Patents

Literature

59results about "Vegetable fibres from other vegetable matter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

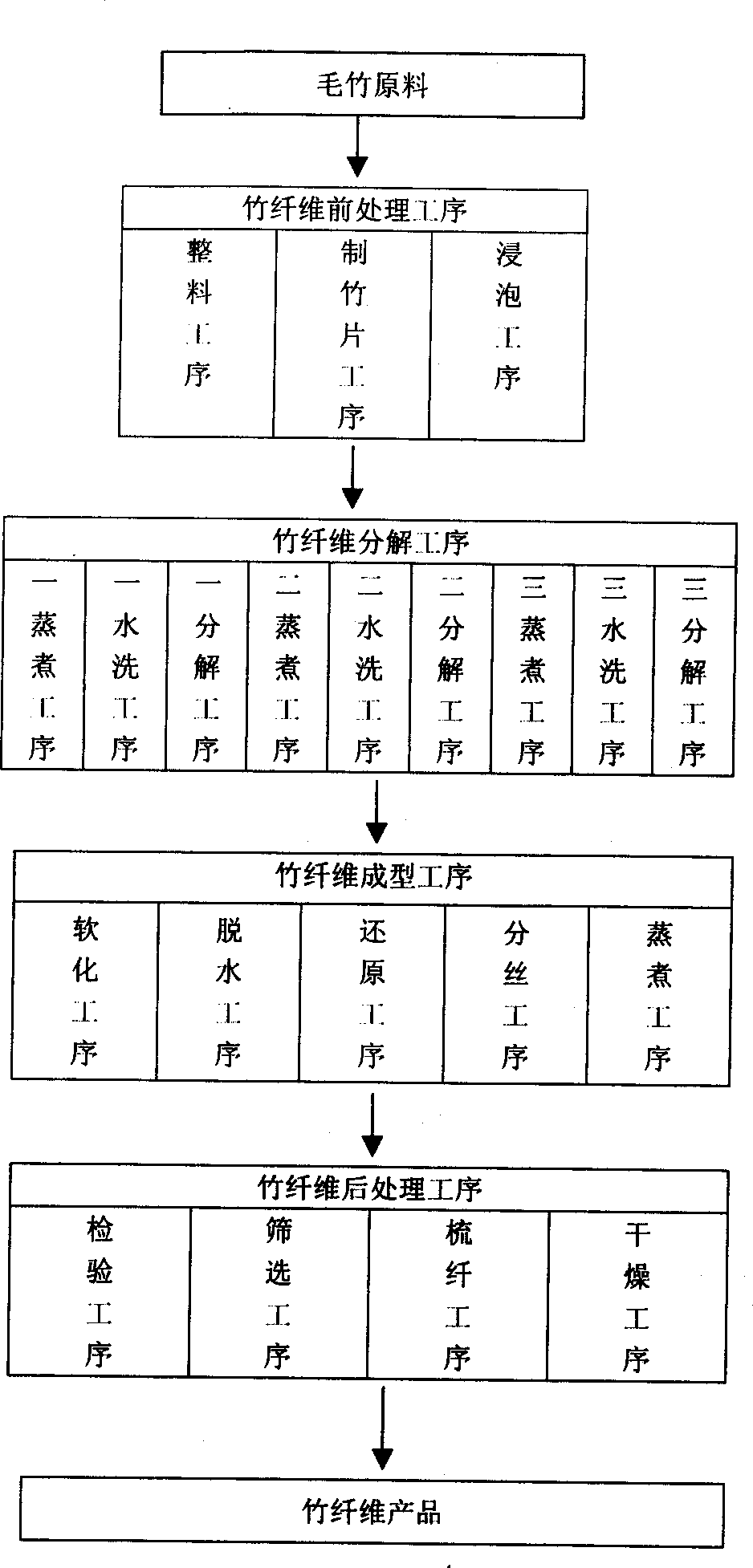

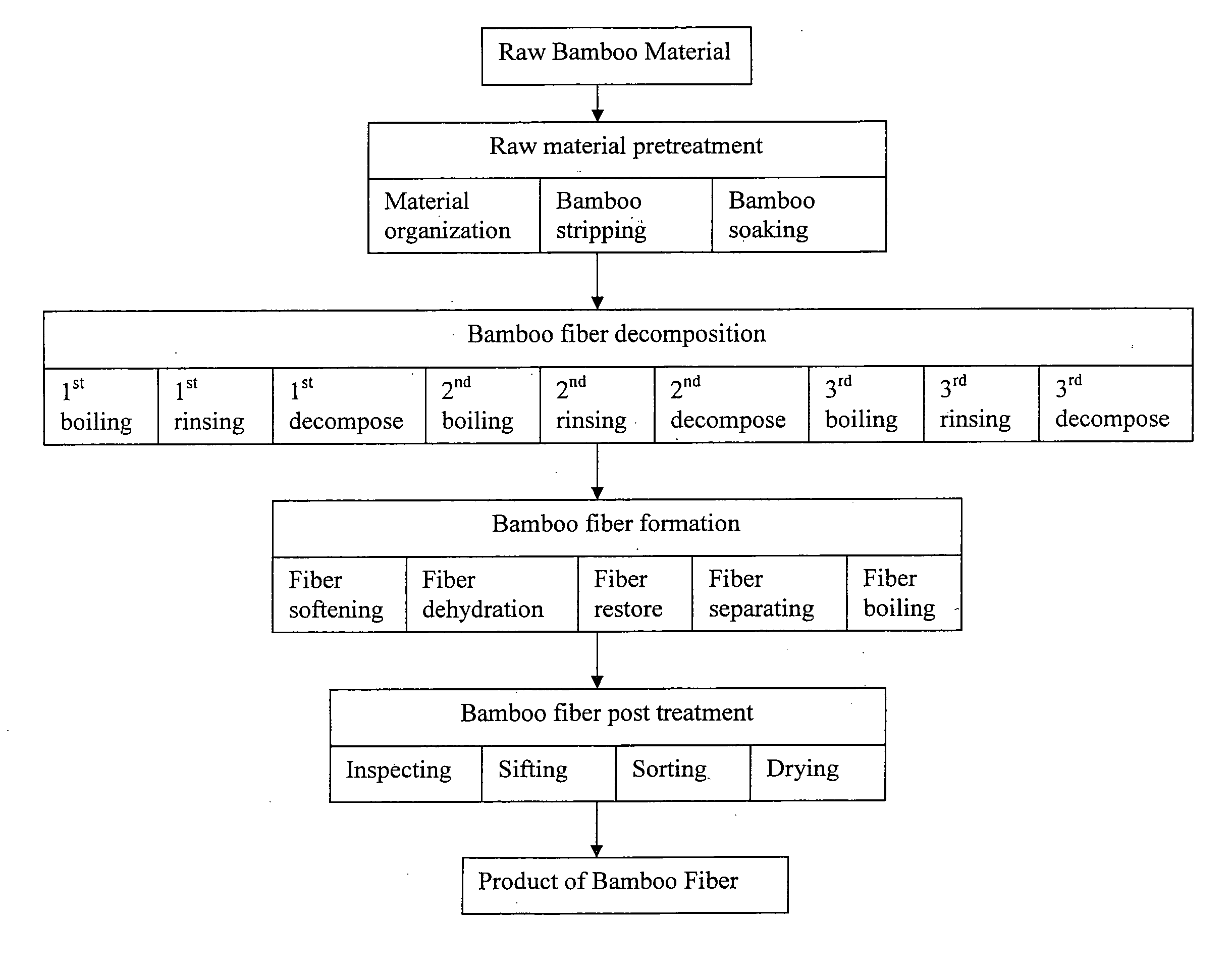

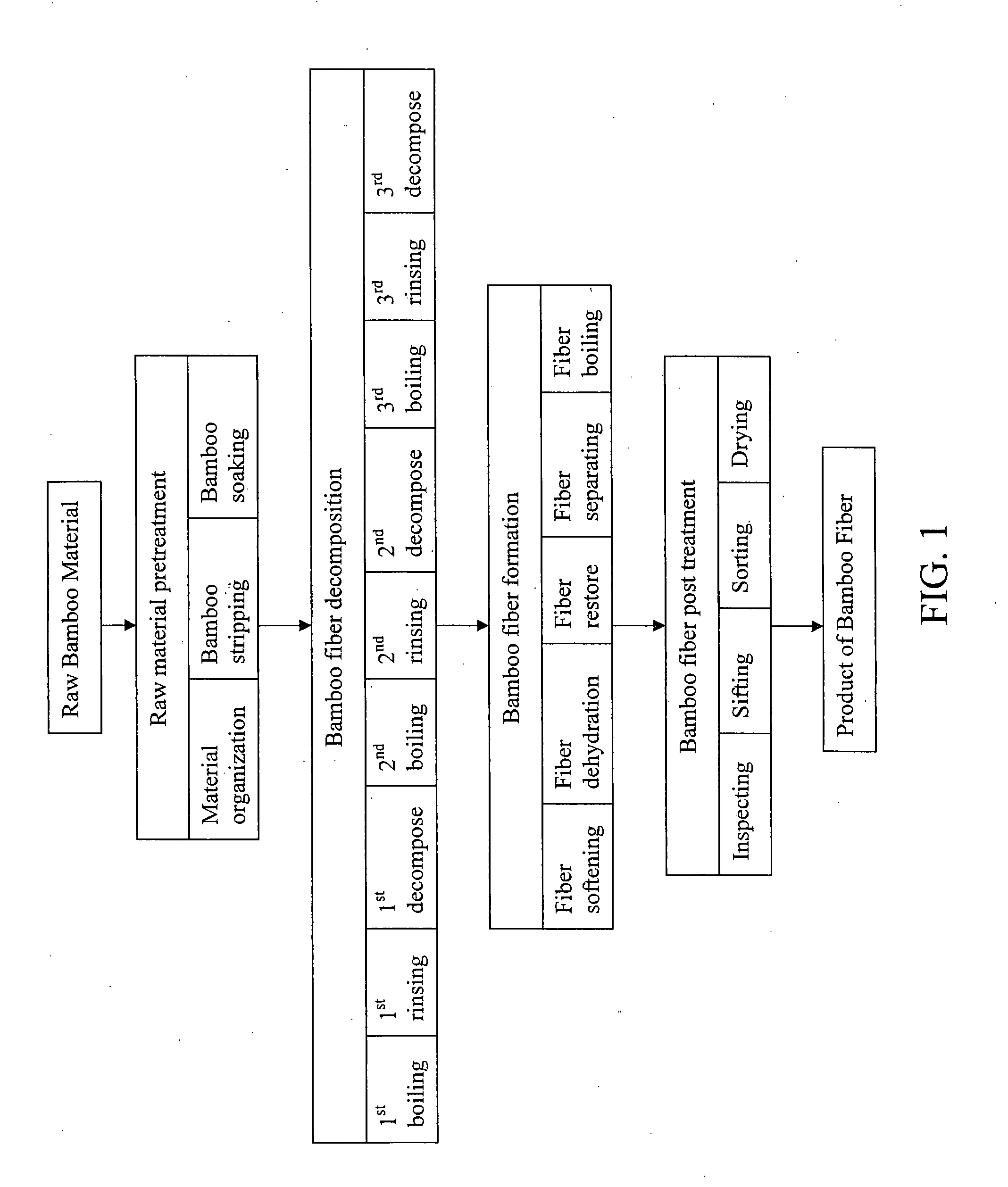

Bamboo fiber and its making process

InactiveCN1375578AGood flexibilityHigh folding resistanceVegetable fibres from other vegetable matterFibrous raw materialsAfter treatmentDecomposition

The present invention uses clustered bamboo as raw material and is aimed at providing a kind of raw material for making shell fabric instead of cotton, chemical fibre, hemp and silk, and its production method incldues the procedures of bamboo fibre pretreatment, bamboo fibre decomposition, bamboo forming and its after treatment, in which it adopts a degumming softening agent made up according to a natural formula, it is neutral in acidity-alkalinity and has no environmental pollution. Said shell fabric made of bamboo fibre is good in flexibility and permeability and is uvioresistant.

Owner:赵子群

Production technology of spinnability soft coconut shell fine fibers and application of fiber product

InactiveCN104195650AGood flexibilityImproved elongation at breakVegetable fibres from other vegetable matterVegetable materialYarnCarding

The invention discloses a production technology of spinnability soft coconut shell fine fibers. The production technology is characterized by comprising the following steps of performing opening and cleaning, carding and impurity and block removing on original fibers of coconut shells serving as a raw material; and preparing a soaking solution, soaking the coconut shells with the solution, dewatering, steaming, drying and performing fine fiber carding, thus producing the soft and puffy ultrafine fibers. By virtue of soaking, most impurities are removed from the coconut fibers, so that the softness is improved, and the fine crushability and the fracture elongation property are improved; the fibers are complete in spinnability; due to chemical soaking, the internal structure is changed; furthermore, lignin is removed from the fibers, so that the water content is increased, and the aim of softening is fulfilled; the softened coconut fibers can be used for spinning various types of yarns which are then woven into textiles.

Owner:ZHEJIANG YIWU HENDRY WOOLEN

Banana fiber and its production and its blending wires and fabrics

InactiveCN1472372ALight materialGood hygroscopicityVegetable fibres from other vegetable matterYarnYarnFiber bundle

Provided is a banana fiber using a banana stem which is an industrial waste as a raw material, a method for producing the banana fiber, a union yarn composed of a staple fiber of the banana fiber and other fiber and a fiber structure prepared from the union yarn. The banana fiber is obtained by drying peeled temporary stem of banana and opening the fiber so as to have 10-50 mm average fiber length and 0.5-80 dtex average fineness. The method for producing the banana fiber comprises a step (a) for cutting stems of banana, a step (b) for peeling and removing colored epidermis of stems, a step (c) for peeling much bark constituting stems to provide a unit bark, a step (d) for taking out a fiber bundle by pressing the unit bark by a press, a step (e) for drying the fiber bundle, a step (f) for obtaining a monofilament from the dried fiber bundle and a step (g) cutting the monofilament into a definite length and obtaining the staple fiber.

Owner:NISSHINBO IND INC

Bamboo fibre and its manufacture

InactiveUS20070267159A1High tensile strengthGood flexibilityNon-fibrous pulp additionNatural cellulose pulp/paperFiberAfter treatment

The present invention is related to a bamboo fiber, which uses bamboo as raw material, providing a kind of raw materials for making face fabric instead of cotton, chemical fiber, hemp and silk, and the production method of this kind of fiber includes the procedures of bamboo pretreatment, bamboo separation, bamboo fiber forming and its after treatment, in which it adopts a degumming softening agent made up according to a wild plant formula, and its neutral in acidity-alkalinity ensures no environmental pollution. The face fabric made of bamboo fiber is good in flexibility, permeability and is UV-resistant or ultraviolet resistant, low cost and high comfort in summer.

Owner:ZHAO ZIGUN

Method for extracting fiber from oil palm fruit bundle and fiber obtained thereby

The invention discloses a method for extracting fiber yarns from palm fruit clusters of oil palm. The palm fruit clusters of the oil palm are cooked by steam with a temperature of between 100 and 200 DEG C for 0.5 to 1.5 hours, oil palm fruit pericarps are separated to obtain empty fruit clusters, then the empty fruit clusters are extruded and torn to obtain fiber blocks, the fiber blocks are washed and then are extruded to ensure that the water content of the fiber blocks is between 30 and 80 percent, then the selection is performed, the selected fiber blocks are subjected to silk fetching treatment to obtain the fiber yarns, and then the fiber yarns are dried, screened and bagged. The applicator aims at the requirement on an elastic material to process and select the fiber yarns in the palm fruit clusters so as to be suitable to process natural oil palm silk mattresses. Natural fiber yarns of the palm fruit clusters obtained by the method can substitute mountain palm fiber yarns to produce various natural palm mattresses, cushions, and products such as fiberboards and sound insulation boards for buildings and so on.

Owner:GUIZHOU DAZIRAN TECH

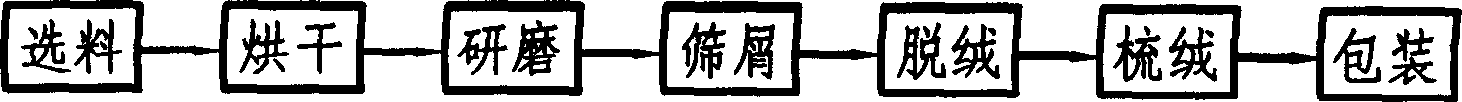

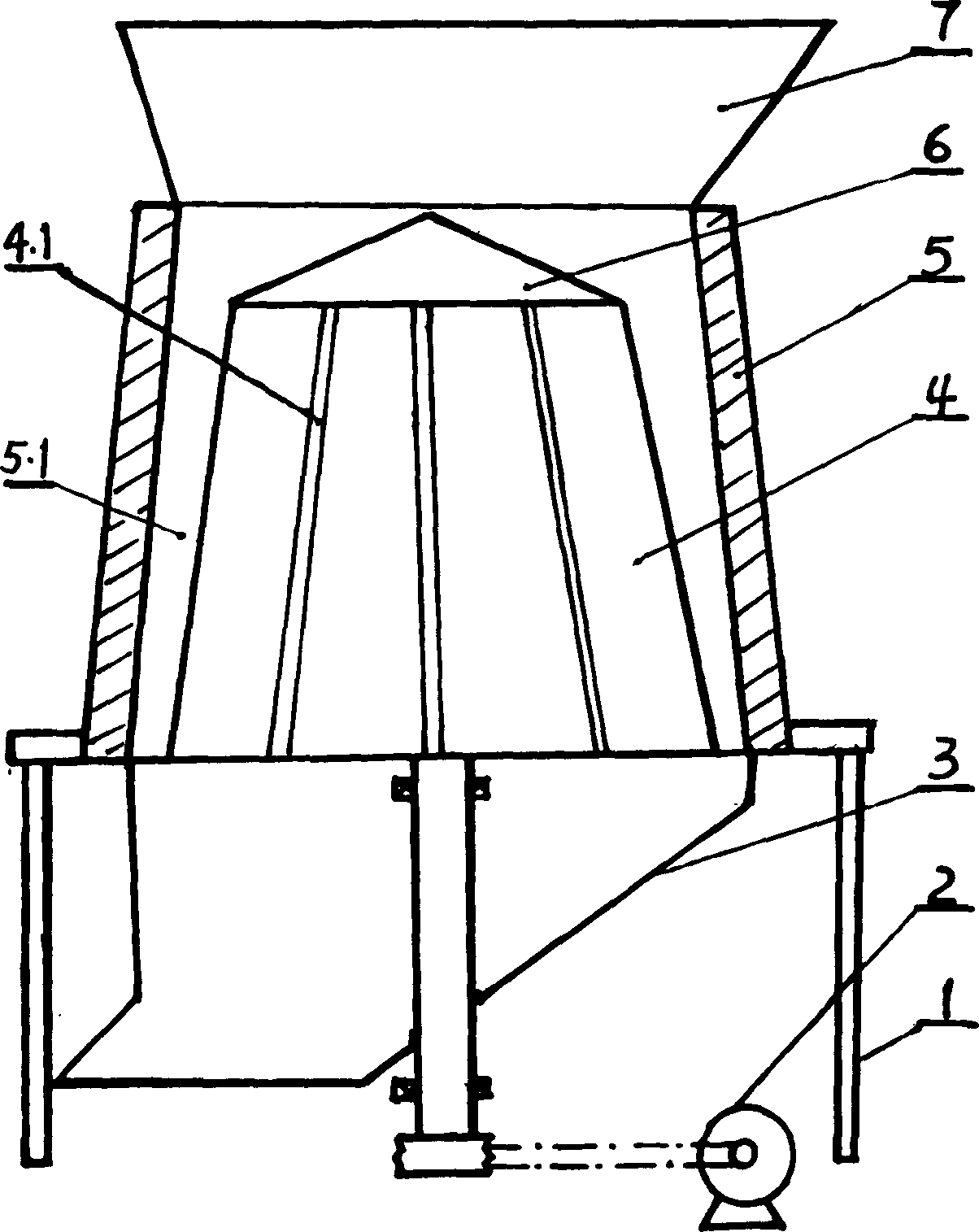

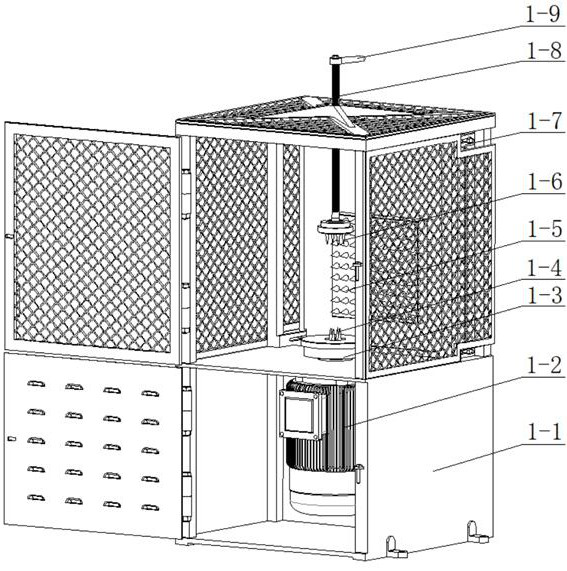

Moxa extraction process and grinder therefor

InactiveCN1864954AImprove crushing qualityImprove crushing effectVegetable fibres from other vegetable matterPlant material mechanical workingFiberEngineering

The invention relates to a method for extracting moxa from argyi leaf and relative grinder. It mainly comprises following steps that selecting material; drying; grinding; screening; removing hair; and combing moxa. Wherein. The invention uses taper grinder whose movable grinding element is a rotary table inside the cylinder fixed grinding element, while there is a grinding chamber between them; the upper end of movable grinding element is mounted with taper setting gauge. The invention can improve the quality of broken argyi leaf, to protect the natural length of moxa, improve the moxa extraction rate. And it uses eccentric moxa combing method, to improve the shape of moxa.

