Patents

Literature

893results about How to "Avoid environmental pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

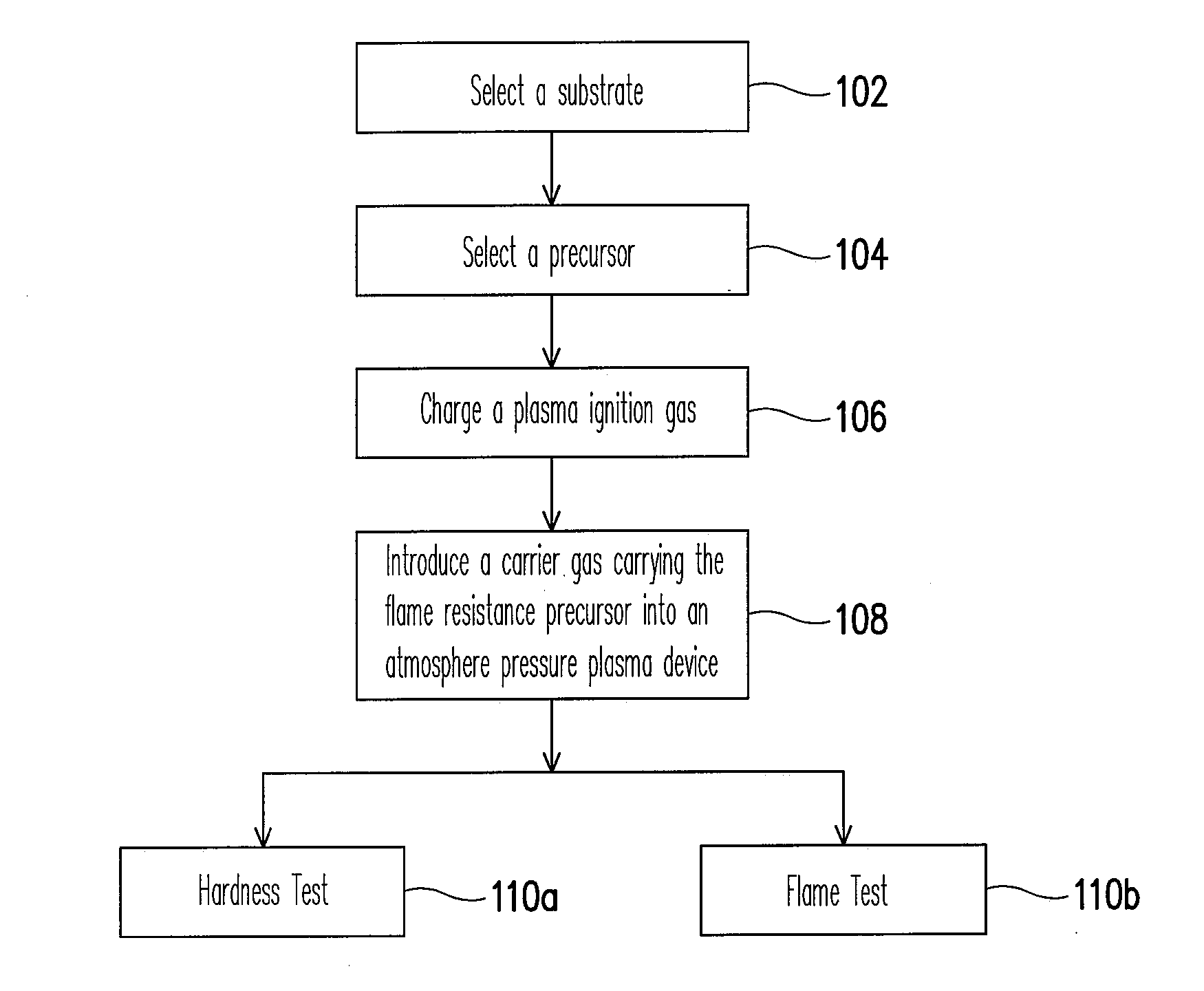

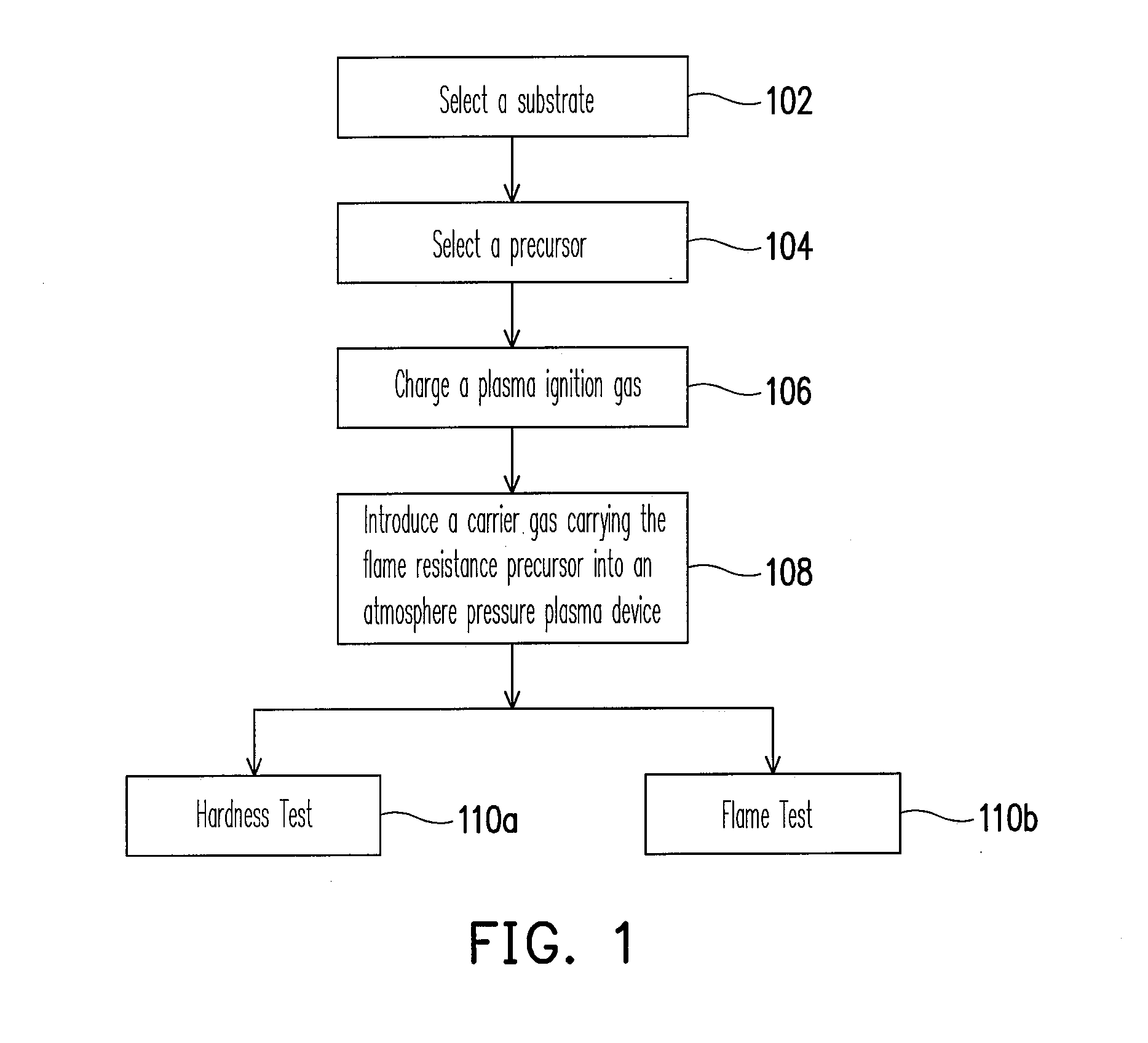

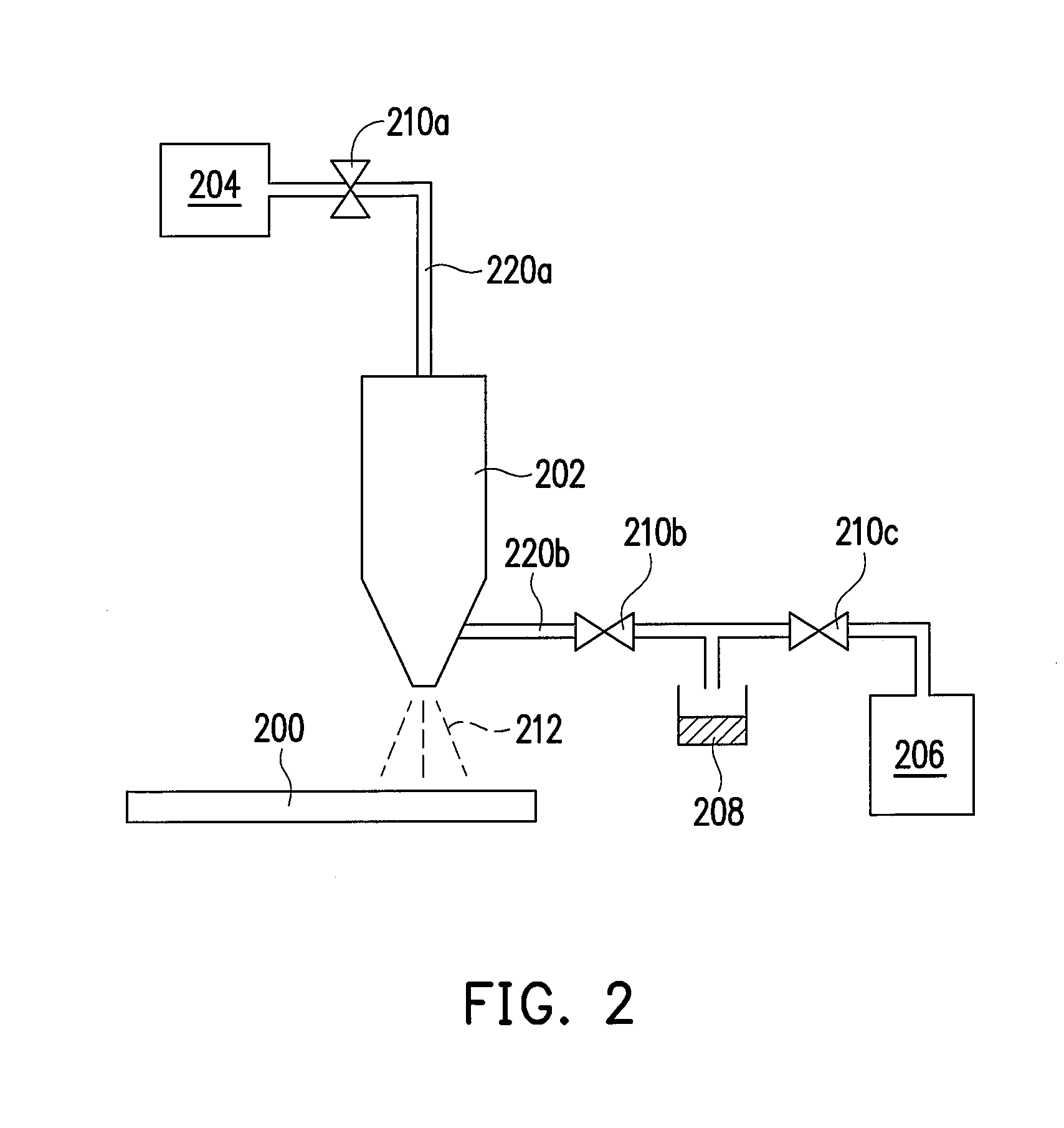

Method of improving surface flame resistnace of substrate

InactiveUS20080105276A1Improve flame retardant performanceSurface cleaningElectrostatic cleaningChemical vapor deposition coatingPlasma ignitionAtmosphere

A method of improving surface flame resistance of a substrate is provided. A substrate is provided. An atmosphere pressure plasma process is performed on the surface of the substrate to form an inorganic film layer on the surface of the substrate, wherein a process gas of the atmosphere plasma process includes a flame resistance precursor, a carrier gas, and a plasma ignition gas. Particularly, the flame resistance precursor is selected from a siloxane compound, an inorganic alkoxide compound and a combination thereof. The siloxane compound has a formula of Si(OCnH2(n+1))4, n=1˜5, and the inorganic alkoxide compound has a formula of A(OCmH2m+1)4, where A represents Sn, Ti, Zr, Ce and m=2.

Owner:IND TECH RES INST

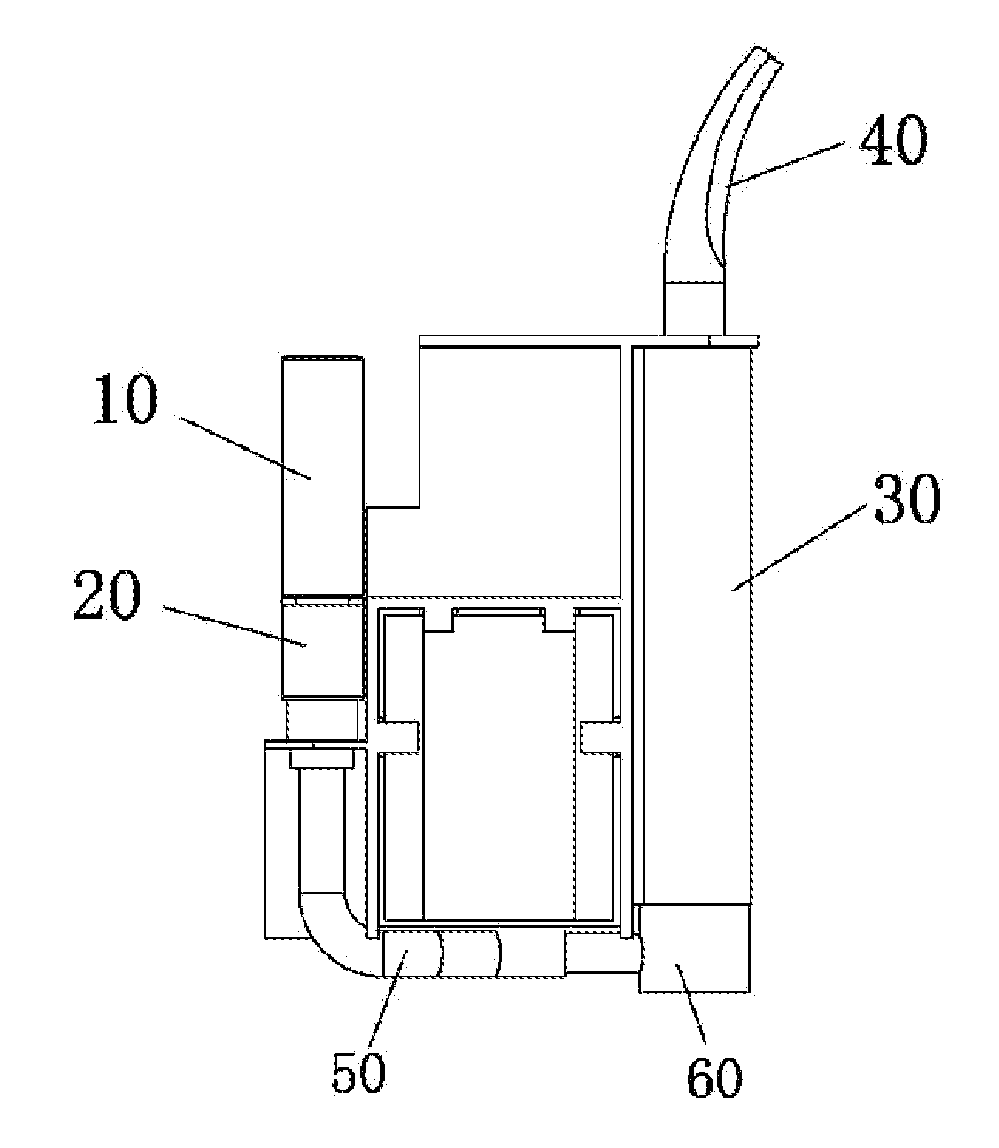

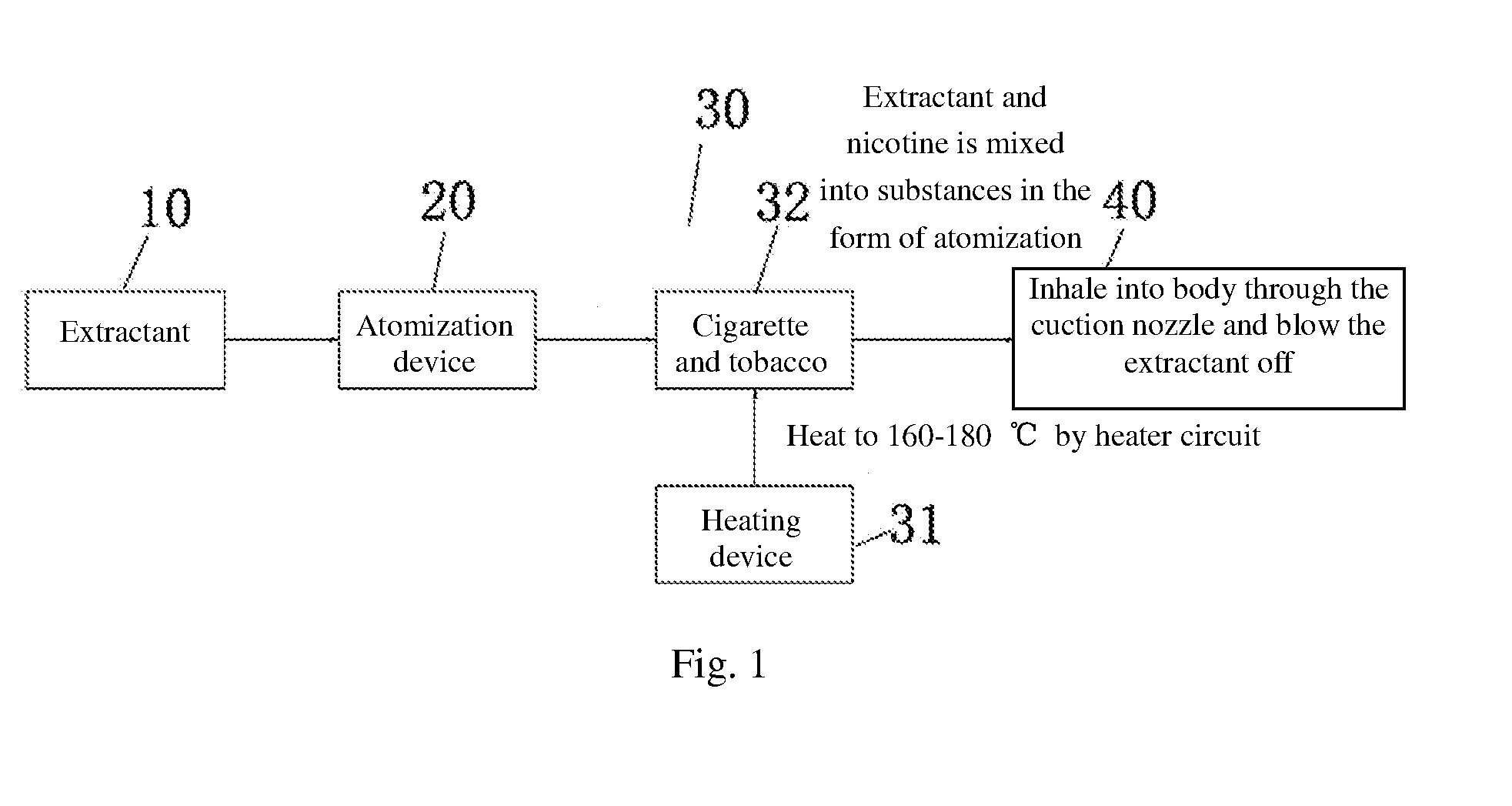

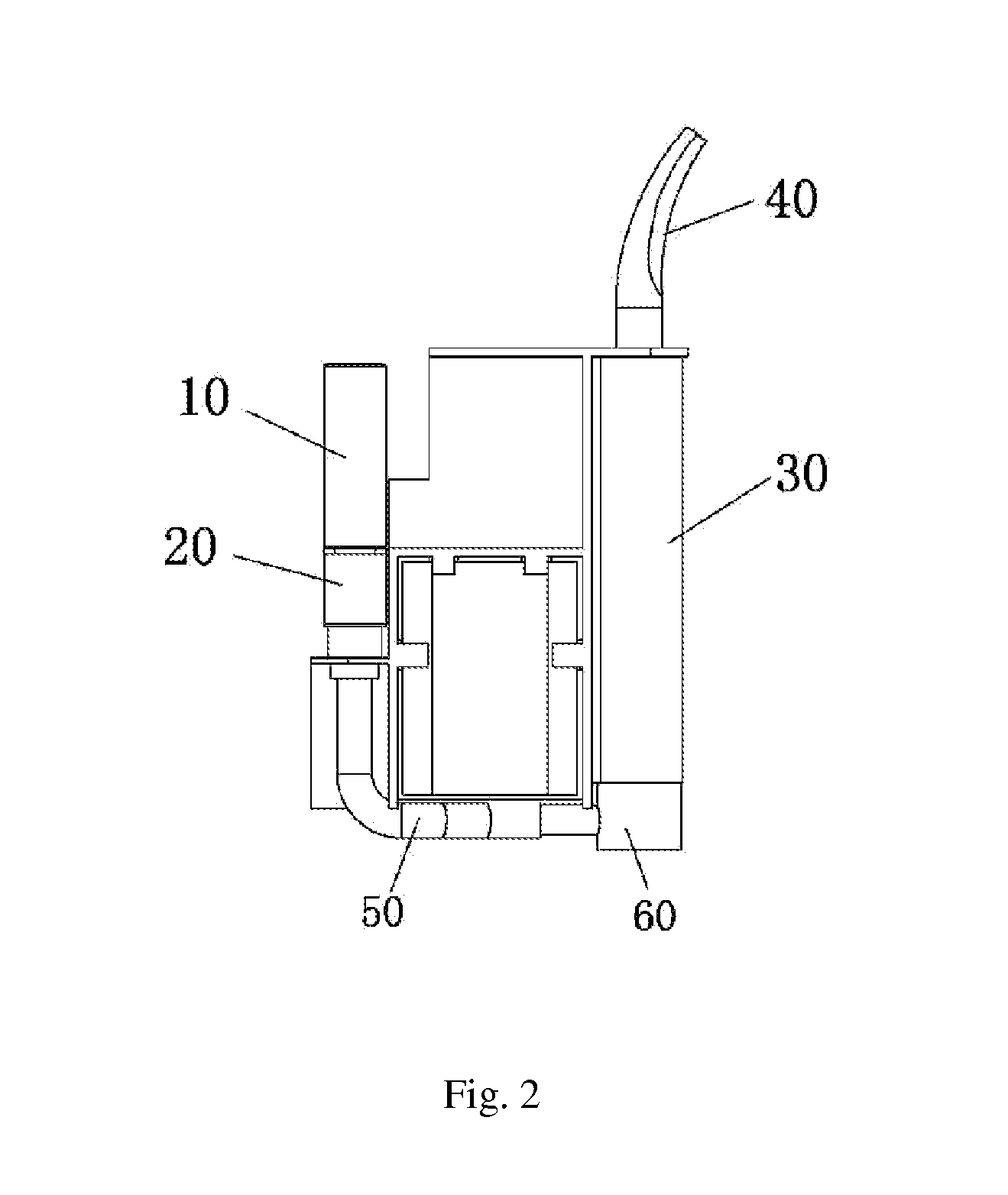

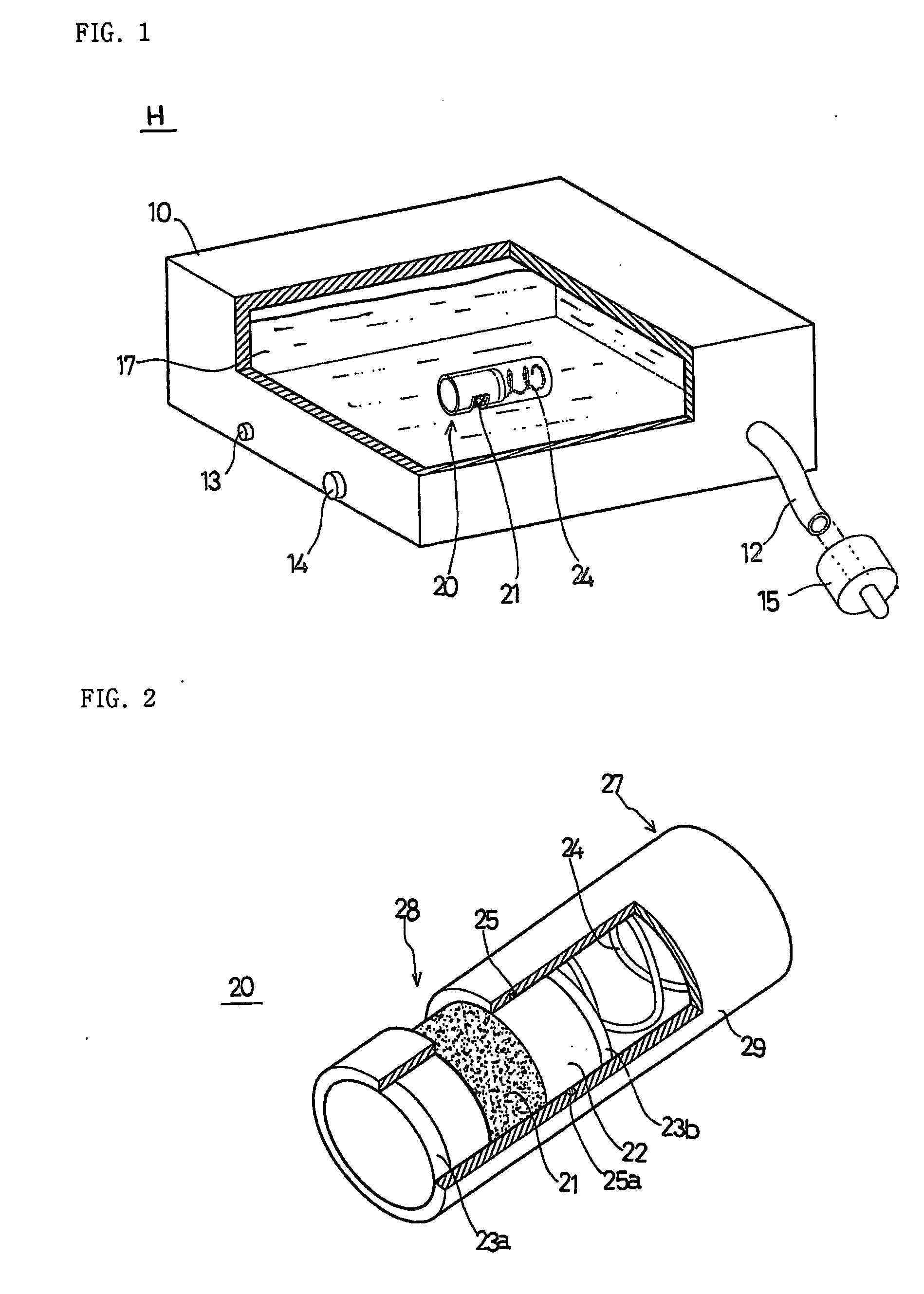

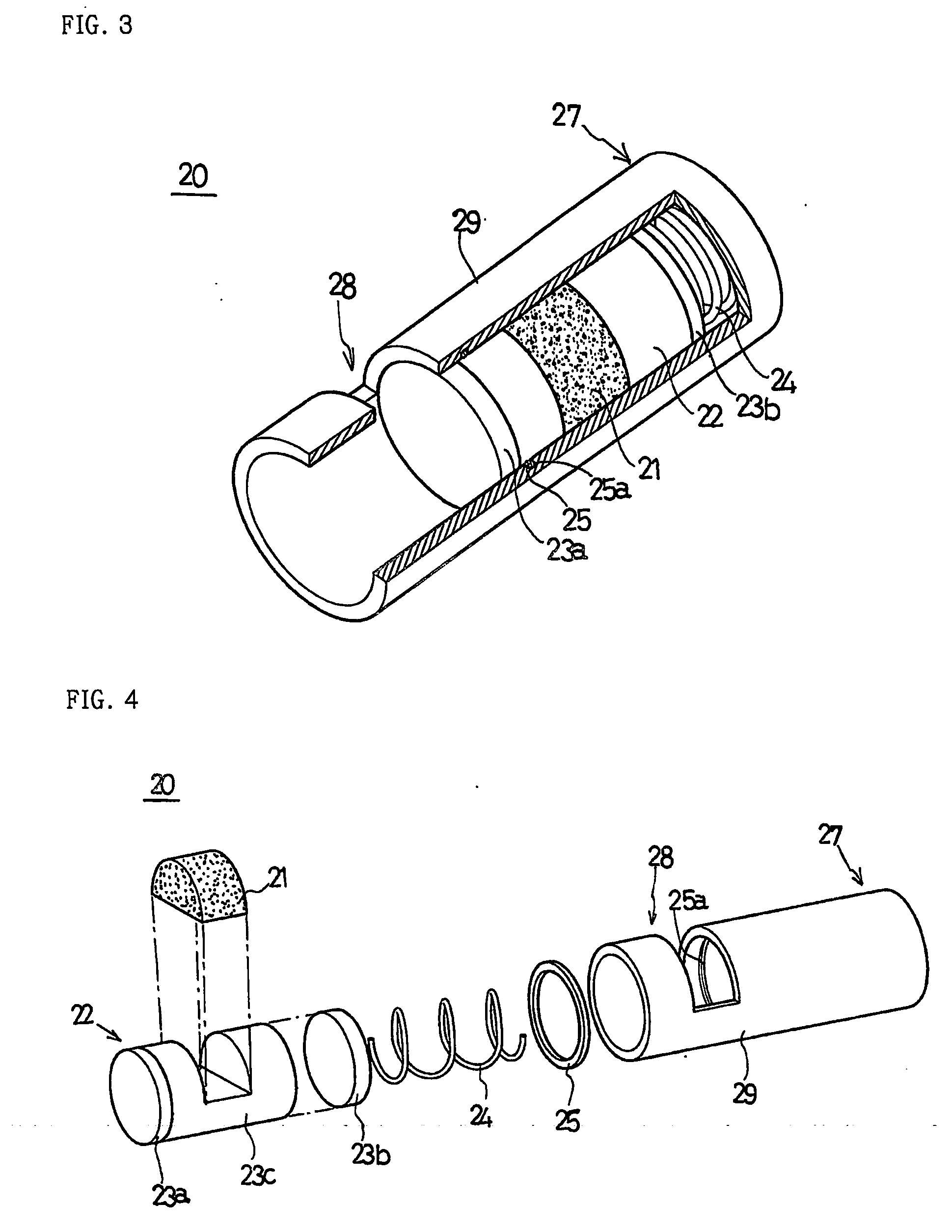

Electric flue-cured tobacco

ActiveUS20130014772A1Avoid environmental pollutionEasily absorbTobacco pipesTobacco devicesFlueElectricity

The present invention relates to an electric flue-cured tobacco. It includes a storage tank filled with extractant and an atomization device. The electric flue-cured tobacco also comprises a device for flue-curing tobacco, which includes a heating mechanism and a heated chamber for loading cigarette or tobacco. The heating mechanism comprises a heating element and a heater circuit for controlling the heating element to be heated to a setting temperature range. An inlet of the heated chamber is connected to an outlet of the atomization device, and its outlet is connected with an opening for suction nozzle. When the electric flue-cured tobacco is working, the extractant is atomized by the atomization device and then guided into the heated chamber. The heat produced by the heating element is applied to the cigarette or tobacco in the heated chamber to generate nicotine. The nicotine and atomized extractant are mixed together and then sucked out through the opening for suction nozzle. By adopting the structure mentioned above, since the nicotine in the form of atomization can be easily absorbed by the lung, most of the gas that smokers blow off is the extractant. Therefore, the environmental pollution and passive smoking for people around can be reduced. On the other hand, it can satisfy smokers' taste.

