Rib rolling device and rib rolling equipment

A technology of bead rolling and mounting seat, which is applied in the field of bead rolling, can solve the problems of high additional cost and low efficiency, and achieve the effect of high cost performance, high work efficiency and reduced additional cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

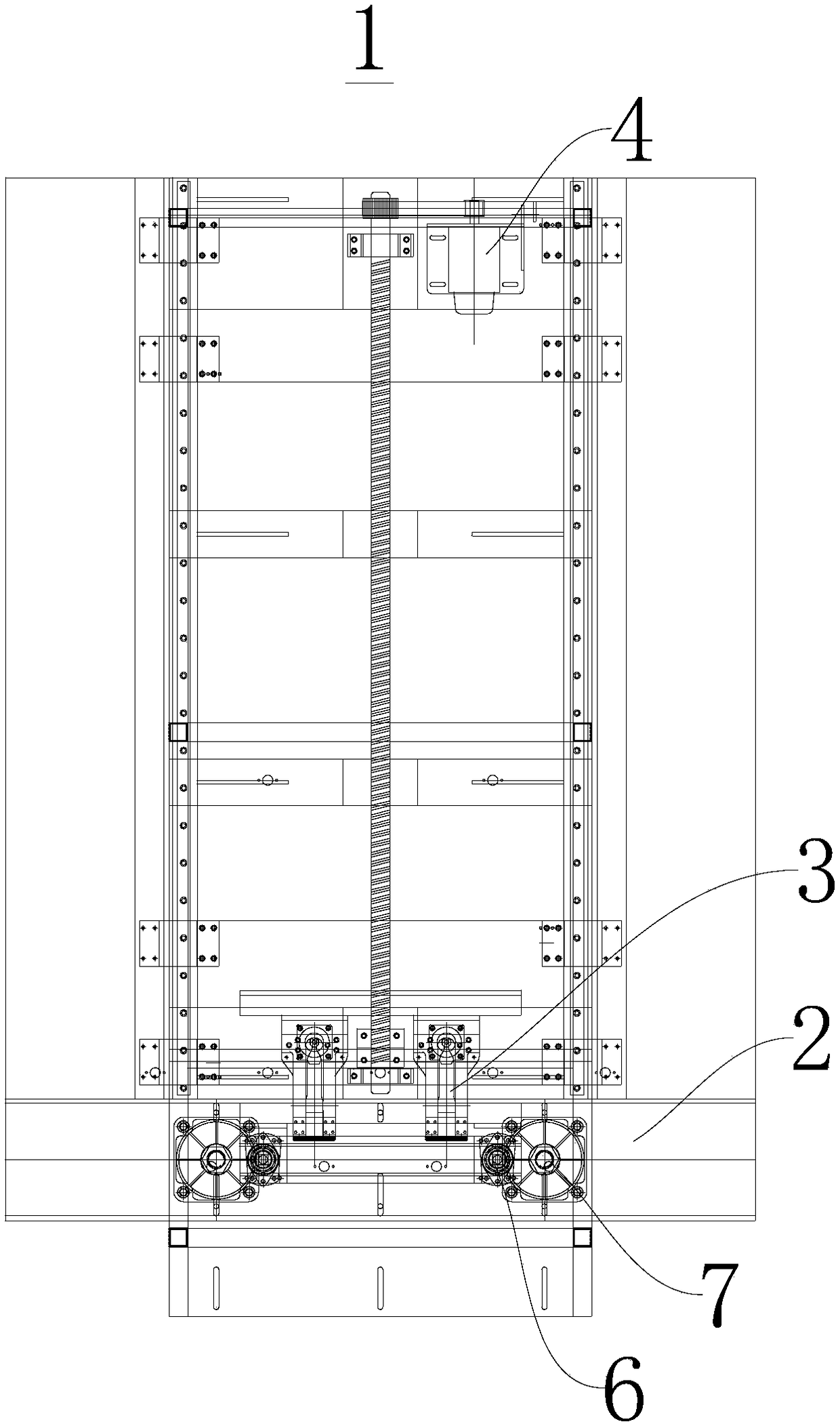

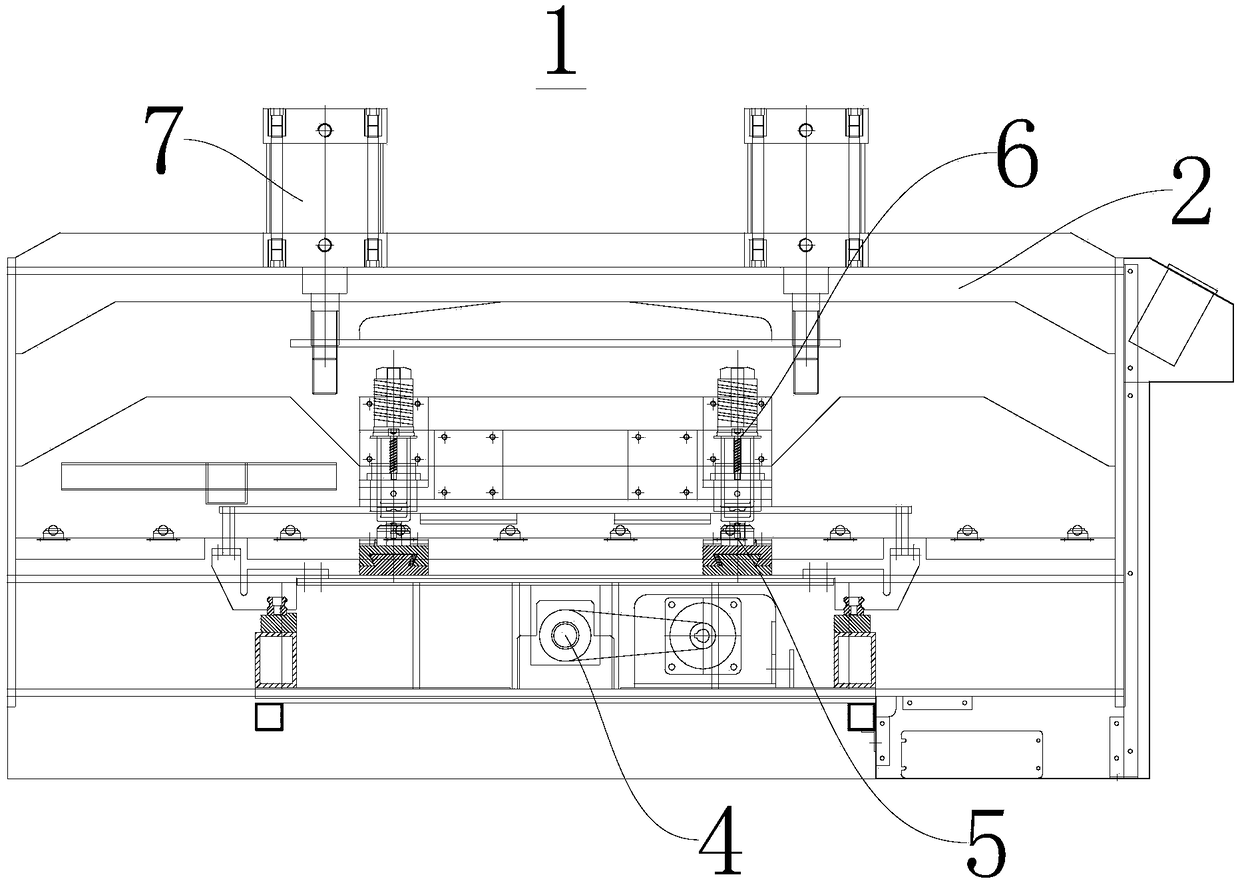

[0036] Please refer to figure 1 with figure 2 , the embodiment of the present invention provides a bead rolling device 1 for performing bead rolling operations on sheet materials. The utility model has the advantages of simple structure, convenient and rapid rolling of steel bars on sheet metal parts, high working efficiency, good rolling effect, reduced additional cost and strong practicability. In this embodiment, the sheet material is a sheet metal part in the air conditioner, and the sheet material is rolled under the action of the bead rolling device 1 to increase its strength, thereby increasing the strength of the internal structure of the air conditioner and avoiding deformation.

