Patents

Literature

113 results about "Hydantoin derivatives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

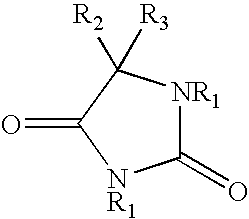

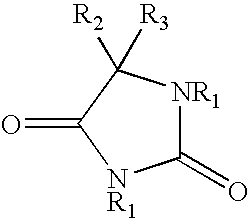

Hydantoin, or glycolylurea, is a heterocyclic organic compound with the formula CH2C(O)NHC(O)NH. It is a colorless solid that arises from the reaction of glycolic acid and urea. It is an oxidized derivative of imidazolidine.

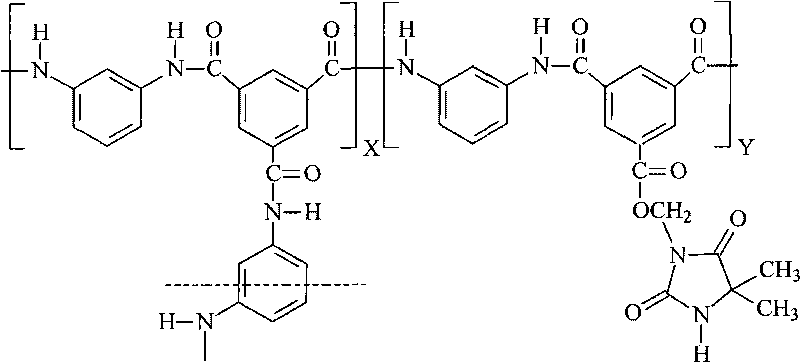

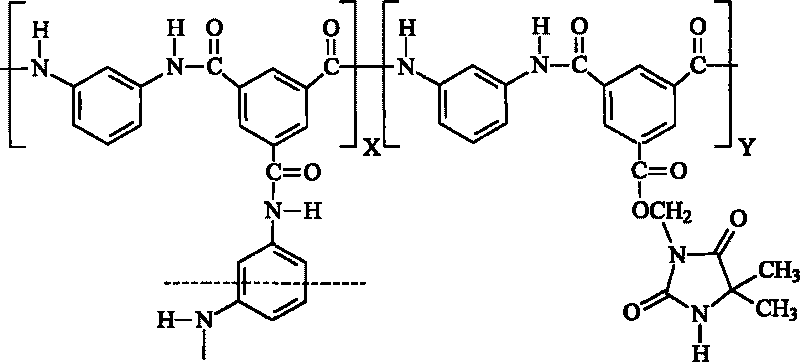

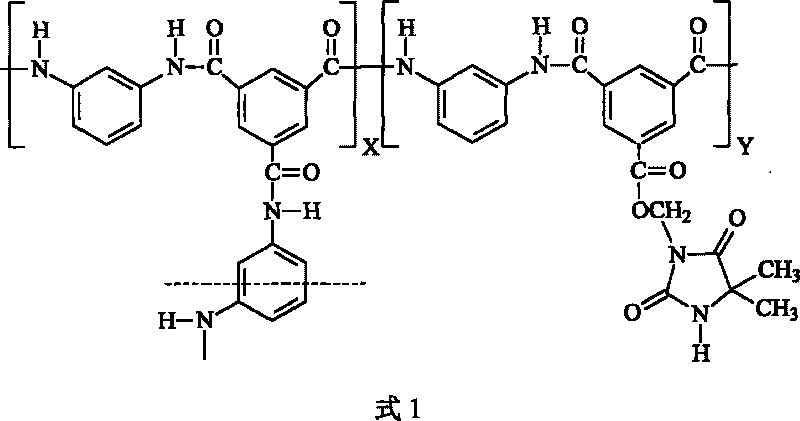

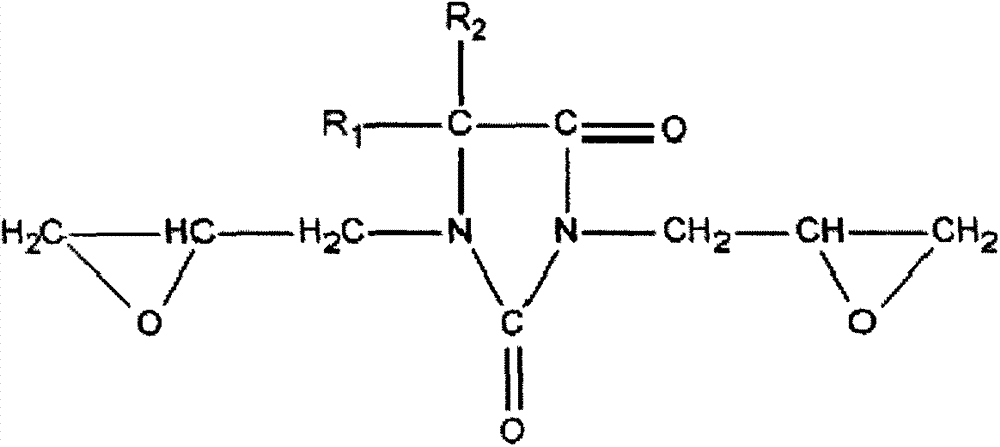

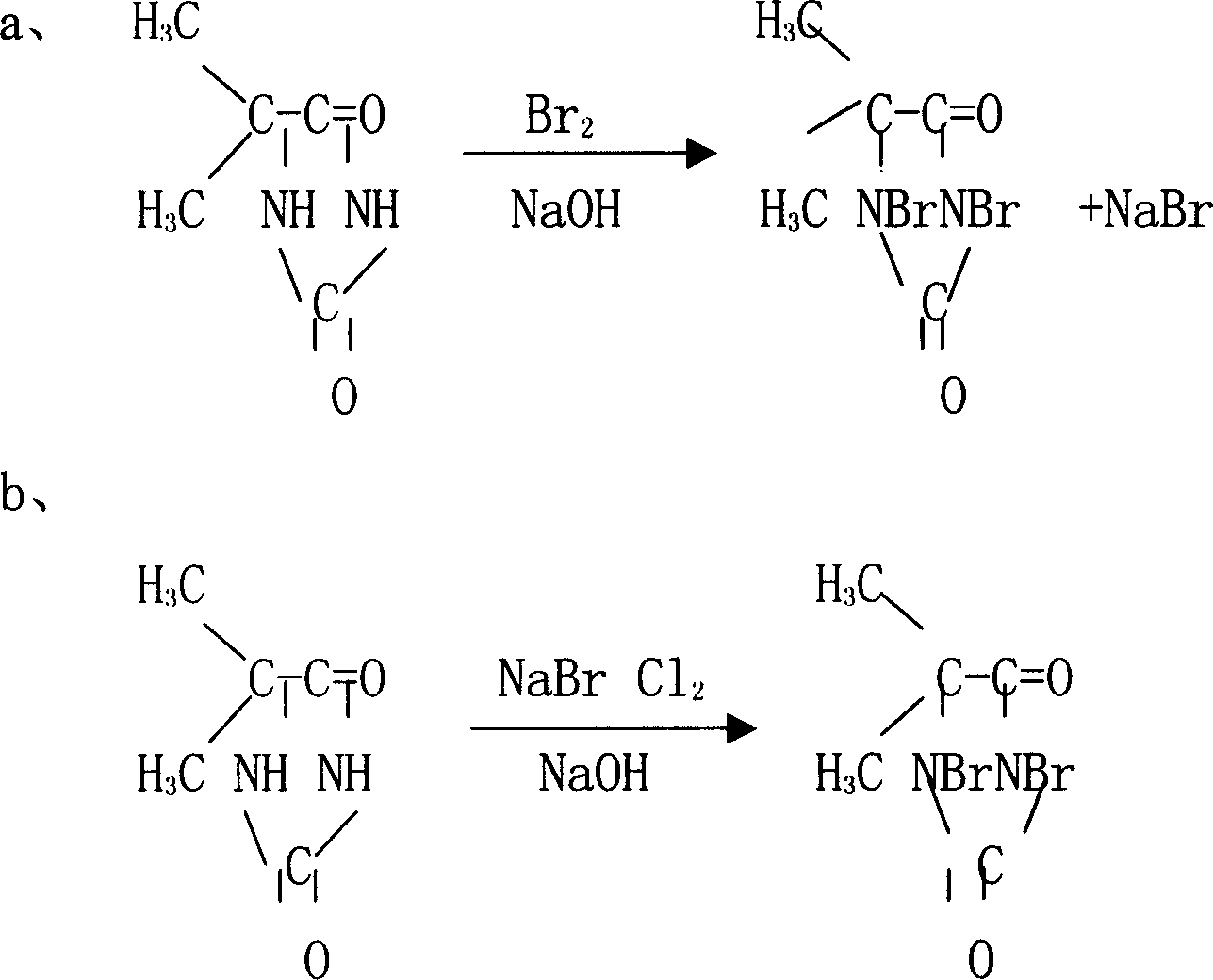

Grafted modified aromatic polyamide composite reverse osmosis membrane and preparation method thereof

ActiveCN101695636AImprove chlorine resistanceSimple methodSemi-permeable membranesHydantoin derivativesPolysulfone membrane

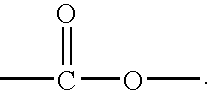

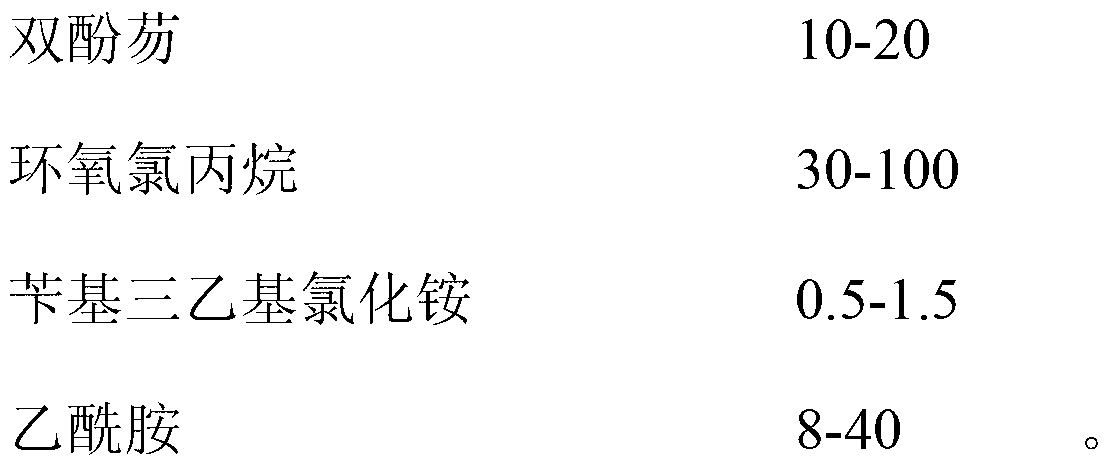

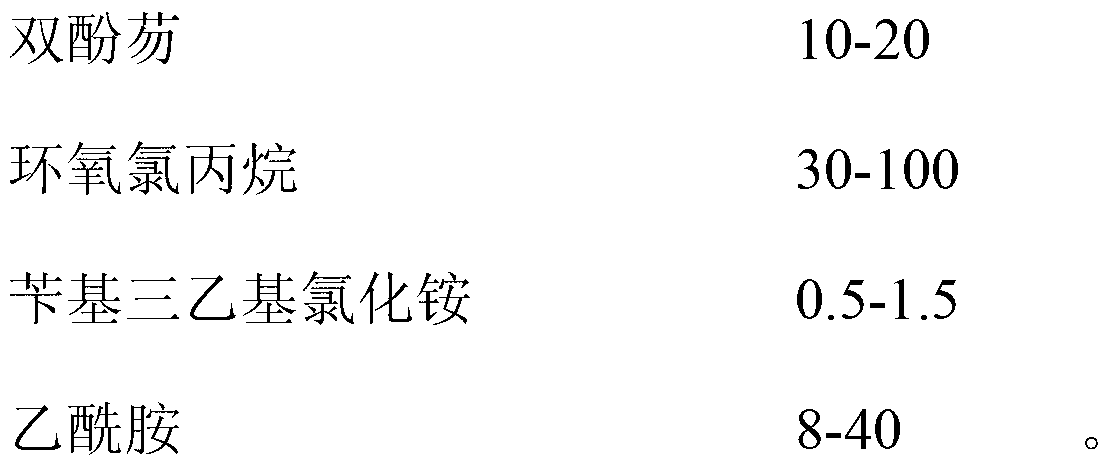

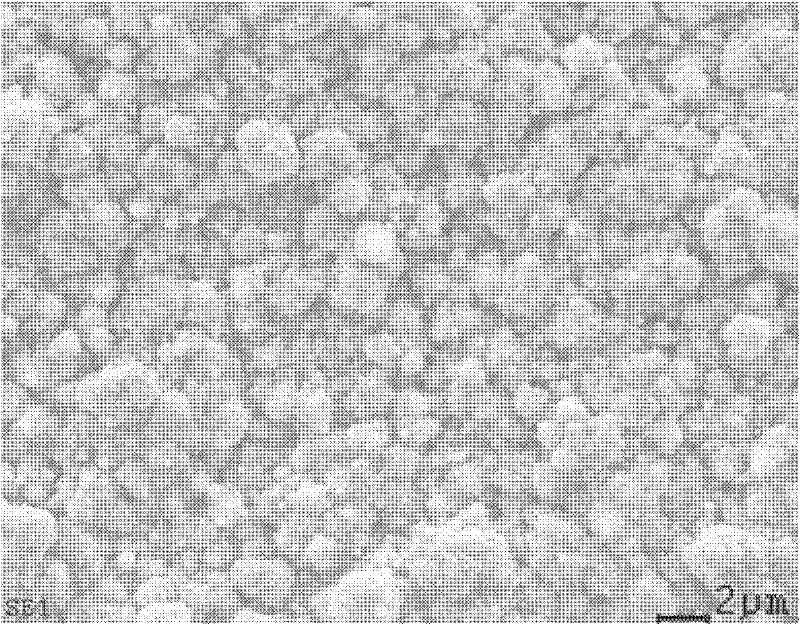

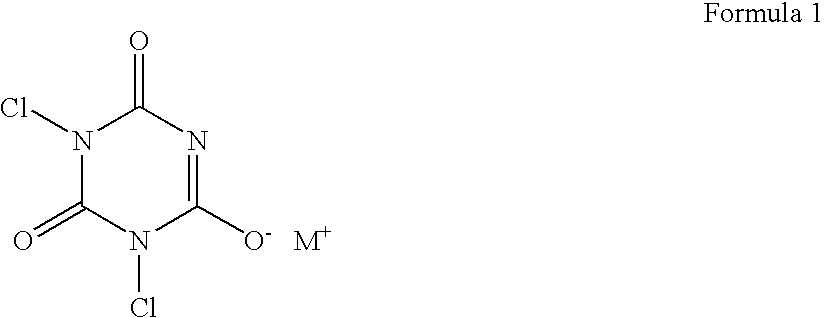

The invention discloses a grafted modified aromatic polyamide composite reverse osmosis membrane and a preparation method thereof, belonging to preparation technology of composite reverse osmosis membranes. The structural formula of the membrane is shown as follow. The preparation process comprises the following steps: taking a polysulphone membrane as a support membrane, preparing an aromatic polyamide composite reverse osmosis membrane to be grafted by an interfacial polymerization; enabling a graft modified solution containing 3-hydroxymethyl-5,5-dimethylhydantoin to contact the surface of the membrane to be grafted quickly for reacting, and conducting heat treatment to obtain the modified aromatic polyamide composite reverse osmosis membrane grafted with hydantoin derivatives. The invention has simple process, and the prepared membrane has the characteristics of good chlorine resistance and good microbial contamination resistance.