Owner:HUIZHOU KIMREE TECH

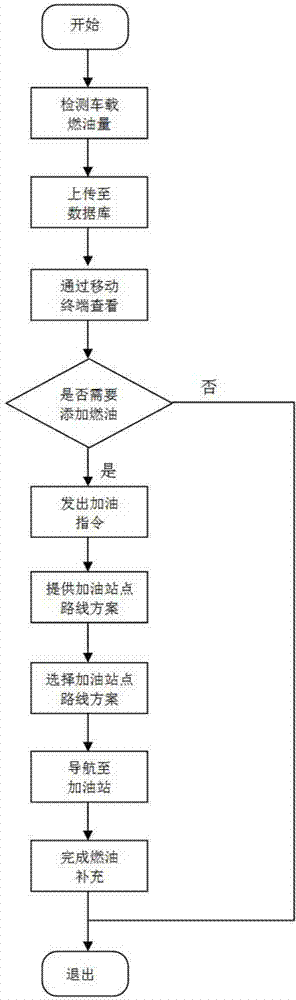

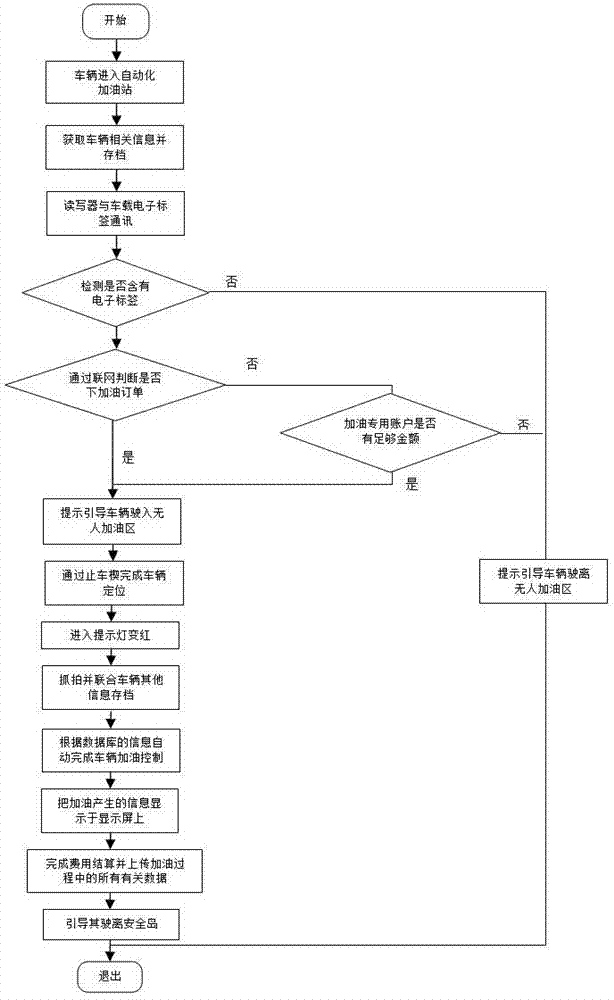

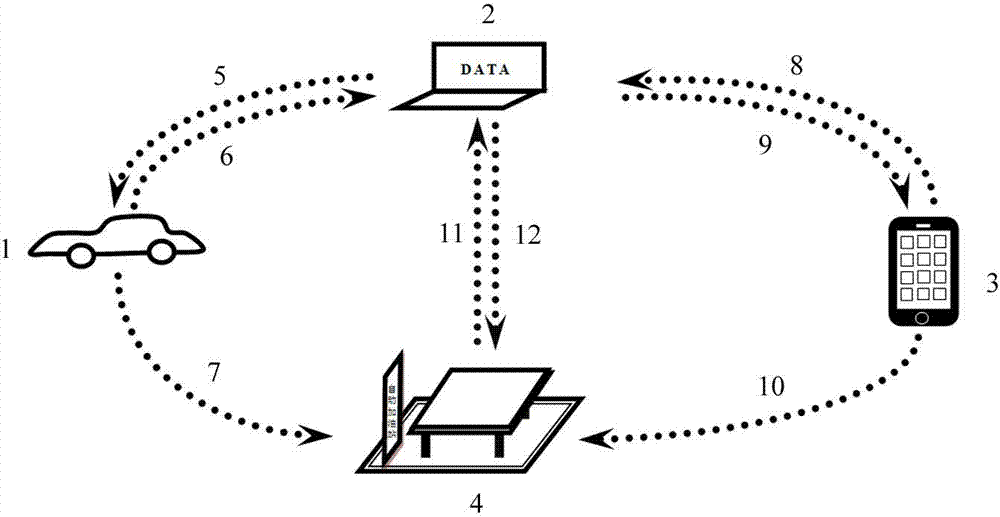

Automatic refueling and payment system for automobile

InactiveCN104778788AIncrease security risksAvoid environmental pollutionApparatus for hiring articlesAutomatic controlOn board

The invention discloses an automatic refueling and expense settlement completing system for an automobile. The system integrates technologies and applications, such as computer software / hardware, an RFID (Radio Frequency Identification) technology, wireless communication, information acquisition, data transmission, network communication, automatic control, network payment and a ranging and positioning system. According to the system, an on-board computer is used for acquiring the volume of a fuel carried by the automobile and transferring data to a database through the Internet of vehicles, so that automobile carried volume can be examined through a mobile terminal; if the fuel is required to be added, ordering and the prepaying of corresponding expense can be completed through the mobile terminal, then, a corresponding user is navigated to a gas station, an automatic refueling system acquires information on a vehicle electronic tag through the RFID technology so as to realize automobile identity identification, then, refueling and information acquisition are completed automatically, and refueled settlement is completed. The system has the advantages that the whole process is carried out automatically, the safety, service level and efficiency of a refueling process are increased, the charge management is simplified, the environmental pollution is lowered, labor is saved, and the like.

