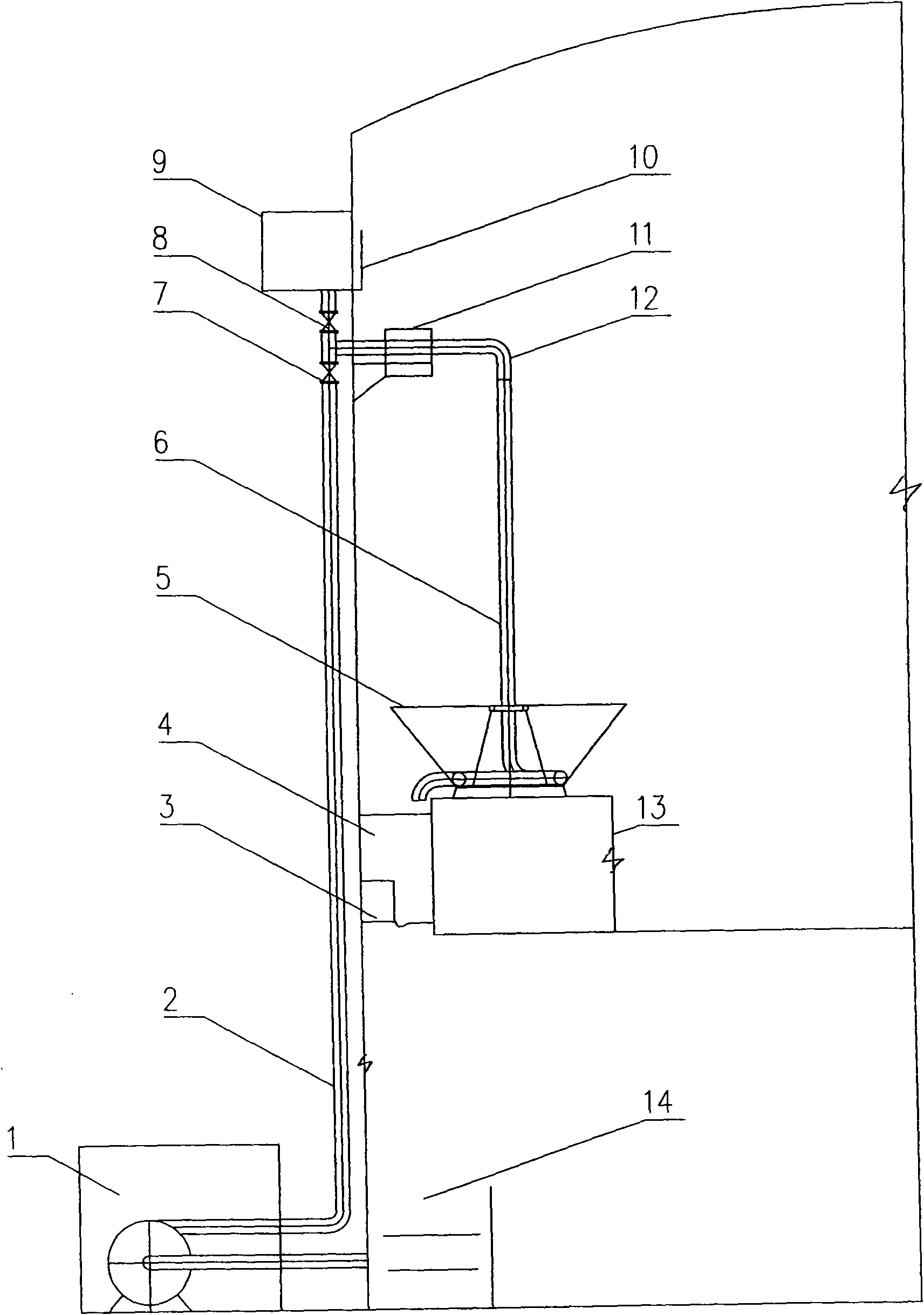

Dry type gas-holder seal oil cycling device

ActiveCN101644380APrevent splashReduce the number of unitsPipe supportsVariable capacity gas holdersPipe supportGas holder

The invention belongs to the technical field of general engineering, and in particular relates to a dry type gas-holder seal oil cycling device, which comprises an oil pump station and a seal oil overflow system, wherein a tee joint arranged between two valves of a seal oil ascension pipe is connected with an upper part fixed joint of an oil rubber hose; the upper part fixed joint is arranged on apipeline support frame; the oil rubber hose is placed in a spooler; the spooler is placed on a gas-holder piston annular beam; and an outlet of the oil rubber hose is in a piston oil gallery. The drytype gas-holder seal oil cycling device has remarkable effect, solves the problem of the splatter of seal oil in a gas holder through a cycling system, reduces the number of the oil pump station, saves the original cost and operating cost and improves safety, and can be widely applied to the dry type gas holder.

Owner:CISDI ENG CO LTD

Little deformation welding process for mini car rear-axle housing

InactiveCN101407013AGood deformation controlReduce the number of equipmentArc welding apparatusEngineeringEnergy consumption

The invention discloses a small deformation welding process for a rear-axle housing of a mini vehicle, which belongs to the field of mechanical processing. The process comprises the welding of a middle segment assembly of a rear axle of the mini vehicle, the welding of a axle sleeve assembly of the rear axle of the min vehicle and the welding of the rear-axle housing assembly of the mini vehicle. The process has the advantages that: 1. a connecting disk is unnecessarily processed after being welded; 2. the welding order (welding unit) is reset for easy deformation control; 3. by adopting the rigid clipping welding, the product quality is ensured; and 4. compared with the prior art, the process has the advantages of few equipment, low process cost, low energy consumption, low processing cost, small manufacturing area, smooth logistics and high labor capacity.