Owner:TIANJIN UNIV

Non-cyanide silver plating bath composition

InactiveUS20050183961A1Chemically stableIncrease brightnessChemical vapor deposition coatingCyanideSilver plate

Disclosed is an electroplating solution for the deposition of silver; said solution containing silver in the form of a complex of silver with hydantoin or a substituted hydantoin compound; said solution also containing an excess of the hydantoin or substituted hydantoin compound employed, together with an effective quantity of a nonprecipitating electrolyte salt, and also an effective quantity of 2,2′ dipyridyl for the purpose of obtaining a mirror-bright to brilliant deposit.

Owner:TECHNIC INC

Non-cyanide silver plating bath composition

Owner:TECHNIC INC

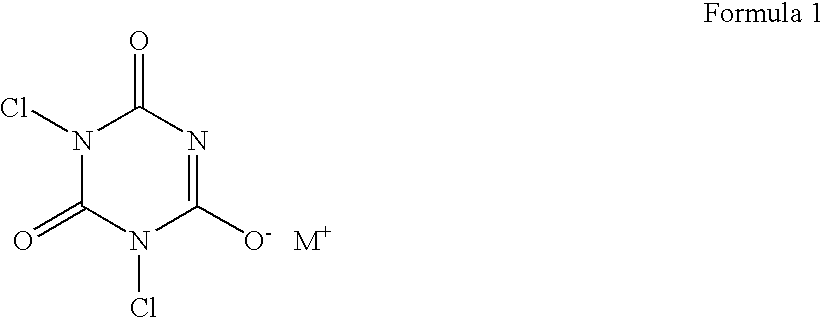

Multi-functional oxidizing composition

A composition comprising a stable anhydrous mixture of an oxidizing agent and an active halogen agent wherein the oxidizing agent is potassium hydrogen peroxymonosulfate and the active halogen agent is an alkali metal salt of dichloro-s-triazinetrione, halogenated dimethylhydantoin, or mixtures thereof, and a method of treating water with such compositions are disclosed.

Owner:LENKSESS CORP

Epoxy resin sealing material and method for preparing same

InactiveCN101696264AOvercome the problem of not being resistant to high temperatureHas a fixedOther chemical processesHydantoin derivativesChemistry

The invention relates to an epoxy resin sealing material capable of resisting high temperature and high pressure and a method for preparing the same. The epoxy resin sealing material consists of an A component and a B component, wherein the A component comprises the epoxy resin formed by selecting one or more of bisphenol A type epoxy resin, AG-80 epoxy resin, hydantoin epoxy resin, p-aminophenolepoxy resin, bisphenol F epoxy resin, m-metaxylylenediamine epoxy resin, resorcin epoxy resin, bisphenol AD epoxy resin, bisphenol S epoxy resin, hydrogenation bisphenol A type epoxy resin, organic silicon modification bisphenol A type epoxy resin, fluorination epoxy resin and o-cresol-formaldehyde epoxy resin, and also comprises the components of a thinner, fillers and the like; and the B component is a curing agent. The epoxy resin sealing material can be used for encapsulation and packaging of various electric elements, and besides the functions of fixing, moisture prevention, anti corrosion, anti-counterfeiting and the like, the epoxy resin sealing material also has the function of bearing high pressure at a high temperature, so that the epoxy resin sealing material is widely used.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

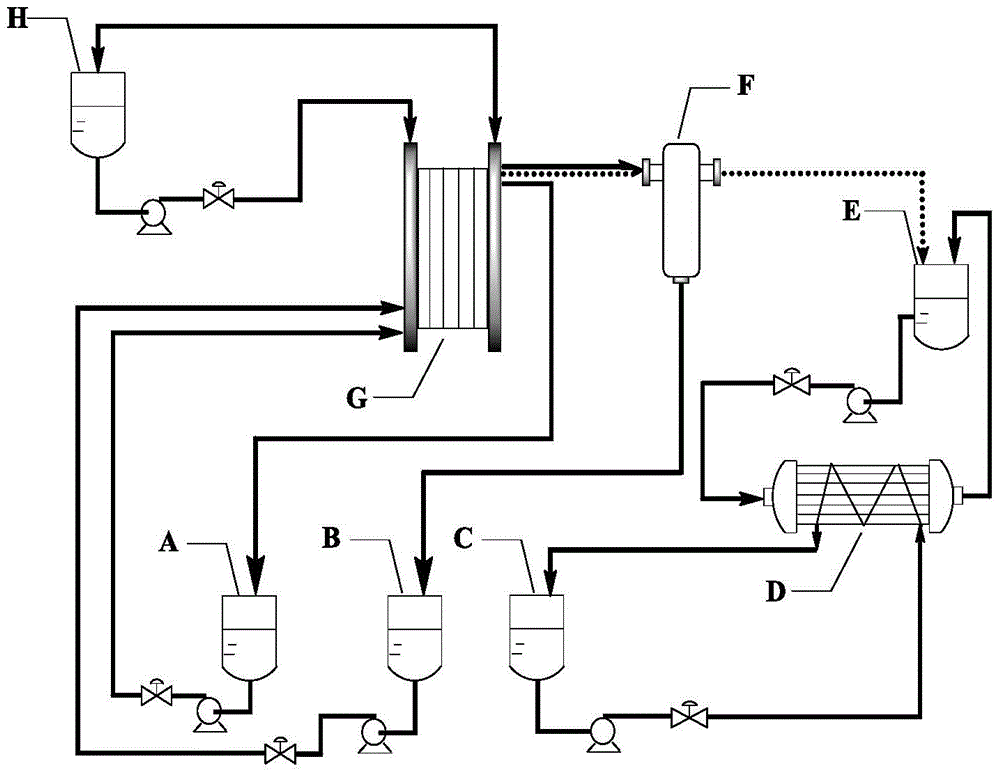

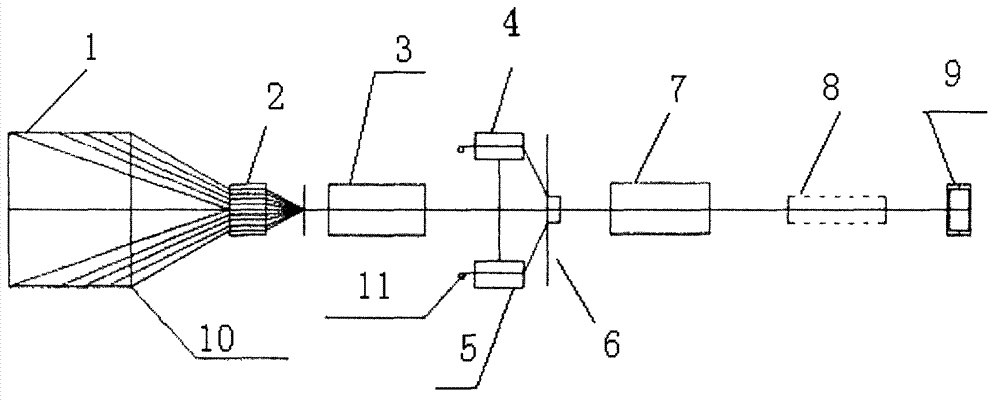

Method and device for preparing methionine and recovering by-product-carbon dioxide

ActiveCN105671587ARealize cleaner productionReduce energy consumptionElectrolysis componentsElectrolytic organic productionHydantoin derivativesCo2 absorption

The invention discloses a method for preparing methionine and recovering a by-product-carbon dioxide. The method comprises the steps that a methionine salt and carbonate mixed solution obtained by hydrolyzing methylmercapto-ethyl hydantoin with alkali is filtered through a microporous membrane, and then filtrate is delivered to a bipolar membrane electrodialysis system to be subjected to electrodialysis treatment, so that acid liquor A and alkali liquor A are obtained; the alkali liquor A is treated continuously and cyclically, and the acid liquor A is subjected to gas-liquid separation, so that gaseous carbon dioxide and acid liquor B are obtained; the acid liquor B is delivered back into the bipolar membrane electrodialysis system to be subjected to cyclic treatment till the pH value of the acid liquor B is 3.8-4.5, the reaction is completed, a methionine solution is prepared, and the methionine is prepared through concentration and crystallization of the methionine solution; the gaseous carbon dioxide is introduced into an absorption cell, and carbon dioxide on the upper portion of the absorption cell absorbs mother liquor, is subjected to membrane distillation and concentration and then is circulated back to the absorption cell; carbonate crystals are grown at the bottom of the absorption cell and guided out from the bottom of the absorption cell; and carbonate is recovered through solid-liquid separation. According to the method for preparing the methionine and recovering the by-product-carbon dioxide, the gaseous carbon dioxide is recycled, so that carbon emission is reduced, and energy resources are saved through the membrane distillation technique.

