Patents

Literature

478results about How to "Will not remain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

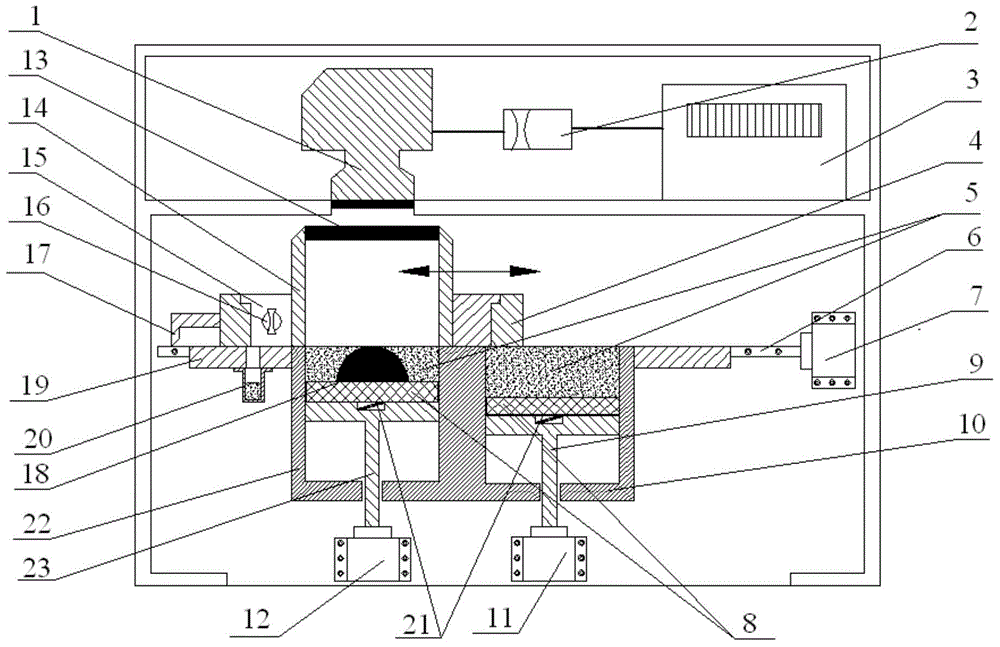

