Patents

Literature

274 results about "Glufosinate-ammonium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

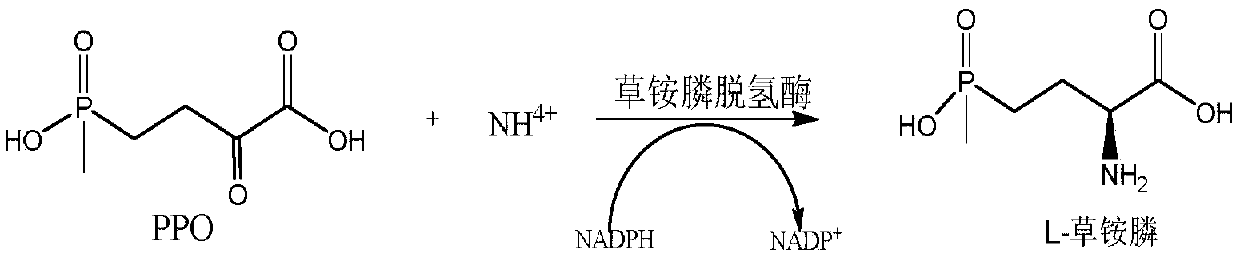

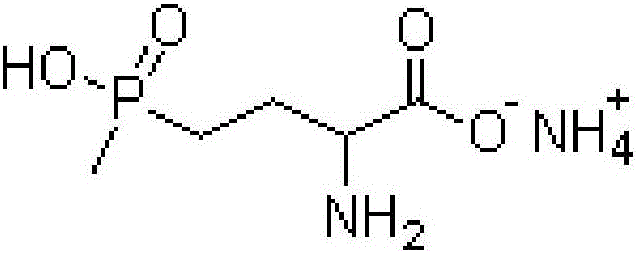

Method for preparing L-glufosinate-ammonium by use of amino acid dehydrogenase

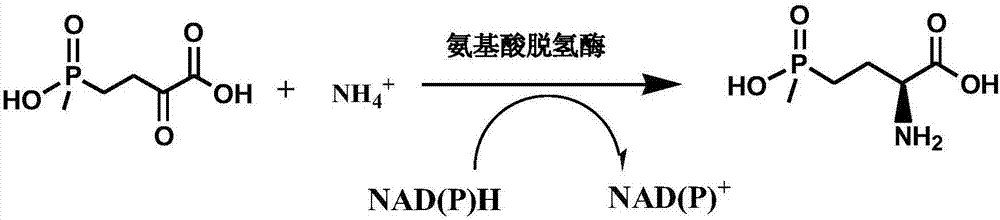

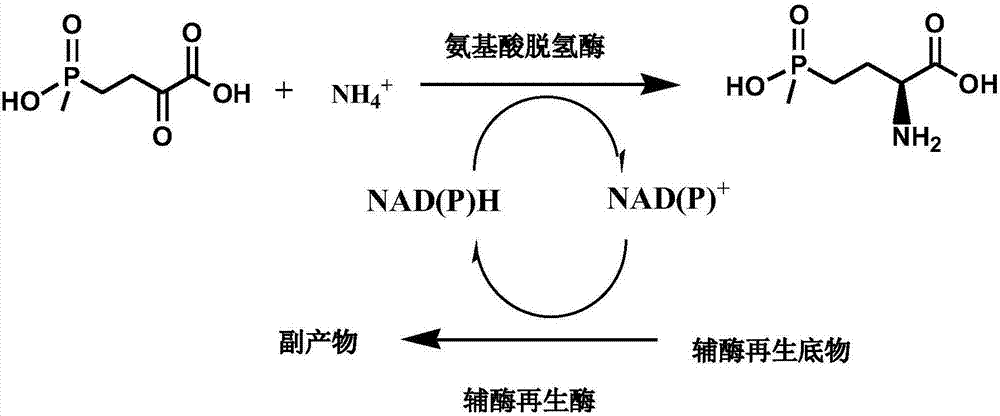

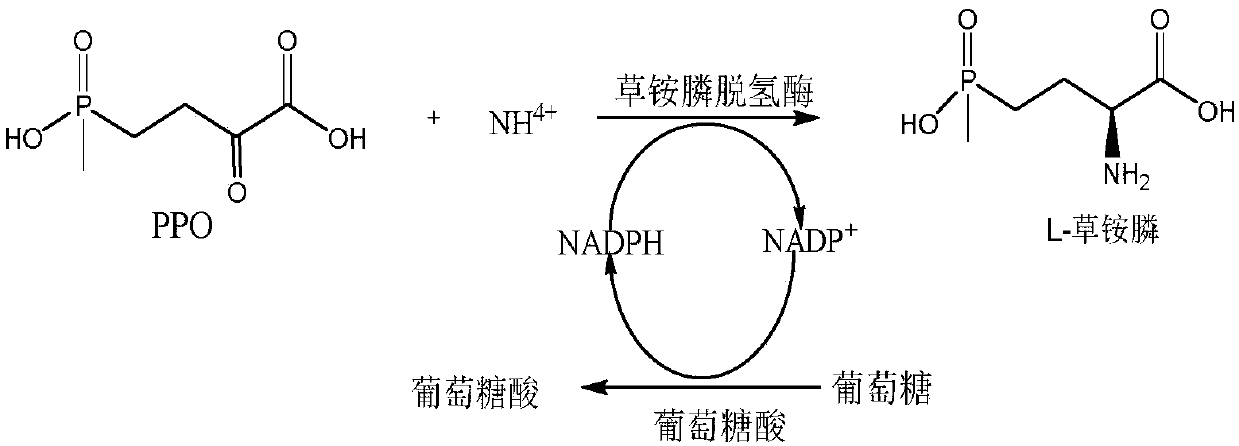

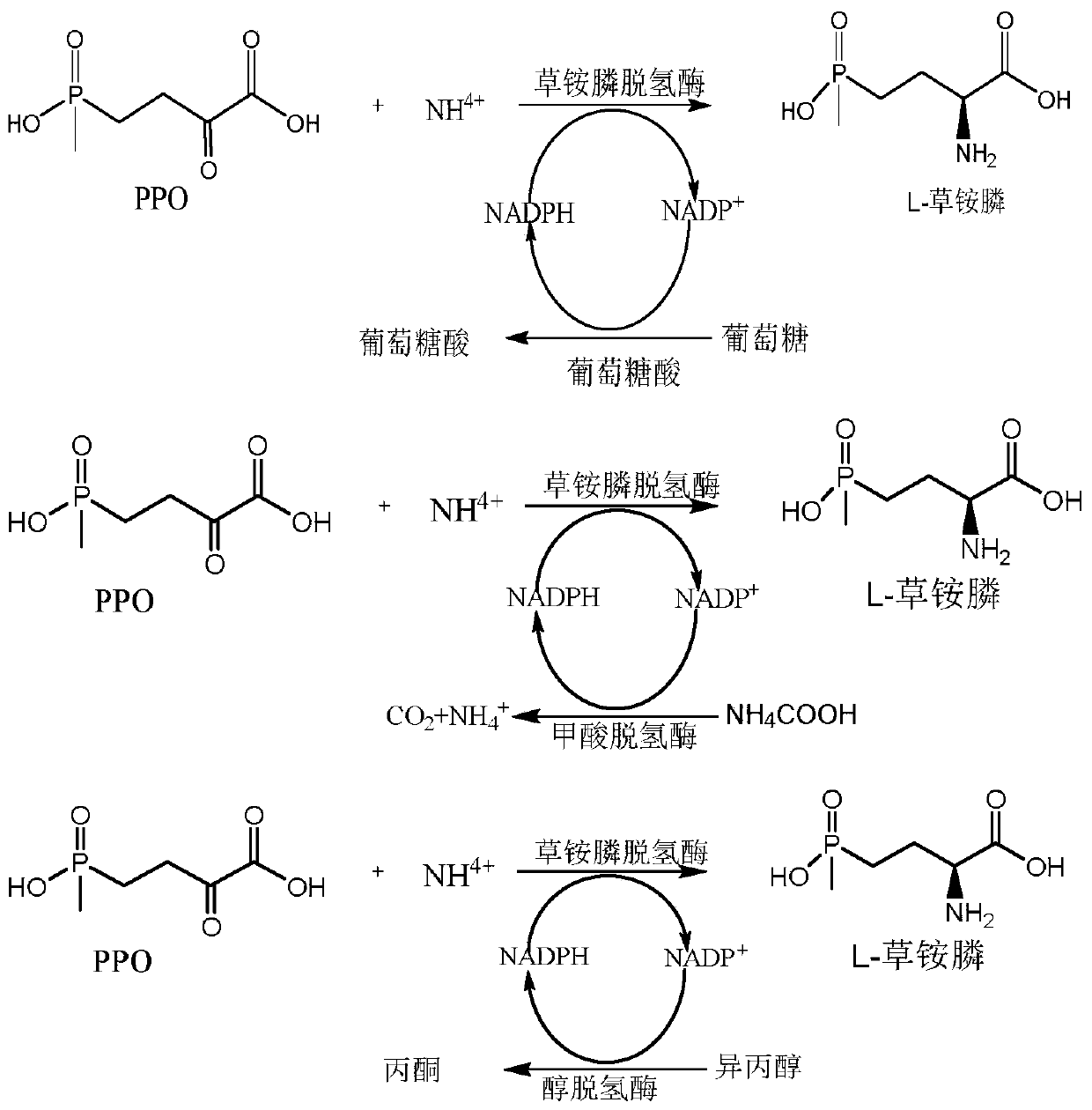

The invention discloses a method for preparing L-glufosinate-ammonium by use of amino acid dehydrogenase. The method comprises the following steps: taking 2-carbonyl-4-(hydroxymethylphosphonyl)butyric acid or a salt thereof as a substrate, taking a cell of the isolated glutamate dehydrogenase or in vitro expression glutamate dehydrogenase as a catalyst to perform reductive amination reaction under the condition of the existence of inorganic amino donor and reduced coenzyme, thereby acquiring the L-glufosinate-ammonium. The method disclosed by the invention is high in raw material conversion rate and high in yield, the product is easy to separate and purify, and the chirality purity is high; compared with the transaminase and like catalysis technology, the process is relatively simple, and the raw material conversion rate reaches up to 100%.

Owner:ZHEJIANG UNIV

A kind of purification process of glufosinate-ammonium

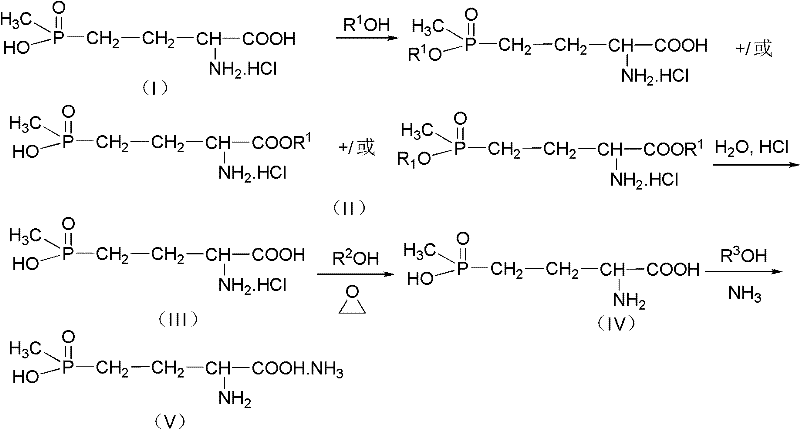

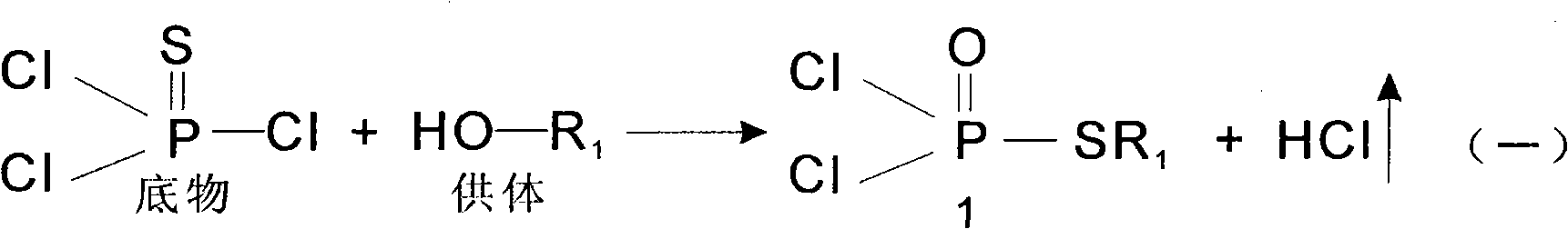

ActiveCN102268037AThe purification process steps are simpleLow Inorganic Salt ContentGroup 5/15 element organic compoundsEpoxySolvent

The invention discloses a process for purifying glufosinate-ammonium, which comprises: (1) adding glufosinate-ammonium hydrochloride into an alcohol R1OH to perform an esterification reaction, and after the reaction is accomplished, cooling, filtering, removing solvent from filtrate and obtaining ester product of glufosinate-ammonium; (2) adding the ester product of glufosinate-ammonium, which isobtained by step (1), into water solution of hydrochloric acid to perform a hydrolysis reaction, and obtaining glufosinate-ammonium hydrochloride by post treatment; (3) adding the glufosinate-ammonium hydrochloride obtained by the step (2) into an alcohol R2OH, introducing epoxy ethane and obtaining glufosinate-ammonium acid; and (4) adding the glufosinate-ammonium acid obtained by the step (3) into an alcohol R3OH, introducing ammonia gas, and obtaining glufosinate-ammonium after the reaction is finished. In the invention, the process for purifying glufosinate-ammonium comprises simple steps, the inorganic salt content in the obtained glufosinate-ammonium is low, and the purity of the obtained glufosinate-ammonium is high; the process for separating glufosinate-ammonium hydrochloride from HCl by epoxy ethane is more economic than the conventional process which adopts epoxypropane and epoxy chloropropane; and the method is very safe and has a very bright industrialization prospect.

Owner:YONGNONG BIOSCI

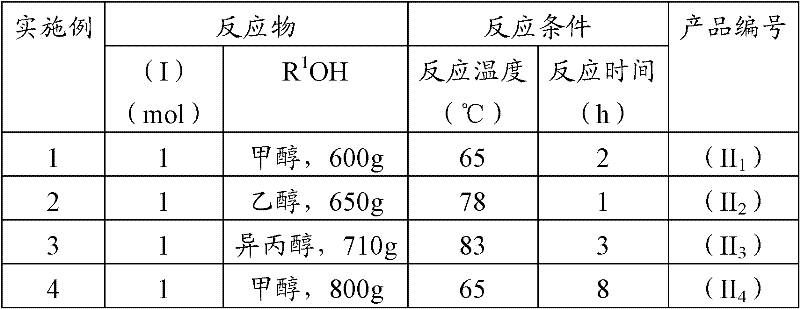

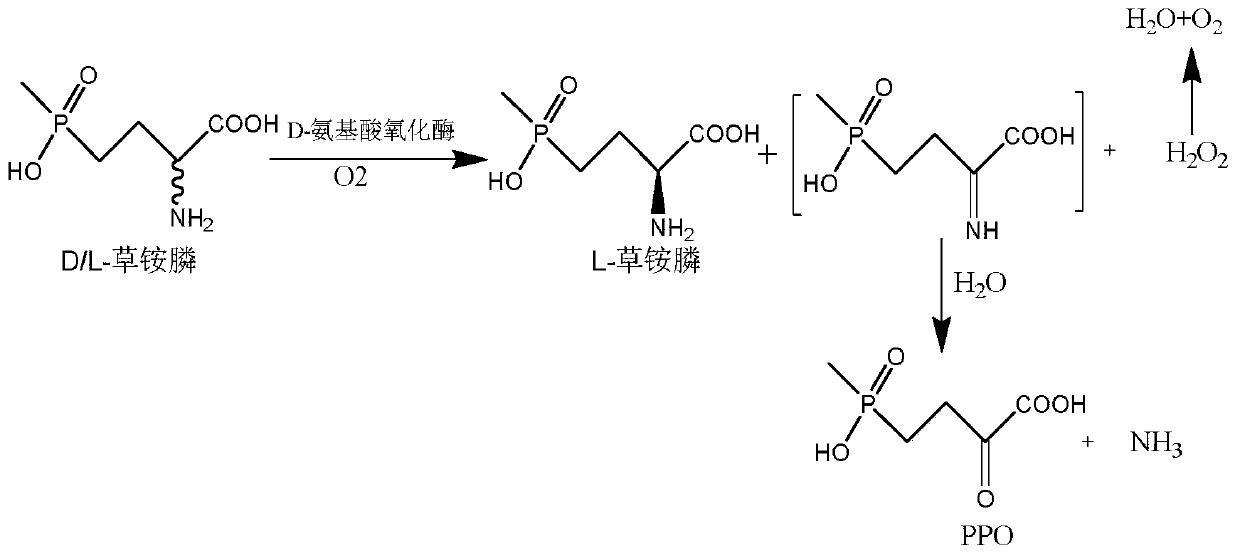

Enzyme-chemocatalysis racemization removing preparation method for L-glufosinate-ammonium

The invention discloses an enzyme-chemocatalysis racemization removing preparation method for L-glufosinate-ammonium. According to the method, a one-pot reaction manner is adopted, under the molecular oxygen, immobilization D-amino acid oxidase catalyzes D-enantiomer in an enantioselectivity mode into 2-imino-4-(hydroxy methyl phosphonyl) butyric acid in a dehydrogenation mode, and palladium-ammonium formate catalyzes 2-imino -4-(hydroxy methyl phosphonyl) butyric acid into DL-glufosinate-ammonium in an in-situ reduction mode. Hydrogen peroxide produced in the process is efficiently decomposed into water and oxygen through catalase. Complete reacemization removing of DL-glufosinate-ammonium and efficient preparing of L-glufosinate-ammonium are achieved through biological oxidation-chemical reduction circulation. The method has the advantages that the process is simple, cost is low, environmental friendliness is achieved, and energy is saved. High-concentration DL-glufosinate-ammonium can be converted into L-glufosinate-ammonium. The yield is 90%, the optical purity of the product is 99%, and the method is suitable for industrial production of L-glufosinate-ammonium.