Owner:王礼

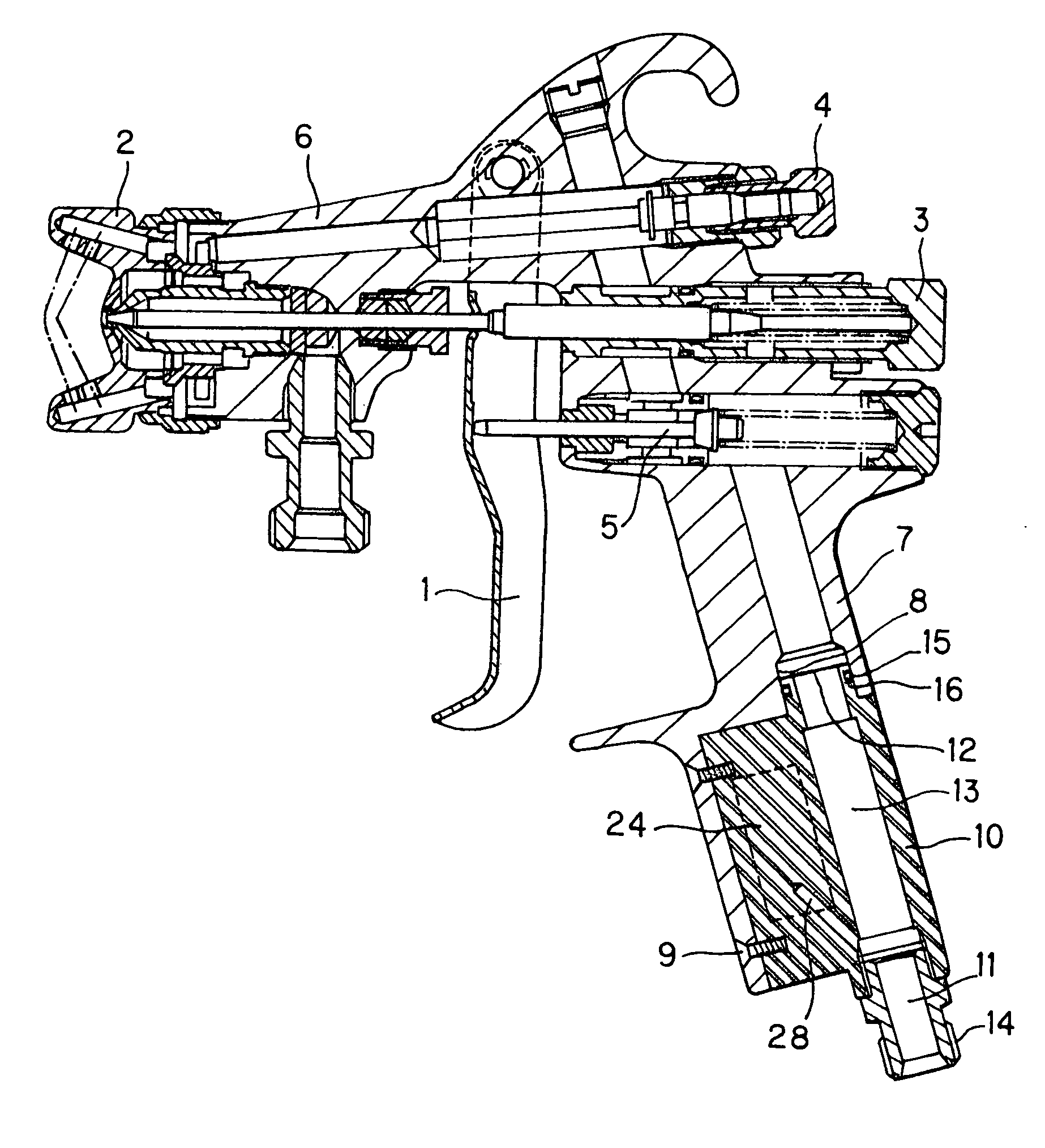

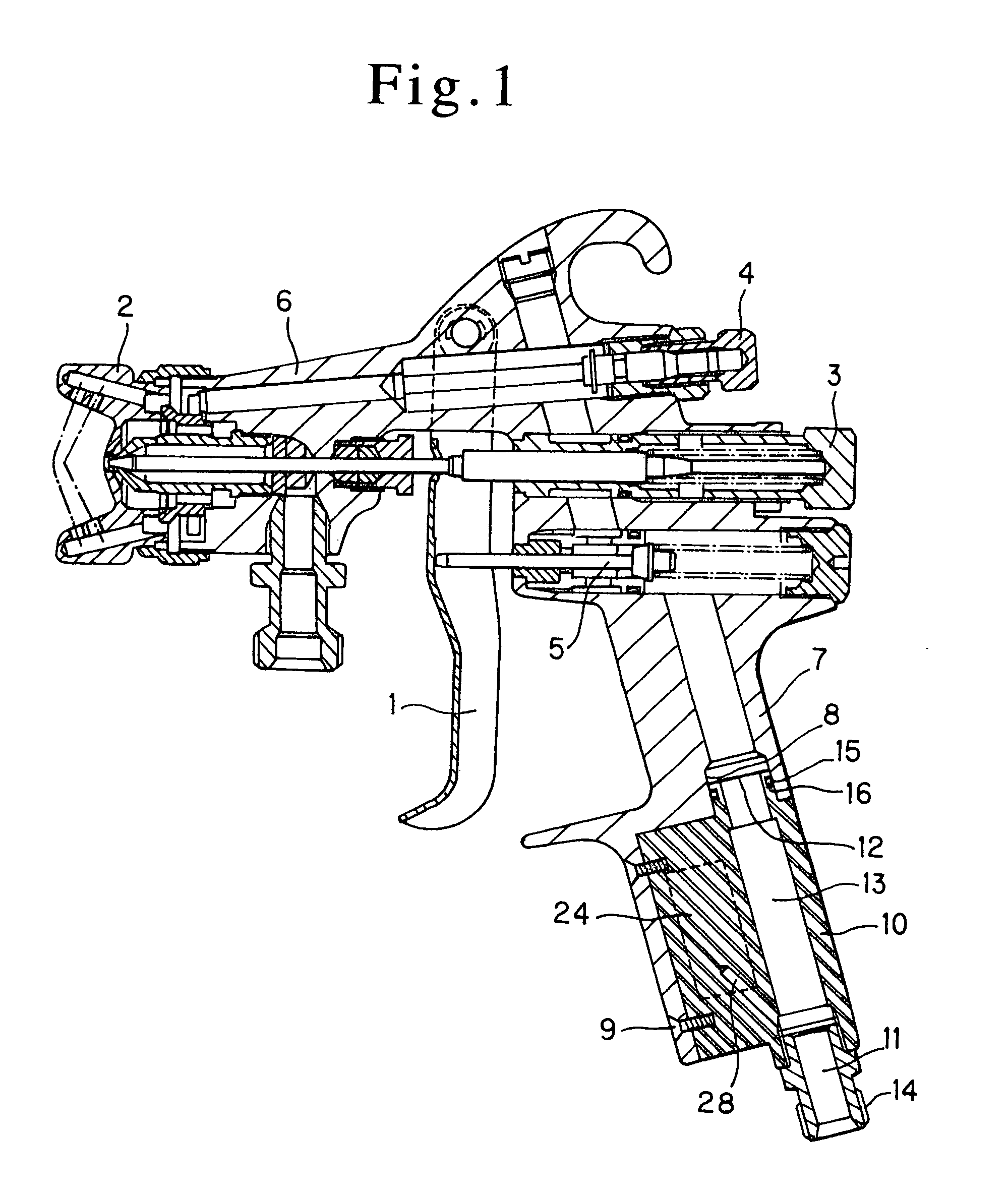

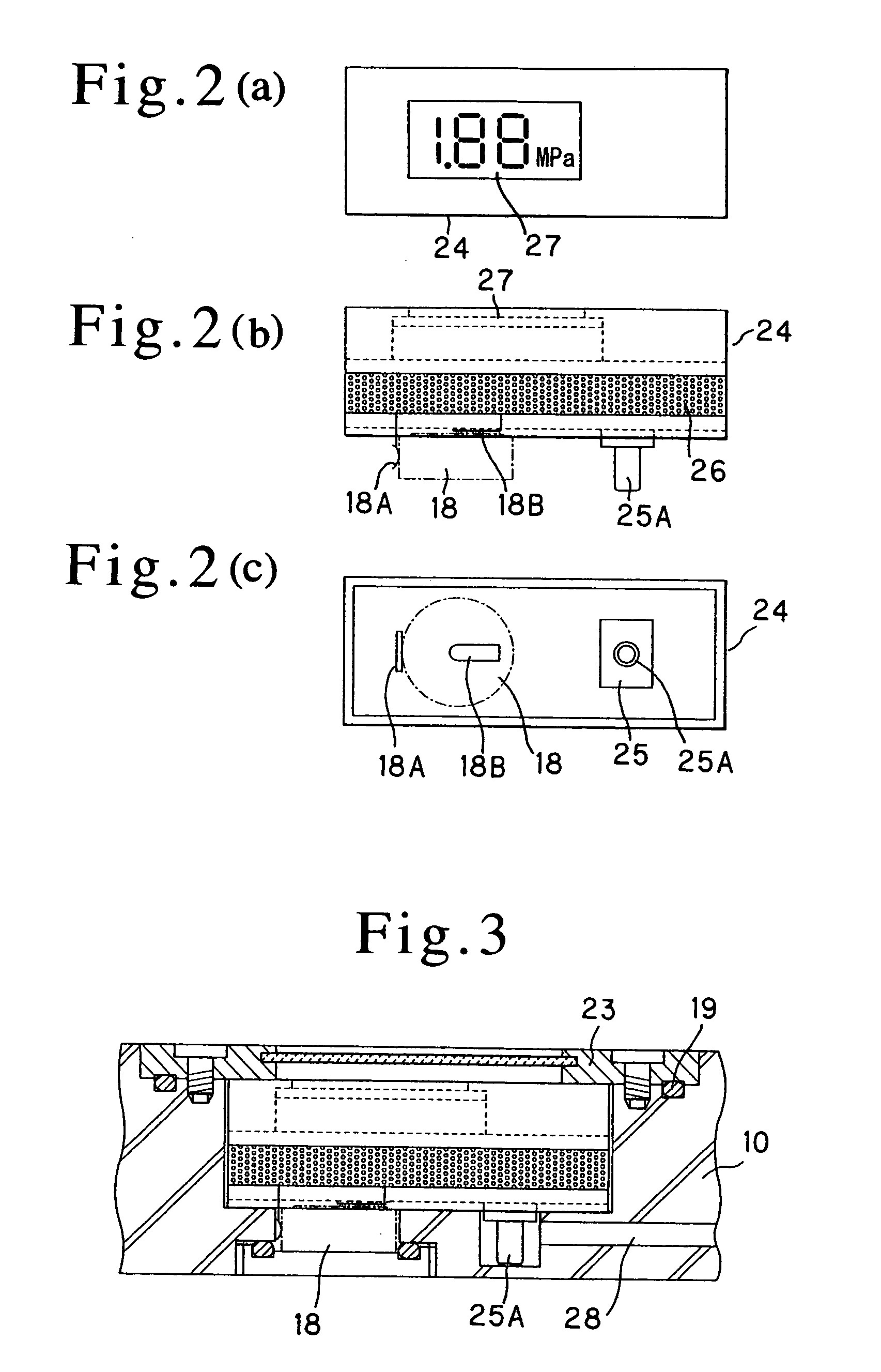

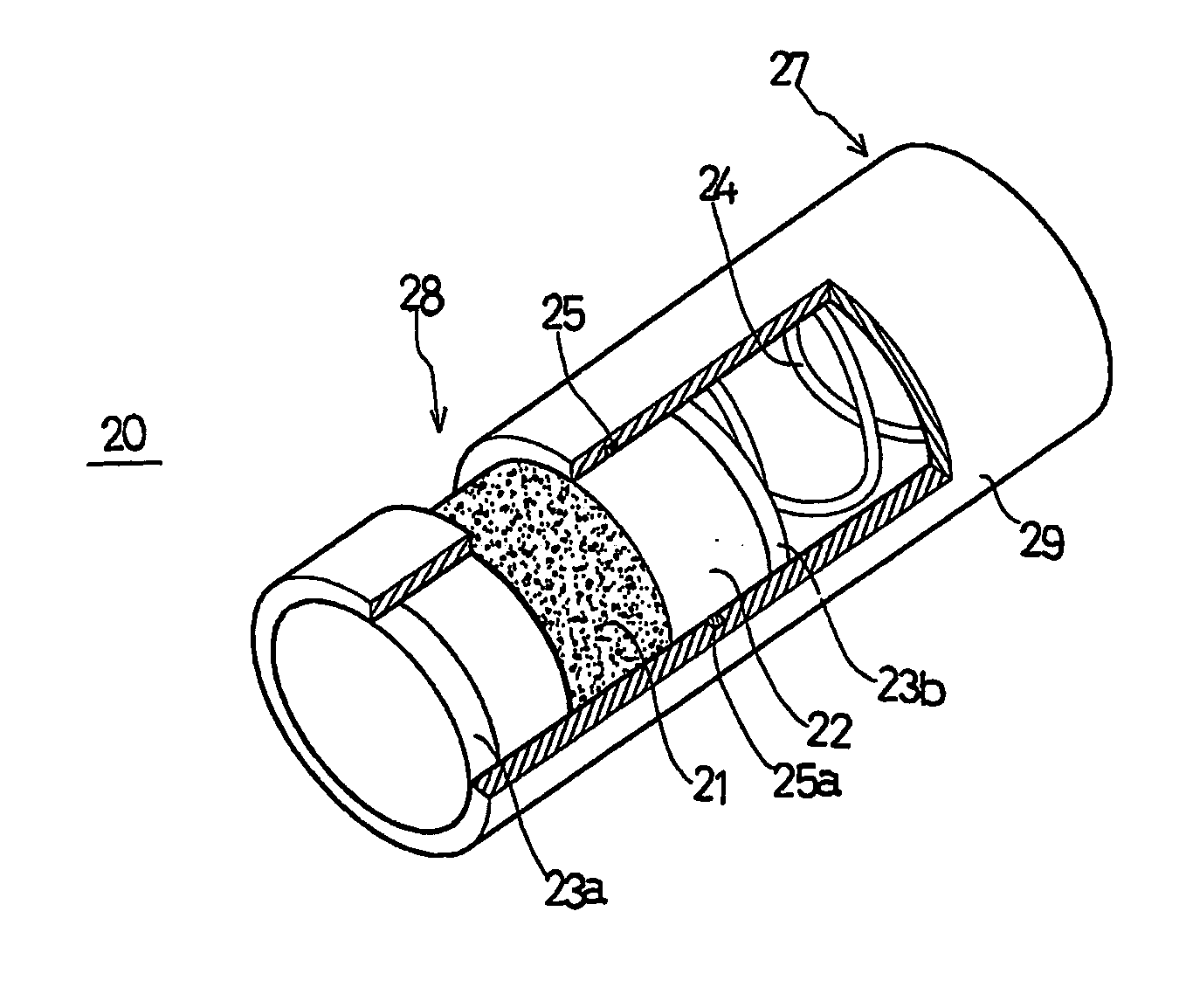

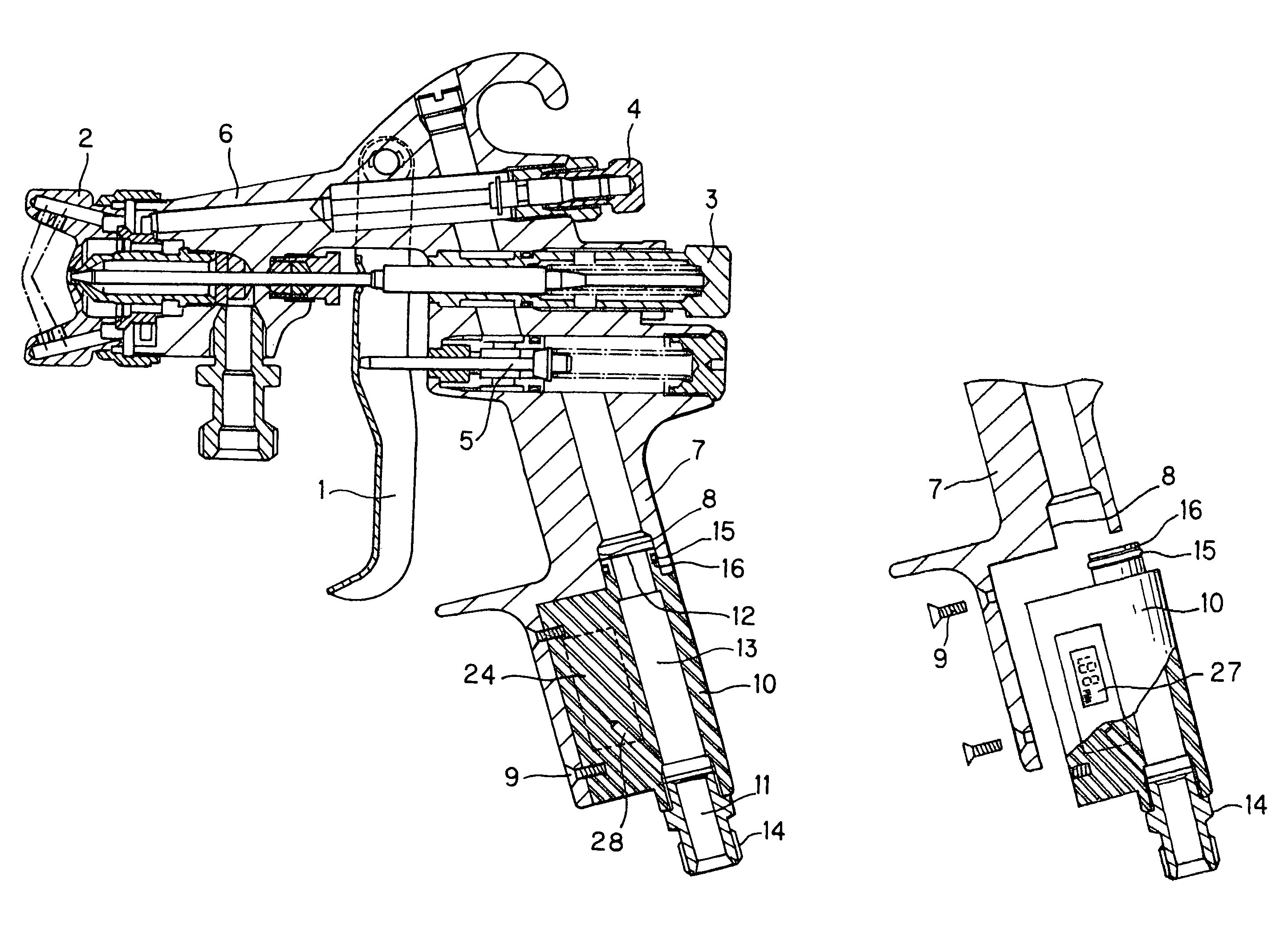

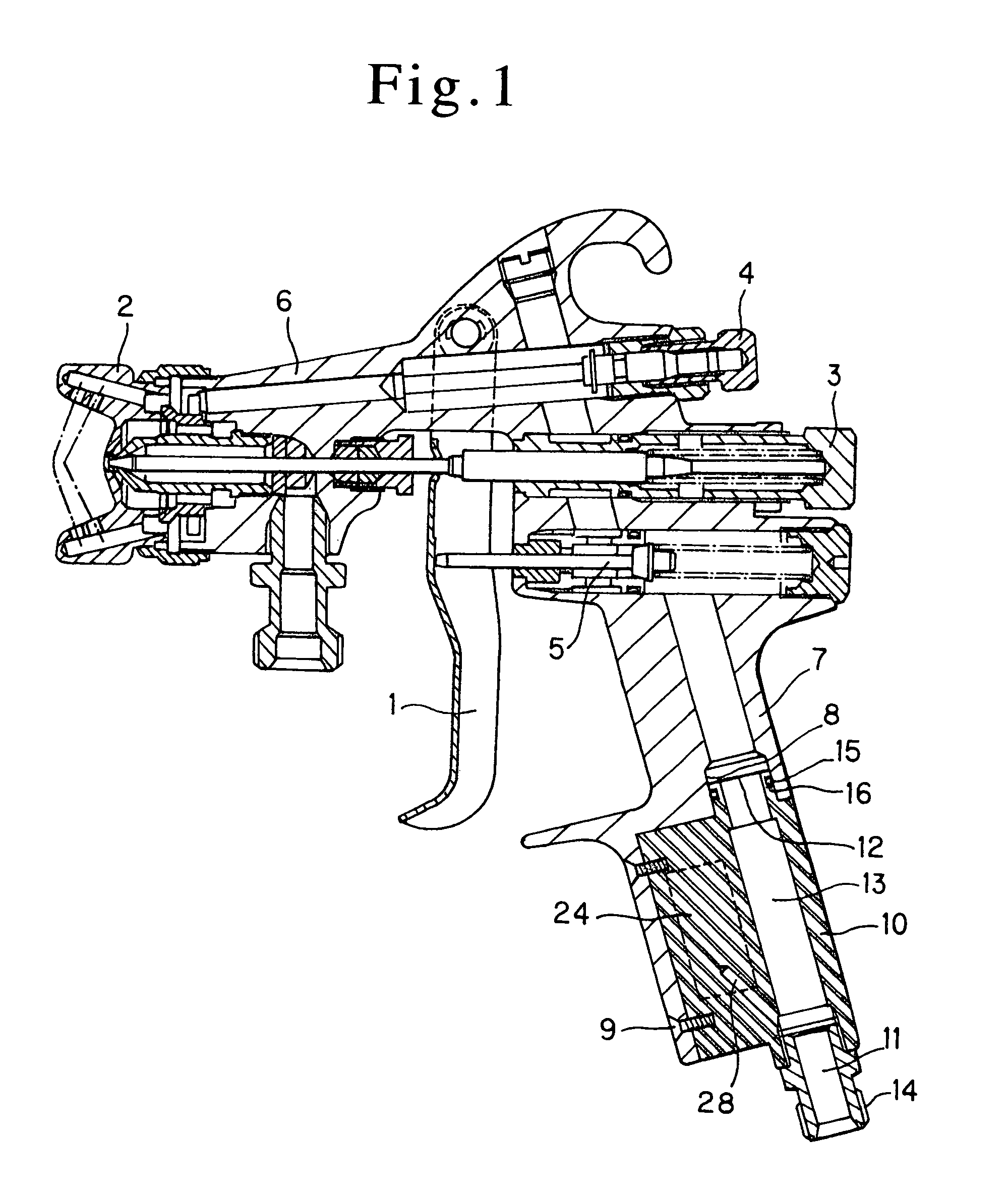

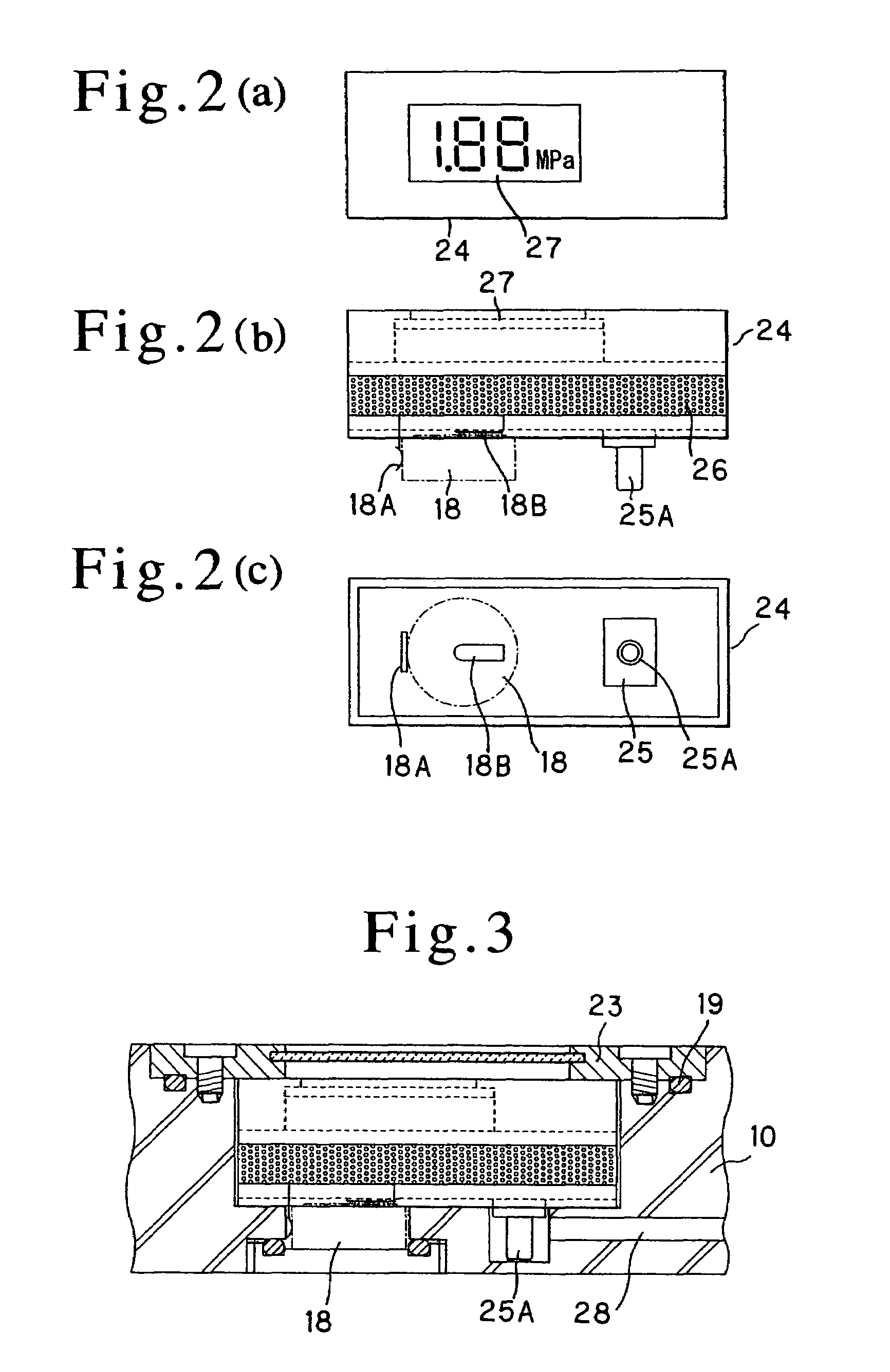

Spray gun with pressure display

ActiveUS20050127201A1Minimize paint consumptionHigh and stable qualitySpray nozzlesFluid pressure measurement by mechanical elementsEngineeringPressure sensor

A spray gun with pressure display for applying paint onto a painted object by atomizing the paint with compressed air, wherein, as a pressure indicating device capable of accurately indicating a pressure at hand where the spray gun is operated, a digitally displayed pressure indication module having a pressure sensor (25), a pressure transducer part (24), and a display part (27) unitized with each other is detachably installed on a spray gun body, and adopters (21, 22) without a pressure indication function are detachably fitted to tie spray gun body according to the shape of a body grip part so that the presence or absence of the pressure indication function can be selected before use, whereby the spray gun can be used under controlled conditions by allowing a worker to detect an air pressure at hand during spraying operation since the spraying air pressure largely affects paint finish as well as dispersion of atomized paint.

Owner:ANEST IWATA CORP

Edible starch-based food packaging film and preparation method thereof

ActiveCN101899173AAvoid environmental pollutionAbundant sources of raw materialsFlexible coversWrappersFood packagingPlasticizer

The invention relates to an edible starch-based food packaging film and a preparation method thereof. The edible starch-based packaging film with high mechanical strength, barrier property, ageing resistance and heat sealability is prepared from a main film-forming raw material stabilized crosslinking compound modified starch, and auxiliary materials such as food grade plasticizers, lubricants, reinforcers, stabilizers and the like through high speed stirring and mixing, twin-screw extrusion granulation and single-screw extrusion blow molding. The preparation method has the characteristics of low energy consumption, high production efficiency and suitability for continuous industrialized production. The film has the advantages of edibility, full-degradable property, wide application for inner packaging of foods and no environmental pollution caused by non-degradable food packages.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

