Patents

Literature

470results about How to "Improve rolling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

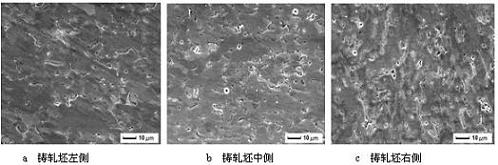

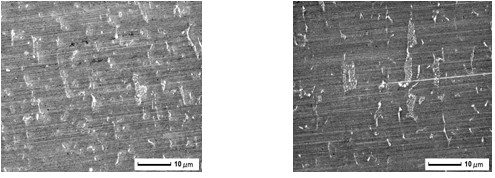

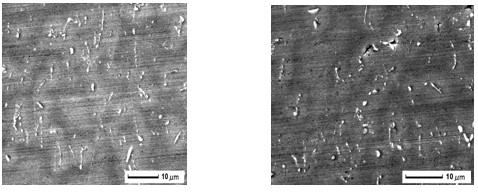

Method for producing wide-amplitude double-zero aluminum foil blank by adopting cast-rolled compact

InactiveCN102492900ASolve the problem of soft tensile propertiesImprove rolling effectMetallurgyCu element

The invention belongs to the technical field of aluminum alloy sheet strip foil material processing, and in particular relates to a method for producing a wide-amplitude double-zero aluminum foil blank by adopting a cast-rolled compact. By adjusting 8079, 1235 and other alloying components and adopting twice intermediate annealing processes, the non-uniform compound scale and distribution, caused by roll cooling intensity difference, of the wide-amplitude cast-rolled compact along the same board plane are eliminated, thus the pinhole degree and performances of the blank foil after rolling are superior to those of 1235; at the same time, through addition of Cu element, the problem of soft tensile property when the wide-amplitude blank is rolled to the double-zero foil after twice annealing is solved; and the rolling performance and foil rolling efficiency of the wide-amplitude blank are improved.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD +1

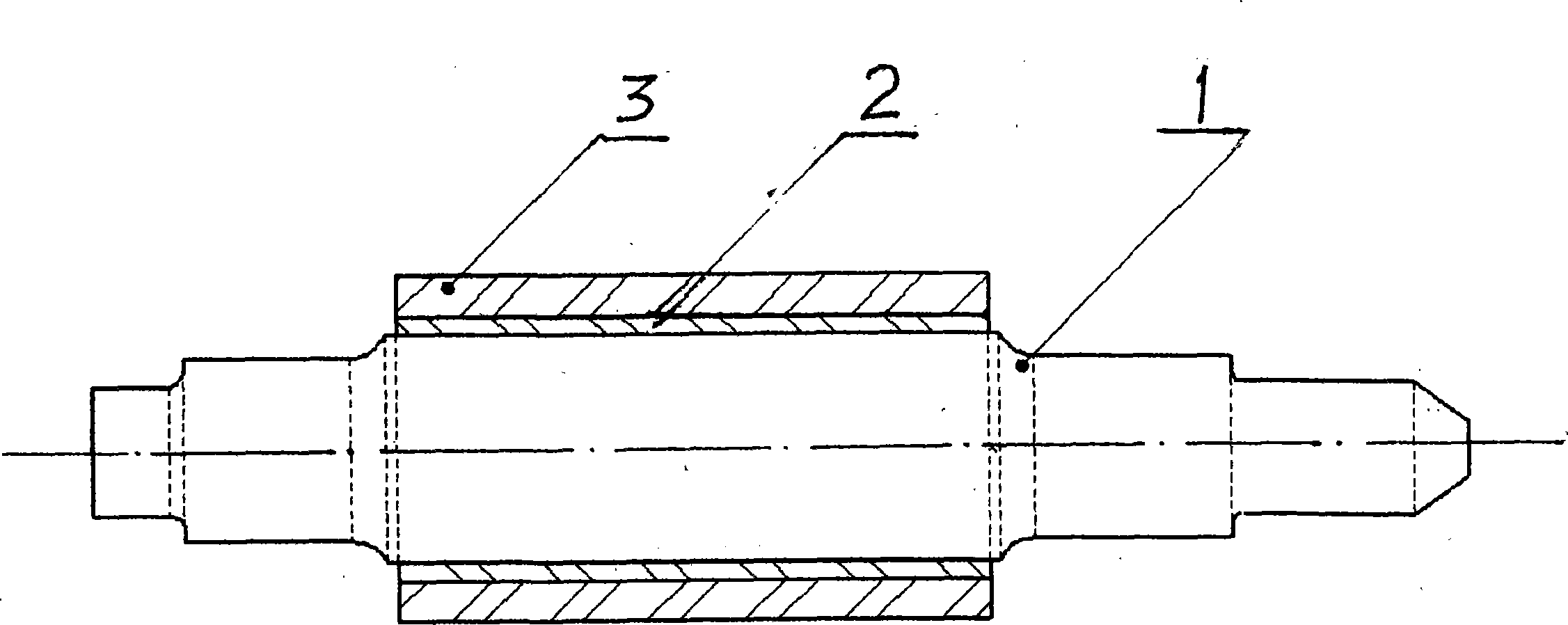

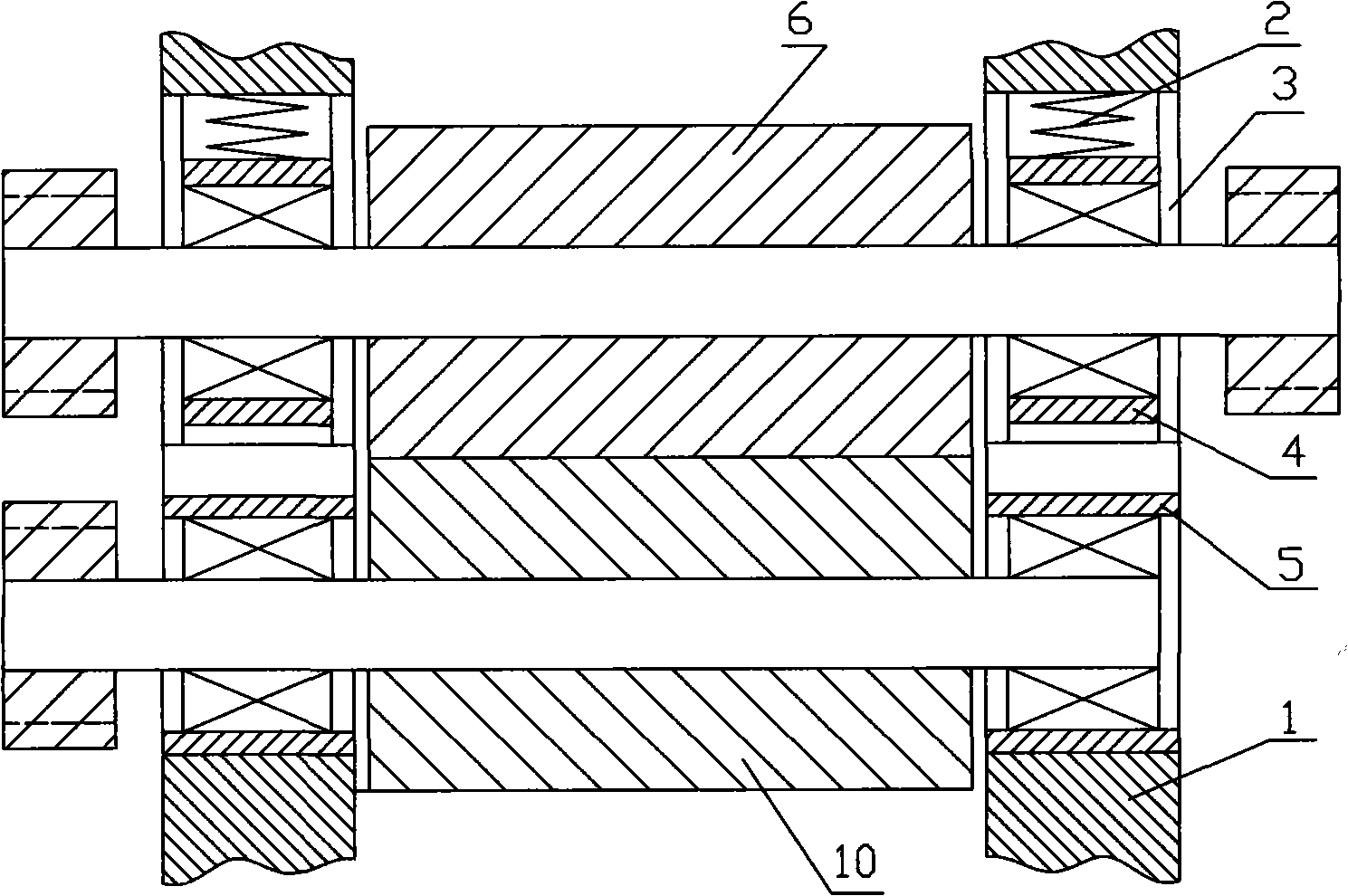

Roll collar roller capable of cyclic utilization and production method

ActiveCN101239359AStable structureImprove securityRollsMetal rolling arrangementsInterference fitIntermediate frequency

The invention discloses a reusable collar roller consisting of a core shaft, an inner ring and an outer ring, and a producing method thereof. A bimetal collar formed by melting the inner ring and the outer ring is disposed at the body part of the core shaft by interference fit. High-speed-steel or high nickel cast iron which is raw material of the outer ring is put into a intermediate frequency stove to be heated and melted to alloy steel fluid with the temperature ranging from 1600 DEG C to 1650 DEG C, the cleaned seamless steel tube or low carbon casting steel tube which is used as the inner ring is preheated to the temperature ranging from 300 DEG C to 800 DEG C, and then is fed into a sand mold, the hyperthermia alloy steel fluid is cast into the sand mold and the casting temperature is held in the range of 1490-1540 DEG C, the inner ring and the outer ring are melt into a bimetal ring during the steel fluid setting process, and the bimetal ring forms a collar roller with the core shaft by interference fit after thermal treatment process. The collar roller is provided with a stable structure and a long life.

Owner:HUNAN 3T NEW MATERIAL

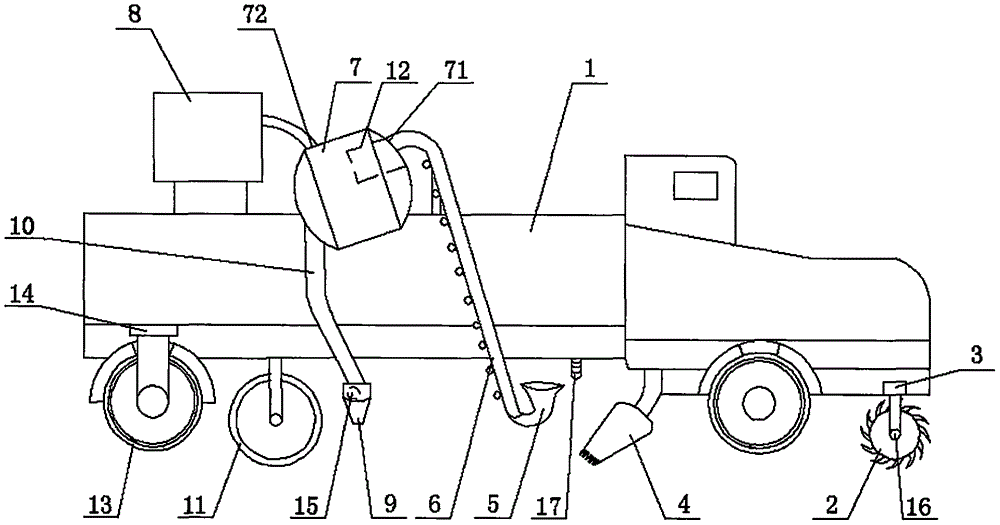

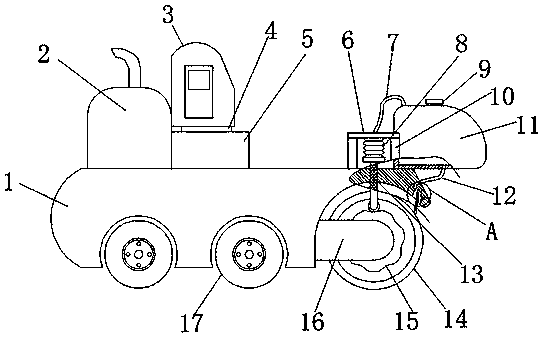

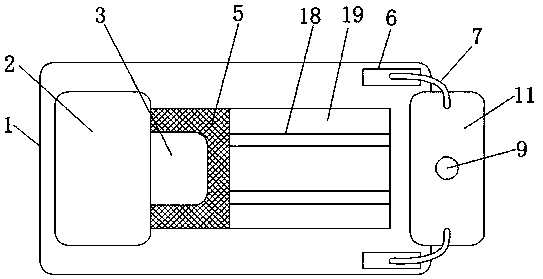

Integrated asphalt road surface planing and milling repair vehicle

ActiveCN105696448AFix issues in a timely mannerImprove maintenance efficiencyRoads maintainenceMechanical shovelButt joint

The invention provides an integrated asphalt road surface planing and milling repair vehicle. The integrated asphalt road surface planing and milling repair vehicle comprises a vehicle body, wherein a planing and milling knife is mounted at the front end of the vehicle body, and is connected with the vehicle body through a first elevating mechanism; a mechanical shovel is mounted at the bottom of the vehicle body and is matched with a hopper which is in butt joint with a feed opening in the bottom end of a conveyor belt, the conveyor belt is obliquely mounted on the vehicle body, and the conveyor belt communicates with a first feed opening of a mixing barrel; the mixing barrel is fixed to the upper part of the vehicle body, an asphalt stirring tank is also mounted at the upper part of the vehicle body, and a discharge opening of the asphalt stirring tank communicates with a second feed opening of the mixing barrel; a discharge spray head is also mounted at the bottom of the vehicle body, and communicates with the discharge opening of the mixing barrel through a feeding pipe; the discharge spray head is positioned behind the hopper, and pinch wheels are mounted at the bottom of the vehicle body behind the discharge spray head. According to the integrated asphalt road surface planing and milling repair vehicle disclosed by the invention, the problem of timely repair of damaged asphalt road surfaces and the problem of treatment of old asphalt layer scraps are solved, the quantity of equipment for repairing road surfaces is reduced, and newly paved road surfaces cannot be influenced.