Owner:刘志宏

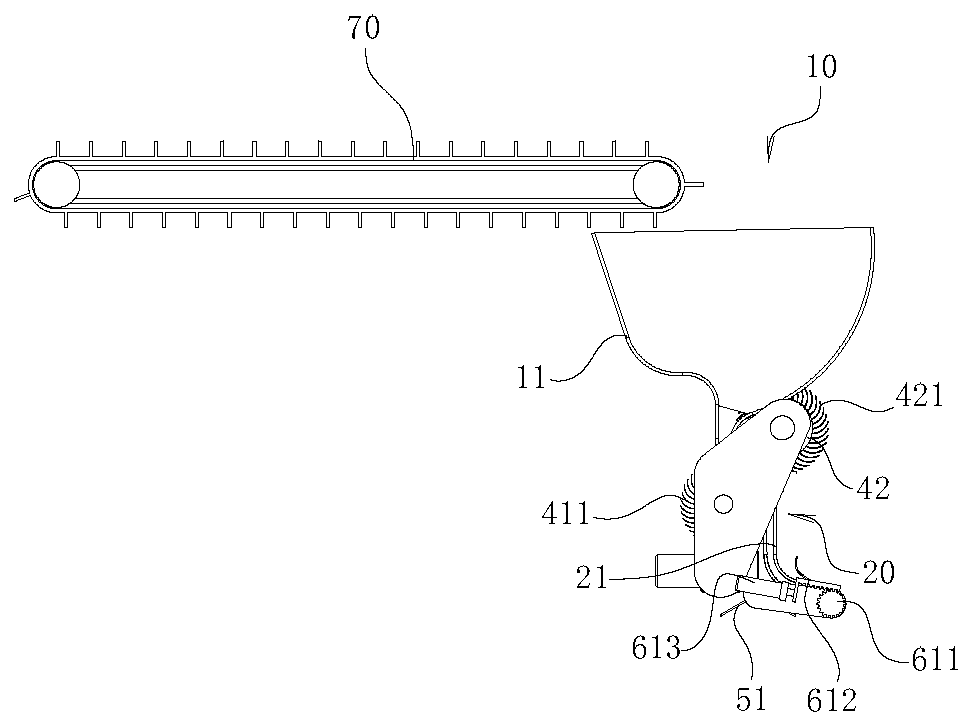

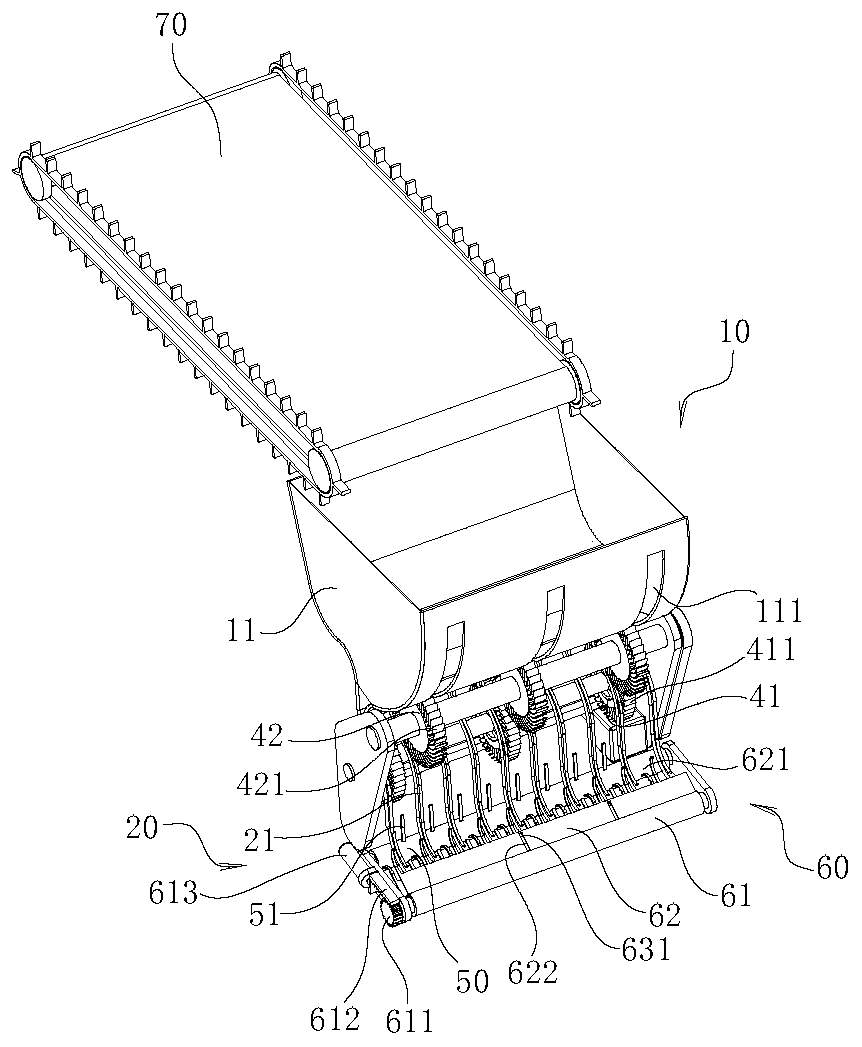

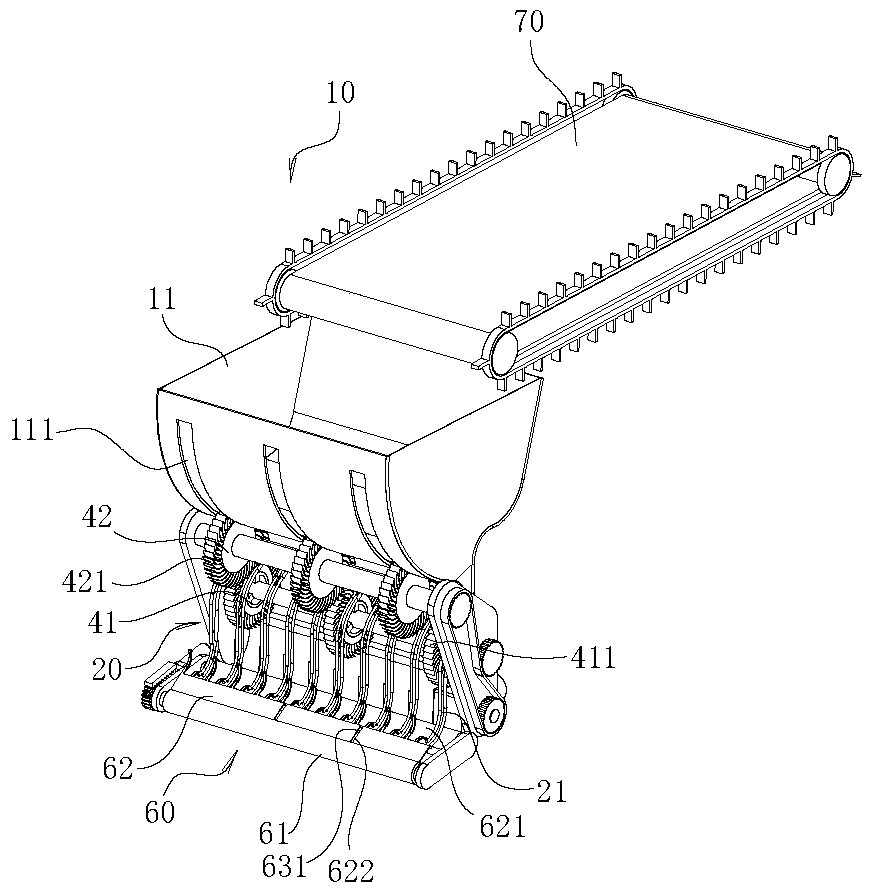

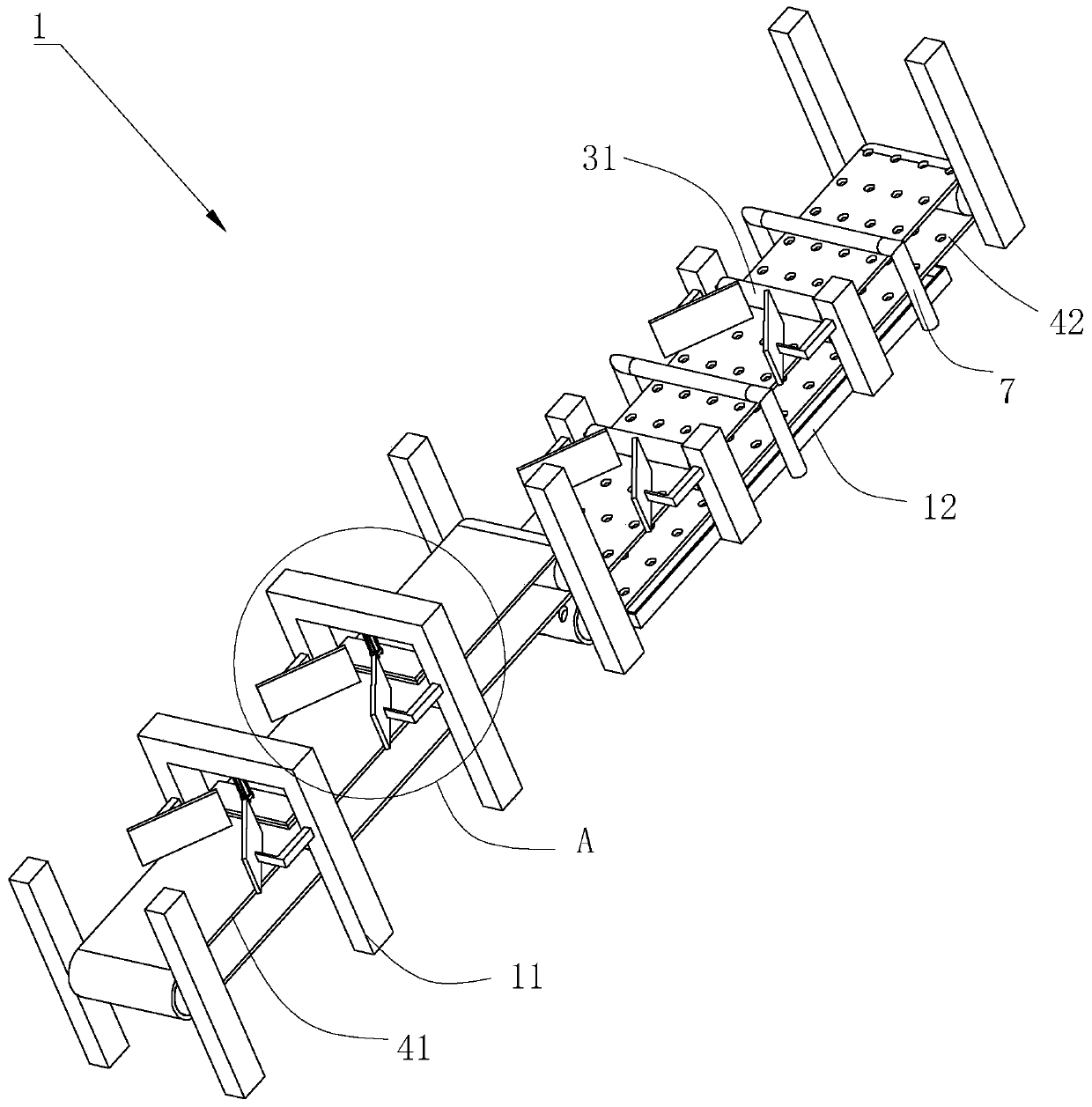

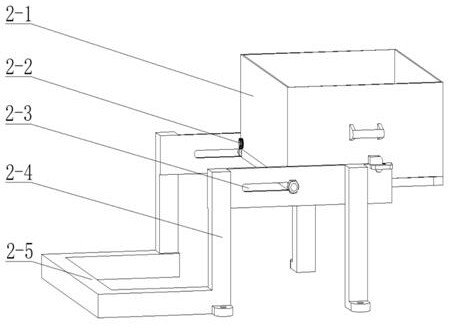

Artware lotus root rod depiler

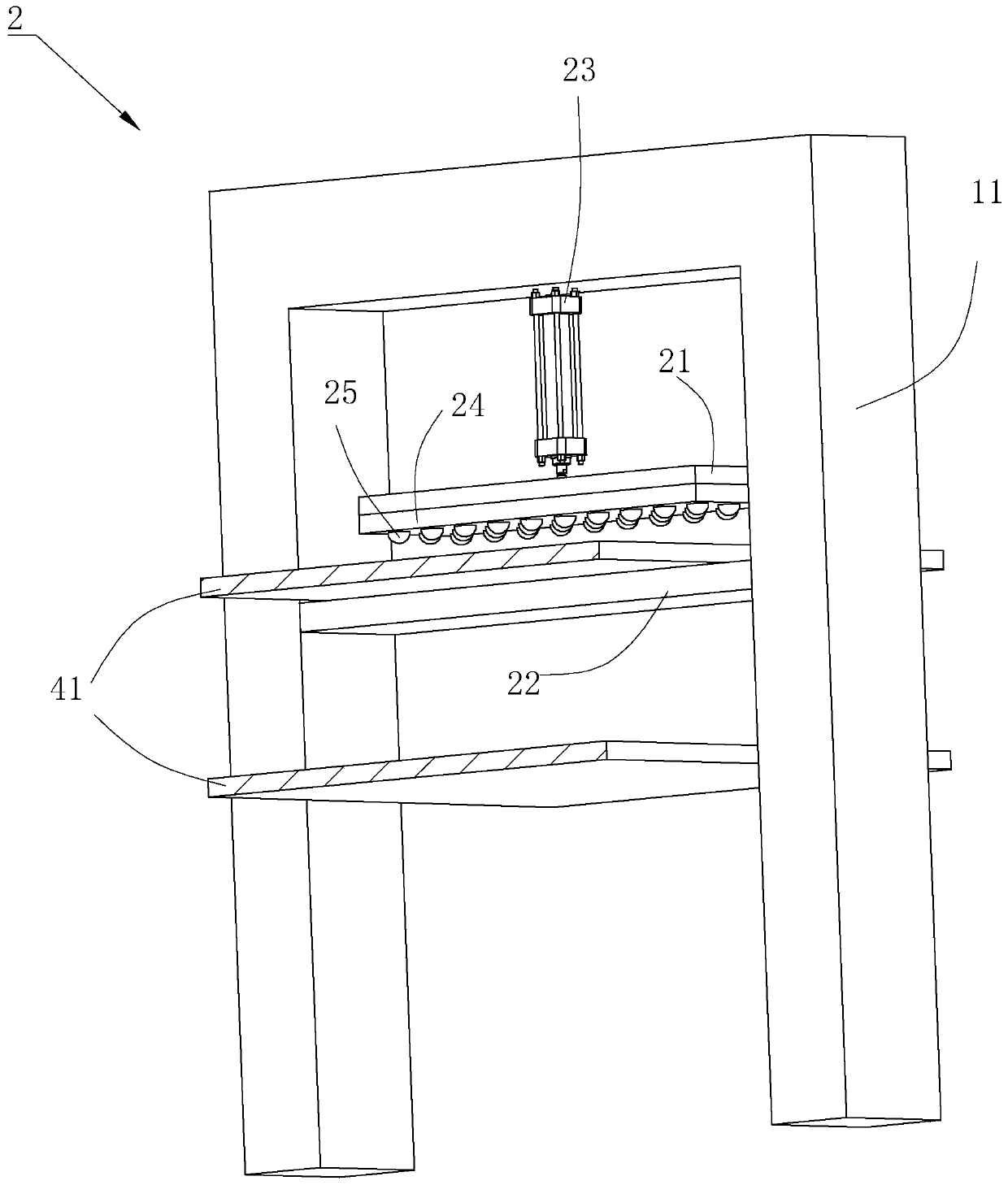

ActiveCN110668141AImplement fiber spinning operationsConveyorsVegetable fibres from other vegetable matterBiotechnologyEngineering

The invention relates to an artware lotus root rod depiler which comprises a feeding mechanism. A guide material slide channel is formed at the outlet of the feeding mechanism and is bent and downwards extends. A pushing mechanism is arranged in the guide material slide channel and pushes lotus root rods to slide along the guide material slide channel. A collecting mechanism is arranged at the outlet of the guide material slide channel, collects the lotus root rods and delivers the lotus root rods into the feeding mechanism so that the lotus root rods can be delivered into a material hopper inthe feeding mechanism step by step. The pushing mechanism makes the lotus root rods slide in the guide material slide channel one by one and guides the lotus root rods out of the outlet of the guidematerial slide channel. After the pushing mechanism guides the lotus root rods out of the outlet of the guide material slide channel one by one and the collecting mechanism fully collects the lotus root rods, the pushing mechanism stops working, and the collecting mechanism guides a certain number of lotus root rods into a spinning mechanism for spinning operation. By means of the depiler, the lotus root rods can be guided out bundle by bundle, so the fiber spinning operation of the lotus root rods is realized.