Owner:浙江佰辰低碳科技有限公司

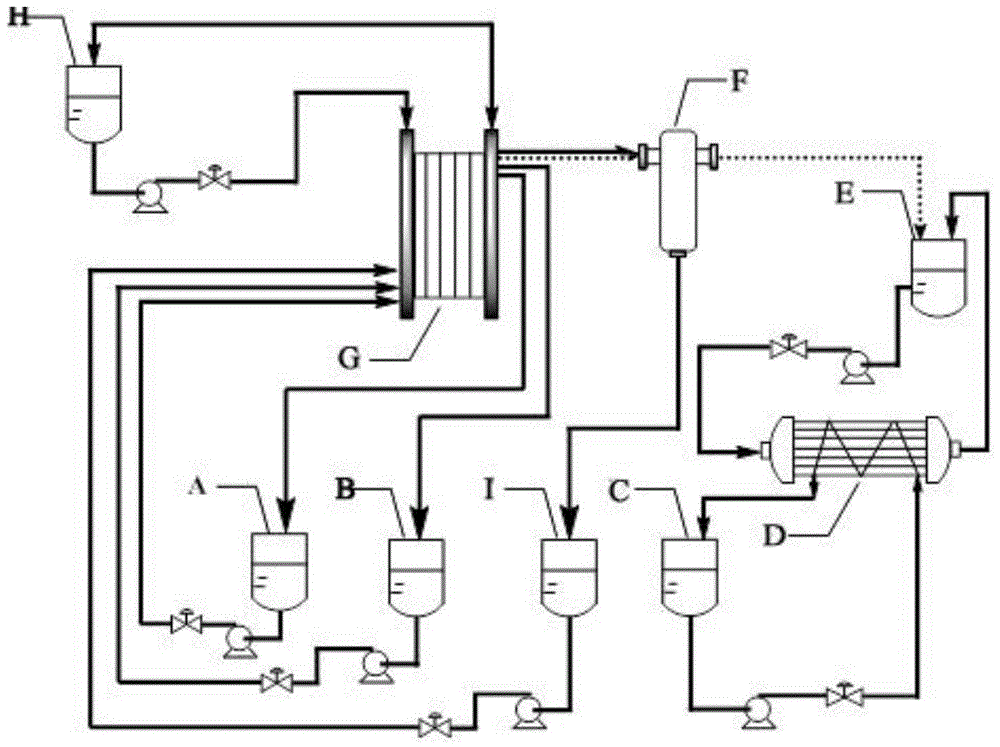

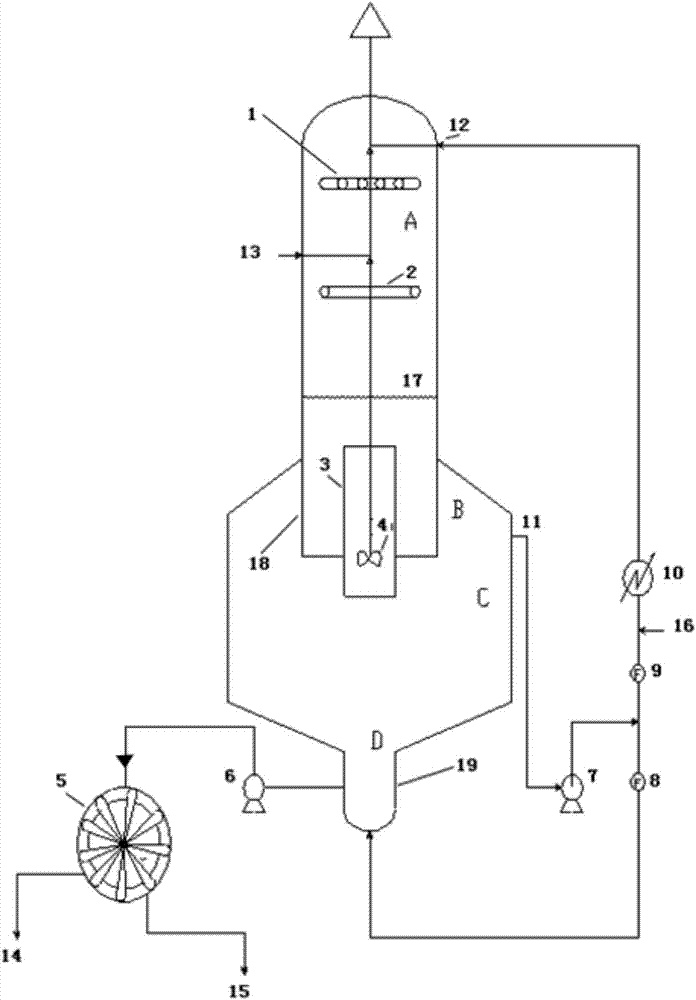

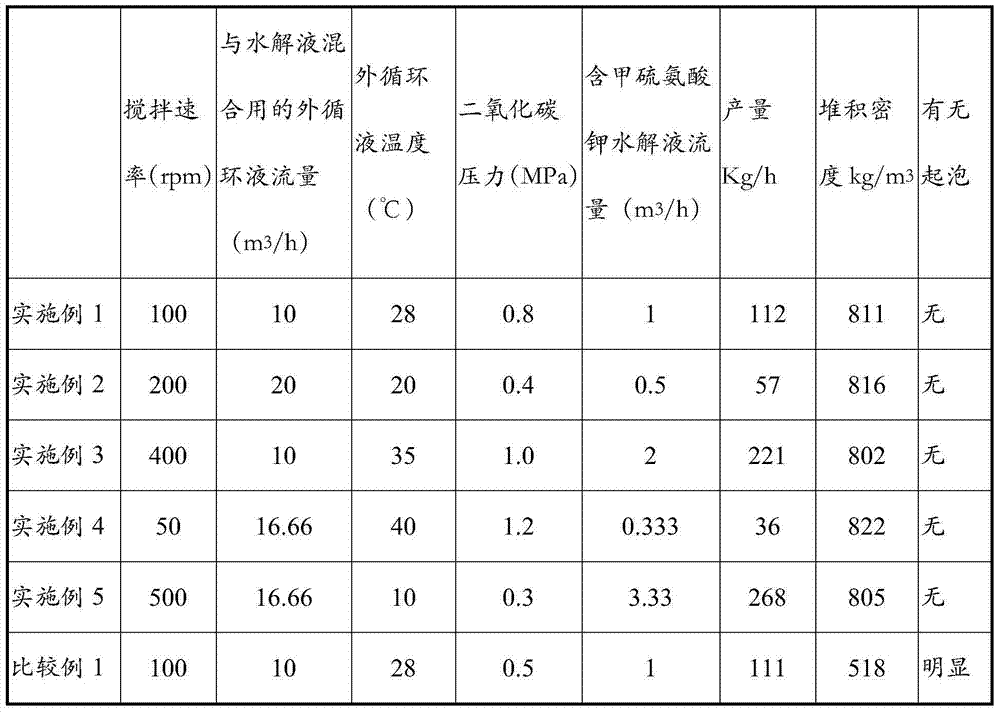

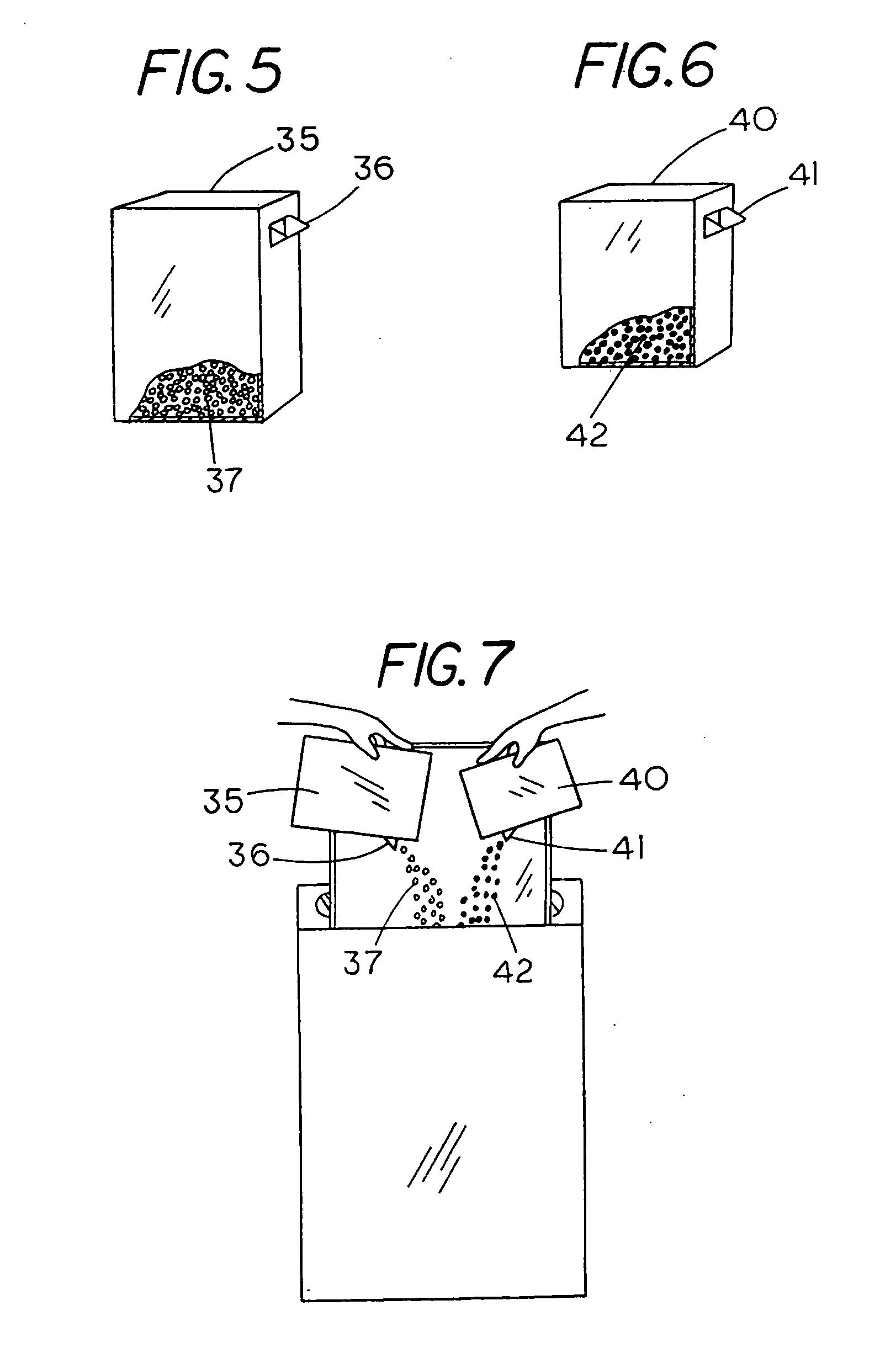

Method for continuously preparing high-bulk density methionine crystals

ActiveCN104744326AImprove product qualityImprove efficiencyOrganic chemistryOrganic compound preparationHydantoin derivativesHydrolysate

The invention relates to a method for continuously preparing high-bulk density methionine crystals. The process of the method is as follows: a hydrolysate, which is obtained from reaction of 5-(beta-methylthioethyl)hydantoin and a potassium carbonate solution, is mixed with an outside circular material from a DTB neutralization crystallizer with a gas phase neutralization section, the mixture is cooled and enters a liquid distributor in a neutralization area in the upper part of the crystallizer, the mixture is sprayed in drops or trickles into carbon dioxide gas for neutralization reaction, and then falls naturally into a crystallization area in the lower part to be mixed with a material in the area, the mixture grows on tiny crystals in a system to form crystals with larger grain sizes, and meanwhile new crystal nucleuses are formed; in a deposition area in the middle part of the crystallization area, the crystals with larger grain sizes sink into a washing leg, the tiny crystals circulate along with the outside circular material, a part of the outside circular material is used for washing the crystals in the washing leg, and the other part of the outside circular materials is mixed with the hydrolysate; the crystals in the washing leg are separated, washed and then dried to obtain the high-bulk density methionine product.

Owner:SHANDONG XINHECHENG AMINO ACID +2

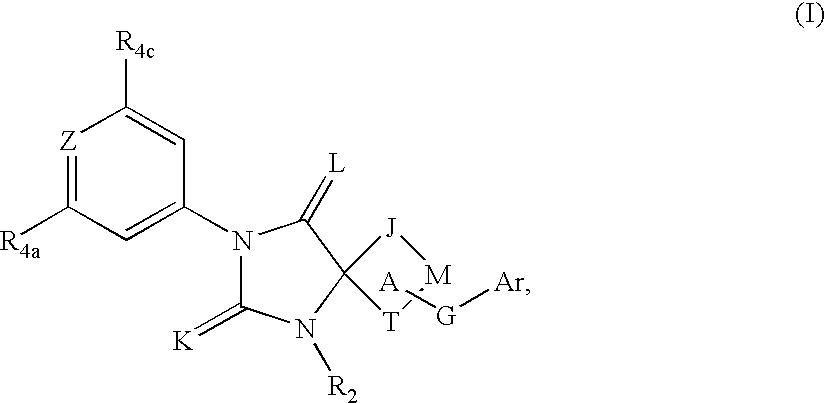

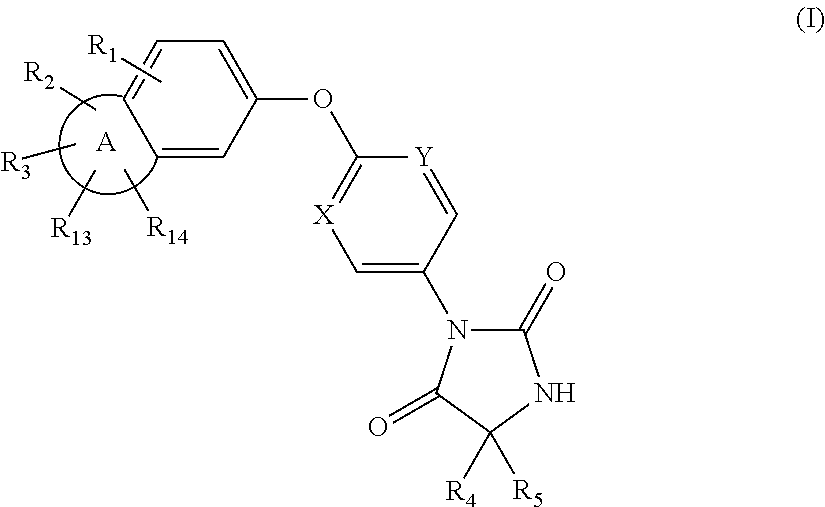

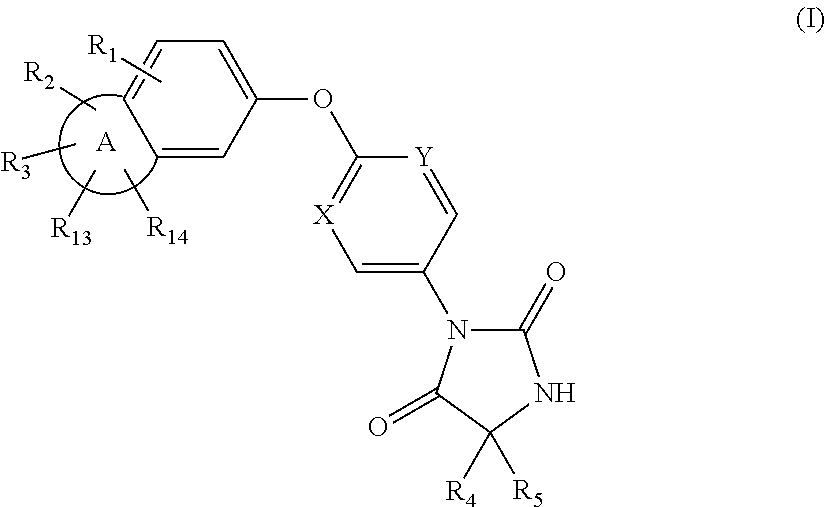

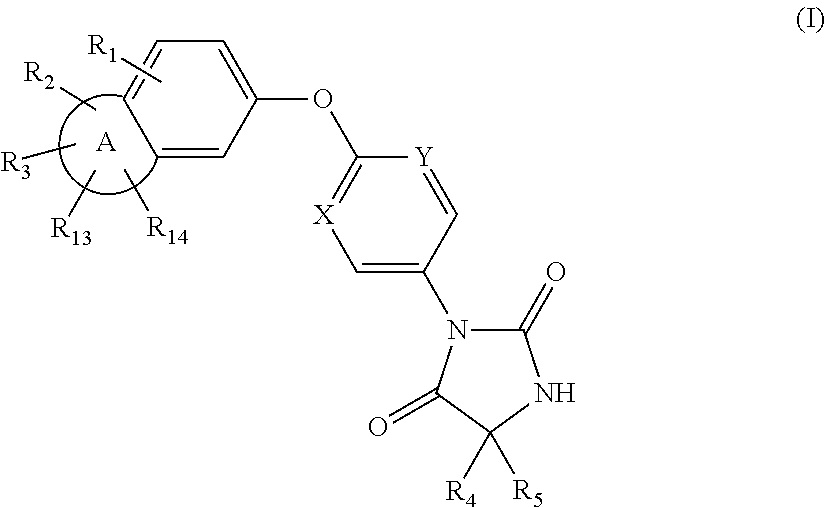

Spiro-hydantoin compounds useful as anti-inflammatory agents

InactiveUS20050004153A1Increase level of cAMP and cGMPGood effectBiocideSenses disorderArylEnantiomer

Compounds having the formula (I), and pharmaceutically-acceptable salts, hydrates, enantiomers, and diastereomers, and prodrugs thereof, are useful as inhibitors of LFA-1 / ICAM and as anti-inflammatory agents, wherein L and K are O or S; Z is N or CR4b; Ar is an optionally-substituted aryl or heteroaryl; G is a linker attached to T or M or is absent; J, M and T are selected to define a three to six membered saturated or partially unsaturated non-aromatic ring; and R2, R4a, R4b, and R4c are as defined in the specification.

Owner:DHAR T G MURALI +5

Cyanide-free monovalent copper eletroplating solutions

A substantially cyanide-free plating solution for depositing copper from the monovalent ionic state, which includes a source of copper ions, a reducing agent capable of reducing divalent copper ions to monovalent copper ions, an alkali material in an amount sufficient to maintain the pH of the solution in the range of about 7 to about 10, and a complexing agent of an imide, such as succinimide, 3-methyl-3-ethyl succinimide, 3-methyl succinimide, 3-ethyl succinimide, 3,3,4,4-tetramethyl succinimide, or 3,3,4-trimethyl succinimide, or a hydantoin, such as dimethyl hydantoin. The substantially cyanide-free plating solutions may also include at least one of a conductivity salt, an additive to promote brightness, or an alloying metal. The reducing agent may be an alkali sulfite, alkali bisulfite, hydroxylamine, or hydrazine. The copper is typically provided in the form of CuC1, CuC12, CuSO4, or Cu20 in an amount sufficient to provide a copper ion concentration of from about 2 to about 30 grams per liter of solution, and the complexing agent is present in an amount sufficient to provide a molar ratio of copper ions to complexing agent of from about 1:1 to about 1:5, preferably about 1:4. The alkali material is typically NaOH, KOH, NH4OH, or Na2CO3, and the conductivity salt is typically NaC1, KC1, Na2SO4, K4P2O7, Na3PO4, C6H5Na3O7, C6H11NaO7, NH4C1, or KNaC4H4O6. Useful additives include organic amines or oxyalkyl polyamines, such as triethylene tetramine, tetraethylene pentamine, and polyoxypropyl-triamine. Methods for preparing such a solution for plating copper onto a substrate, and of plating copper onto a substrate with such a solution are also disclosed.

Owner:LEARONAL

Method for treating waste water in production of para-hydroxyphenyl hydantoin

InactiveCN1884144AGood environmental benefitsThe principle is simpleWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentHydantoin derivativesSalt-wasting

The invention discloses a disposing method of waste water in the p-hydroxybenzene hydantoin manufacturing course, which comprises the following steps: salting waste water with phenol mother liquid through soluble salt; stewing to divide water-phase; blending salted water phase and waste water according to 1:1-8; adsorbing the composite liquid in the resin adsorbing column under normal temperature at 0.1-2 BV per h flow; desorbing the adsorbed saturated resin; preparing for next adsorbing disposal. The invention removes p-phenolsulfonate by over 99 percent, which doesn't pollute environment.

