Patents

Literature

42results about How to "Quick roll" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

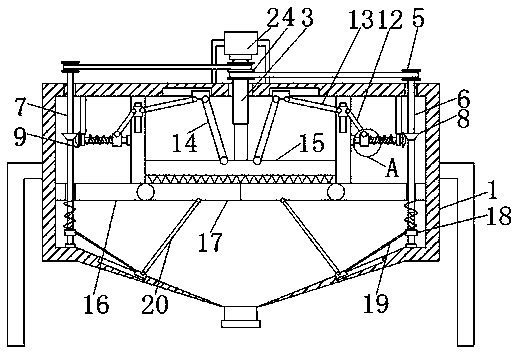

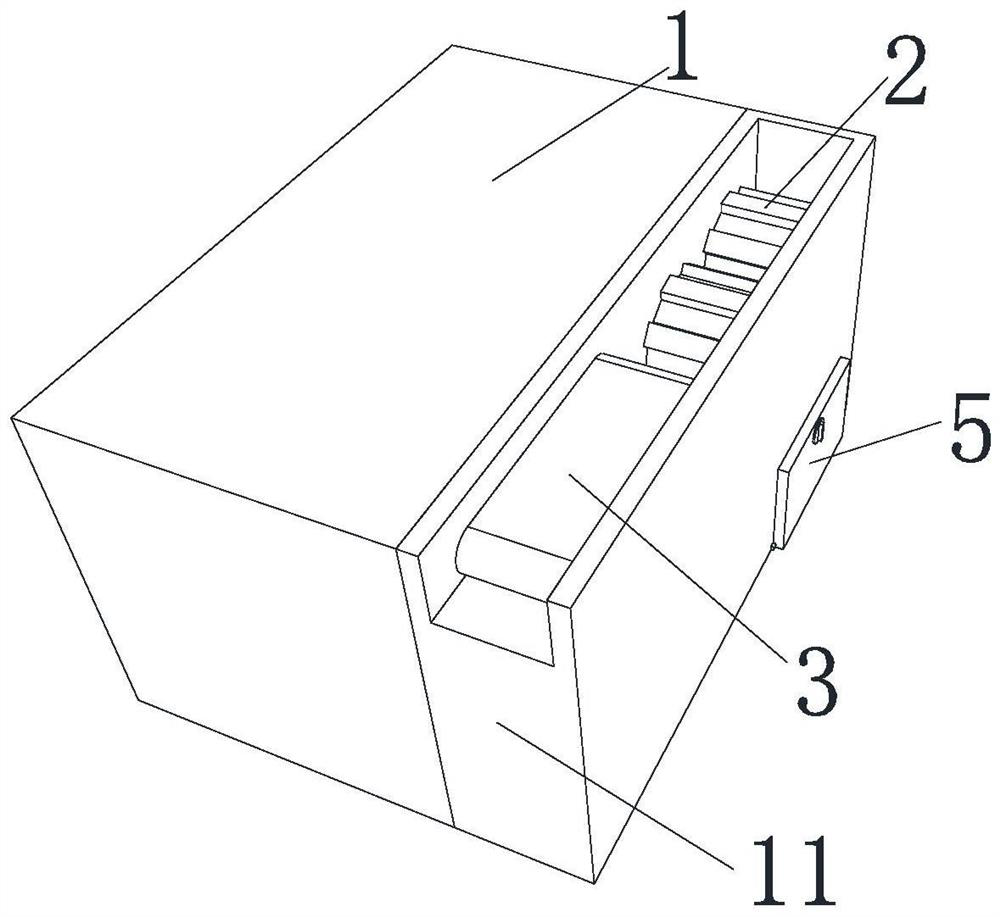

Health food material grinding device achieving complete grinding

The invention discloses a health food material grinding device achieving complete grinding. The health food material grinding device achieving complete grinding comprises a shell, a feeding hopper, agrinding cavity, discharging openings and a supporting base. The grinding cavity is arranged in the shell. The feeding hopper is arranged in the middle of the upper surface of the shell. The feeding hopper communicates with the grinding cavity. The discharging cavities are symmetrically formed in the bottom of the side wall of the shell. The grinding cavity communicates with the discharging openings. The supporting base is arranged at the bottom of the shell. The supporting base is rotationally connected with the shell. The health food material grinding device is characterized in that a servomotor is installed on the right side of the supporting base, a first rotating shaft is welded to the left side of an output shaft of the servo motor, a first bevel gear is fixedly installed on the left side of the first rotating shaft, and a second rotating shaft is vertically arranged above the first bevel gear. The health food material grinding device achieving complete grinding has the advantages of quantitative feeding, rapid grinding and time and effort saving. Meanwhile, raw material blockage of raw materials in the grinding process can be avoided, operation is easy, and the health foodmaterial grinding device achieving complete grinding is suitable for application and popularization.

Owner:山西华欣久泰科技有限公司

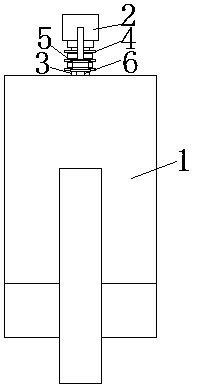

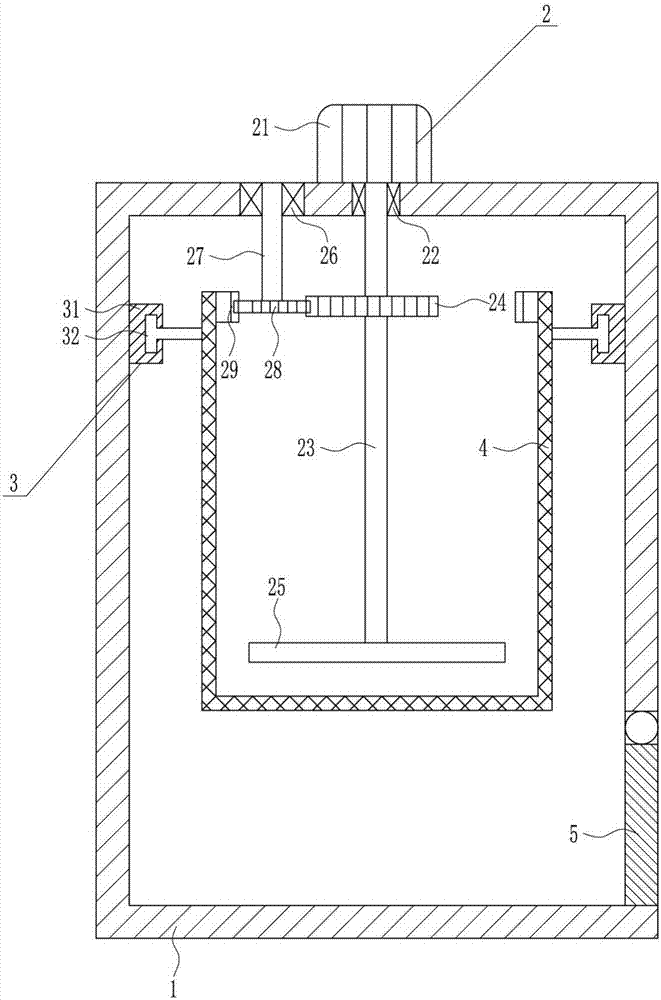

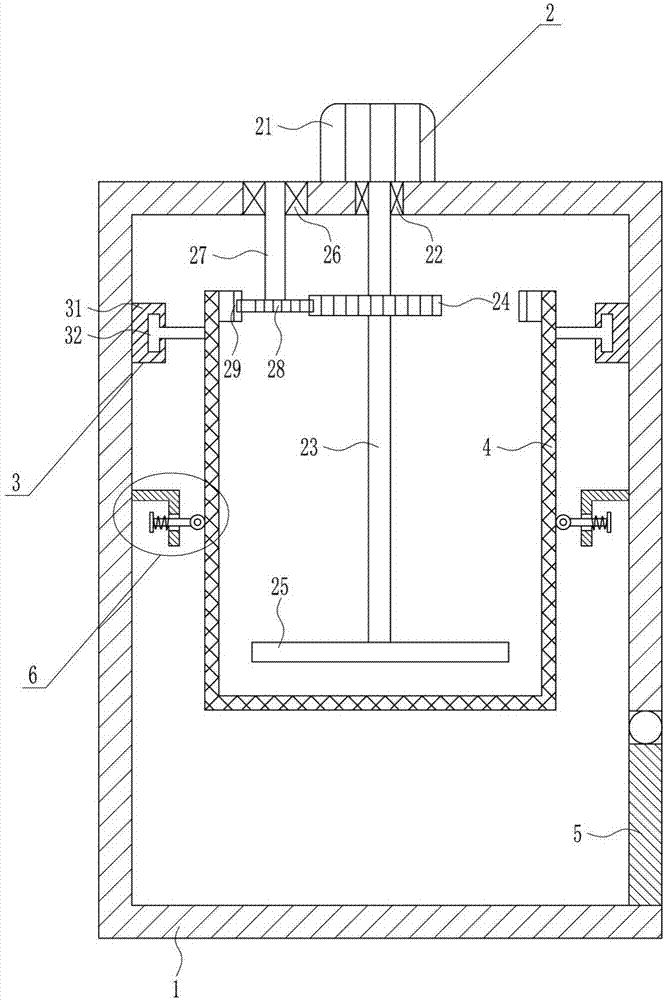

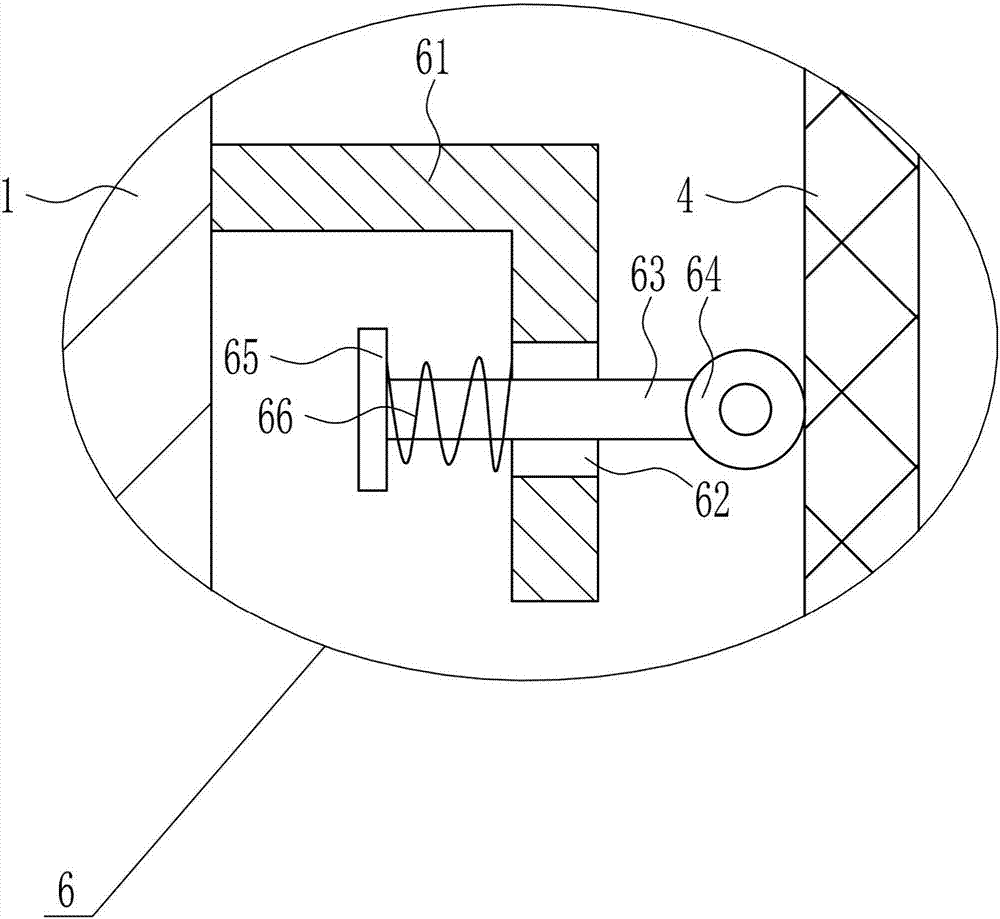

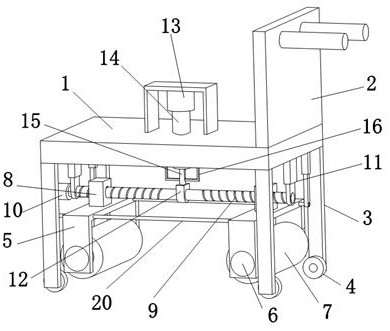

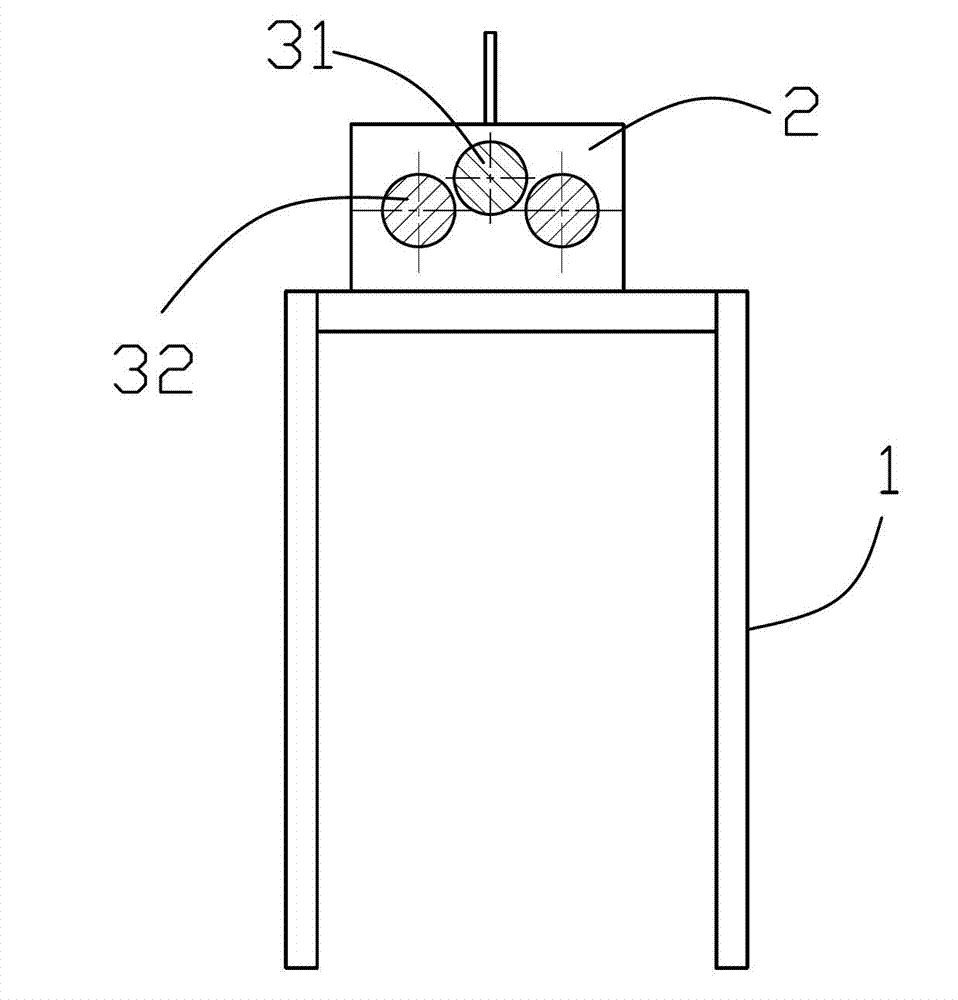

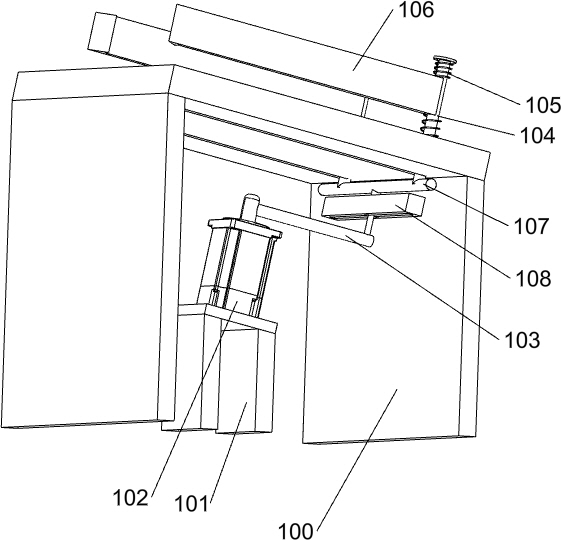

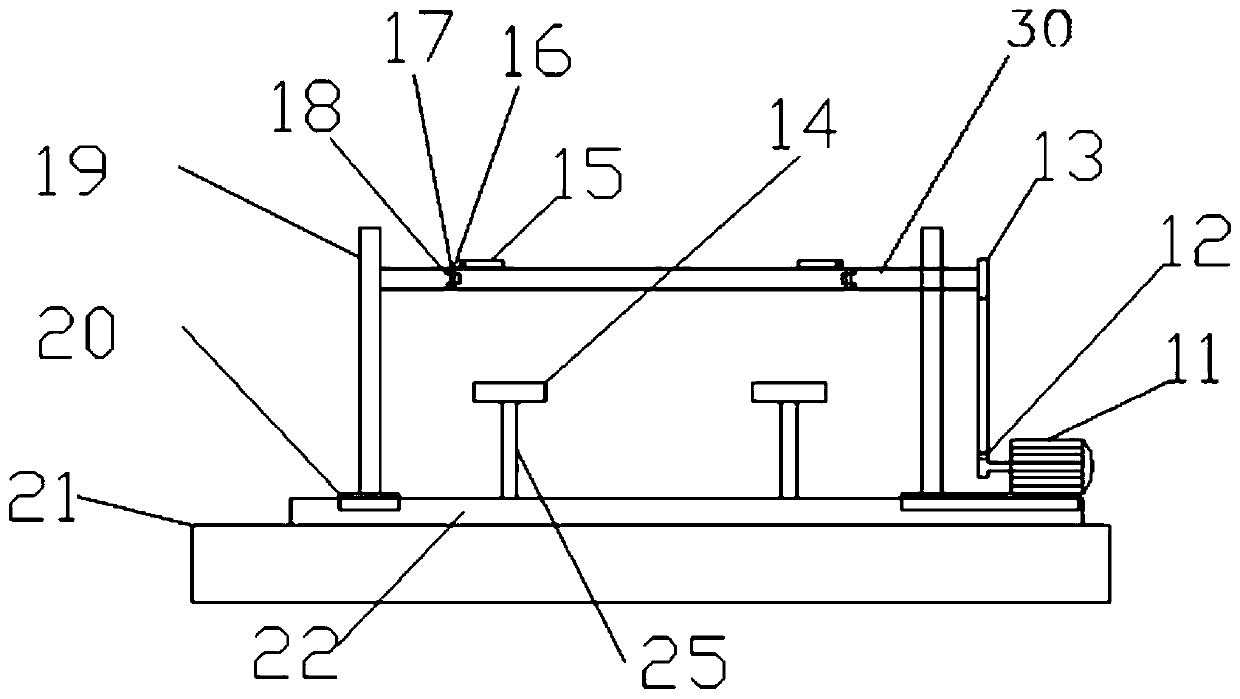

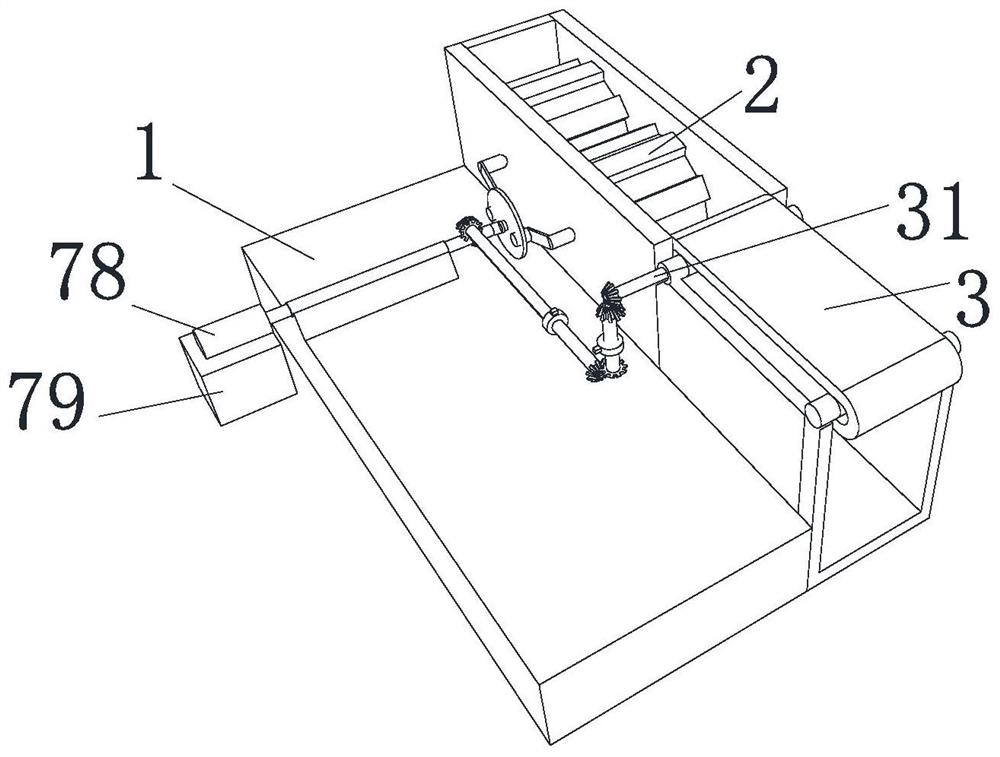

Tablet grinding device conveniently used for pediatric nursing

InactiveCN111389486AConvenient feedingImprove work efficiencyGrain treatmentsElectric machineryPediatric nursing

The invention discloses a tablet grinding device conveniently used for pediatric nursing, and relates to the technical field of pediatric nursing. The following solution is proposed to achieve tabletgrinding in the pediatric nursing process. The tablet grinding device comprises a shell, fixing frames are welded to the outer walls of two sides of the shell, and a motor is fixedly connected to theouter wall of the top of the shell. A telescopic rod is mounted at the output end of the motor and connected with a double-groove driving belt wheel through bolts, driven belt wheels are arranged on two sides of the double-groove driving belt wheel, a second screw rod is connected to the bottom end of the left driven belt wheel through a bolt, and a first screw rod is connected to the bottom of the right driven belt wheel through a bolt. Through the combination of various structures, the tablet grinding device can grind tablets conveniently and rapidly, the ground tablets can be conveniently taken out, and thus tablet grinding work efficiency is improved, the grinding effect is improved, medicine feeding nursing of children is convenient, and troubles of medical staff are reduced.