Owner:薛金波

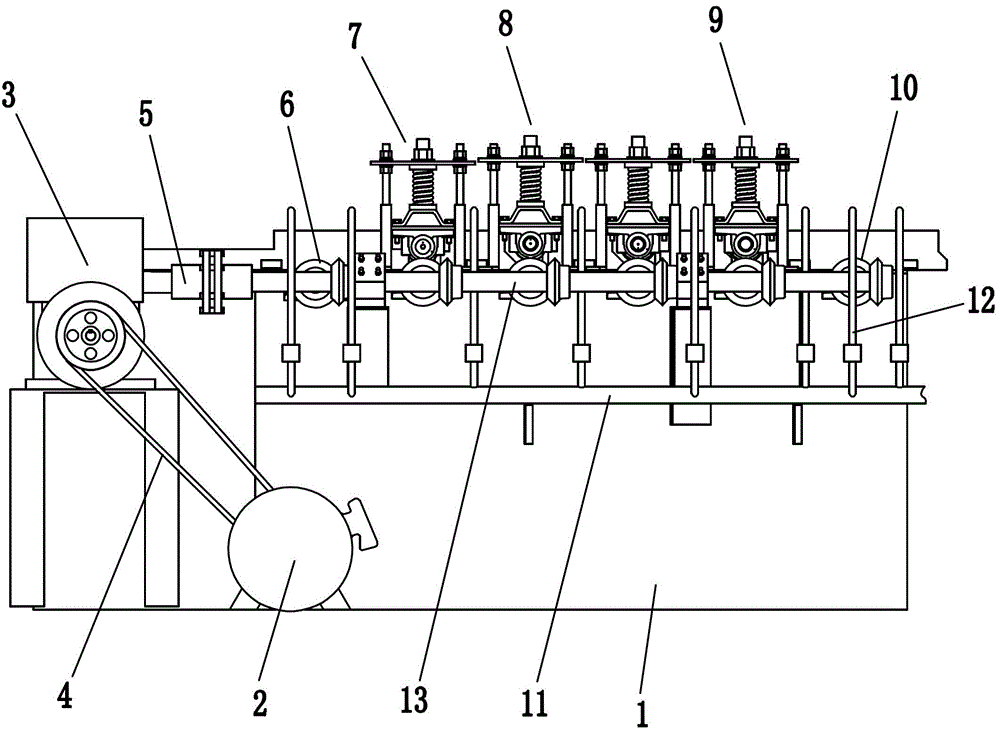

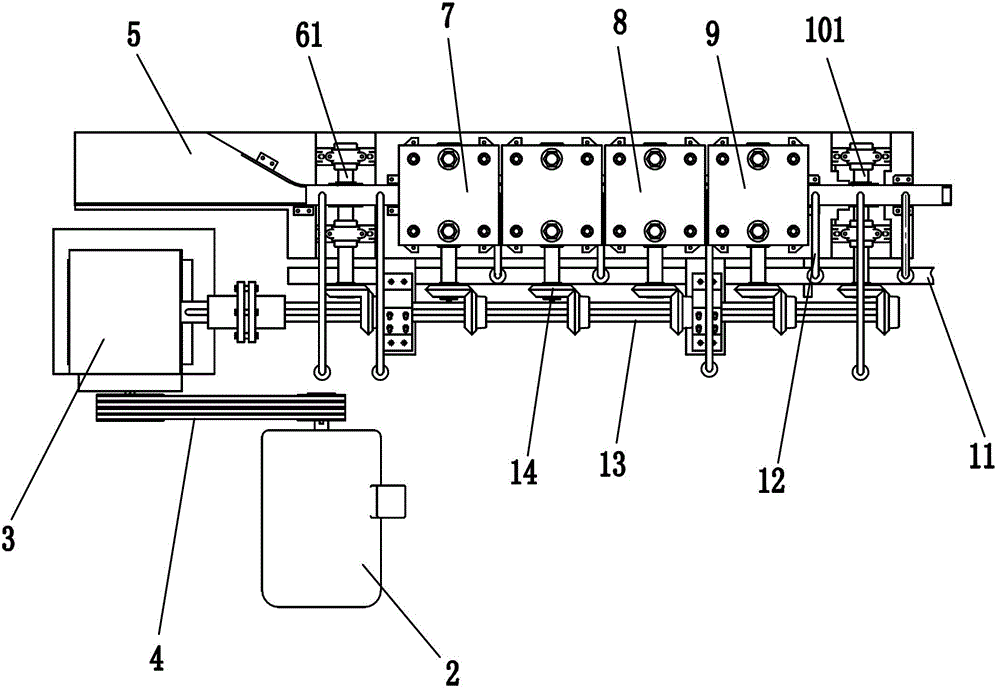

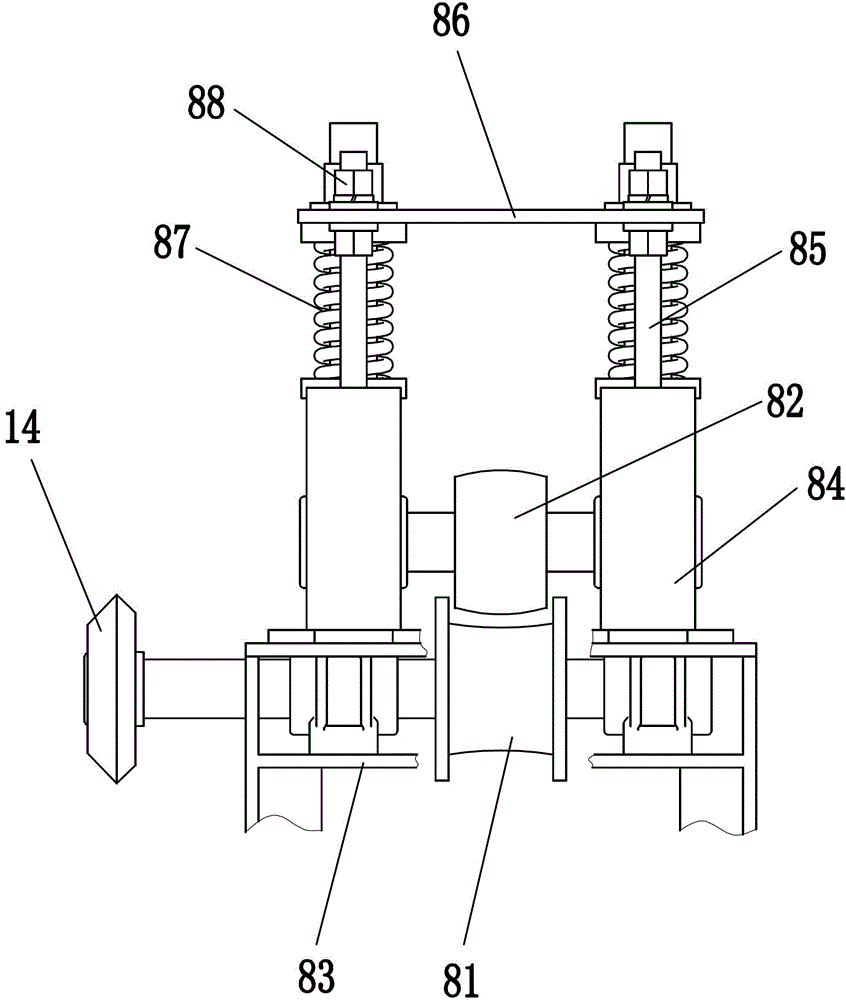

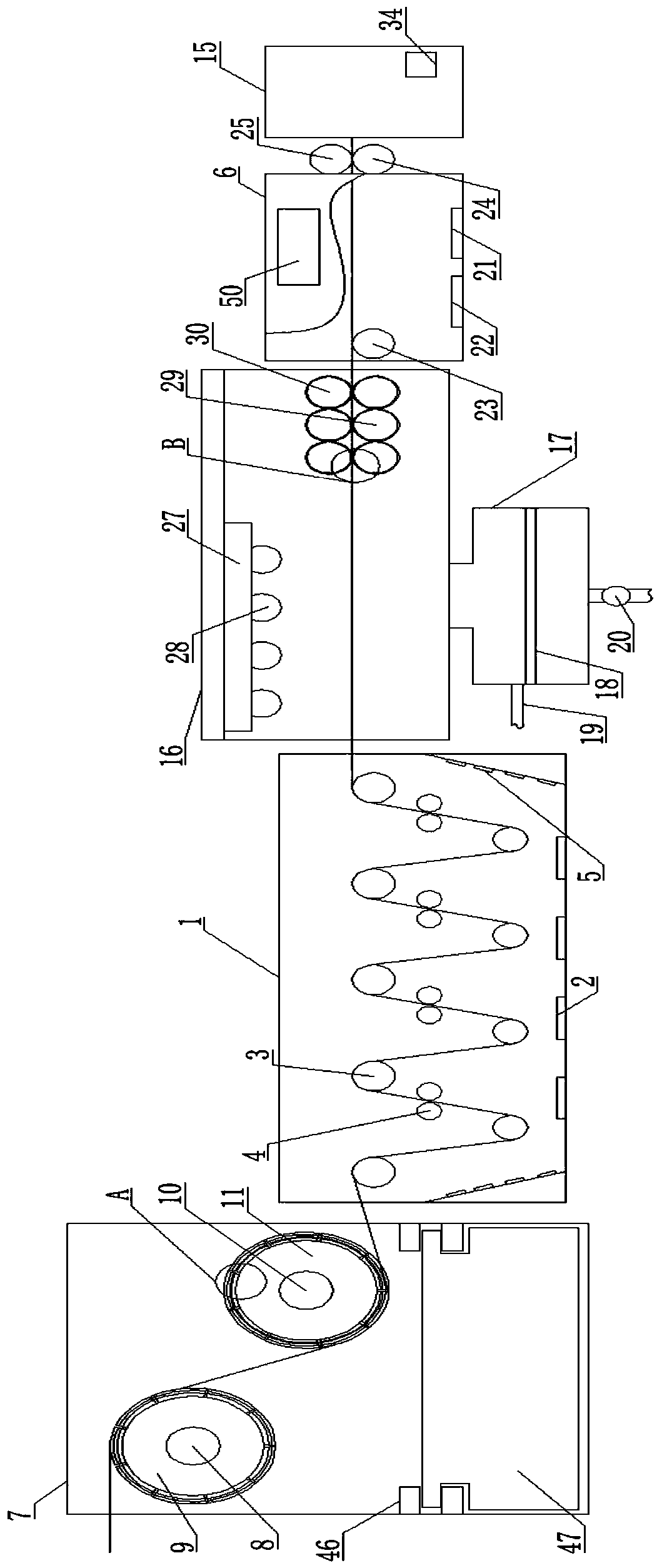

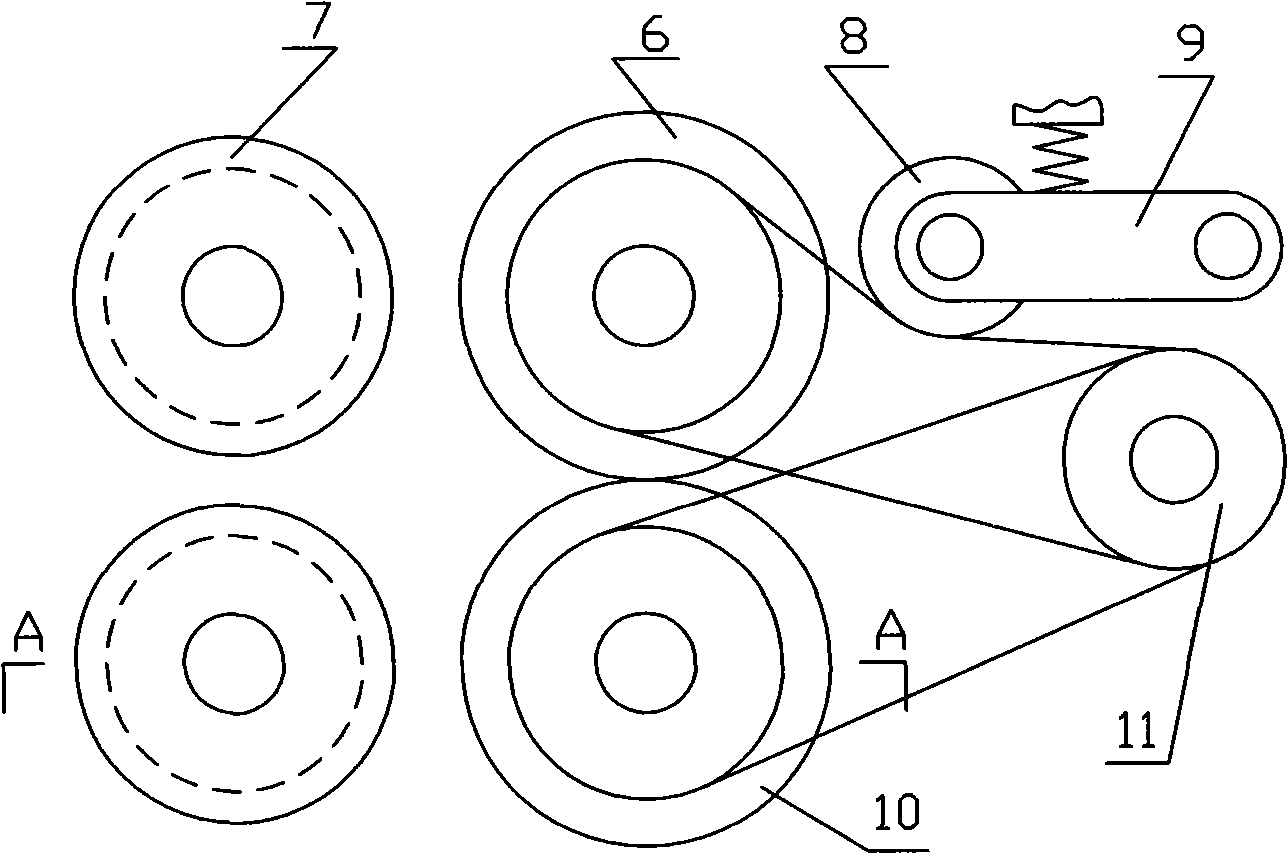

Continuous processing device for bamboo filament bundle

InactiveCN103331794ARolling effect is goodImprove efficiencyWood working apparatusContinuous productionEngineering

The invention relates to a processing device for bamboo wood, in particular to a continuous processing device for a bamboo filament bundle. The continuous processing device for the bamboo filament bundle comprises a rack, a motor and a reducer, wherein a feed groove, at least one grinding roll mechanism and a blanking groove are sequentially arrayed on the rack from one end close to a charging groove; the feed groove comprises a feed conveying roll; the grinding roll mechanism comprises a driving roll and a driven compression roll with pretightening force; the diameter of a section of the driving roll ascends uniformly from the middle part to the two ends; the shape of the external surface of the driven compression roll is matched with that of the external surface of the driving roll; the blanking groove comprises a feed output roll with the same structure as the feed conveying roll; a steam conveying pipe is horizontally arranged below the feed groove, the grinding roll mechanism and the blanking groove; and a plurality of steam spray pipes which are arranged at intervals and used for heating bamboos are connected with the steam conveying pipe. The continuous processing device has the benefits that the continuous processing device can process and separate the bamboo wood into the bamboo filament bundle, can be continuously produced, and can effectively prevent the bamboo wood from rupture.

Owner:ZHEJIANG FORESTRY UNIVERSITY

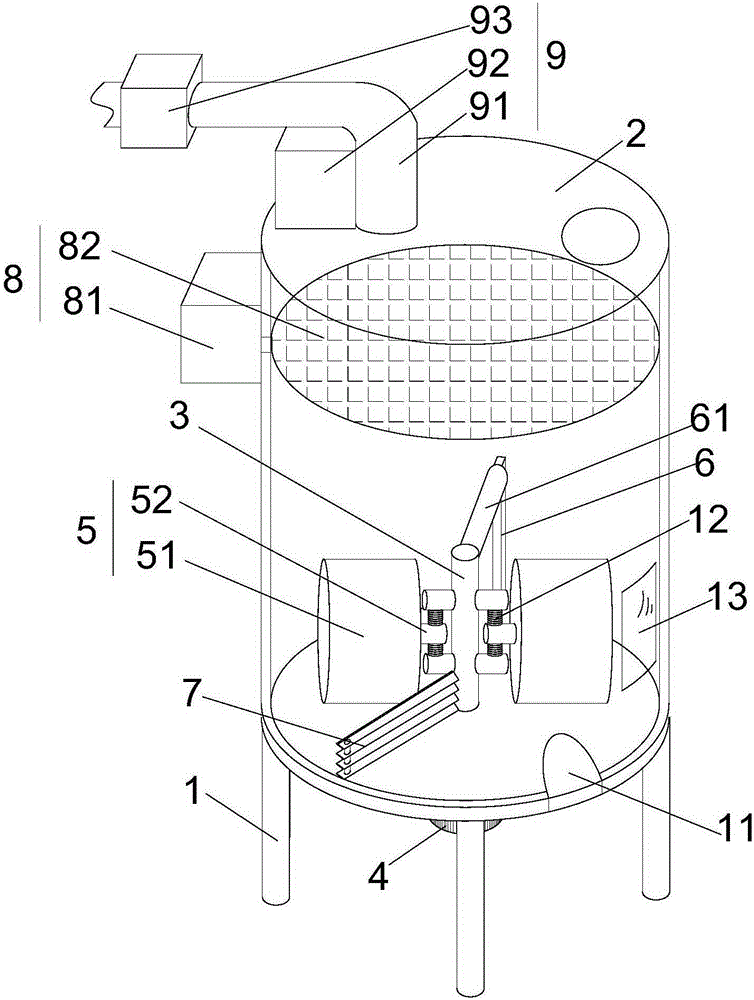

Grape juice extractor

InactiveCN105077520AIncrease contact areaPress the juice thoroughlyJuice extractionGrape wineEngineering

The invention relates to mechanical grape crushing and processing equipment, in particular to a grape juice extractor for grade seed and peel removal. The grape juice extractor for grade seed and peel removal comprises a circular truncated cone shaped grinding box, wherein a circular truncated cone shaped grinding disc matched with the grinding box is arranged in the grinding box, grinding teeth are arranged on the side face of the grinding disc, an axial rotary shaft and a motor are arranged in the grinding disc, and an output shaft of the motor is connected with the rotary shaft. An inlet is formed in the top end of the grinding box, a filtering mechanism is arranged at the bottom end of the grinding box and comprises a filter screen and a stirring ball for stirring grape pomace on the filter screen, the stirring ball is connected with the bottom of the rotary shaft, the filter screen is inverted-cone-shaped, and the top of the filter screen is connected with the bottom end of the grinding box. A conveying trough for receiving juice is arranged under the filter screen. The grape juice extractor makes grape juice in a mechanical way, is high in production efficiency and thorough in juice extraction, is not in contact with the outside in the whole process, is clean and hygienic and is suitable for popularization and application in grape juice production and wine production.

Owner:重庆龙佰绪生态农业开发集团有限公司

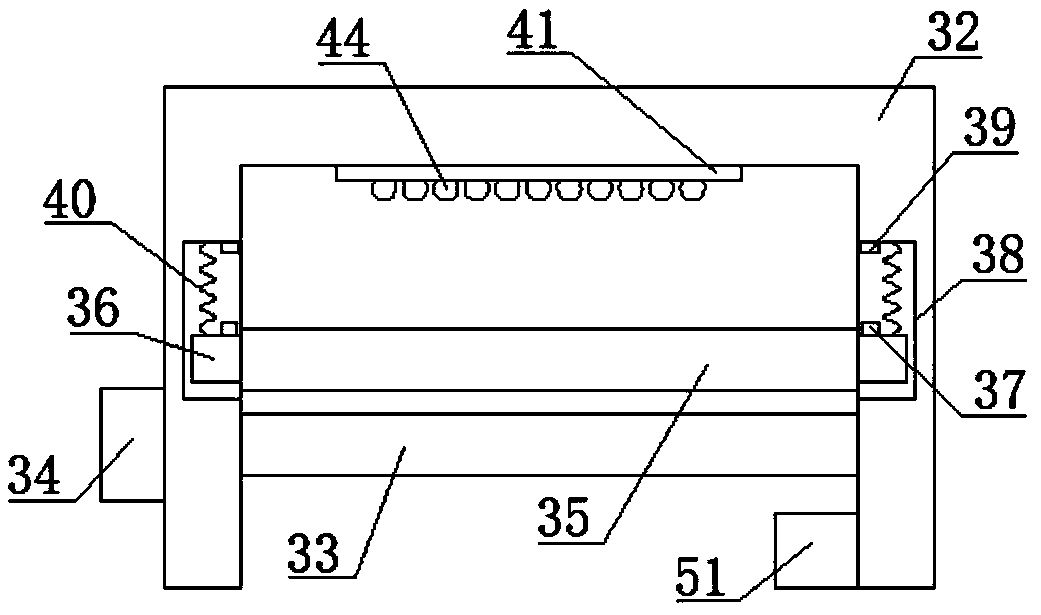

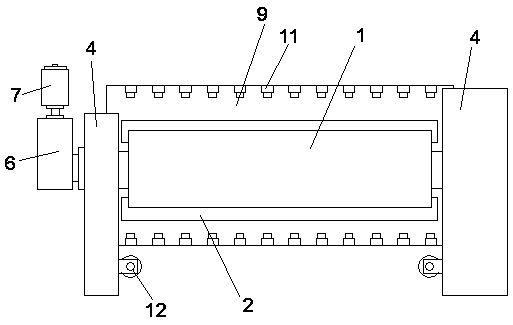

Integrated efficient dyeing and finishing device for textile fabric

InactiveCN109355838AGuaranteed liquidityGuaranteed uniformityMechanical cleaningLiquid/gas/vapor treatment machines driving mechanismsEnvironmental resistanceBristle

The invention discloses an integrated efficient dyeing and finishing device for textile fabric. The device comprises a fixation dyeing box, and multiple vibration plates, rolling shafts, brushing rollers and heating strips are installed in the fixation dyeing box; a drying box is arranged at one side of the fixation dyeing box, and a dust removal box is arranged at the outer side of the fixation dyeing box; a first dust removal roller and a second removal roller are arranged in the dust removal box; multiple arc static plates are both installed on the outer surface of the first dust removal roller and the outer surface of the second dust removal roller, and an arc brushing plate is arranged between each arc static plate and the second dust removal roller or between each arc static plate and the first dust removal roller; multiple evenly-distributed carding bristles are arranged on each arc brushing plate; a rolling device is connected to one side of the drying box, and a rinsing box isconnected to the outer side of the drying box; a dye filter box is connected to the lower portion of the rinsing box, and a filter screen, a return pipe and a water pump are arranged on the dye filter box. The integrated efficient dyeing and finishing device for the textile fabric has the advantages that the dyeing quality and working efficiency can be improved, dyeing is even, the utilization rate of dye is high, the environment is protected, the drying speed is high, sterilization is achieved, the cloth rolling effect is good, and the device is convenient to clean.

