Full-effect refining agent for regenerated mulberry fiber and use method of full-effect refining agent

A technology of mulberry fiber and refining agent, applied in the direction of biochemical fiber treatment, bast fiber produced by chemical method, fiber treatment, etc., can solve the problems of no research on the additional properties of regenerated mulberry fiber, no biological enzyme technology to use mulberry fiber, etc. , achieve the effects of improving strength and additional properties, making the surface soft and imparting flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

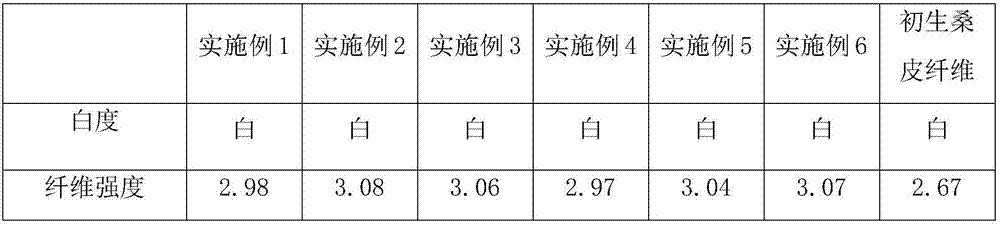

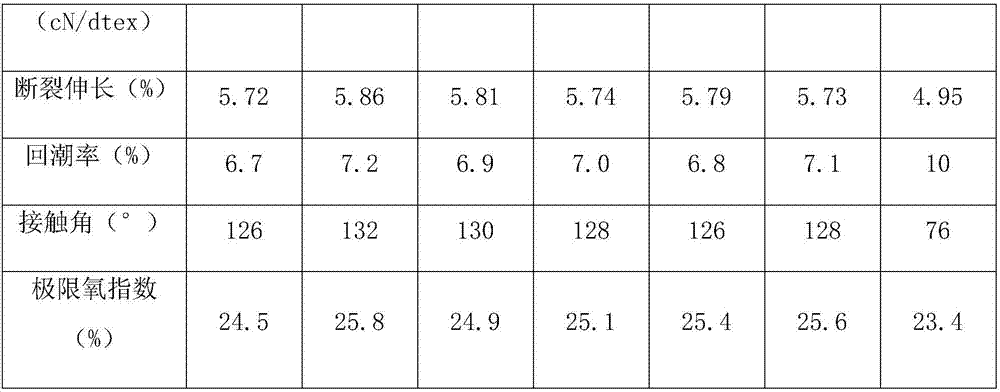

Examples

Embodiment 1

[0027] (1) The fresh mulberry bark is beaten and dedusted, treated with 10g / L of sulfuric acid for 30min, and treated with 15g / L of sodium hydroxide for 60min, and immersed in mulberry bark containing 2wt% neutral cellulase and 1wt% pectinase. solution, boiled for 20 minutes, taken out, rolled and dried to obtain pretreated mulberry fiber.

[0028] (2) The pretreated mulberry fiber is placed in a steam explosion treatment device, and the mulberry fiber is subjected to gas explosion treatment for 5 minutes under a pressure of 3 MPa, and is taken out for washing to obtain long mulberry fibers and short mulberry fibers with a length greater than 5 cm. The fibers are carded and twisted to form as-spun mulberry fibers, wherein the number of as-spun mulberry fibers is 5, and the twist number is 5 twists / cm.

[0029] (3) According to the mass ratio of 1:5, short mulberry fibers are placed in a mixed solution of acetic acid and boric acid with a volume ratio of 1:1, ultrasonically pul...

Embodiment 2

[0032] (1) fresh mulberry bark is through beating dedusting, through the sulfuric acid treatment of 10g / L 30min, the sodium hydroxide treatment 60min of 15g / L, the mulberry bark is immersed in containing 3wt% neutral cellulase and 2wt% pectinase solution, boiled for 30 minutes, taken out, rolled and dried to obtain pretreated mulberry fiber.

[0033] (2) place the pretreated mulberry fiber in a steam explosion treatment device, carry out gas explosion treatment 20min under 5MPa pressure, take out and wash, obtain long mulberry fibers and mulberry short fibers with a length greater than 5cm, and mulberry long fibers The fibers are carded and twisted to form as-spun mulberry fibers, wherein the number of as-spun mulberry fibers is 12, and the twist number is 10 twists / cm.

[0034] (3) According to the mass ratio of 1:8, short mulberry fibers are placed in a mixed solution of acetic acid and boric acid with a volume ratio of 1:1, ultrasonically pulverized for 10 minutes, centrifu...

Embodiment 3

[0037] (1) Fresh mulberry bark is beaten and dedusted, treated with 10g / L sulfuric acid for 30min, 15g / L sodium hydroxide for 60min, and soaked with 2.3wt% neutral cellulase and 1.4wt% pectin containing mulberry bark The enzyme solution was boiled for 25 minutes, taken out, rolled and dried to obtain pretreated mulberry fiber.

[0038] (2) the pretreated mulberry fiber is placed in a steam explosion treatment device, and the mulberry fiber is subjected to gas explosion treatment for 15min under a pressure of 3.5MPa, taken out and washed to obtain long mulberry fibers and short mulberry fibers with a length greater than 5cm, and the mulberry The long fibers are carded and twisted to form as-spun mulberry fibers, wherein the number of as-spun mulberry fibers is 6, and the twist number is 7 twists / cm.

[0039] (3) According to the mass ratio of 1:6, short mulberry fibers are placed in a mixed solution of acetic acid and boric acid with a volume ratio of 1:1, ultrasonically pulver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com