Owner:NANJING UNIV

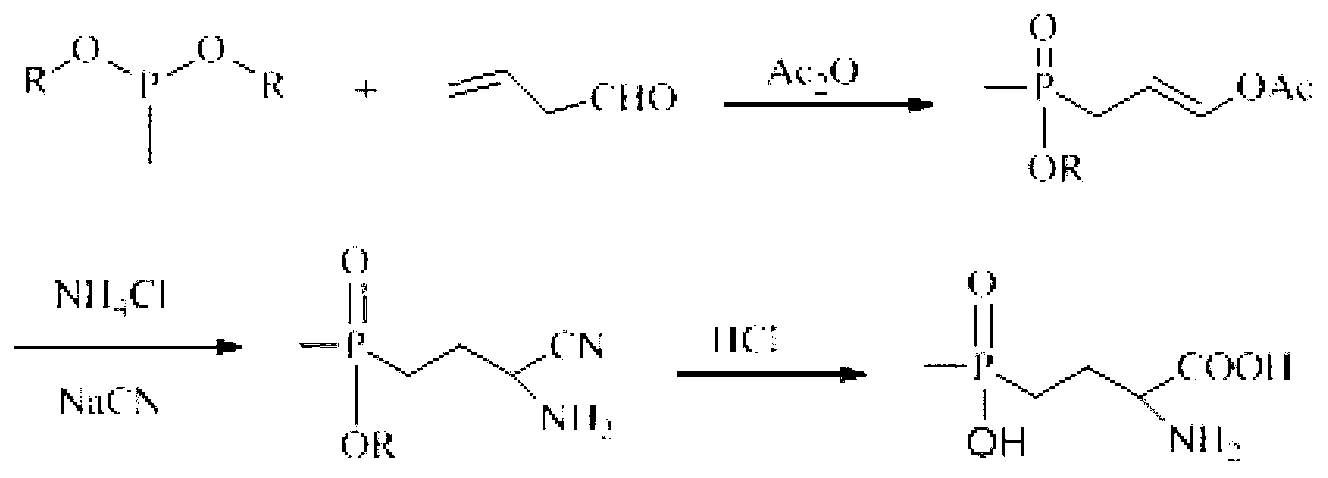

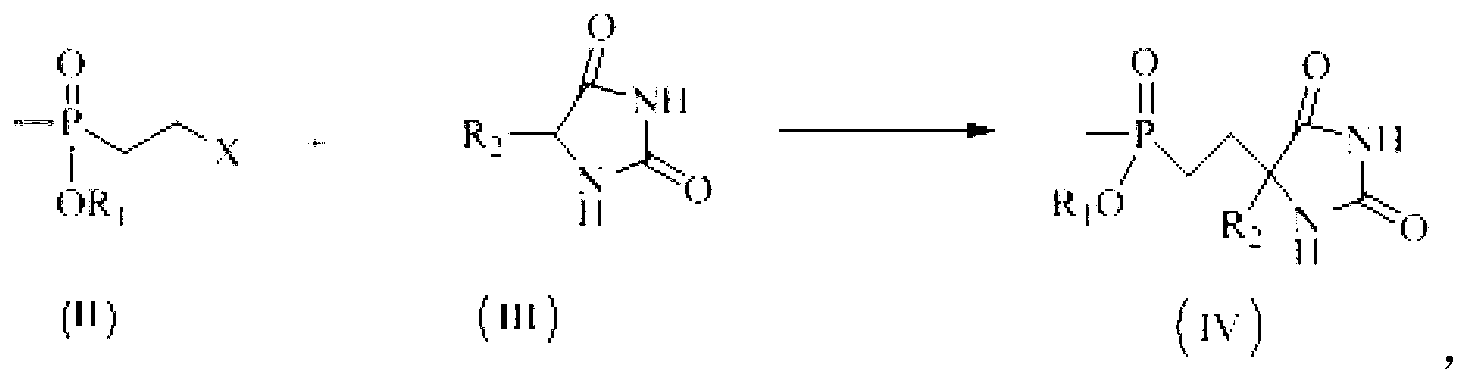

Preparation method of glufosinate-ammonium and derivatives thereof

InactiveCN103288874AHigh yieldEasy to detectBiocideGroup 5/15 element organic compoundsHydantoin derivativesReaction temperature

The invention discloses a preparation method of glufosinate-ammonium and derivatives thereof. The method comprises the following steps: (1) by using a substituted hydantoin and methylphosphonate compounds as a raw material, adding alkali, carrying out nucleophilic substitution reaction at the reaction temperature of 20-100 DEG C in a reaction solvent to obtain a hydantoin derivative, and tracing product generation condition by high performance liquid chromatography in the reaction process to judge the reaction endpoint, wherein the molar ratio of the methylphosphonate compounds, substituted hydantoin and alkali is 1:(1.0-5.0):(1.0-4.0); (2) carrying out reflux reaction for prepared hydantoin derivative prepared and an inorganic acid in water for 30-60 hours; after reaction, adding ammonia water to adjust the pH of the liquor to 12; spirally distilling to remove the solvent; adding absolute methanol for reflux for 30-60 minutes; filtering; spirally drying the mother liquor; adding methanol for recrystallization to obtain pure glufosinate-ammonium shown in formula (I) or derivatives thereof, wherein the molar ratio of the hydantoin derivative and inorganic acid is 1.0:(4.0-9.0).

Owner:SHANDONG ACADEMY OF PESTICIDE SCI +1

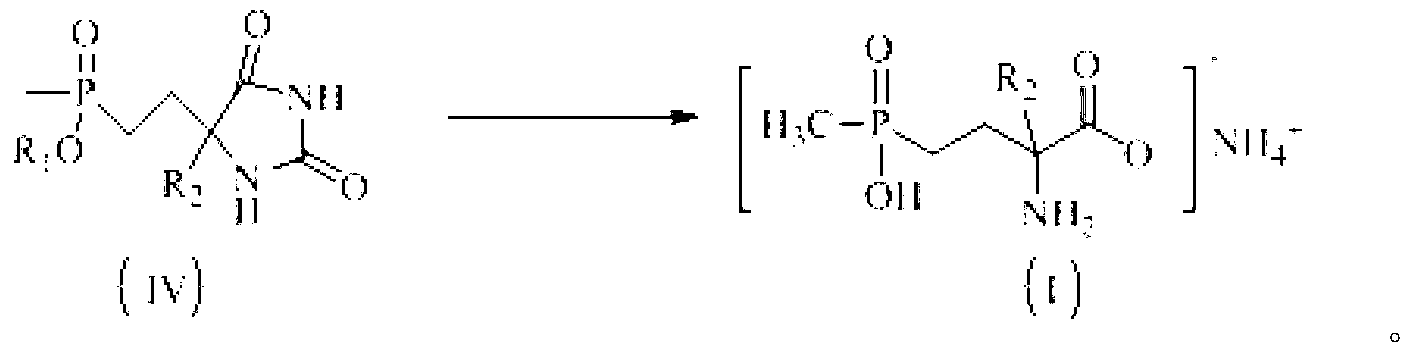

Electroplating liquid for pulse electroplating for compact silver film on ceramic surface and electroplating method thereof

InactiveCN105316716AUniform brightnessUniform film thicknessHydantoin derivativesPolyethylene glycol

The invention discloses an electroplating liquid for pulse electroplating for a compact silver film on a ceramic surface and an electroplating method thereof. The electroplating liquid comprises 2-50g / L of silver citrate, 10-120g / L of 2-sulpho-5,5-dimethyl hydantoin, 10-50g / L of succinimide, 10-50g / L of potassium hydroxide, 10-40g / L of potassium citrate, 1-3g / L of ammonium molybdate, 0.5-2g / L of polyethylene glycol, 20-150g / L of sodium sulphite, and 5-20g / L of isonicotinic acid, wherein the pH value of the electroplating liquid is adjusted to 8-10 by virtue of potassium hydroxide, and the temperature of the electroplating liquid is kept at 25-45 DEG C; and the ceramic pre-plated metal layer surface is electroplated by a square-wave pulse current method, and a layer of compact silver film can be electrodeposited. The electroplating liquid is high in stability; and the plating layers obtained by the pulse electroplating method are smooth and compact, uniform in brightness, and high in performance of binding with a ceramic matrix.