Owner:曹佳

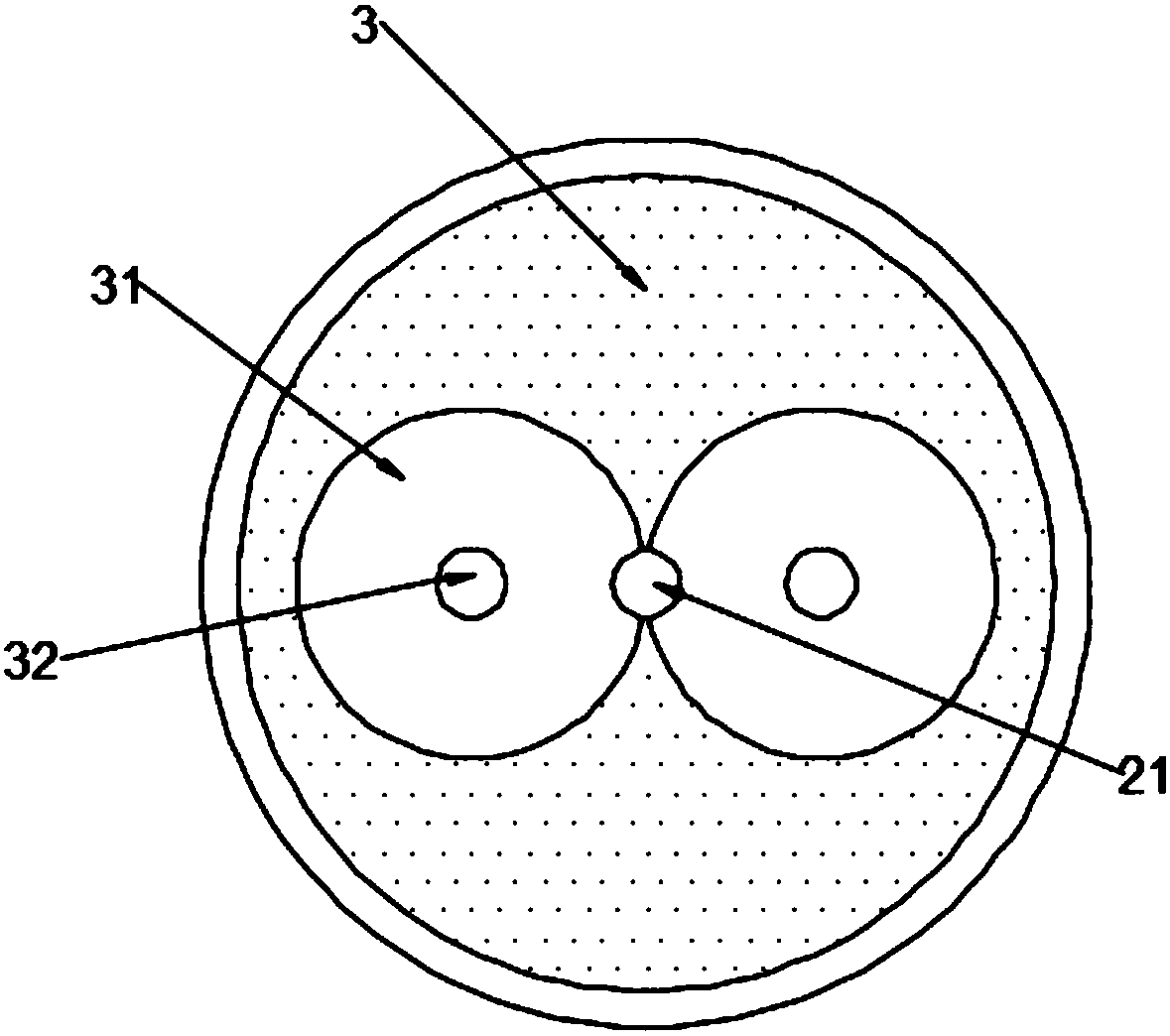

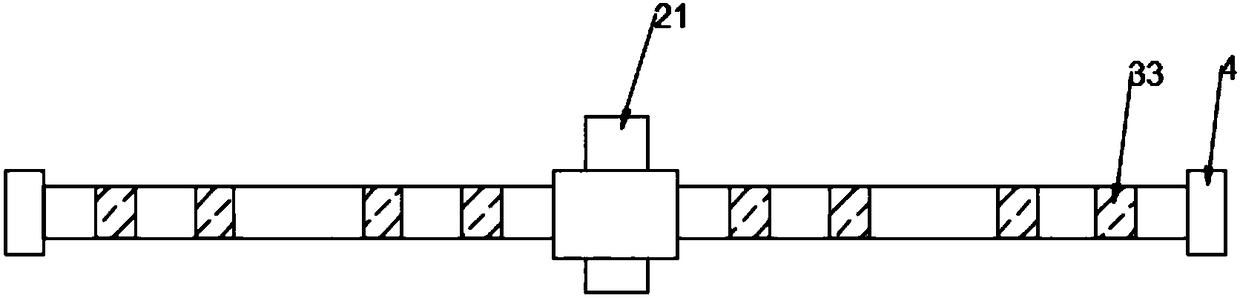

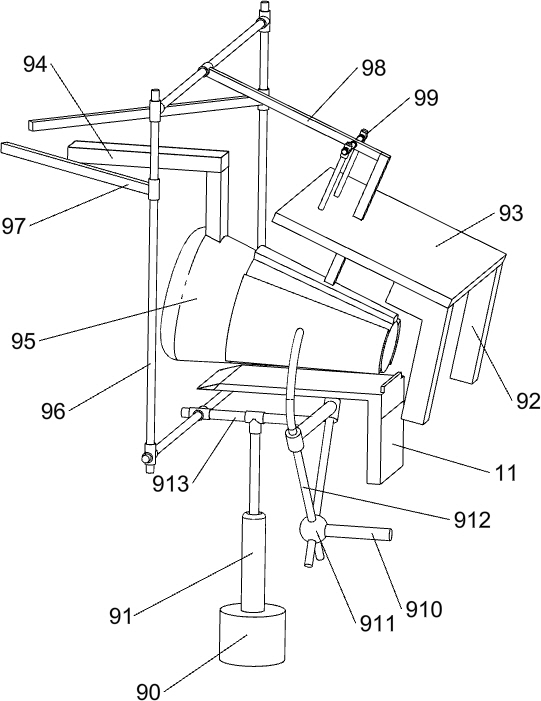

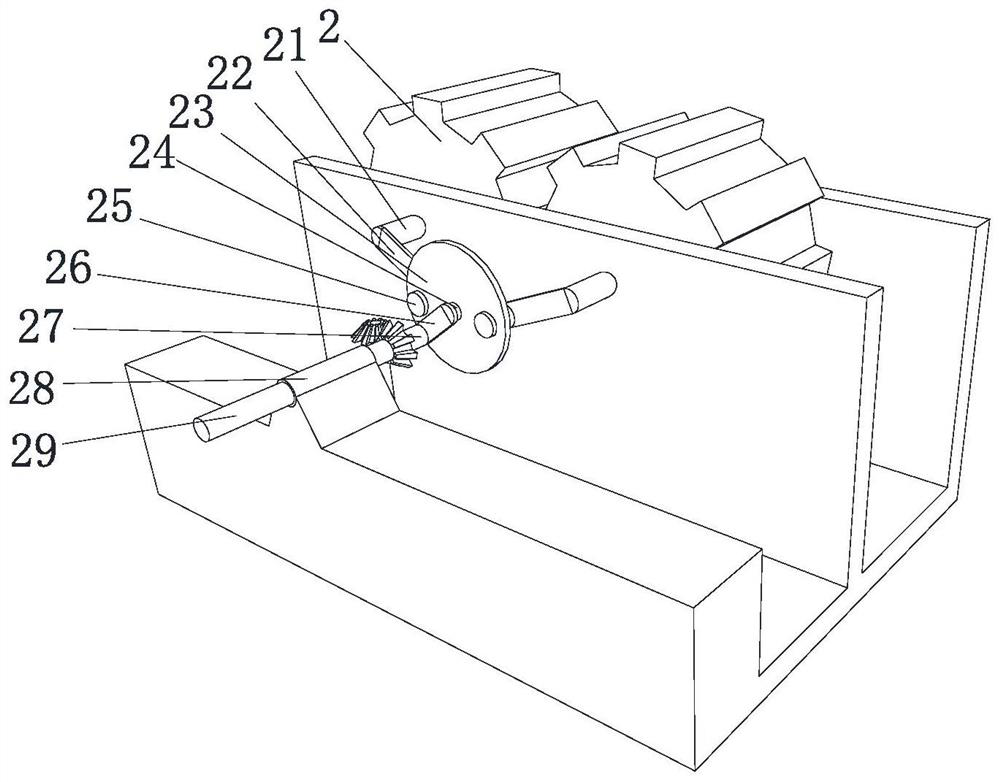

Fermentation system and fermentation method for strawberry wine

PendingCN111363652AReduce blind spotsSave operating timeAlcoholic beverage preparationFragariaProcess engineering

The invention provides a fermentation system and a fermentation method for strawberry wine. The fermentation system for the strawberry wine comprises: a base and a tank body, wherein the tank body isarranged at the top part of the base. According to the fermentation system and the fermentation method for the strawberry wine provided by the invention, through a crushing structure, a strawberry rawmaterial can be rapidly crushed; through arrangement of arc-shaped blocks, strawberries can be effectively ground, so juice in the strawberries can be conveniently and rapidly extruded out; through arrangement of two crushing wheels, the strawberries can be well rolled and crushed, and rolling and crushing are thorough, so the blind area of crushing is reduced, and the juice can be fully sucked;through arrangement of a filtering structure, pulp is prevented from existing to affect the taste of the strawberry wine; subsequent better cleaning is facilitated; the fermentation speed of the strawberry wine during brewing is effectively increased; fragrance of the strawberry wine is prevented from being emitted; and the original flavor is effectively reserved.

Owner:FUYANG NORMAL UNIVERSITY

Kitchen garbage treating machine

The invention discloses a kitchen garbage treating machine which comprises a shell, wherein a water discharging opening is formed in the middle of the shell; a suck disc assembly is arranged below the shell; a cone-shaped rolling bin is arranged in the shell; a connection piece is arranged above the rolling bin; a spiral inverted-step-shaped platform is arranged on the inner wall of the rolling bin; the upper part of the rolling bin is provided with an automatic water supplying device and a food waste probe; the lower part of the rolling bin is provided with a rolling disc; a crushing axe is arranged at the center of the rolling disc; the lower end of the rolling disc is connected with a motor; the lower end of the rolling disc is provided with a water discharging bin; the water discharging bin is connected with the water discharging opening; and the motor, the automatic water supplying device and the food waste probe are connected with an integrated controller. According to the kitchen garbage treating machine, a low-speed forced rolling manner is adopted for crushing food waste, simultaneously the crushing is performed automatically by fully intelligent control, so that the abrasion and the corrosion are prevented, the noise is reduced, and the blockage of a sewer line is reduced; the kitchen garbage treating machine can be used for completing procedures of low-speed rolling crushing, pressurizing water flushing discharging, machine cleaning and the like once, is high in efficiency, is short in running time and can be used for achieving the aim that a relatively large amount of water and electricity can be saved.

Owner:ZHENGZHOU WUTENG MACHINERY MFG

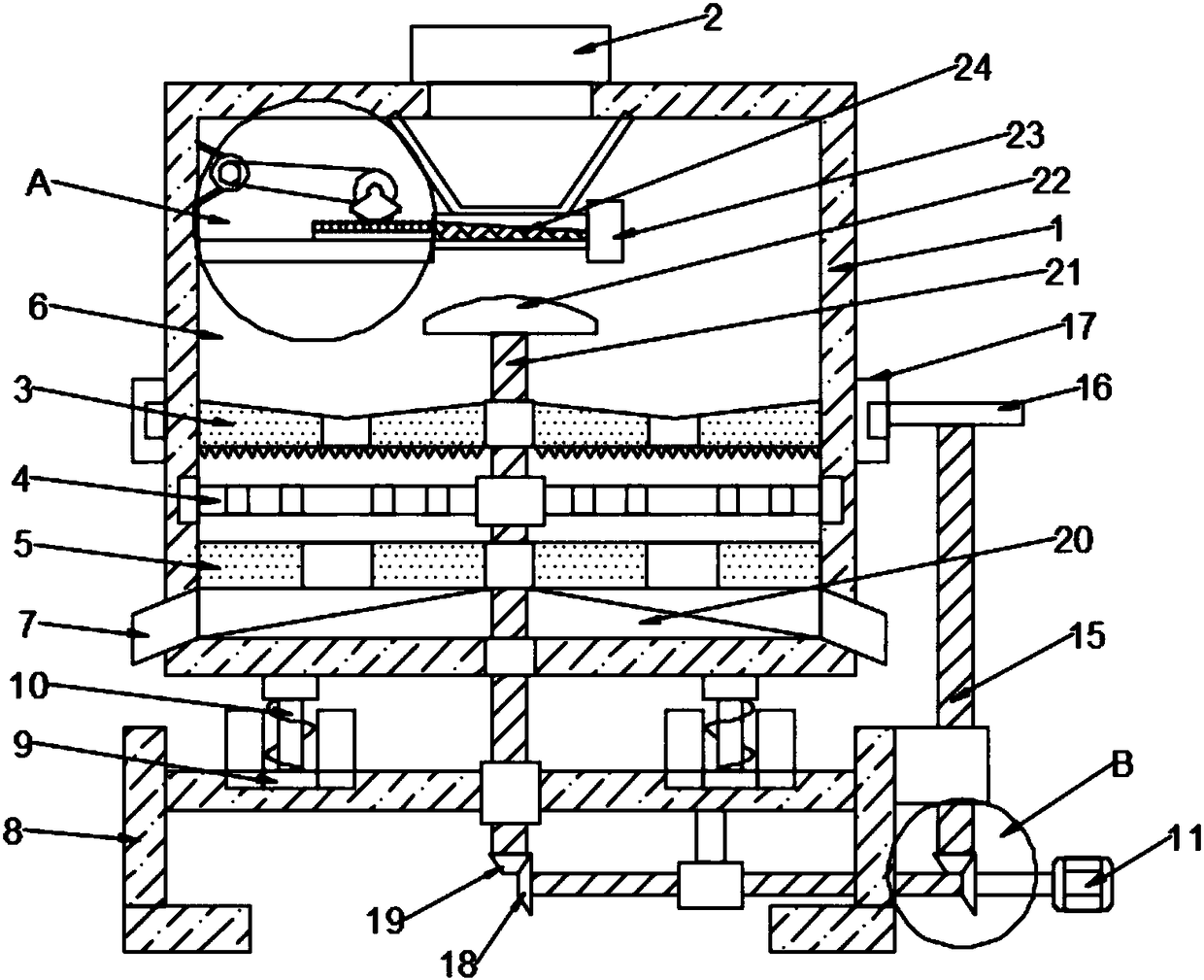

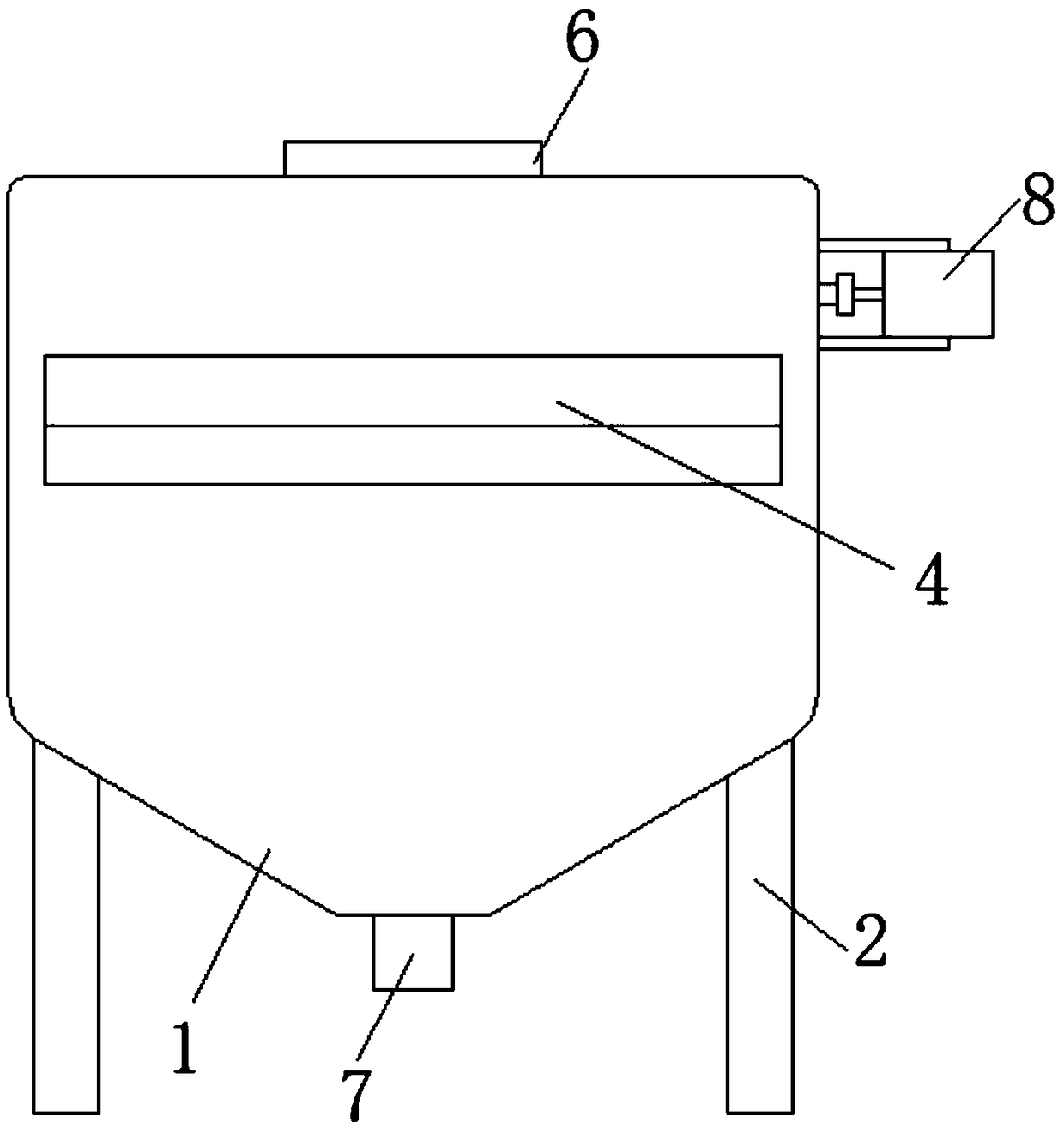

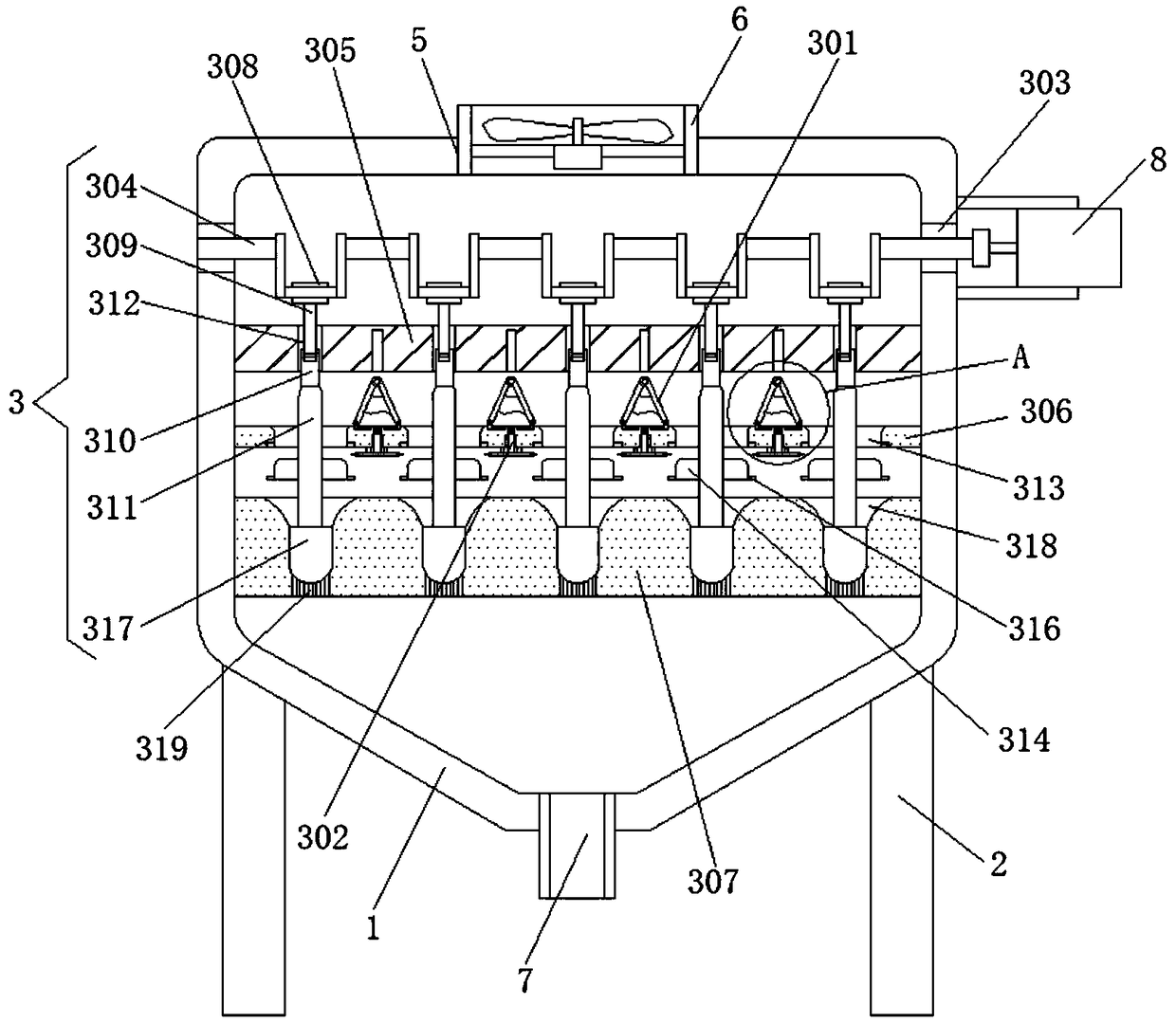

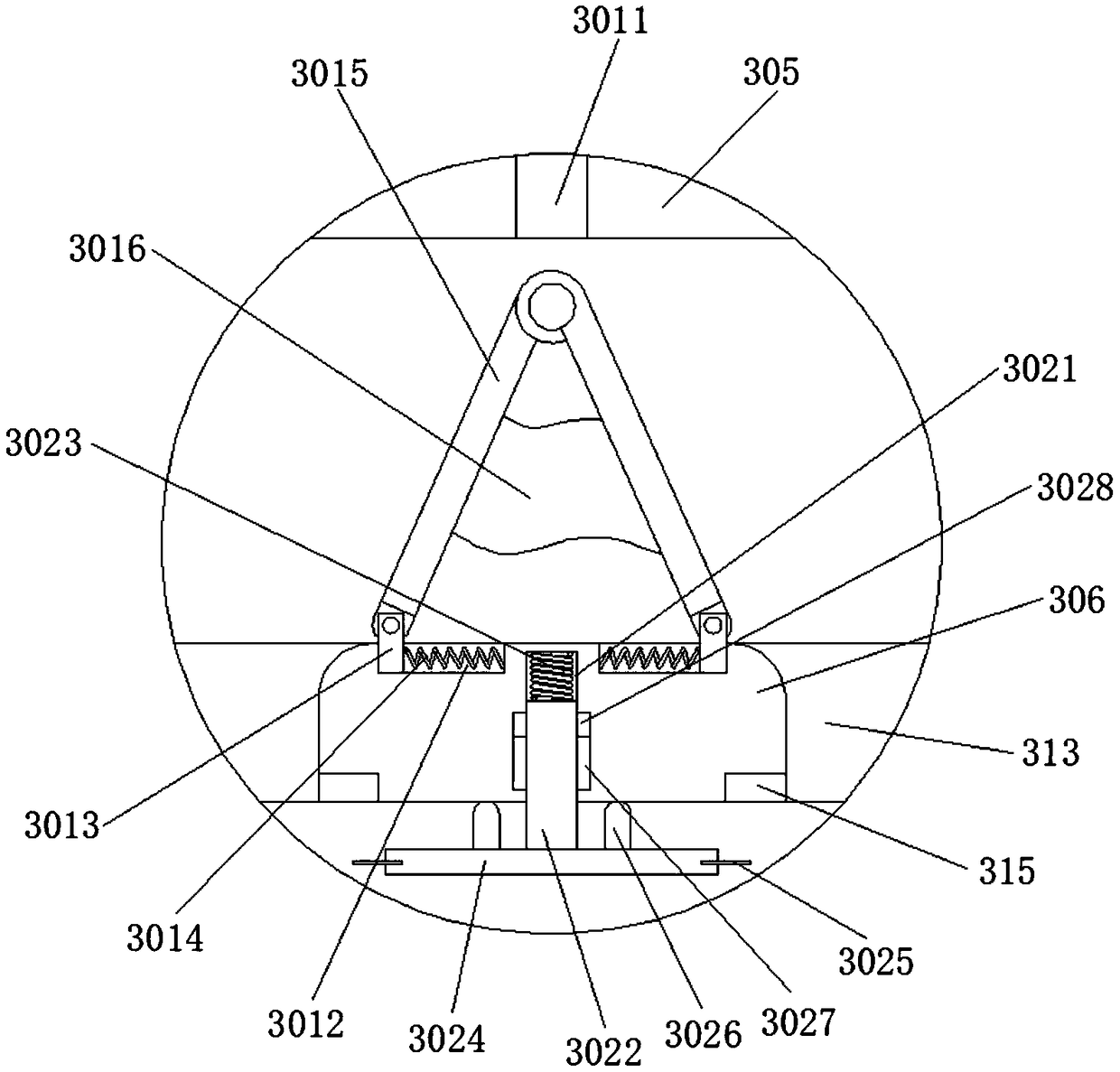

Vertical-linkage and reciprocating rolling-type mashed potato preparing device

The invention belongs to the technical field of food processing, and discloses a vertical-linkage and reciprocating rolling-type mashed potato preparing device. The vertical-linkage and reciprocatingrolling-type mashed potato preparing device comprises a box, wherein the section of the bottom wall of the box is funnel-shaped; supporting legs are fixedly connected to four corners of the bottom wall of the box; the discharge end of a feed hopper is fixedly communicated with the front surface of the box; a mounting hole is formed in the middle part of the top wall of the box; an exhaust fan is fixedly mounted inside the mounting hole; the feed end of a discharge pipe is fixedly communicated with the middle part of the bottom wall of the box; a driving motor is fixedly mounted at the top endof the right side surface of the box through a mounting rod; a rolling mechanism is arranged inside the box. Through arrangement of the rolling mechanism, the vertical-linkage and reciprocating rolling-type mashed potato preparing device can quickly roll potatoes after feeding to quickly destroy the structures of the potatoes, so that rapid mashing of the potatoes is achieved and improvement on the preparation efficiency of mashed potato is facilitated.

Owner:曾早生

Blended yarn bleaching equipment

PendingCN111705453AStable deliveryThe conveying process is smooth and there will be no confusionTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsYarnStructural engineering

The invention discloses blended yarn bleaching equipment. The equipment comprises a treatment box, an input roller and a guide roller are rotatably connected to the inner wall of the treatment box, aworm is rotatably connected to the inner bottom of the treatment box, rotating blades are fixed to the circumferential side wall of the upper portion of the worm, stirring blades are fixed to the circumferential side wall of the lower portion of the worm, an output roller and a drying box are rotatably connected to the inner wall of the treatment box, the worm penetrates through the drying box, avortex tube is fixed to the outer wall of the treatment box, a cold outlet and a hot outlet of the vortex tube are connected with a cold flow tube and a hot flow tube respectively, and a hollow rotating shaft penetrates through the side wall of the drying box and is rotatably connected to the side wall of the drying box. The equipment has the advantages that through rotation conveying of the worm,yarns can collide with and rub bleaching liquid, the effect of contact between the yarns and the bleaching liquid is improved, the bleaching quality is further improved, through conveying of the worm, conveying in an initial state can be stably continued after preliminary winding, the circumstance that the yarns are disordered and knotted in the midway is avoided, and the yarns cannot be damagedor disordered in the bleaching and drying process.