Owner:湖州市菱湖石淙兴吴绸厂

Magnesium alloy sheet with low Gd content and high ductility and malleability, and hot rolling technology thereof

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

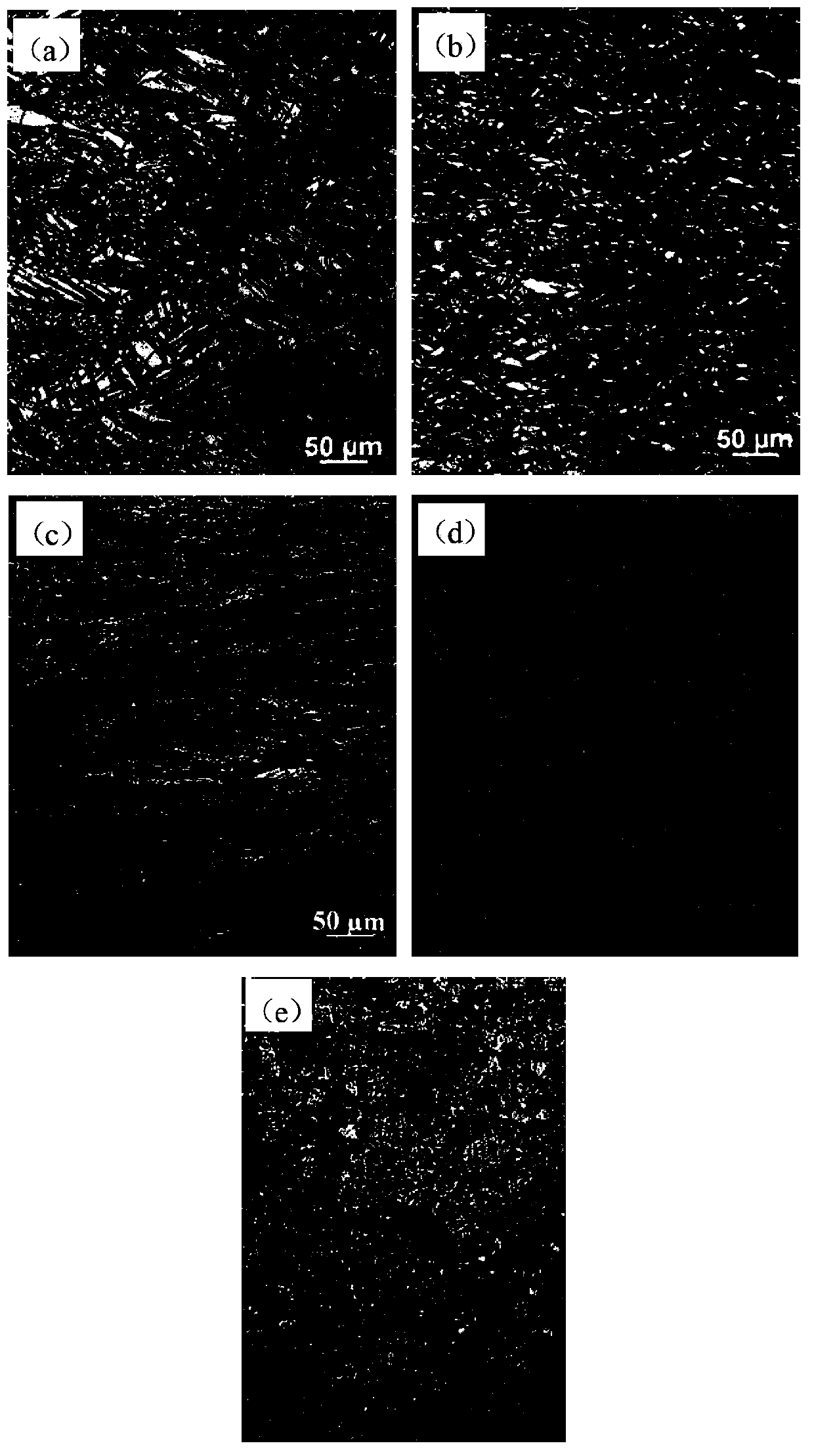

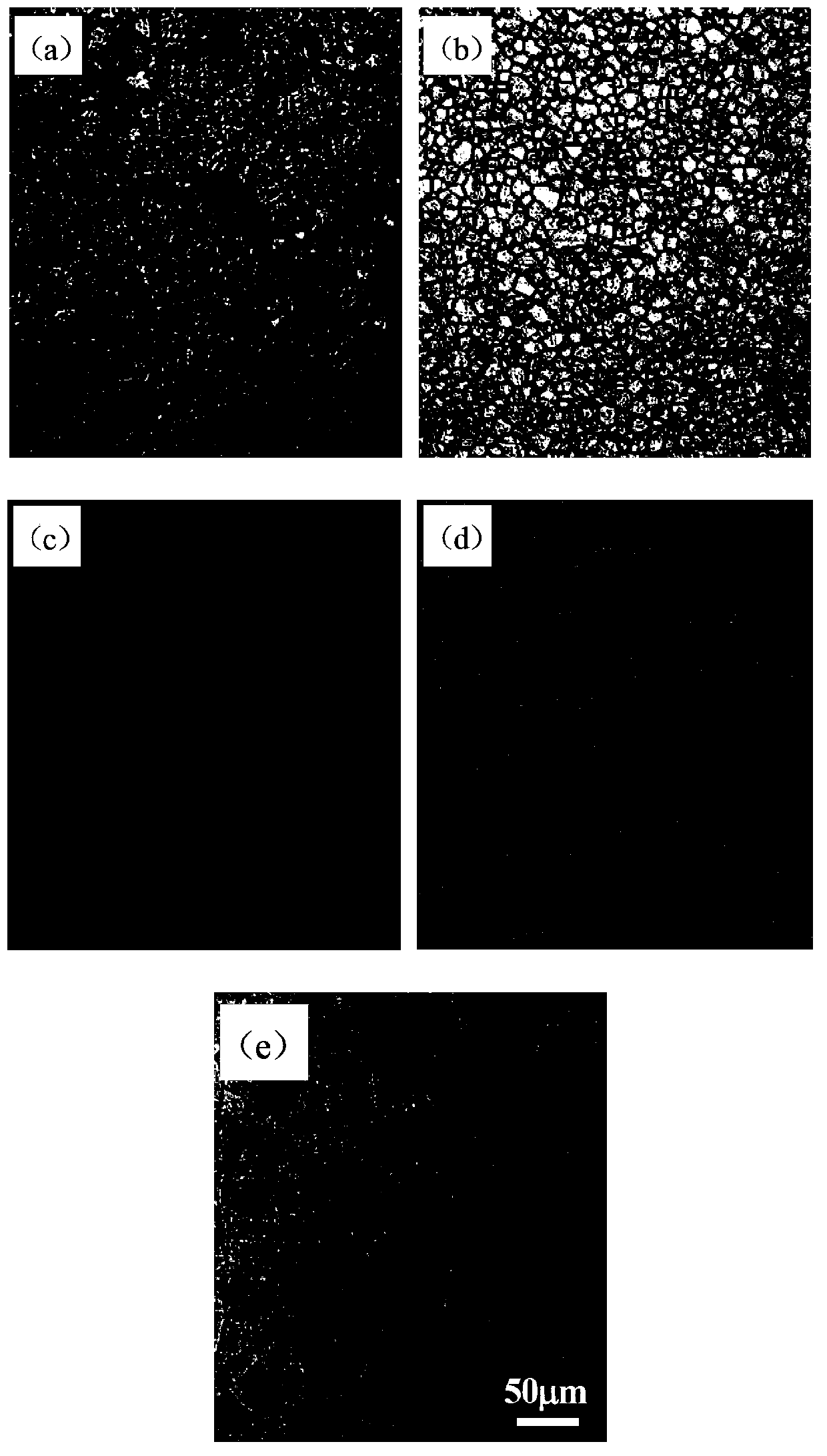

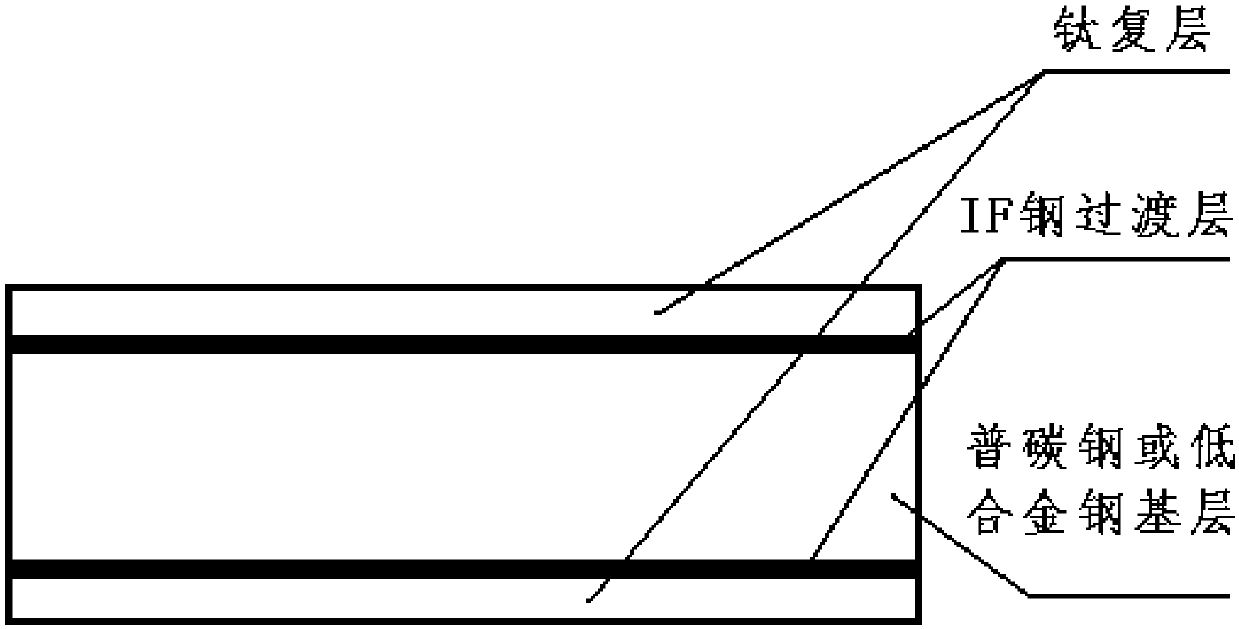

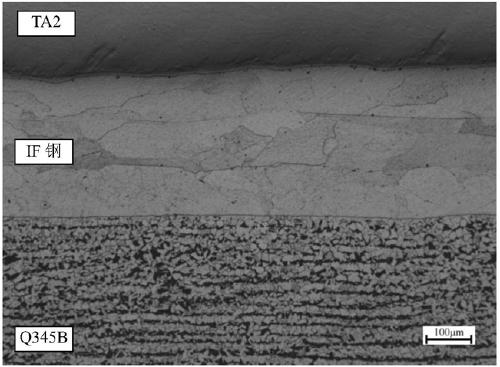

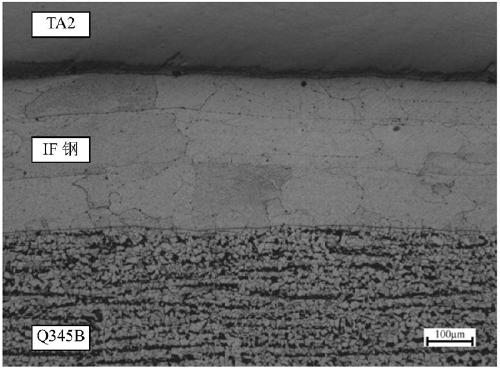

Double-sided titanium steel composite plate taking IF steel as transition layer and high-temperature preparation method thereof

ActiveCN109695000AImprove distributionImprove and enhance bond qualityMetal layered productsComposite plateMechanical property

The invention discloses a double-sided titanium steel composite plate taking IF steel as a transition layer and a high-temperature preparation method thereof. A composite blank for preparing the composite plate comprises a base material, the IF steel and a titanium composite material, wherein the base material is plain carbon steel or low alloy steel with C less than or equal to 0.22%, the titanium composite material is industrial pure titanium TA2, the thickness ratio of the base material to the titanium composite material is 5-10, the length and width of the titanium composite material are smaller than those of the base material, and the margin between the titanium composite material and four sides of the base material is 60-100 mm; and the vacuum welded composite blank is heated to 1040-1060 EDG C for heat preservation, the heat preservation time is 1 min / mm * the total thickness of the composite blank, the initial rolling temperature is 1020-1040 DEG C, the single-pass reduction rate is 15%-25%, the total reduction rate is greater than or equal to 70%, the finish rolling temperature is greater than or equal to 850 DEG C, air cooling is carried out to a room temperature, the thickness of the rolled IF steel transition layer is 280-320 [mu]m, and the double-sided titanium steel composite plate with the thickness of 6-75 mm is obtained after plate splitting, and excellent corrosion resistance and mechanical properties are achieved.

Owner:ANGANG STEEL CO LTD

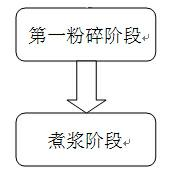

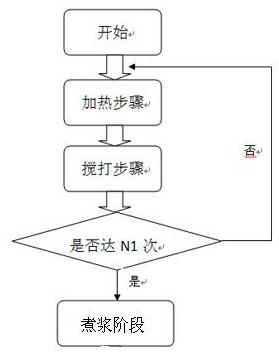

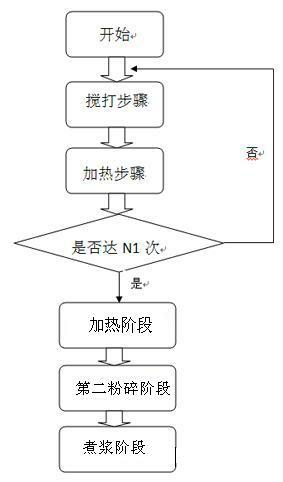

Originally ground soybean milk preparation method of soybean milk grinder and soybean milk grinder for preparing originally ground soybean milk

InactiveCN102144889ANot easy to burnImprove homogeneityBeverage vesselsMilk substitutesFlavorLiquid temperature

The invention relates to an originally ground soybean milk preparation method of a soybean milk grinder, which comprises: (a) a first grinding stage and (b) a boiling stage, wherein in the first grinding stage, materials for preparing soybean milk are ground by a grinding blade under the driving of an electric motor of the soybean milk grinder, and the liquid temperature during the first grinding stage is not more than 70 DEG C; and in the boiling stage, the soybean milk is heated by a heating component of the soybean milk grinder until the soybean milk is boiled up, and the heating component is used for persistently or interruptedly heating the materials in a cup during the first grinding stage. The soybean milk prepared according to the soybean milk preparation method has bean flavor and better mouthfeel.