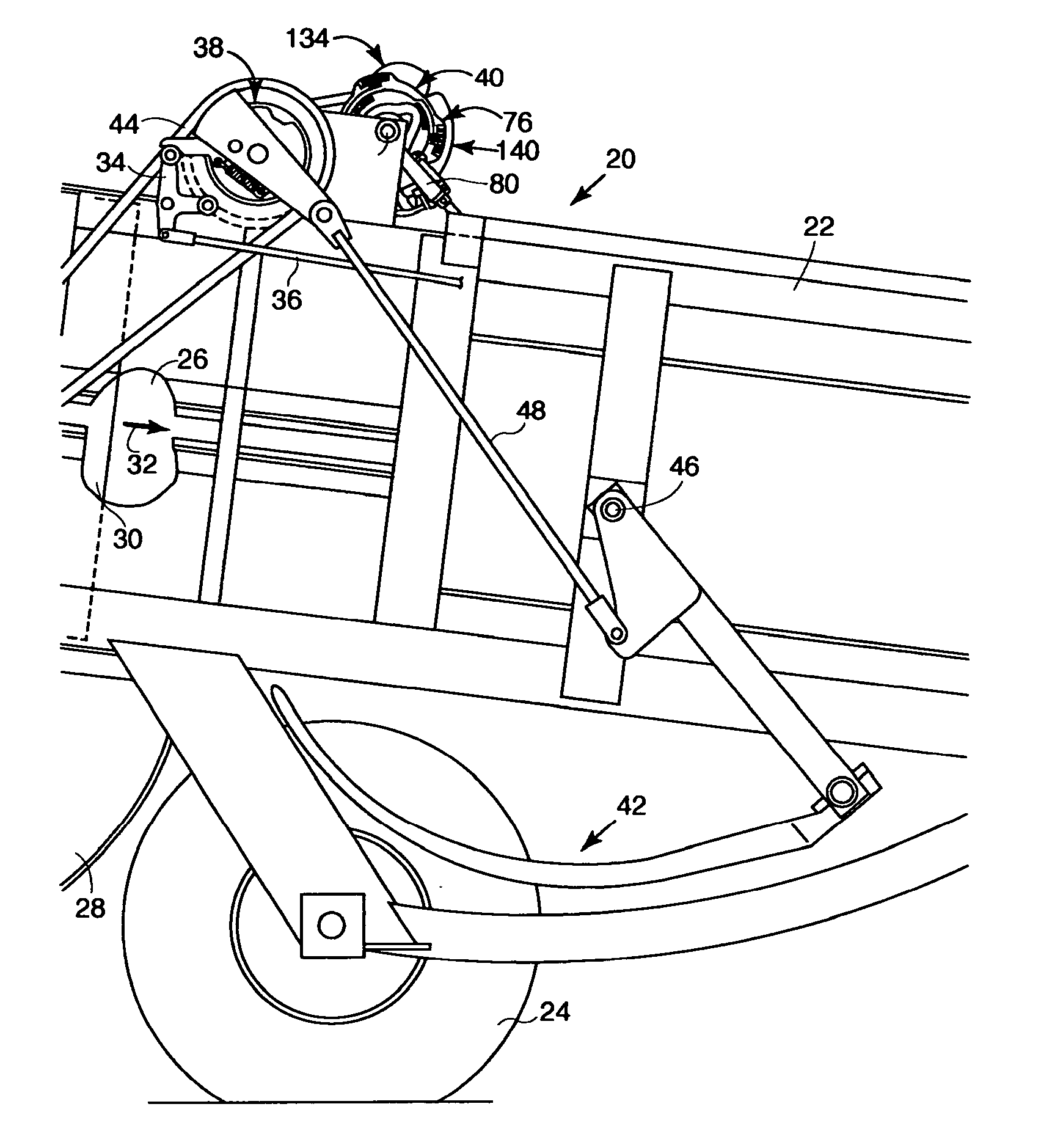

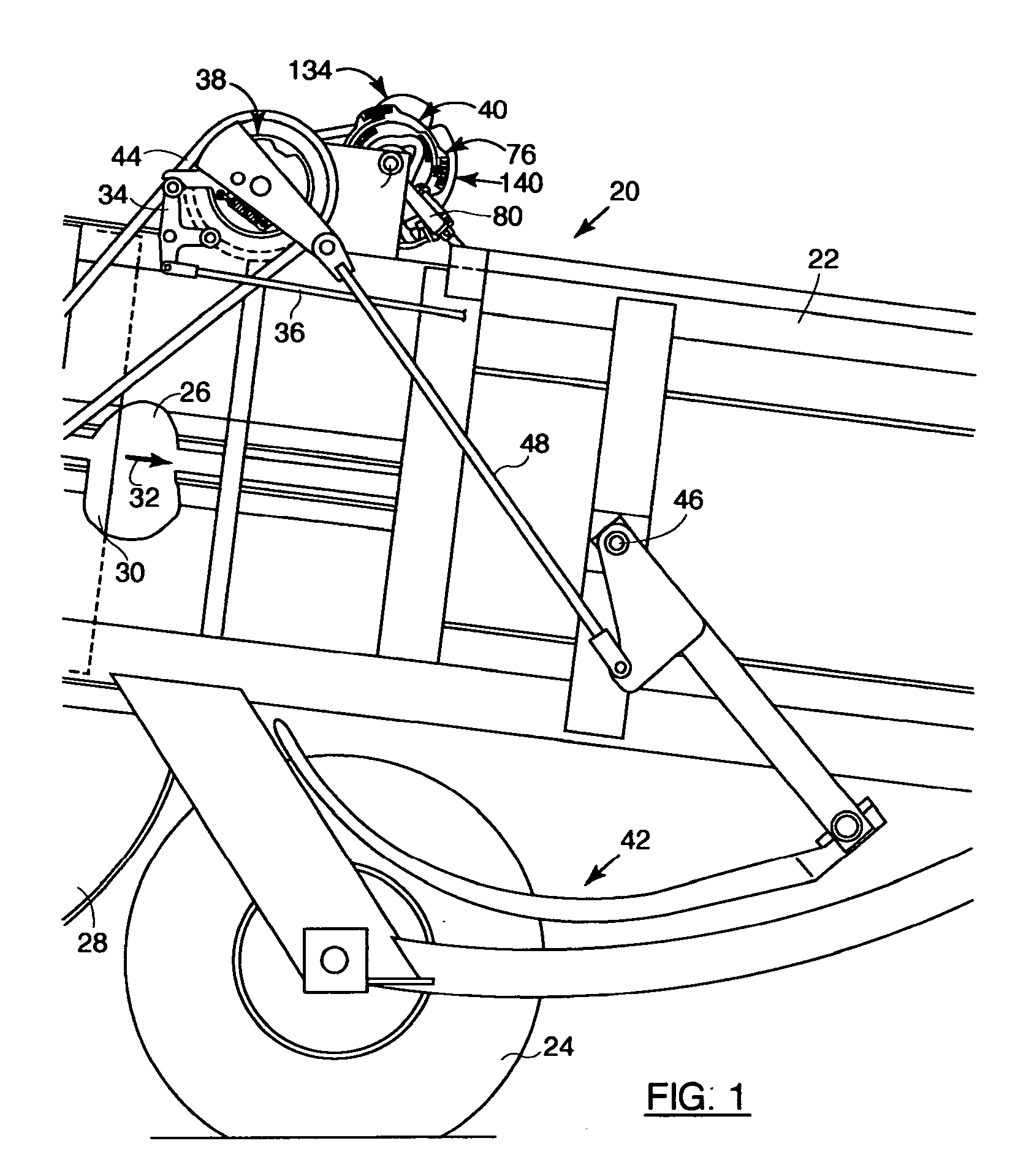

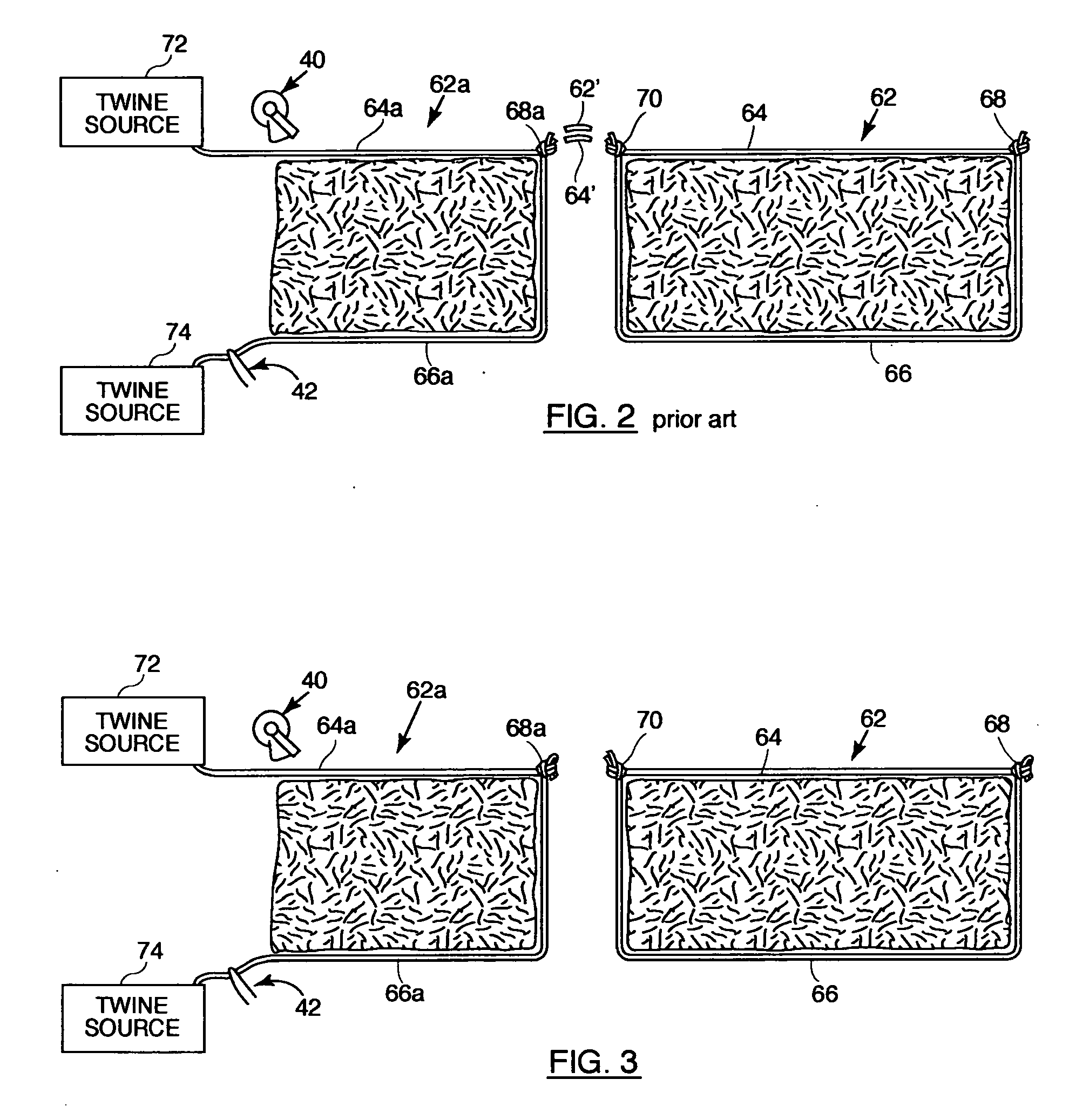

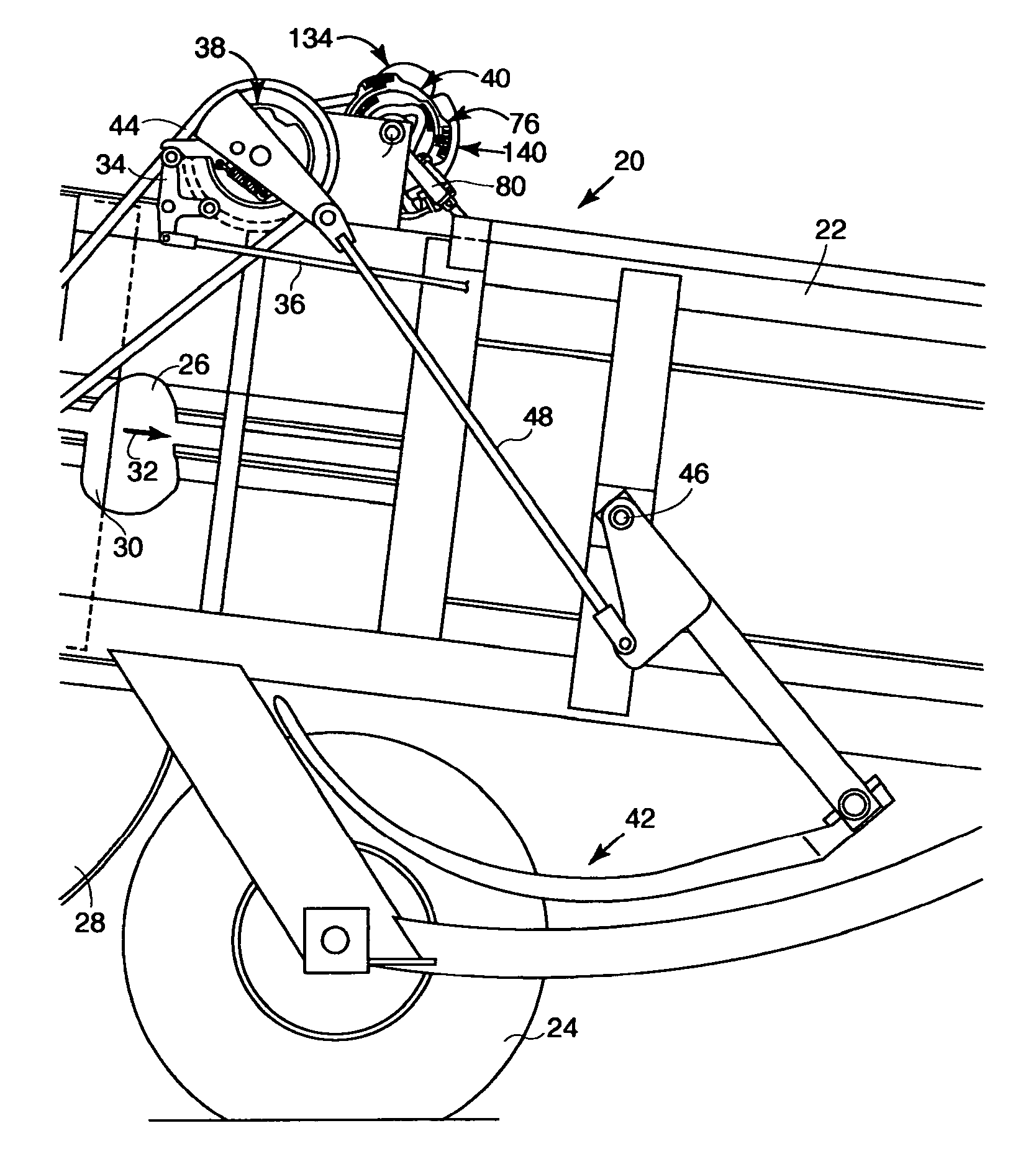

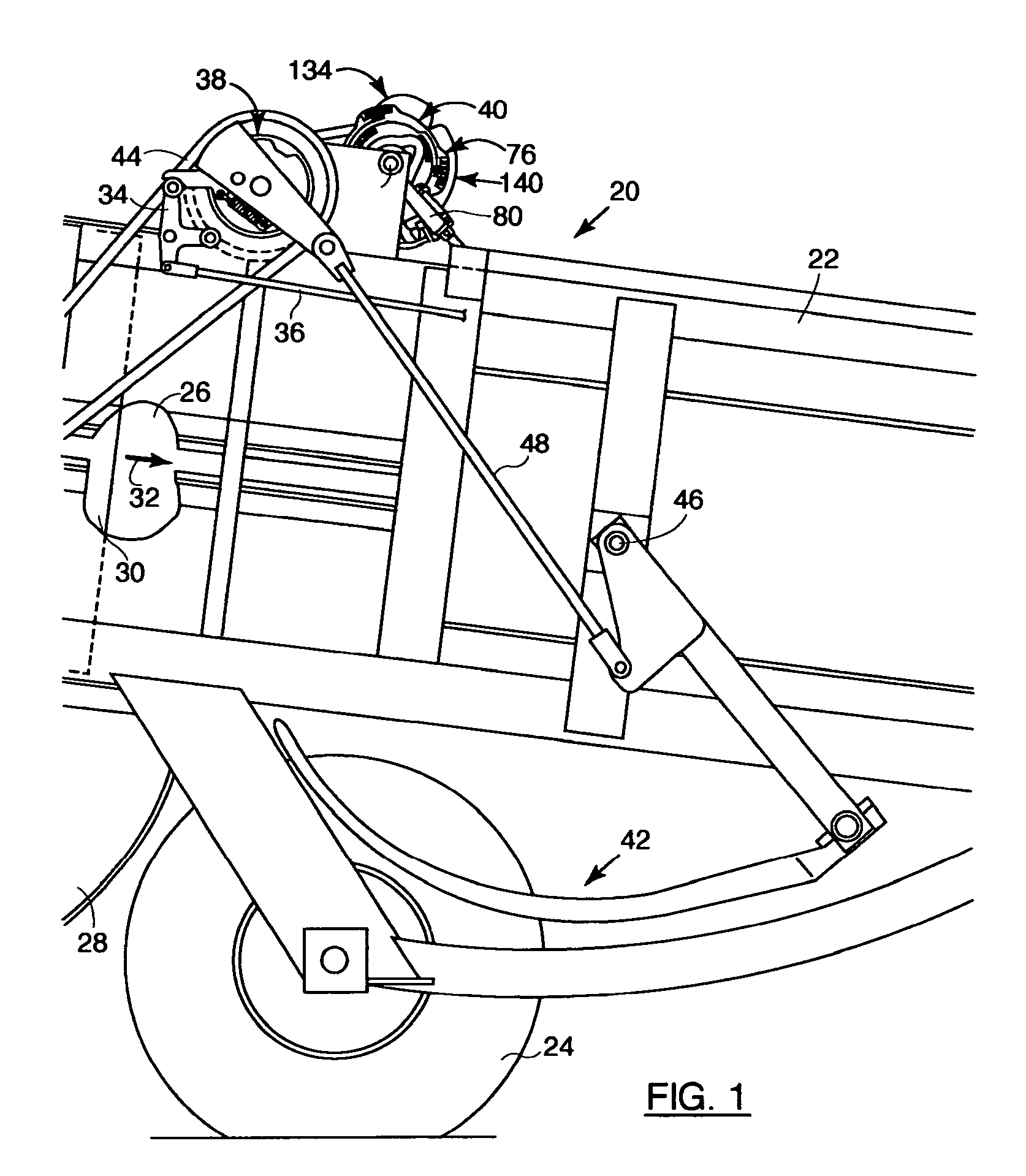

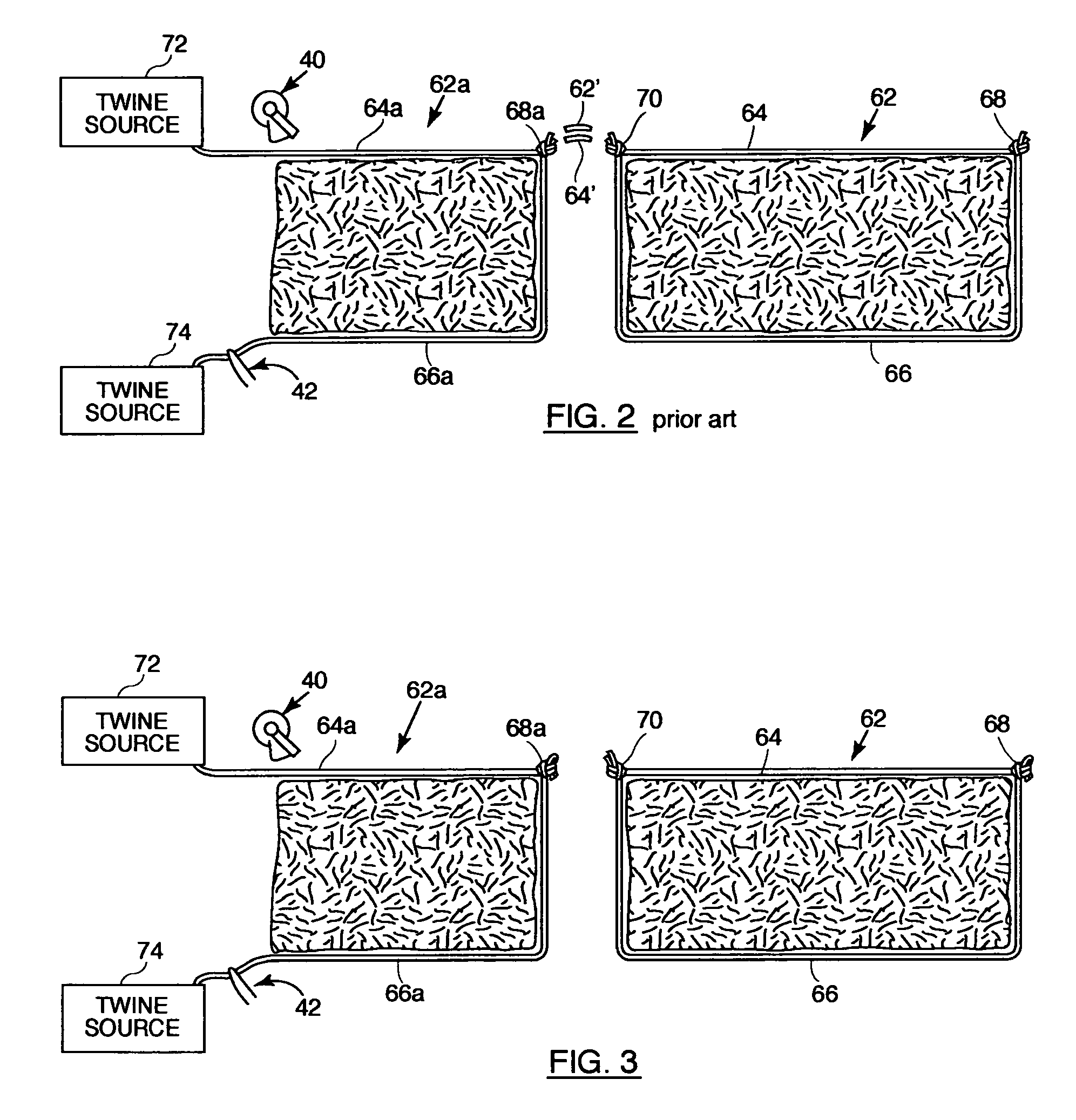

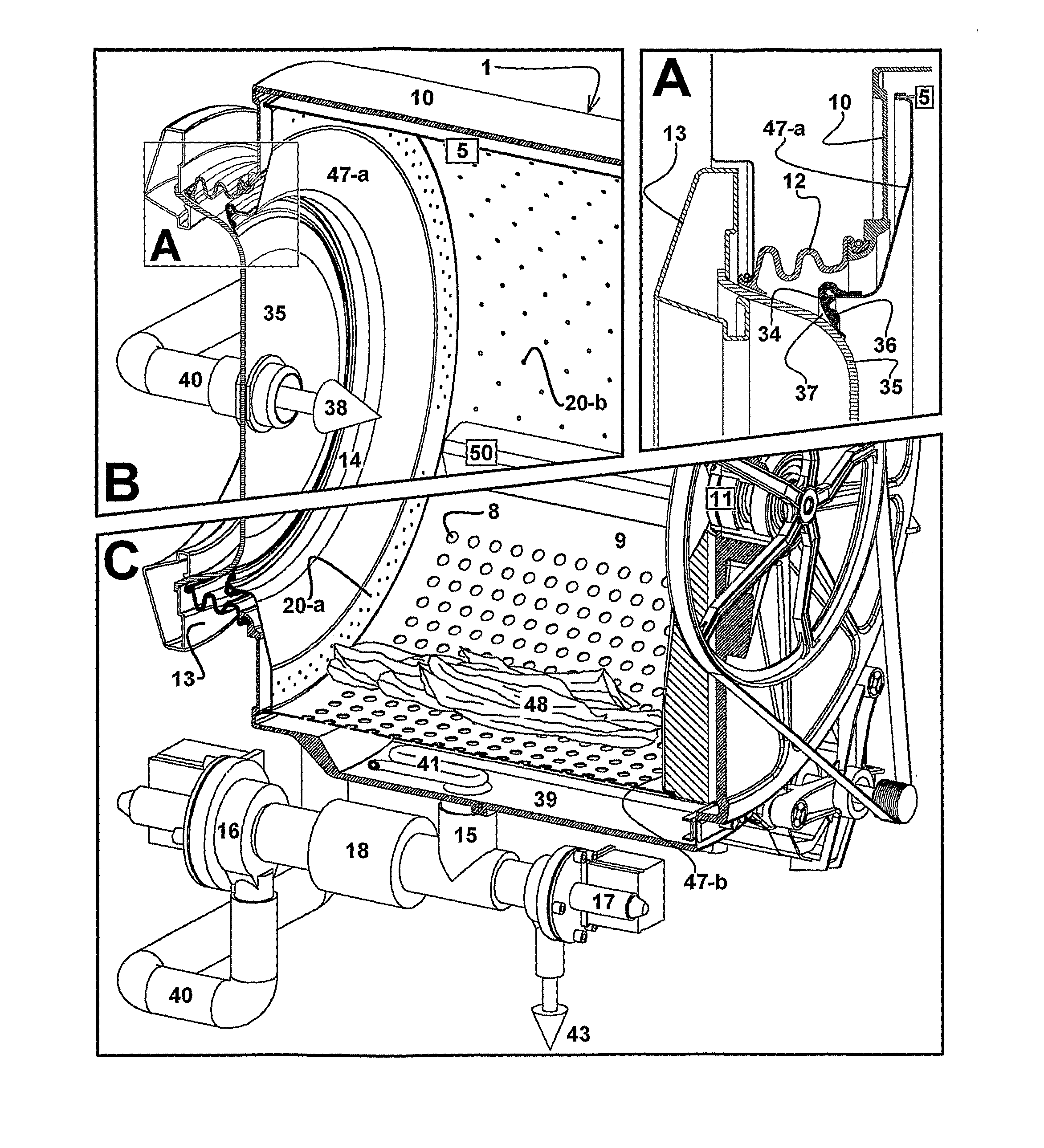

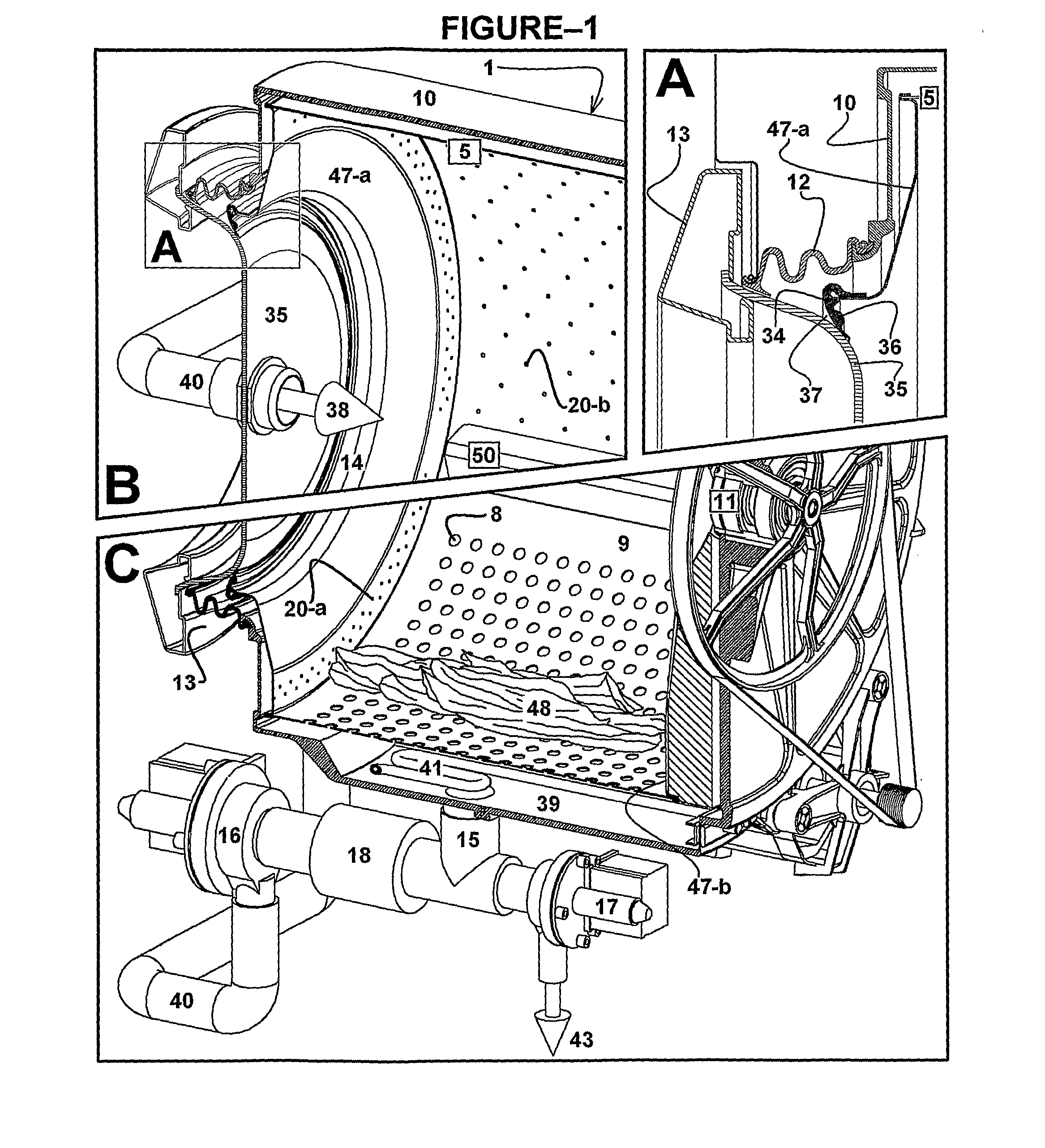

Double knotting system for an agricultural baler

ActiveUS20060012176A1Reliable constructionEasy to manufactureHarvestersFilament handlingEngineeringOperating cycle

A tying mechanism for a baler, operable to produce two successive knots in a pair of strands during one full operating cycle of the tying mechanism; the mechanism comprising a twine holder for maintaining the pair of strands in a suitable position throughout the complete formation of a first one of said two successive knots and to continue to maintain the pair of strands in a suitable position during the initial stage of the formation of a second one of said successive knots, and a cutter co-operating with the twine holder for severing the strands during formation of said first one of said two successive knots. The tying mechanism further comprises releasing means to release said pair of strands from the twine holder before full completion of said second one of said two successive knots. No twine tails will be formed, preventing knotter problems occurring during the baling process. Also environmental pollution will be prevented since no twine tails will be removed from the baler.

Owner:BLUE LEAF I P INC

Hydrogen gas generator

InactiveUS20060185242A1Avoid environmental pollutionIncrease profitPhysical/chemical process catalystsReactant parameters controlFuel tankHydrogen fuel cell

Disclosed is a self-regulating hydrogen gas generator for a hydrogen fuel cell. The self-regulating hydrogen gas generator includes a fuel tank, defining an inner space having a designated volume, provided with a hydrogen outlet communicating the inner space, a fuel solution, containing a hydrogen storing material, stored in the fuel tank, and a catalyst contacting the fuel solution for generating hydrogen gas, wherein the catalyst fills a catalytic reactor, provided with a closed portion for interrupting the contact between the catalyst and the fuel solution, and an opened portion contacting the fuel solution, so that the generation and interruption of hydrogen gas are actively regulated based on the increase and decrease of the pressure of the fuel tank.

Owner:TEMCO

Spray gun with pressure display

InactiveUS7422164B2Stable and high qualityPoor coatingSpray nozzlesFluid pressure measurement by mechanical elementsTransducerDisplay device

A spray gun with pressure display for applying paint onto a painted object by atomizing the paint with compressed air. A pressure indicating device includes a digitally displayed pressure sensor (25), a pressure transducer part (24), and a display part (27) unitized with each other. The pressure indicating device is detachably installed on a spray gun body, and adapters (21, 22) without a pressure indication function are detachably fitted to the spray gun body according to the shape of the body grip part so that the presence or absence of the pressure indication function can be selected before use. The spray gun can be used under controlled conditions by allowing a worker to detect an air pressure at hand during spraying operation since the spraying air pressure largely affects paint finish as well as dispersion of atomized paint.

Owner:ANEST IWATA CORP

Novel production technique of xylose

ActiveCN101392009AReduce the amount of sulfuric acidAvoid environmental pollutionSugar derivativesSugar derivatives preparationRegenerative processXylose

The invention discloses a new manufacturing technique of a xylose and relates to a technique for manufacturing the xylose. The technique adopts the technology of electrodialysis recycling sulphuric acid, a bag adopted by a nanofiltration concentration device and a special nanofiltration separation system concentrates the liquid in the technique for manufacturing the xylose at normal temperature, therefore water and other impurities can be removed from the product; the manufacturing technique comprises: 1. pretreatment, 2. hydrolyzation, 3. decoloration, 4. electrodialysis, 5. ion exchange, 6. nanofiltration, 7. concentration, 8. ferment, 9. crystallization, 10. centrifugation, and 11. drying, then the high purity xylose is obtained. The new manufacturing technique of the xylose can not only recycle 50 percent sulphuric acid in the hydrolyze liquid, but also can recycle waste acid and spent caustic produced in the regenerative process of duolite, therefore the dosage of sulphuric acid can be saved and the environment pollution is avoided. The technique solves the problems of scale formation in device in the neutralizing deacidification technique, large usage of duolite in deacidification technique, large usage of devices, large investment, large consumption of acid and alkali, high costs and the like; thus improving the device utilization rate and the service life, decreasing the ash and the acid contents in the hydrolyze liquid, improving the quality of the hydrolyze liquid and enhancing the product quality and separating efficiency.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

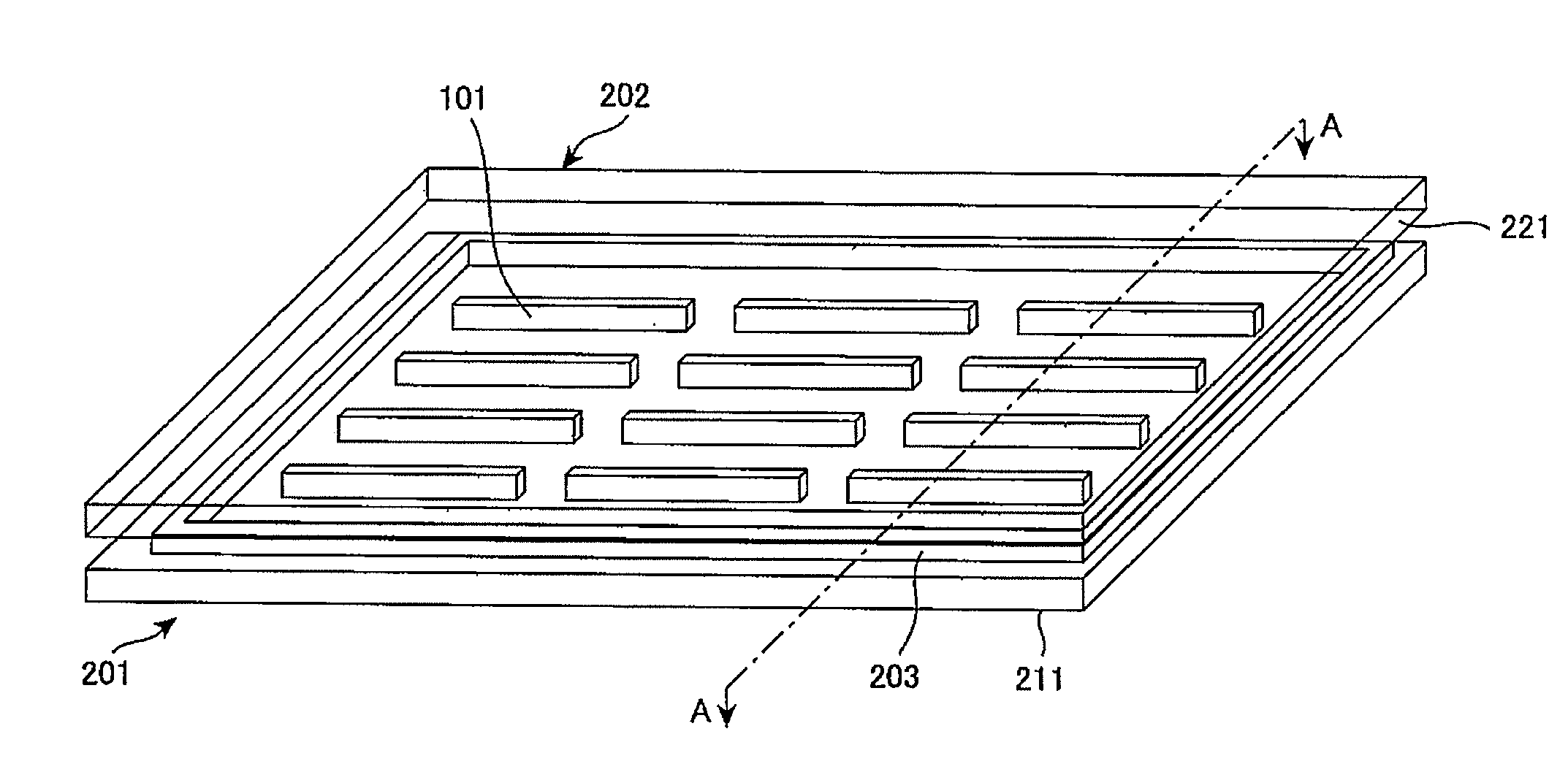

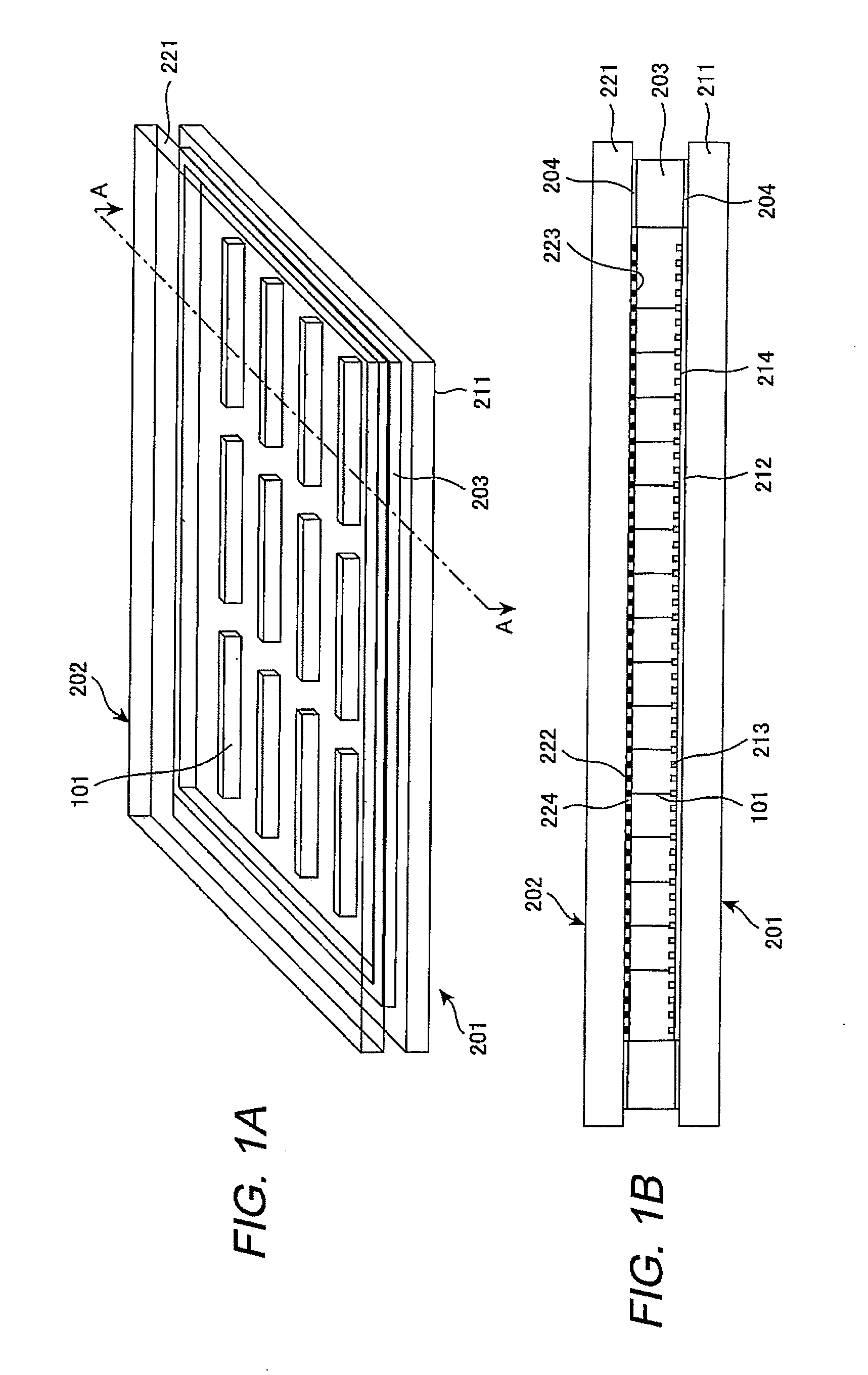

Display Apparatus

ActiveUS20070286973A1High bonding strengthAvoid environmental pollutionLiquid crystal compositionsStatic indicating devicesPhosphate glassVanadate

A sealing glass of a low melting point glass composition which is a phosphate glass that contains transition metal wherein the glass contains 15 to 35% of BaO and Sb2O3 (in total) and the ratio by weight of BaO to Sb2O3 or Sb2O3 to BaO is 0.3 or less. Particularly the transition metal is vanadium and the glass contains V2O5 of 45 to 60 wt % as vanadium oxide and P2O5 of 15 to 30 wt % as phosphorus oxide. The bonding material is a mixture of a filler and a vanadate-phosphate glass that contains V2O5 as the main ingredient and the glass contains V2O5 of 45 to 60%, P2O5 of 20 to 30%, BaO of 5 to 15%, TeO2 of 0 to 10%, Sb2O3 of 5 to 10%, and WO3 of 0 to 5%. The particle size of the filler is in the range of 1 to 150 μm and the ratio of filler is 80% by volume or less of the adhesive glass.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD

Method for processing fish collagen oligopeptide

ActiveCN101297673AReduce qualityAvoid environmental pollutionCosmetic preparationsPeptide/protein ingredientsProtein contentPre treatment

The invention discloses a processing method of fish collagen oligopeptide, which comprises the following steps: delimed and degreased dry scales are selected as raw material, after being treated with cleaning, pretreatment, enzymolysis, filtration, decolorization, taste escaping, desalinization, aseptic filtration, concentration, and spray drying, fish collagen oligopeptide powder is obtained; according to dry basis, the fish collagen oligopeptide powder contains: protein content of no less than 95 percent, ash content of less than 0.5 percent, and average molecular weight of 700Dalton. The product processed by the method of the invention has the advantages of high quality, colorlessness, no bitter taste or stink, low salt content, no poisonous or side effect, and short enzymolysis time, the resin filling used during the adsorption process is renewable and can be repeatedly used for a plurality of times, and the problems of wasting of resources and high ash content of the product caused by using the disposable activated charcoal are avoided, thus being widely applied in the fields of food, health products, medicine and cosmetics, etc.

Owner:BEIJING SEMNL BIOTECHNOLOGY CO LTD +2

Preparation method of active lactobacillus pickle pickling liquor

ActiveCN103251008ARealize standardized productionAdd flavorFood preparationBiotechnologyCapsicum annuum

Belonging to the technical fields of biology and food, the invention relates to a preparation method of an active lactobacillus pickle pickling liquor. The method includes: taking a fermentation pickling solution of pickled pepper, a fermentation pickling solution of pickled capsicum frutescens and cold boiled water as raw material water, subjecting the pickling solutions to rough filtration, and mixing them with the cold boiled water uniformly, then carrying out cooling and high speed centrifugation degerming, and adding a direct vat set lactobacillus starter, thus obtaining the pickling liquor. The method provided in the invention realizes standardized preparation of pickling liquor, ensures the viable count of lactobacilli in the pickling liquor, endows the newly prepared pickling liquor with the flavor of aged pickling liquor and better flavor. At the same time, the use problem of the pickling solutions of pepper and capsicum frutescens is solved, the environmental pollution caused by emission and the potential safety hazard caused by repeated use in the next year can be avoided, so that the biological safety, quality and homogeneity of the product are significantly improved. Further, upgrading and industrial, large-scale and standardized production of traditional active lactobacillus pickles can be realized.

