Patents

Literature

84results about How to "Fully rolled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

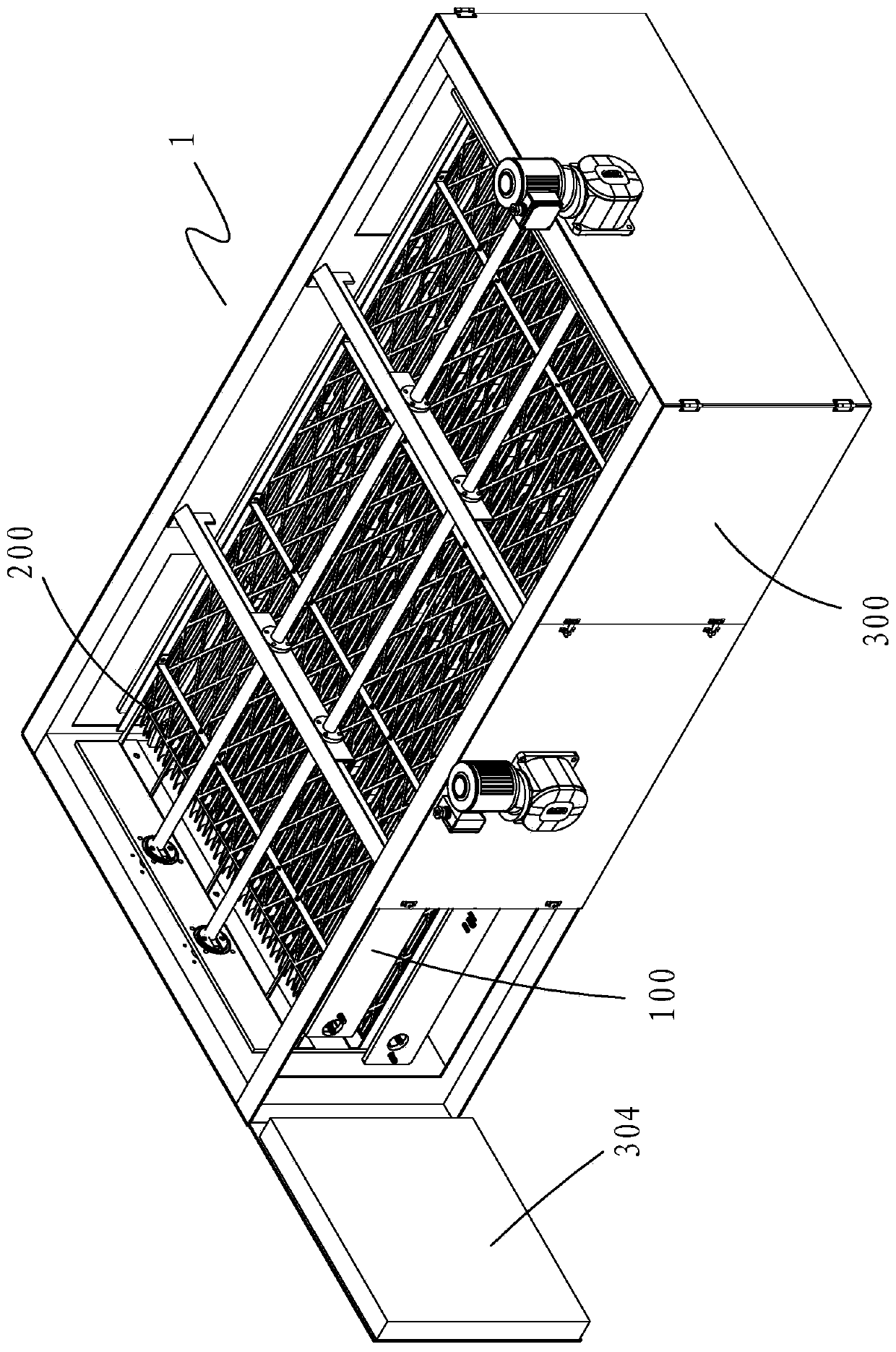

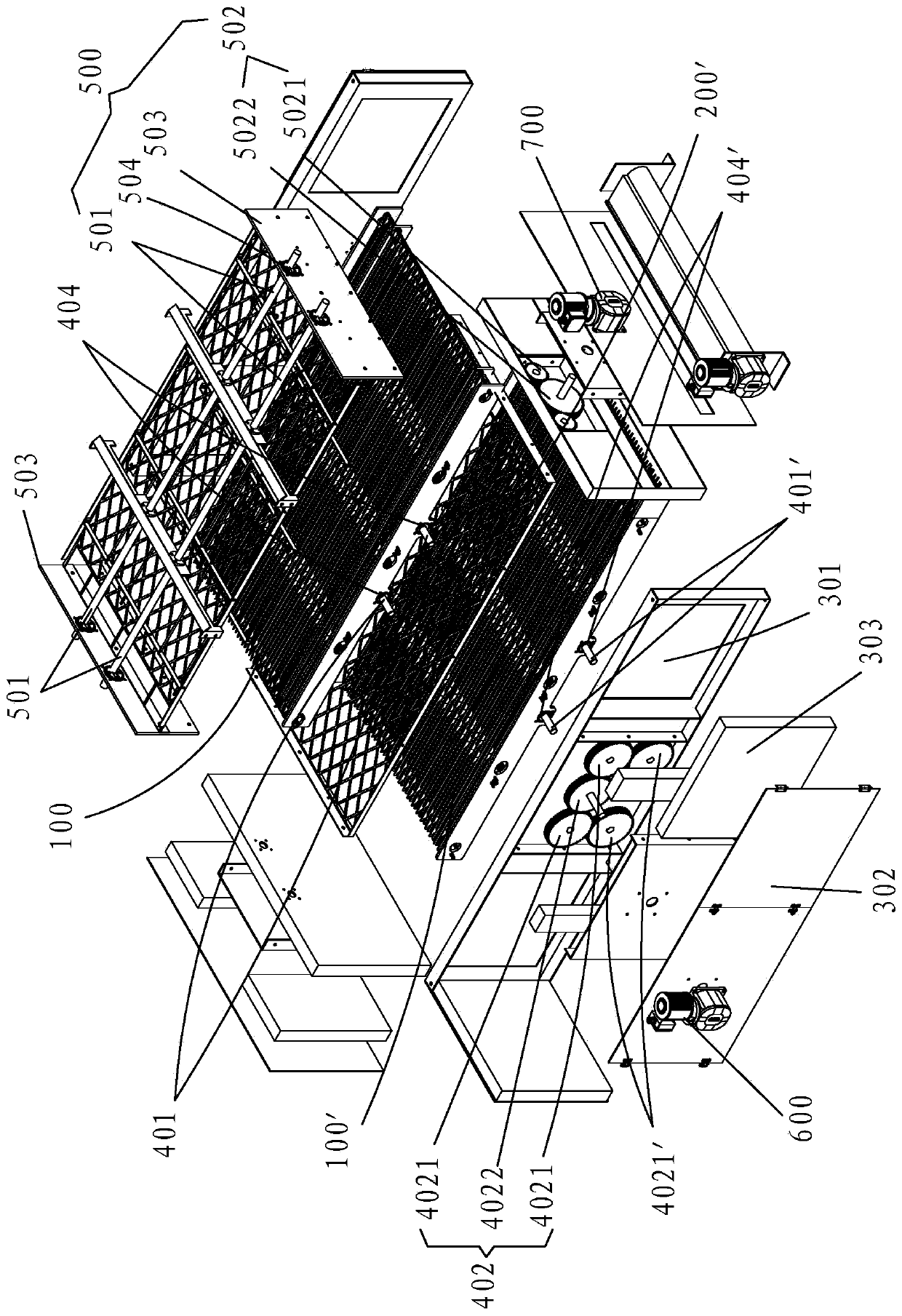

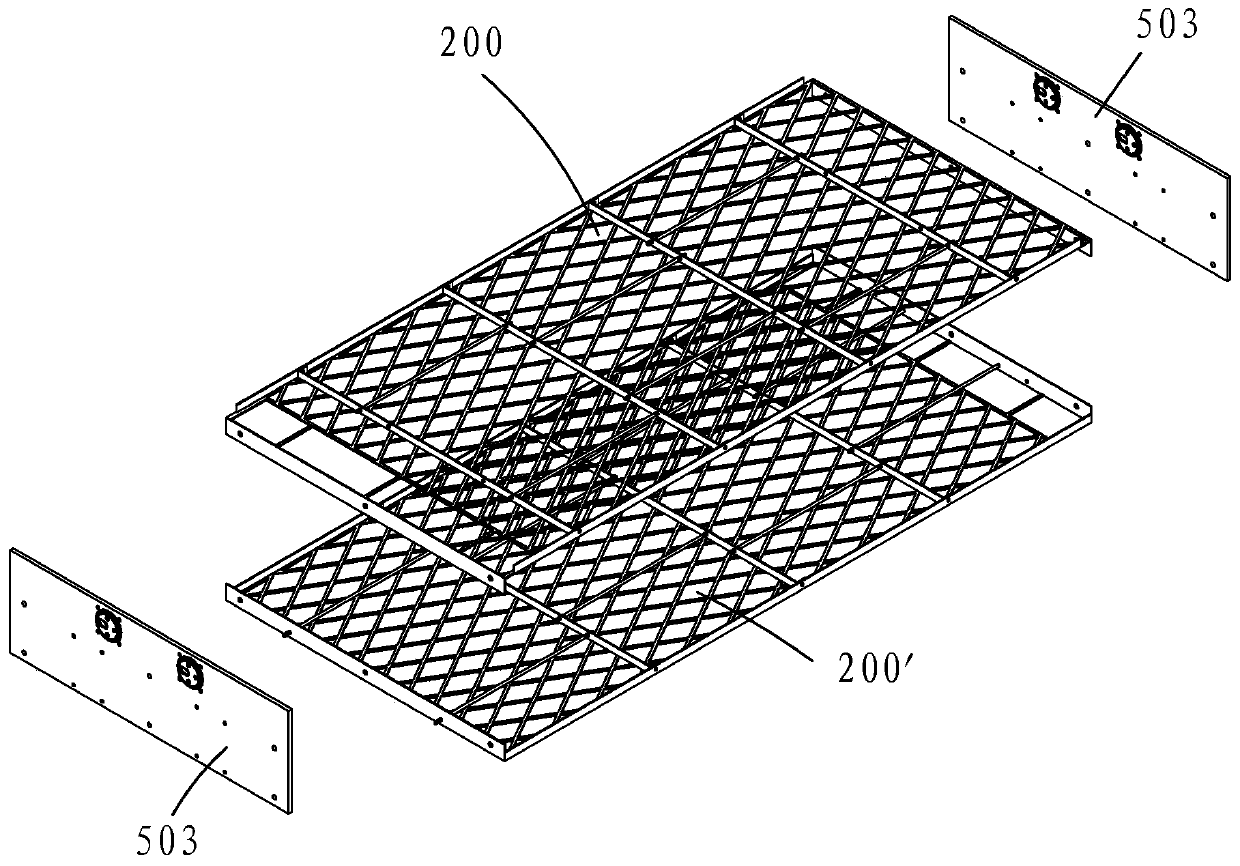

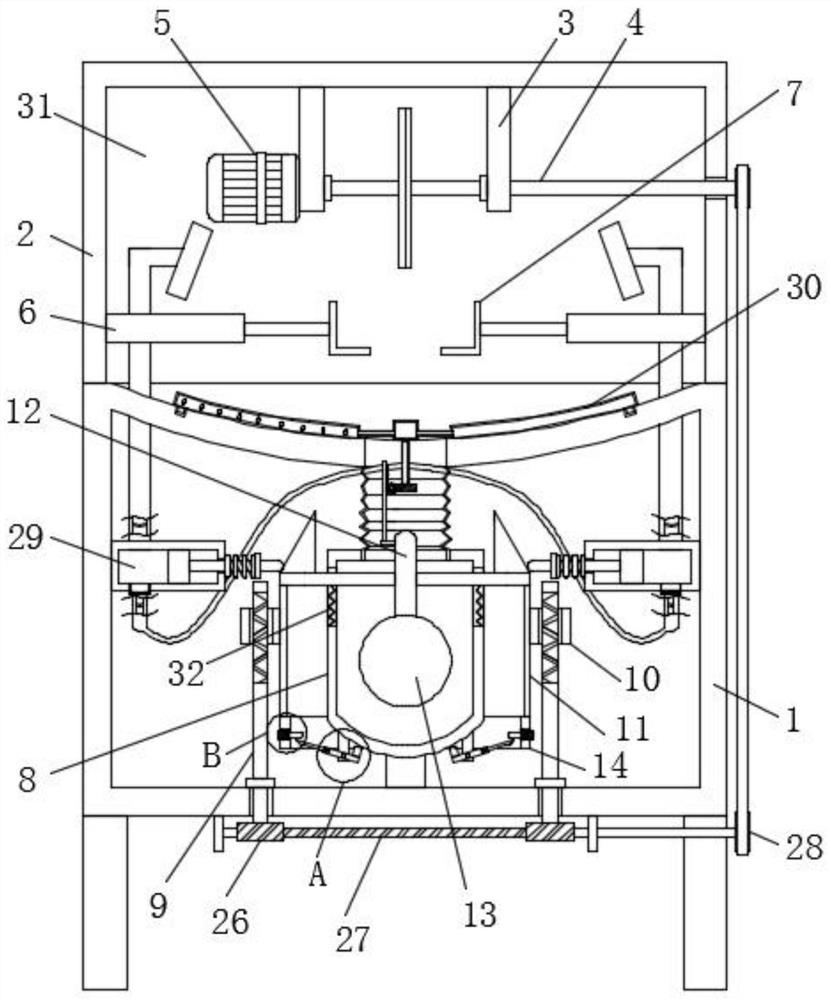

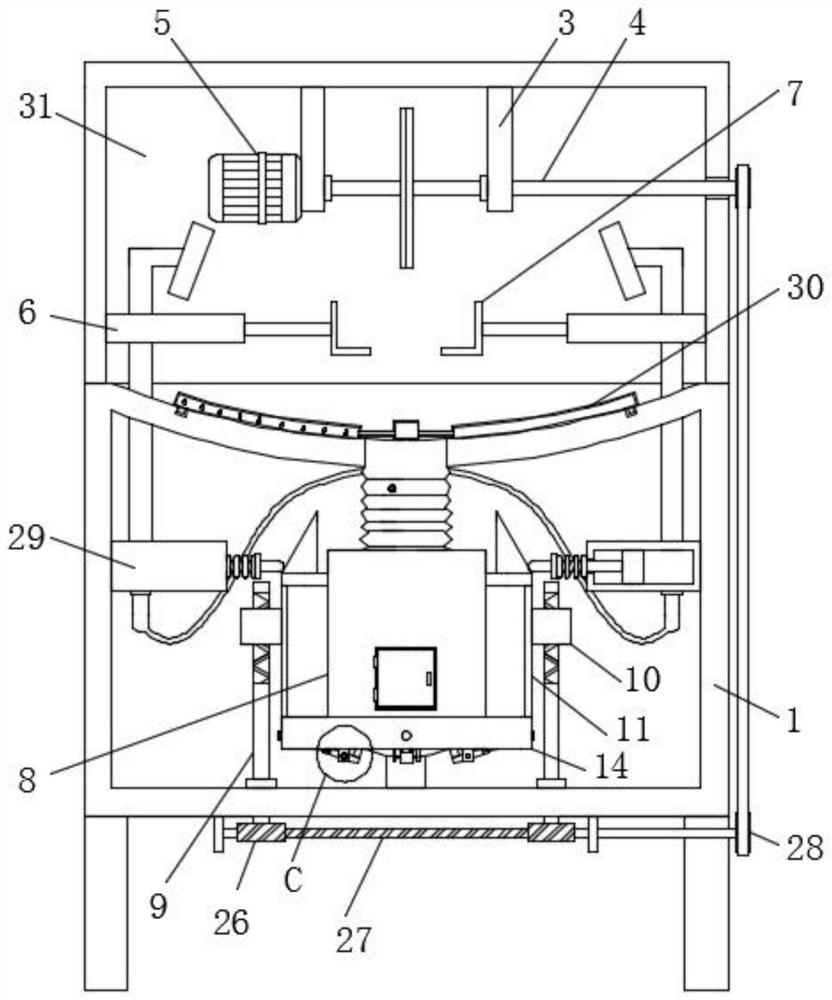

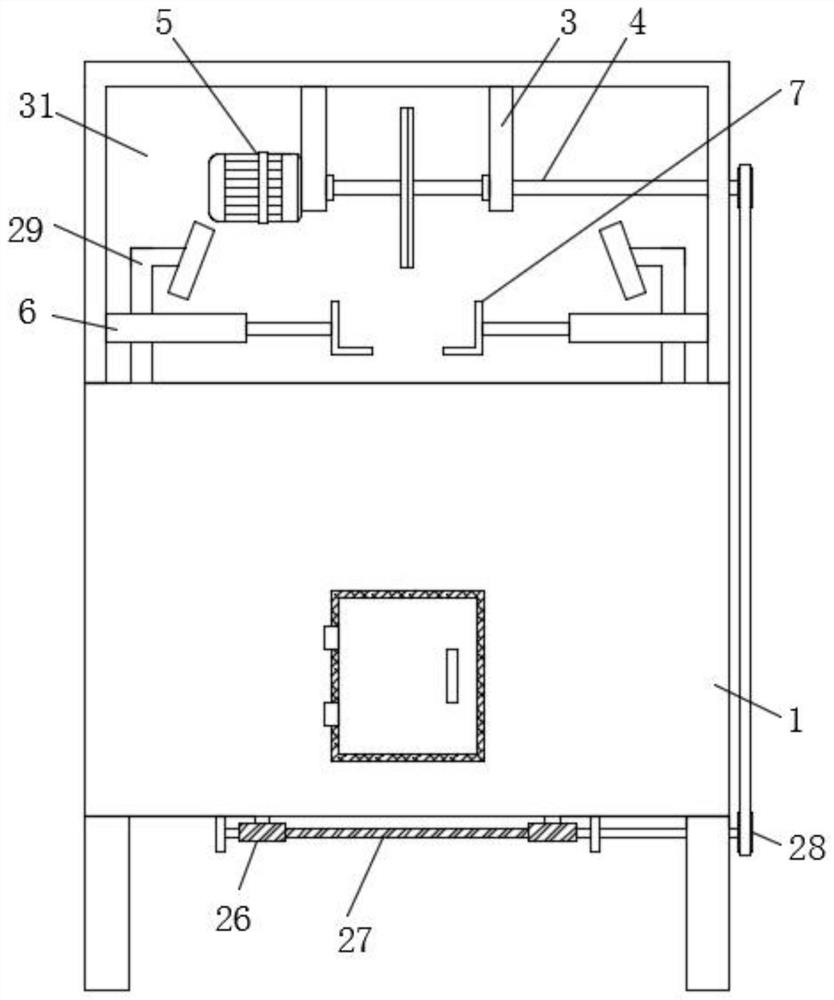

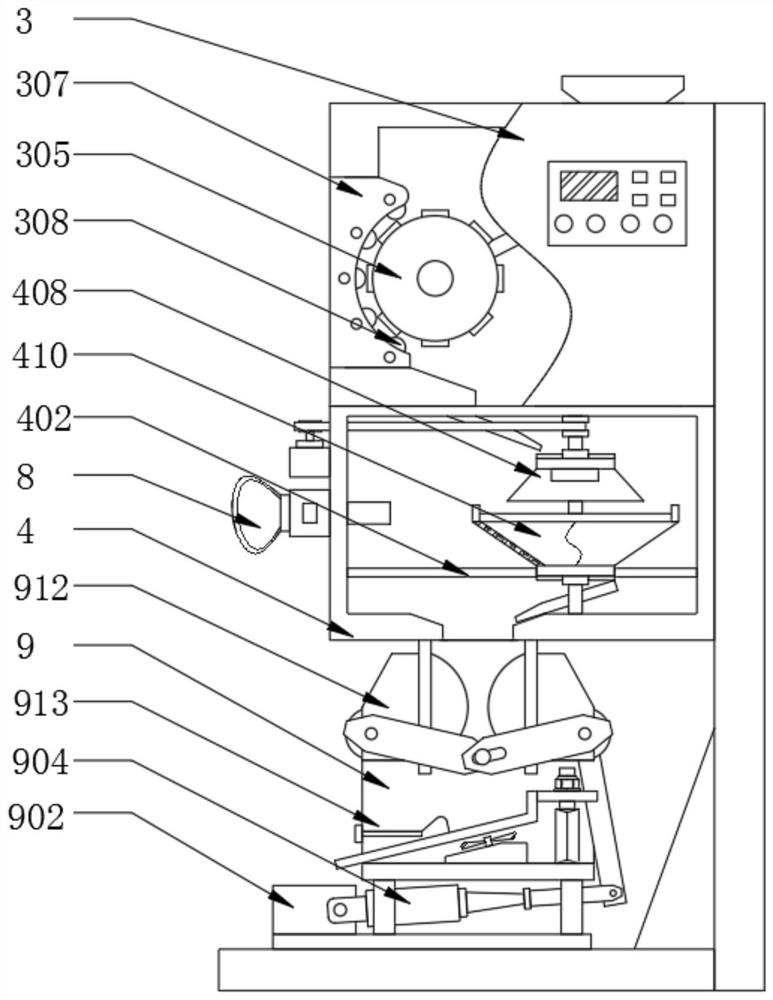

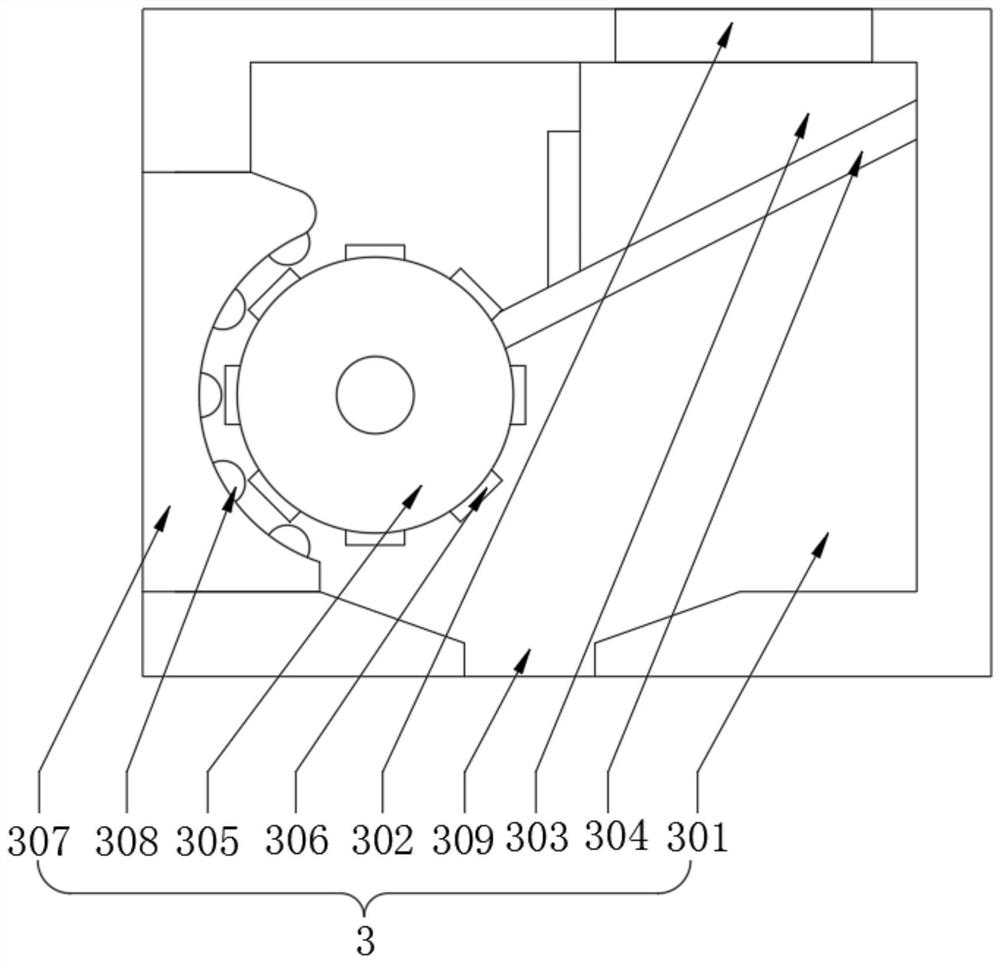

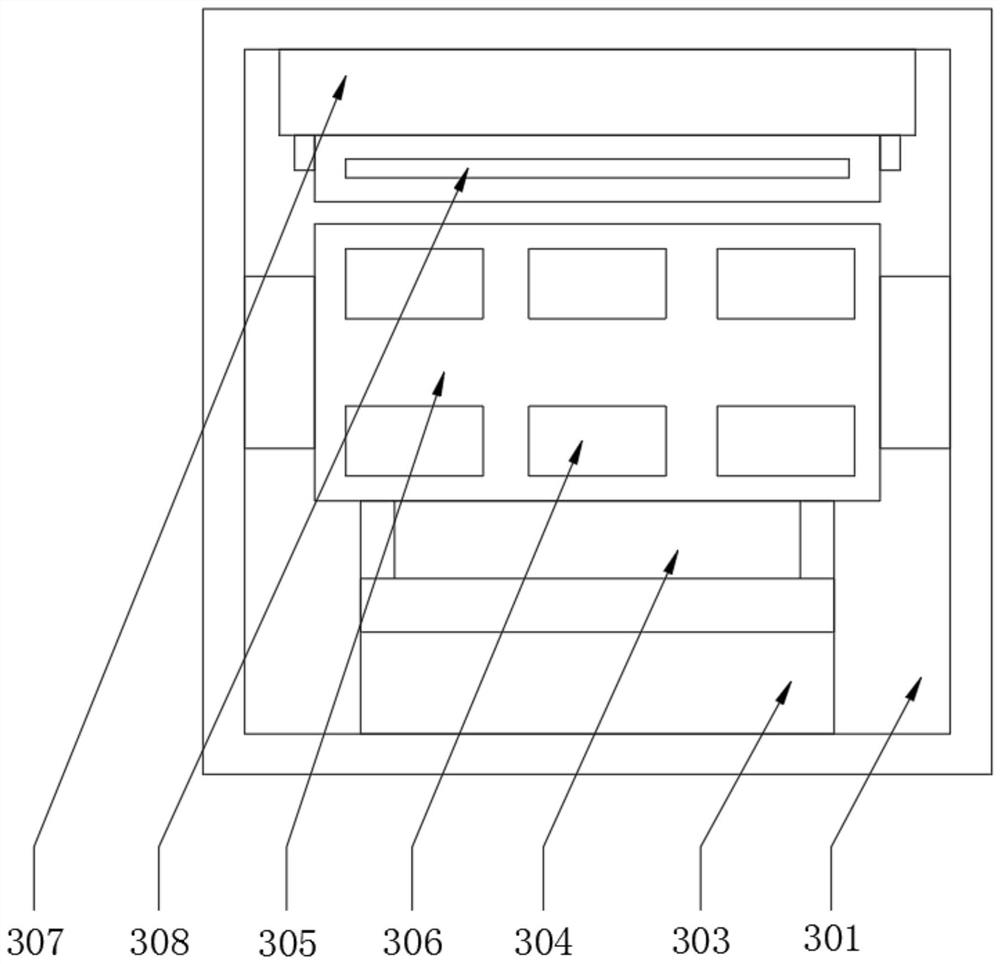

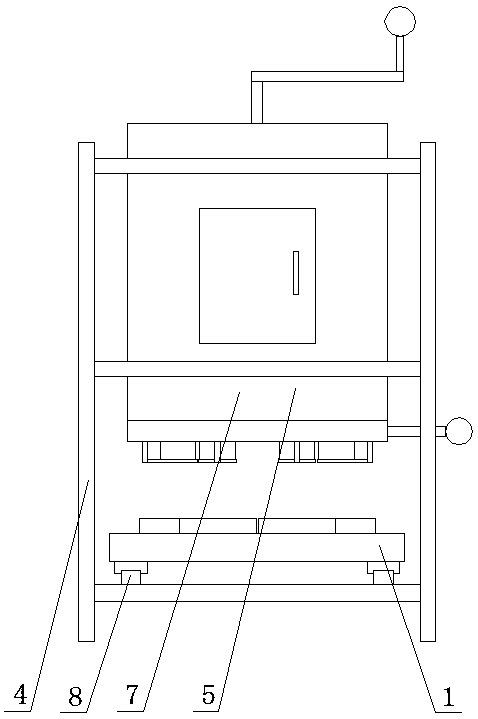

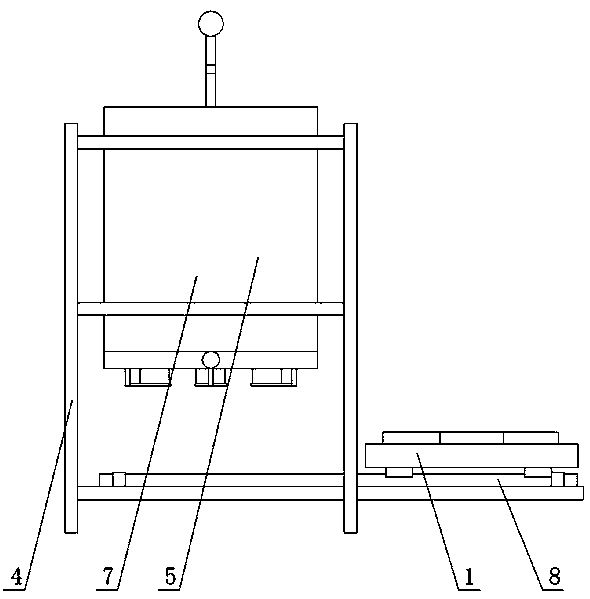

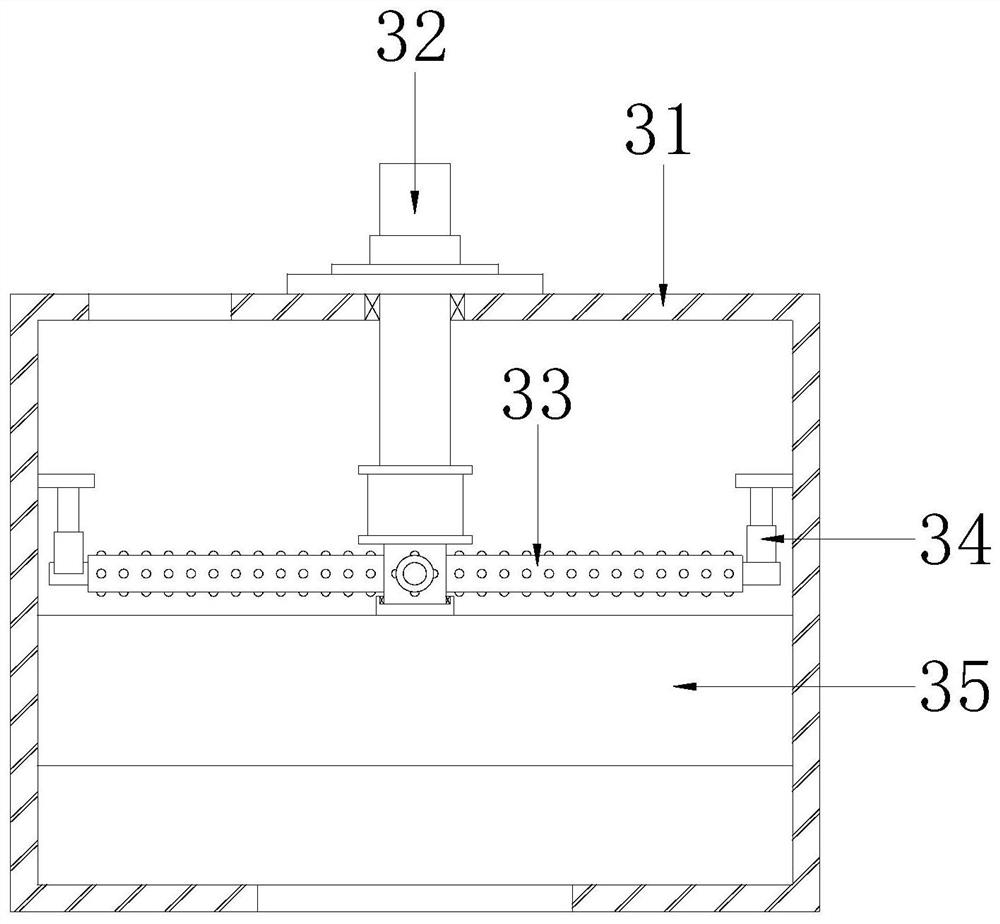

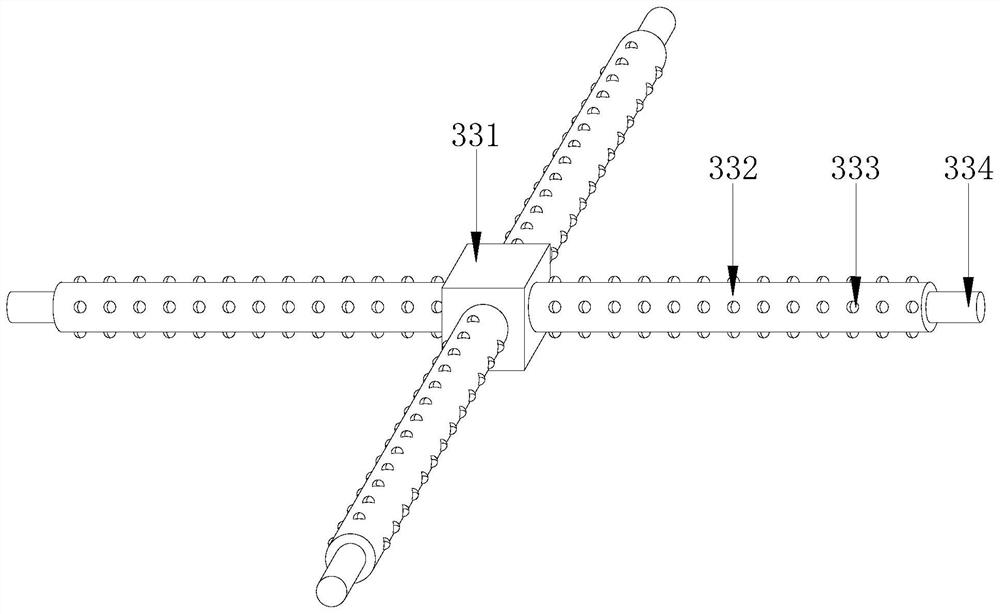

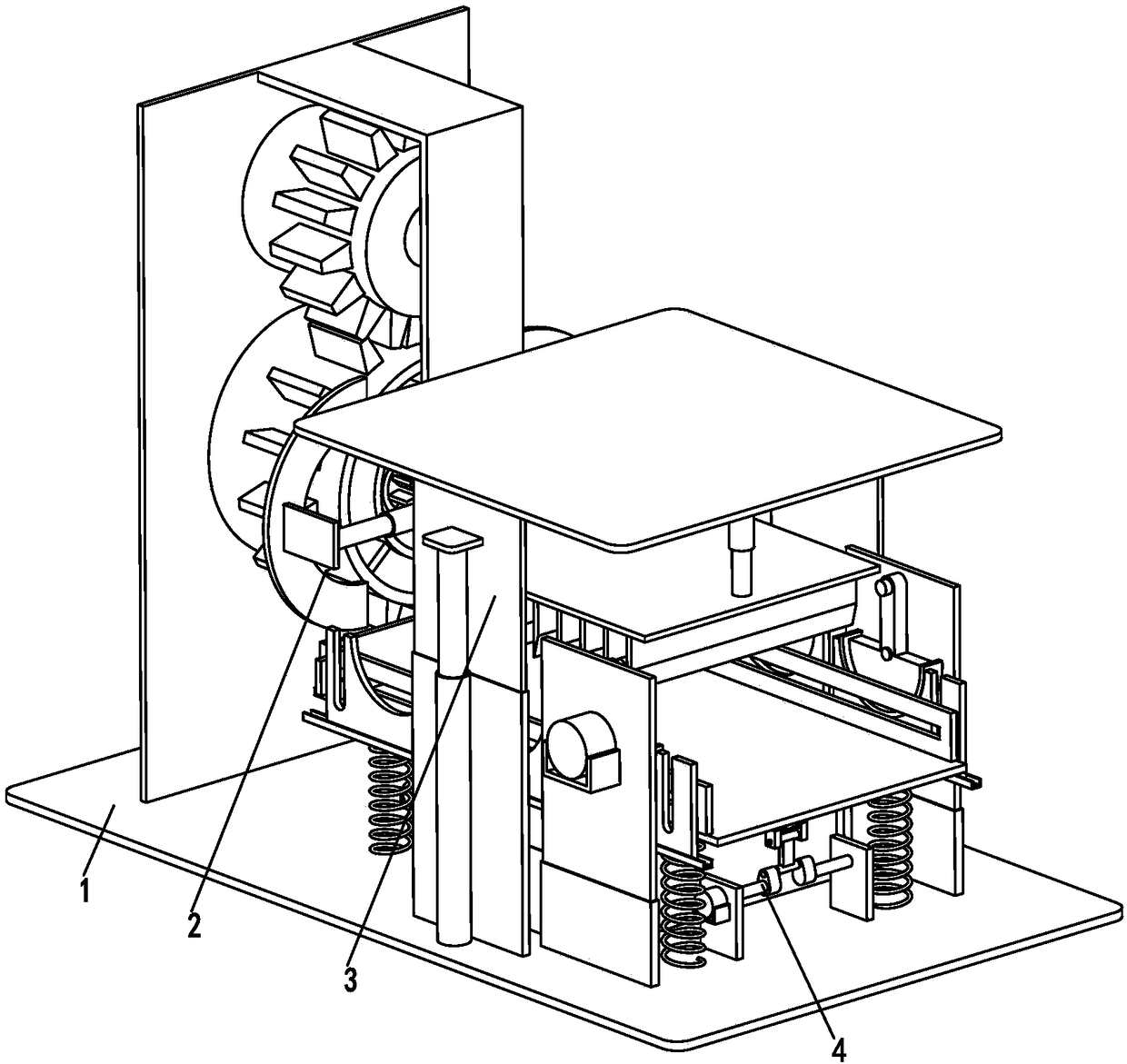

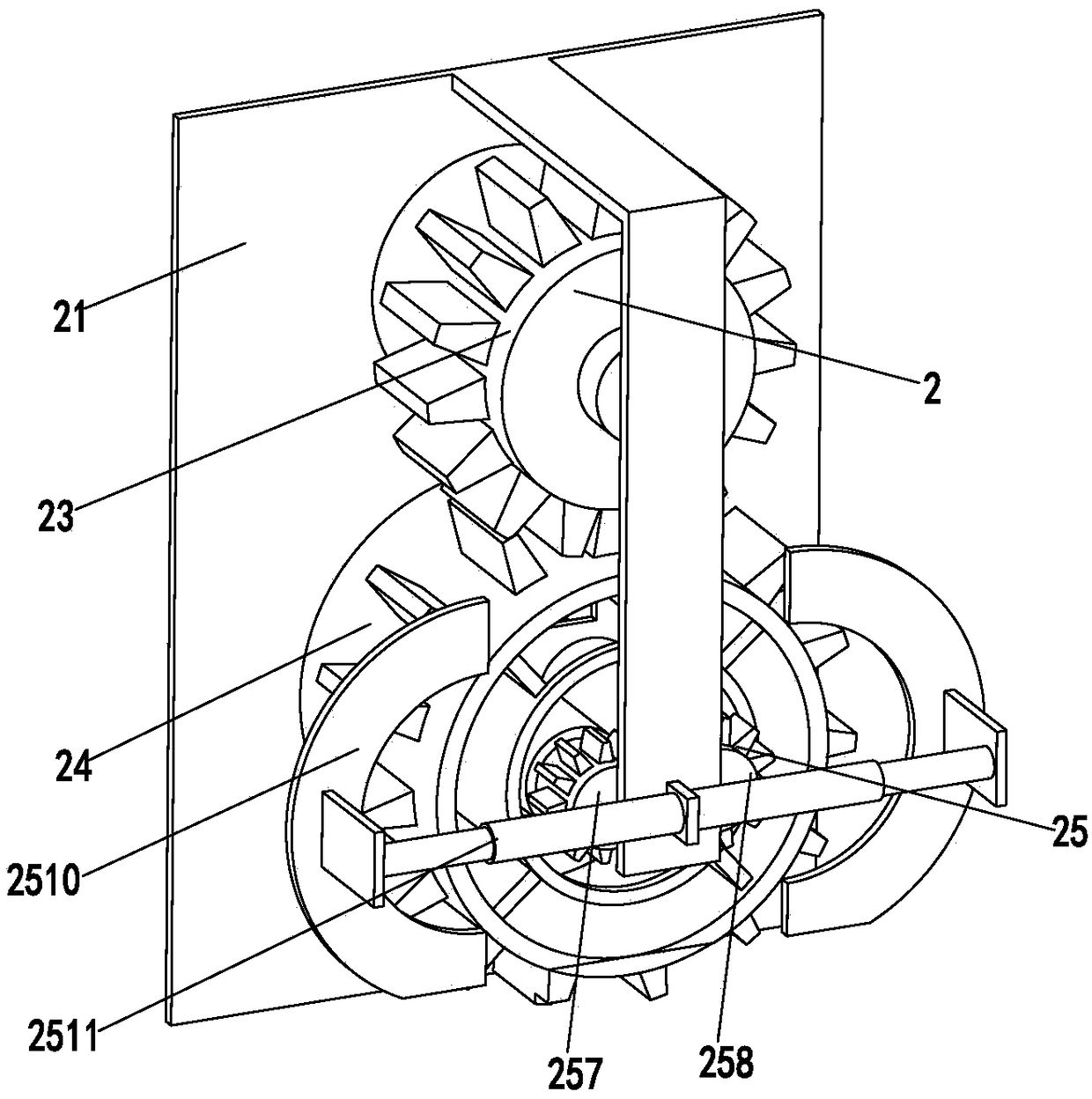

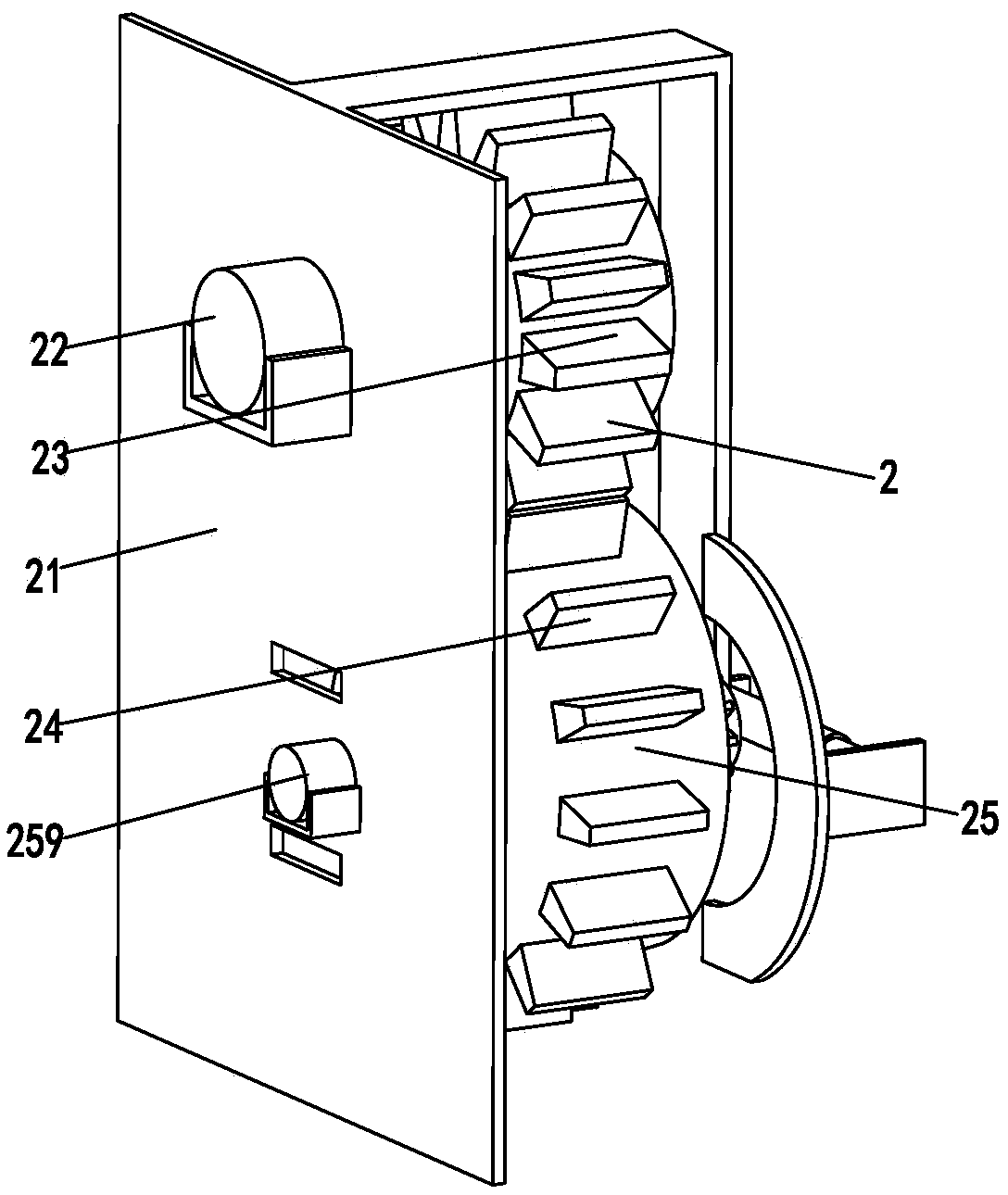

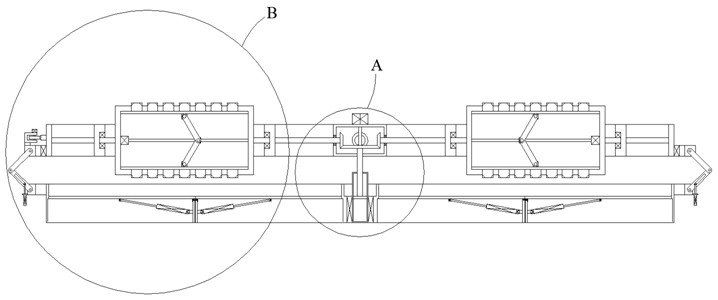

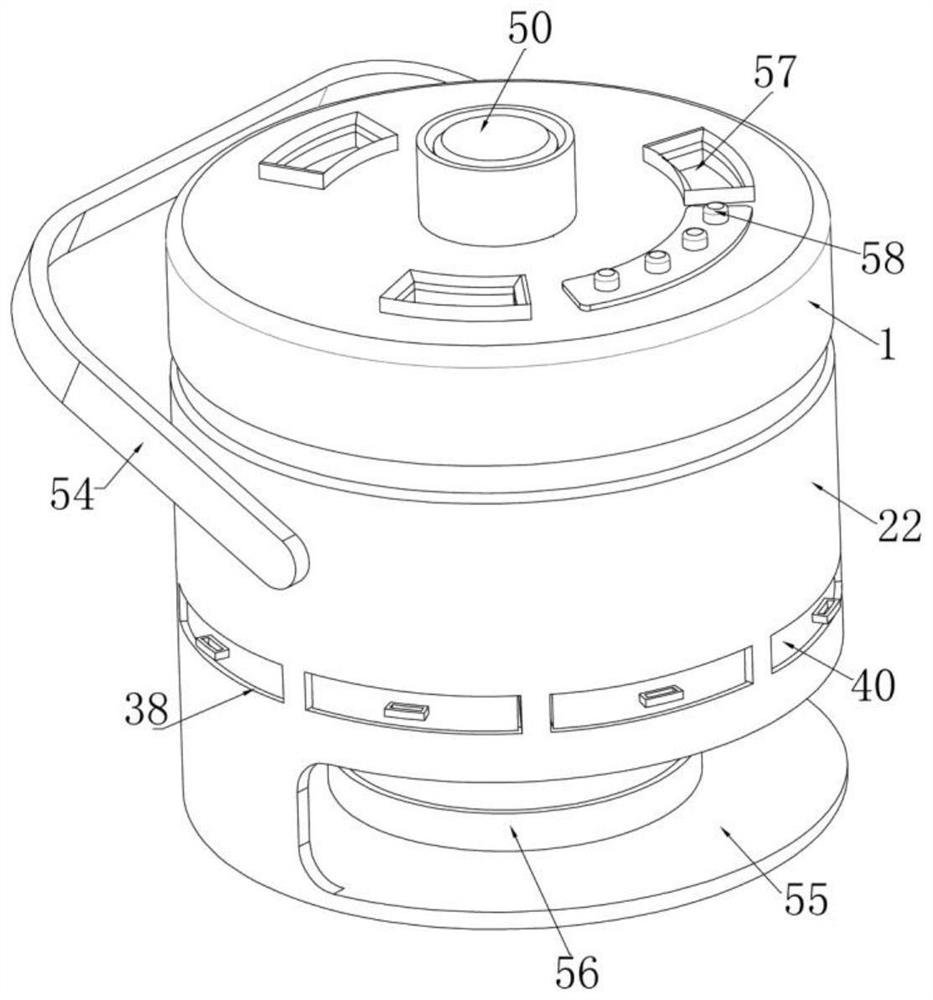

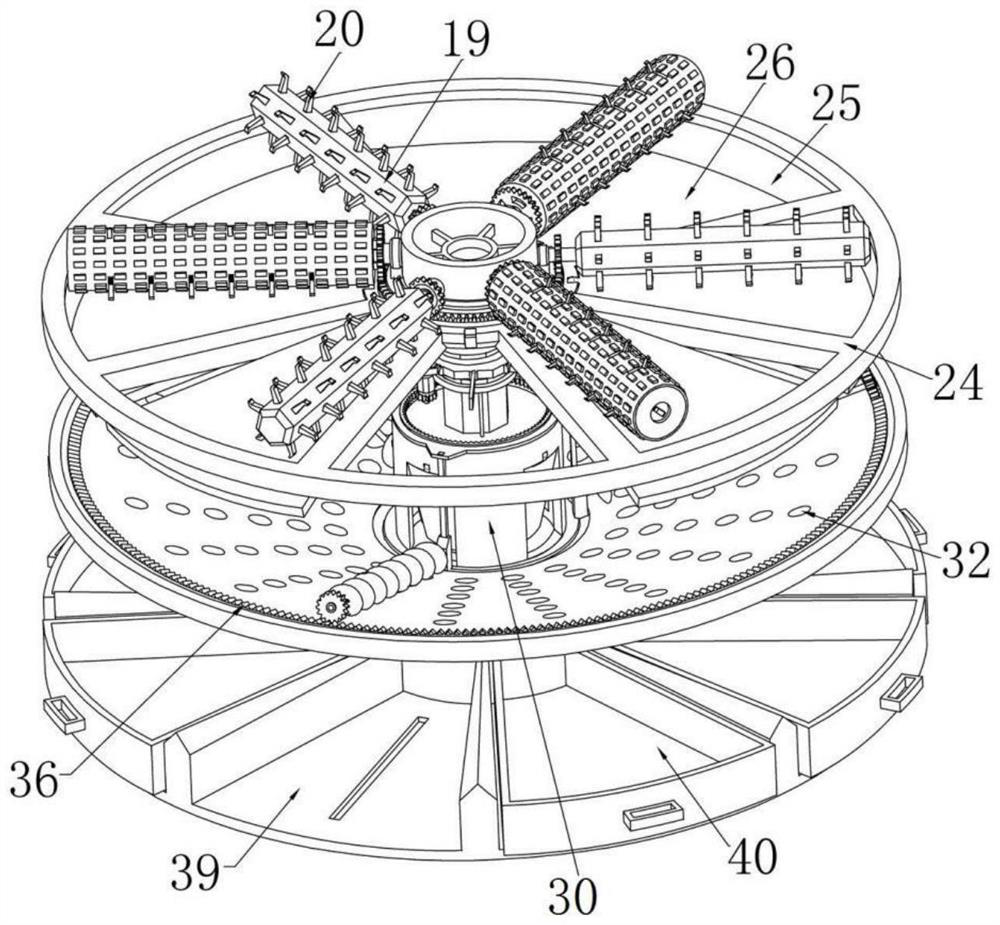