Owner:陈勇

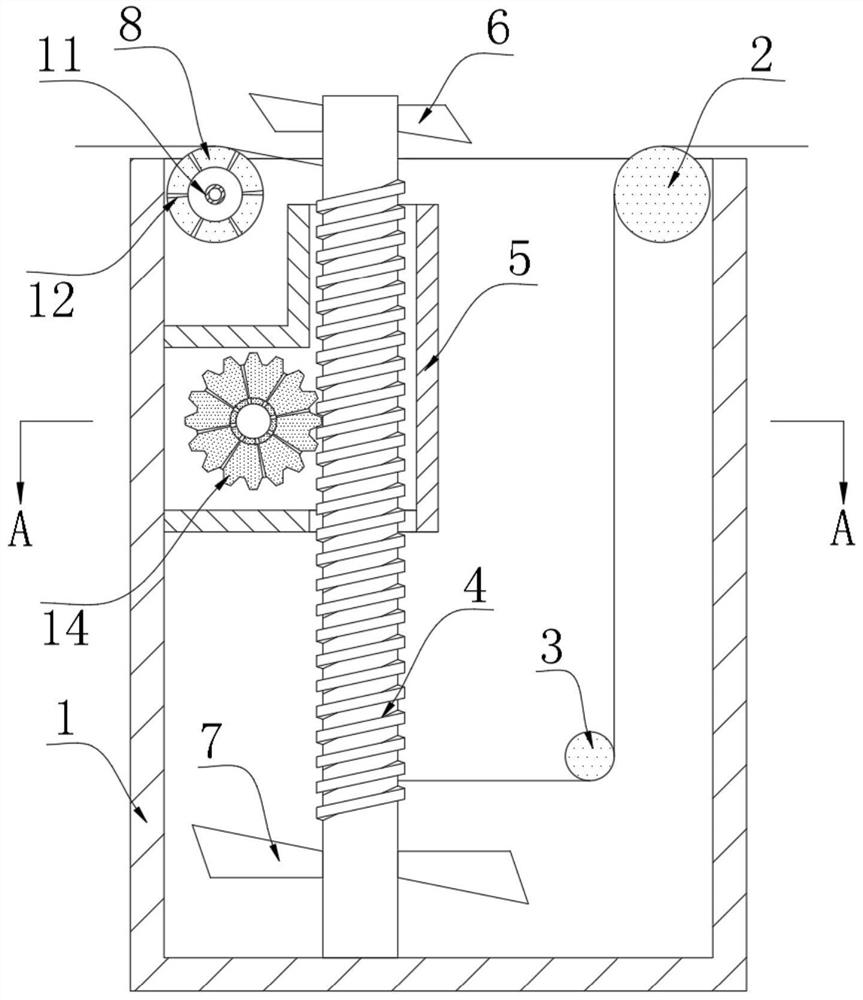

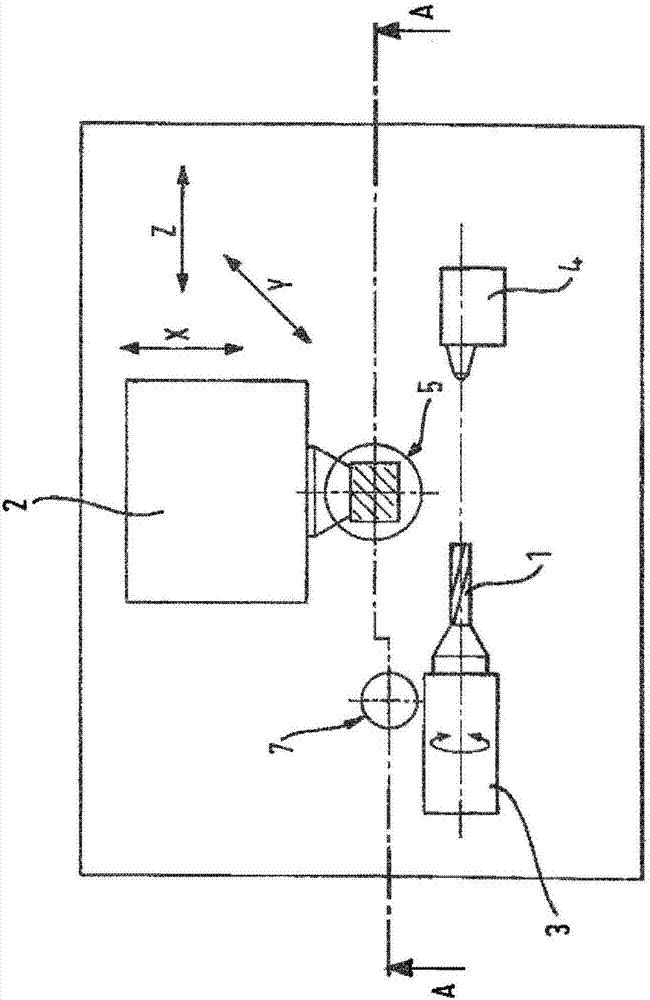

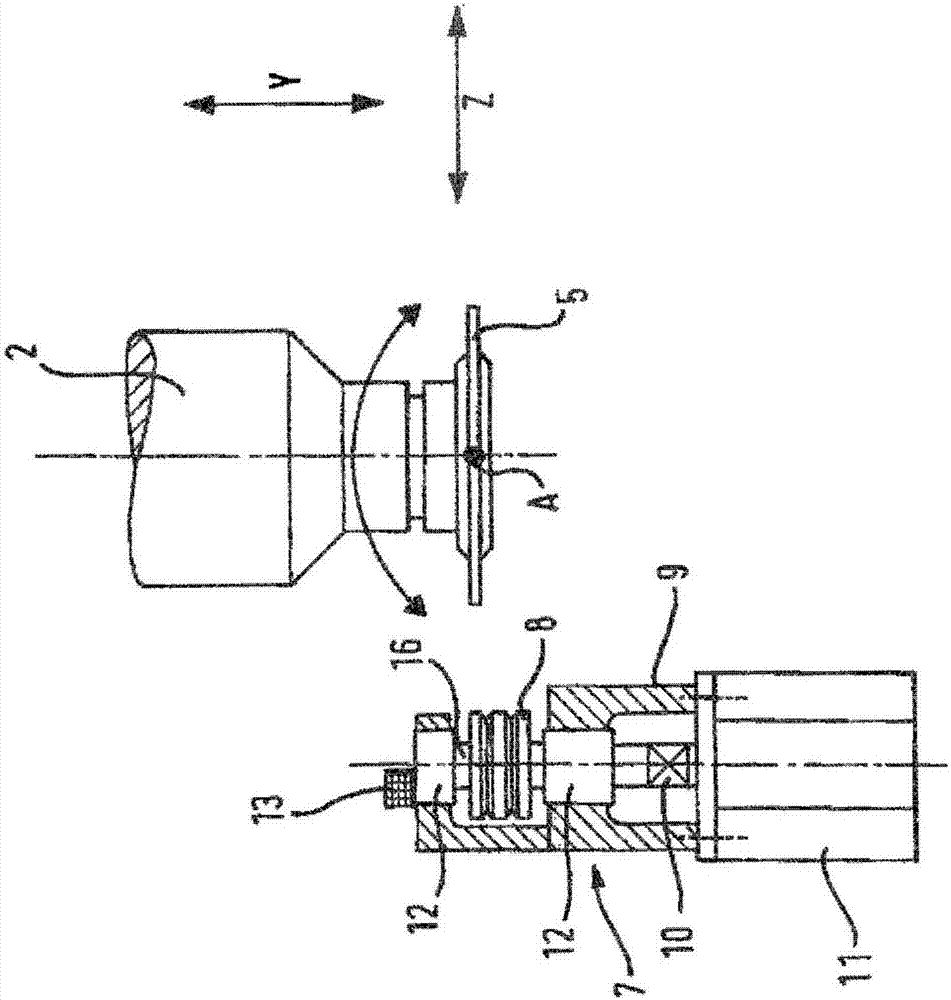

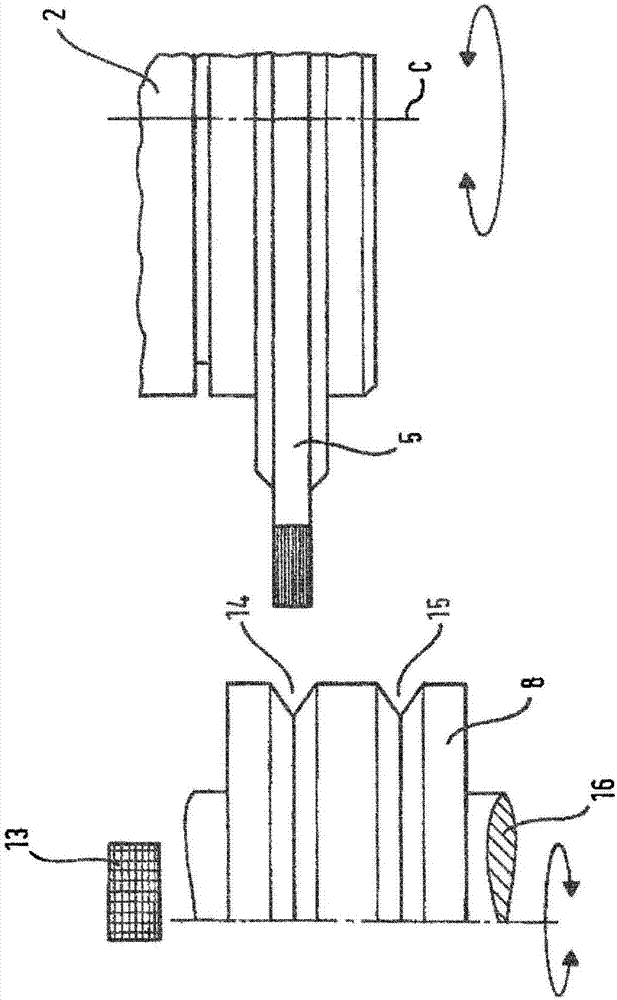

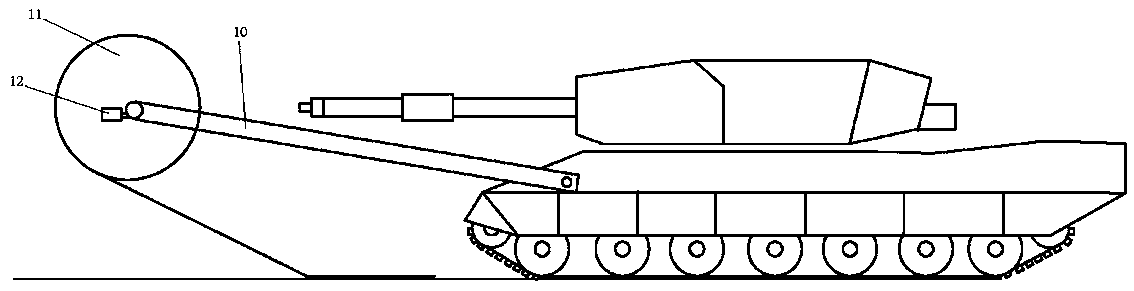

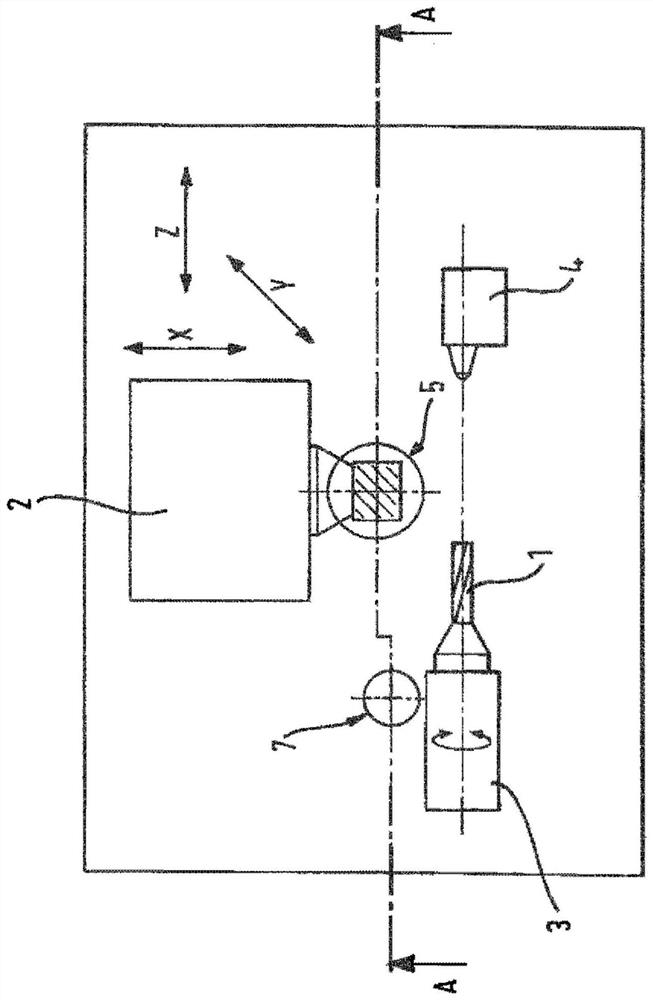

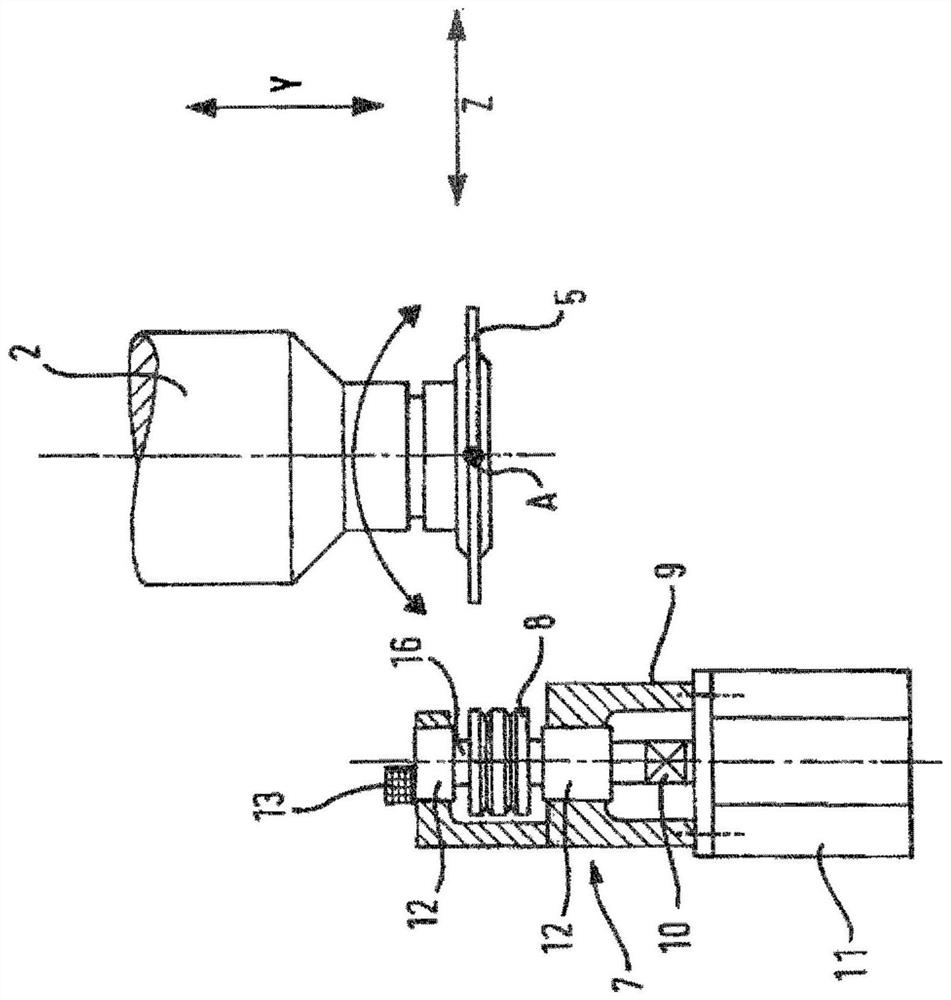

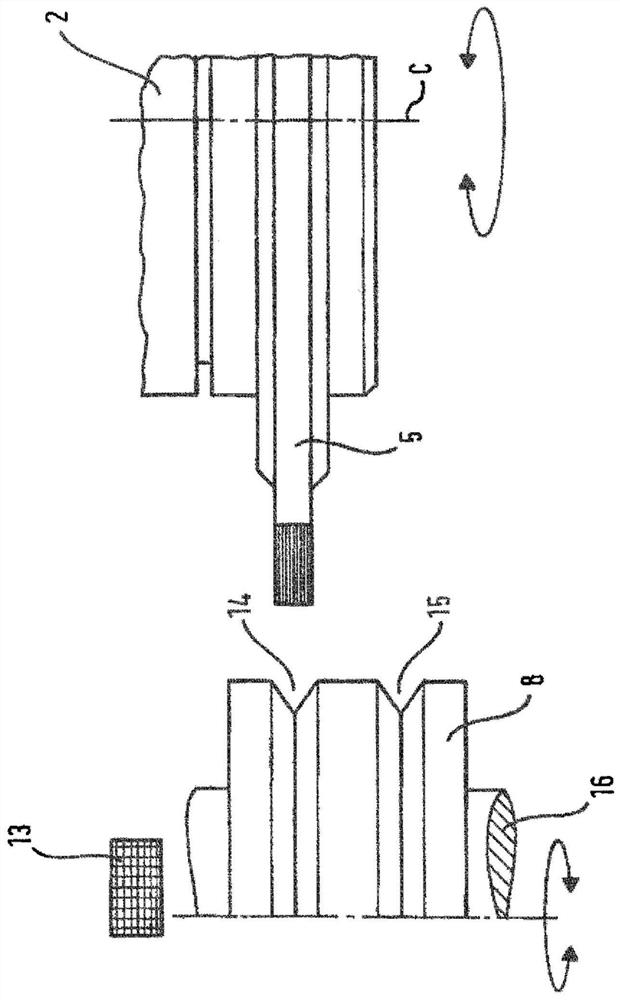

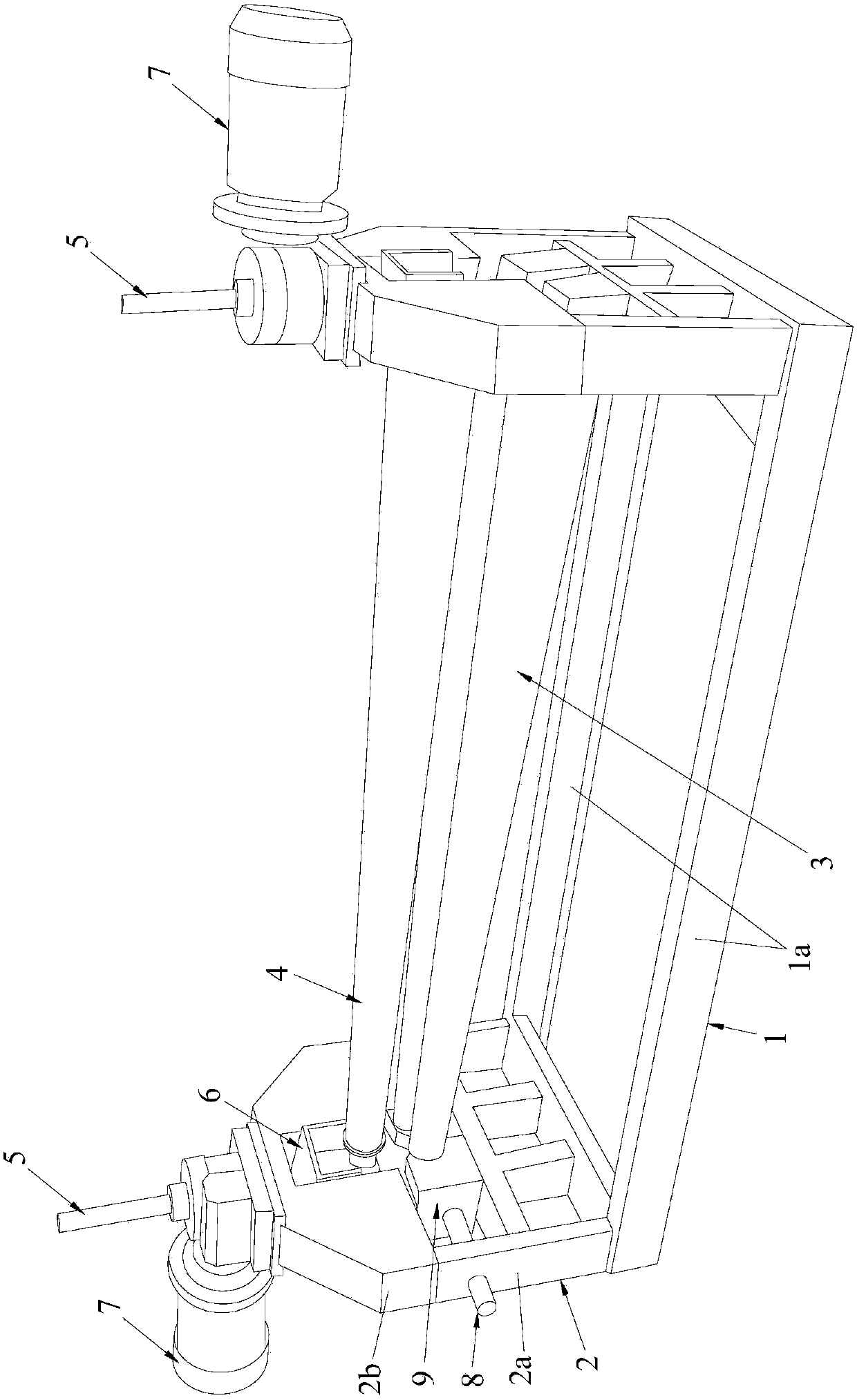

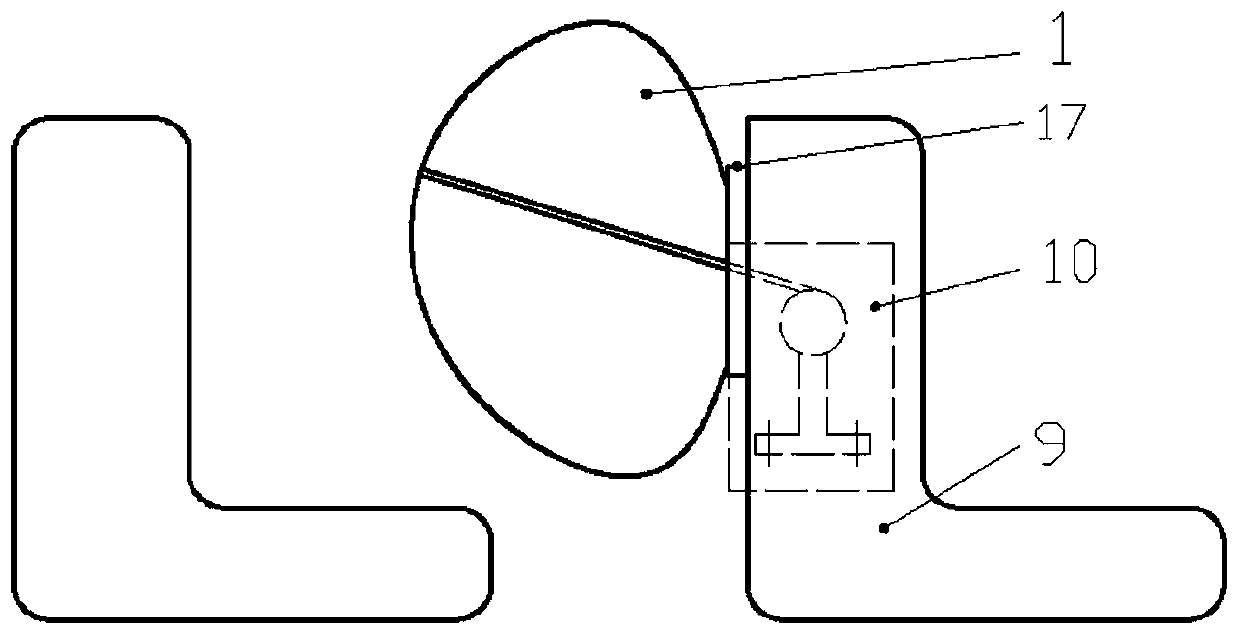

Method and grinding machine for grinding grooved workpieces

ActiveCN107427983ASimple structureStructural stabilityGrinding feed controlAbrasive surface conditioning devicesEngineeringMachine

The invention relates to a method for grinding grooves or profiles on workpieces. The grooves are ground using a correspondingly profiled grinding wheel (5), the profile (6) of the grinding wheel (5) being crushed. According to the invention, a reshaping crush process of the grinding wheel is carried out by means of crush rollers which are driven during the process, and each of the crush rollers (8) is controlled on the basis of a measurement of the rotational speed and the current consumption, thus a relative advancement between the grinding wheel (5) and the crush roller (8) is controlled during the crush process on the basis of said measurement. The invention further relates to a grinding machine for grinding a workpiece provided with such grooves, wherein the workpiece is held in a clamping by means of a workpiece spindle head (3), and a rigidly installed crush device (7) comprising a crush roller (8) with a dedicated rotary drive (11) is additionally provided on the grinding machine. The grinding wheel (5) is applied to the crush roller (8) in order to dress the grinding wheel profile (6). For this purpose, the crush roller (8) has a profile-crushing portion (14) for profile-crushing the grinding wheel (6) with a first dressing volume and a reshaping profile-crushing portion (15), which is arranged on the same crush roller (8), for profile-crushing the grinding wheel (6) with a second dressing volume for reshaping purposes.