Owner:重庆惠健生物科技有限公司

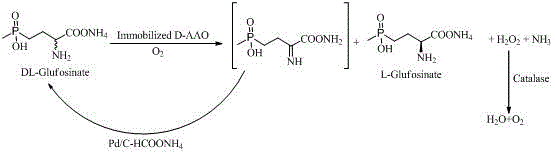

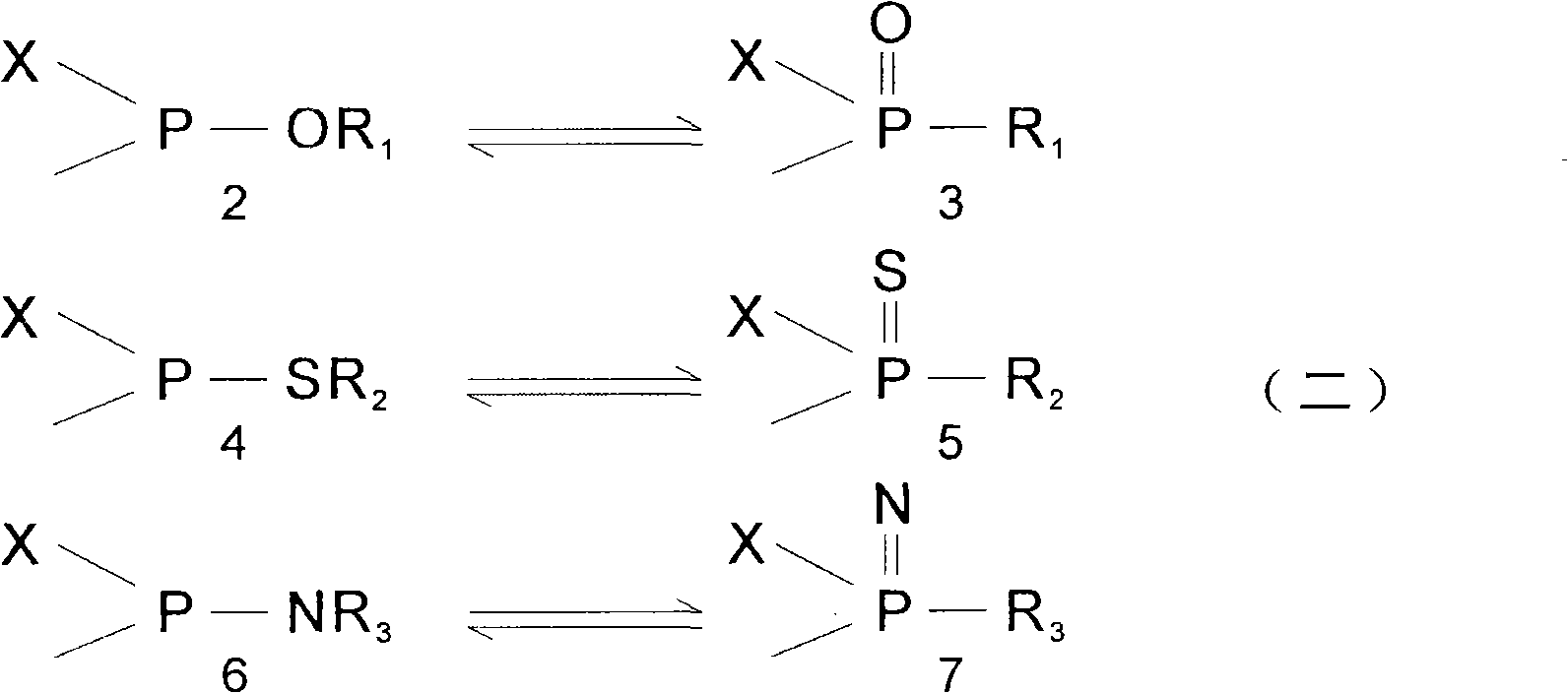

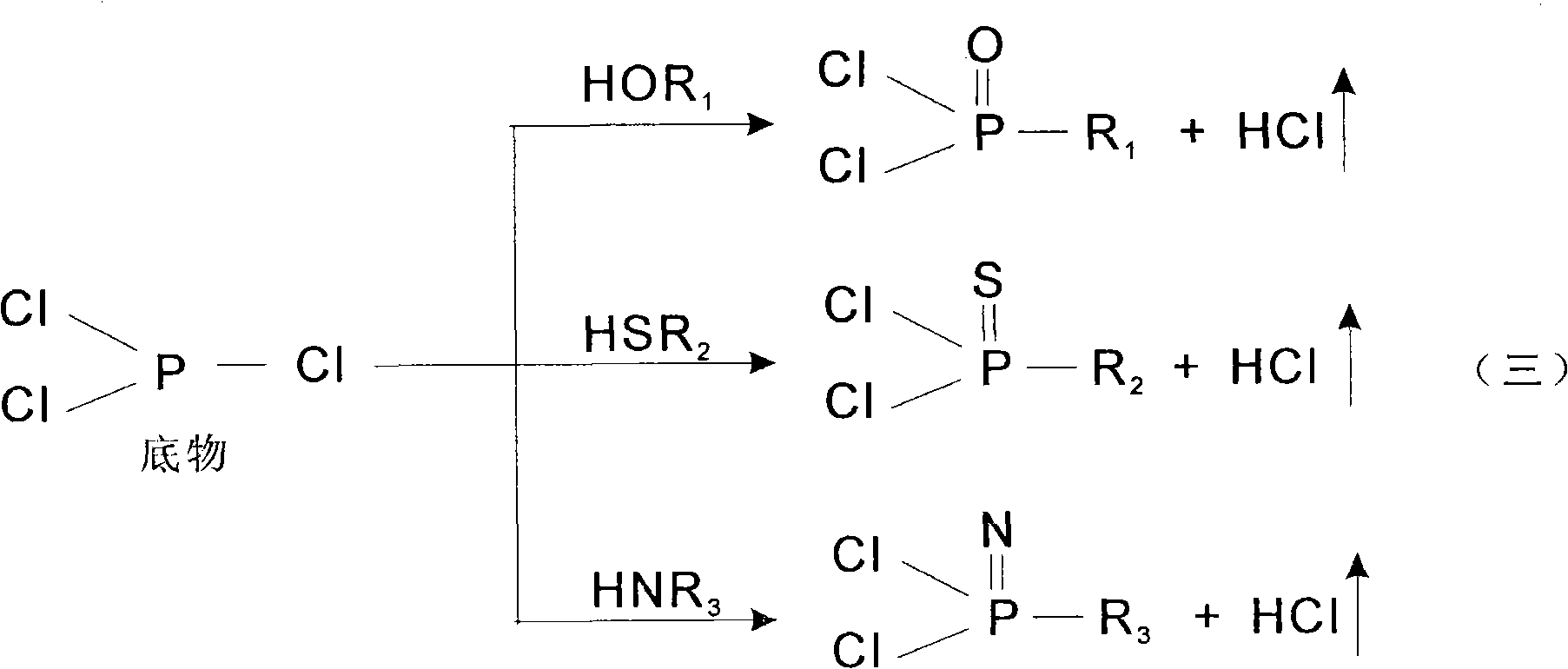

Isomerization reaction

The invention discloses a highly selective novel reaction with an important application value in organic phosphorus synthesis methodology. The reaction can be applied in important pesticide commodities of acephate, glyphosate, glufosinate-ammonium, chloramine phosphorus, profenofos, and the like. With the reaction, innovative technical synthetic routes can be designed. With the reaction, standards of clean production technologies can be satisfied, and the production cost is greatly reduced compared to existing technical routes.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

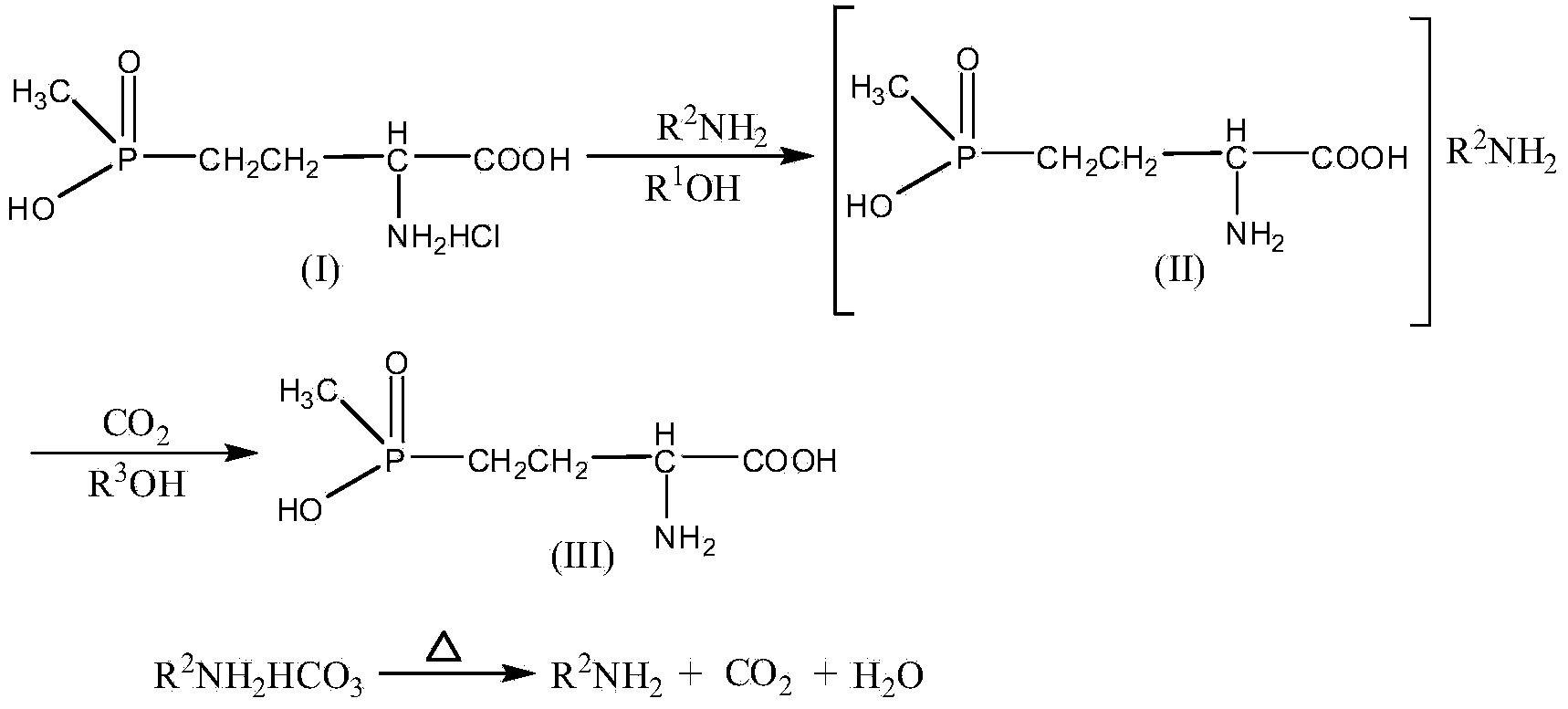

Glufosinate purifying technology

ActiveCN103819503AThe purification process steps are simpleLow Inorganic Salt ContentGroup 5/15 element organic compoundsDecompositionSolvent

The invention provides a glufosinate purifying technology including the following steps: (1) adding glufosinate hydrochloride to alcohol R1OH, adding R2NH2 for ammoniation, adjusting the pH to 7.0-14.0, cooling and filtering, removing a solvent from a filtrate to obtain glufosinate ammonium salt and a small amount of organic impurities; (2) dissolving the glufosinate ammonium salt obtained by the steps (1) in an appropriate amount of water, leading in CO2 for neutralizing to the pH of 2.0-5.0, adding a proper amount of alcohol R3OH for precipitation of glufosinate acid, centrifugally filtrating to obtain the glufosinate acid which contains a small amount of ammonium hydrogen carbonate or organic amine carbonates; (3) heating for drying a glufosinate acid filtering cake obtained by the step (2) for decomposition and volatilization of the ammonium hydrogen carbonate or organic amine carbonates to obtain high purity glufosinate acid. The glufosinate purifying technology is simple in steps, the obtained glufosinate is low in inorganic salt content and high in purity, and compared with a traditional technology using epoxy ethane and epoxy propane, the purifying technology using carbon dioxide for separation of glufosinate hydrochloride and HCl is more economical, and high in safety, and has a higher industrialization prospect.

Owner:SHANDONG BINNONG TECH

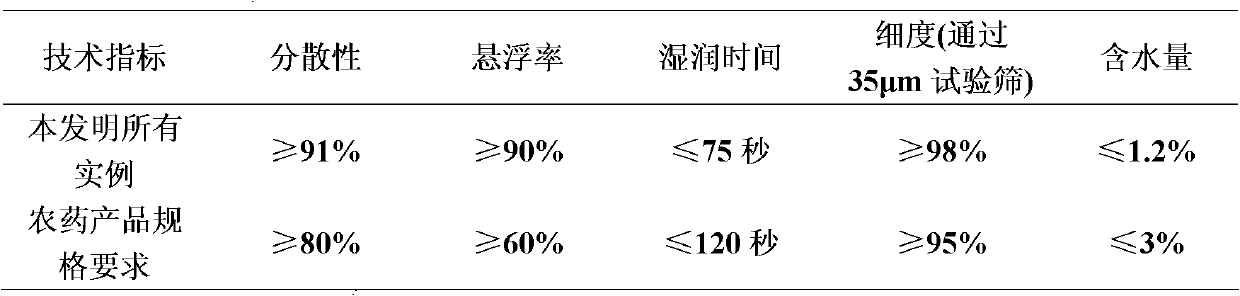

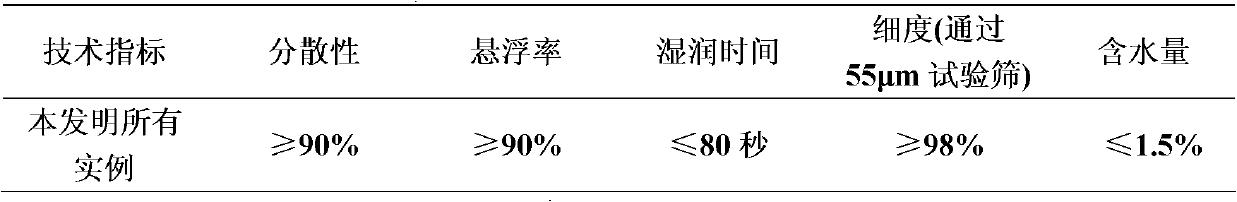

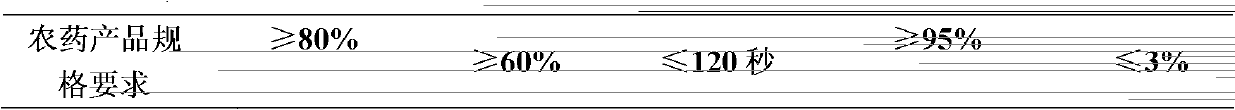

Glufosinate-ammonium-containing weeding composition

InactiveCN103371175ADelay drug resistanceReduce developmentBiocideAnimal repellantsGlufosinate-ammoniumFluroxypyr

The invention relates to a glufosinate-ammonium-containing weeding composition which is mainly characterized by containing 1-80% of effective component A glufosinate-ammonium and 1-60% of effective component B, wherein the effective component B is selected from any one of the following weedicides: sodium 2-methyl-4-chlorophenoxyacetate, carfentrazone-ethyl and fluroxypyr. The glufosinate-ammonium-containing weeding composition is prepared into wettable powder, water-dispersible granules, microemulsion, aqueous emulsion, aqueous solution, soluble solution, soluble powder or oil suspending agent. The weeding composition provided by the invention is used for controlling weed.

Owner:陕西亿田丰作物科技有限公司

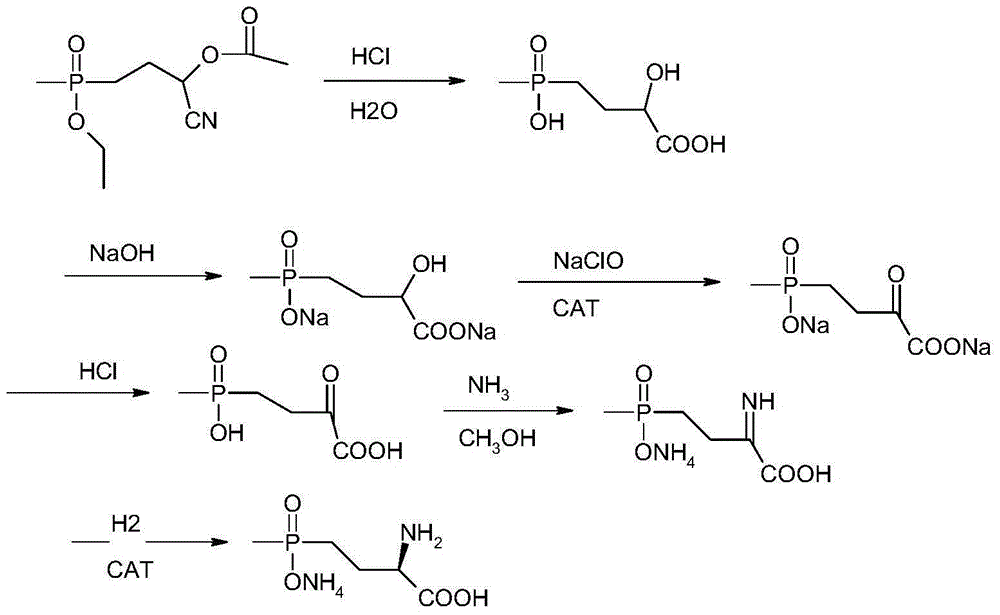

Synthetic method for L-type glufosinate ammonium

ActiveCN105218579AEfficient weed controlImprove weed control efficacyGroup 5/15 element organic compoundsSodium hydroxideHydroxy compound

The invention relates to a synthetic method for L-type glufosinate ammonium. The synthetic method includes the steps that 4-(oxethyl-(methyl) phosphinyl)-2-acetoxyl butyl cyanide and hydrochloric acid react to obtain 4-(hydroxyl-(methyl) phosphinyl)-2-hydroxybutyric acid; 4-(hydroxyl-(methyl) phosphinyl)-2-hydroxybutyric acid reacts with a sodium hydroxide water solution to obtain 4-(sodium hydroxyl-(methyl) phosphinyl)-2-sodium hydroxyl butyrate; 4-(sodium hydroxyl-(methyl) phosphinyl)-2-sodium hydroxyl butyrate reacts with a sodium hypochlorite water solution to obtain 4-(sodium hydroxyl-(methyl) phosphinyl)-2-sodium carbonyl butyrate; 4-(sodium hydroxyl-(methyl) phosphinyl)-2-sodium carbonyl butyrate reacts with hydrogen chloride gas to obtain 4-(hydroxyl-(methyl) phosphinyl)-2-carbonyl butyric acid; 4-(hydroxyl-(methyl) phosphinyl)-2-carbonyl butyric acid reacts with liquid ammonia, and then hydrogen is introduced for reacting to obtain L-type glufosinate ammonium. The synthetic method is simple in technical process, small in pollution, high in yield and low in cost, the obtained finished product is levorotatory glufosinate ammonium with the efficient weeding effect, and the weeding effect of glufosinate ammonium is greatly improved.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