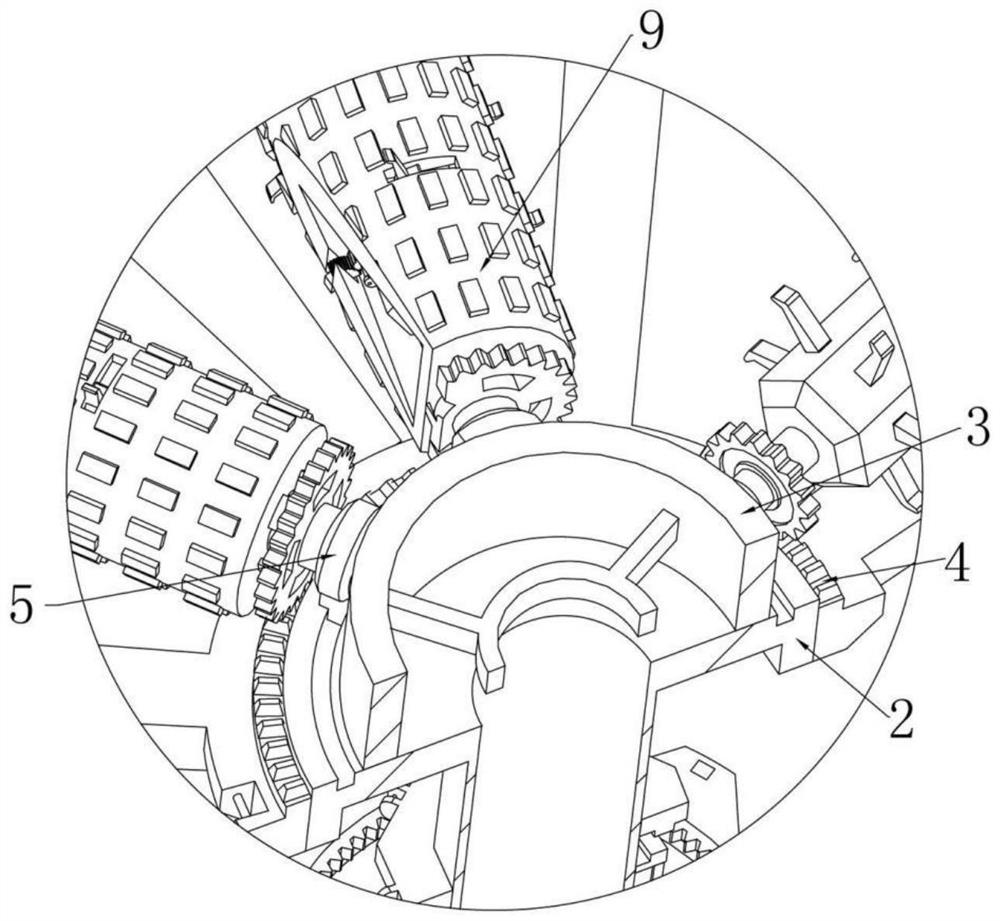

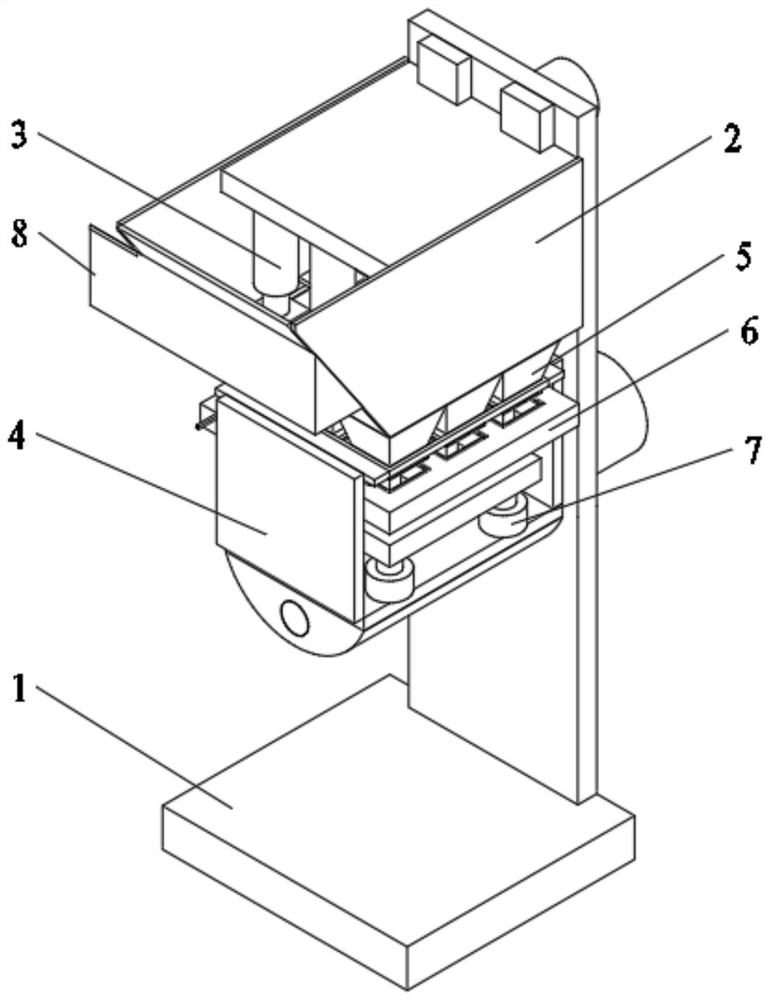

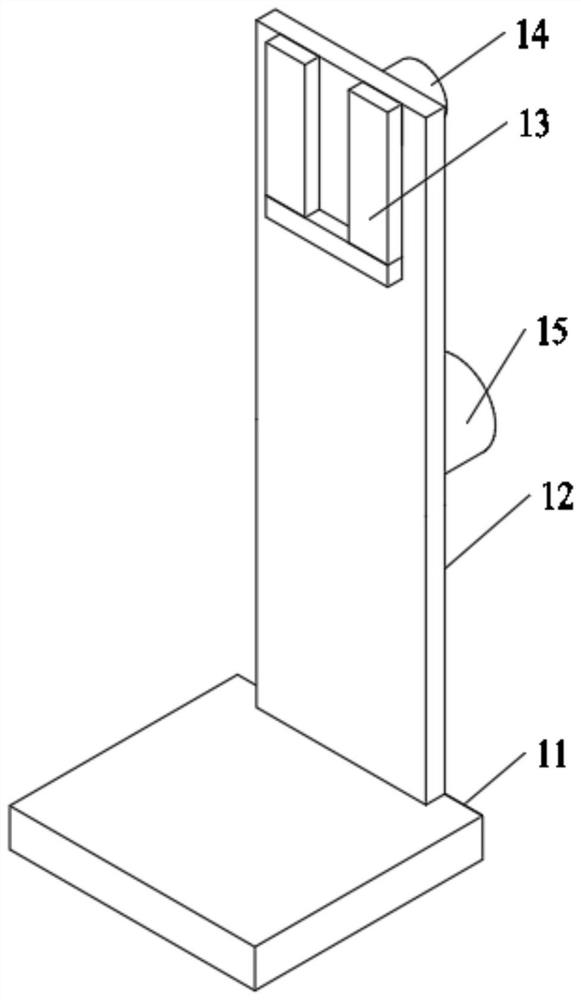

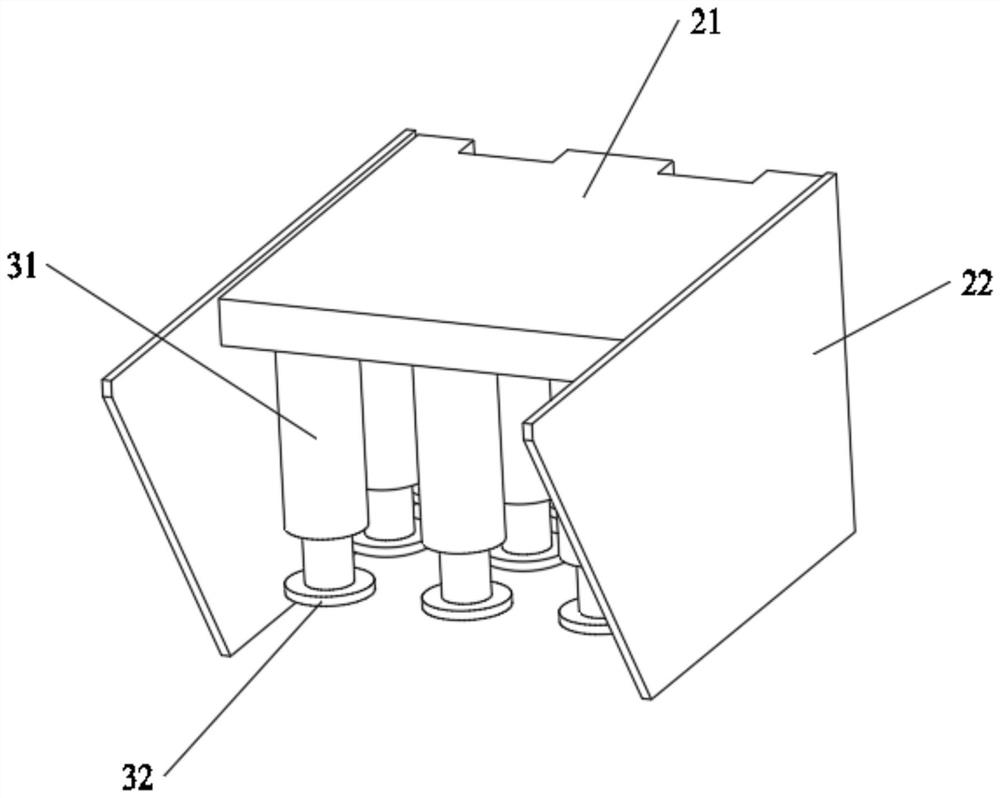

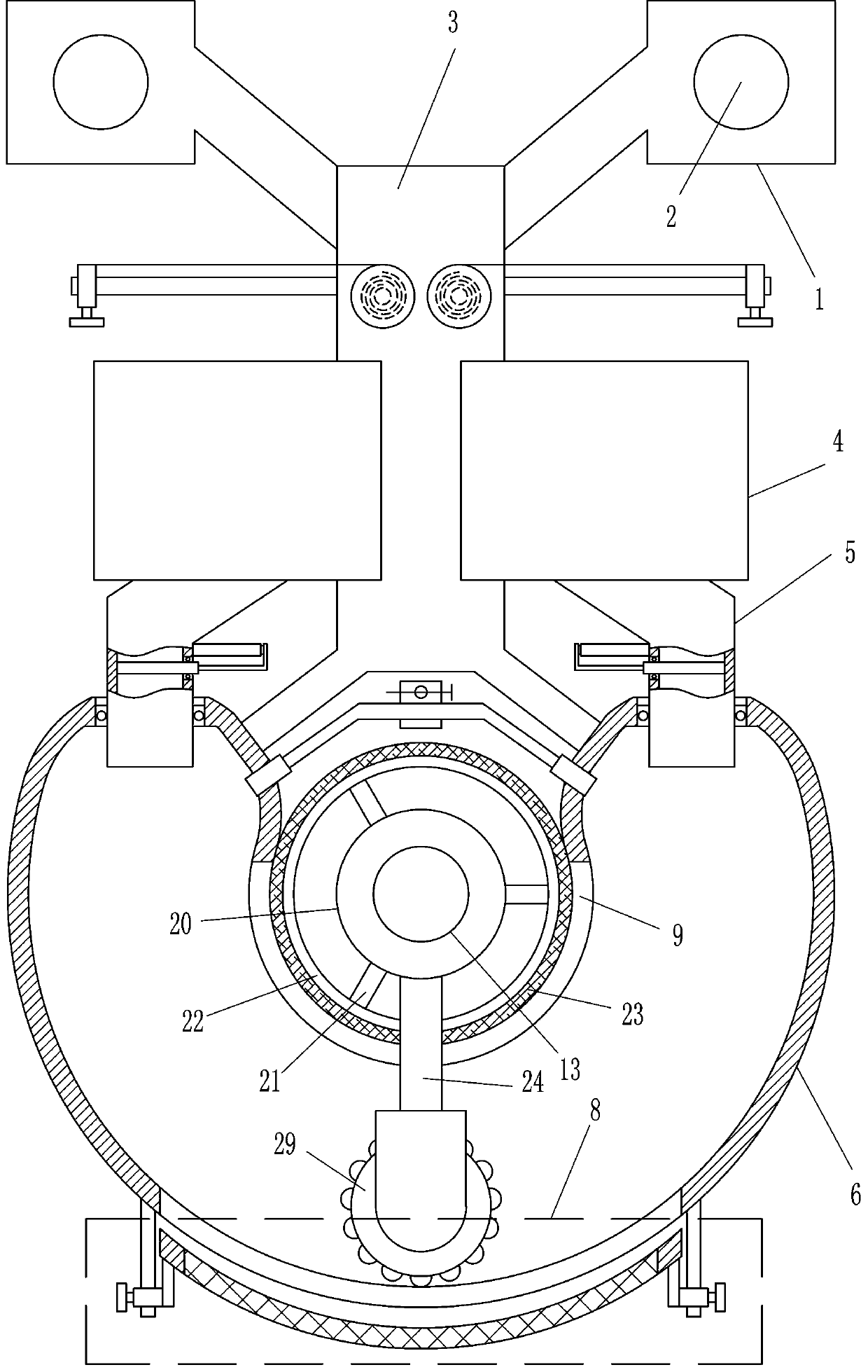

Material grinding and conveying module and drying chamber thereof

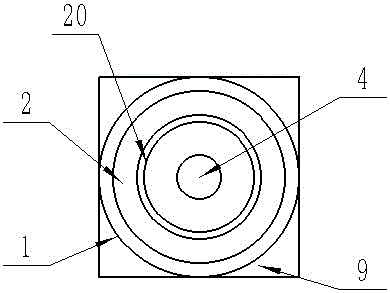

PendingCN111377588AFully rolledEvenly distributedSludge treatment by de-watering/drying/thickeningElectric machineEngineering

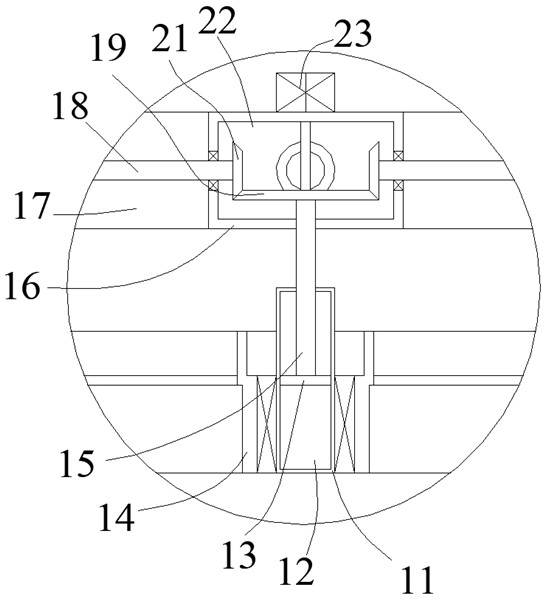

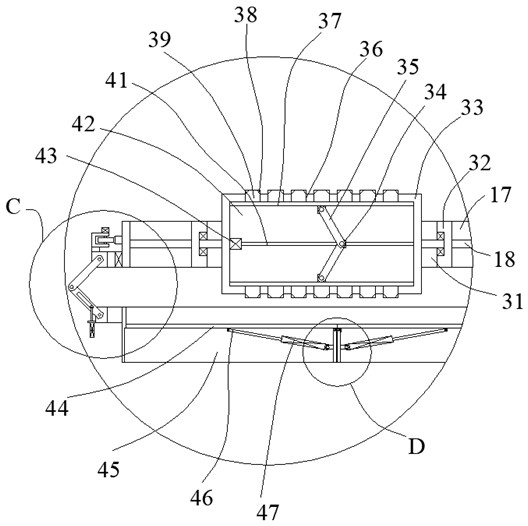

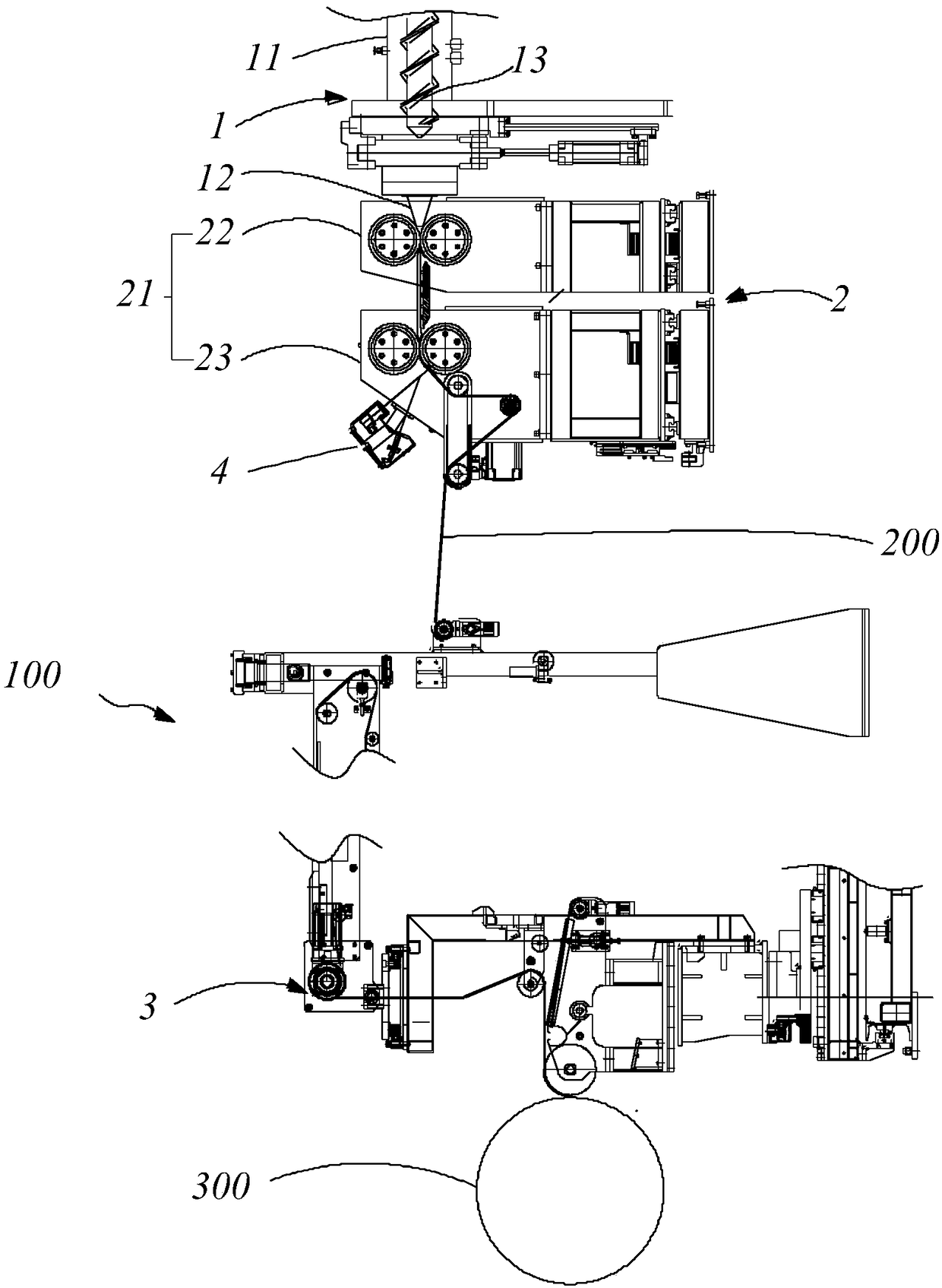

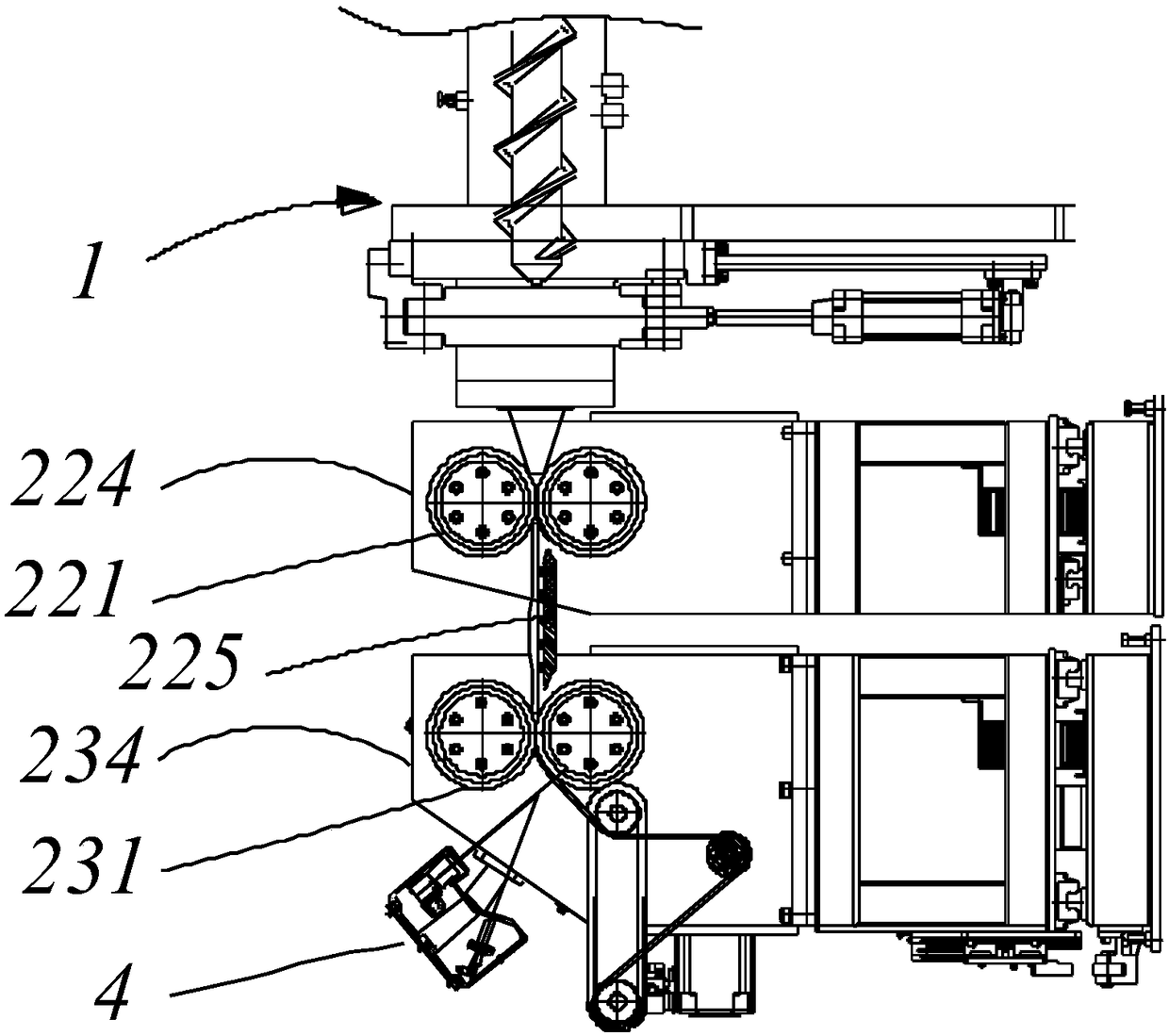

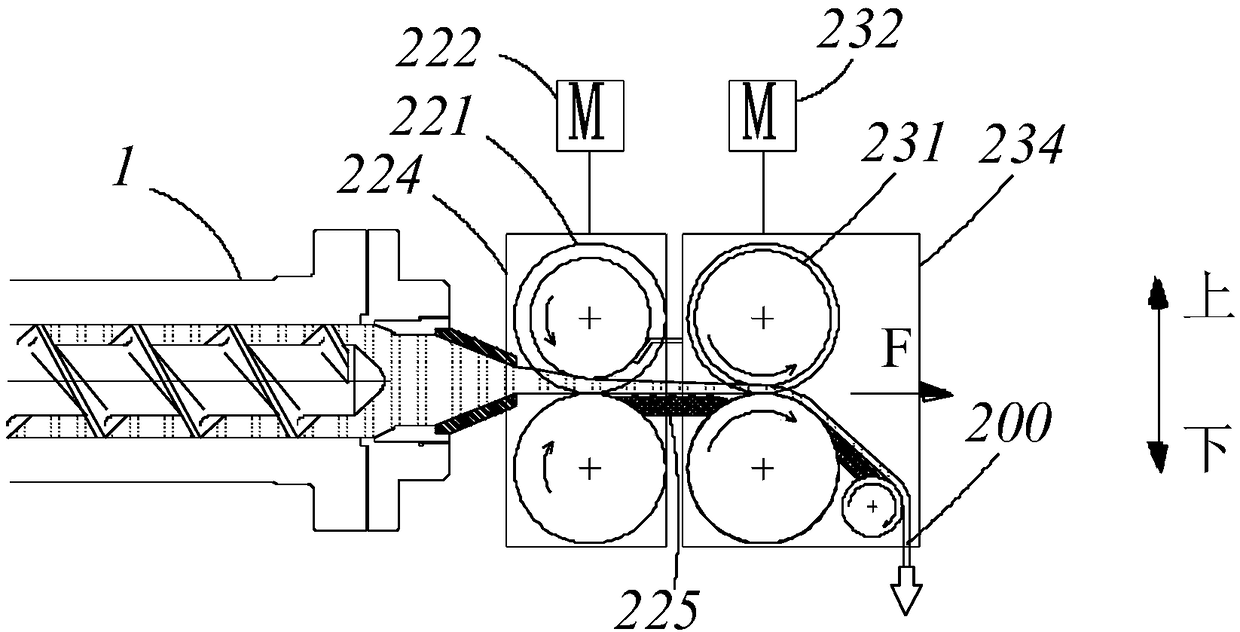

A material grinding and conveying module comprises a conveying platform composed of grid bar assemblies, a grinding device arranged above the conveying platform and a supporting frame. A first motor drives a first driving mechanism to drive the conveying platform to do reciprocating synchronous circular motion to bear and propel materials to advance; the grinding device comprises a grinding platform and a second driving mechanism; a second motor drives the second driving mechanism to drive the grinding platform to do reciprocating type synchronous circular motion perpendicular to the pushing direction of the materials to grind and scrape the materials; the second motor alternately performs forward rotation and reverse rotation, and the forward rotation time is equal to the reverse rotationtime. A drying chamber comprises a material grinding and conveying module, and the number of the material grinding and conveying module is one or more than one which are stacked. The grinding platform conducts grinding in the forward direction and the reverse direction, materials can be more evenly distributed on the conveying platform, the evaporation area is increased, and the drying efficiencyis improved.

