Method for preparing L-glufosinate-ammonium through microorganism catalysis and deracemization

A technology of glufosinate-ammonium and deracemization, applied in the biological field, can solve the problems of high preparation cost and achieve the effects of low cost, reduced process cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

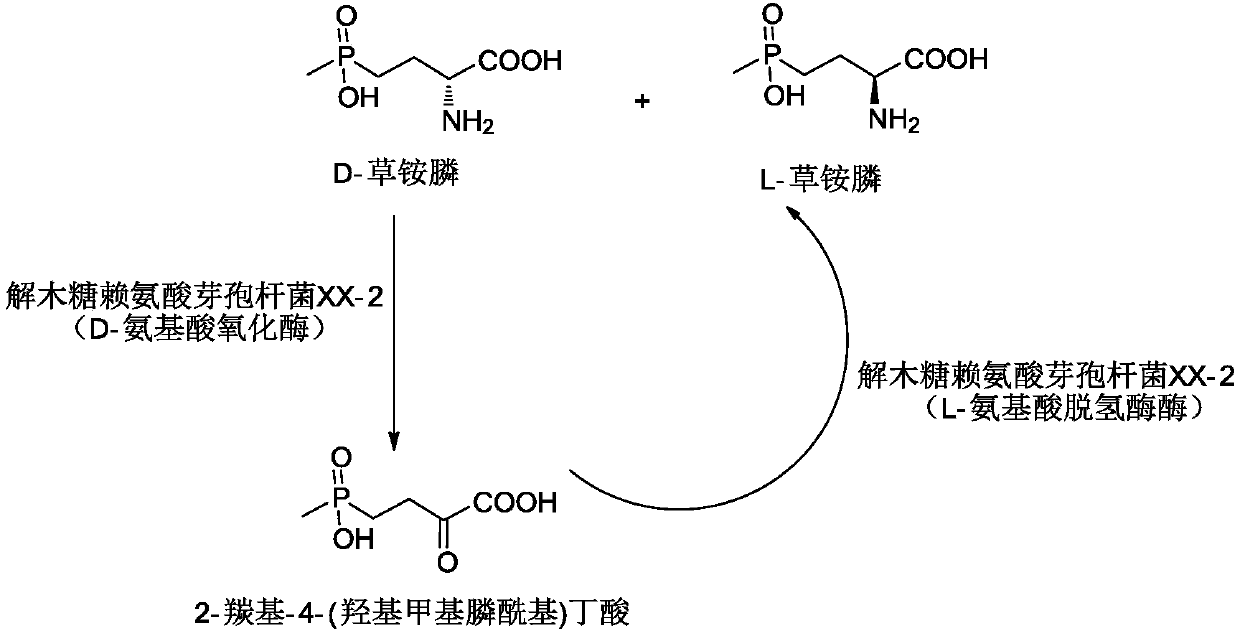

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: cell culture

[0033] Bacillus xylosinolyticus XX-2 was fermented in shake flasks. The seed solution was inserted into the sterilized enzyme-producing medium with a 10% inoculation amount, and cultured on a shaker (180 rpm) at 30° C. for 48 hours. The bacterial solution was centrifuged at 4°C and 8000 rpm for 5 minutes, the bacterial cells were collected, and washed twice with sodium phosphate buffer ((100mmol / L, pH8.0). The bacterial cells were resuspended in sodium phosphate buffer (100mmol / L, pH8.0) for later use.