Owner:岳西神农氏农业科技有限公司

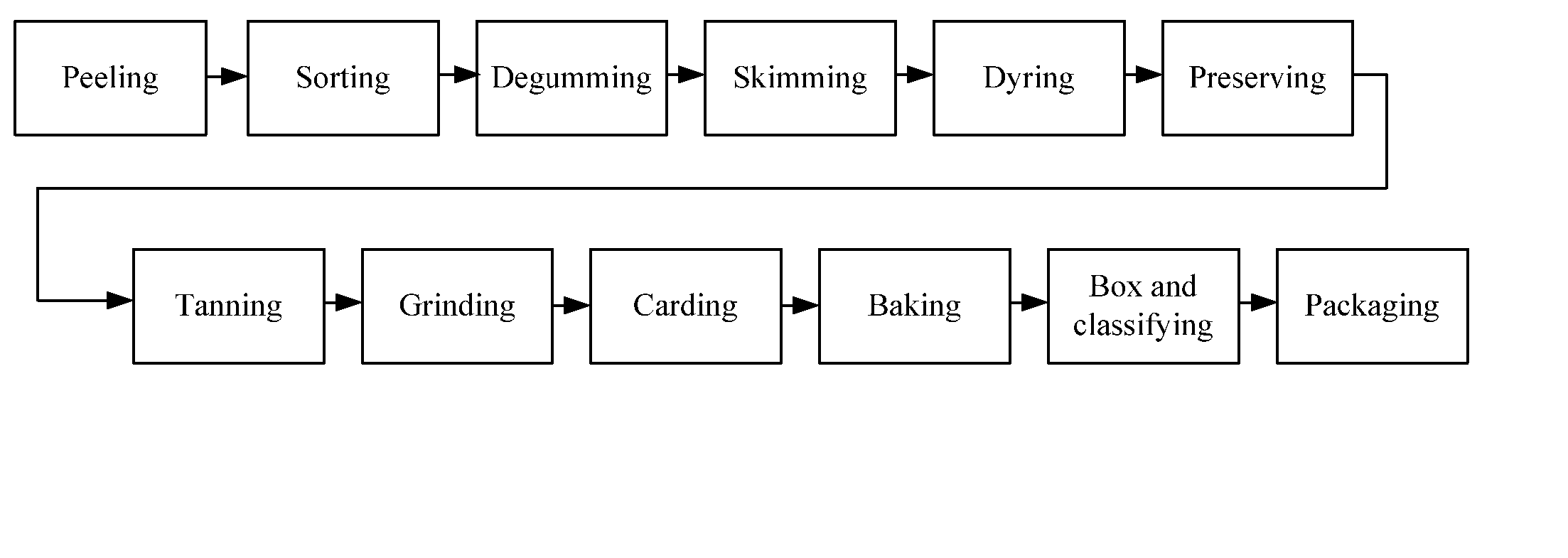

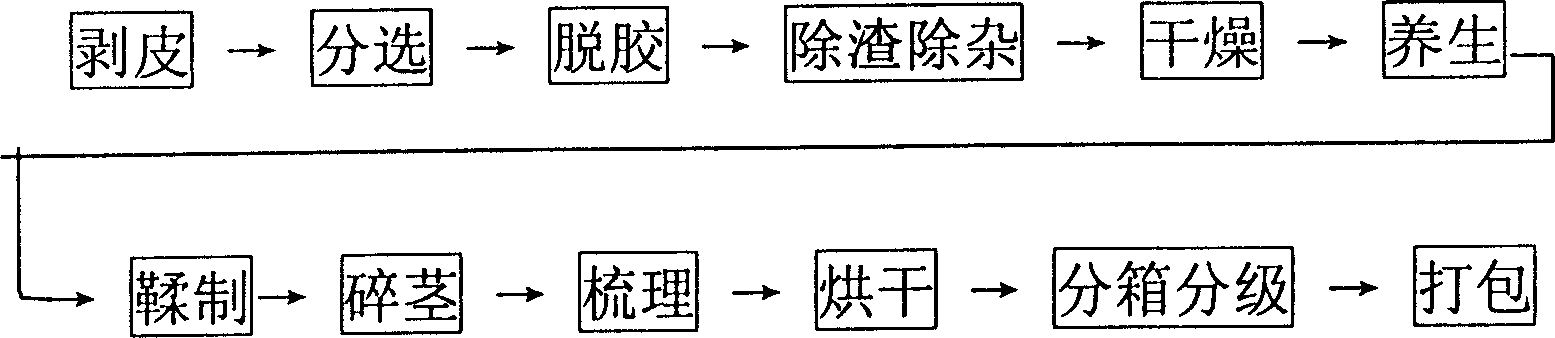

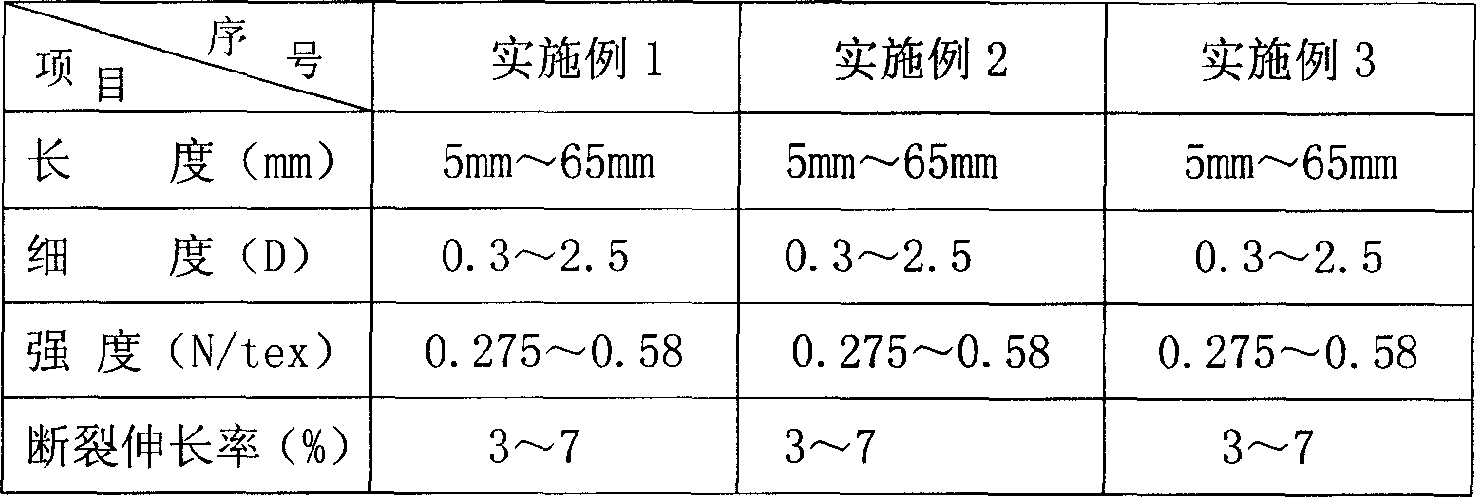

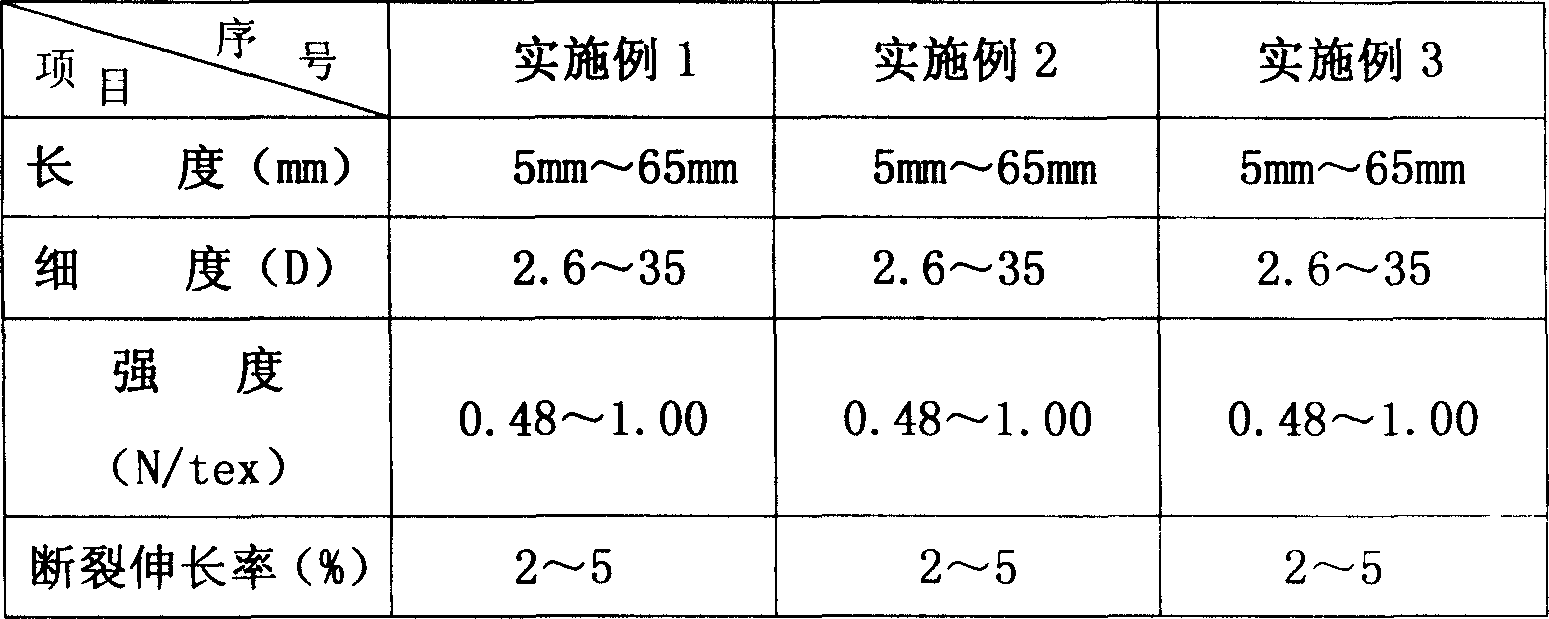

Tree bast fiber and method for processing tree bast

InactiveUS20080090078A1Economical priceWide applicationVegetable fibres from other vegetable matterYarnYarnTextile fiber

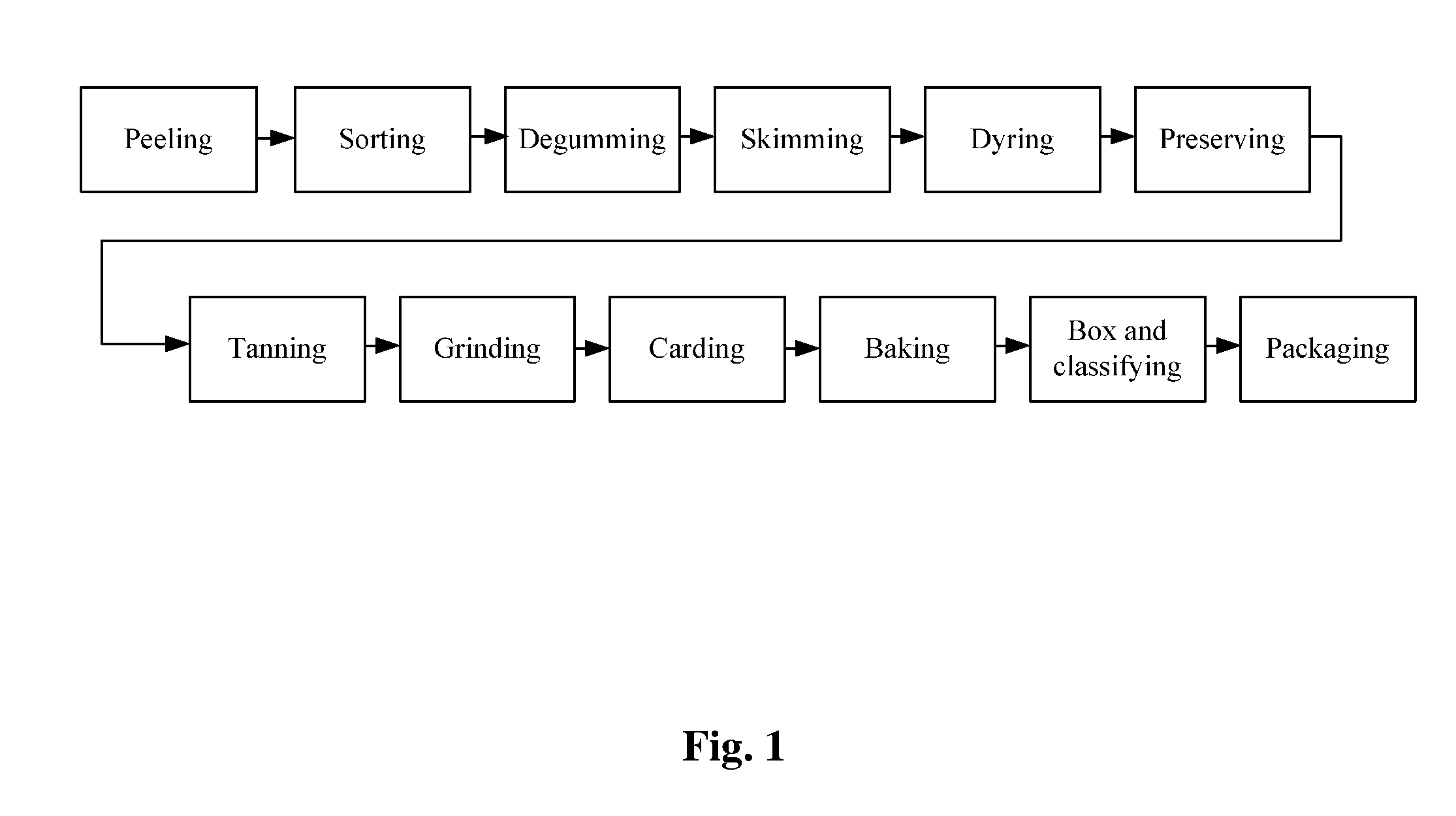

Taught is tree bast fiber, along with a method for processing the same, the fiber being a natural textile fiber made of bark of trees except for mulberries and paper mulberries. The length of the fiber is 5 mm-65 mm. The fineness of the fiber is 0.3-2.5D. The intensity of the fiber is 0.275-0.582 N / tex. The breaking elongation rate of the fiber is 3%-7%. The method comprises the steps of peeling, sorting, degumming, skimming, drying, preserving, tanning, grinding, carding, baking, boxing and classifying, and packaging. The textile fiber is produced from a resource abundant in nature. The fiber has similar performance to bast fiber, higher intensity than cotton fiber, good dyeing properties, and wide application prospects. It can be blended with other natural fibers, man-made fibers and recycled fibers to form fiber yarn for various purposes. This method changes waste into a commodity, and brings about great economic and social benefits.

Owner:LIU LEI +1

Coconut fiber automobile backrest and method for manufacturing back cushion of backrest

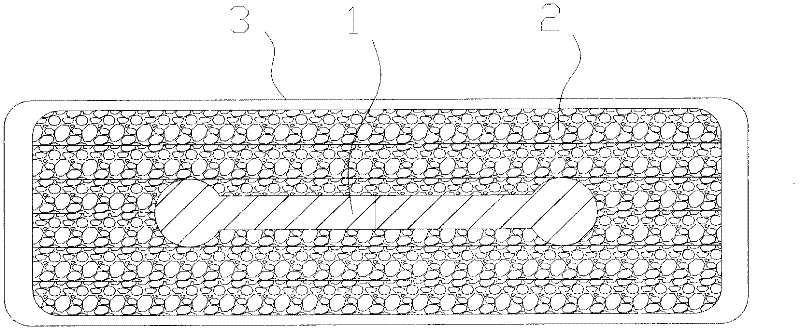

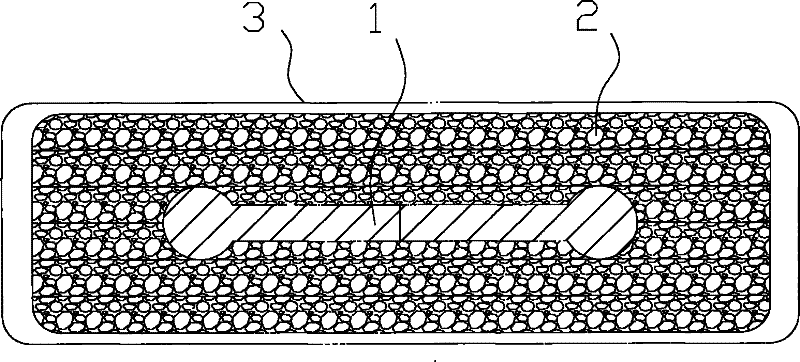

InactiveCN102632821AAbundant sources of raw materialsReduce manufacturing costBack restsVegetable fibres from other vegetable matterFiber layerCushion

The invention provides a coconut fiber automobile backrest and a method for manufacturing a back cushion of the backrest. The coconut fiber automobile backrest comprises a backrest supporting structure, a wrapping fabric layer and an automobile back cushion layer, wherein the automobile back cushion layer is arranged on the backrest supporting structure; the wrapping fabric layer is wrapped on the automobile back cushion layer; and the automobile back cushion layer is a coconut fiber layer. The back cushion of the coconut fiber automobile backrest has the advantages that raw materials are readily available, the manufacturing cost is low, the natural pollution-free environment friendliness is achieved, and the air permeability is good.