Owner:苏州市金星工艺镀饰有限公司

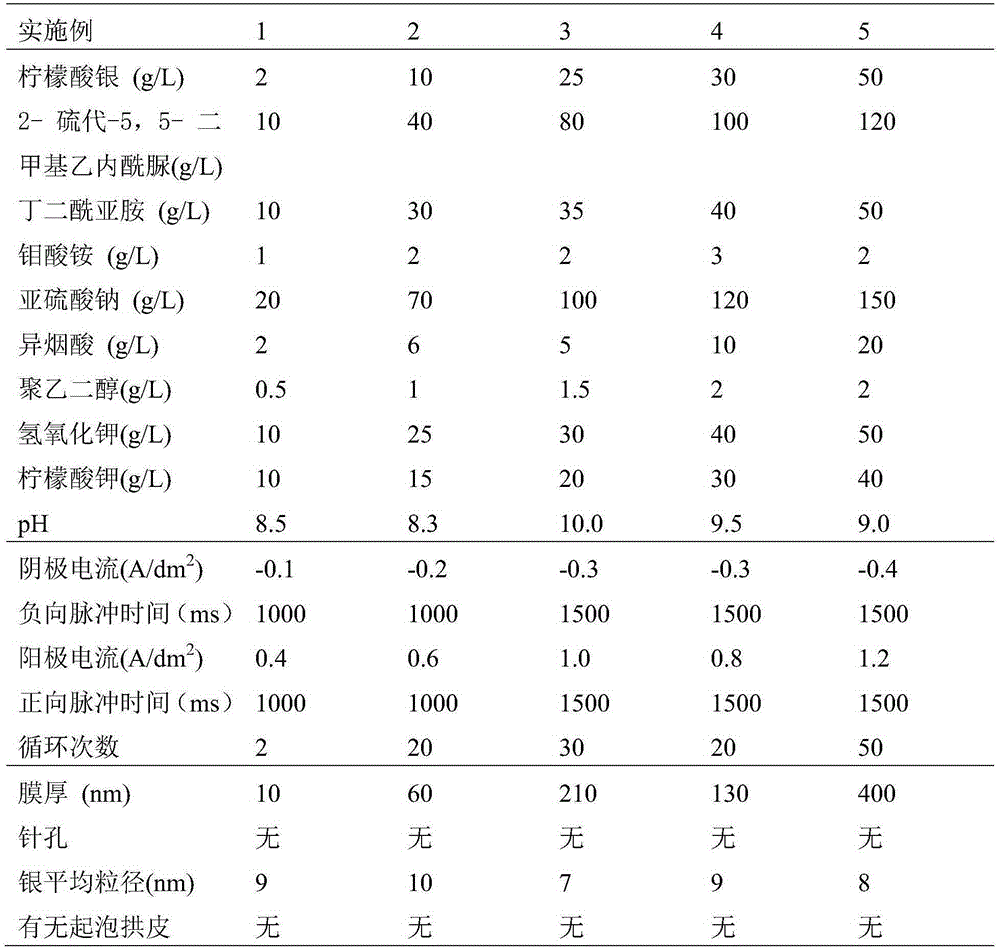

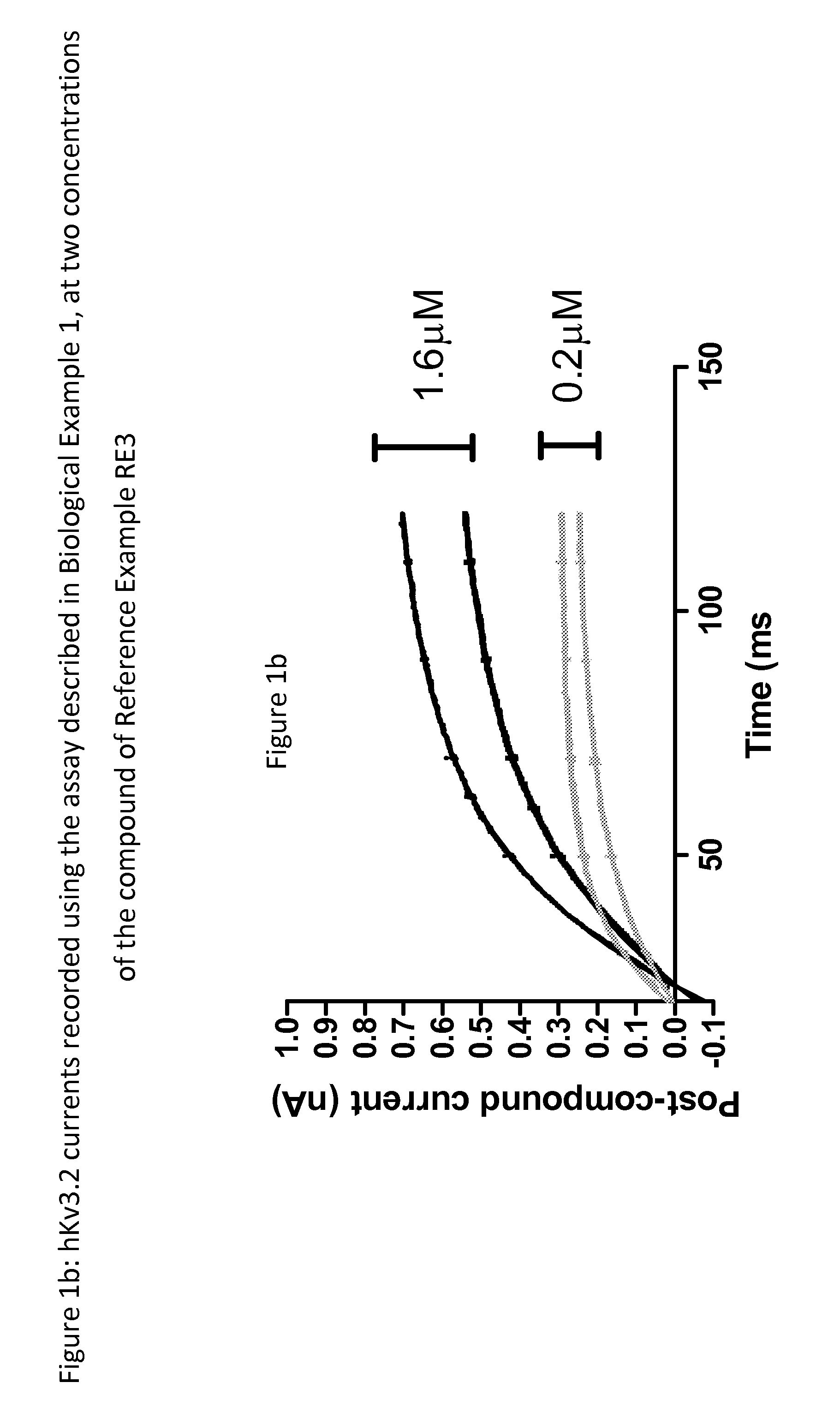

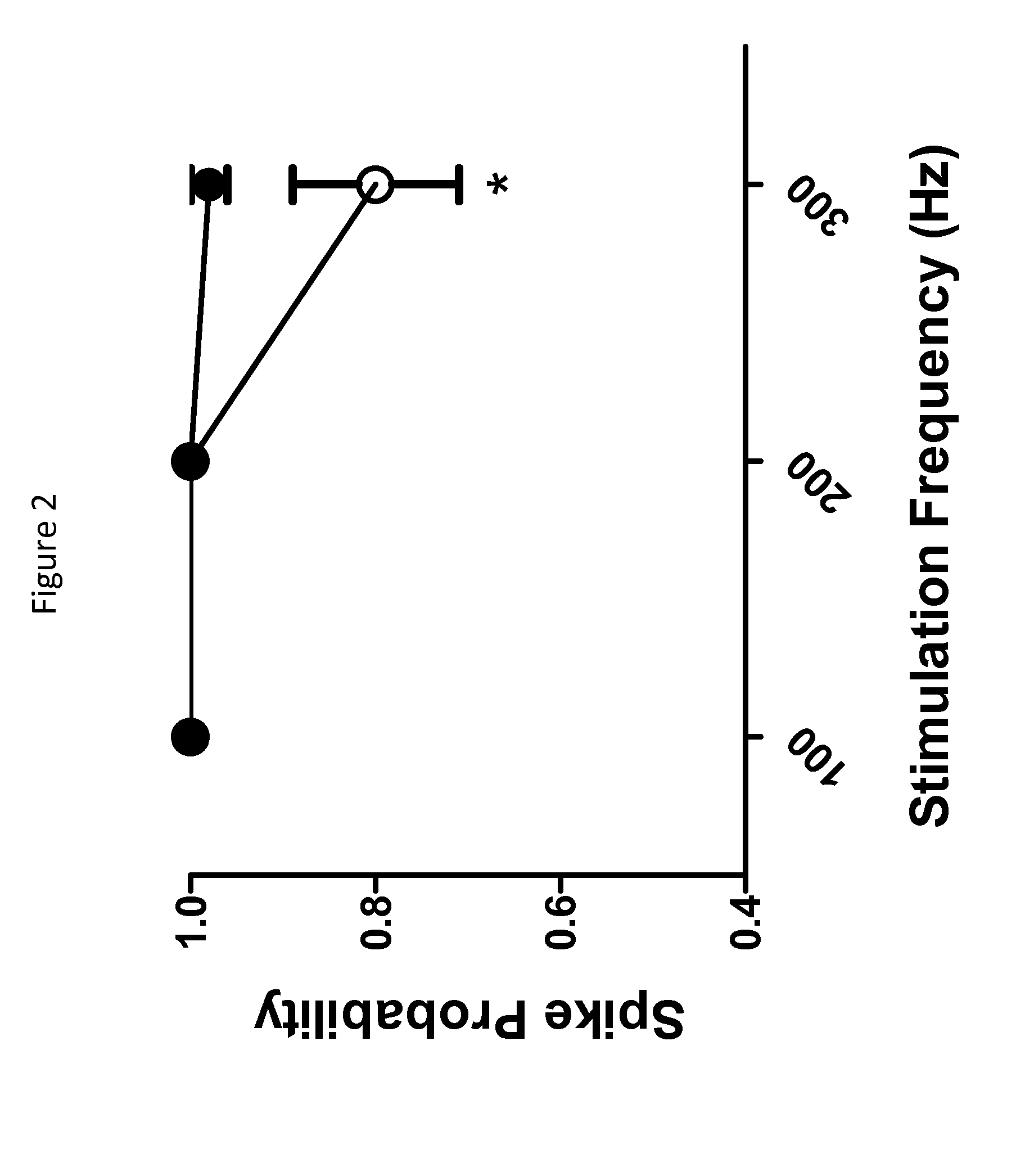

Hydantoin derivatives useful as kv3 inhibitors

Owner:AUTIFONY THERAPEUTICS

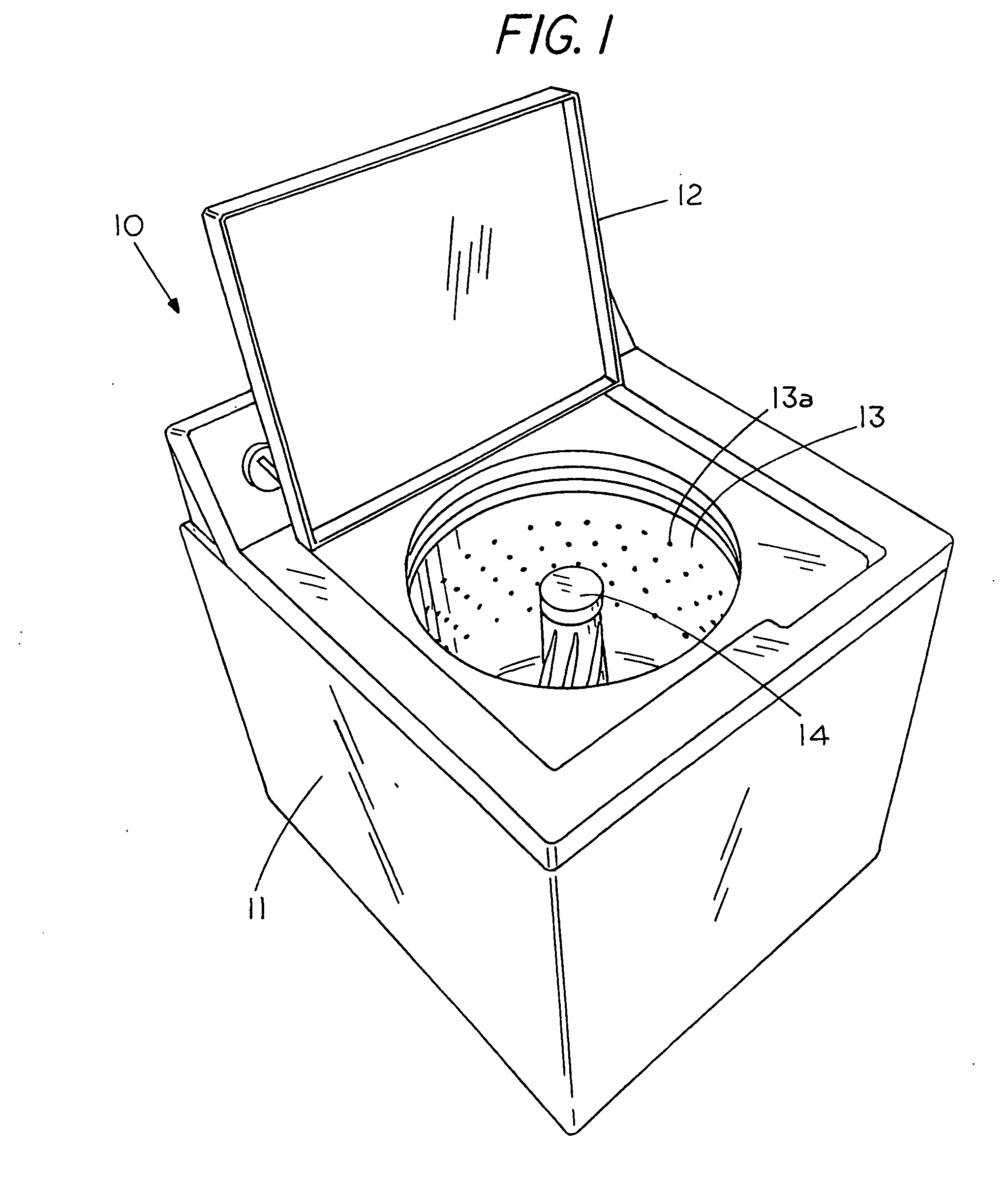

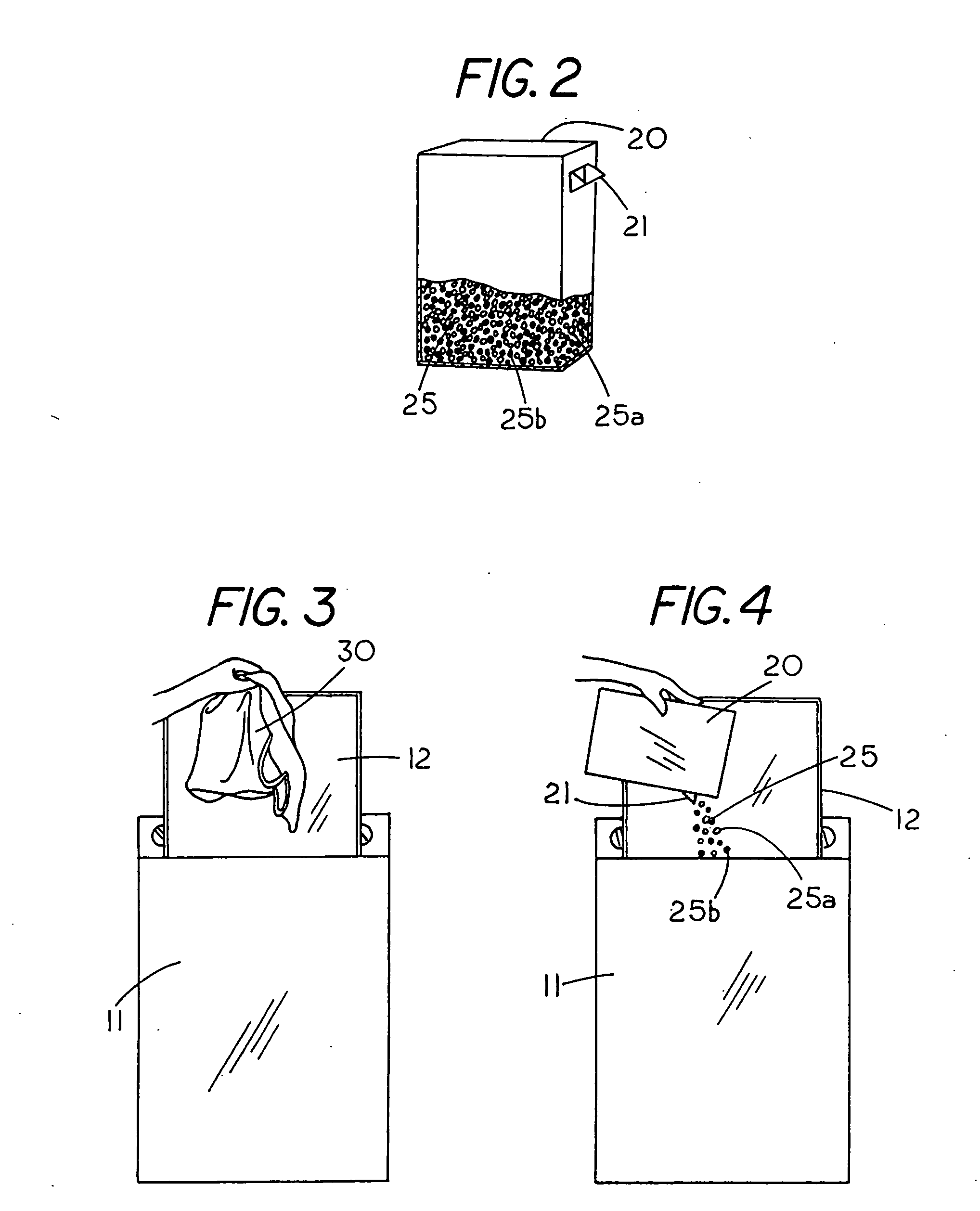

Wash products

Owner:KING TECH

Hydantoin derivatives as kv3 inhibitors

Owner:AUTIFONY THERAPEUTICS

Preservative systems and their use in cosmetic preparations

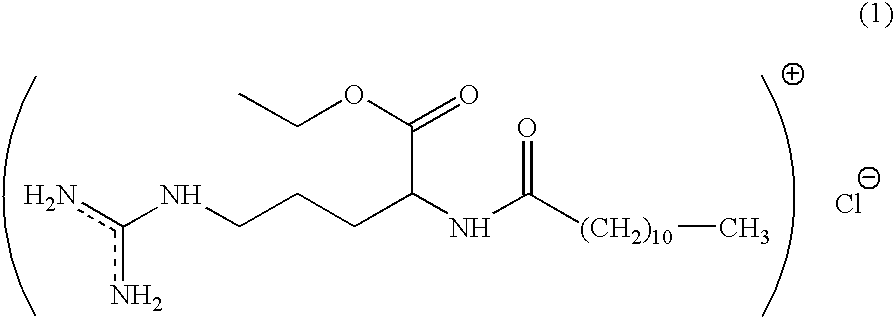

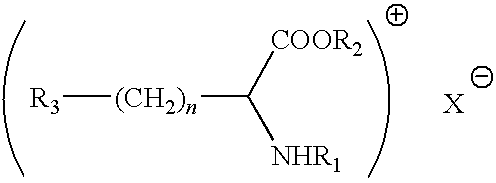

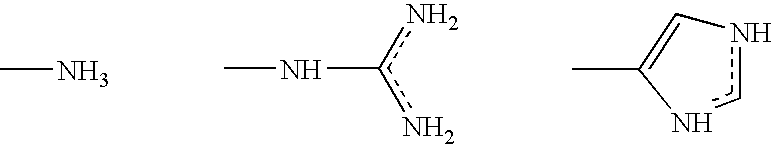

The invention relates to preservative systems which are particularly suitable in cosmetic and dermatological preparations. The preservative system which comprises a cationic surfactant, derived from the condensation of fatty acids and esterified dibasic amino acids, having the formula (I) where: X− is Br−, Cl−, or HSO4 R1: is a straight alkyl chain from an acid or saturated fatty hydroxy acid from 8 to 14 atoms of carbon bonded to the α-amino acid group through amidic bond. R2: is a straight or branched alkyl chain from 1 to 18 carbon atoms or aromatic. R3: is: (II) where n can be from 0 to 4, is combined with at least one other ionic or non-ionic preservative agent, whereby the combination displays a synergetic activity. A preservative system, wherein the cationic surfactant preservative derived from the condensation of fatty acids and esterified dibasic amino acid is LAE is particularly preferred. The other ionic or non ionic preservative agent is preferably at least one component selected from the group consisting of 2-bromo-2-nitro-1,3-propanediol (bronopol), parbens, imidazolidinyl urea, phenoxyethanol, DMDM hydantoin, 2-methyl-5-chloro-3,4-isothiazolinone / 2-methyl-3,4-isothiazolinone and quaternium-15.

Owner:LAB MIRET

Synergistic composition and method for inhibiting growth of microorganisms

The present invention provides a composition and method for inhibiting the growth of microorganisms in industrial water systems. Methods employing the composition comprising halogen-based hydantoin or hydantoin-stabilized halogen in combination with peracetic acid demonstrate synergistic control of microbial growth, particularly control of slime deposition.

Owner:ECOLAB USA INC

Color-change-preventing cyanide-free silver plating electroplating liquid and electroplating method thereof

The invention discloses color-change-preventing cyanide-free silver plating electroplating liquid and an electroplating method thereof. The electroplating liquid comprises, by mass volume concentration, 38-50 g / L of silver nitrate, 110-120 g / L of 2-sulpho-5,5-dimethyl hydantoin, 10-30 g / L of succinimide, 40-100 g / L of sodium pyrophosphate, 30-70 g / L of pyrophosphoric acid, 35-55 g / L of methionine, 0.5-2 g / L of polyethylene glycol, 4-10 g / L of benzotriazole, 1-8 g / L of nonylphenol polyoxyethylene laurel ether and 20-150 g / L of sodium sulfite. The pyrophosphoric acid is used for adjusting the pH to range from 3 to 5, and the temperature of the electroplating liquid ranges from 20 DEG to 55 DEG C. According to the color-change-preventing cyanide-free silver plating electroplating liquid and the electroplating method thereof, the combining force between a silver plating layer obtained through the electroplating method and a plating part base material is good, the leveling capability is good, the covering capability is excellent, the color is bright and not likely to become dark, an intermediate layer does not need to be pre-plated on the surface of the base material, the electroplating liquid can be used in a wide current range, and repeatability is good.

Owner:苏州市金星工艺镀饰有限公司

Bi-component epoxy adhesive and preparation method thereof

InactiveCN103173173AGood adhesionSimple processCarboxyl rubber adhesivesEpoxy resin adhesivesHydantoin derivativesCeramic

The invention discloses a bi-component epoxy adhesive and a preparation method thereof. The adhesive comprises a component A and a component B, wherein the component A is prepared from the following ingredients in parts by weight: 30-80 parts of modified bisphenol A epoxy resin, 20-70 parts of fluorene epoxy resin and 15-50 parts of hydantoin epoxy resin; the component B is prepared from 20-150 parts of anhydride curing agent. The preparation method comprises the following steps of weighing each component according to the ratio, putting the modified bisphenol A epoxy resin, the fluorene epoxy resin and the hydantoin epoxy resin into a reaction kettle and agitating evenly, so as to obtain the component A; heating the component A to 30-60 DEG C, and adding the component B which is the anhydride curing agent; and finally evenly agitating. The bi-component epoxy adhesive is good in adhesion and simple in process and has good adhesion when applied to the materials such as metal, glass, plastic ceramic and the like.