Owner:CHENGDU XINFAN FOOD

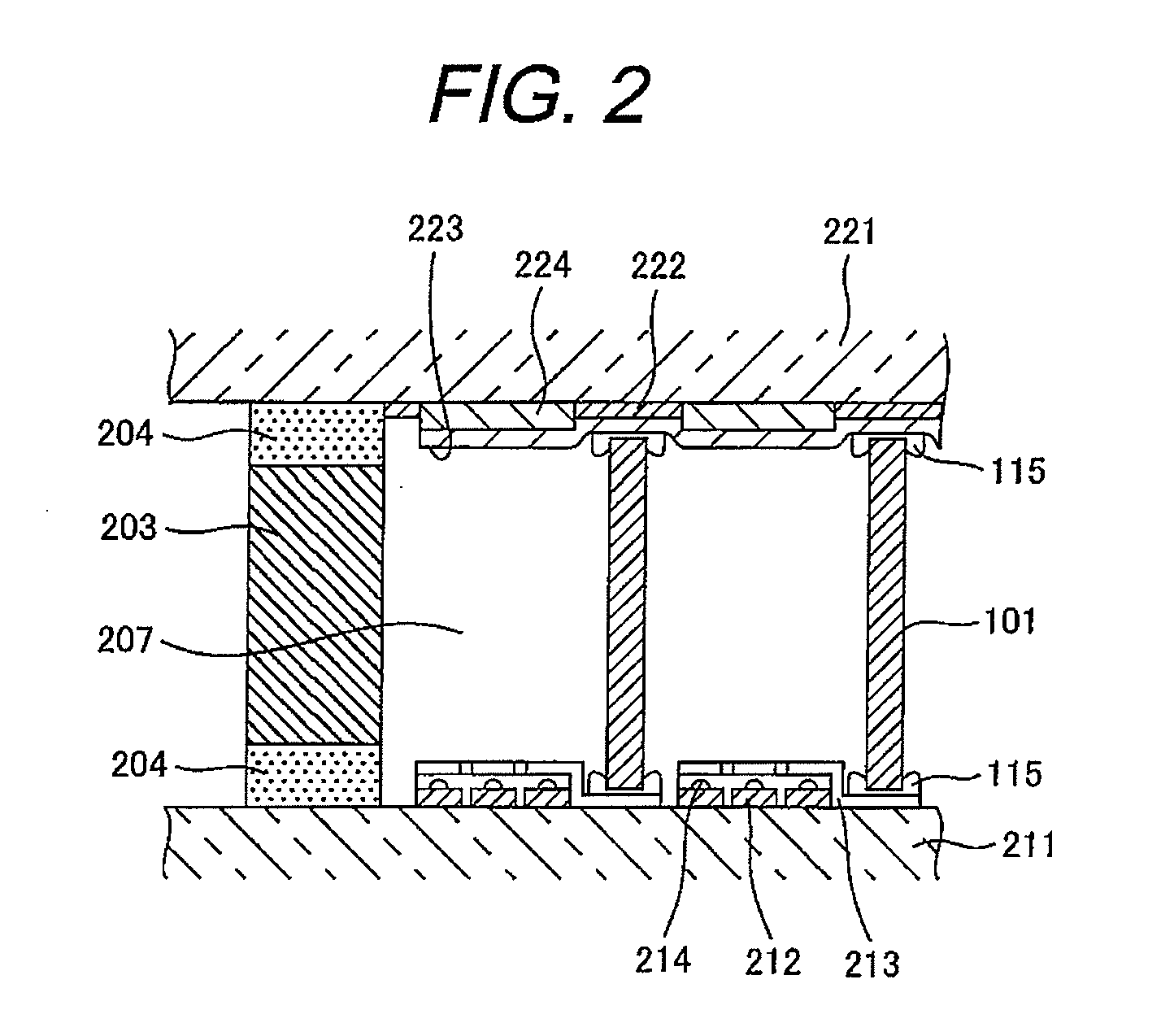

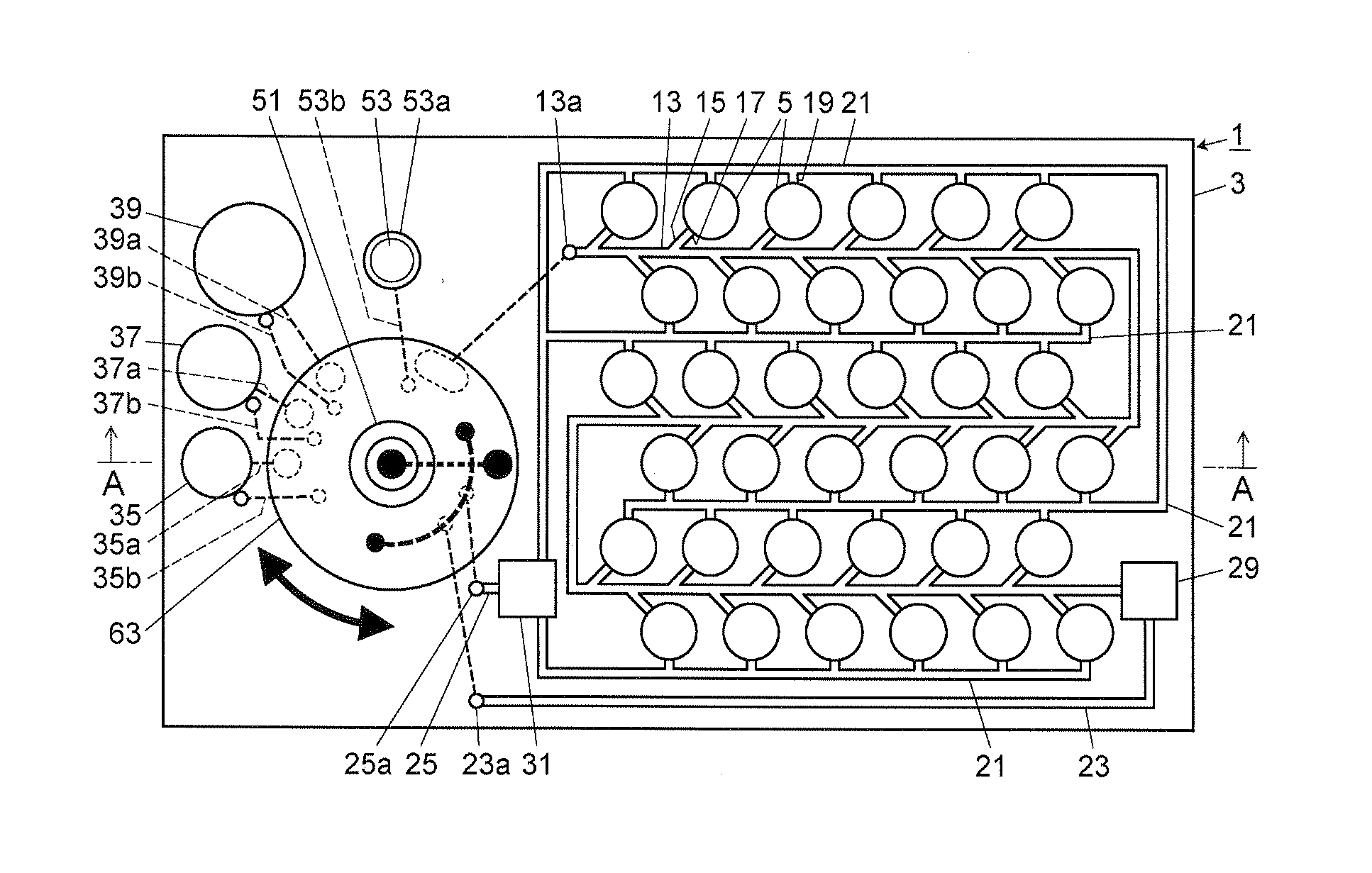

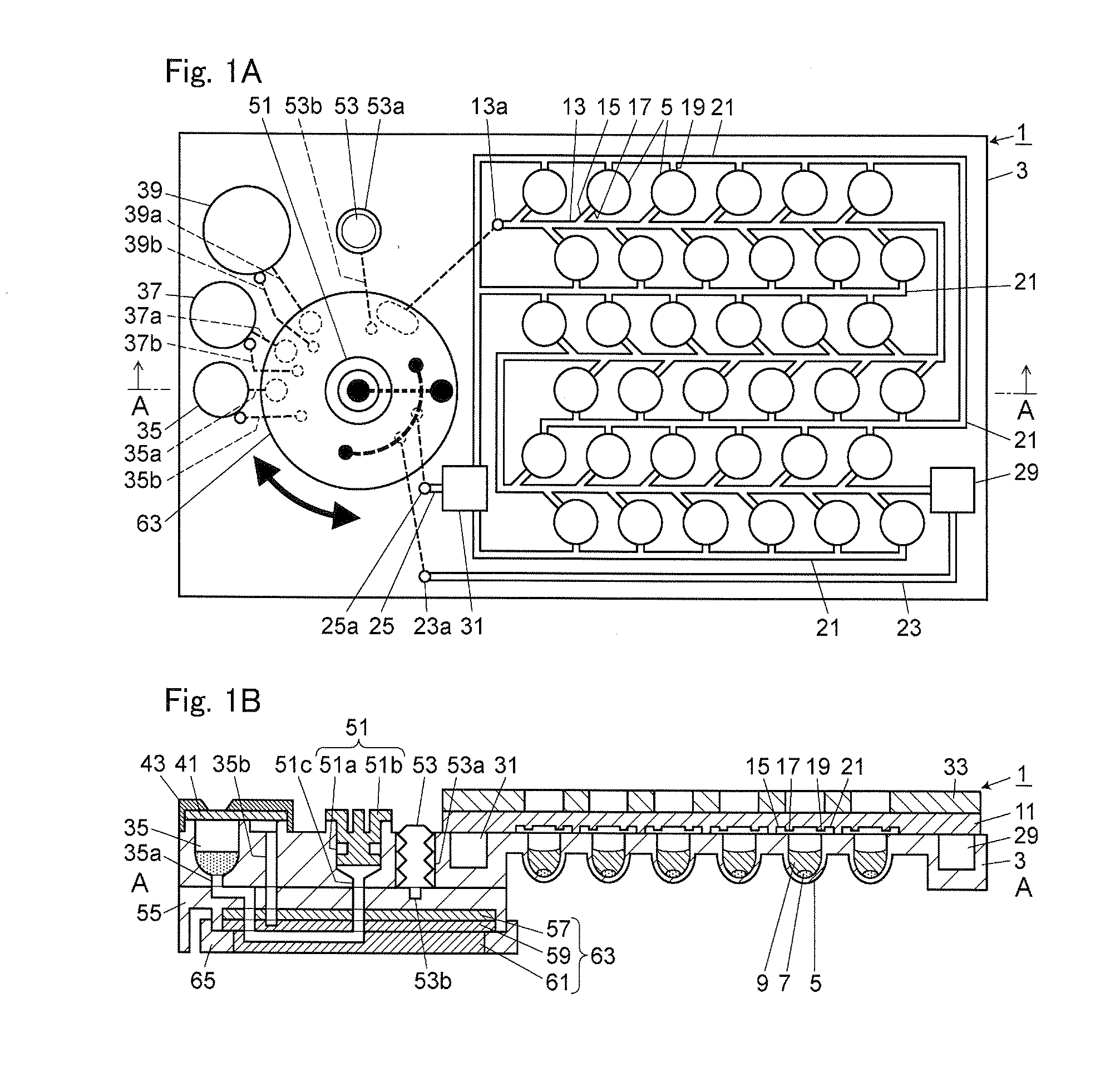

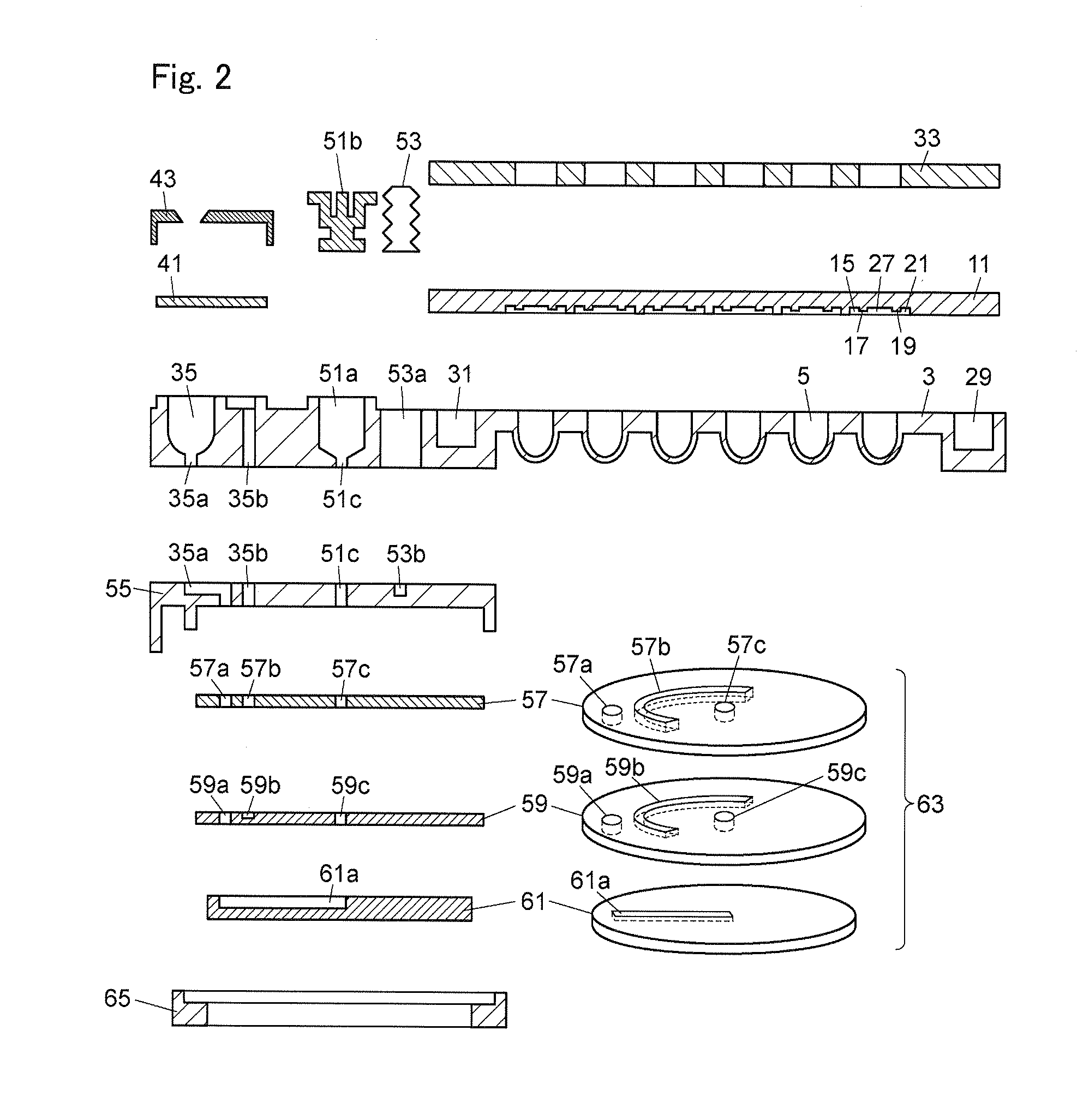

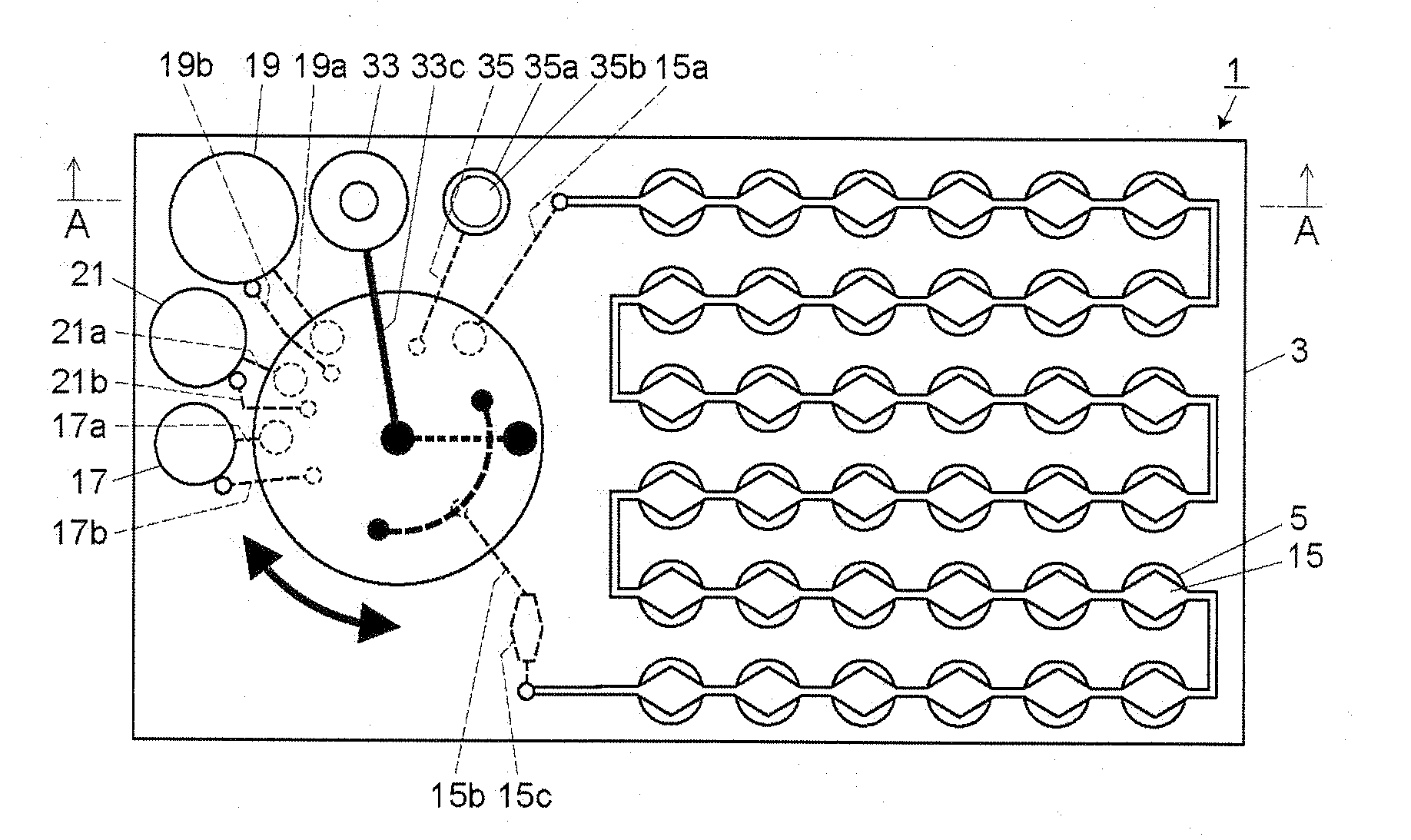

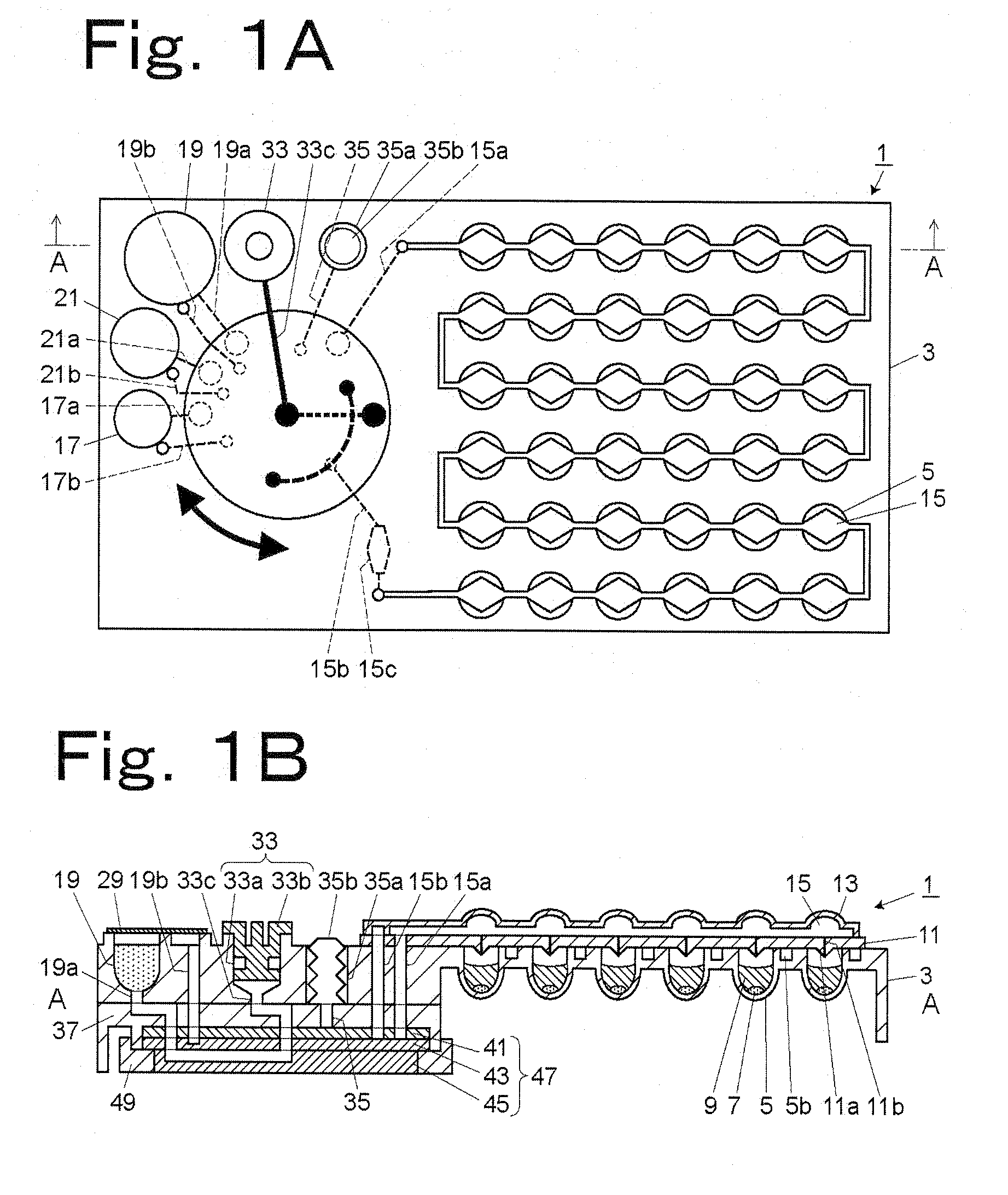

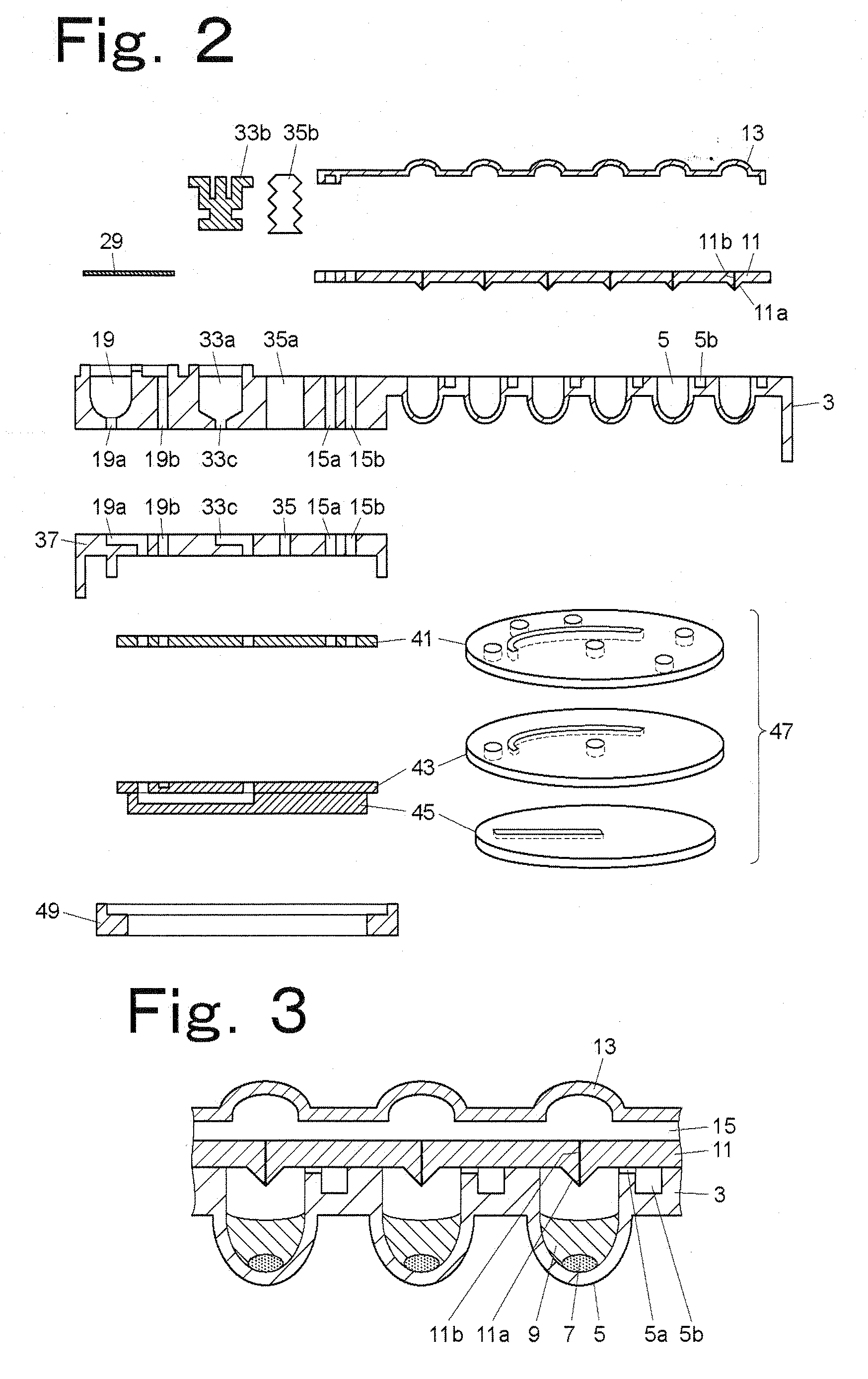

Reactor plate and reaction processing method

ActiveUS20110003286A1Avoid enteringInject evenlyBioreactor/fermenter combinationsBiological substance pretreatmentsForeign matterMain channel

Disclosed herein is a reactor plate which prevents the entry of foreign matter from the outside and the pollution of a surrounding environment. A reactor plate (1) includes a reaction well (5), a reaction well channel connected to the reaction well (5), and reaction well air vent channels (19) and (21) connected to the reaction well (5). The reaction well channel has a main channel (13), a metering channel (15) branched off the main channel (13), and an injection channel (17) of which one end is connected to the metering channel (15) and the other end is connected to the reaction well (5). The main channel (13) and the reaction well air vent channel (21) can be hermetically sealed. The injection channel (17) is formed narrower than the metering channel (15) not so as to allow the passage of a liquid at a liquid introduction pressure applied to introduce the liquid into the main channel (13) and the metering channel (15) and at a purge pressure applied to purge the liquid from the main channel (13) but so as to allow the passage of the liquid at a pressure higher than the liquid introduction pressure and the purge pressure.

Owner:SHIMADZU CORP

Reusing method for galvanization sintered neodymium iron boron waste

ActiveCN103440948AAvoid environmental pollutionSimple reuse processInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementScrap

Provided is a reusing method for galvanization sintered neodymium iron boron waste. A galvanization layer is removed through a hot deplating method, then milling, forming and sintering are carried out, neodymium iron boron materials of middle-high marks are prepared; for galvanization sintered neodymium iron boron waste with the ratio of galvanization layer weight to magnet weight smaller than 0.5%, zinc can be regarded as an impurity which cannot be removed, hot deplating is not carried out, crushing and milling are directly carried out, then pressing forming and sintering are carried out again, and neodymium iron boron materials of middle-low marks are prepared. According to the reusing method, environment pollution caused by chemical deplating is completely avoided, the reusing process of the valuable elements in the neodymium iron boron waste is simple, and rare earth element loss is low.