Owner:ERWIN JUNKER MASCHNINENFAB

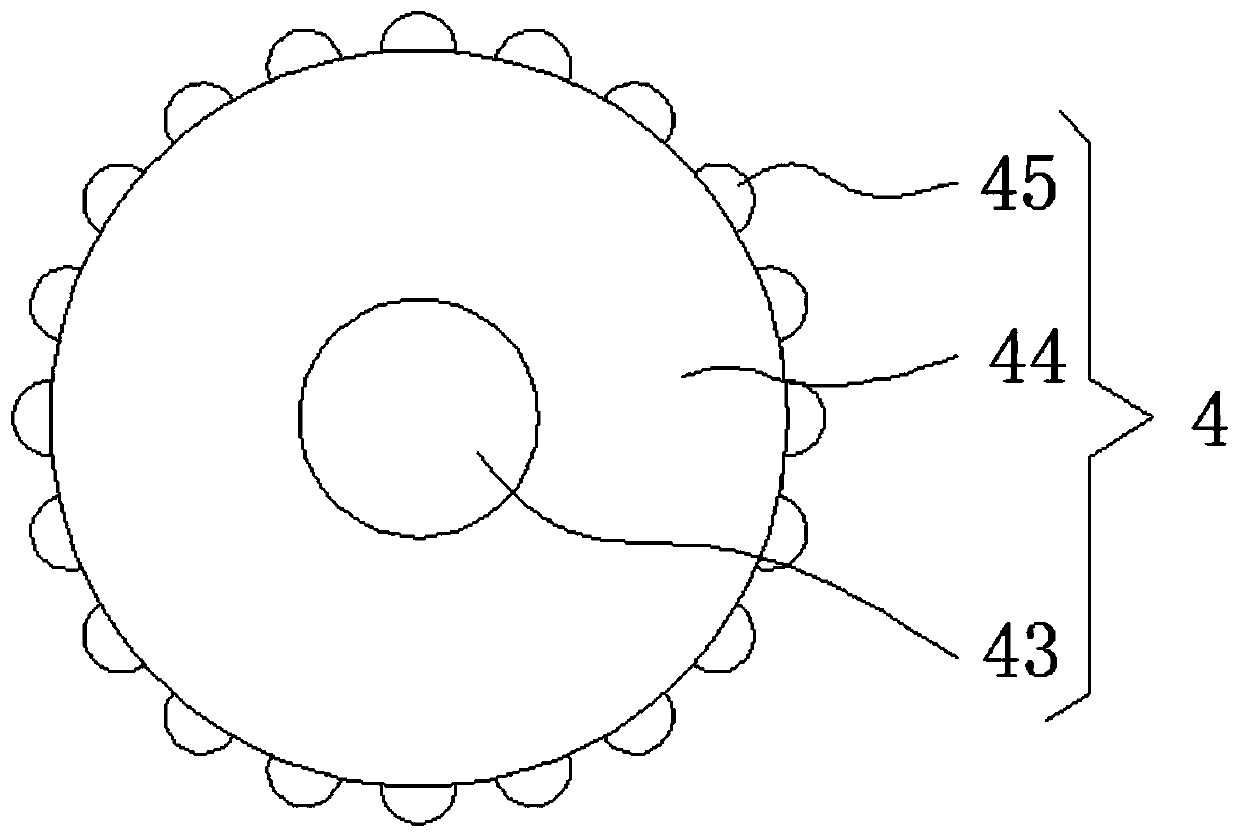

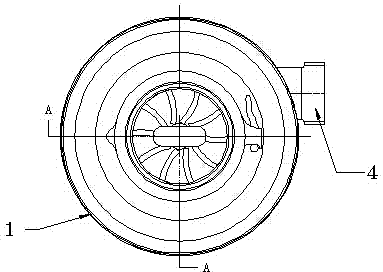

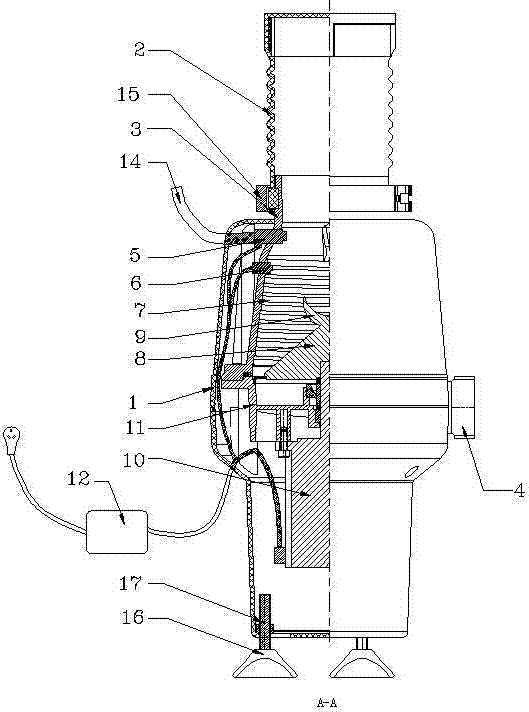

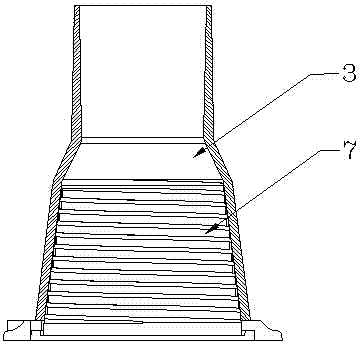

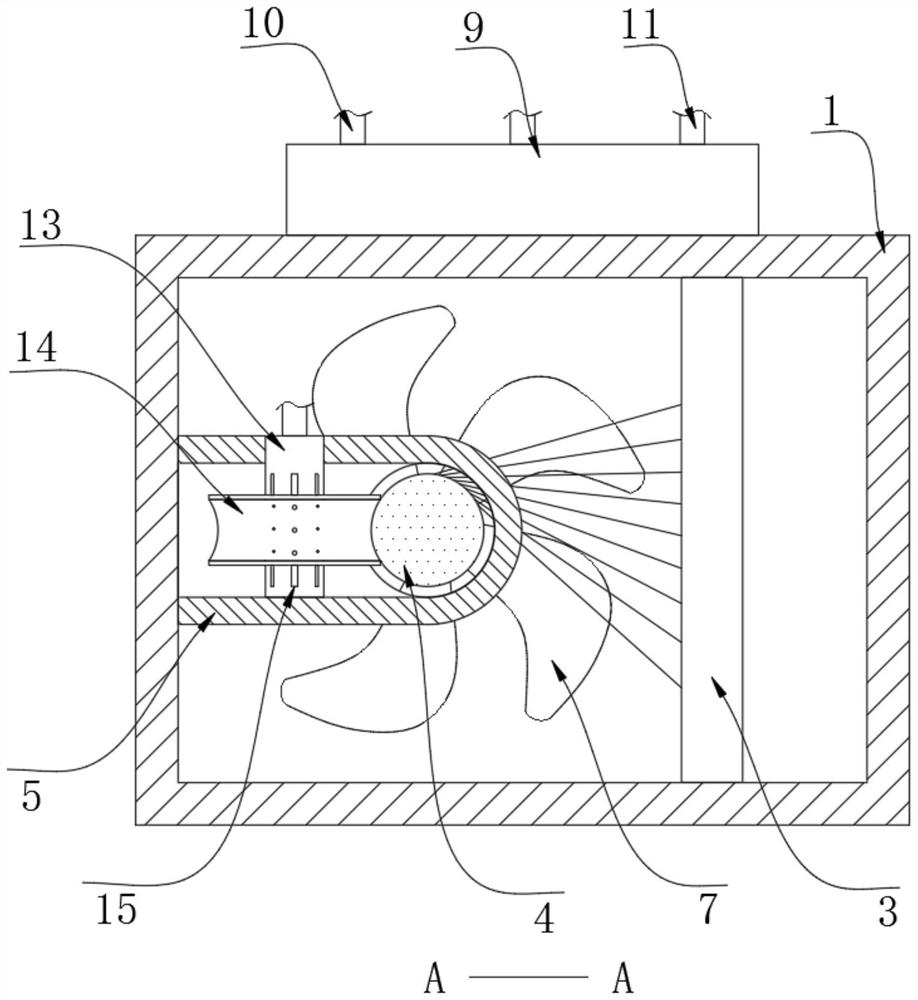

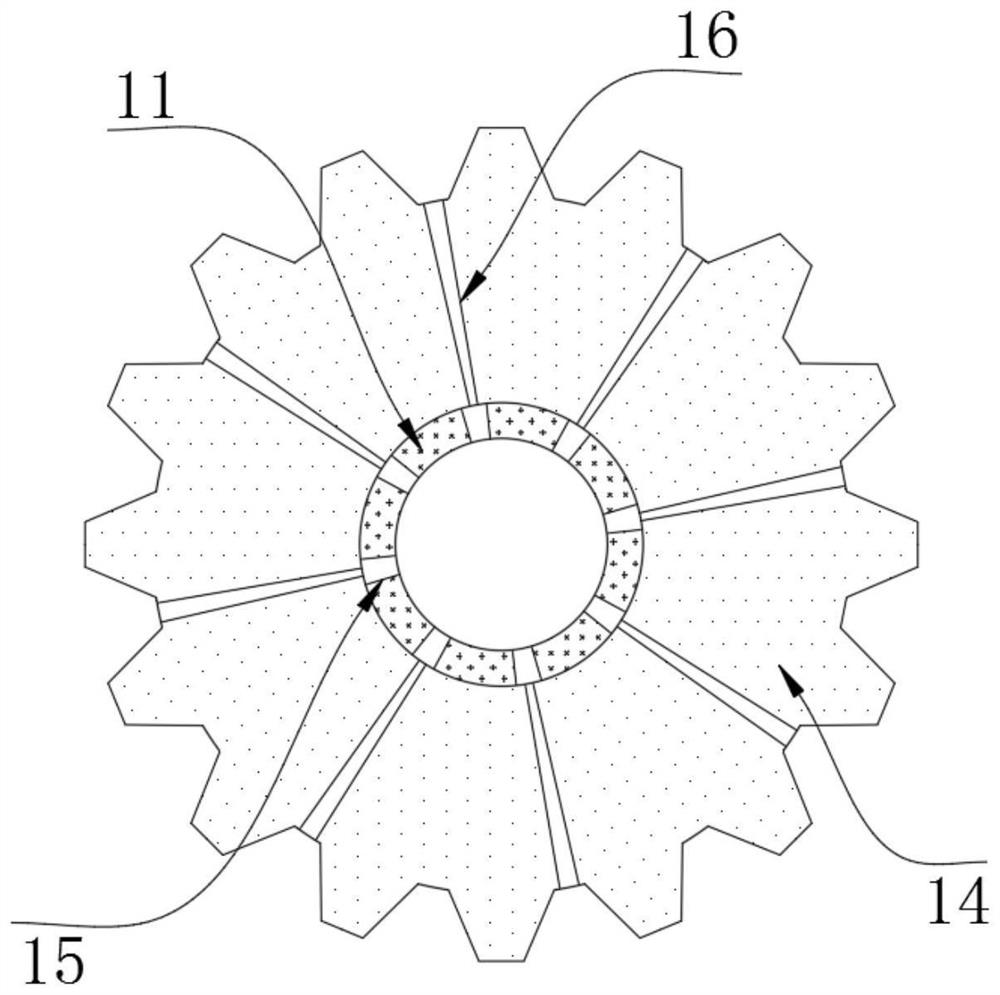

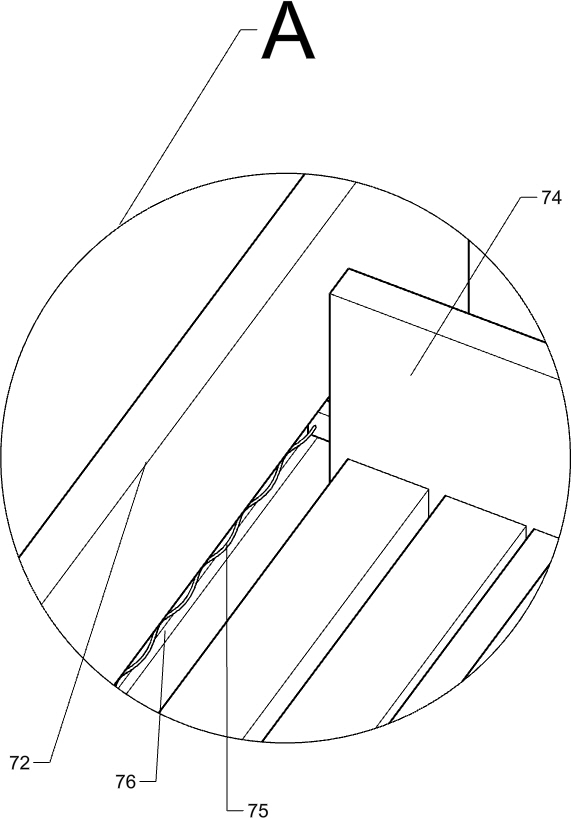

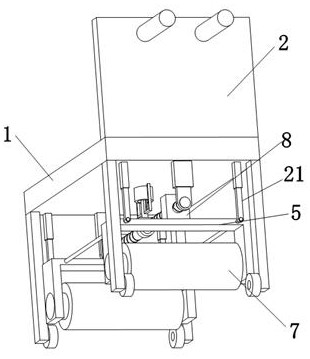

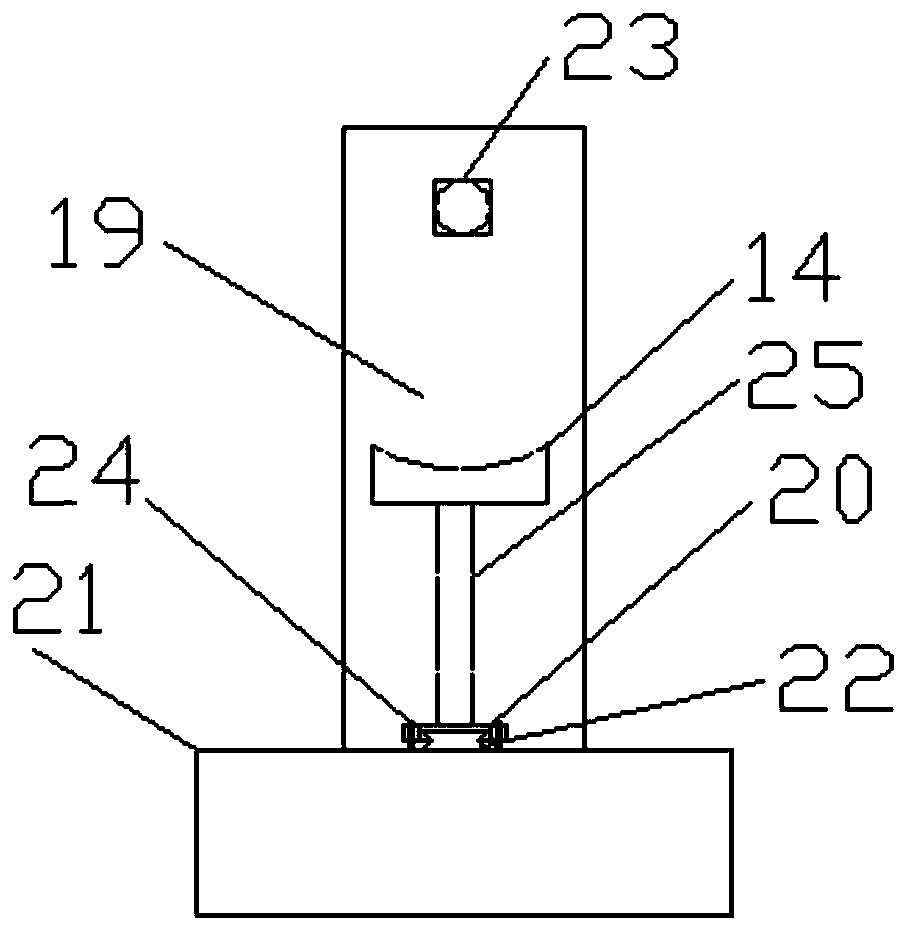

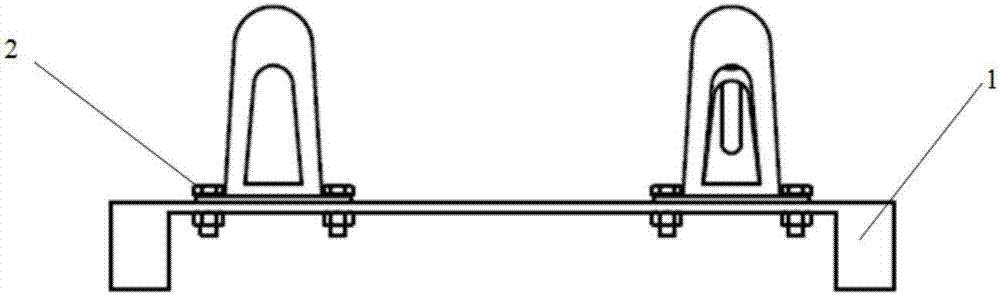

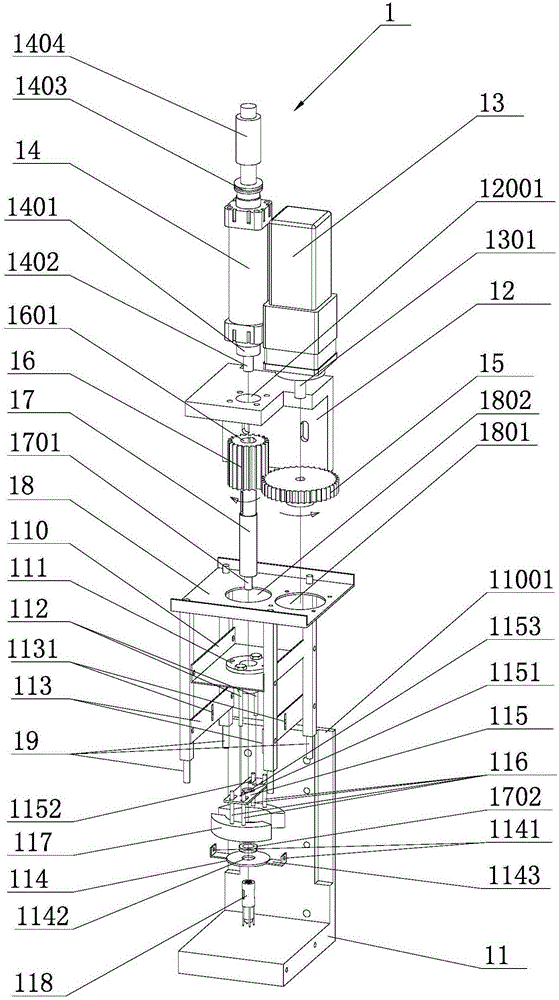

Medicinal material grinding device for traditional Chinese medicine department

InactiveCN111633702AAvoid scratchesQuick rollGrain treatmentsMetal working apparatusMedicinal herbsElectric machinery

The invention relates to grinding equipment, in particular to a medicinal material grinding device for the traditional Chinese medicine department. The invention aims at providing the medicinal material grinding device for the traditional Chinese medicine department, which has the advantages that the ceaseless action of people is not needed, so that the manpower is reduced, the efficiency is improved, and meanwhile, medicinal materials are evenly grinded. According to the technical scheme, the medicinal material grinding device for the traditional Chinese medicine department comprises a base,a collecting frame, a knife net, a first mounting base, a motor and the like, wherein the collecting frame is arranged on one side of the top of the base, the knife net is arranged on the upper portion of the inner wall of the collecting frame, the first mounting base is arranged on the side, far away the collecting frame, of the base, and the motor is arranged at the top end of the first mountingbase. Through cooperation of a gear, a rack, a knife rest frame and a medicine pushing rod, after a blade cuts the medicinal materials, the medicine pushing rod can push the cut medicinal materials into the collecting frame, then manual operation is not needed, so that time and labor are saved, and meanwhile, a worker can be prevented from being scratched by the blade.

Owner:KAILUAN GENERAL HOSPITAL

Quick crushing device for petroleum coke

The invention relates to a petroleum coke crushing device, in particular to a petroleum coke rapid crushing device. The technical problem to be solved by the present invention is to provide a quick crushing device for petroleum coke with good crushing effect, simple operation and high working efficiency. In order to solve the above technical problems, the present invention provides such a quick crushing device for petroleum coke, which includes a box body, etc.; Connected with a mesh cylinder, the crushing parts of the crushing device are located in the mesh cylinder, the lower part of the right side of the box body is hinged with a baffle plate through a pin shaft, and the baffle plate cooperates with the box body. The present invention can quickly crush the petroleum coke through the rotation of the mesh cylinder and the rotation of the rolling plate, and achieves the effects of good crushing effect, simple operation and high work efficiency.

Owner:冷国强

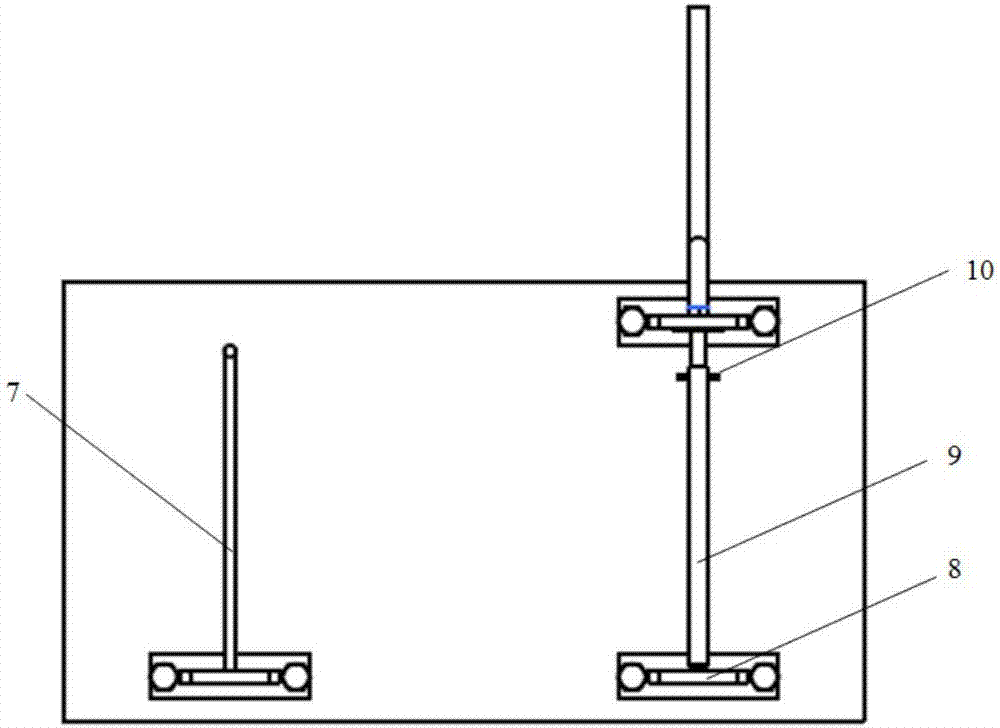

Method for rolling conical barrel through plate rolling machine

The invention discloses a method for rolling a conical barrel through a plate rolling machine. A cone rolling tool is arranged on the inner side of a turnover rack or the inner side of a fixed rack, and comprises a support, two sets of friction limiting devices are arranged on the support, and the structures of the two friction limiting devices are arranged in an axial symmetry mode. Each friction limiting device comprises a supporting seat fixedly connected with the support, a pin shaft, a hinge supporting shaft and a rolling sleeve. Supporting shafts are arranged on the upper portions of the hinge supporting shafts, locating pull arms are arranged on the lower portions of the hinge supporting shafts, and mounting holes are formed in the middles of the hinge supporting shafts. The locating pull arms are fixedly connected with the supporting seats through pins, the hinge supporting shafts are rotatably connected to the pin shafts, the two ends of each pin shaft are respectively and fixedly arranged on the corresponding supporting seat, and the rolling sleeves are fixed to the supporting shafts. When a workpiece is rolled on the plate rolling machine, the outer circle faces of the rolling sleeves are close to the small end face of the rolled conical barrel. The method has the advantages that the operation is easy and convenient, work efficiency is high, and the precision for rolling the conical barrel is high. The method is especially suitable for rolling the large-diameter thin-walled conical barrel with the conical angle larger than 15 degrees on the plate rolling machine.

