Patents

Literature

52results about How to "Safe and convenient transportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

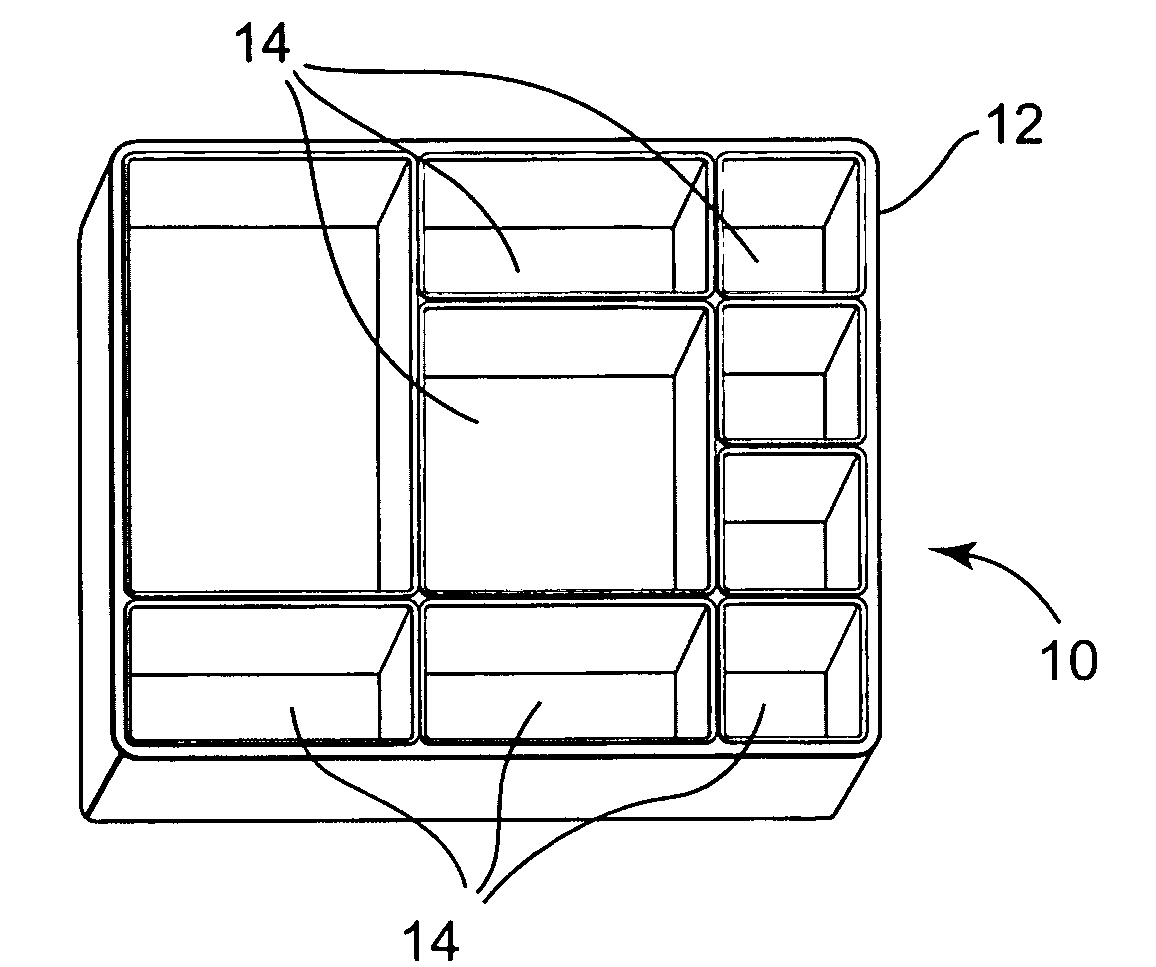

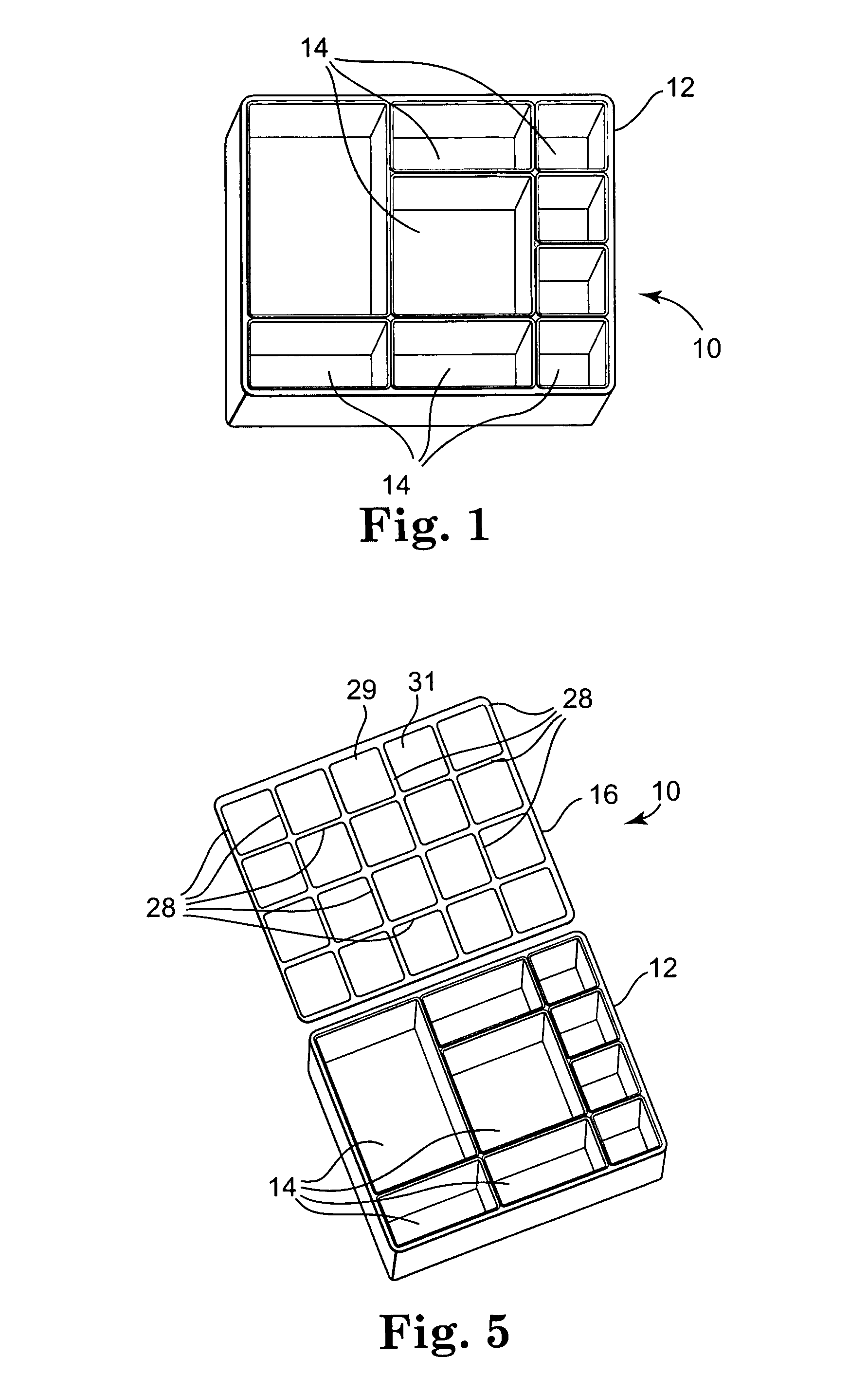

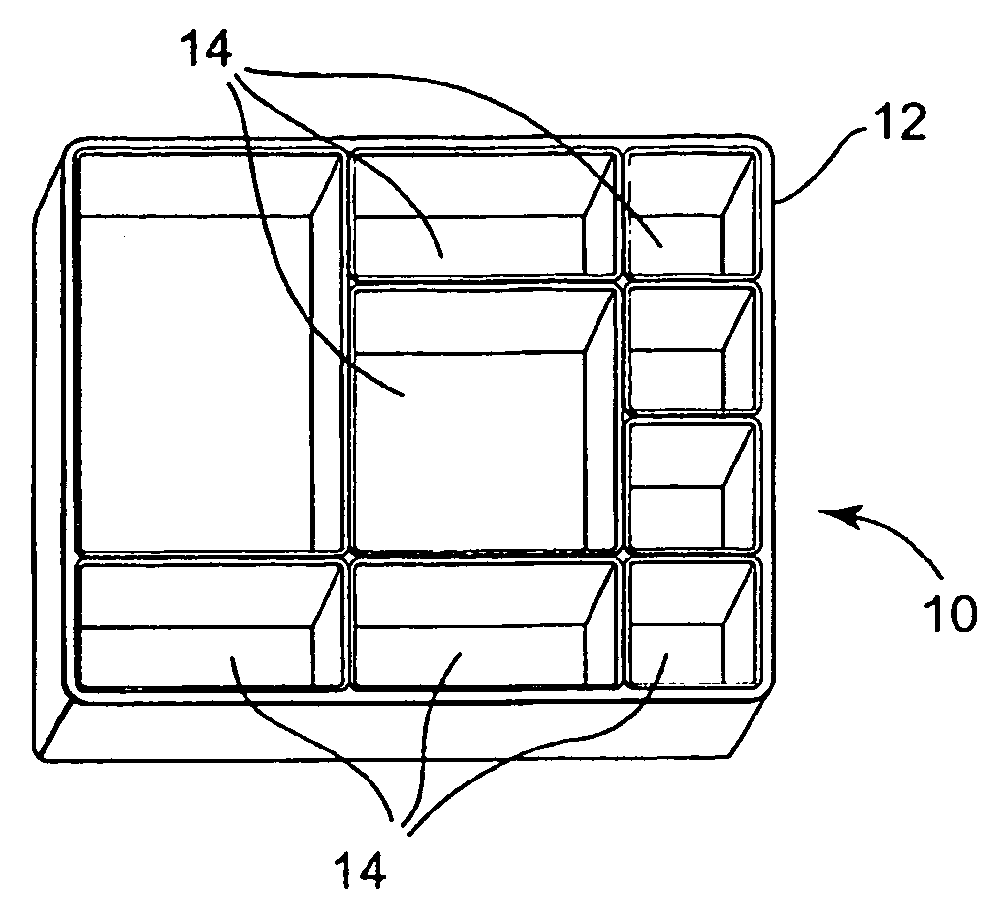

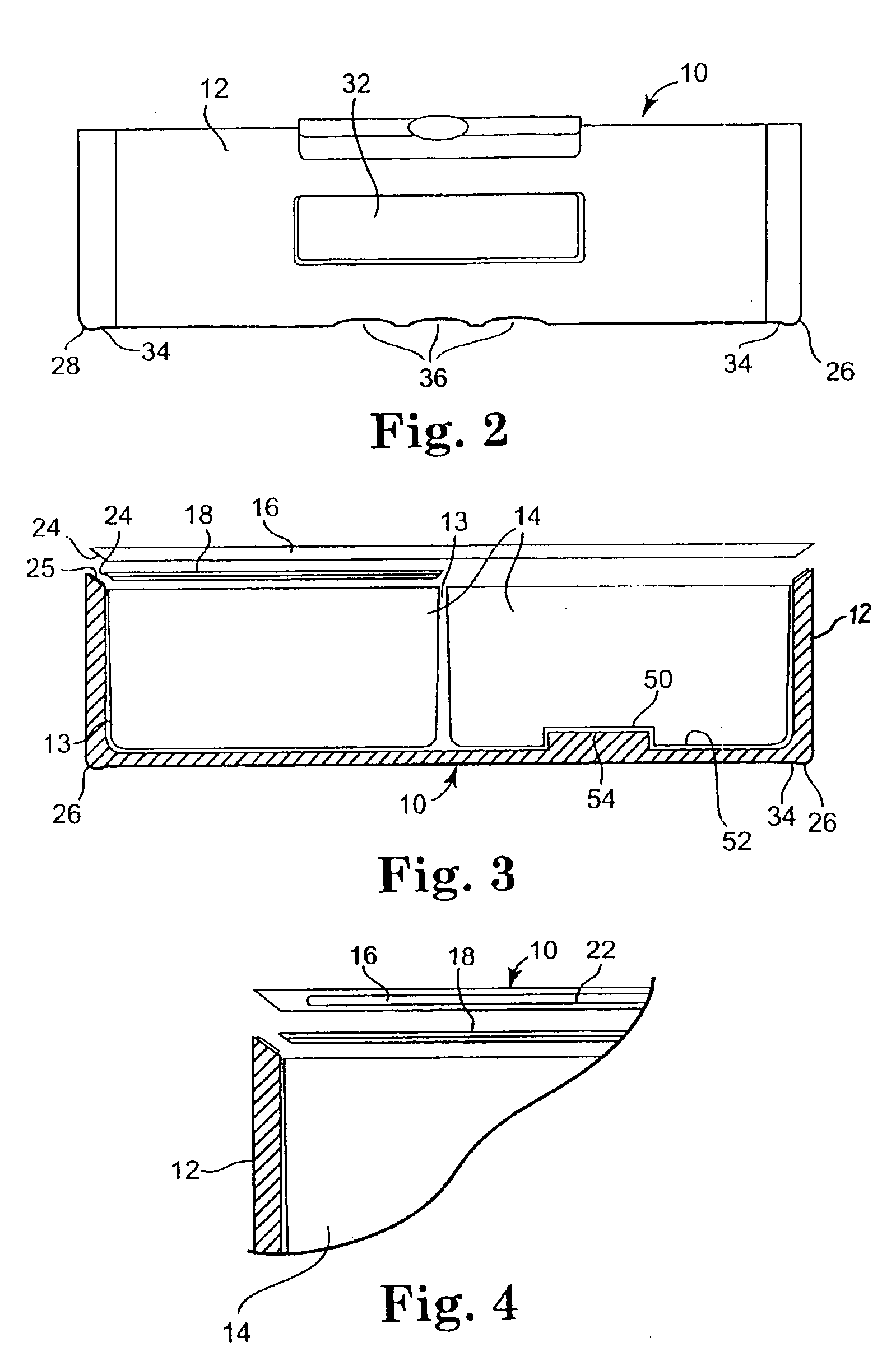

Multi-compartment container and lid assembly

ActiveUS7326428B2Safe and convenient transportationEfficient separationReady-for-oven doughsInternal framesEngineeringMechanical engineering

A divided container system comprising a master tray having an interior portion and a peripheral top edge, at least one insertable sub-tray positionable within the interior portion of the master tray, wherein each sub-tray includes a peripheral top edge and an interior portion, and a lid for sealing both the master tray and the at least one insertable sub-tray. The lid comprises an upper surface, a lower surface, a plurality of sealing surfaces extending from the lower surface of the lid, wherein the sealing surfaces are arranged to abut with the peripheral top edge of the at least one insertable sub-tray to thereby seal the interior portion of the at least one insertable sub-tray from the interior portion of the master tray, and a peripheral sealing surface for sealable contact with the peripheral top edge of the master tray.

Owner:VW DESIGN

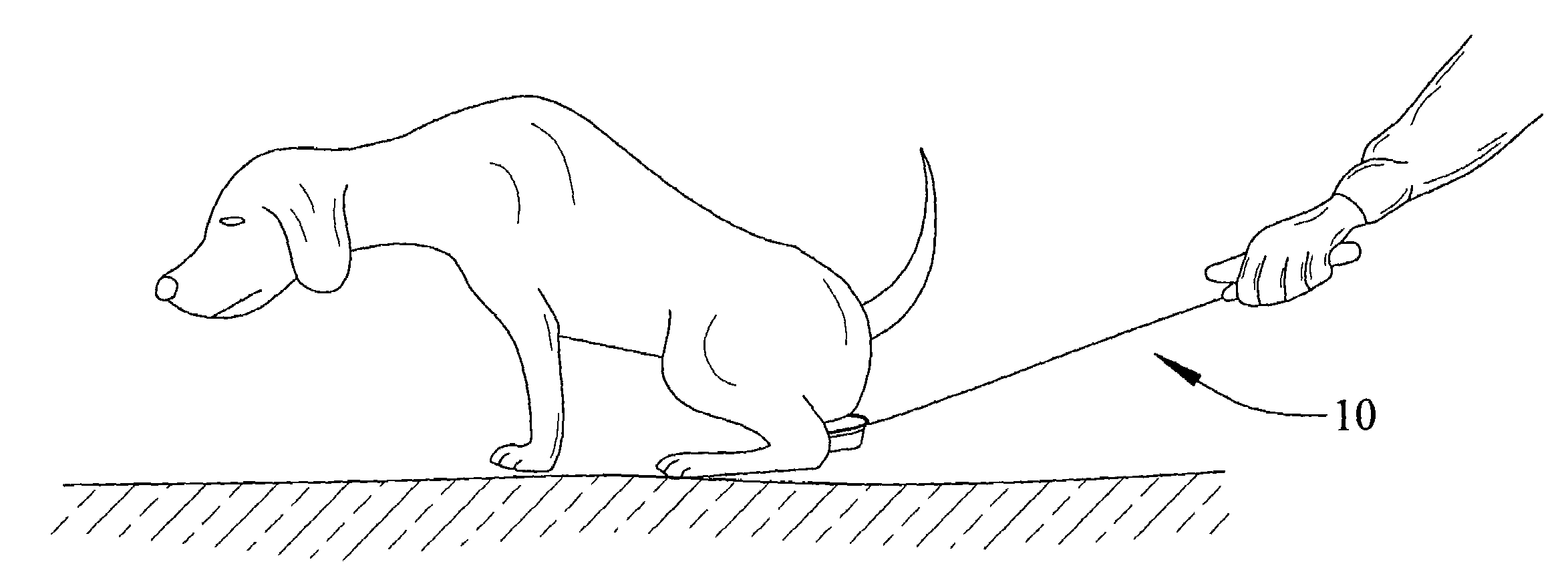

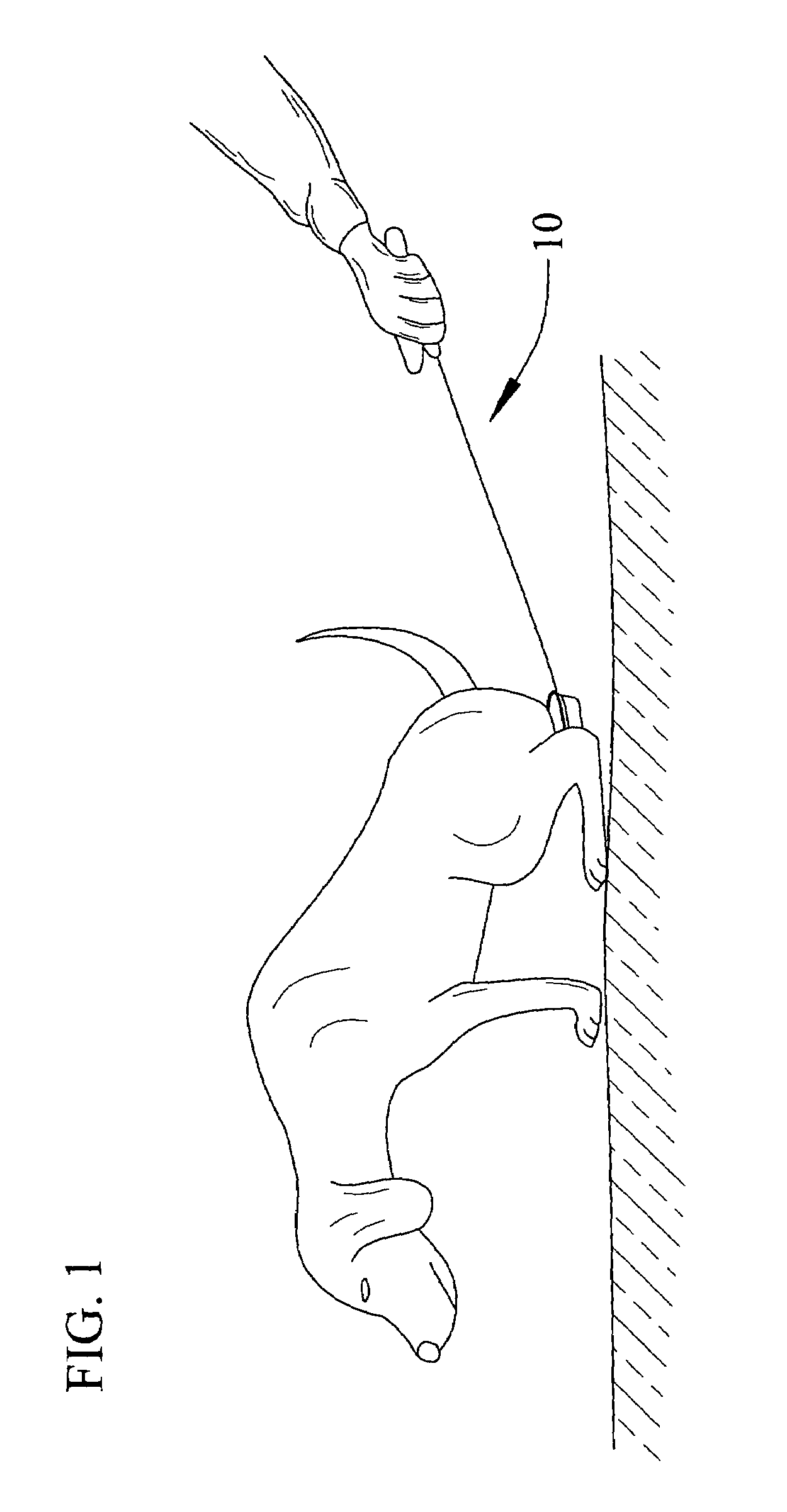

Animal urine specimen collection device

InactiveUS7128352B1Reduce total usageConvenient and less intrusive to useOther apparatusTaming and training devicesEngineeringSpecimen collection

A device, method and kit for collection of a urine specimen from an animal includes a cup to receive and hold the urine specimen, a lid to close cup after collection of the specimen, and a holder with a generally upright center extension member, a handle connected at the upper end of the extension member, and a cup holder extending forwardly from the lower end of the extension member and having an opening slidably receiving the cup for manual positioning of the cup under the animal from which the urine specimen is to be collected.

Owner:PHIPPEN GERALDINE

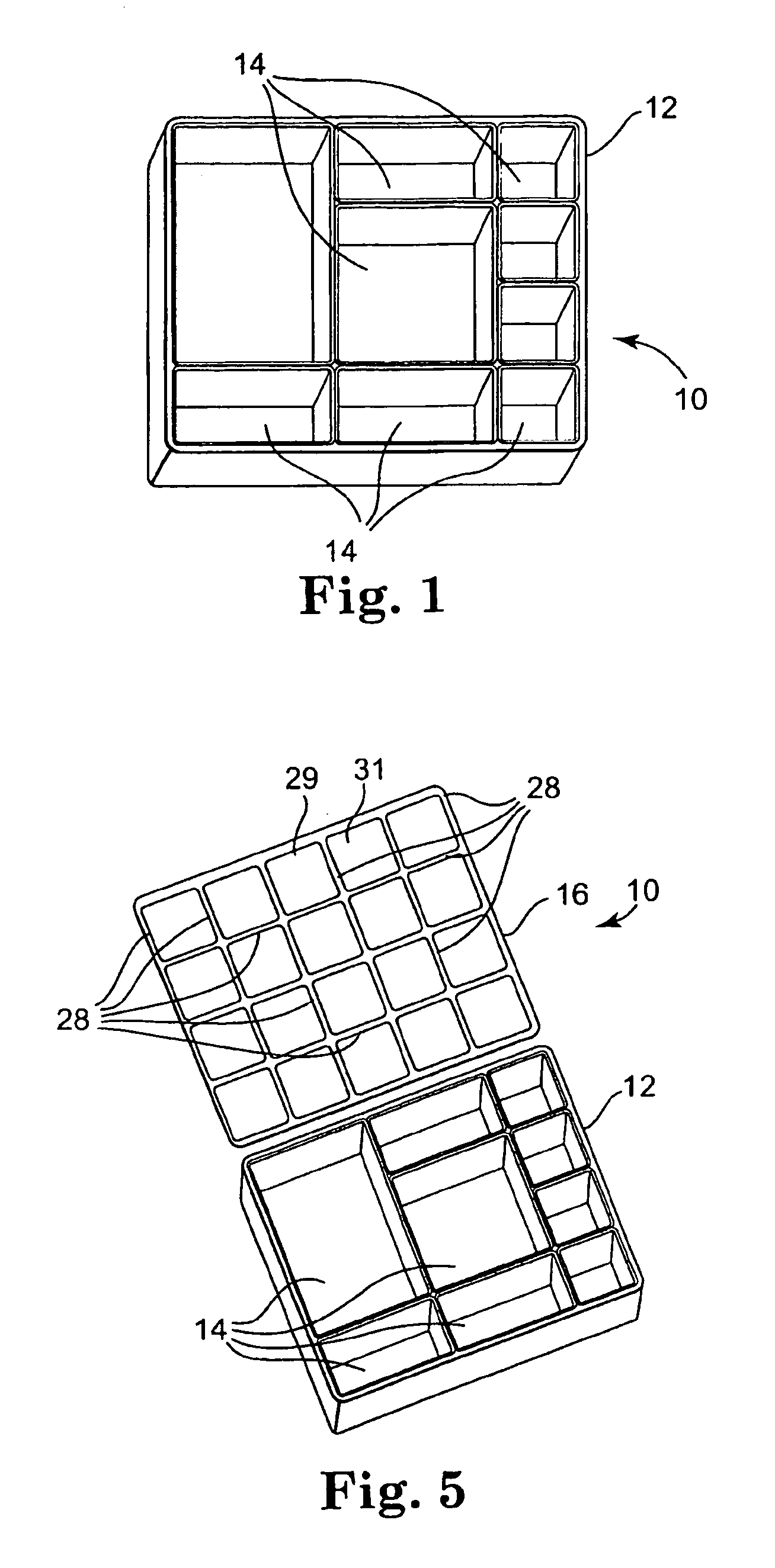

Methods of preparing food and a multi-compartment container and lid assembly for practicing the methods

InactiveUS20090162506A1Safe and convenient transportationEfficient separationKitchen equipmentPackaging protectionMechanical engineering

Methods of preparing food and a divided container system used in the preparation. The container system has a master tray having an interior portion and a peripheral top edge, at least one insertable sub-tray positionable within the interior portion of the master tray, in which each sub-tray includes a peripheral top edge and an interior portion, and a lid for sealing both the master tray and the at least one insertable sub-tray. There are means securing a sub-tray in place within in the master tray.