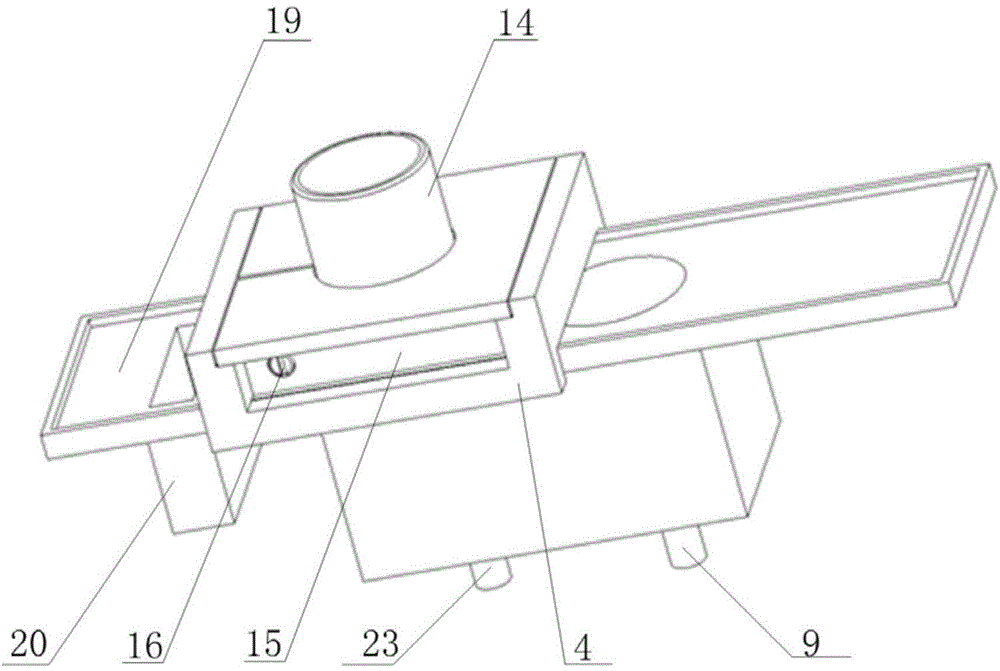

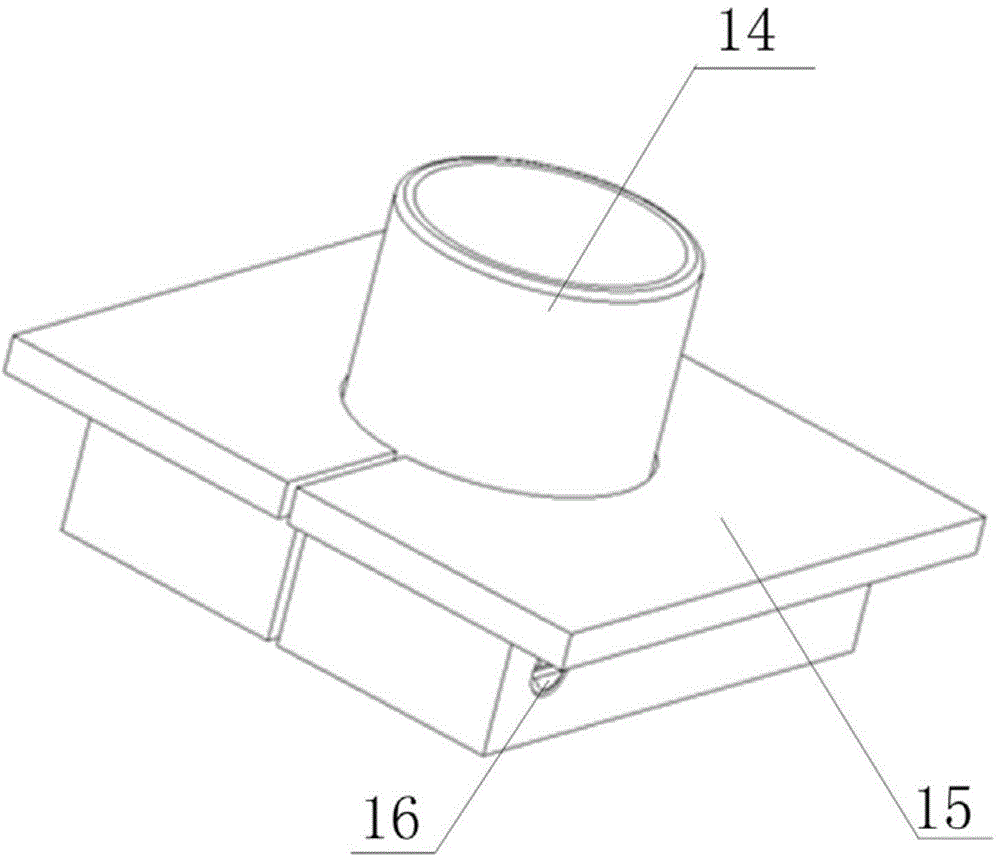

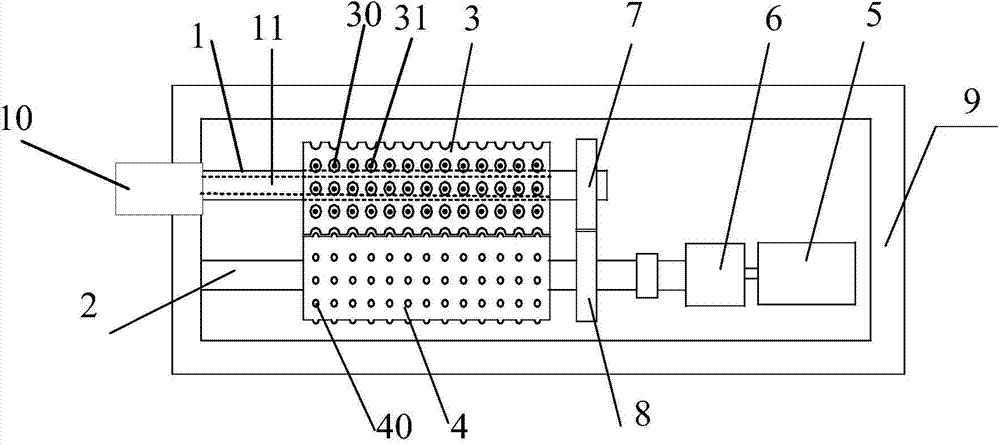