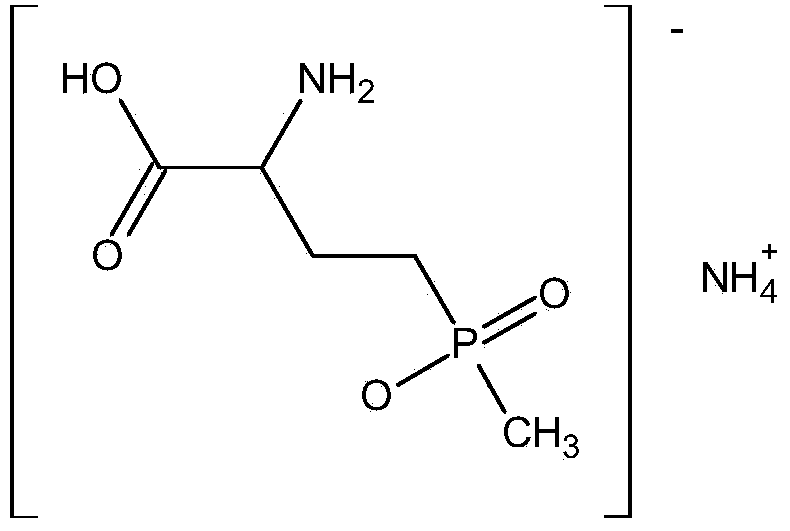

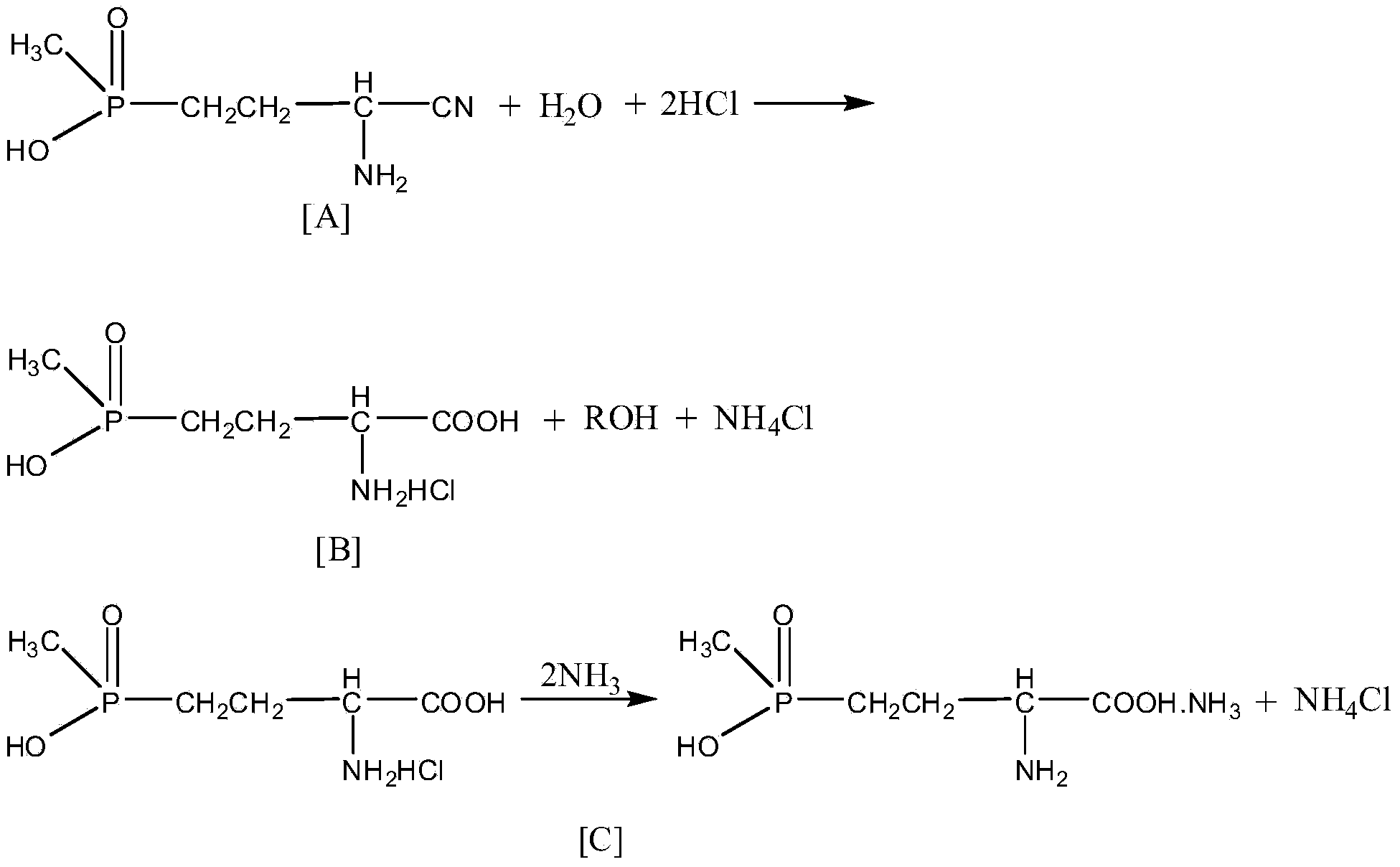

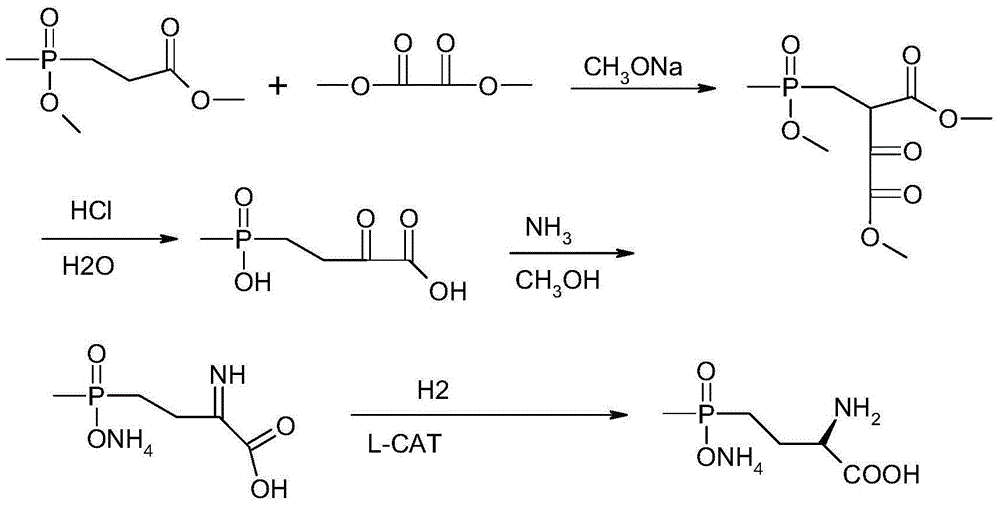

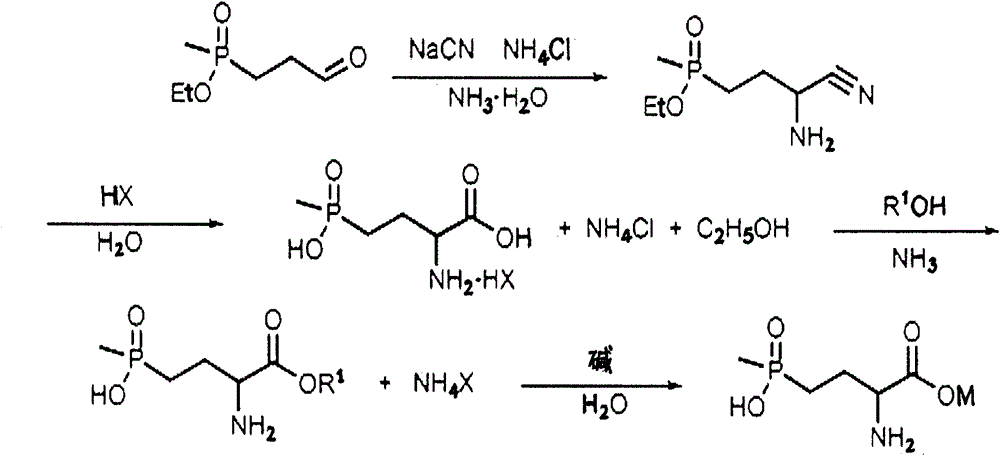

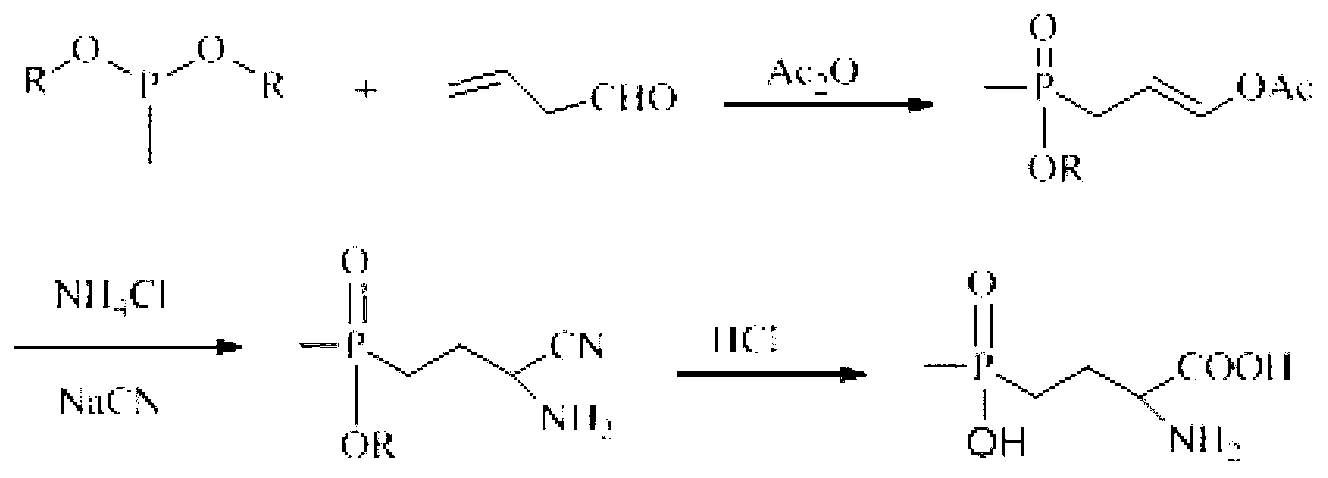

Glufosinate-ammonium preparation method

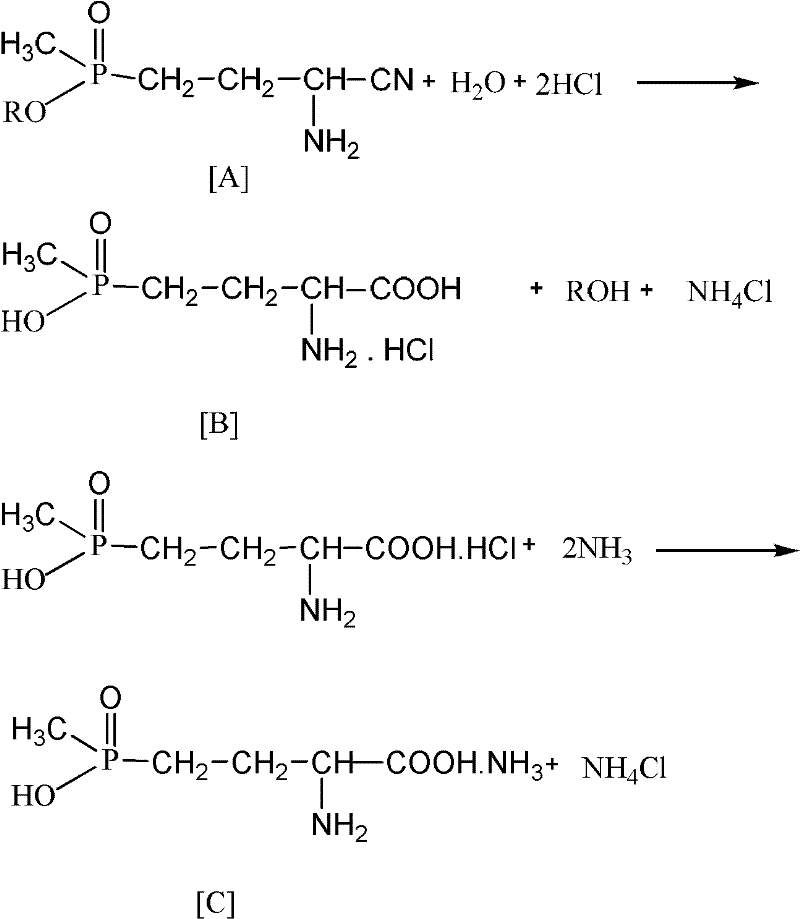

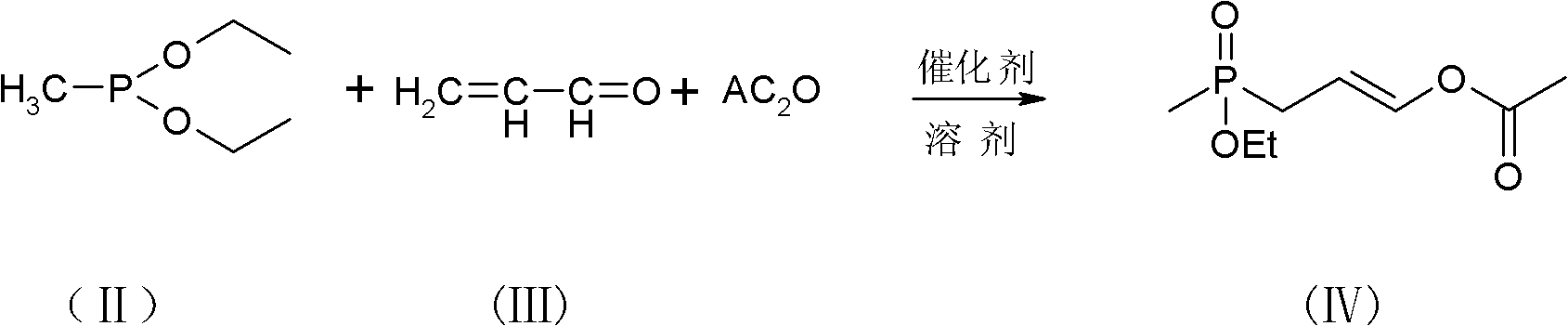

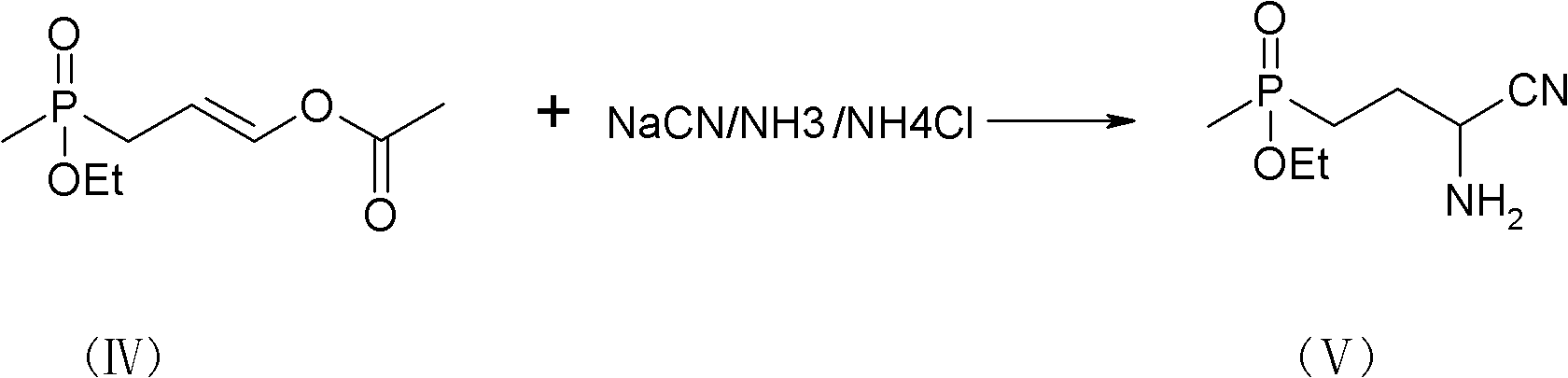

ActiveCN103183707AHigh selectivityHigh yieldGroup 5/15 element organic compoundsGlufosinate-ammoniumAcetic anhydride

The invention discloses a Glufosinate-ammonium and its derivative improved preparation method, the method comprises the following steps: diethyl methyl-phoshphonite, acraldehyde and acetic anhydride are subjected to an addition reaction, a reactant, sodium cyanide (editpotassium cyanide for replacing) and an ammonia water solution of ammonium chloride are subjected to an improved STRECKER reaction without separation, the product is subjected to hydrolysis and ammonification for forming salt to obtain Glufosinate-ammonium. The preparation method has the characteristics of high selectivity and high yield.

Owner:SINOCHEM LANTIAN +1

Glufosinate-ammonium dehydrogenase mutant and application thereof to synthetizing L- glufosinate-ammonium

ActiveCN109609475AIncrease concentrationHigh activityBacteriaMicroorganism based processesGlufosinate-ammoniumMutant