Owner:厦门盛方生态技术集团有限公司

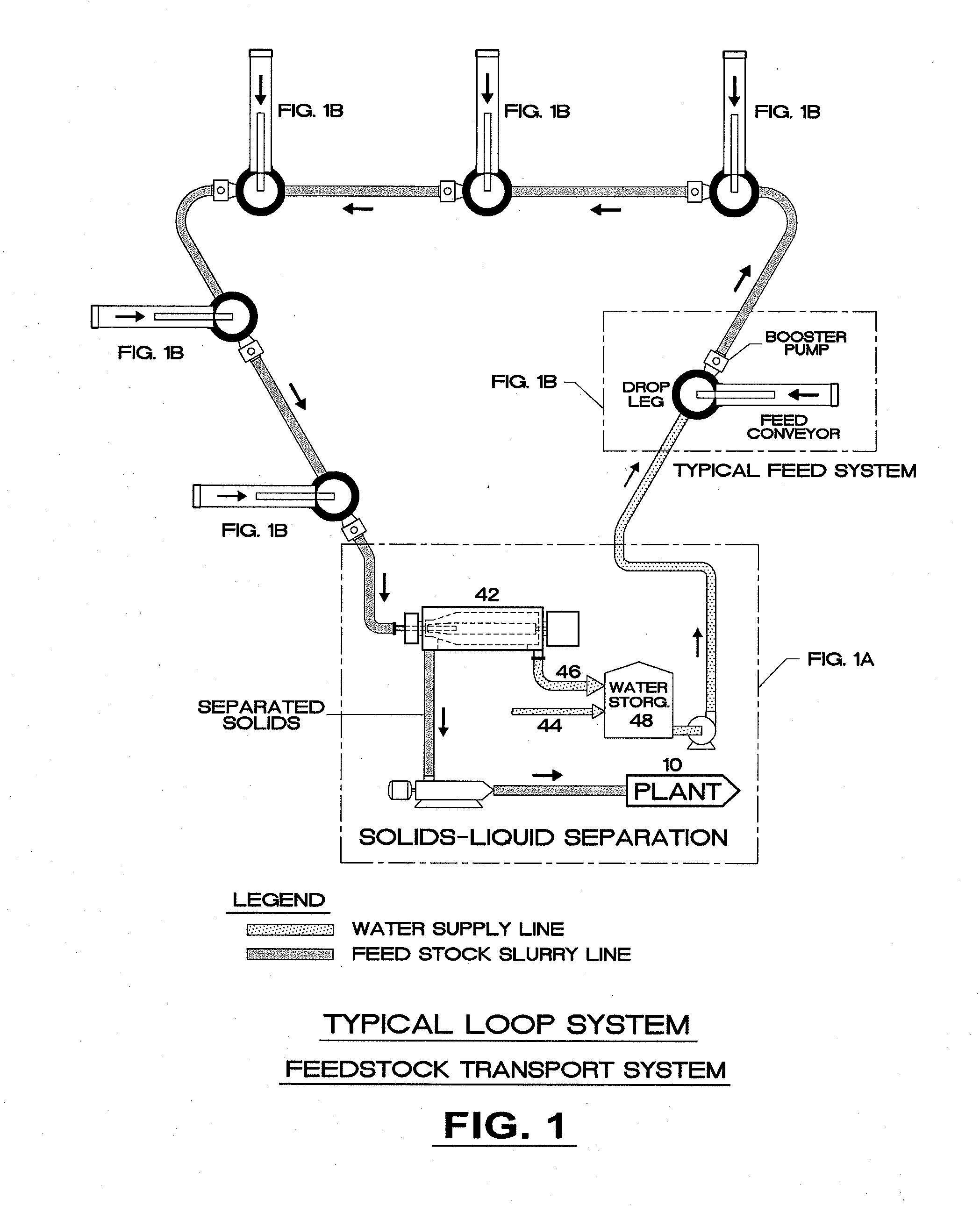

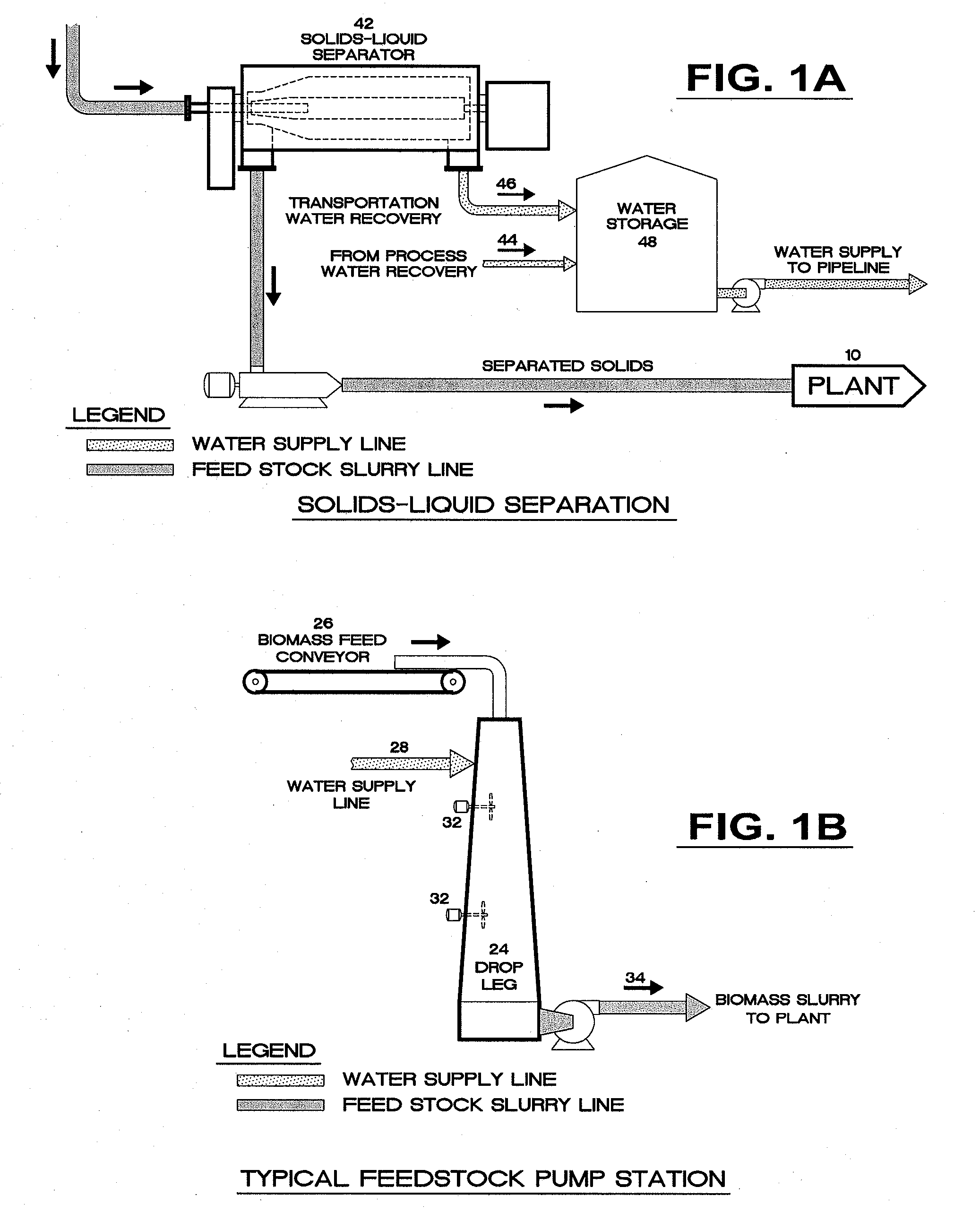

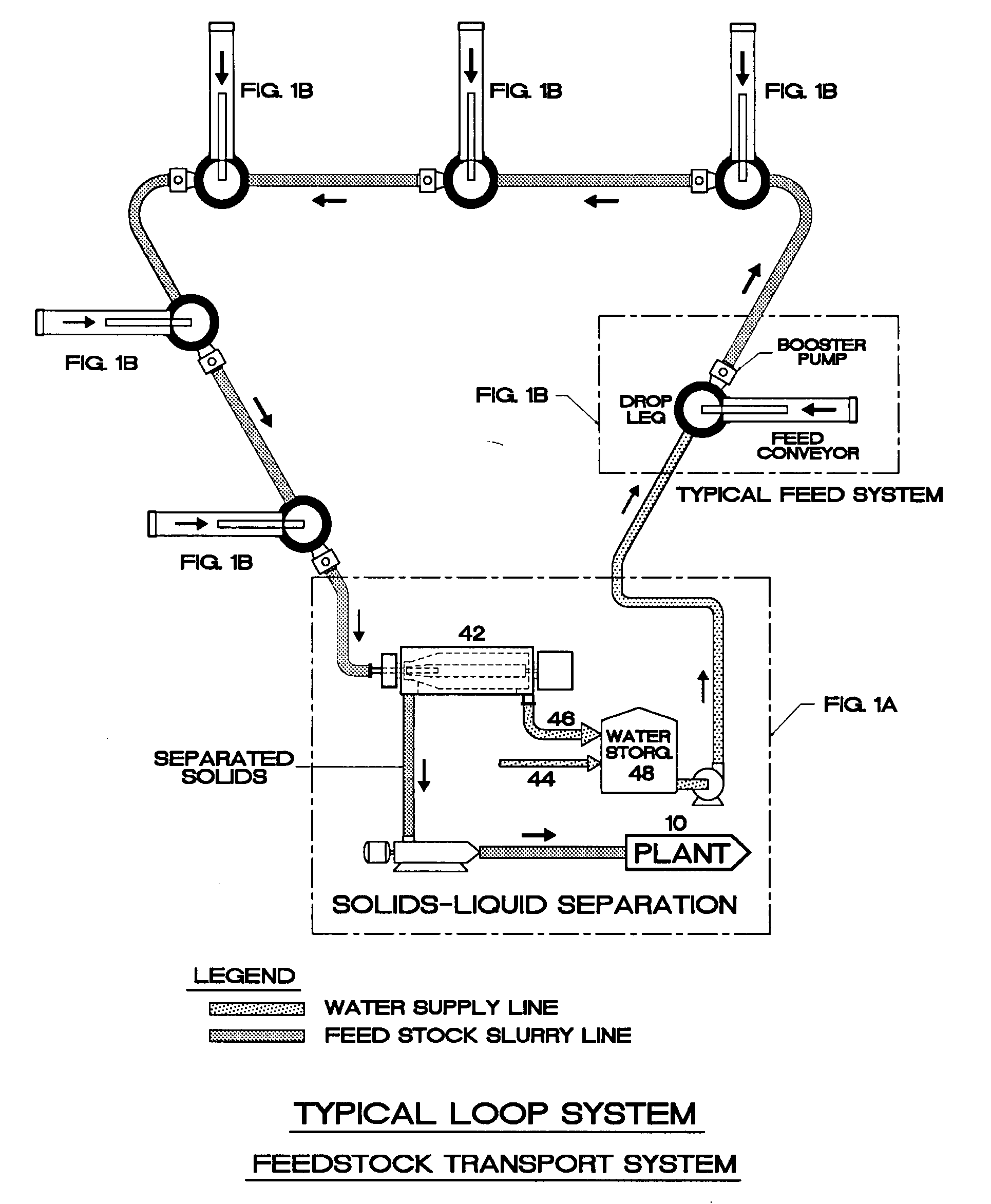

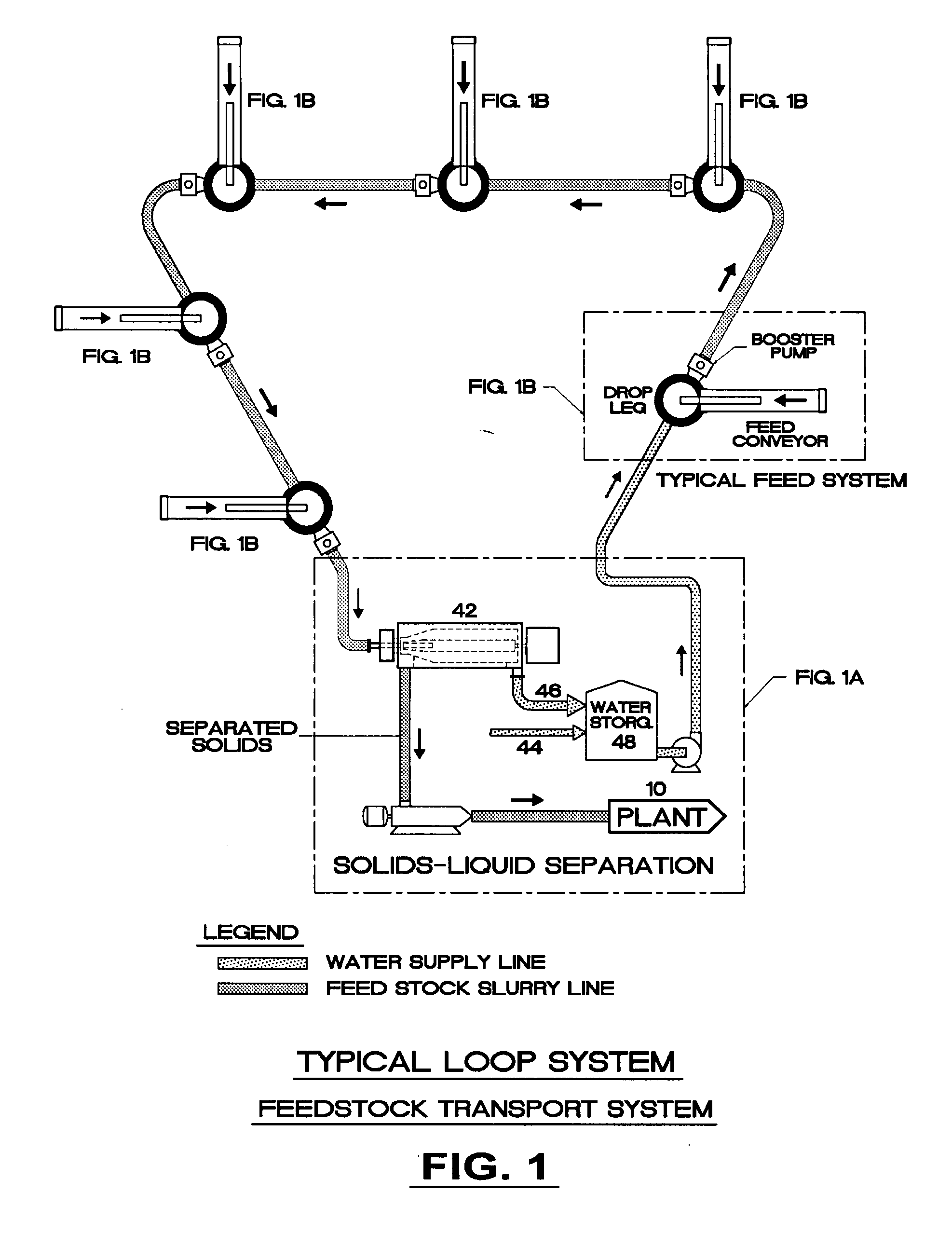

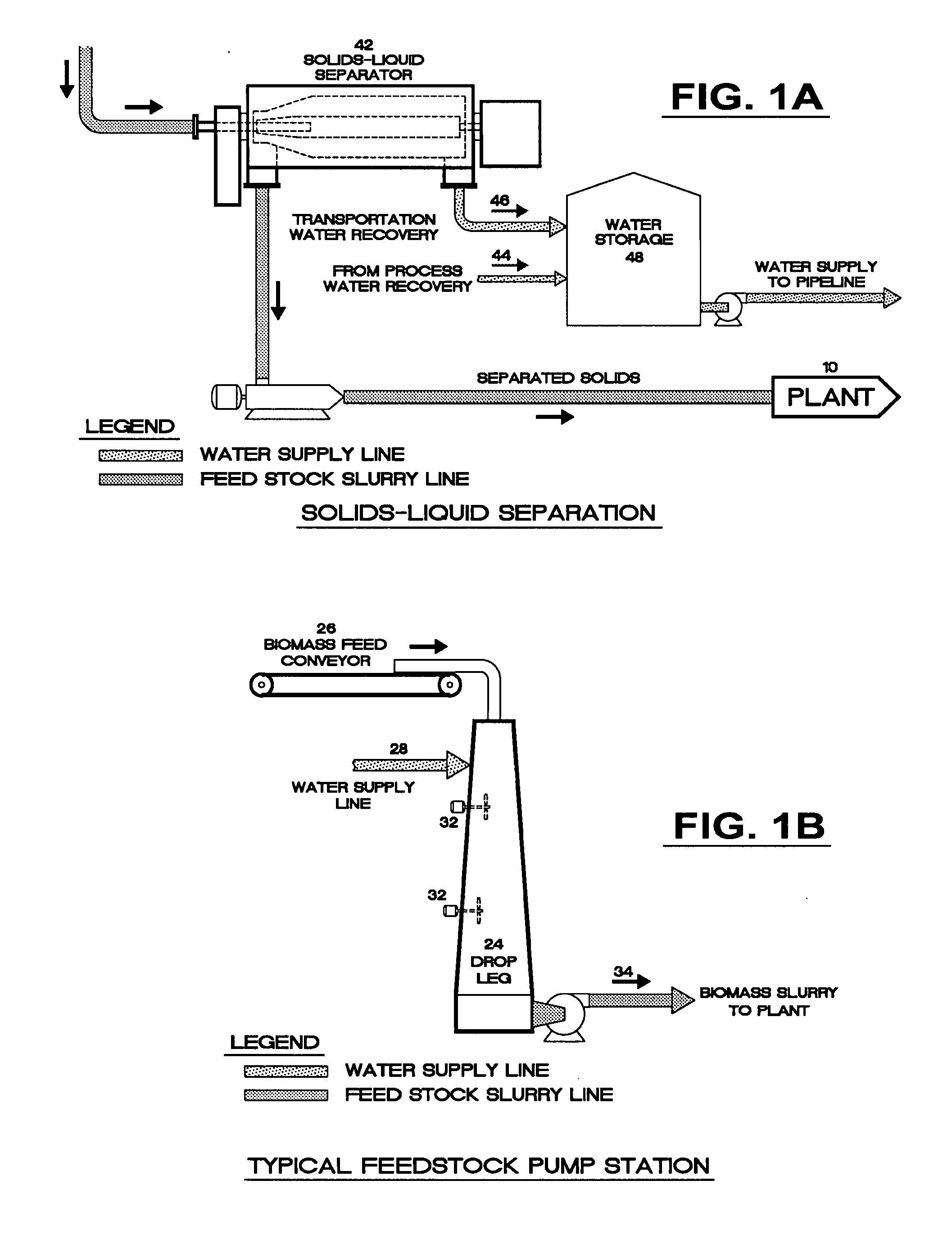

Method and system for the large scale collection of ligno-cellulosic biomass

InactiveUS20110188949A1Vegetable fibres from other vegetable matterPaper recyclingCelluloseWater use

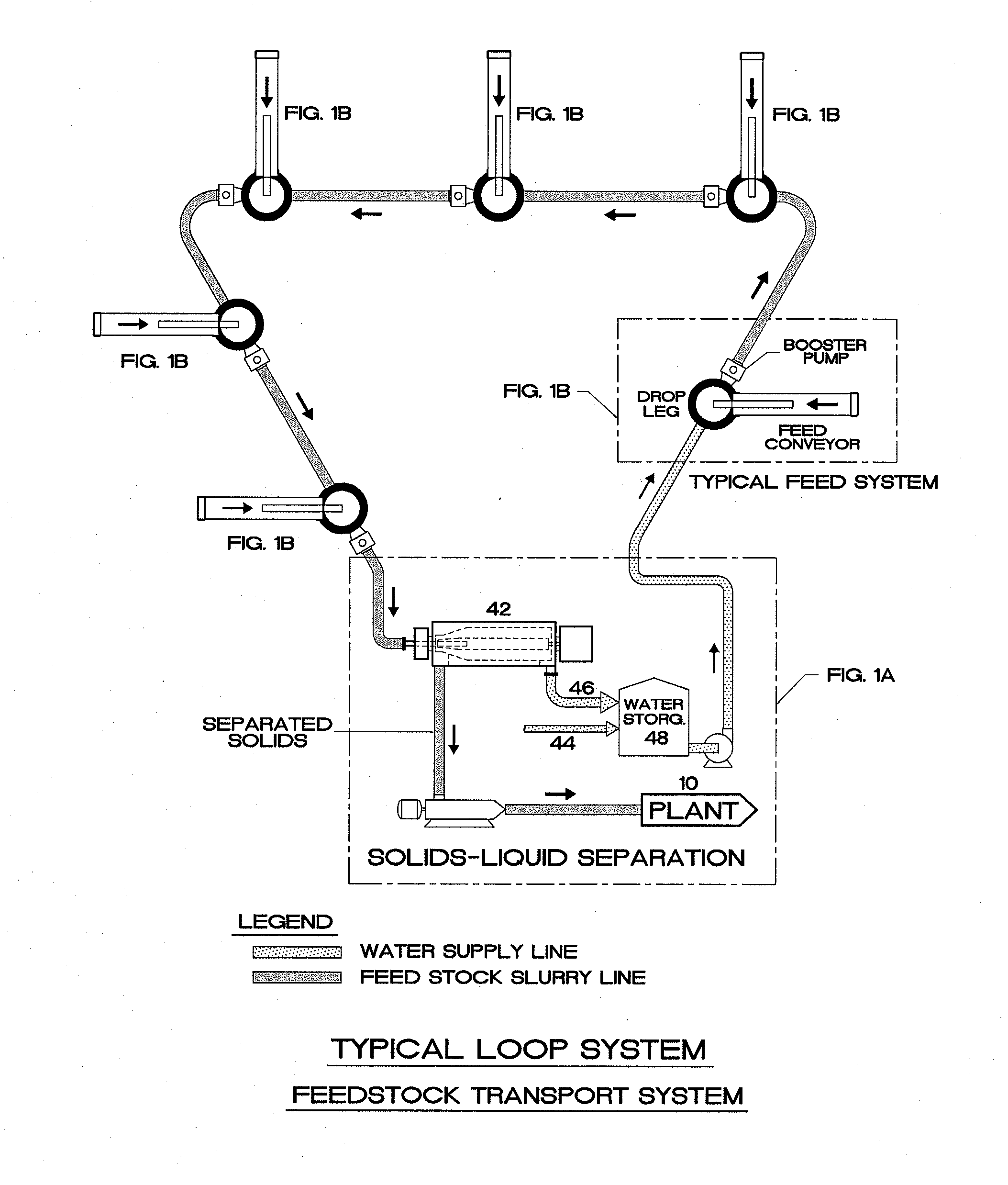

A system for collecting ligno-cellulosic biomass over a large area to enable the commercial refining of biomass from 2,500 to in excess of 50,000 tons of biomass per day to produce ethanol or other products. The biomass is collected at a series of collection points and then transported through a network of conduit “loops” interconnecting each of the collection points and the central refining plant. The water used to transport the biomass, as a slurry, is recovered and sequentially recycled in the same pipeline system to push the biomass slurry around the system in a “loop.” The outgoing and return legs of each loop optionally are located adjacent each other.