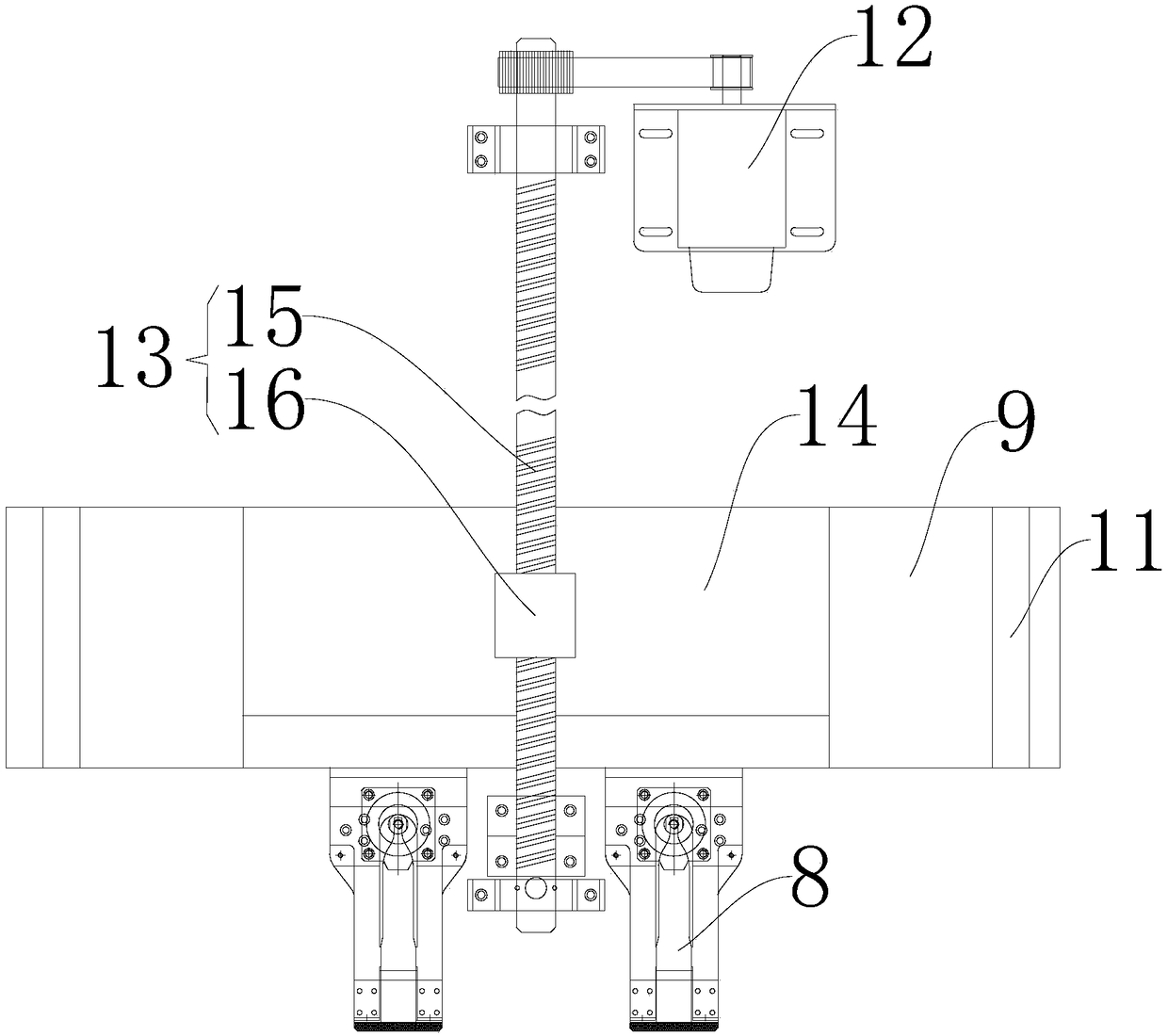

[0037] The bead rolling device 1 includes a frame 2 , a clamping mechanism 3 , a first driving mechanism 4 , a lower mold assembly 5 , an upper mold assembly 6 and a second driving mechanism 7 . The first driving mechanism 4 is installed on the frame 2 and connected with the clamping mech...

no. 2 example

[0051] Please refer to Figure 8 , the embodiment of the present invention provides a bead rolling equipment 27, which is used to perform bead rolling operations on sheet materials. The bead rolling equipment 27 includes a universal wheel 28 and a bead rolling device 1 . Wherein, the basic structure, principle and technical effect of the bead rolling device 1 are the same as those of the first embodiment. For a brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0052] In this embodiment, the universal wheels 28 are installed on the bottom of the frame 2, and the frame 2 can move through the universal wheels 28, which is convenient for movement and transportation.

[0053] The beneficial effect of the bead rolling device 27 described in the embodiment of the present invention is the same as that of the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com