Owner:ZHEJIANG UNIV OF TECH

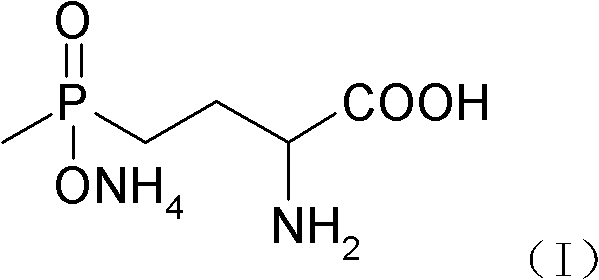

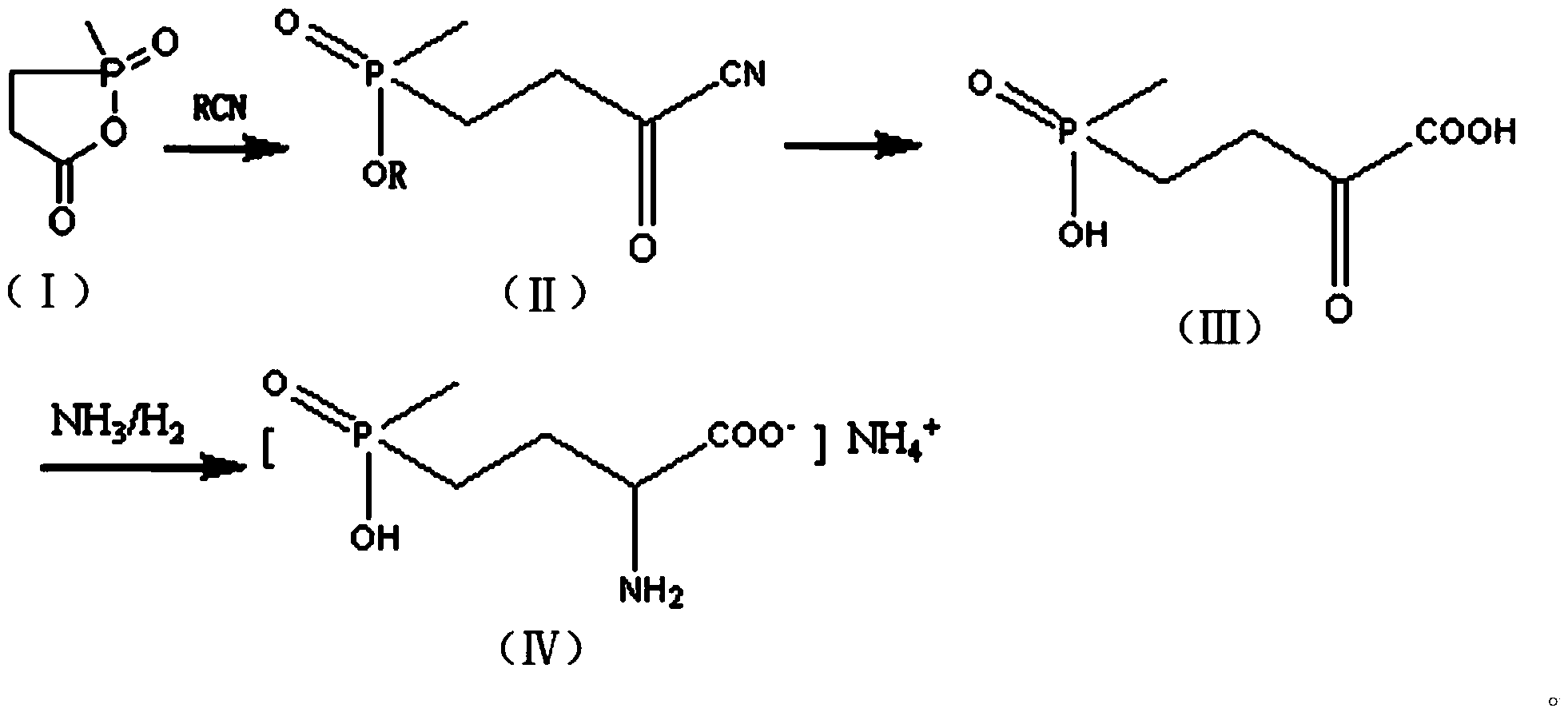

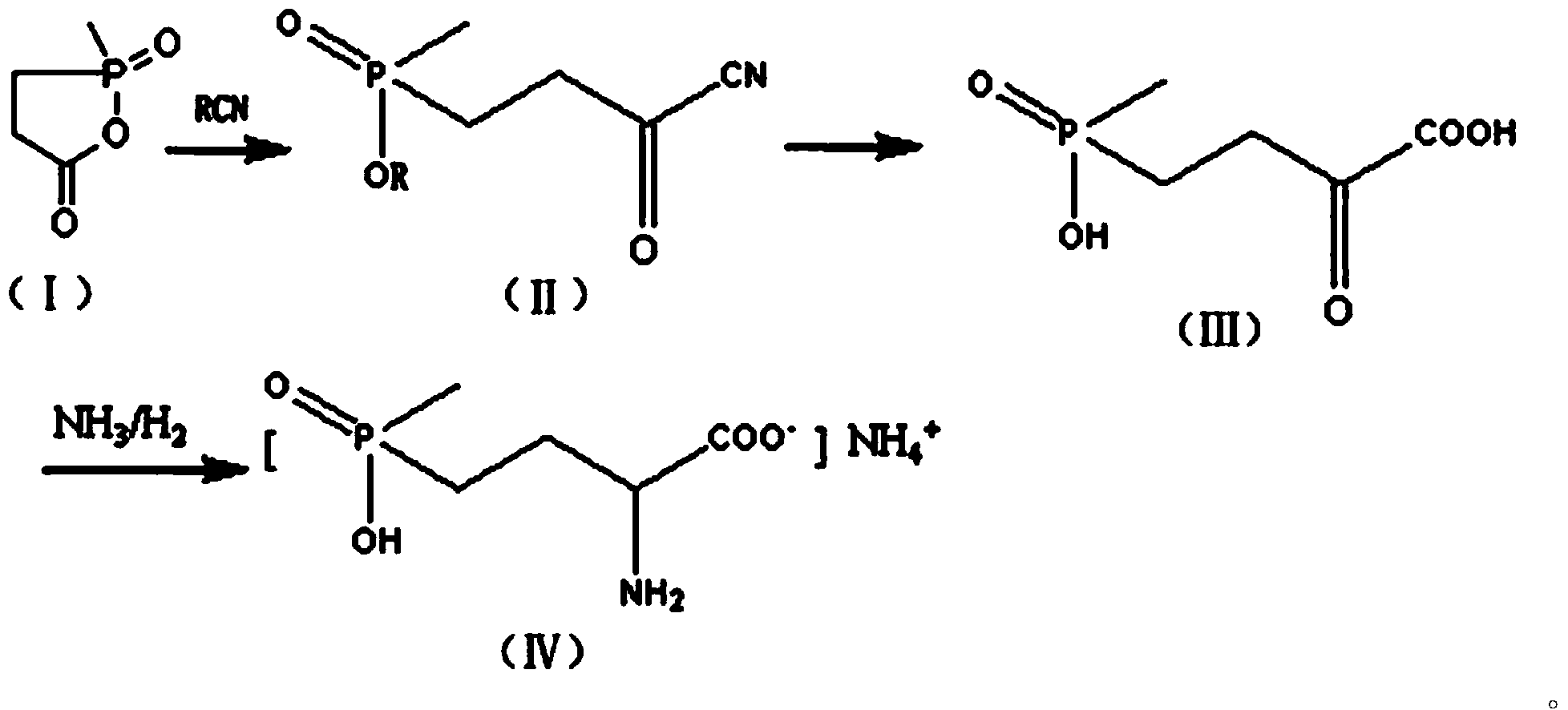

Preparation method of glufosinate

The invention relates to a preparation method of glufosinate. The preparation method comprises the following steps: with a compound represented by a formula (I) as a starting material, reacting the compound represented by the formula (I) with cyanide RCN to obtain ketone nitrile; then hydrolyzing ketone nitrile in the presence of an acidic substance and water so as to obtain ketoacid; and reacting ketoacid successively with ammonia gas and hydrogen under the action of a catalyst so as to obtain glufosinate; wherein the compound represented by the formula (I) is cyclic phosphonic acid anhydride. The preparation method in the invention has the advantages of simple process, convenient operation, high product purity, high yield, no need for repeated recrystallization, ect.; and the final product of the preparation method is directly glufosinate ammonium, the step of converting glufosinate chloride into glufosinate ammonium is omitted, so the method has great economic benefit and is suitable for industrialization production.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

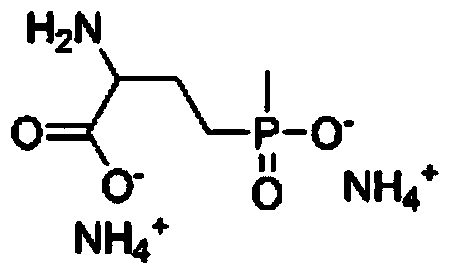

Preparation method of L-glufosinate-ammonium

The invention discloses a preparation method of L-glufosinate ammonium. The preparation method comprises the steps: in the presence of L-amino acid dehydrogenase, an inorganic amino donor and a reductive coenzyme nicotinamide adenine dinucleotide, 2-oxo-4-(hydroxymethoxyphosphonyl)butyrate is subjected to ammoniation reaction, and then the prepared L-glufosinate ammonium is subjected to acidification reaction; the L-amino acid dehydrogenase is L-amino acid dehydrogenase derived from bacillus stearophilus and / or L-amino acid dehydrogenase derived from intermediate high temperature actinomycetes. The preparation method of L-glufosinate-ammonium is simple to operate, does not use expensive reductive coenzyme NADPH, adopts a coenzyme NADH, reduces the cost of reaction and is beneficial to industrialized production.

Owner:SHANGHAI QIZHOU ZIYUE BIOTECHNOLOGY CO LTD

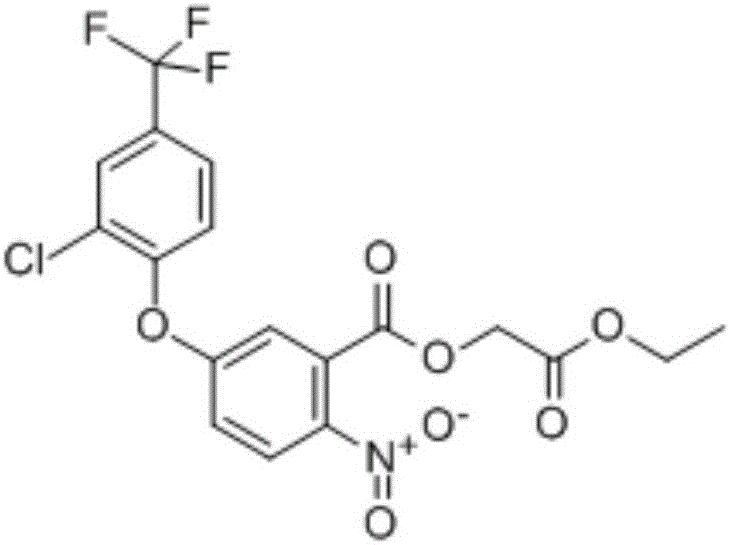

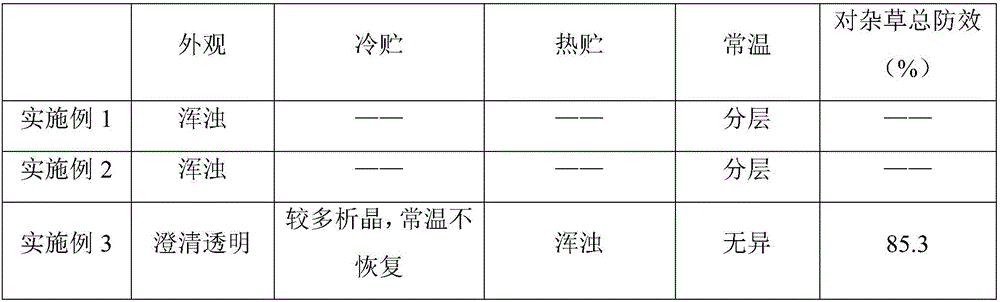

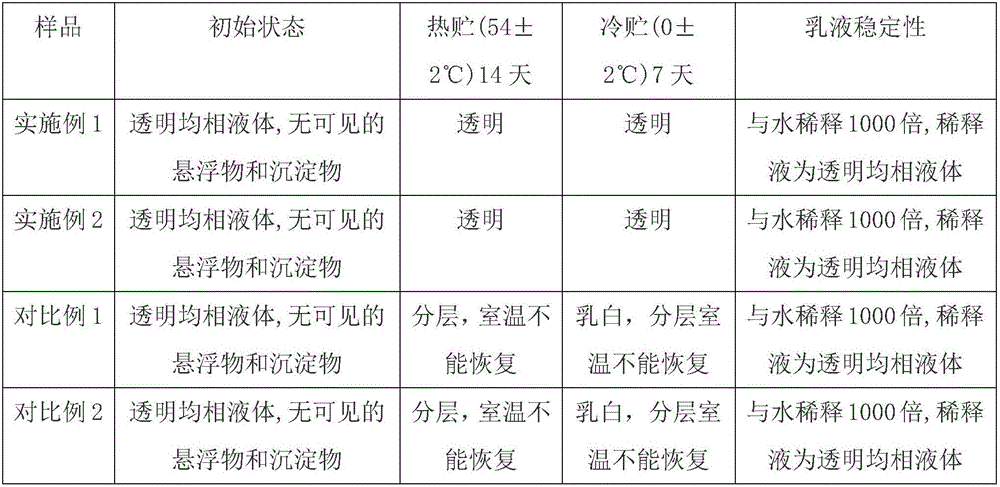

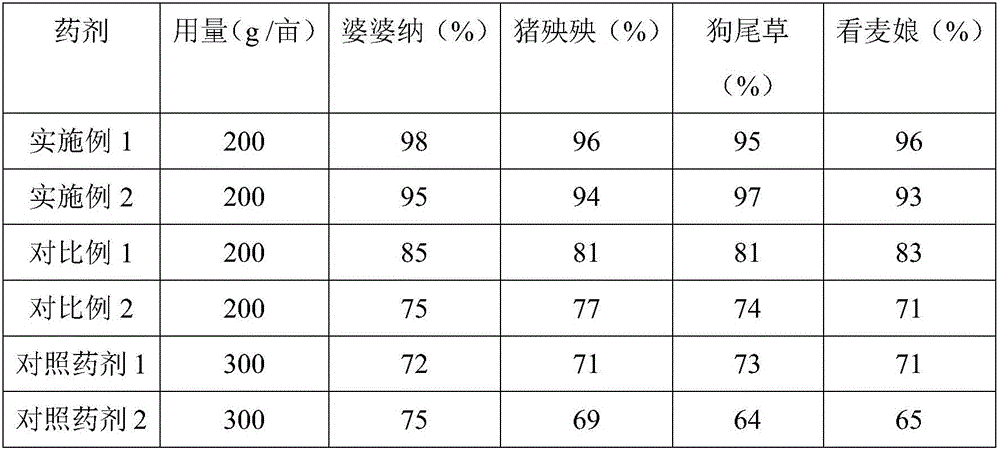

Weeding composition containing glufosinate-ammonium and fluoroglycofen-ethyl, and preparation method of composition

InactiveCN106070305AProtect healthImprove protectionBiocideDead animal preservationGlufosinate-ammoniumEmulsion

The invention provides a weeding composition containing glufosinate-ammonium and fluoroglycofen-ethyl, and a preparation method of the composition, and belongs to the technical field of pesticides. The dosage form of the composition is a micro-emulsion, the composition comprises glufosinate-ammonium, fluoroglycofen-ethyl, a cosolvent, a first surfactant and a second surfactant, the first surfactant is alkyl glycoside, and the second surfactant is polyoxyethylene phosphonate or polyoxyethylene phosphonate salt. The weeding composition prepared in the invention has the characteristics of fast weeding speed, good weeding effect, low production cost and environmental protection, and has an obvious better weeding effect than single doses of glufosinate-ammonium and fluoroglycofen-ethyl. The preparation method has the advantages of simplicity, convenience in operation, and high feasibility; and the above product has stable quality, still has good quality stability after being stored for a long term, has obvious market values, and is suitable for large-scale promotion application.

Owner:济南绿霸农药有限公司

Synthetic method for glufosinate ammonium

InactiveCN109232644AMild reaction conditionsEasy to operateGroup 5/15 element organic compoundsPhosphorus tribromideDistillation

The invention relates to a synthetic method for glufosinate ammonium. The synthetic method comprises the following steps: single-bromine substitution, amination, amino protection, chlorination ring opening, Arbuzov reaction and acidizing hydrolysis ammoniation; the single-bromine substitution means triggering alpha-site single-bromine substitution betweengamma-butyrolactone I and bromine under theexistence of catalyst and performing reduced pressure distillation, thereby acquiring a pure intermediate II alpha-bromine-gamma-butyrolactone; phosphorus tribromide is served as the catalyst; amination means triggering amination reaction between alpha-bromine-gamma-butyrolactone II and ammonium hydroxide, and then adding hydrochloric acid and reflowing, thereby acquiring an intermediate IIIalpha-amino-gamma-butyrolactone hydrochloride. The invention has the beneficial effects: 1) low-costgamma-butyrolactone is taken as a raw material, is subjected to single-bromine substitution with bromineand then is subjected to amination reaction with ammonium hydroxide; the adopted raw materials are low-cost and easily acquired; reaction conditions are mild; operation is simple and convenient; safety is high; amplifying production is feasible; reaction yield is high; product purity is high; cost is greatly lowered; the synthetic method is suitable for industrial production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

