Tree bast crude fiber and its producing process

A processing method and crude fiber technology, applied in the field of textile fibers, can solve problems such as the impossibility of providing mulberry bark, and achieve the effects of excellent dyeing performance, wide application prospects, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

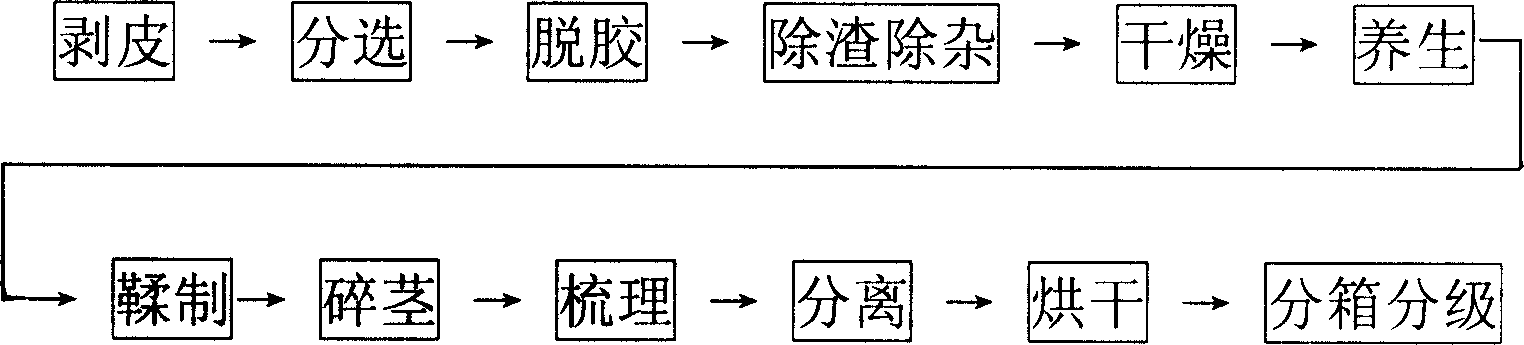

Method used

Image

Examples

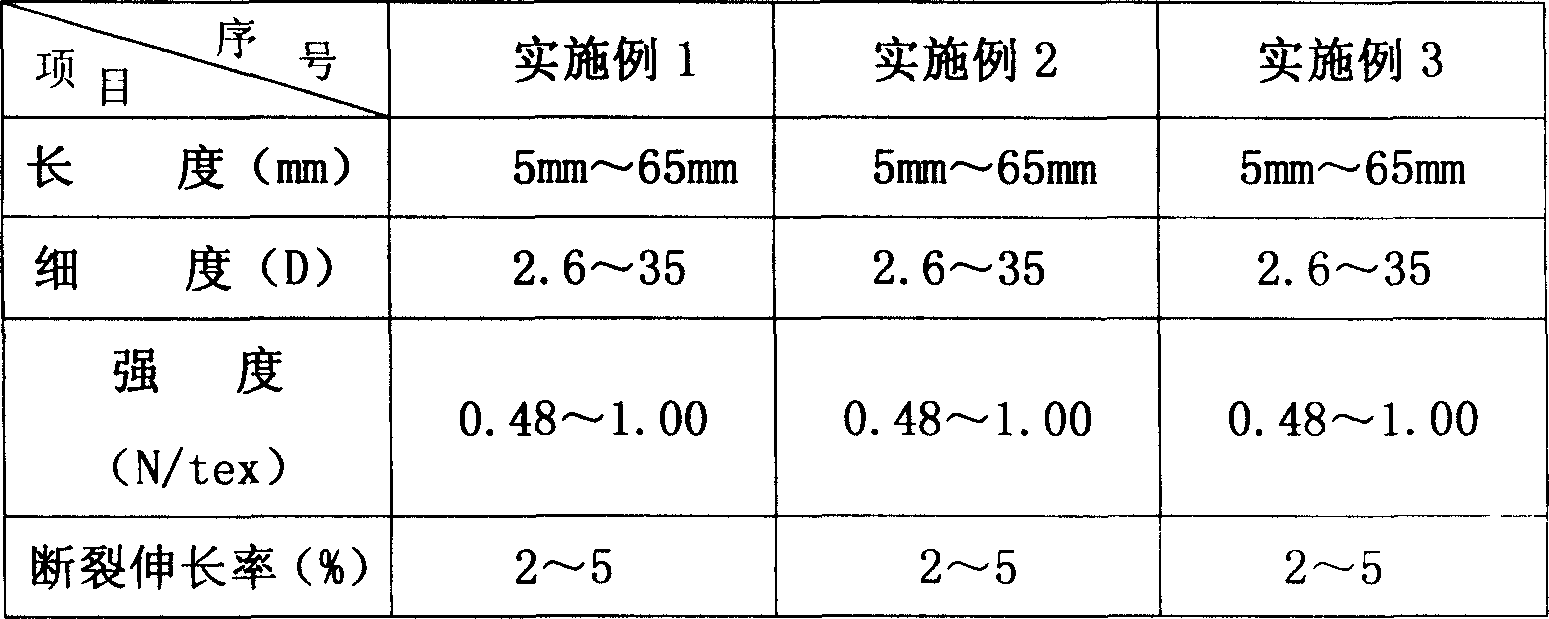

Embodiment 1

[0025] Take the spruce tree that has just been felled, remove the old bark on the surface of the tree by hand, and then separate the bast layer from the tree trunk. Try to avoid bringing the hard wood fiber layer in the tree trunk, and classify the tree according to the size of the bast , putting the bast of trees with substantially the same size into a pool with a sodium hydroxide concentration of 12g / L, 0.5% by weight of washing powder, and a temperature of 60°C, soaking it for 12 hours, taking it out, and putting it into drying Dry in the machine, then use a cutting machine to cut the fiber bundles to a length of about 70mm, use a cotton opener for preliminary carding and loosening, remove impurities in the fiber bundles, dry them naturally in the shade, put them in a humidification chamber and spray the emulsion evenly before use Cover with cloth for 18 hours; put the bast fiber after the health treatment into the tanning agent containing Remy Bang A, JFC, palm oil, machine...

Embodiment 2

[0027] Get freshly felled banyan tree branches, separate the bark from the branches by hand, put into a water pool with a sodium hydroxide concentration of 3g / L and 1% by weight of washing powder at a temperature of 20°C, and soak for 48 hours Finally, take it out and put it in the