Special sinking and pressing preventive straw tandem wheel for paddy field

An anti-subsidence and paddy field technology, applied in applications, crop processors, cutters, etc., can solve problems that affect farmers' normal work, straw cannot be handled, and endanger life and health. It achieves simple structure, good rolling effect, and increased grounding. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

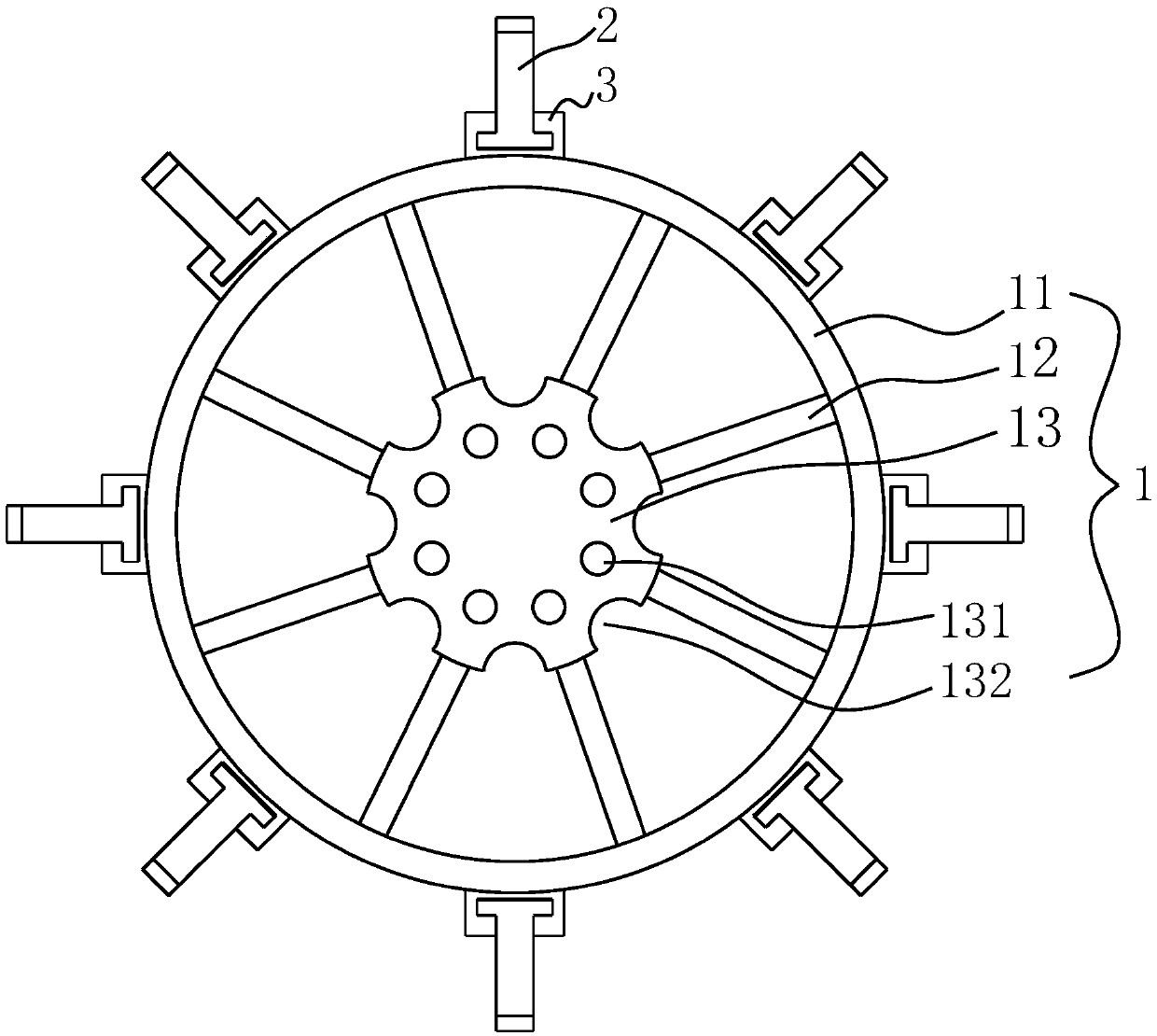

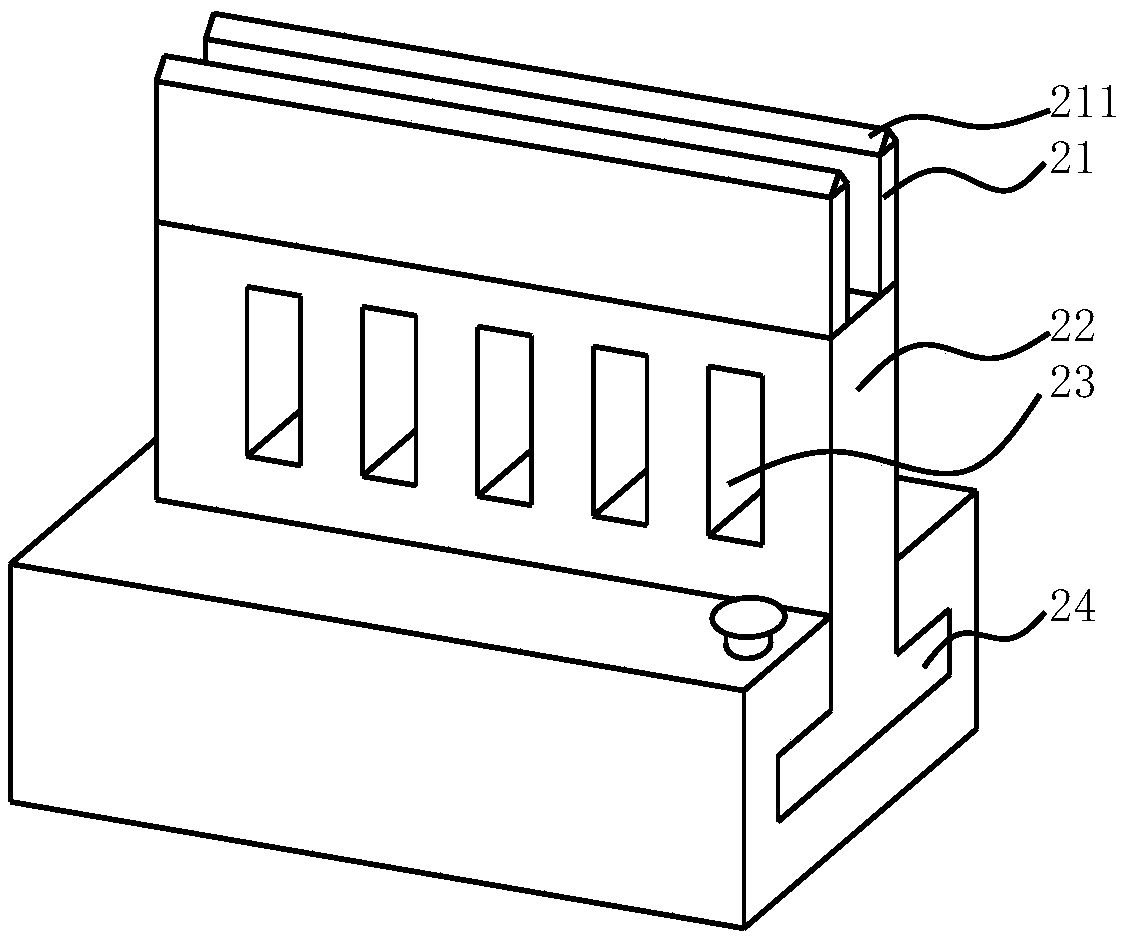

[0031] Such as Figure 1 to Figure 3 , Figure 5 , Figure 6 As shown, the present invention provides a special anti-subsidence straw string wheel for paddy fields, including a wheel body 1, a fixed plate 3 evenly welded on the surface of the wheel body 1, a guillotine plate 2 installed on the fixed plate 3, and a rubber wheel for connecting the outer rubber. No. 1 connector 4 and No. 2 connector 6 of wheel 7;

[0032] The wheel body 1 includes a rim 11 and a connecting plate 13 located at the center of the rim 11. The rim 13 is composed of steel rings 111 arranged side by side. The surface of the connecting plate 13 is uniformly provided with mounting holes 131. The edge of the connecting plate 13 The fixed flanges 132 are evenly distributed, and the fixed flanges 132 and the connecting plate 13 are integrally formed, and the fixed flanges 132 are fixedly connected to the rim 11 through the wheel shaft 12;

