Patents

Literature

69 results about "Inorganic salt level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of purification process of glufosinate-ammonium

ActiveCN102268037AThe purification process steps are simpleLow Inorganic Salt ContentGroup 5/15 element organic compoundsEpoxySolvent

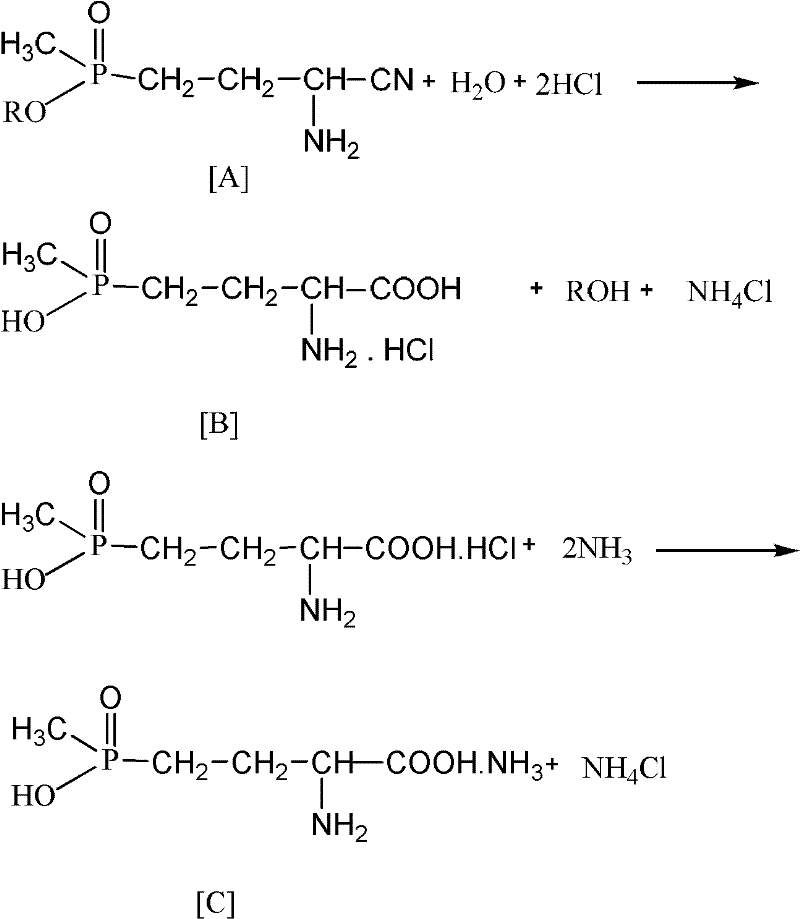

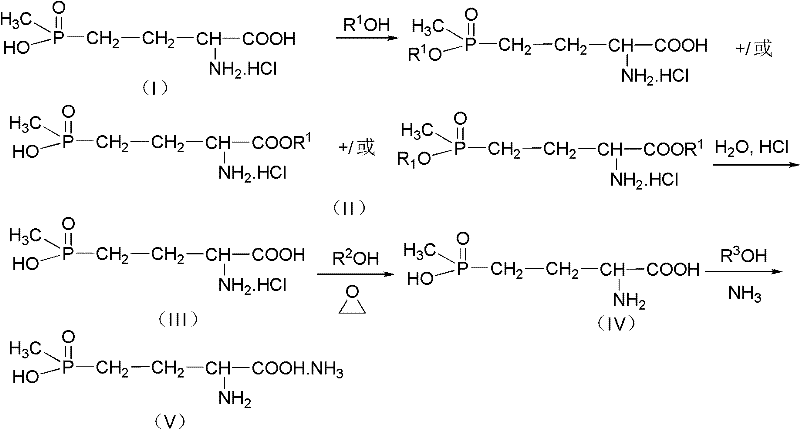

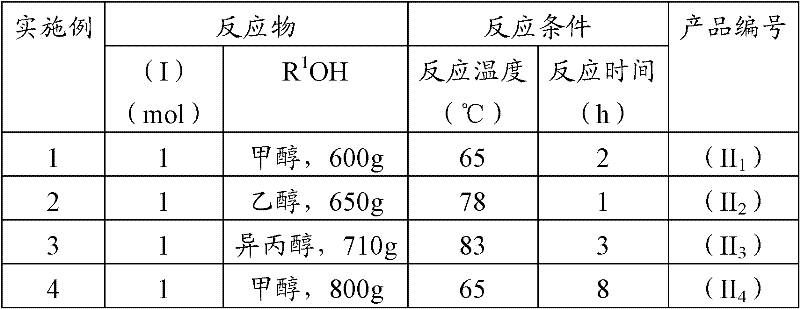

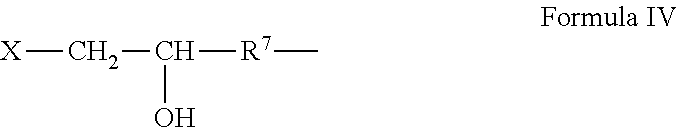

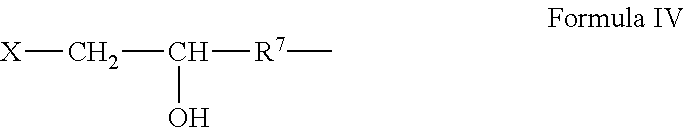

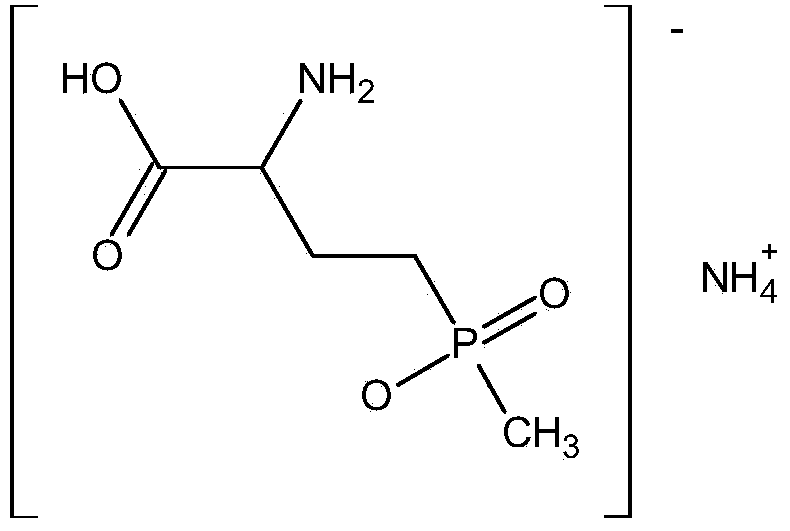

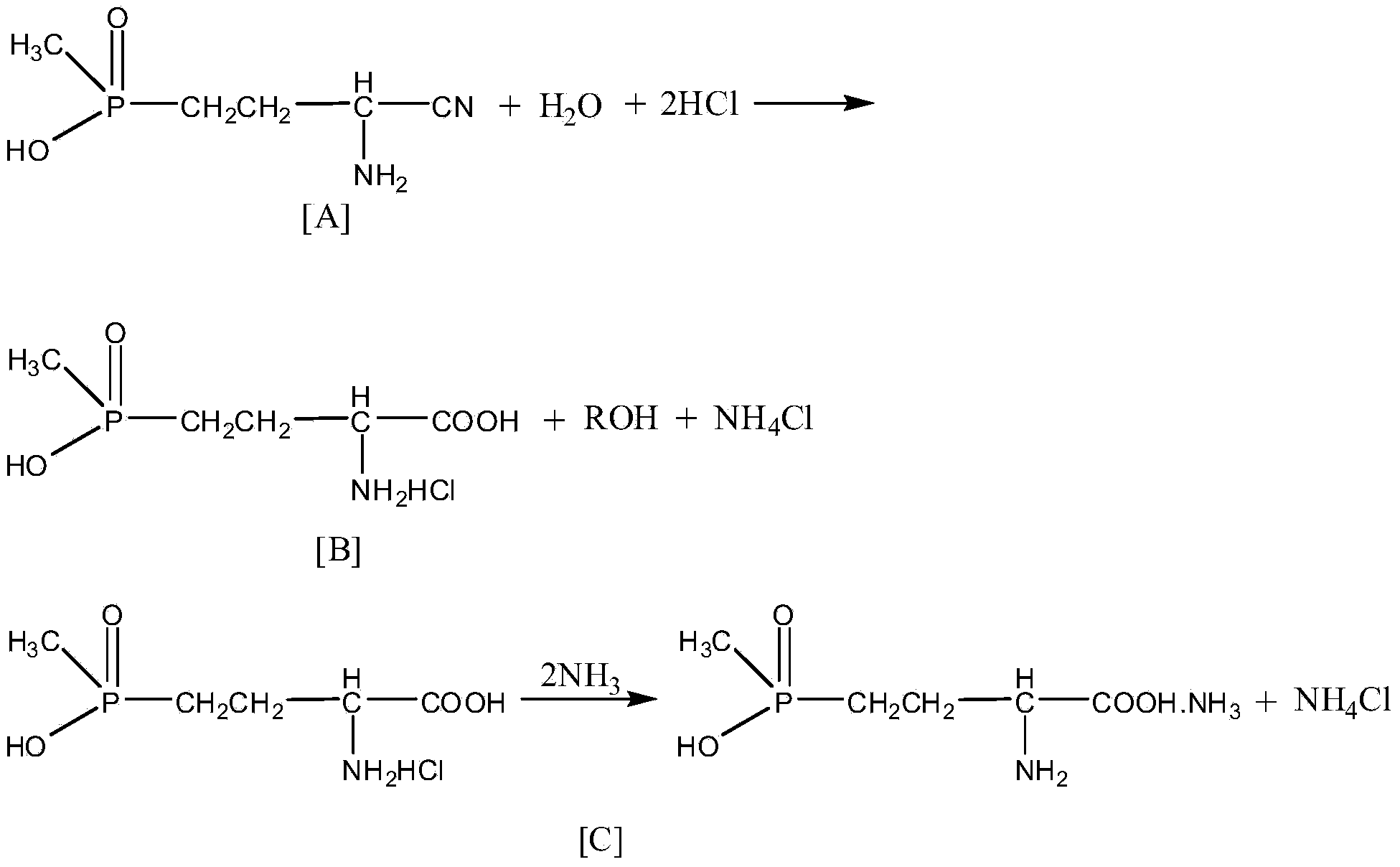

The invention discloses a process for purifying glufosinate-ammonium, which comprises: (1) adding glufosinate-ammonium hydrochloride into an alcohol R1OH to perform an esterification reaction, and after the reaction is accomplished, cooling, filtering, removing solvent from filtrate and obtaining ester product of glufosinate-ammonium; (2) adding the ester product of glufosinate-ammonium, which isobtained by step (1), into water solution of hydrochloric acid to perform a hydrolysis reaction, and obtaining glufosinate-ammonium hydrochloride by post treatment; (3) adding the glufosinate-ammonium hydrochloride obtained by the step (2) into an alcohol R2OH, introducing epoxy ethane and obtaining glufosinate-ammonium acid; and (4) adding the glufosinate-ammonium acid obtained by the step (3) into an alcohol R3OH, introducing ammonia gas, and obtaining glufosinate-ammonium after the reaction is finished. In the invention, the process for purifying glufosinate-ammonium comprises simple steps, the inorganic salt content in the obtained glufosinate-ammonium is low, and the purity of the obtained glufosinate-ammonium is high; the process for separating glufosinate-ammonium hydrochloride from HCl by epoxy ethane is more economic than the conventional process which adopts epoxypropane and epoxy chloropropane; and the method is very safe and has a very bright industrialization prospect.

Owner:YONGNONG BIOSCI

Sulfate free clear personal cleansing composition comprising low inorganic salt

A clear personal cleansing composition having an anionic surfactant, a cationic deposition polymer, an aqueous carrier and a level of inorganic salt of from about 0 to about 1 wt %. The composition is substantially free of sulfates and has a % T of greater than about 80%. The composition can further comprise amphoteric surfactants. The composition remains phase stable and minimizes coacervate formulation until after dilution with water.