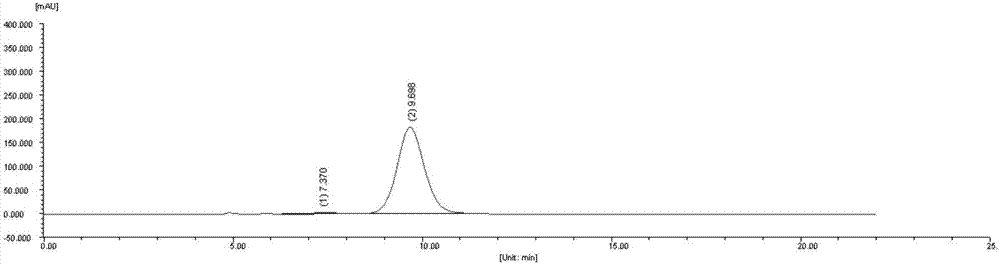

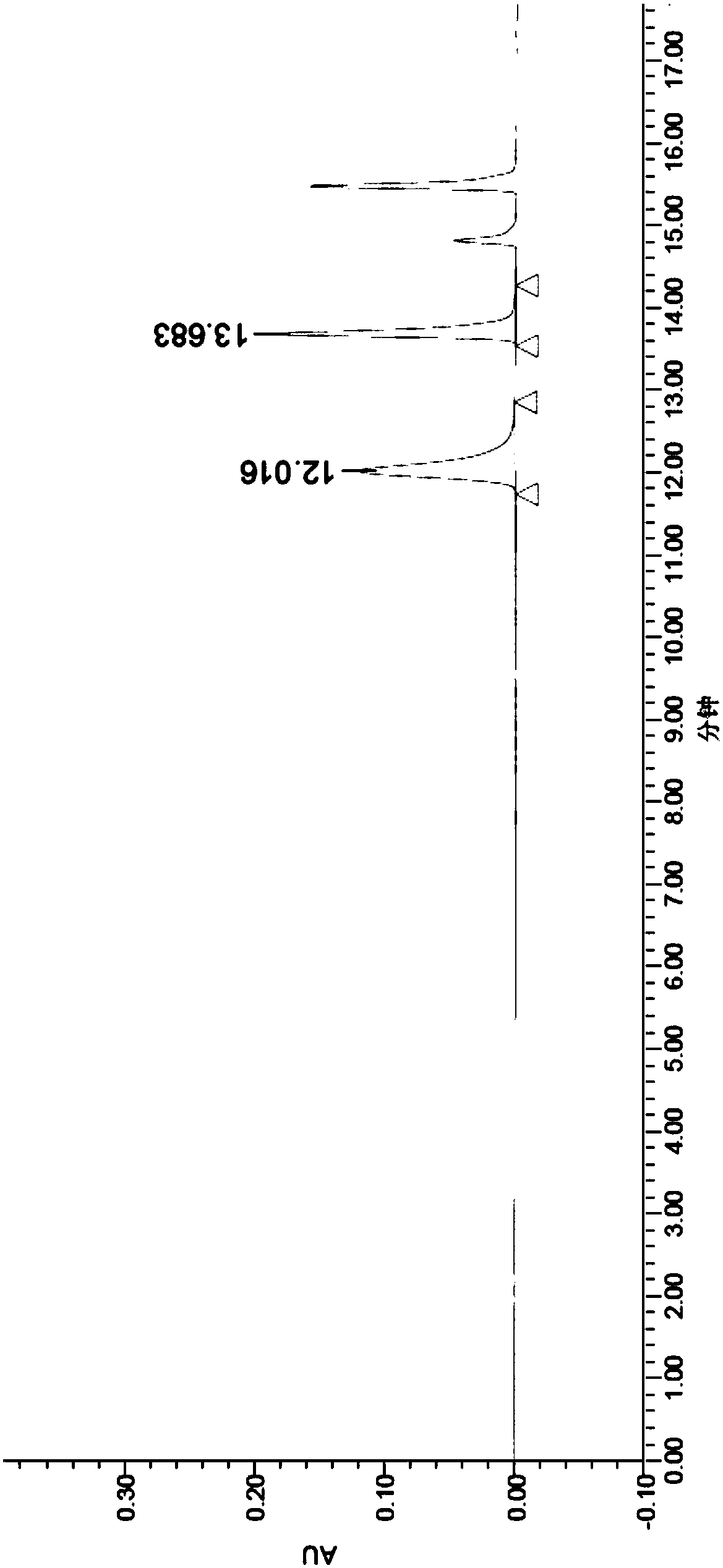

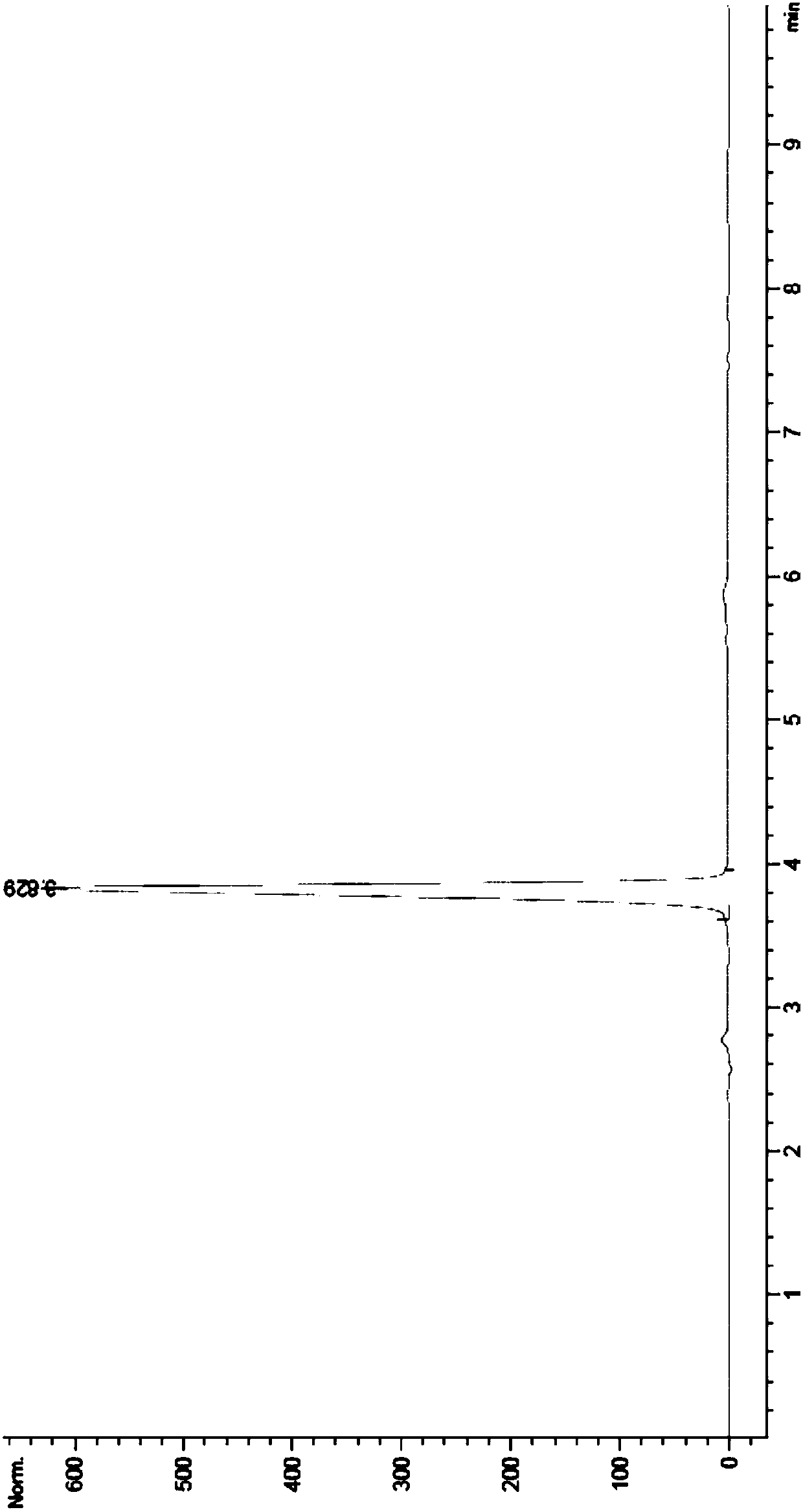

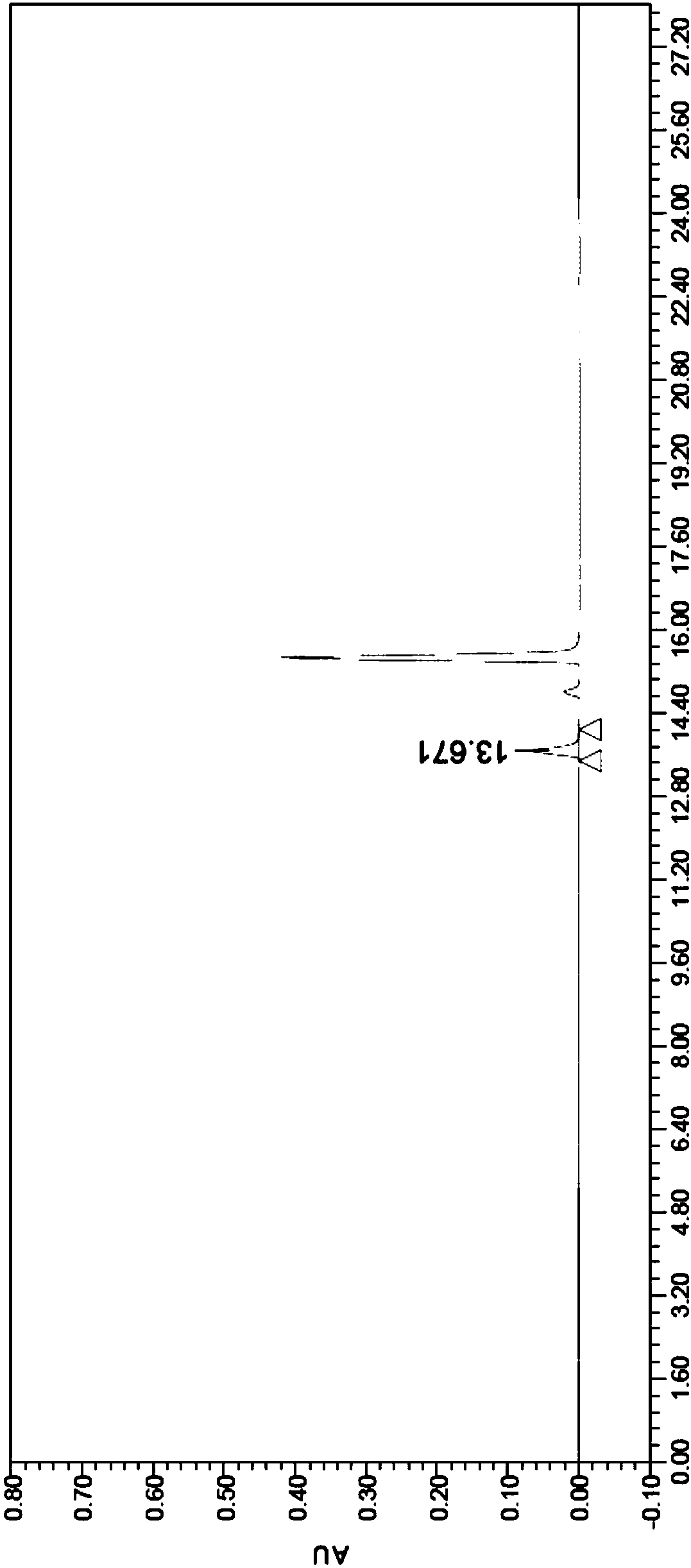

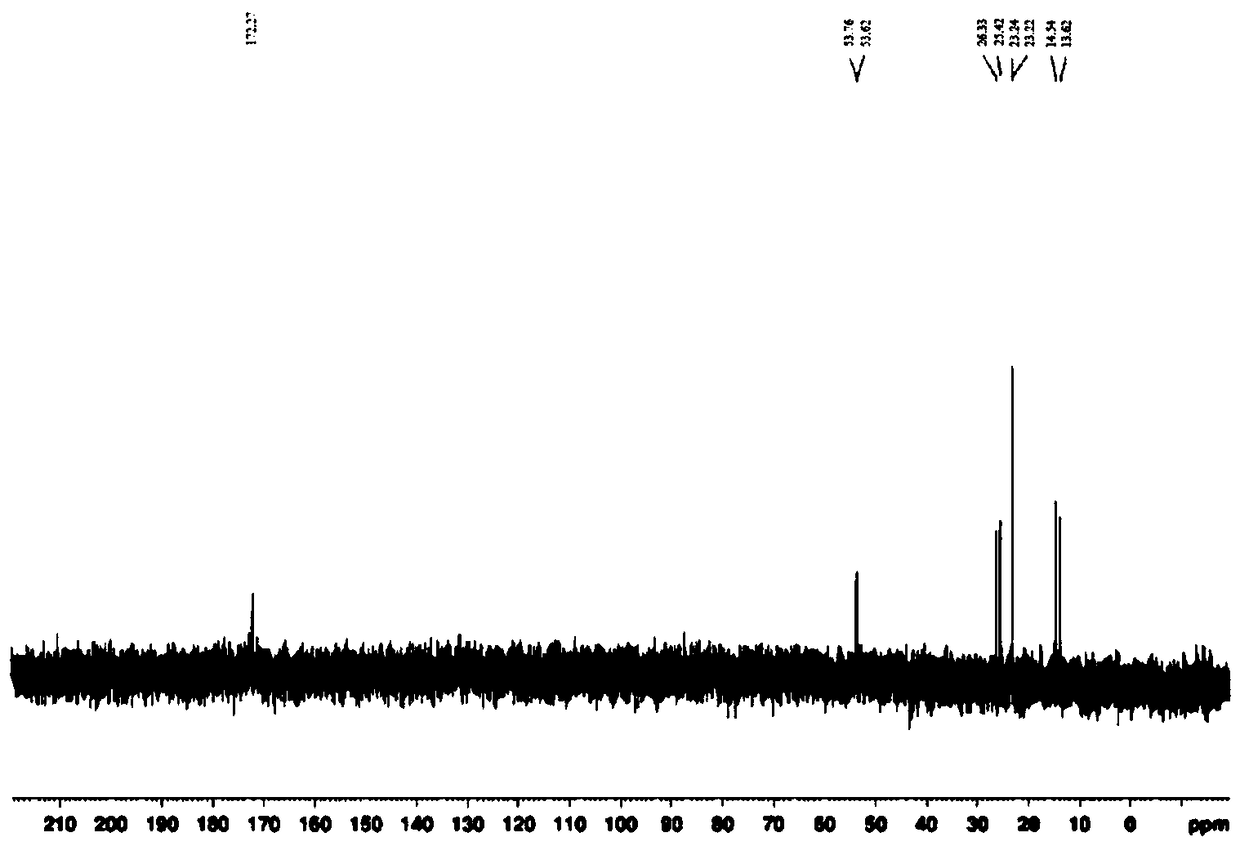

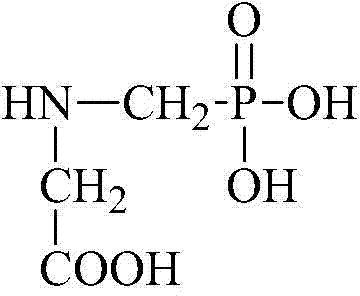

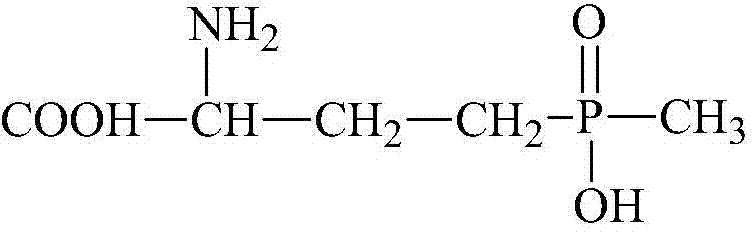

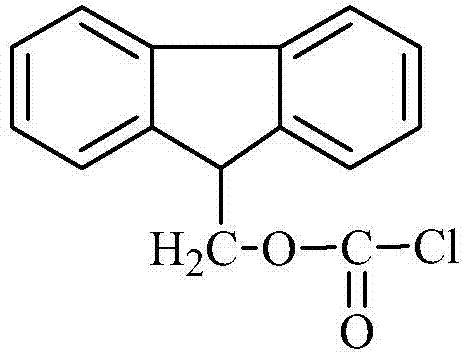

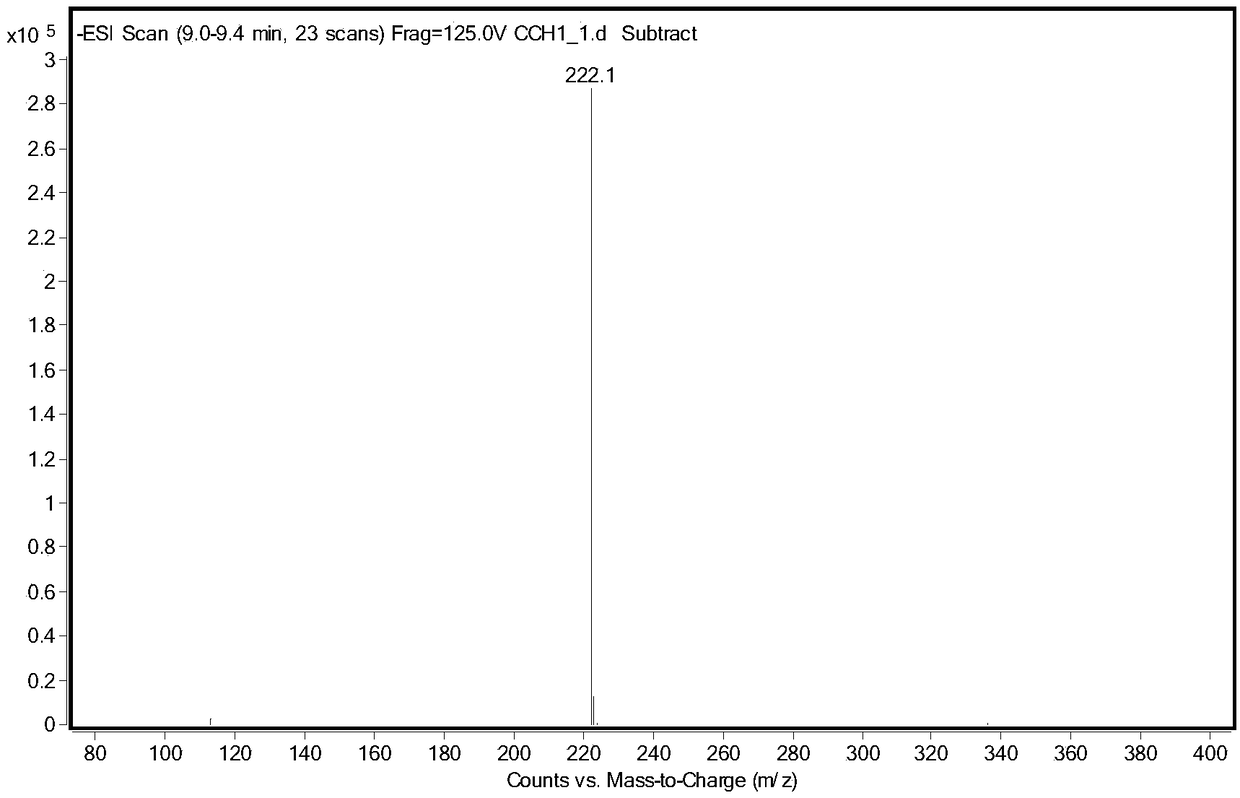

Precolumn derivatization-UPLC(ultra performance liquid chromatography)-ESI(electronic spray ion)+-MS/MS (mass spectrometry) detection method of glyphosate and glufosinate-ammonium pesticide residue in tea

The invention discloses a precolumn derivatization-UPLC(ultra performance liquid chromatography)-ESI(electronic spray ion)+-MS / MS (mass spectrometry) detection method of glyphosate and glufosinate-ammonium pesticide residue in tea, sodium borate is used as a buffer salt, a relatively pure target derived product can be obtained by derivatization of glyphosate and glufosinate-ammonium and FMOC-Cl and then ultra performance liquid chromatography (UPLC) washing out and separation, and response signals can be detected by tandem mass spectrometry (MS-MS). According to the method, competition between the two pesticide residue derivatization can be eliminated, the detection effect caused by matrix effect can be effectively weakened, and the derivatization time is shortened. By experimental verification, the detection method of glyphosate and glufosinate-ammonium pesticide (herbicide) residue in tea has the characteristics of being efficient, fast and accurate, good in sensitivity and the like, is applicable in detection of the glyphosate and glufosinate-ammonium pesticide residue in tea samples of sundried green crude tea, fermented tea and substitutional tea (green food substitutional tea of agricultural industry standards of NY / T2140-2012 of the people's Republic of China) and finished tea (brick tea, Tuo tea, melon-shaped tea, cake tea, scattered tea and bagged tea and the like).

Owner:MENGHAI TEA IND

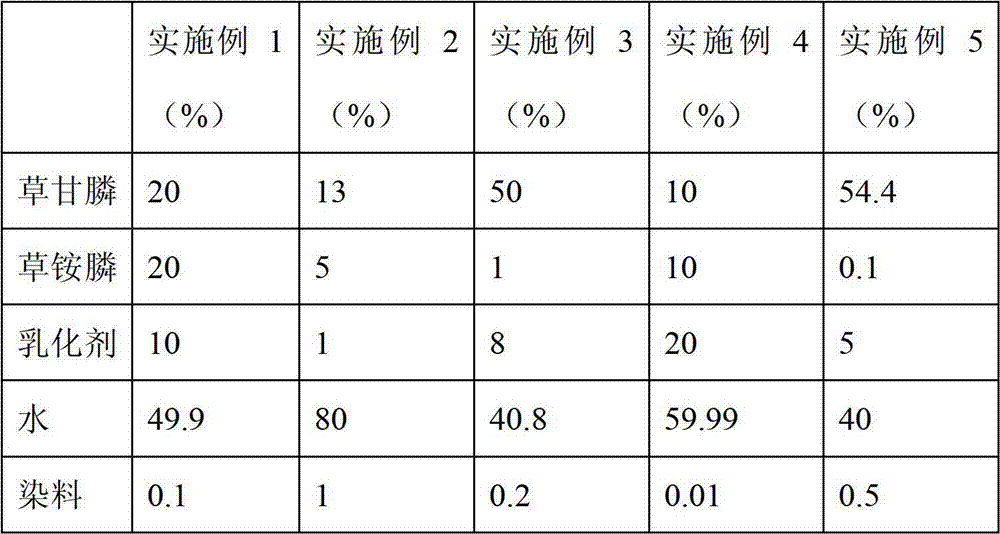

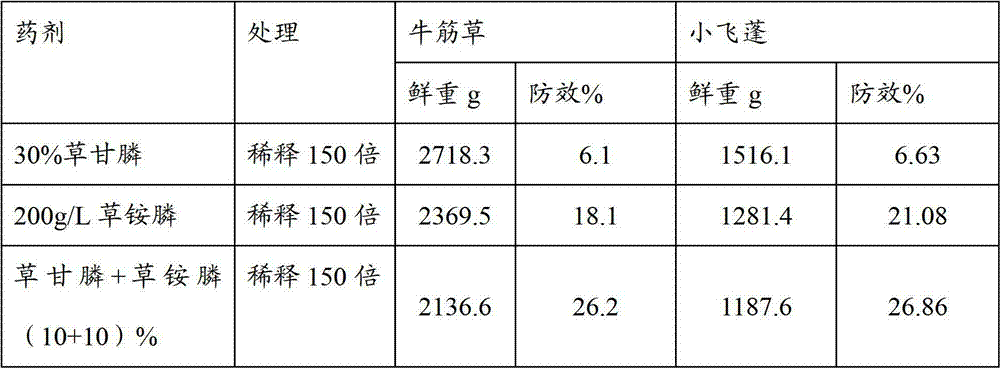

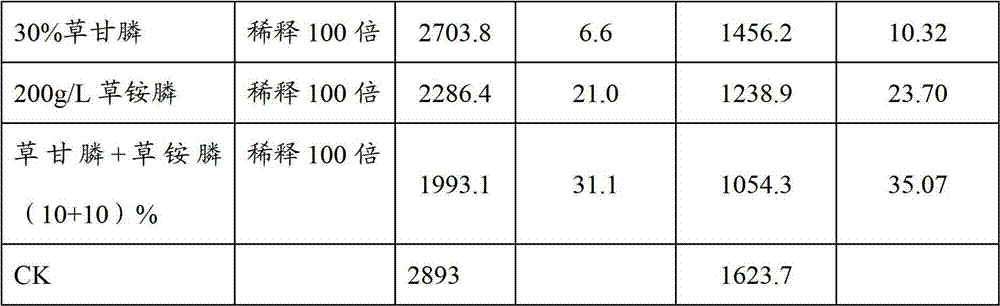

Weedicide composition and preparation method thereof

InactiveCN103168798AReduce use costFast weedingBiocideAnimal repellantsGlufosinate-ammoniumToxicology

The invention discloses a weedicide composition and a preparation method thereof, wherein the weedicide composition comprises the following components in percentage by weight: 1-50% of glyphosate and 0.1-50% of glufosinate-ammonium. The weedicide composition disclosed by the invention has the advantages that the glufosinate-ammonium can be compounded with the glyphosate, and the glufosinate-ammonium has no negative effect on the using effect of the glyphosate, so that the resistance problem of the single glufosinate is solved, the using cost of the glufosinate-ammonium is also effectively reduced, meanwhile, the weeding speed of the glufosinate is accelerated, and the using effect of a glufosinate product is also enhanced.