Embodiment 2

[0034] Embodiment 2: the stereo inversion of D-glufosinate-ammonium

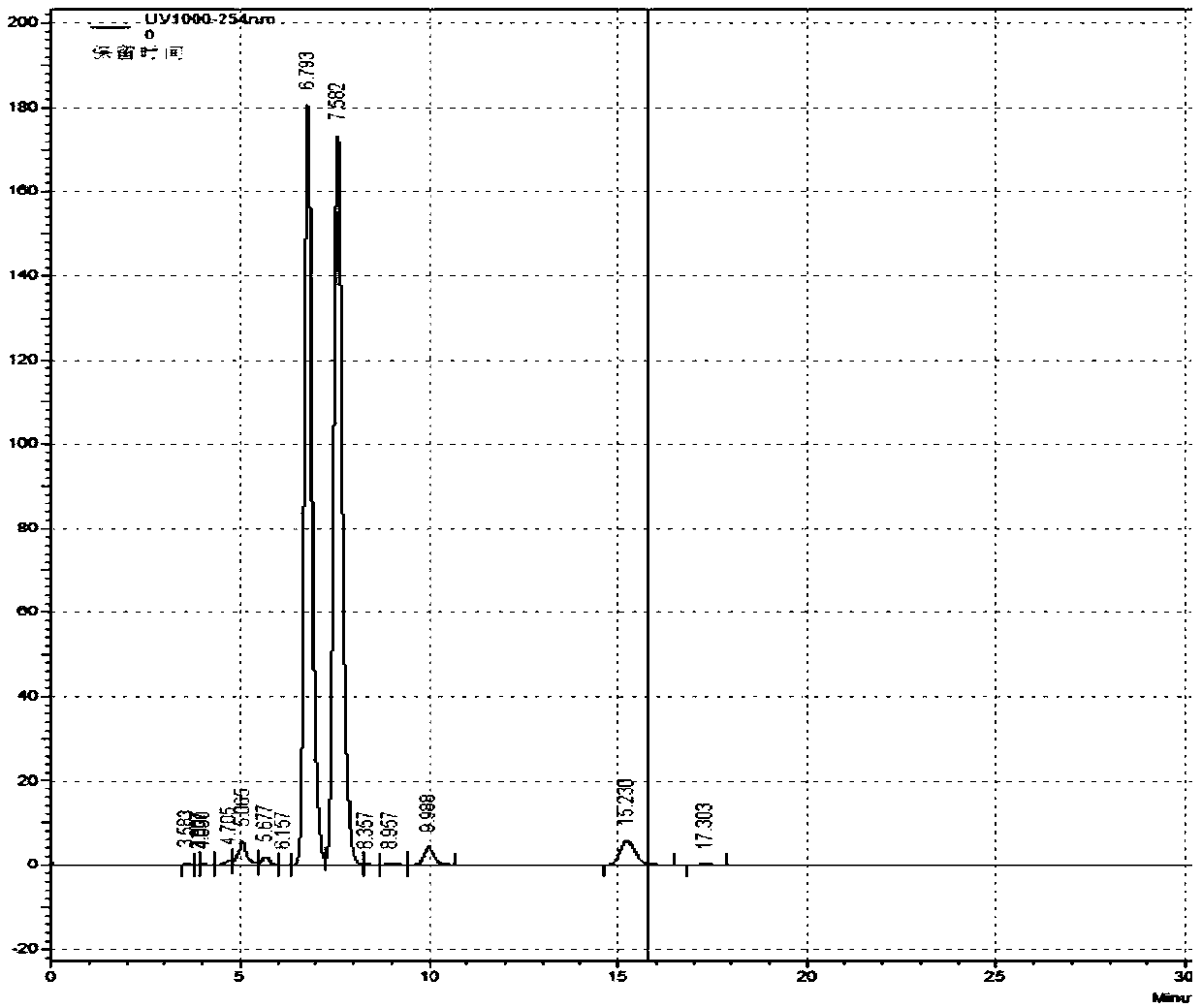

[0035] The reaction solution (10ml) contained 100mmol / L phosphate buffer (pH8.0), 100mmol / L D-glufosinate-ammonium, and 500mg (dry weight) of Bacillus xylosinolyticum XX-2 cells. The reaction was shaken on a constant temperature shaker at 30°C and 180 rpm. Samples were taken at regular intervals, the cells were removed by centrifugation to collect the supernatant, and the concentration of L- and D-glufosinate-ammonium in the supernatant was determined by pre-column chiral derivatization-HPLC. After 24 hours, the reaction of D-glufosinate-ammonium was complete, and the concentration of L-glufosinate-ammonium in the reaction liquid was 66mmol / L, ee 99.8%.