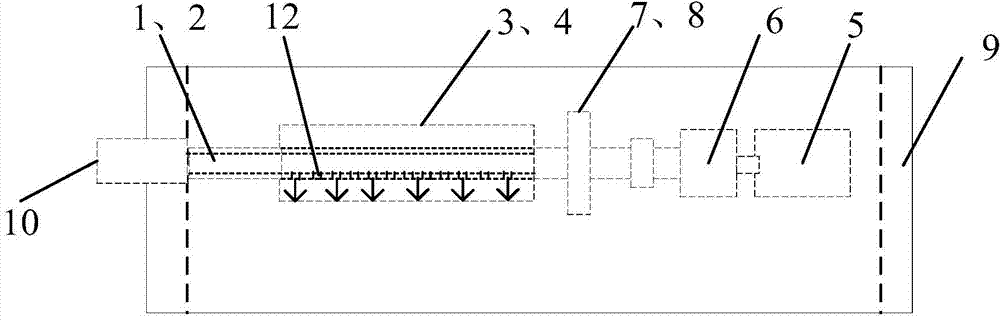

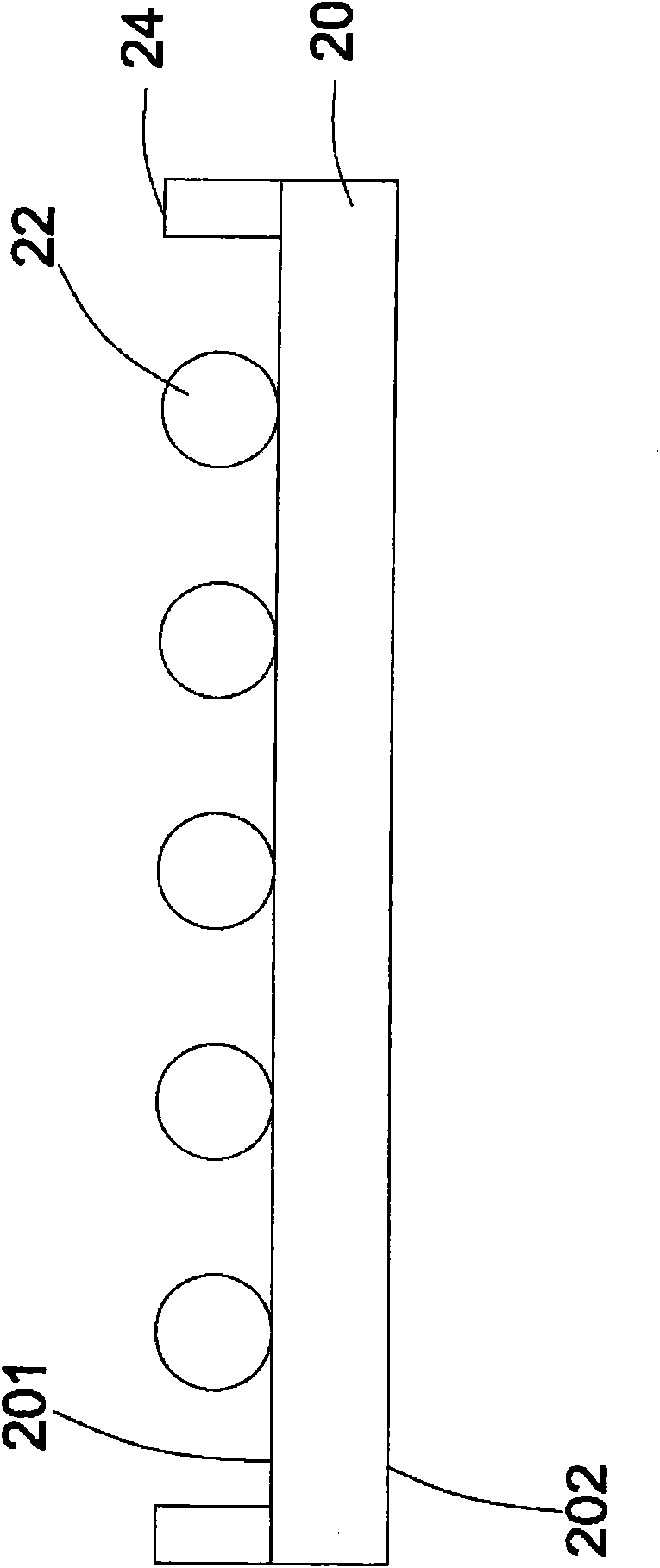

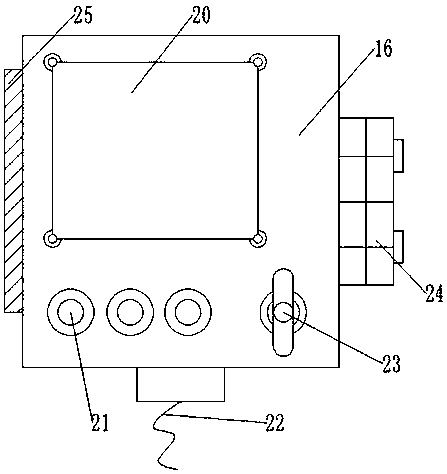

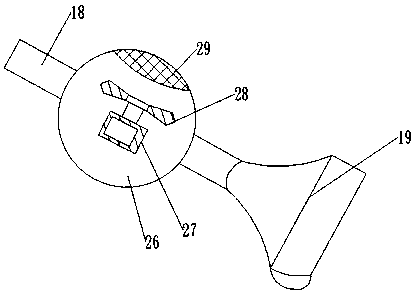

Dual-cylinder tabletop-type selective laser melting molding equipment and dual-cylinder tabletop-type selective laser melting molding method