Owner:NINGBO KETIAN MAGNET +1

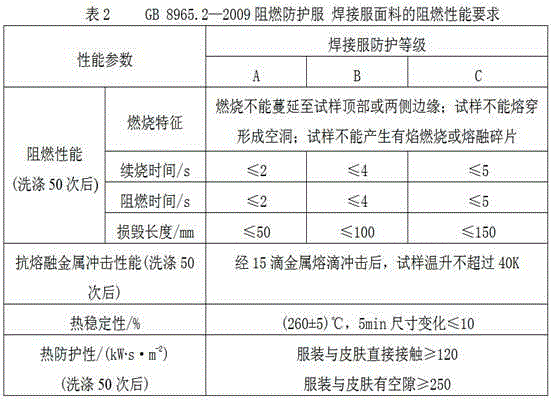

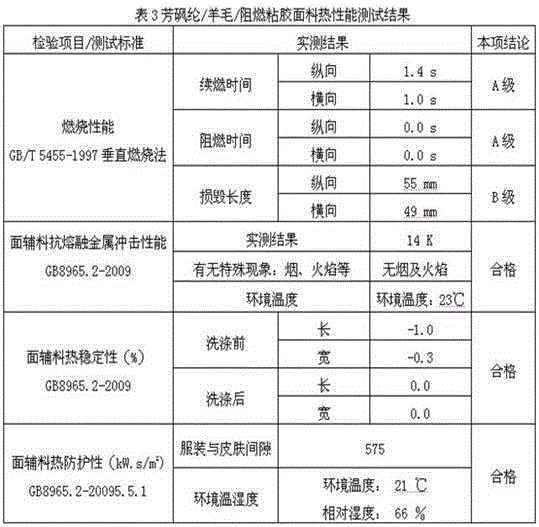

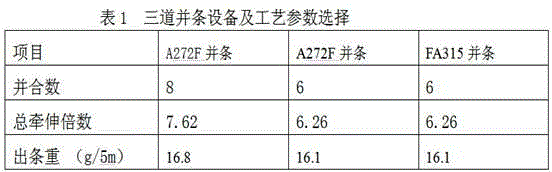

Fabrics for electric welding protective clothing and processing method thereof

InactiveCN102747504AImprove wearing comfortReduce riskWoven fabricsProtective garmentYarnPolymer science

The invention provides polysulfonamide fiber / wool fiber / flame-retarding viscose blended fabric for electric welding protective clothing and a processing method thereof. Blended yarn is designed and developed according to a semi-fine-spinning route. The processing method comprises the steps of wool blending, cotton carding, drawing, roving, spinning, stranding, weaving, cleaning, drying, brushing, shearing, softening and decating. The linear density of the yarn is 50Nm / 2, theblending ratio among the polysulfonamide fiber / wool fiber / flame-retarding viscose is 50 / 30 / 20, and spinnability of the blended yarn is improved by means of high moisture absorption and good crimpiness of the wool fiber. 2 / 1 twill weave is adopted in the fabric, warp density of a finished product is 330 per 10cm, the weft density is 278 per 10cm, and the area density is 260g per square meters. Combustion performance of the final product can reach the level B of the welding clothing national standard, and the resistance to impact of molten metal, thermal stability and thermal protection can reach the level A of the welding clothing national standard. The blended fabric achieves a flame-retarding function, simultaneously has style characteristics of wool fabrics and comfort in wearing and is soft in touch.

Owner:INST OF WOOL & HEMP TEXTILE SCI SHANGHAI

Double knotting system for an agricultural baler

ActiveUS7296828B2Reliable constructionEasy to manufactureHarvestersFilament handlingEngineeringOperating cycle

A double knotting method and apparatus capable of producing two successive knots in a pair of strands during one full operating cycle of a tying mechanism. The tying mechanism is comprised of a twine holder for maintaining a pair of strands in a suitable position, a cutter that co-operates with the twine holder for severing the strands during formation of successive knots, and a release mechanism for releasing the pair of strands from the twine holder before frill successive knot completion. The method and apparatus avoid twine tail formation.

Owner:BLUE LEAF I P INC

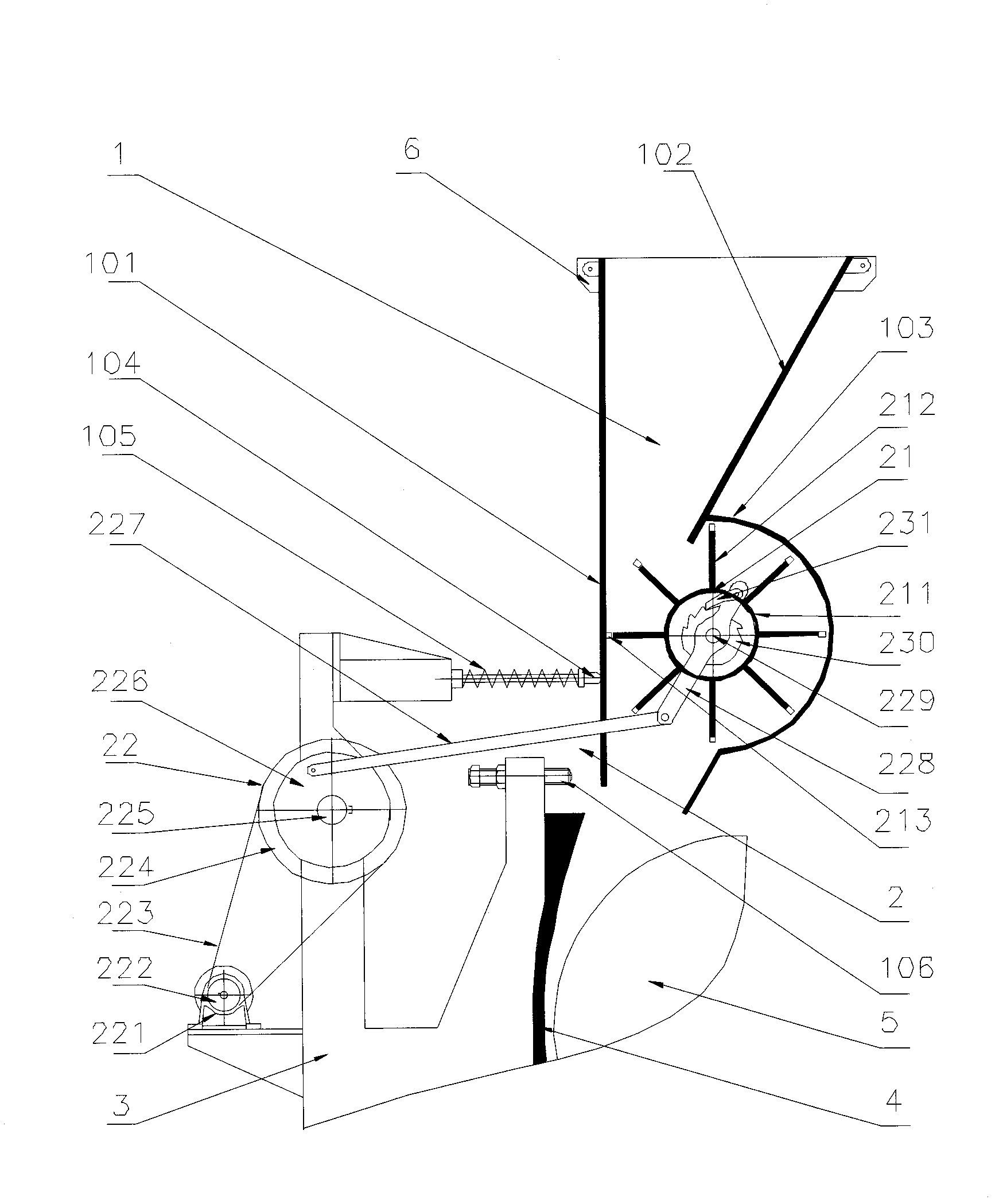

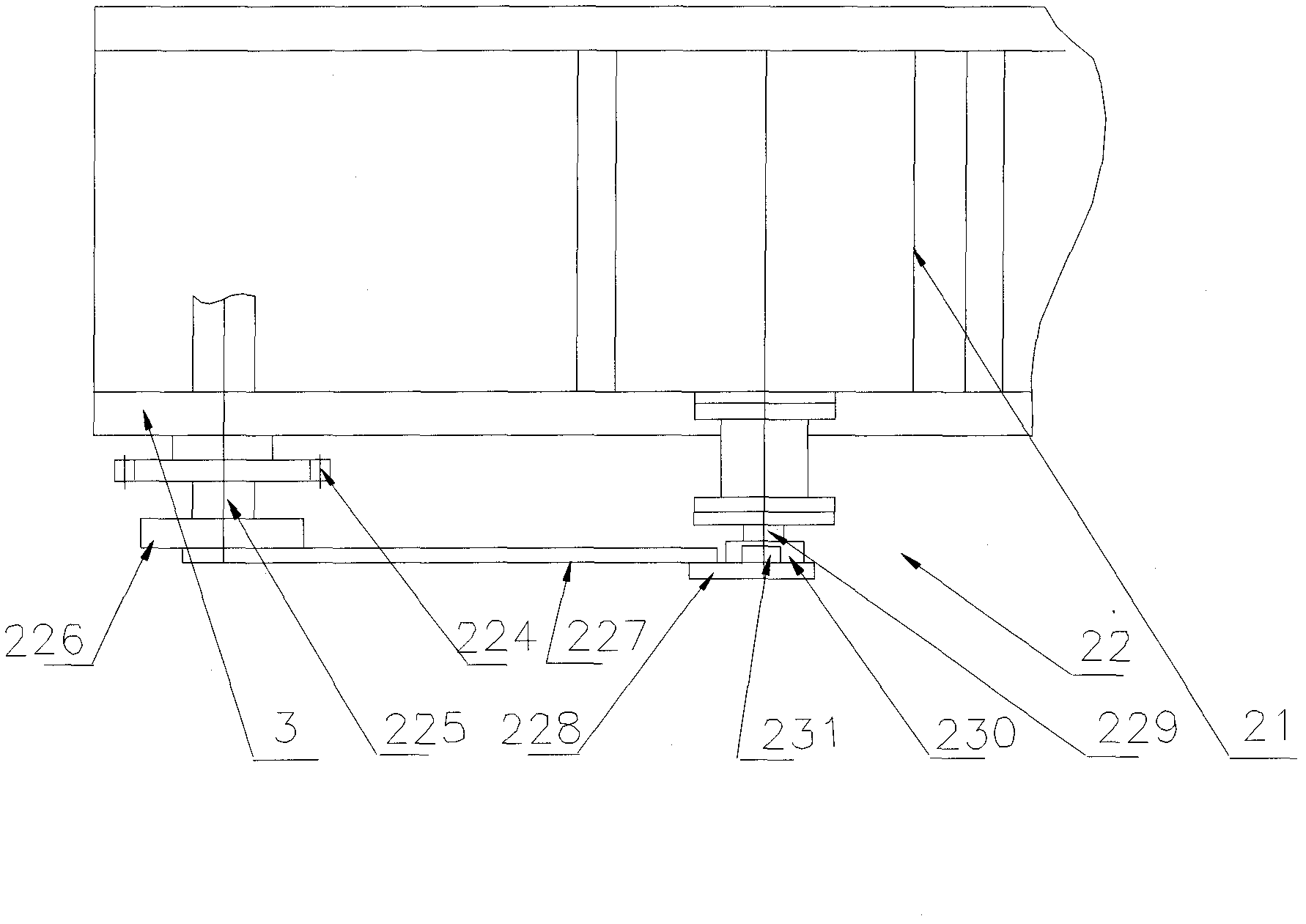

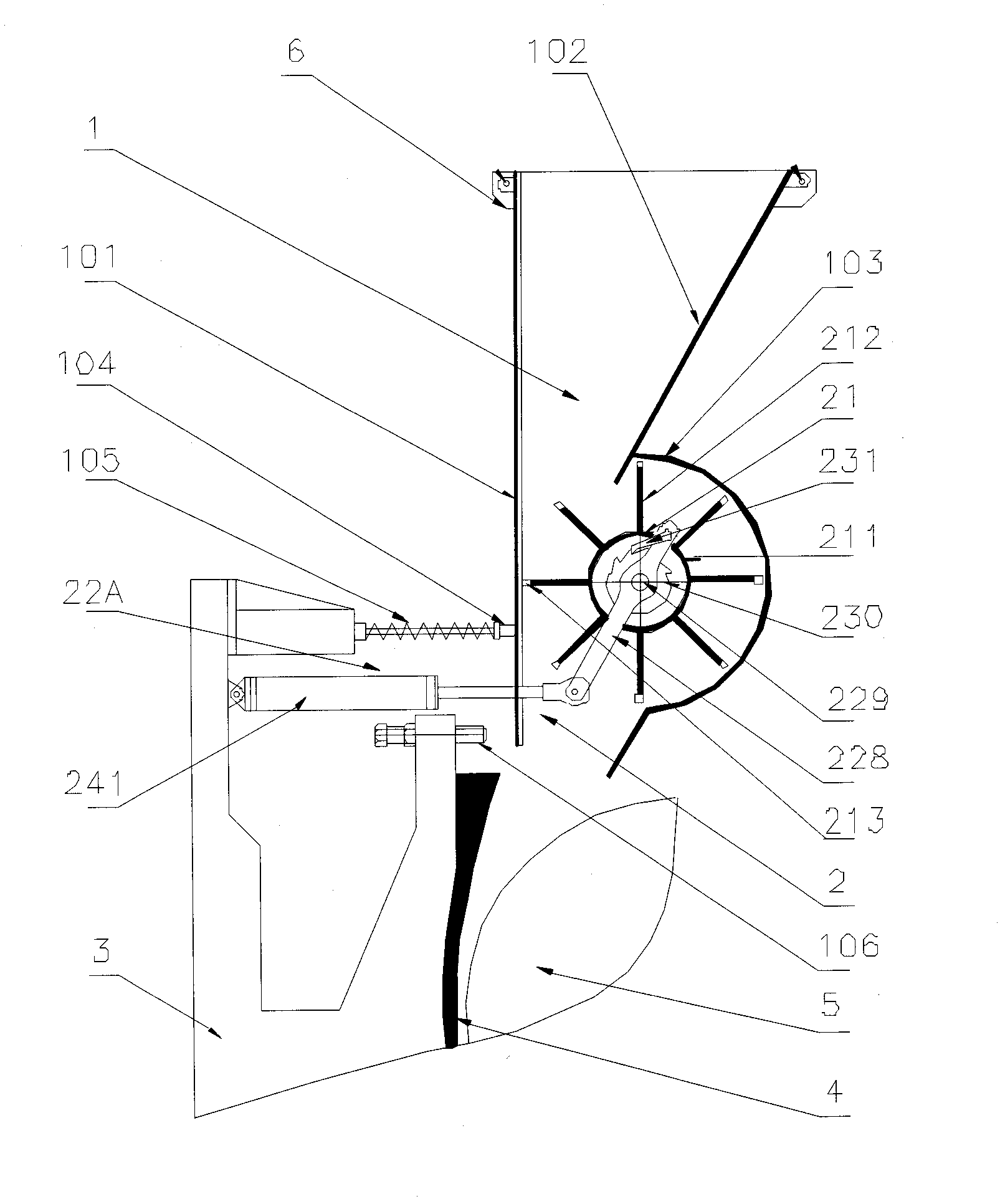

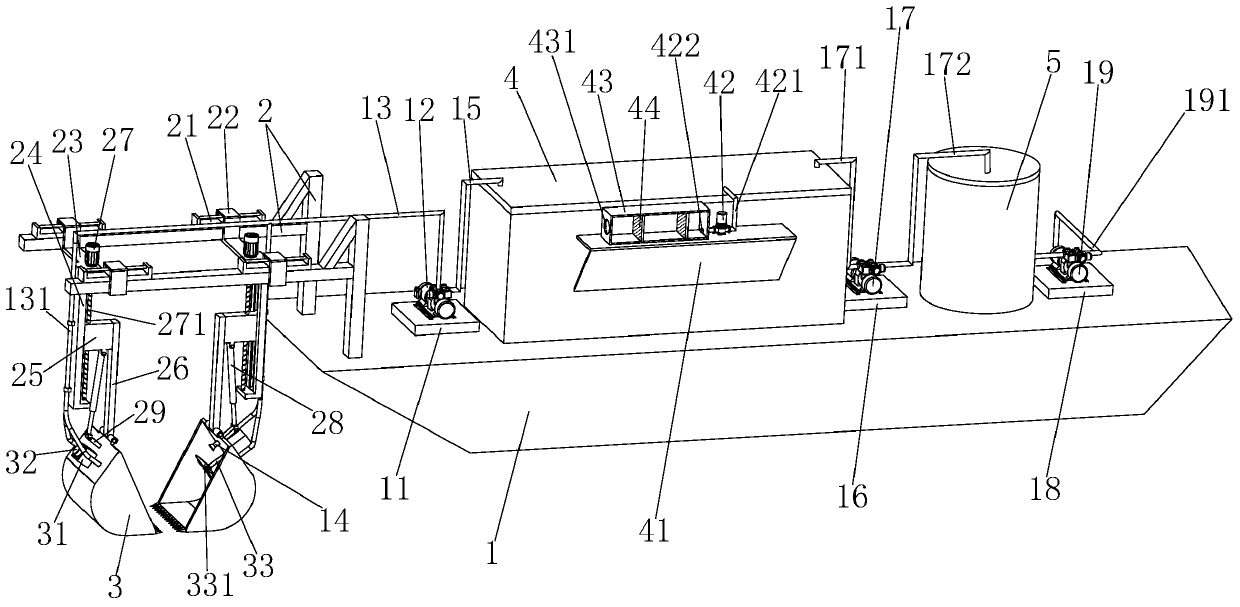

Feeding device of material crushing apparatus

A feeding device of a material crushing apparatus comprises a deformed bunker and an intermittent feeding mechanism, wherein one side of the deformed bunker is provided with a pendulous movable straight plate, the upper end of the movable straight plate is hinged to a fixed hopper lower edge, the other side of the deformed bunker is provided with a fixed semicircular plate and a movable inclined plate, the fixed semicircular plate makes a semicircular cavity, the upper end of the movable inclined plate is hinged to the fixed hopper lower edge, the lower end of the movable inclined plate is laid on the upper edge of the fixed semicircular plate in an inclined manner, and the outside of the movable straight plate is provided with a bunker plate resetting device; and the intermittent feeding mechanism comprises a uniform feeder and a stepping driving part, the uniform feeder is positioned in the cavity of the fixed semicircular plate and comprises a central ring and a plurality of separation plates fixed on the central ring in an equant manner, the central ring is arranged on the wheel shaft of a frame, the length of each of the separation plates can realize a case that the outer ends of the separation plates can successively move the movable inclined plate and the movable straight plate in the rotation of the separation plates, the outer end of the one of the separation plates props against the movable straight plate in the pause of the separation plates, and the stepping driving part intermittently pushes the uniform feeder to rotate. The feeding device realizes the uniform and quantitative feeding and the smooth production, and is suitable for the feeding of large-granule materials.

Owner:卢小平 +1

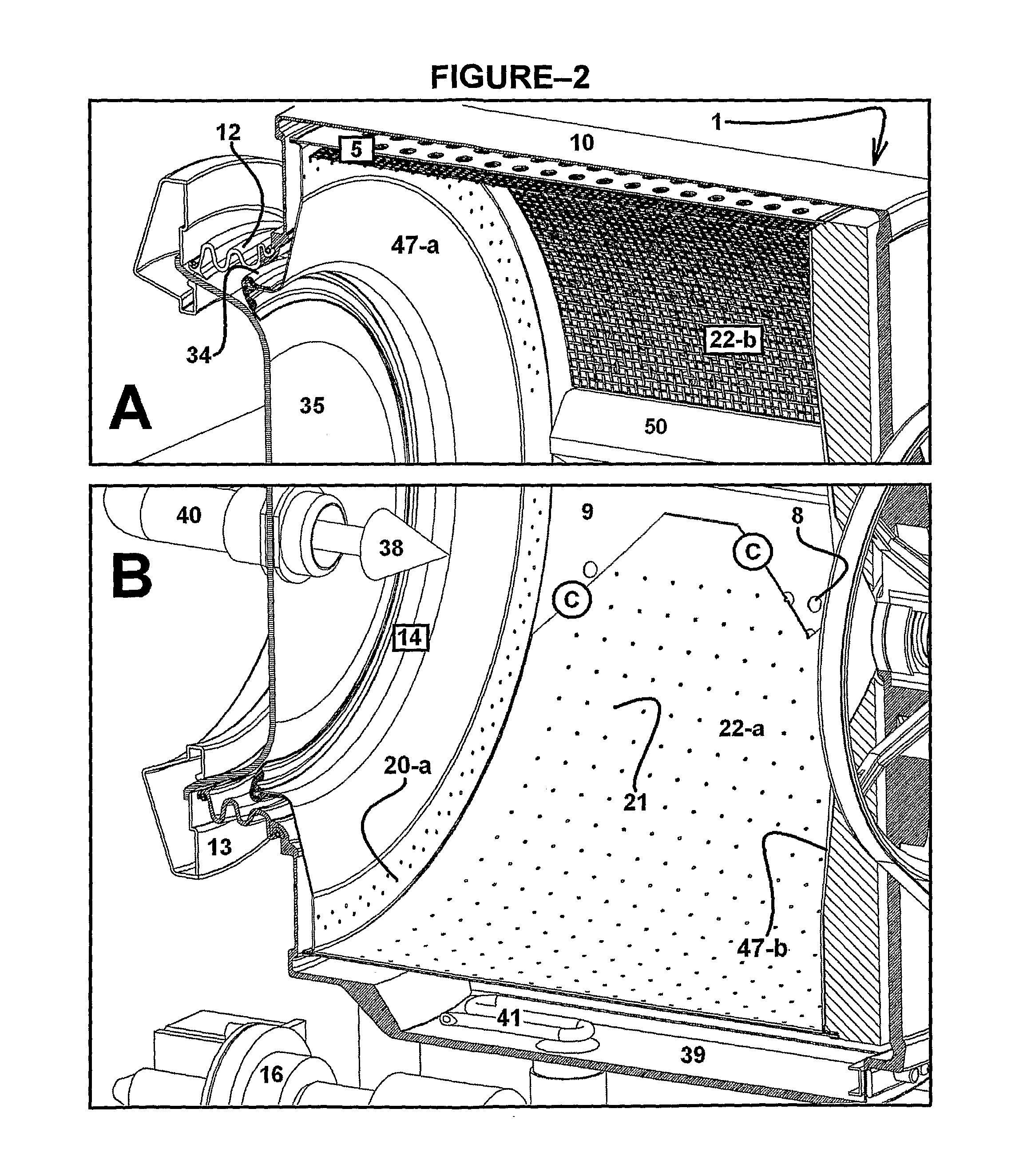

Washer-extractor machine

InactiveUS20110100068A1Avoid harmSave energyOther washing machinesControl devices for washing apparatusProcess engineeringEnergy analysis

This invention is related to washer-extractor machines and in particular to drum type washing machines that provide saving from water, energy and time and at the same time increase washing and extraction efficiency. This invention is also related to a washing and rinsing process realized using this machine.

Owner:SIMSEK TULGA

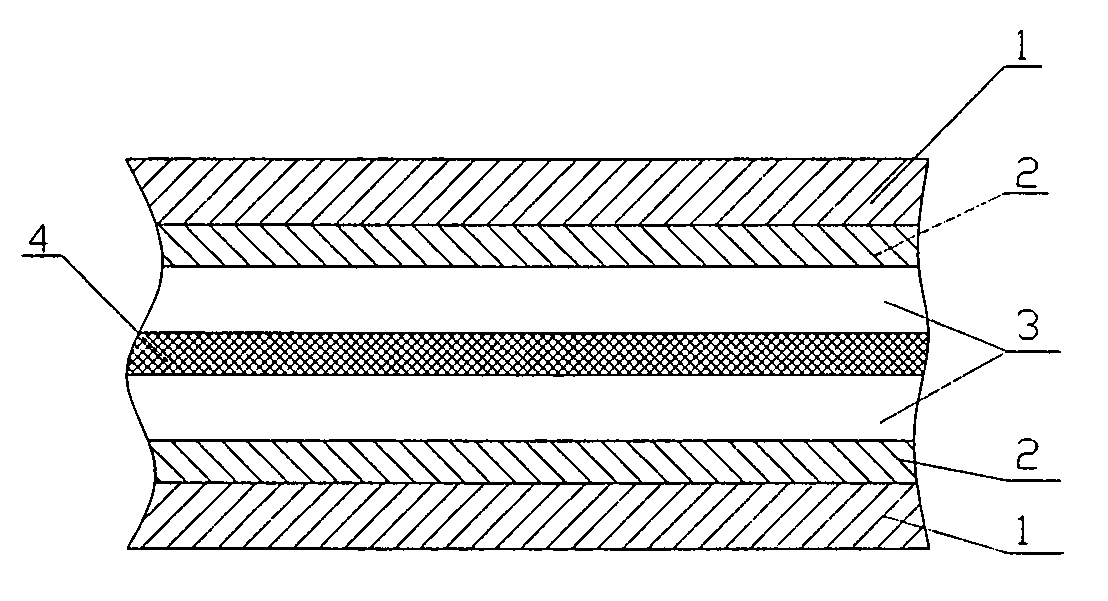

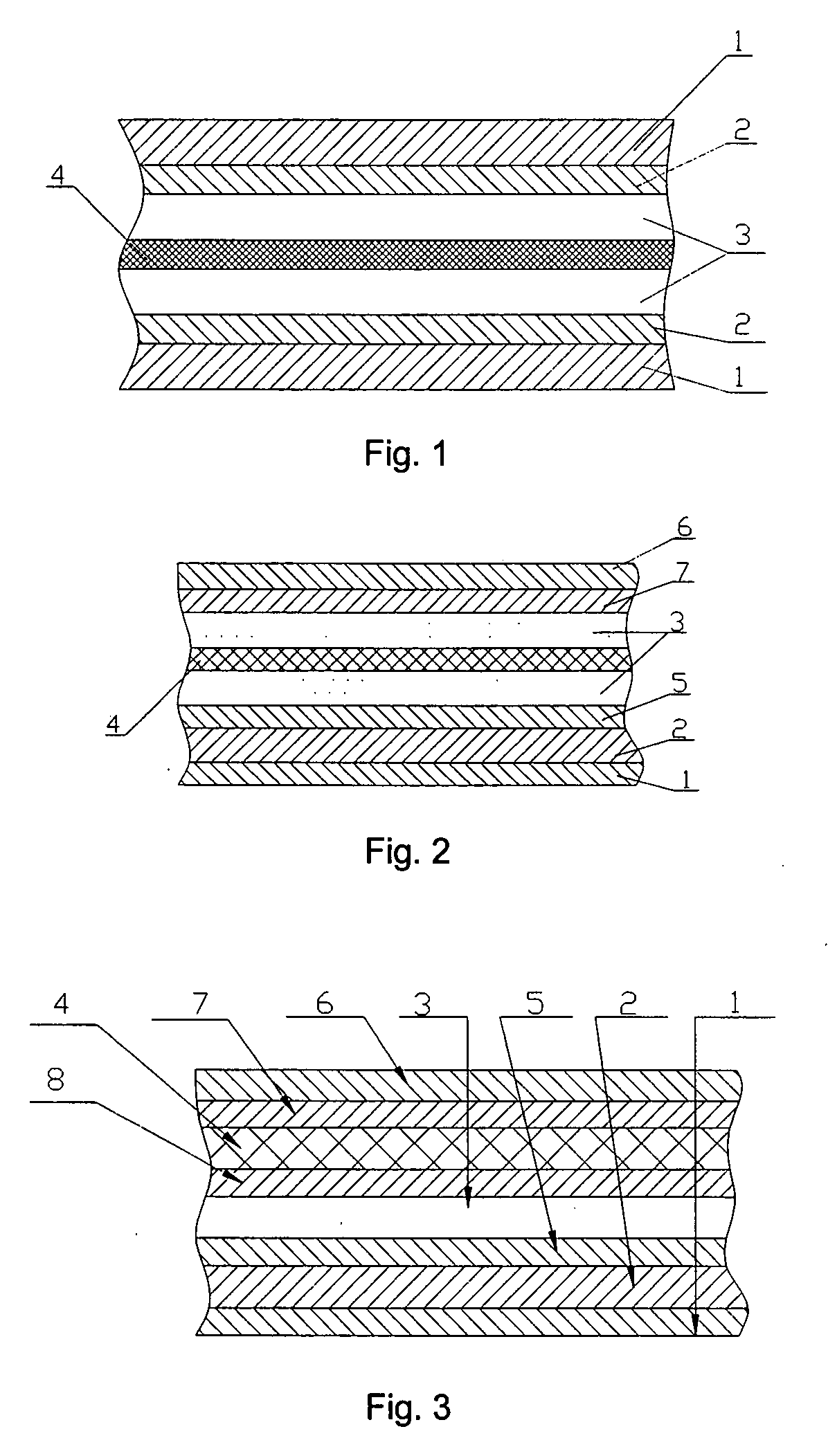

Roofing underlayment material and process for making the same

InactiveUS20080026663A1Improve propertiesAvoid environmental pollutionRoof covering using flexible materialsSynthetic resin layered productsFiberglass meshGlass fiber

The present invention relates to a waterproof material, wherein film layers are set between non-woven fabric layers, an asphalt layer is set between the film layers, and a net reinforcement layer is set within the asphalt layer. The advantages of the present invention include: (1) film layers are formed by laminating it on the compositing surfaces of the upper and lower non-woven fabric layers, which overcomes the drawback of water leaking in the background art, prevents the leaking of asphalt into the non-woven fabric or out of the non-woven fabric during the compositing process, so that the environmental pollution during transportation and application is avoided; (2) a glass-fiber netlike reinforcement layer is set within the asphalt layer, so that not only the tensile strength and compressive strength of the asphalt layer, but also the tensile strength and tear strength of the roofing underlayment material are improved; (3) the thickness and number of film layers are set to ensure the temperature-resistance and puncturing-resistance of film layers.