Owner:WEIR MAJORIE

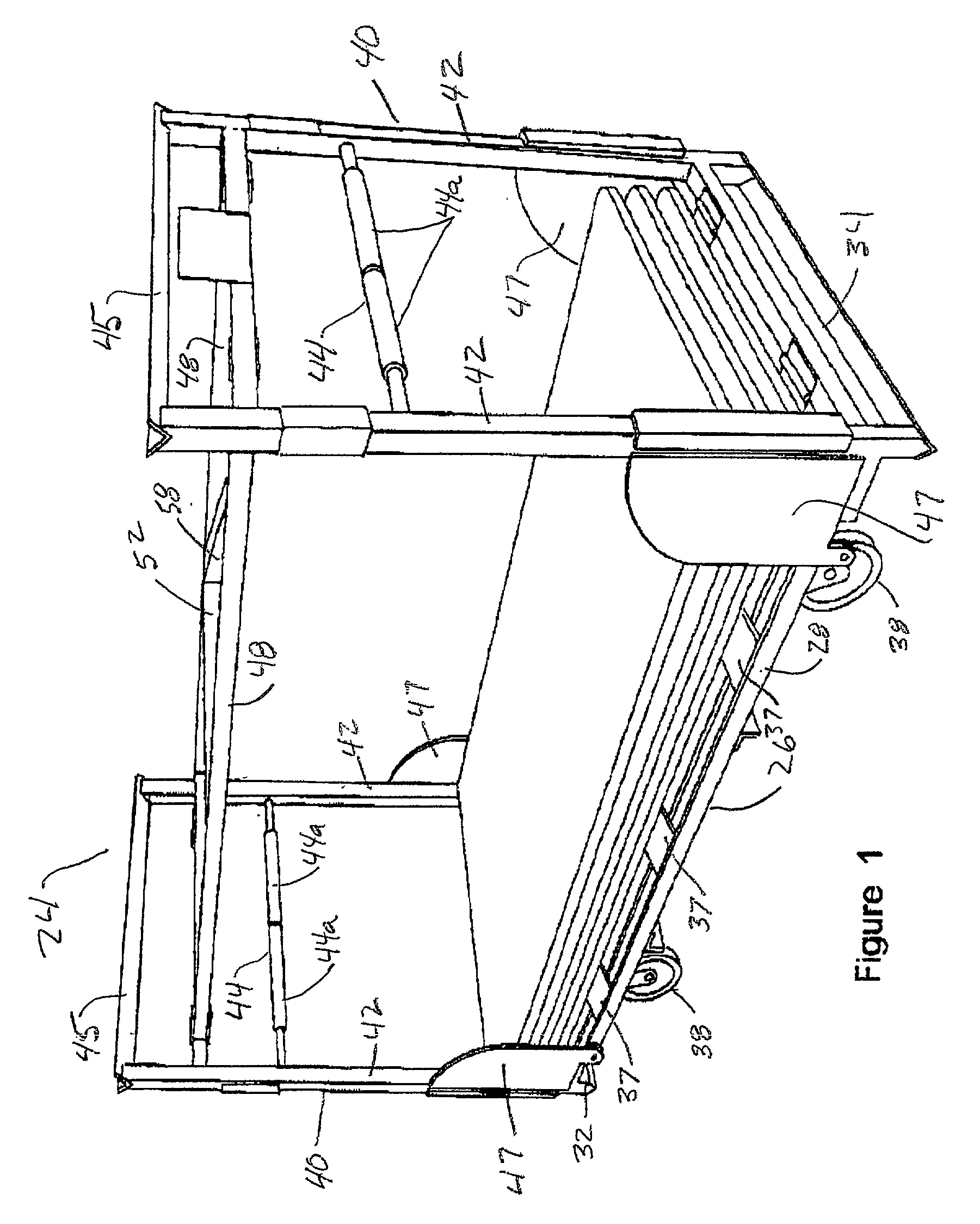

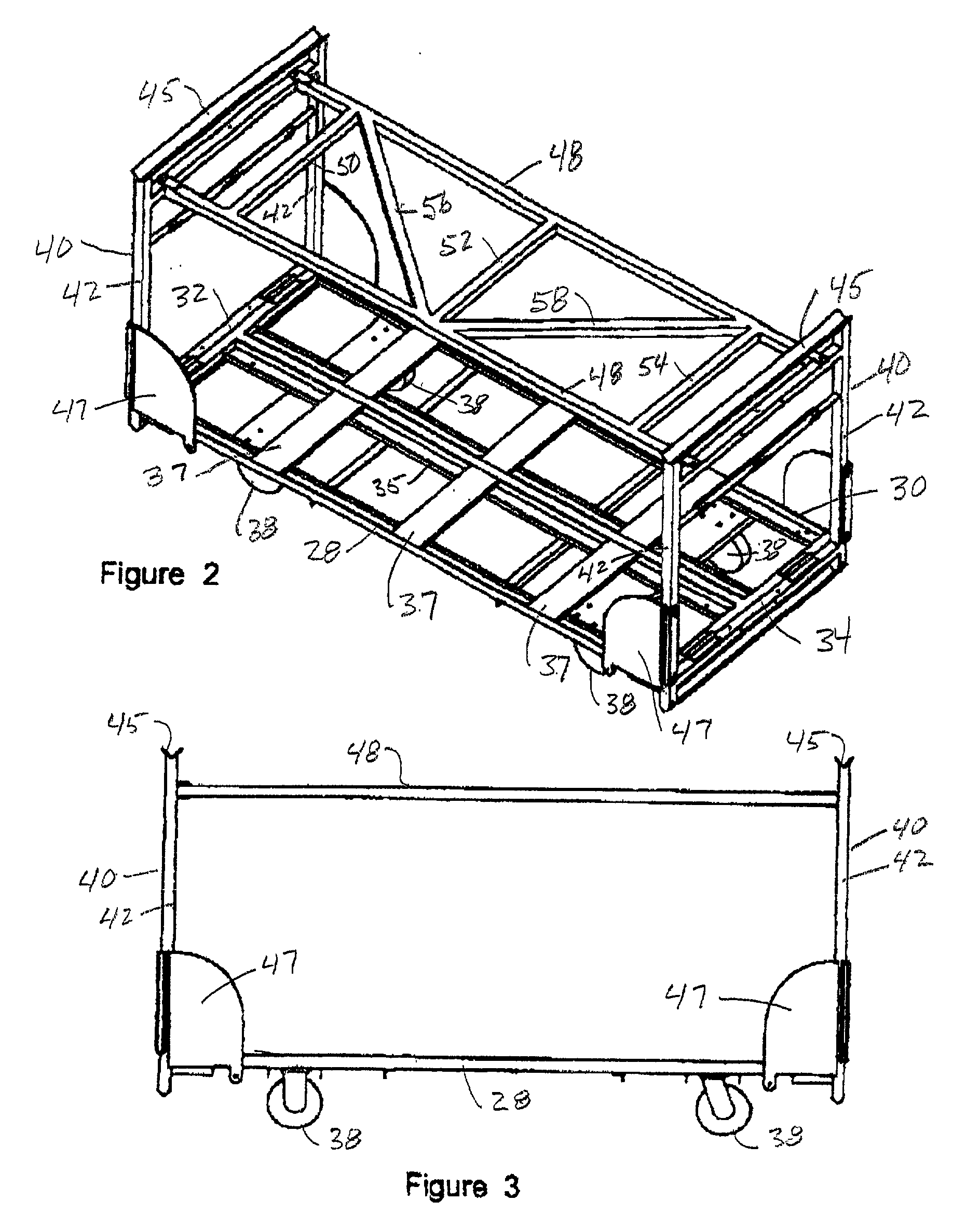

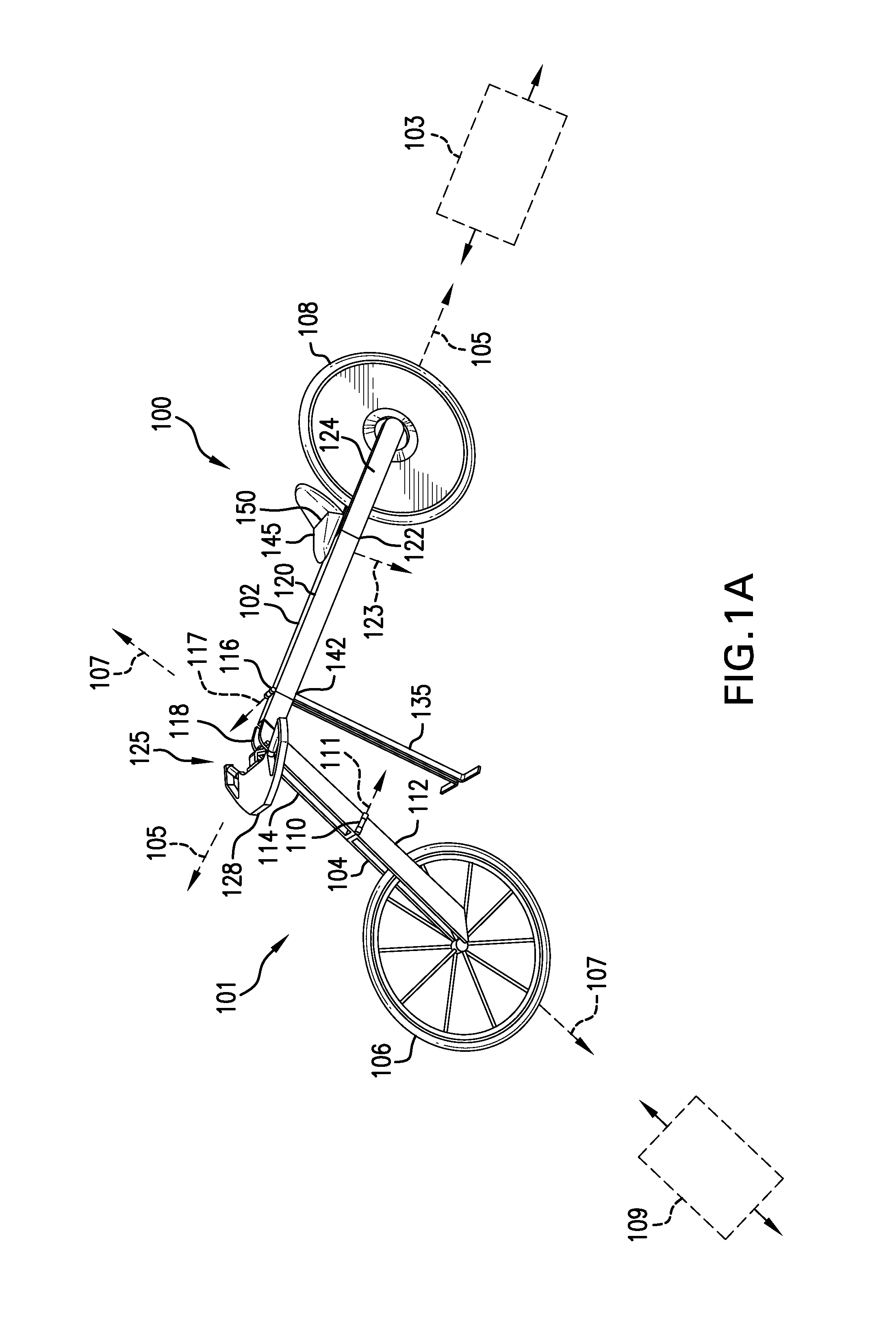

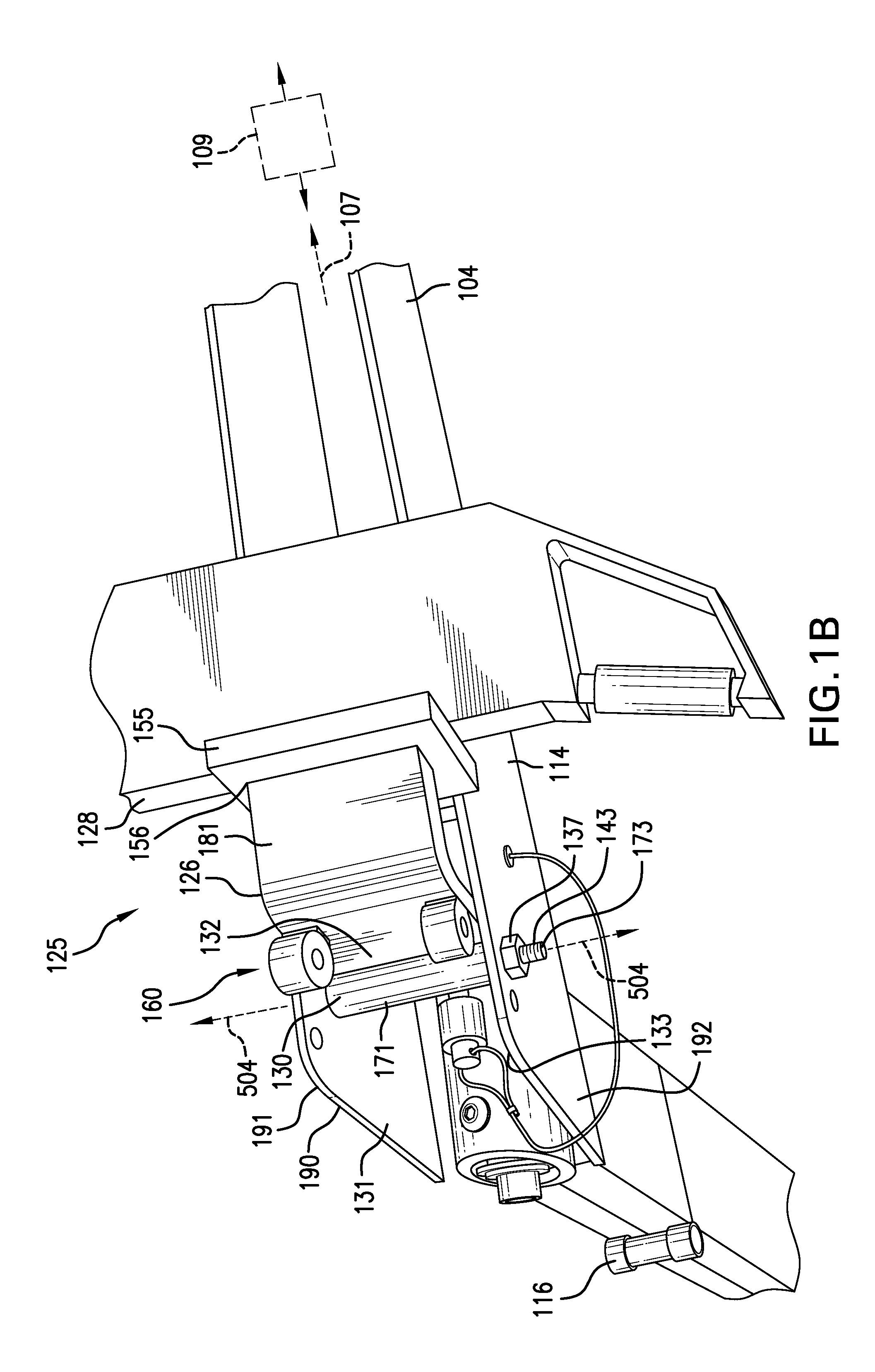

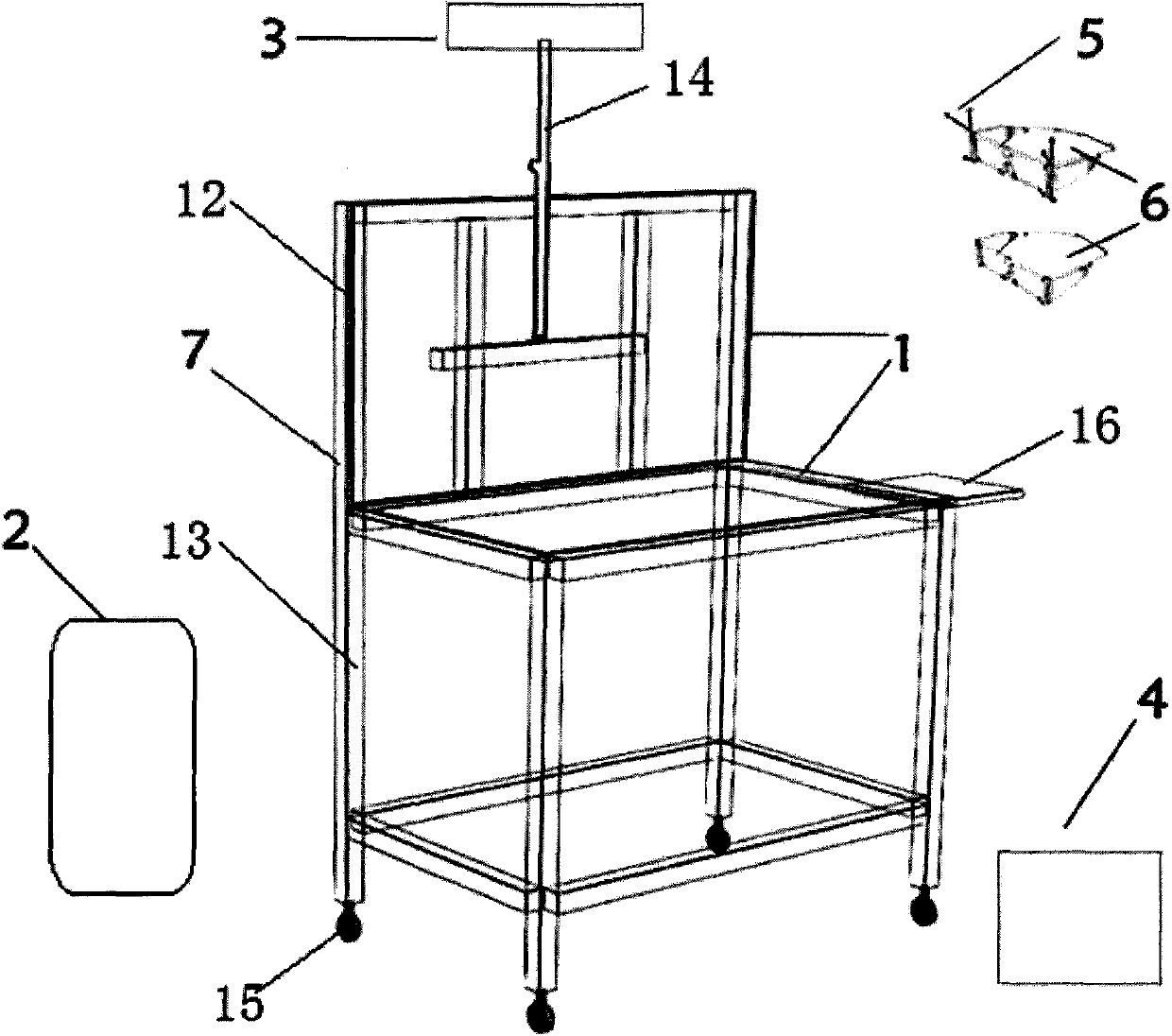

Furniture transport truck

InactiveUS20010005070A1Safe and convenient transportationGuarantee support safetyCarriage/perambulator with single axisHand carts with one axisTruckTransport engineering

A transport truck that can be used to safely move various articles of furniture, including heavy stacks of differently configured chairs from one location to another. The transport truck includes specially configured article support members and assemblies that can be affixed to the base of the transport truck to safely transport various kinds of furniture from auditoriums, conference rooms and like to storage areas.

Owner:KEMNITZER RONALD B

Coal additive and method for raising coke output and performance

InactiveCN101020831AFully carryFast and Efficient CarryCoke ovensSolid fuelsEngineeringProcess engineering

The present invention relates to coal additive and method for raising coke output and performance. The coal additive contains surface activating catalyst, co-solvent, permeation assistant and solvent. When the coal additive is used, the surface activating catalyst is dissolved in the solvent, added into coal through a specific mode, and distributed on the surface of coal and inside coal under the action of the permeation assistant. During producing coke, the coal additive is heated and the volatile component is separated out, to raise the output and performance of the produced coke. The high performance coke may be used in coal burning, dry distilling, gasifying, liquefying and other fields. The present invention can reach the aims of raising the utilization rate of coal, saving coal resource, reducing pollutant, etc.