Owner:AMCON FUJIAN ENVIRONMENT PROTECTION EQUIP CO LTD

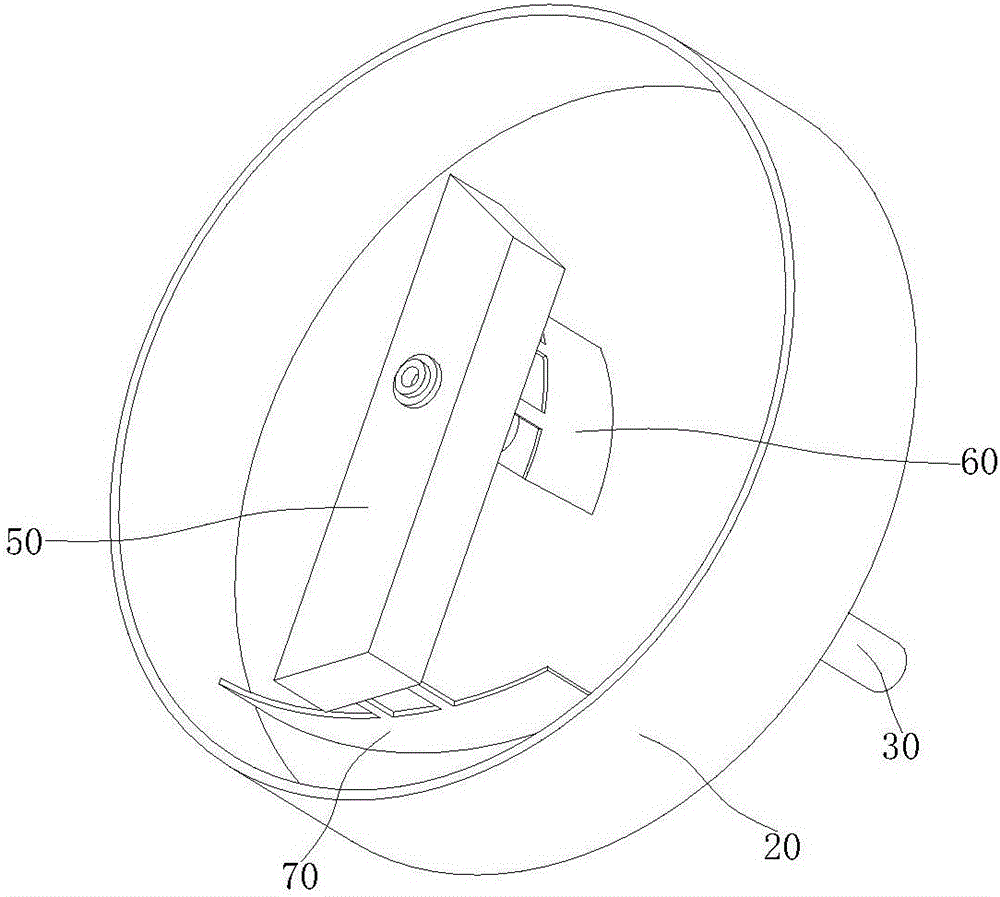

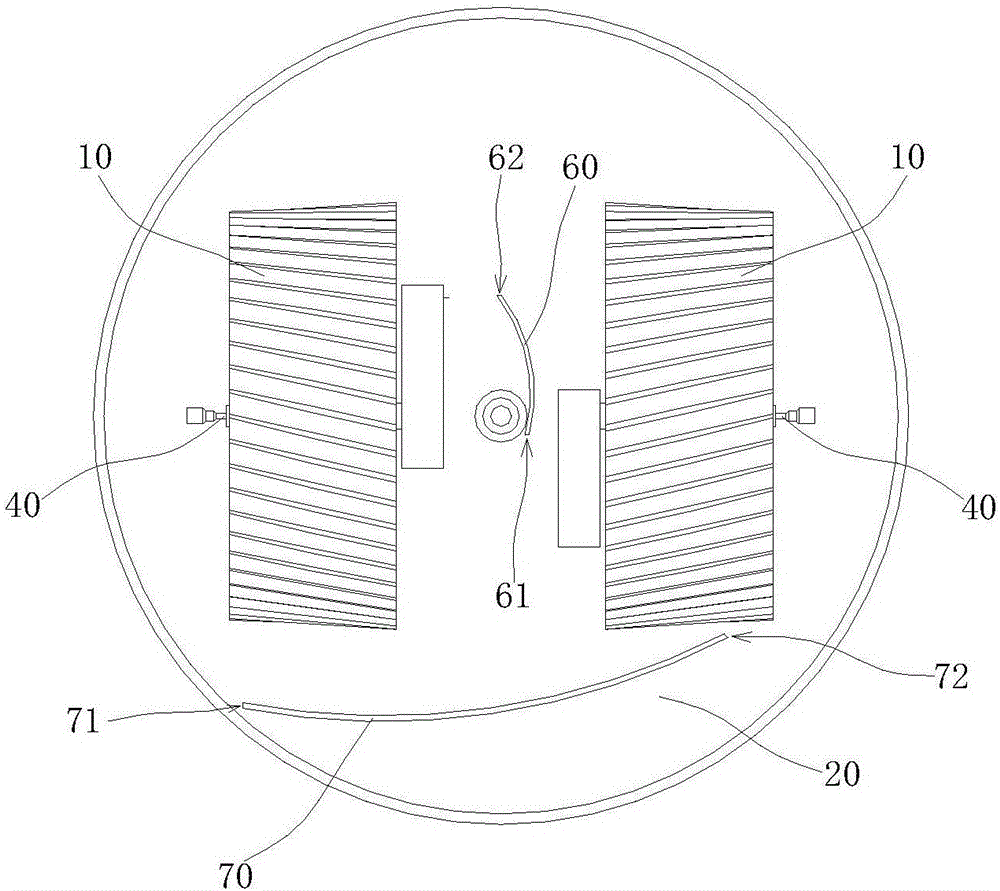

High-efficiency iron removal device for lithium battery material

InactiveCN106824368ASimple designGood working performanceMagnetic separationGrain treatmentsElectrical batteryIron removal

The invention provides a high-efficiency lithium battery material iron removal device, which includes a crushing cylinder and a conical collecting cylinder; the crushing cylinder is provided with a feeding port, a connecting column, a cover plate, a wheel column, a motor, a funnel bottom plate, and a ring mouth, material removal rod, transition box, screen, draw frame and feet; the feed inlet is set at the upper end of the crushing cylinder; there are two connecting columns, which are respectively vertically arranged on the left and right sides of the edge of the feed inlet ; The receiving cone is provided with rollers, electromagnetic boards, dust-proof boxes, drawer boxes, cross bars, rotating rods and scrapers; the receiving cone is docked at the lower end of the transition box and the two are connected; The feed port of the present invention is convenient for workers to put in battery materials; the cover plate is used to prevent the materials from splashing out during the process of crushing battery materials and accidentally injuring workers; the side wall of the wheel column interacts with the inner wall of the crushing cylinder during the rotation process, and the grinding crushed materials; the bottom plate of the funnel facilitates the collection of falling battery materials to the middle of the bottom of the wheel post for crushing.

Owner:陈萍

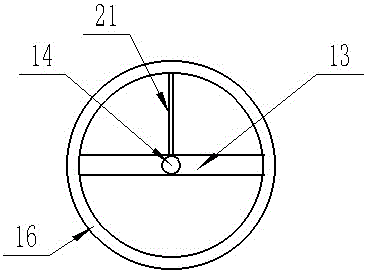

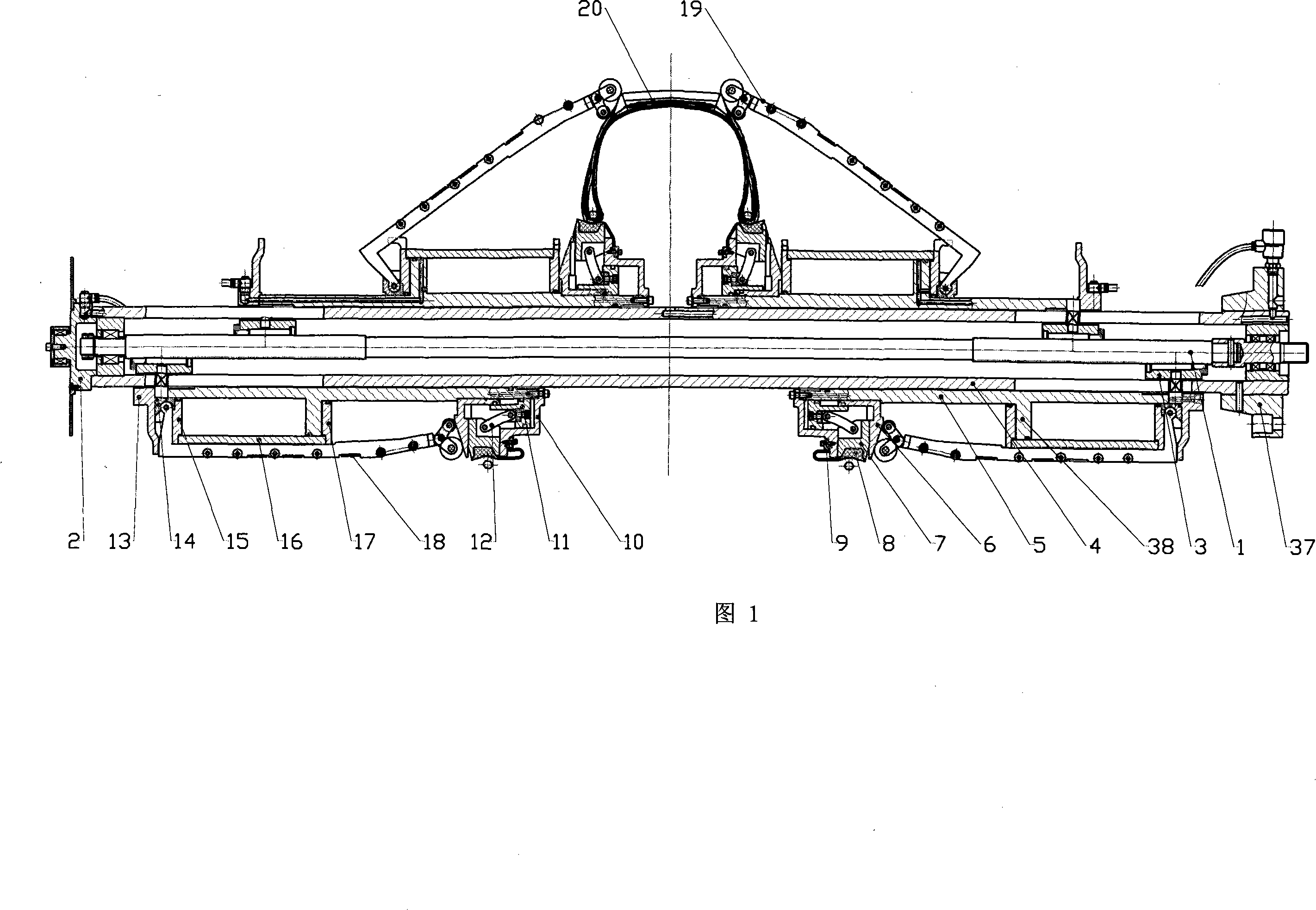

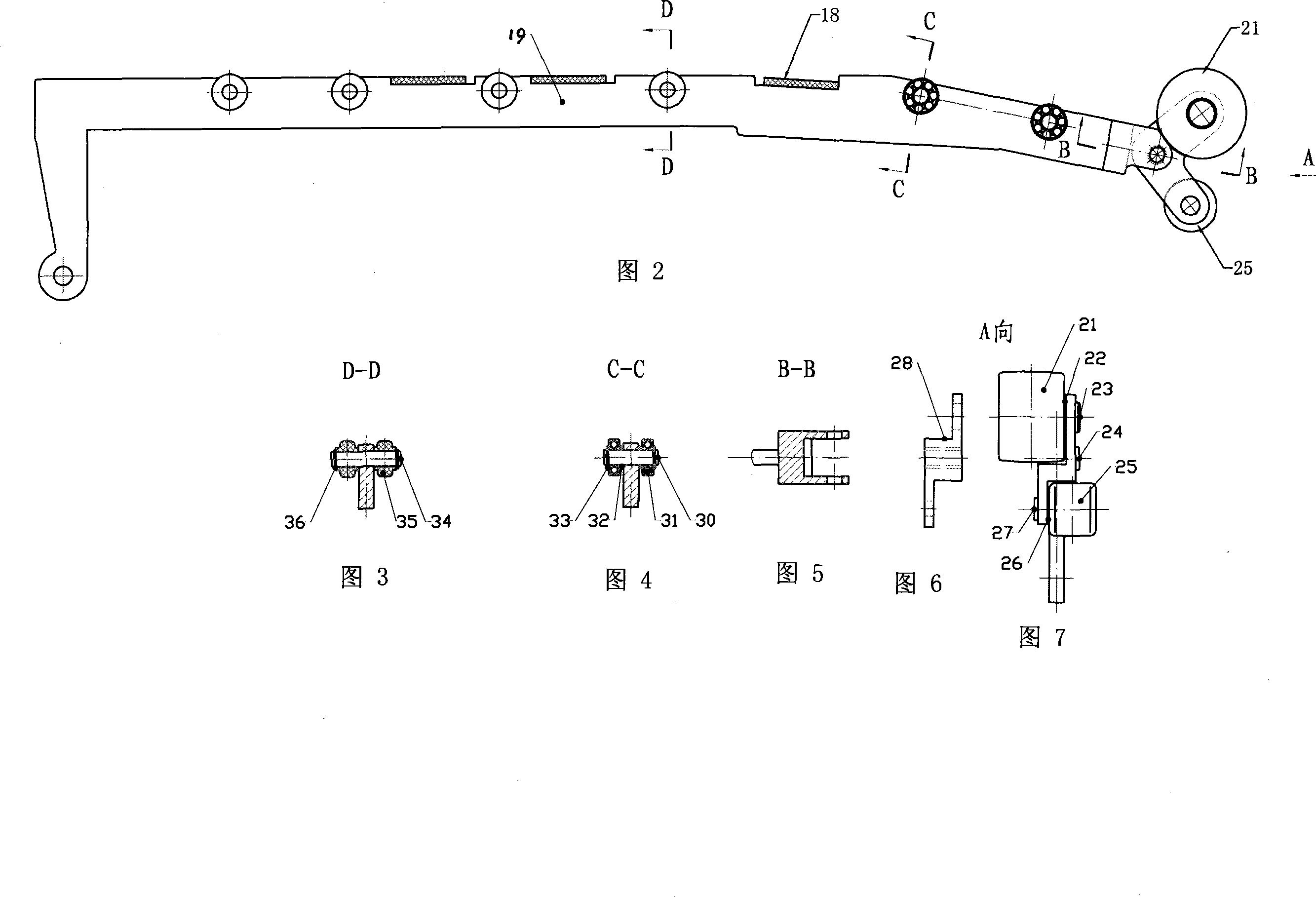

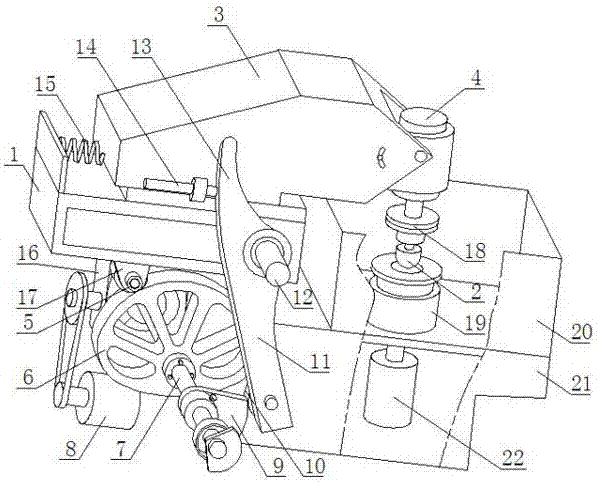

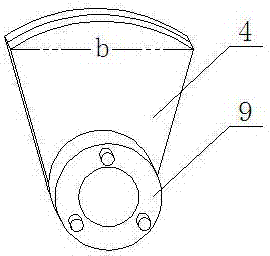

Anti-package metal drum of single rod and dual-wheels machine

The invention relates to a mechanical drum used for the turn-up rolling of an all steel wire radial loading tyre special equipment once forming machine, which is mainly composed of a mainshaft device, a left side drum and a right side drum; each side drum comprises a group of turn-up rods which are uniformly distributed in radial direction; the front end of each turn-up rod is provided with a large idler wheel and a small idler wheel alternately; the large idler wheel and the small idler wheel can be arranged on an eccentric Y-shaped wheel seat which can be hinged with the front end of the turn-up rod. Owning to the dual idler wheel structure of the turn-up rod and the alternating arrangement of the large idler wheel and the small idler wheel, the small idler wheel achieves the rolling again after the large idler wheel achieves the rolling, thus leading to a more sufficient rolling when the tyre side is turned up; meanwhile, the small idler achieves complementary rolling to the rolling blind area of the large idler wheel, eliminates or reduces rolling blind areas, leads to shallow impression of the tire rough to be processed, and has no residual bubble, thus improving the quality of forming.

Owner:JIEYANG TIANYANG MOLD +1

Cutting equipment with recycling and anti-pollution mechanism for transformer copper busbar machining

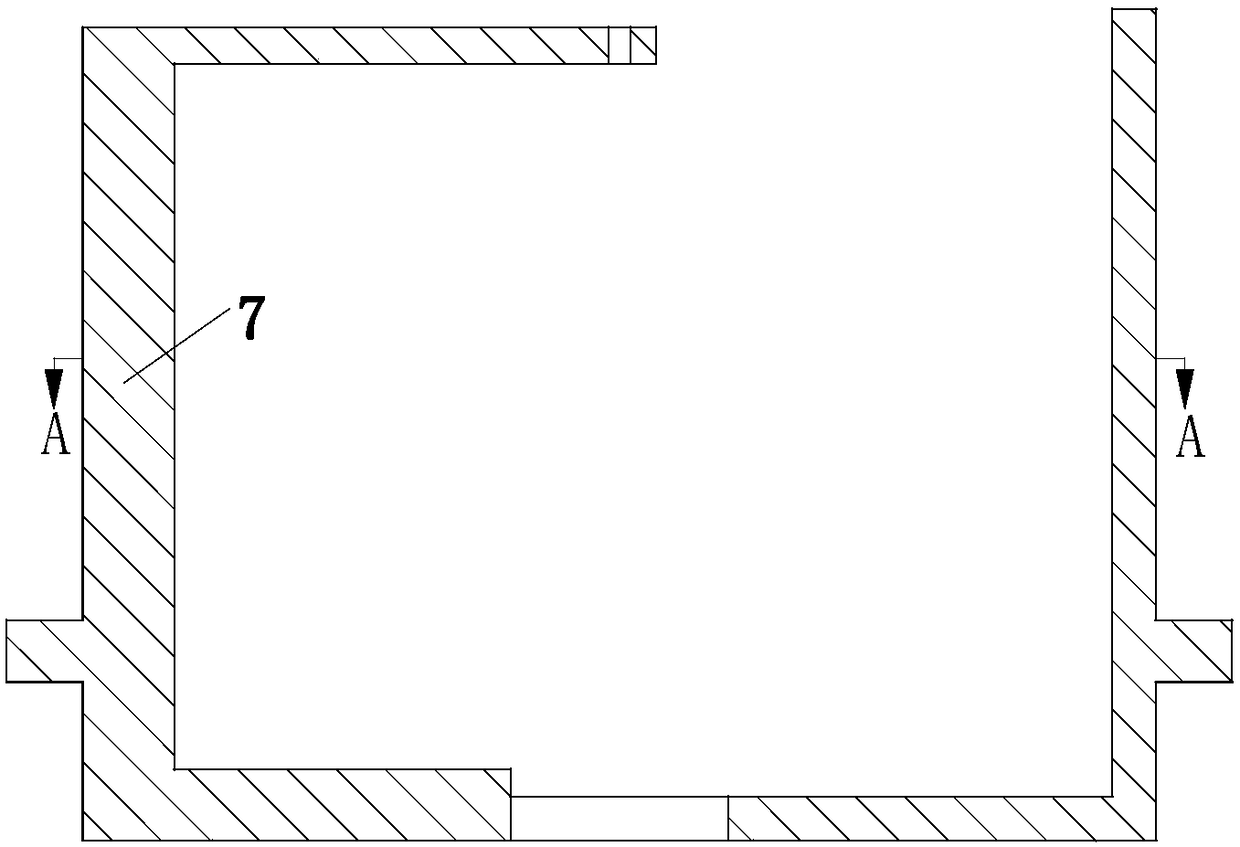

PendingCN113894352ACombine thoroughlyFully rolledCleaning using gasesMaintainance and safety accessoriesBusbarTransformer

The invention relates to the technical field of cutting equipment, and particularly relates to cutting equipment with a recycling and anti-pollution mechanism for transformer copper busbar machining. The cutting equipment comprises a box body, supporting legs are arranged at the four corners of the bottom end of the box body, a mounting frame is fixedly arranged at the top end of the box body, first side plates are symmetrically and fixedly arranged in the middle of the top end of the mounting frame, and a rotating rod is movably arranged between the pair of first side plates. According to the cutting equipment, generated chippings can be rolled in the cutting process to form a whole, so that recycling is facilitated; meanwhile, the chippings can be collected towards the center of a rolling box, so that sufficient rolling is facilitated, the chippings can form a more complete whole, and collection is facilitated; and meanwhile, dust generated by cutting can be treated, so that the dust is prevented from being inhaled by a human body to pollute the human body, the falling chippings can be scraped and blown to fall into a round opening more thoroughly to enter the rolling box for rolling, so that manual sweeping is not needed, and the cutting equipment is worthy of popularization and use.

Owner:南通斯固机械设备有限公司

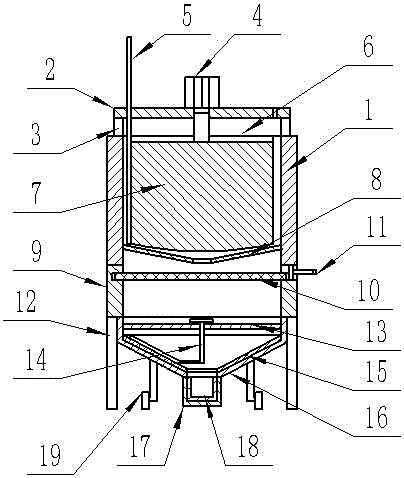

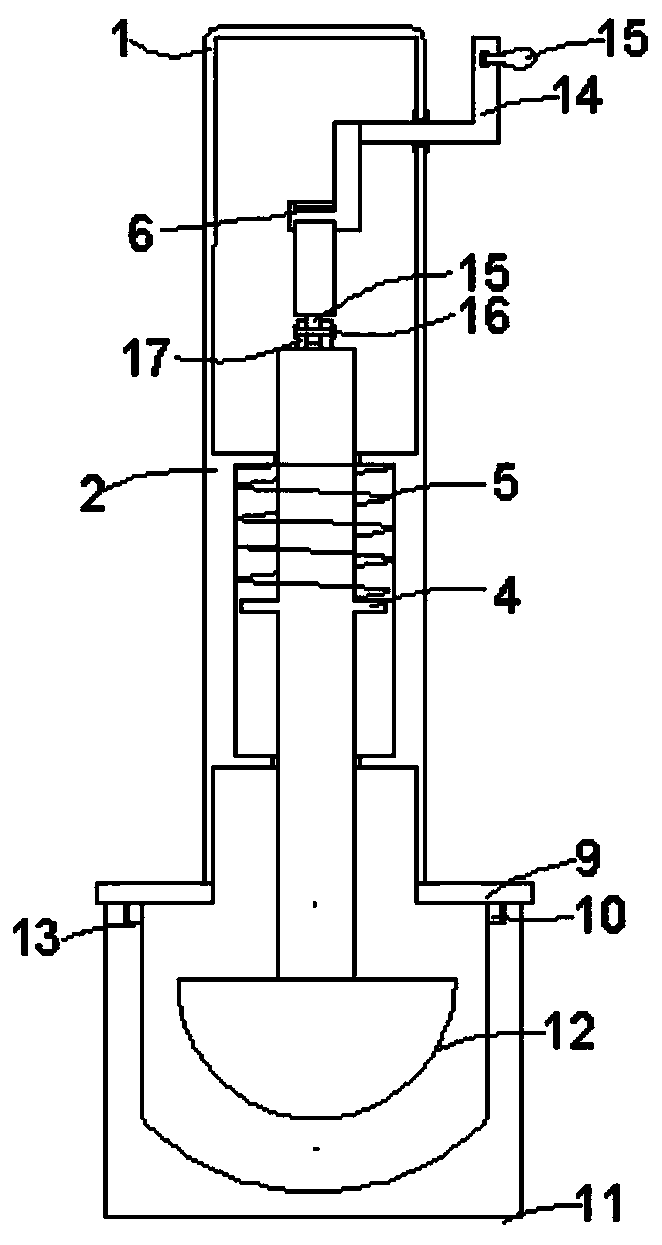

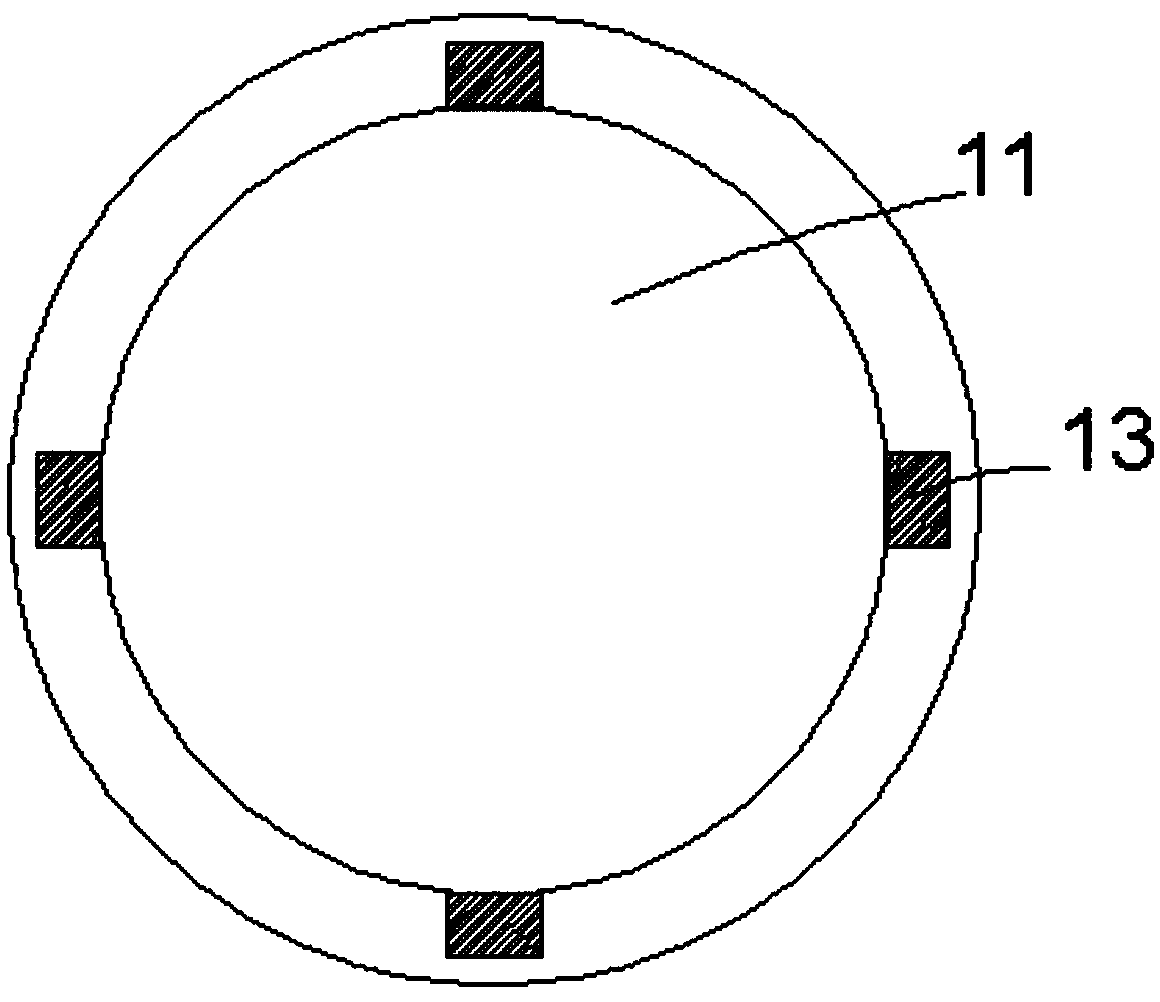

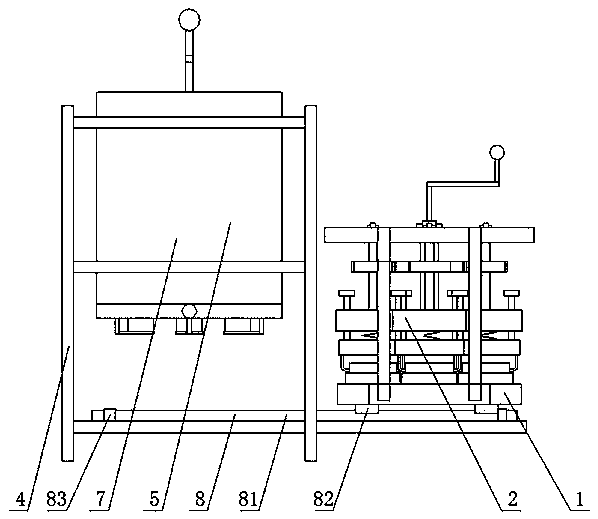

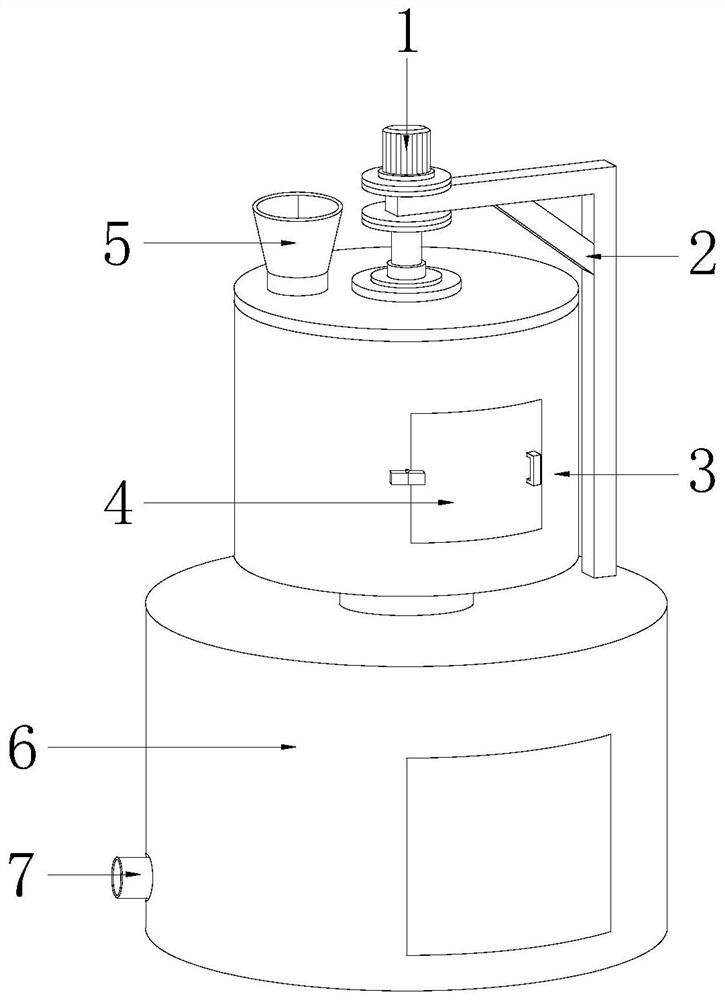

Reaction kettle for preparing graphene oxide

PendingCN108455589AImprove production efficiencySimple structureCarbon compoundsChemical/physical/physico-chemical stationary reactorsManufacturing technologyEngineering