Owner:IOGEN ENERGY CORP

Tree bast fiber and processing method therefor

InactiveCN1699643AHigh strengthImprove dyeing effectVegetable fibres from other vegetable matterVegetable materialExtensibilityYarn

The present invention discloses a kind of tree bast fiber and its method for processing, wherein the fiber is a natural spinning fiber made of bark from the trees except mulberry and paper mulberry with its length of 5mm-65mm, the fineness of 0.3-2.5D, the strength of 0284-0432N / tex and the extensibility at break of 3%--7%. The processing method is as follows:peeling-sorting-degumming-skimming-drying-preserving-tanning-grinding-combing-baking-boxing and classifying-baling. The invention provides a kind of basic spinning fiber for textile industry, which has cheap and wide sources of tree bast, the similar performance of jute fiber, stronger strength than that of cotton fiber and good dyeing ability with wide use prospect, and can be co-spinned with other natural fibers, staple fiber or regenerated fiber into fiber yarns.

Owner:周勇

Method and system for the large scale collection, preparation, handling and refining of ligno-cellulosic biomass

InactiveUS20080038815A1Bioreactor/fermenter combinationsBiological substance pretreatmentsWater useCellulose

Owner:IOGEN ENERGY CORP

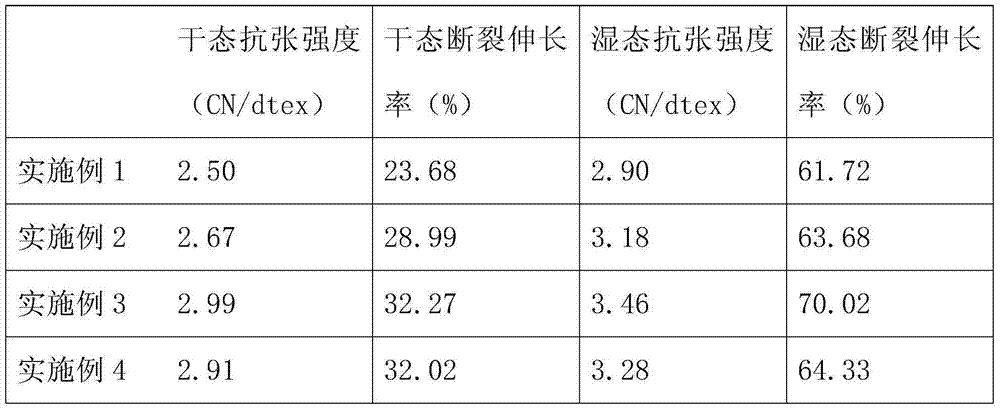

Manufacturing method of seaweed carbon fiber blended fabric

InactiveCN104213302APromote blood circulationWith insulationSucessive textile treatmentsVegetable fibres from other vegetable matterFiberCarbon fibers

The invention is suitable for the technical field of socks and discloses a manufacturing method of a seaweed carbon fiber blended fabric. The seaweed carbon fiber blended fabric is prepared by the following steps: carrying out preprocessing on seaweed, i.e. removing rhizoid and rotten leaves of the seaweed, washing clean, then cutting the seaweed into segments with lengths of 3 to 4cm and drying the seaweed segments in a drying oven at a temperature of 80 to 95 DEG C until the moisture content is 8 to 10 percent; then grinding the dried seaweed segments into the specification of 0.3 to 0.5cm in a grinder. According to the manufacturing method of the seaweed carbon fiber blended fabric, which is provided by the invention, the seaweed carbon fiber blended fabric has very high intensity and breaking elongation performance, is suitable for garments such as underwear and socks and has an excellent far infrared radiation function; the far infrared radiation can enable molecules in cells to move livelily to generate resonance and gives energy and vitality to cells; after a user wears the seaweed carbon fiber blended fabric, molecules of a human body are rubbed to generate thermal reaction so as to promote body blood circulation; the seaweed carbon fiber blended fabric has heat preservation, antibacterial and deodorizing effects, so that the seaweed carbon fiber blended fabric is beneficial for improving comprehensive performance and market competitiveness of a health care sock.

Owner:浙江久渔针纺织有限公司

Softening treatment method of columnar loofah sponge

ActiveCN105803759AAvoid yellowingKeep shapeVegetable fibres from other vegetable matterGrip property fibresFiberSurface layer

The invention provides a softening treatment method of a columnar loofah sponge. The method comprises the following steps of: firstly, cutting the columnar loofah sponge with the size of 3cm-5cm and measuring the density; carrying out hot pressing and compression treatment on the cut columnar loofah sponge; then treating the columnar loofah sponge subjected to the hot pressing treatment with an alkali and hydrogen peroxide mixed solution, wherein an alkali is sodium hydroxide and the content of sodium hydroxide is 5%-10%, the content of hydrogen peroxide is 5%-10%, the temperature of the solution is 70-90 DEG C and the immersing time is 40min-1.5h; and finally, carrying out water washing and constant-temperature and constant-humidity treatment to finally obtain the softened columnar loofah sponge. By virtue of the method provided by the invention, the aim that fibers of an outer surface layer, an inner surface layer and a core layer of the columnar loofah sponge can be subjected to the softening treatment very well can be realized; meanwhile, the elasticity in the longitudinal direction of the columnar loofah sponge is relatively good, so that the aim of filling a mattress can be met very well; and meanwhile, the columnar loofah sponge subjected to the softening treatment of the method can meet the requirements of use comfort of the mattress, prevention of yellowing and the like very well.

Owner:ANHUI AGRICULTURAL UNIVERSITY

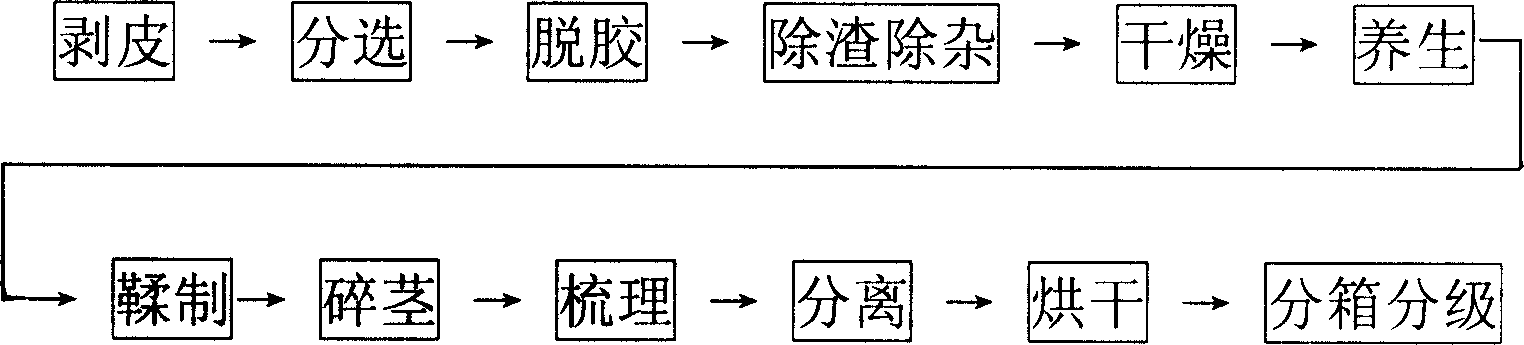

Tree bast crude fiber and its producing process

InactiveCN1888151AHigh strengthImprove dyeing effectVegetable fibres from other vegetable matterForeign matterYarn

The present invention discloses one kind of crude tree bast fiber and its production process. The crude tree bast fiber is one kind of natural fabric fiber prepared with tree bast peel and has fiber length of 5-65 mm and fineness of 2.6-40 D. Its production process includes the steps of: peeling, sorting, degumming, stoving, cutting, opening, eliminating slag and foreign matter, drying, curing, bating, carding and grading. The crude tree bast fiber as one kind of natural fiber has performance approach that of hemp fiber, strength higher than that of cotton fiber, good dyeing performance, capacity of being blended with other fiber and wide use.

Owner:周勇

Banana fiber and banana peel fiber extraction process and device

ActiveCN110029399AGood browning reactionEasy to separateVegetable fibres from other vegetable matterVegetable materialSocial effectsNonwoven fabric

The invention relates to a banana fiber and a banana peel fiber extraction process and device. By extracting the banana peel fiber to serve as a raw material of fibers, banana peels which are a cheapfiber source can be utilized, and the social effect of environmental protection is achieved; moreover, the banana peels are rich in magnesium, phosphorus, zinc, amino acids and other various nutrientsand minerals and can have a moisturizing and anti-oxidization effect on the skin of the human body after being used as textile clothing, masks and the like. Compared with existing mask base cloths made from plant fibers such as cotton and linen and non-woven fabrics or protein fibers such as silk, the banana peel fiber has a soft and skin-fitting effect, the comfort of a user during mask application can be improved, the skin fitting effect is better, and the adsorption of mask essence by the skin can be improved.

Owner:上海棉芙生物科技有限公司

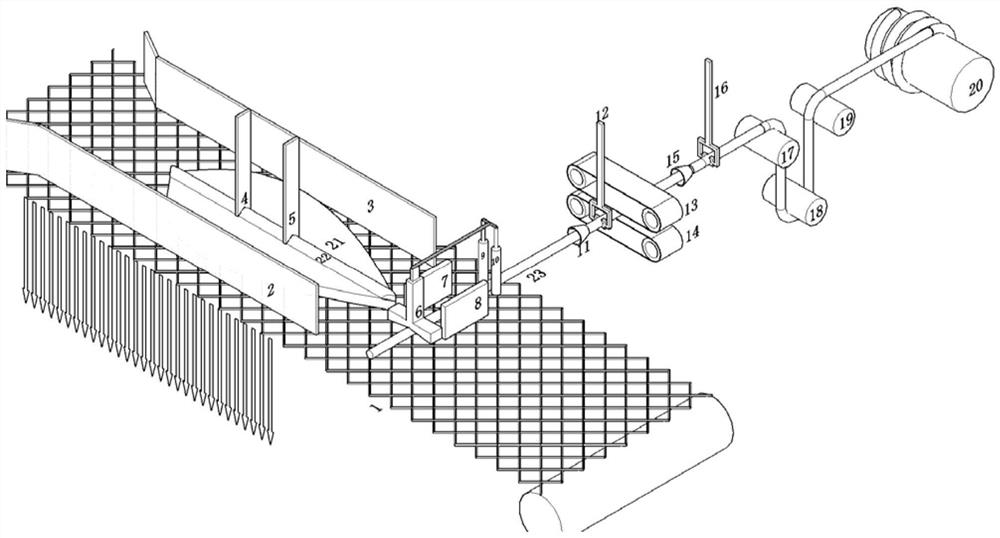

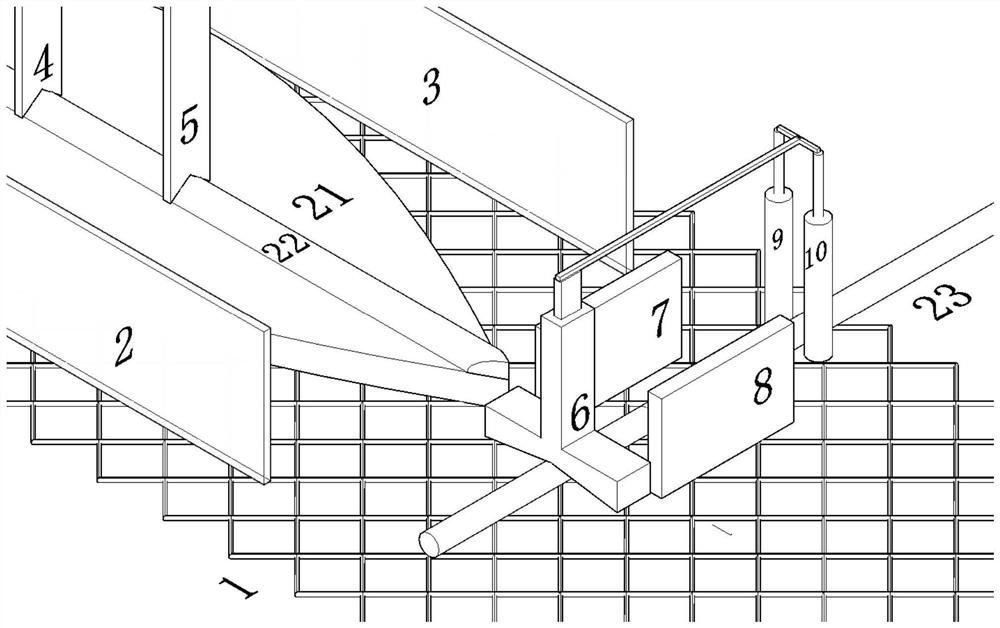

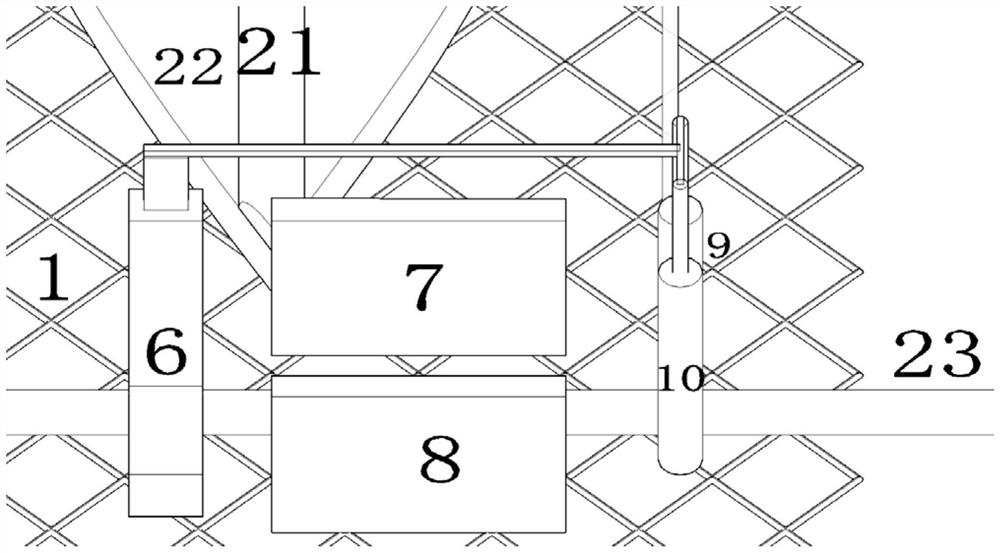

Gerbera delavayi fiber collecting method and device

ActiveCN112226861AImprove continuityRealize automatic twistingVegetable fibres from other vegetable matterYarnYarnFiber

The invention relates to a gerbera delavayi fiber collecting method and device. The collecting method comprises the steps of conveying a gerbera delavayi leaf to the lower part of a lead in a state that the leaf back texture faces upwards; enabling a part of the length section of the lead to be tightly attached to a partial region, namely a yarn forming operation region, of the leaf back texture of the gerbera delavayi leaf; while conveying the gerbera delavayi leaf, twisting the lead to roll on the yarn forming operation region to form a gerbera delavayi yarn; and while collecting the gerberadelavayi yarn, finishing the collection of gerbera delavayi fibers. The collecting device comprises a conveying assembly (comprising a net-shaped conveying belt and a negative pressure suction device), a positioning assembly (comprising a baffle M, a baffle N, a jaw J and a jaw K), a yarn forming assembly (comprising a pressurizing handle, a chuck C, a twisting belt set and a chuck D) and a winding assembly (used for collecting the gerbera delavayi yarn and meanwhile used for being matched with the chuck C and the chuck D to connect yarn forming work of two continuous gerbera delavayi leaves). The method and the device provided by the invention are simple, and can efficiently, continuously and mechanically collect the gerbera delavayi fibers with uniform quality.