Owner:北京金源化学集团有限公司

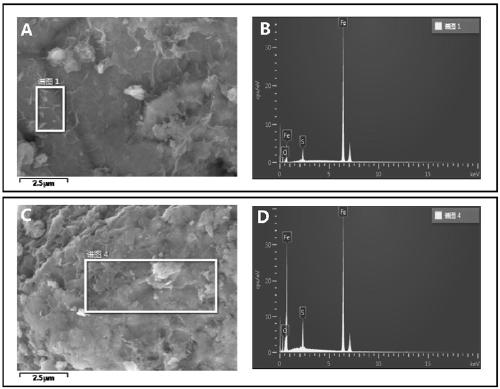

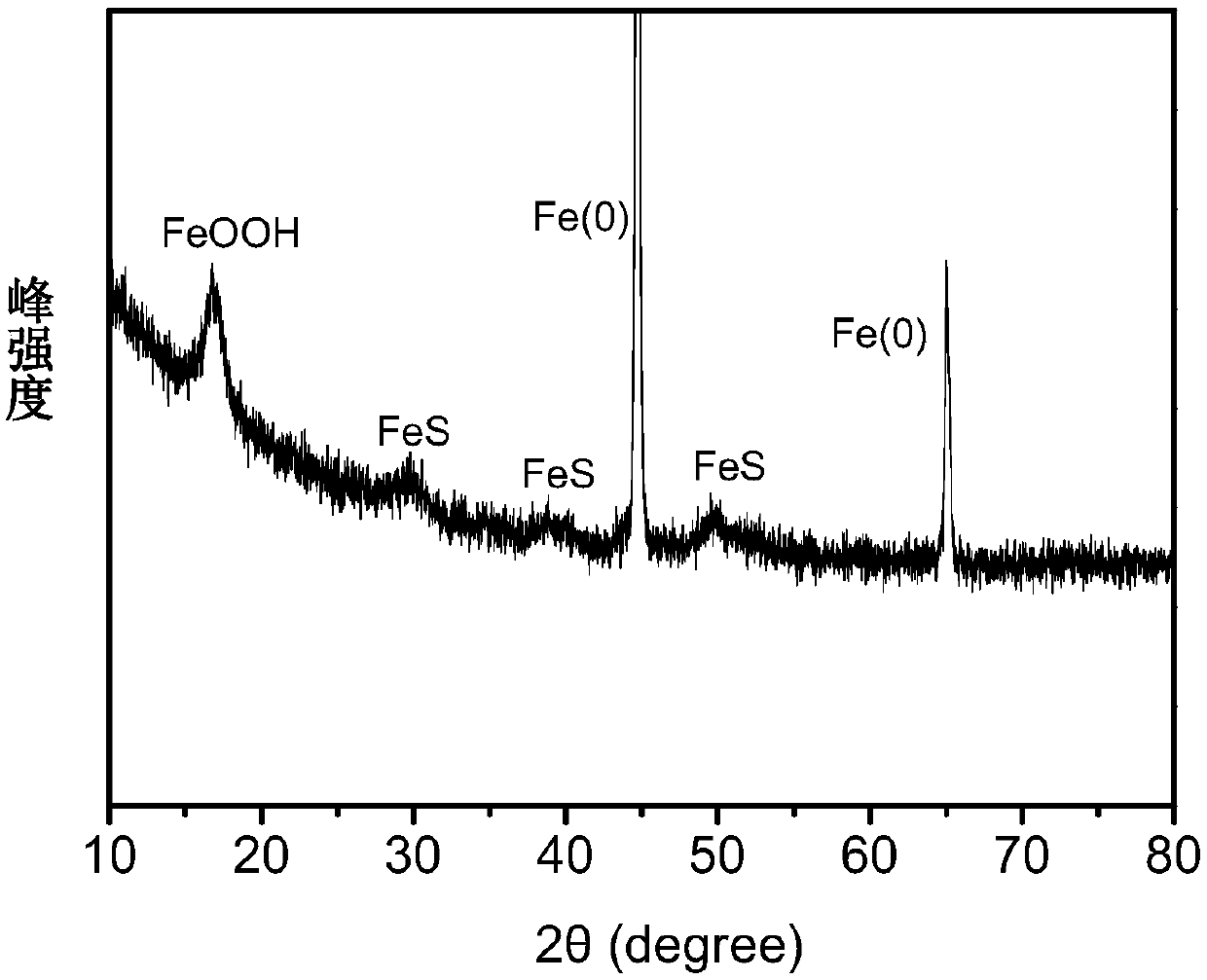

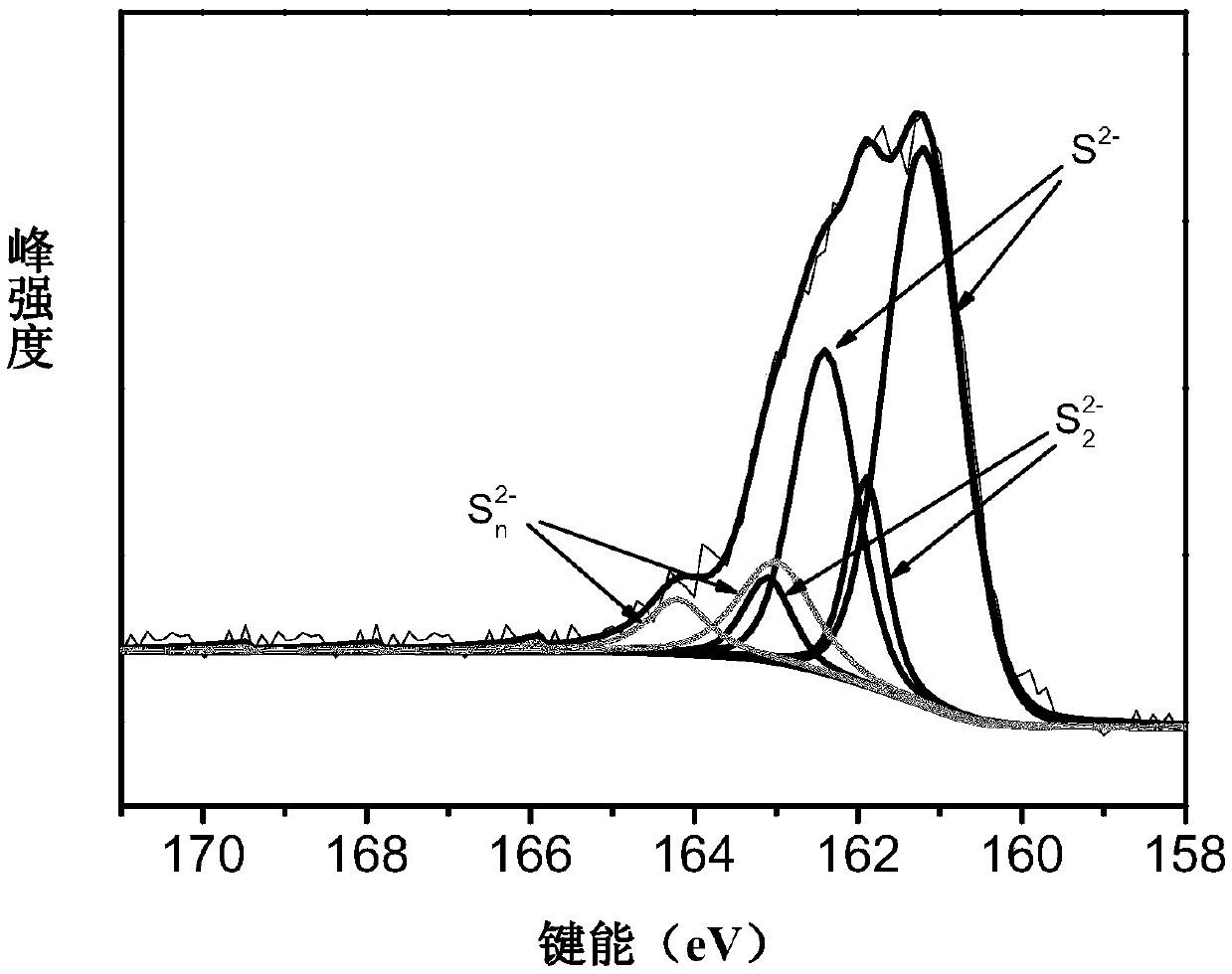

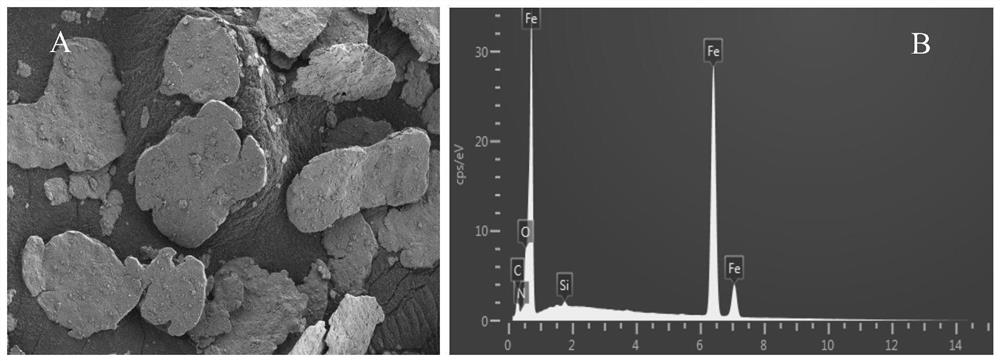

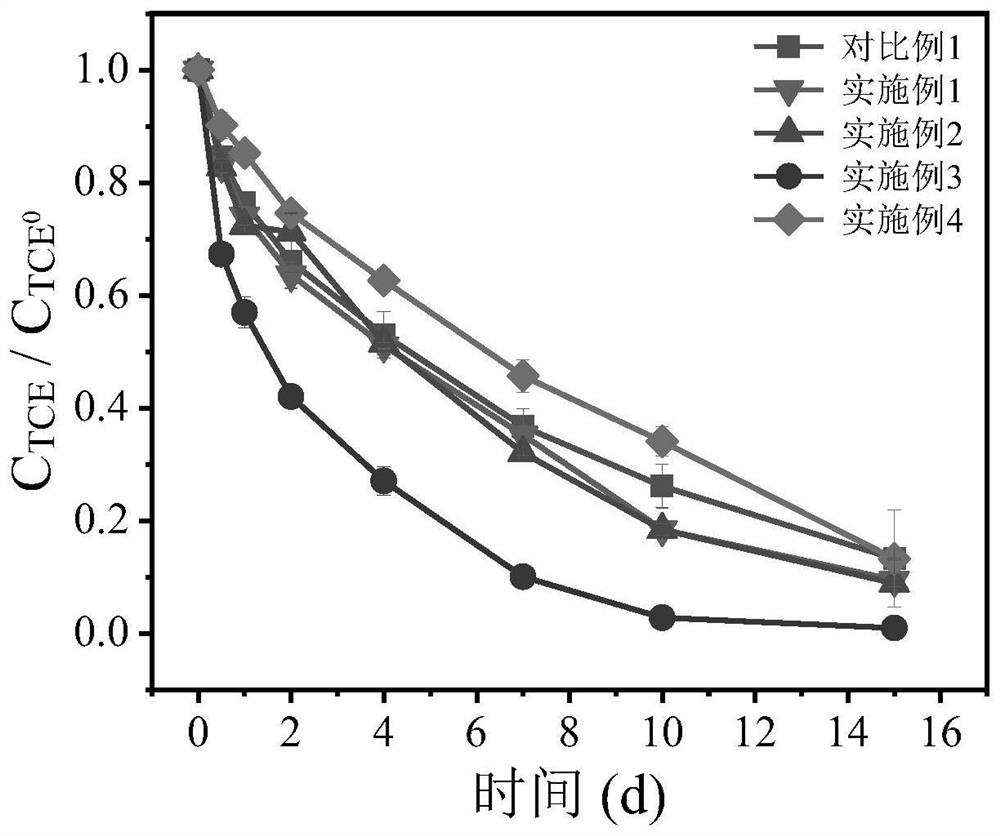

Preparation method of zero-valent iron sulfide and application thereof

ActiveCN109607635ALess energy consumptionSimple and efficient operationWater contaminantsWater/sewage treatmentHeavy metalsAqueous solution

The invention discloses a preparation method of zero-valent iron sulfide and application thereof. The preparation method comprises the steps that under the ambient temperature condition, zero-valent iron and simple-substance powdered sulfur are mixed to be subjected to a reaction in a water solution to obtain zero-valent iron sulfide. According to the method, zero-valent iron and simple-substancepowdered sulfur are mixed to be subjected to the reaction in the water solution, little energy is consumed, operation is easy and convenient, the preparation time is relatively short, the preparationcost is low, and the obtained zero-valent iron sulfide has the high removal efficiency for heavy metal and organic contaminants.

Owner:ZHEJIANG UNIV OF TECH

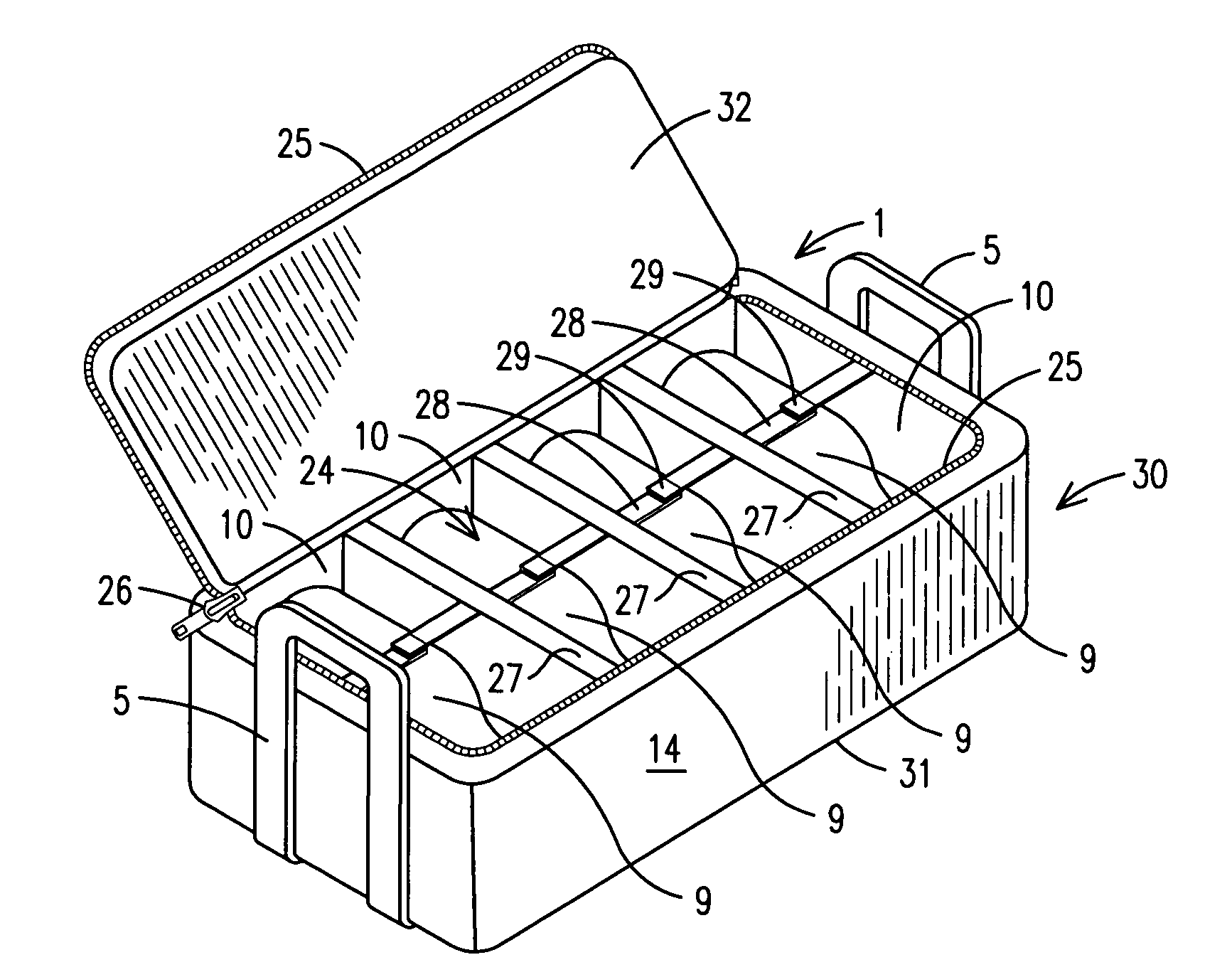

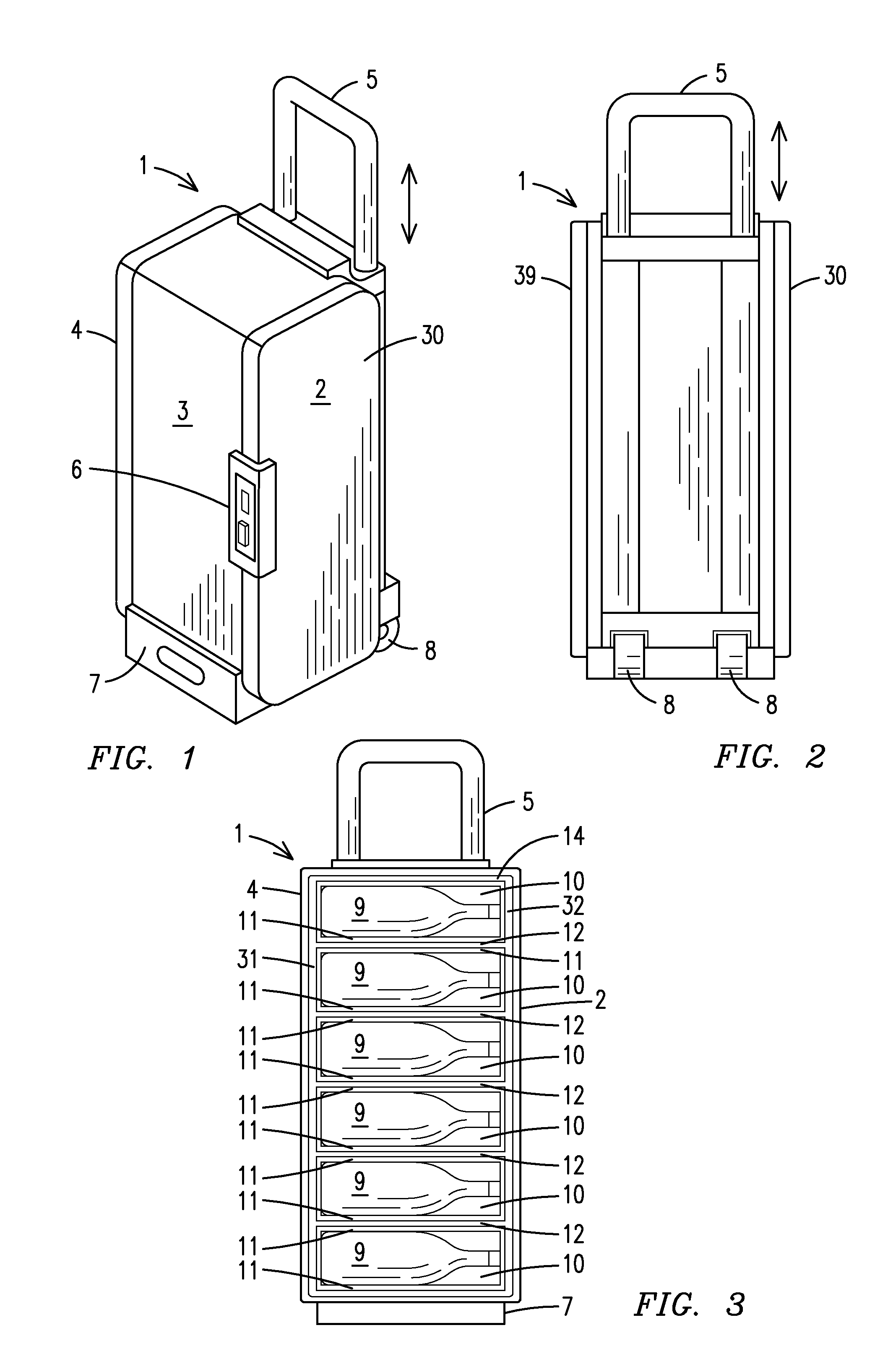

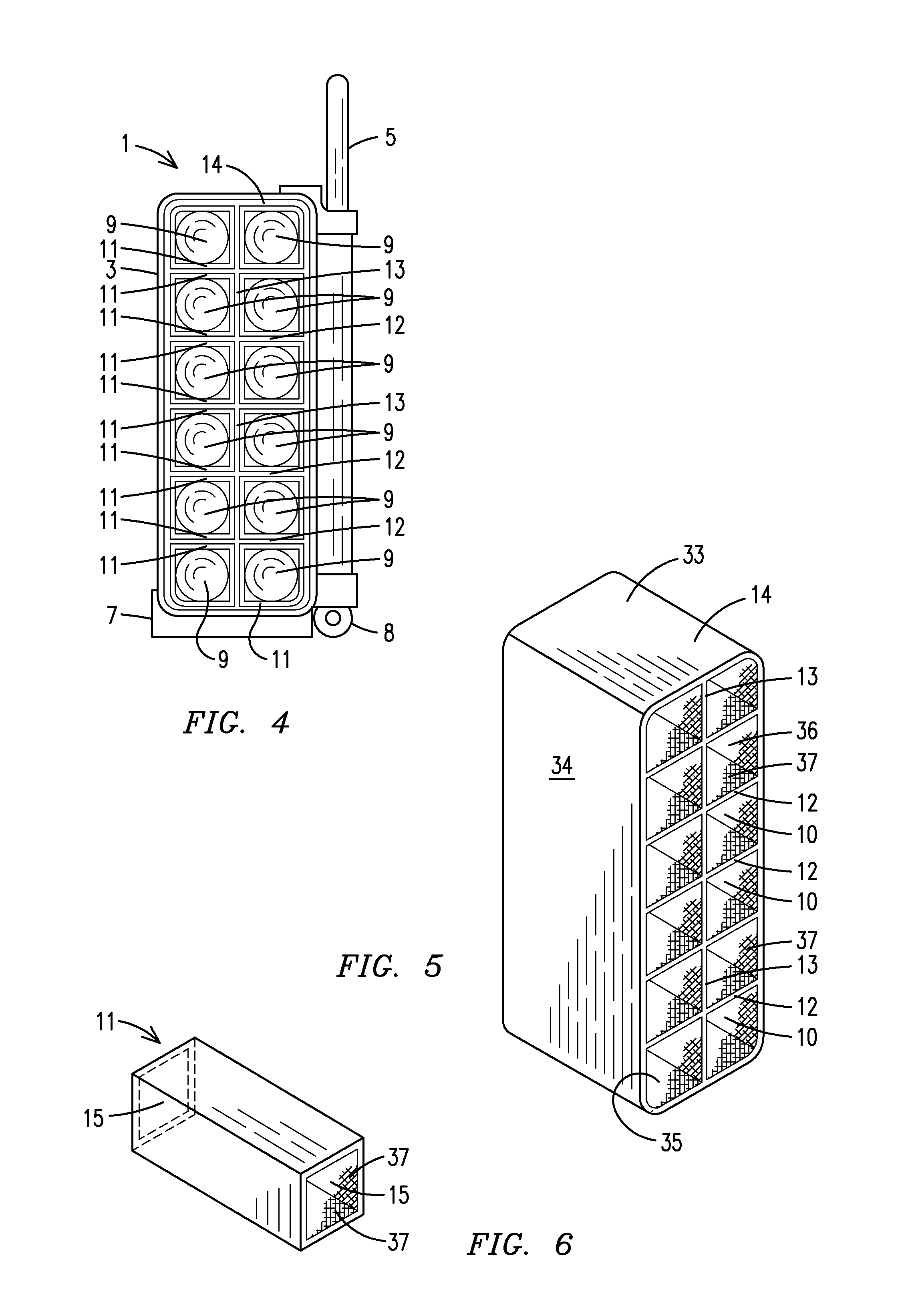

Bottled beverage holding luggage

InactiveUS7565974B2Safe and convenient transportationReduce riskFlexible coversWrappersEngineeringBottle

A bottled beverage holding luggage (1) having a core (14), a vertical wall (13) located within the core and a plurality of horizontal walls (12) located within the core (14). The horizontal walls (12) intersect with the vertical wall (13) to form a plurality of openings (10) for the acceptance of bottles (9), which may be bottled beverages. Shock-absorbent sleeves (11) having at least one aperture (15) may be inserted into the openings (10). Thus, the bottles (9) are placed within the sleeves (11) and the sleeves (11) are ultimately placed within the openings (10) in the core (14) to protect the bottles (9) from breakage during transit. Alternatively, the core (14) may include removable horizontal and vertical shelves (17 and 22) which form the openings (10) or include a plurality of foldable dividers (27) which form the openings (10) for acceptance of the bottles (9). The core (14) may be removable from a luggage case (30), built into a luggage case (30) or have wheels (8), a handle (5) and a rigid exterior shell (41) so as to be its own luggage case (30).

