Glufosinate purifying technology

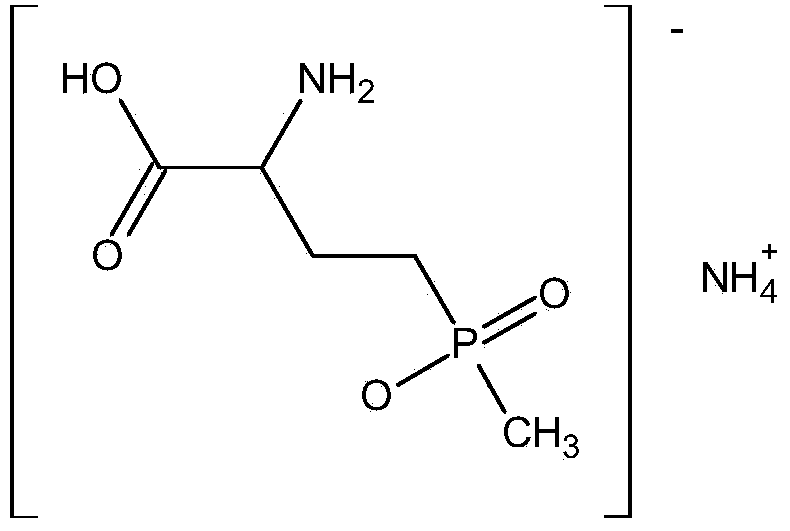

A technology of glufosinate-ammonium and glufosinate-ammonium hydrochloride is applied in the fields of compounds of Group 5/15 elements of the periodic table, organic chemistry, chemical instruments and methods, etc., and can solve the problem of long process route and low purification yield of purification process. , low yield and other problems, to achieve the effect of simple process steps, high industrialization prospects, and low inorganic salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