Owner:ZHANG GUORONG

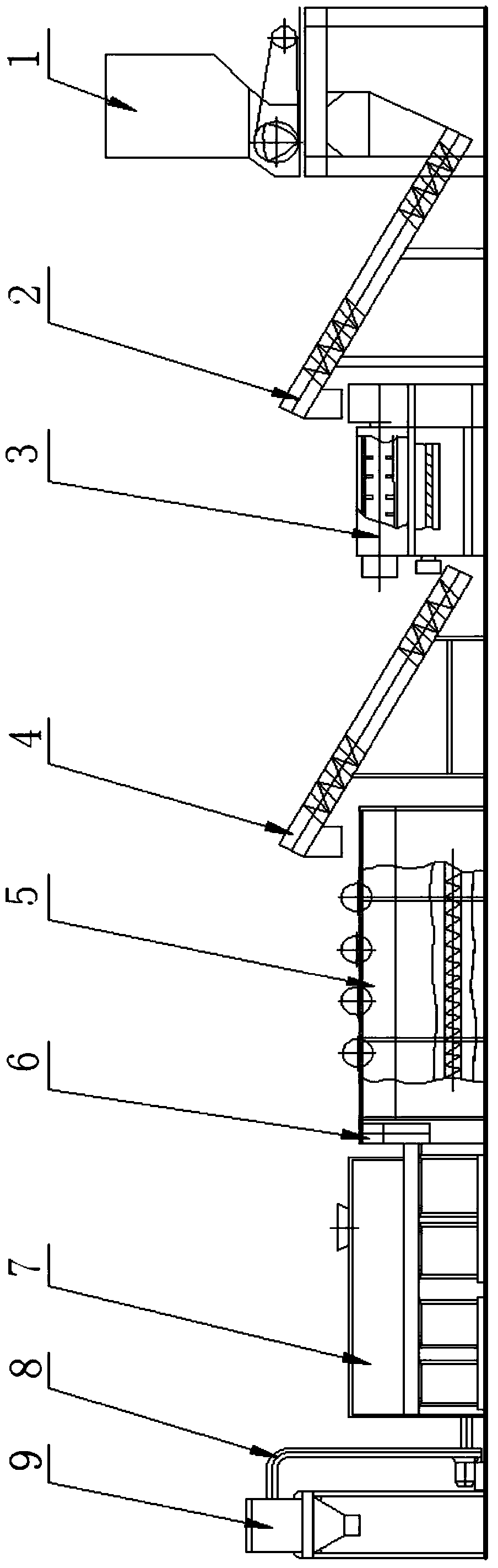

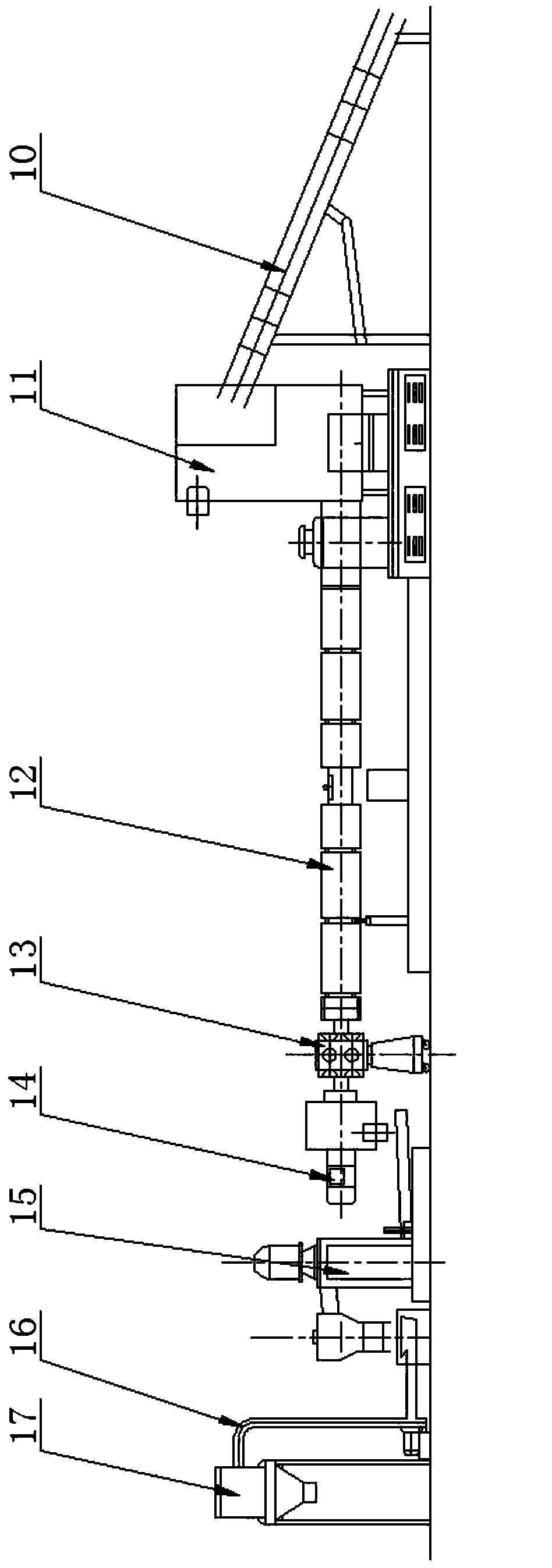

Method for recycling, cleaning and granulating waste mulching films

InactiveCN103640104AAvoid environmental pollutionRecycle resourcesPlastic recyclingPelletizingCrusher

The invention relates to a method for recycling, cleaning and granulating waste mulching films. The method comprises the steps of cleaning and granulating. In the cleaning step, the recycled waste mulching films are classified, sorted and pretreated, are conveyed into a thin film crusher for crushing, are conveyed into a frictional cleaner through a spiral conveyor I for cleaning, are conveyed to a rinsing tank through a spiral conveyor II for secondary cleaning, are conveyed to a squeezing machine through a spiral conveyor III, and are conveyed into a storage bin through a pneumatic conveying system I. In the granulating step, the waste mulching films are conveyed to a cutting compaction cylinder through a conveying belt for treatment, treated materials are automatically forced to be pushed into an SJ150 / 26 single-screw extruder, a melt is extruded through a hydraulic screen exchanger and is directly cut into uniform particles on a mold surface through a water ring granulator, the particles are conveyed into a centrifugal dehydrator for dehydration treatment, and the dehydrated particles are conveyed into the storage bin through a pneumatic conveying system II, and are bagged and stored at an outlet of the storage bin. According to an advanced method for recycling, cleaning and granulating the waste mulching films, the environment pollution is avoided, and resources are recycled.

Owner:甘肃宏鑫农业科技有限公司

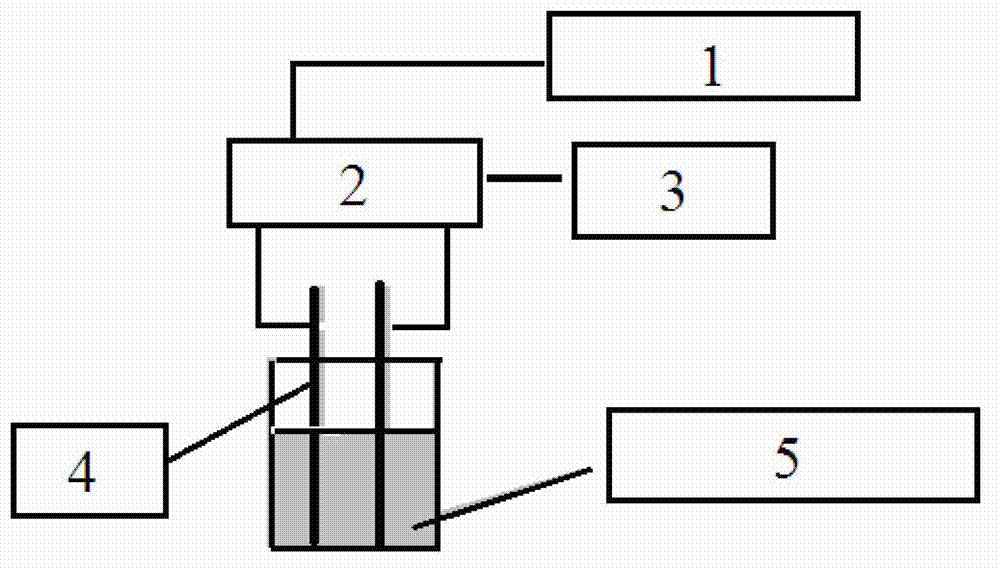

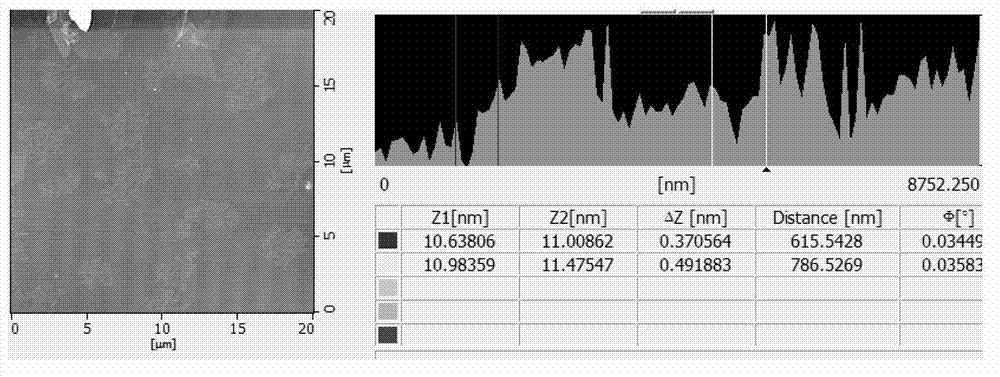

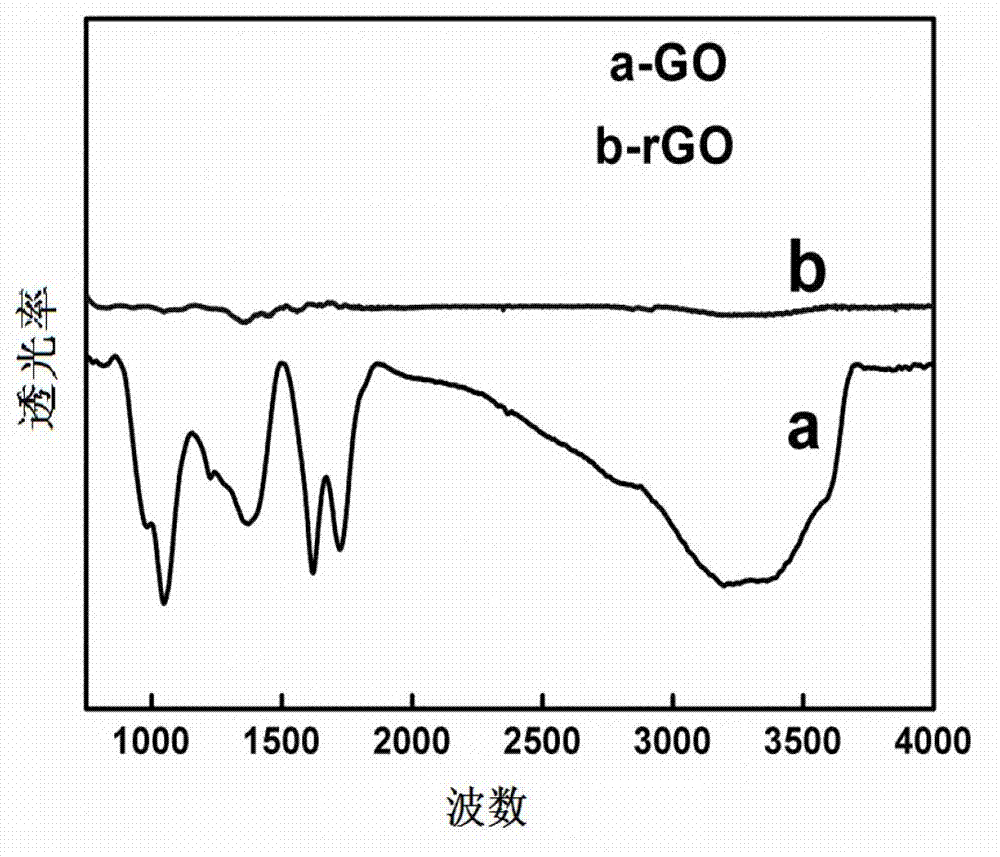

Electrochemistry stripping and reducing integrated graphene preparation method

InactiveCN102963887AEasy to manufactureAvoid damageCarbon compoundsState of artElectrochemical response

The invention relates to an electrochemistry stripping and reducing integrated graphene preparation method. The method comprises the following steps of: (1) taking graphite oxide and dissolving the graphite oxide in deionized water so as to prepare a graphite oxide solution with a concentration range of 0.1-1mg / ml; (2) adding the graphite oxide solution into a reaction container; (3) applying an alternating electric field to the graphite oxide solution; and (4) generating an electrochemistry reaction via the graphite oxide in the environment of the alternating electric field so as to generate the graphene. Compared with the prior art, the method provided by the invention has the following beneficial effects: the principle of the electrochemistry reduction and the excellent electrochemistry property of the graphene are effectively combined, so that the defects existing in other preparation methods are overcome; and the electrochemistry stripping and reducing integrated graphene preparation method not only can be used for realizing a graphene preparing method with integrated stripping and reducing, but also has the advantages of simplicity in operation, low cost, safety, no pollution and the like.

Owner:TONGJI UNIV

Reaction container plate and reaction treatment apparatus

InactiveUS20100028986A1Avoid enteringInject evenlyBioreactor/fermenter combinationsBiological substance pretreatmentsForeign matterEngineering

Disclosed herein is a reaction container plate which prevents the entry of foreign matter from the outside and the pollution of an outside environment. A reaction container plate (1) includes a sealed reaction container (5), a reaction container channel (15) connected to the reaction container (5), a sealed container (17) provided separately from the reaction container (5), a sealed container channel (17a) connected to the sealed container (17), a syringe (33) for sending a liquid, a switching valve (47) for connecting the syringe (33) to the introduction channel (15) or the sealed container channel (17a), and a sealed container air vent channel (17b) of which one end is connected to the sealed container (17). When the syringe (33) is connected to the sealed container (17) via the switching valve (47) to inject a liquid contained in the syringe (33) into the sealed container (17) and to suck a liquid contained in the sealed container (17) into the syringe (33), a gas contained in the sealed container (17) is moved between the sealed container (17) and the sealed container air vent channel (17b).

Owner:SHIMADZU CORP

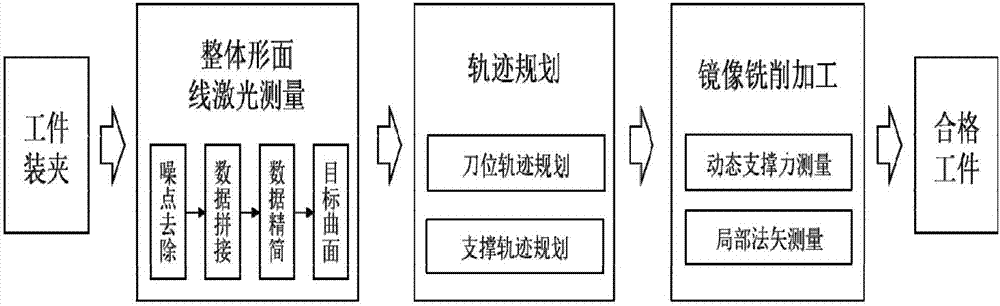

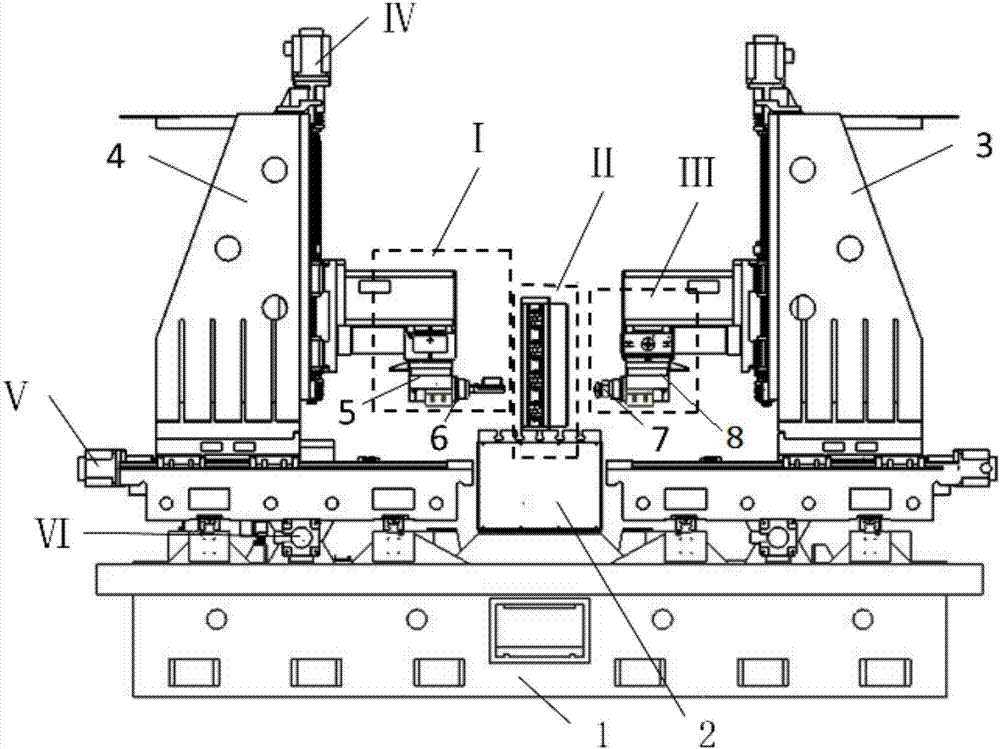

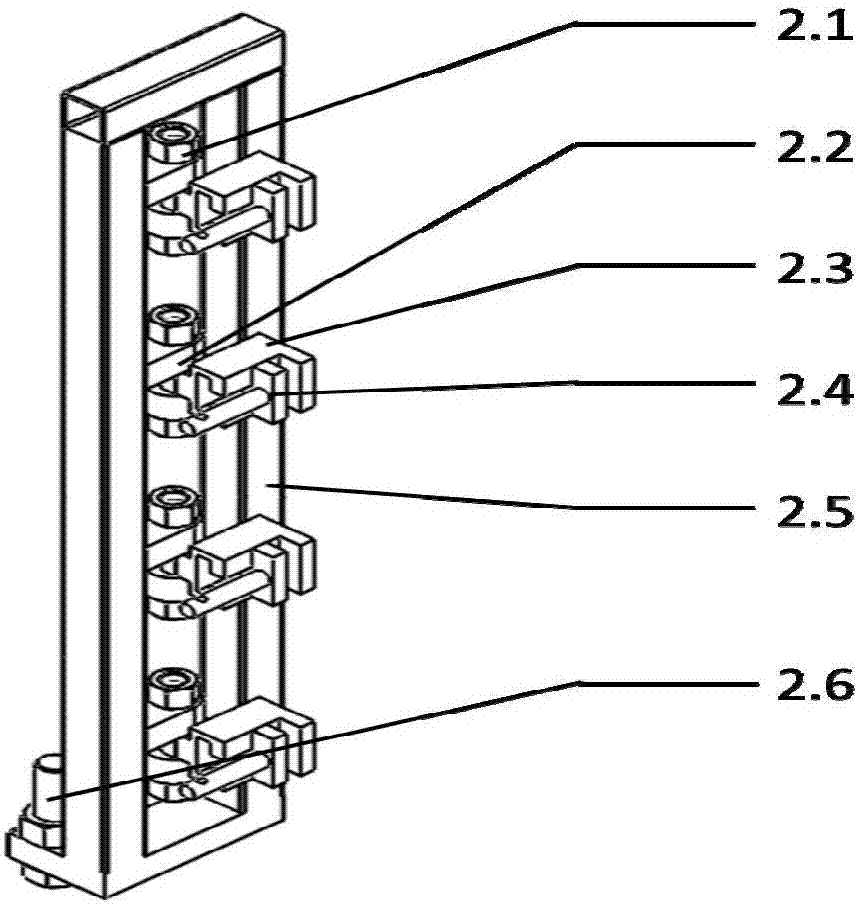

Large thin-walled component complex curved surface mirroring processing method

ActiveCN107976955AGuaranteed mirror relationshipGuaranteed measurement - mirror image processingNumerical controlLaser sensorSuperficial mass

The invention relates to a large thin-walled component complex curved surface mirroring processing method, and belongs to the technical field of large thin-walled component processing, and especiallyrelates to a large thin-walled component complex curved surface mirroring processing method. An employed processing device is laid in a bilaterally symmetrical structure, the specially-produced processing device is employed to carry out measuring and mirroring processing, a line laser sensor is employed to measure a workpiece, a current vortex sensor is employed to measure displacement with respect to the workpiece surface, and a piezoelectric transducer is employed to measure the value of a support force. Noise removal, data compaction, data splicing are carried out on measured data, and a target curved surface is generated. Processing path planning and support path planning are carried out, a local normal vector and a dynamic support force are measured, and mirroring milling is carried out. According to the invention, after once clamping installation, measuring and mirroring processing can be carried out on the thin-walled component, and the large thin-walled component complex curvedsurface mirroring processing method is good in measuring real-time performance, high in accuracy and convenient to use. Accurate milling of thin-walled components can be achieved, the processing precision is high, and the surface quality is high after processing.

Owner:DALIAN UNIV OF TECH

Water conservancy engineering river course dredging device and method

ActiveCN111188375AFast dredging efficiencyEasy to dig on the goDispersed particle filtrationMechanical machines/dredgersRiver routingEcological environment

The invention relates to a water conservancy engineering river course dredging device, which comprises a ship body. Bearing frames are arranged on one side of the ship body, buckets symmetrical to each other and used for digging mud are slidably connected with the bearing frames, driving assemblies used for driving the buckets to move are correspondingly arranged on the bearing frames, and the buckets are provided with mashing assemblies used for mashing the mud in the buckets; and the ship body is further provided with a mud storage tank, mud suction assemblies used for sucking the mud in thebuckets are arranged between the mud storage tank and the buckets, and a purification assembly used for filtering and purifying the mud is arranged on the ship body and is located one side of the mudstorage tank. The water conservancy engineering river course dredging device has the effect of effective absorption and purification of sewage and the mud, thus functions of fast dredging efficiency,energy conservation and environmental protection on a river course can be convenient to achieve, and thus occurrence of the situation that secondary pollution caused by the sewage and the mud affectsthe surrounding ecological environment is avoided.

Owner:众达(广东)建设工程有限公司

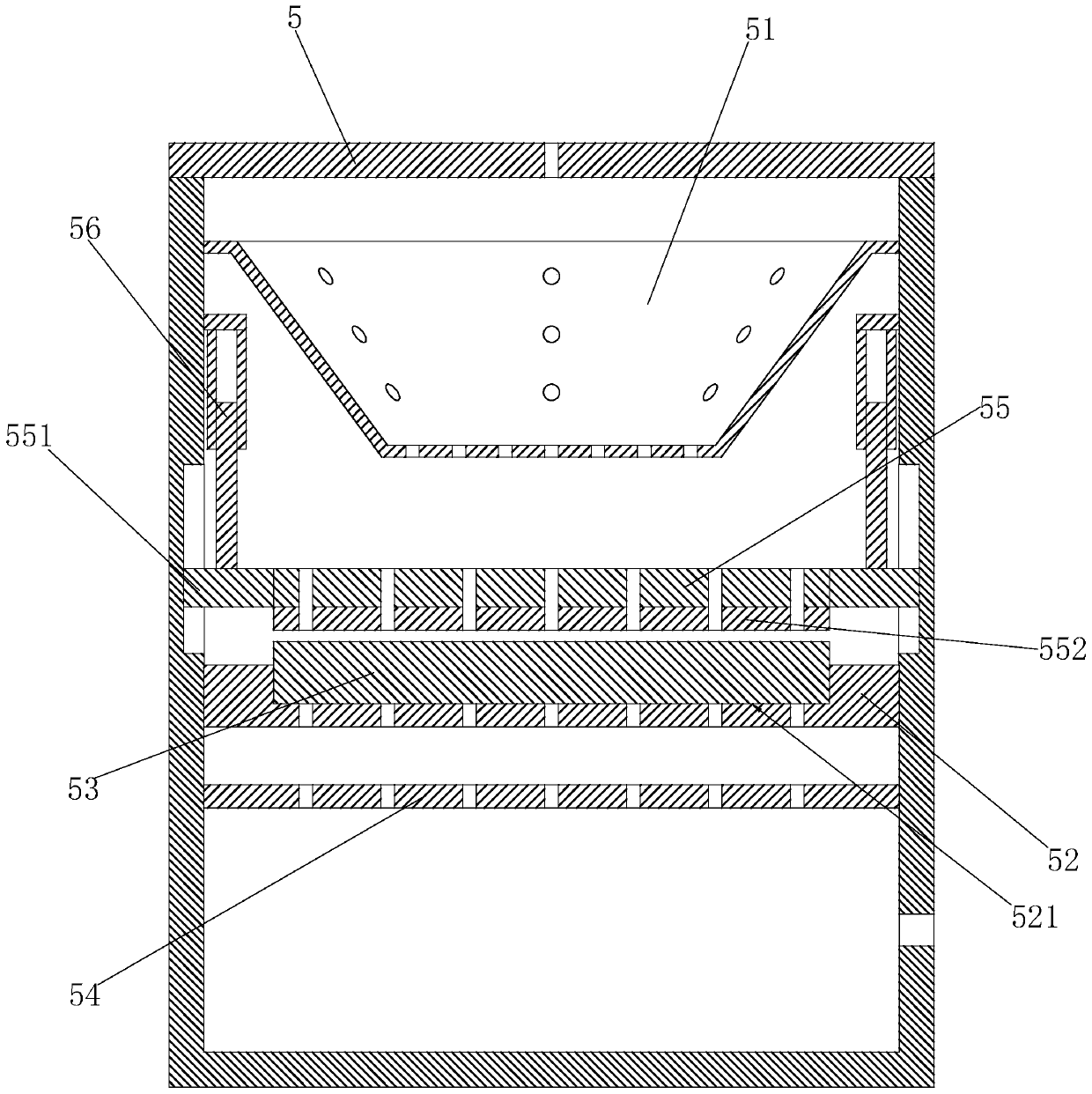

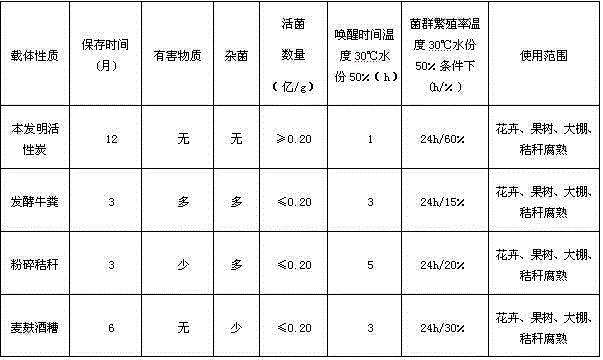

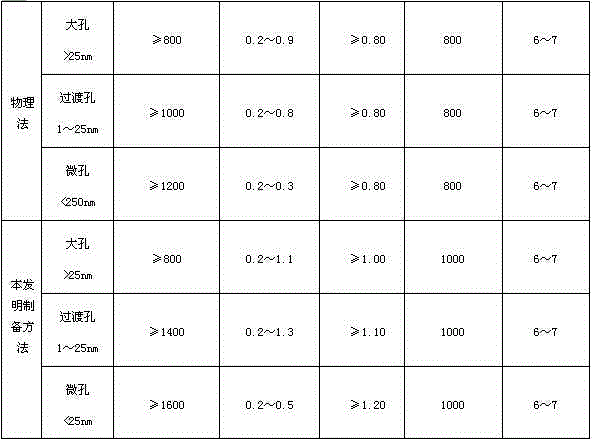

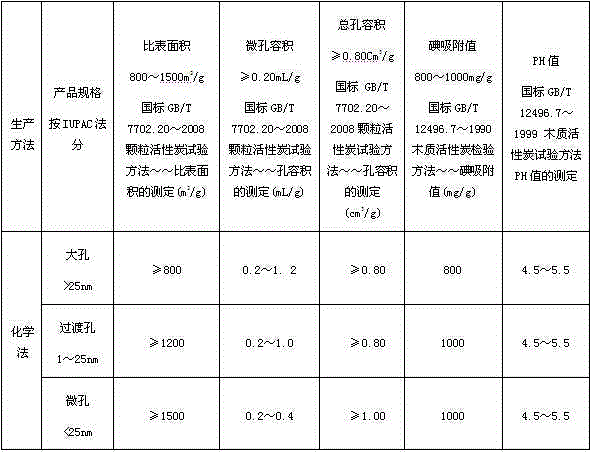

Active carbon preparing method by adopting walnut shell as raw material and application of the active carbon

ActiveCN103979534AShorten the production cycleLow reaction temperatureCarbon compoundsFertilizer mixturesActivated carbonControl release

The invention relates to an active carbon preparing method by adopting walnut shell as raw material and an application of the active carbon. The walnut shell is adopted as the raw material. The active carbon is prepared by adoption of a vacuum pyrolysis method through steps of smashing, drying, charring, puffing for activation, cooling, discharging, sieving, and the like. The obtained active carbon is applied as a microbial fertilizer carrier. The preparing method and the application are advantaged by: short production period, low reaction temperature, low production cost, low energy consumption, no pollution to the environment, and capability of improving the soil granular structure, reducing soil hardening, enhancing the water retention property of the soil, playing a role of nitrogen-fixation controlled release fertilizers, and reducing the using amount of fertilizers and decomposed crop straw when the active carbon is applied as a microbial fertilizer carrier and used in the agriculture.