Owner:ADAMS JR A STANLEY

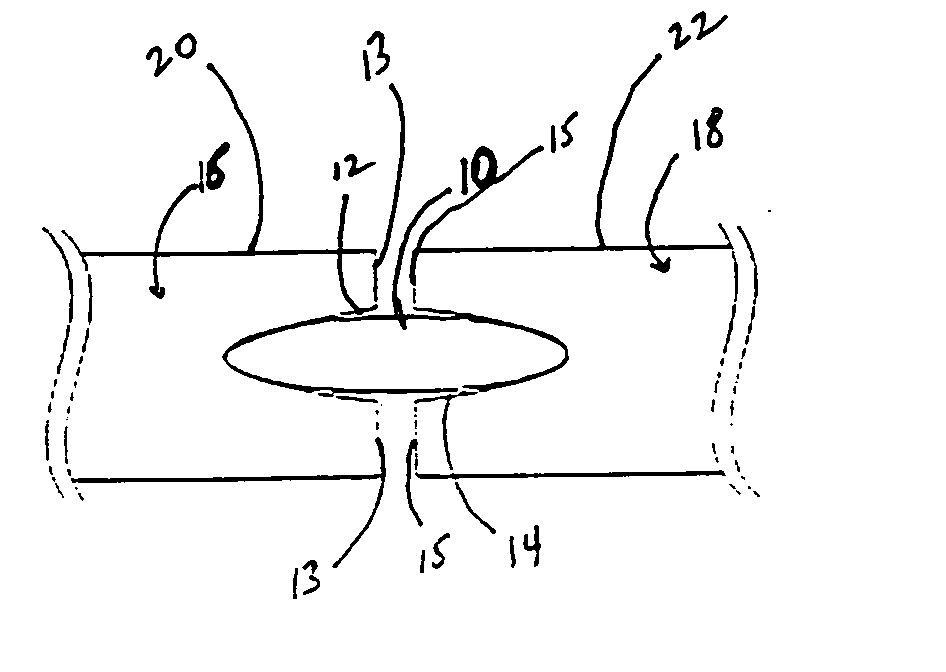

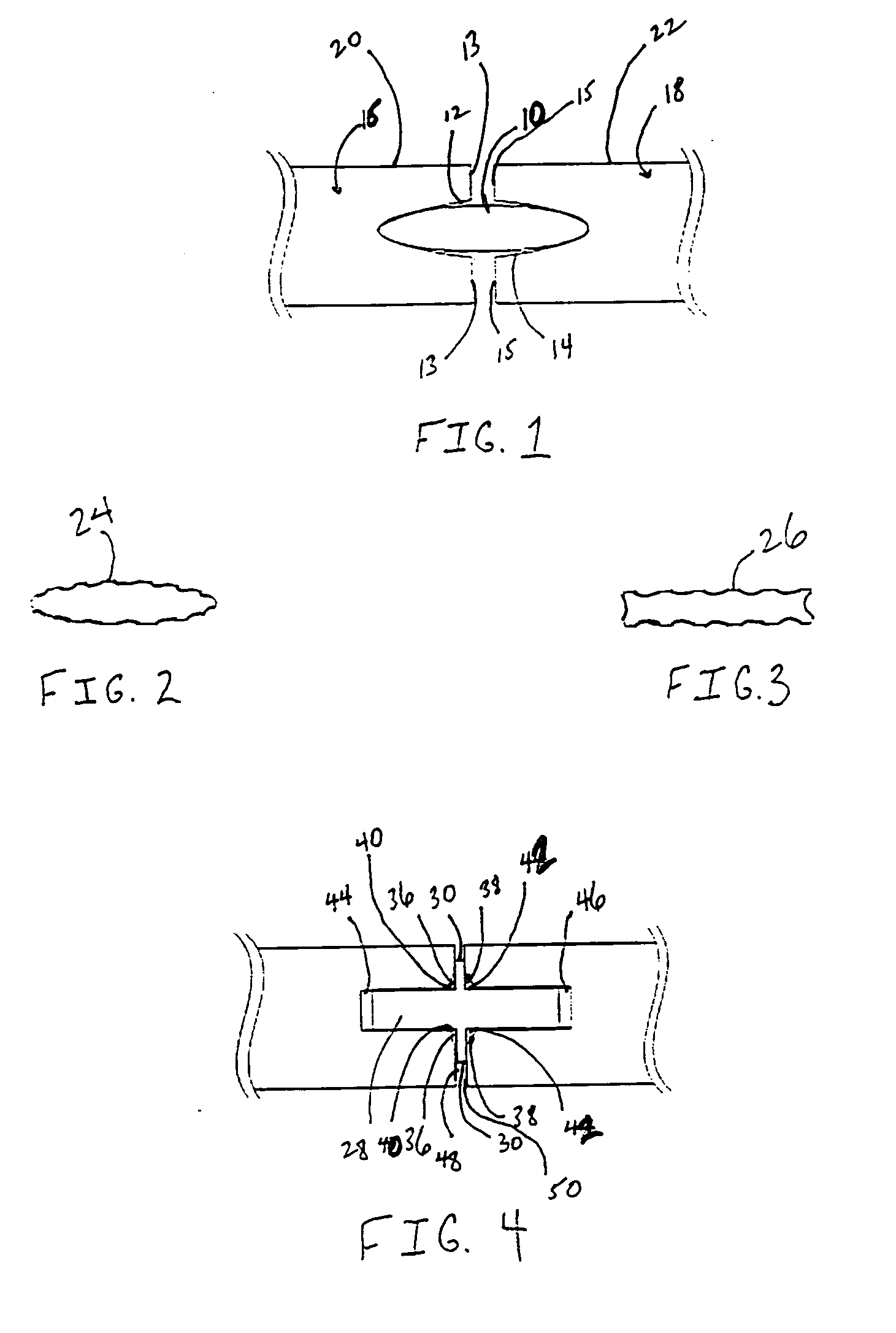

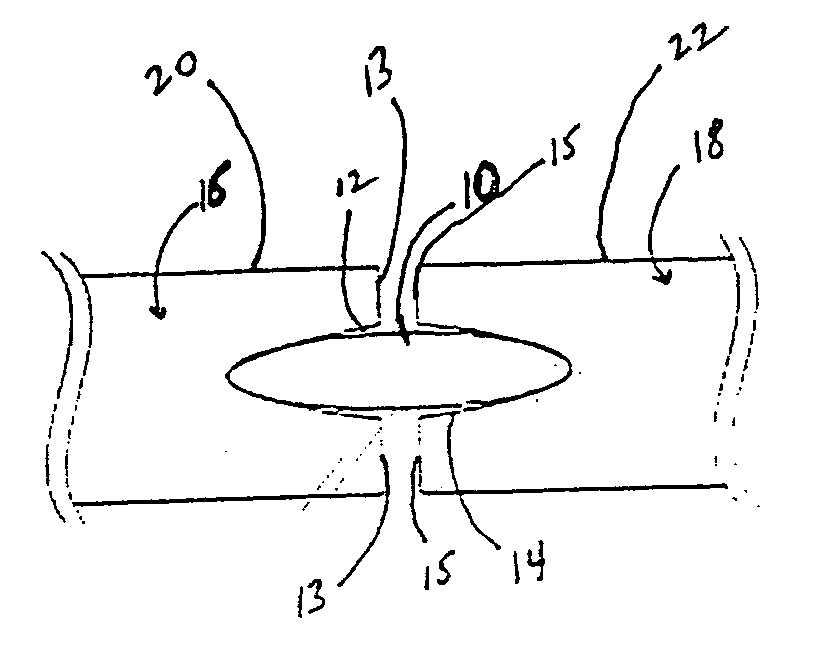

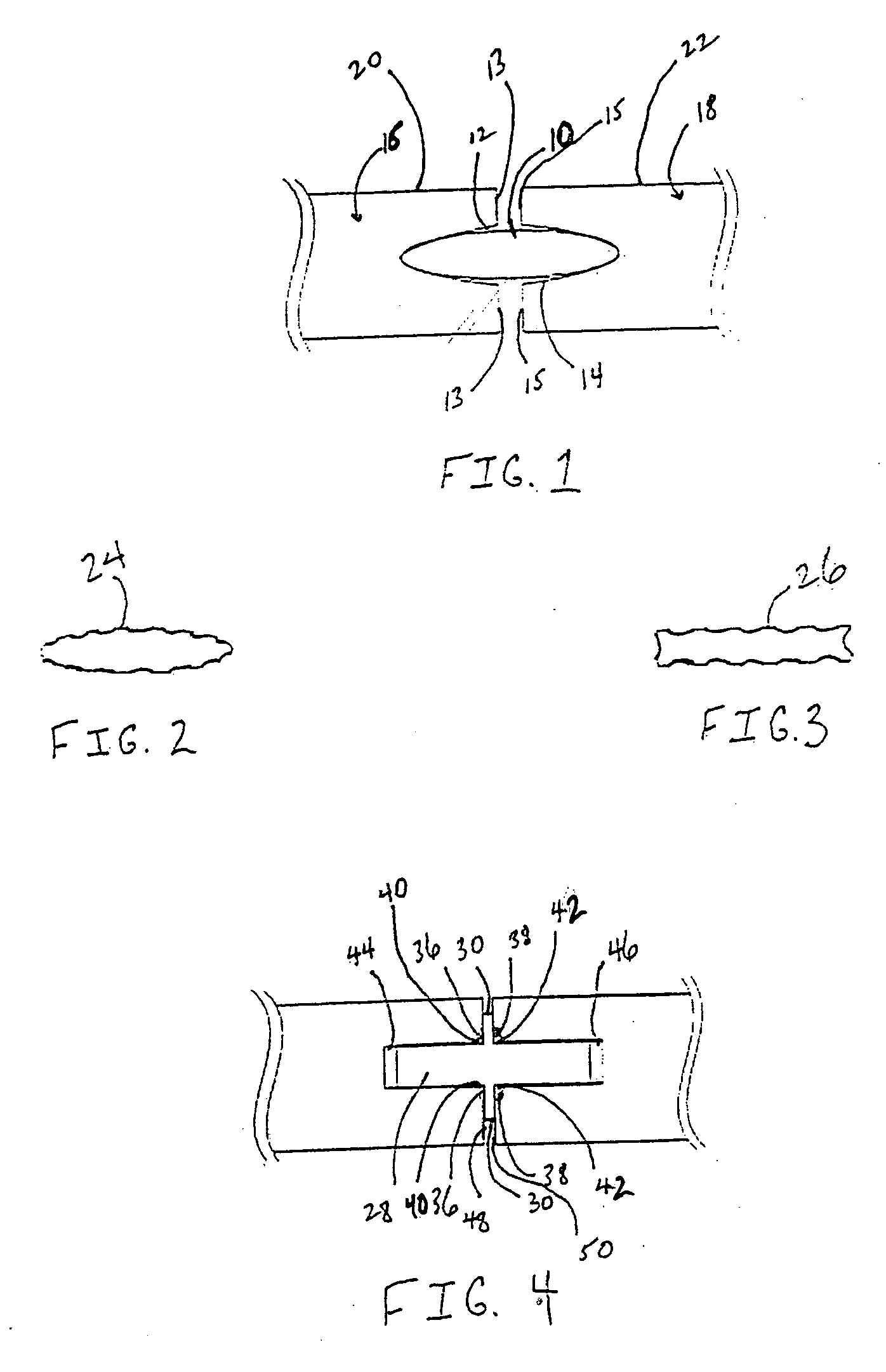

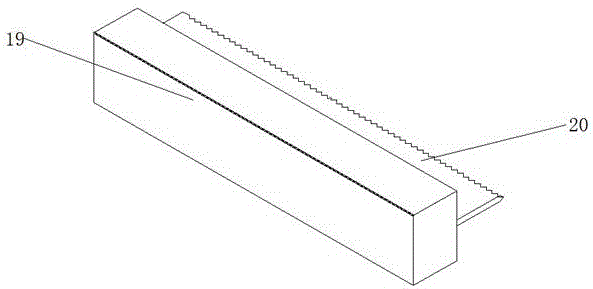

Contained load transfer device for wood sheathing products and roof construction method therewith

InactiveUS20070240375A1Easy to installSimple wayRoof covering using slabs/sheetsWallsUltimate tensile strengthSealant

The utilization of a specific load transfer device for the purpose of allowing for reliable connection and adhesion of composite wood boards during edifice manufacture therewith is provided. Such a device is configured for containment within slots cut into the peripheral edges of such wood boards and cut into a shape therein that is complementary to that of the device itself. In such a manner, the device, when introduced within the properly shaped slot, permits separation of adjacent wood boards that are sequentially applied to the frame of the target edifice, as well as, ultimately, sufficient load bearing strength for the overall construction (such as a roof) within which such connected wood boards are utilized. The separation of wood boards thus permits proper sealing therebetween (with tape, sealant, or other like material) as well as proper distance for shrinking or swelling (due to moisture / temperature variations) to be taken into account during the lifetime of the edification (thereby permitting expansion as needed). The ability to impart increased load bearing strength thus allows for an increase in construction materials (in number and in weight) to be carried and kept on such a structure during construction as well. The method of manufacture of an edifice utilizing such load transfer devices between wood boards is also encompassed within this invention.

Owner:HUBER ENGINEERED WOODS

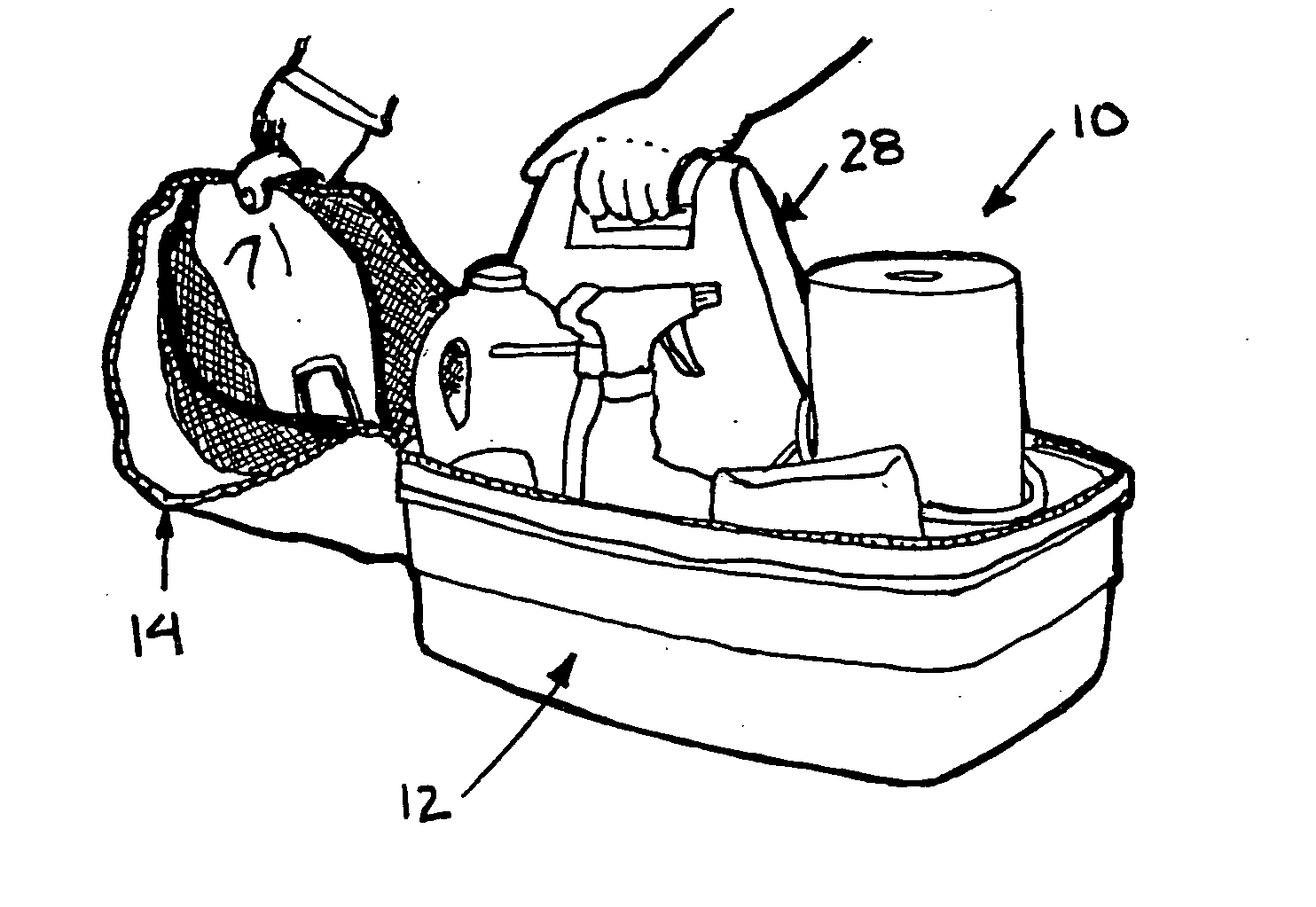

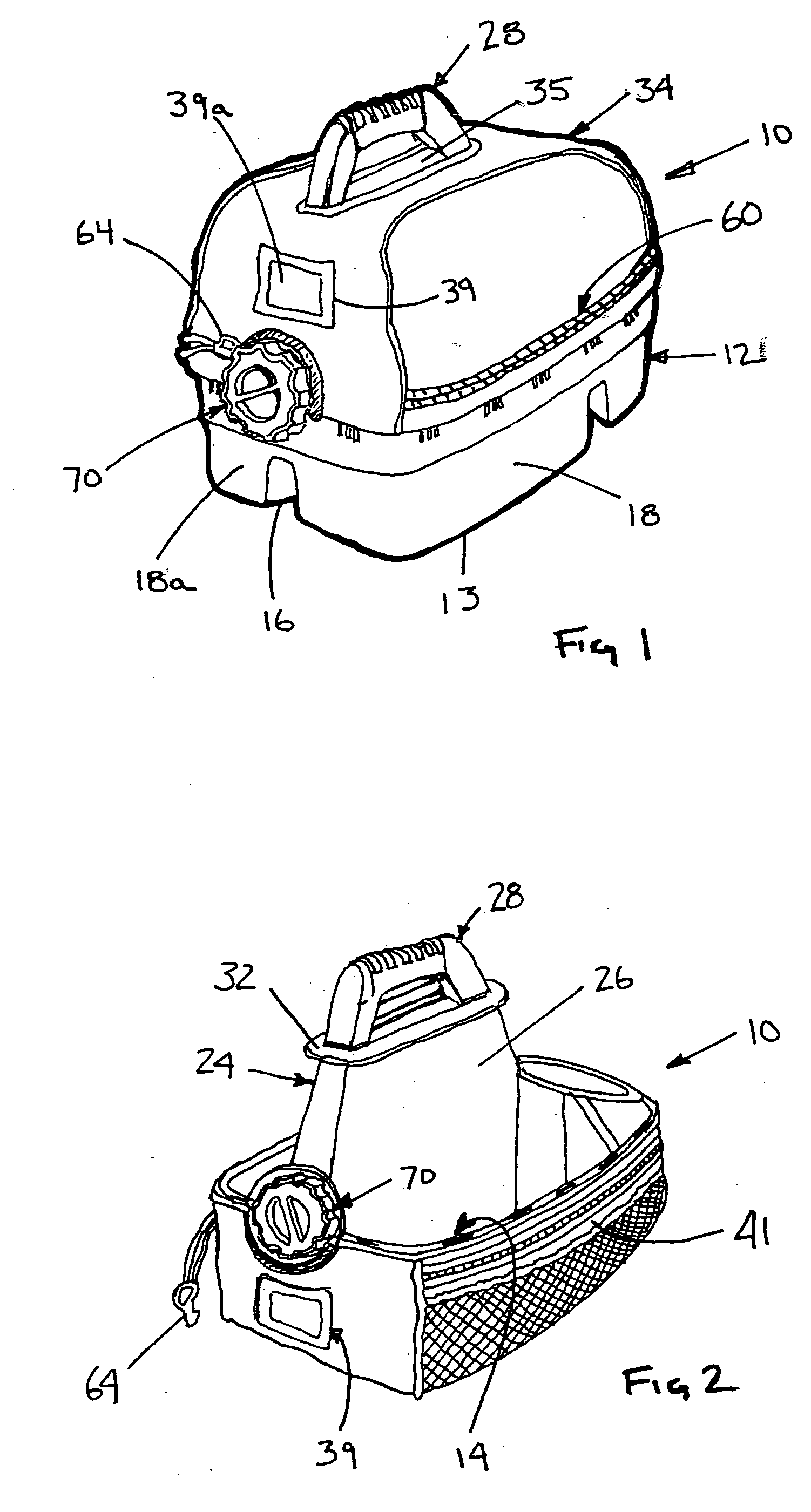

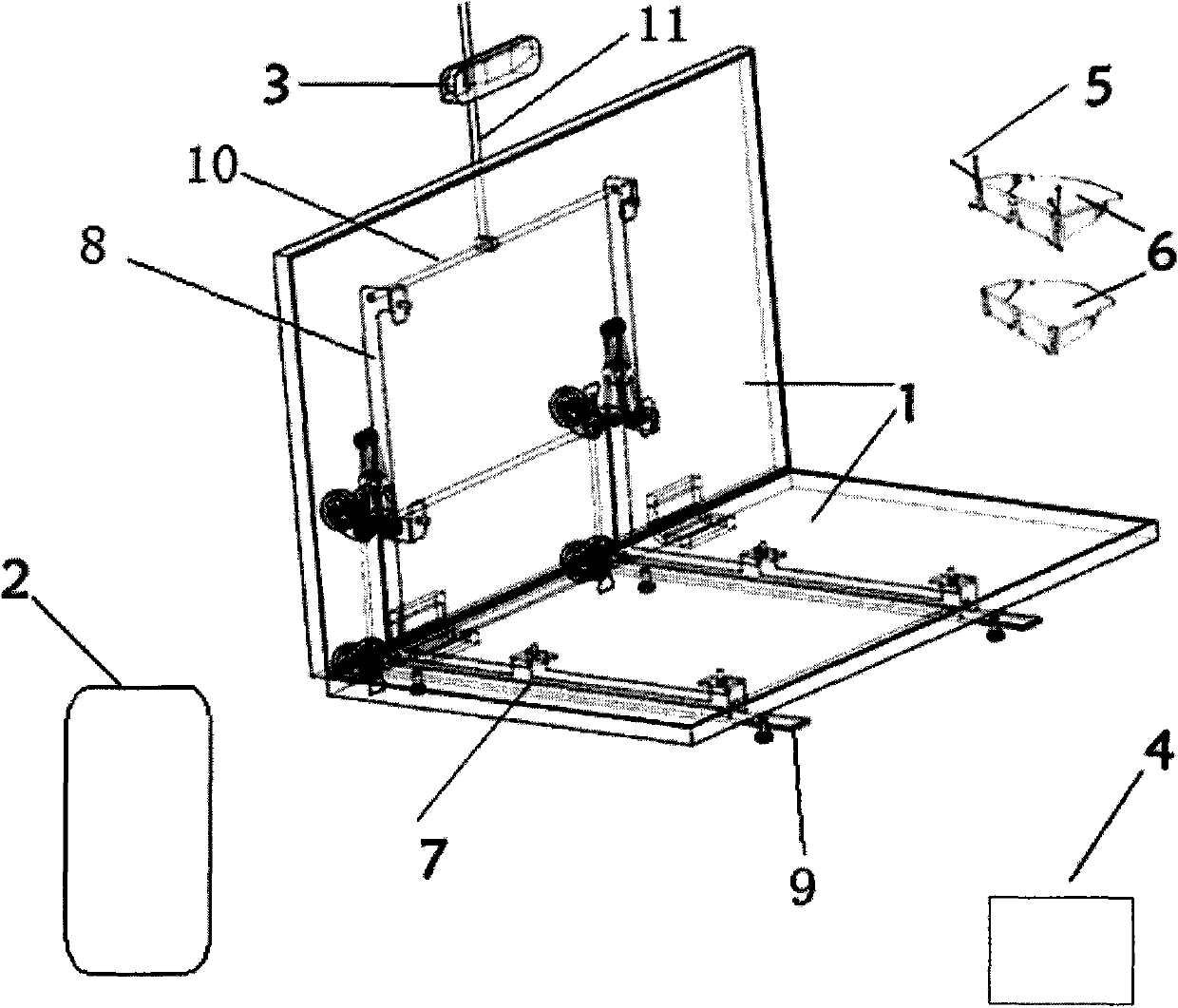

Portable carrier

InactiveUS20050045640A1Safeguard storageSafe and convenient transportationCarpet cleanersFloor cleanersEngineeringElectrical and Electronics engineering

A portable carrier includes a base housing and a cover member secured to the base housing. The base housing is provided with an internal cavity defined by a bottom wall and an enclosing wall extending substantially upwardly from the bottom wall. The cover member is adapted for selectively reconfiguring the portable carrier between a first, closed position preventing access to the internal cavity and a second, open position providing access to the internal cavity. The cover member is dimensioned to closely conform an outer peripheral surface of the base housing so that in the second position the cover member is nested under the base housing over and around the outer peripheral surface thereof. The portable carrier further includes a child-resistant locking device provided for preventing the portable carrier from being open.