Owner:CHINA NAT OFFSHORE OIL CORP +1

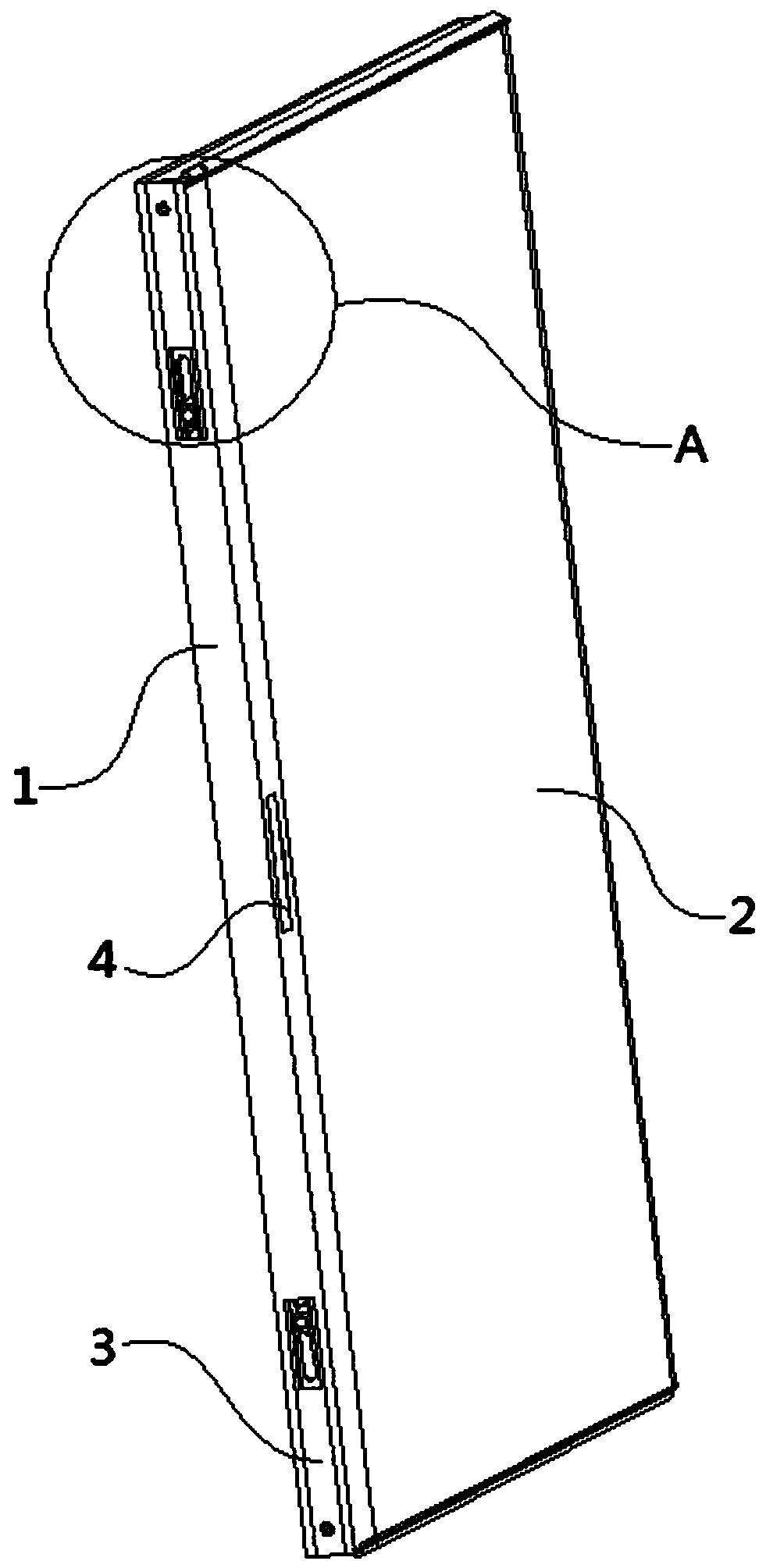

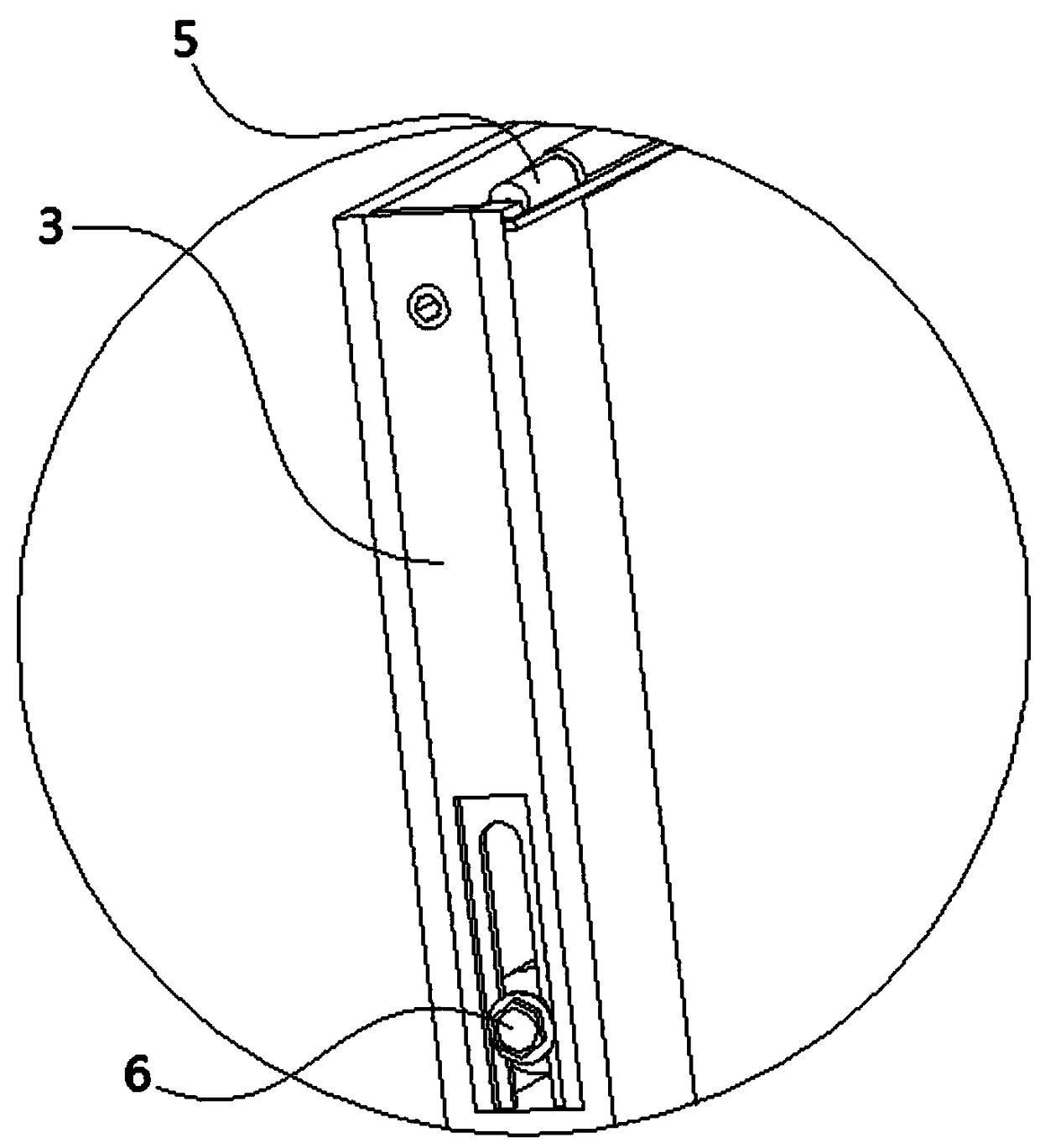

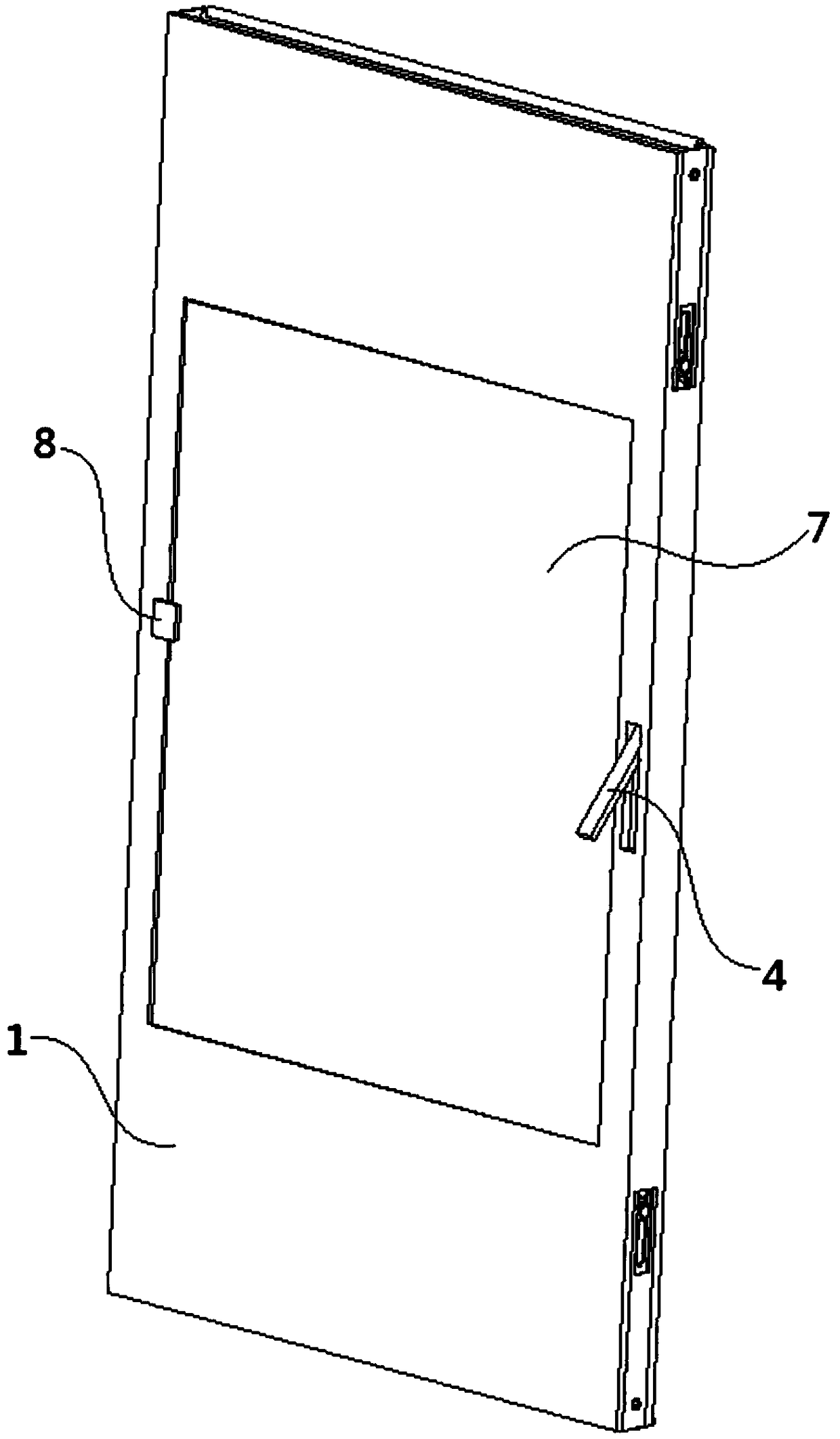

Solid wood door facilitating rapid clearing of adlets

InactiveCN108798395AQuickly clean up small adsWide range of adaptationSpecial door/window arrangementsDoor leavesSolid woodMechanical engineering

The invention discloses a solid wood door facilitating rapid clearing of adlets and relates to the technical field of solid wood doors. The solid wood door comprises a solid wood door body. A flexibleprotecting layer is arranged on one side face of the solid wood door body in a sleeving mode, the two sides of the solid wood door body are both slidably connected with a plurality of disassembly andassembly pieces, the front face and the back face of the solid wood door body are both rotatably connected with concealed handles, and the top and the bottom of the solid wood door body are both rotatably connected with rolling rods; driving rollers are rotatably connected between the opposite surfaces of the multiple disassembly and assembly pieces, adjustable shafts are arranged between the opposite surfaces of the multiple disassembly and assembly pieces in a penetrating mode, and the peripheral side faces of the adjustable shafts are rotatably connected with movable rollers; and the top and the bottom of one side face of the solid wood door body are both fixedly connected with pressing buckles. According to the solid wood door facilitating rapid clearing of the adlets, through mutualcooperation of the driving rollers and the movable rollers, the flexible protecting layer is rapidly released and wound, the flexible protecting layer occupied by the adlets is stored into the solid wood door body, and the solid wood door has the advantage that the adlets are rapidly cleared.

Owner:安庆市美尔家木业有限公司

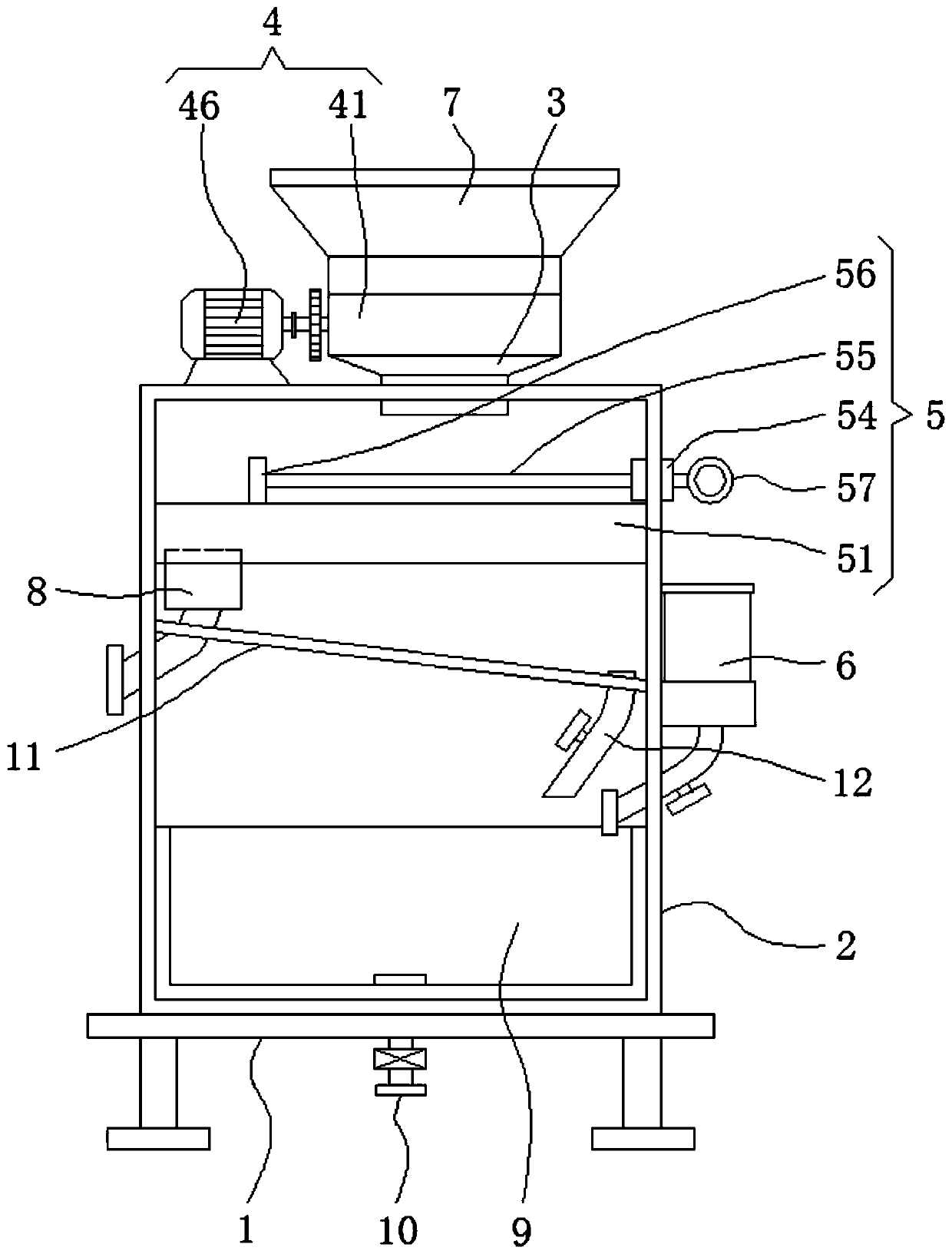

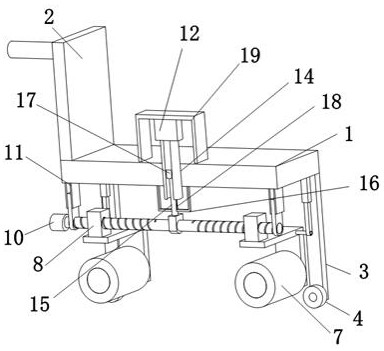

Road pavement repairing device for highway bridge construction

InactiveCN114032740AEasy to adjustEasy double rollingRoads maintainenceArchitectural engineeringElectric machinery

The invention relates to the technical field of bridge construction, and discloses a road pavement repairing device for highway bridge construction. The device comprises a bottom plate, a push plate is arranged on one side of the top end of the bottom plate, supporting columns are arranged on the periphery of the bottom end of the bottom plate, a moving wheel is arranged at the bottom end of each supporting column, two mounting plates are symmetrically arranged below the bottom plate, a mounting shaft is arranged at the bottom end of each mounting plate, and a pressing roller driven by a driving motor is arranged on each mounting shaft. In the process of leveling the repaired pavement, when a distance sensor detects that a distance value is larger than a preset value, a second electric telescopic rod is controlled to stretch out and draw back repeatedly, and when a pressure sensor detects that a pressure value is smaller than the preset value, a first electric telescopic rod is controlled to stretch out, so that a convex repairing material in the front can be quickly bulged and rolled under the condition that the pressing roller and the repairing pavement are kept at fixed pressure, and the working efficiency is improved.

Owner:王亚军

Equipment used for rolling cones

The invention discloses equipment used for rolling cones. A cone rolling tool is mounted on the inner side of an overturn rack or the inner side of a fixed rack and comprises a bracket and two sets of friction limit devices structurally arranged in axial symmetry are arranged on the bracket; each friction limit device comprises a support, a pin shaft, a hinge fulcrum shaft and a roll sleeve; the upper portion of the hinge fulcrum shaft is provided with a support shaft, the lower portion of the hinge fulcrum shaft is provided with a positioning pull arm, and the middle portion of the hinge fulcrum shaft is provided with a mounting hole; the positioning pull arm is fixedly connected with the support through a pin, the hinge fulcrum shaft is rotatably connected on the pin shaft, two ends of the pin shaft are respectively fixed on the support, the roll sleeve is fixed on the support shaft, and when a workpiece is rolled on a plate rolling machine, the outer cylindrical surface of the roll sleeve is closely attached to the end face of a small end of each cone to be rolled. The equipment has the advantages of simplicity in operation, high working efficiency and high precision in rolling the cones; the equipment is especially suitable for rolling of the thin-walled cones with large-diameter taper angles larger than 15 degrees.