Owner:THE PROCTER & GAMBLE COMPANY

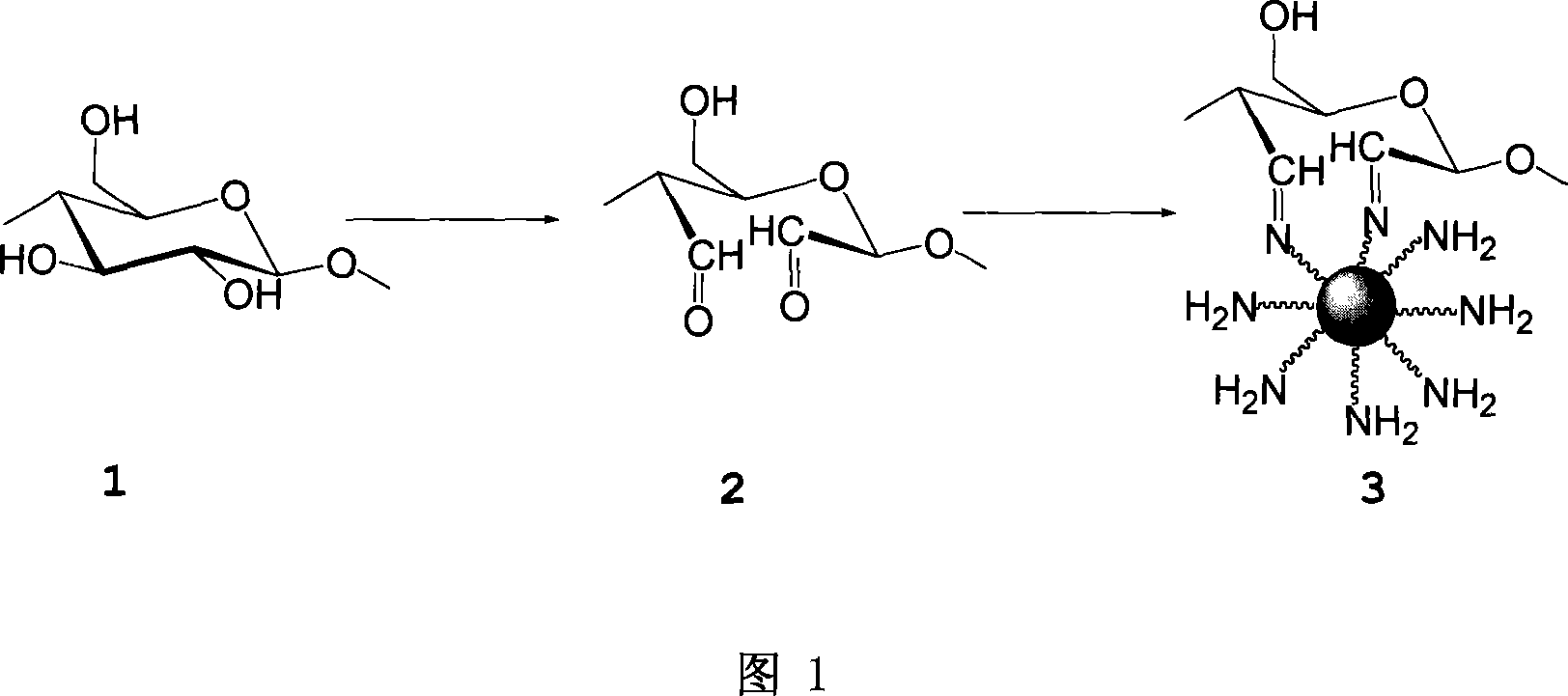

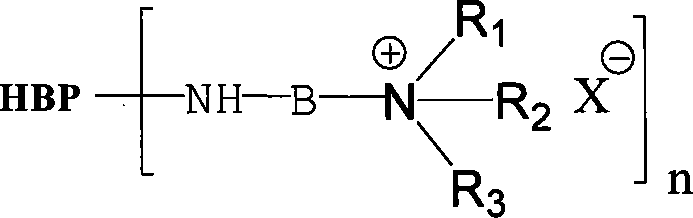

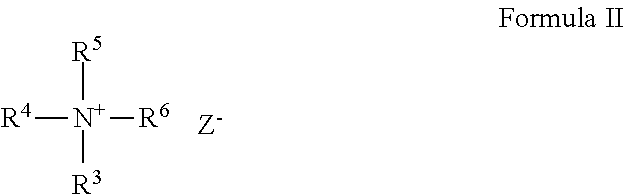

Fibrilia grafting amination modifying process

InactiveCN101225602AQuick responseImprove grafting efficiencyDyeing processVegetal fibresFiberReaction rate

The invention discloses a linen fiber modification method, in particular to a linen fiber graft aminization modification craft, belonging to the technical field of printing and dyeing, which is characterized in that the linen fiber is selectively oxidized with oxidant solution such as sodium periodate, and oxidation linen fiber is obtained; the surface aldehyde group of the oxidation linen fiber is reacted with the surface amino of amine-terminated overbranched compound and the quaternary ammonium salt, which are combined by covalent bond, and the graft aminization linen fiber is prepared; the abundant amino, imino group and quaternary ammonium branched chain are introduced on the surface of obtained fiber, which can increase significantly the dyeing performance of linen fiber, and simultaneously increase the pliability softness, hygroscopicity and antibacterial performance of linen fiber. The linen fiber modification method has the advantages of fast reaction rate, high graft efficiency, good fastness, convenient and easy operation, realization of non-salt dyeing for linen fiber after modification treatment, environment protection, simplified normal dyeing craft and wide potential application.

Owner:SUZHOU UNIV

Sulfate free personal cleansing composition comprising low inorganic salt

Personal cleansing compositions having an anionic surfactant, cationic deposition polymer, a level of inorganic salt of from about 0 to about 1 wt %, and an aqueous carrier. The composition is substantially free of sulfate containing surfactants. The composition can further comprise amphoteric surfactants. The composition remains phase stable, and minimizes coacervate formulation until after dilution with water.

Owner:THE PROCTER & GAMBLE COMPANY

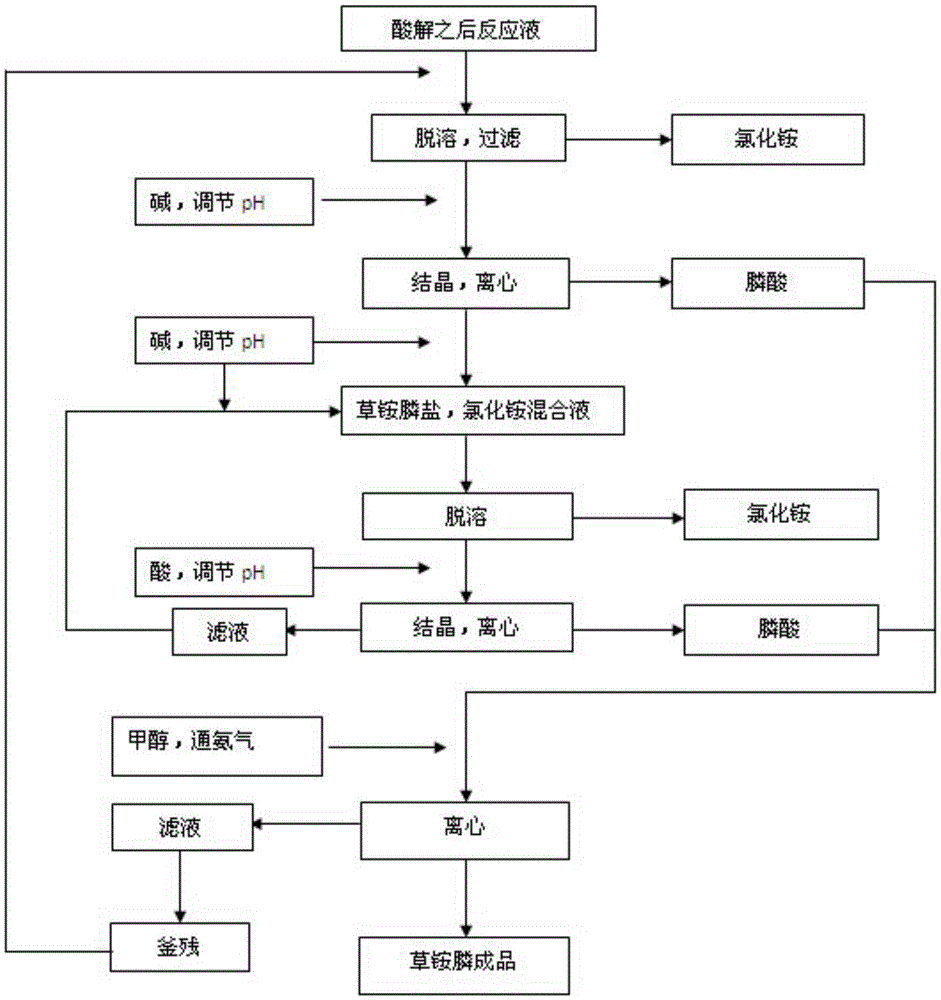

Glufosinate purifying technology

ActiveCN103819503AThe purification process steps are simpleLow Inorganic Salt ContentGroup 5/15 element organic compoundsDecompositionSolvent

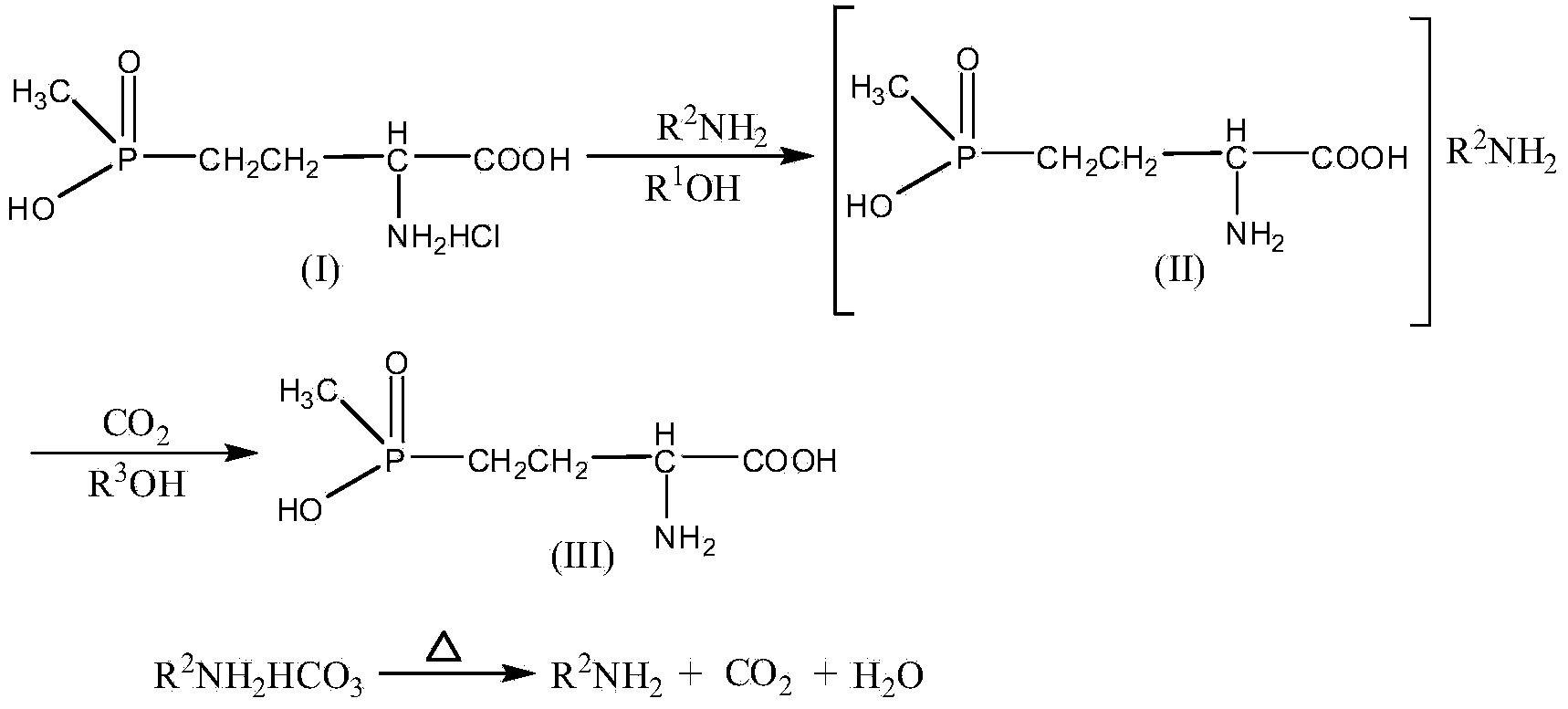

The invention provides a glufosinate purifying technology including the following steps: (1) adding glufosinate hydrochloride to alcohol R1OH, adding R2NH2 for ammoniation, adjusting the pH to 7.0-14.0, cooling and filtering, removing a solvent from a filtrate to obtain glufosinate ammonium salt and a small amount of organic impurities; (2) dissolving the glufosinate ammonium salt obtained by the steps (1) in an appropriate amount of water, leading in CO2 for neutralizing to the pH of 2.0-5.0, adding a proper amount of alcohol R3OH for precipitation of glufosinate acid, centrifugally filtrating to obtain the glufosinate acid which contains a small amount of ammonium hydrogen carbonate or organic amine carbonates; (3) heating for drying a glufosinate acid filtering cake obtained by the step (2) for decomposition and volatilization of the ammonium hydrogen carbonate or organic amine carbonates to obtain high purity glufosinate acid. The glufosinate purifying technology is simple in steps, the obtained glufosinate is low in inorganic salt content and high in purity, and compared with a traditional technology using epoxy ethane and epoxy propane, the purifying technology using carbon dioxide for separation of glufosinate hydrochloride and HCl is more economical, and high in safety, and has a higher industrialization prospect.