Owner:INNOVATIVE DESIGN SOLUTIONS

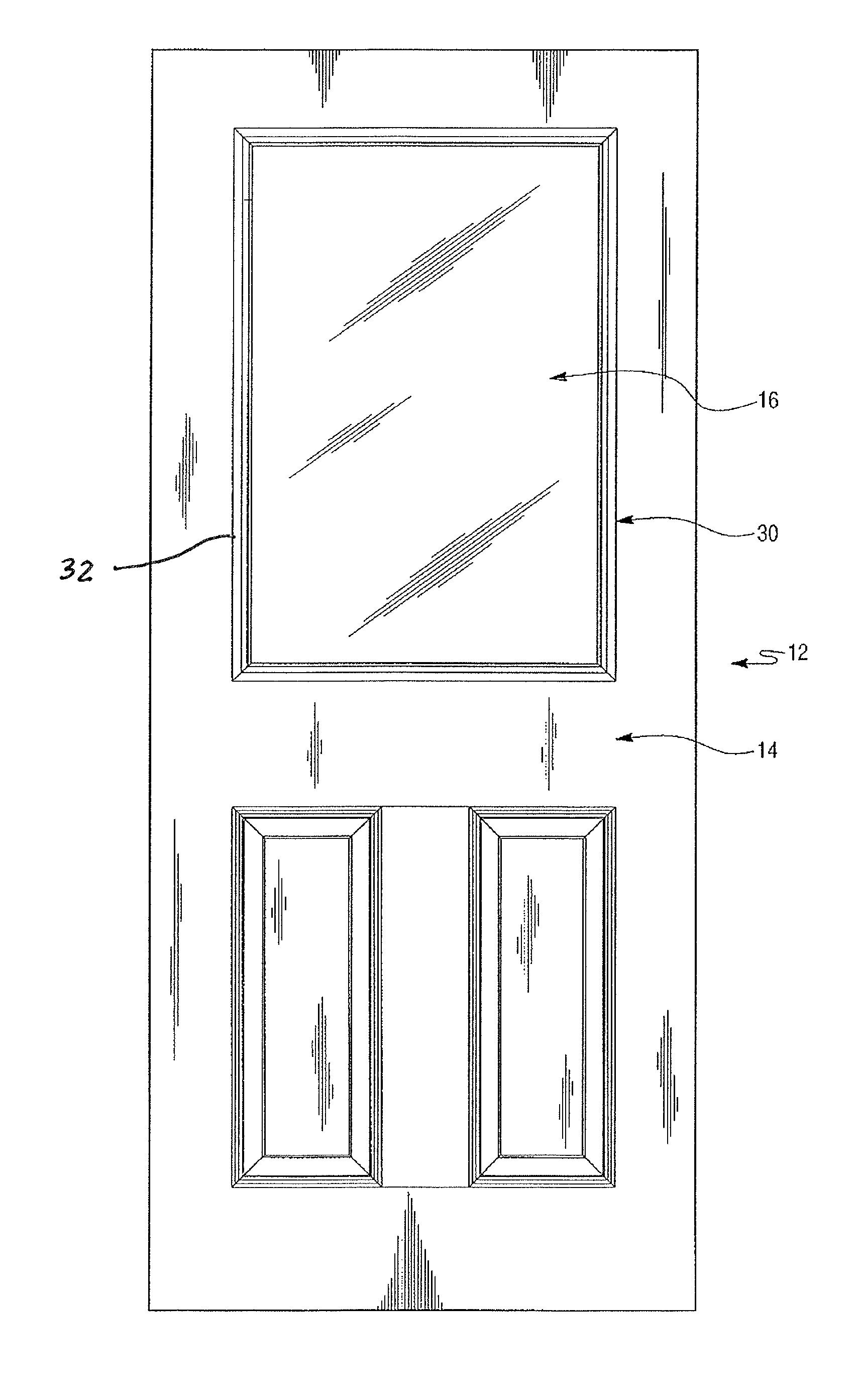

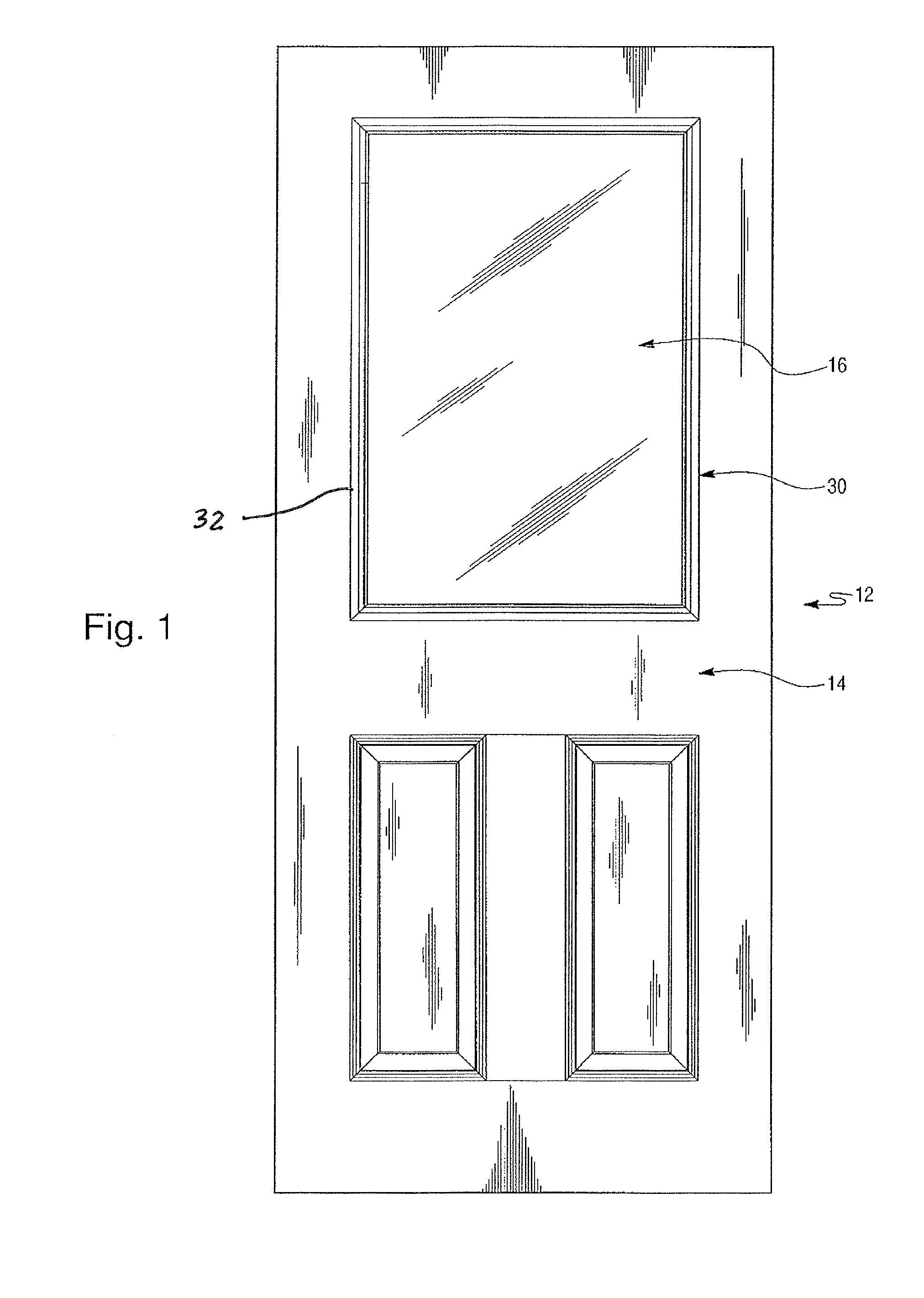

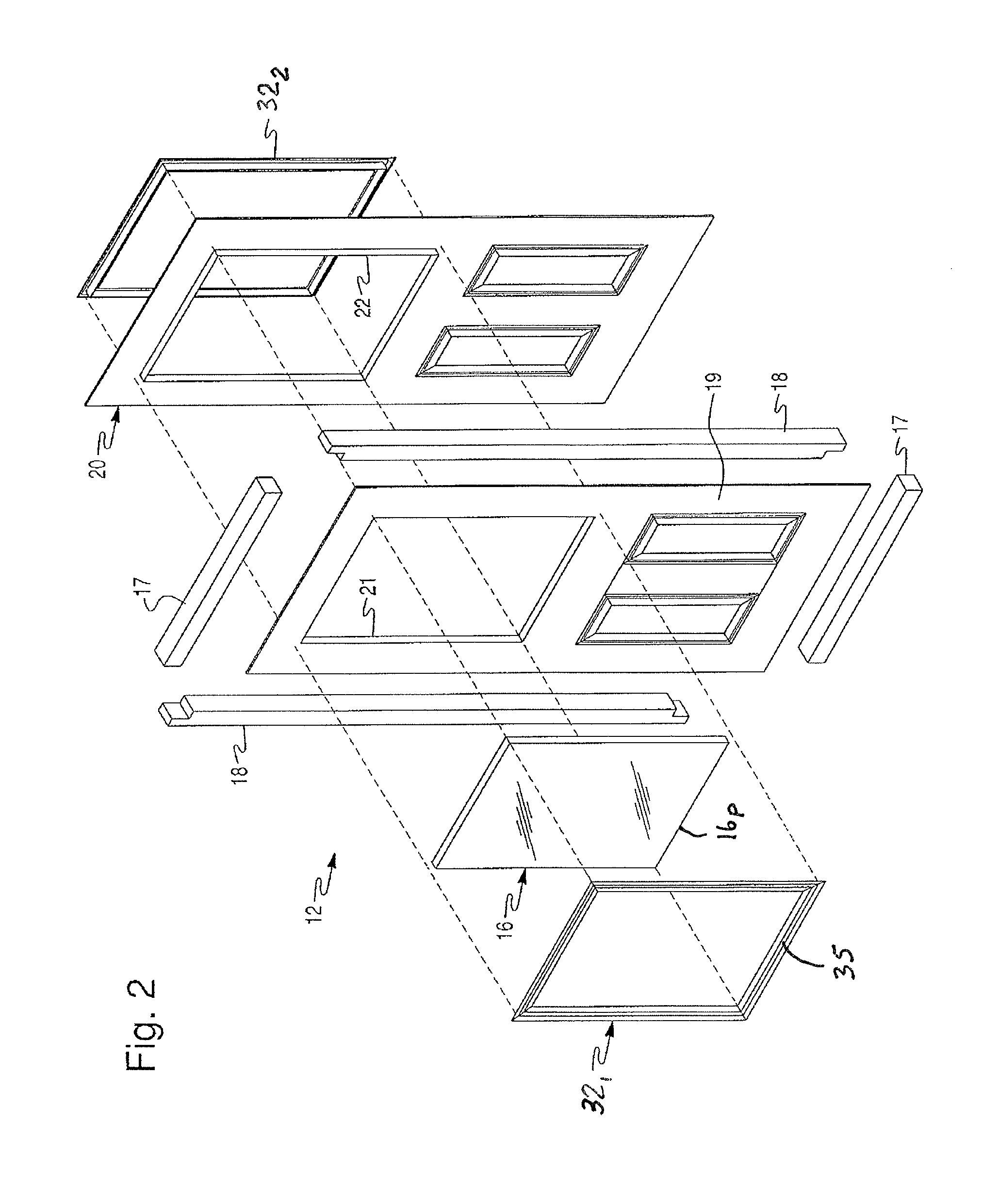

Door lite frame with nestable frame components

InactiveUS8707639B2Safe and convenient transportationWindow/door framesEngineeringMechanical engineering

Owner:MASONITE CORP

Solid preparation of chlorine dioxide

The invention relates to the technical field of disinfectants, in particular to a solid preparation of chlorine dioxide. In recent years, various types of solid preparations of chlorine dioxide packed in single-ingredient are developed, but a common defect exists, namely the content of chlorine dioxide is low, no more than 8 percent in general, and the application range is limited. In the technical scheme of the invention, a mass part ratio of the components is as follows: 40 to 42 parts of sodium chlorite (NaClO2), 0 to 16 parts of sulfamic acid (NH2SO3H), 20 to 44 parts of sodium bisulphate (NaHSO4.H2O), 0 to 6 parts of magnesium sulfate (MgSO4.7H2O) and 18 to 22 parts of sodium dichloroisocyanurate (C3O3N3Cl2Na). In the solid preparation of chlorine dioxide of the invention, the content of chlorine dioxide can reach over 20 percent.

Owner:张家口市净宇天成化工有限公司

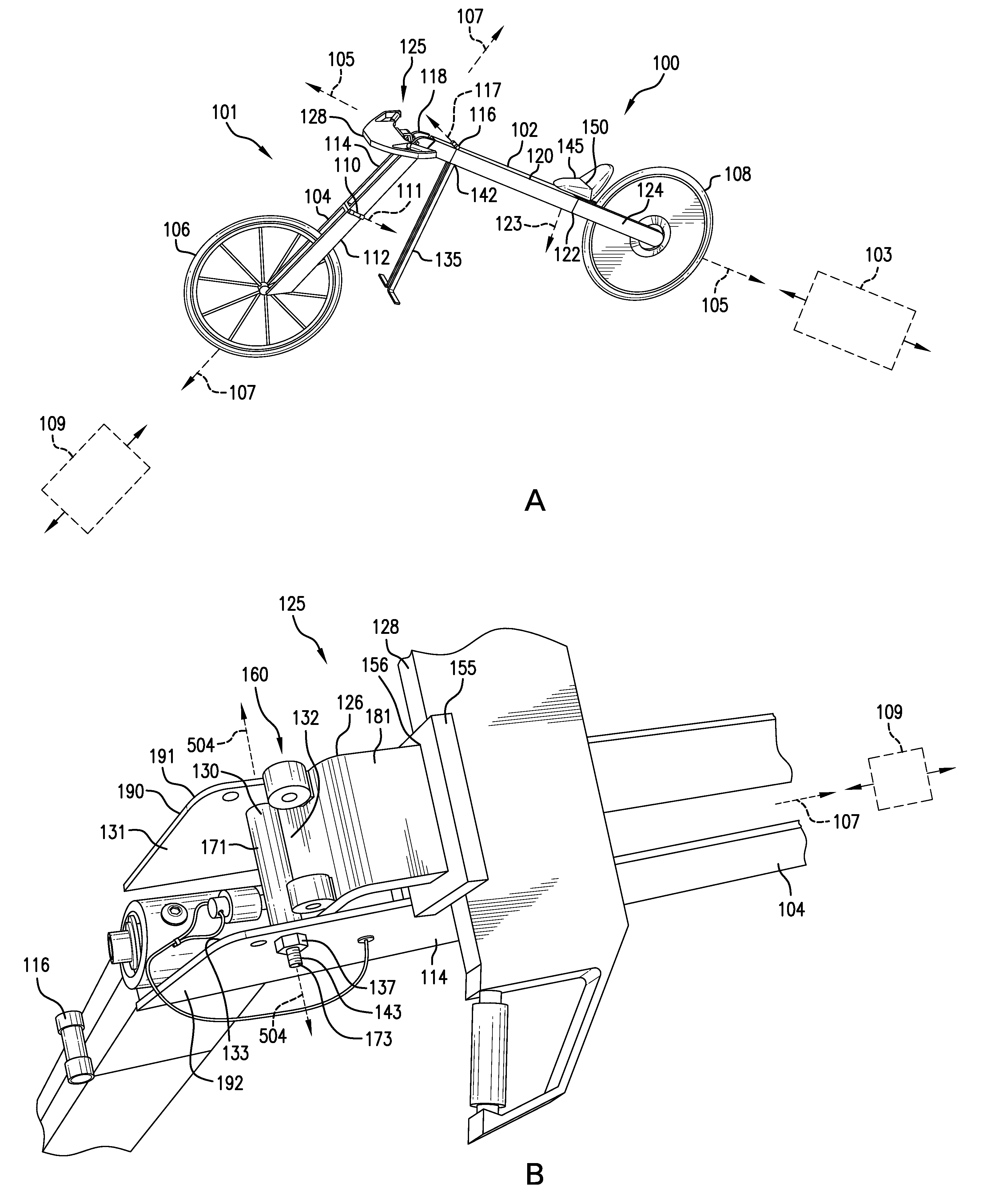

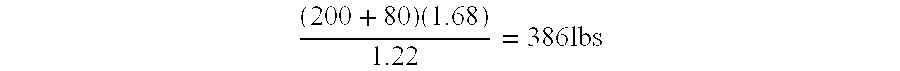

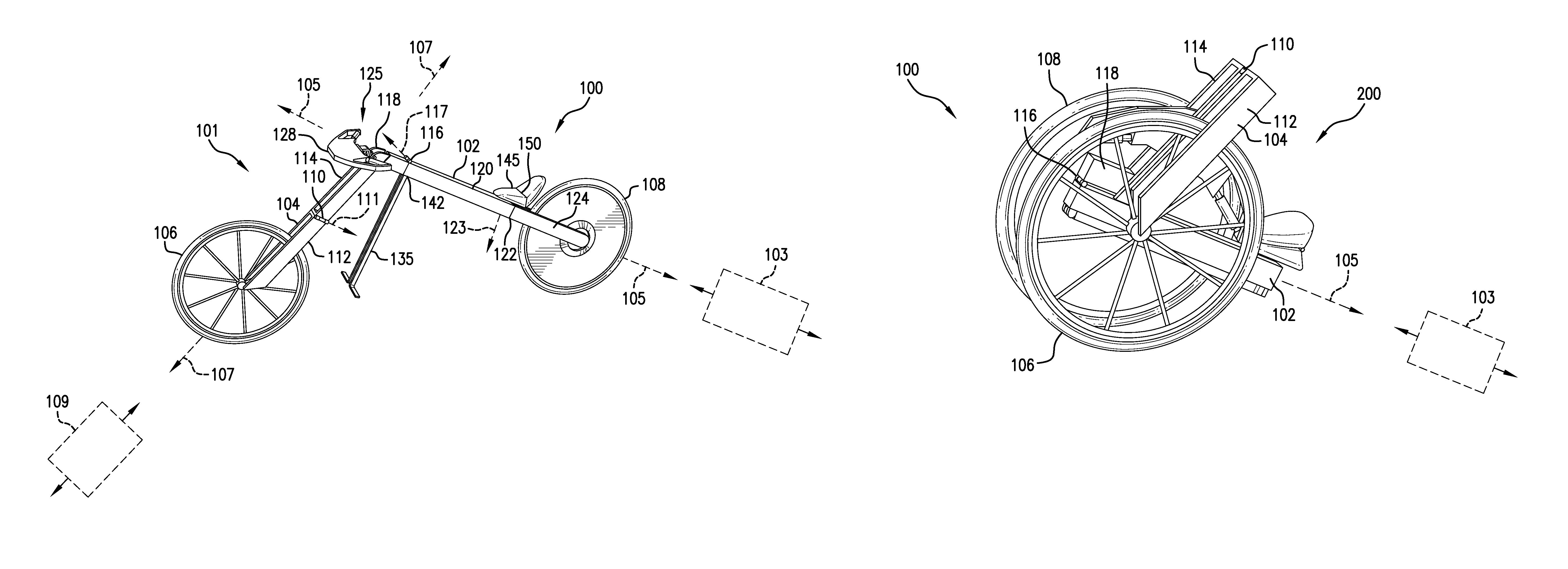

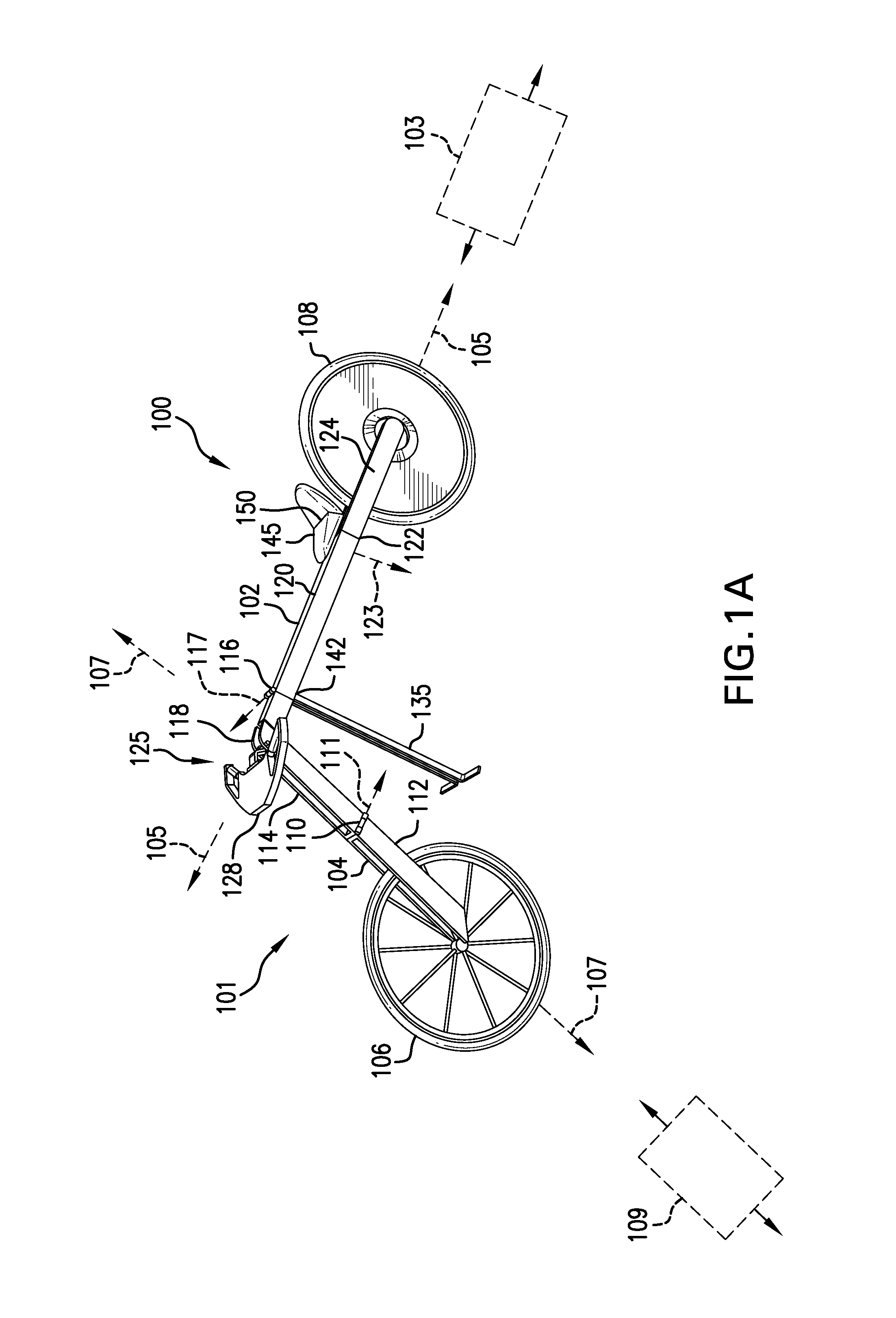

Folding bicycle and method of use

ActiveUS20140077474A1Easy to foldEasy to storeFoot-driven leversWheel based transmissionEngineeringMechanical engineering

Owner:PRIEST RICHARD +2

Method of constructing a wall or roof using a contained load transfer device for wood sheathing products

InactiveUS20070240374A1Easy to installSimple and reliable connectionRoof covering using slabs/sheetsBuilding roofsAdhesive beltUltimate tensile strength

The utilization of a specific load transfer device for the purpose of allowing for reliable connection and adhesion of composite wood boards during edifice manufacture therewith is provided. Such a device is configured for containment within slots cut into the peripheral edges of such wood boards and cut into a shape therein that is complementary to that of the device itself. In such a manner, the device, when introduced within the properly shaped slot, permits separation of adjacent wood boards that are sequentially applied to the frame of the target edifice, as well as, ultimately, sufficient load bearing strength for the overall construction (such as a roof) within which such connected wood boards are utilized. The separation of wood boards thus permits proper sealing therebetween (with tape, sealant, or other like material) as well as proper distance for shrinking or swelling (due to moisture / temperature variations) to be taken into account during the lifetime of the edification (thereby permitting expansion as needed). The ability to impart increased load bearing strength thus allows for an increase in construction materials (in number and in weight) to be carried and kept on such a structure during construction as well. The method of manufacture of an edifice utilizing such load transfer devices between wood boards is also encompassed within this invention.

Owner:HUBER ENGINEERED WOODS

Folding bicycle and method of use

ActiveUS8789840B2Easy to foldEasy to storePassenger cyclesWheel based transmissionEngineeringMechanical engineering

Owner:PRIEST RICHARD +2

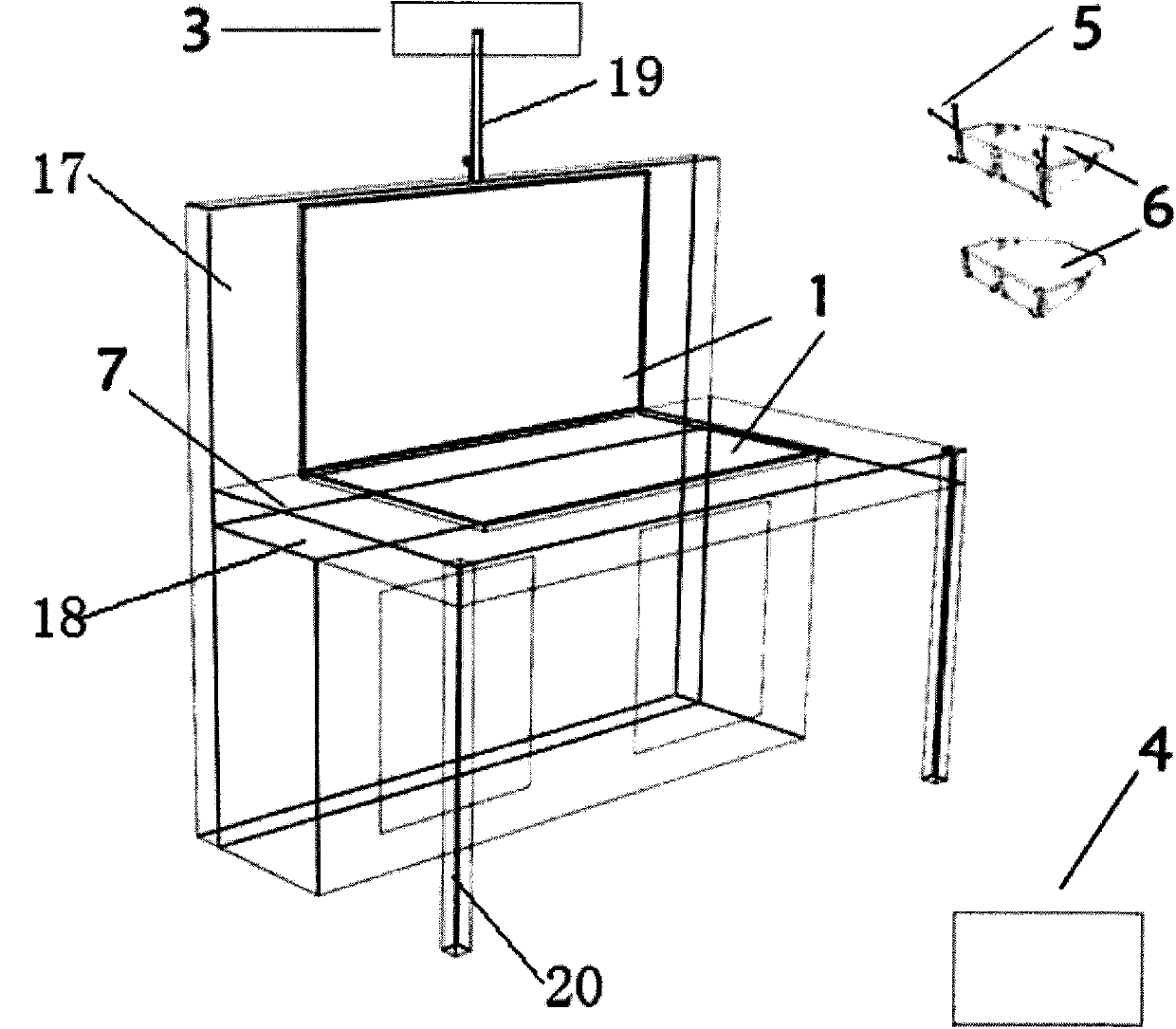

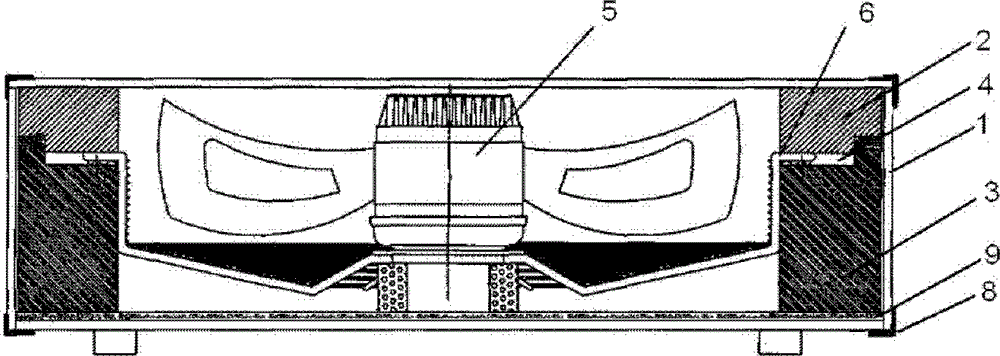

Stereo display system

InactiveCN103631024AGood value for moneySolve the requirements of high quality and high immersionInput/output for user-computer interactionGraph readingGraphicsLiquid-crystal display

The invention provides a stereo display system realizing realtime positioning and tracking of a stereo graph picture. The stereo display system comprises two 3D (three dimensional) liquid crystal displays which are vertical to each other, one server, one piece of positioning equipment, one handheld roaming service device, a plurality of pairs of stereoscopic glasses and a bracket for supporting the two 3D liquid crystal displays, wherein the server is respectively connected with the 3D liquid crystal displays, the handheld roaming service device and the positioning equipment which performs realtime tracking on human eye positions, a user can freely change view angles and can acquire correct stereo images in time, and sufficient man-machine interaction is realized. The stereo display system provided by the invention is high in cost performance, meets the requirement of virtual reality demonstration images on high quality and high immersion, realizes realtime positioning and tracking of the 3D stereo graph picture, realizes the function of sufficient man-machine interaction, is low in platform hardware cost and is more advantageous in price relative to other 3D stereo display modes.