Owner:JOYOUNG CO LTD

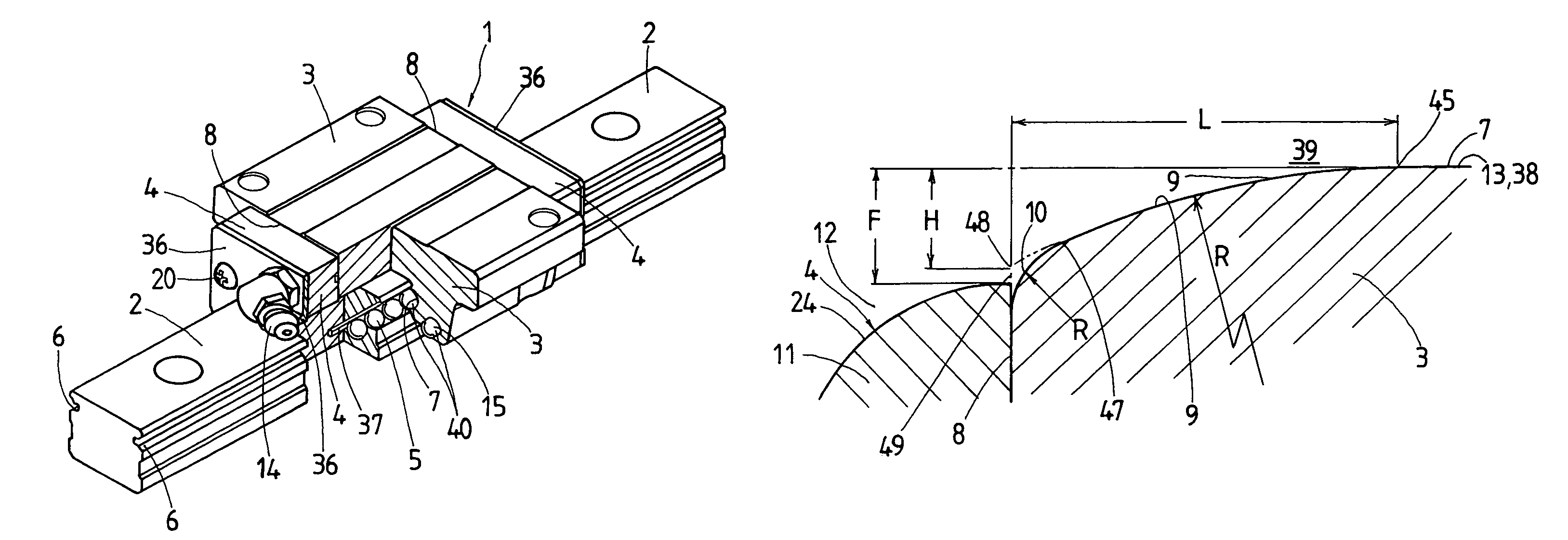

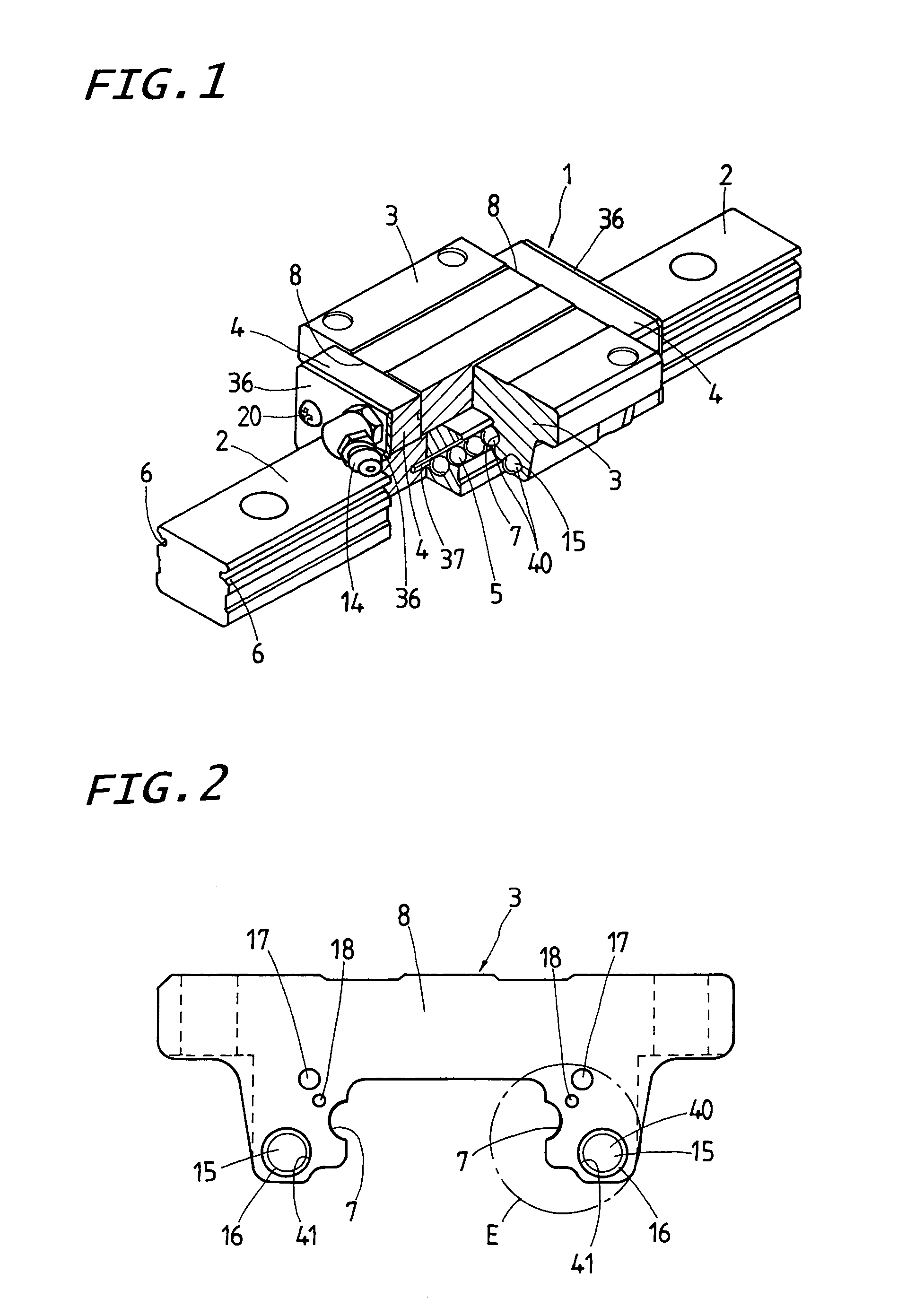

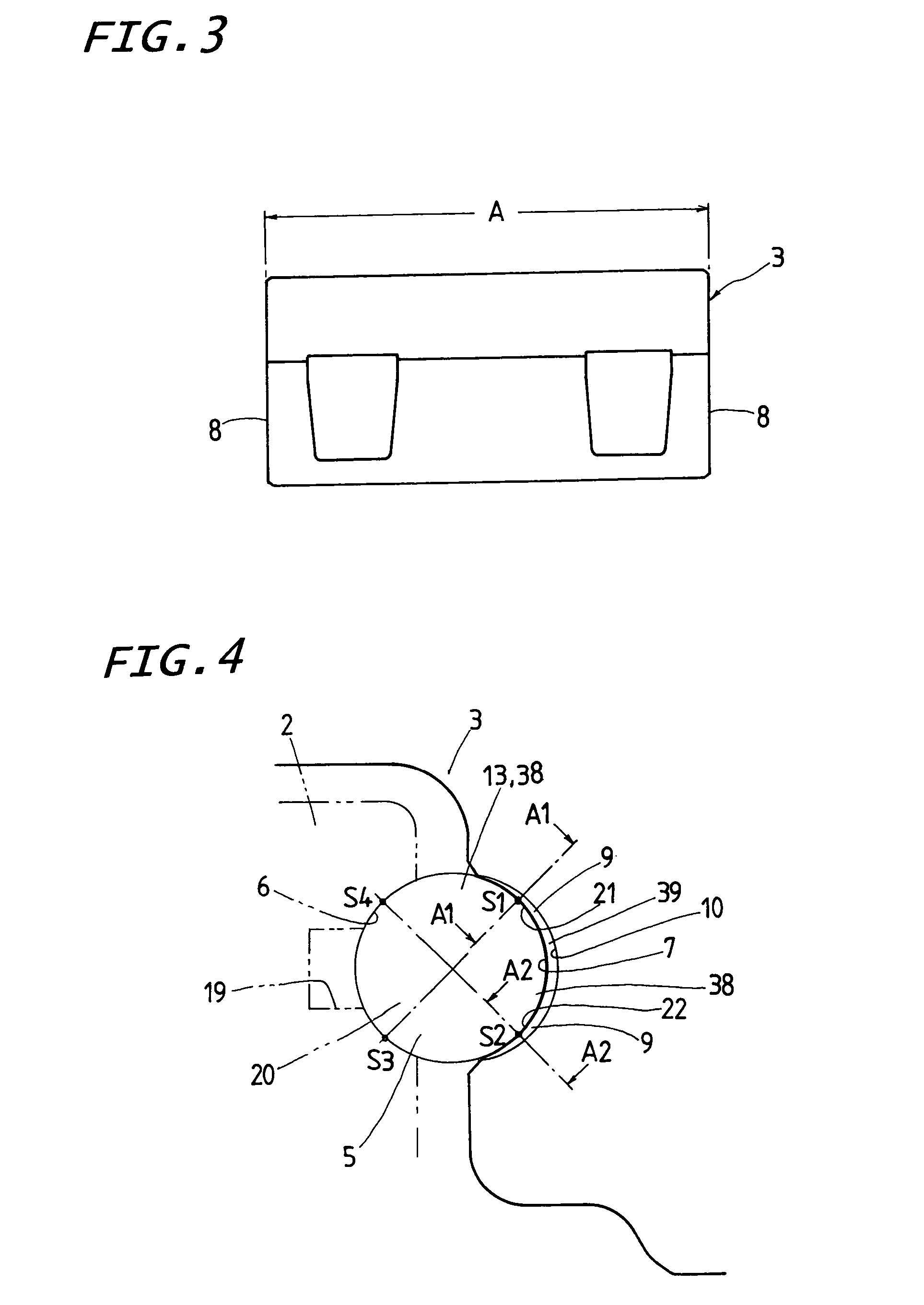

Linear motion guide unit

ActiveUS7677804B2Effectively complyRaising traveling accuracy and durabilityLinear bearingsLinear motionEngineering

A linear motion guide unit is provided in which a crowning portion available extensively for standard specification is made easily. The crowning portion is comparatively small in depth, and rich in high accuracy and high durability. A raceway groove for a load race in a carriage is made at an ingress / egress area thereof with the crowning portion of a curved profile that varies gently to allow the rolling element to move in and out of the load race with smoothness. The carriage is provided at the forward and aft ends of the raceway groove with rounded bevels, which are made in a curved contour merging into the associated crowning portion without causing any discontinuity at a junction of the rounded bevel with the crowning portion.

Owner:NIPPON THOMPSON

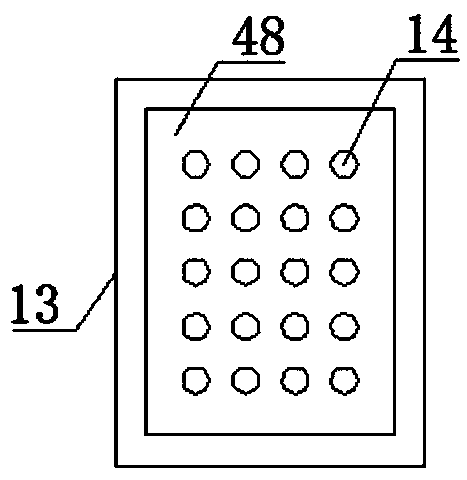

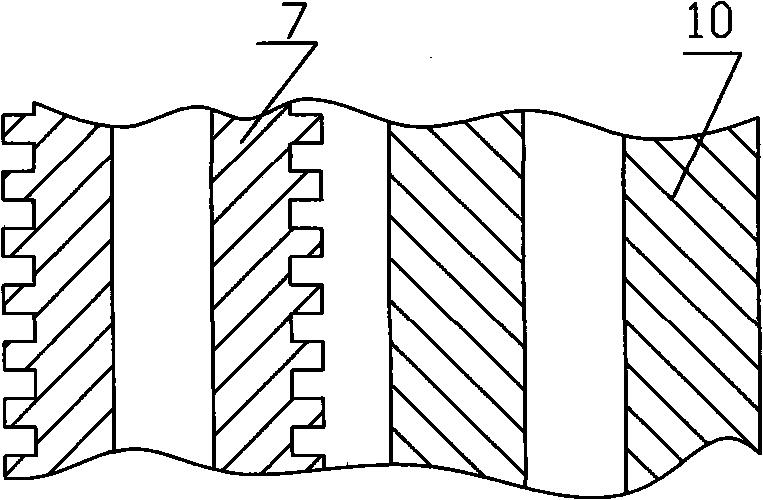

Bamboo fiber grinding device

InactiveCN101491911AFine internal spaceSmall internal spaceWood working apparatusFiber bundleReduction drive

The invention relates to a bamboo fiber roller, which relates to a bamboo product processing machine, and is characterized in that: the profiles of rolls are of a cylindrical surface shape instead of a tooth shape, the bearing seat of a lower roll is fixed on a machine frame, the bearing seat of an upper roll is matched with and arranged on slide rails which are arranged on the machine frame, the bearing seats are fixed with pressure springs, a transmission mechanism comprises the transmission between an output wheel arranged on the output shaft of a reducer and chain wheels or belt wheels, with a fixed center distance, of the lower roll and the transmission between the output wheel arranged on the output shaft of the reducer and the chain wheels or belt wheels of the upper roll, and a tension pulley is arranged between each two chain wheels or belt wheels. The roller has the advantage that bamboo bundle pieces rolled by tooth-shaped rolls are rolled by cylinder rolls and the blocky objects of blocky bamboo bundles are broken by the roller into bamboo fiber bundles having loose, thinner and softer unit fibers. During the press forming of plates, the smaller the clearance leads to better penetrability of gum. Due to the action of the pressure elastic bearing seats, thicker bamboo chip leads to higher pressure and better rolling effect.

Owner:杨明杰 +1

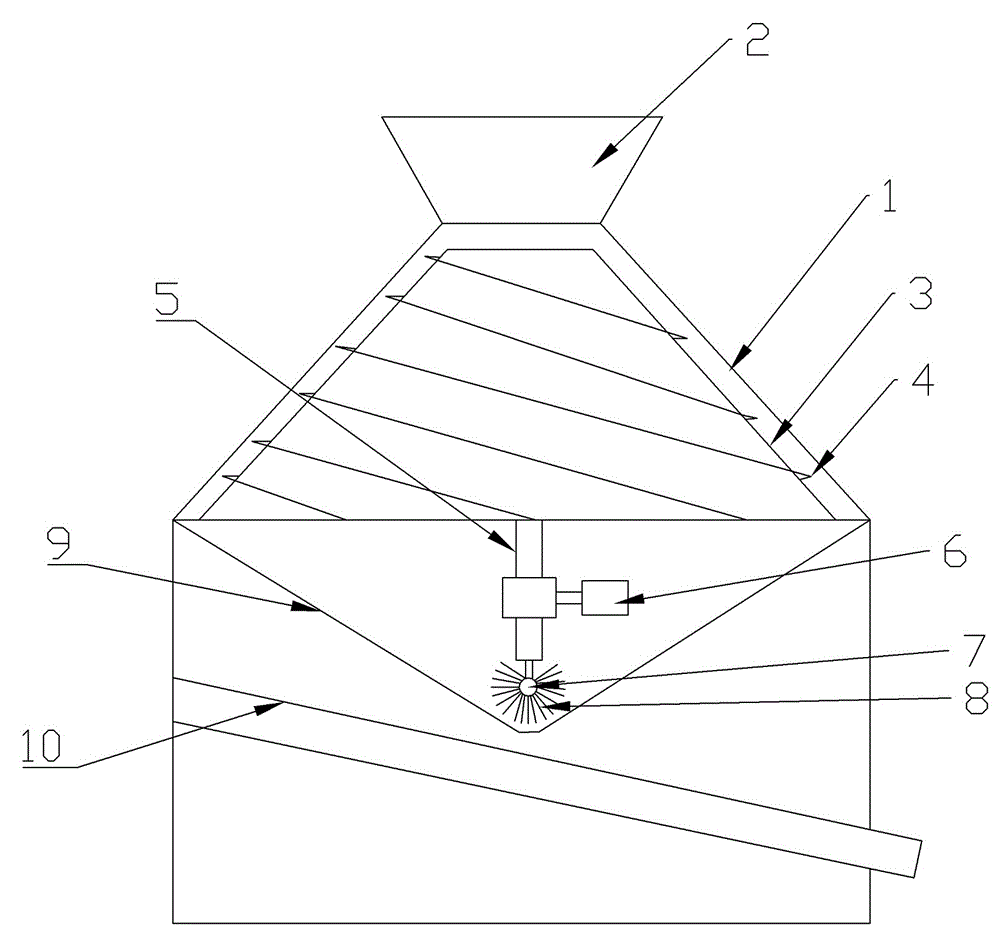

Sand grinding equipment

InactiveCN105170895AIncrease the amount of rollingAvoid accumulationMould handling/dressing devicesEngineeringMechanical engineering

The invention discloses sand grinding equipment. The sand grinding equipment comprises a support, a grinding box, a first rotating shaft, a driving device and at least one grinding roller, wherein the grinding box is mounted on the support; a feed port is formed in the upper part of the grinding box; a discharge port is formed in the lower part of the grinding box; a discharge door is detachably mounted in the position corresponding to the discharge port of the grinding box; the first rotating shaft is rotationally mounted in the grinding box; the driving device is connected with the first rotating shaft and drives the first rotating shaft to rotate; each grinding roller comprises a main grinding roller body and a second rotating shaft, the main grinding roller body is rotationally mounted on the second rotating shaft, the second rotating shaft is mounted on the first rotating shaft through an elastic piece, and the second rotating shaft and the first rotating shaft are perpendicular to each other in the axial direction. According to the sand grinding equipment, the grinding quantity of materials each time can be increased, and the grinding effect of the materials can be guaranteed effectively.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

High-efficiency crushing grinder for food processing

InactiveCN110976039AEasy to cutEasy to crushBone-shears/bone-crushersGrain treatmentsGrinding millEngineering

The invention discloses a high-efficiency crushing grinder for food processing. The high-efficiency crushing grinder for food processing comprises a crushing box, a crushing mechanism, a conveying mechanism, a smashing box, a smashing mechanism, a rocker mechanism, a grinding mechanism and a grinding table. According to the high-efficiency crushing grinder for food processing, the treated bone isput into the crushing box, a pressing plate and a cutting knife intermittently reciprocate up and down through a cam assembly, a crushing assembly and a cutting assembly are mutually matched, the crushing assembly gradually crushes the bone more conveniently for cutting, meanwhile, the surface structure of the bone is damaged through cutting, even the bone is chopped into one segment, and the boneis more conveniently crushed; and after crushing, the crushed bone residues is conveyed to the smashing box through a discharging mechanism and a conveying mechanism, the crushed bone residues is further smashed through two crushing rollers, the intermittent discharging is realized through the action of a rotating shaft and a partition plate, the smashed bone residues falls to the middle of the grinding area on the grinding table through a second feeding port, and grinding is repeatedly carried out through the rocker mechanism and the grinding mechanism.

Owner:安徽华芯智能科技有限公司

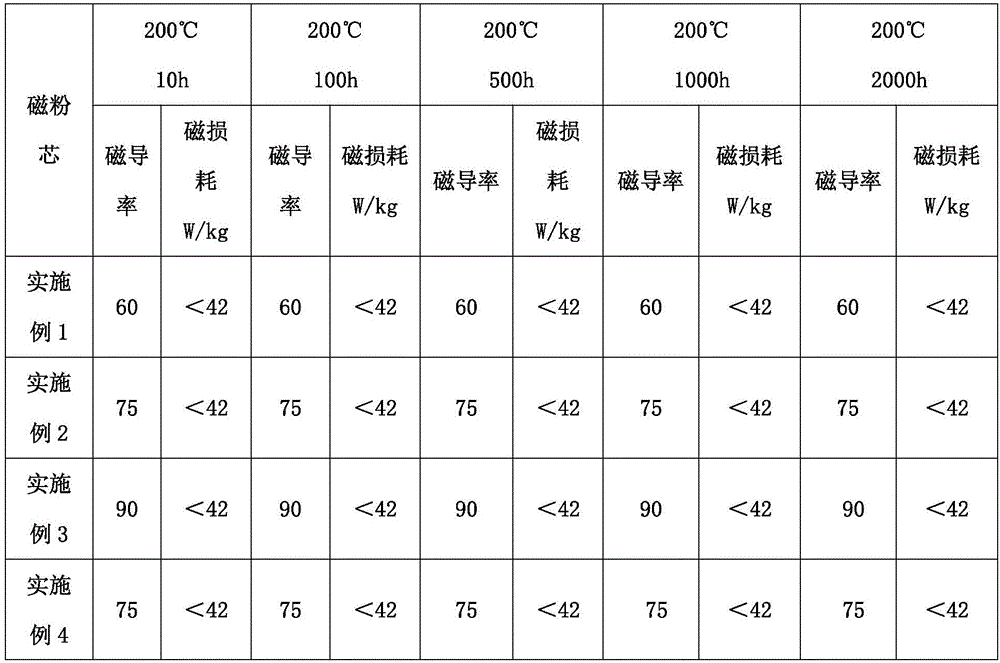

Amorphous soft magnetic composite magnetic powder core and preparation method thereof

ActiveCN106205935AGood calenderabilityExcellent magnetic propertiesTransportation and packagingMetal-working apparatusMagnetic powderPrecursor polymer

The invention belongs to the field of a metal-based soft magnetic composite material. A preparation method comprises the following steps of preparing amorphous alloy powder from an amorphous alloy thin strip; screening and compounding the amorphous alloy powder to obtain a first product; performing passivation and coupling processing on the first product to obtain a second product; mixing and stirring the second product and a ceramic precursor polymer solution to obtain composite amorphous powder; and performing formation, thermal processing and insulation layer coating on the composite amorphous powder to obtain amorphous soft magnetic composite magnetic powder. By adopting a ceramic precursor polymer as an insulation binding agent, the step of adding insulation agent powder is omitted, the problems of unstable magnetic conductivity and poor thermal stability during traditional preparation of the magnetic powder core by crashing the amorphous thin strip are solved, the production cost is reduced, and the amorphous soft magnetic composite magnetic powder can be applied to a certain electronic device with application requirements for high frequency and low loss.

