Bamboo fibre and its manufacture

a technology of bamboo fiber and manufacturing method, which is applied in the field of bamboo fiber, can solve the problems of affecting the current world trend of back-to-back, polluting the environment during the manufacturing, and easy to break bamboo fiber to manufacture clothing shell fabric materials, etc., and achieves good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

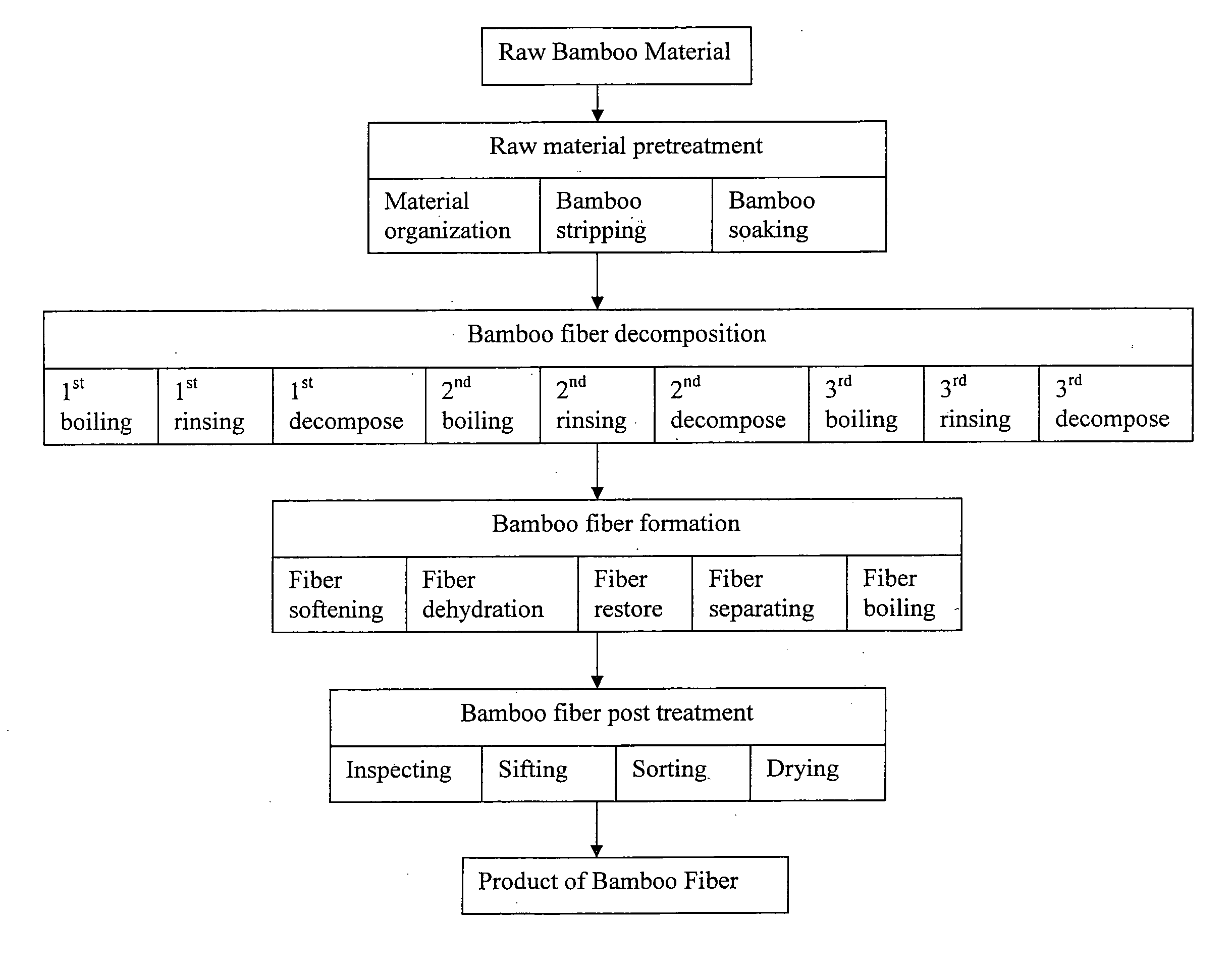

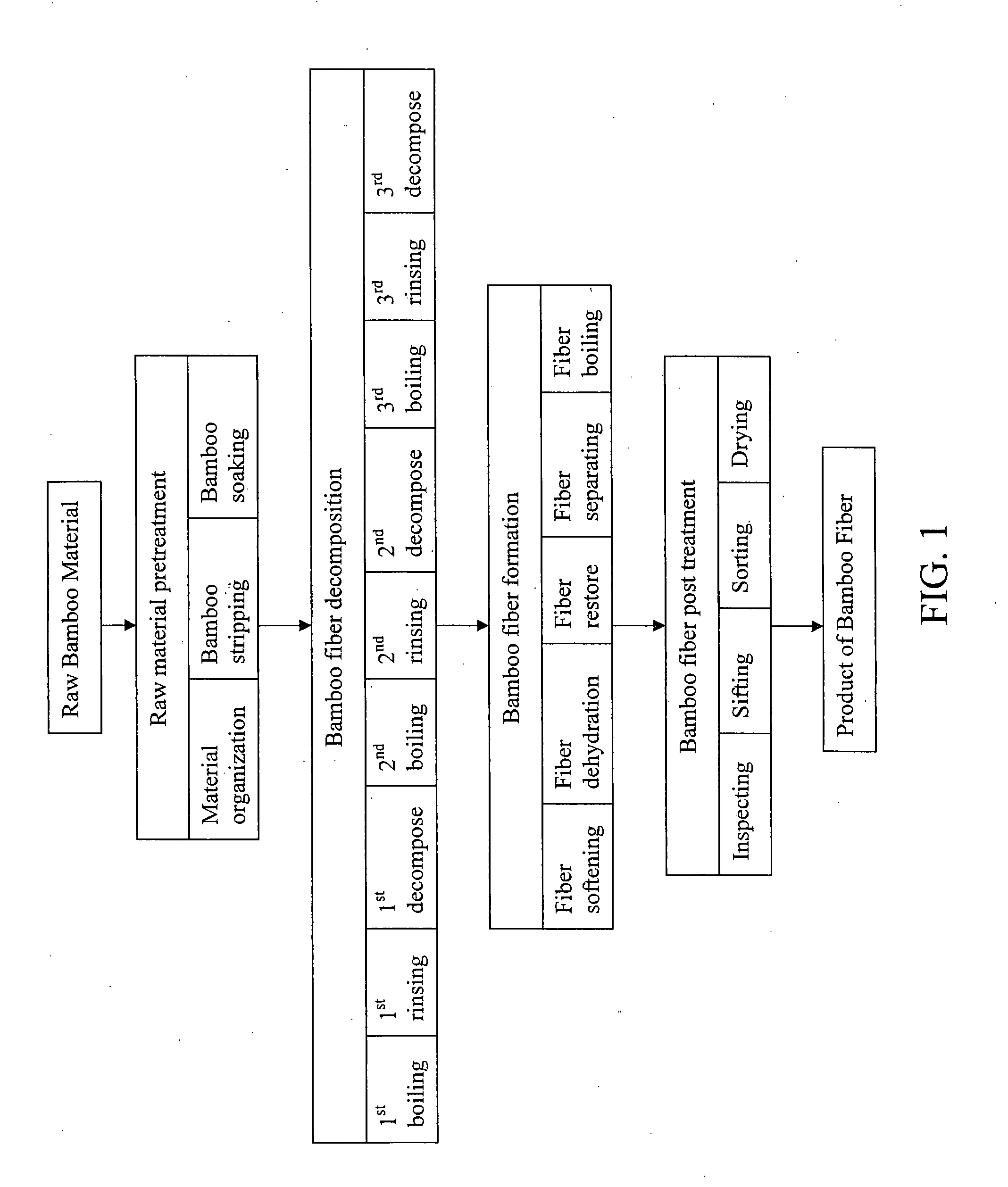

[0011] Referring to FIG. 1 drawing, a bamboo fiber and its manufacture according to a preferred embodiment of the present invention is illustrated, wherein the manufacturing process of the bamboo fiber comprises the following steps.

[0012] (1) Material organization: cutting a bamboo as a raw material by removing branches, throwing sharp-pollard and sawing into a fixed length of bamboo segment.

[0013] (2) Bamboo stripping: cutting the bamboo segment to form at least a bamboo strip having a width approximately 2 mm by a bamboo colliding machine or manually.

[0014] (3) Bamboo soaking: disposing the bamboo strips into a solution with a specific degumming softening agent for 4 hours, wherein the degumming softening agent is a natural botanical prescription without acidity-alkalinity chemical agent and the concentration ratio of the degumming softening agent to water is 30%.

[0015] (4) First time boiling: boiling the bamboo strip in the soaking solution by a steam boiler at the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com