Owner:CHENGDU HANYAN TECH +1

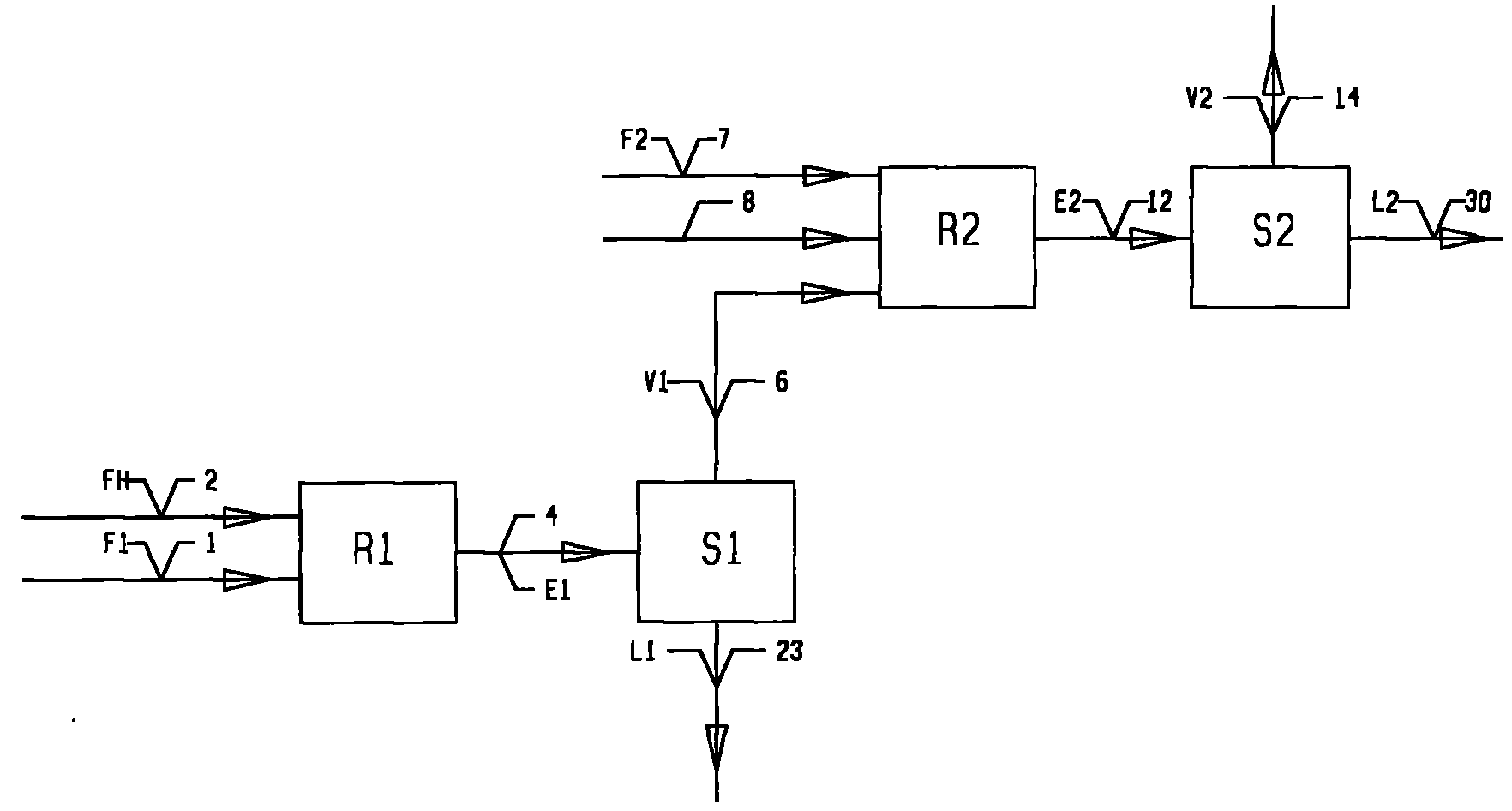

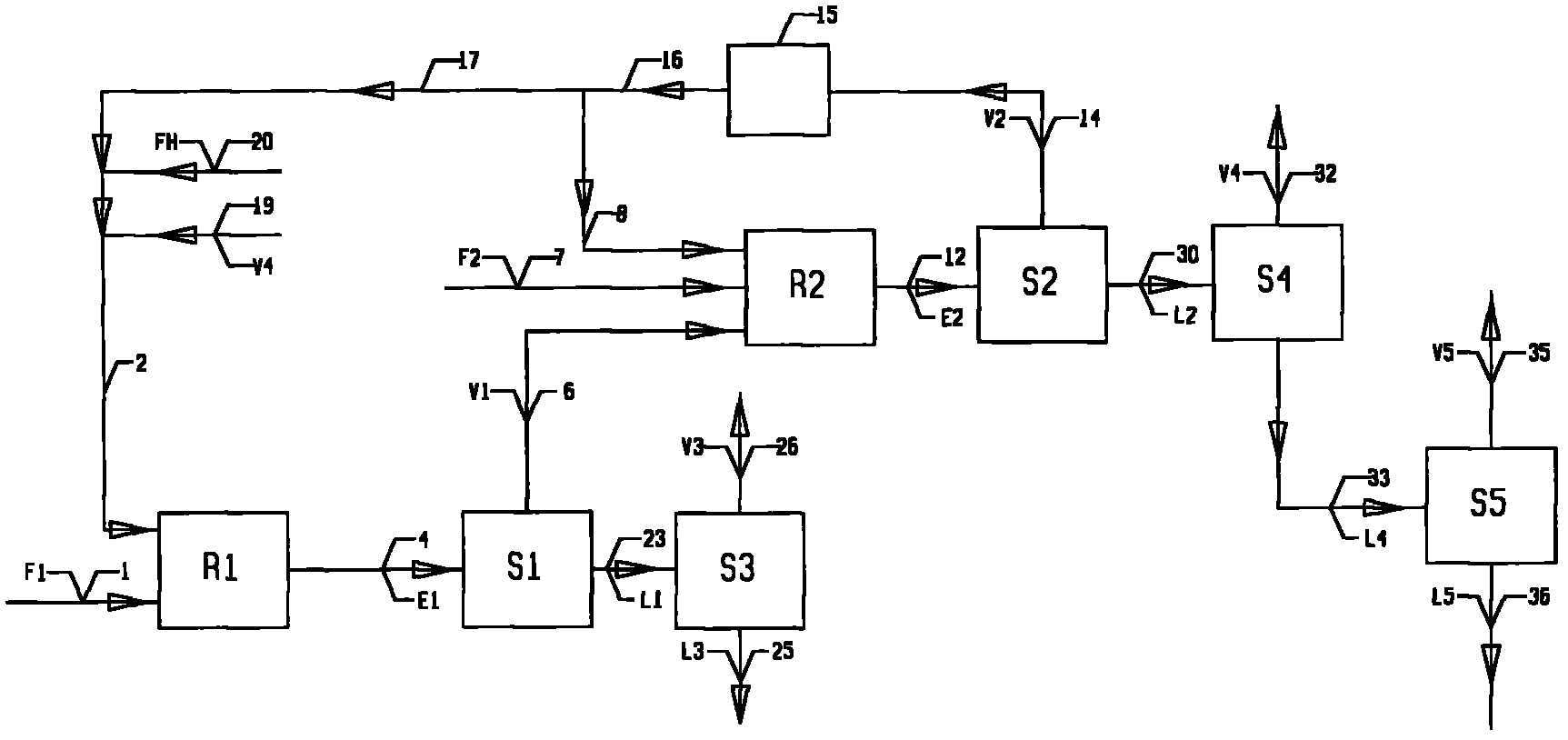

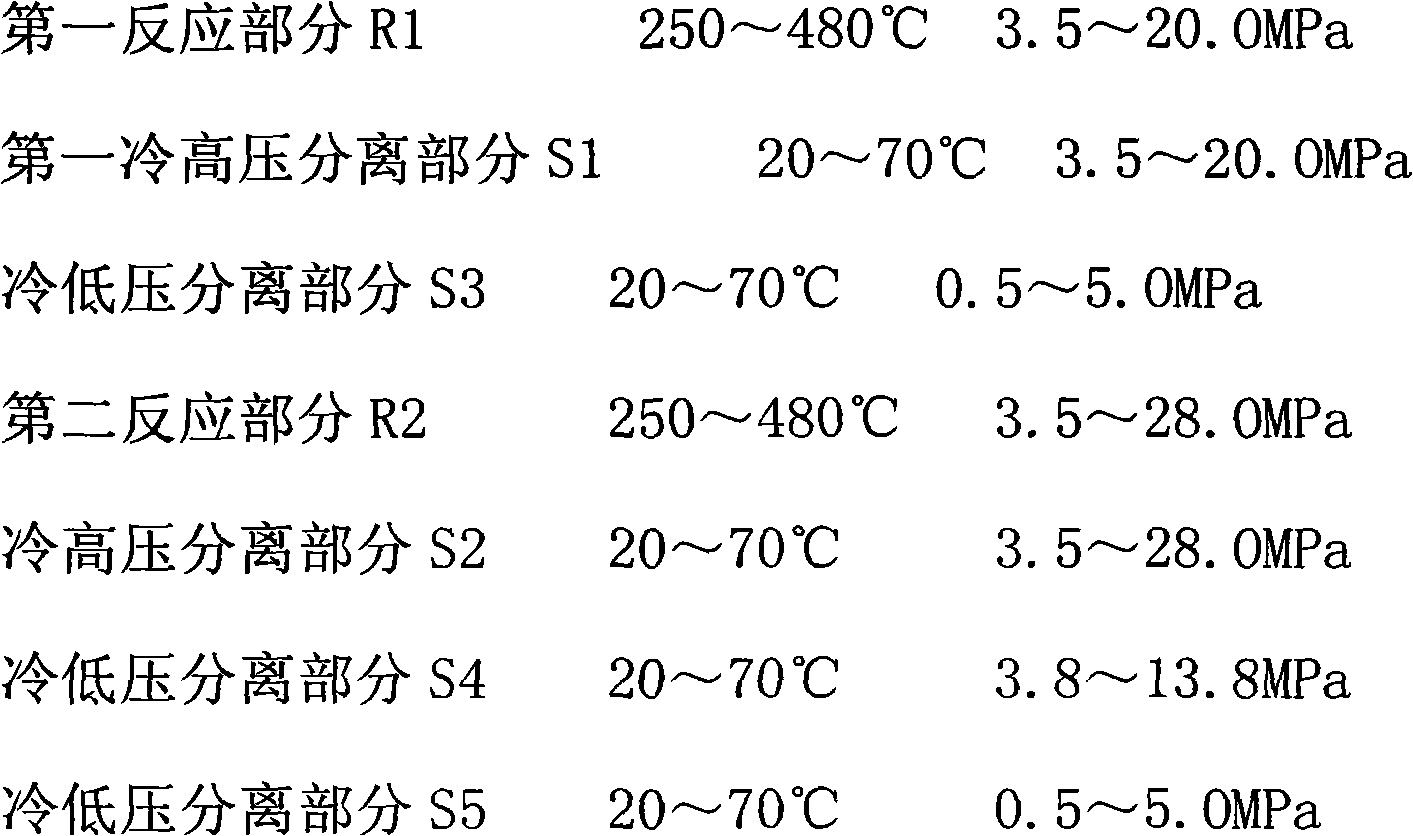

Hydrocarbon hydrogenation conversion process combined method

InactiveCN102146298AReduced dedicated cycle hydrogen volumeLess investmentTreatment with hydrotreatment processesHydrodesulfurizationCombined method

The invention relates to a hydrocarbon hydrogenation conversion process combined method which comprises steps as follows: a first reaction effluent E1 obtained by new hydrogen FH and a first hydrocarbon raw material F1 at a first reaction part R1 is separated into a first cold high-pressure hydrogen-rich gas V1 and a first cold high-pressure hydrocarbon liquid L1 at a first cold high-pressure separation part S1; at least part of V1 enters a second reaction part R2 for treating a second hydrocarbon raw material F2; and a second reaction effluent E2 is separated into a second cold high-pressure hydrogen-rich gas V2 and a second cold high-pressure hydrocarbon liquid L2 at a second cold high-pressure separation part S2. The invention also comprises the step of recovering dissolved hydrogen in the L2. The invention has obvious effects of saving the step of high-pressure operation, reducing the hydrogen consumption and the like, is suitable for the combination of a medium / low-pressure low-hydrogen-consumption hydrocarbon hydrogenation process (such as petroleum-based gasoline / diesel hydrofining, wax oil hydrodesulfurization or low-sulfur diesel hydrogenation and aroma removal process) and a high-pressure high-hydrogen-consumption hydrocarbon hydrogenation process (such as coal tar hydrogenation process).