Owner:CHINA NAT OFFSHORE OIL CORP +1

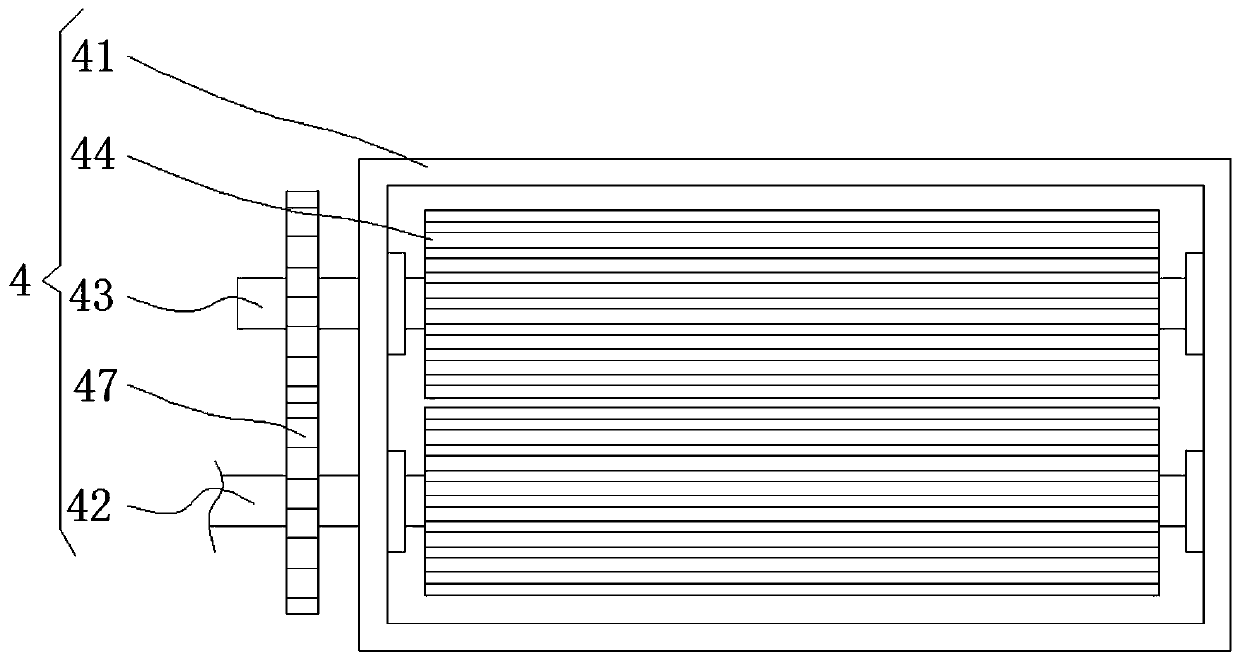

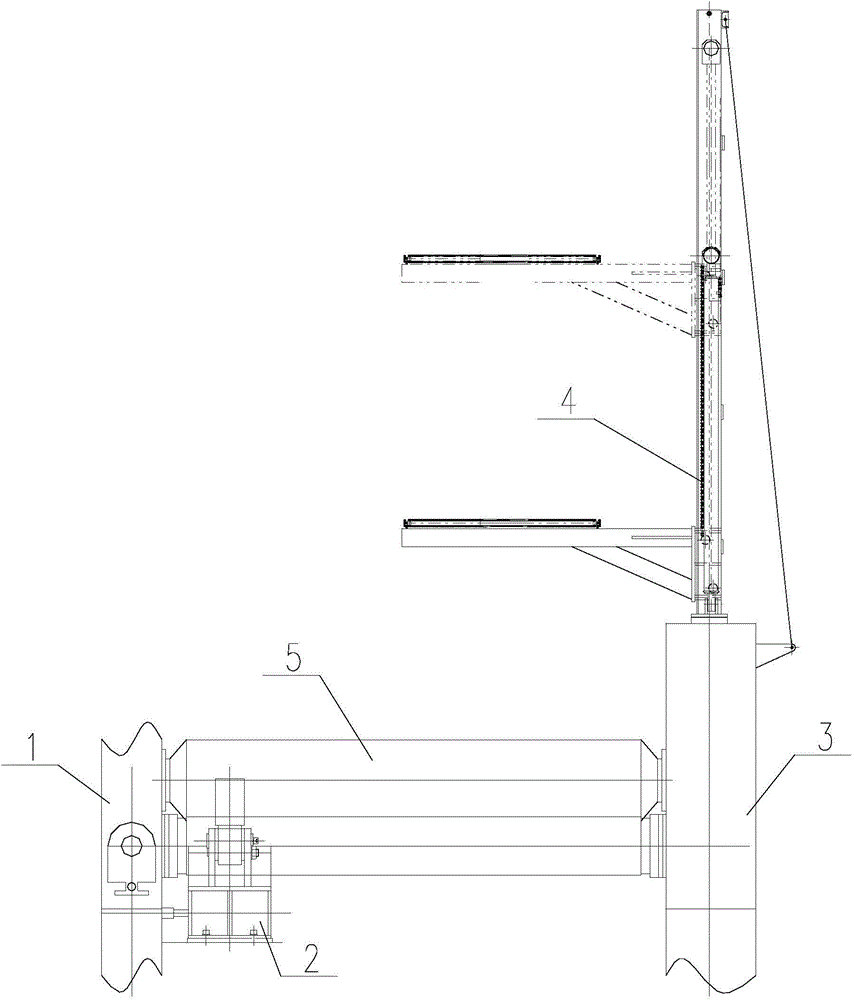

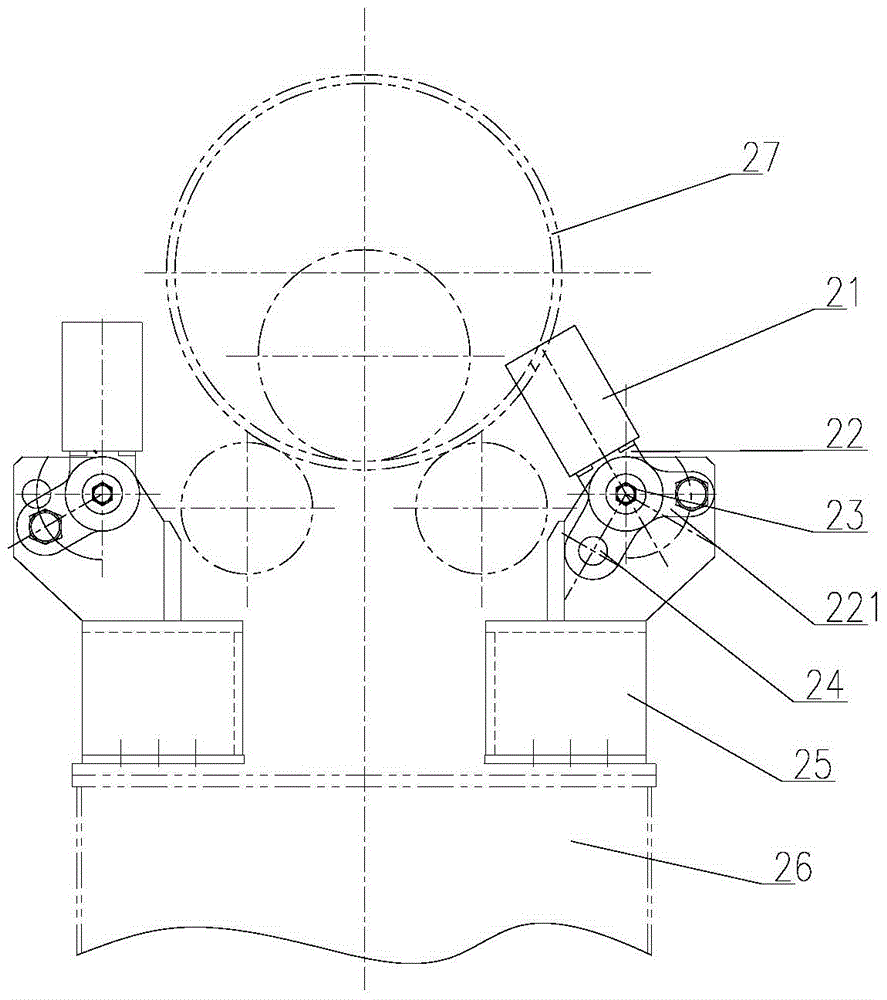

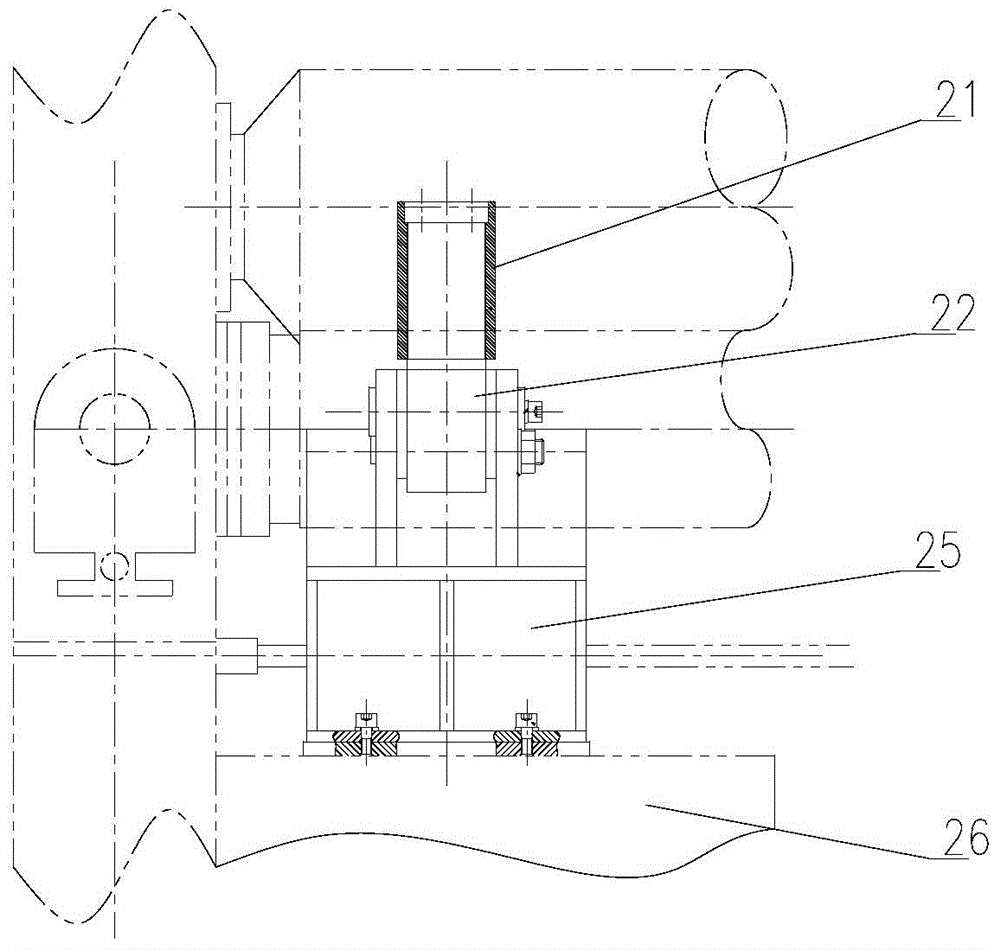

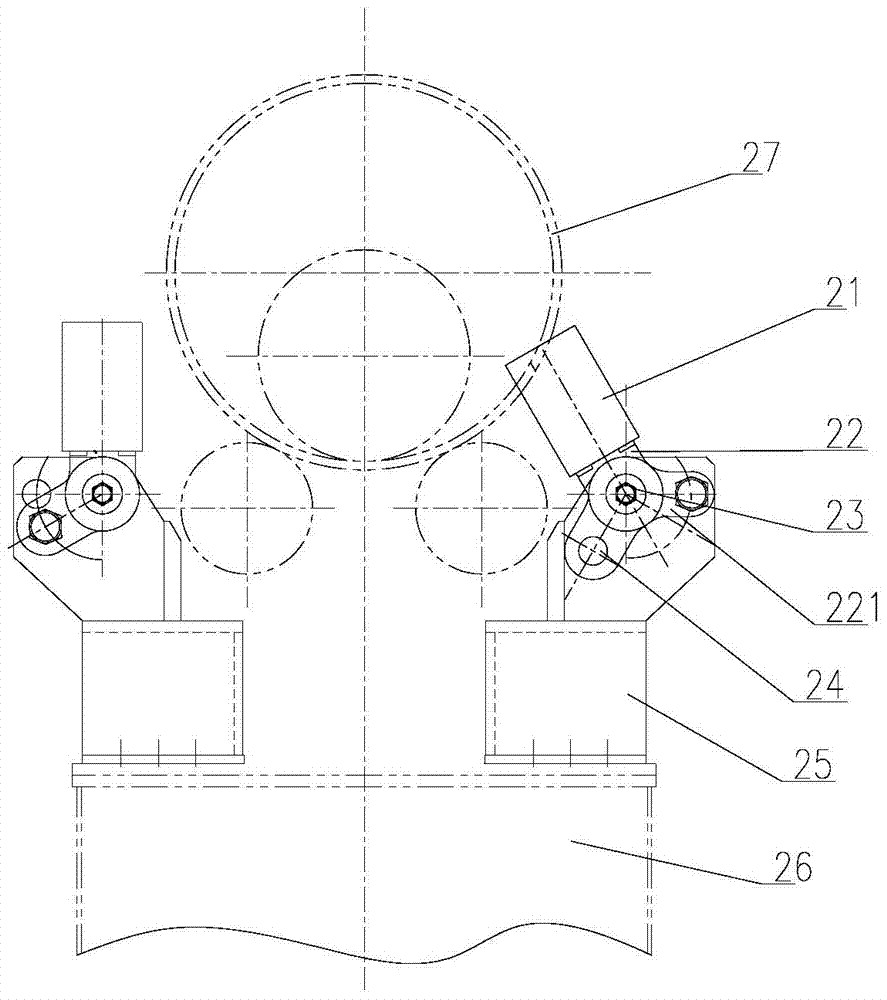

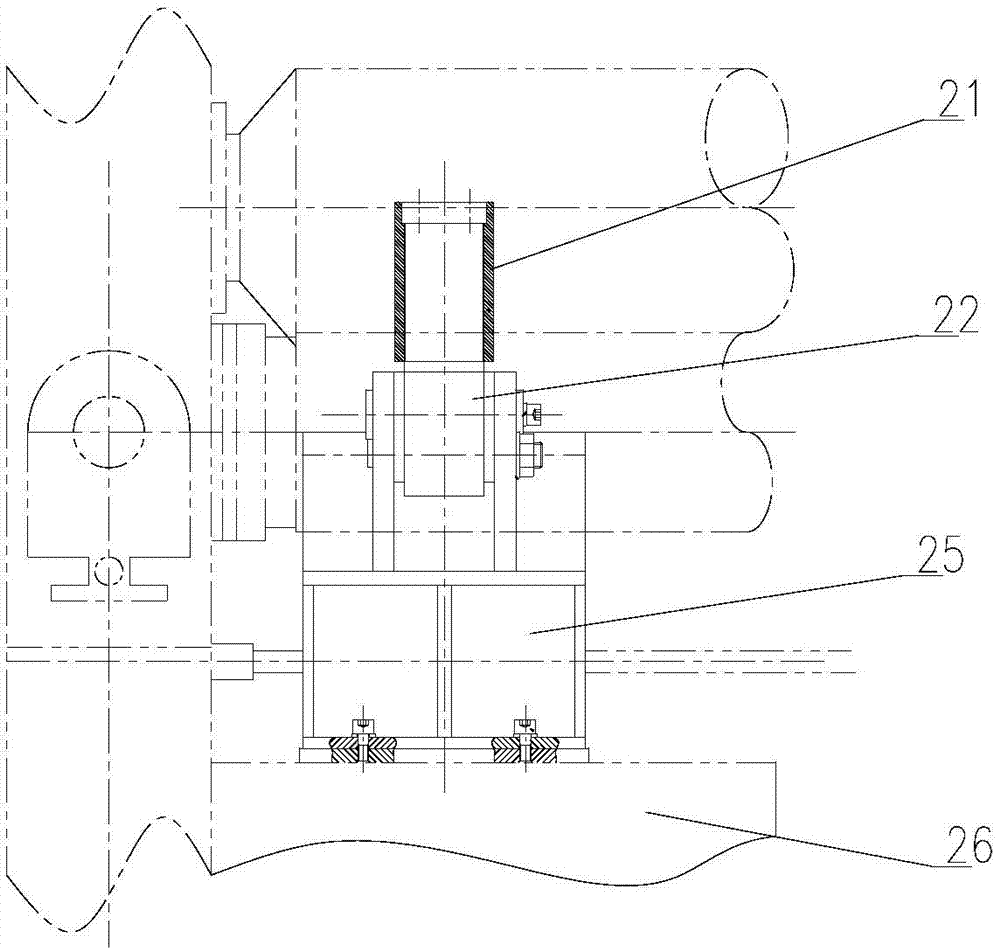

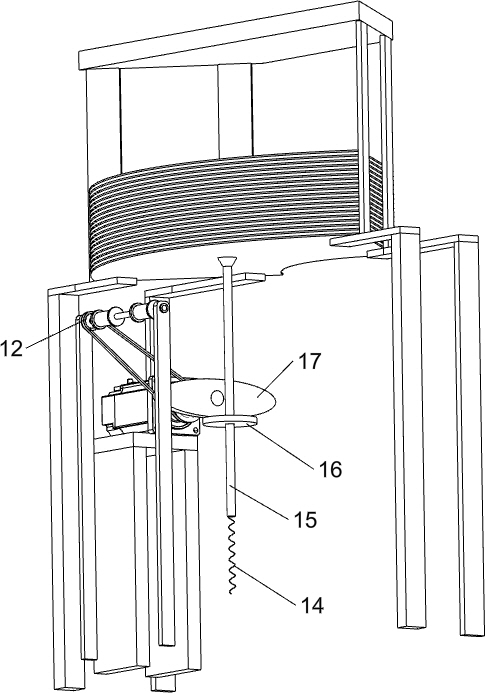

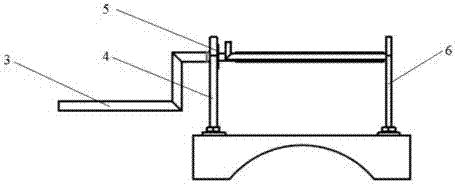

Plate rolling machine

The invention discloses a plate rolling machine which comprises a base. Two vertical mounting racks are respectively arranged at both ends of the base; two lower rolling barrels and an upper rolling barrel are mounted between the two vertical mounting racks; the upper rolling barrel and the lower rolling barrels are all conical barrels; a lifting screw rod is arranged on each vertical mounting rack; a first mounting base is fixedly arranged at the lower end of each lifting screw rod; both the thin end and the thick end of the upper rolling barrel are respectively mounted on the corresponding first mounting base; a motor is mounted on each vertical mounting rack; each motor is in linkage with the corresponding lifting screw rod by a worm gear and worm structure; two horizontal screw rods are mounted on each vertical mounting rack; a second mounting base with a nut structure is mounted on each horizontal screw rod; the nut structure of each second mounting base is matched with the corresponding horizontal screw rod; the thin ends and the thick ends of two lower rolling barrels are all respectively mounted on the corresponding second mounting bases. The plate rolling machine disclosed by the invention is simple in structure, stable in structure, high in strength and convenient to use, saves materials, and can fulfill the aim of rapidly rolling plates.

Owner:TENGXIAN SHUNZHOU SHIPBUILDING CO LTD

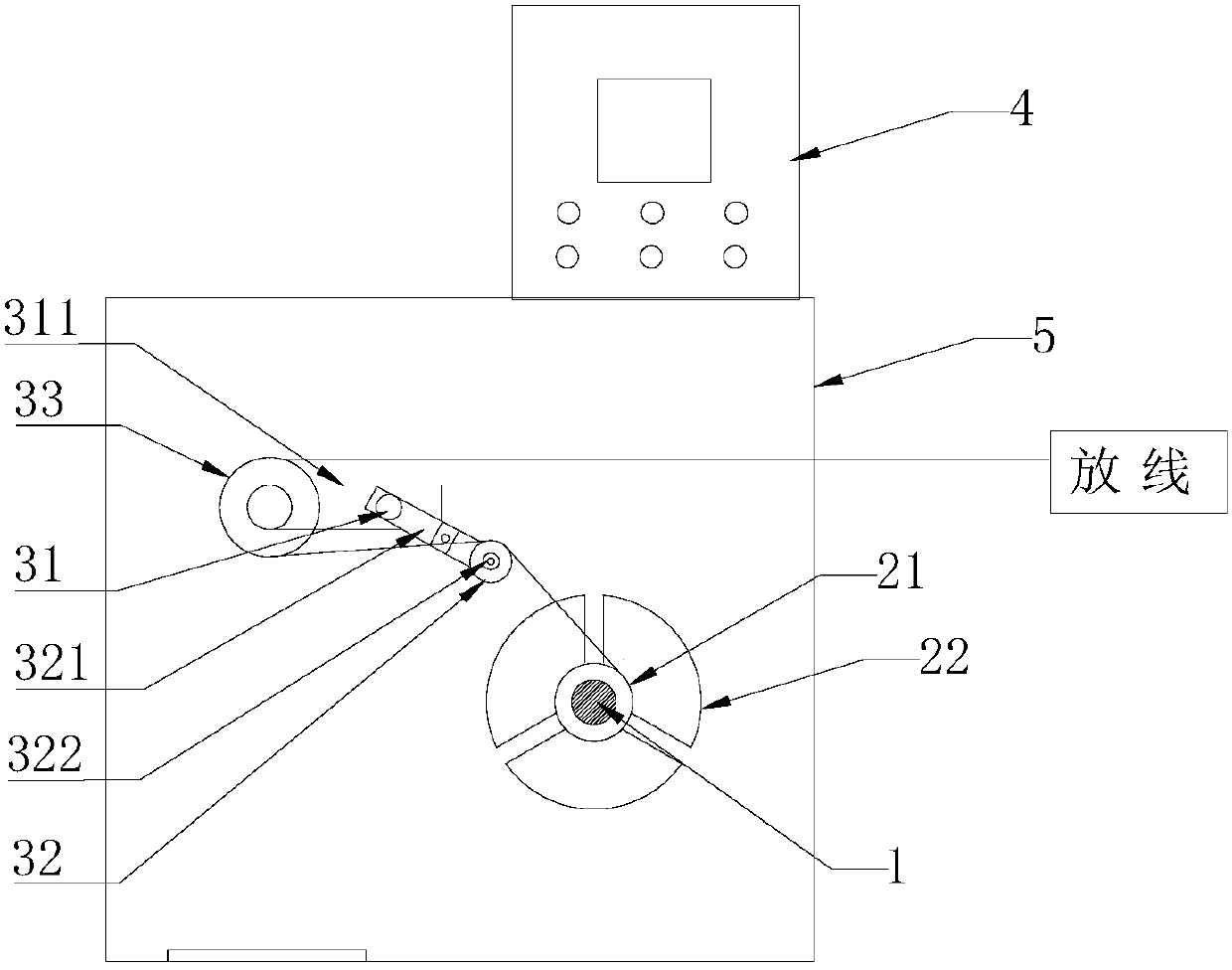

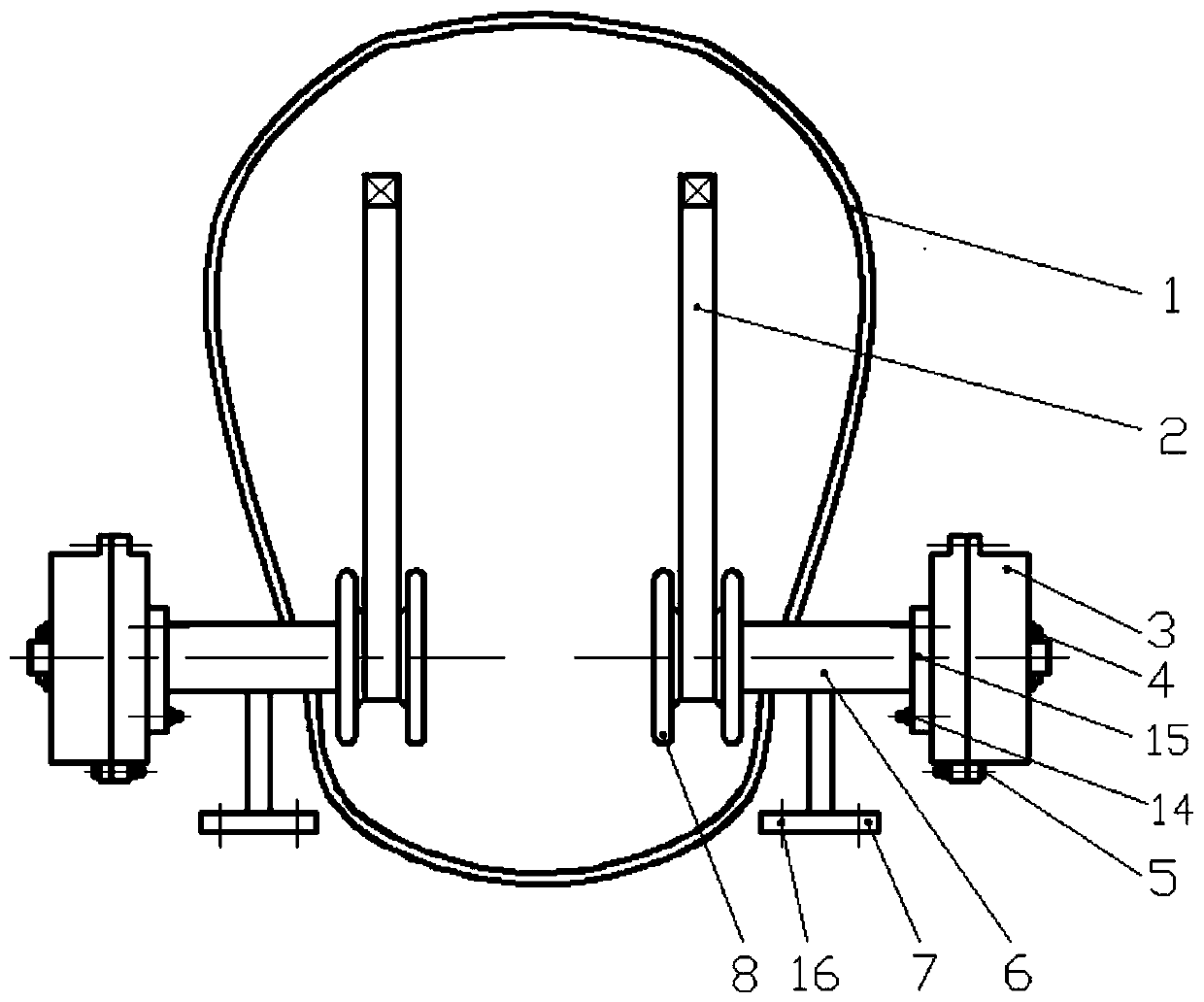

Uniform rolling equipment

The invention provides uniform rolling equipment. The uniform rolling equipment comprises a rack, a guide wheel, a rolling mechanism and a wire arrangement control mechanism. The guide wheel is drivenby a motor to rotate and fixed to the rack. The rolling mechanism comprises a mandrel and a rolling disk. The guide wheel drives the mandrel to rotate. The rolling wheel is detachably arranged on themandrel in a sleeving mode, and a limiting device used for limiting the rolling disk is arranged on the mandrel. The wire arrangement control mechanism comprises a wire arrangement device and a wireposition wheel, wherein the wire arrangement device is fixed to the rack, the wire arrangement device is driven by a servo motor to move transversely, and the transverse moving direction of the wire arrangement device is parallel to the mandrel; and the wire position wheel is rotatably connected with the wire arrangement device. According to the uniform rolling equipment, the wire arrangement device moves front and back to control the rolling position of an electric wire, the position is accurately controlled through digital control, rolling is accurate and ordered, and the situation that theelectric wire is splayed or is likely to be unrolled is avoided.

Owner:广州丰泰美华电缆有限公司

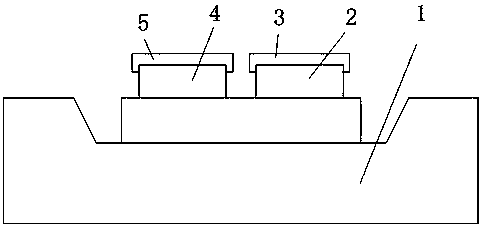

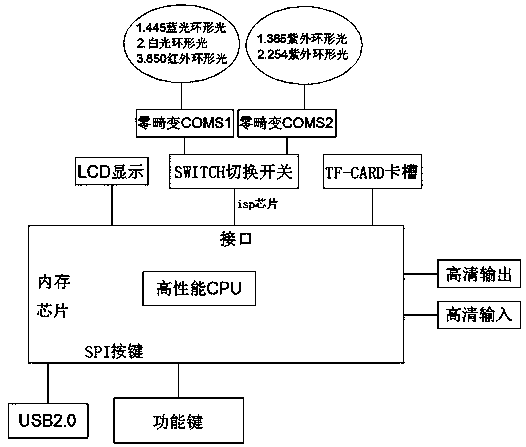

Intelligent field investigation device

InactiveCN108282624AQuick rollQuick MappingTelevision system detailsColor television detailsTablet computerUltraviolet

The invention relates to the technical field of physical evidence investigation and extraction devices, and particularly relates to an intelligent field investigation device. The device comprises an industrial tablet computer, wherein the industrial tablet computer is connected with a zero-distortion CCD and a high-pass ultraviolet CCD, a change-over switch is arranged between the zero-distortionCCD and the high-pass ultraviolet CCD and the industrial tablet computer, a first light source is arranged on the zero-distortion CCD, and a second light source is arranged on the high-pass ultraviolet CCD. According to the scheme of the invention, by replacing different light sources on different CCDs, the purpose of investigating and extracting different types of physical evidences can be achieved, the disadvantages that a large number of field investigation equipment exists, each equipment has poor compatibility, and the like can be well solved, and the device has the functions of acquiringfield base station information and other basic information, rapidly producing an investigation record in the field, carrying out rapid on-site mapping and rapidly making a roll at the scene of a case.

Owner:HEFEI HENGLEI POLICE EQUIP TECH CO LTD

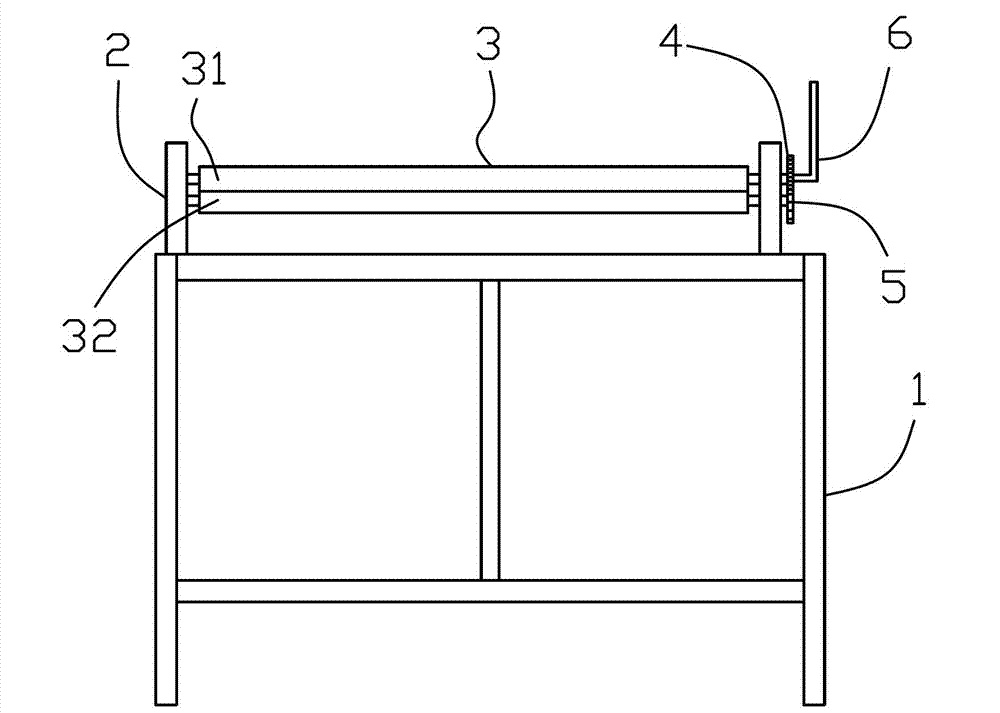

Rapid plate rolling device

The invention relates to a rapid plate rolling device and relates to the technical field of printing. The rapid plate rolling device comprises a support. Two fixed plates are arranged on the support. Rollers are mounted on the fixed plates. The fixed plates are perpendicularly fixed on the support. The rollers are mounted between the two fixed plates. The rollers include one upper roller and two lower rollers and form a triangle structure. An active rotating gear is mounted on the upper roller and is connected with a rotating handle. Driven gears are mounted on the lower rollers and mesh with the active rotating gear. The rapid plate rolling device has the advantages of reasonable structure, simplicity in operation, convenience in use and the like, and has the function of rapid plate rolling.

Owner:ANHUI HONGGUANG ENTERPRISE INVESTMENT GROUP

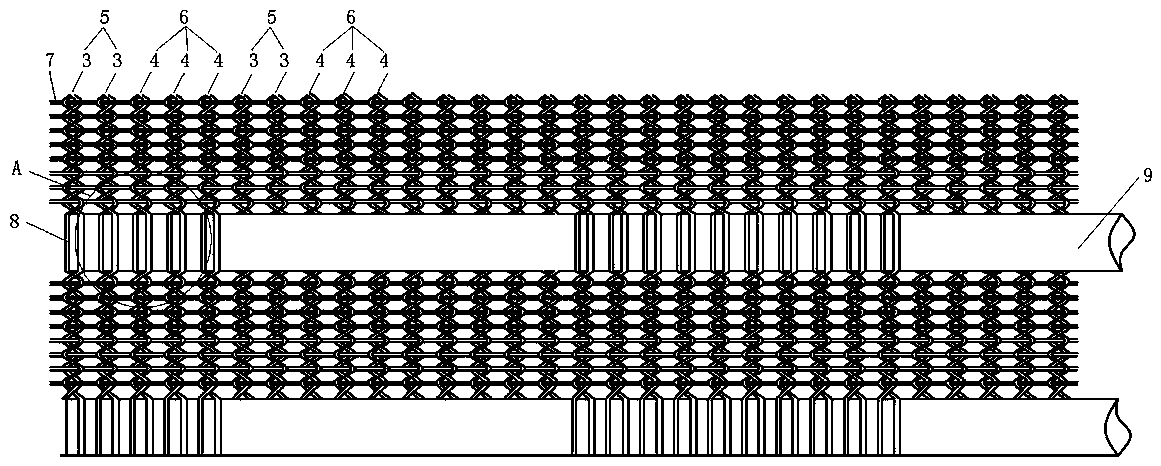

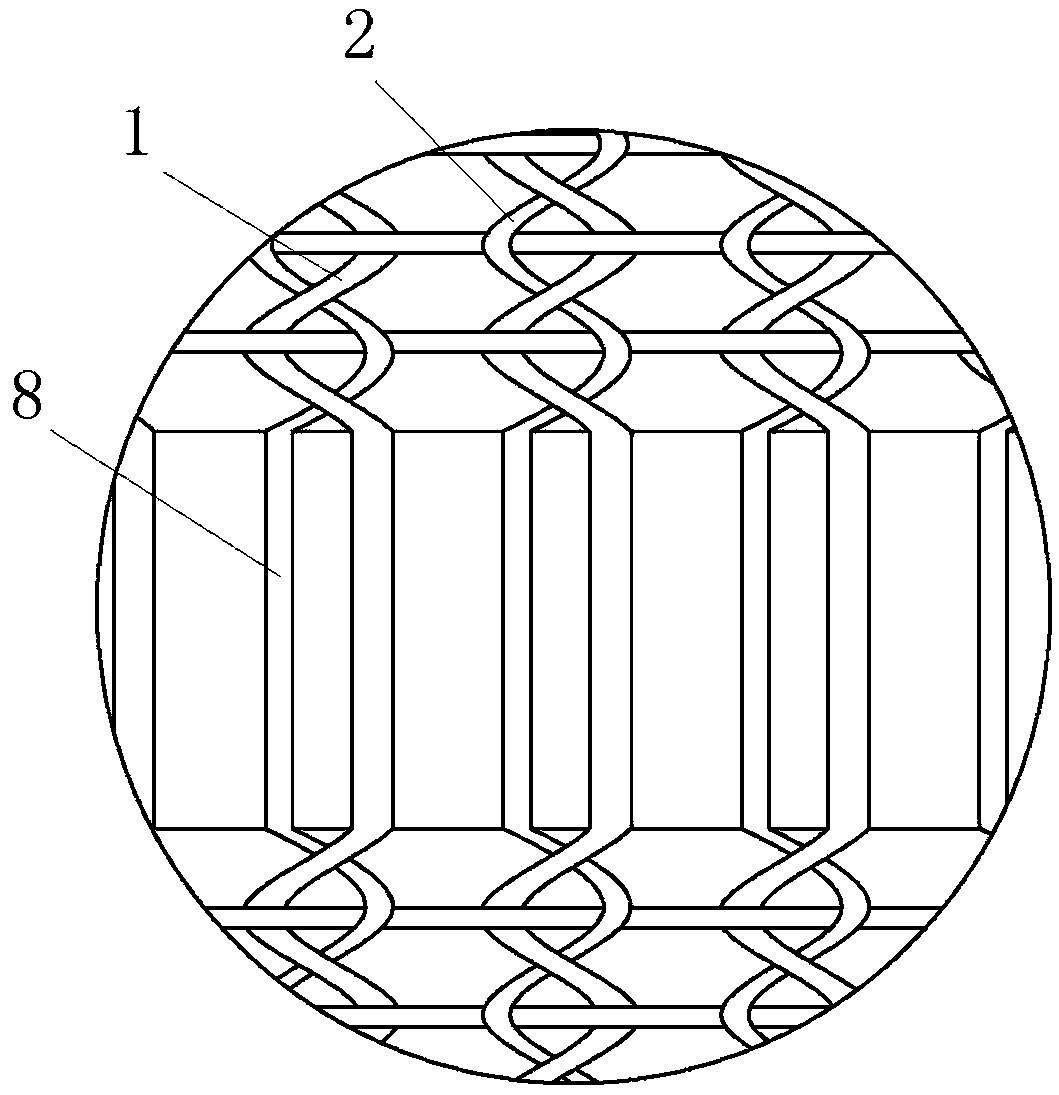

Crawler belt fabric for emergency rescue and application thereof

PendingCN110714258AWeight toleranceQuick rollSwivel-woven fabricsVehiclesEmergency rescueStructural engineering

The invention relates to crawler belt fabric for emergency rescue and belongs to the field of functional fabrics. The crawler belt fabric is characterized by comprising a first warp unit, a second warp unit and the weft, wherein the first warp unit and the second warp are arranged at an interval, the first warp unit includes at least two first warp groups, each first warp group includes two piecesof first warp, the second warp unit includes at least two second warp groups, and each second warp group includes two pieces of second warp; the first warp groups and the second warp groups are bothconnected with the weft in two stitch structures, the first stitch structure refers to a cross woven structure formed of the two pieces of first warp or two pieces of second warp and the weft, and thesecond stitch structure refers to forming warp floats by the first warp or second warp along the warp direction through surfaces of several pieces of the weft; and reinforcing ribs penetrate betweenthe warp floats and the weft. The invention further relates to application of the crawler belt fabric in bogging-down preventing facility of tanks. The crawler belt fabric aims to improve the bogging-down preventing facility of military tanks, can achieve quick extrication of the tanks, can be rolled up rapidly, and is convenient to use.