Owner:DONGHUA UNIV

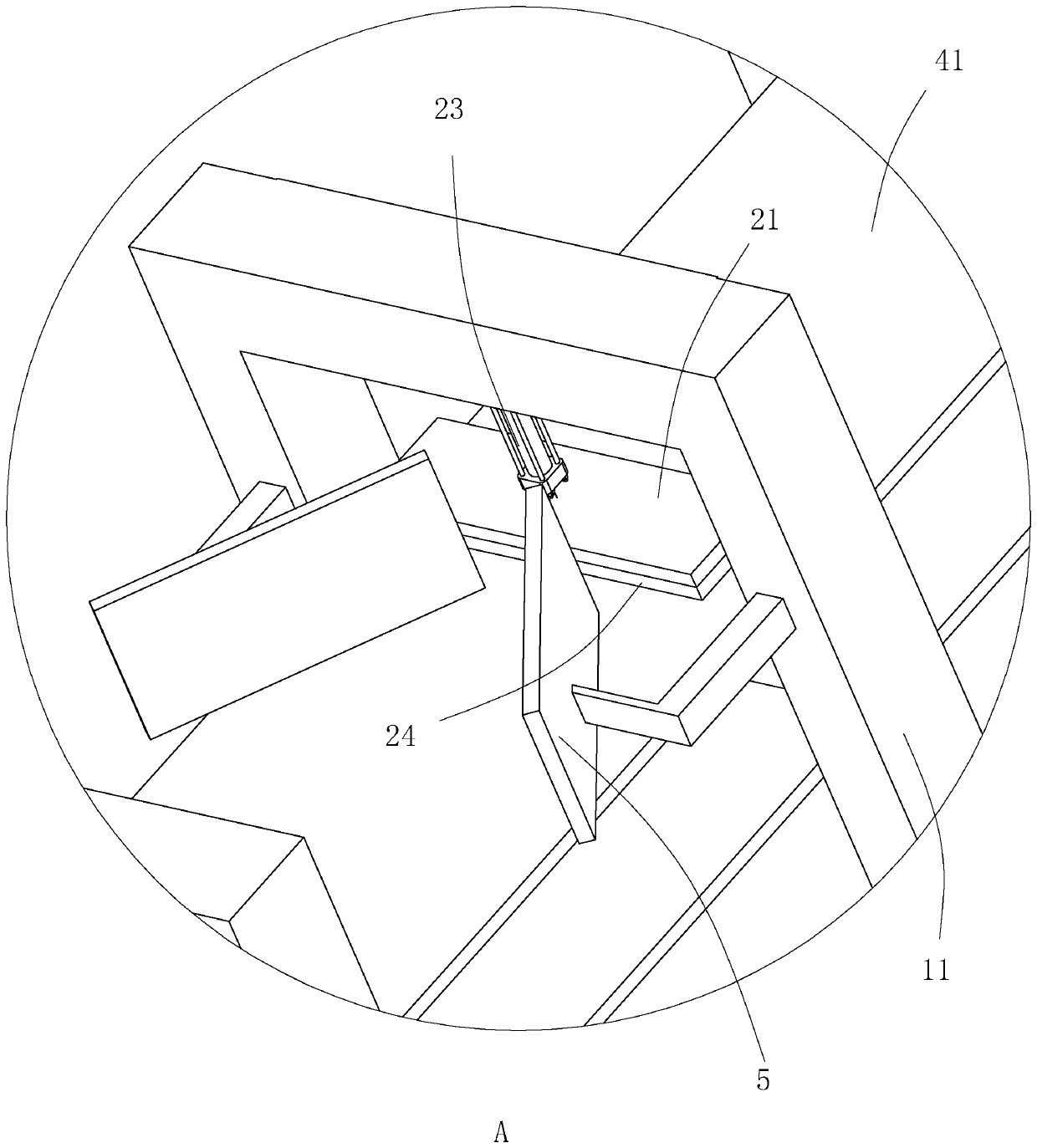

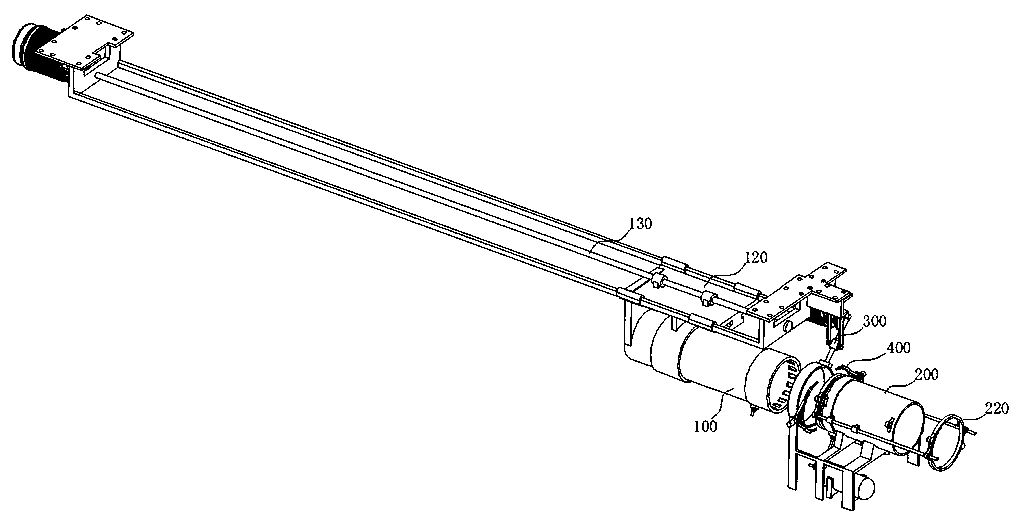

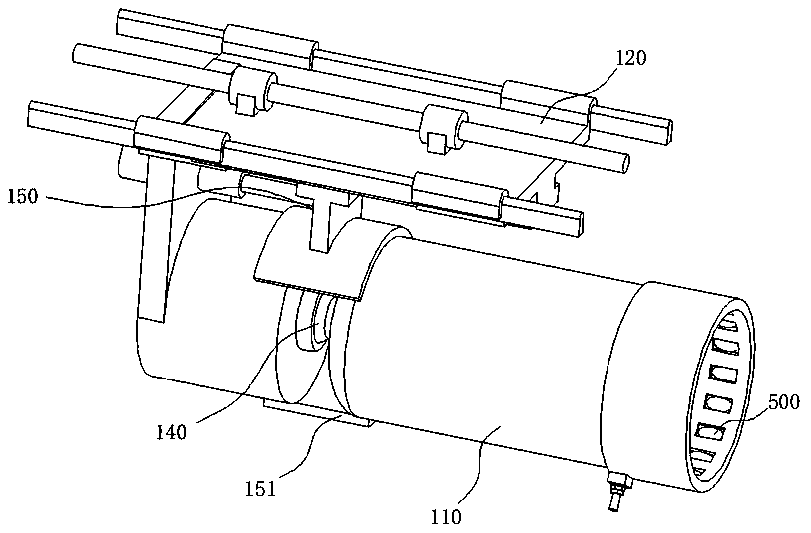

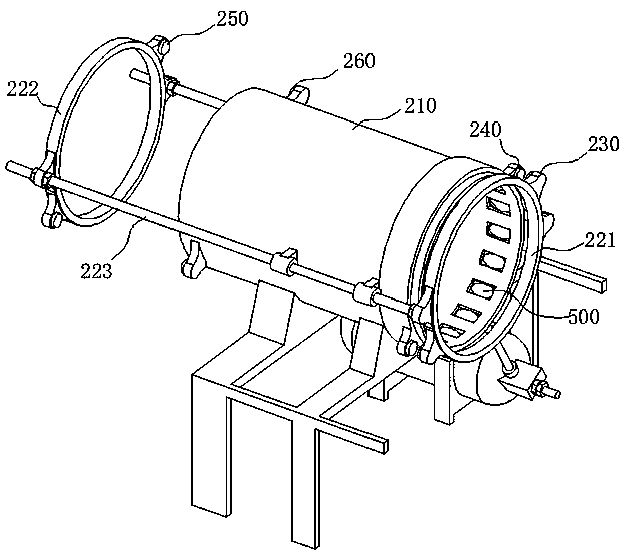

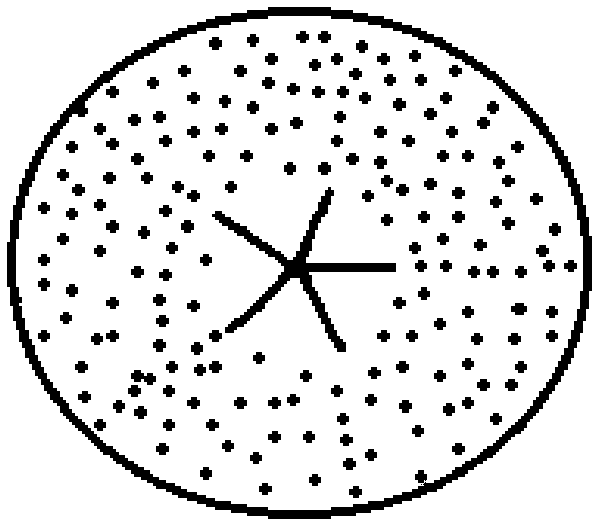

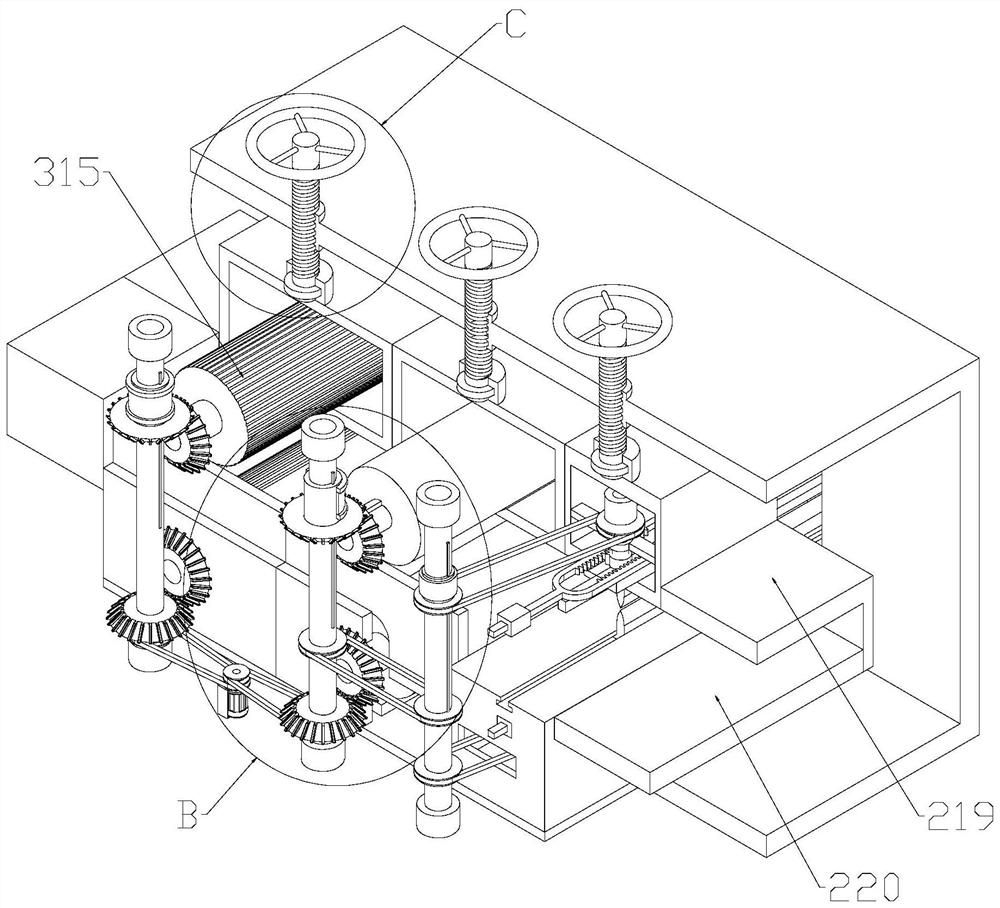

Automatic swing-type material twisting-off mechanism

ActiveCN110699761ARealize the clamping functionEasy to holdVegetable fibres from other vegetable matterEngineeringMechanical engineering

The invention relates to an automatic swing-type material twisting-off mechanism which comprises a clamping mechanism A for clamping a material section A, a clamping mechanism B for clamping a material section B, and a regulating mechanism; the material section A and the material section B refer to two adjacent rod sections of material; the regulating mechanism is connected with the clamping mechanism A and / or the clamping mechanism B; the regulating mechanism is used for regulating adjacent ends of the clamping mechanism A and the clamping mechanism B to move relatively in a direction A, andthe plane of the direction A and the length direction of the material form an included angle. The automatic swing-type material twisting-off mechanism has reasonable arrangement, stable structure andstable running, realizes automatic twisting-off process of the material with high processing efficiency, and meets current service requirements.

Owner:安庆中巨机电科技有限公司

Method for processing kapok fiber raw material

InactiveCN102304769AEfficient removalQuick dust and impurity removalFibre cleaning/opening by air draught arrangementsVegetable fibres from other vegetable matterKapok fiberImpurity

The invention relates to a method for processing kapok fiber raw material. The method comprises the following steps of: selecting a kapok fruit with the length of 15-20cm, opening a wood wall and removing the wood wall and short fibers at a fruit core, taking out and spreading out a fiber bundle layer to dry, and removing dust and impurities by a suction pump to obtain the kapok fiber raw material. By the method for processing the kapok fiber raw material, the short fibers are effectively removed according to the features of an interior structure of the kapok fruit, and fast and scatheless dust and impurity removal is carried according to the air bag structure features of kapok monofilament, thus simple, high-speed and scatheless batch production of the high-quality kapok fiber raw material is realized, wherein a method for controlling the length of the kapok fiber lays the foundation of reasonable and effective utilization of the kapok fibers.

Owner:DONGHUA UNIV +1

Cigarette filter tip

InactiveCN102669819AGreat tasteReduce inhalationVegetable fibres from other vegetable matterTobacco smoke filtersActivated carbonFiber

The invention relates to a cigarette filter tip. A filter material of the filter tip consists of astragalus fibers and activated carbon, and can be wrapped by outer package paper, so that the volume of sucking tar and other harmful substances in tobacco by a smoker can be effectively reduced, and the filtering and adsorption efficiency can be improved; and the astragalus fibers has the effects of invigorating qi for strengthening superficies, stopping sweating and removing toxin, promoting granulation, promoting urination and diminishing swelling, so that the filter tip contributes to inhibiting damage of cigarettes to the health of the smoker.

Owner:张荔

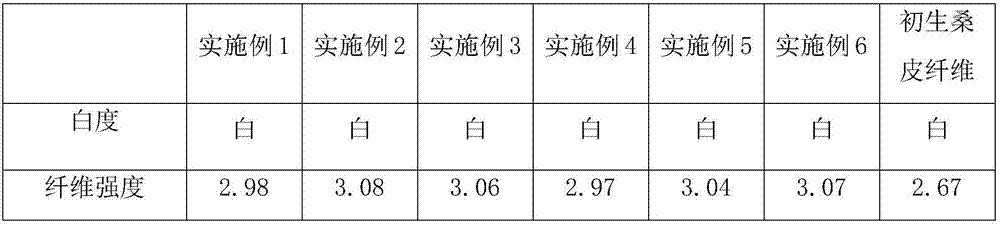

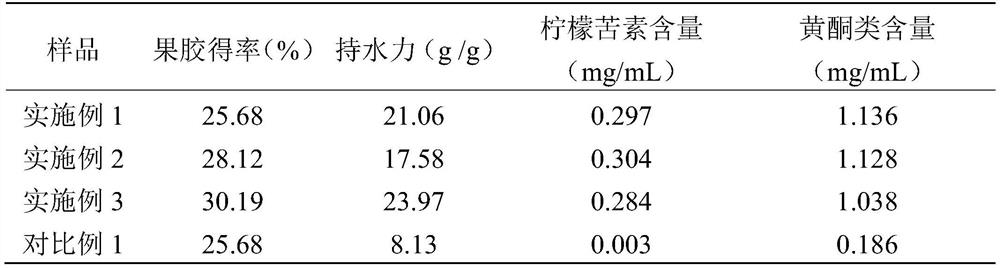

Full-effect refining agent for regenerated mulberry fiber and use method of full-effect refining agent

InactiveCN107083687AEfficient separationConducive to follow-up process finishingVegetable fibres from other vegetable matterHeat resistant fibresFiberPectinase

The invention provides a full-effect refining agent for regenerated mulberry fiber and a use method of the full-effect refining agent. The full-effect refining agent comprises bio-enzyme, mulberry nano-crystalline cellulose and aids. The use method comprises the following steps: beating fresh mulberry, removing dust, performing acid-alkali pretreatment, and performing boiling treatment with a solution of neutral cellulase and pectinase so as to obtain pretreated mulberry fiber; performing aeration treatment on pretreated mulberry fiber so as to obtain long mulberry fiber and short mulberry fiber, and combing and kneading the long mulberry fiber so as to obtain primary spinning mulberry fiber; performing reaction on the short mulberry fiber in an inorganic acid solution, performing centrifugal separation, and performing filtration and washing so as to obtain mulberry nano-crystalline cellulose; treating the primary spinning mulberry fiber with peregal O and vinyl triethoxy silane, further adding into the mulberry nano-crystalline cellulose, dropping ammonia water, and performing vacuum drying, thereby obtaining the regenerated mulberry fiber. The regenerated mulberry fiber prepared with the agent is soft in hand feeling, good in mechanical property and good in properties such as thermal resistance and flame retardancy.

Owner:苏州凯邦生物技术有限公司

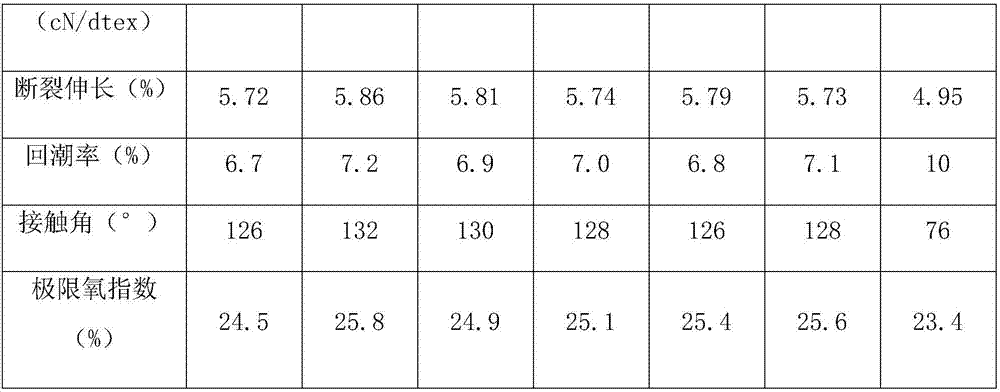

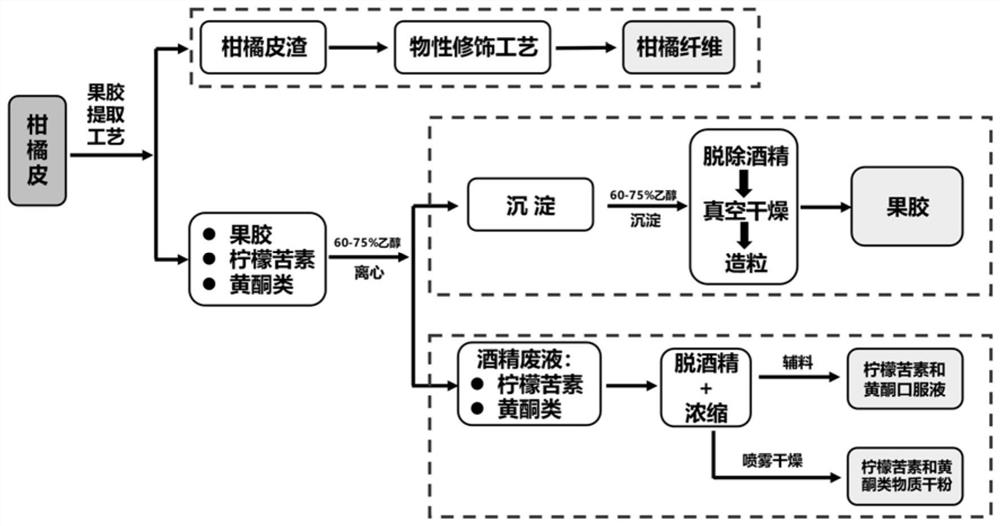

Combined extraction method of different functional components in citrus fruit peel residues

ActiveCN113501892AEmission reductionReduce sewage costsAntipyreticFood processingOrganic chemistryCitrus fruit

The invention discloses a combined extraction method of different functional components in citrus fruit peel residues. The method comprises the steps: adding water into the citrus fruit peel residues, adjusting the pH value to be acidic, stirring and extracting at constant temperature, centrifuging extracted pectin liquid, collecting supernate, carrying out alcohol precipitation on the supernate, precipitating and drying to obtain pectin; adding water into the obtained residues, stirring, firstly, carrying out physical pretreatment, homogenizing, carrying out alcohol precipitation, precipitating and drying to obtain citrus fibers; and carrying out alcohol recovery on the alcohol precipitation waste liquid, and carrying out purification and concentration to obtain limonin and flavonoid substances. According to the invention, three functional products of pectin, limonin and flavonoid extracts and citrus fibers applied in different fields are obtained through a continuous step-by-step separation and extraction process and a combined chemical and physical modification process, and through reasonable arrangement and planning of an industrialization route, 'thorough eating and squeezing' is really realized. As a novel low-pollution agricultural product biological environment-friendly processing scheme, the combined extraction process route has good conversion application expectation.

Owner:广州市莱檬生物科技有限公司 +3

Environmentally friendly preparation method of cyperus tegetiformis fiber

ActiveCN106637424AReduce hardnessIncrease in sizeVegetable fibres from other vegetable matterVegetable materialSodium bicarbonateChemical treatment

The invention discloses an environmentally friendly preparation method of cyperus tegetiformis fiber. First, fiber after pretreatment is put into sodium chloride solution; then a mixed water solution containing glycerinum and sodium hydrogen carbonate is added; then the mixture is placed in a refrigeration house for quick-freezing and vacuumized; then the mixture is processed in boiling acid liquor and enzyme treatment is carried out; finally, pelelith is added and ultrasonic treatment is carried out. The method combines physical treatment, biological treatment and chemical treatment; no strong base or softeners which have bad influence on the environment are added so that the influence on the environemtn is small; the requirements of low pollution and low emission for textile industry are met; glycerinum is added during the treatment phrase of the cyperus tegetiformis fiber to protect the alcohols, acids and esters and reduce the influence of later freezing treatment, acid treatment and high-temperature treatment; therefore, the finally prepared fiber has certain antibacterial effect.