Owner:SHANDONG BINNONG TECH

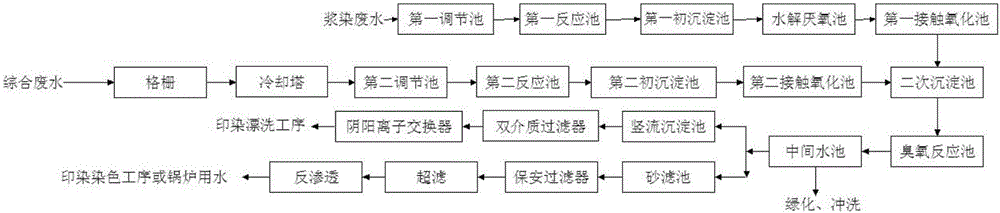

Complex printing and dyeing wastewater quality-divided treating and reusing integrated technology

ActiveCN105859055AReduce work intensityProtection securitySpecific water treatment objectivesWater contaminantsTextile printerWater use

The invention relates to a complex printing and dyeing wastewater quality-divided treating and reusing integrated technology. The technology comprises two parts of quality-divided treating and quality-divided reusing, the whole technical process is realized through an automatic detection and control mode. For the characteristics that wastewater in a textile printing and dyeing garden is large in water quality change, high in chromaticity, difficult to biologically decompose and high in inorganic salt content, an existing efficient ozonation technology, an ultrafiltration-reverse osmosis membrane technology, an economical biochemical treatment technology, a double-tower filtration technology and an cation and anion exchange technology are integrated and optimized, for meeting the water quality requirement of water used in all processes of the garden, and efficient and low-cost treatment of the printing and dyeing wastewater is achieved by means of quality-divided treating and quality-divided reusing. Compared with a traditional treatment technology, though the water is more complex, high in chromaticity and difficult to decompose, treatment cost is lower, and the reuse rate of reclaimed water is larger and can reach 70-80%.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Rapid hosta plantagineu propagation method

InactiveCN103858770APromote differentiationLow Inorganic Salt ContentHorticulture methodsPlant tissue cultureInorganic saltsHydrolysate

The invention relates to a rapid hosta plantagineu propagation method which mainly comprises the following steps: selecting and sterilizing an explant, performing subculture multiplication culture, performing rooting culture and acclimatizing and transplanting. Particularly, in the subculture process, the light intensity is improved, the content of inorganic salts in a culture medium is reduced, and monopotassium phosphate and lactoalbumin hydrolysate are increased. Meanwhile, the technical means of converting a subculture culture medium is adopted, and thus excellent effects of high multiplication speed, stable inheritable characters and high propagation coefficient are achieved.

Owner:INST OF BOTANY CHINESE ACAD OF SCI

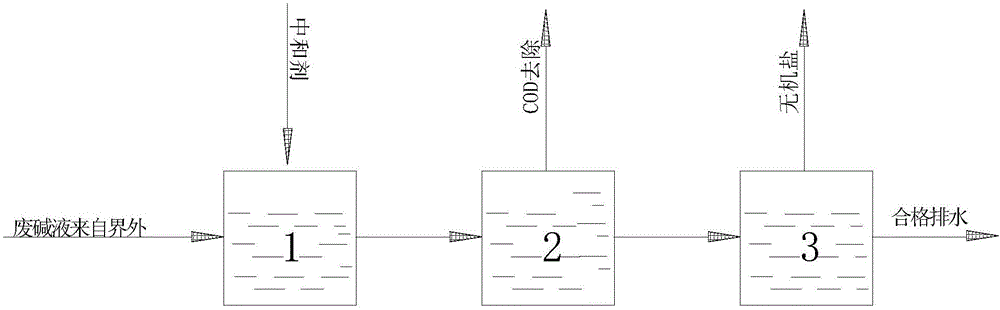

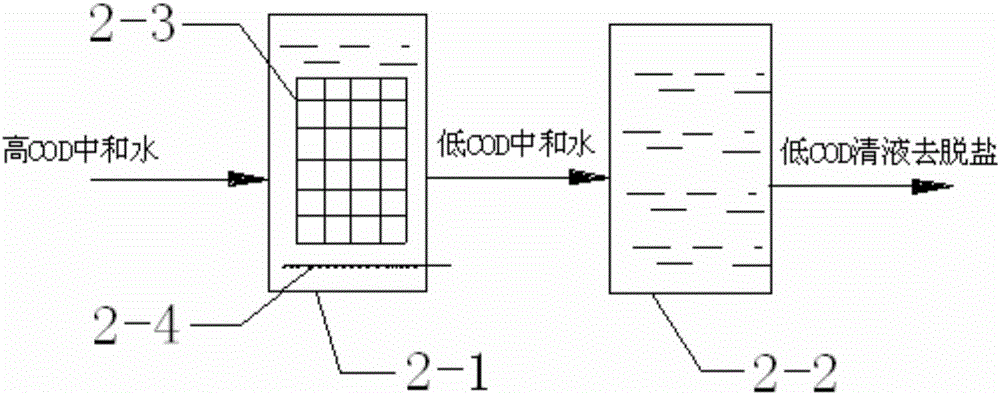

Method and process system for innocuous treatment of high-salt and high-COD waste alkali liquid

InactiveCN106587470ALower quality requirementsEasy to handleMultistage water/sewage treatmentWater/sewage treatment by neutralisationInorganic saltsProcess systems

The invention discloses a method and a process system for innocuous treatment of high-salt and high-COD waste alkali liquid. The method includes the steps of: adding a neutralizer to pre-treat the high-salt and high-COD waste alkali liquid, wherein the pH of the treated waste alkali liquid is 2-8; adding a catalyst to perform a catalytic reaction under an aeration or a stirring condition to remove COD in the waste alkali liquid; and performing evaporating desalination to the waste alkali liquid to complete the treatment. The method has lower requirement on the quality of the waste alkali liquid and can be used for treating the waste alkali liquid well even inorganic salt content reaches 20% and COD content reaches 10%. The method has more environment-friendly treatment process and is free of addition of microorganisms. The treated liquid is not more than 45 ppm in COD content and is not more than 200 ppm in inorganic salt content.

Owner:SHANDONG DONGYUE FLUO SILICON MATERIALS CO LTD

Chromium-free passivation solution

InactiveCN102409330AImprove corrosion resistancePH value is stableMetallic material coating processesChromium freeInorganic salts

The invention discloses a chromium-free passivation solution, which has the pH value 1-5 and consists of rare-earth salt, inorganic salt, boric acid, nitric acid and water serving as raw materials. In the chromium-free passivation solution, the content of the rare earth salt is 1-15 g / L, the content of the inorganic salt is 3-30 g / L, the content of the boric acid is 0.1-3 g / L, and the content of the nitric acid is 3-30 ml / L; the rare earth salt is a mixture of vanadate and cerium slat in the weight ratio 1:(1.33-6.5); and the inorganic salt is sodium chloride or potassium chloride. The chromium-free passivation solution has the advantages of good passivation effect, low application cost, high production efficiency, stable performance, difficulty in deteriorating and long storage time.

Owner:WEIFANG UNIVERSITY

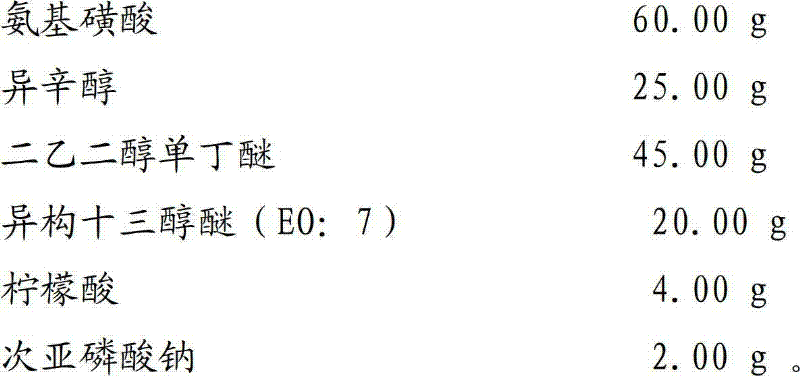

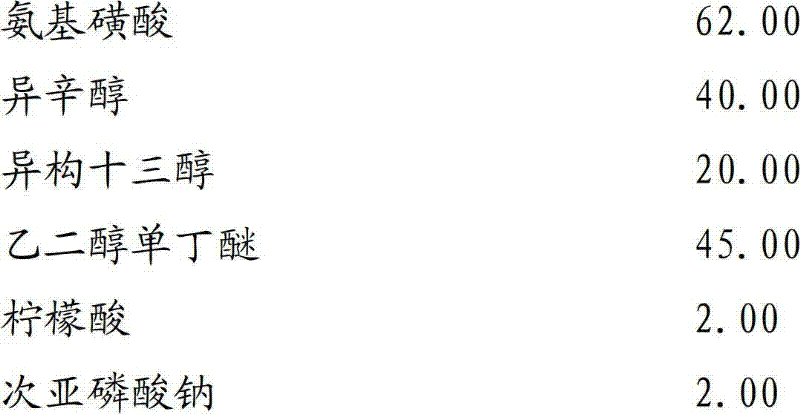

Alkali-resisting penetrating agent for cotton fabric mercerization

InactiveCN102653921AGood dimensional stabilitySoft and plumpVegetal fibresInorganic saltsAqueous sodium hydroxide

The invention relates to an alkali-resisting penetrating agent for cotton fabric mercerization. The penetrating agent is characterized by comprising the following ingredients in parts by weight: 60-100 parts of sulfamic acid, 25-80 parts of fatty alcohol, 45-150 parts of (EO:7-10) fatty alcohol ether and 2-45 parts of catalyst. A preparation method of the alkali-resisting penetrating agent comprises the following steps: putting the fatty alcohol and the fatty alcohol ether in proportion into a three-opening bottle of 500ml, starting stirring, adding the catalyst and the sulfamic acid, powering on a condenser for backflow, heating to 120 DEG C, performing heat preservation for 120 minutes, adding 100 parts of soft water slowly when the temperature is less than 100 DEG C, and stirring uniformly and subsequently regulating the pH value to 8-8.5 by use of a sodium hydroxide water solution. The alkali-resisting penetrating agent provided by the invention has the beneficial effects that the investment is less, three wastes (waste air, waste water and industrial residual) are prevented, the product is low in color, and the inorganic salt content is low.

Owner:天津达一琦精细化工有限公司

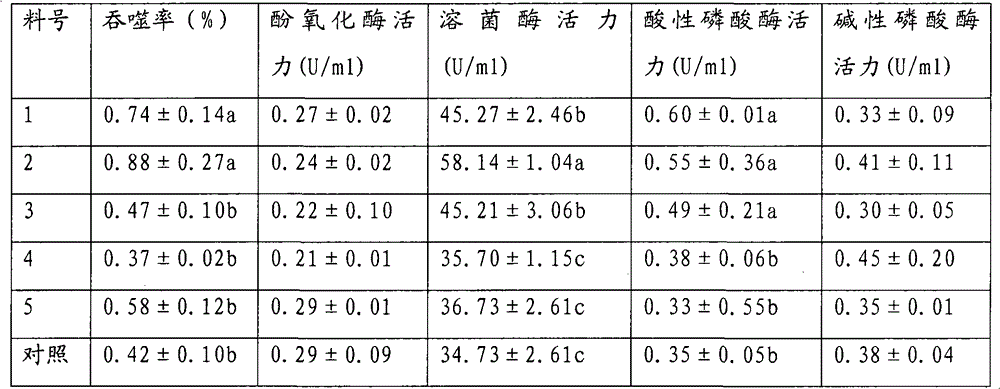

Compound feed for improving non-specified immunity of stichopus japonicus

ActiveCN102871002AIncrease growth rateNutritional diversityAnimal feeding stuffBiotechnologyAdditive ingredient

The invention discloses compound feed for improving non-specified immunity of stichopus japonicus, belonging to the field of nutrition and feed for aquatic livestock. The compound feed consists of the following ingredients in percentage by weight: 10-30 percent of scallop skirt powder, 2-10 percent of krill powder, 10-14 percent of sargassum thunbergii kuntze powder, 14-20 percent of fermented bean pulp, 25-45 percent of clover powder, 8-10 percent of edible yeast, 1 percent of compound vitamin, and 1 percent of compound minerals. According to the compound feed, the clover powder is taken as main raw materials of the compound feed for stichopus japonicus, the problem of shortage of sea-plant resources is solved, the advantages of relative complete amino acid in protein, high content of necessary amino acid, richness in content of vitamin, particularly in families of VA and VB, and richness in content of inorganic salt, and content of immunity promotion materials of the clover powder are fully functionalized, being reasonably compatible with other raw materials, the compound feed is enabled to have overall nutrition, and a growth rate and non-specific immunity of the stichopus japonicus are remarkably improved.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