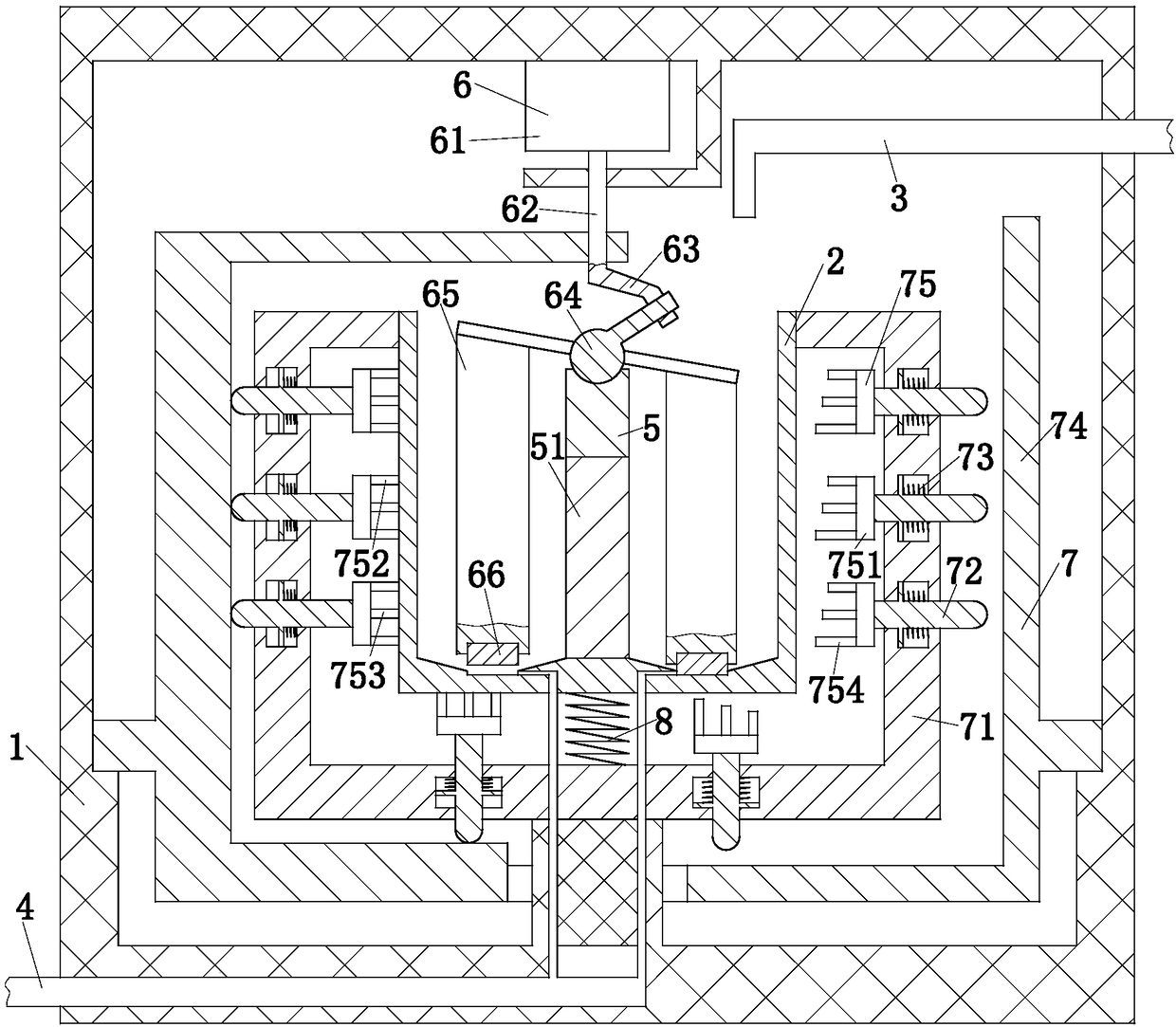

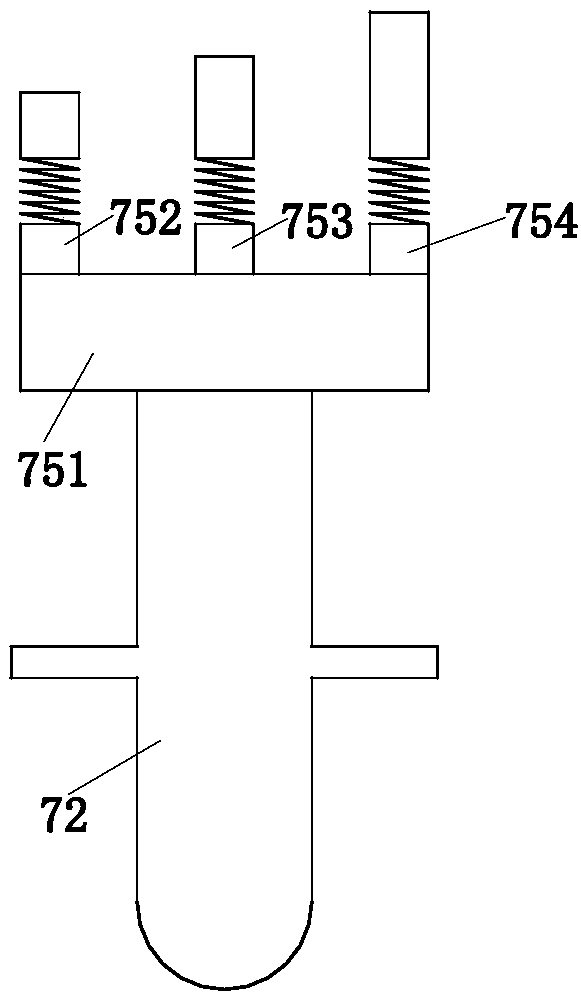

The invention belongs to the technical field of preparation and production of graphene oxide and particularly relates to a reaction kettle for preparing graphene oxide. The reaction kettle comprises acasing, a reaction barrel, a feeding pipe, a collecting pipe, a pillar, a stirring module, a shock module and a supporting spring, wherein the reaction barrel is positioned inside the casing and is used for reaction of reactants; the feeding pipe is positioned at the upper part of the reaction barrel; the collecting pipe is positioned at the lower end of the reaction barrel; the pillar is positioned in the center of the reaction barrel; the stirring module is positioned on the reaction barrel; the upper end of the stirring module is fixed on the casing; the stirring module is used for stirring the reactants and providing power for the shock module; the shock module is positioned outside the reaction barrel; the outer part of the shock module is rotationally connected with the casing; theshock module is used for knocking and shocking the reaction barrel; the supporting spring is positioned between the shock module and the reaction barrel and is used for supporting the reaction barrel.By use of the reaction kettle disclosed by the invention, raw materials for preparing the graphene oxide are enabled to quickly react, and the preparation efficiency of the graphene oxide is improved.

Owner:李训祺

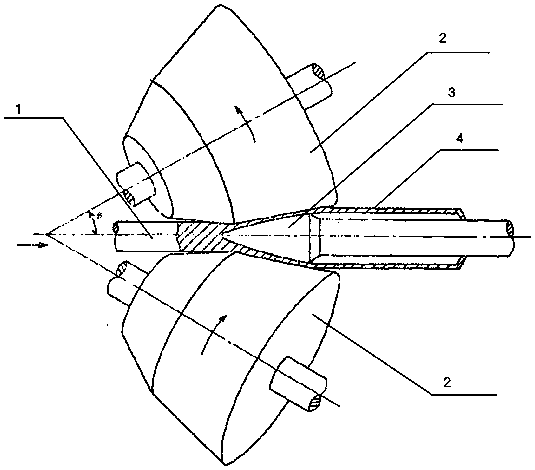

Perforating and rolling method for producing thin-wall seamless steel pipes and special equipment

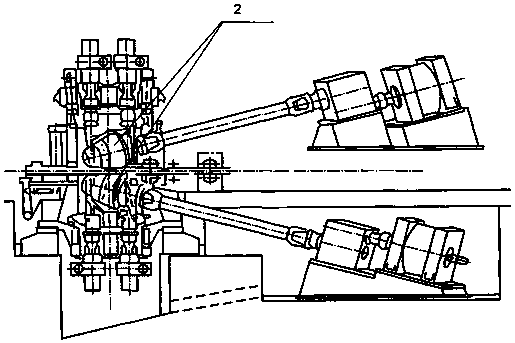

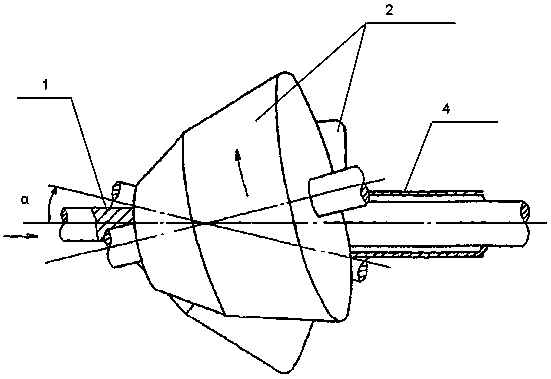

ActiveCN107138532AOutstanding FeaturesHighlight significant progressMandrelsRollsHeating timeMetallurgy

The invention discloses a perforating and rolling method for producing thin-wall seamless steel pipes and special equipment, and belongs to the technical field of steel rolling technologies. The perforating and rolling method is characterized in that the ratio delta of expanding diameter of a perforated hole is larger than 30% and less than or equal to 45% and is designed according to specific technological parameters of perforating deformation, and a conical angle lambda2 of an outlet of each conical roll is equal to 6 degrees; the value of a top conical angle gamma3 within the range of a primary perforating area L21 is small than that of a top conical angle gamma1 within the range of a uniform-wall rolling area L23, and gamma3 is equal to gamma1-(2-2.5 degrees); when the seamless steel pipes with the same specification are produced, the small pipe blank diameter can be selected, the heating time is shortened, and the production efficiency of the seamless steel pipes is improved; and meanwhile, the coefficient of elongation of a perforator can be decreased, and the tail quality of the steel pipes is improved.

Owner:烟台宝钢钢管有限责任公司

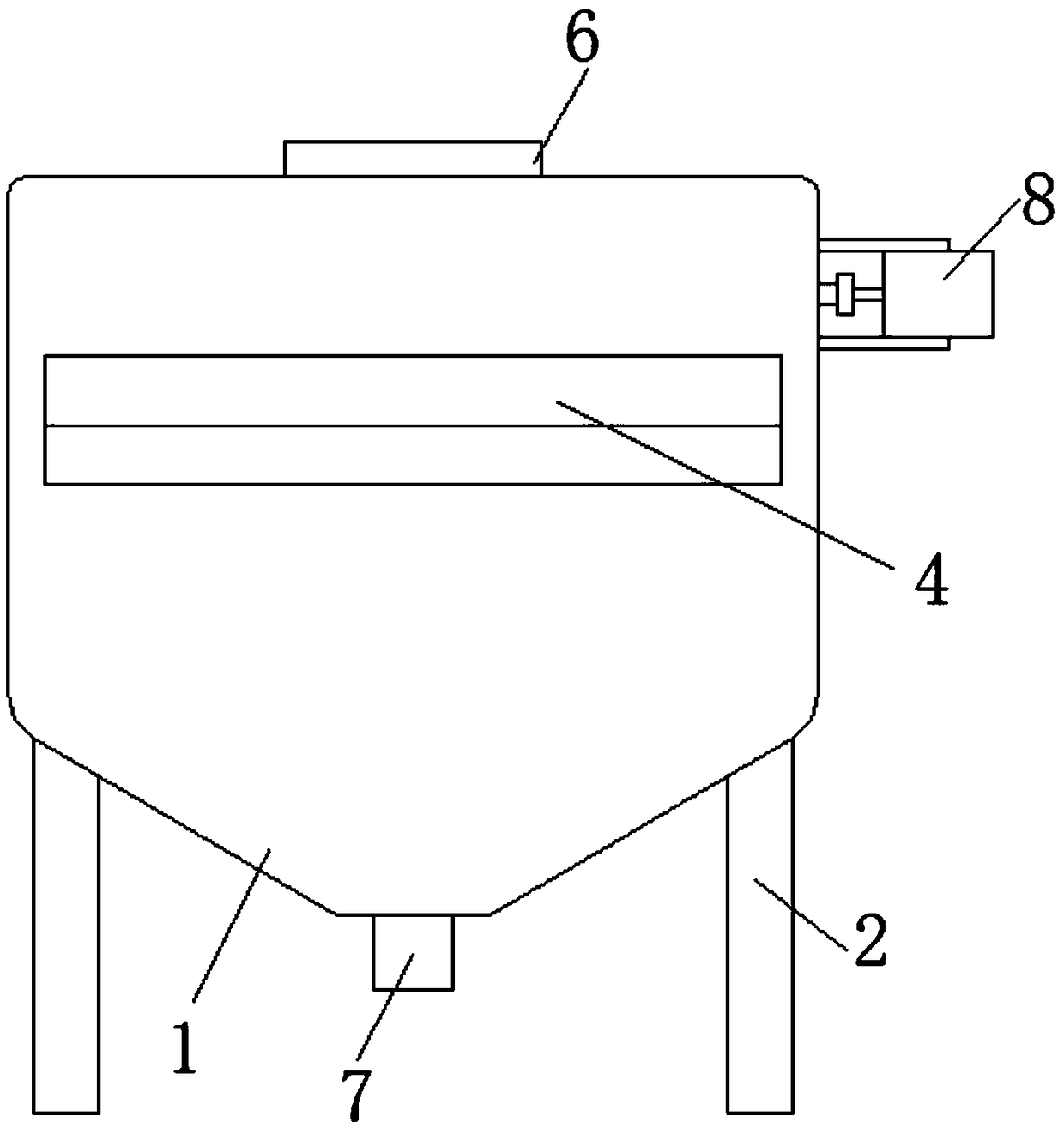

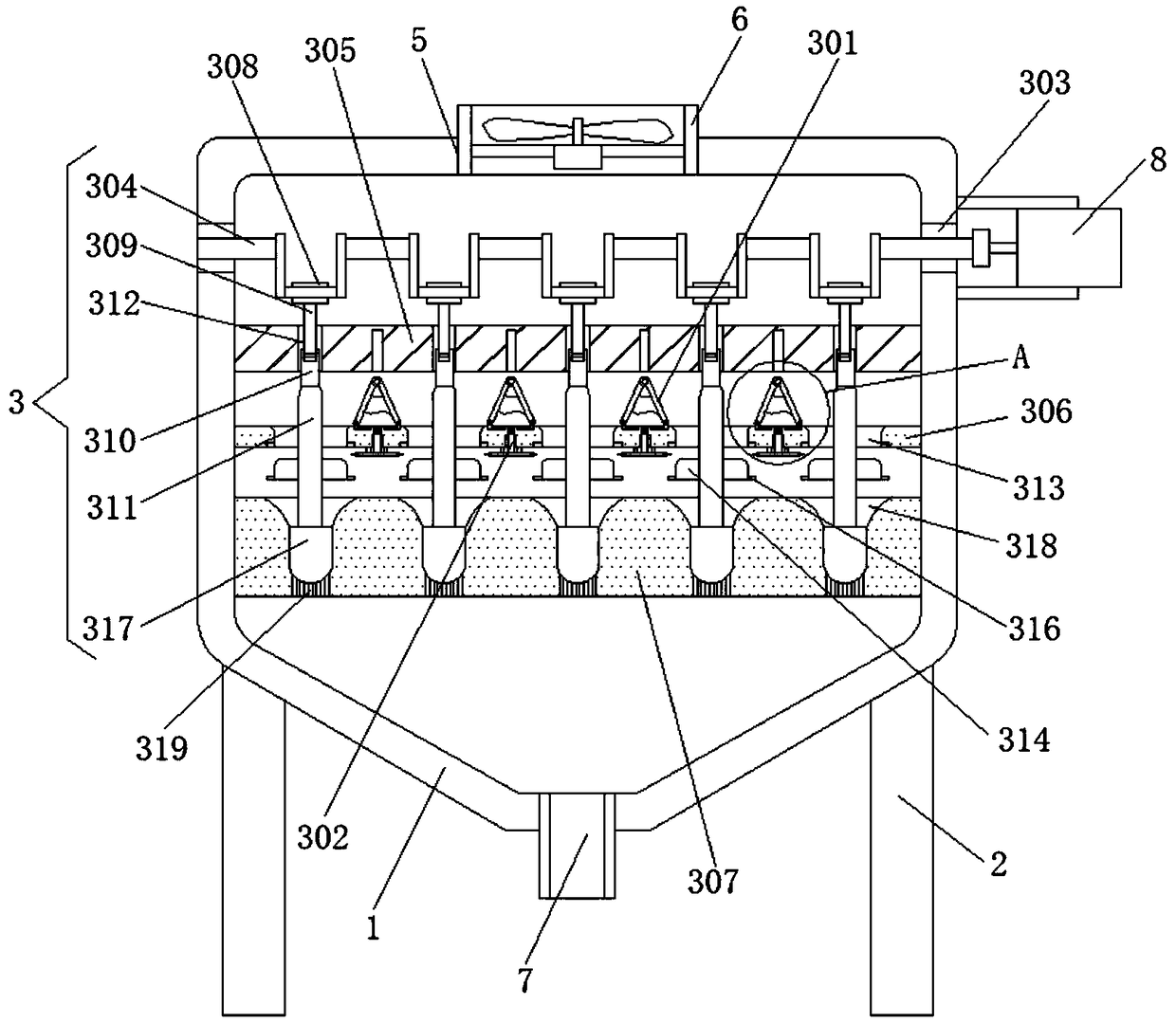

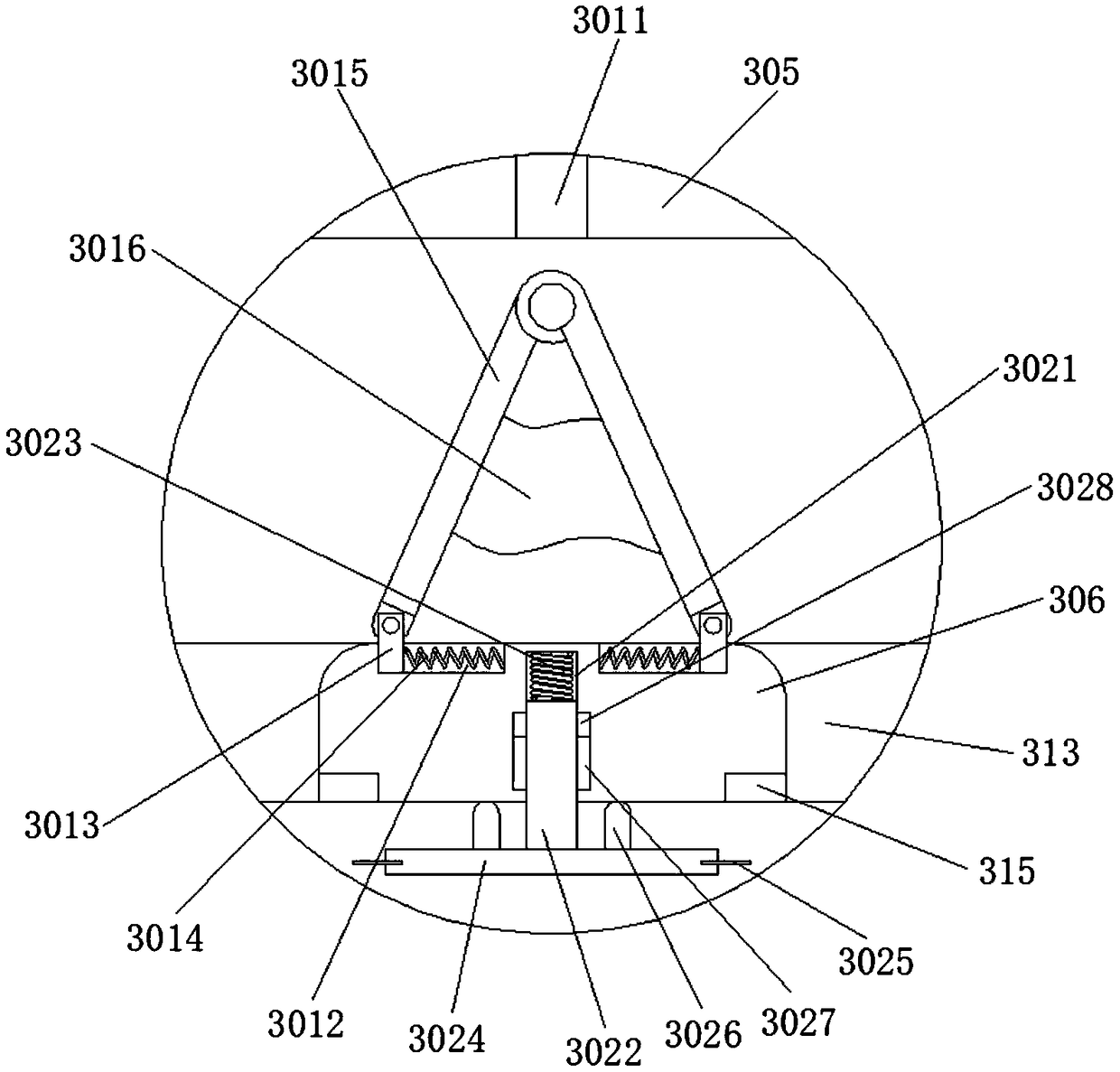

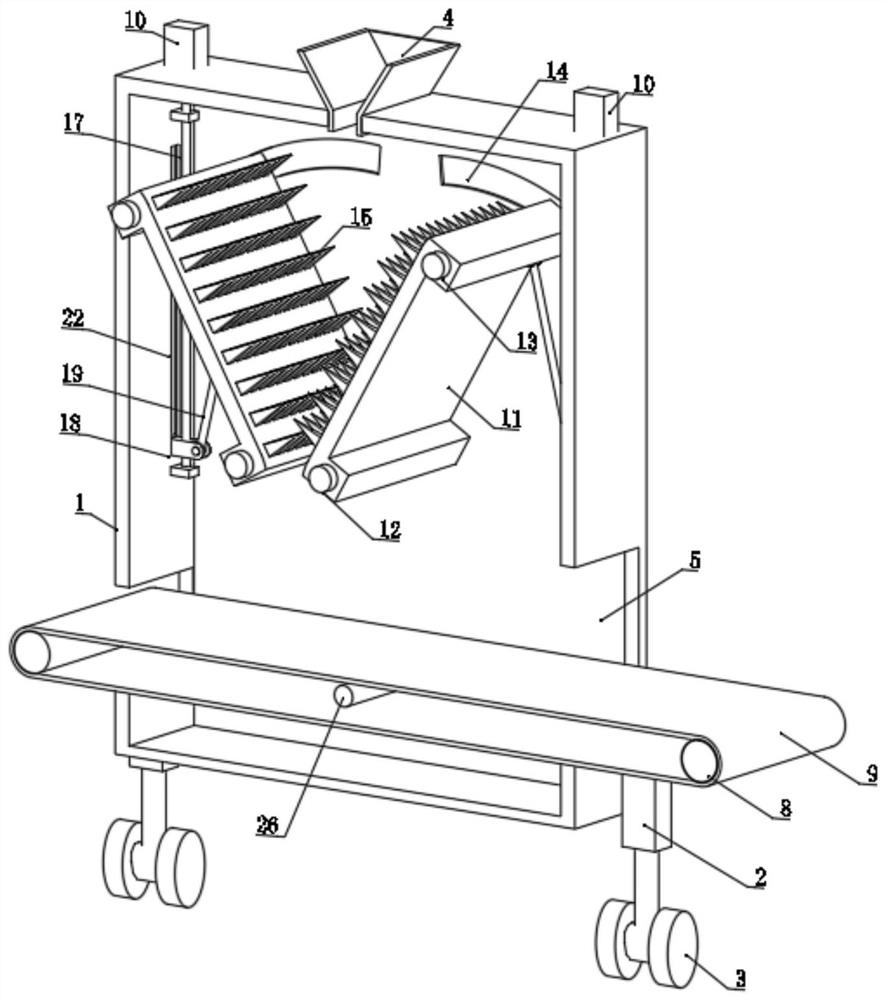

Vertical-linkage and reciprocating rolling-type mashed potato preparing device

The invention belongs to the technical field of food processing, and discloses a vertical-linkage and reciprocating rolling-type mashed potato preparing device. The vertical-linkage and reciprocatingrolling-type mashed potato preparing device comprises a box, wherein the section of the bottom wall of the box is funnel-shaped; supporting legs are fixedly connected to four corners of the bottom wall of the box; the discharge end of a feed hopper is fixedly communicated with the front surface of the box; a mounting hole is formed in the middle part of the top wall of the box; an exhaust fan is fixedly mounted inside the mounting hole; the feed end of a discharge pipe is fixedly communicated with the middle part of the bottom wall of the box; a driving motor is fixedly mounted at the top endof the right side surface of the box through a mounting rod; a rolling mechanism is arranged inside the box. Through arrangement of the rolling mechanism, the vertical-linkage and reciprocating rolling-type mashed potato preparing device can quickly roll potatoes after feeding to quickly destroy the structures of the potatoes, so that rapid mashing of the potatoes is achieved and improvement on the preparation efficiency of mashed potato is facilitated.