Owner:张听

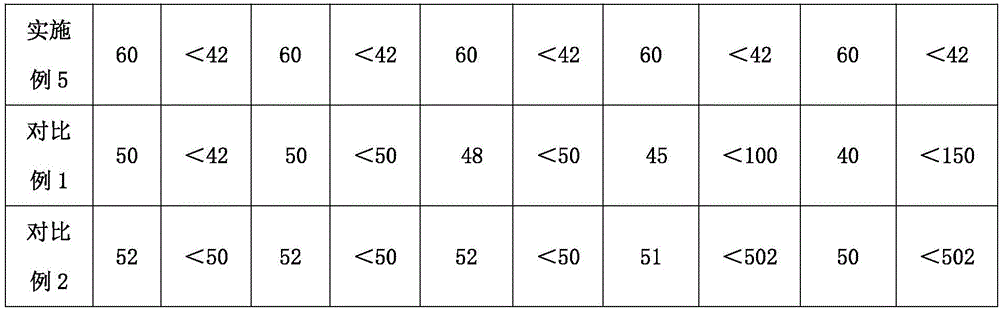

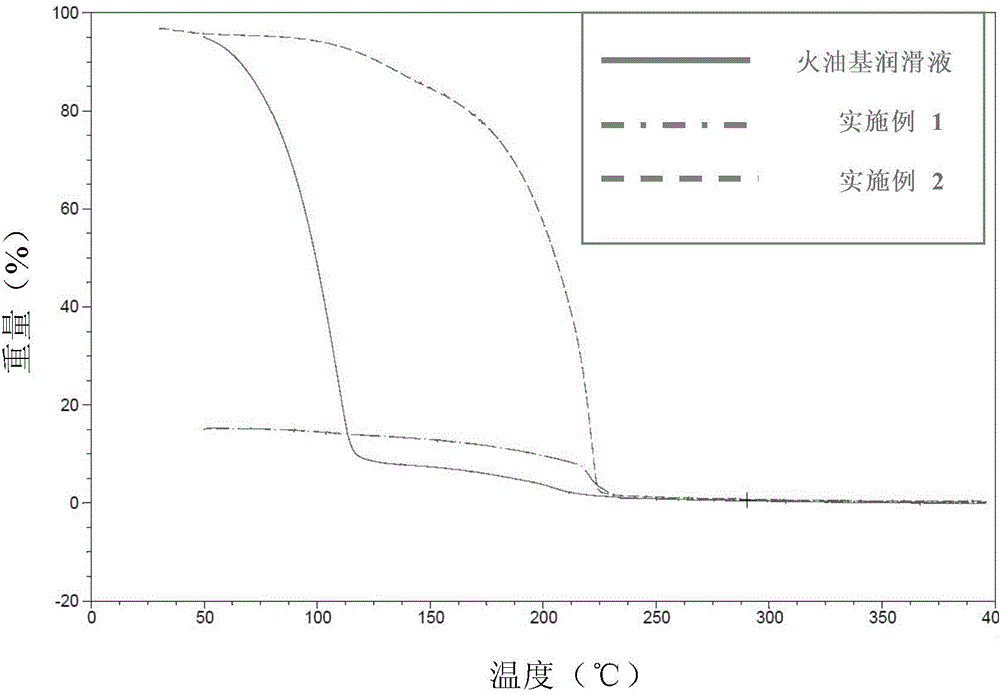

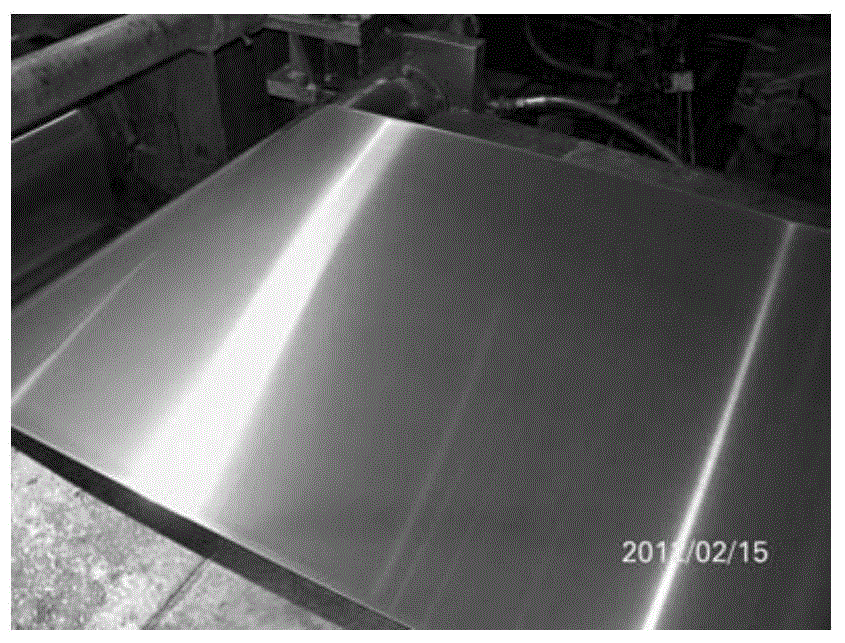

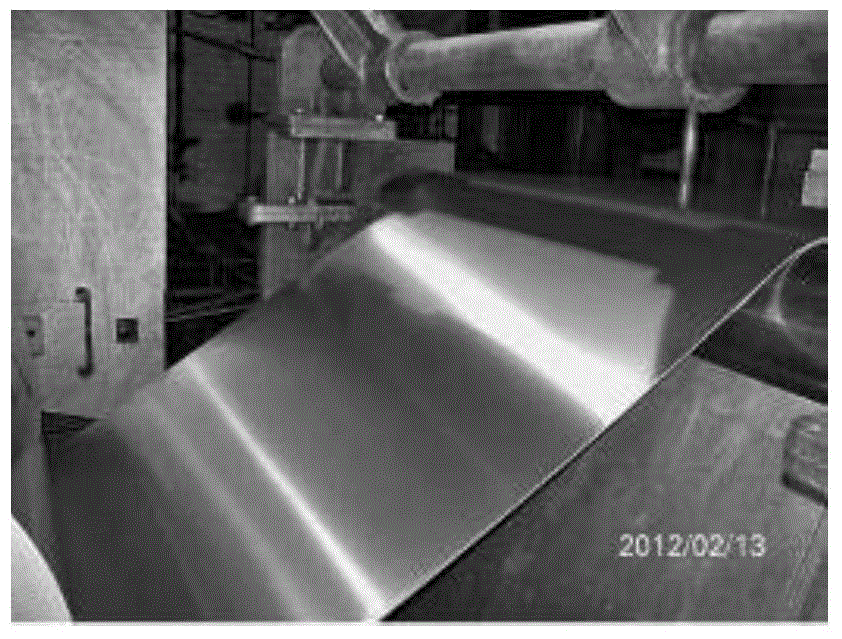

Water-base lubricating fluid for aluminum cold-rolling and preparation method thereof

The invention discloses a water-base lubricating fluid for aluminum cold-rolling, which comprises the following components in percentage by weight: 5-99% of water-soluble polymer, 0.1-2.0% of lubricant additive, 0.05-5% of functional additive and the balance of deionized water. The invention also discloses a preparation method of the water-base lubricating fluid. The water-base lubricating fluid disclosed by the invention overcomes the defects in pure oil and emulsion, and can ensure the rolling safety and effective control on oil consumption on the premise of providing favorable rolling effect.

Owner:QUAKER CHEM CHINA

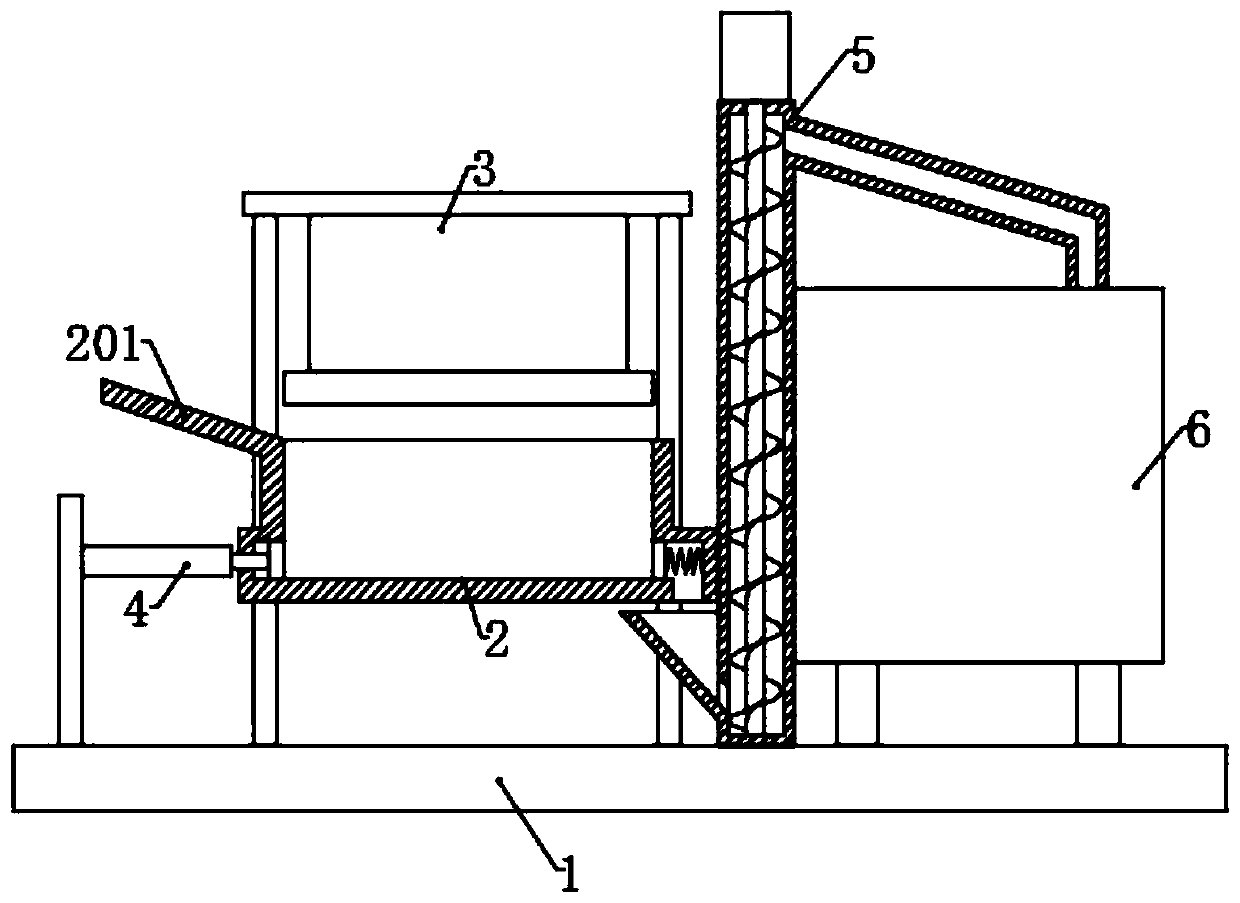

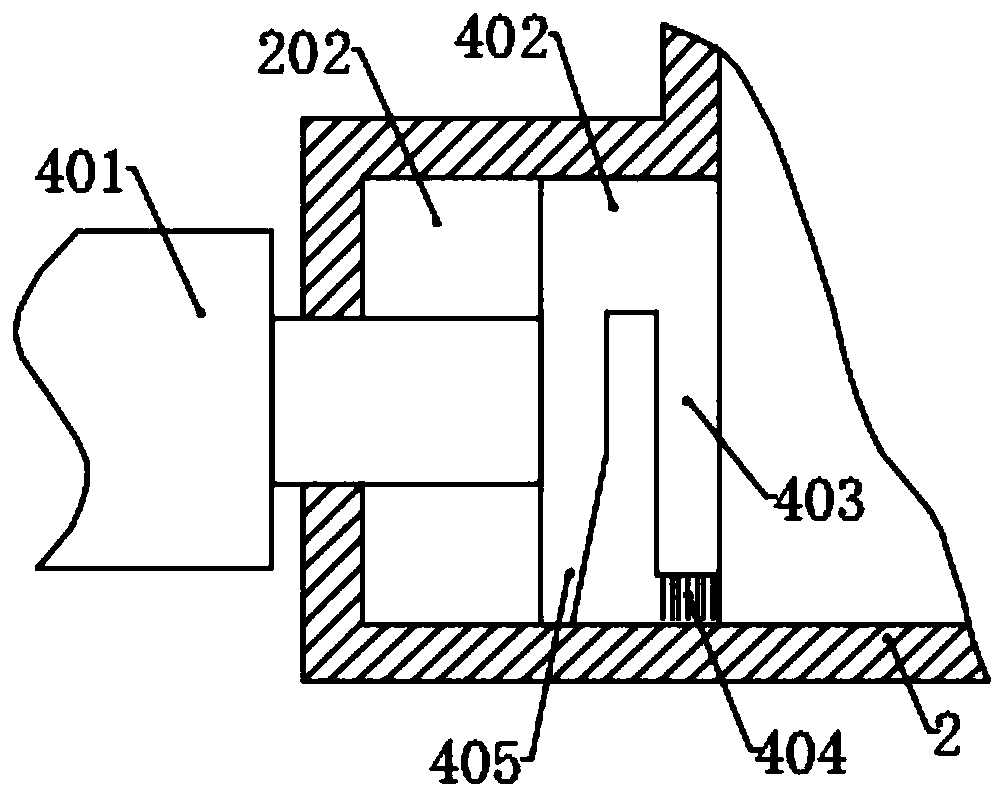

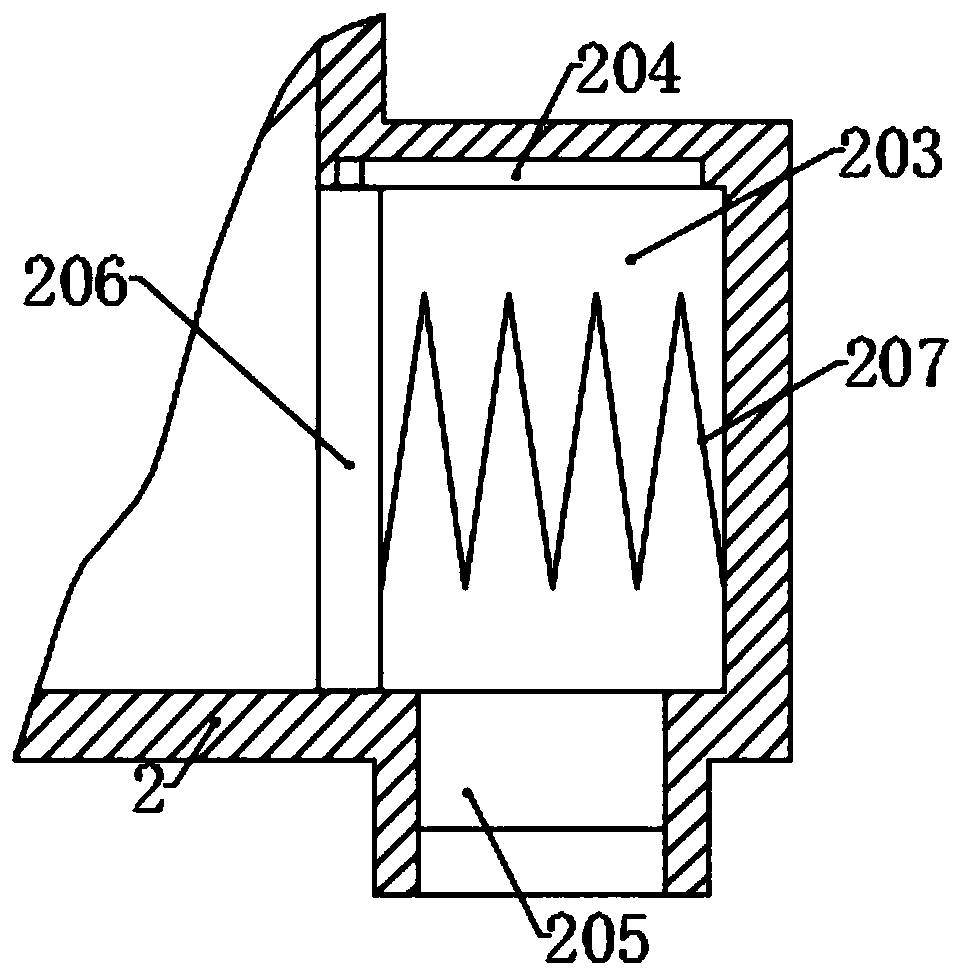

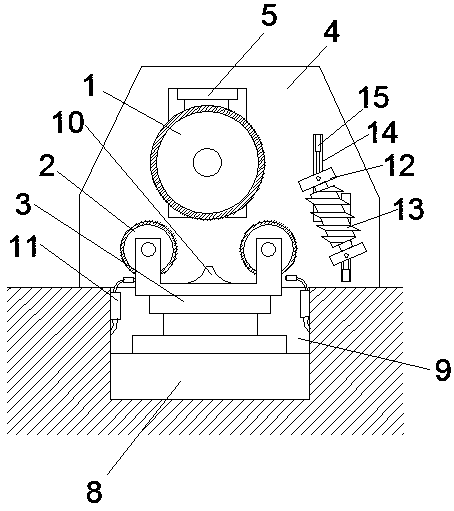

Plate rolling machine

InactiveCN107900156ARolling effect is goodStable board entryShaping toolsMetal-working feeding devicesSteel platesSheet steel

A plate rolling machine comprises an upper press roller. Two lower press rollers are arranged below the upper press roller in parallel. The lower press rollers are rotationally arranged on a press roller seat. The upper press roller is rotationally fixed to a downward press end of a downward press oil cylinder arranged on a fixing seat. The bottom of the press roller seat is provided with a lifting oil cylinder. The lifting oil cylinder is arranged in a recessed pit. The middle portion of the press roller seat is provided with a guide portion parallel to the lower press rollers. The side wallof the recessed pit is provided with a hot air opening wherein the air discharge direction of the hot air opening always faces the guide portion. The feeding side of the upper press roller and the feeding side of the lower press rollers are provided with guide rollers. According to the plate rolling machine, the guide portion is arranged to cooperate with the hot air opening to conduct heat preservation on the space between the two lower press rollers, and therefore the steel plate is kept at a certain preset temperature during rolling.

Owner:滁州市嘉固商贸有限公司

Preparation method of base material for anion wall plates and floors capable of purifying indoor air

The invention discloses a preparation method of anion wall plates and floors capable of purifying indoor air. The preparation method comprises the steps of preparing materials, wherein polypropylene resin and a performance improving agent are weighed and put into a mixing machine; conducting heating and stirring, so that a material mixture is formed; raising the temperature of the material mixture, conducting stirring, and sending the material mixture into a cold mixing treatment machine for conducting slow stirring and temperature lowering; weighing other raw materials other than the polypropylene resin and the performance improving agent, and putting the materials into the mixing machine; conducting heating, raising the temperature, conducting stirring, and putting obtained materials into an extruder for pressure extrusion; and conducting cooling, traction and cutting on extruded sheets, so that finished products are obtained. The products manufactured through the method are high in surface brightness, free of clamminess, attractive in appearance, firm, durable, free of deformation, good in quality and wide in application scope and has good development prospect.

Owner:SHANDONG XINHAI NEW MATERIAL

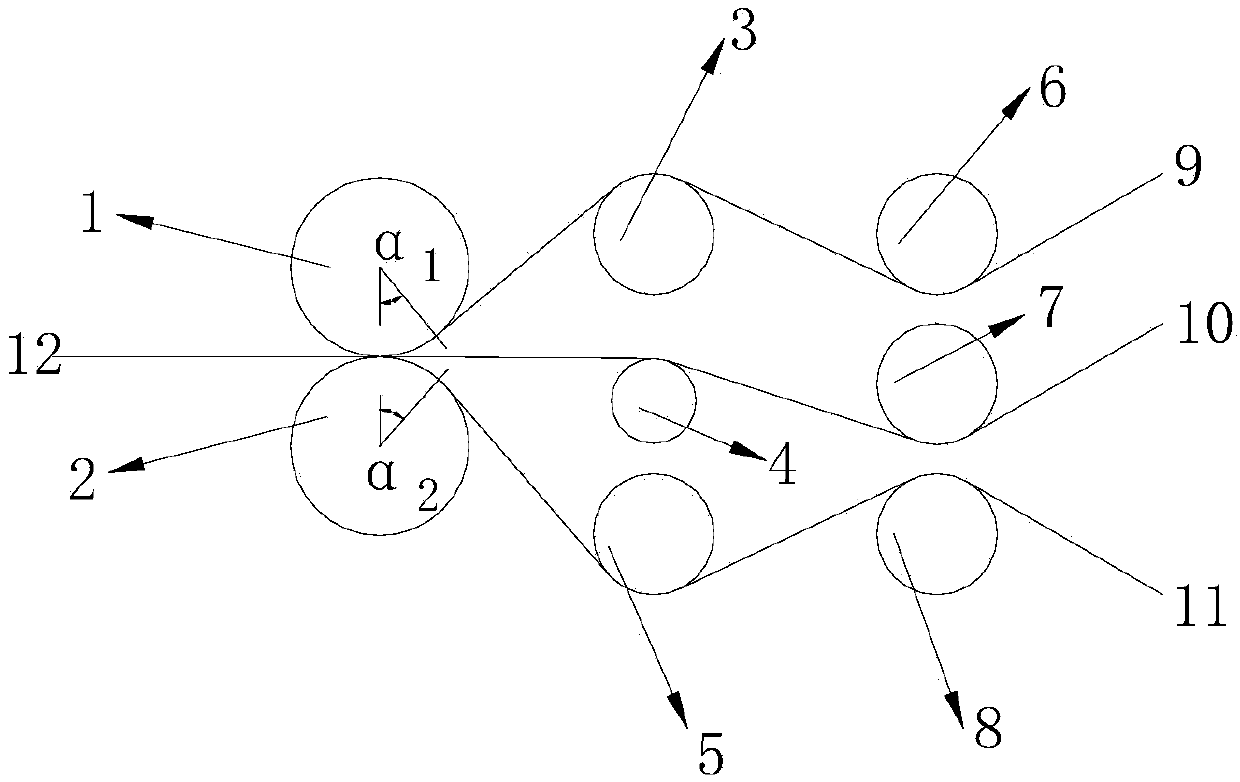

Prelithiation method and prelithiation device for negative electrode of lithium battery

PendingCN107910499AEasy to set upReduce manufacturing costCell electrodesSecondary cellsMetallurgyCopper foil