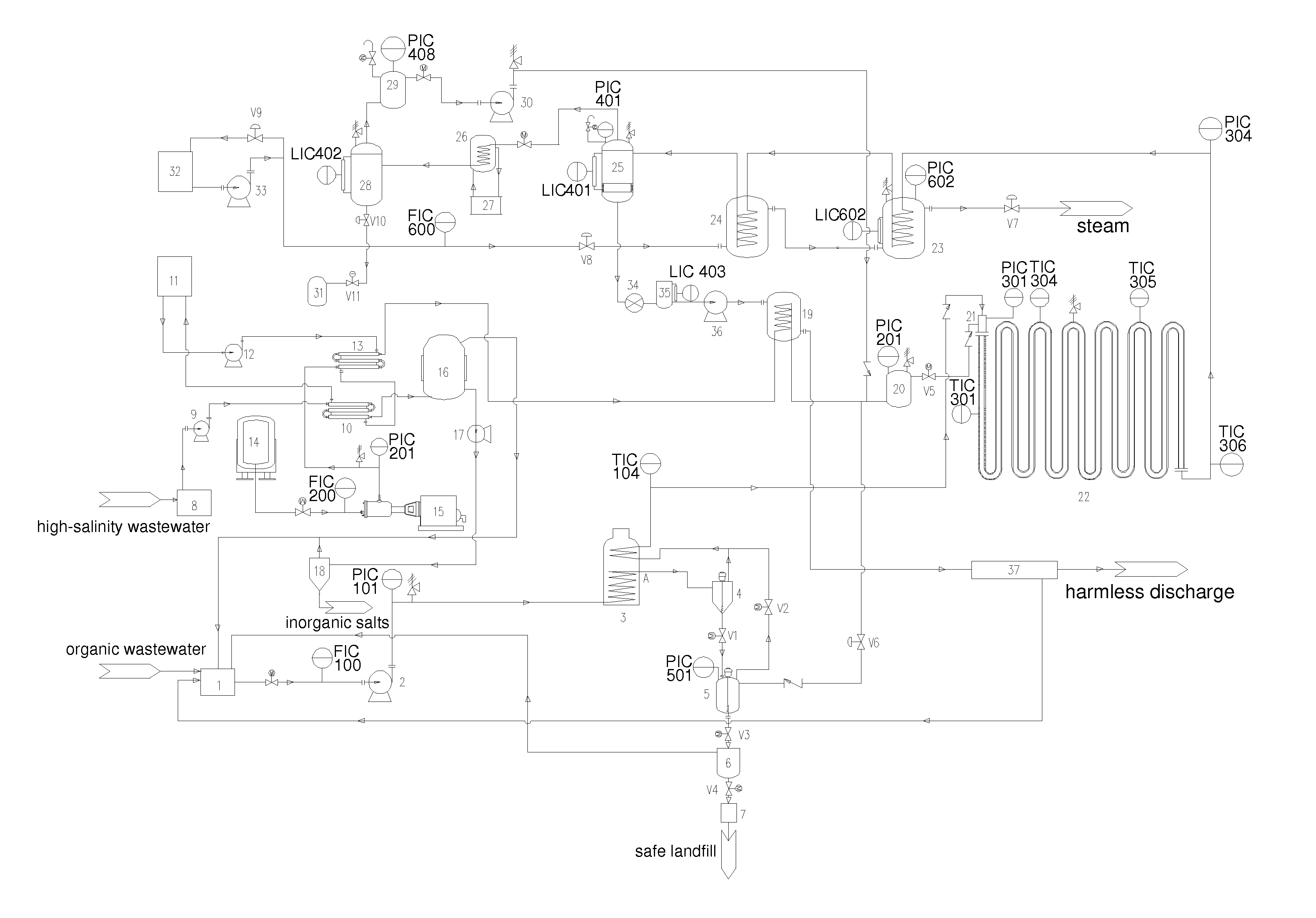

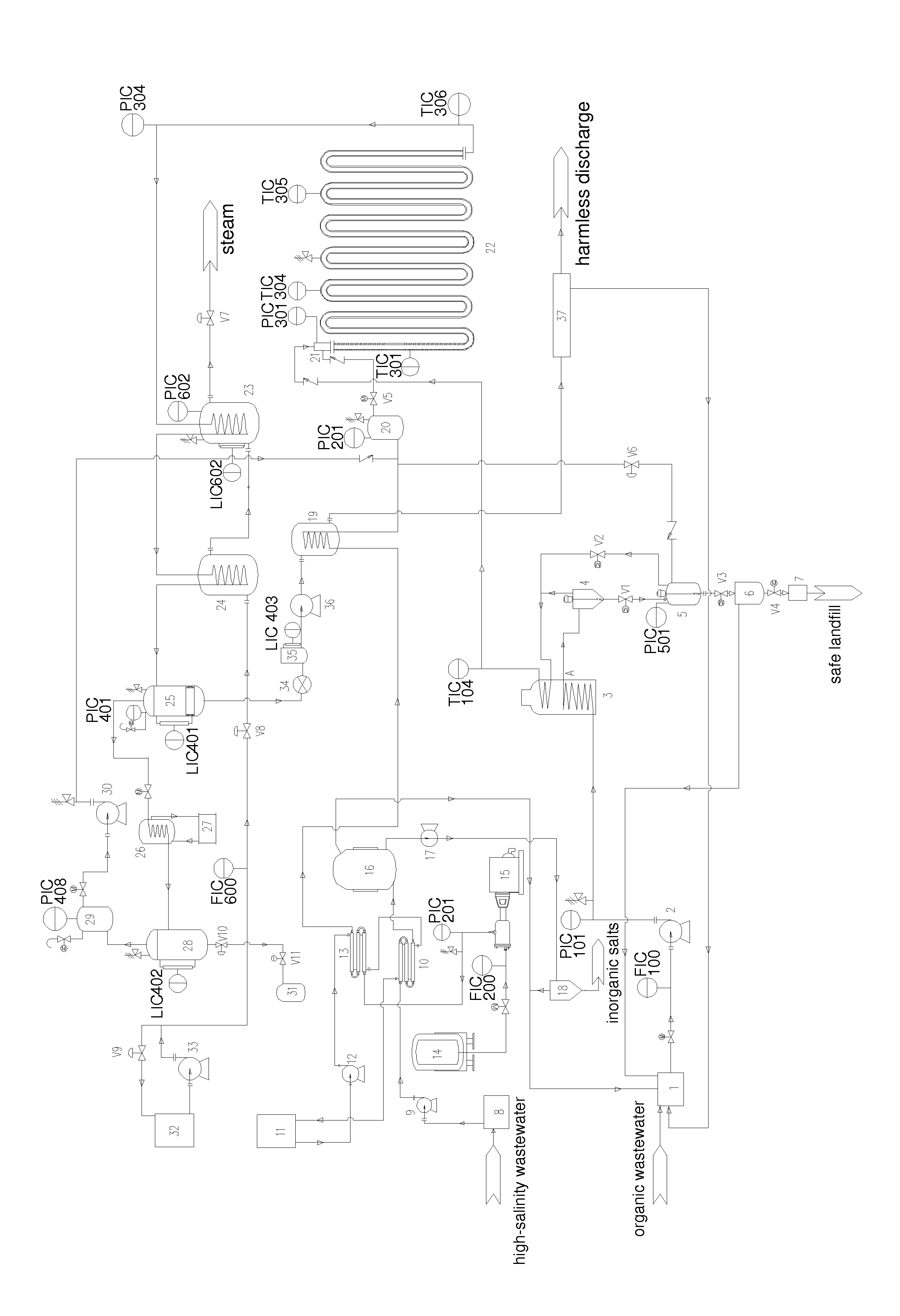

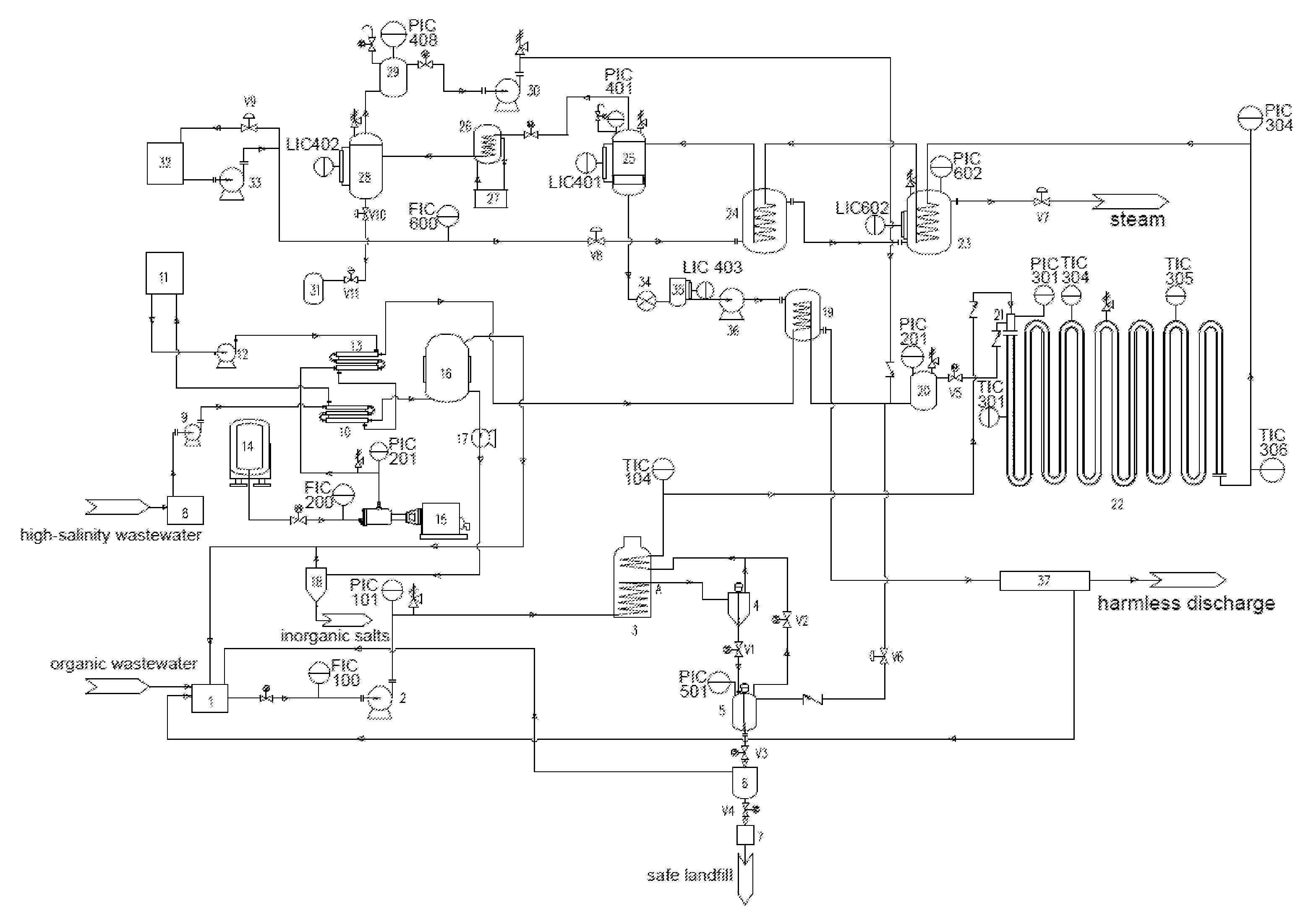

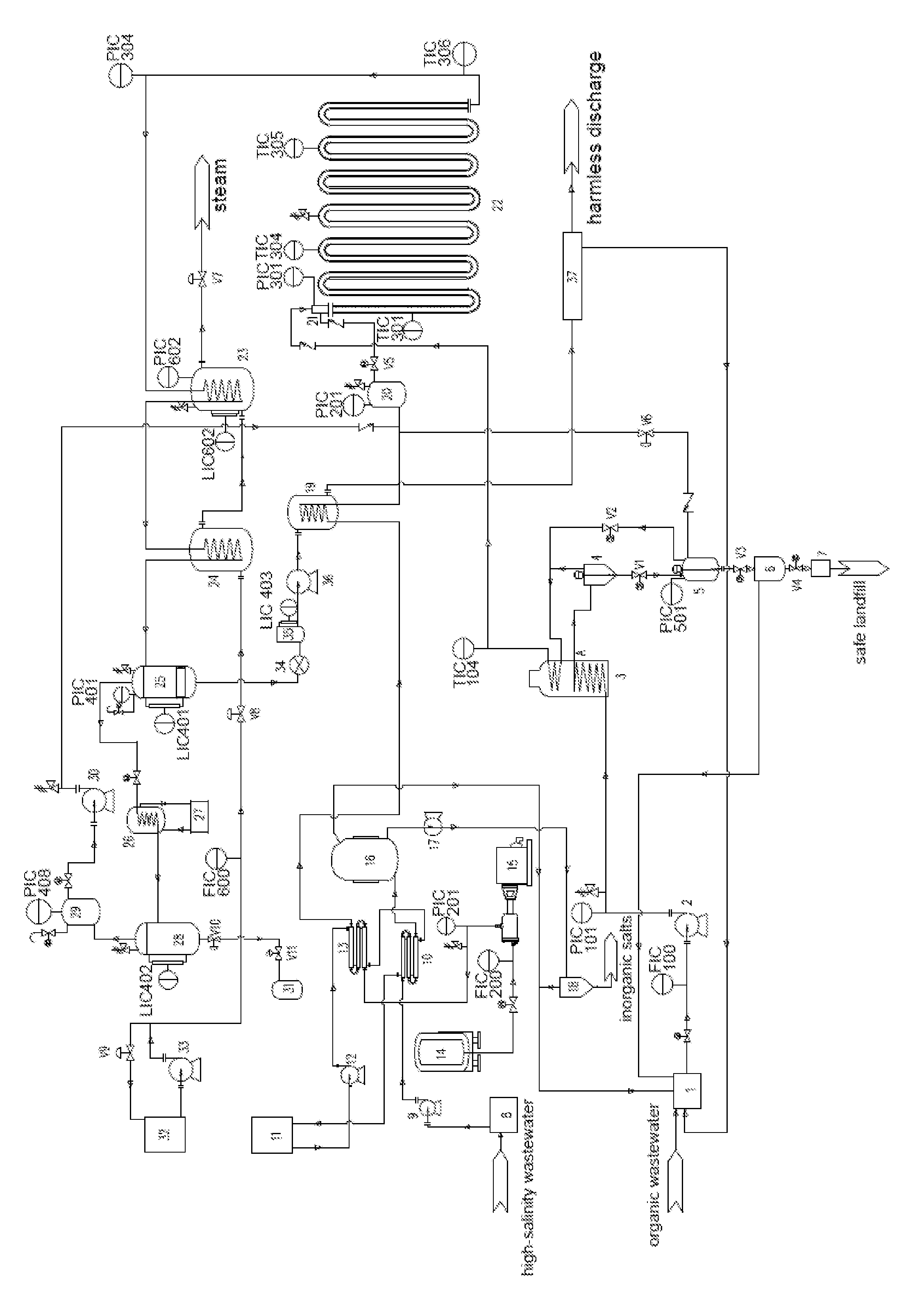

Supercritical water oxidation treatment system for organic wastewater with high salinity

ActiveUS20150128642A1Reduce operating costsHigh salinitySolidificationLiquefactionWater desalinationReaction temperature

A supercritical water oxidation treatment system for organic wastewater with a high salinity crystallizes high-salinity wastewater by a low temperature of liquid oxygen, and decreases an inorganic salt content in the wastewater. Under supercritical water conditions, a hydrocyclone (4) separates most precipitated solid salts in the wastewater, so effectively prevents pipes and the tubular reactor (22) after the hydrocyclone (4) from plugging. Inorganic salts are able to be continuously separated from the system by the hydrocyclone (4) at the bottom of a desalination device, In addition, excess oxygen and gaseous products CO2 are recovered by a separation recovery part. The reaction time and the reaction temperature of supercritical water oxidation reaction are lowered due to the installation of a simple post-treatment unit (37). Moreover, the heat of the reactor effluent with a high temperature is recovered in the system, so operation cost of the system is reduced evidently.

