Rolling equipment for electric wires

A technology of equipment and wires, which is applied in the field of rolling equipment, can solve the problems of affecting the rolling efficiency, large pieces slipping off users, irregularities, etc., and achieve the effects of improving product quality, fast and uniform rolling, and regular wire coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

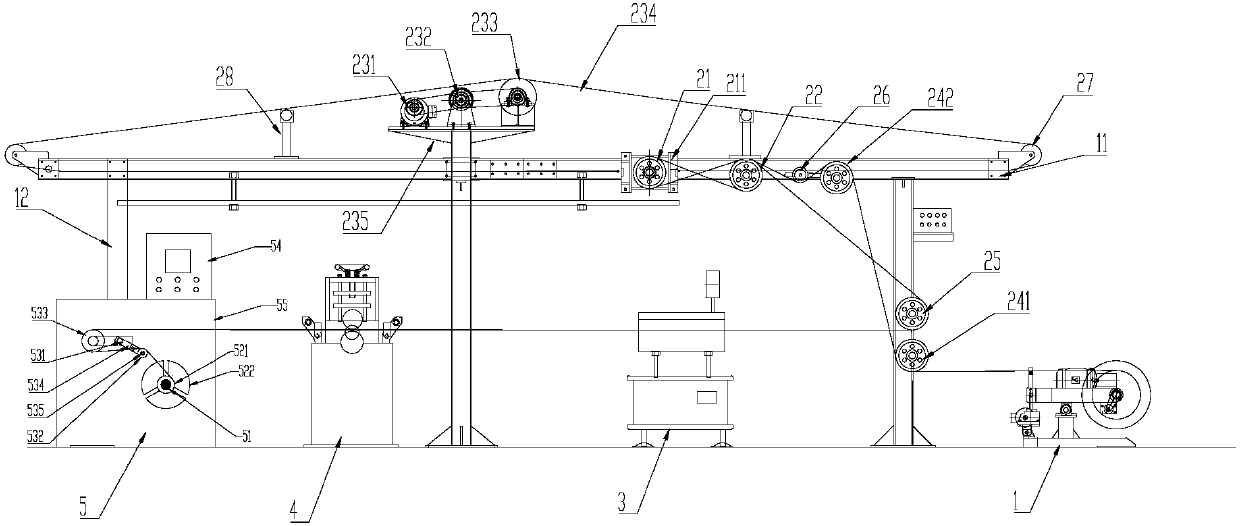

[0030] This embodiment provides a coiling device for electric wires, such as figure 1 As shown, it includes: a frame, a wire storage device, and a coiling device 5 .

[0031] The frame includes cross bars 11 and several columns 12 .

[0032] The wire storage device comprises a movable wire storage wheel group 21, a fixed wire storage wheel group 22, an incoming wire guide wheel group, an outgoing wire guide wheel 25, and a slider driving device; the fixed wire storage wheel group 22 is fixedly installed on the cross bar 11, and the movable storage The wire wheel set 21 is fixedly installed on the slider 211 ; the slider driving device drives the slider 211 to slide on the cross bar 11 .

[0033] The slider drive device is a tension adjustment device, and the tension adjustment device includes a motor 231, a drum 233 driven by the motor, and a steel wire rope 234. The steel wire rope 234 is wound on the drum 233, and the fixed pulley 27 and the sliding pulley at both ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com