Owner:何巨堂

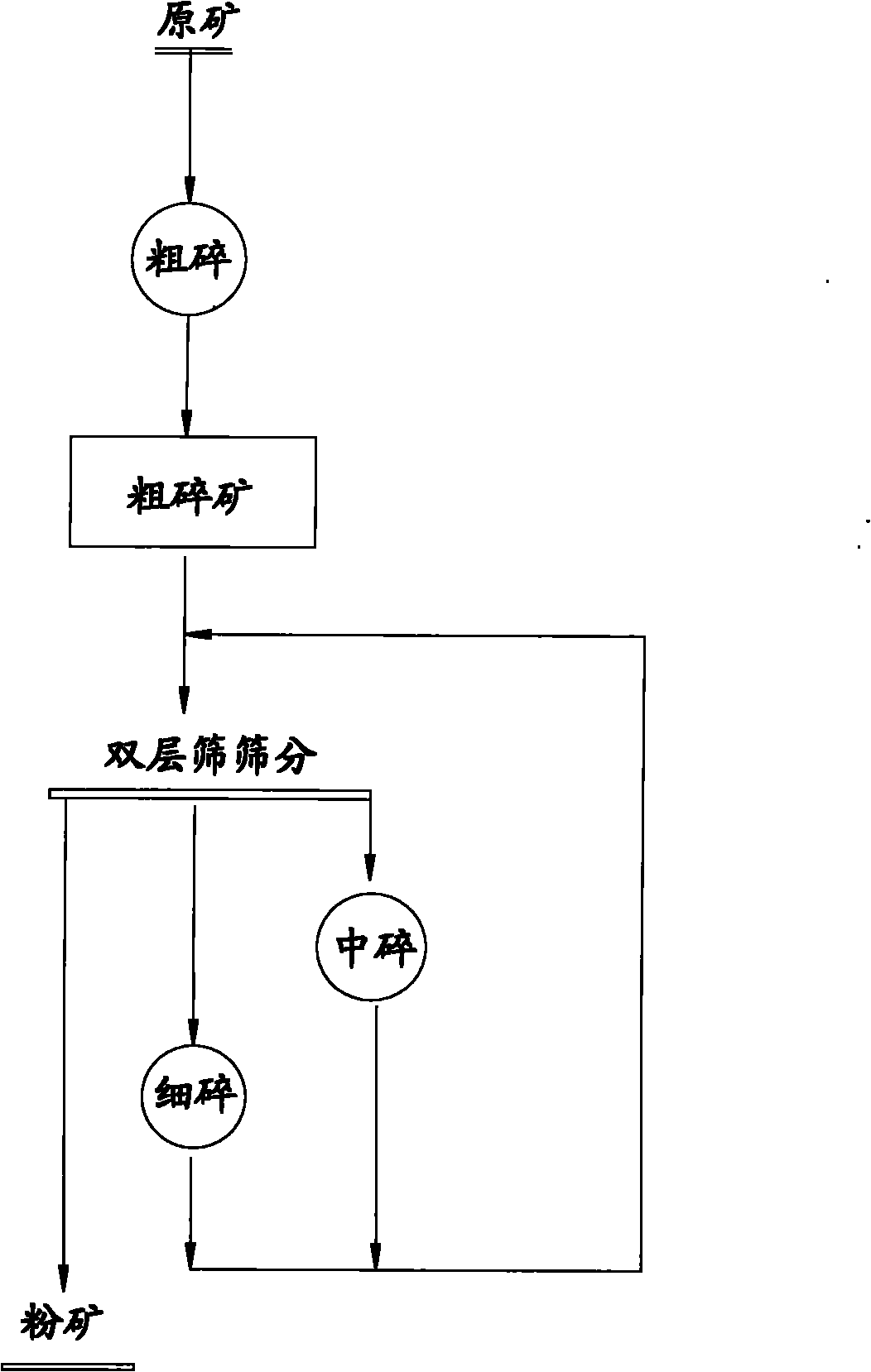

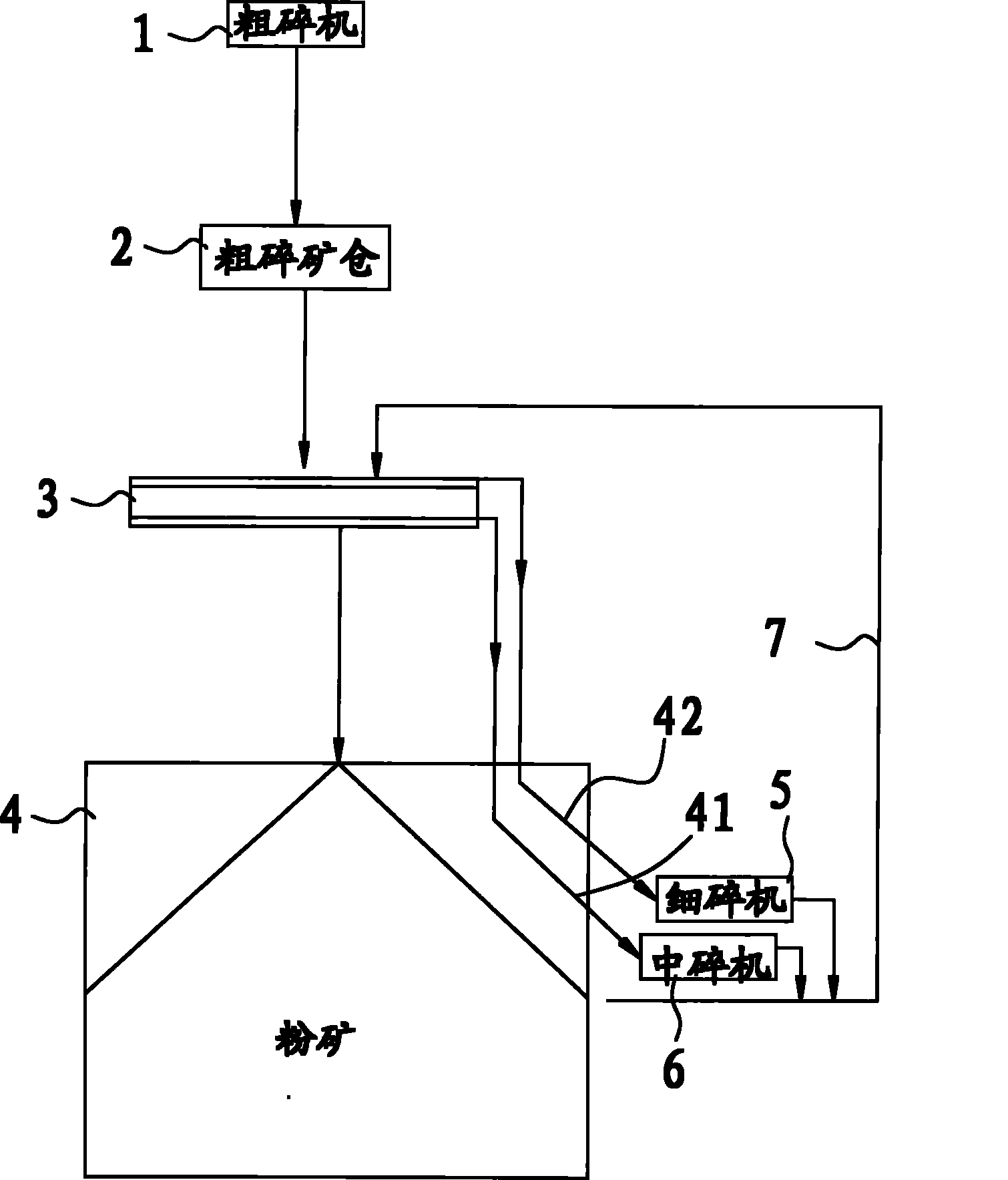

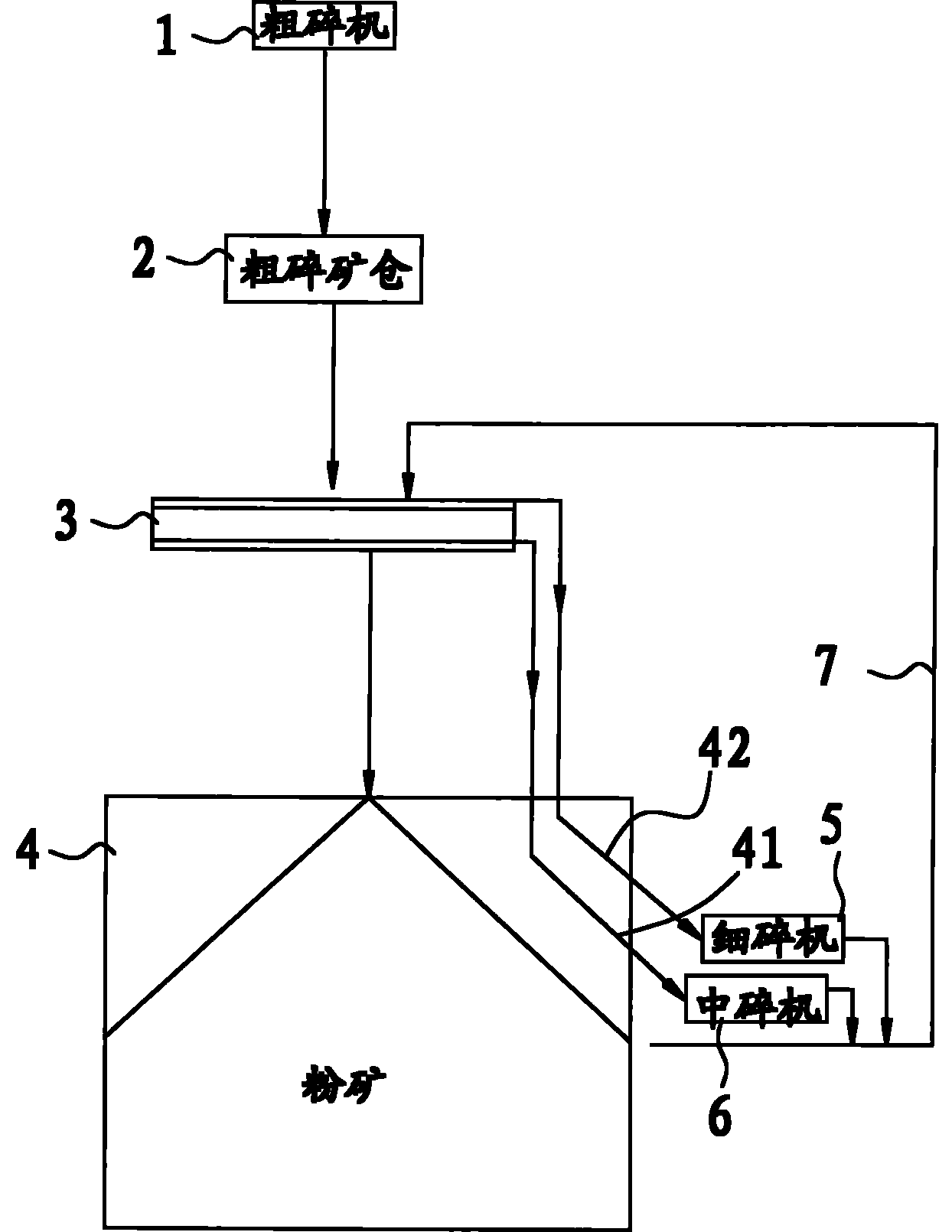

Ore-crushing device

The invention discloses an ore-crushing device which comprises a coarse crusher, a double-layer sieve, an intermediate crusher, a fine crusher and a conveyor; the coarse crusher crushes raw ore coarsely; the double-layer sieve is connected with the coarse crusher and is used for receiving coarsely crushed ore from the coarse crusher and sieving the coarsely crushed ore in two stages; the intermediate crusher is connected with the double-layer sieve and is used for receiving ore on an upper-layer sieve from the double-layer sieve and intermediately crushing the ore on the upper-layer sieve; the fine crusher is connected with the double-layer sieve and is used for receiving ore on a lower-layer sieve from the double-layer sieve and finely crushing the ore on the lower-layer sieve; and the conveyor is respectively connected with the intermediate crusher and the finer crusher and is used for returning and conveying the intermediately crushed ore and the finely crushed ore to the double-layer sieve. The ore-crushing device has simple structure, less equipment and low cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