Owner:HOCK TECH CO LTD

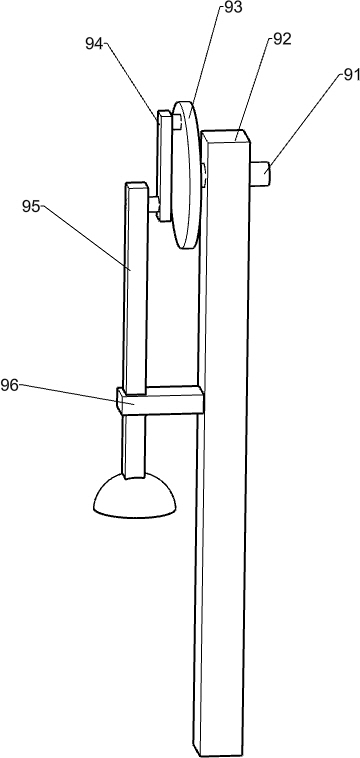

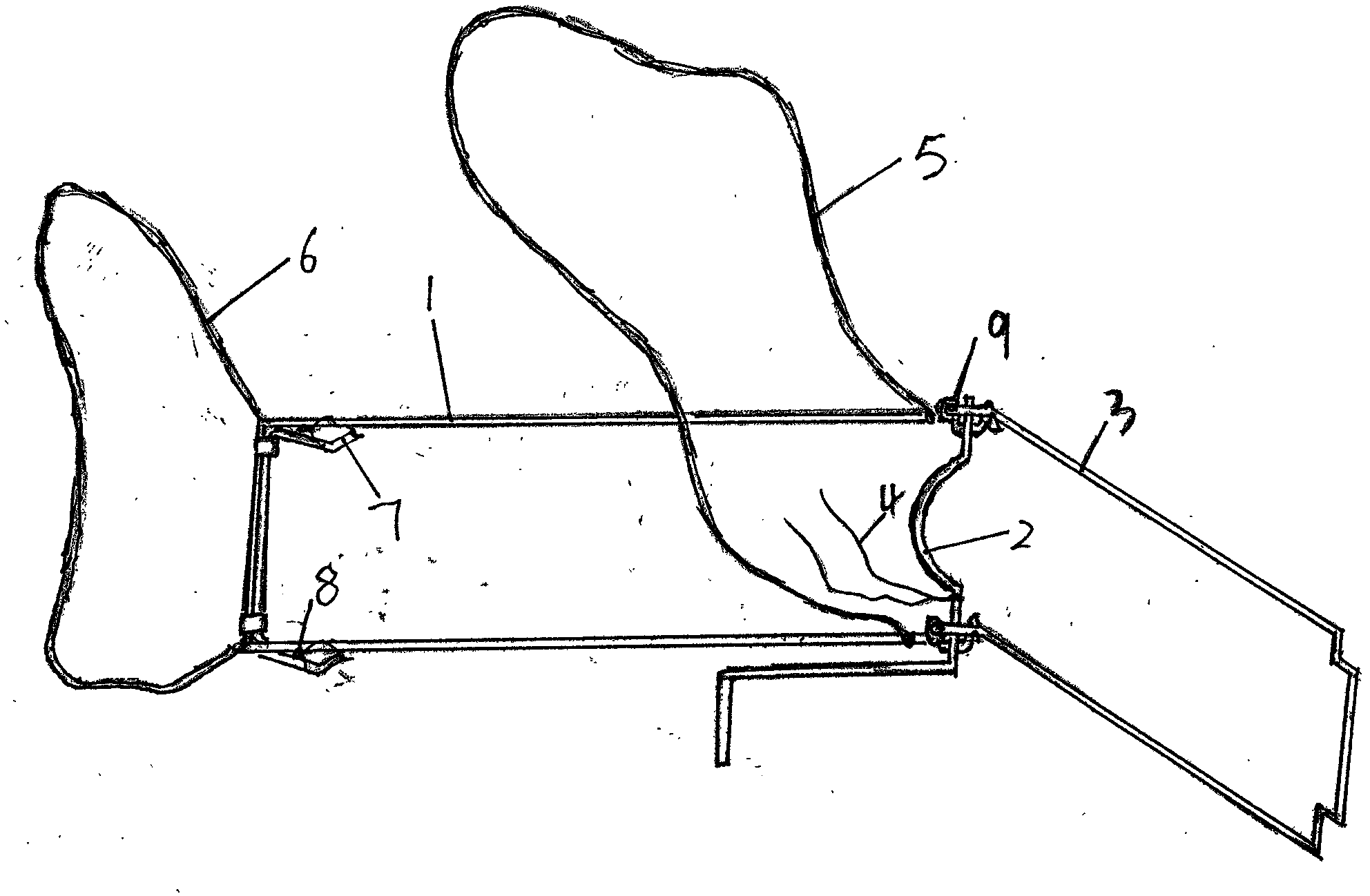

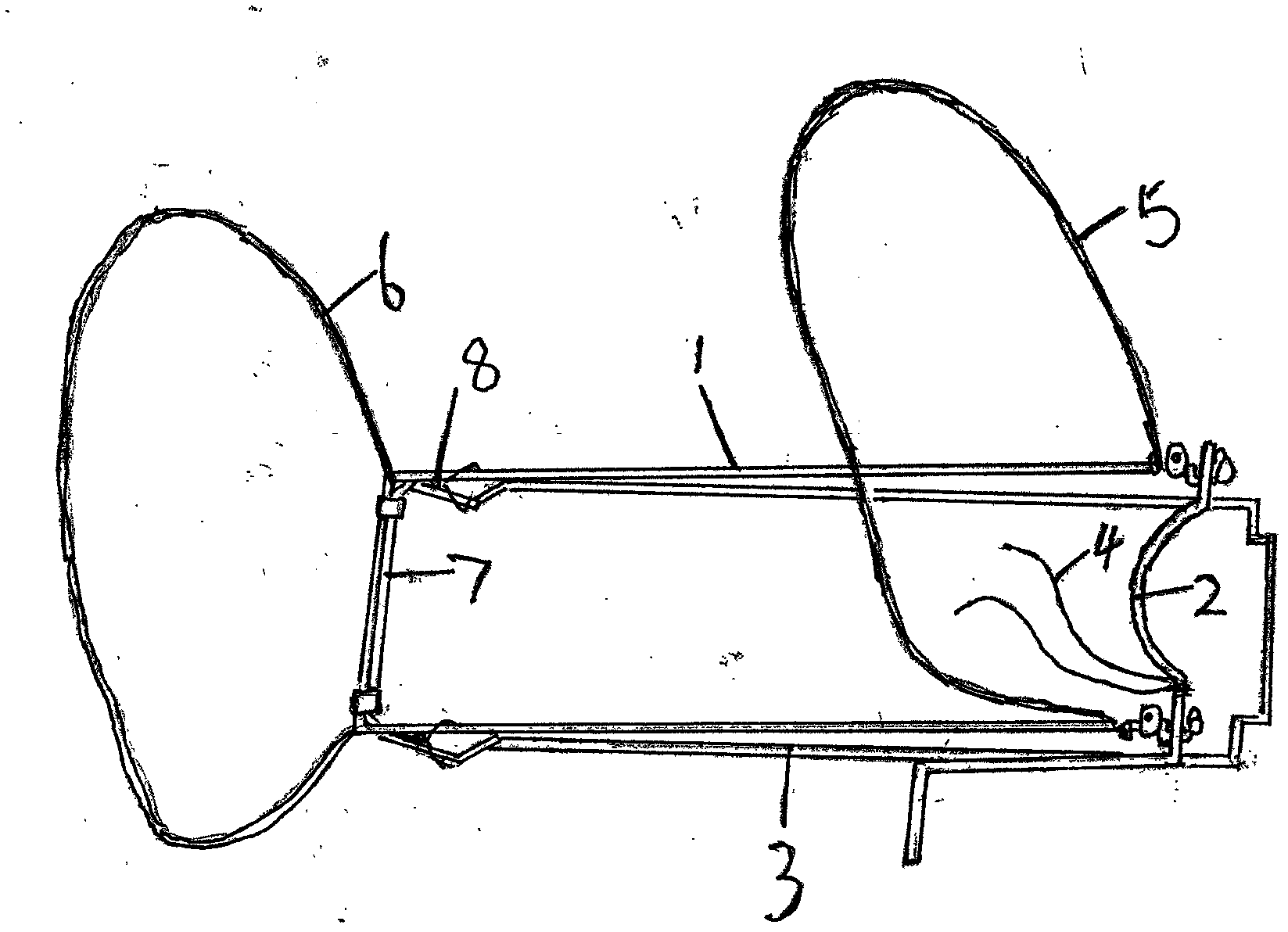

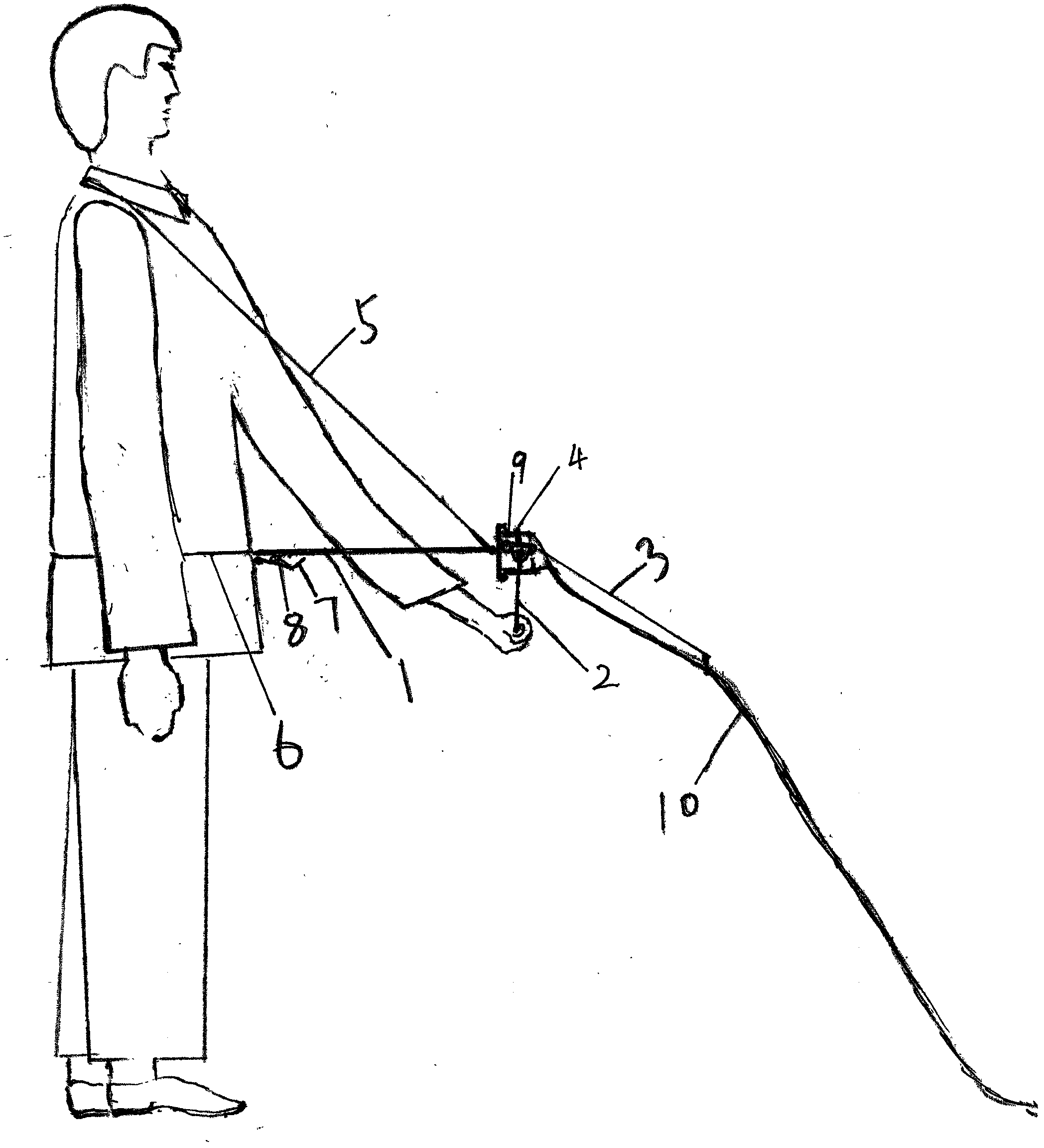

Waist-hung hand-operated pipe coiling device

The invention discloses a waist-hung hand-operated pipe coiling device, which can be used for coiling soft water pipes easily, lightly and rapidly. In the waist-hung hand-operated pipe coiling device, a forward rectangular strip frame which can be hung in an opening in front of the waist is taken as a support frame; a swinging coiling structure which can used for clamping a water pipe head and coiling the water pipe and can be extracted from the support frame and the coiled water pipe is arranged at the front end of the support frame; a pipe correcting frame which can be used for correcting the moving position of the water pipe is arranged on the support frame; the water pipe head is clamped on the swinging coiling structure after the water pipe passes through the correcting position of the pipe correcting frame; and the swinging coiling structure is swung for coiling the water pipe into a coil; and the water pipe and the swinging coiling structure are extracted from the support frame and put onto the ground, so that the swinging coiling structure is extracted from the water pipe.

Owner:李保瑞

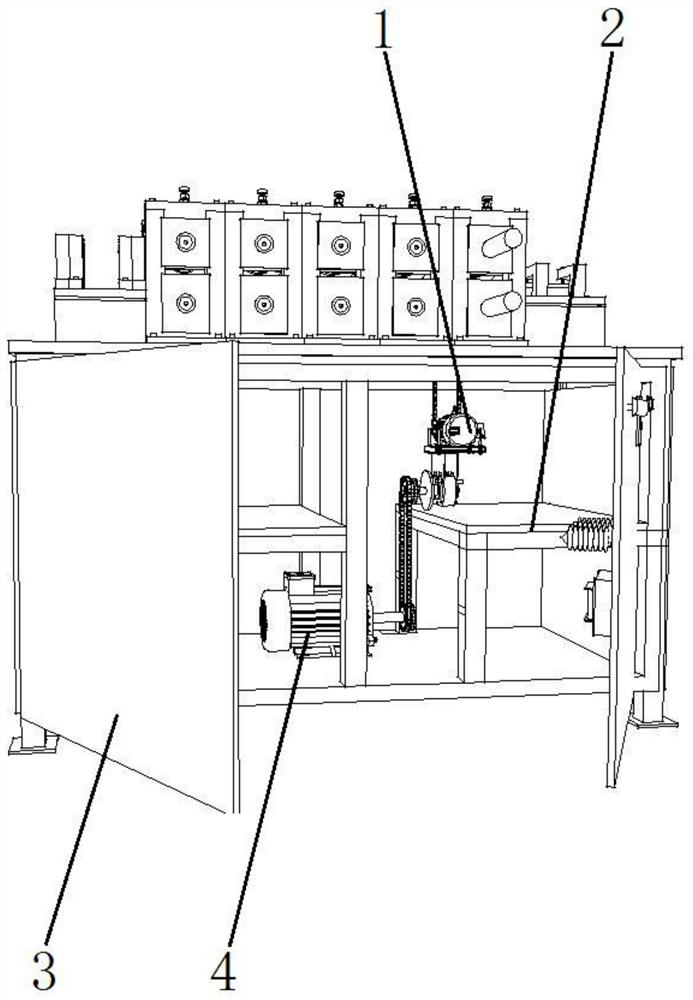

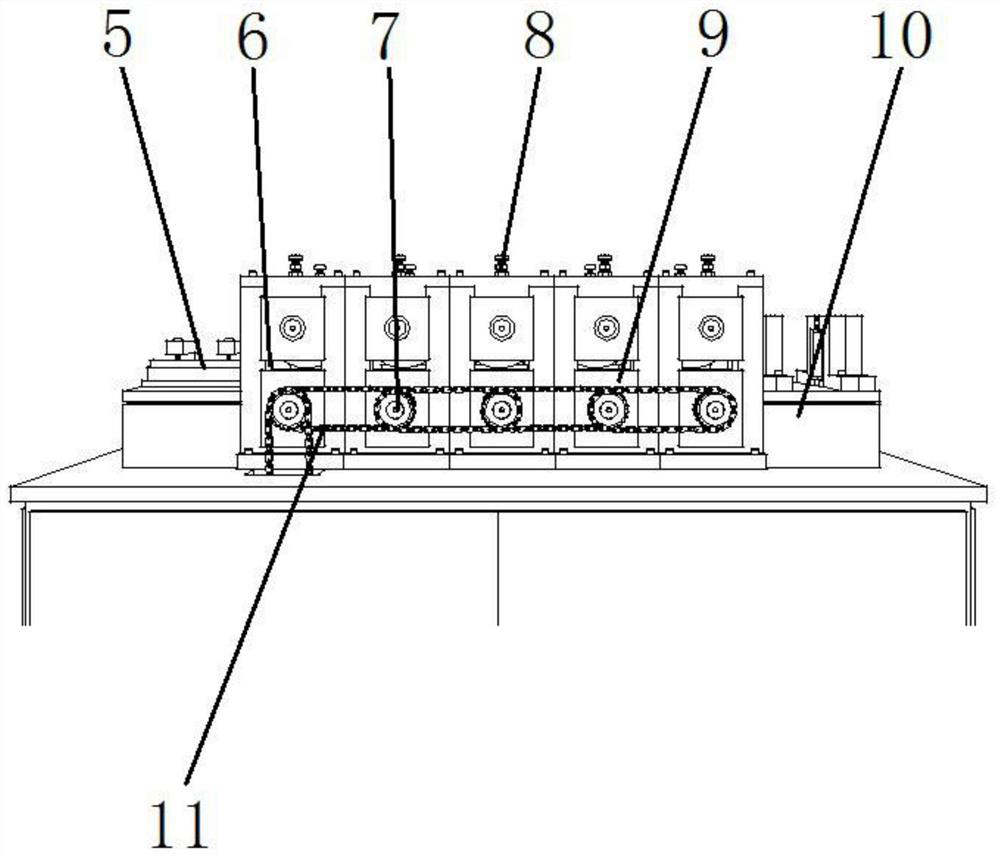

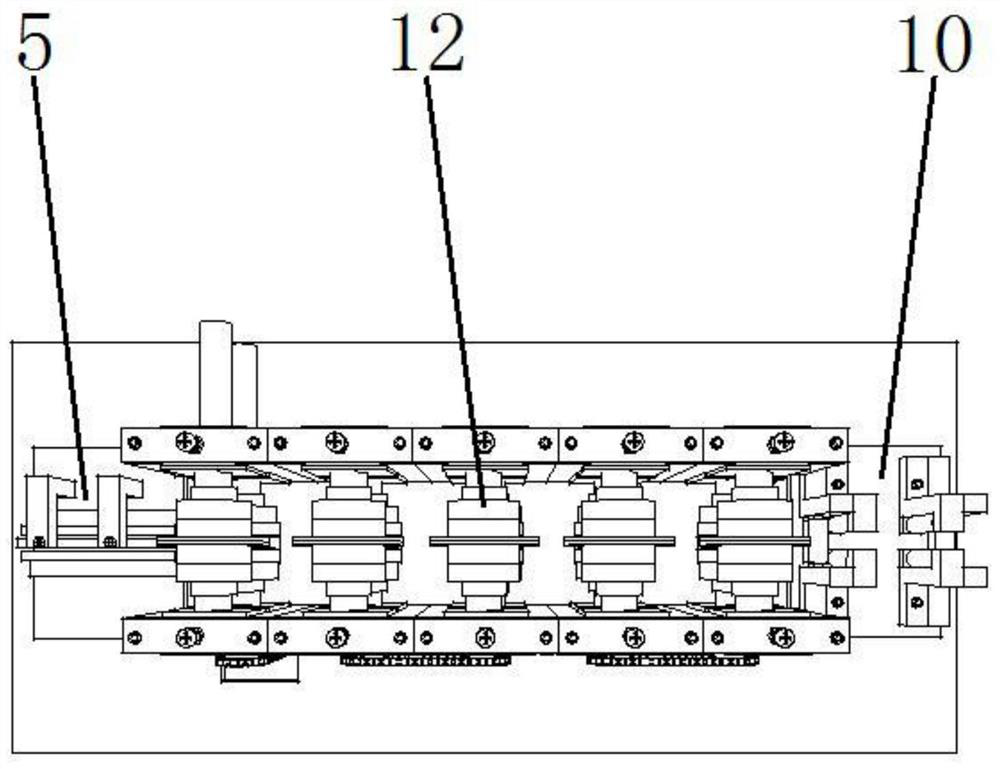

Automobile body bright strip rolling machine

The invention provides an automobile body bright strip rolling machine, and belongs to the technical field of automatic mechanical equipment. The automobile body bright strip rolling machine comprisesa main cabinet body and a rolling mill main body, wherein an adjustable speed motor is arranged inside the main cabinet body; a rolling mill power cabinet body is arranged on the right side of the adjustable speed motor; a speed reducer is arranged above the rolling mill power cabinet body; the speed reducer is connected with the adjustable speed motor; the rolling mill main body is arranged above the main cabinet body, and comprises two sets of bearing bases which are arranged oppositely; two rows of rollers are arranged between the two sets of bearing bases; downward-pressing adjusting bolts are arranged above bearings; decompression springs are arranged between the upper row of rollers and the lower row of rollers; pressing roller shafts are arranged on the other side of the joint of the lower row of rollers and the bearing bases; and the pressing roller shafts are connected with the speed reducer through a transmission chain. Through mechanical automated operation, automobile bodydecoration strips meeting the requirements of automobiles can be rolled more quickly and accurately, the cost is saved, and the efficiency is improved.

Owner:成都兴三和汽车文化传播有限公司

Method and grinding machine for grinding workpieces with grooves

ActiveCN107427983BSimple structureStructural stabilityGrinding feed controlAbrasive surface conditioning devicesElectrical energy consumptionMachine

Owner:ERWIN JUNKER MASCHNINENFAB

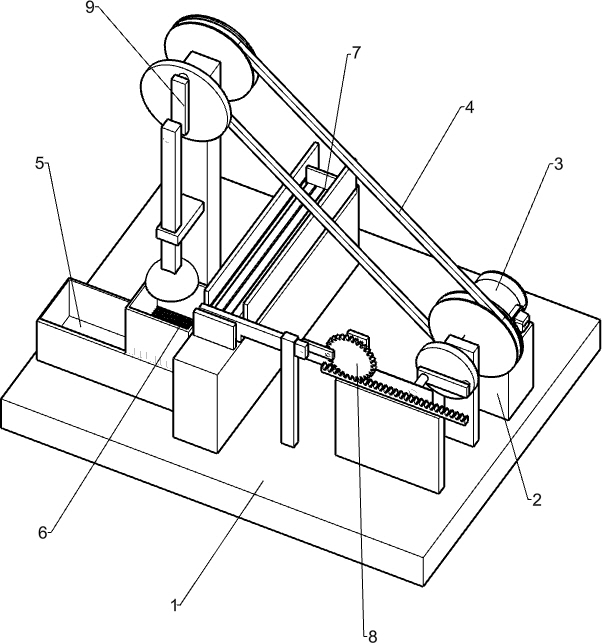

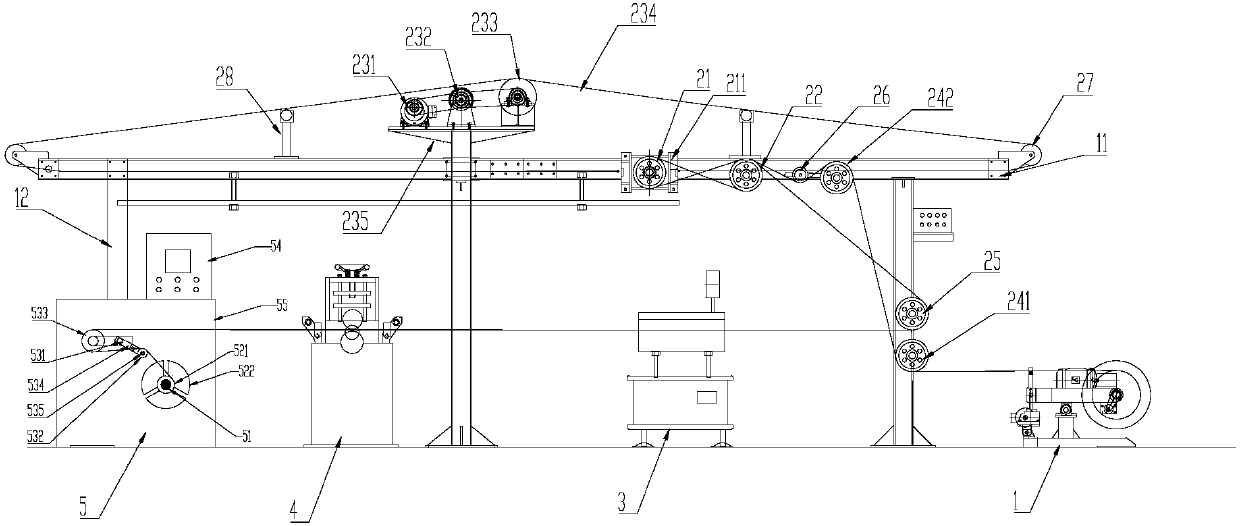

Equipment for winding paper cups into cylinders

InactiveCN111823640AQuick rollTo achieve the cutting effectBox making operationsPaper-makingPaperboardPaper cup

The invention relates to equipment for winding into cylinders, in particular to equipment for winding paper cups into cylinders. In order to solve the technical problems, the equipment for winding thepaper cups into the cylinders can sequentially feed paperboards and quickly wind the paperboards into cylinders. The equipment for winding the paper cups into the cylinders comprises one bottom plate, two groups of support frames symmetrically arranged on the left side of the upper part of the bottom plate in a front-back mode, a connecting plate, and a first supporting piece, wherein the connecting plate is arranged on the two groups of support frames; and the first supporting piece is arranged on the left rear side of the upper part of the bottom plate. According to the equipment, the effects that the paperboards can be sequentially fed and can be rapidly wound into the cylinders are achieved, a second lifting rod moves up and down to drive clamping supports on the front side and the rear side to rotate, so that the clamping supports can drive the paperboards to wrap a fixed round table, and the paperboards can be rapidly wound into the cylinders.