The invention provides a prelithiation method and prelithiation device for a negative electrode of a lithium battery. A prelithiated negative plate of the lithium battery is formed mainly through laminating copper foil and lithium foil which are not coated with a negative electrode material into a prelithiated copper foil composite material under the cold-pressing actin of a precision roller pressand carrying out coating, drying and rolling on the copper foil composite material. The prelithiation device has the characteristics of being simple in mechanism arrangement, relatively low in manufacturing cost, good in rolling effect, smooth in surface and stable in shape.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

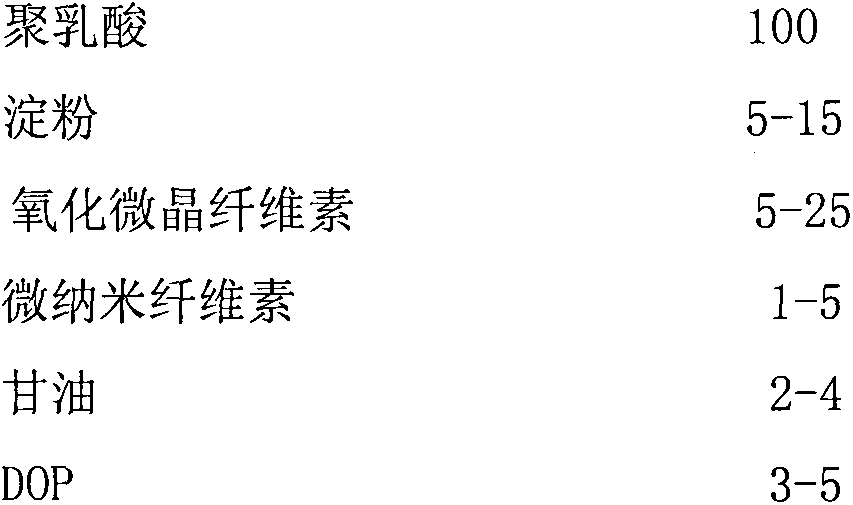

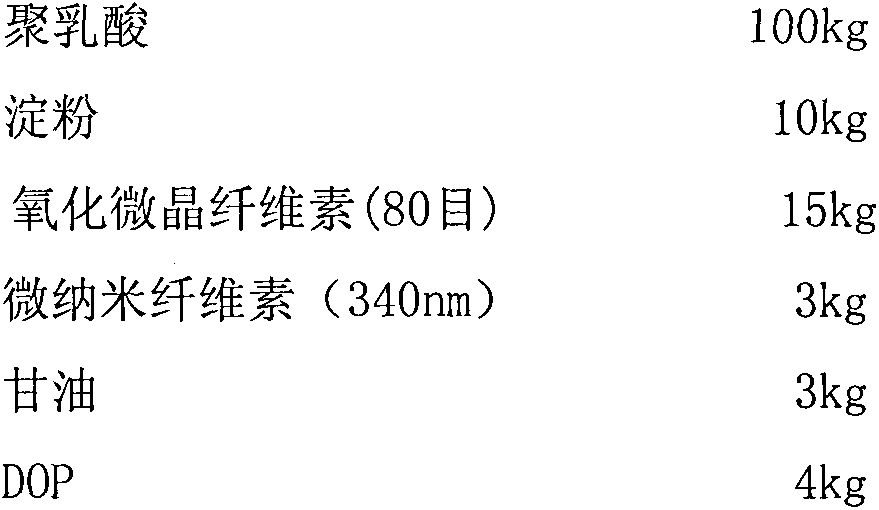

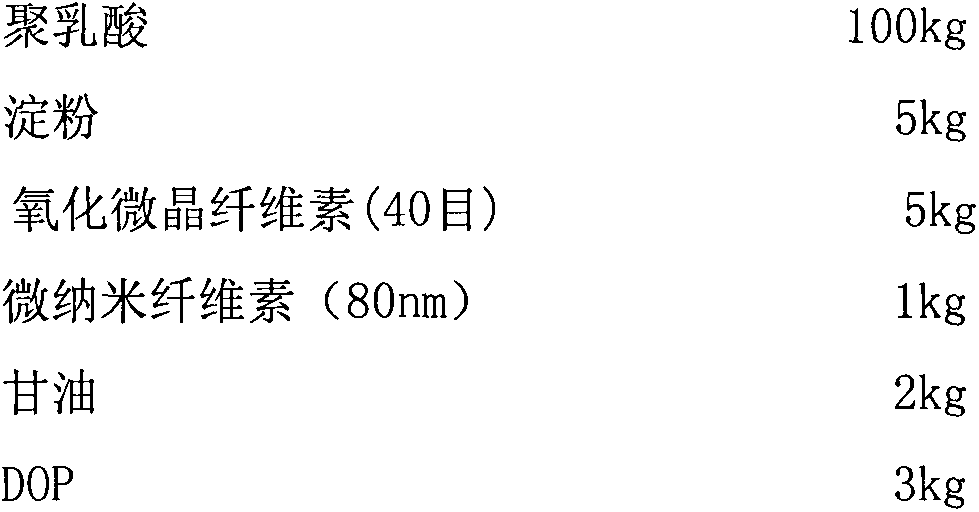

Composite material for 3D printing and production method therefor

Polylactic acid, starch, oxidized microcrystalline cellulose, micro-nano cellulose, glycerin and DOP are composited to prepare a composite material for 3D printing. Production and manufacturing are convenient, and the traditional plastic extrusion production technology can be used for production and processing of the composite material. The mechanization degree is high, the required labor is low, and the production cost is low in the production process. The composite material for 3D printing is advantaged by high intensity, high toughness, high size stability, low number of bubbles, low shrinkage, smooth surface, good linearity and coiling performances, being capable of degradation and environment protection.

Owner:NANJING FORESTRY UNIV

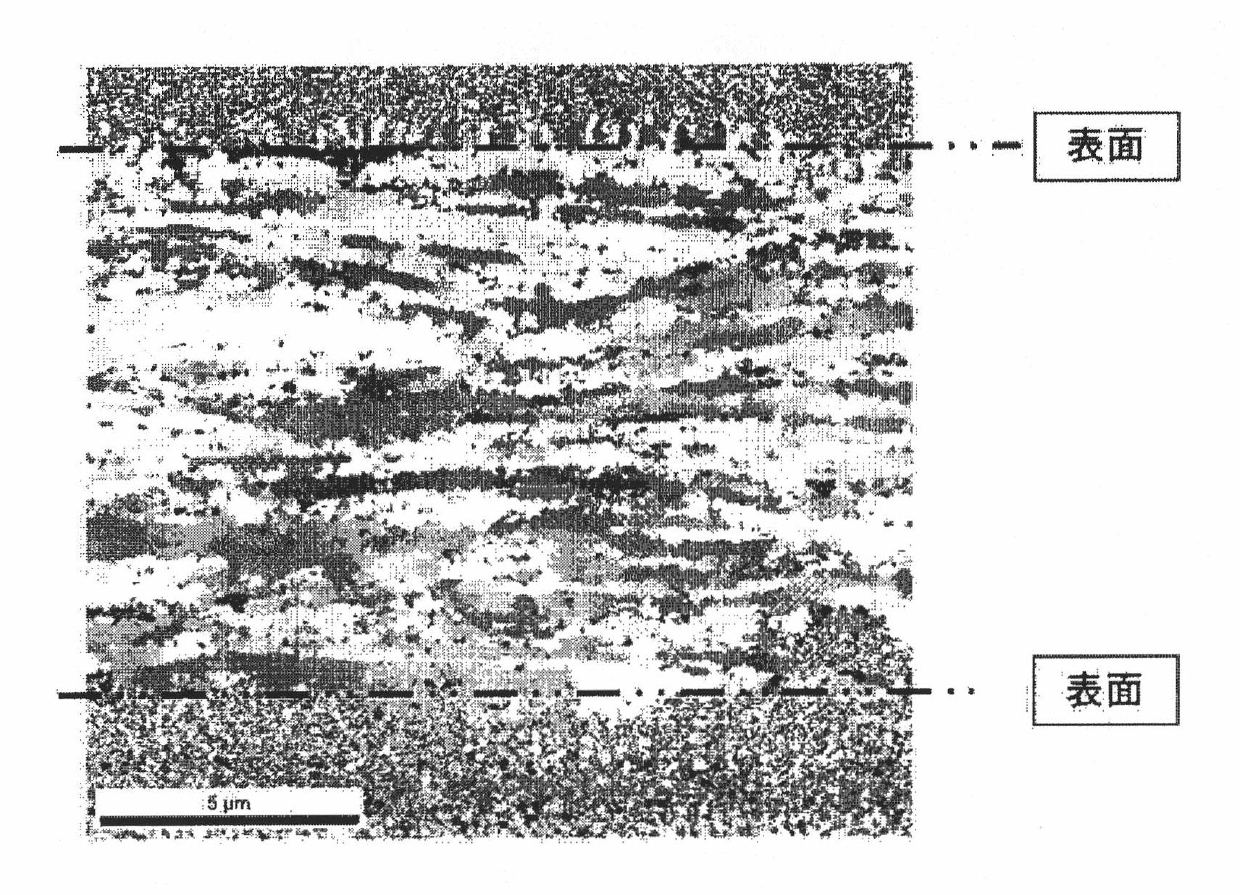

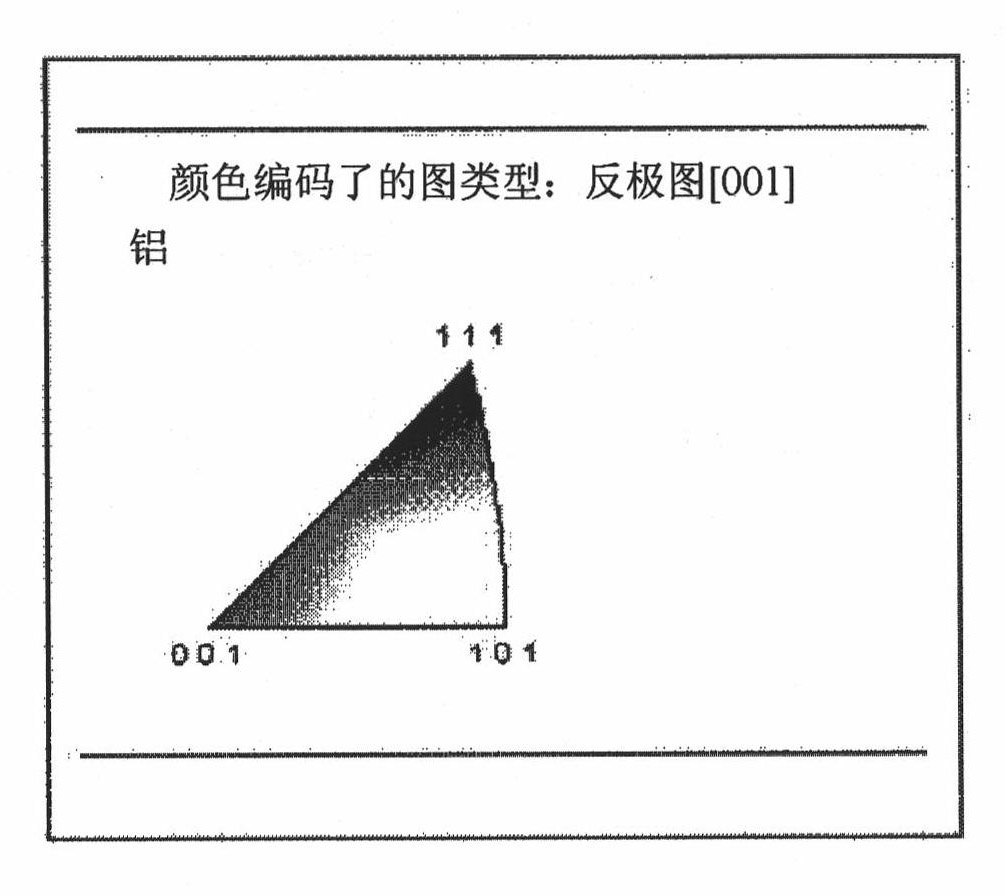

Aluminum alloy hard foil for battery collector

ActiveCN102031428AHigh capacityGood elongationElectrode carriers/collectorsSecondary cellsAluminium alloyExtensibility

An aluminum alloy hard foil for battery collector comprises the following components: 0.8-1.5wt% of Mn; 0.05-0.20wt% of Cu; 0.3-0.7wt% of Fe, and the balance of Al and inevitable impurity. The thickness of the alminium alloy hard foil for battery collector is 9-20 mu m. More than thirty subgrains are provided in a thickness direction. The tensile strength is 280-350MPa and the extensibility is more than 3.5%. According to the composition, the aluminum alloy hard foil for battery collector has a high strength and excellent extensibility.

Owner:KOBE STEEL LTD

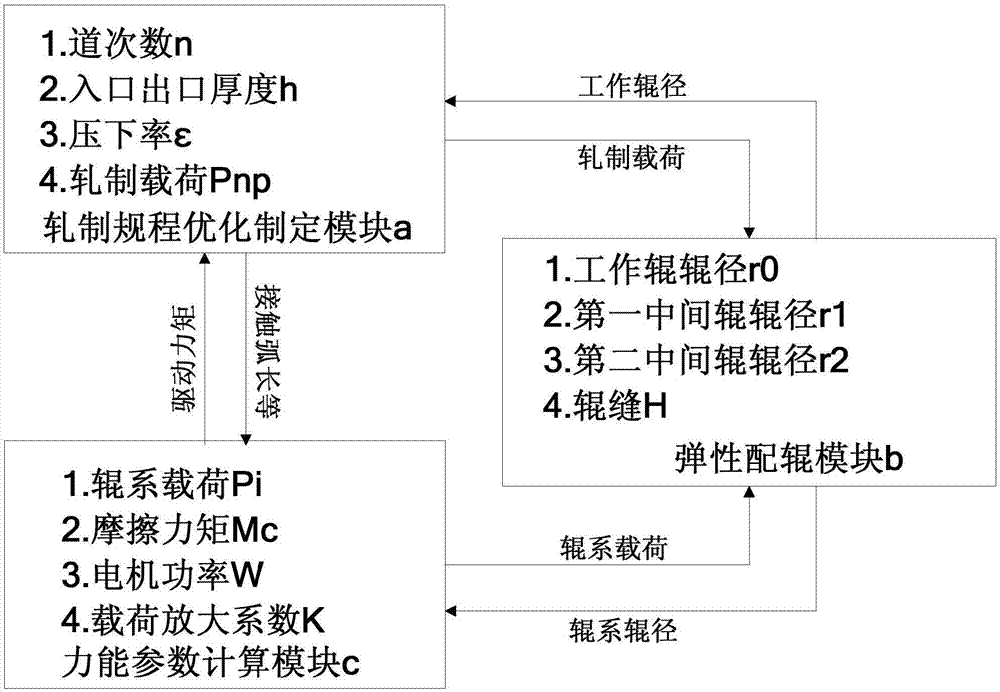

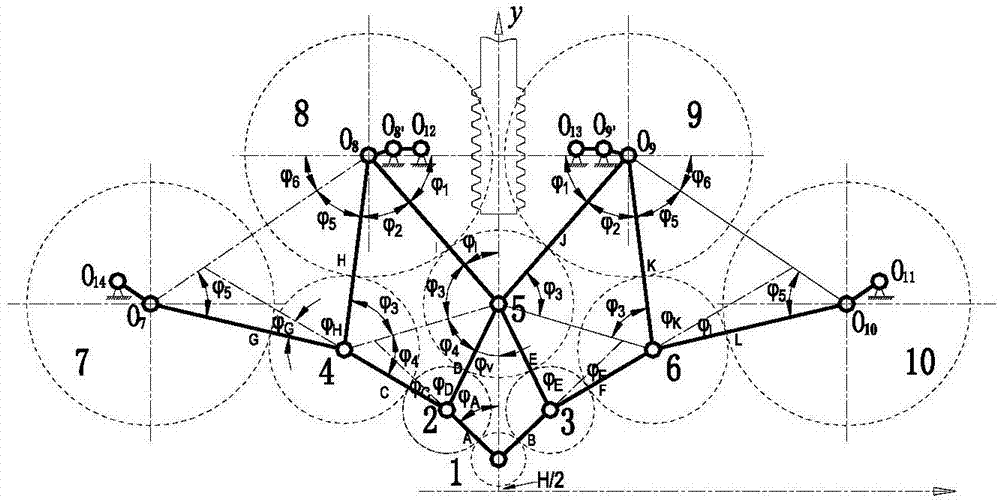

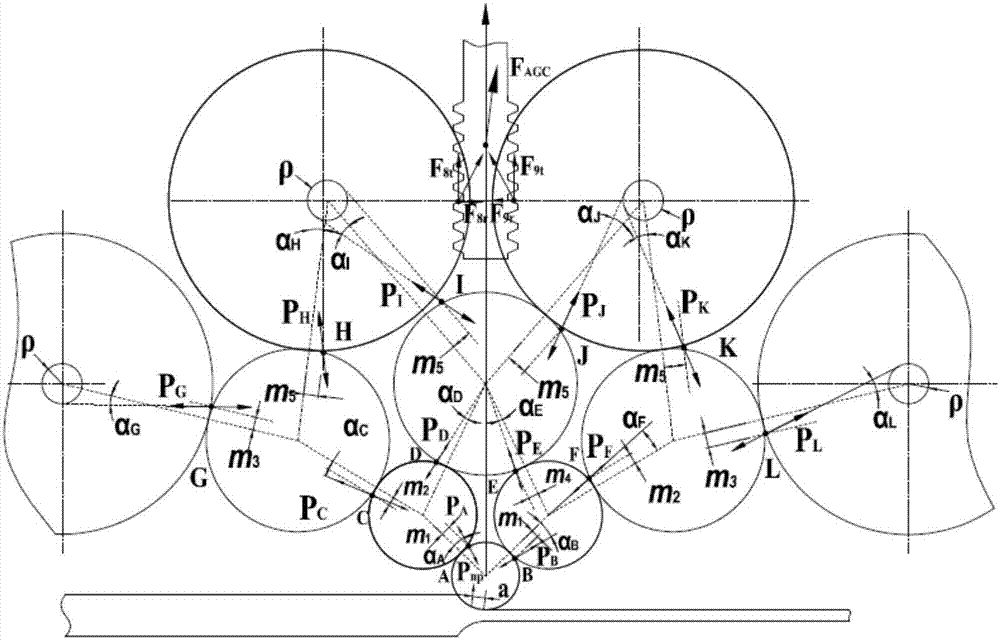

Novel parameter setting integrated system of twenty-high rolling mill control technology

ActiveCN107321799AOptimizing Process ParametersExtended service lifeRoll mill control devicesMetal rolling arrangementsIntegrated systemsEngineering

The invention provides a novel parameter setting integrated system of a twenty-high rolling mill control technology. The novel parameter setting integrated system of the twenty-high rolling mill control technology comprises a rolling schedule optimization setting module, an elastic roll diameter roll-arranging module, an energetic parameter calculating module and a mill roll system. After the incoming material thickness, the finished product thickness, the strip material width, the maximal rolling force, a maximal rolling reduction ratio and the work roll diameter are input into the rolling schedule optimization setting module, the rolling pass, the total rolling reduction ratio, the rolling reduction ratio of each pass, the rolling force, the forward tension and the backward tension, the rolling speed, the rolling power and the rolling pass outlet thickness are output; and after the roller diameter compensation eccentric distance, the rolling reduction adjusting eccentric distance and the rolling pass outlet thickness are input into the elastic roll diameter roll-arranging module, the work roll diameter, a first middle roll diameter, a second middle roll diameter and the rolling reduction adjusting angle are output. According to the novel parameter setting integrated system of the twenty-high rolling mill control technology, setting of parameters of the rolling mill control technology can be conducted by adopting the incoming material thickness, the finished product thickness and the like without the need of accumulating long-term production data.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