Owner:XI AN JIAOTONG UNIV

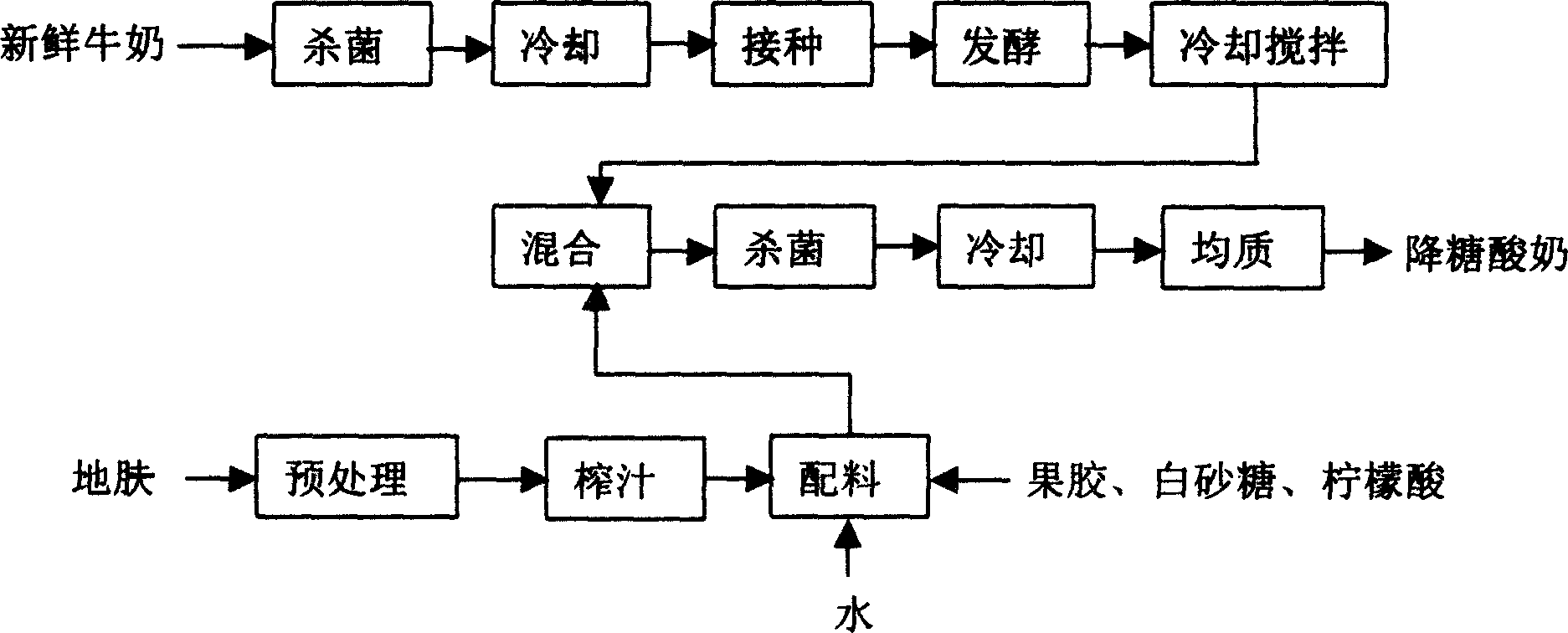

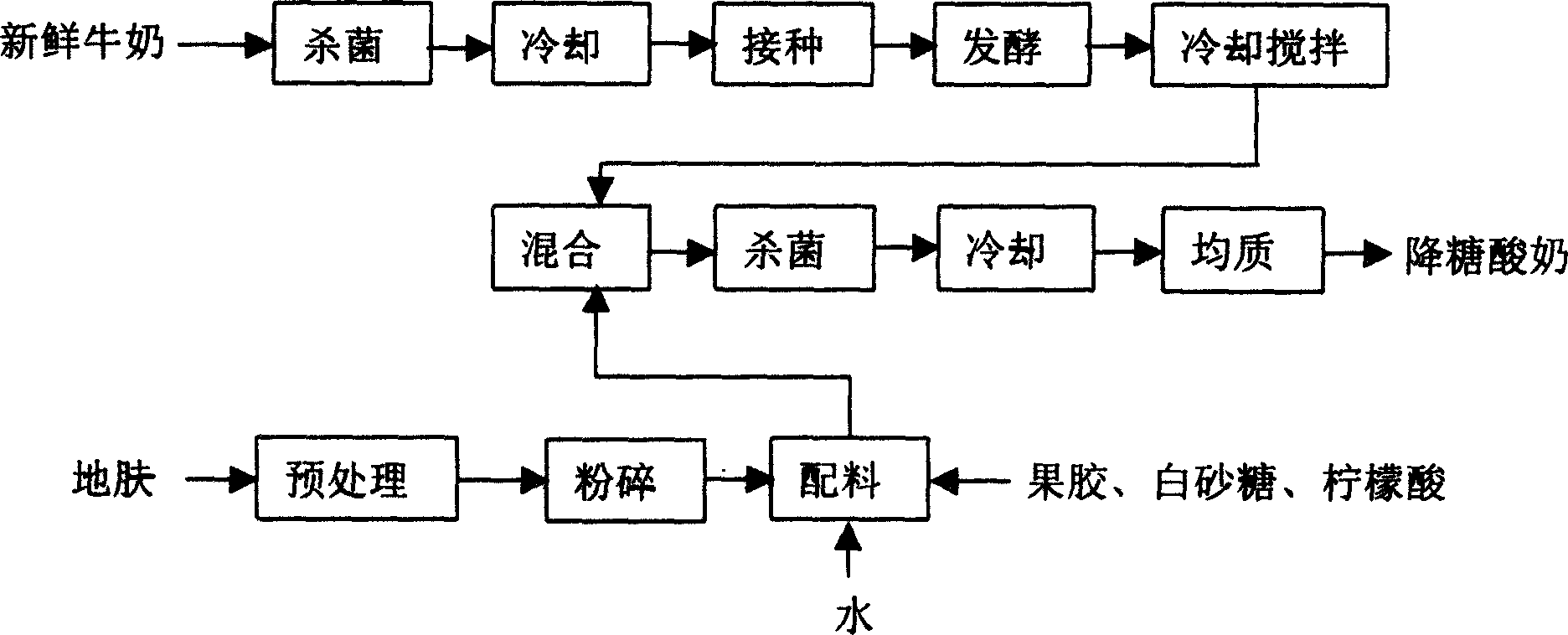

Sugar reducing yoghurt

InactiveCN1561767AGuaranteed tasteKeep the flavorMilk preparationUnknown materialsDiabetes mellitusAdditive ingredient

Owner:林红伍

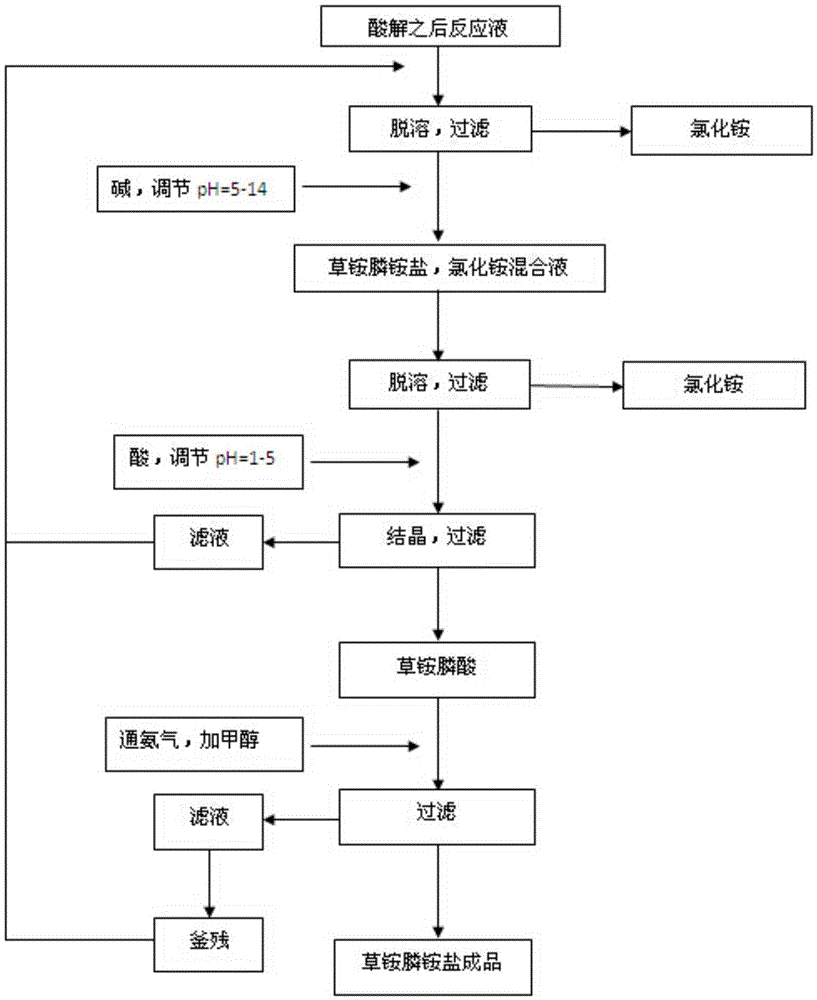

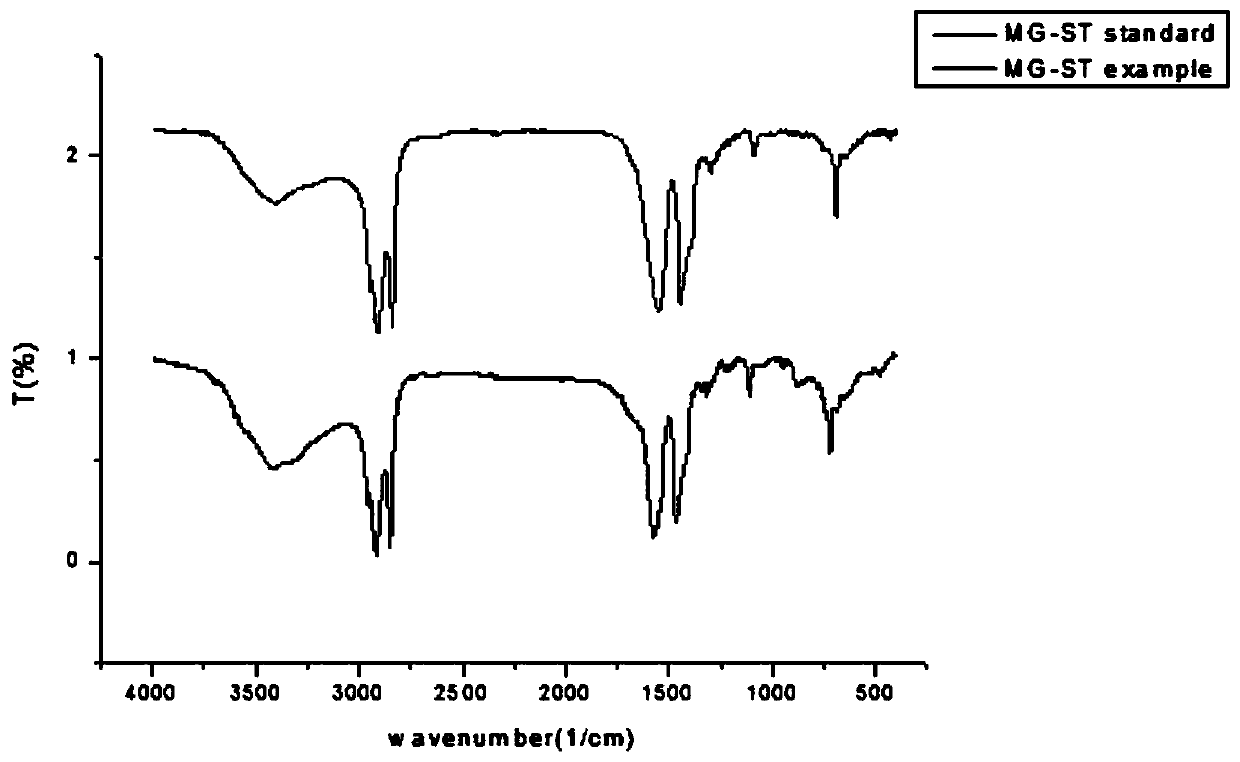

Purification method for glufosinate-ammonium

ActiveCN105541904AHigh purityHigh yieldGroup 5/15 element organic compoundsPurification methodsFatty amine

The invention relates to a purification method for glufosinate-ammonium. The method comprises the following steps that 1, a glufosinate-ammonium hydrochloride crude product is added into a solvent, then, an alkaline water solution is added to be subjected to a neutral reaction, the pH value of the reaction system is adjusted to be 1-4.5, and then filtering and drying are performed to obtain glufosinate-ammonium acid; 2, the glufosinate-ammonium acid obtained in the first step is dissolved into the solvent, then, ammonia gas is introduced to be subjected to a salt forming reaction, glufosinate-ammonium solid is separated out, and filtering and drying are performed to obtain high-purity glufosinate-ammonium. According to the purification technology, fatty amine hard to remove and high-risk ethylene oxide and epoxypropane are prevented from being used, the steps are simple, the obtained glufosinate-ammonium is low in inorganic salt content and high in purity, yield and safety, water or alcohol is used as the solvent in the technological process, ammonium hydroxide and inorganic base are used for being subjected to a neutral reaction, the purification method conforms to the environmental protection and economy principle, and the good industrial prospect is achieved.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

