Continuous processing device for bamboo filament bundle

A processing device and technology of bamboo tow, applied in the field of bamboo processing devices, can solve the problems of low production efficiency and achieve the effects of improving production quality, obvious rolling effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

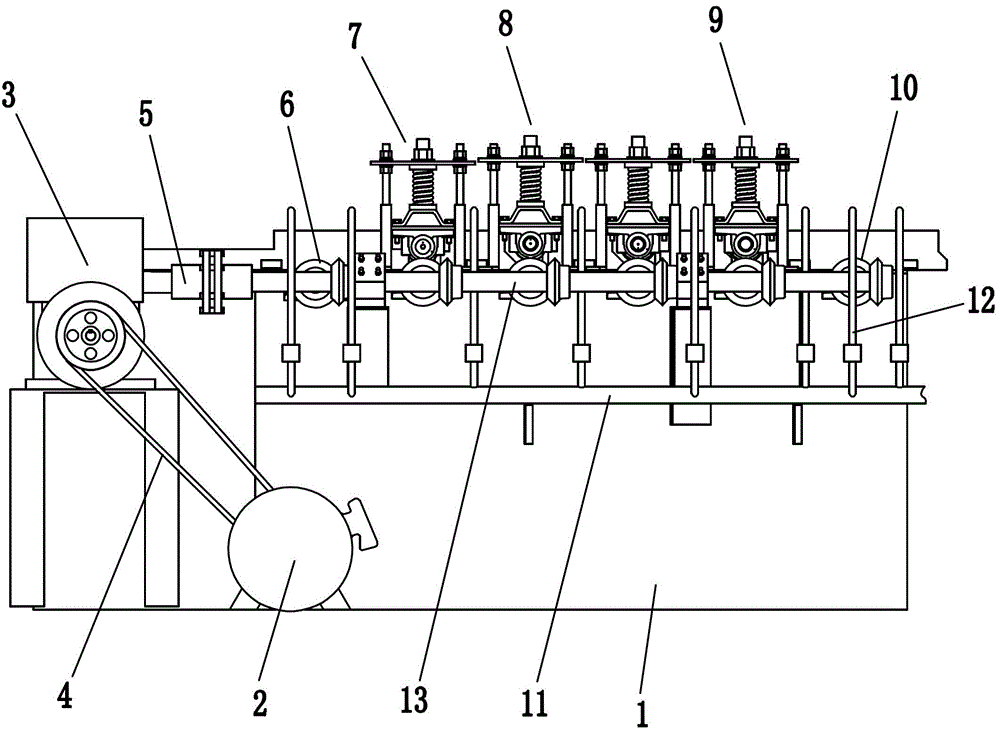

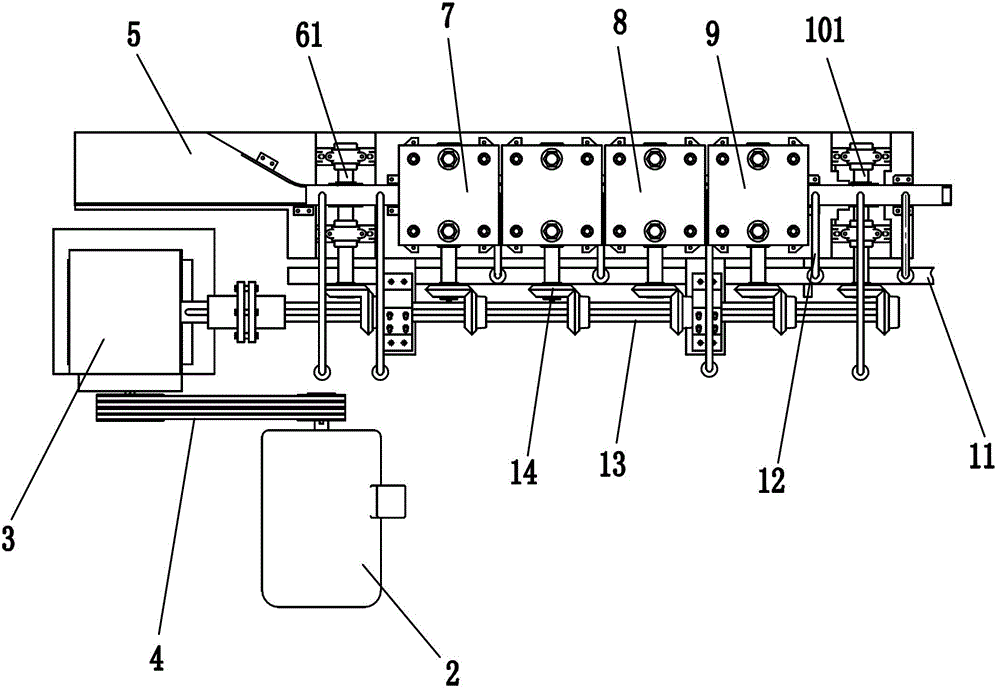

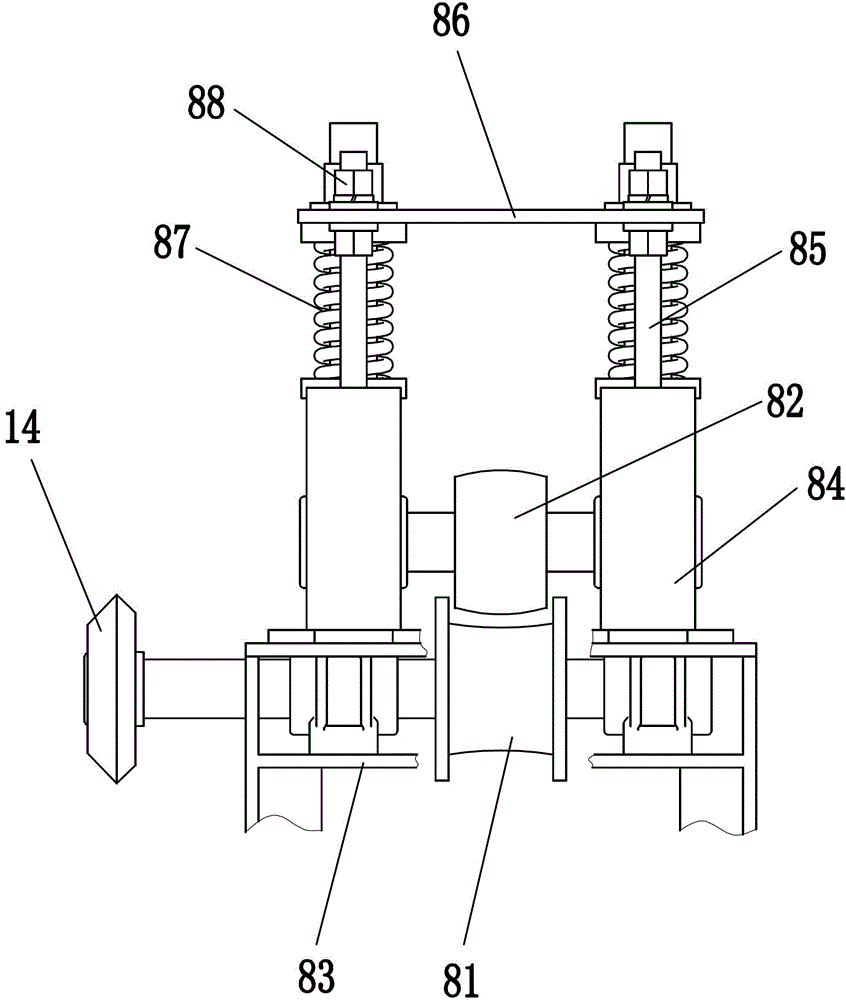

[0026] Example 1: Such as figure 1 , 2 As shown, a continuous processing device for bamboo tows includes a frame 1, a motor 2 and a reducer 3. The motor 2 drives the reducer 3 through a belt 4, and one end of the frame 1 has a feeding slot 5. On the frame 1 from the end close to the feeding trough 5, a feeding trough 6, a pre-tensioning roller mechanism 7, two side-by-side rolling roller mechanisms 8, a conveying roller mechanism 9 and an unloading trough 10 are arranged in sequence. The feeding trough 6 includes a feeding and conveying roller 61, and the unloading trough 10 includes a feeding and outputting roller 101, such as Figure 5 , 6 As shown, the structures of the feeding and conveying roller 61 and the feeding and outputting roller 101 are the same in ratchet structure, and the ends are sharpened. Such as image 3 , 4 As shown, the rolling roller mechanism includes a driving roller 81, a driven pressing roller 82, a driving roller frame 83 and a driven roller frame. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com