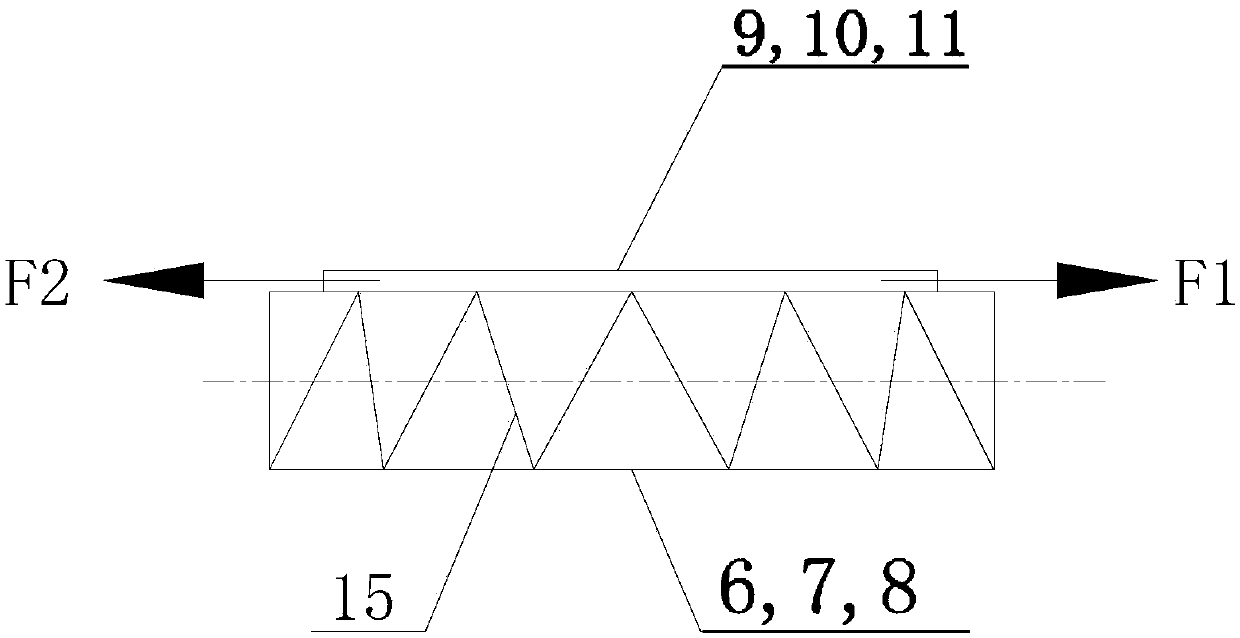

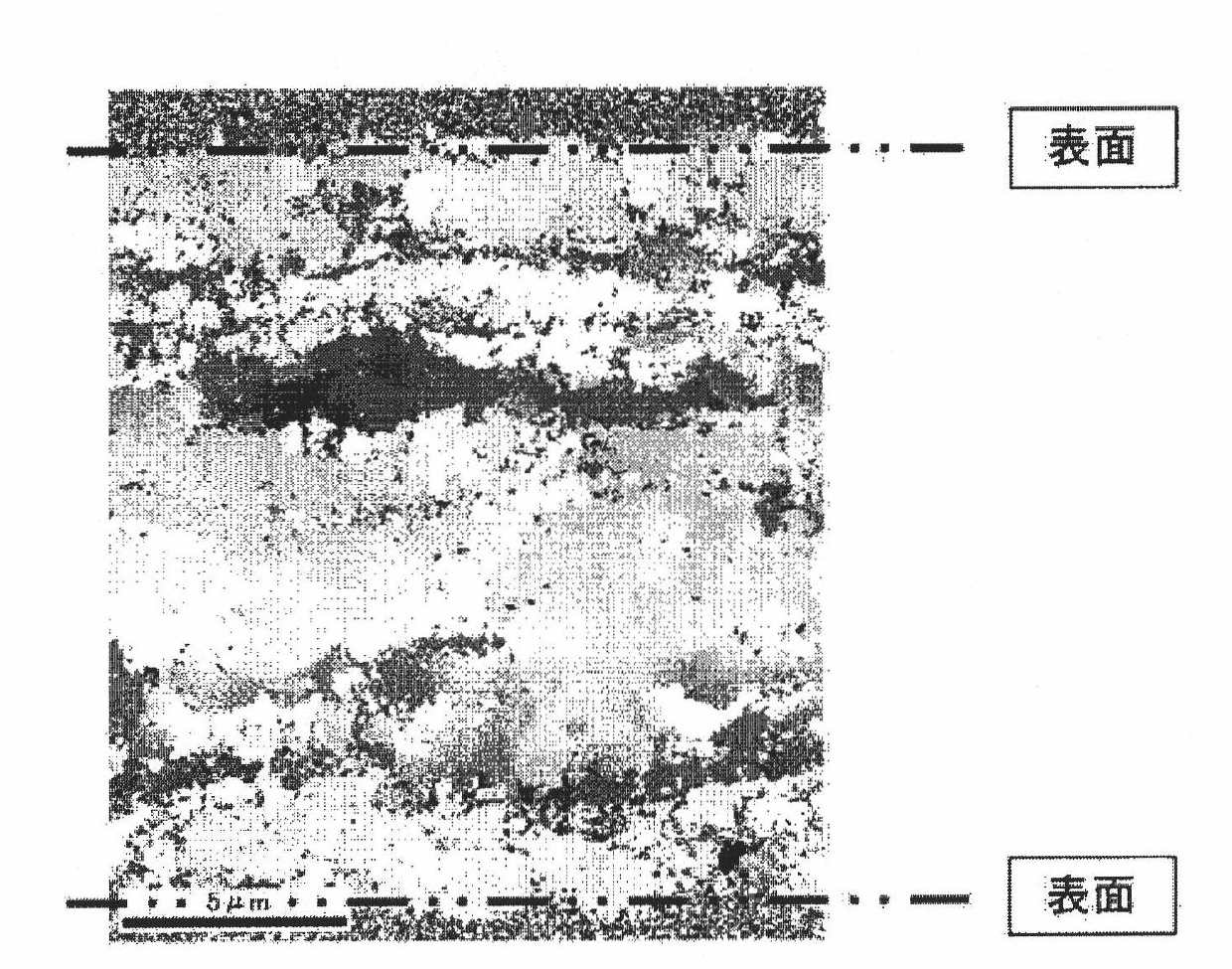

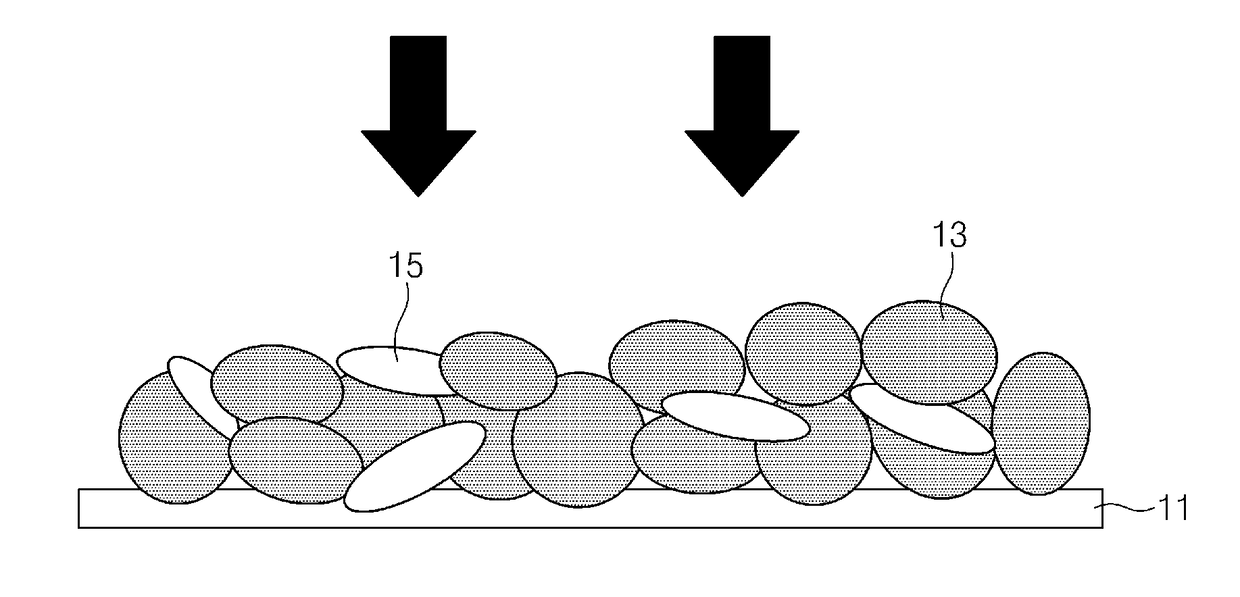

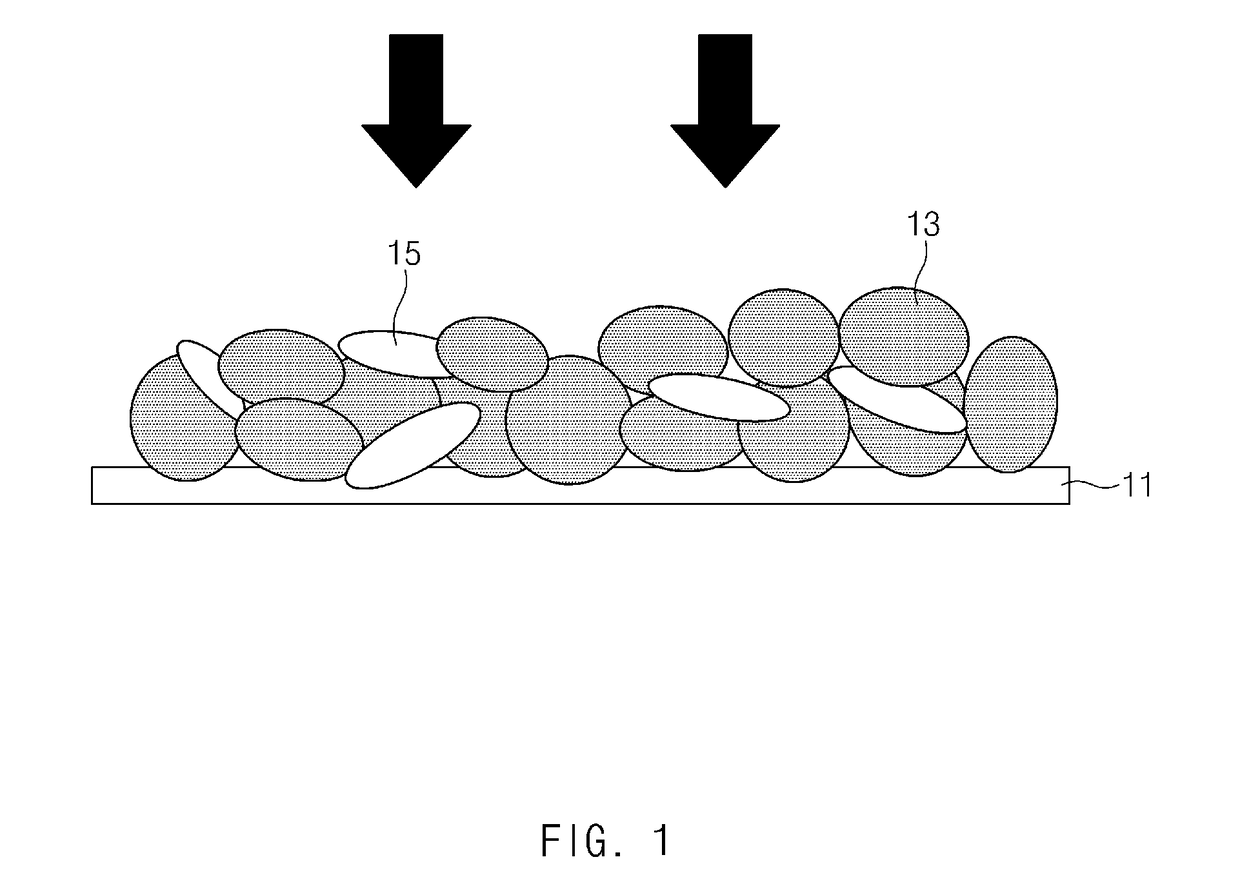

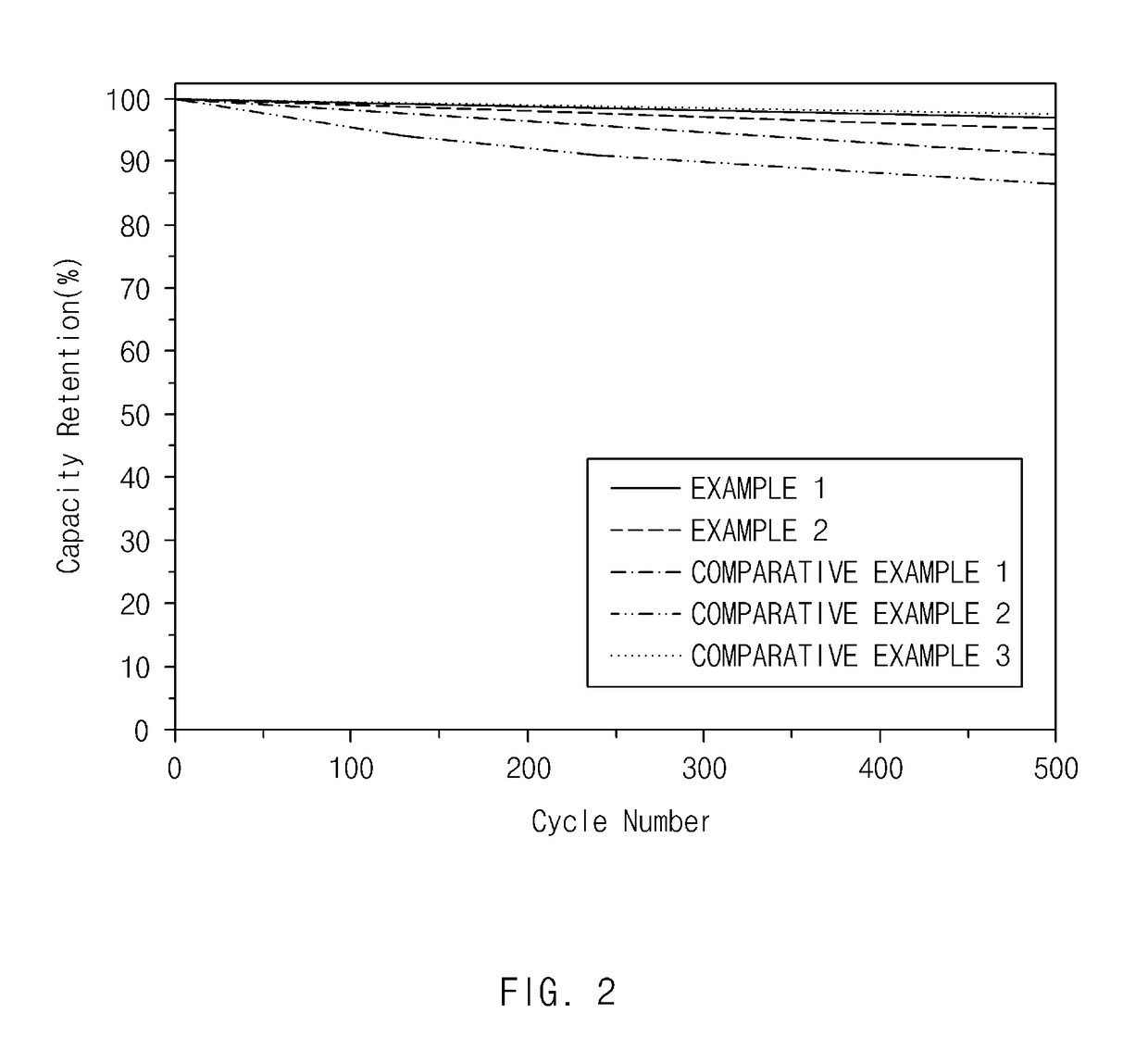

Negative electrode active material and negative electrode for secondary battery comprising the same

ActiveUS20170133682A1Improve rolling effectImprove discharge characteristicsNegative electrodesLi-accumulatorsLithiumFlake graphite

Provided are a negative electrode active material including spherical artificial graphite and natural flake graphite, wherein the spherical artificial graphite and the natural flake graphite are included in a weight ratio of 80:20 to 95:5, and a negative electrode for a lithium secondary battery including the same.

Owner:LG ENERGY SOLUTION LTD

High silicon steel for thin slab casting and rolling production and preparation method thereof

The invention discloses high silicon steel for thin slab casting and rolling production. The high silicon steel comprises the following components in percentage by weight: less than or equal to 0.003 percent of C, 4.5-7.0 percent of Si, 0.25-1.0 percent of Mn, less than or equal to 0.008 percent of Al, less than or equal to 0.0050 percent of S, less than or equal to 0.0030 percent of N and less than or equal to 20PPm of [O]. The preparation method comprises the following steps: smelting; casting; heating the cast slab; rolling; coiling; insulating in a bell-type furnace; performing warm-rolling, namely performing cold rolling at a temperature of 150 to 500 DEG C; and annealing at a high temperature. On the basis of the conventional thin slab casting and rolling equipment, a proper casting process is adopted, the columnar crystal ratio is improved, and the columnar crystal size is reduced; and the hot-rolling process is controlled, a fine fiber structure is obtained, and the warm-rolling property is guaranteed. The high silicon steel with good processability and magnetic performance can be produced.

Owner:武汉钢铁有限公司

Titanium alloy coil rod and production method thereof

The invention provides a titanium alloy coil rod and a production method thereof. The titanium alloy coil rod comprises the following components in percentage by weight: 15.0 to 6.0 percent of A, 3.0 to 4.0 percent of V, less than or equal to 0.25 percent of Fe, less than or equal to 0.06 percent of C, less than or equal to 0.05 percent of N, less than or equal to 0.012 percent of H, less than or equal to 0.16 percent of O and the balance of Ti and unavoidable impurities. The titanium alloy coil rod is obtained by performing steps of heating, rough rolling, medium rolling, pre-finish-rolling, finish rolling, spinning looping, air cooling, coil collection and air cooling. According to the invention, heating only needs to be carried out once; the rhythm of production is rapid; production efficiency and yield of the titanium alloy coil rod are greatly improved; mass continuous production can be realized; heating cost is effectively reduced; the energy saving effect is obvious; large-coil heavy titanium alloy coil rod can be efficiently produced by utilizing the method; and the product has high size accuracy and good structure property.

Owner:WUKUN STEEL

Production method of industrial pure titanium wire rod

InactiveCN102974610AIncrease productivityHigh yieldTemperature control deviceMetal rolling arrangementsWire rodTitanium

The invention provides a production method of an industrial pure titanium wire rod, which comprises the following steps of heating of an industrial pure titanium square billet, rough rolling, middle rolling, prefinish rolling, finish rolling, spinning in circles, wind cooling, coil collection and air cooling, and then the industrial pure titanium wire rod is obtained. The industrial pure titanium wire rod, the piece weight of which exceeds 400 kg, can be produced, the production efficiency and the yield of the industrial pure titanium wire rod are effectively increased, the problems of easiness in oxidation and hydrogen embrittlement of industrial pure titanium in prior art are solved, the heating cost of the industrial pure titanium square billet is effectively reduced, continuous production on a large scale can be realized, the rolling speed and the rolling power are increased, and an ideal metallographic structure and physical properties are obtained. By utilizing the method, the industrial pure titanium wire rod with large coil weight can be efficiently produced, the precision of the product size is high, and the structure property is good.