Owner:BEIJING WINCOMN TECH DEV

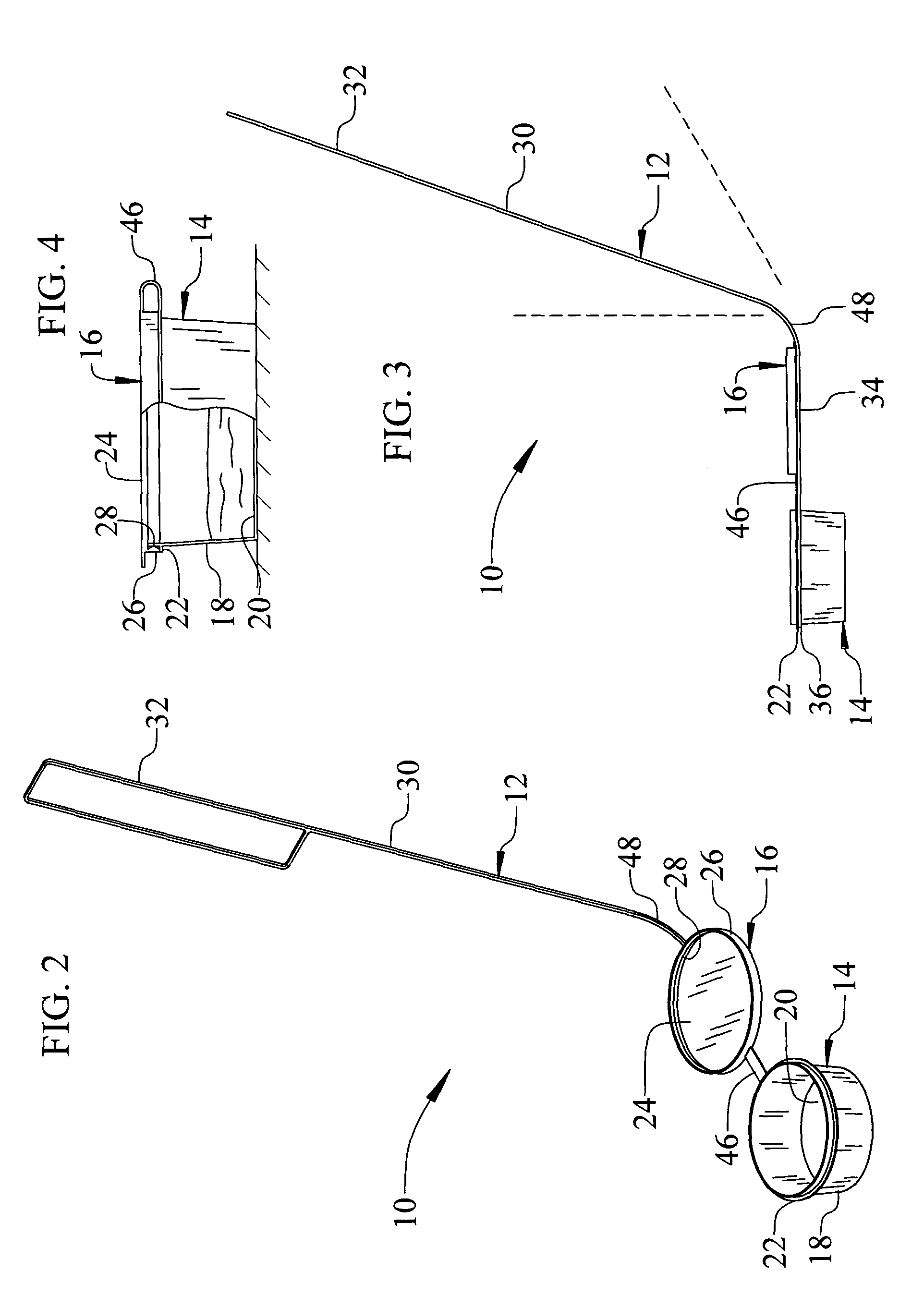

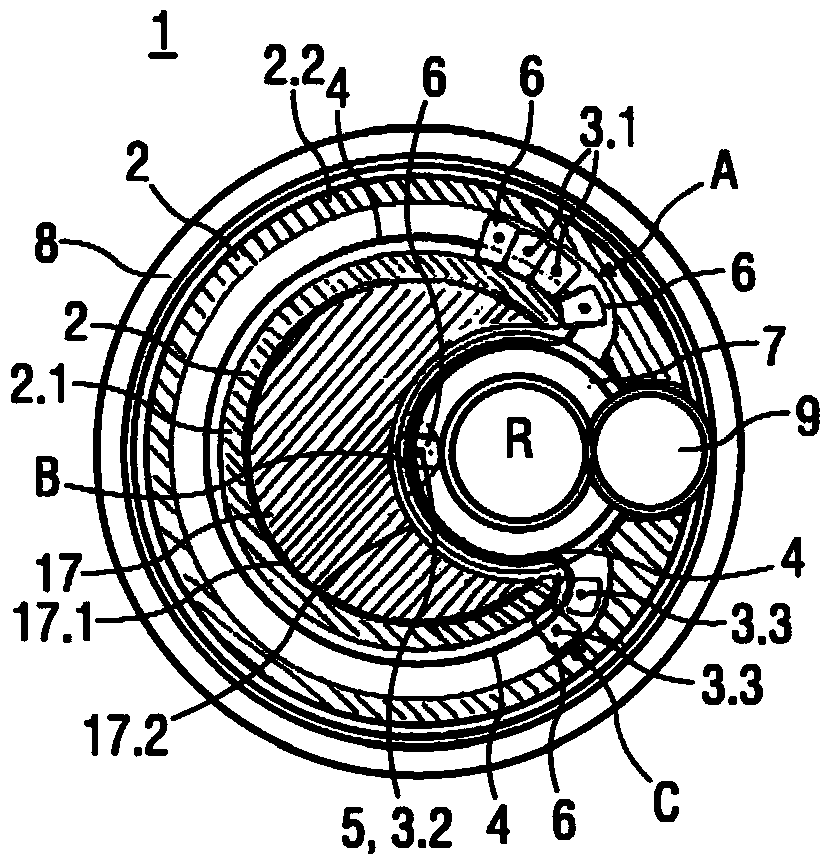

Needle storage magazine

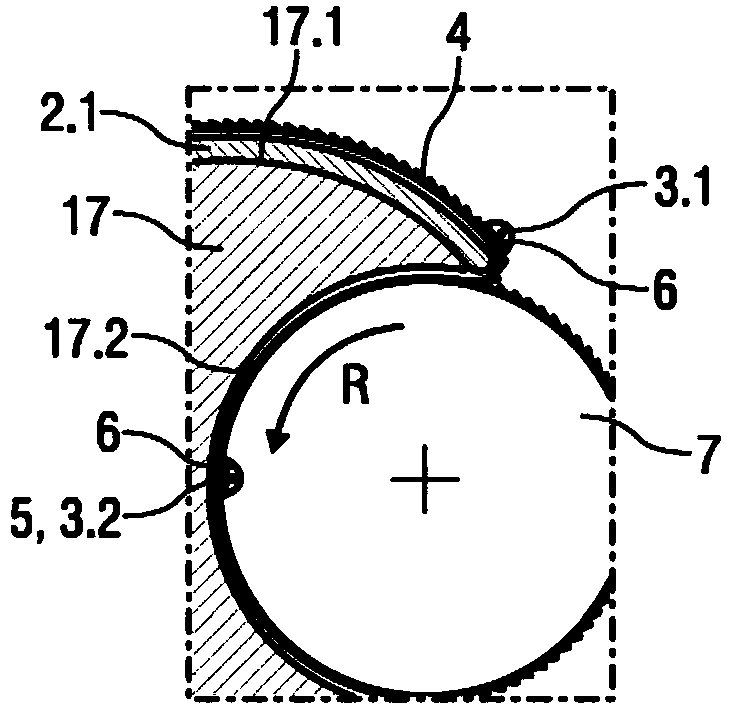

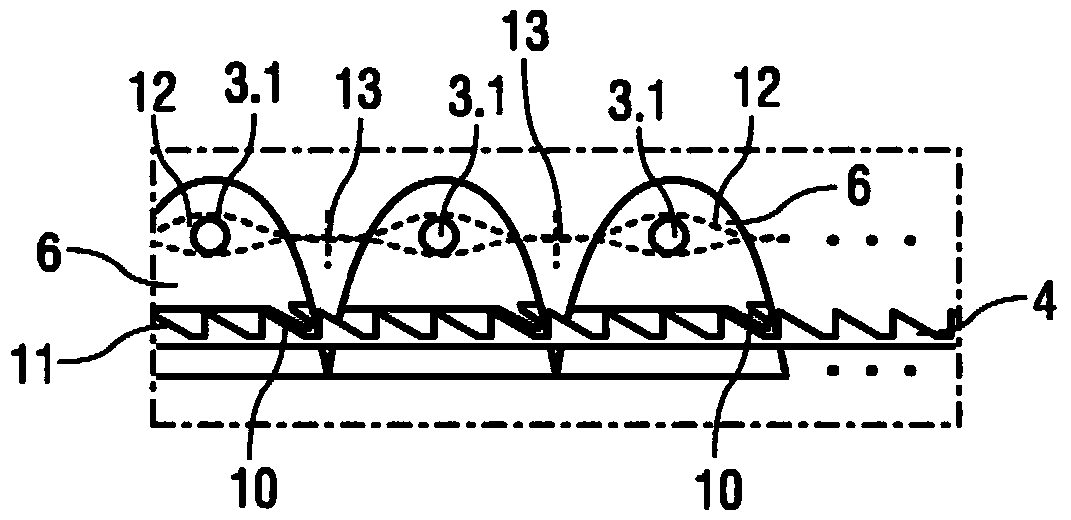

InactiveCN104114207ASafe and convenient transportationImprove securityInfusion needlesCarriageSyringe needle

The invention relates to a needle storage magazine (1) for storing a number of injection needles (3.1, 3.2, 3.3) and attaching and / or detaching them to or from an injection device (14), the needle storage magazine (1) comprising a crescent shaped track having a convex part and a concave part, wherein the track is adapted to hold a set of needles (3.1, 3.2, 3.3) in respective needle supports (6) within the track, wherein the convex part is adapted to hold unused needles (3.1) and used needles (3.3), wherein a centre position (B) is defined within the concave part for a needle (3.2) in use or to be used, wherein a sliding carriage (17) is arranged for attaching the injection device (14) to the needle storage magazine (1) such that the centre position (B) is essentially concentric to a longitudinal axis (5) of the injection device (14), wherein a separation wheel (7) is rotatably arranged, the separation wheel (7) having at least one notch (15) for entraining the needle support (6) of one unused needle (3.1) at a time from the convex part into the centre position (B) or the needle support (6) of the needle (3.2) in use out of the centre position (B) onto the convex part.

Owner:SANOFI AVENTIS DEUT GMBH

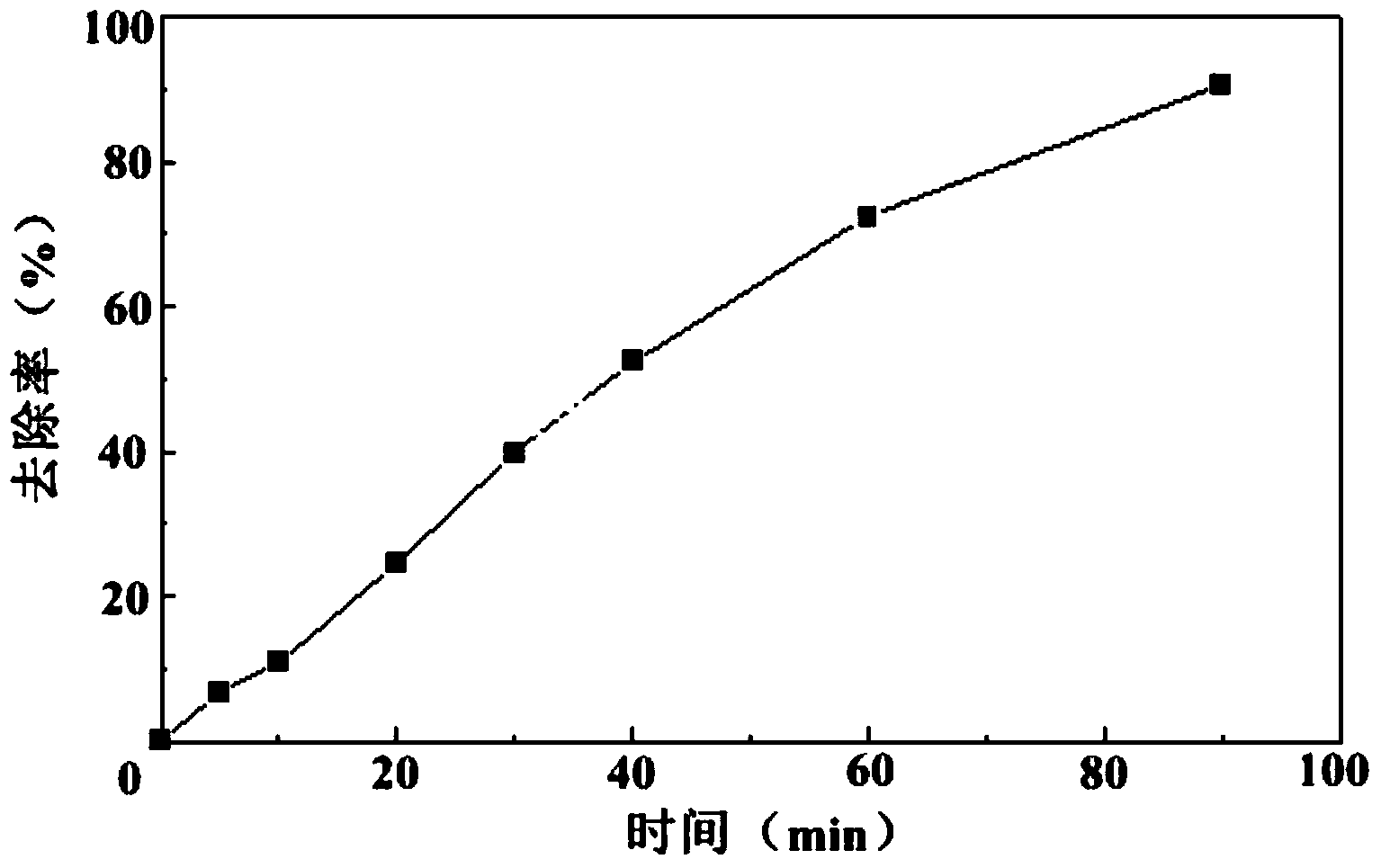

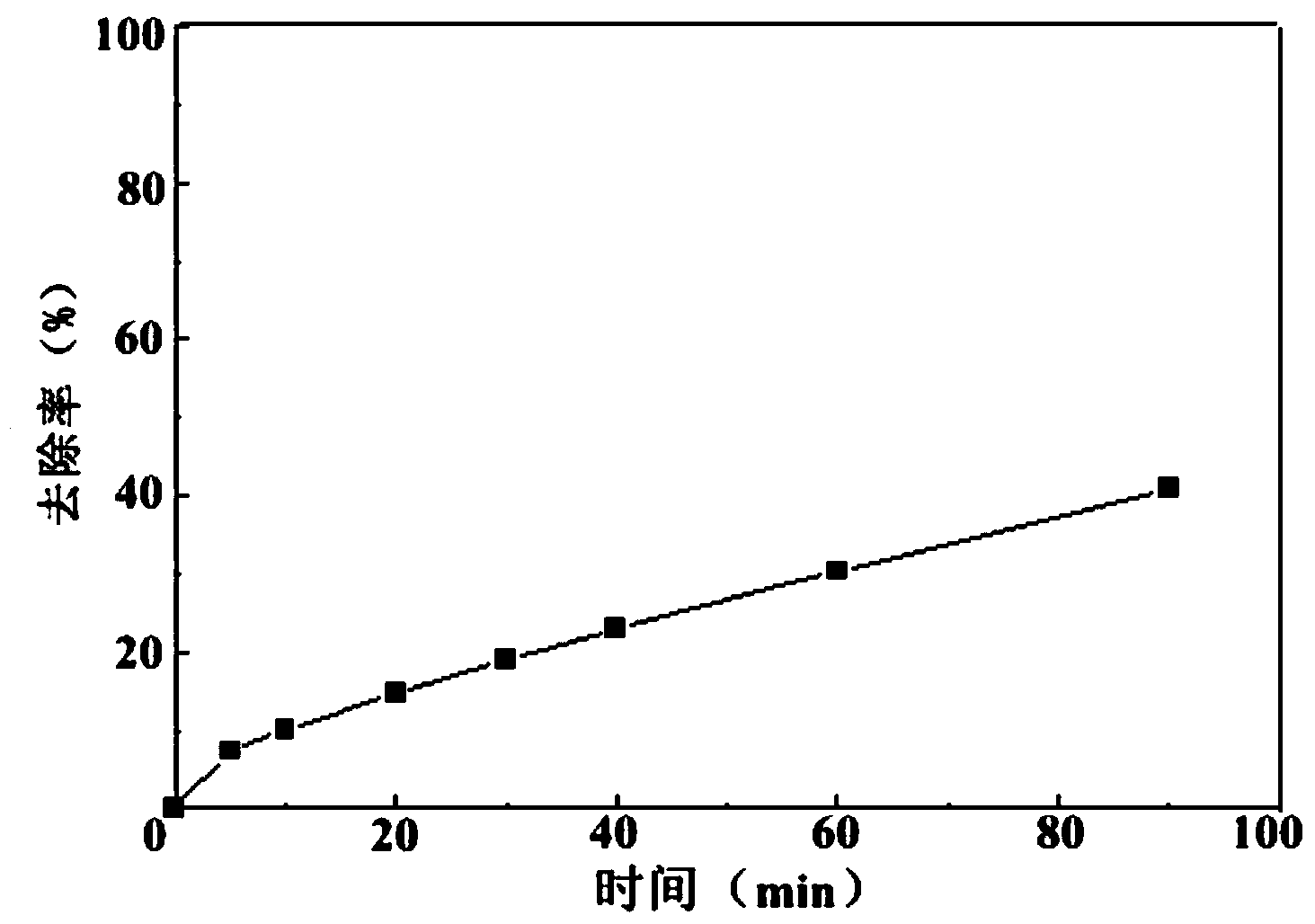

Method for water treatment through permanganate homogeneous catalytic oxidation

InactiveCN103523894AHigh removal rateImprove water qualityWater contaminantsWater/sewage treatment by oxidationCatalytic oxidationSURFACTANT BLEND

The invention provides a method for water treatment through permanganate homogeneous catalytic oxidation, and relates to a method for water treatment. The method is to solve the problem of low removal rate of organic pollutants in existing methods water treatment. The preparation method is as follows: surfactants and permanganate are added in raw water; after stirring and dissolving, the mixture is subjected to air floatation; the scum layer is scraped, and the processed raw water is obtained. The removal rate of organic pollutants is above 90% during the water treatment process. When only potassium permanganate is added for oxidation, the removal rate of organic pollutants in water is only 40%. The removal rate of organic pollutants in water is increased by 50%. The method is used for removing organic pollutants in water.

Owner:HARBIN INST OF TECH

Sulfur-fixation, denitration and coke-cleaning additive for coal-fired boiler

InactiveCN107739642AImprove breathabilityAccelerated destructionSolid fuelsEmission standardRare earth

The invention discloses a coal-fired boiler sulfur-fixing, denitrification and coke-clearing additive, which is composed of the following raw materials in parts by weight: 8-20 parts of nano-titanium dioxide; 20-50 parts of natural marble; 1-6 parts of rare earth components; 20-20 parts of nitrate 30 parts; 3-10 parts of plant ash; 5-10 parts of activated carbon; each raw material in said parts by weight is stirred evenly and added to coal powder for further mixing. The invention can effectively reduce coal consumption, reduce sulfur dioxide emission rate and nitrogen oxide emission, and has coke cleaning effect, realize effective sulfur fixation, denitrification and coke cleaning, stable performance, high coal saving rate, high emission reduction rate, simple use and convenient application Advantages, what is more characteristic is that it overcomes the defects of traditional pulverized coal boilers relying on external exhaust pipes to implement flue gas desulfurization and denitrification equipment with large investment and poor results. The invention is combined with the traditional flue gas wet desulfurization and denitrification process, can effectively reduce the desulfurization and denitrification cost of enterprises, and fully complies with the national air pollution emission standards.

Owner:李旺

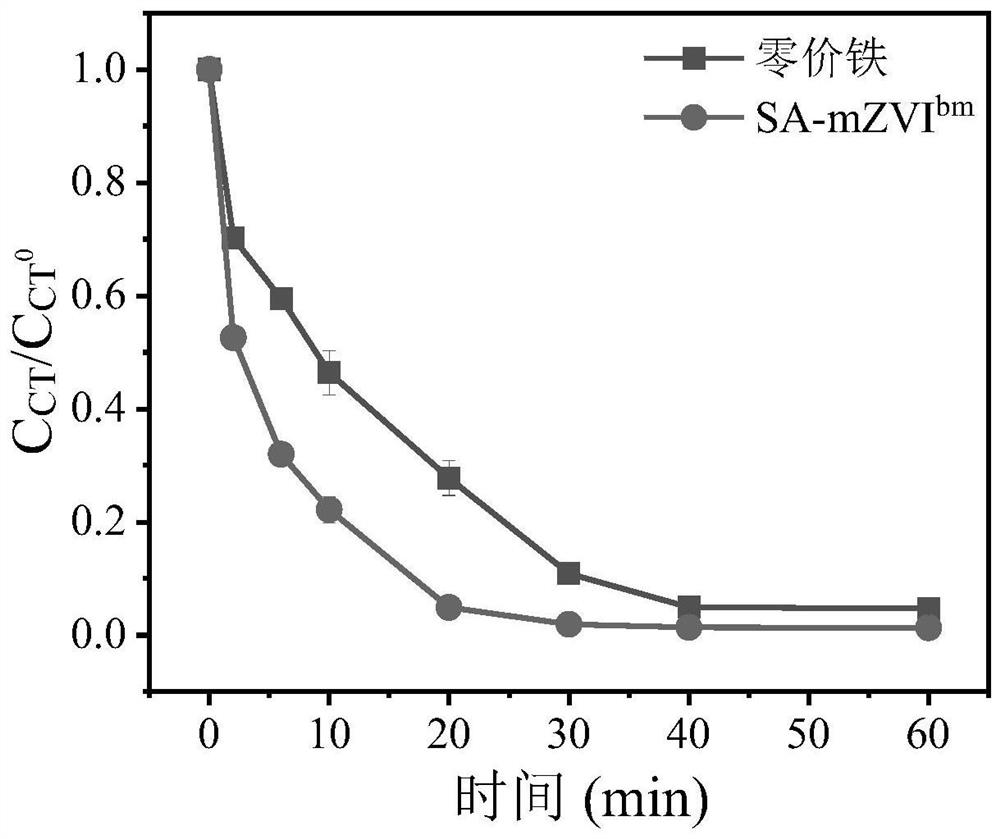

Preparation method and application of stearic acid modified zero-valent iron composite material

PendingCN112139507AInhibition of cold weldingIncreased fracturing rateTransportation and packagingMetal-working apparatusZerovalent ironStearic acid

The invention discloses a preparation method and application of a stearic acid modified zero-valent iron composite material. The preparation method comprises the following steps: in a vacuum or inertgas atmosphere, mixing stearic acid and iron powder according to the mass ratio of 1: 125-2000, then carrying out ball milling, and obtaining the stearic acid modified zero-valent iron composite material after ball milling is finished. According to the method, the stearic acid and the iron powder are mixed and then subjected to ball milling, and the stearic acid is used as a process control agentto be adsorbed onto new surfaces of particles; and the particle surface state is changed by hindering collision required by intermetallic cold welding and reducing the surface activity of the powder particles, so that cold welding is inhibited, the intergranular fracturing rate is increased, and finally the removal efficiency of the stearic acid modified zero-valent iron composite material on heavy metals and organic pollutants is improved.