Owner:梁闰强

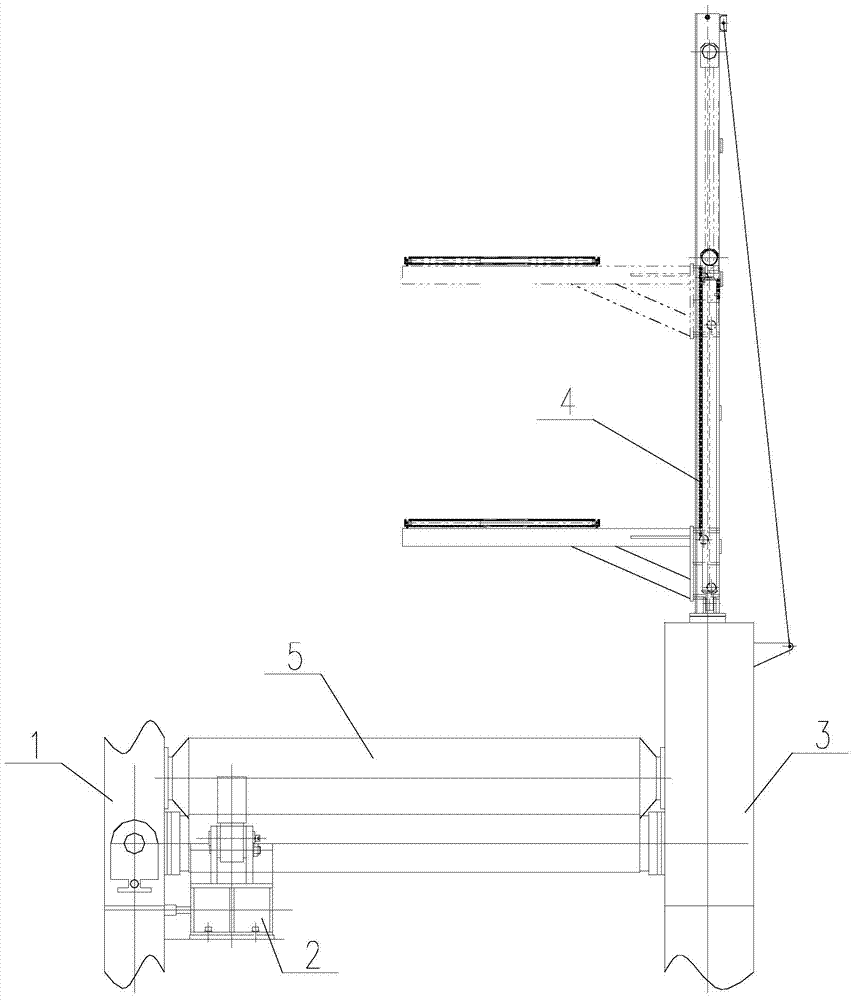

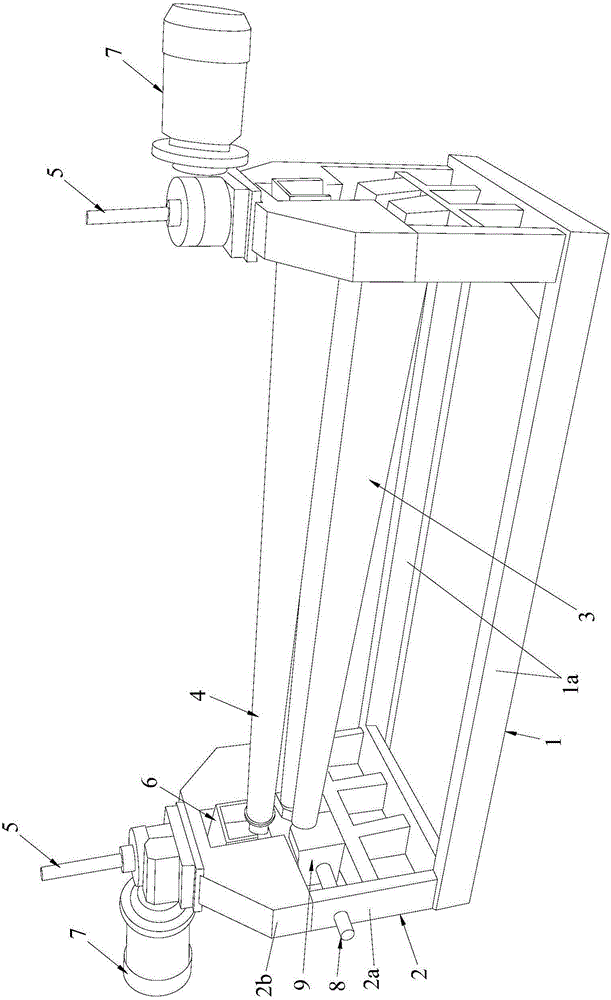

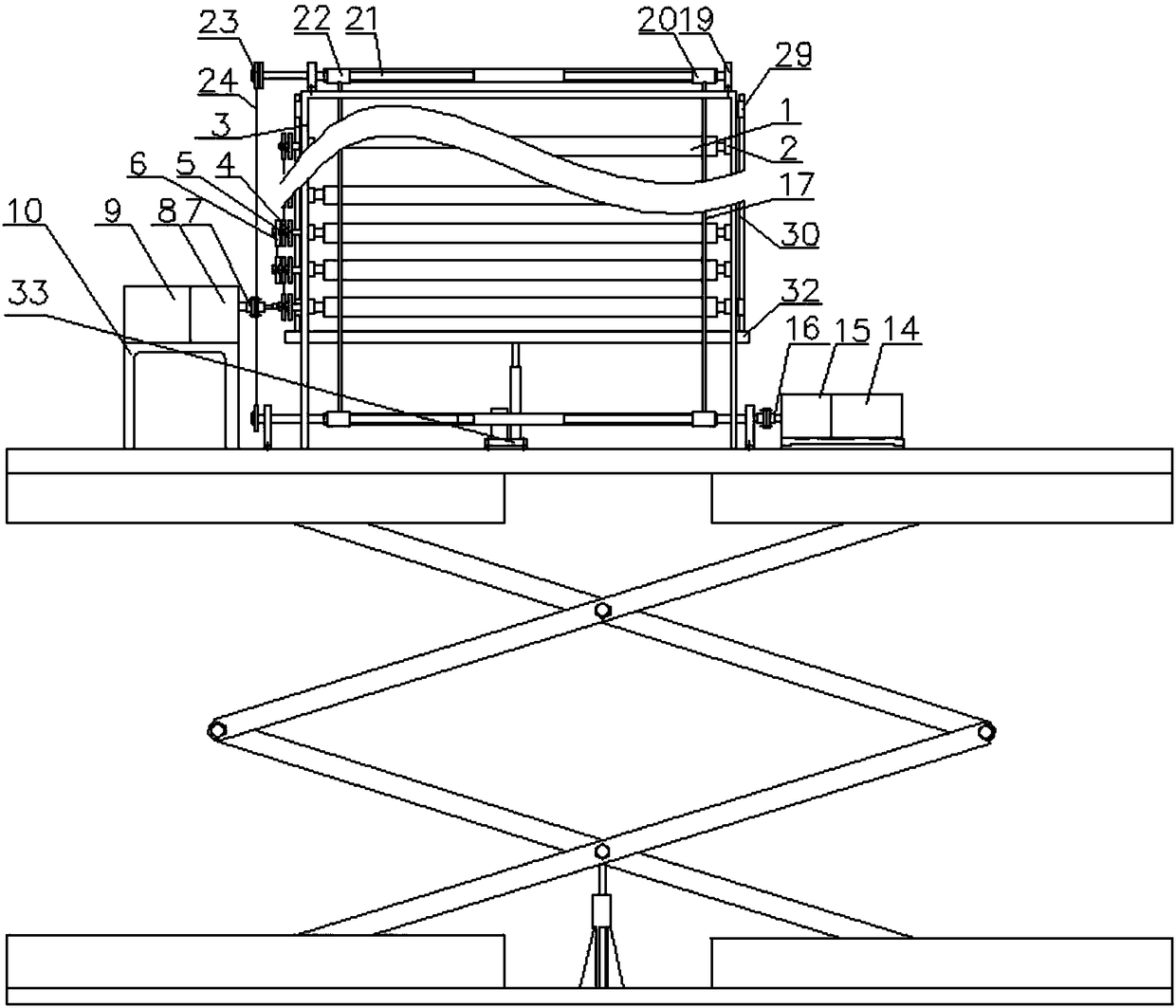

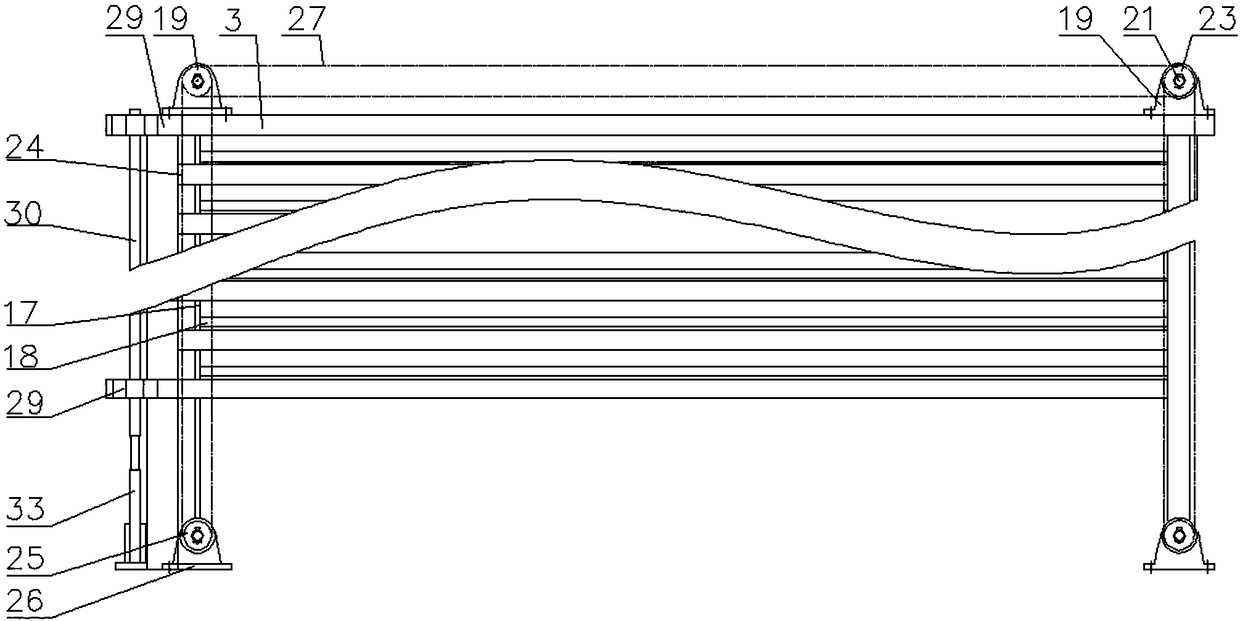

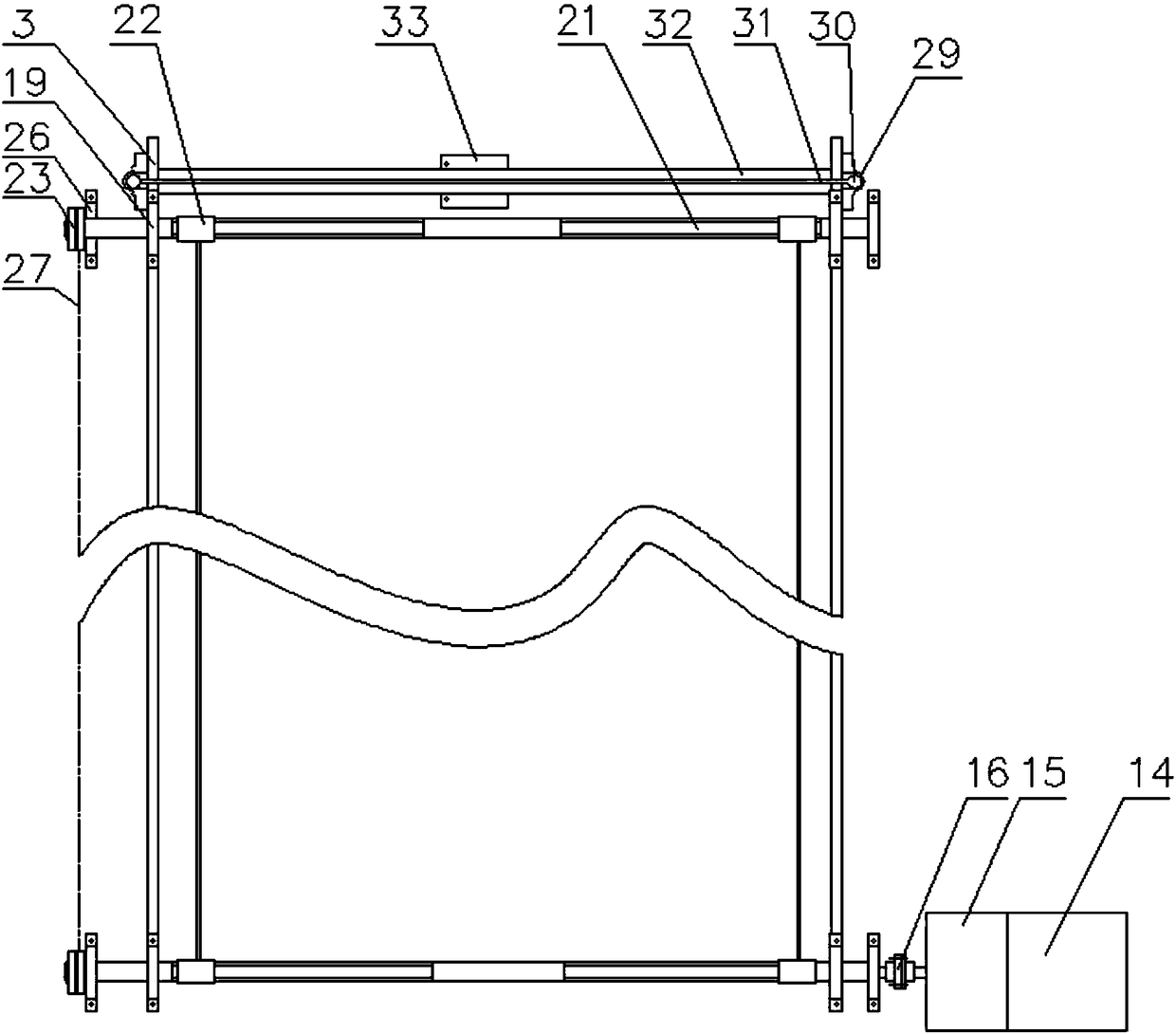

A three-dimensional storage device for glass magnesium boards and storage method thereof

ActiveCN106348017BNon-stop operationGuaranteed to rollCharge manipulationConveyor partsPhysical chemistryEngineering

A three-dimensional storage device for glass magnesium boards, including a three-dimensional shelf assembly for storing glass magnesium boards, a guide assembly for adjusting the width to adapt to glass magnesium boards with different width specifications, and preventing the glass magnesium boards from rushing out of the shelves due to inertia after entering the three-dimensional shelves. Components, and the lifting platform components that make the storage device move up and down so that the glass magnesium board can be smoothly sent into the three-dimensional shelf. When the three-dimensional shelf is full of glass magnesium plates, the glass magnesium plate rolling three-dimensional storage device will roll all the plates to another free three-dimensional shelf at one time, so as to receive new glass magnesium plates. This invention realizes that after a three-dimensional shelf is filled with glass magnesium plates, all the glass magnesium plates can be quickly rolled to another free three-dimensional shelf, ensuring that the production line can run without stopping and improving the operating efficiency of the production line.

Owner:JIANGSU UNIV OF SCI & TECH

Rolling equipment for electric wires

The invention provides rolling equipment for electric wires. The rolling equipment for the electric wires comprises a rack, a wire storage device and a rolling device, wherein the rack comprises a cross bar and a plurality of stand columns, the wire storage device comprises a moving wire storage wheel group, a fixed wire storage wheel group, a wire inlet guide wheel group, a wire outlet guide wheel and a sliding block driving device, the fixed wire storage wheel group is fixedly mounted on the cross bar, the moving wire storage wheel group is fixedly mounted on a sliding block, the sliding block driving device drives the sliding block to slide on the cross bar, the rolling device comprises a guide wheel, a rolling mechanism and a wire traverse unit for controlling the rolling position of wires on the rolling mechanism. The electric wire rolling equipment can keep the electric wires in order in a fast wire operation status. After the wires are broken, the rolling equipment has a bufferfunction, and therefore the situation is avoided that the quality of the wires is influenced because large tension is generated due to inertia. The wires which are thinner and smoother in surface canbe rapidly and evenly rolled, the rolling effect is good, and the phenomenons of splayed rolling, scattering and wire dropping do not happen. After being rolled, wire coils are neat and orderly, and therefore the product quality can be improved.

Owner:广州丰泰美华电缆有限公司

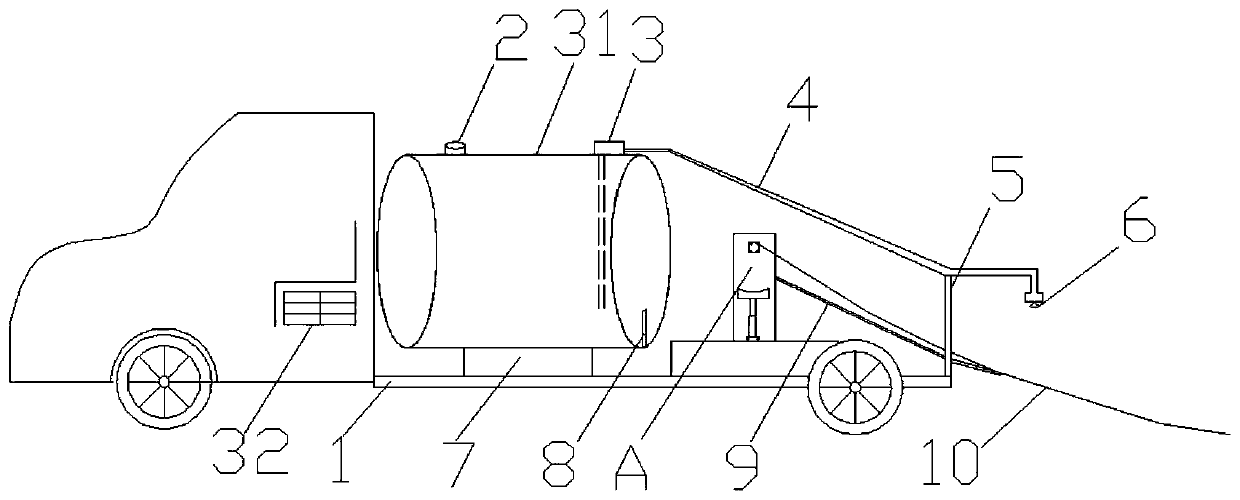

Cement pavement maintenance device

PendingCN111155407AAchieve mechanical propertiesAchieve roll upRoads maintainenceWater storageVehicle frame

The cement pavement maintenance device comprises a first base, a water tank and a storage battery, the first base is arranged on a frame of a tractor, the water tank is arranged above the first base,a water storage port is formed in the top of the water tank, a water pump is arranged at the top of the rear end of the water tank, and a water inlet pipe of the water pump extends into the bottom ofthe water tank; the nozzle is arranged at the rear end of the tractor; a health maintenance cloth paving and rolling device is further arranged on the first base, the health maintenance cloth paving and rolling device comprises a supporting frame and a cloth rolling roller, the two ends of the cloth rolling roller are connected with the supporting frame through bearings, and the cloth rolling roller is connected with a driving mechanism; health maintenance cloth is wound on the cloth roller; the electric energy output end of the storage battery is connected with the water pump, laying and folding of the cement pavement maintenance cloth can be achieved, meanwhile, watering maintenance can be conducted in the laying process, in addition, the device can be used for watering maintenance in the maintenance period, the laying efficiency is improved, and the labor intensity of workers is also reduced.

Owner:CHANGAN UNIV

A rolling machine

The invention discloses a plate rolling machine which comprises a base. Two vertical mounting racks are respectively arranged at both ends of the base; two lower rolling barrels and an upper rolling barrel are mounted between the two vertical mounting racks; the upper rolling barrel and the lower rolling barrels are all conical barrels; a lifting screw rod is arranged on each vertical mounting rack; a first mounting base is fixedly arranged at the lower end of each lifting screw rod; both the thin end and the thick end of the upper rolling barrel are respectively mounted on the corresponding first mounting base; a motor is mounted on each vertical mounting rack; each motor is in linkage with the corresponding lifting screw rod by a worm gear and worm structure; two horizontal screw rods are mounted on each vertical mounting rack; a second mounting base with a nut structure is mounted on each horizontal screw rod; the nut structure of each second mounting base is matched with the corresponding horizontal screw rod; the thin ends and the thick ends of two lower rolling barrels are all respectively mounted on the corresponding second mounting bases. The plate rolling machine disclosed by the invention is simple in structure, stable in structure, high in strength and convenient to use, saves materials, and can fulfill the aim of rapidly rolling plates.

Owner:TENGXIAN SHUNZHOU SHIPBUILDING CO LTD

Scrap bridge recycling machine

The invention discloses a scrap bridge recycling machine, and relates to the technical field of bridge recycling machines. The scrap bridge recycling machine comprises a case. The right side of the case is fixedly connected with a case side cover. A bridge grinding device is arranged in the case and comprises two grinding gears. The rotation of a third bevel gear drives a fourth columnar connecting rod to rotate. The rotation of the fourth columnar connecting rod drives a second bevel gear to rotate. The rotation of the second bevel gear drives a first bevel gear to rotate. The rotation of thefirst bevel gear drives a third columnar connecting rod to rotate. The rotation of the third columnar connecting rod drives a transfer rod to rotate. The rotation of the transfer rod drives a conveying belt to rotate. The rotation of the conveying belt drives the other transfer rods to rotate. The rotation of the conveying belt can convey scrap bridges on the upper surface backwards. By means ofthe conveying belt, the situation that the scrap bridges are conveyed forwards manually is avoided, the purpose of saving manpower is achieved, and more time and efforts are saved.

Owner:王水成

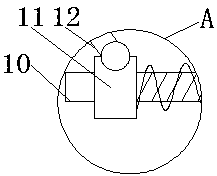

A recovery device for vehicle active airbag airbag

InactiveCN107472181BEasy to operateImprove securityPedestrian/occupant safety arrangementActive safetyEngineering

The invention discloses a recovering device of a vehicle active safety airbag air pocket. The recovering device comprises the safety airbag air pocket, a pulling belt, a shell body, a shaft sleeve, a base, a rolling drum, a clockwork spring and a rolling drum shaft; the upper end of the pulling belt extends into the airbag air pocket and is fixed with the part of the inner end face of the airbag air pocket in a seaming mode; the lower end of puling belt is glued on the rolling drum; one end of the rolling drum shaft is fixed to the central position of the rolling drum; the direction, deviating from rolling drum, of the rolling drum shaft is sleeved with the shaft sleeve, and the shaft sleeve makes contact with the rolling drum; the shaft sleeve is connected with the shell body through a shaft sleeve connecting piece; the rolling drum shaft is positioned through a gasket and a split pin in sequence after penetrating through the shell body; and the top end of the base is fixedly connected with the shaft sleeve, one end of the clockwork spring is inlaid in the shell body, and the other end of the clockwork spring is inlaid in the rolling drum shaft. When the air pocket expands, the air pocket pulls the pulling belt to drive the rolling drum and the rolling drum shaft to rotate, so that the clockwork spring stores the energy; and when the air pocket deflates, the clockwork spring drives the rolling drum and the rolling drum shaft to rotate toward the opposite direction, the pulling belt is recovered, and the air pocket is recovered, and the purpose of repeated using of the air pocket is achieved.

Owner:JIANGSU UNIV

Small film rolling machine used for spacecraft hot test electrical fitting technology

The invention discloses a small-sized film rolling machine used for the thermal test electrical assembly process of spacecraft, which includes a base, a rotating shaft frame, an auxiliary shaft frame, a film rolling roller, a rocker, etc.; wherein, a rolling bearing is arranged on the rotating shaft frame After the rocker passes through the bearing, the variable diameter section is used to ensure close contact with the inner ring of the bearing; a pin hole is provided on the rocker on the side passing through the bearing, and the pin penetrates into the pin hole; a limit groove is provided at one end of the roll film roller When in use, the pin snaps into the limit slot, and the other end of the roll film roller is set on the extension rod of the auxiliary shaft frame; the straight rod is extended from the film fixing bracket fixed on the other end of the base and parallel to the roll film roll, The front end is provided with a 90° elbow, which is used to cover the polyester film sleeve on the straight rod of the film fixing bracket. The invention is designed to be light and simple, can quickly roll the polyester film, and improves the work efficiency of craftsmen.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

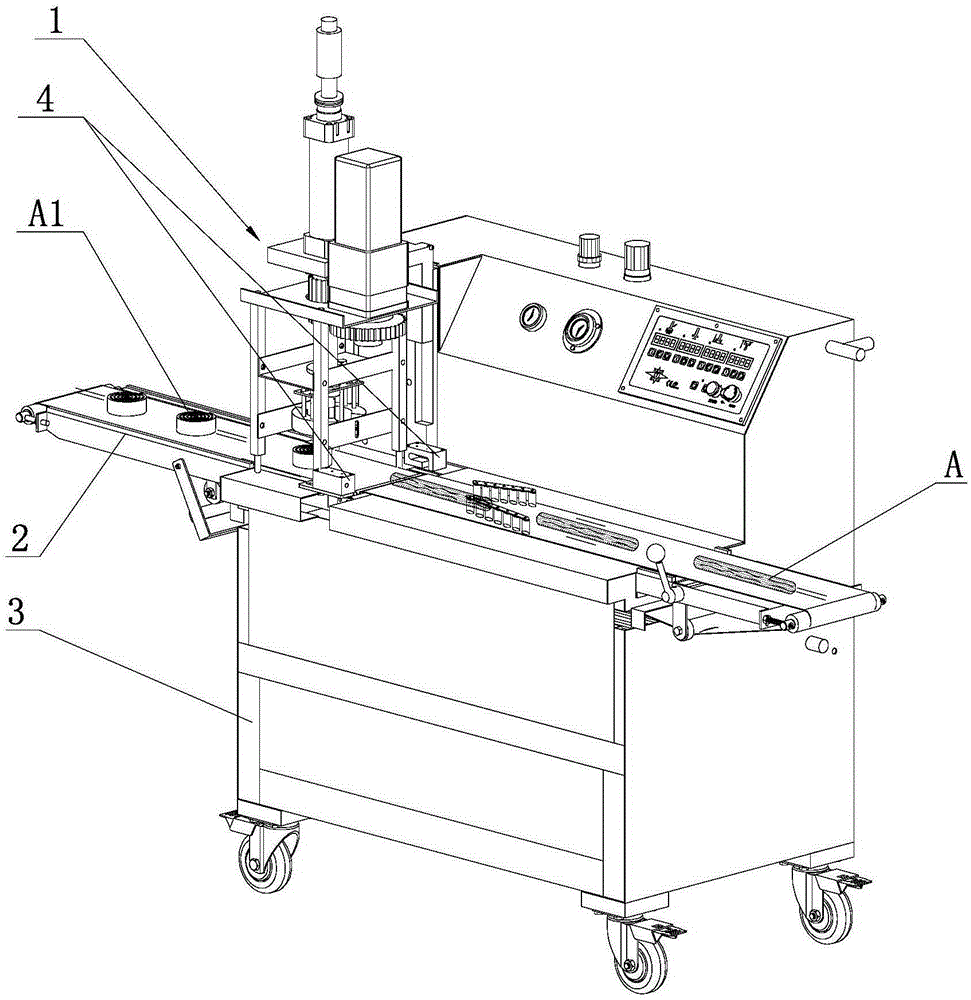

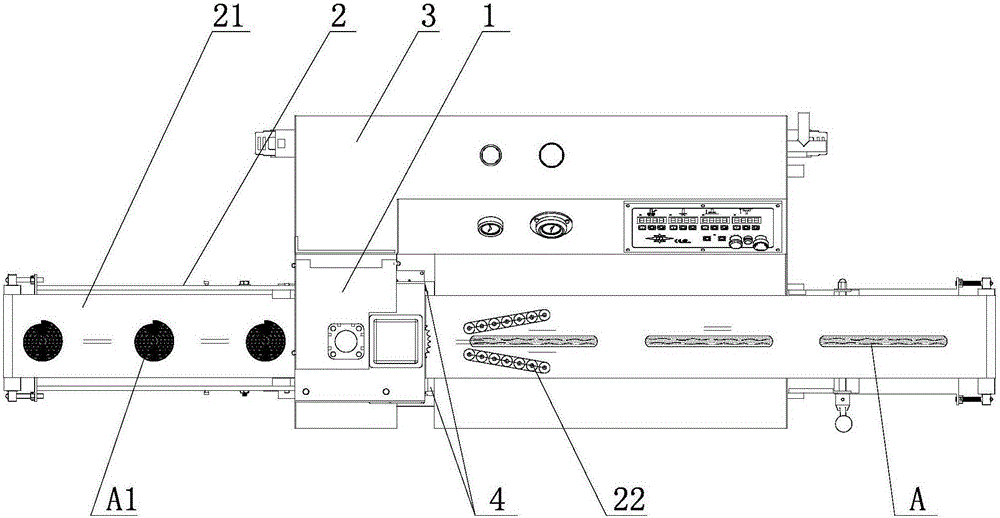

A device and method capable of rolling long stick-shaped dough into circular spiral dough

InactiveCN104186587BAchieve compactionFlexible and preciseDough sheet coiling machinesTransmission beltEngineering

The invention relates to a device and a method for rolling a long-strip rod-like dough into a circularly spiral dough. The motion of an insertion pin head assembly and a die set in a linear direction is achieved by virtue of a cylinder; meanwhile, a servo motor is arranged, and the rotary motion of the insertion pin head assembly is achieved by virtue of a transmission element; the action processes of all mechanisms are accurate and flexible, and an insertion pin of the insertion pin head assembly can be quickly inserted into the long-strip rod-like dough; due to the adoption of the cylinder, a transmission belt, the insertion pin head assembly, the die set and the servo motor, the long-strip rod-like dough is automatically rolled into the circularly spiral dough. The whole rolling process is quick and convenient, the problems of manual operation in the prior art can be fully avoided, the human resource cost of an enterprise is saved and the production efficiency of the enterprise is improved.

Owner:YANG JENQ MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com