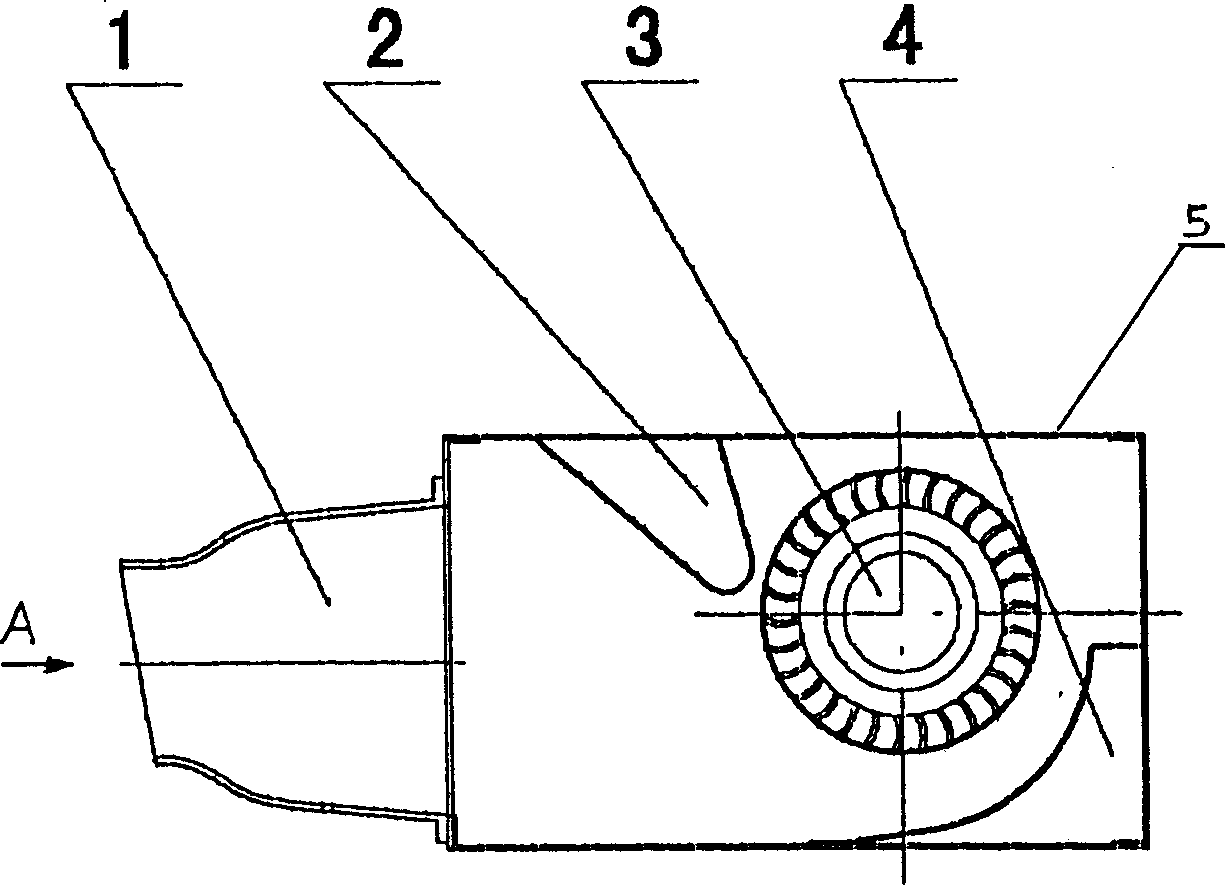

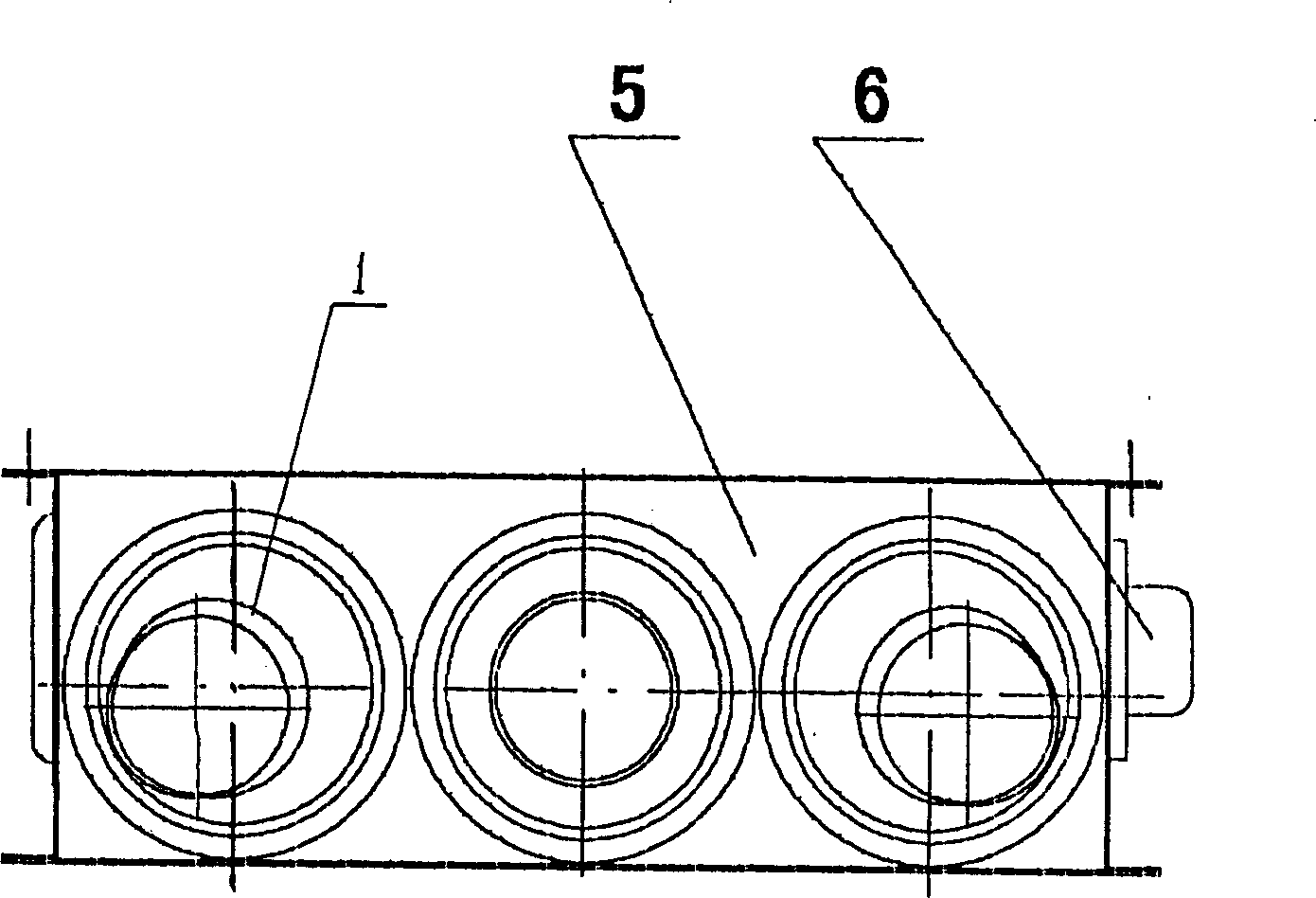

Induced fan

InactiveCN1508485AReduce construction costsLarge thrustLighting and heating apparatusVentilation systemsImpellerElectricity