Owner:石家庄金太阳生物有机肥有限公司

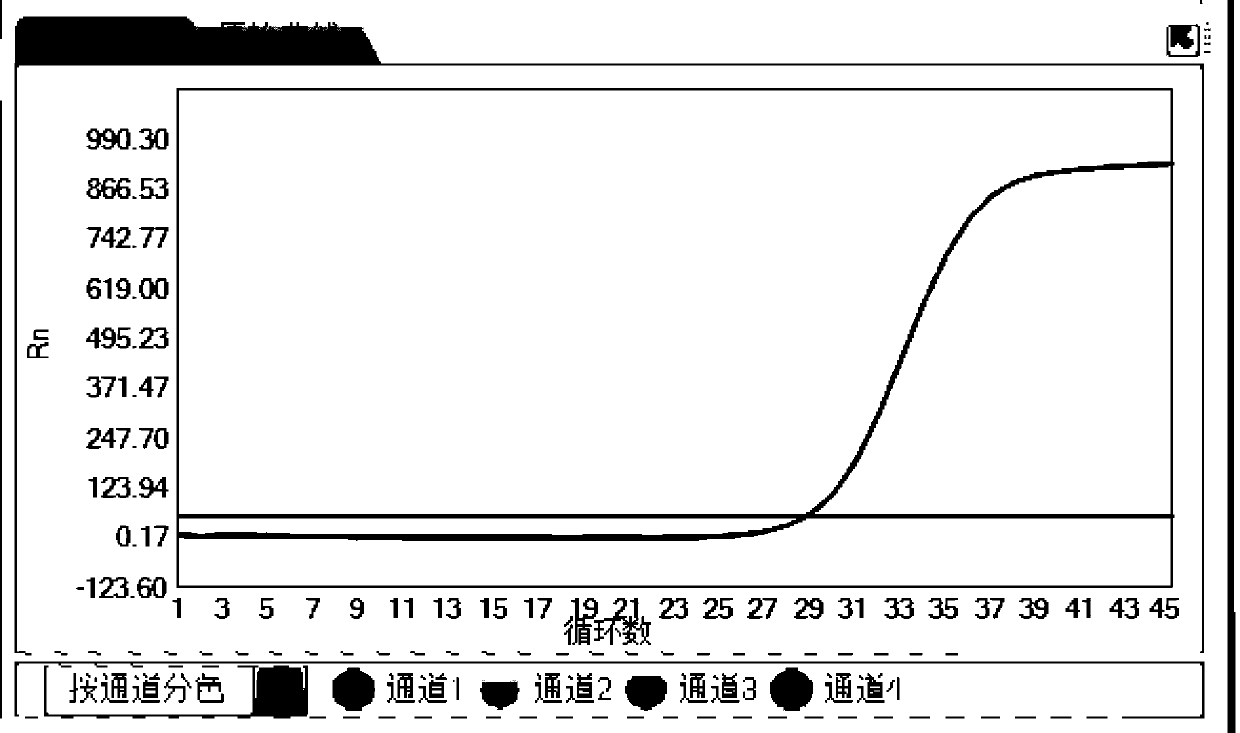

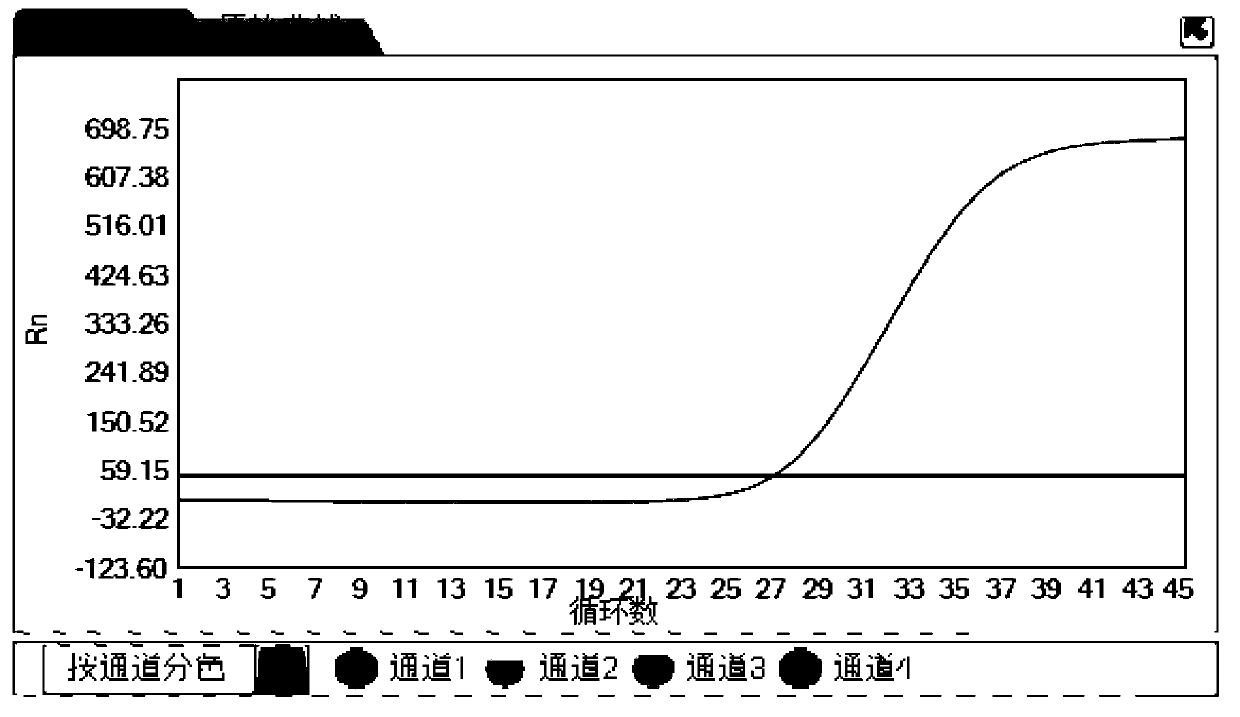

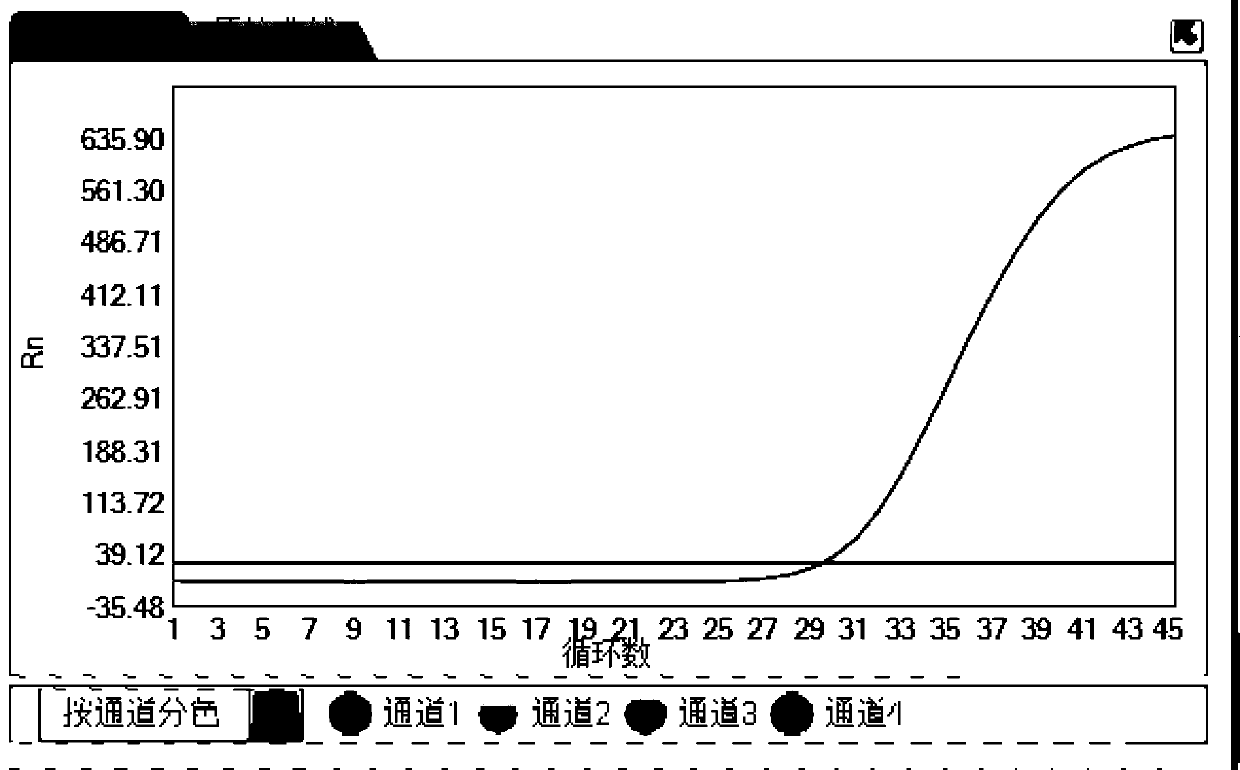

Composition, kit and method for detecting and typing viruses causing respiratory tract infection and application of composition, kit and method

ActiveCN111074011AReduce wasteReduce psychological burdenMicrobiological testing/measurementMicroorganism based processesBioinformaticsInfluenza B viruses

The invention relates to the field of molecular biology detection, in particular to detection of novel coronavirus, influenza A virus and influenza B virus. The invention provides a composition for detecting the viruses, and meanwhile, the invention further provides a kit containing the composition, application of the composition and a method for detecting and typing the viruses causing respiratory tract infection. The composition is combined with a fluorescent probe method, three viruses causing respiratory tract infection can be detected and typed at the same time in one tube, and the composition, the kit and the method have the advantages of being low in cost, high in flux, short in consumed time, easy and convenient to operate and capable of avoiding false positive caused by cross among samples and environmental pollution.

Owner:SANSURE BIOTECH INC

Composite pre-mix material for pig and preparation thereof

InactiveCN101326967AEasy to absorbAvoid environmental pollutionFood processingAnimal feeding stuffNutrientChemistry

The invention provides a composite pre-mix material used for pigs, which is characterized by comprising components in the following weight percent: 20 percent to 50 percent of calcium carbonate, 1 percent to 25 percent of calcium hydrophosphate, 2.01 percent to 27 percent of synthetic amino acid, 0.5 percent to 17 percent of organic microelement, 0.001 percent to 0.2 percent of potassium iodide with 5 percent of purity, 1.1 percent to 5.5 percent of enzyme preparation, 5 percent to 10 percent of salt, 0.2 percent to 2 percent of composite multi-fiber used for pigs, 0.3 percent to 2 percent of antioxidant, and 1 percent to 40 percent of carrier. The invention also provides the preparation method of the composite pre-mix material used for pigs. The product of the invention reduces the addition of phosphorus and improves the ration nutrient digestion rate by adding the enzyme preparation , so as to reduce the emission of nitrogen and the phosphorus; provides microelements, such as copper, iron, zinc, manganese, selenium, etc. by adding composite amino acid chelate complex, which not only greatly reduces the emission of the microelements and prevents environmental pollution, but also prevents the sediment of the microelements in pork, and ensures the eating safety of the pork.

Owner:CHONGQING ACAD OF ANIMAL SCI

Permeable and elastic pavement blocks

InactiveUS6960046B2Avoid environmental pollutionShock absorptionShow cabinetsLighting and heating apparatusSports activityEngineering

Permeable and elastic pavement blocks comprising waste-polyurethane chips, which use a binder specially developed to secure the binding between an upper polyurethane-chip layer and a lower permeable-concrete layer as well as the binding among the waste-polyurethane chips, resulting in excellent strength and durability, and use recycled polyurethane chips to provide elasticity and permeability suitable for sports activities, walking, and outdoor exercises the like.

Owner:KANG SUNG SOON

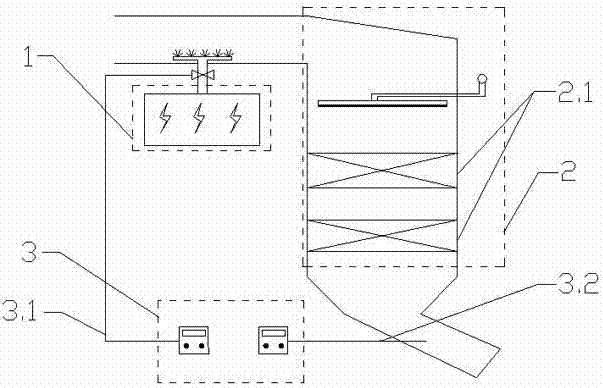

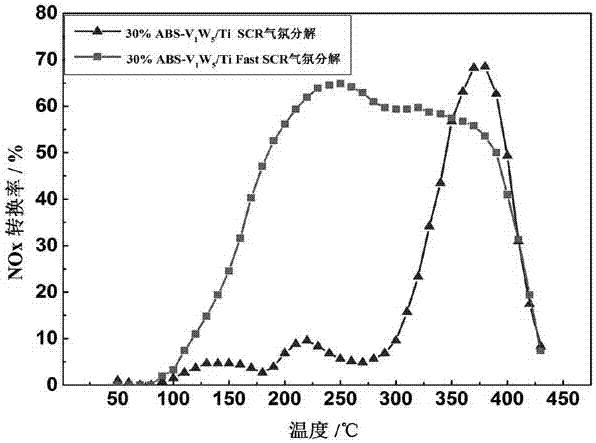

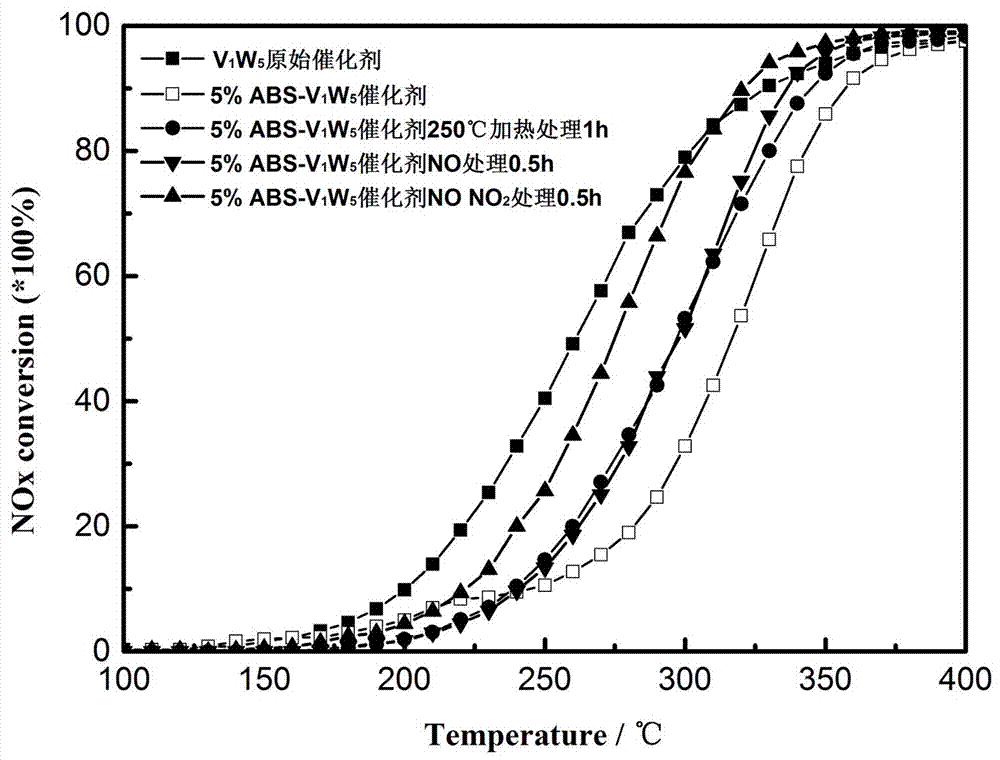

Method and device applied to in-situ regeneration of sulfur-poisoning SCR denitration catalyst

ActiveCN107376930AReduce catalytic activityLower decomposition temperatureGas treatmentHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention provides a method and a device applied to in-situ regeneration of a sulfur-poisoning SCR denitration catalyst. The method comprises the following steps: pre-oxidizing part of smoke before entering to an SCR denitration reactor when the SCR denitration catalyst is deactivated by sulfur poisoning, oxidizing part of NO in the smoke, then enabling the smoke to enter into the SCR denitration reactor, accelerating decomposition of ammonium sulfate on the surface of the catalyst, and carrying out regeneration process of the catalyst. The device applied to in-situ regeneration of the sulfur-poisoning SCR denitration catalyst comprises an ozone generator, an electromagnetic valve, an SCR denitration reactor and a smoke NOx component online monitor. The method and the device are capable of effectively decomposing ammonium sulfate deposited on the surface of the catalyst under the condition with temperature of 200-380 DEG C; the activity of the treated sulfur-poisoning catalyst is improved; the service life of the catalyst is prolonged; the replacement cost of the catalyst is reduced.

Owner:CHONGQING UNIV +1

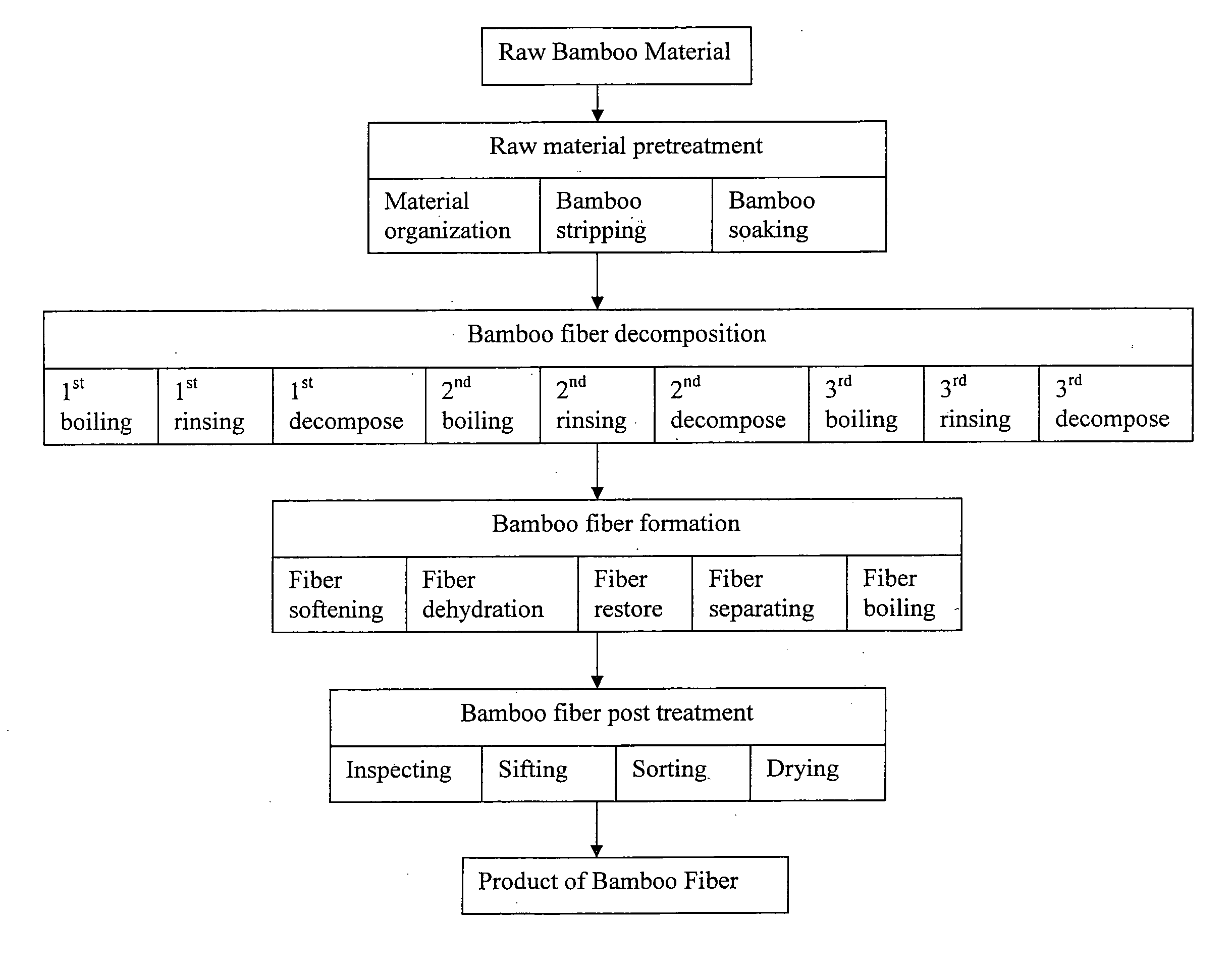

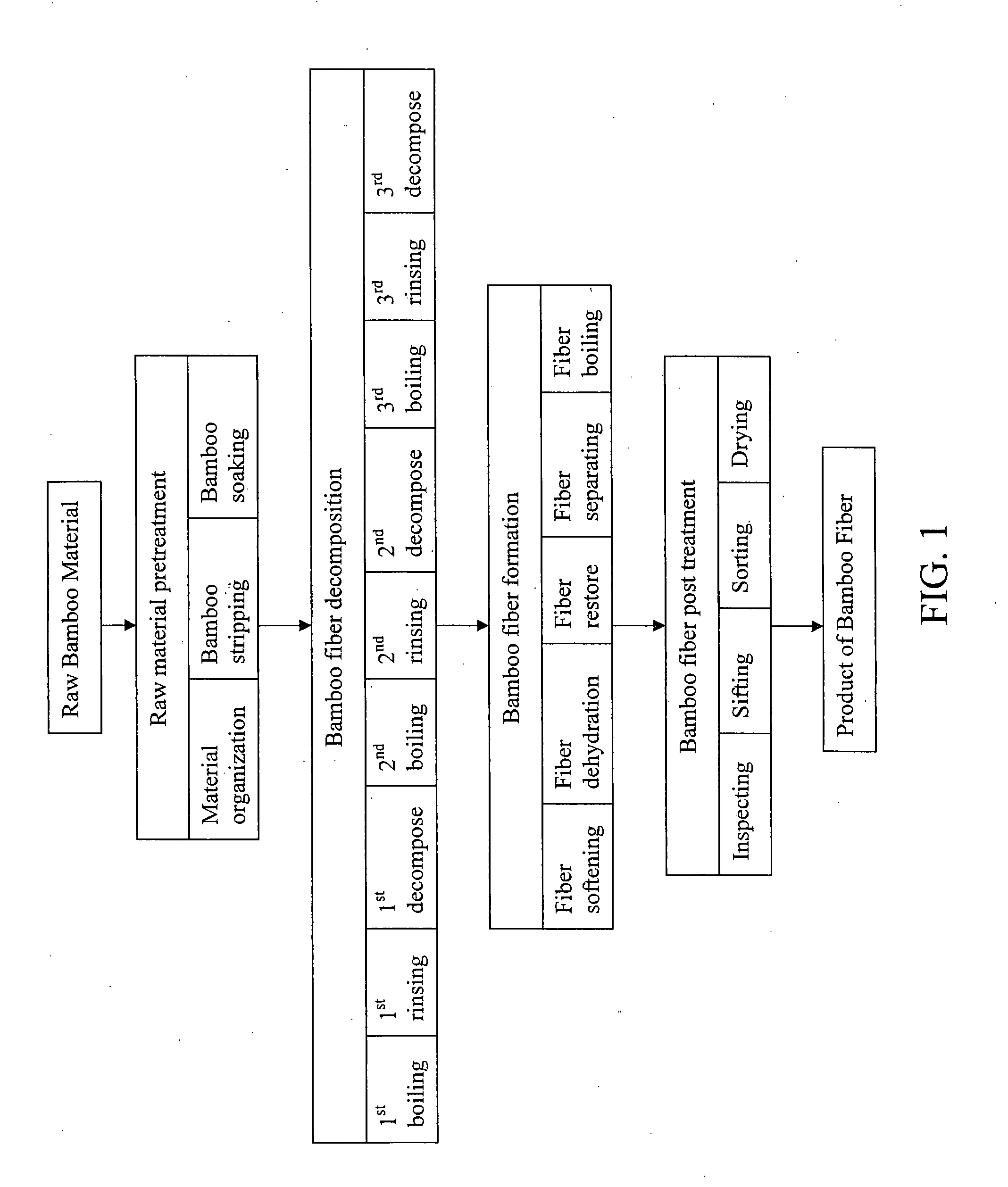

Bamboo fibre and its manufacture

InactiveUS20070267159A1High tensile strengthGood flexibilityNon-fibrous pulp additionNatural cellulose pulp/paperFiberAfter treatment

The present invention is related to a bamboo fiber, which uses bamboo as raw material, providing a kind of raw materials for making face fabric instead of cotton, chemical fiber, hemp and silk, and the production method of this kind of fiber includes the procedures of bamboo pretreatment, bamboo separation, bamboo fiber forming and its after treatment, in which it adopts a degumming softening agent made up according to a wild plant formula, and its neutral in acidity-alkalinity ensures no environmental pollution. The face fabric made of bamboo fiber is good in flexibility, permeability and is UV-resistant or ultraviolet resistant, low cost and high comfort in summer.

Owner:ZHAO ZIGUN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com