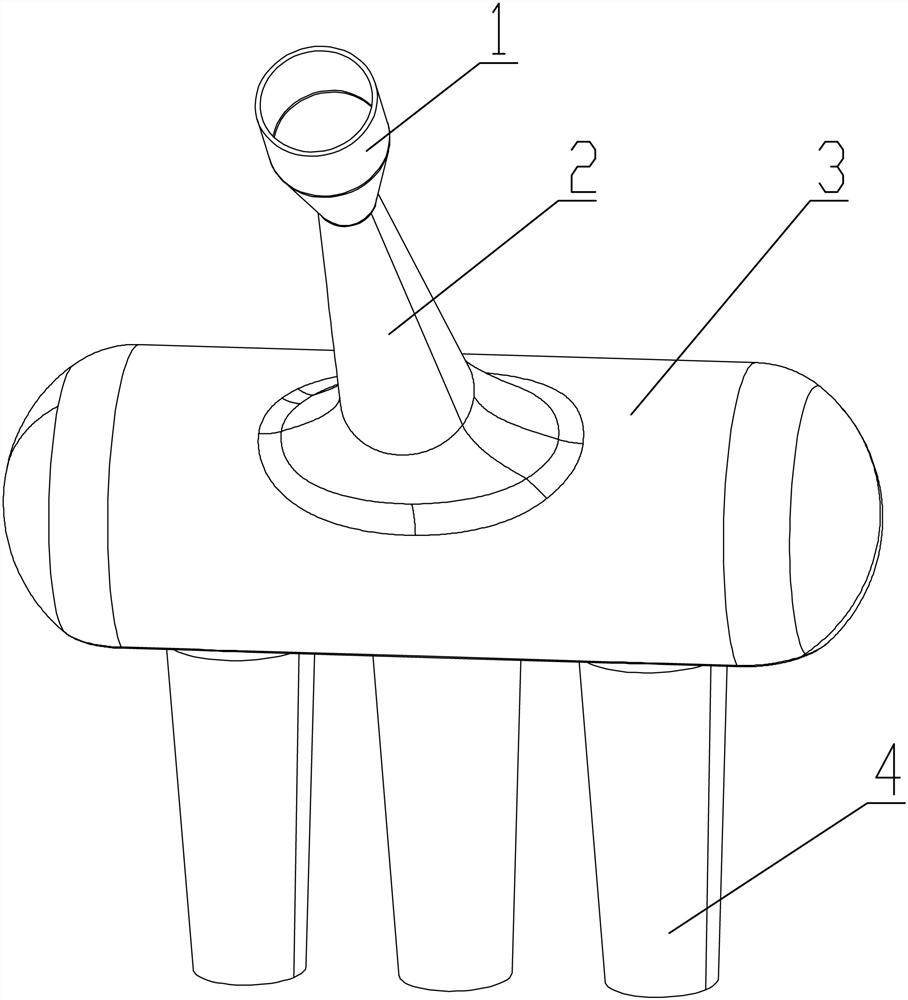

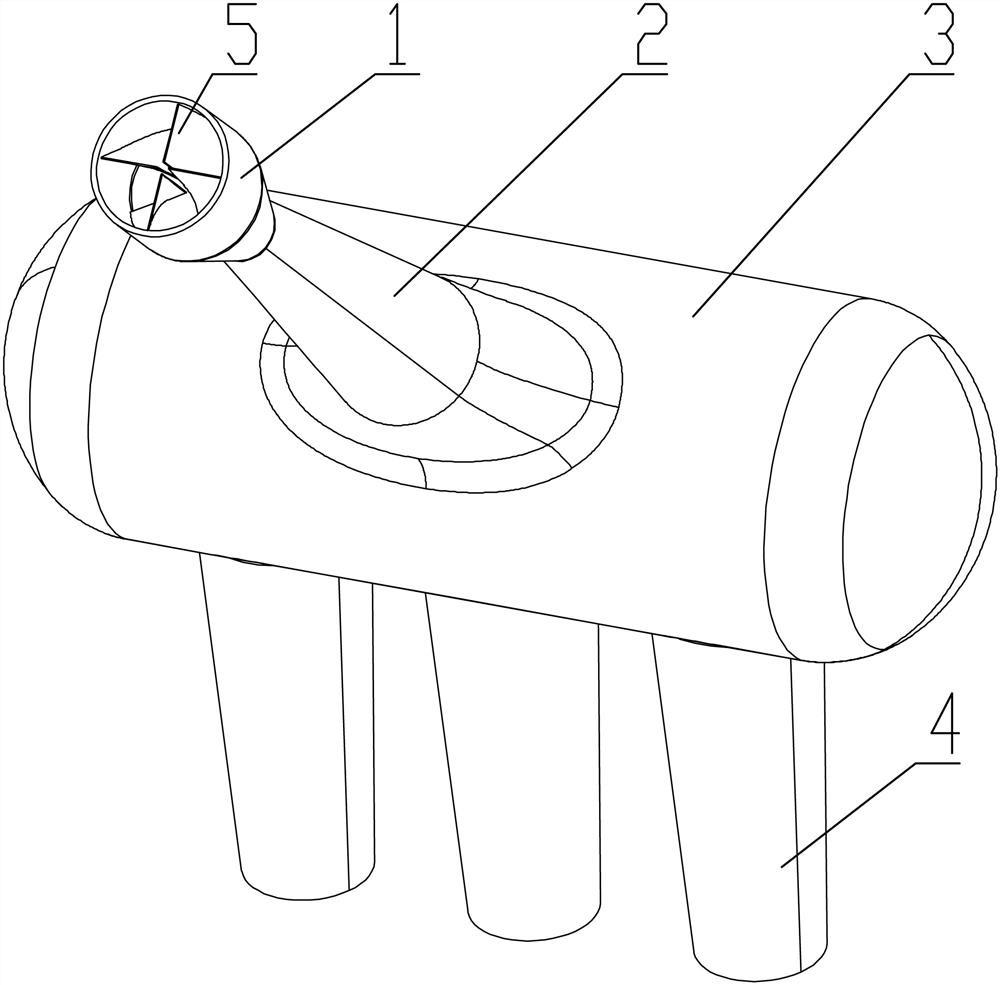

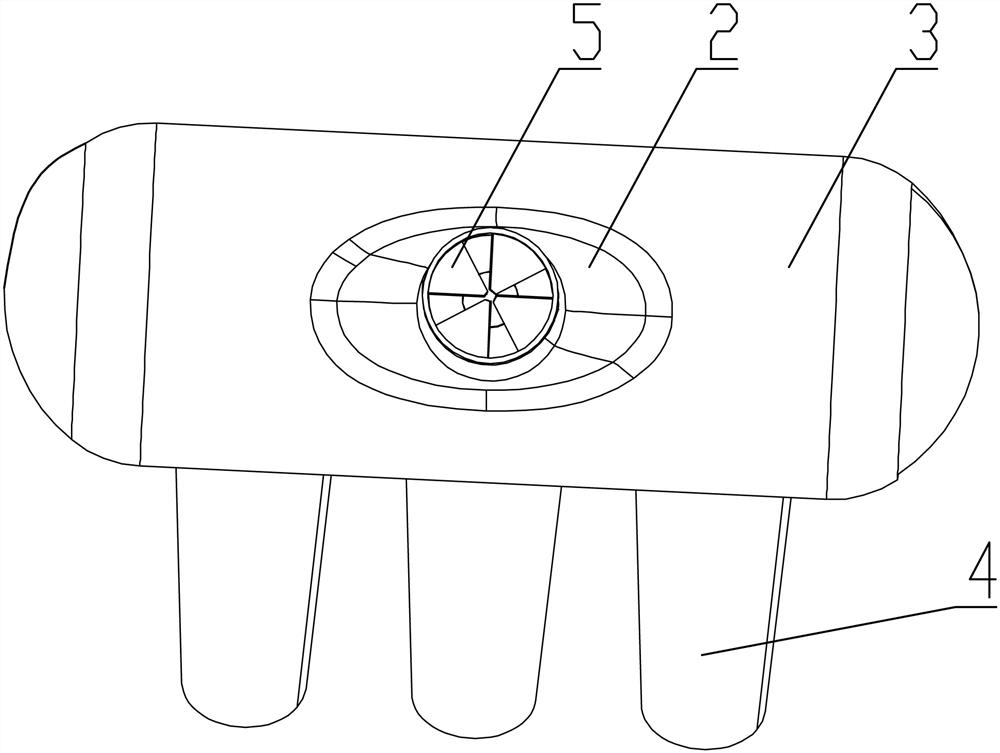

Engine air intake system with air inlet flow guiding blade grid and simulated analysis method

A technology of air intake system and simulation analysis, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of engine crankshaft acceptance imbalance, air intake imbalance, etc., and achieve a friendly working environment for the engine, rapid power output, and The effect of speeding up the response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0054]The simulation analysis method of the engine air intake system with air intake guide leaves includes the following steps:

[0055] Step 1: Establish a three-dimensional model of the intake system;

[0056] Step 2: Import the 3D model into Fluent software;

[0057] Step 3: Structural grid division of the 3D model;

[0058] Step 4: Use Realizable's turbulent flow model to perform rotational flow simulation analysis, and set boundary conditions and initial conditions;

[0059] Step 5: Use the turbulence empirical value calculator to simulate and calculate the turbulence intensity at the inlet end and the turbulence intensity at the outlet end.

[0060] When performing structural grid division in the step 3, the QUICK format is adopted;

[0061] The discretization methods all use the second-order upwind model.

Embodiment 3

[0063] This embodiment mainly uses Fluent software to analyze the existing air intake system and the new air intake system, and compare the total air intake volume and air intake balance between the two. This analysis uses the Realizable k-ε turbulence model. For the convenience of comparison, the same boundary conditions and initial conditions are set before and after improvement. This embodiment adopts the boundary condition of constant pressure difference, the reference pressure is set to 101300Pa, the inlet pressure is 0Pa, and the outlet pressure is -10000Pa. The hydraulic diameter of the inlet end is 45mm, and the hydraulic diameter of the outlet section is 40.6mm. Using the turbulence k-ε empirical value calculator, the turbulence intensity at the inlet end is 3.75%, and the turbulence intensity at the outlet end is 3.9%. The QUICK format can provide higher computational accuracy when computing rotating flow problems with structured meshes, but in other cases the accur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com