Owner:GUANGDONG XINZHAN NEW CHEM MATERIAL

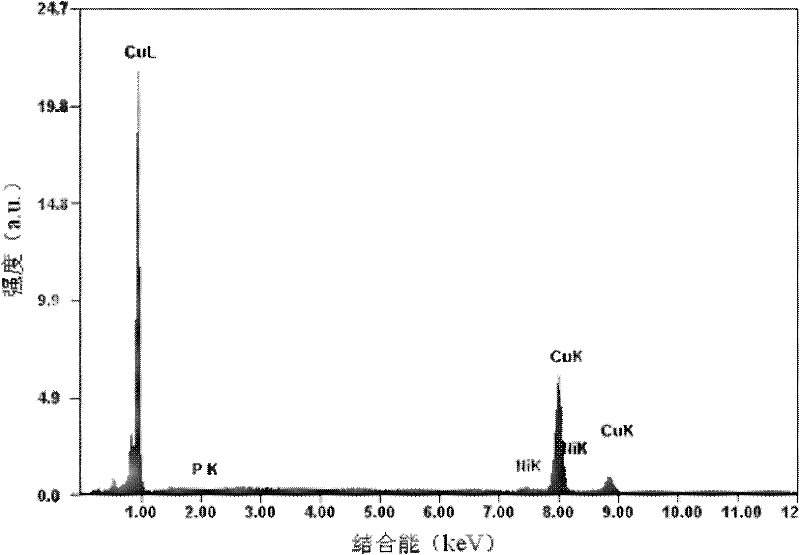

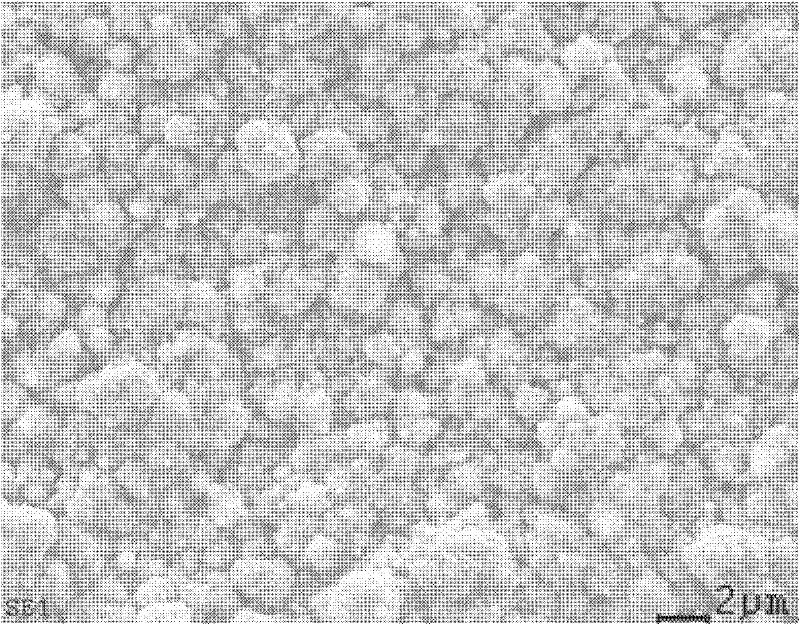

High-speed environment-friendly chemical copper plating solution

InactiveCN102337527AFriendly working environmentIncreased chemical deposition rateLiquid/solution decomposition chemical coatingCopper platingHydantoin derivatives

The invention discloses a high-speed environment-friendly chemical copper plating solution, which relates to a chemical copper plating solution and solves the technical problem of low copper plating speed of the conventional chemical copper plating solution. The high-speed environment-friendly chemical copper plating solution consists of copper sulfate, sodium hypophosphite, guanidine monohydrochloride, a catalyst, a combined coordination agent, a combined stabilizing agent and water, wherein the catalyst is metal salt containing nickel, cobalt and iron; the combined coordination agent consists of iminodiacetic acid, dimethyl hydantoin and potassium sodium tartrate, the mass ratio of the dimethyl hydantoin to the potassium sodium tartrate is 1:(2-3), and the mass ratio of the dimethyl hydantoin to the iminodiacetic acid is 1:(7-8); and the combined stabilizing agent consists of thiocarbamide and 2,2'-bipyridyl in the mass ratio of 1:(5-6). In the invention, the plating solution has the chemical deposition speed of 10 to 40 micrometers / hour, and can be used for chemically plating copper on the surfaces of matrixes such as printed circuit board holes, ceramics, plastics and the like.

Owner:HARBIN INST OF TECH

Cyanide-free silver plating method

InactiveCN104342726AGood for healthIdeal cyanide-free silver plating processHydantoin derivativesSilver plate

The invention discloses a silver nitrate-dimethyl hydantoin system cyanide-free silver plating process, and belongs to the field of electrosilvering. A plating solution is prepared as follows: the concentration of dimethyl hydantoin is 50-200 g / L; the concentration of silver nitrate is 8-30 g / L; the concentration of sulfamic acid is 50-150 g / L; the concentration of potassium hydroxide is 65-125 g / L; and components and contents of a brightening agent are as follows: 1 g / L of salicylic acid, 0.8 g / L of 22 dipyridyl, 1 g / L of alanine, and 1 g / L of imidazole. The substances are diluted to 1 L with water or distilled water to become the brightening agent. The plating solution is excellent in stability; silver ions in the plating solution are not replaced with such monometals as copper and nickel and alloy substrates; the silver preplating or the silver dipping is not needed for plating pieces; plating layers have the characteristics of excellent binding force, brightness, smooth surface, good tarnishing resistance, corrosion resistance and wear resistance; and the cyanide-free silver plating can compete with or even be superior to the cyaniding silver plating in some respects, satisfies the requirements for the application in such fields as the decorative electroplating and the functional electroplating, and has higher promotion and application values.

Owner:SHENZHEN ZHONGYU ZHAORI TECH

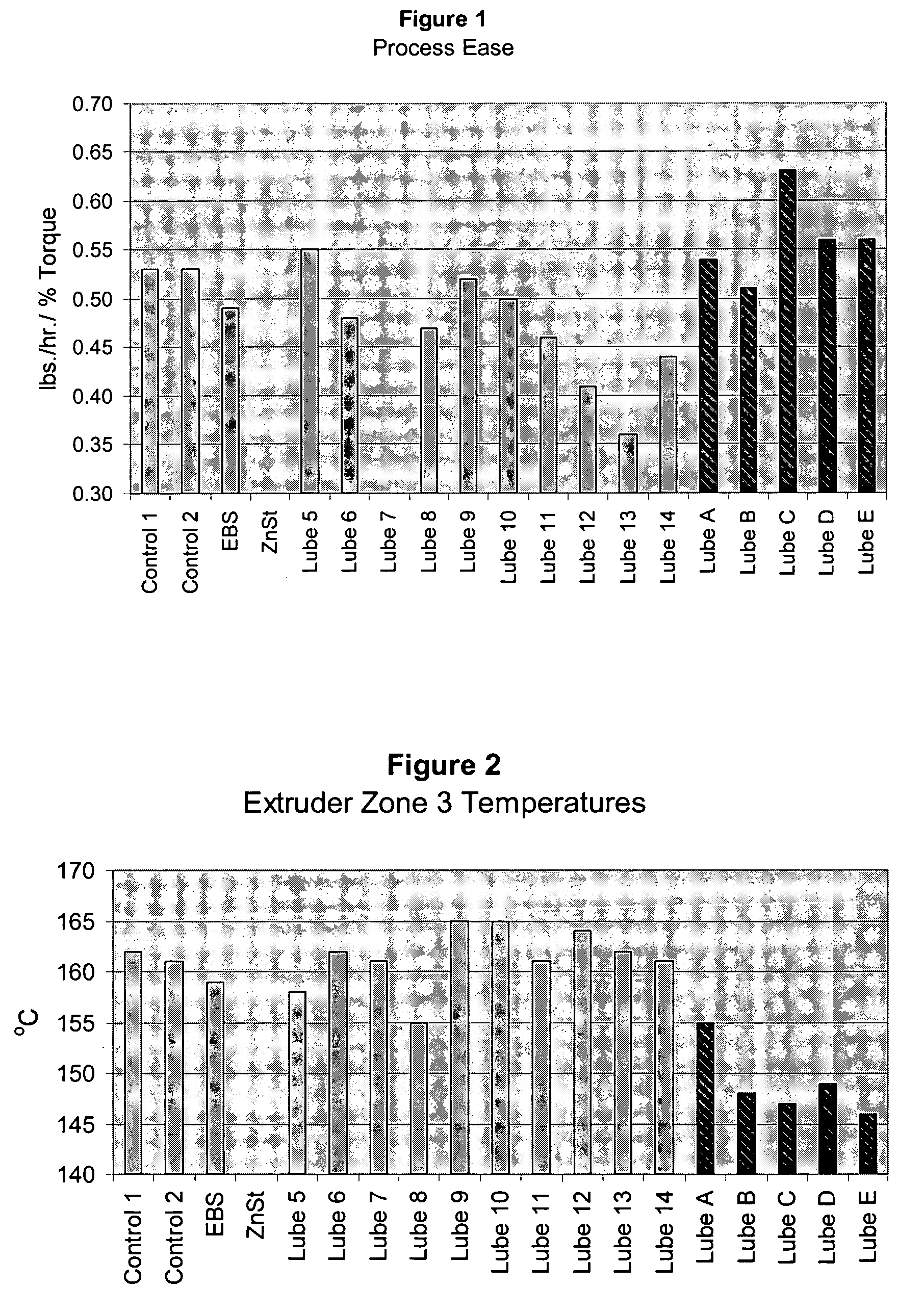

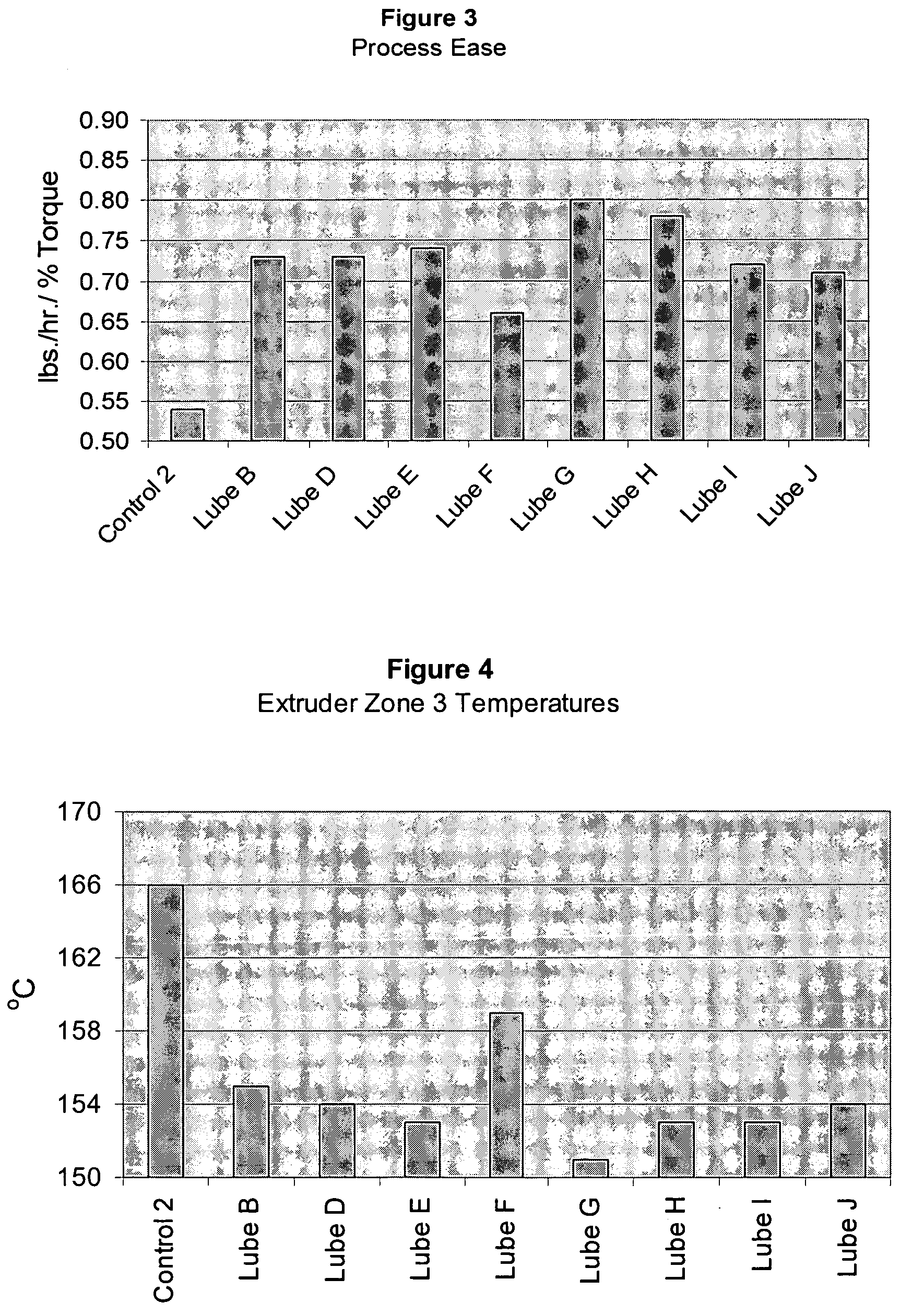

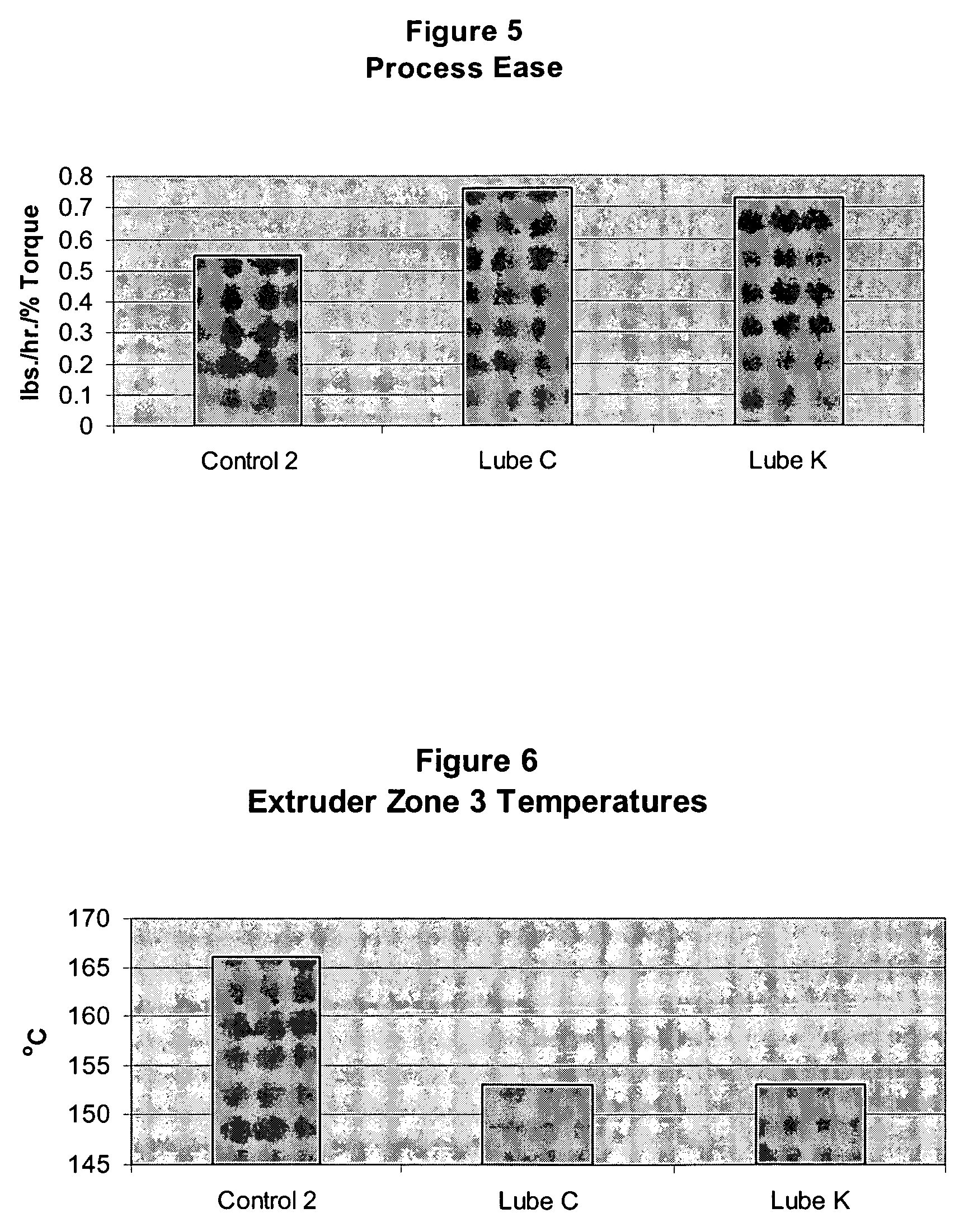

Cellulose fiber-plastic composition containing a lubricant

ActiveUS20060100318A1Increased output per percent extruder torqueReduce the temperatureCosmetic preparationsToilet preparationsHydantoin derivativesCellulose fiber

This invention is directed to an extruded product, extrudable compound, and an extrusion method using a polymer, a cellulosic fiber, and at least one lubricant selected from the group consisting of ethoxylated esters of hydantoins, ethoxylated esters of sorbitol or sorbitan, or N, N′-bisalkanoylethylenediamines containing from 8 to 14 carbons of the alkanoyl group and compositions manufactured through such processes which simulate conventional wood products. The N,N′-bisalkanoylethylenediamines are new compositions of matter containing from 8 to 14 carbons of the alkanoyl group having a particle size range from about 90 to 150 μm, preferably from about 120 to 140 μm.

