Continuous crystallizer

A technology of crystallizer and crystal slurry, which is applied in the direction of solution crystallization, etc., can solve the problems of poor ability to resist fluctuations in raw material quality, high impurity content of MSG finished products, low degree of automation, etc., and achieve quality improvement, high production capacity, and production cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

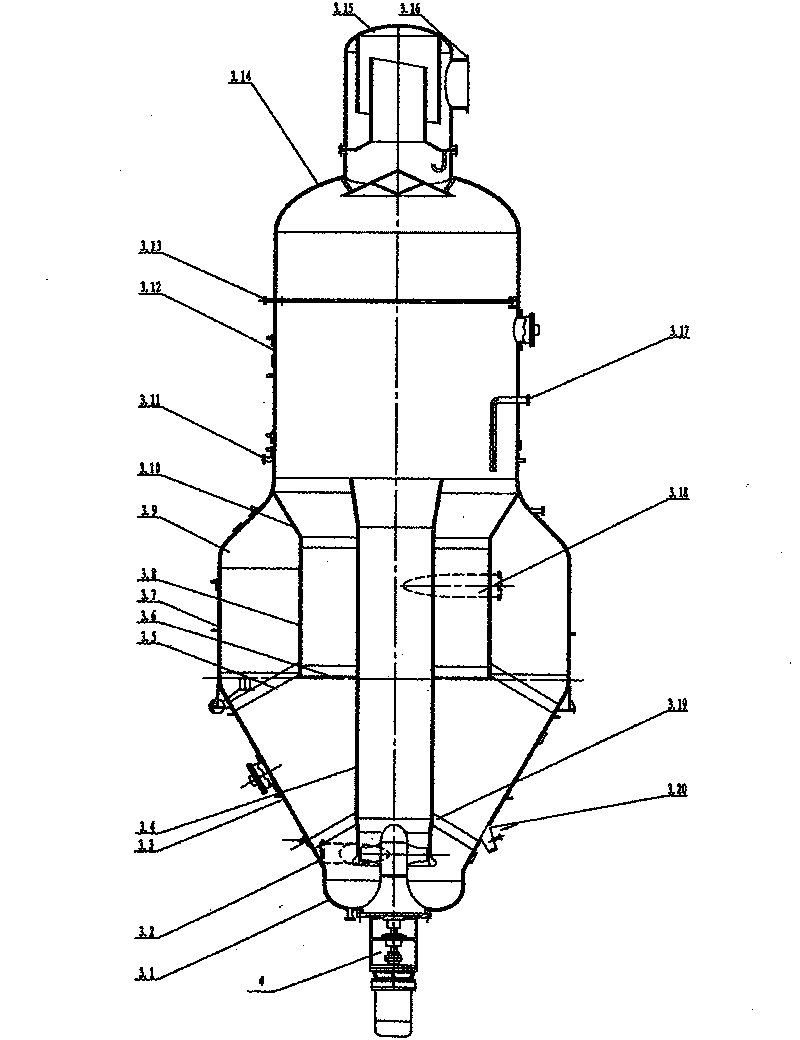

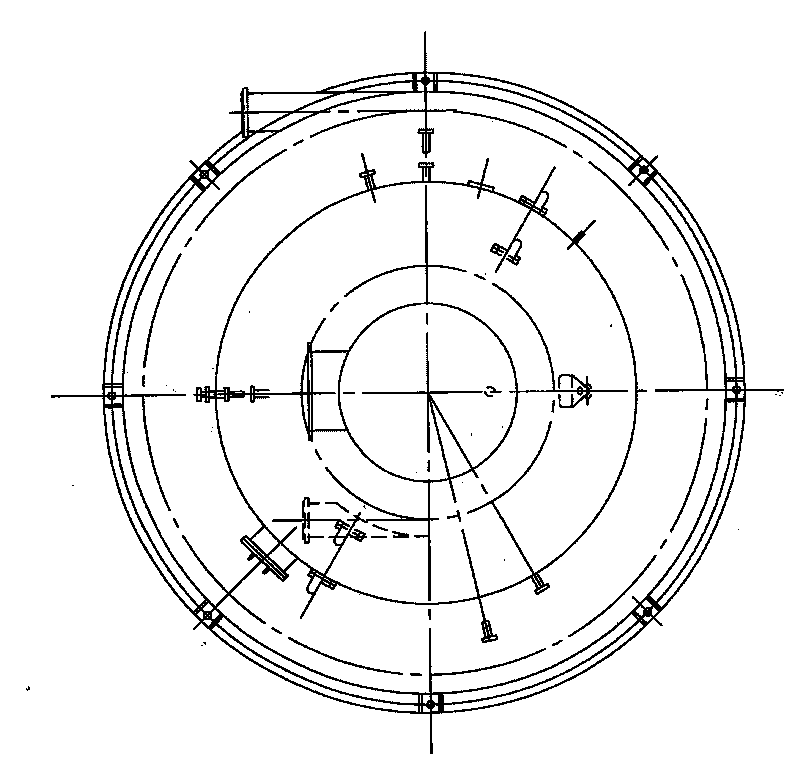

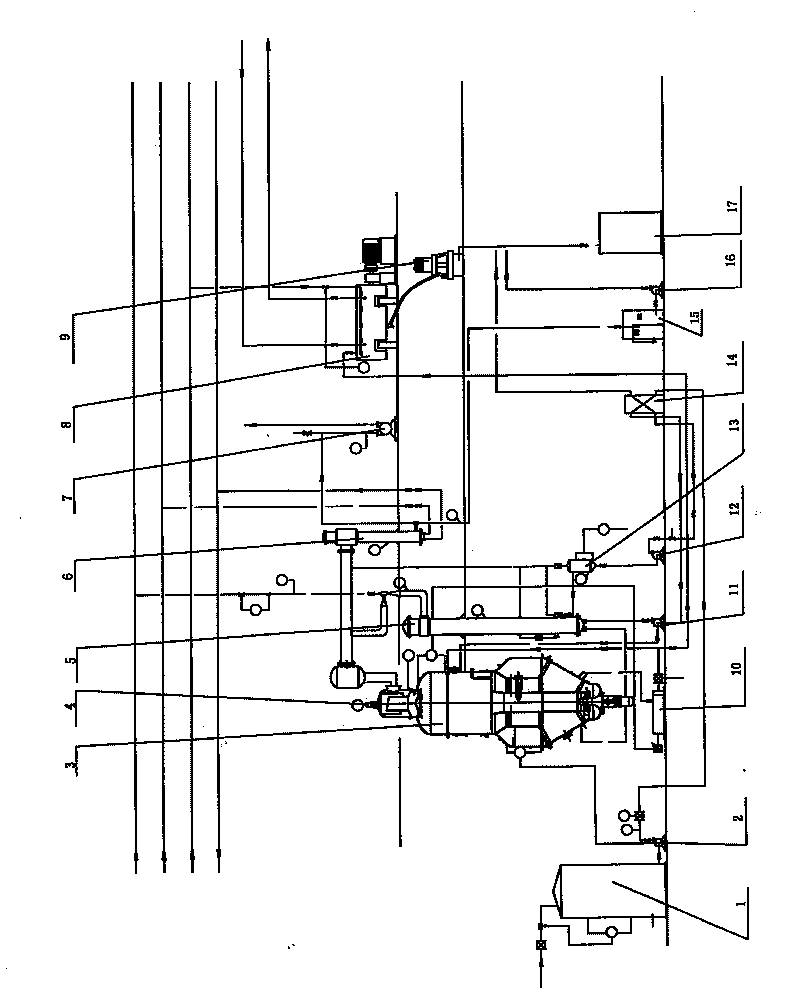

[0030] see Figure 1~2 , figure 1 It is a structural schematic diagram of the continuous crystallizer of the present invention. figure 2 for figure 1 top view. Depend on figure 1 and figure 2 It can be seen that the crystallizer 3 of the present invention consists of an upper head 3.14, an upper cylinder 3.12, an upper cone 3.9, a middle cylinder 3.7, a lower cone 3.3 and a bottom head 3.1 from top to bottom. connected. A spray pipe 3.13 is arranged horizontally inside the upper cylinder 3.12, and a crystal slurry circulation port 3.11 and an inoculation port 3.17 are connected to the wall of the upper cylinder 3.12 below the spray pipe 3.13. In order to prevent crystal deposition and Poor circulation, an inner cone 3.10 and an inner cylinder 3.8 are respectively arranged in the upper cone 3.9 and the middle cylinder 3.7, the inner cone 3.10 is connected to the top of the inner cylinder 3.8 in an inverted cone shape, the inner The outer edge of the cylinder body 3.8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com