High-speed environment-friendly chemical copper plating solution

An electroless copper plating, environmental protection technology, applied in the field of electroless copper plating solution, can solve the problem of low copper plating speed of electroless copper plating solution, and achieve the effect of improving the chemical deposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

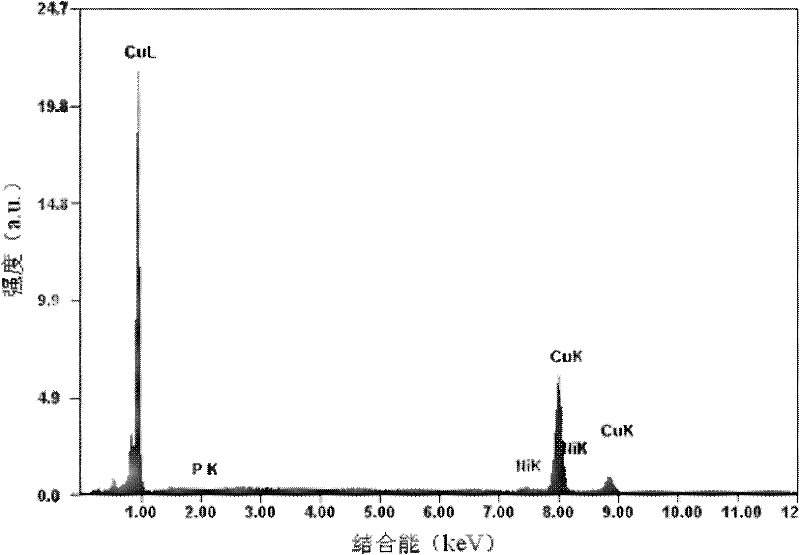

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment one: the high-speed environment-friendly electroless copper plating solution of the present embodiment is made up of copper sulfate, sodium hypophosphite, carbamide hydrochloride, catalyst, combination complexing agent, combination stabilizer and water, sulfuric acid in the high-speed environment-friendly electroless copper plating solution The concentration of copper is 5g / L~15g / L, the concentration of sodium hypophosphite is 10g / L~40g / L, the concentration of carbamide hydrochloride is 1mg / L~20mg / L, and the concentration of catalyst is 0.5g / L~3g / L, the concentration of the combined complexing agent is 10g / L~40g / L, the concentration of the combined stabilizer is 5g / L~100mg / L, the pH value of the high-speed and environmentally friendly electroless copper plating solution is 9~14; the catalyst is nickel-containing , cobalt, and iron metal salts; the combined complexing agent is composed of aminodiacetic acid, dimethylhydantoin, and potassium sodium tar...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of copper sulfate is 8g / L˜12g / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the concentration of sodium hypophosphite is 12 g / L-35 g / L. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com