dryer for drying, then use a cutting machine to cut the fiber bundles to a length of about 70mm, use a cotton opener to perform preliminary carding and loosening, remove impurities in the fiber bundles, dry them, and put them in a humidifier After the emulsion is evenly sprayed in the warehouse, it is covered with cloth for 24 hours of health maintenance; the bast fiber after health treatment is put into the tanning agent containing Remy Bang A, JFC, peanut oil, machine oil and water for tanning, and the bast fiber after tanning Put it into combing machine for combing once, and combing machine for combing once. After combing, the crude fibers of 2.6-35D are collected and separated into different spec...

Embodiment 3

[0029] Get the oleander just felled, bark is separated from bark by hand, and bark is put into sodium hydroxide concentration and is 8g / L, adds the washing powder of 1% weight part, and temperature is in the pool of 50 ℃, After soaking for 24 hours, take it out and put it in the dryer for drying, then cut the fiber bundles to a length of about 70mm with a cutting machine, use a cotton opener to perform preliminary carding and loosening, remove impurities in the fiber bundles, and then dry them , put it into the humidification chamber and spray the emulsion evenly, and then cover it with cloth for 24 hours; put the bast fiber after the health treatment into the tanning agent containing Remy Bang A, JFC, peanut oil, machine oil and water for tanning, after tanning The bast fibers were put into the combing machine and combed once, and the comber was combed once. After combing, the crude fibers of 2.6-35D were collected and separated into different specifications of tree bast crude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com