Owner:GUANGDONG ZHENGE BIOLOGICAL TECH CO LTD

Method for separating and purifying glufosinate-ammonium

ActiveCN103483377AHigh selectivityEasy to separateGroup 5/15 element organic compoundsInorganic saltsGlufosinate-ammonium

The invention discloses a method for separating and purifying glufosinate-ammonium. The method comprises the steps: 1, diluting glufosinate-ammonium crude liquid into a solution with mass fraction of 10-80% by water; then, carrying out pretreatment on the solution by a 20-100mu m filter bag to remove mechanical impurities which are possibly caused in the glufosinate-ammonium synthesis process; and 2, adjusting the pH of the solution to be within the range of 3-9, and enabling the solution to enter a chromatographic column filled with strong acid type cation exchange resin at the temperature of 0-100 DEG C, with water as an eluting agent, and respectively collecting eluant and residual liquid, wherein the eluant is a glufosinate-ammonium solution, and the residual liquid is an inorganic salt solution. After the technical scheme is adopted, the method for separating and purifying the glufosinate-ammonium has the beneficial effects that the method is high in selectivity, degree of separation, product concentration and purity and simple in technology; the feed of the whole technology comprises raw materials and pure water, and the discharge of the whole technology comprises the glufosinate-ammonium and the inorganic salt, so that other wastes are not produced.

Owner:XIAMEN STARMEM TECH

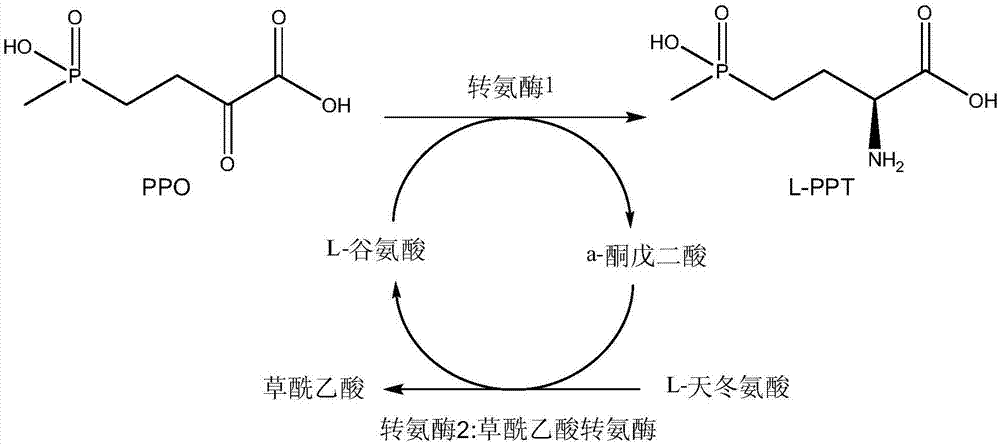

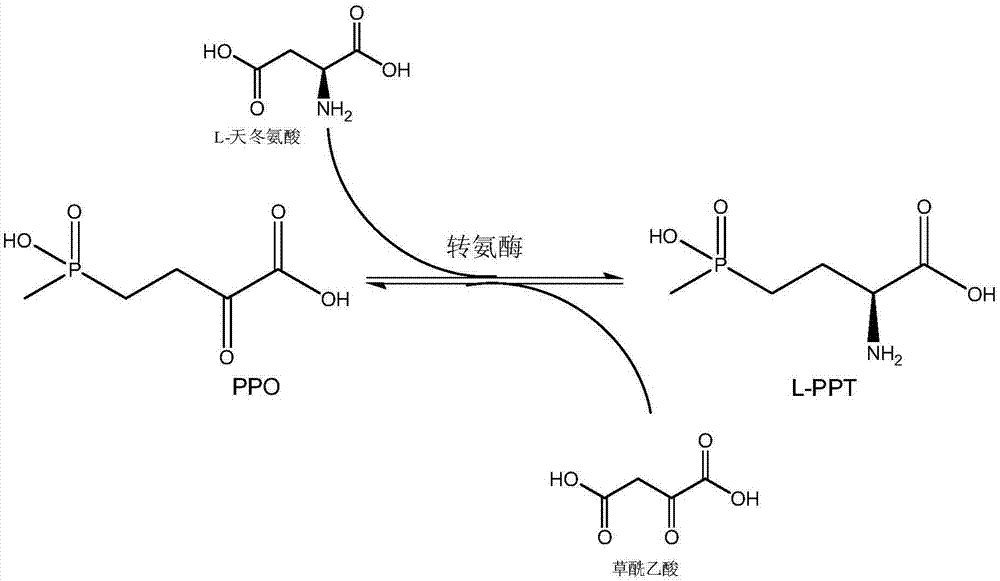

Transaminase, mutant and application thereof in production of L-glufosinate ammonium

The invention discloses transaminase, a mutant and application thereof in production of L-glufosinate ammonium. The mutant is characterized in that isoleucine at the 62nd site of amino acid in SEQ IDNO:2 is substituted by valine; serine at the 74th site is substituted by threonine; methionine at the 93rd site is substituted by isoleucine; tyrosine at the 167th site is substituted by phenylalanine; alanine at the 220th site is substituted by proline; arginine at the 282nd site is substituted by lysine; alanine at the 353rd site is substituted by serine; isoleucine at the 355th site is substituted by valine. The transaminase is characterized in that 4-(methyl hydroxyphosphoryl)-2-carbonyl-butyric acid is used as a primer to prepare the L-glufosinate ammonium, the transaminase product ee isgreater than 99.9%; the 4h primer conversion rate is 56.31%; the transaminase mutant product ee is greater than 99.9%, and the 4h primer conversion rate is 95.42%.

Owner:ZHEJIANG UNIV OF TECH

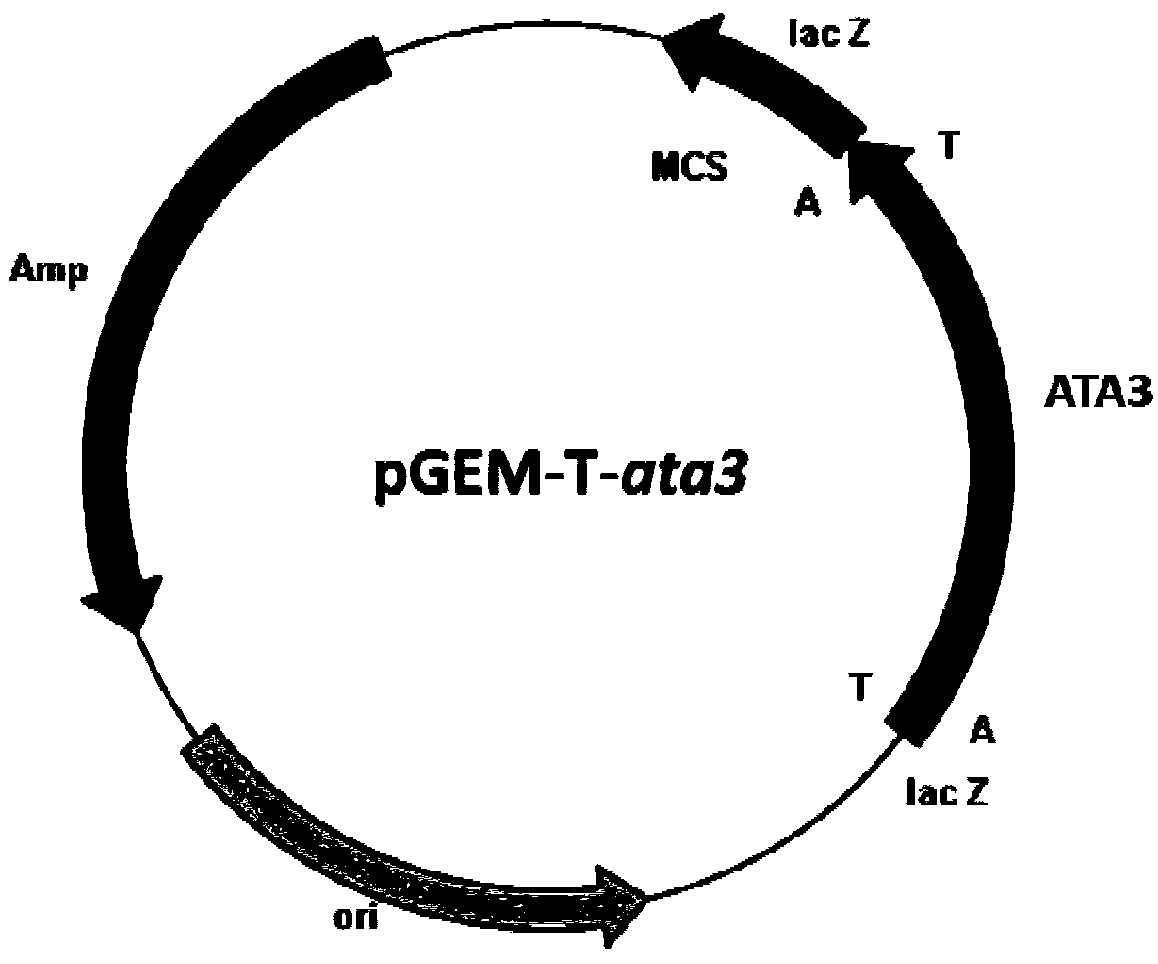

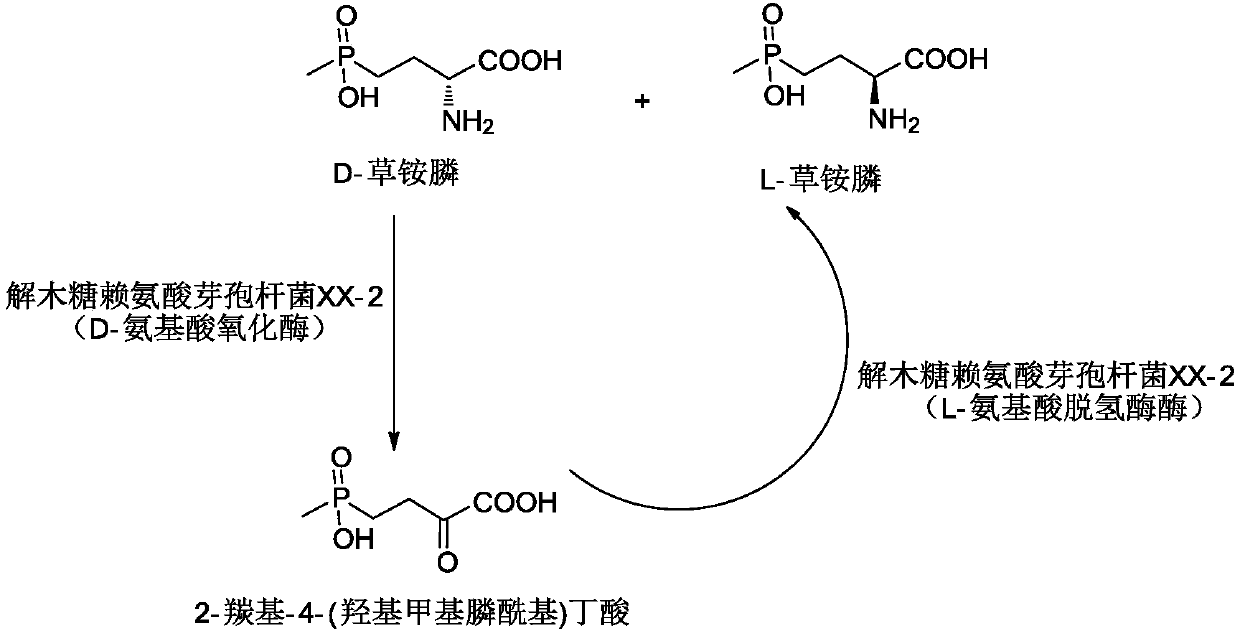

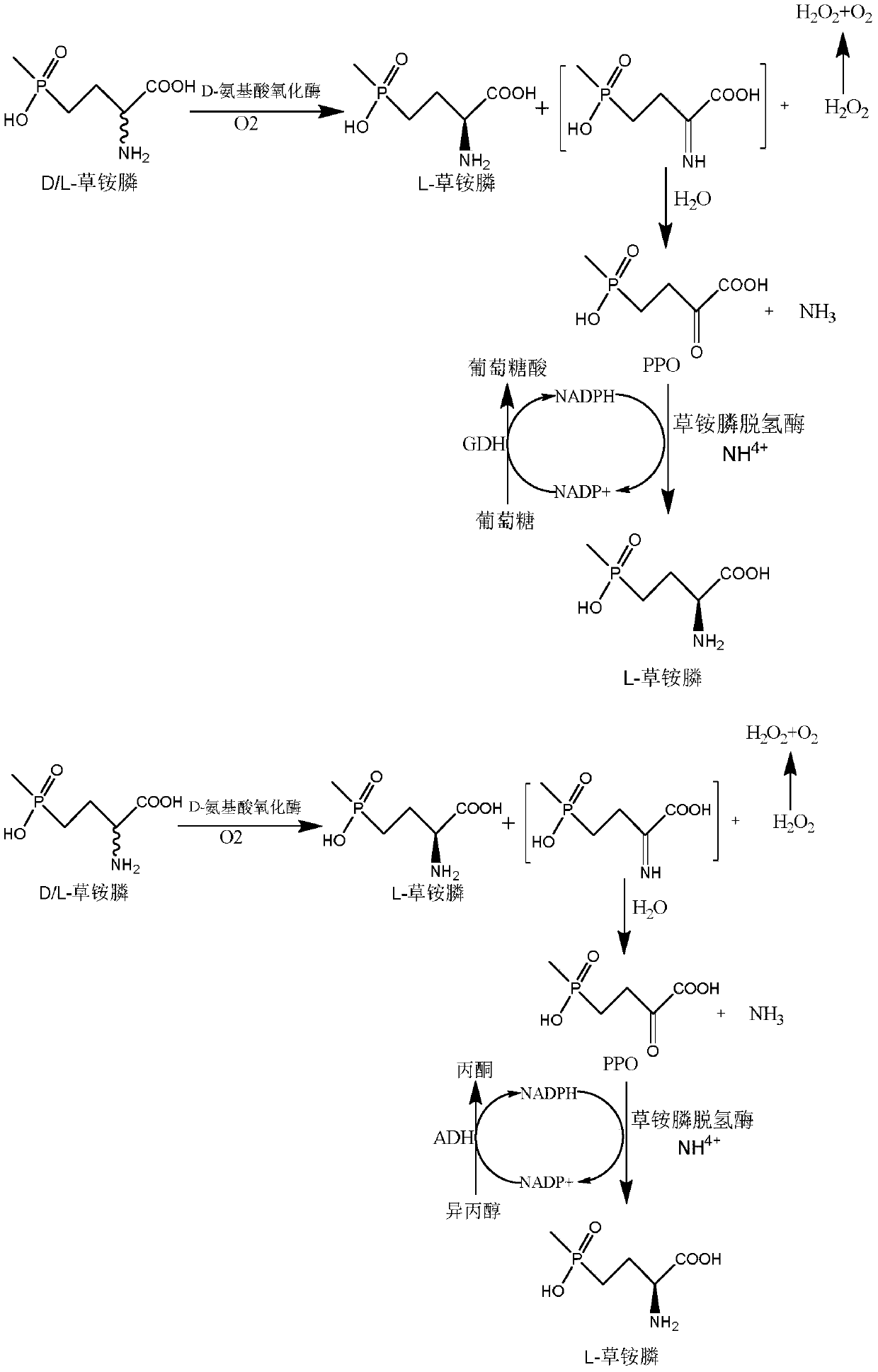

Method for preparing L-glufosinate-ammonium through microorganism catalysis and deracemization

ActiveCN109609582AAchieve separationSimple processMicroorganism based processesFermentationXyloseD-amino acid oxidase

The invention discloses a method for preparing L-glufosinate-ammonium through microorganism catalysis and deracemization. According to the method, DL-glufosinate-ammonium is used as a raw material, D-amino acid oxidase in lysinibacillus xylanilyticus XX-2 whole cells catalyzes D-glufosinate-ammonium to be subjected to oxidative deamination to obtain 4-(hydroxymethylphosphinyl)-2-oxobutanoic, and L-glufosinate-ammonium is reserved. The amino acid dehydrogenase co-expressed in cells catalyzes the 4-(hydroxymethylphosphinyl)-2-oxobutanoic to be subjected to in-situ reduction and ammoniation to obtain the L-glufosinate-ammonium, so that complete deracemization of the DL-glufosinate-ammonium is realized. The prepared L-glufosinate-ammonium does not have any other by-products, the total yield isgreater than 70%, and the optical purity is greater than 99%.

Owner:重庆惠健生物科技有限公司

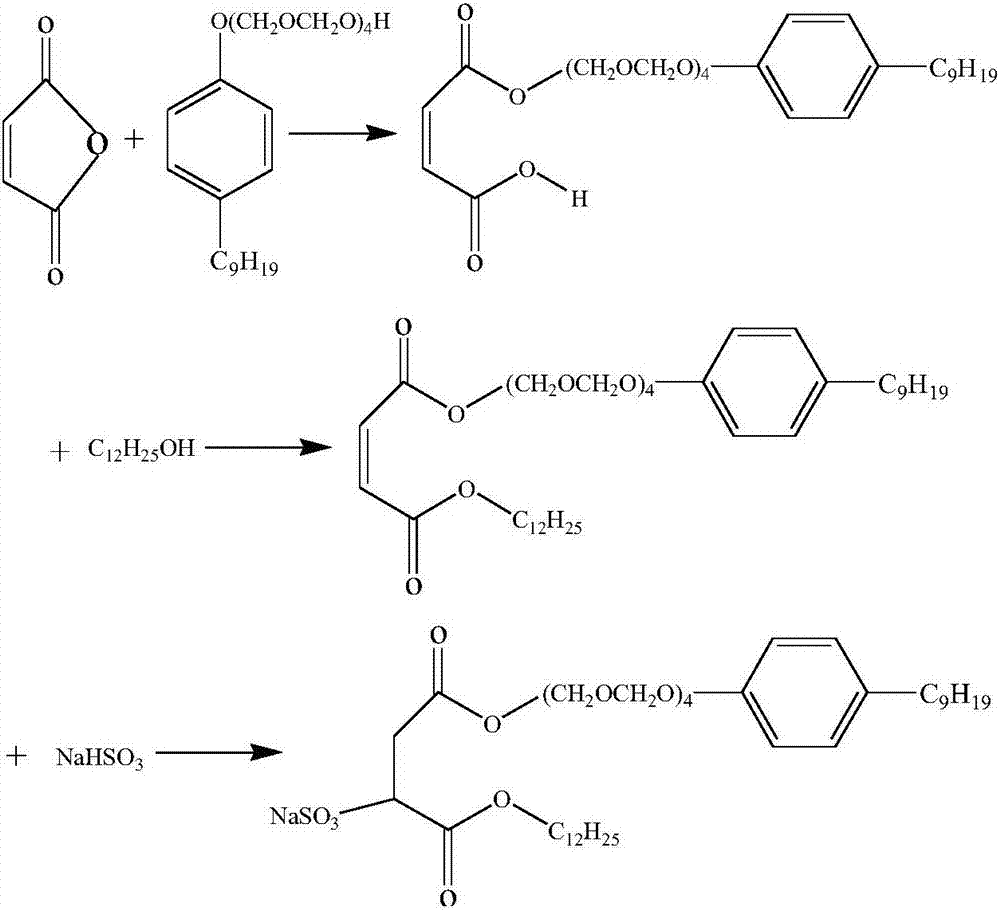

Low-foam glufosinate-ammonium synergist and preparation method thereof

InactiveCN106689124ASimple production methodEasy to manufactureBiocideDead animal preservationGlufosinate-ammoniumBetaine

The invention relates to a low-foam glufosinate-ammonium synergist and a preparation method thereof. The low-foam glufosinate-ammonium synergist provided by the invention is prepared from the following substances in parts by mass: 10 to 30 parts of glycine betaine substance, 10 to 30 parts of surface active agent, 0.1 to 20 parts of dispersing agent, 0.1 to 20 parts of wetting agent, 0.1 to 10 parts of penetrating agent, and 0.1 to 10 parts of pH (Potential Of Hydrogen) regulator. The preparation method comprises the steps of adding the glycine betaine and the surface active agent into a reaction vessel, and stirring and heating to 80 DEG C; adding the dispersing agent, the wetting agent and the penetrating agent into a product, and uniformly stirring; then adding metered pH regulator, carrying out neutral reaction completely, and cooling for discharging materials. The low-foam glufosinate-ammonium synergist provided by the invention has the advantages of simple production method, easiness in preparation, low foamability and excellent wettability; a glufosinate-ammonium aqueous solution pesticide prepared by the synergist provided by the invention has a good weeding effect and slow reviving speed; the prepared synergist is safe to use without environment pollution.