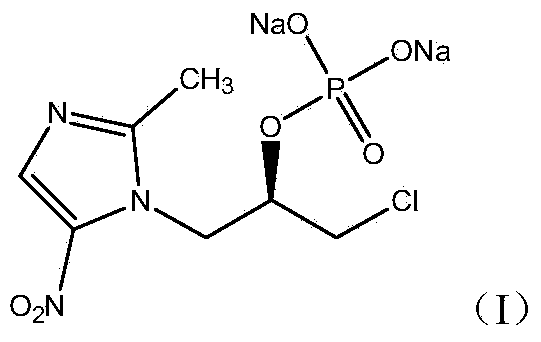

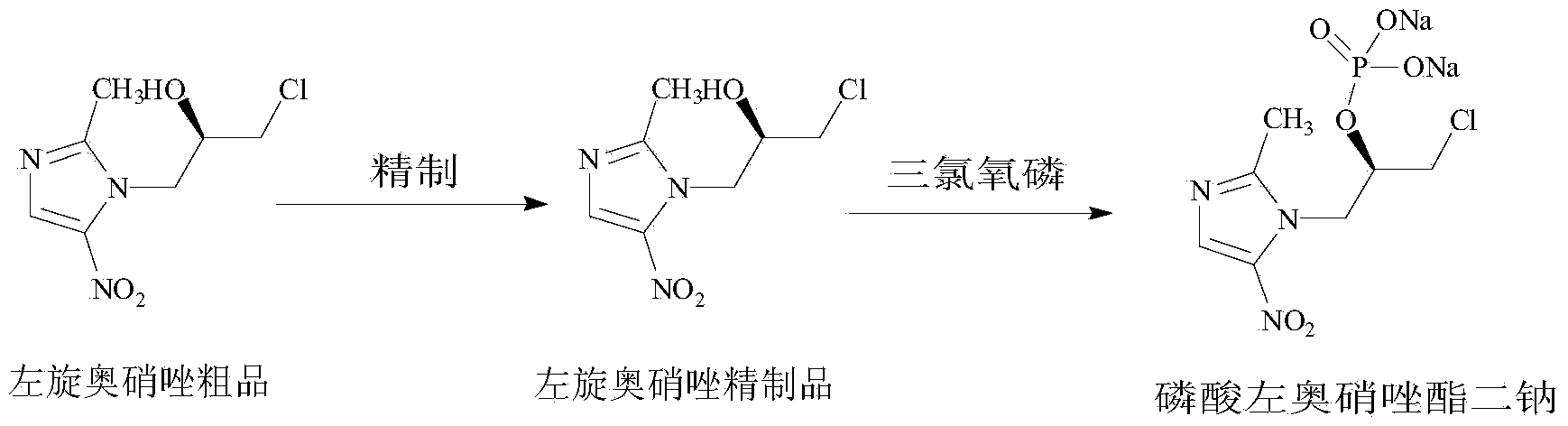

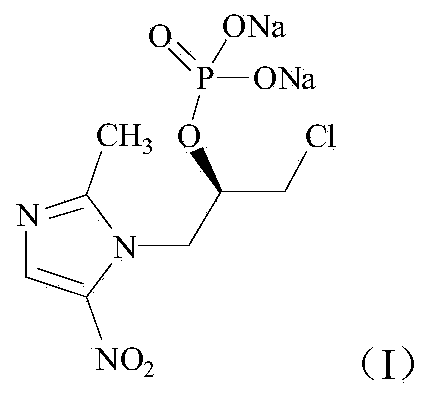

Industrial production method of s-(-)-ornidazole disodium phosphate

InactiveCN104311597ALow Inorganic Salt ContentImprove product qualityGroup 5/15 element organic compoundsInorganic saltsDisodium phosphate

The invention relates to a preparation method of s-(-)-ornidazole disodium phosphate suitable for industrialization. Through the adoption of the scheme, the solvent of methylbenzene in the recrystallization process of S-ornidazole is prevented from being used, and a recrystallization scheme completely without pollution is adopted. Moreover, excess phosphorus oxychloride is removed in advance in the preparation process of the s-(-)-ornidazole disodium phosphate, and thus the content of inorganic salt in a prepared sample is obviously reduced, and the product quality is obviously improved.

Owner:YANGTZE RIVER PHARM GRP NANJING HAILING PHARM CO LTD +1

Preparation method of N-lauroyl-L-alanine saline solution with low inorganic salt content

InactiveCN105001111ALow Inorganic Salt ContentLow content of ethyl ester by-productsOrganic compound preparationCarboxylic acid amides preparationInorganic saltsSaline solutions

The invention discloses a preparation method of N-lauroyl-L-alanine saline solution with low inorganic salt content. The method comprises a reacting step, a separating step, a desolventizing step and a neutralizing step. According to the invention, after reaction, the separating frequency and the separating technological parameters can be controlled for obtaining the end-product with low inorganic salt content, and the content of ethyl ester by-products in the N-lauroyl-L-alanine saline solution is lower than 0.1%.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

Method for preparing Igepon A series anionic surfactant

InactiveCN101157643AImprove product qualityImprove performanceTransportation and packagingMixingSodium dithioniteOrganic compound

The invention relates to a preparative method of anion surfactant of IgeponA series belongs to the technical field of organic compound synthesis. By mixing fatty acyl chloride, fatty acid and hydroxyethyl sodium dithionite, reacting in a normal-pressure reaction apparatus in a heated manner, the product is produced. The invention adopts a few HCI produced in the reaction as the catalyst to speed up the reaction and reduce the irritant property of the product as well as the contact of the organic salt. The odor and the color of the product are thin. With wide application range, the invention is consistent with the basic principle of green chemistry.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Supercritical water oxidation treatment system for organic wastewater with high salinity

ActiveUS9328008B2High salinityLow-cost and efficientWater/sewage treatment by centrifugal separationSolidificationWater desalinationReaction temperature

Owner:XI AN JIAOTONG UNIV

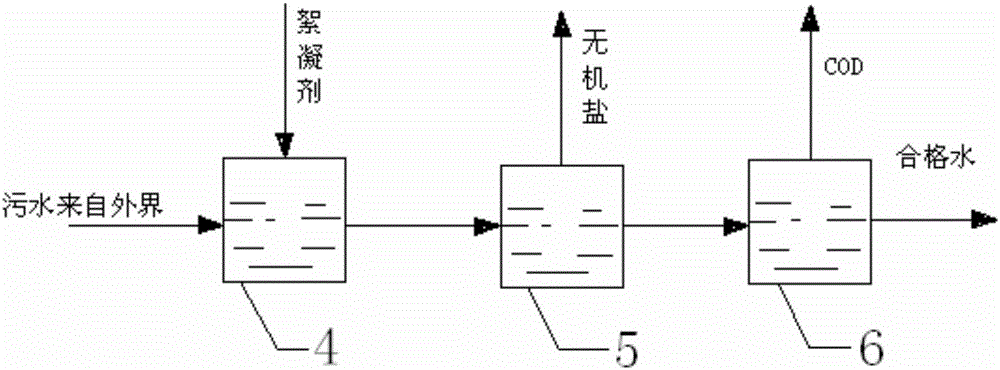

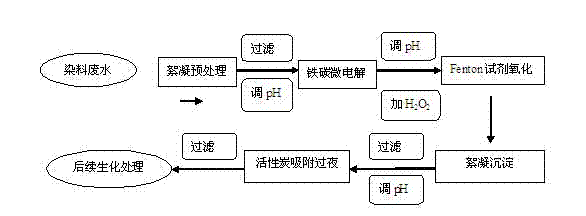

Combination technology for processing difficultly-degraded dye waste water

InactiveCN104743714AComplete decolorization and deodorization treatmentLow priceMultistage water/sewage treatmentInorganic saltsHigh concentration

The dye waste water has the characteristics of high concentration, deep chroma, complex organic matter component, high inorganic salt content, high toxicity and poor biodegradability, which is one of the difficult processing waste water at home and abroad. For the dye waste water containing the difficultly-degraded metal complexation dye, a single Fenton method or an iron-carbon micro-electrolysis technology can not realize complete decolouring, According to the invention, a preflocculation-microelectrolysis-Fenton-postflocculation-adsorption combination technology is employed for degrading the dye waste water, complete decolouring and deodorization treatment of the difficultly-degraded dye waste water can be realized, and COD is decreased by more than 90%.

Owner:JIANGNAN UNIV

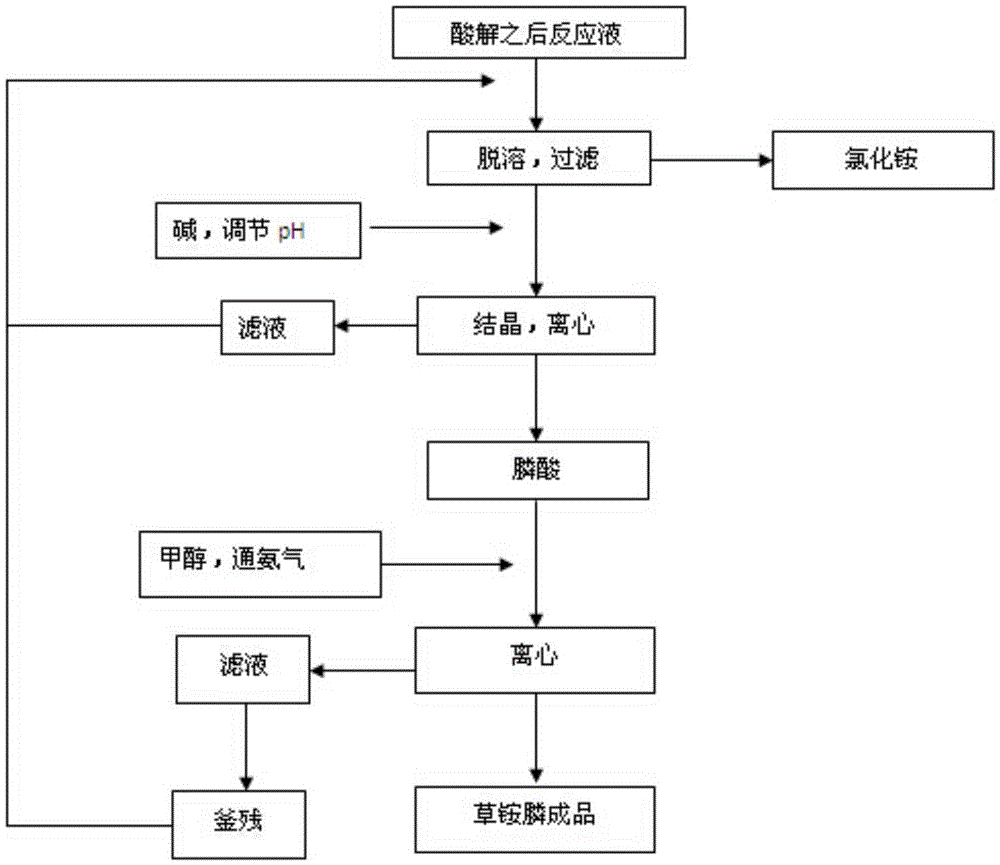

Purification method for glufosinate-ammonium

ActiveCN105541907ALow Inorganic Salt ContentHigh purityGroup 5/15 element organic compoundsPurification methodsFatty amine

The invention relates to a purification method for glufosinate-ammonium. The method comprises the following steps that an acidolysis glufosinate-ammonium hydrochloride reaction solution is heated and distilled to remove low-boiling-point organic solvent and some water, and filtering is performed to remove some ammonium chloride and other insoluble impurities; the pH value of the filtrate is adjusted to be 1-5, and then filtering, washing and drying are performed to obtain glufosinate-ammonium acid; the glufosinate-ammonium acid is dissolved into the solvent, then, ammonia gas is introduced to be subjected to a salt forming reaction, glufosinate-ammonium solid is separated out, and then filtering, washing and drying are performed to obtain high-purity glufosinate-ammonium; the filtrate and glufosinate-ammonium hydrochloride reaction solution are combined. According to the purification technology, fatty amine hard to remove and high-risk ethylene oxide and epoxypropane are prevented from being used, the steps are simple, the obtained glufosinate-ammonium is low in inorganic salt content and high in purity, yield and safety, water or alcohol is used as the solvent in the technological process, ammonium hydroxide and inorganic base are used for being subjected to a neutral reaction, the glufosinate-ammonium conforms to the environment-friendly and economical principle, and the good industrial prospect is achieved.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

Method for improving use ratio of sulfonating agent

ActiveCN103420876AIncrease profitReduce production processSulfonic acids salts preparationInorganic saltsAmmonium hydroxide

Provided is a method for improving the use ratio of a sulfonating agent in the production process of petroleum sulfonate. The method for improving the use ratio of the sulfonating agent is characterized by comprising the steps that (1) the dried air is preheated to be at the temperature from 50DEG C to 80DEG C, the air serves as a stripping medium, the air enters a stripping tower through the bottom of the stripping tower, sulfonation is carried out between raw oil and liquid sulfur trioxide in a sulfonation system to form a sulfonation product, the sulfonation product enters the stripping tower through the top of the stripping tower, the air is 3-20 times the volume of the sulfonation product, neutralization is carried out on acid fluid discharged through the bottom of the stripping tower through a solution with 30% sodium hydroxide or 25% ammonium hydroxide, and solvent is removed to obtain a petroleum sulfonate product; (2) acid gas which contains sulfur trioxide and is discharged through the top of the stripping tower enters the bottom of an absorption tower, fresh raw oil enters the absorption tower through the top of the absorption tower, and the acid gas is 5-30 times the volume of the fresh raw oil; (3) distillate oil discharged from the absorption tower enters the sulfonation system again to carry out a reaction with the liquid sulfur trioxide, then, the process of stripping of the sulfonation product in the stripping tower and the process of absorption of the raw oil to stripped gas are carried out in sequence, and normal production of the petroleum sulfonate can be achieved. The method for improving the use ratio of the sulfonating agent effectively solves the problems that the use ratio of the sulfonating agent in the production process of the petroleum sulfonate is low, and inorganic salt in products is high in content.