Owner:ZHEJIANG UNIV OF TECH

Welding flux used for ferrum-based material heat-released jointing and igniting agent thereof

ActiveCN103894755AAccelerateLarge heat releaseWelding/cutting media/materialsSoldering mediaFerrosiliconLanthanum

The invention relates to a welding flux used for ferrum-based material heat-released jointing and an igniting agent of the welding flux. The welding flux and the igniting agent aim to solve the problems that supply of welding fluxes special for heat-released jointing of ferrum-based materials is not enough, welding joints acquired through prior heat-released jointing welding fluxes contain impurities, large residual stress is caused by difference in coefficients of thermal expansion, and welding joint performance is poor. The welding flux used for ferrum-based material heat-released jointing is composed of ferric oxide powder, 304 stainless steel powder, commercial-purity aluminum powder, niobium powder, copper powder, ferrosilicon powder, ferromanganese powder, fluorite powder, marble powder and lanthanum-cerium alloy powder. The igniting agent of the welding flux used for ferrum-based material heat-released jointing is composed of magnesium powder, barite powder, commercial-purity aluminum powder, red phosphorus powder and fluorite powder. In the using process, the weight ratio of the welding flux used for ferrum-based material heat-released jointing to the igniting agent is (50-60):1. The welding flux and the igniting agent are used for ferrum-based material jointing.

Owner:HARBIN INST OF TECH

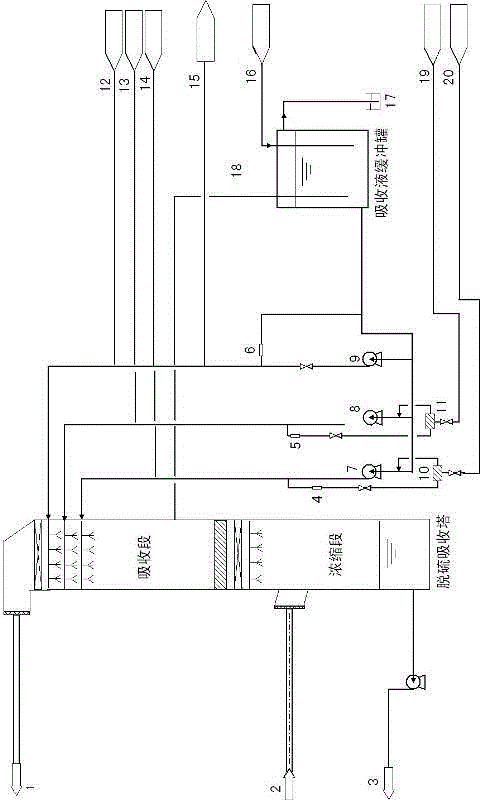

Two-phase ammonifying method of wet ammonia desulfurization process

InactiveCN104147913AEasy to transportPrevent escapeDispersed particle separationBuffer tankGas phase

The invention relates to a two-phase ammonifying method of a wet ammonia desulfurization process. The method comprises the following steps: fully mixing liquid ammonia from a liquid ammonia tank with a solution from an absorbent buffer tank in a static mixer at the outlet of the absorbent buffer tank, and adjusting the additive amount of liquid ammonia according to the pH value of the solution at the outlet of the static mixer; directly adding gas-phase ammonia from the liquid ammonia tank into the absorbent buffer tank by pressure difference, and dissolving in absorption liquid. According to the method, gas-phase ammonia and liquid-phase ammonia in the liquid ammonia tank can be added into a desulfurization system simultaneously, so that the gas-liquid balance of the liquid ammonia tank is guaranteed and the knocking of the absorbent buffer tank caused by direct addition of liquid ammonia is avoided; in addition, liquid ammonia and the solution are fully mixed in the static mixer, so that an ammonia absorbent can be fully utilized and ammonia can be effectively prevented from escaping.

Owner:SHANGHAI UNIV

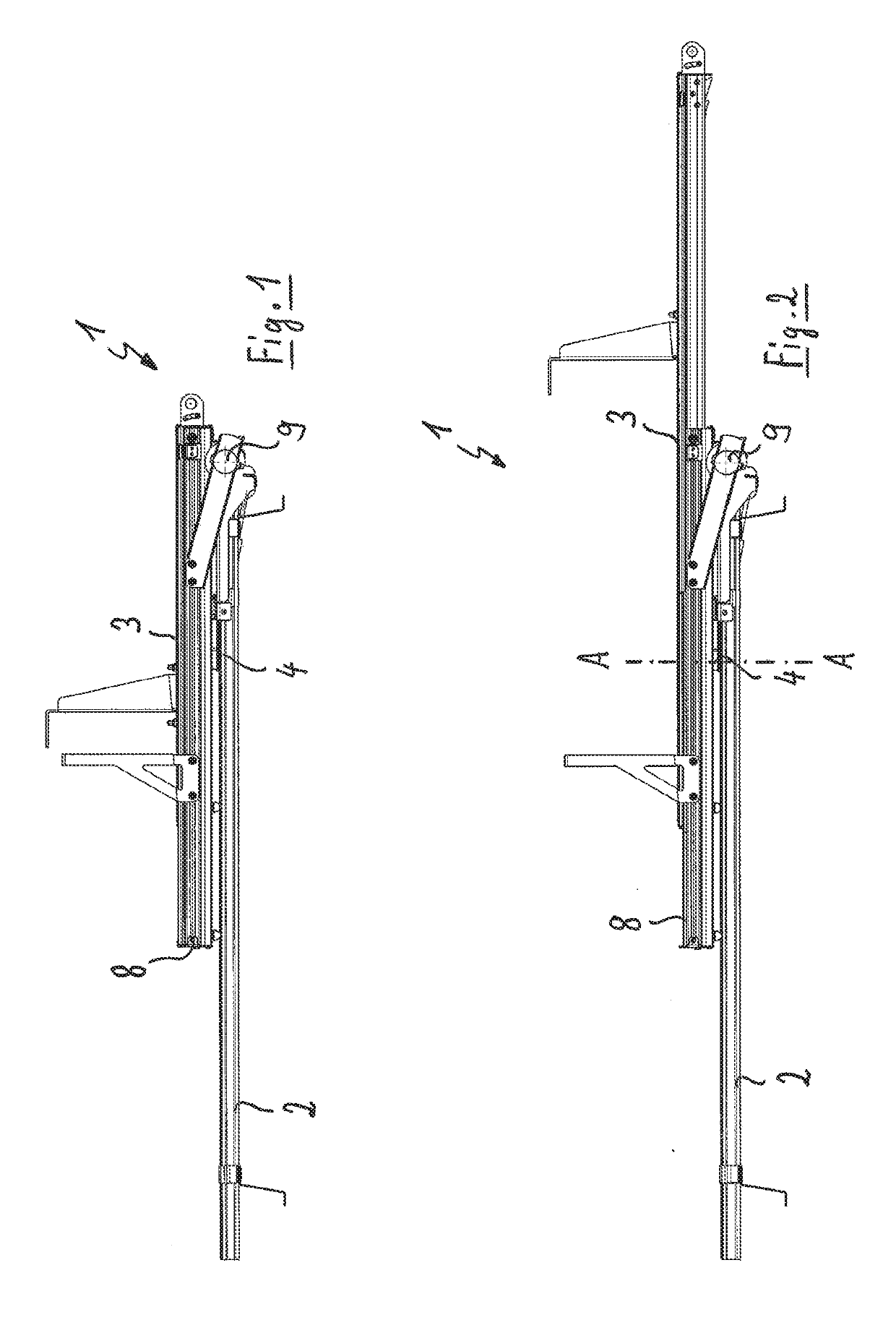

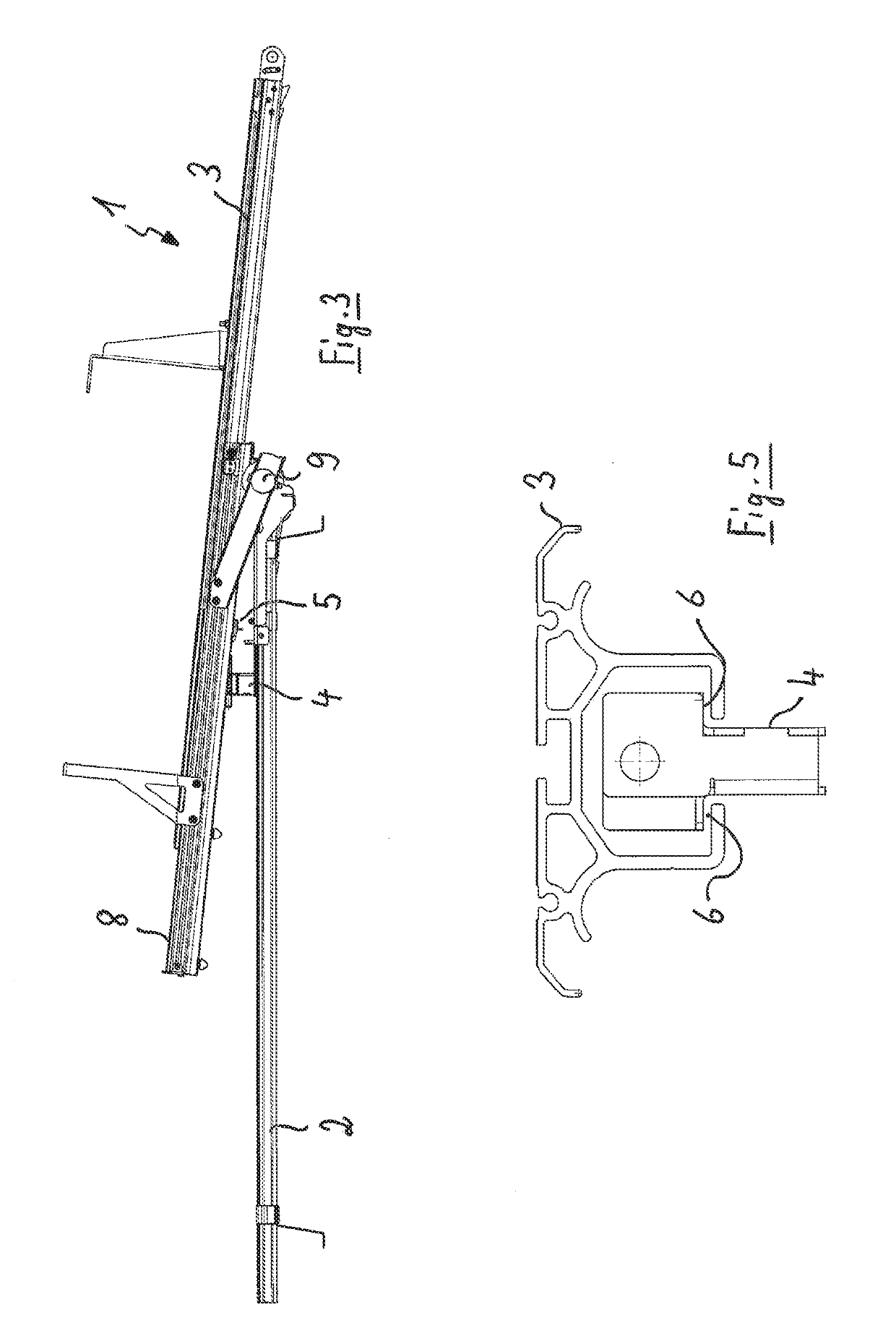

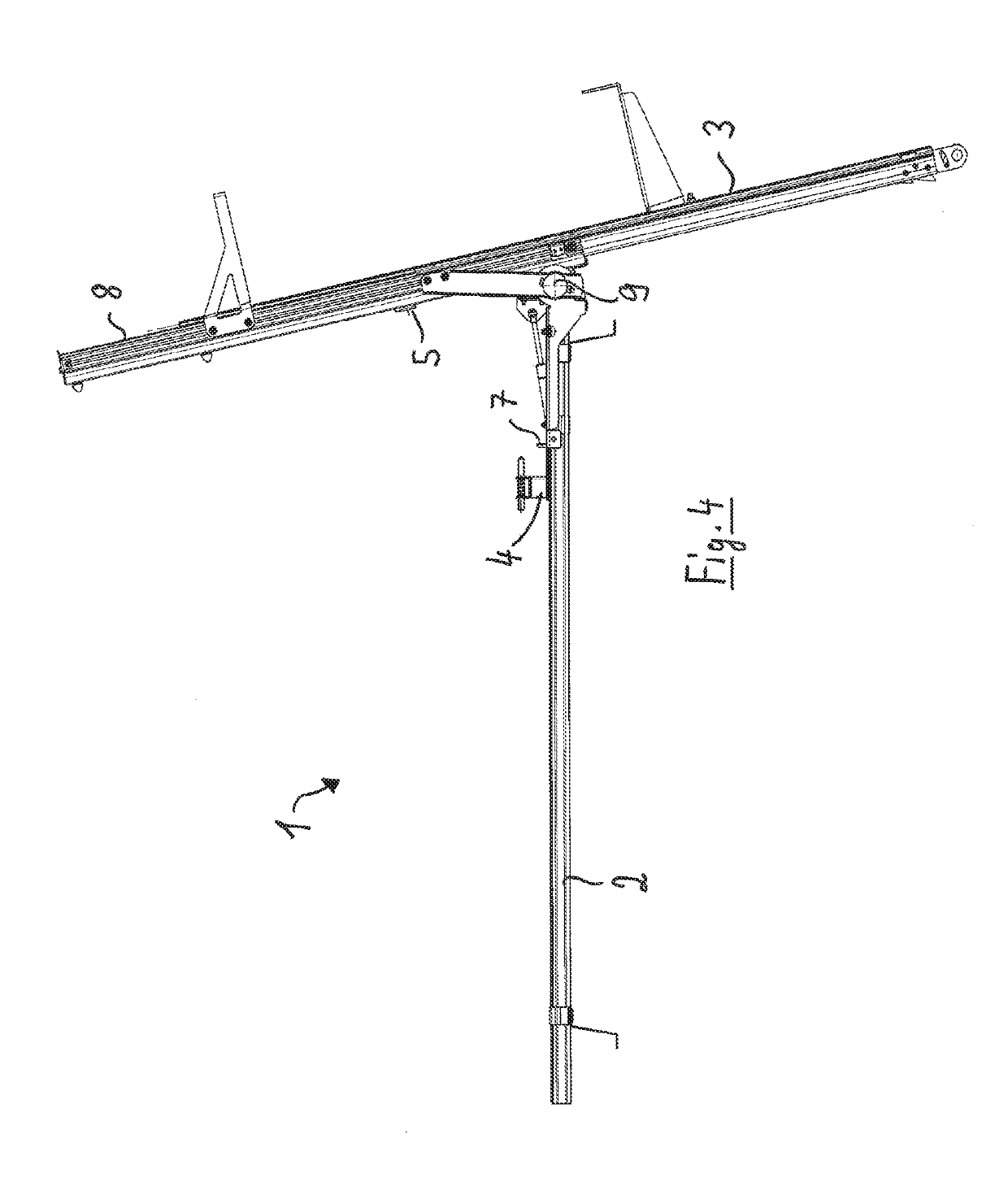

Rooftop cargo carrier

ActiveUS20190248295A1Safe and convenient transportationSupplementary fittingsEngineeringCargo vessel

A rooftop cargo carrier having a rack that can be mounted on the roof of an automotive vehicle and on which a linear rail is disposed, along which linear rail a support structure for an object to be transported can be moved between a transport position, in which the support structure is disposed above the linear rail, and an intermediate position, in which the support structure is disposed on the side as an extension of the linear rail. The configuration comprising the linear rail and the support structure can be pivoted between the intermediate position and a loading position, in which the linear rail and the support structure are disposed at a blunt angle relative to the rack. The rooftop cargo carrier also includes a retainer that allows joint pivoting movement of the linear rail and the support structure relative to the rack only after the intermediate position has been reached.

Owner:SORTIMO INT

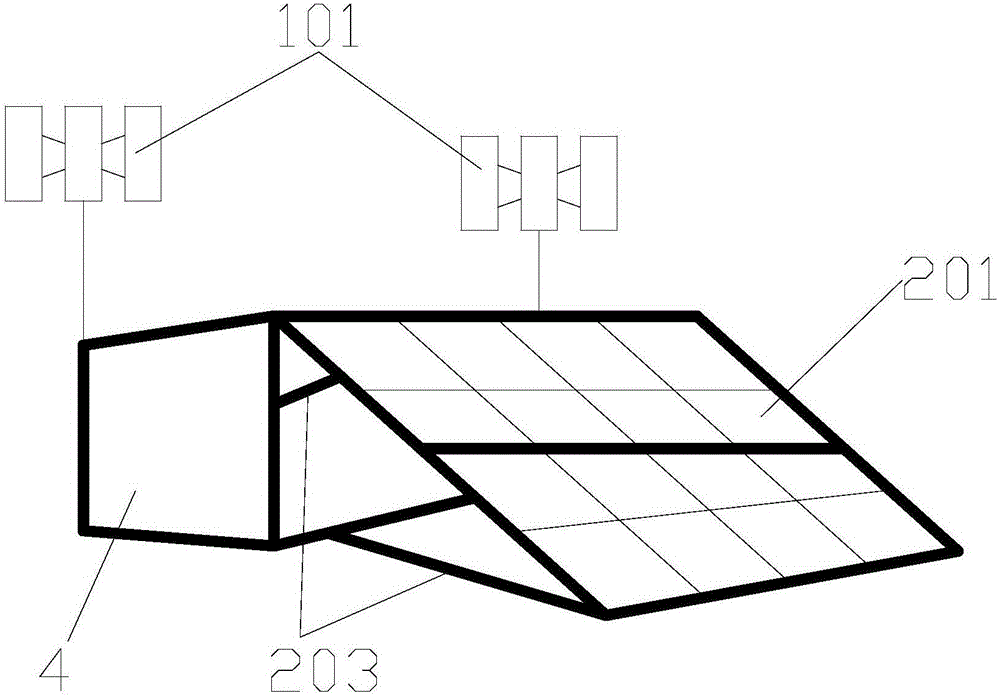

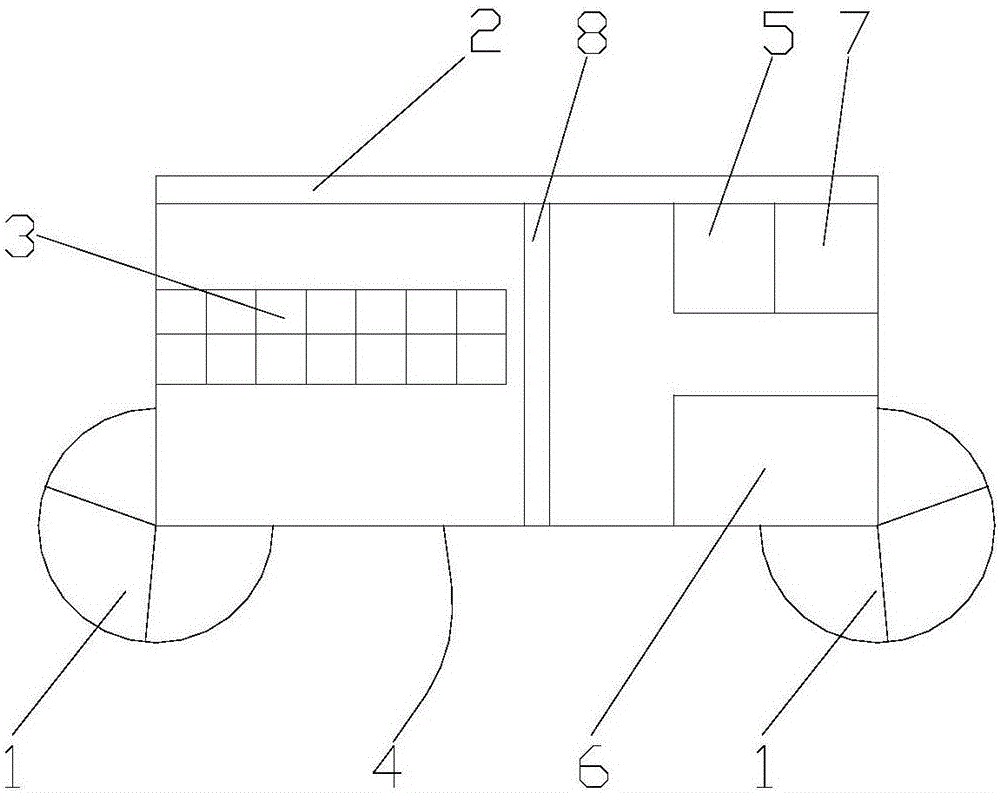

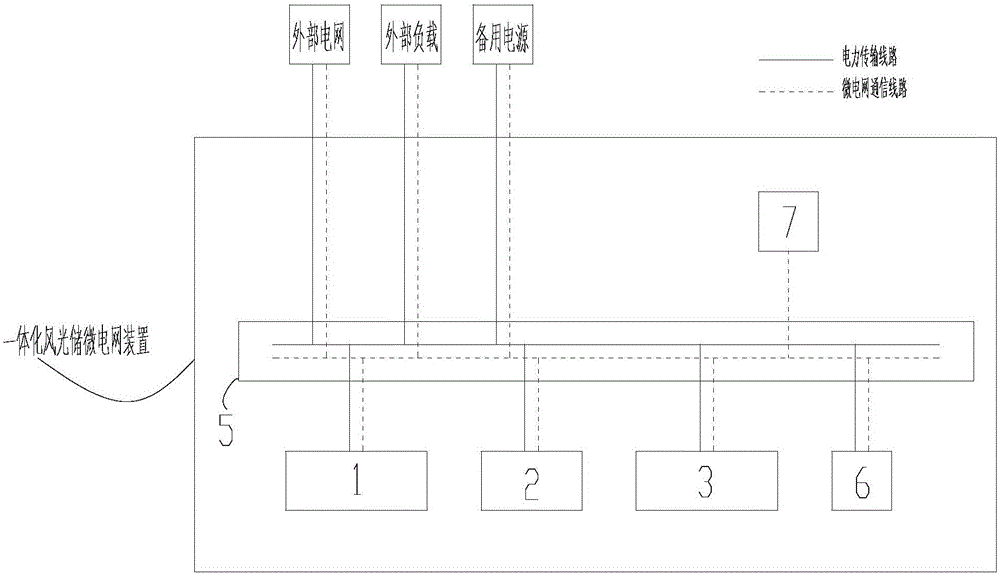

Wind-PV-ES (wind/photovoltaic/energy storage) integrated microgrid device

PendingCN107181283AEasy to integrateSmall footprintBatteries circuit arrangementsPower network operation systems integrationSmart microgridPower grid

The invention discloses a microgrid device, especially a wind-PV-ES (wind / photovoltaic / energy storage) integrated microgrid device, and belongs to the technical field of intelligent microgrids. The device comprises a power generation system, an energy storage system, a box body, an intelligent distribution system, and an energy management system. The power generation system depends on the box body and is disposed outside the box body. The energy storage system, the intelligent power distribution system and the energy management system are all disposed in the box body. The power generation system and the energy storage system are respectively electrically connected to the intelligent power distribution system, and the power generation system, the energy storage system and the intelligent power distribution system are respectively in communication connection with the energy management system. According to the invention, all equipment and the box body are integrated into one body, so the installation efficiency of the microgrid device is improved, there is no need of additional civil construction, and the transportation is safe and convenient. Moreover, the high cost of the early construction and later maintenance is reduced.