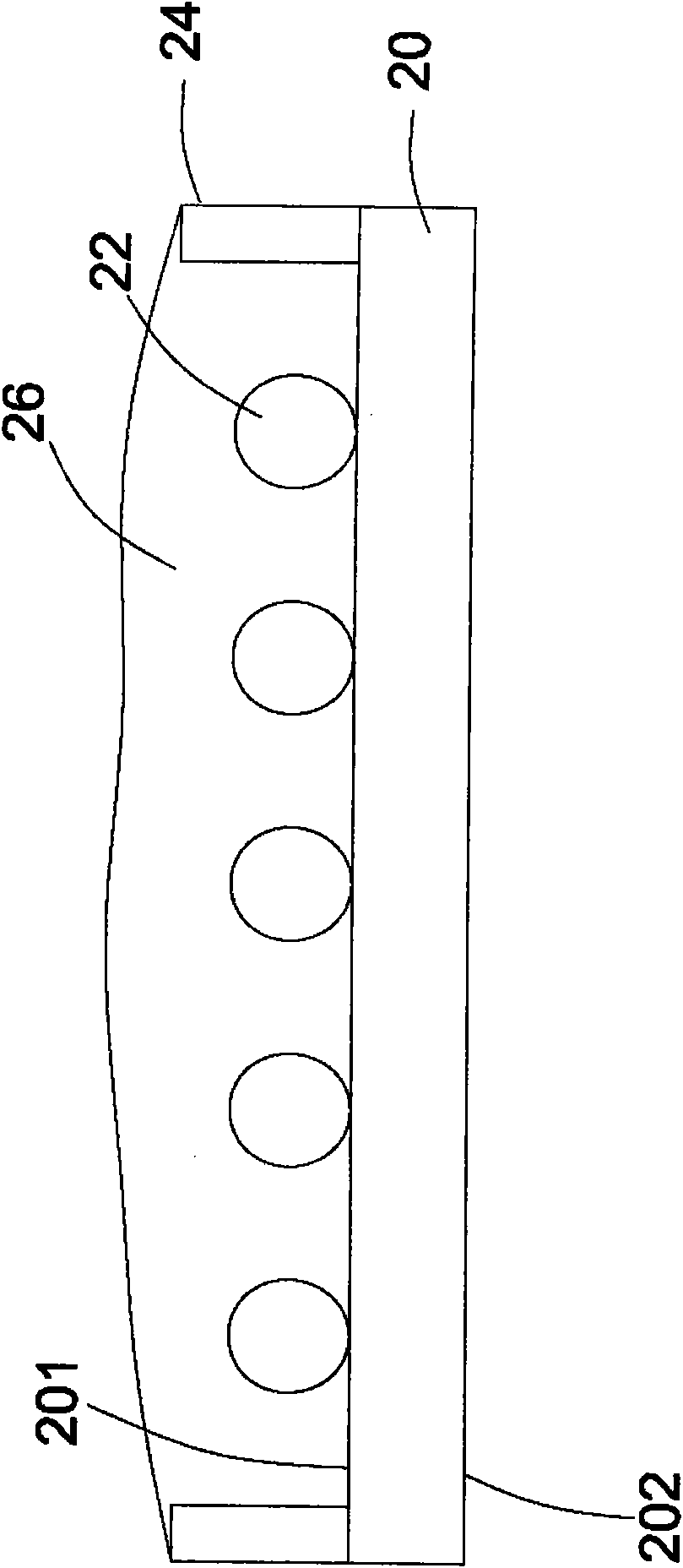

The invention discloses dual-cylinder tabletop-type selective laser melting molding equipment and a dual-cylinder tabletop-type selective laser melting molding method. The dual-cylinder tabletop-type selective laser melting molding equipment comprises a sealed molding chamber, an optical transmission system, a powder spreading device, a molding cylinder and a powder cylinder, wherein a molding platform is arranged on the upper part of the molding cylinder and the powder cylinder; a movable platform is arranged above the molding platform; the molding platform serves as a guide rail of the movable platform, so that the movable platform can move left and right on the molding platform; the molding platform is provided with a powder spreading device and a powder acquiring system; the powder acquiring system comprises a powder acquiring base platform and a powder acquiring barrel, the powder acquiring barrel is arranged on the upper part of the powder acquiring base platform. Aiming at key points of a direct precious metal molding system, namely powder recovering and clearing, the dual-cylinder tabletop-type selective laser melting molding equipment is provided with the powder acquiring structure which can be completely taken out easily, and no powder is remained on the inner corners of the molding cylinder / powder cylinder, so that material wastes in a molding process are reduced, and the dual-cylinder tabletop-type selective laser melting molding equipment can be applied to direct molding of individual parts made of precious metals such as gold, silver and platinum in the bijouterie industry.

Owner:GUANGZHOU LEIJIA TECH CO LTD

Method for extracting cannabidiol from industrial hemp

InactiveCN109970518AHigh extraction rateReduce pollutionOrganic chemistryOrganic compound preparationWater contentChemistry

The invention relates to a method for extracting cannabidiol from industrial hemp. The method includes crushing and drying one or more of flowers, leaves and hemp seed bran of industrial hemp, as rawmaterials, to obtain a crushed raw material the water content of which is not more than 5%; subjecting the crushed raw material to supercritical carbon dioxide extraction to obtain cannabidiol preliminary extract; performing molecular distillation after the cannabidiol preliminary extract is heated to obtain a cannabidiol-enriched product; and subjecting the cannabidiol-enriched product to supercritical fluid chromatography for separation and purification to obtain cannabidiol free of tetrahydrocannabinol and having purity higher than 99%, with macroporous resin or MCI resin or C18 silica gelbeing adopted as a stationary phase, supercritical carbon dioxide being adopted as a mobile phase, and ethanol being adopted as an entrainer. The method is simple in process and easy to operate, and solves problems that cannabidiol extracted by solution leaching methods in the prior art is low in purity, that psychotoxic component tetrahydrocannabinol is left, that a large amount of organic solvents are consumed and that environment is polluted.