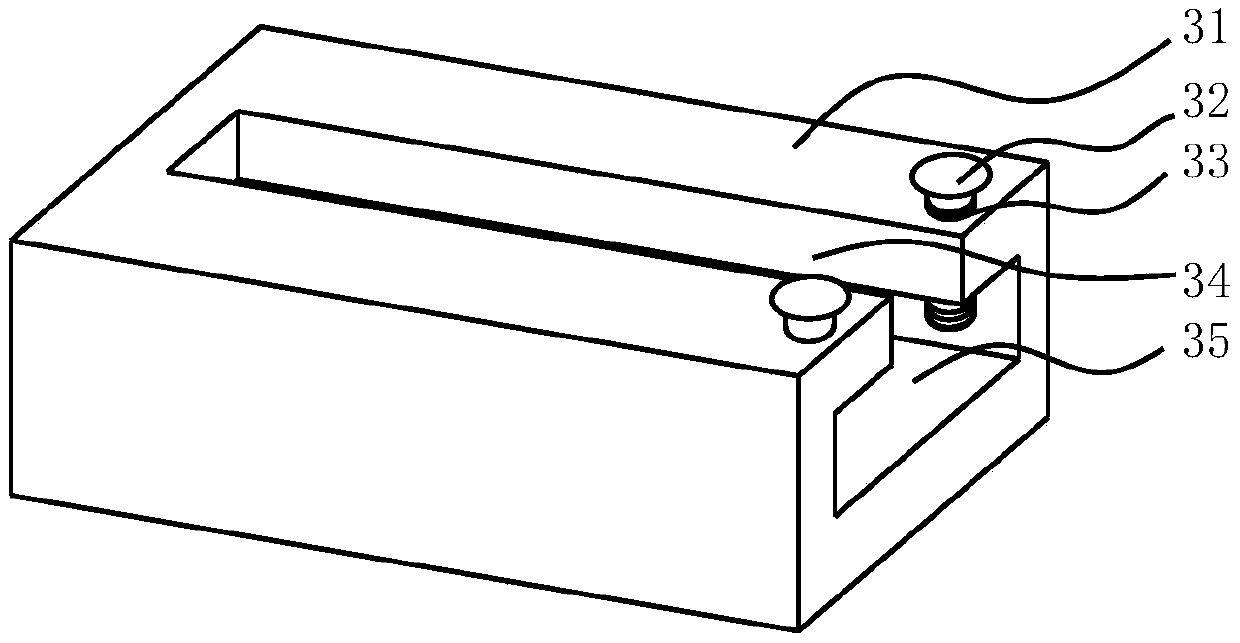

[0033] Fixed plate 3 comprises plate body 31, and the middle part...

Embodiment 2

[0041] Such as Figure 1 to Figure 6 As shown, the present invention provides a special anti-subsidence straw string wheel for paddy fields, including a wheel body 1, a fixed plate 3 evenly welded on the surface of the wheel body 1, a guillotine plate 2 installed on the fixed plate 3, and a rubber wheel for connecting the outer rubber. No. 1 connector 4 and No. 2 connector 6 of wheel 7;

[0042] The wheel body 1 includes a rim 11 and a connecting plate 13 located at the center of the rim 11. The rim 13 is composed of steel rings 111 arranged side by side. The surface of the connecting plate 13 is uniformly provided with mounting holes 131. The edge of the connecting plate 13 The fixed flanges 132 are evenly distributed, and the fixed flanges 132 and the connecting plate 13 are integrally formed, and the fixed flanges 132 are fixedly connected to the rim 11 through the wheel shaft 12;

[0043] Fixed plate 3 comprises plate body 31, and the middle part of plate body 31 has cavi...

Embodiment 3

[0052] Such as Figure 1 to Figure 6 As shown, the present invention provides a special anti-subsidence straw string wheel for paddy fields, including a wheel body 1, a fixed plate 3 evenly welded on the surface of the wheel body 1, a guillotine plate 2 installed on the fixed plate 3, and a rubber wheel for connecting the outer rubber. No. 1 connector 4 and No. 2 connector 6 of wheel 7;

[0053] The wheel body 1 includes a rim 11 and a connecting plate 13 located at the center of the rim 11. The rim 13 is composed of steel rings 111 arranged side by side. The surface of the connecting plate 13 is uniformly provided with mounting holes 131. The edge of the connecting plate 13 The fixed flanges 132 are evenly distributed, and the fixed flanges 132 and the connecting plate 13 are integrally formed, and the fixed flanges 132 are fixedly connected to the rim 11 through the wheel shaft 12;

[0054] Fixed plate 3 comprises plate body 31, and the middle part of plate body 31 has cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com