Production process of non-phosgene synthesis of scarlet acid

A production process and technology of scarlet acid, applied in the preparation of sulfonic acid, organic chemistry, etc., can solve the problems of increased production cost, severe reaction, complicated operation, etc., and achieve the effects of improving product quality, safe reaction conditions, and safe and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

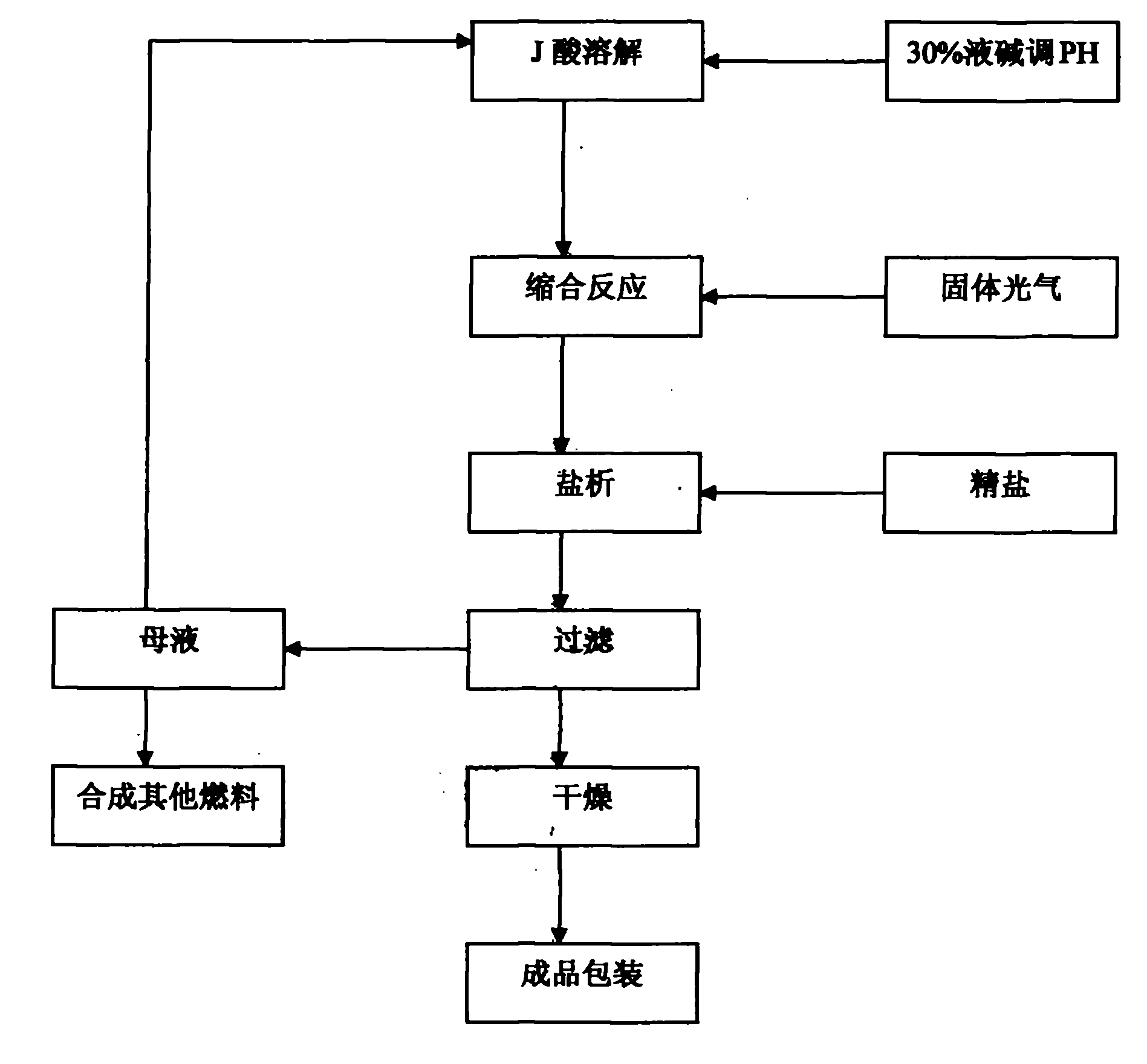

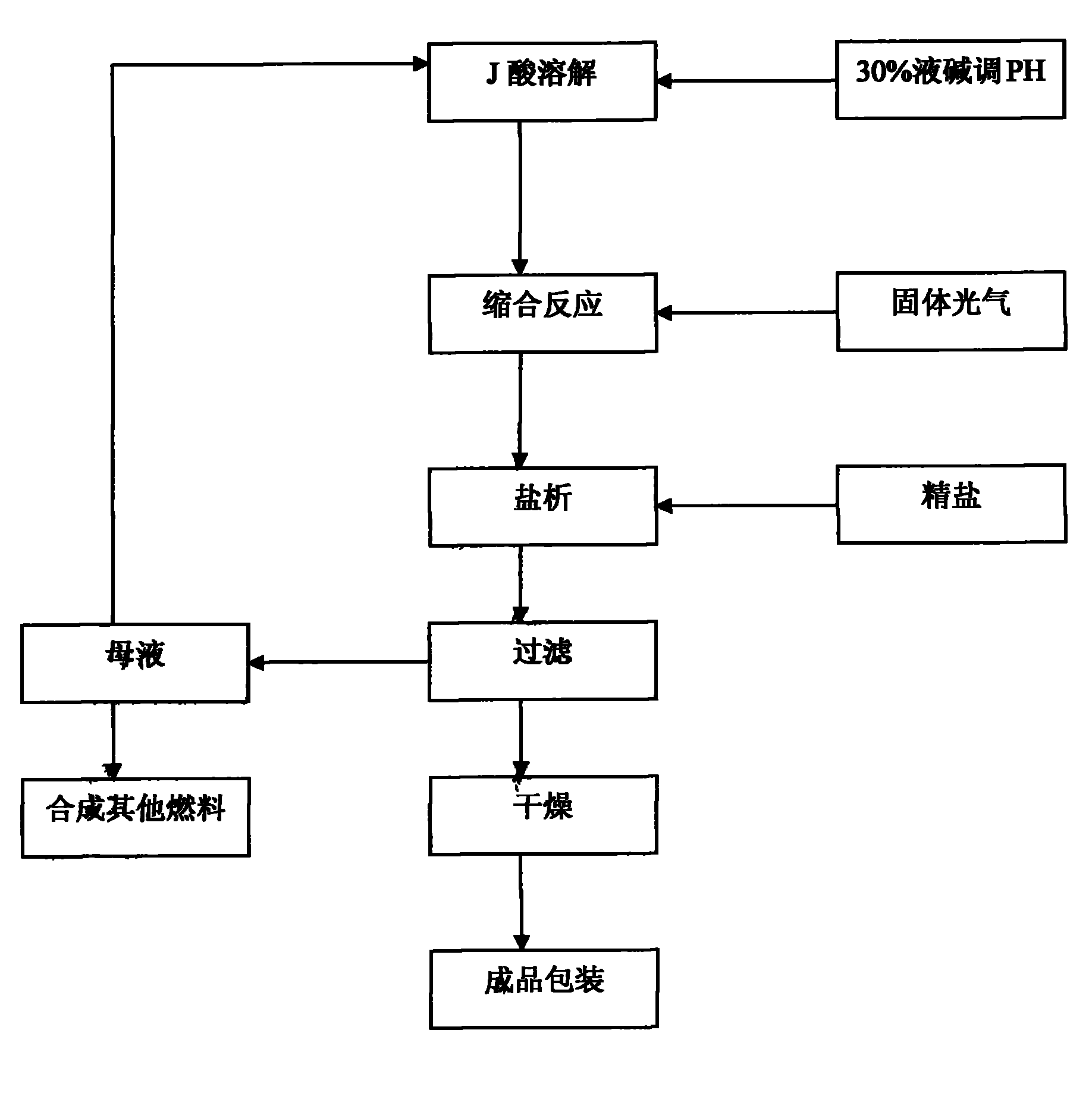

Image

Examples

Embodiment Construction

[0010] 1. Put 2500L of water in a 5000L reactor (the first batch uses water once, and the second batch uses 2000L of mother liquor from the previous batch), then pour the J acid into the reactor and turn on the stirring to make the J acid stir evenly , then adjust the pH of the solution medium to about 7 with 30% liquid caustic soda, make it all dissolve, then measure the temperature in the reactor, then observe whether the material is completely dissolved, adjust the volume to 3500L after fully dissolved, then add the weighed two ( Two-thirds of the amount of trichloromethyl)carbonate, the temperature is raised to 30°C, and the change of the reaction medium is measured at any time. When the pH of the reaction medium is lower than 7, slowly add 30% liquid caustic soda to keep the reaction medium Around PH=7.

[0011] 2. In the process of phosgenation, the reaction speed will slow down when the temperature remains constant, so there is no need to increase the temperature in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com