Owner:江苏凯元科技有限公司

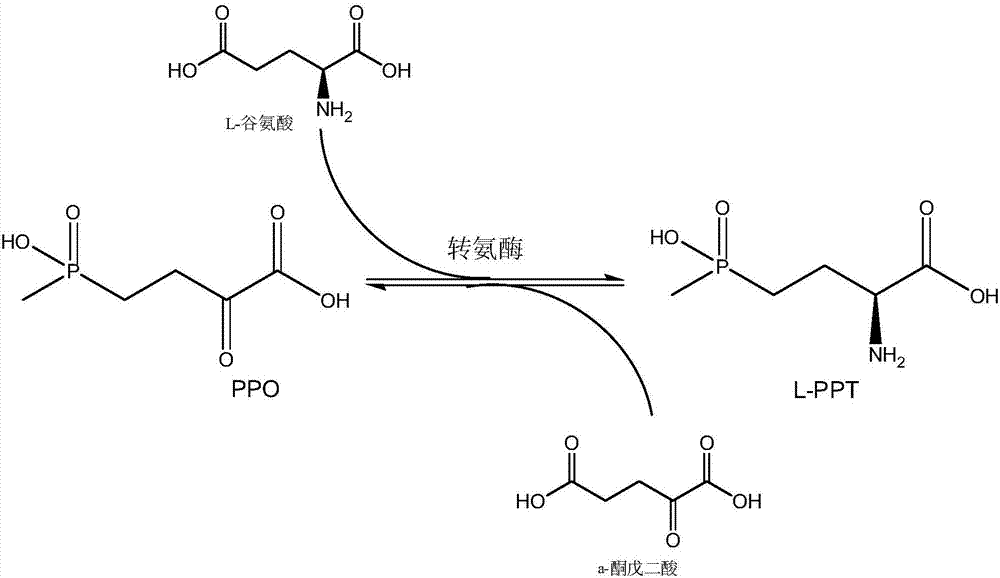

Method for producing L-glufosinate-ammonium by using transaminase and ethylene-forming enzyme

The invention discloses a method for producing L-glufosinate-ammonium by using transaminase and an ethylene-forming enzyme. According to the method, 2-carbonyl-4-(hydroxyl methyl phosphoryl) butyric acid or salt thereof is taken as a raw material, and the L-glufosinate-ammonium is obtained through a catalytic reaction of the transaminase and the ethylene-forming enzyme under the condition of taking glutamic acid or salt thereof as an amidogen donor. According to the method, the 2-carbonyl-4-(hydroxyl methyl phosphoryl) butyric acid or the salt thereof is taken as a substrate, and the L-glufosinate-ammonium is obtained through the co-catalysis of the transaminase and the ethylene-forming enzyme under the condition of taking the glutamic acid or the salt thereof as the amidogen donor, so that by-product alpha-dibasic ketonic acid after a transamination reaction is completely converted into carbon dioxide and ethylene through catalysis of the ethylene-forming enzyme, under the condition of guaranteeing few using amount of the raw materials, the conversion rate of the raw materials is obviously improved, the cost of the raw materials is reduced, the subsequent purification technology is simplified, and the product total recovery is improved.

Owner:ZHEJIANG UNIV

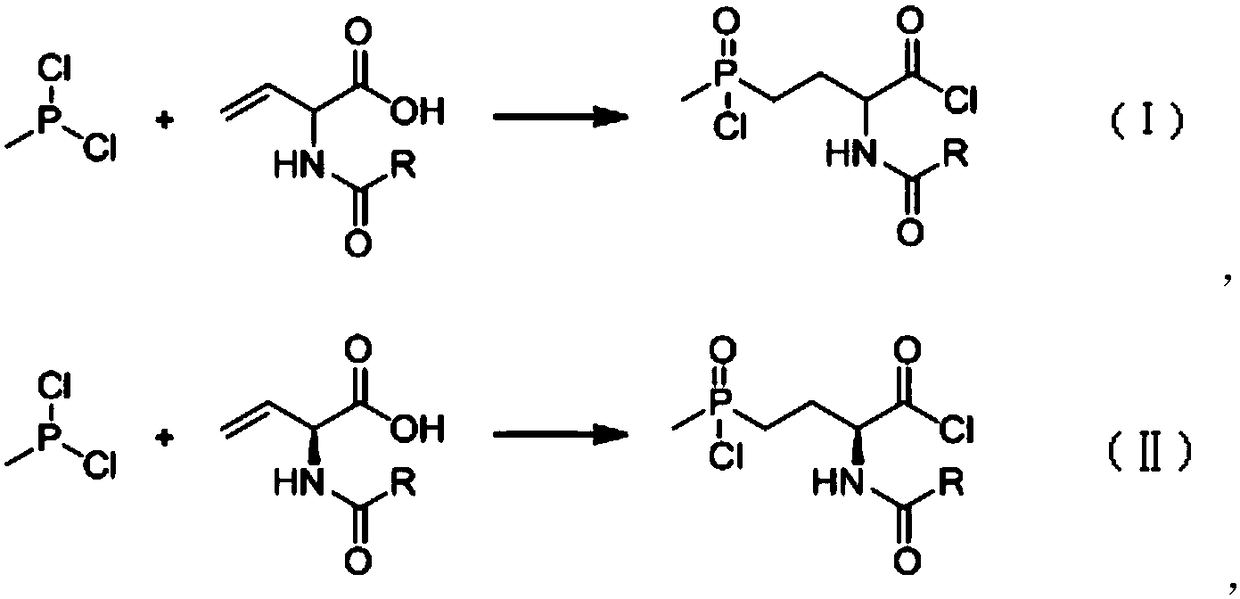

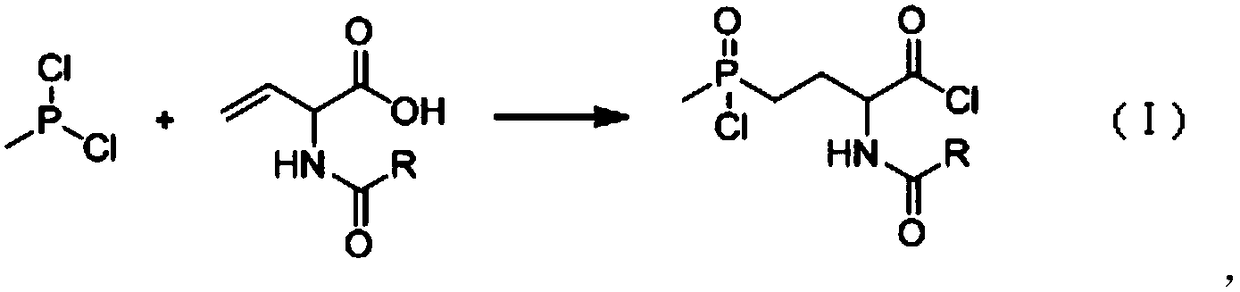

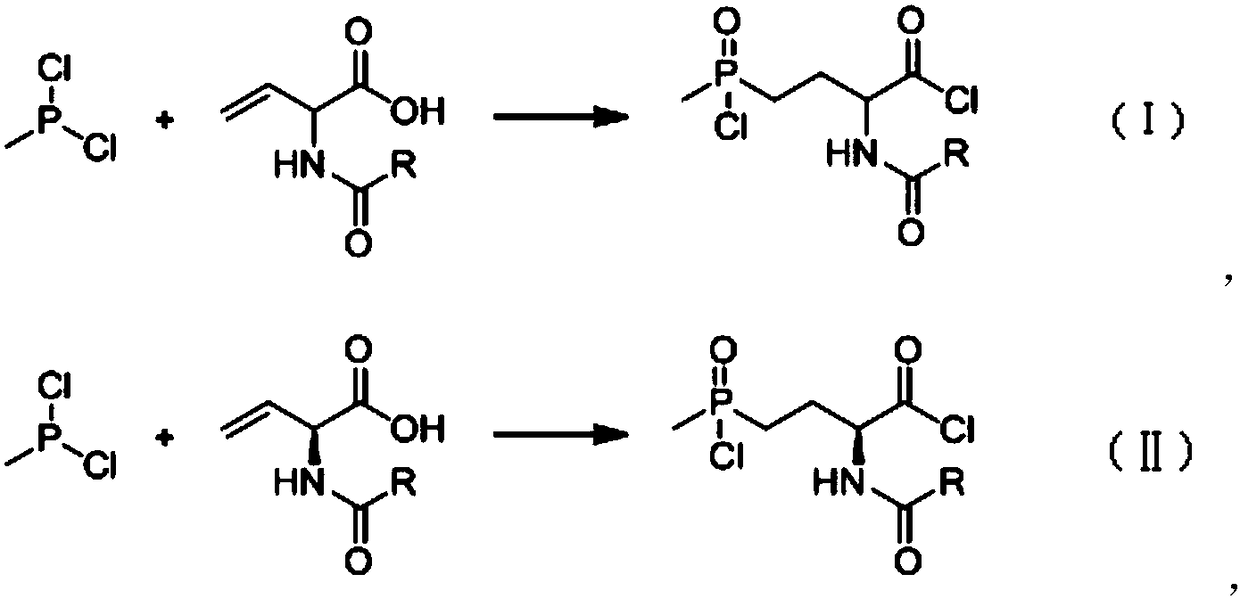

New method or preparing glufosinate ammonium salt

ActiveCN105481894AHigh puritySimple preparation processGroup 5/15 element organic compoundsGlufosinate-ammoniumAlcohol

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

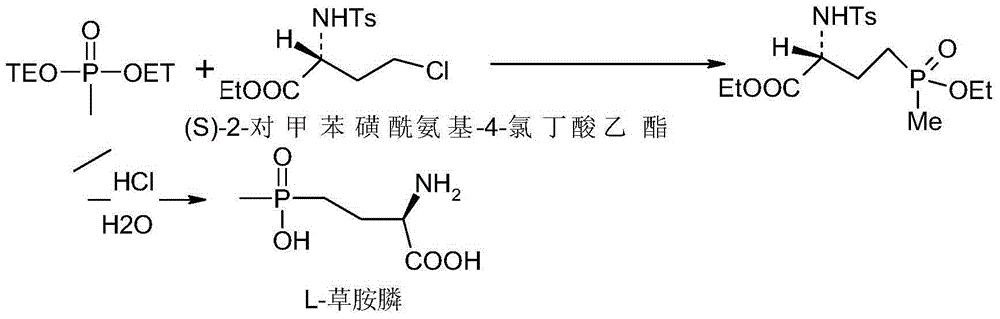

Concise glufosinate ammonium synthesizing method

ActiveCN108727427ASolve application problemsReduce labor intensityOrganic chemistry methodsGroup 5/15 element organic compoundsDiethyl phosphateGlufosinate-ammonium

The invention discloses a concise glufosinate ammonium synthesizing method and aims at solving the problem that an existing method needs to use toxic sodium cyanide to synthesize glufosinate ammonium.Being different from an existing method of using diethyl methyl phosphite to prepare the glufosinate ammonium, the concise glufosinate ammonium synthesizing method disclosed by the invention can effectively avoid using toxic chemicals; thus, the problem of using the sodium cyanide is solved. By means of the synthesizing method, use of toxic chemicals is reduced, operation steps are simplified, equipment investment is reduced, the amount of three wastes is reduced, a requirement for clean production is met, and more environmental friendliness is achieved. Meanwhile, the synthesizing method disclosed by the invention not only can synthesize racemate glufosinate ammonium, but also can synthesize optical pure-chirality glufosinate ammonium, so that the synthesizing method has obvious progressive significance. According to the synthesizing method disclosed by the invention, technique connection is orderly, no solid material is used, convenience in operation is achieved, a technological process is simple, automatic production is achieved, labor intensity of workers is greatly reduced, and a production efficiency is improved; thus, the synthesizing method has a better application prospect and is worth of popularizing and applying in a large scale.

Owner:LIER CHEM CO LTD

Weeding composition and application thereof

ActiveCN106359445AImprove washing effectGood resistance to rain erosionBiocideDead animal preservationGlufosinate-ammoniumSolvent

The invention relates to a weeding composition and application thereof. The weeding composition is a microemulsion containing glufosinate-ammonium and fluoroglycofen ethyl and comprises 1 to 30% of glufosinate-ammonium, 1 to 10% of fluoroglycofen ethyl, 10 to 15% of a solvent, 5 to 10% of a cosolvent and 1 to 33% of a surfactant, with the balance being soft water. The microemulsion has the advantages of good stability, rational composition, good wetability and rain wash resistance, no pollution to environment, and no harm to people and livestock, and is suitable for promotion.

Owner:LIER CROPSCIENCE CO LTD

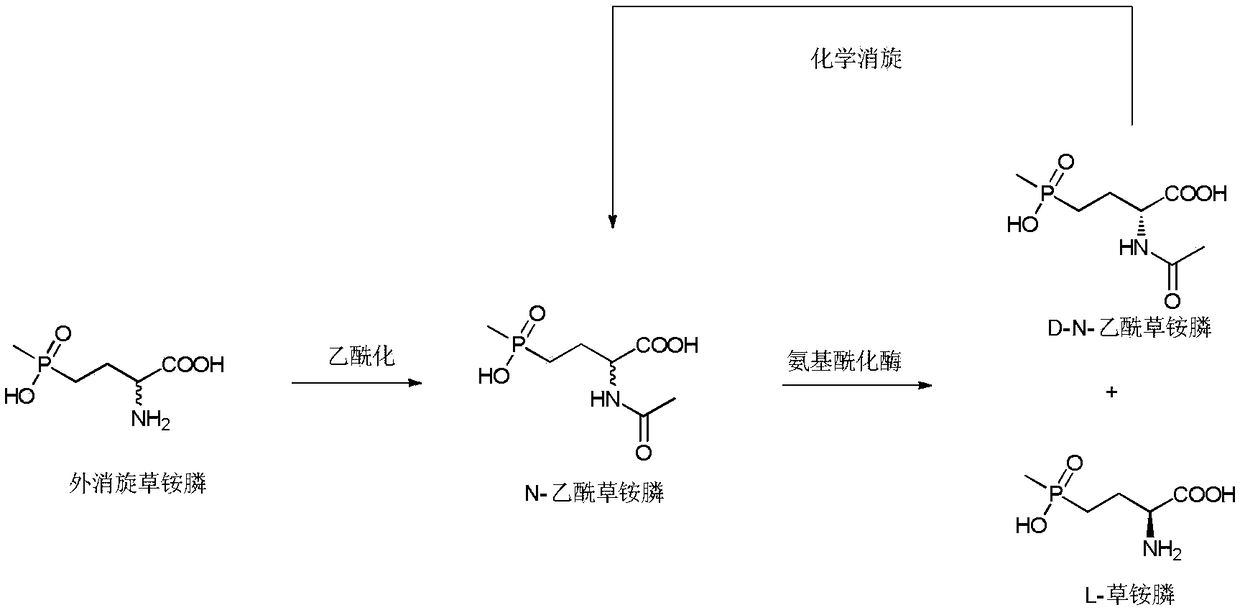

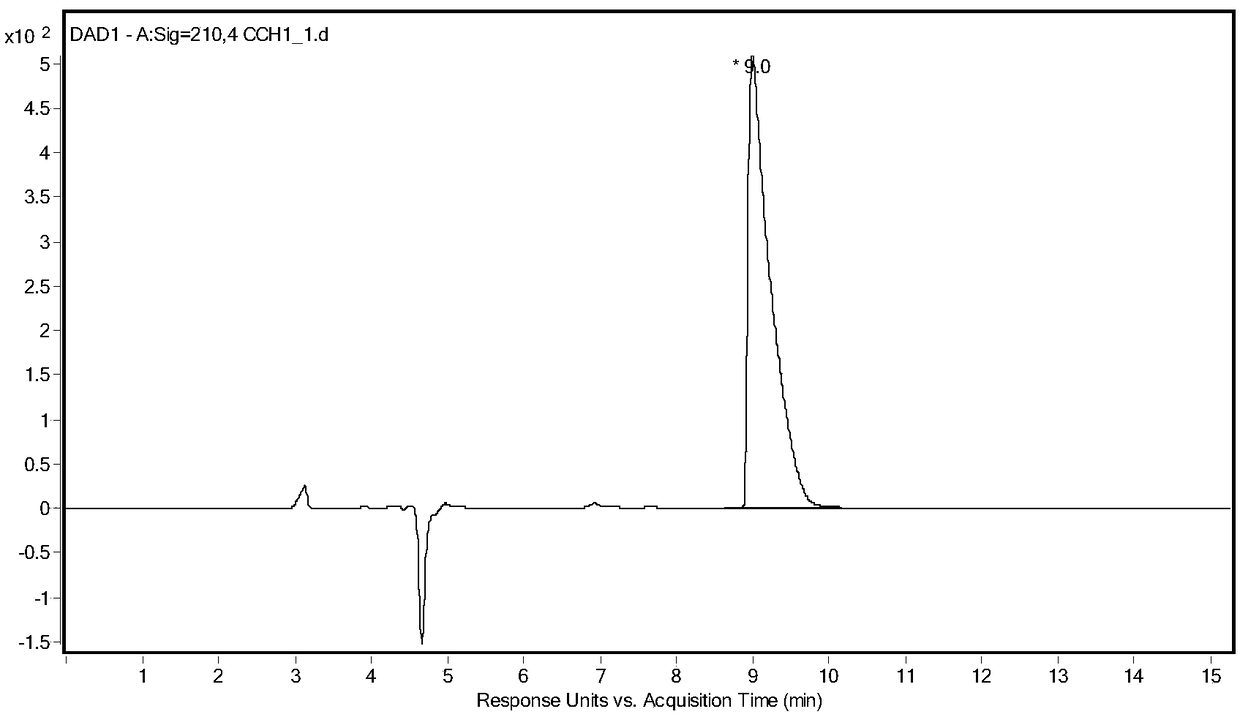

Method of utilizing chemistry-enzyme method to produce L-glufosinate ammonium

The invention discloses a method of utilizing a chemistry-enzyme method to produce L-glufosinate ammonium. According to the method, racemic N-acetyl glufosinate ammonium is taken as the substrate, engineering bacteria containing carboxyl-peptidase genes are subjected to fermentation culture to obtain wet cells, wet cells or pure enzymes, which are obtained by steps of grinding wet cells through ultrasonic waves and extracting grinded wet cells, are taken as the catalyst, a buffer solution with a pH value of 5-10 is taken as the reaction medium, reactions are performed in a water bath with a temperature of 45 DEG C at a rotation speed of 200 rpm, after complete reactions, a reaction solution containing D-N-acetyl glufosinate ammonium and L-glufosinate ammonium is obtained, the reaction solution is separated and purified, and collected D-N-acetyl glufosinate ammonium is subjected to racemization and then split in cycles to obtain L-glufosinate ammonium at the same time. The provided method does not need a coenzyme circulation system or an amino donor with a structure that is similar with the product; the reaction steps are simple, the reaction product is easy to separate, the opticalselectivity is high (ee value is 99%), the separation effect of the ion exchange column is obvious, and L-glufosinate ammonium with higher purity can be obtained more easily (purity is 98%).