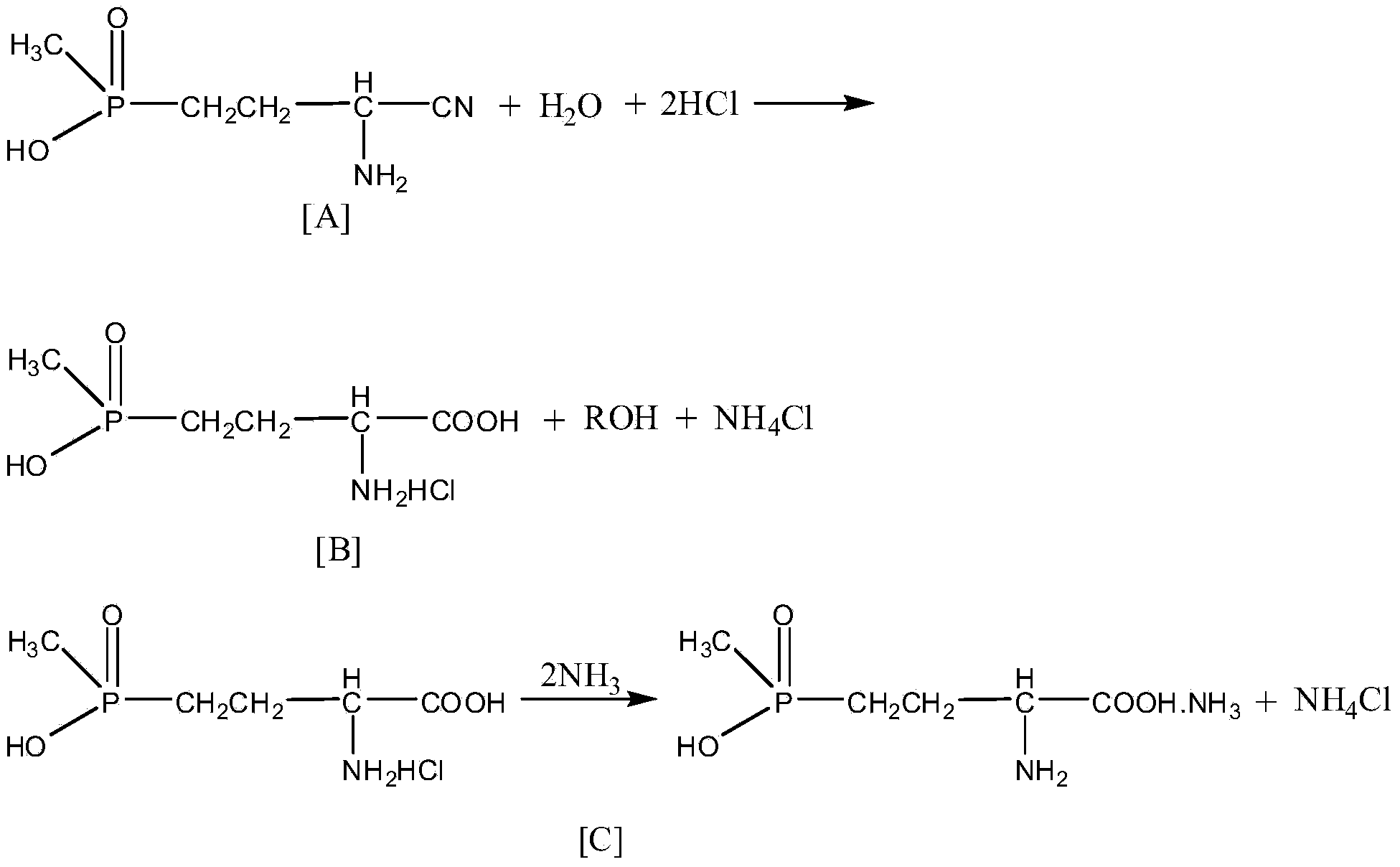

Method used

Image

Examples

Embodiment 1-4

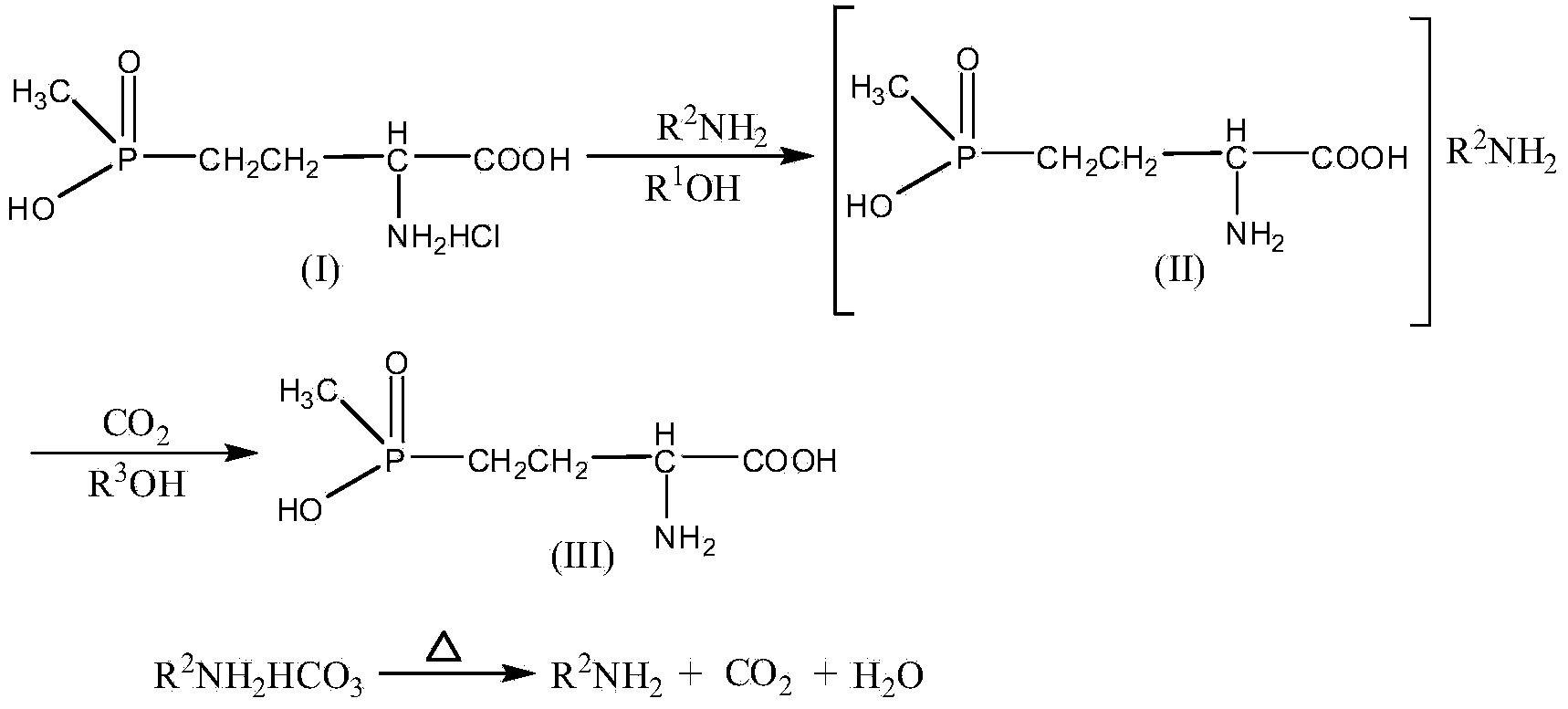

[0023] According to the feed ratio of Table 1, glufosinate-ammonium hydrochloride (I) is added in 200ml methanol, add R 2 NH 2 Carry out the ammoniation reaction until the pH value is 9. After the reaction is complete, cool to below 20°C and filter to remove the insoluble matter in the system (the white solid is NH 4 Cl and a small amount of sodium chloride), the filtrate decompresses and removes the solvent to obtain glufosinate-ammonium ammonium salt (II) and a small amount of organic impurities, and the alcohol solvent that evaporates can be recycled;

[0024] Table 1 Feed ratio and reaction conditions of ammoniation reaction

[0025]

[0026] According to the proportioning and reaction conditions of table 2, the glufosinate-ammonium ammonium salt product (II) that embodiment 1-4 prepares 1 )-(II 4 ) were added to 60ml water respectively, and CO 2 Gas, carry out neutralization reaction until the pH value is 3.0, after the reaction is complete, cool down to below 20°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com