Owner:LONZA INC

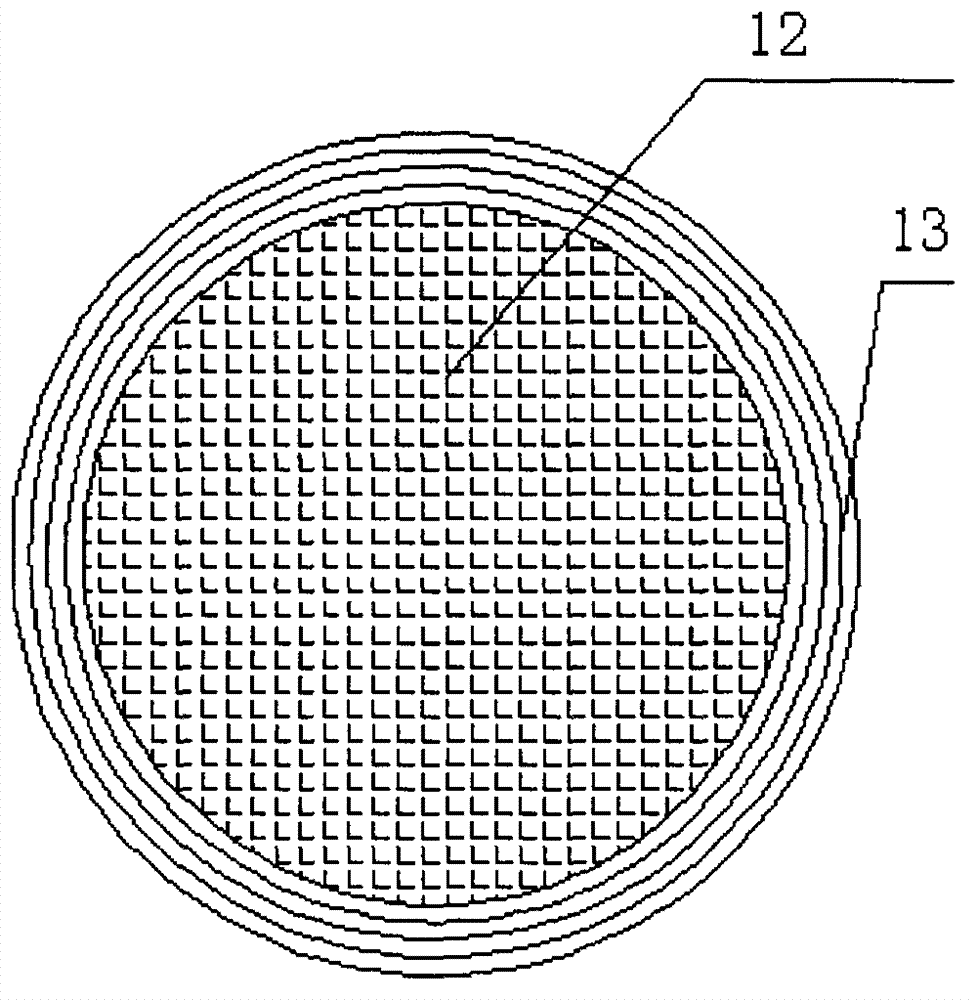

Carbon fiber composite material cable core

InactiveCN103310878ALow viscosity requirementImprove high temperature resistancePlastic/resin/waxes insulatorsInsulated cablesFiberEpoxy

The invention relates to a carbon fiber composite material cable core, which comprises a load bearing core (12) and a protection layer (13), wherein the protection layer (13) is covered outside the load bearing core (12) through a winding process, the load bearing core (12) is a high-temperature-resistance mechanical property epoxy resin and carbon fiber compound, and the protection layer (13) is a compound of high-temperature-resistance and weather-resistance epoxy resin compositions and glass fibers. The carbon fiber composite material cable core adopts the blending epoxy resin of the hydantoin epoxy resin and low-viscosity epoxy resin as resin substrates, the requirement of glass fibers on the low viscosity of the resin can be met, and the cable core can also have excellent high-temperature-resistance performance.

Owner:喻聪

Technology for treating waste water containing phenol in synthetic process of p-hydroxy-phenyl-hydantoin

InactiveCN101591083AReduce pressure on environmental protectionMultistage water/sewage treatmentNature of treatment waterInorganic saltsIndustrial waste water

The invention provides a method for treating waste water containing phenol in a synthetic process of p-hydroxy-phenyl-hydantoin, which belongs to the technical field of the treatment of organic chemical industrial waste water. The method comprises the following step: synthetic waste water is distilled and pretreated, wherein the treatment of the synthetic waste water comprises the processes that acidizing pretreatment is firstly carried out on the synthetic waste water, and then the collected waste water containing phenol is adsorbed by macroporous resin. Because the method removes phenol-containing substances in the waste water in advance, the difficulty of the recovery processing of inorganic salt subsequent can be greatly improved, and recovered sodium phenolate can be reused for a synthetic working process of the p-hydroxy-phenyl-hydantoin. The method has stable and reliable treatment effect, low treatment cost, convenient and easy operation and easy realization of industrialized application.

Owner:HENAN NEWLAND PHARMA +2

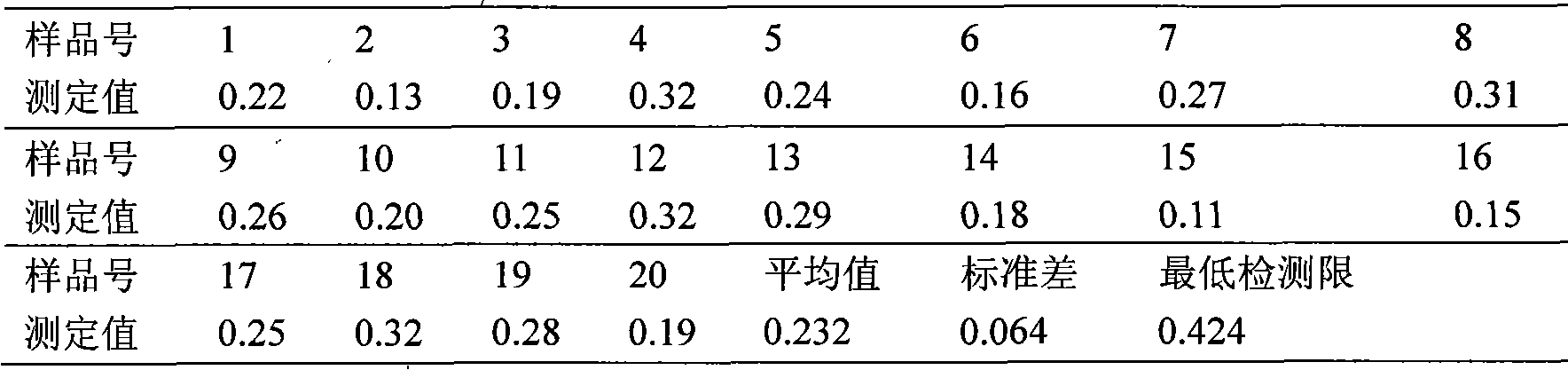

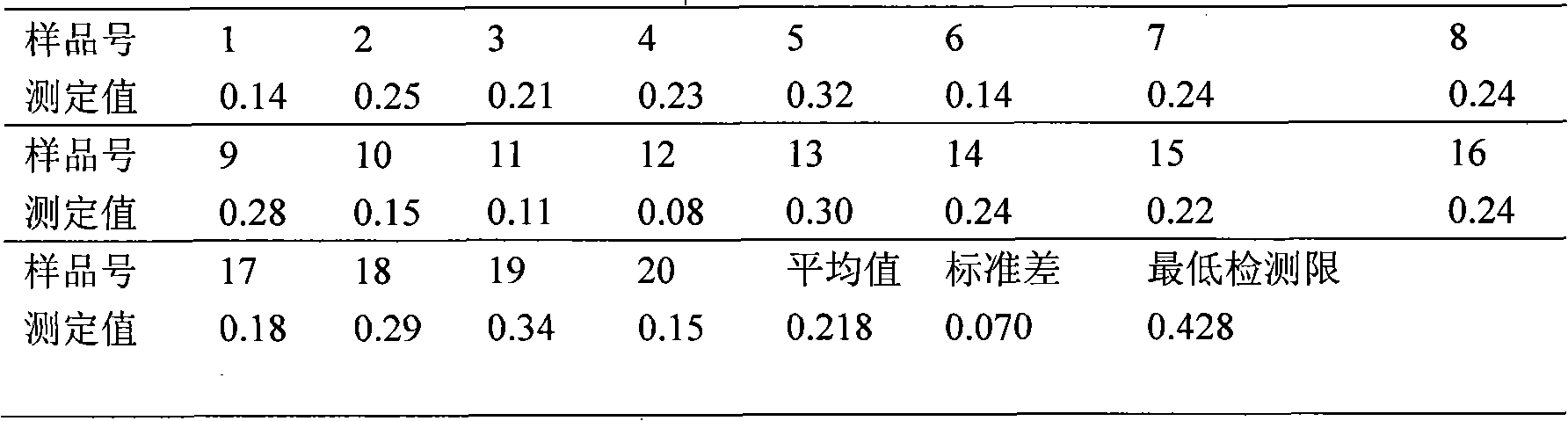

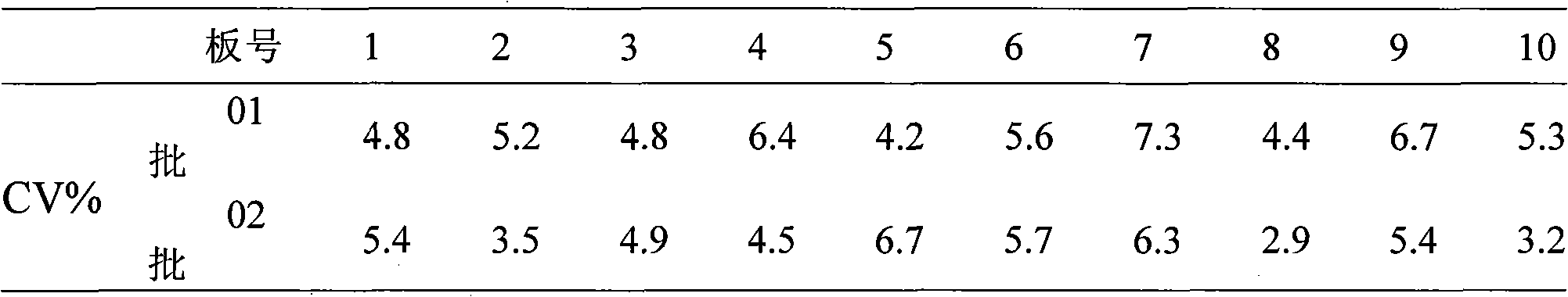

Nitrofurantoin residue enzyme-linked immunoassay kit

The invention discloses a nitrofurantoin residue enzyme-linked immunoassay kit which comprises a) an ELIAS plate, b) a standard solution, c) an antibody working solution, d) a cleaning solution, e) an enzyme marker, f) a substrate developing solution and g) a stopping solution, wherein the ELIAS plate is coated with nitrofurantoin metabolite AHD or coupling antigen of a derivative of the nitrofurantoin metabolite and a protein; and the standard solution is prepared by o-nitrobenzaldehyde which is dissolved in the dimethyl sulfoxide and then reacts with hydantoin derivative. The invention is mainly provided in a form of working solution, is characterized by convenient use, high specificity, high sensitivity, high precision, high accuracy and the like, and is applied to the detection of nitrofurantoin residues in animal food such as aquatic products and the like.

Owner:FOOD INSPECTION CENT OF CIQ SHENZHEN

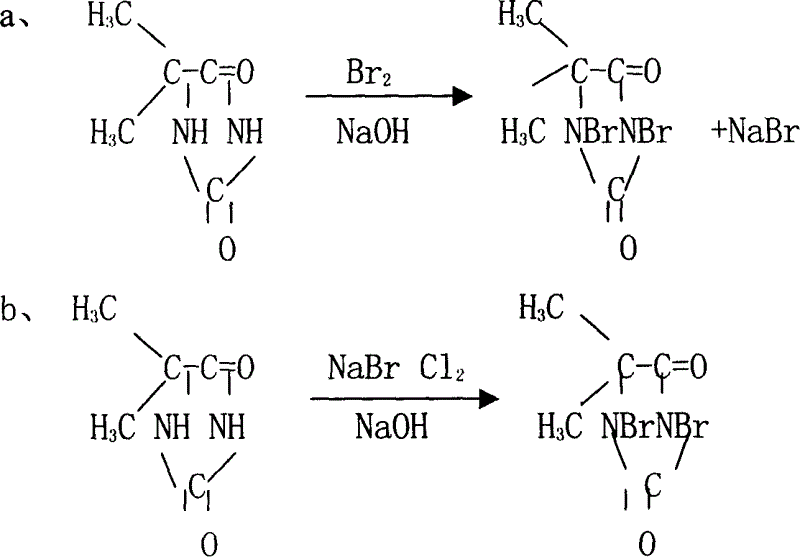

Dibromo glucolycurea sterilizing and disinfecting algaecide preparing method

The invention relates to a kind of manufacturing method of dibromine hydantoin disinfection algaecide. It uses 5,5-dimethyl hydantoin as main material; and then make it dissolve in water or in mother liquor; then add halogen this solution, at the same time, dropwise sodium hydroxide solution in order to proceed bromination reaction; after, make the product have water washing, filtration and drying treatment in order to get dibromine hydantoin. The features are as follows: the concentration of sodium hydroxide solution added in is 33-37%; use online measurement to control adding molar composition of material, so that it can proceed instant optimal controls all through the reaction. It has the remarkable effictiveness, such as simple operation, high product yield that can reach up to more than 96%, high product purity that can reach to more than 99%, low discharge capacity.