Owner:南通江淮衬布有限公司

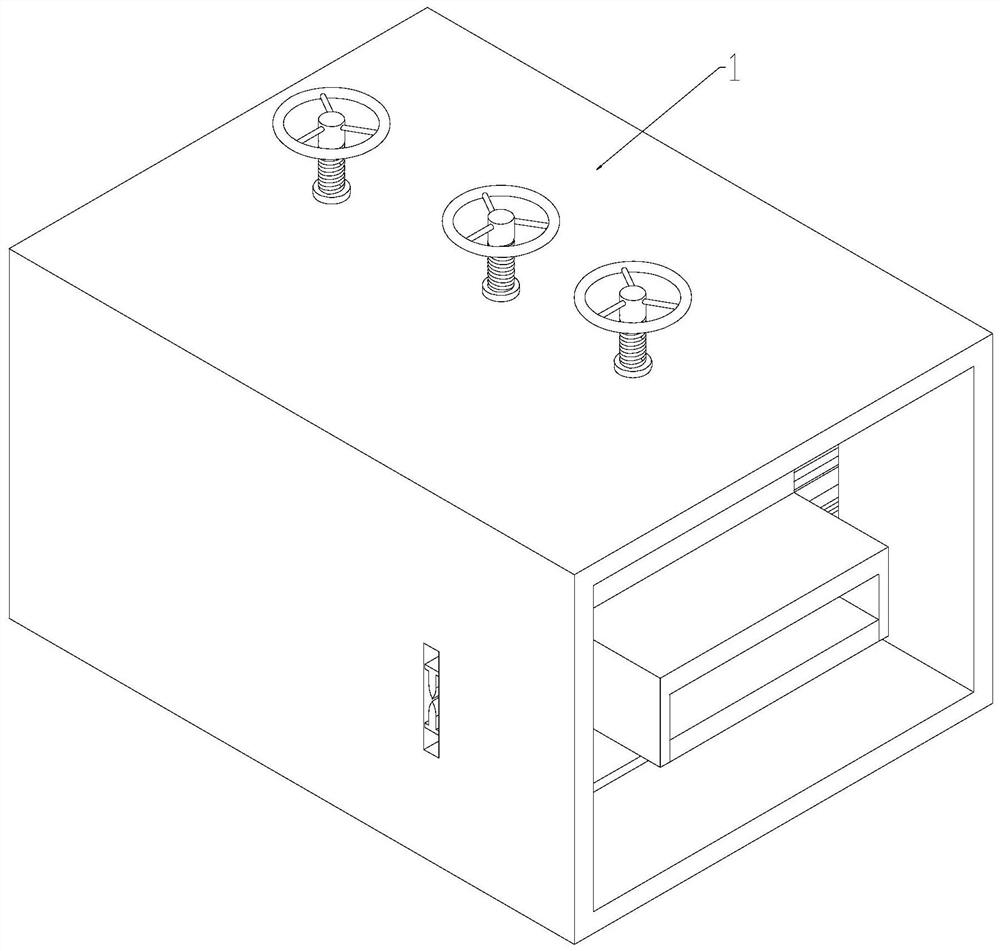

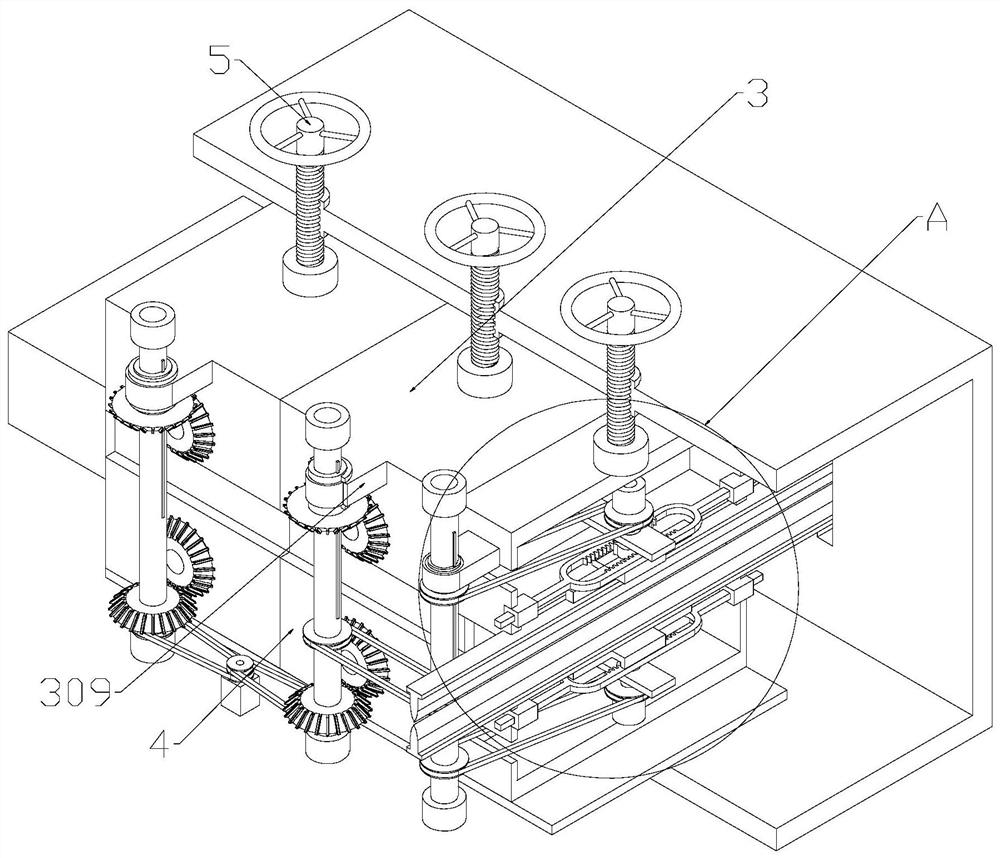

Regenerated fiber manufacturing device capable of improving flatness

InactiveCN113445133AQuick cutImprove purityVegetable fibres from other vegetable matterCleaning using toolsFiberGear wheel

The invention discloses a regenerated fiber manufacturing device capable of improving flatness. The regenerated fiber manufacturing device comprises an outer box, and one end in the outer box is provided with cleaning boxes which are symmetrical up and down; the cleaning boxes are internally provided with rotating rods; the bottom ends of the rotating rods are provided with semi-surface gears; the outer sides of the semi-surface gears are engaged with gear rings; one end of each gear ring is provided with a connecting seat; a cleaning brush is mounted at the other end of each connecting seat; symmetrical top boxes are mounted at the other end in the outer box; rotating shafts are mounted in the top boxes; a pressure roller is mounted at the middle end of the rotating shaft in the top box on one side, and a cutting roller is mounted at the middle end of the rotating shaft in the top box on the other side; a bottom box is installed below the top boxes; three sets of lifting assemblies are installed at the top end of the outer box; and symmetrical cleaning brushes move in a reciprocating mode to clean the surfaces of bamboos, the bamboos are crushed through opposite rotation of the pressure roller and the cutting roller, and therefore the flatness of bamboo fibers is improved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Preparation method of banana fiber and hemp mattress

InactiveCN107569003AElasticLow costStuffed mattressesVegetable fibres from other vegetable matterChemical treatmentCarding

The invention provides a preparation method of a banana fiber and hemp mattress, comprising the following steps of obtaining fibers from tree trunks that are cut after fruiting of banana trees every year by the following two ways: (1) feeding the tree trunks into a duel-roller machine with roller control for peeling of coarse barks and pectin to obtain the banana fibers; (2) stacking the tree trunks in the open air, naturally fermenting for 35 to 40 days and washing by using water to obtain the fibers; then placing the fibers under natural sunlight for drying or placing in a dryer of 100 to 105 DEG C for drying, and packaging for later use, wherein the moisture regain is 14% or below; then treating the extracted fiber raw material by adopting a biological or chemical treatment method; adding meldable fibers in the treated banana fibers, carrying out opening, impurity removal, carding and net formation, and carrying out hot melting and setting to prepare a blocky banana fiber elastic plate-type material; then according to design requirements, sewing and coating the blocky banana fiber plate-type material by a hemp fabric to finally prepare the banana fiber and hemp mattress. The mattress prepared by the method has the advantages of antibacterial effect and low price.

Owner:湖南华升益鑫泰科技有限公司

Method for extracting fibril by means of enzymolysis method

PendingCN110453293AWill not affect contentEfficient extractionVegetable fibres from other vegetable matterVegetable materialFiberPectinase

The invention provides a method for extracting fibril by means of an enzymolysis method. The method is specifically used for fibril extraction in Lvzhou No.1 forage, lignin and the like are removed through indefinite number of a bio-enzyme enzymatic hydrolysis reaction, only required cellulose and hemicellulose are retained, and ten the extraction effect of the fibril is achieved; specifically, the combination of scouring enzyme and pectinase is adopted, enzyme agents with different concentrations are adopted according to the steps, reacting is conducted under specific conditions, and finallythe fibril retaining various excellent properties is obtained; the extracted fibril can be used for textile preparation, and meanwhile waste which pollutes the environment cannot be generated.

Owner:运城市绿碧源农林开发有限公司

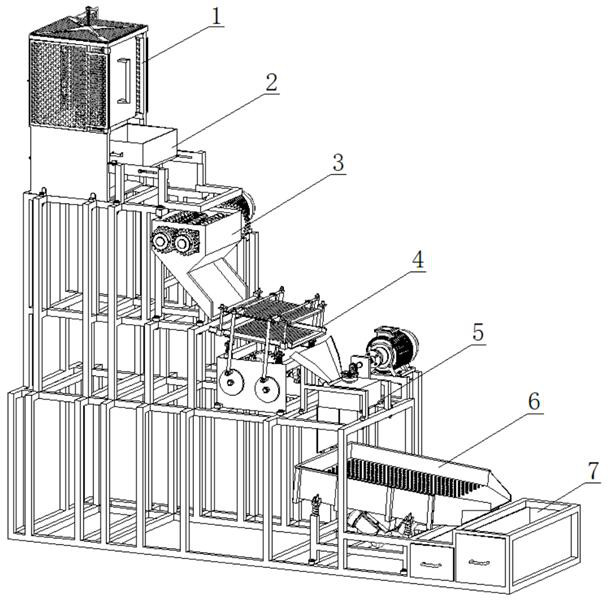

Mechanical coconut fiber extraction method and device

ActiveCN112921411AImplement extractionReduce workloadVegetable fibres from other vegetable matterEngineeringProcess engineering

The invention relates to a mechanical coconut fiber extraction method and device. The device is composed of a preliminary extraction mechanism, a soaking mechanism, a coconut shell smashing mechanism, a mechanical loosening mechanism, a drying mechanism, an impurity removing and screening mechanism and a collecting mechanism. Mature coconuts are placed in the preliminary extraction mechanism, and preliminary extraction of coconut fibers is completed by fixing, clamping and cutting the mature coconuts. Then the coconut fibers enter the soaking mechanism, after soaking is completed, large coconut shells are smashed, the coconut fibers are mechanically loosened through the mechanical loosening mechanism, and the coconut fibers are dried under the action of the drying mechanism. Finally, the coconut fibers and impurities are screened through the impurity removing and screening mechanism, and the coconut fibers and the impurities are subpackaged in a coconut fiber collecting box and an impurity collecting box, so that the whole process of coconut fiber extraction is completed. The mechanical coconut fiber extraction method and device provided by the invention are suitable for extraction of the coconut fibers of the mature coconuts, and manual operation is replaced, so that the workload is reduced, and the working efficiency is improved.

