Back-and-forth scraping and brushing type large pig raising system

A scraping and back-and-forth technology, which is applied in the field of pig raising system, can solve the problems of poor working environment for workers, inconvenient cleaning of pig farms, time-consuming, labor-intensive and labor-intensive problems, and achieve full mixing in all directions, high work efficiency and good working environment. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

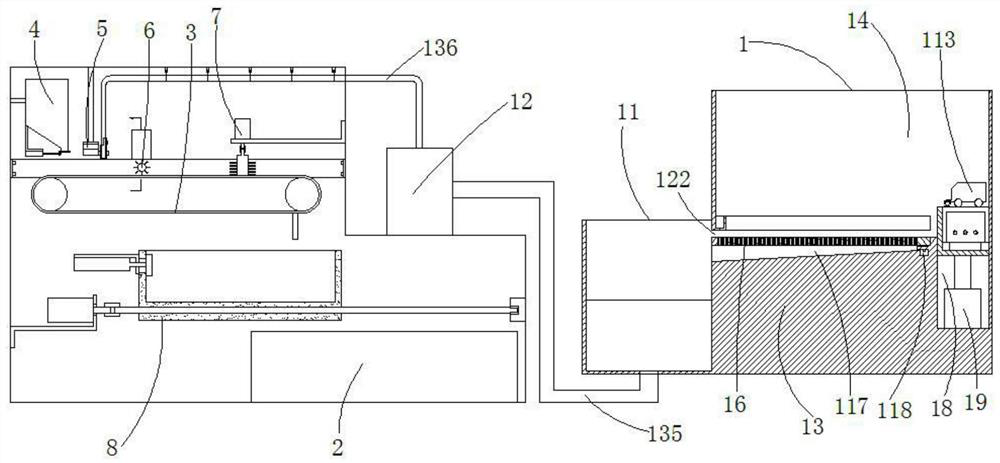

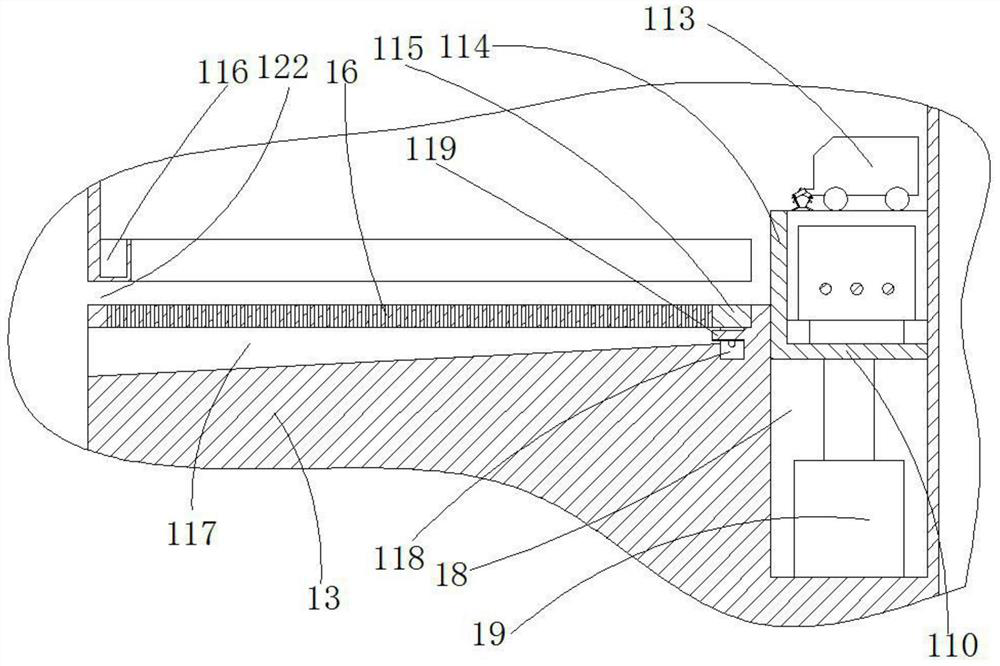

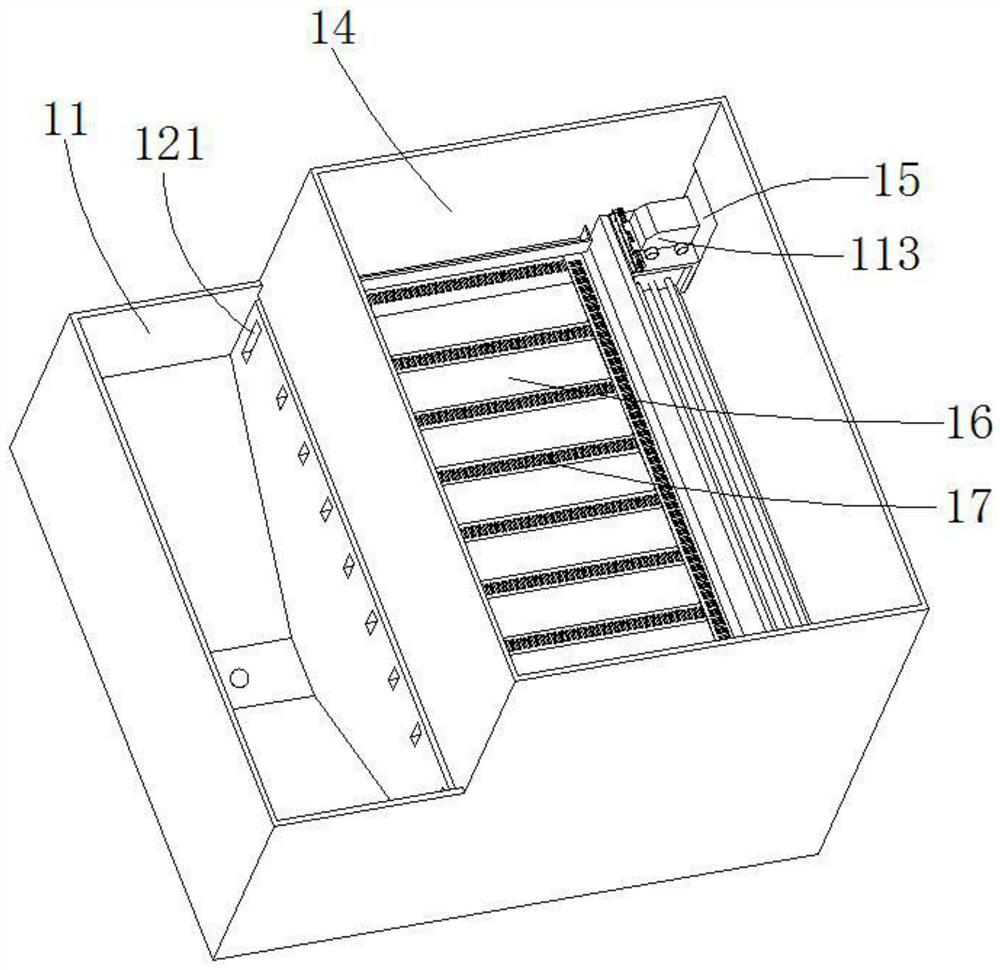

[0034] Such as Figure 1-13 As shown, a large-scale pig raising system of scraping back and forth, including a pig farm 1, a collection chamber 11, a pump 12, a linear motor, a conveyor belt 3, a mixing chamber 4, a first stirring device 6, and a second stirring device , material receiving device 8 and second treatment chamber 2, described pig farm 1 comprises foundation 13 and the feeding ground 14 that is positioned at the top of foundation 13, and feeding ground 14 is used for raising pigs, and feeding ground 14 is a large-scale place similar to a football field .

[0035]The breeding site 14 is laid with a first backing plate 16, the first backing plate 16 is provided with a first backing plate hole 17, pigs are raised on the first backing plate 16, and the setting of the first backing plate hole 17 makes the pig breeding The urine and some exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com