The invention discloses a kind of guiding fan for ventilation in large location, the structure comprises chassis, snoot with variable angles, there sets electricity machine and cross-flow blade wheel connecting to the output shaft at the side of the chassis, its shaft direction corresponds to the shaft of the snoot. There has a guiding volute on the inner wall of chassis back of the blade wheel, there has a countercurrent resisting volute tongue, when the electricity machine drives the blade wheel to rotate, the air enters form the back of the chassis, through guiding volute, countercurrent resisting volute tongue and snoot, it uses high speed air to guide air to the fixed direction and region.

Owner:北京新安特风机有限公司

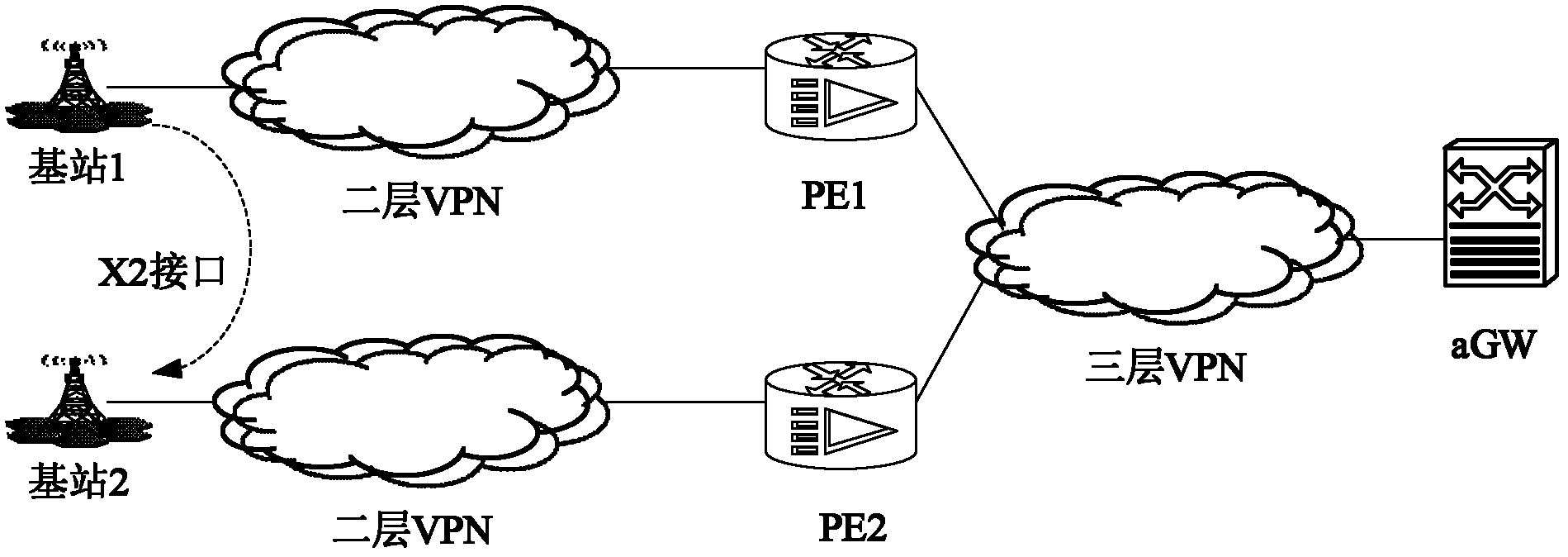

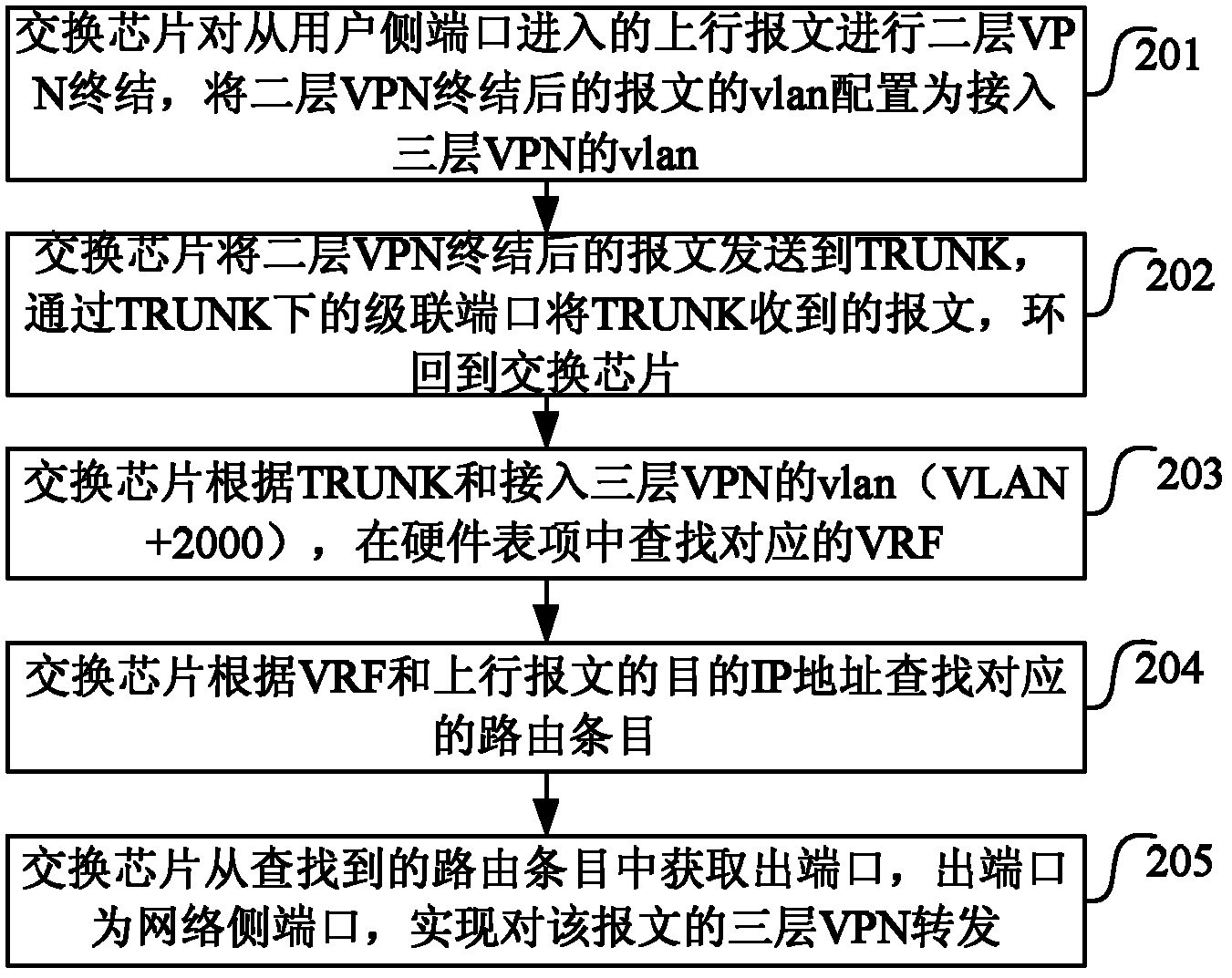

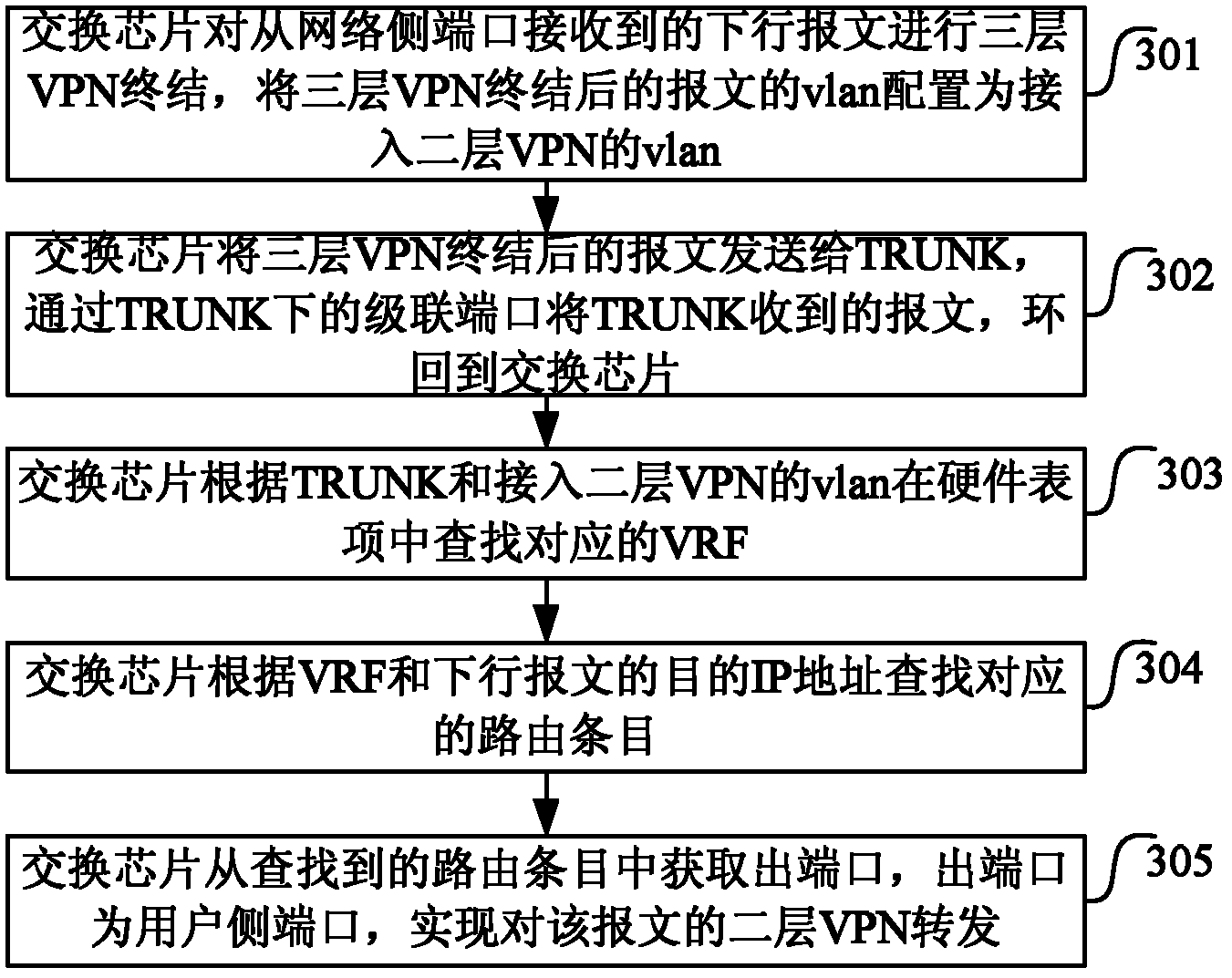

Method and device for forwarding virtual private network message

ActiveCN102291317AReduce complexityReduce the number of unitsEnergy efficient ICTNetworks interconnectionPrivate networkTrunking

A method and device for forwarding message of virtual private network. The method comprises: a Network Provider Edge Router(PE) carries out two-layer Virtual Private Network(VPN) conclusion on an uplink message received from a two-layer VPN and sends the uplink message subjected to the two-layer VPN conclusion to a port configured as a self loop; the PE receives the uplink message looped by the port configured as the self loop and subjected to the two-layer VPN conclusion and carries out three-layer VPN forwarding on the uplink message subjected to the two-layer VPN conclusion. According to the method and device, the two-layer VPN conclusion to the three-layer VPN forwarding is enabled by adopting a port trunking, uplink and downlink can be distinguished by only using one port trunking in a two-layer VPN and three-layer VPN networking, and therefore, the number of used networking equipment is decreased, the complexity of a networking is reduced, maintenance and management cost is saved and networking becomes more flexible.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com