Owner:HAINAN UNIVERSITY

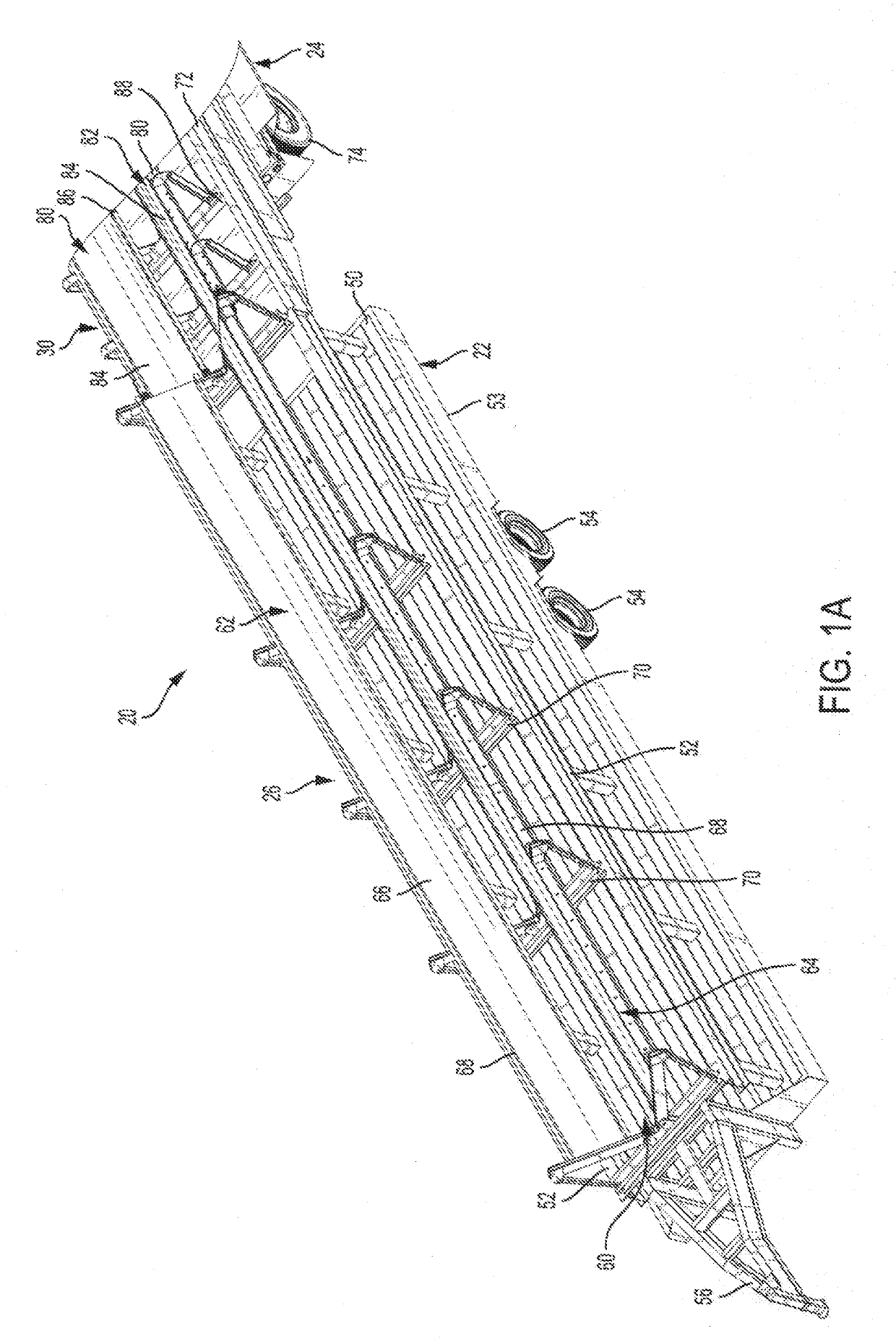

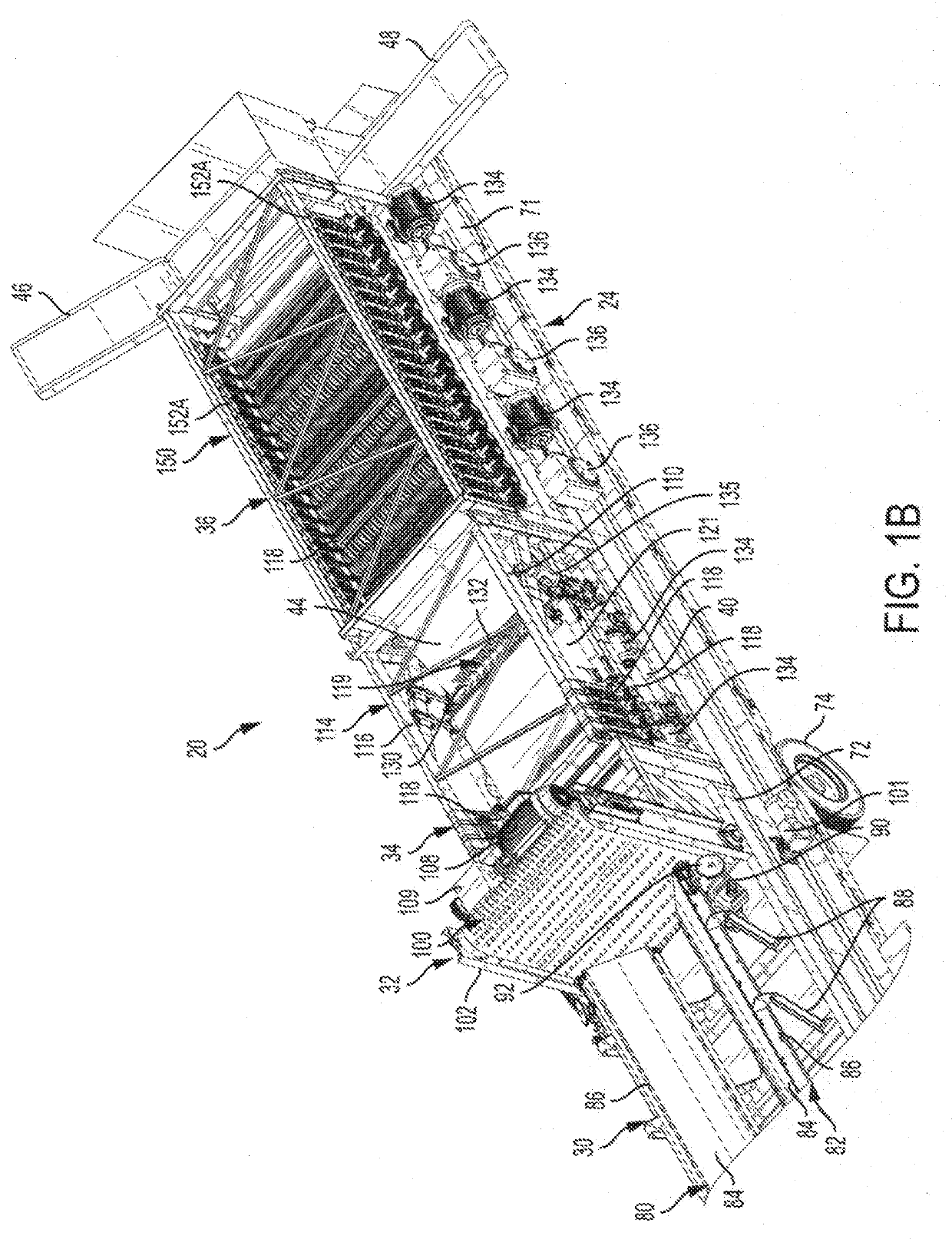

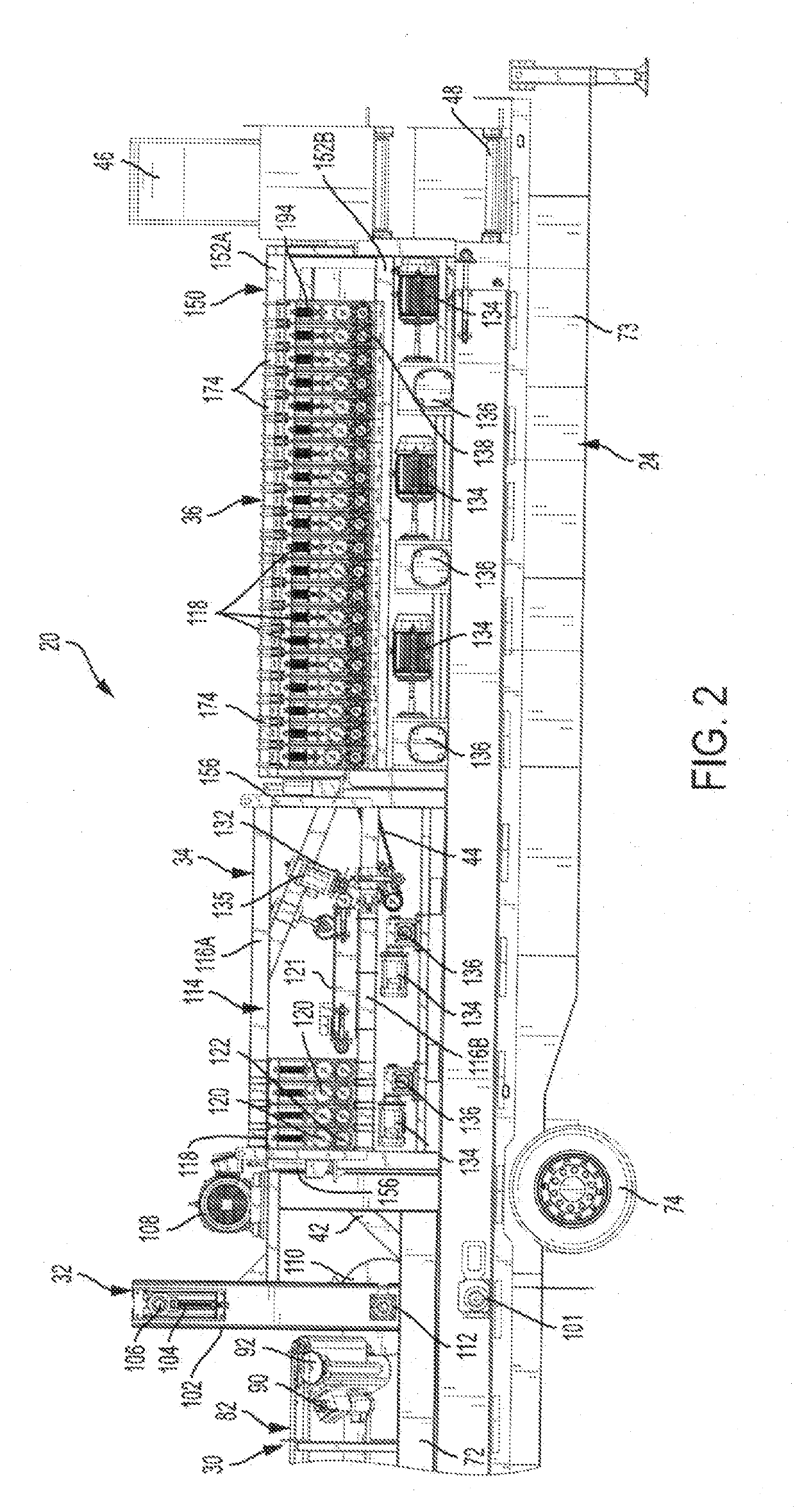

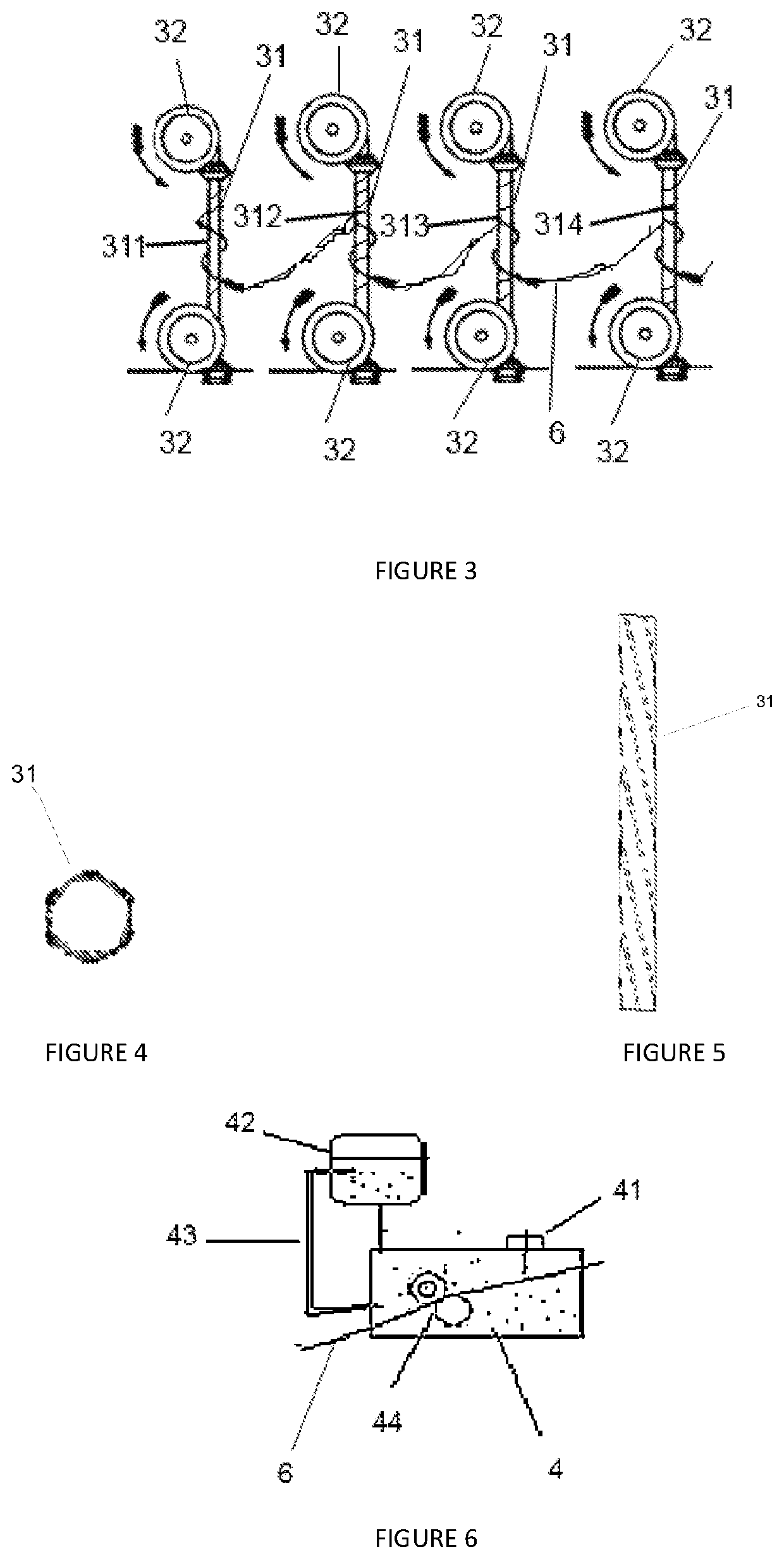

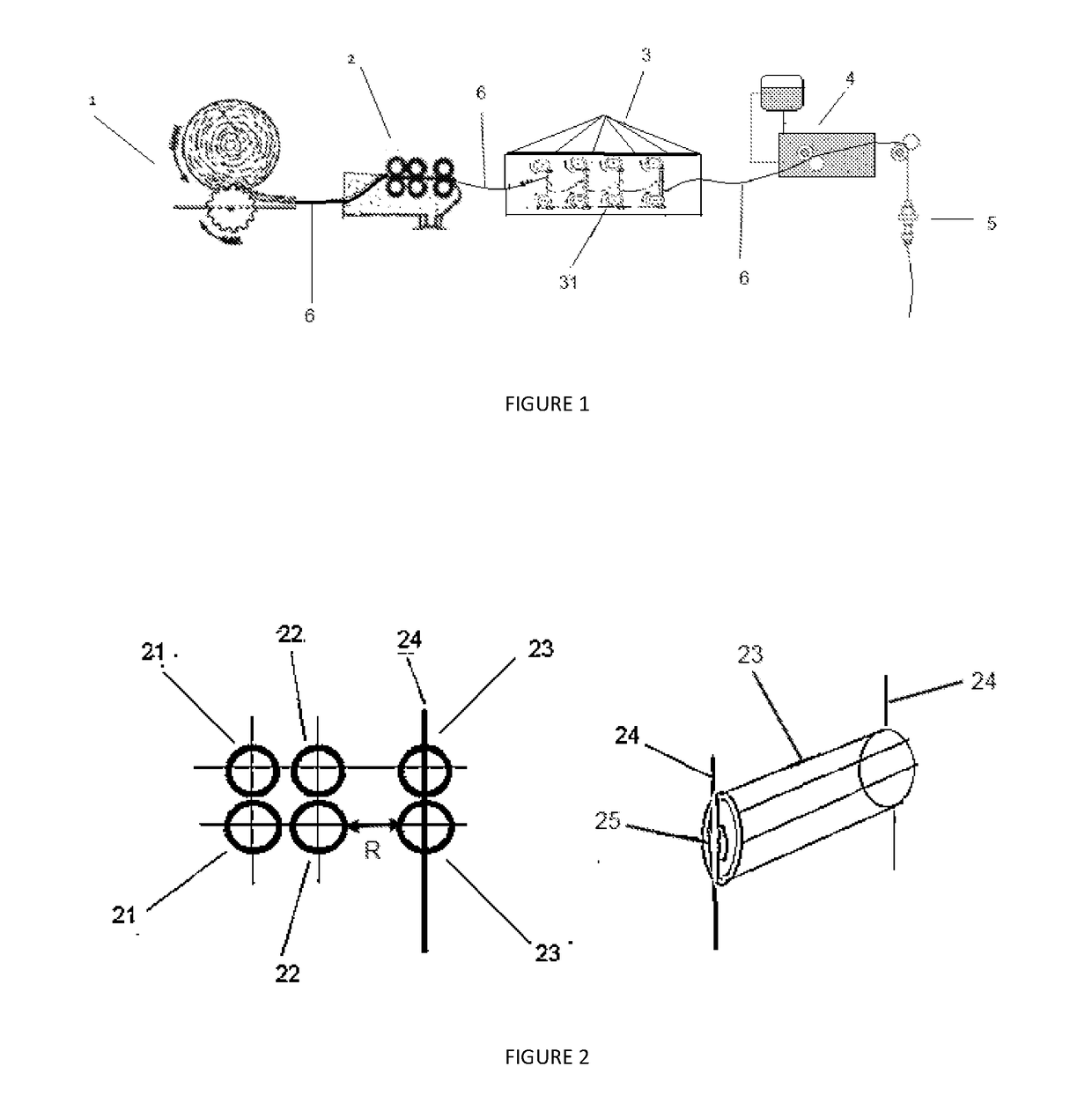

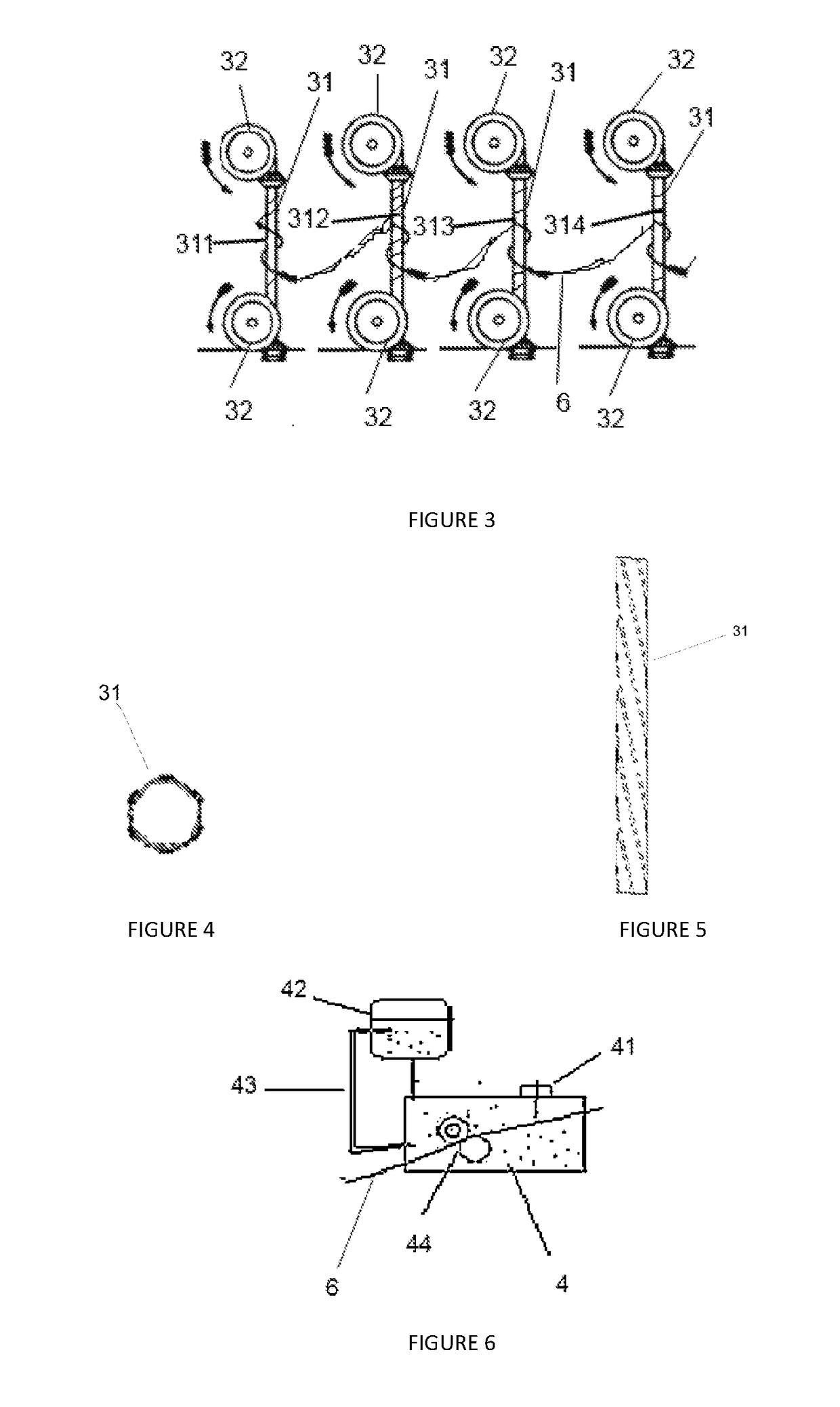

Decortication system and process

A decortication system includes a feeder configured to convey unoriented fiber-bearing plant stalks in a bulk mass and a decorticator assembly comprising a multi-stage decorticator assembly. The decorticator assembly includes at least a first stage decorticator and a second stage decorticator arranged in series with one another. The first stage decorticator comprises a ripper that is configured to separate stalks from the bulk mass delivered by the feeder and to meter movement of stalks away from the ripper. The second stage decorticator is located downstream of the ripper and further decorticates the stalks to produce fiber and hurd that are separated from one another. It may comprise a roller-roller breaker assembly comprising plurality of roller-breaker assemblies located in series with one another. A third stage decorticator may be located downstream of the second stage decorticator and may comprise a second roller-breaker assembly.

Owner:POWER ZONE EQUIP INC

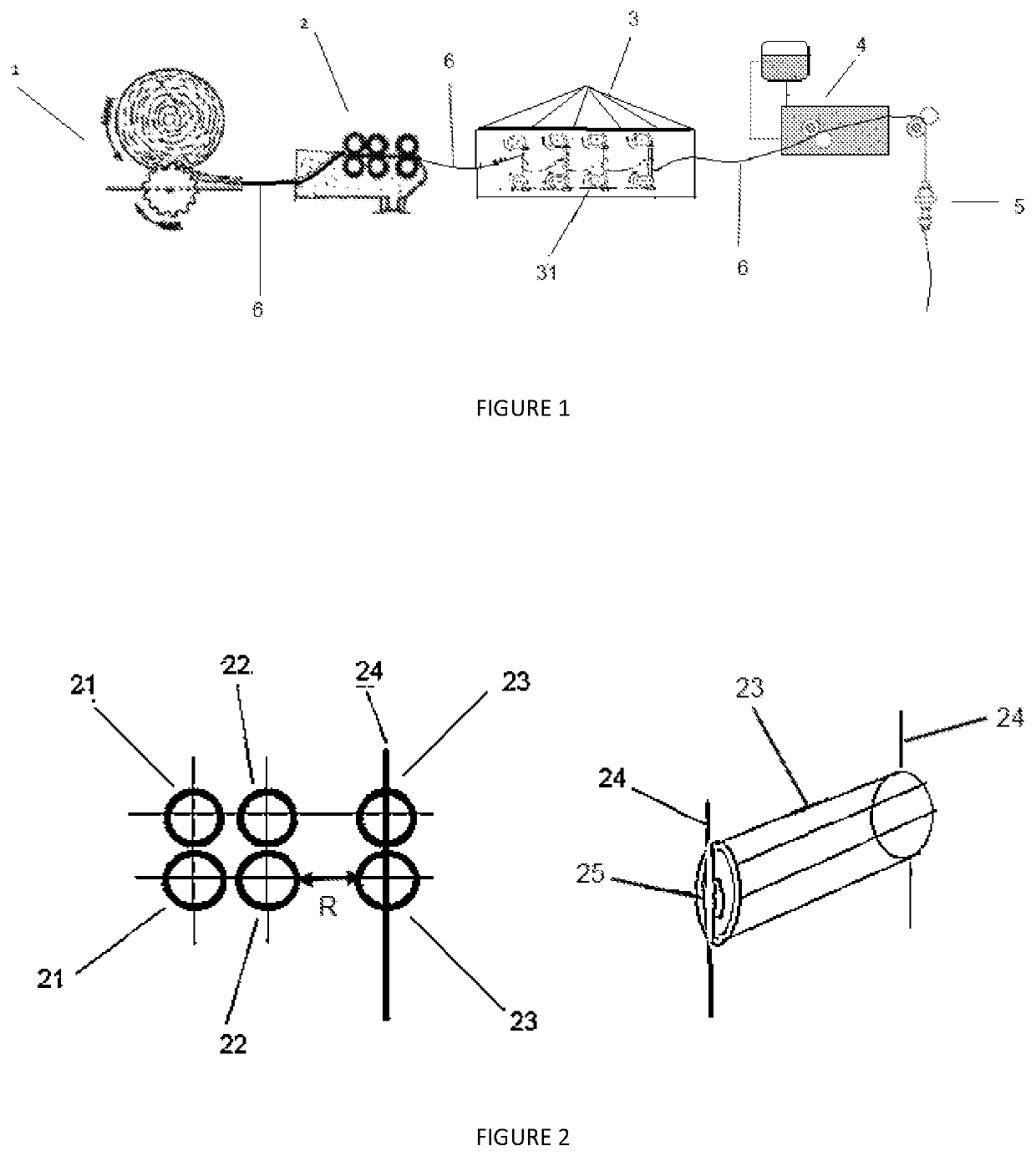

Production of paper yarn from cellulose-containing plant species

ActiveUS10822727B2Shorten the time periodVegetable fibres from other vegetable matterContinuous wound-up machinesBiotechnologyCellulose

The method disclosed relates to the production of paper yarn from cellulose-containing plant species, in the textile sector, and particularly relates to obtaining a paper yarn by a wet spinning method using high or low purity cellulose raw material isolated from the wild plant species of Calluna Vulgaris.

Owner:VERITAS TEKSTIL KONFEKSIYON PAZARLAMA & SANAYI TICARET ANONIM SIRKETI

Production of paper yarn from cellulose-containing plant species

ActiveUS20190010633A1Shorten the time periodVegetable fibres from other vegetable matterContinuous wound-up machinesYarnCellulose

The method disclosed relates to the production of paper yarn from cellulose-containing plant species, in the textile sector, and particularly relates to obtaining a paper yarn by a wet spinning method using high or low purity cellulose raw material isolated from the wild plant species of Calluna Vulgaris.

Owner:VERITAS TEKSTIL KONFEKSIYON PAZARLAMA & SANAYI TICARET ANONIM SIRKETI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com