Owner:LONGKOU KEDA CHEM

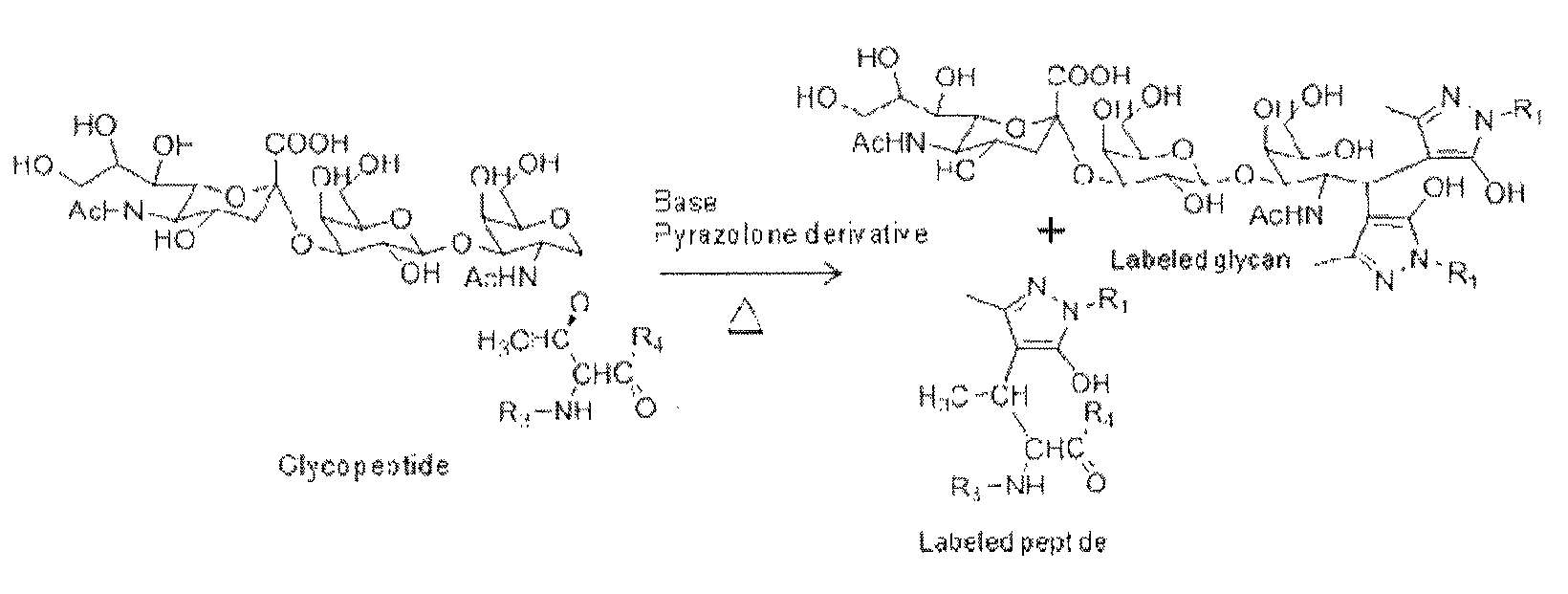

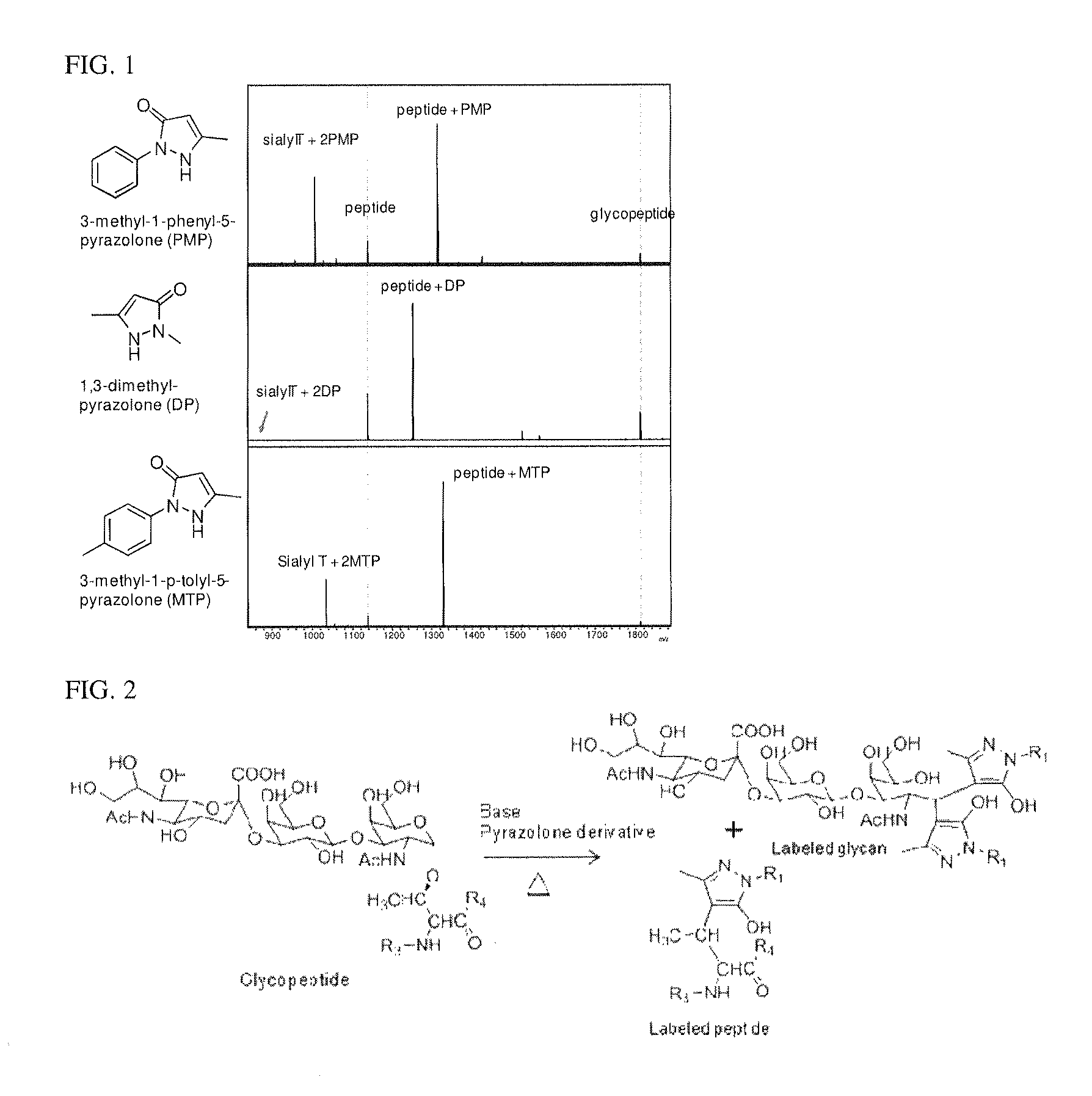

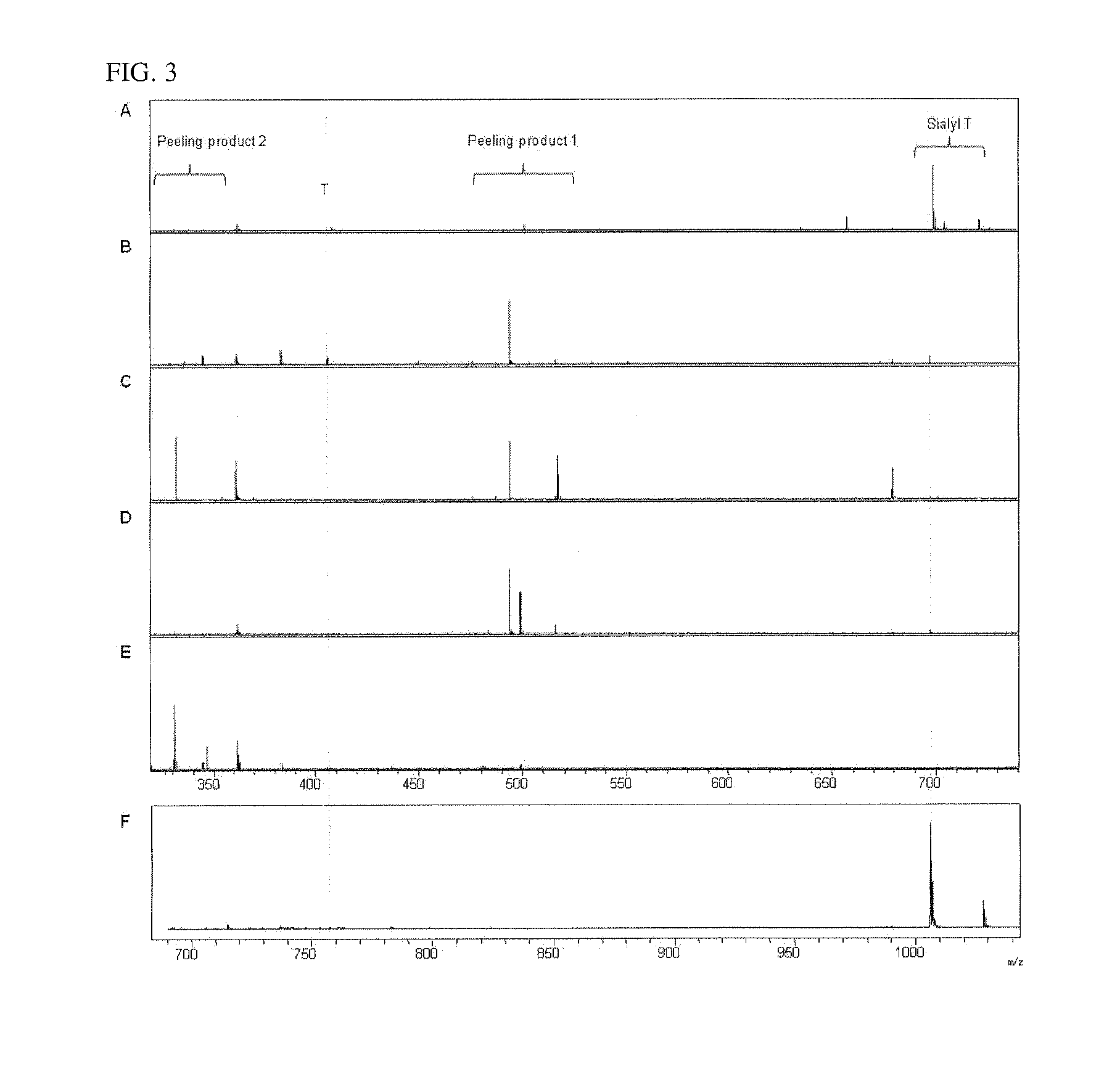

Labeling agent for analyzing post-translational modifications of serine and threonine

InactiveUS20140024124A1Easy to operateEasiness of subsequent separationOrganic chemistryComponent separationAnserinePost translational

A glycoprotein and / or a glycopeptide which are a test substance is heated in the presence of a pyrazolone derivative, an isoxazolone derivative, a hydantoin derivative, a rhodanine derivative, a maleimide derivative, or the like under a basic condition to cleave and label a post-translational modification group for analysis, thereby enabling analysis of a post-translational modification of a serine residue and / or a threonine residue.

Owner:HOKKAIDO UNIVERSITY

Multi-functional oxidizing composition

A composition comprising a stable anhydrous mixture of an oxidizing agent and an active halogen agent wherein the oxidizing agent is potassium hydrogen peroxymonosulfate and the active halogen agent is an alkali metal salt of dichloro-s-triazinetrione, halogenated dimethylhydantoin, or mixtures thereof, and a method of treating water with such compositions are disclosed.

Owner:LENKSESS CORP

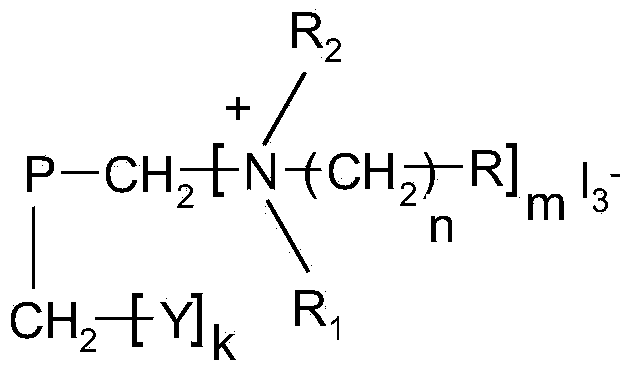

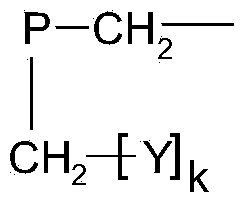

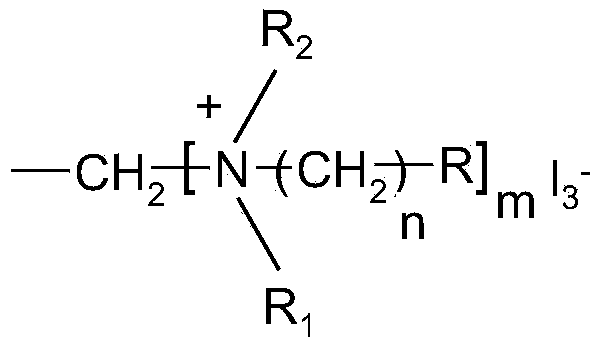

High molecular polymer material having anti-bacterial and trace element slow release functions and preparation method thereof

InactiveCN103880991AHas antibacterial propertiesFunctionalBiocideDisinfectantsHydantoin derivativesQuaternary ammonium cation

The invention discloses a high molecular polymer material having anti-bacterial and trace element slow release functions and a preparation method thereof. The method comprises the following steps: reacting a halomethylation-supporting high molecular polymer serving as a carrier with a hydantoin derivative containing a tertiary amine functional group to generate a high molecular polymer containing a quaternized hydantoin functional group; carrying out an exchange reaction on hydrogen on an imido group on a hydantoin loop and metal ions to immobilize the metal ions onto the high molecular polymer; immobilizing I3<-> through a quaternary ammonium salt functional group to obtain the high molecular polymer material having anti-bacterial and trace element slow release functions. The high molecular polymer material has rapid, efficient and broad-spectrum anti-bacterial and trace element slow release functions, and is suitable for disinfecting purified water and replenishing trace elements.

Owner:SHANGHAI NORMAL UNIVERSITY

Low-cost oil-based annulus protection fluid applicable to CO2 flooding well and preparation method thereof

InactiveCN107603579AReduce corrosionImprove protectionBorehole/well accessoriesHydantoin derivativesMorpholine

The invention provides low-cost oil-based annulus protection fluid applicable to a CO2 flooding well and a preparation method thereof and belongs to the technical field of corrosion protection of an oil and gas well. A low-cost oil-based annulus protection fluid system applicable to the CO2 flooding well is prepared by compounding engine oil, a corrosion inhibitor, a bactericide, an oxygen removing agent, a density regulator and a surfactant. The annulus protection fluid is prepared from the following components in percentage by mass: 1 percent to 3 percent of a morpholine derivative compoundcorrosion inhibitor, 0.8 percent to 1.6 percent of halogenated hydantoin bactericide, 3 percent to 5 percent of the oxygen removing agent, 5 percent to 30 percent of an organic acid salt density regulator, 3 percent to 5 percent of a non-ionic type polyoxyethylene type surfactant and the balance of the engine oil. The oil-based annulus protection fluid provided by the invention has a very good protection effect on a shaft tubular column of the CO2 flooding well and has the advantages of good high-temperature stability, good low-temperature freezing resistance and long-period stability; meanwhile, the refrigeration engine oil is used as a dispersant, so that the low-cost oil-based annulus protection fluid has the advantages of low cost and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com