Owner:SHANDONG DAMING FINE CHEM CO LTD

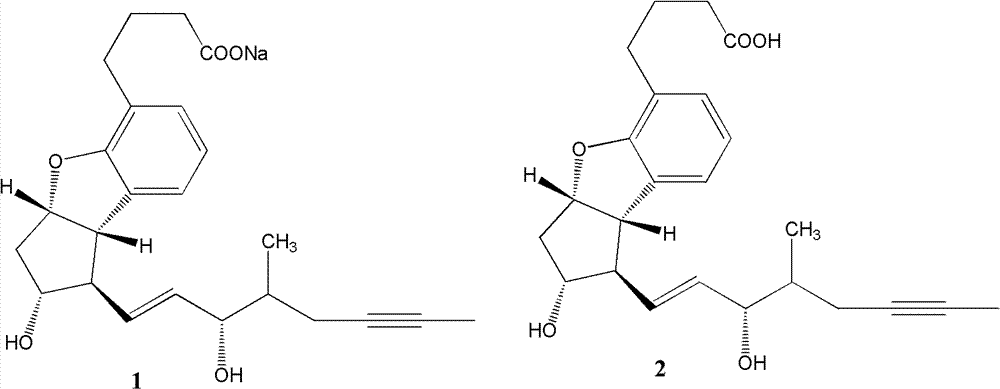

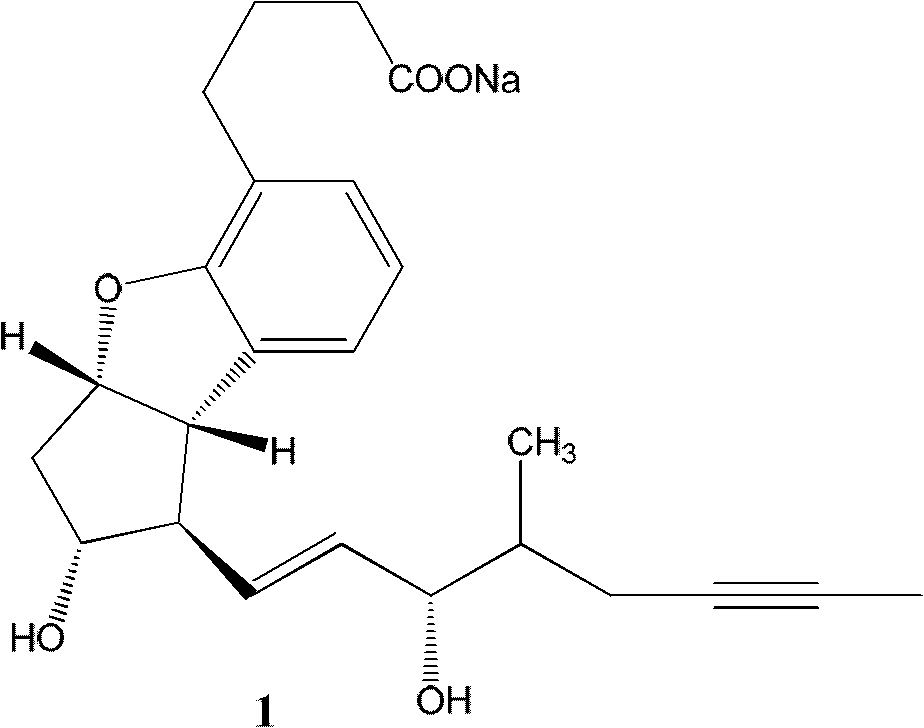

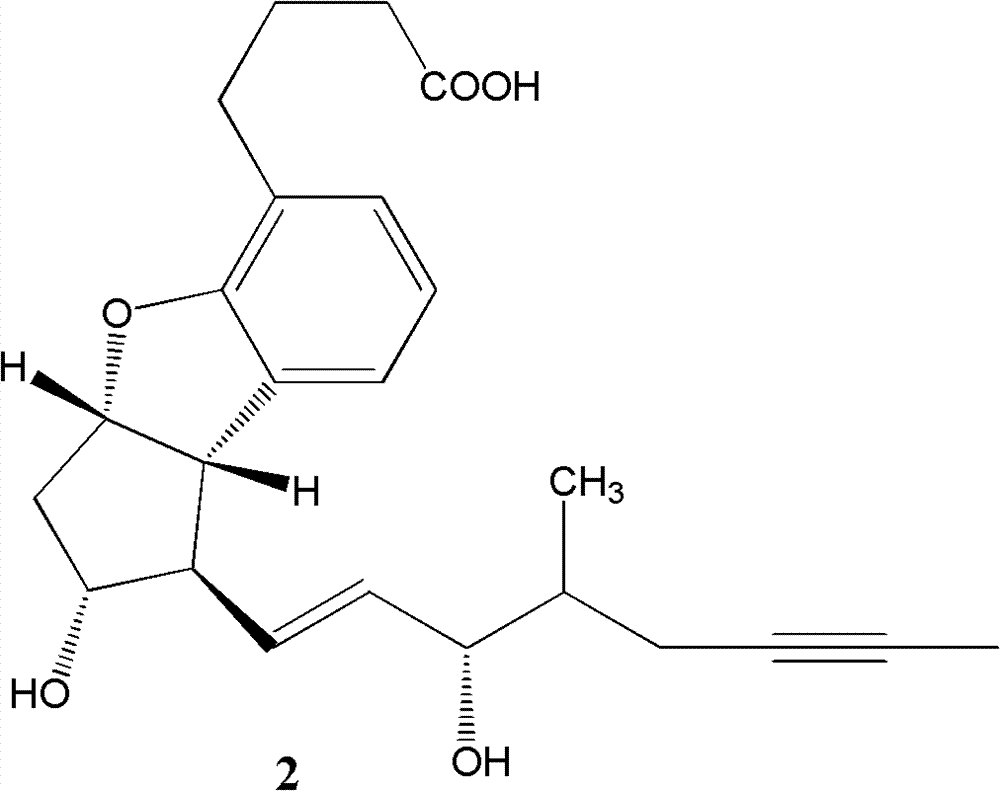

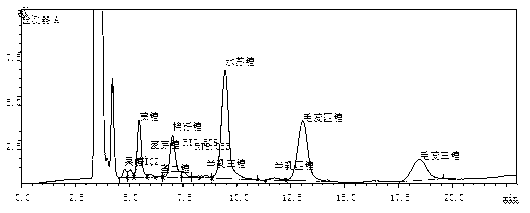

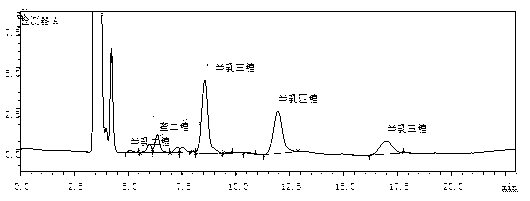

High-purity beraprost sodium as well as preparation method and application thereof

InactiveCN102952107AHigh yieldMild conditionsOrganic active ingredientsOrganic chemistryBeraprost sodiumInorganic salts

The invention discloses high-purity beraprost sodium as well as a preparation method and application thereof. The preparation method of the high-purity beraprost sodium comprises the steps of: desalting a solution containing a beraprost sodium crude product through macroporous resin, then concentrating and drying to obtain the high-purity beraprost sodium with a low inorganic salt content, wherein the mass percent of inorganic salt contained in the high-purity beraprost sodium is less than 0.5 percent. The invention also discloses application of the high-purity beraprost sodium and a medicine composition containing the high-purity beraprost sodium.

Owner:SHANGHAI TECHWELL BIOPHARMACEUTICALS CO LTD

Preparation method of high-purity plant source oligomerization galactose

InactiveCN103131744AHigh Active Ingredient YieldThe fermentation process is simple and controllableMicroorganism based processesFermentationIon exchangePlant Sources

The invention discloses a preparation method of high-purity plant source oligomerization galactose. The preparation method comprises the following steps of obtaining saccharide liquid by the utilization of water extraction or concentrating soybean waste water to use the soybean waste water as to-be-fermented saccharide liquid, consuming monosaccharide and disaccharide in the saccharide liquid by the adoption of a fermentation method, breaking and dissolving fructose bonds in the structure of raffinose-type functional oligosaccharide, and reducing the contents of protein, organic acid, and inorganic acid to the lowest level through precipitation, decoloration, ion exchange, film filtering and the like to obtain the high-purity plant source oligomerization galactose. The oligomerization galactose is composed of galactobiose, galactotriose, galactotetrose and galactopentaose and the content ratio of the oligomerization galactose in total sugar is improved to 70-95% from 5-10% which is before the fermentation.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

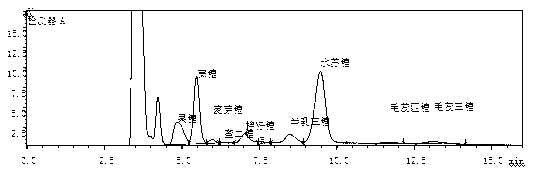

Method of using SO*-air mixture to produce alkylphenol sulfonic acid and salts thereof via film sulfonator sulfonated alkylphenol

ActiveCN101585786AHigh sulfonation rateLow free oil contentLiquid-gas reaction of thin-film typeSulfonic acids salts preparationInorganic saltsAlkylphenol

Method of using SO*-air mixture to produce alkylphenol sulfonic acid and salts thereof via film sulfonator sulfonated alkylphenol, belongs to sulphonate preparing technology field. The invention uses alkylphenol as raw material, and uses SO[3]-air mixture to sulfonate the raw material via film sulfonator to obtain alkylphenol sulfonic acid, and uses alkaline solution such as NaOH to neutralize the alkylphenol sulfonic acid to obtain alkylphenol sulphonate, the alkylphenol used is a alkylphenol containing one or two C[1]-C[20] straight-chain or branched chain alkyl; the alkylphenol sulfonic acid and salt thereof prepared by the method has high sulphonation rate, low free oil content, low inorganic salt content and producing no spend acid, which is no corrosion to equipments and helpful for environmental protection.