Embodiment 3

[0036] Example 3: DL-glufosinate-ammonium deracemization

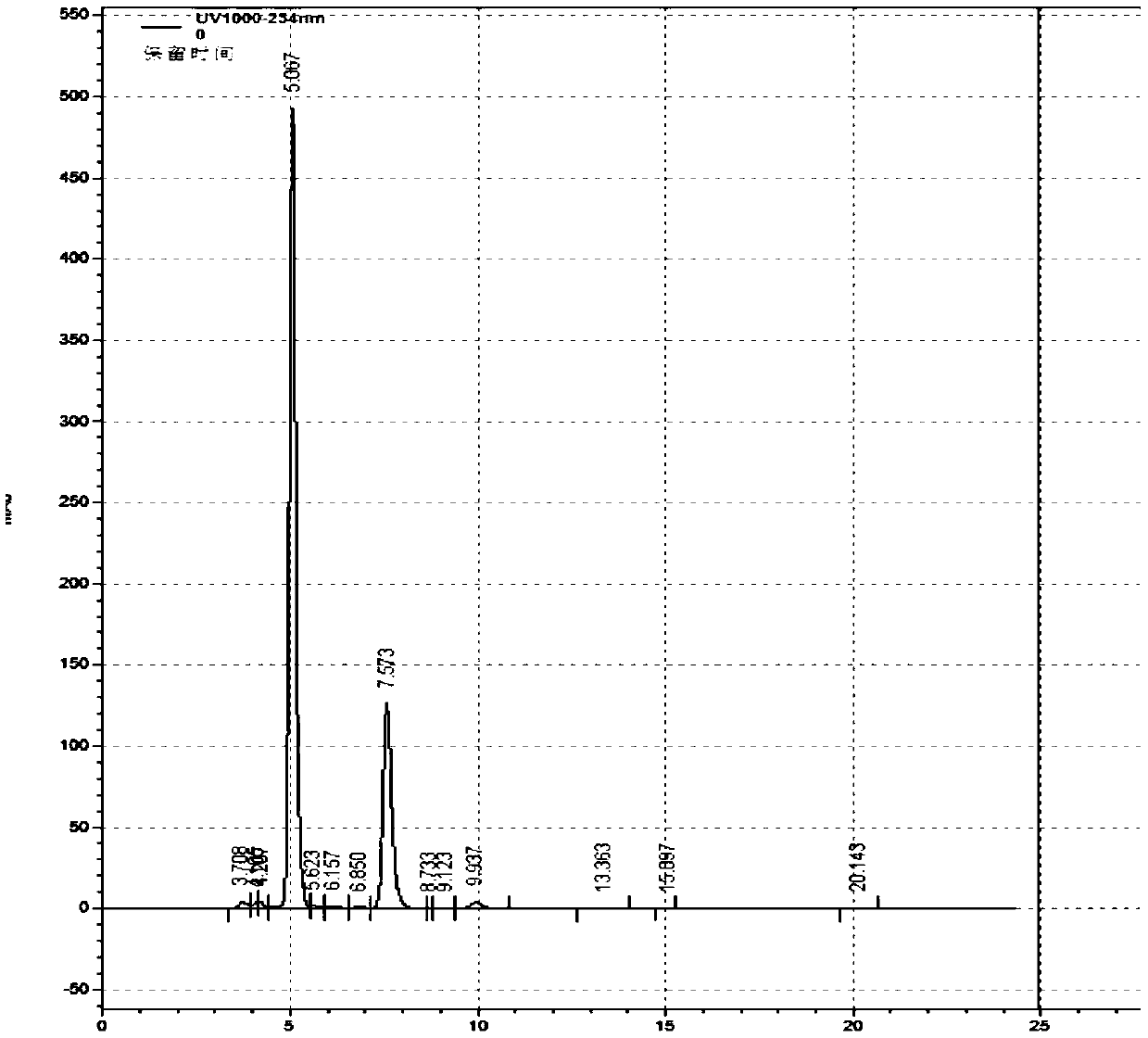

[0037]The reaction solution (10ml) contained 100mmol / L phosphate buffer (pH8.0), 200mmol / L DL-glufosinate-ammonium, and 500mg (dry weight) of Bacillus xylosinolyticum XX-2 cells. The reaction was shaken on a constant temperature shaker at 30°C and 180 rpm. Samples were taken at regular intervals, the cells were removed by centrifugation to collect the supernatant, and the concentration of L- and D-glufosinate-ammonium in the supernatant was determined by pre-column chiral derivatization-HPLC. After 24 hours, the reaction of D-glufosinate-ammonium was complete, and the concentration of L-glufosinate-ammonium in the reaction liquid was 166mmol / L, ee99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com