Owner:曾早生

Rice huller with protective structure for agricultural production

InactiveCN113996372AStrong applicabilityGuaranteed pureSievingGrain huskingAgricultural engineeringAgricultural science

The invention discloses a rice huller with a protective structure for agricultural production, and relates to the field of rice hullers. The rice huller comprises: a base and an awn removing mechanism. A mounting plate is fixedly mounted on the side end face of the base, wherein the awn removing mechanism is mounted on the inner side of the top of the mounting plate; the awn removing mechanism comprises a machine body, a feeding port, a storage bin, a discharging plate, a rotating wheel, plastic grinding blocks, a guide plate, driven grinding wheels, and a first channel, wherein the feeding port is formed in the right side of the top of the machine body. According to the rice huller with the protection structure for agricultural production, the defect that a large number of grain spikelet thorns with awns of many crop varieties such as rice and the like cannot be removed by equipment in the prior art is overcome, the awns of the rice are removed preferentially in a targeted mode, and the awns, dust, and sundries carried in the rice are removed in time, so that the purity of the quality of the rice subjected to subsequent hulling is guaranteed, efficient and high-quality hulling is conducted in a mode of overturning and kneading through rollers on the two sides, and the applicability is higher.

Owner:徐州腾鸿建设工程有限公司

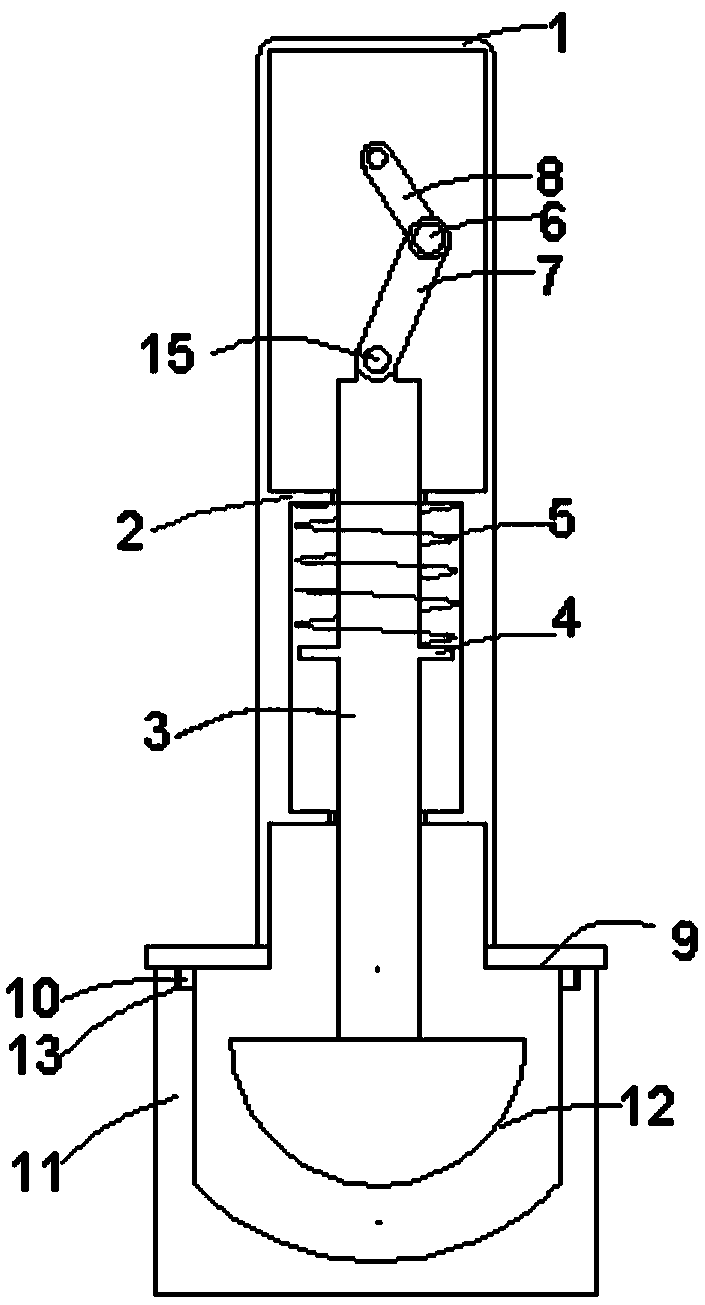

Household garlic rammer

The invention discloses a household garlic rammer includes a protective sleeve. The household garlic rammer includes the protective sleeve. A first cavity and a second cavity are arranged in the protective sleeve, A tam bar is arranged in that second cavity, both ends of the tamping bar penetrate the second cavity and extend outwardly. The outside wall of the tamping bar is connected with the inside wall of the second cavity through a resetting mechanism. A first rotating rod is rotatably connected to the top of the tamping bar, a second rotating rod is rotatably connected to an end of the first rotating rod away from the tamping bar. The protective sleeve is connected with the second rotating rod through a handle driving mechanism, a tamping garlic block is fixedly connected to the bottomof the tamping bar, and a baffle is fixedly connected to an outer wall of the bottom of the protective sleeve. The L-shaped rod drives the tamping rod to squeeze the garlic up and down to produce thegarlic mud, and the tamping rod reciprocates through the setting of the spring, so that the garlic can be tamped with less effort and the baffle plate can be arranged to prevent the garlic from flying out of the bowl body in the tamping process from causing waste. The invention discloses a method for preparing the garlic mud by using the L-shaped rod.

Owner:梁林燕

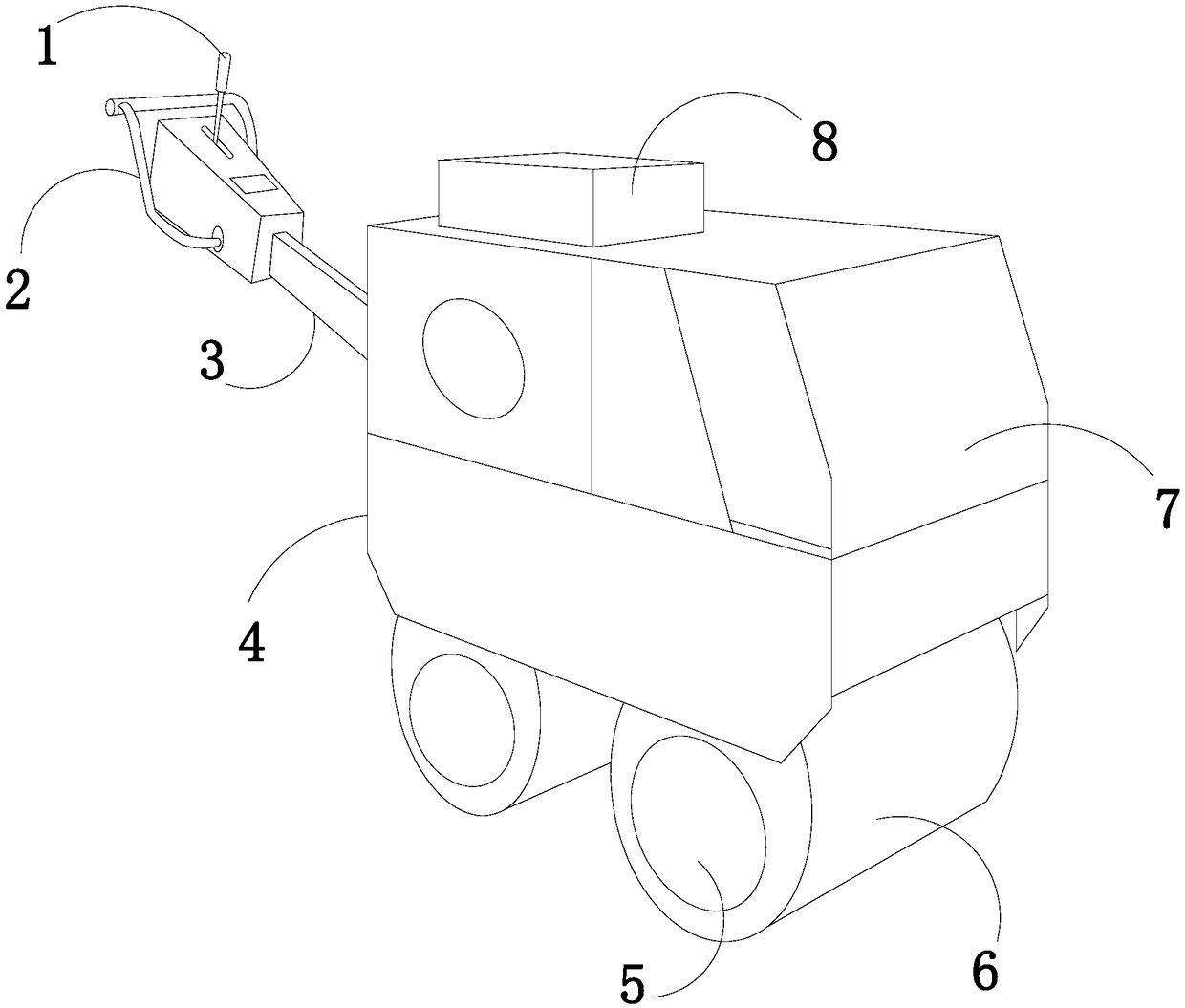

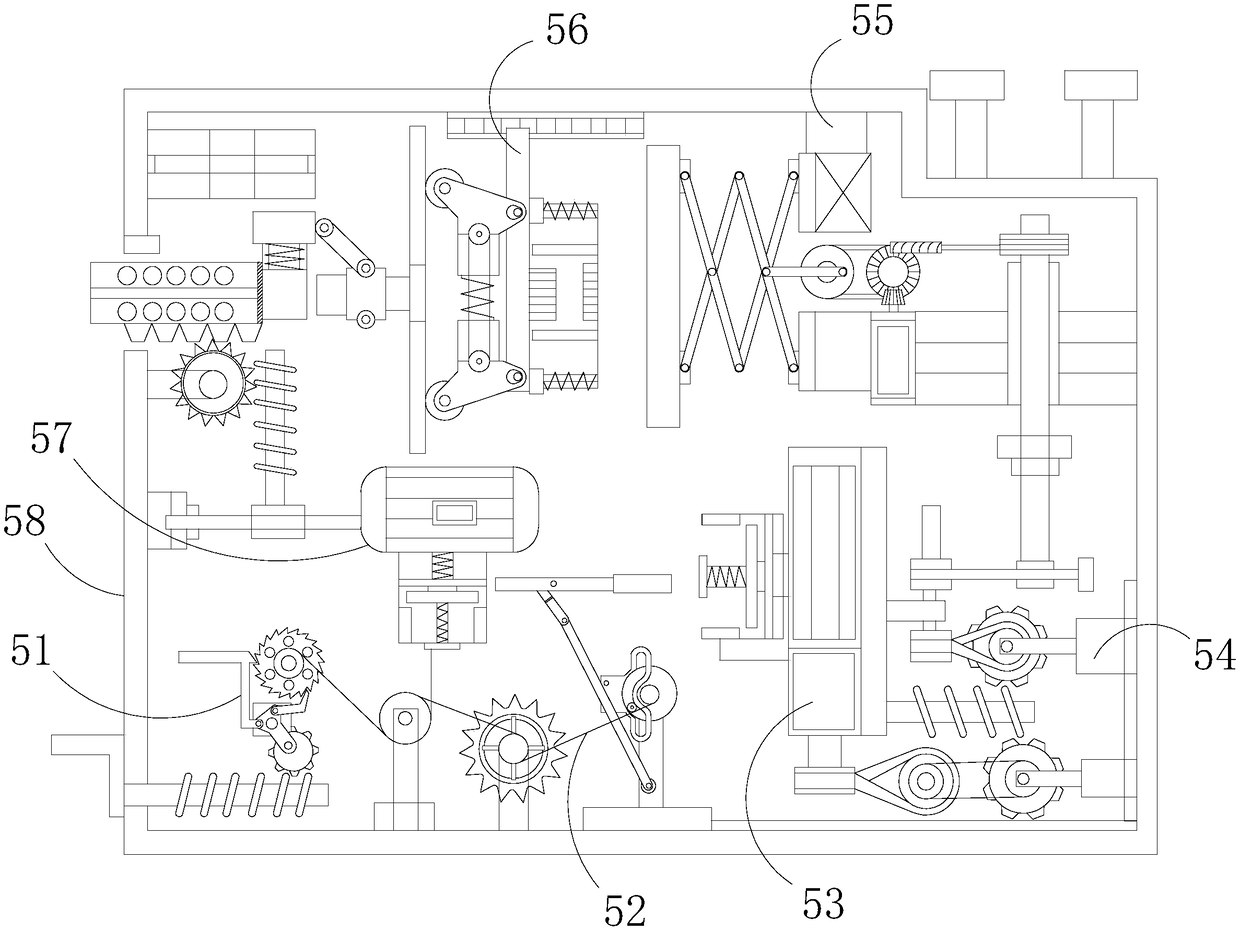

Heat rolling device for asphalt road construction

InactiveCN108842573AImprove work efficiencyImprove practicalityRoads maintainenceRoad surfaceRoad construction

The invention discloses a hot rolling device for asphalt road construction. The device structurally comprises a starting button, a handle, a supporting column, a rolling machine body, a connecting mechanism, rolling wheels, a metal shell and an electric box, wherein the electric box is fixed on the left side at the upper part of the rolling machine body by rivets, the metal shell is arranged on the outer surface of the rolling machine body in a welding manner, the supporting column is fixed in the middle of the left side of the rolling machine body by rivets, the handle is fixed at the tail end of the supporting column by screws, and the connecting mechanism is provided with a starting mechanism, a driving mechanism, a gear mechanism, a transmission mechanism, a screw rod mechanism, a pushing mechanism, a linkage mechanism, and a shell. The hot rolling device has the beneficial effects: the connecting mechanism is arranged, so that thin-layer pavements can be rolled, thus ensuring sufficient pavement rolling; and the device can be adjusted, mounted and dismounted according to the actual width of a construction site, and the mounting and dismounting are easy, so that the device canadapt to the rolling of pavements with various uneven base courses, working surfaces can be flexibly operated, the work efficiency and practicability of the hot rolling device are improved, and the labor of worker is reduced.

Owner:郑菁清

Thermosetting powder coating production device

The invention discloses a thermosetting powder coating production device, which comprises an extrusion chamber and a rolling cylinder, the rolling cylinder is located above the extrusion chamber, a rolling shaft is rotatably connected inside the rolling cylinder, and the rolling cylinder One end is provided with a limit plate, one end of the rolling shaft is provided with a pull rod, the pull rod passes through the limit plate, the other end of the pull rod is provided with a first movable rod, and the other end of the first movable rod is rotatably connected to a second A movable rod, the second movable rod is clamped with a fixed shaft, the other end of the second movable rod is provided with a third movable rod, the other end of the third movable rod is rotatably connected to a rotating shaft, and one side of the rotating shaft is provided There is a turntable, and the rotating shaft is fixedly arranged on the turntable. The invention is easy to operate, through the mutual cooperation of the extrusion roller, the conveyor belt, the frame, the rolling cylinder, the rolling shaft and the turntable, the sufficient rolling of the thermosetting powder coating can be realized, the production can be completed with high efficiency, the production efficiency can be improved, and a kind of Efficient thermosetting powder production unit.

Owner:YANCHENG YONGYUE NEW MATERIAL CO LTD

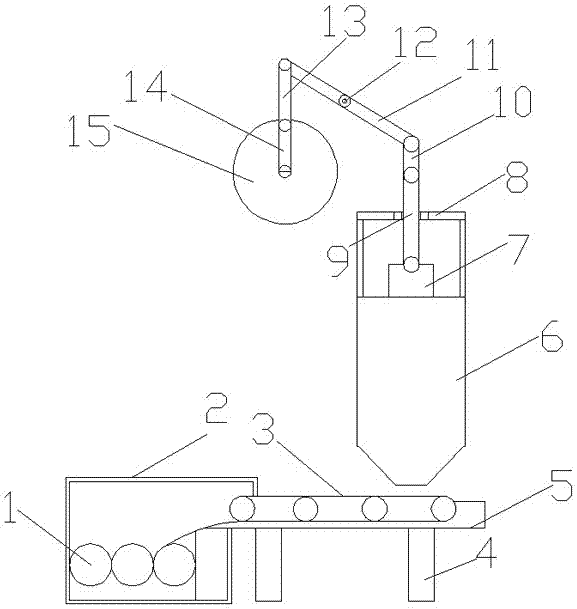

Domestic wrapper rolling device and using method thereof

ActiveCN108812737AReduce difficultyReduce manual workDough-sheeters/rolling-machines/rolling-pinsDough dividingEngineeringMechanical engineering

The invention discloses a domestic wrapper rolling device and a using method thereof. The device comprises a wrapper rolling mechanism, and also comprises a dough feeding mechanism matched with the wrapper rolling mechanism; the dough feeding mechanism comprises a frame, and a dough extruding device is arranged above the frame. The dough extruding device is used for extruding the dough to producedough pieces, a sliding component is arranged below the frame, a dough holding mechanism is arranged above the sliding component, the sliding component can drive the dough holding mechanism to slide on the horizontal plane, and the dough holding mechanism is used for containing the dough pieces which are extruded from the dough extruding device; the wrapper rolling mechanism can be arranged on thedough holding mechanism, and rolls the dough pieces in the dough holding mechanism into wrappers. The purpose is to solve the problems of a prior wrapper rolling device, such as high cost, large occupied area, low production efficiency and poor quality of the manufactured wrappers.

Owner:江苏恒卫防护器材制造有限公司

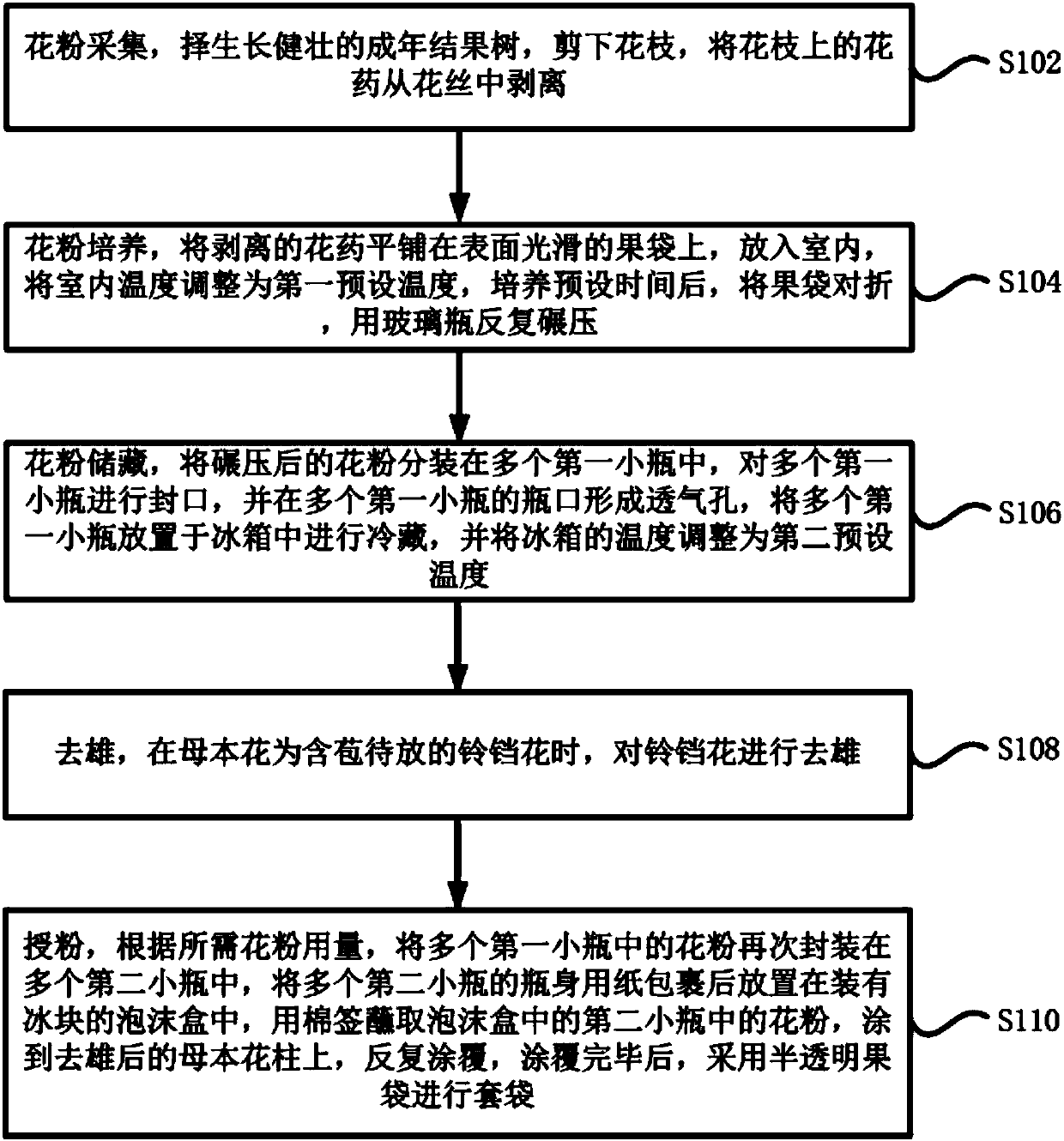

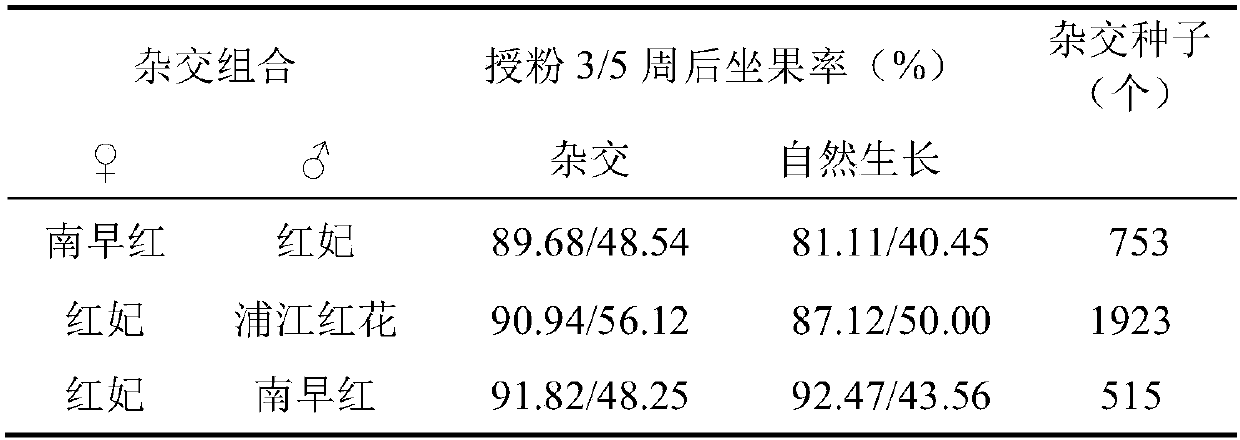

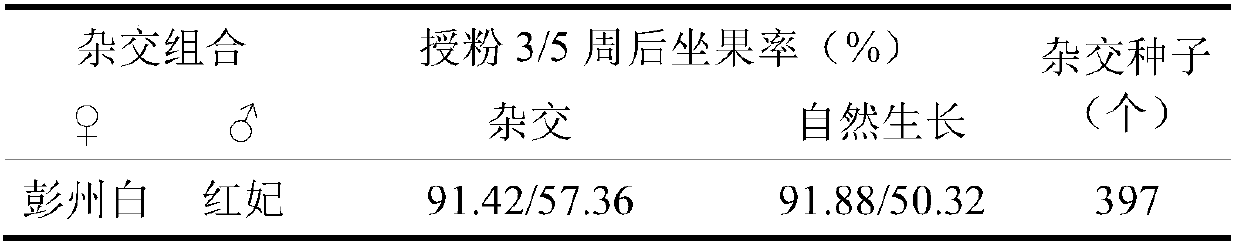

Hybridization method for cherry

PendingCN107896971ASolve the condition requirements of cultivationAvoid the danger of loss of vitalityPlant genotype modificationPollinationPollen

The invention provides a hybridization method for a cherry. The hybridization method comprises the following steps: collection of pollen; culture of the pollen; storage of the pollen: subpackaging therolled pollen with a plurality of first small bottles, sealing the plurality of first small bottles, forming air vents in the bottlenecks of the plurality of first small bottles, refrigerating the plurality of first small bottles in a refrigerator and adjusting the temperature of the temperature of the refrigerator to a second preset temperature; castration: carrying out castration on bell-like flowers when the flowers of female parents are the bell-like flowers ready to burst; and pollination: based on the desired amount of the pollen, packaging the pollen in the plurality of first small bottles into a plurality of second small bottles, wrapping the bodies of the plurality of second small bottles with paper, then placing the plurality of second small bottles into a foam box filled with ice cubes, dipping the pollen in the plurality of second small bottles with a cotton swab, repeatedly coating the styles of the castrated female parents with the pollen, and carrying out bagging with semi-transparent bags after completion of coating. The method provided by the invention improves the vitality of pollen and enhances artificial hybridization efficiency of the cherry.