Owner:TAIXING LINGFEI CHEM TECH CO LTD

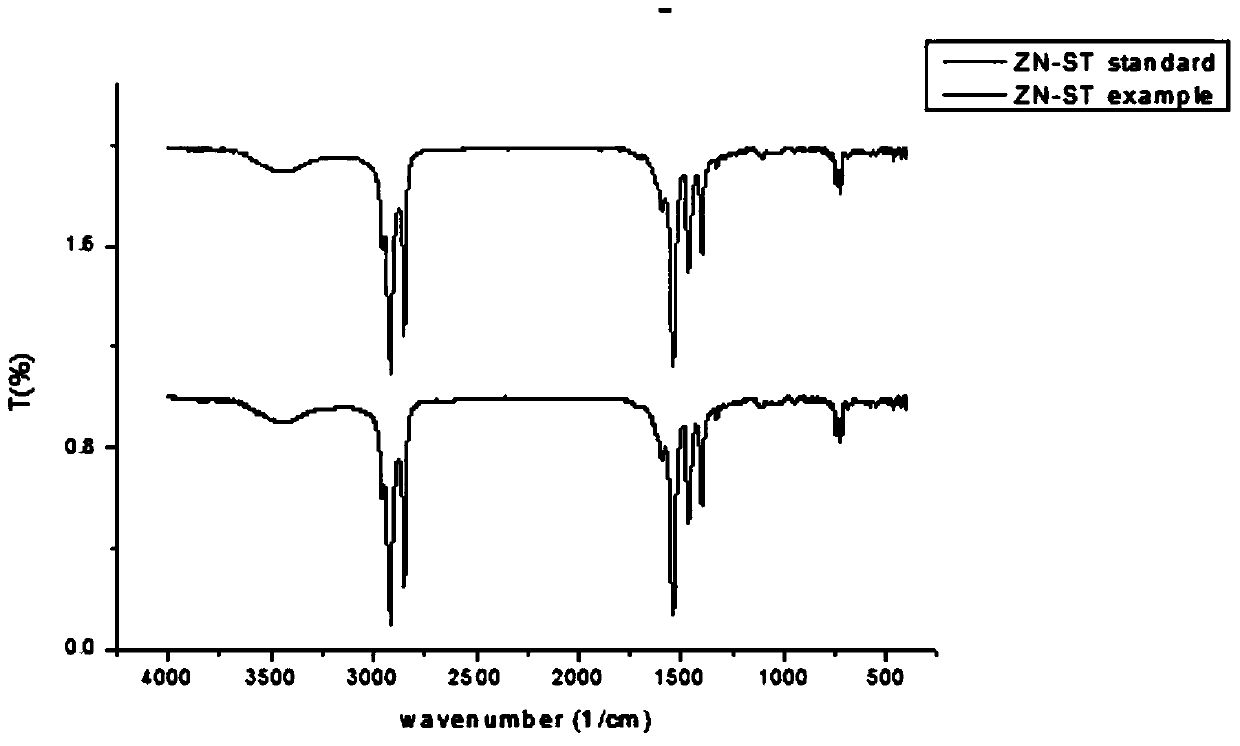

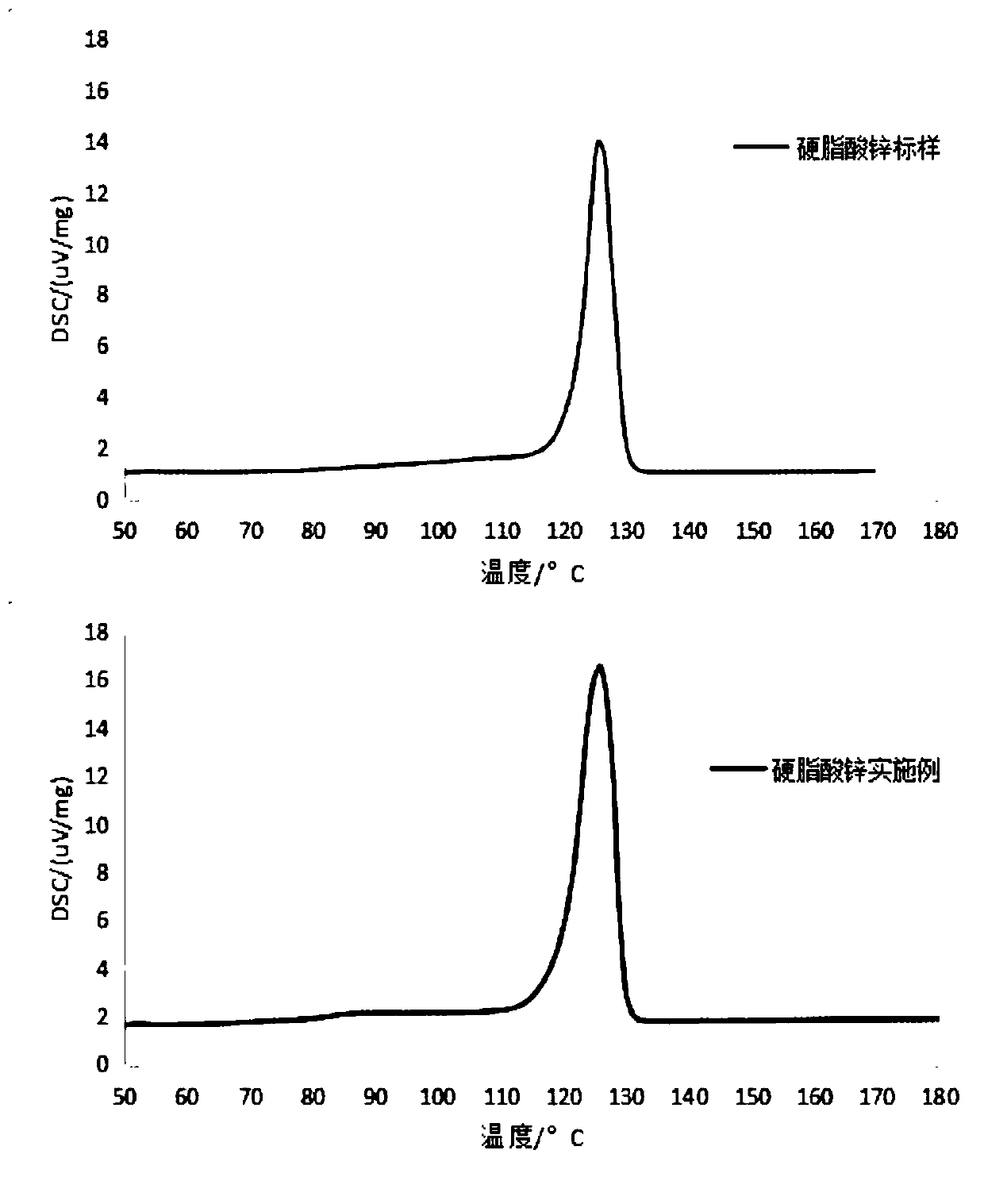

Preparation process of stearate

ActiveCN110183324AUniform product qualityThorough responseOrganic compound preparationCarboxylic acid salt preparationInorganic saltsProcess loss

The invention discloses a preparation process of stearate, which is a preparation method for preparing stearate by directly reacting metal oxide or hydroxide with stearic acid. The process has the advantages of short flow, less equipment consumption, low investment, no waste liquid generation, environmental pollution elimination, saving of a large amount of caustic soda, product cost reduction, less process loss of raw materials, contribution to improving the product yield, and the yield of the finished stearate being 98 percent or more calculated by stearic acid. In addition, no other salt isgenerated in the preparation process, and the stearate product has low inorganic salt content, so that the quality of the product is improved, and the technical scheme disclosed by the invention is suitable for popularization and application.

Owner:DONGGUAN CHNV TECH CO LTD

Method of removing inorganic salt in sulfonate

ActiveCN105801452AWide variety of sourcesLow priceOrganic compound preparationSulfonic acids salts preparationInorganic saltsSulfonate

Disclosed is a method of removing an inorganic salt in sulfonate; the method comprises the following steps: neutralizing sulfonated acidic oil with a neutralizing agent aqueous solution until the pH value is 7-8, and separating out the neutralized sulfonate aqueous solution; adding a water carrying agent, carrying out a dehydration operation, and dehydrating the sulfonate aqueous solution to the water content of less than 1 wt%; cooling the sulfonate after dehydration to 40 DEG C-100 DEG C, taking a physical adsorbent according to 0.1 wt%-5 wt% of the sulfonate, adding the physical adsorbent into the sulfonate after dehydration, and carrying out heat preservation stirring for 1-30 minutes, to obtain an adsorbent-containing sulfonate mixture; filtering the adsorbent-containing sulfonate mixture to obtain sulfonate, and testing the content of the inorganic salt in the sulfonate; and if the content of the inorganic salt is greater than or equal to 0.5 wt%, repeatedly filtering until the content of the inorganic salt in the sulfonate is less than 0.5 wt%. The higher efficacies of effective components in the sulfonate can be achieved.

Owner:PETROCHINA CO LTD +1

Low-cost environment-friendly enzyme powder for clothing and application method thereof

InactiveCN108374282AReduce usageAvoid harmDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsEpoxyCellulose

The invention belongs to the technical field of textile printing and dyeing and in particular relates to low-cost environment-friendly enzyme powder for clothing and an application method thereof, aims at solving the problems in the prior art that the content of inorganic salt is high, after water-washing wastewater is difficult to treat, the use amount of the enzyme powder is great and the environment pollution is caused. The low-cost environment-friendly enzyme powder for the clothing is prepared from the following raw materials: a neutral cellulose raw enzyme, sodium tripolyphosphate, adipic acid, sodium dihydrogen phosphate, xanthan gum, mannan, sodium dodecylbenzene sulfonate, fatty alcohol polyoxyethylene ether and waterborne epoxy resin powder. The application method of the low-costenvironment-friendly enzyme powder comprises the following steps: adding jeans into a washing machine; adding water and setting water temprature; adding the enzyme powder and carrying out enzyme washing; discharging the water and washing the jeans for one time by clean water; fishing, dehydrating and drying to finish an enzyme water washing process. The enzyme powder provided by the invention hasthe advantages of reasonable formula, environment friendliness, low cost, high activity, good anti-dyeing effect, rapid pattern forming speed, small dosage and simple utilization method.

Owner:广州市德鹏新材料科技有限公司

Method for extracting total flavonoids from hibiscus manihot

The invention discloses a method for extracting total flavonoids from hibiscus manihot. The method comprises the following steps: (1) extracting, wherein an ethanol solution having the mass concentration of 40-99% is used as an extraction solution and a hibiscus manihot total flavonoid extract is obtained by virtue of microwave extraction; (2) purifying, namely enabling the hibiscus manihot total flavonoid extract to sequentially pass through hollow fiber ultrafiltration membranes having the molecular weight cutoffs of 10000-50000Da and 2000-6000Da and collecting penetration liquid; next, concentrating the penetration liquid by use of a nanofiltration membrane having the molecular weight cutoff of 100-500Da, thereby obtaining a hibiscus manihot total flavonoid concentrated liquid; (3) refining, namely adsorbing the hibiscus manihot concentrated liquid by use of a macroporous adsorption resin, orderly performing water washing and alcohol washing, and performing freeze-drying to obtain the hibiscus manihot total flavonoids. Compared with the prior art, the technology of the method is capable of greatly increasing the hibiscus manihot total flavonoid extraction ratio, and also capable of reducing the content of macromolecular saccharides and protein in the product, reducing the content of metal ions and inorganic salt in the product and improving the product purity.

Owner:TIANJIN POLYTECHNIC UNIV

Biochemical pretreatment technology of high-hardness and high-salinity papermaking wastewater

InactiveCN106045215AReduce hardnessLow Inorganic Salt ContentSludge treatment by de-watering/drying/thickeningWater treatment parameter controlWater qualityPapermaking

The invention discloses a biochemical pretreatment technology of high-hardness and high-salinity papermaking wastewater. The biochemical pretreatment technology comprises a physicochemical treatment step, a conveying step, a strong aeration step, a precipitating step and a discharging step, wherein strong aeration is performed through a jet aeration system adopting variable frequency control and a staggered perforated aeration pipe which are arranged inside a strong aeration tank, so that the papermaking wastewater is fully mixed in the strong aeration tank. The biochemical pretreatment technology of the high-hardness and high-salinity papermaking wastewater, provided by the invention, is simple and feasible, and stable in treatment effect; by the biochemical pretreatment technology, the high-hardness and high-salinity papermaking wastewater can be effectively softened to improve water quality and reduce water hardness and inorganic salt content, so that a requirement on continuous and stable operation of a subsequent biochemical system is met; a whole process is clean and pollution-free, environment-friendly and energy-saving, and very low in running energy consumption and running cost.

Owner:东莞顺裕纸业有限公司

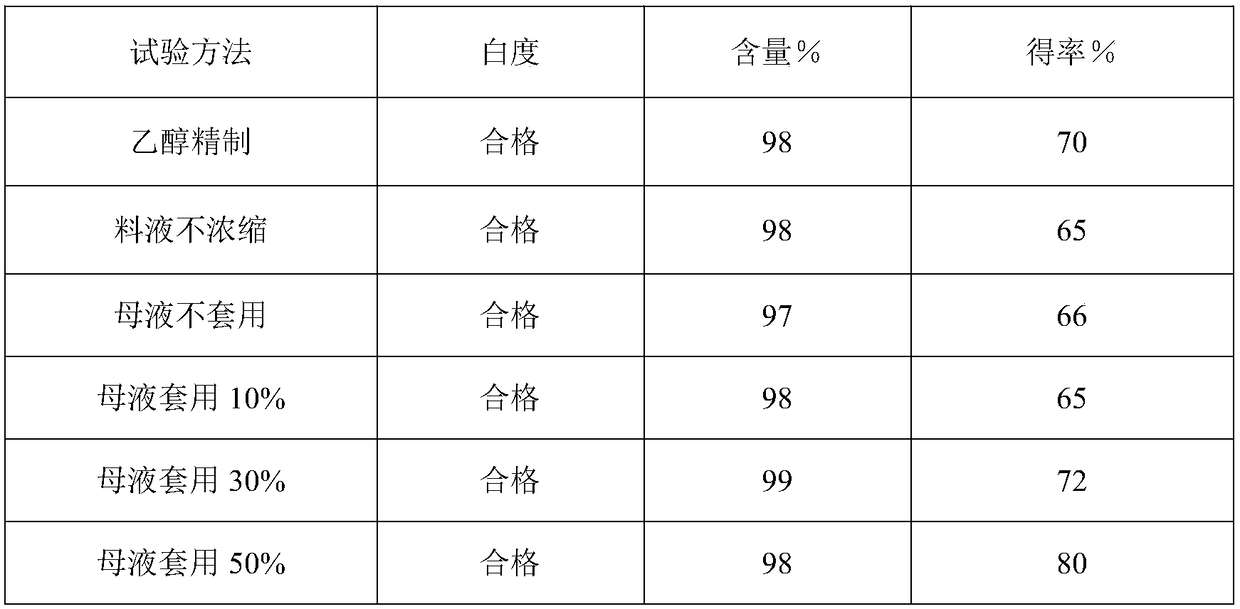

Inositol refining method

InactiveCN108689801ALow Inorganic Salt ContentSave inorganic saltHydroxy compound separation/purificationInorganic saltsAlcohol

The invention relates to an inositol refining method. The inositol refining method comprises the following steps of: (1) dissolving a crude inositol product in distilled water to prepare inositol solution, and then heating; (2) adding active carbon into the inositol solution to carry out decolorization; (3) carrying out negative-pressure suction filtration at the temperature of 90 DEG C to removeactive carbon, crystallizing after concentrating and cooling to 25 DEG C, and filtering to obtain a primary refined product of inositol and collecting refined mother liquid; (4) redissolving the crystallized primary refined product of inositol in the distilled water, repeating the step (2) and the step (3) to obtain an inositol finished product, and collecting filtered mother liquid. The inositolrefining method has the beneficial effects that by adoption of multiple dissolution, filtration and cooling crystallization for inositol, the content of inorganic salt of the finished product is low,the product yield is high when the mother liquid is applied, and is highest when the mother liquid is mechanically applied by 50%; compared with a method for refinement by adopting alcohol as a solvent, the product safety is higher, the solvent does not need to be recovered, the production cost is lower, the inorganic salt is less and the product quality is higher.

Owner:安徽谷天下食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com