Owner:CHINA HUADIAN ENG +1

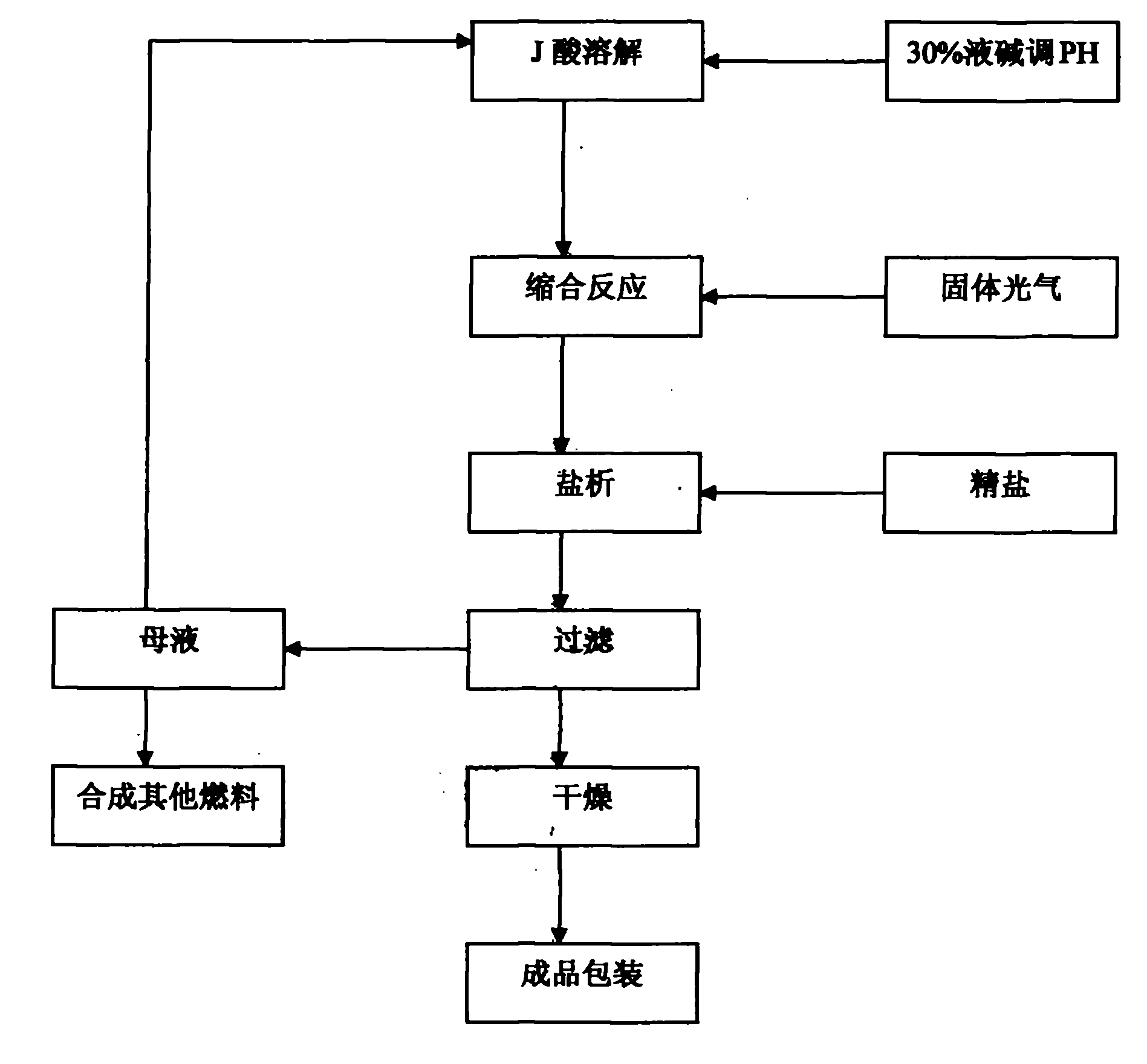

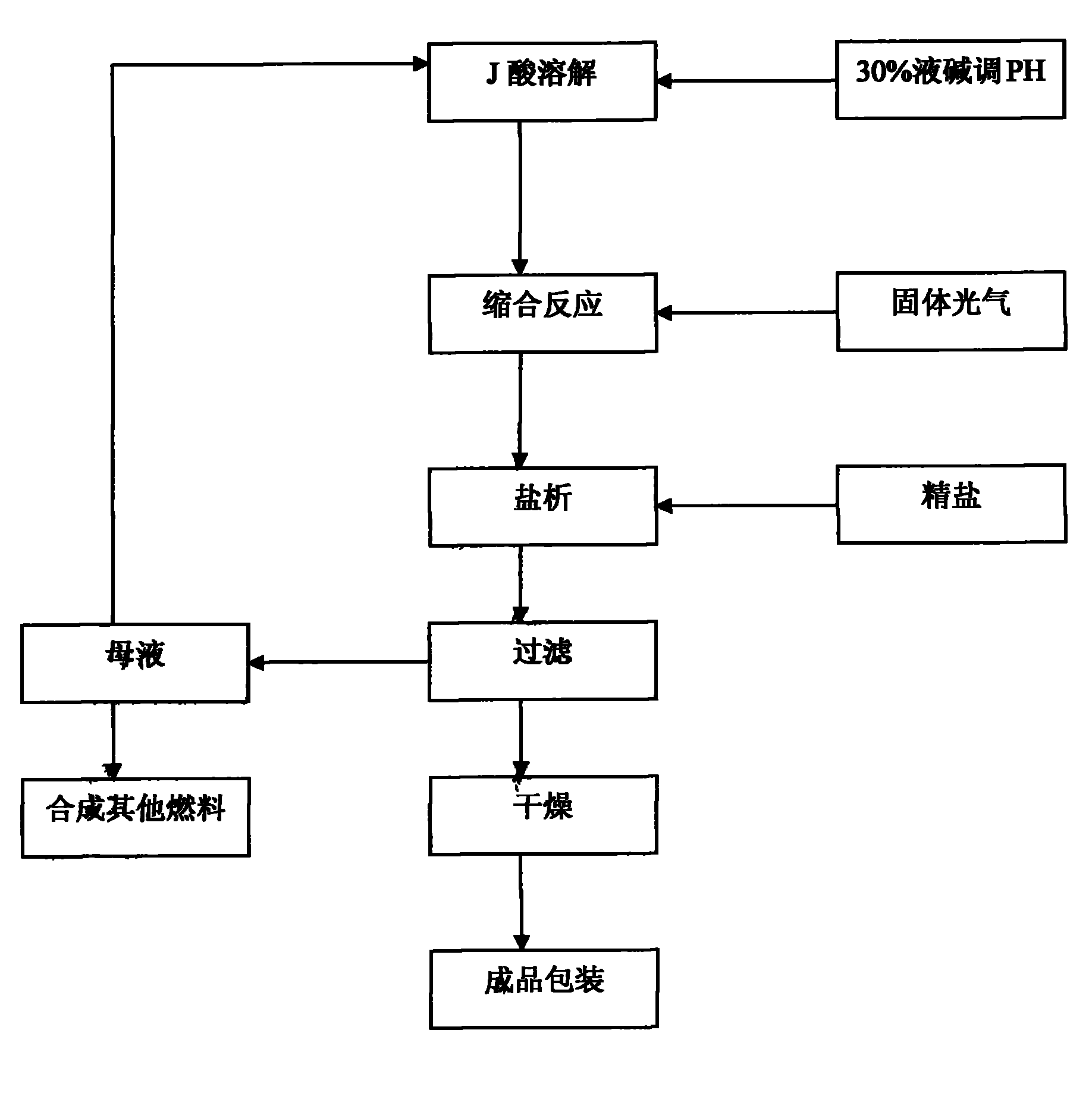

Production process of non-phosgene synthesis of scarlet acid

InactiveCN102108056AReduce the use of liquid caustic sodaLow Inorganic Salt ContentSulfonic acid preparationInorganic saltsCarbonate ester

A production process of the non-phosgene synthesis of scarlet acid particularly comprises the following steps: firstly dissolving J acid into water, adjusting the pH of the solution medium with 30% liquid alkali to obtain a pH of about 7, after complete dissolution, adding bis(trichloromethyl)carbonate with a theoretical amount being 16.7% of the feeding amount of the J acid, performing phosgenation reaction under a controlled temperature of 35-65 DEG C, wherein a reaction end point is reached when no NaOH is consumed and the content of the J acid in materials is not more than 5 g / L. In the process, the amount of bis(trichloromethyl)carbonate approaches the theoretical amount, so the amount of the liquid alkali is reduced by two-thirds; the inorganic salt content in the product is greatly decreased; the product quality is improved; the reaction condition is safe and moderate; the danger of the phosgene toxicity is eliminated essentially; and the process is applicable to industrial production.

Owner:天津节省资源利用工程技术有限公司 +2

Granular carbon dioxide and its preparation method

InactiveCN1807361AImprove performanceWith preservationCarbon dioxide producing fertilisersCarbon dioxideRaw material

The invention discloses a kind of granular form carbon dioxide gaseous fertilizer and method for preparation, wherein the gaseous fertilizer is prepared from the following raw material (by weight portions): aluminum sulfate 2-2.2, light calcium carbonate 1.

Owner:王维超

Coking additive for improving coke performance and coking method

The invention discloses a coking additive for improving coke performance. The coking additive consists of surface activation catalysts, dissolution aids, penetrating aids and oily solvents, wherein the surface activation catalysts refer to SiC powder and sodium naphthenate; the dissolution aids refer to alpha-hydroxyl propanamide, acetylthiophene and p-toluene sulfonic acid; the penetrating aids refer to polyoxyethylene polyoxypropylene monobutyl ether, polyoxyethylene sorbitan tristearate, chlorophenyl silicone oil and molybdenum triethanolamine; and the oily solvents refer to coal tar, asphalt and residual oil. The coking method comprises the step of adding the coking additive into coal, wherein the addition amount of the additives in the coal is 0.5-3wt%.

Owner:马新攀

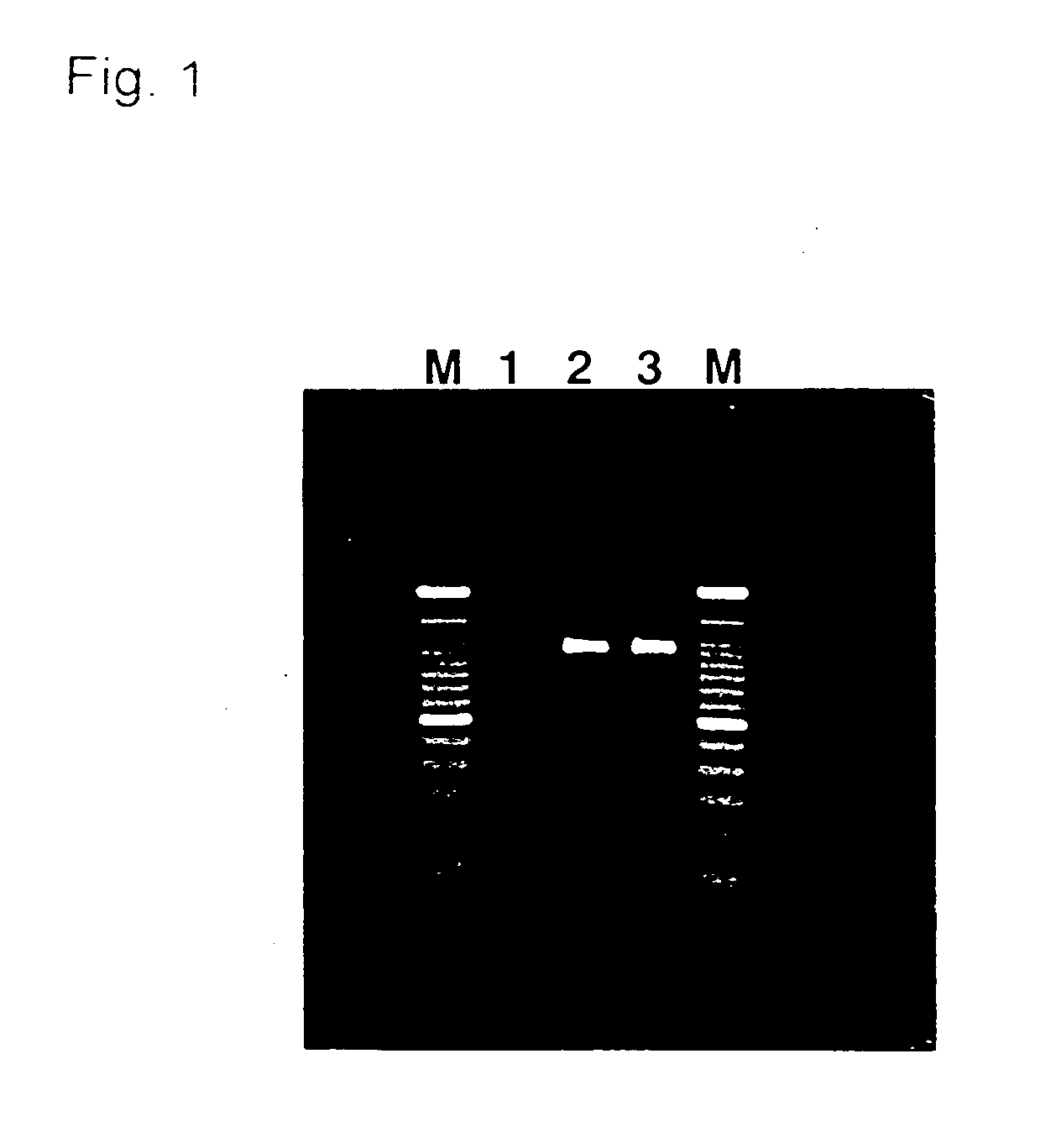

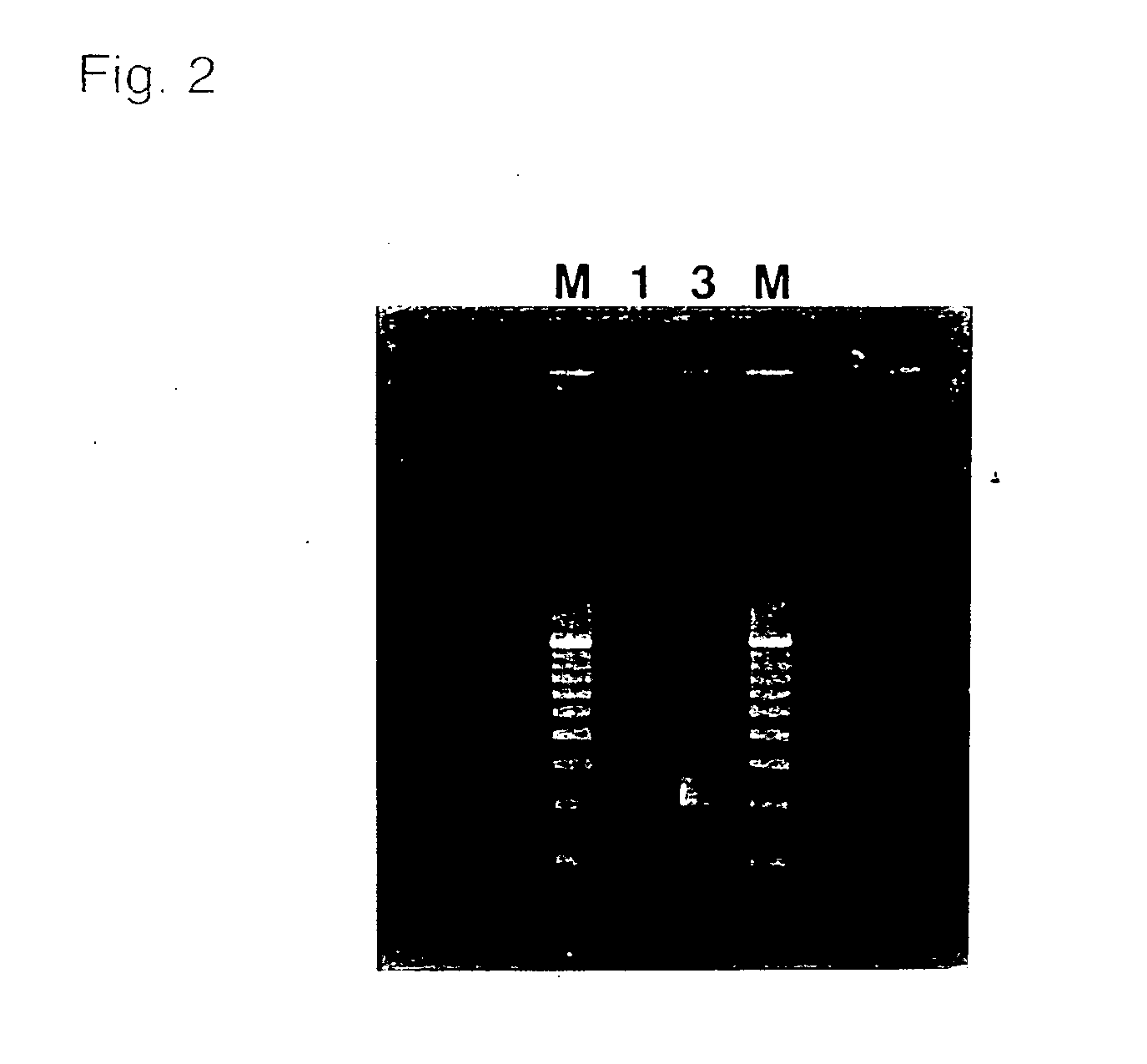

Method for HLA-typing

InactiveUS20040175746A1Safe and convenient transportationLow costMicrobiological testing/measurementBiological testingAmplification dnaTyping

The present invention provides a HLA-typing technique that uses samples that are safe and convenient for storage and transportation and therefore can significantly reduce the cost associated with the analysis and ensure high accuracy of the analysis as well as high processing efficiency. A method for HLA typing, comprising the steps of: directly amplifying DNA from a biological sample; determining a base sequence of DNA in the biological sample; and determining HLA type on the basis of the base sequence. Preferably, the DNA amplification reaction is Polymerase Chain Reaction, the biological sample is a paper-spotted blood sample obtained by spotting blood on filter paper and drying the blood.

Owner:SHIMADZU CORP

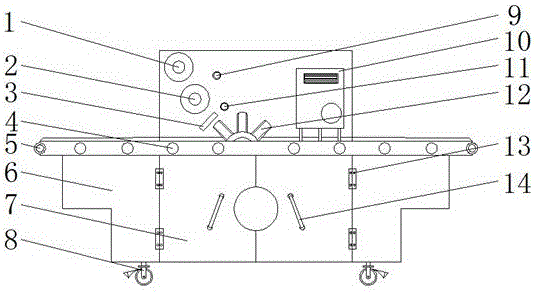

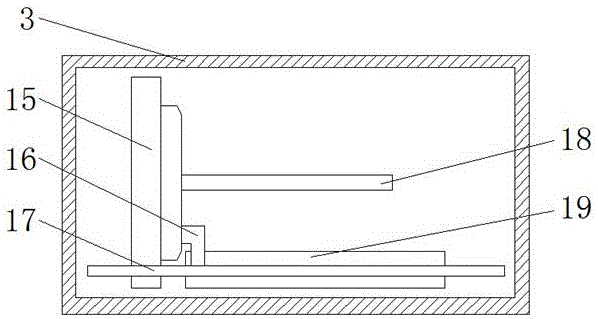

Biodegradable film cutting mechanism

InactiveCN106426338AScientific and reasonable structureSafe to useMetal working apparatusEngineeringCam

The invention discloses a biodegradable film cutting mechanism. The biodegradable film cutting mechanism comprises a body shell and a disc-shaped cam, wherein a driving wheel is mounted on the upper part of the body shell; a stepping device is mounted above a driven wheel; a miniature PLC is mounted on one side of the stepping device; a cutting mechanism is mounted on the other side of the stepping device; a second storage drum is mounted above a buffer roll; a first storage drum is mounted above the second storage drum; and a steering roll is mounted on one side, which is close to the miniature PLC, of the first storage drum. The biodegradable film cutting mechanism is provided with the miniature PLC, by the miniature PLC, the cutting length of a biodegradable film can be accurate, and efficiency can be improved; the biodegradable film cutting mechanism is provided with the storage drums, a material change gap can be reduced, and production period is shortened; and the biodegradable film cutting mechanism is provided with a serrated knife, blades of saw teeth are independent relatively, cutting capability is improved, the service life is long, and production cost is reduced while the cutting effect is guaranteed.

Owner:HUNAN KELAIBAO BIO ENERGY TECH CO LTD

Novel wooden box for packaging external rotor axial flow fan

InactiveCN102795376ATight and reliable installationTo achieve shockproofRigid containersInternal fittingsWooden boxAerospace engineering

The invention discloses a novel wooden box for packaging an external rotor axial flow fan. The novel wooden box comprises a box body, a foam bottom plate, upper foam blocks and lower foam blocks, wherein the foam bottom plate is arranged at the bottom of the box body; the main cross sections of the upper and lower foam blocks are quadrantal triangles; the upper foam blocks and the lower foam blocks are positioned at four corners of the box body; matching surfaces of the upper and lower foam blocks have staggered step structures; and one part of each matching surface is reserved with a gap for accommodating a mounting rib of the external rotor axial flow fan. The mounting rib of the fan is located by the structures of the upper and lower foam blocks and the foam bottom plate, so the tight and reliable mounting is ensured, and aims of resisting quake and preventing damage of fan equipment are fulfilled; meanwhile, safety and convenience are really achieved in the transporting process.

Owner:宜兴市中超机电科技有限公司

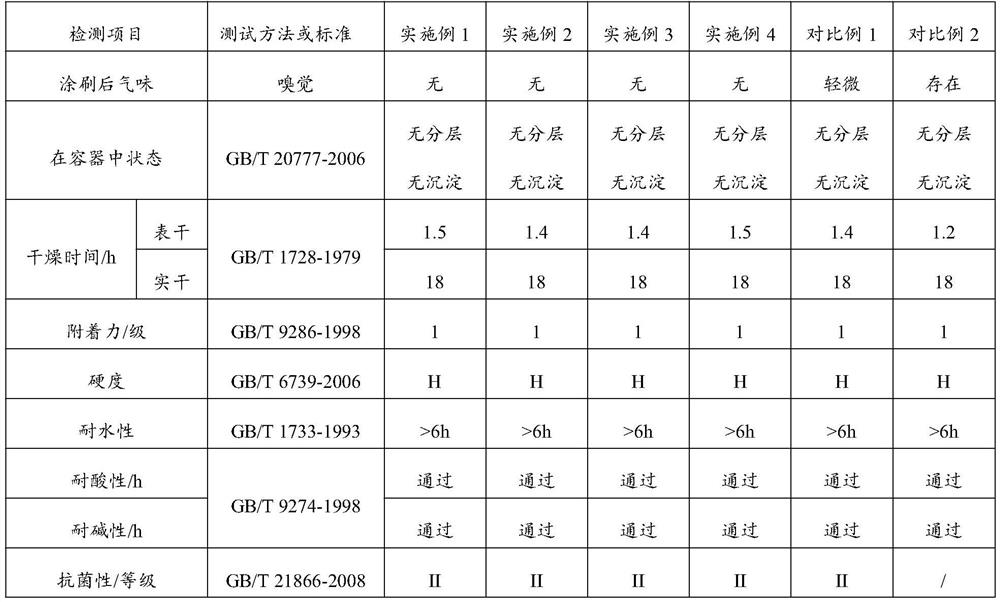

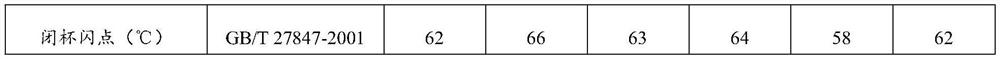

High-flash-point odorless coating as well as preparation method and application thereof

The invention belongs to the technical field of coatings, and particularly relates to a high-flash-point odorless coating as well as a preparation method and application thereof. The invention provides a high-flash-point odorless coating. The high-flash-point odorless coating comprises the following components in parts by weight: 50-60 parts of alkyd resin; 10-20 parts of a solvent; 5-10 parts of zinc oxide; 10- 25 parts of titanium dioxide; 3- 5 parts of alpha-terpilenol; 4-5 parts of a coalescing agent; 0.3- 0.5 part of a dispersant; 0.4 - 0.6 part of an anti-settling agent; 0.1 - 0.3 part of a wetting agent; 0.5 - 0.7 part of a drier; and 0.1- 0.3 part of an anti-skinning agent. According to the invention, the high-flash-point compound is taken as a main body and is matched with the high-flash-point auxiliary agents; under the action of the zinc oxide, the titanium dioxide, the alpha-terpilenol, the dispersing agent, the anti-settling agent, the drier, the wetting agent and the anti-skinning agent, the flash point of the coating is increased, so that the flash point of the coating is maintained at 61 DEG C or above; and the coating provided by the invention has no special smell, and is green and environment-friendly.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com