Owner:WUKUN STEEL +1

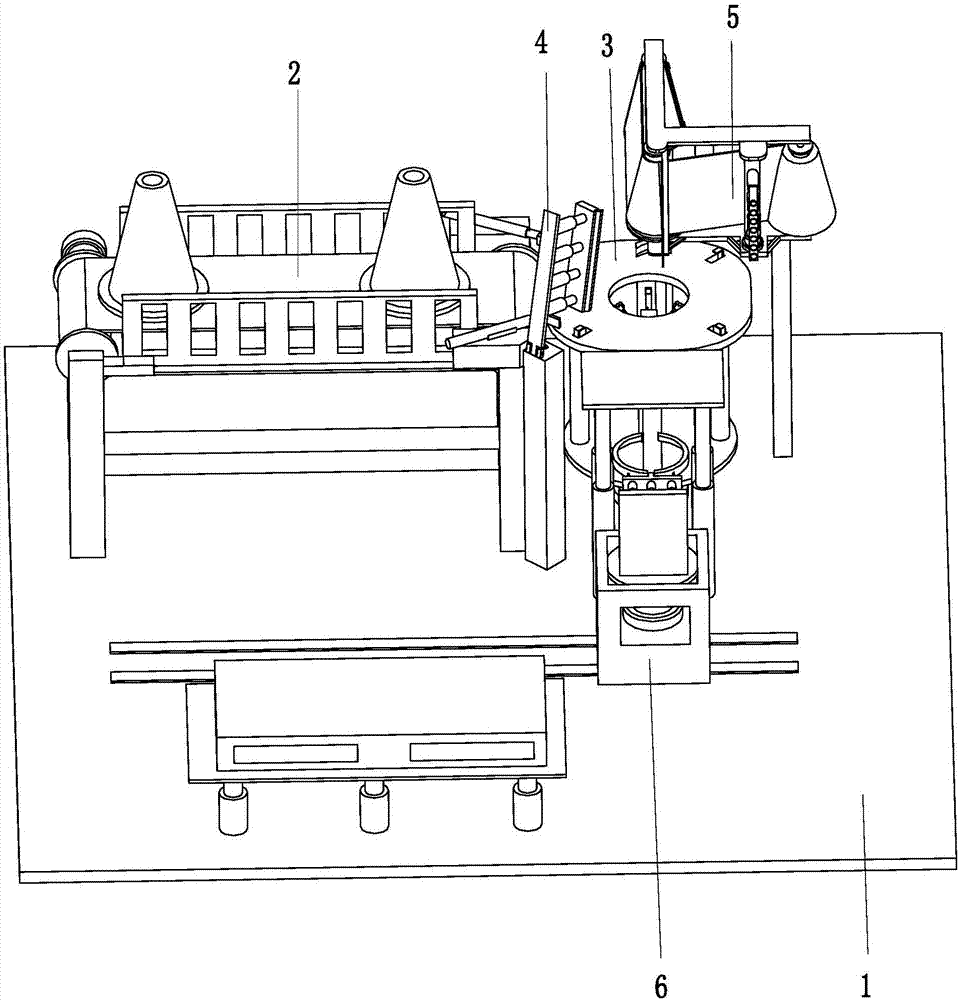

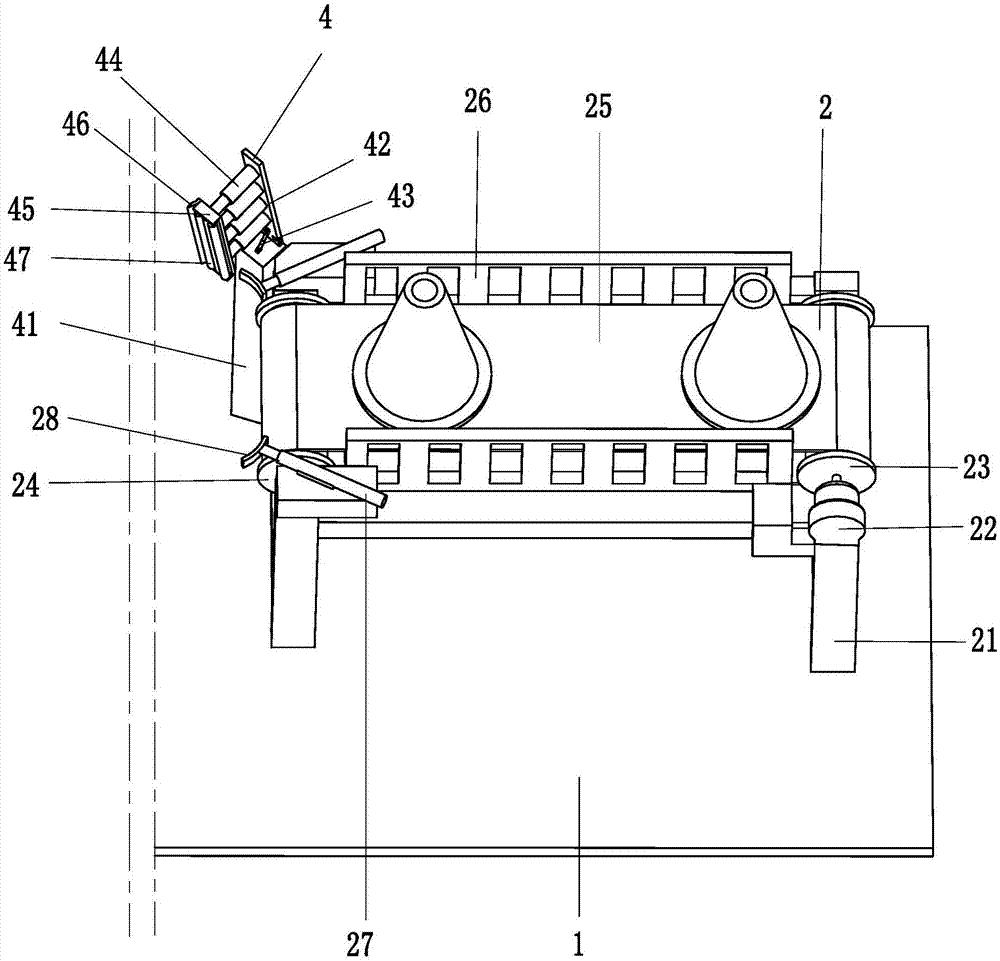

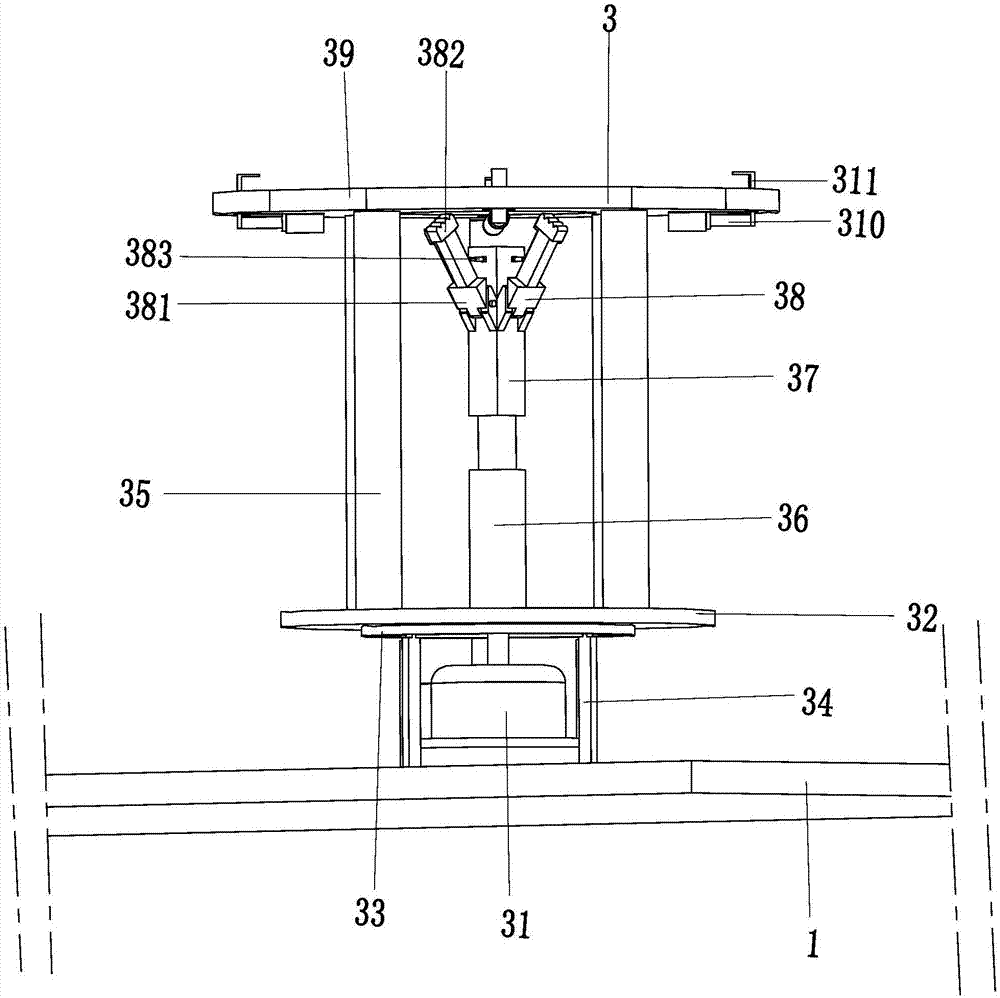

PET reflective sticker automatic sticking machine capable of automatically placing traffic cone

InactiveCN107187681ARealize automatic deliveryImprove work efficiencyLabelling flat rigid surfacesConveyor partsReflective layerComputer engineering

The invention relates to a PET reflective sticker automatic sticking machine capable of automatically placing a traffic cone. The PET reflective sticker automatic sticking machine capable of automatically placing the traffic cone comprises a bottom seat, a transmission device, a positioning rotating device, a rolling pressing device and a sticking device; the transmission device is mounted on the left side of the bottom seat; the positioning rotating device is mounted on the bottom seat; the rolling pressing device is mounted on the bottom seat; the sticking device is positioned on the rear side of the rotating device; the sticking device is mounted on the bottom seat. According to the PET reflective sticker automatic sticking machine capable of automatically placing the traffic cone, the difficult problems that the work efficiency is low, the work is too cumbersome, a reflective sticker is stuck on the traffic cone unevenly, reflective paper on the reflective sticker is difficult to process, the traffic cone to which the reflective sticker is stuck is required to be placed manually and the like when the reflective sticker is stuck to the traffic cone manually in the prior art can be solved; the functions of automatically conveying the traffic cone, automatically sticking the reflective sticker, and automatically placing and transporting are realized; the PET reflective sticker automatic sticking machine capable of automatically placing the traffic cone has the advantages that the work efficiency is high, the reflective sticker is stuck mechanically, the reflective sticker is stuck to the traffic cone smoothly the reflective paper on the reflective sticker is wound automatically, and traffic cones are stacked and placed mechanically.

Owner:合肥集知网信息技术有限公司

Heat treatment technology for 8021 high-performance aluminum foil for soft package

The invention relates to a heat treatment technology for 8021 high-performance aluminum foil for a soft package. Two times of intermediate annealing and final finished product annealing are conducted in a cold rolling stage in an existing 8021 aluminum foil production technology. By means of the heat treatment technology, on the basis of a traditional preparing technology, a '2+1' annealing manner is used for improving the performance of the 8021 aluminum foil for the soft package of a lithium battery; precipitation, growth and distribution of second phases are effectively controlled, so that multiple second phases and fine grain structures are obtained and are well matched in the aspects of strength and plasticity (the tensile strength ranges from 101 MPa to 110 MPa, and the elongation percentage ranges from 16% to 23%); and in addition, the cupping value is larger than or equal to 6.5 mm, and the requirement for the use performance of the soft package of the lithium ion battery can be met. The technology is simple in operation, relatively low in production cost and capable of improving alloy structures and obviously increasing the alloy elongation percentage and the cupping value; and meanwhile the produced aluminum foil has extremely-high isolation performance. The aluminum foil can be compounded with other materials, simultaneous stretching and flowing can be achieved, and in addition, the requirement for the scouring depth of composite film soft packages of food, medicines and even lithium ion batteries can be met.

Owner:CENT SOUTH UNIV

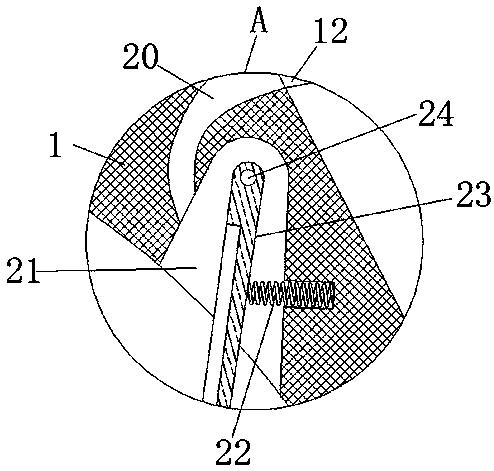

Road roller with good pavement leveling effect

InactiveCN110468661AImprove flatnessImprove rolling effectRoads maintainenceLeveling effectRoad engineering

The invention belongs to the technical field of road engineering mechanical equipment, and particularly relates to a road roller with a good pavement leveling effect. Aiming at solving the problem that in the process of rolling an asphalt pavement by a road roller, attachments are likely to be carried, and consequently pavement smoothness is affected, the following scheme is proposed currently, the road roller comprises a bracket, two connecting bodies are welded to one side of the bracket, cams are rotationally connected to the sides, close to each other, of the two connecting bodies correspondingly, a working wheel is welded between the two cams, and two circular through holes are formed in one side of the top end of the bracket. An inflating pump inflates the interior of a water tank byutilizing kinetic energy of the road roller during travelling, a water flow is evenly sprayed to the surface of the working wheel, asphalt adsorption is avoided, the center of gravity of the road roller shifts due to a counterweight block, thus the rolling force of the working wheel is conveniently controlled when the temperature of asphalt is different, the rolling effect is improved, meanwhile,the shock absorption effect of a cockpit is good, a scraper can scrape off the asphalt on the surface of the working wheel, at the same time the situation is fed back to a solenoid valve, the water amount of a water delivering pipe is increased, and the situation that the working wheel adsorbs the asphalt again is avoided.

Owner:HUBEI UNIV

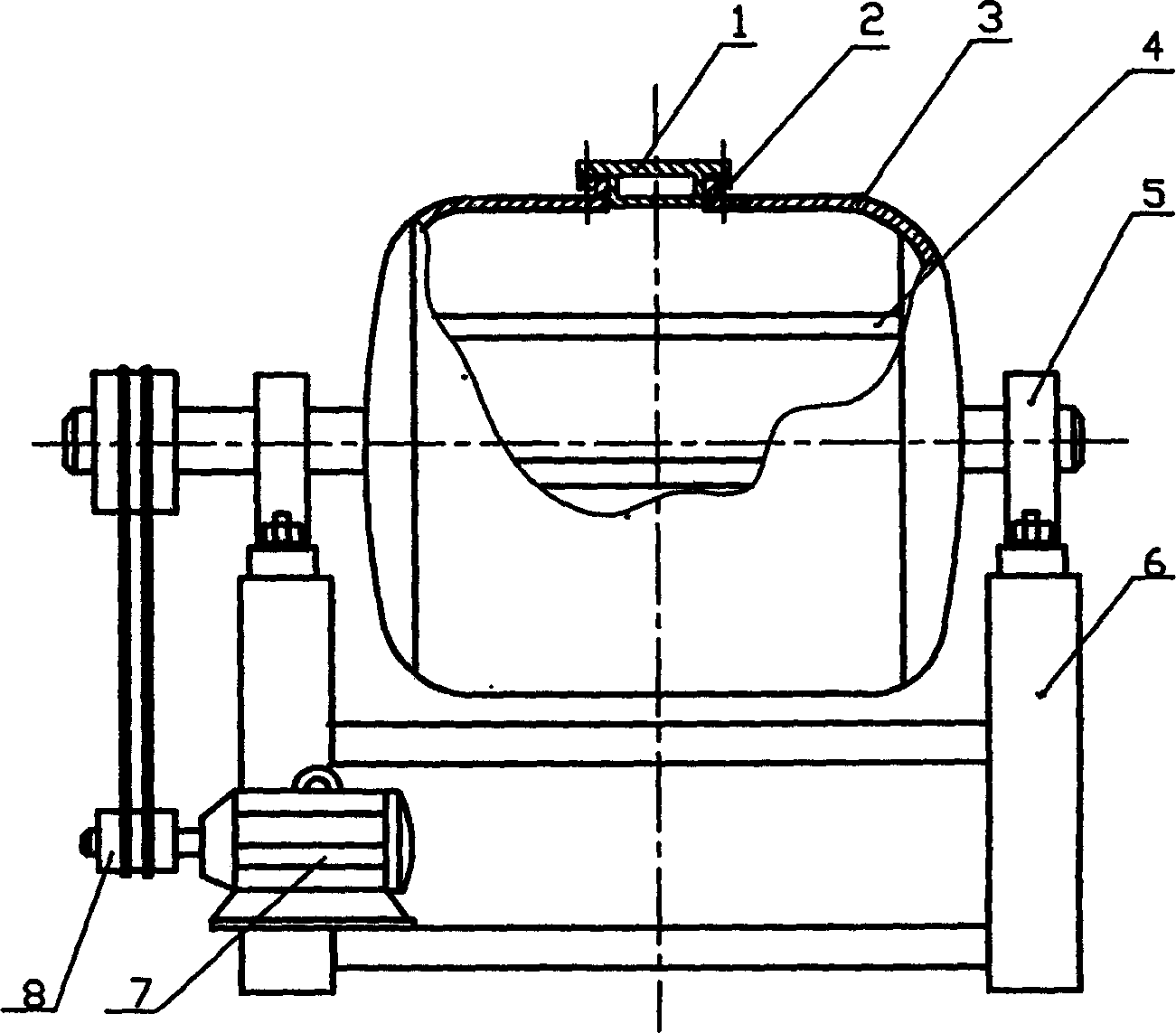

Energy-saving and effect-enhancing type rolling and kneading machine

InactiveCN1559233AUniform structureStructural symmetryMeat tenderisingEngineeringMechanical engineering

An energy-saving rolling and kneading machine has a drum body with feeding opening, a cover of said opening, and the material kneading plates in said drum body. Its advantages are high volume and high stability.

Owner:刘长雁

Physical preparation method for bamboo fibers

InactiveCN105316770AShort processReduce manufacturing costMechanical fibre separationHigh pressureFiber

The invention provides a pure physical and pollution-free extraction technology for bamboo fibers. By means of the technology, coarse bamboo fibers with the diameter ranging from 0.03 mm to 0.3 mm, the length larger than 20 cm, the elongation at break ranging from 3% to 7%, the break force ranging from 3 N to 15 N and the break strength ranging from 100 MPa to 600 MPa can be obtained. The technological process includes the steps of pretreatment, high-temperature and high-pressure cooking, mechanical softening fibrillation, screening and separation, drying, and packaging and warehousing, wherein pretreated bamboo chips are put into a cooking container to be cooked and softened for 14-15 h, and then mechanical grinding fibrillation is performed through a softening machine. The product prepared through the technology meets the requirement for bamboo-plastic composites, production cost is low, the technological process is short, cleanliness and environment friendliness are achieved, and preparation is simple and easy.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com