Owner:SICHUAN AGRI UNIV

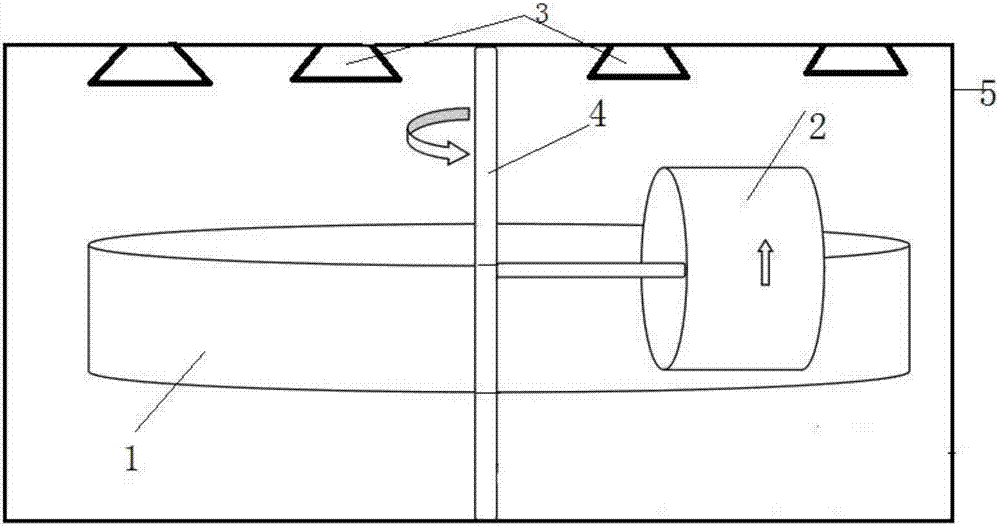

Rolling machine

The invention discloses a rolling machine. The rolling machine is characterized in that the rolling machine comprises a disc body, a rolling wheel, a draught fan and an outer shell. A rotating shaft is arranged in the middle of the disc body, and the rolling wheel is mounted on the rotating shaft; the draught fan is mounted at the top end in the outer shell; and the bottom surface of the disc body is in a mesh hole shape. The rolling machine for agriculture is simple in structure, sufficient in rolling and good in effect and cannot cause dust pollution.

Owner:JIANGSU CHUANTIAN MCN ELECTRICAL MASCH CO LTD

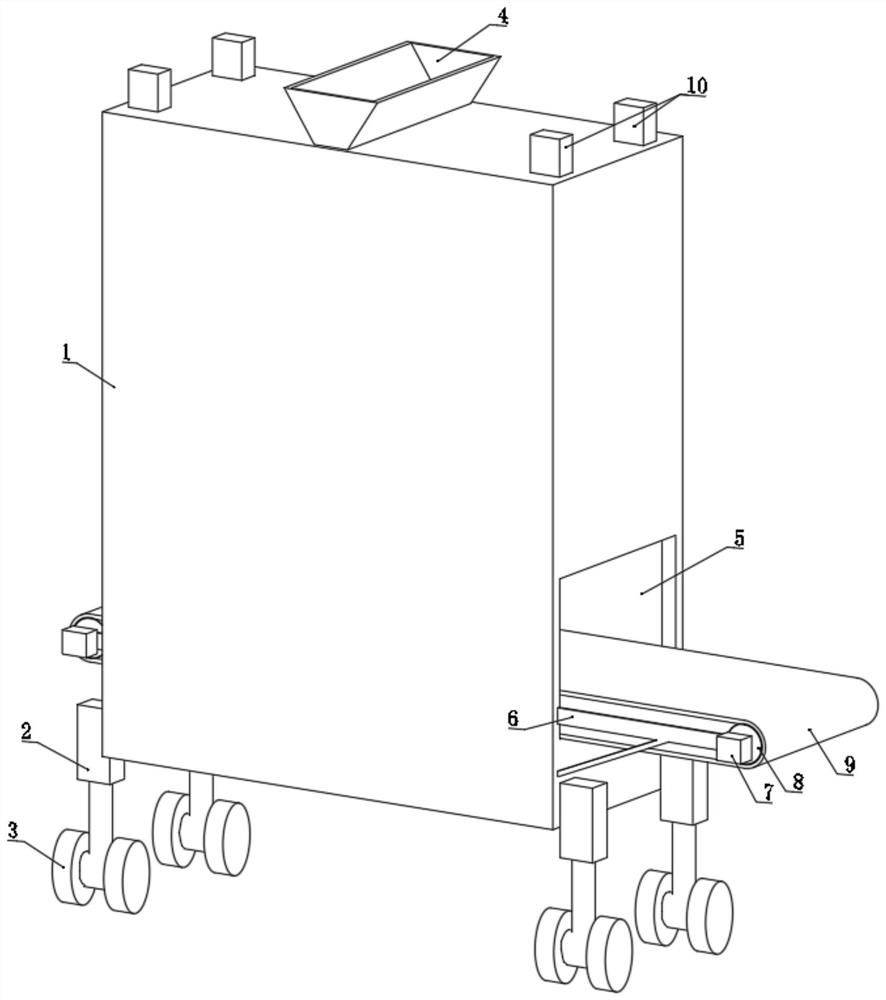

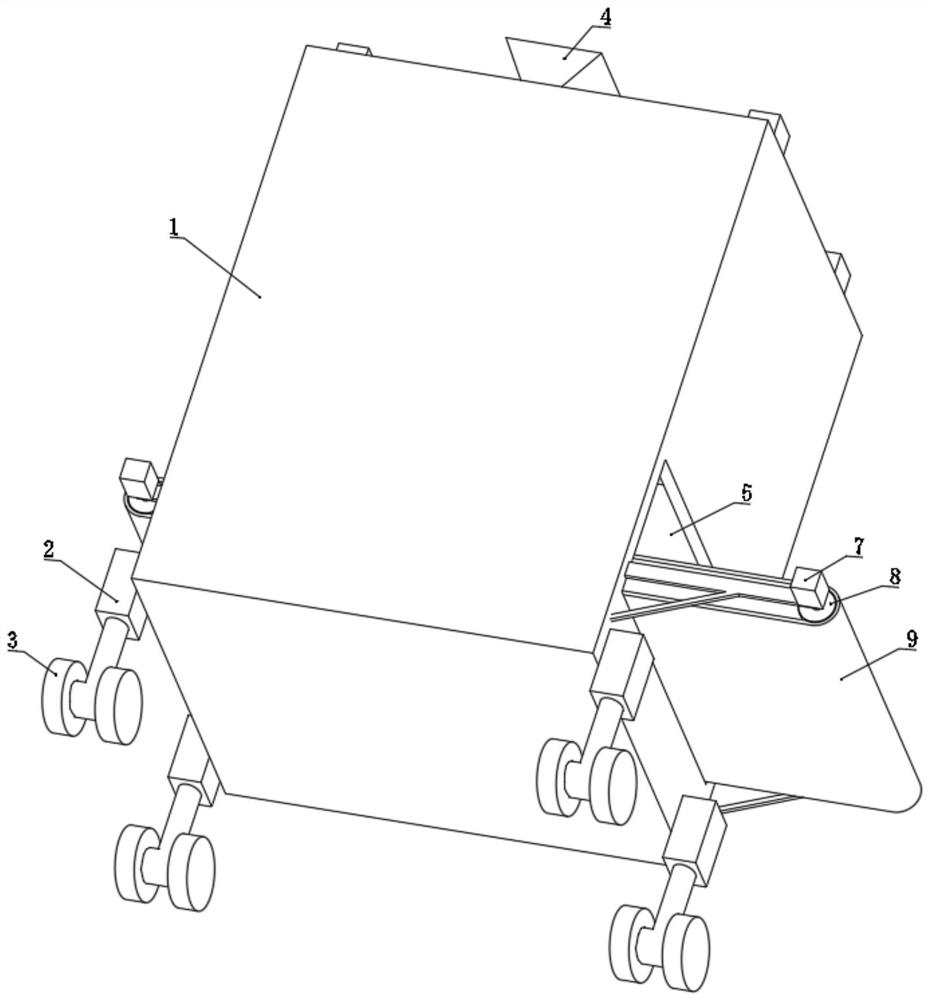

Garbage treatment device for building

The invention discloses a garbage treatment device for building, and belongs to the field of construction equipment. The garbage treatment device comprises a box body, a plurality of mounting seats are mounted at the bottom of the box body, moving wheels are mounted at the bottom ends of the mounting seats, a feeding hopper is mounted on the top wall of the box body, the bottom of the feeding hopper communicates with the interior of the box body, a side face outlet is formed in one side of the bottom of the box body, a conveying mechanism is transversely arranged inside the box body, the conveying mechanism comprises a first motor, a conveying roller and a conveying belt, a support is fixed to the outer side wall of the box body, and the conveying roller and the support are rotationally installed. According to the device, building garbage, especially bricks and concrete blocks, can be fully ground and crushed, the crushed garbage is more uniform, in addition, the crushed garbage and steel bars can be automatically separated and discharged, wast caused by incomplete separation of the steel bars is avoided, the situation that equipment components are clamped by the steel bars is also avoided, and therefore, the crushing efficiency and the utilization rate of the garbage are high.

Owner:NORTHEAST FORESTRY UNIVERSITY

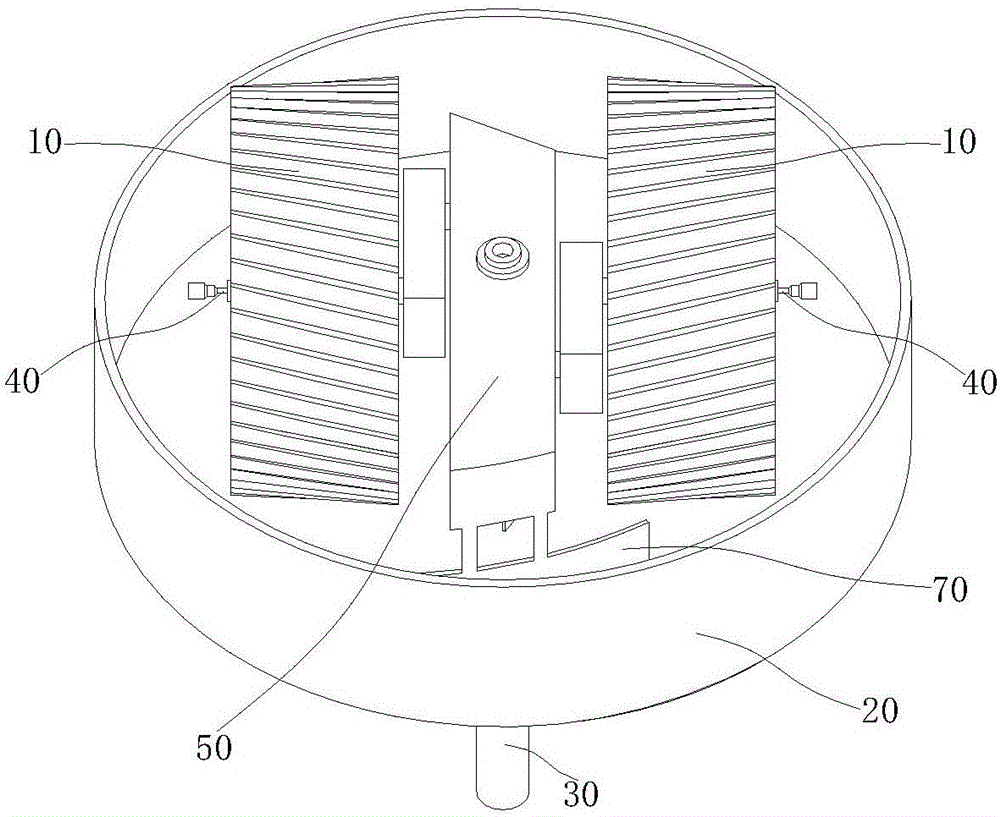

Multi-functional agricultural product processing equipment

ActiveCN111772202AAvoid breakingFully rolledHuskingHullingAgricultural scienceAgricultural engineering

The invention discloses multi-functional agricultural product processing equipment. The multi-functional agricultural product processing equipment structurally comprises a motor, a support frame, a peeling box, a box door, a feed hopper, a dust suction box and an air outlet, wherein the motor is fixedly mounted at the upper end of the support frame; through lugs and a gap between the lugs, peanutkernels being different in granule sizes can be sufficiently rolled, and besides, in the rotating process of rolling rollers, an adjusting rod can smoothly and vertically slide in a sliding rail, so that adjustment can be performed between the rolling rollers and a prodding mechanism; and due to downward pressing pressure of the rolling rollers, the peanuts being large in shelled peanuts can be broken, shelled peanuts enter a placing groove, the shelled peanuts can be separately stored, the condition that the shelled peanuts are broken can be avoided, and when the prodding mechanism is used for prodding, a film generates certain resilience, so that the shelled peanuts in the placing groove can be ejected out, the shelled peanuts are guaranteed to be upwards prodded, and the effect of peeling the shelled peanuts can be increased.

Owner:衡阳市星乐农业科技股份有限公司

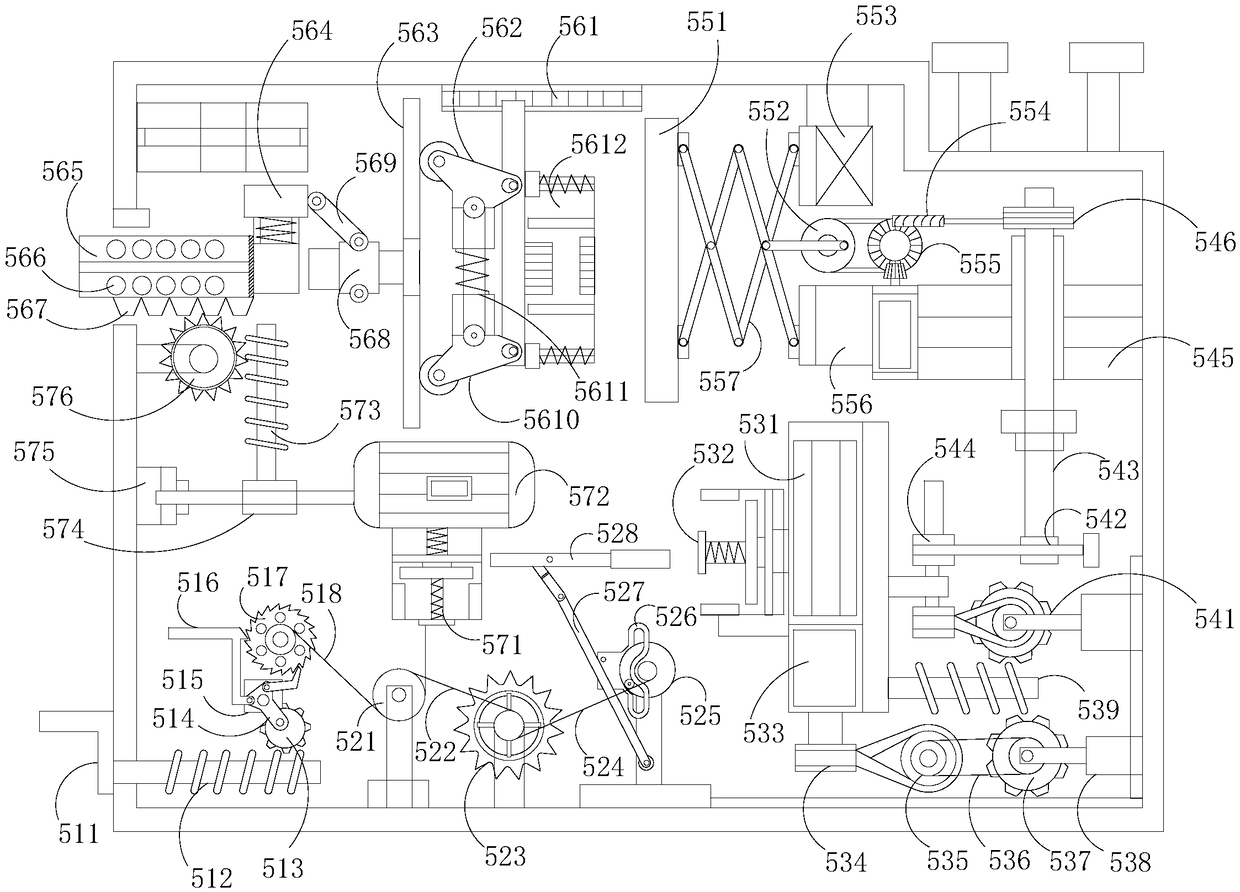

Plastic film machining production line and production and machining method thereof

ActiveCN109016250AIncrease labor costImprove work efficiencyPlastic recyclingProduction linePlastic film

The invention relates to a plastic film machining production line and a production and machining method thereof. The plastic film machining production line comprises a bottom plate, a grinding device,a pelleting device and auxiliary devices. The bottom plate is sequentially provided with the grinding device and the pelleting device from left to right. The auxiliary devices are symmetrically mounted at the left end and the right end of the pelleting device and mounted on the bottom plate. The grinding device comprises a working frame, a rotary motor, a driving rotary barrel, a driven rotary barrel and a grinding mechanism. Each auxiliary device comprises buffer springs, a first auxiliary supporting plate, a second auxiliary supporting plate, an auxiliary motor, rotary shafts, cams, a connecting rotary frame, a vibrating frame, a limiting frame and a fixing column. The problems that in the existing plastic film lug material recycling and treating processes, the labor cost is high, the working efficiency is low, potential safety hazards exist, and grinding is not complete can be solved, the functions of automatically grinding and pelleting plastic film lug materials can be achieved,and the plastic film machining production line has the beneficial effects that the labor cost is high, the working efficiency is high, the safety is high, and grinding is complete.

Owner:青岛正大环保科技有限公司

Biomass recovery equipment

ActiveCN111871523AShattered fullySmash efficientRenewable energy machinesCuttersEngineeringProcess engineering

The invention discloses biomass recovery equipment which comprises a bottom box body. A top box body is arranged on the upper side of the bottom box body, a containing and discharging device used forcontaining biomass raw materials and facilitating discharging of the biomass raw materials out of the equipment is arranged in the bottom box body, and a top rotating ring is rotationally arranged onthe outer side of the top box body; and a distance adjusting device for changing the distance between the top box body and the bottom box body is arranged between the top rotating ring and the bottombox body, and a driving device for driving the top box body to rotate is arranged on one side of the top rotating ring. The biomass recovery equipment is simple in structure; according to the equipment, the manner that the heights of an upper machine body and a lower machine body of the equipment can be adjusted is adopted, in the adjusting process, the upper machine body can rotate to fully smashthe biomass raw materials, and the interior of the equipment can be adjusted according to a smashing area; and the equipment can efficiently smash the materials with different heights and different distribution conditions.

Owner:博兴兴博投资有限公司

Multistage profiling device for rubber tape, and rubber part winding unit

The invention provides a multistage profiling device for a rubber tape. The multistage profiling device for the rubber tape is used for roll forming rubber extruded by an extruding machine and comprises profiling roller assemblies, wherein each profiling roller assembly comprises two profiling rollers arranged correspondingly and moving rotatably; a special-shaped groove is formed in the surface of at least one profiling roller; a special-shaped profiling space is formed between the inner surface of the groove and the outer surface of the other profiling roller of each profiling roller assembly; at least two sets of profiling rollers are arranged adjacently; and in addition, the cross sections of the profiling spaces of the different profiling roller assemblies are decreased progressivelyalong a rubber conveying direction. The invention further provides a rubber part winding unit with the multistage profiling device for the rubber tape. The rubber part winding unit has the advantagesof high profiling accuracy and high winding efficiency.

Owner:LINK-ASIA SMART TECH (SUZHOU) CO LTD

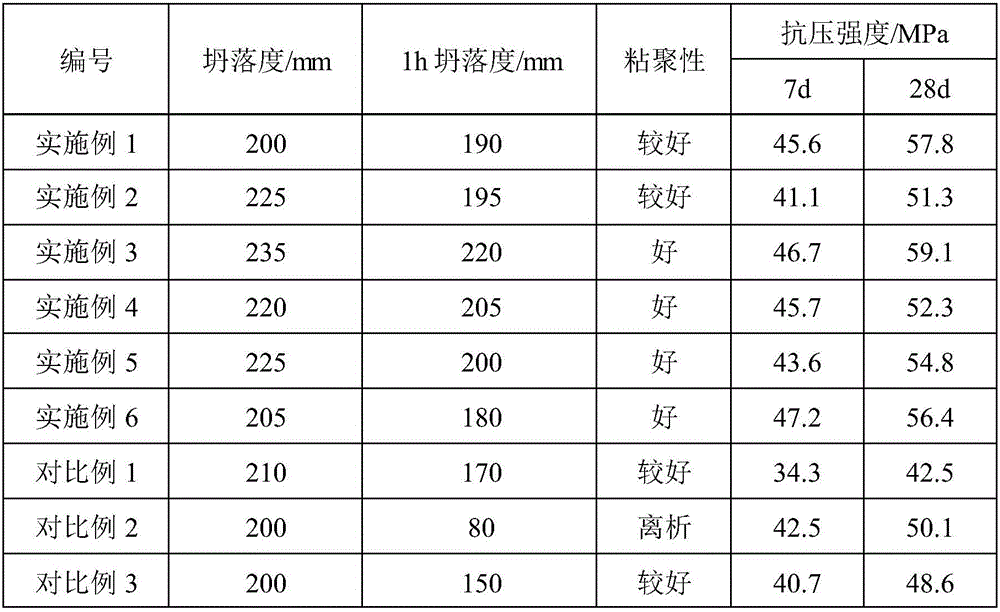

Environment-friendly compound admixture for architectural decoration engineering and preparation method thereof

The invention belongs to the technical field of architectural decoration engineering, specifically to an environment-friendly compound admixture for architectural decoration engineering and a preparation method thereof, and the compound admixture comprises the following substances by weight: 20wt%-30wt% of steel slag, 1wt%-5wt% of hydrotalcite, 0.05wt%-0.3wt% of a material layer stabilizing agent, 0.1wt%-0.2wt% of magnesium fluorosilicate, 0.1wt%-1wt% of an enhancing material, 0.1wt%-0.5wt% of fiber, 1wt%-5wt% of nano-alumina and the balance slag. The environment-friendly compound admixture for architectural decoration engineering provided by the invention is good in use effects, and can comprehensively improve the concrete performance, and is also beneficial to the recycling economic construction of iron and steel enterprises, and protects the environment.

Owner:SHENZHEN HONGTAO DECORATION

Perforated molybdenum piercing head structural member

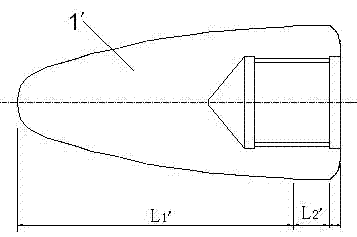

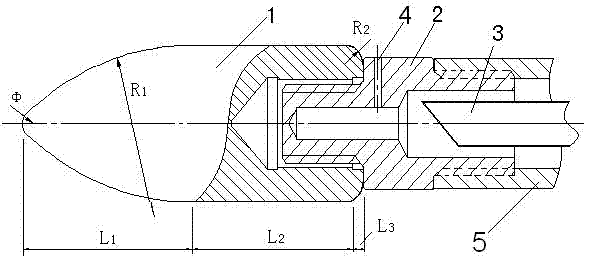

InactiveCN103286133AImprove surface qualityFully rolledMandrelsMetal rolling arrangementsCooling pipeSteel tube

The invention relates to the seamless steel tube production equipment and discloses a perforated molybdenum piercing head structural member. The perforated molybdenum piercing head structural member comprises a piercing head and a connecting joint; the piercing head is formed by a piercing area, a roll-off area and an adhering to round area; the length of the roll-off area is 75 to 90 % length of the piercing area; the connecting joint is in a hollow shape; one end of the connecting joint is a blind hole and a middle section of the connecting joint is provided with steps which are radially provided with cooling water outlet holes; the blind hole end of the connecting joint is in internal thread connection with the piercing head; the other end of the connecting joint is in internal thread connection with a piercing rod; and an inner hole is provided with a cooling pipe. The perforated molybdenum piercing head structural member has the advantages of enabling internal surface quality of a capillary pipe to be good, enabling surface fracturing and surface sticking which are generated on a full molybdenum piercing head to be reduced, improving the service life by four times and greatly decreasing workloads and auxiliary material consumption in artificial polishing and changing.

Owner:XINYU IRON & STEEL CO LTD

Portable medicine dispensing device based on clinical pharmacy

InactiveCN114367359ASave energyImprove efficiencyPharmaceutical product form changeGrain treatmentsMedicinal herbsEngineering

The invention provides a portable medicine dispensing device based on clinical pharmacy, and effectively solves the problems that an existing grinding roller can only grind traditional Chinese medicinal materials with the surfaces in contact with the traditional Chinese medicinal materials; the problems that medicinal materials which are not in contact with the grinding roller cannot be effectively ground, the fan-shaped plate cannot be thoroughly cleaned by manually holding a corresponding tool traditionally, and multi-stage crushing cannot be achieved are solved; a supporting assembly is fixedly connected into the upper box body, a fixing ring is fixedly connected to the upper end of the middle of the supporting assembly, a synchronous ring is rotatably connected to the upper end of the middle of the fixing ring, and a reversing gear ring located on the outer side of the fixing ring is fixedly connected to the upper end of the supporting assembly. The upper end of the fixing ring is evenly and slidably connected with a plurality of driving moving discs fixedly connected with the synchronous rings correspondingly, through cooperative use of rolling claws, sliding-in holes, torsional spring rods and grinding rollers, medicinal materials on the supporting assembly can be rolled up and down, the medicinal materials are ground to be finer, blocky particles are avoided, and therefore the medicinal materials can be more effectively ground. And the medicinal materials are ground more thoroughly.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

Paper pulp material pulverizing device

The invention discloses a paper pulp material pulverizing device which comprises a stone roll. A cylinder opening of a roll cylinder is upward, the middle of the roll cylinder is provided with a vertically arranged rotary spindle, the rotary spindle is connected with the stone roll through a flatly arranged stone roll shaft, the roll surface of the stone roll and the inner cylindrical bottom of the roll cylinder form rolling match, a cross rod is arranged on the rotary spindle, the middle of the cross rod is fixedly connected with the periphery of the rotary spindle, and inner and outer scraping plates are arranged below the cross rod and scrape and push a processed Xuan paper raw material to a rolling path of the stone roll in the process of rotating with the rotary spindle. The cross rod rotates by following the rotary spindle to drive the inner and outer scraping plates to move the processed Xuan paper raw material in the roll cylinder and scrape and push the processed Xuan paper raw material to the rolling path of the stone roll, the processed Xuan paper raw material can be uniformly and efficiently rolled in time, the fiber length of the processed Xuan paper raw material can be ensured, and the uniformity meets the quality requirement.