Owner:ZHEJIANG UNIV OF TECH

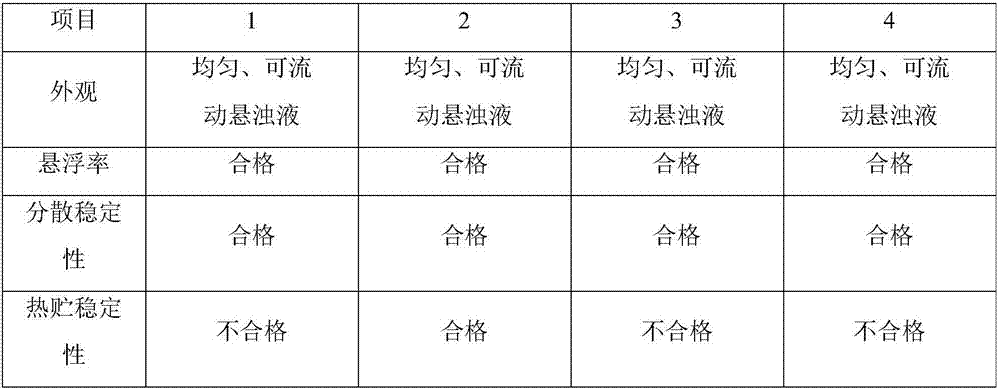

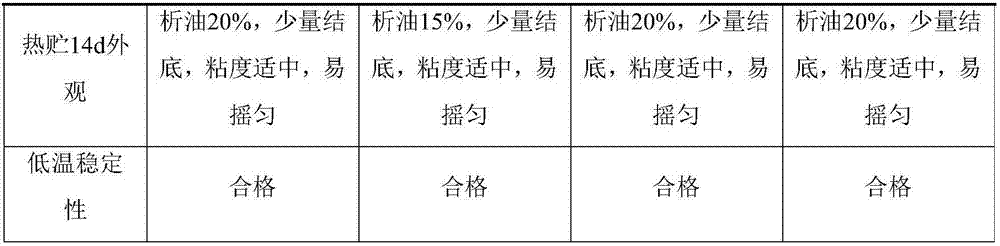

Glufosinate-ammonium dispersible oil suspension and preparation method therefor

ActiveCN107969421ABottomless phenomenonImprove stabilityBiocideOrganic compound preparationGlufosinate-ammoniumEnvironmental resistance

The invention discloses a glufosinate-ammonium dispersible oil suspension. The glufosinate-ammonium dispersible oil suspension is prepared from the following substances in percentage by weight: 5% to30% of glufosinate-ammonium, 5% to 20% of emulsifier, 1% to 5% of wetting dispersant, 0.1% to 5% of thixotropic agent and the balance of dispersing medium. The preparation method for the glufosinate-ammonium dispersible oil suspension comprises the following steps: (1) uniformly mixing and dispersing the emulsifier, the oil-phase-soluble wetting dispersant and the dispersing medium; (2) adding original glufosinate-ammonium; (3) adding the thixotropic agent, carrying out stirring and mixing, and then, carrying out high-velocity shearing; and (4) carrying out sanding for 1 to 2 hours until the grain size D90 is 5 microns or less under the condition of a grinding medium. The glufosinate-ammonium dispersible oil suspension disclosed by the invention is relatively low in oil deposition during normal-temperature and hot storage, can restore original condition through shaking at room temperature and is free of a deposition phenomenon; and the glufosinate-ammonium dispersible oil suspension has good hot storage stability and low-temperature stability, is safe and environmentally friendly and is resistant to rainfall erosion, good in pesticide effect and long in effect duration.

Owner:南京太化化工有限公司

Glufosinate-ammonium dehydrogenase mutant and application thereof to production of L-glufosinate-ammonium through oxidation-reduction of multienzymes

InactiveCN110592036AHigh catalytic activityHigh substrate concentrationBacteriaMicroorganism based processesMutantSubstrate concentration

The invention discloses a glufosinate-ammonium dehydrogenase mutant and an application thereof to production of L-glufosinate-ammonium through oxidation-reduction of multienzymes. According to the method, a method for preparing an L-glufosinate-ammonium precursor through D-amino acid oxidase is utilized, D, L-glufosinate-ammonium or D-glufosinate-ammonium is used as substrate, and in aerobic environment or under the situation that catalase exists, through excised D-amino acid oxidase or in vitro expression of cells of D-amino acid oxidase, the D-glufosinate-ammonium is catalyzed to obtain 4-(hydroxymethylphosphinyl)-2-oxobutanoic; and under the action of glufosinate-ammonium dehydrogenase, the 4-(hydroxymethylphosphinyl)-2-oxobutanoic is catalyzed to generate the L-glufosinate-ammonium, the activity of a catalyst is improved by about 10 times, and the concentration of the substrate is increased by 5 times. The method is high in raw material conversion rate and high in yield, and products are easy to separate and purify.

Owner:ZHEJIANG UNIV OF TECH

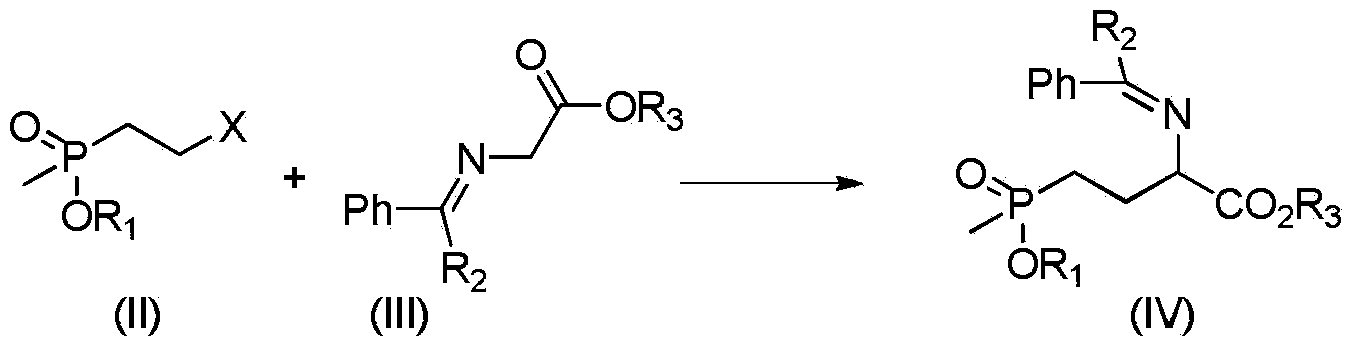

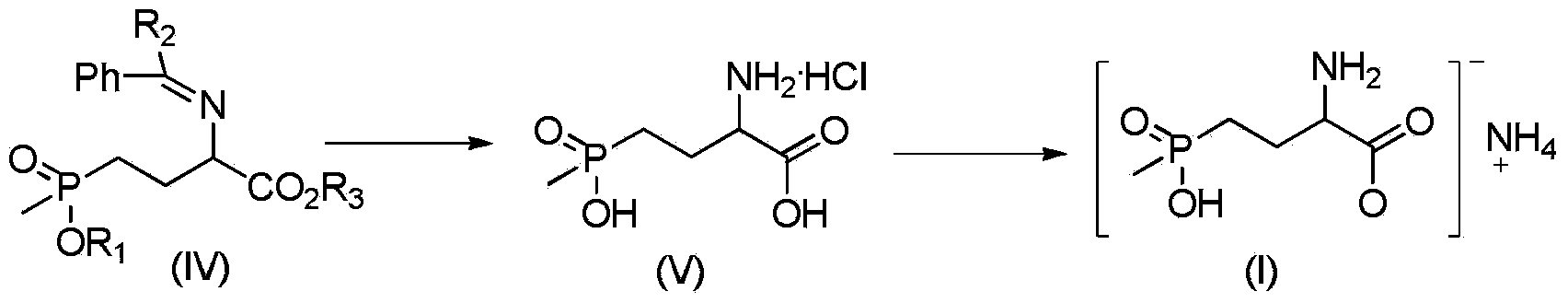

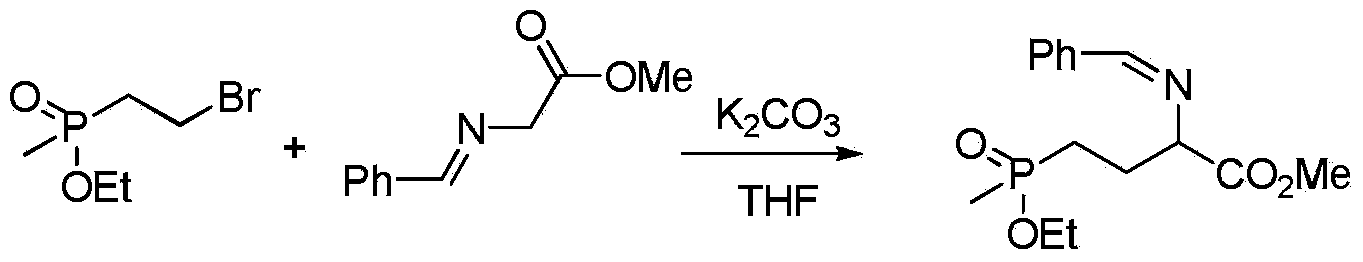

Preparation method of glufosinate-ammonium

InactiveCN103965241AHigh yieldEasy to monitorGroup 5/15 element organic compoundsGlycineInorganic salts

The invention discloses a preparation method of glufosinate-ammonium. The method comprises the steps that methylphosphonate compound (II) and benzylidene glycine ester compound (III) are reacted, so as to obtain benzylidene phosphonic butyric ester compound (IV); the benzylidene phosphonic butyric ester compound (IV) is further hydrolyzed, so as to obtain hydrochloride (V); finally, the target product glufosinate-ammonium (I) is obtained. The method has the advantages that the utilization of extremely toxic substance cyanide is avoided, the reaction condition is mild, monitoring is easy, and repeated recrystallization is not required for removing inorganic salt. (img file='DDA0000501075940000011.TIF' wi='1408' he=' 672' / ).

Owner:XIAN MODERN CHEM RES INST

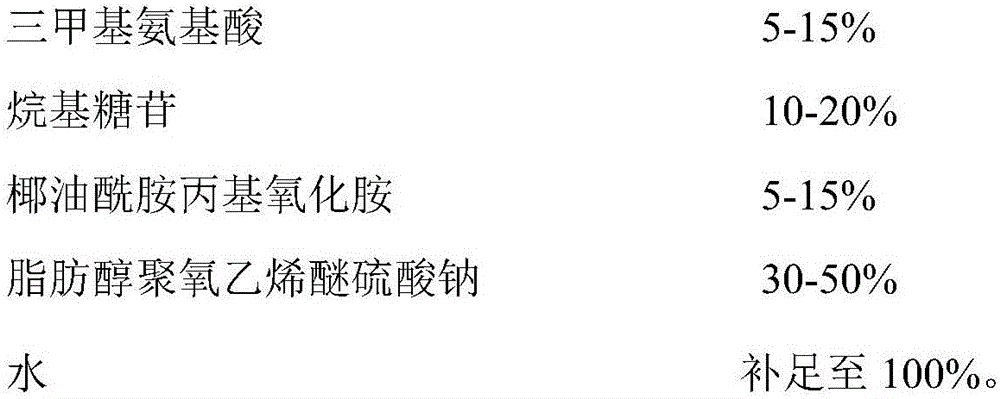

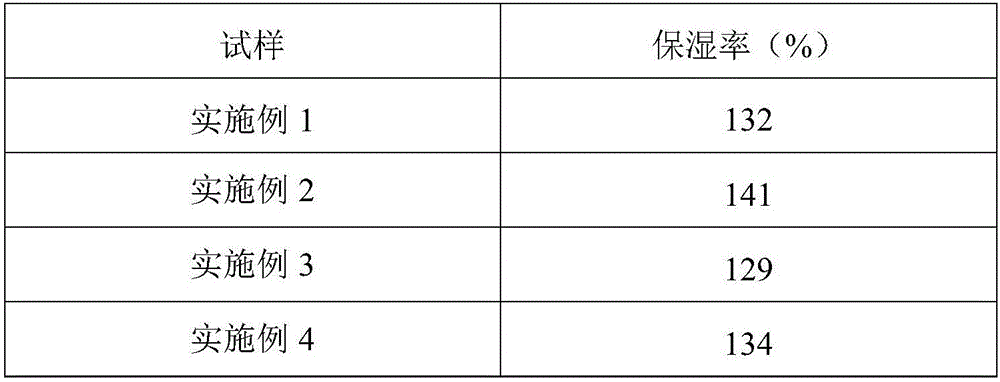

Glufosinate-ammonium water agent synergy additive containing trimethyl amino acid

ActiveCN106212453AGood moisturizing effectGood synergistic effectBiocideAnimal repellantsGlufosinate-ammoniumMoisture

The invention discloses a glufosinate-ammonium water agent synergy additive containing trimethyl amino acid. The synergy additive contains an effective amount of trimethyl amino acid. The surfactant composition is suitable for multiple glufosinate-ammonium water agents with the glufosinate-ammonium content of 5%-50%, has excellent moisture-preserving and synergistic effects, has strong biodegradability and is more environmentally friendly.

Owner:NANJING KEYI NEW MATERIALS

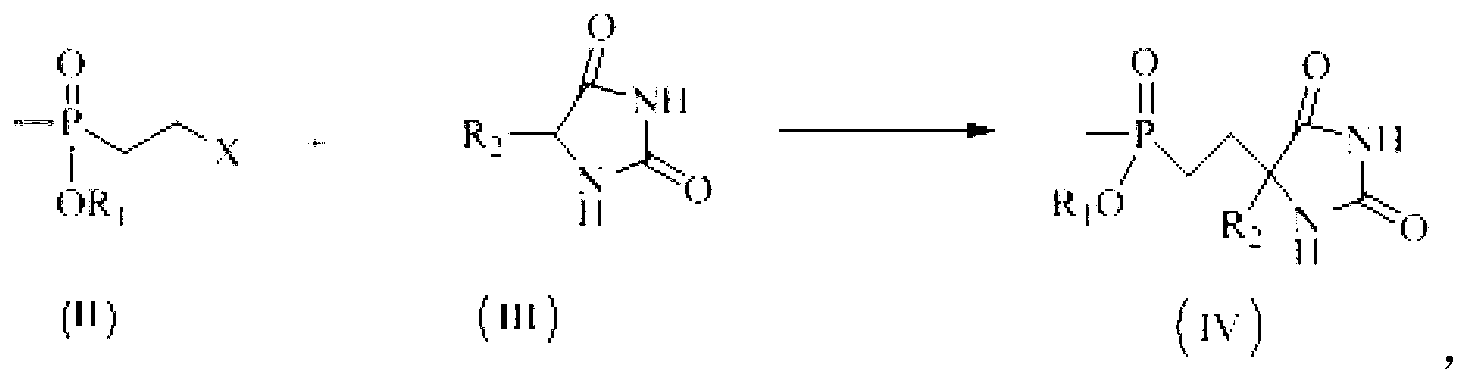

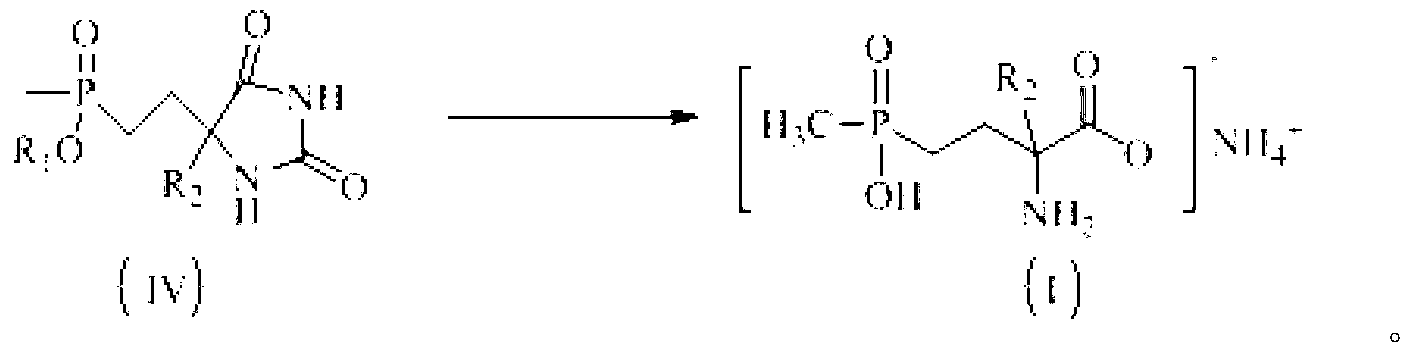

Preparation method of glufosinate-ammonium and derivatives thereof

InactiveCN103288874AHigh yieldEasy to detectBiocideGroup 5/15 element organic compoundsHydantoin derivativesReaction temperature

The invention discloses a preparation method of glufosinate-ammonium and derivatives thereof. The method comprises the following steps: (1) by using a substituted hydantoin and methylphosphonate compounds as a raw material, adding alkali, carrying out nucleophilic substitution reaction at the reaction temperature of 20-100 DEG C in a reaction solvent to obtain a hydantoin derivative, and tracing product generation condition by high performance liquid chromatography in the reaction process to judge the reaction endpoint, wherein the molar ratio of the methylphosphonate compounds, substituted hydantoin and alkali is 1:(1.0-5.0):(1.0-4.0); (2) carrying out reflux reaction for prepared hydantoin derivative prepared and an inorganic acid in water for 30-60 hours; after reaction, adding ammonia water to adjust the pH of the liquor to 12; spirally distilling to remove the solvent; adding absolute methanol for reflux for 30-60 minutes; filtering; spirally drying the mother liquor; adding methanol for recrystallization to obtain pure glufosinate-ammonium shown in formula (I) or derivatives thereof, wherein the molar ratio of the hydantoin derivative and inorganic acid is 1.0:(4.0-9.0).

Owner:SHANDONG ACADEMY OF PESTICIDE SCI +1

Glufosinate-ammonium aqua and preparation method thereof

InactiveCN102845465AGood weeding effectLow costBiocideAnimal repellantsGlufosinate-ammoniumPreservative

The invention discloses a glufosinate-ammonium aqua and a preparation method thereof; the glufosinate-ammonium aqua comprises the following components by weight: 10-50% of glufosinate-ammonium, 1-15% of a surfactant, 0.1-1% of a preservative, 1-5% of a synergist, and the balance of deionized water. The invention also discloses a preparation method of the glufosinate-ammonium aqua. The glufosinate-ammonium aqua of the invention is an agricultural herbicide with good effect, safety, and environmental protection.

Owner:GUANGDONG ZHONGXUN AGRI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com