Owner:CHINA XUAN PAPER

Ceramic rolling and pressing machine

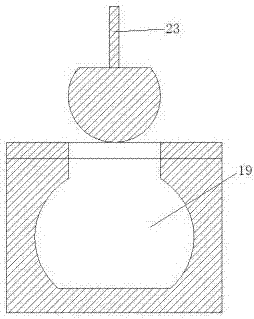

The invention discloses a ceramic rolling and pressing machine, and belongs to the field of production of ceramic utensils. The ceramic rolling and pressing machine is characterized by comprising a rack and a rolling and pressing head, wherein a support beam is arranged on the rack in a sliding manner; the rolling and pressing head is driven by a rotating motor; a motor base of the rotating motor is in transmission connection with an end part of the support beam; a first pulley is arranged at the bottom, close to rear end, of the rack; the first pulley is in sliding contact with an edge of a lifting cam; a rotating shaft of the lifting cam is driven by a lifting motor; a crank is arranged on the rotating shaft of the lifting arm and is in sliding contact with the second pulley; the second pulley is rotatably arranged at bottom end of the connecting plate; a middle part of the connecting plate is rotatably arranged on a fixed shaft of the rack; the top part of the connecting plate extends upwards to form a pulling block; the support beam is provided with a connecting rod which can collide with the pulling block on the rear part of the pulling block; and the rear end of the support beam is connected with the rear end of the rack by a spring. According to the ceramic rolling and pressing machine disclosed by the invention, the rolling and pressing head can be positioned in a ceramic container for a long time, the inner surface of the ceramic container is fully rolled so as to prepare the ceramic container with small aperture and large inside diameter.

Owner:许文瑜 +1

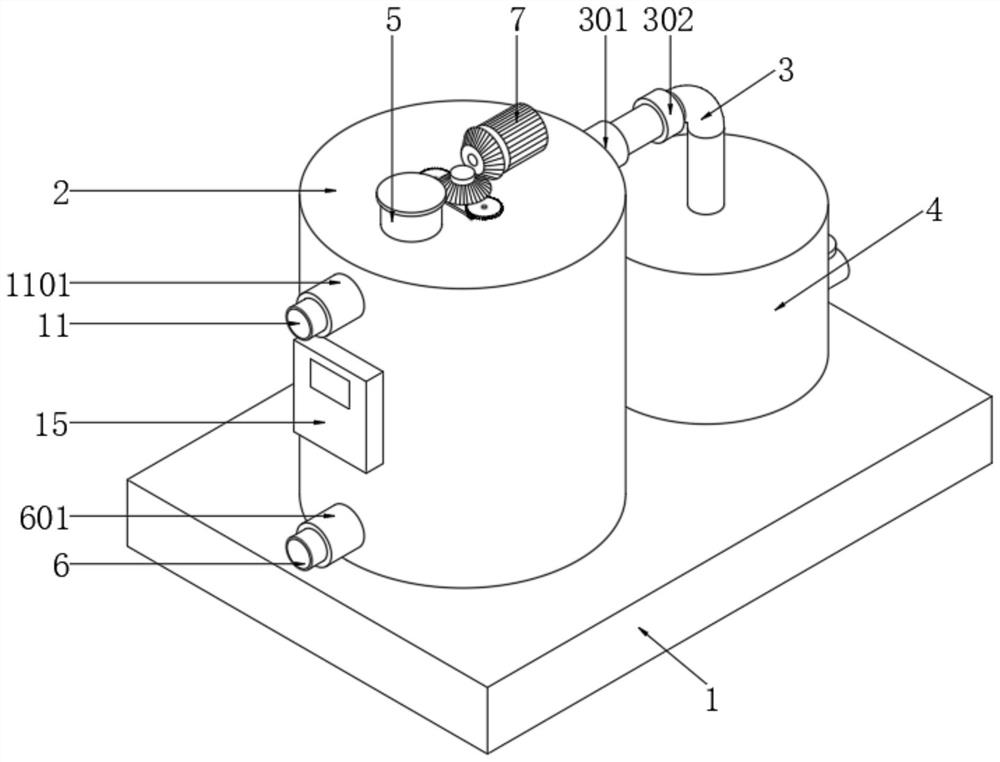

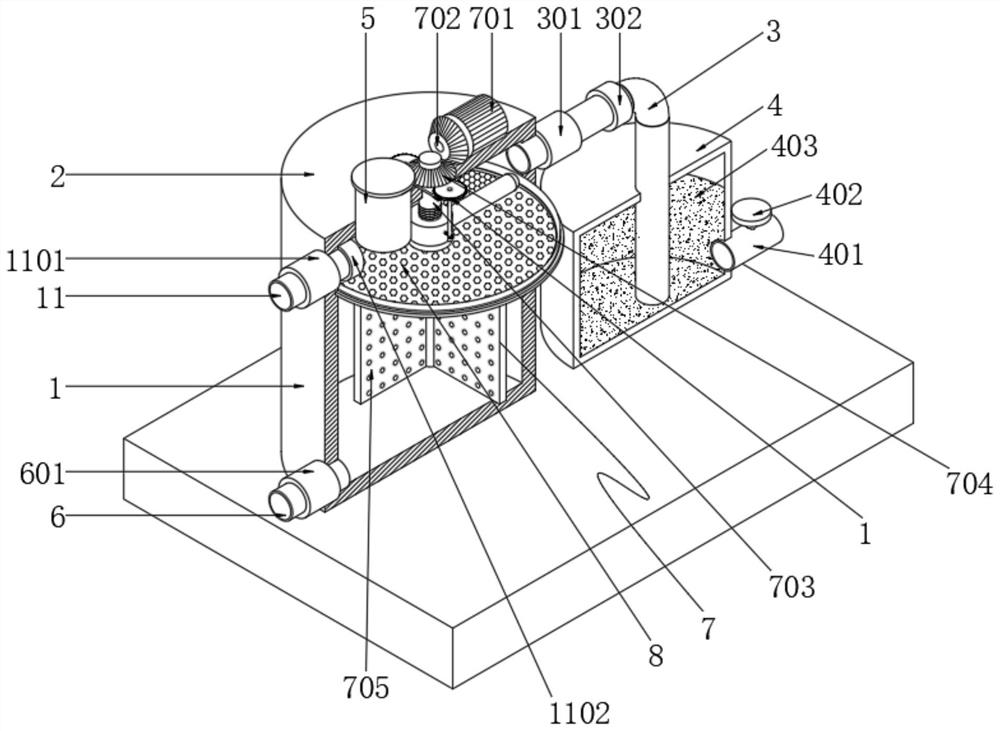

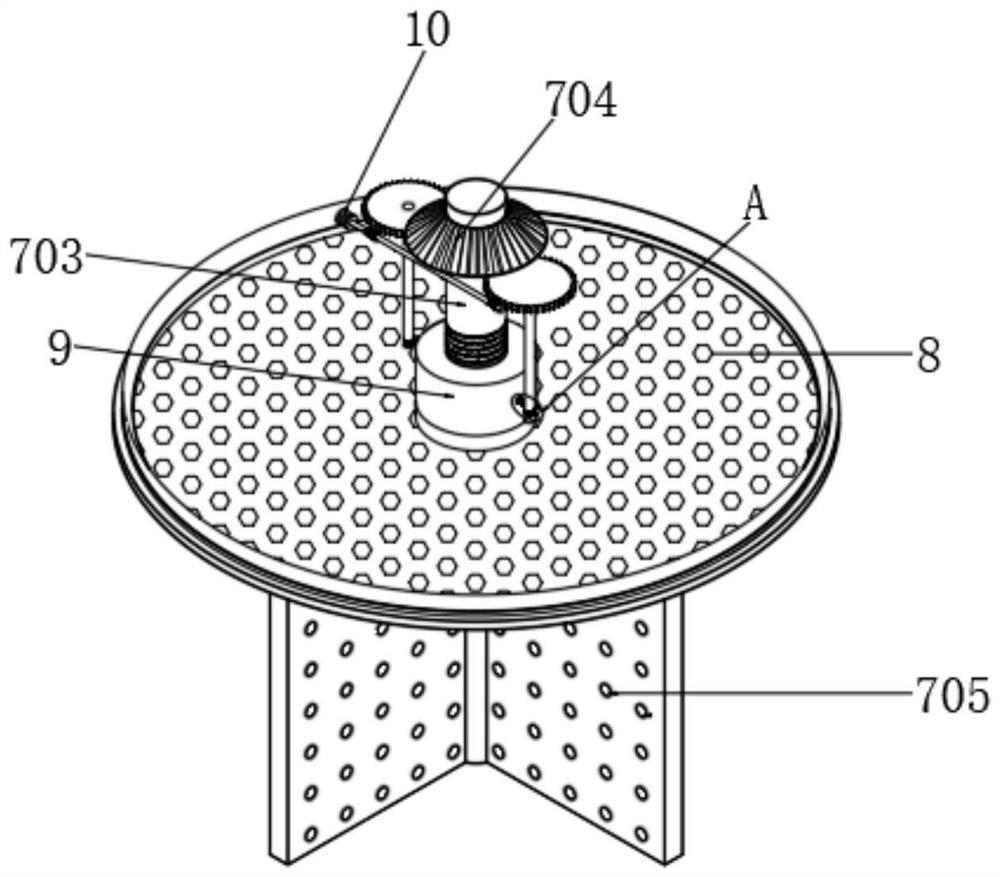

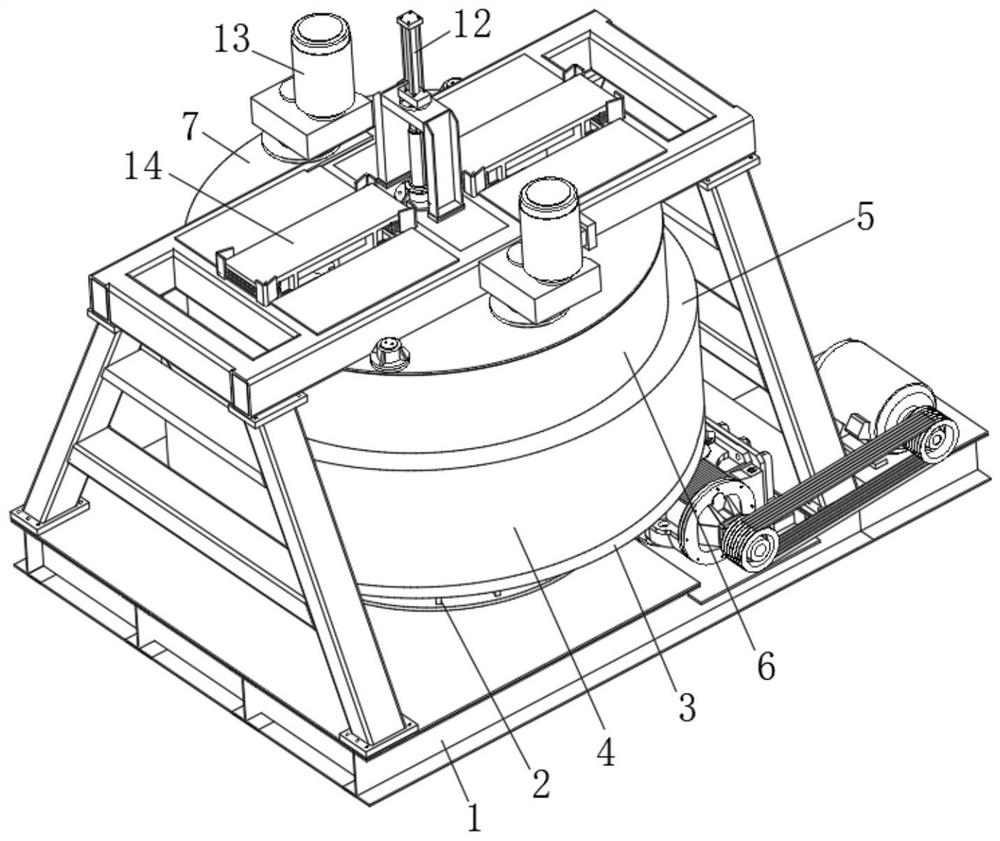

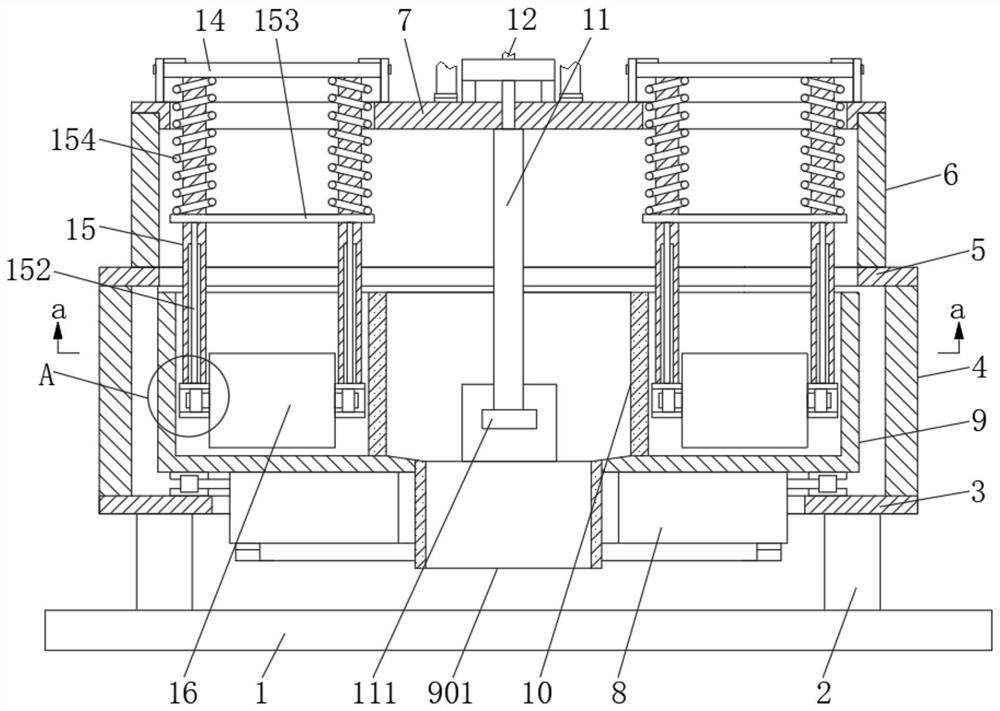

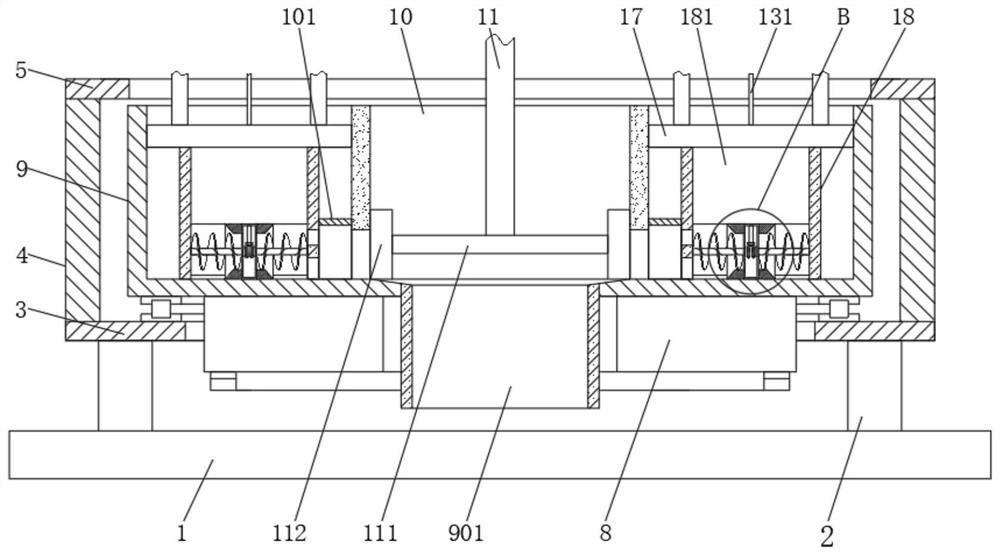

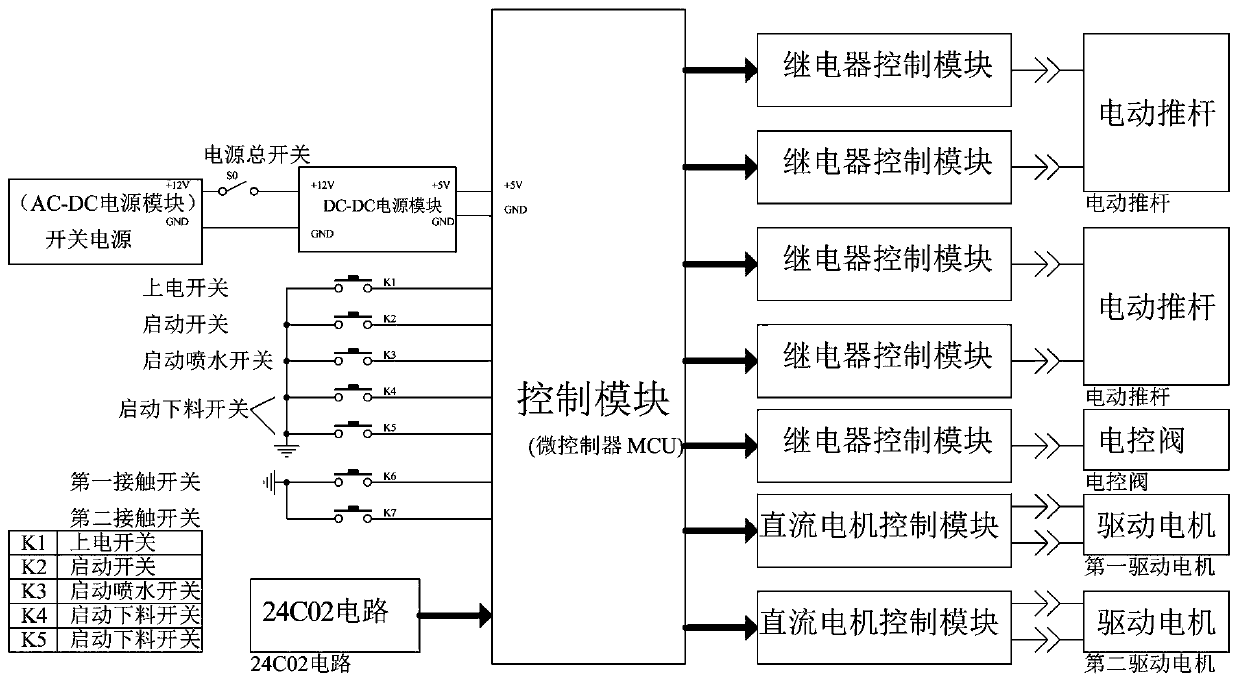

Aluminum alloy refining system

ActiveCN113758250AFully rolledSmash thoroughlyStirring devicesCharge manipulationEngineeringGrinding wheel

The invention discloses an aluminum alloy refining system. The system comprises a base, wherein a refining rabbling furnace is fixedly installed at the upper end of the base; a pressure transducer is arranged at the inner top end of the refining rabbling furnace; the right side of the refining rabbling furnace is connected with a dissolving tank through an air outlet pipe; the left side of the upper end of the refining rabbling furnace is fixedly connected with a feeding port; a molten aluminum outlet pipe is fixedly connected to the left side of the bottom end of the refining rabbling furnace; a stirring device is arranged in the refining rabbling furnace; a filter sieve is arranged on the stirring device; a connecting base is arranged at the upper end of the filter sieve; and adjusting devices are arranged at the two sides of the connecting base. The invention relates to the technical field of smelting devices. According to the aluminum alloy refining system, through the arranged adjusting devices, lifting of the connecting base can be controlled, then the distance between a grinding wheel and the surface of the filter sieve is controlled, coagulums are fully ground and smashed, and the situation that blocky refining agents block outlets of screening holes of the filter sieve and cannot uniformly enter an aluminum alloy solution is prevented.

Owner:包头市亿江铝业有限公司

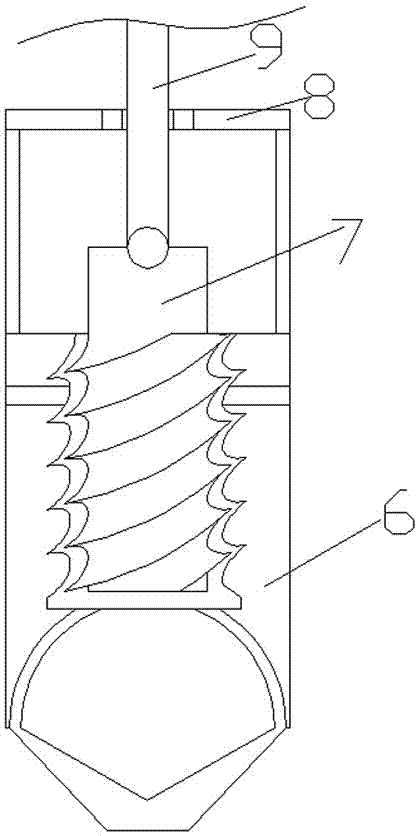

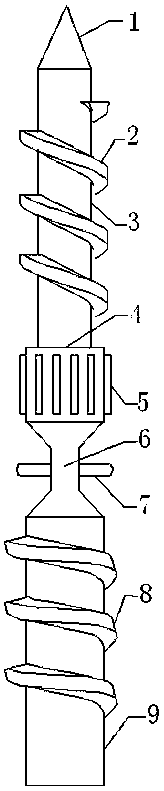

High-precision novel screw

The invention discloses a high-precision novel screw. The high-precision novel screw comprises a screw head, a first screw edge, a first screw body, a second screw body, multiple convex columns, a third screw body, stirring rods, a second screw edge and a fourth screw body; the first screw body is arranged under the screw head, the second screw body is arranged under the first screw body, the third screw body is arranged under the second screw body, and the fourth screw body is arranged under the third screw body; the first screw edge extending from top to bottom is arranged on the outer sideof the first screw body; the multiple convex columns are arranged on the outer side of the second screw body; the third screw body and the second screw body achieve transition through a slope; the third screw body and the fourth screw body achieve transition through a slope; the left side and the right side of the third screw body are provided with the stirring rods correspondingly; and the secondscrew edge extending from top to bottom is arranged on the outer side of the fourth screw body. The high-precision novel screw has the advantage that the screw edge structure is complex.

Owner:ZHEJIANG JINGJIN MACHINERY

Device capable of fully recycling and treating rose essential oil production wastewater

PendingCN114524586AEfficient use ofFully rolledTreatment using aerobic processesSpecific water treatment objectivesProcess engineeringEssence oil

The invention belongs to the technical field of wastewater treatment equipment, and particularly relates to a device capable of fully recycling and treating rose essential oil production wastewater. Comprising a first mounting seat, a first moving seat, a plurality of groups of grinding assemblies, a turnover assembly, a plurality of groups of separating assemblies, a plurality of groups of filtrate assemblies and a telescopic assembly; the first moving seat is movably mounted at the upper end of the first mounting seat; the grinding assembly is mounted in the first moving seat in a transmission manner; the overturning assembly is rotationally mounted on the first mounting seat and is positioned below the crushing assembly; one end of a body of the telescopic assembly is fixedly mounted on the turnover assembly; the liquid filtering assembly comprises a liquid filtering disc, a second baffle, a third supporting plate and a third baffle, and a third clamping groove is further formed in the outer wall of the liquid filtering disc; the second baffle is elastically connected with the groove top of the third clamping groove through a spring; through the arrangement, the device can effectively utilize the wastewater generated by refining the rose essential oil.

Owner:新疆和田阳光沙漠玫瑰有限公司

Raw materiel cement additive and application thereof

The invention aims to provide a raw material cement additive. The additive comprises the following substances in parts by weight: 8-15 parts of diethanol isopropanol amine, 15-25 parts of sodium tripolyphosphate, 3-7 parts of molasses, 8-15 parts of propylene glycol, 1-6 parts of nitrophenol, 10-15 parts of calcium chloride, 1-3 parts of potassium nitrate, 1-5 parts of sodium nitrate, 2-8 parts of sodium silicate, 1-6 parts of sodium carbonate, 2-5 parts of sodium bicarbonate and 8-15 parts of modified sodium humate. According to the additive, gaps among raw material particles are reduced, a material layer is more stable, grinding of a grinding roller is more sufficient, the grinding efficiency of the raw material is effectively improved, the grinding power consumption is reduced, through interaction of mutual permeation, catalysis, oxidation and the like of components in the combustion process, the activation energy of the carbon oxidation reaction is promoted to be reduced, macromolecular organic matter cracking is accelerated, oxygen consumption is reduced, stable and sufficient combustion is achieved, and therefore the coal saving effect is achieved.

Owner:江西富创新材料有限公司

Double-runner-wheel pressure-regulating lifting type mixing mill

ActiveCN112892745AImprove work efficiencyImprove mixing efficiencyGrain treatmentsEngineeringCentrifugal force

The invention relates to the field of refractory dry material mulling equipment, and discloses a double-runner-wheel pressure-regulating lifting type mixing mill which comprises a support; a supporting column is arranged at the top of the support; a lower carrier plate is arranged at the top of the supporting column; a lower barrel is fixedly connected to the outer edge of the top of the lower carrier plate; an upper carrier plate is fixedly connected to the top of the lower barrel; and the top of the upper carrier plate is fixedly connected with an upper barrel. According to the double-runner-wheel pressure-regulating lifting type mixing mill, through the structural design that a rotary charging barrel disc rotates relative to runner wheels and scrapers, compared with the mode that an existing mixing mill controls runner wheels to rotate for rolling, the problems that the runner wheels are heavy and rotate around respective horizontal shafts under the action of a material friction force, when the edge runner mill works, large centrifugal force is generated, vibration is large, especially when the two runner wheels are unbalanced, the phenomenon is more serious, consequently driving energy consumption is high, and damage is prone to occurring are solved.

Owner:JIANHU SHENJIANG MACHINERY

Rose essential oil squeezing and extracting device

The invention relates to an extraction device, in particular to a rose essential oil squeezing and extracting device. The technical problem to be solved is how to provide a rose essential oil squeezing and extracting device which is simple in manufacturing process and high in essential oil yield. The rose essential oil squeezing and extracting device comprises a wall-mounted plate, mounting screws, an N-shaped mounting rack, material boxes, a blanking pipe, a processing box and the like; the wall-mounted plate is mounted on a wall through the two mounting screws, the N-shaped mounting rack isarranged in the middle of the lower side of the wall-mounted plate, and the material boxes are mounted on the left side and the right side of the middle of the N-shaped mounting frame. A second driving motor of the rose essential oil squeezing and extracting device drives a rolling wheel to rotate through a second rotating rod so that the rolling wheel can rotate on its axis while rotating along the lower wall of the processing box, rose petals can be rolled more thoroughly, then essential oil components in the rose petals can be extracted fully, and the effect of increasing the yield of essential oil is achieved.

Owner:张文格

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com