Owner:开远伯盛科技有限公司

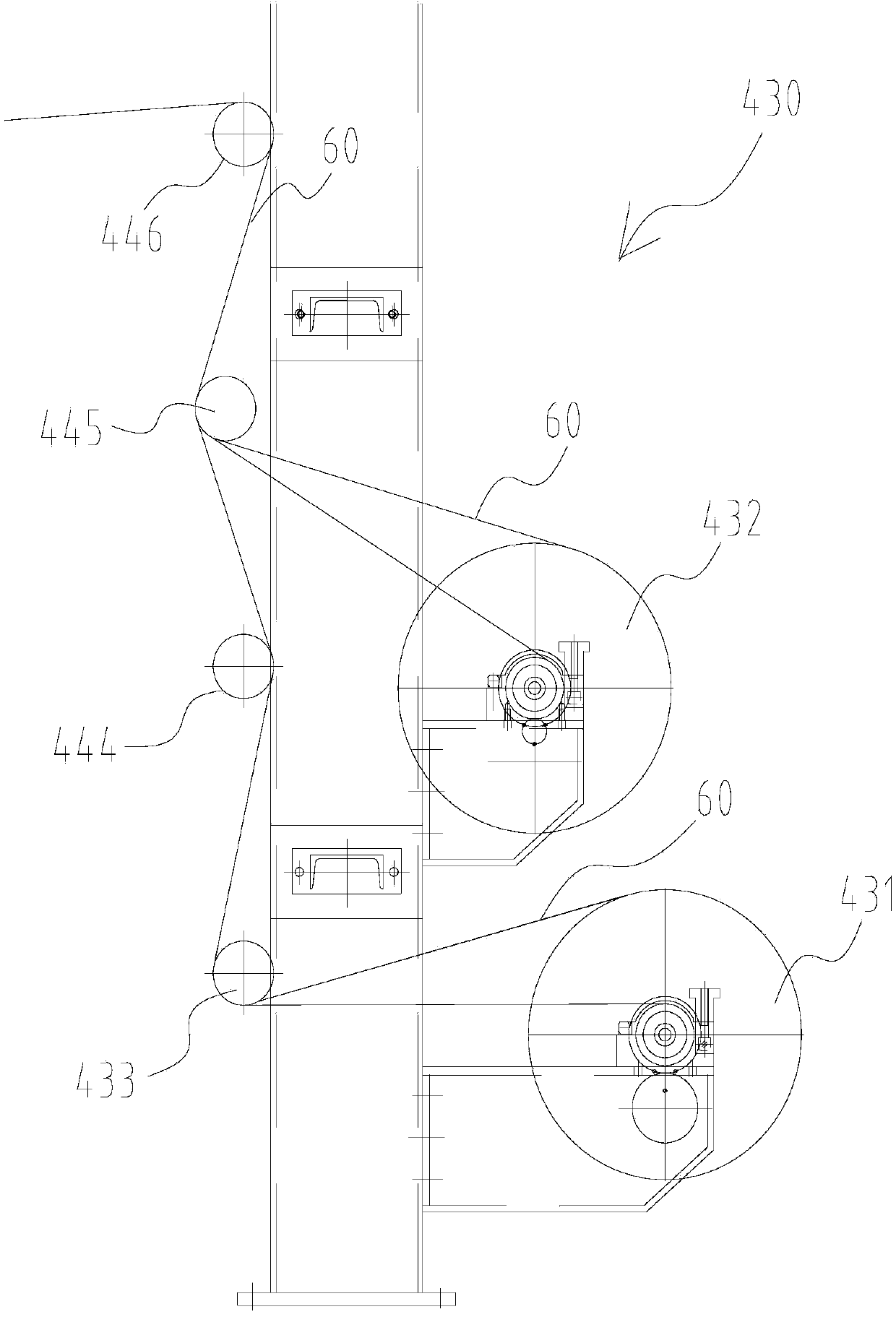

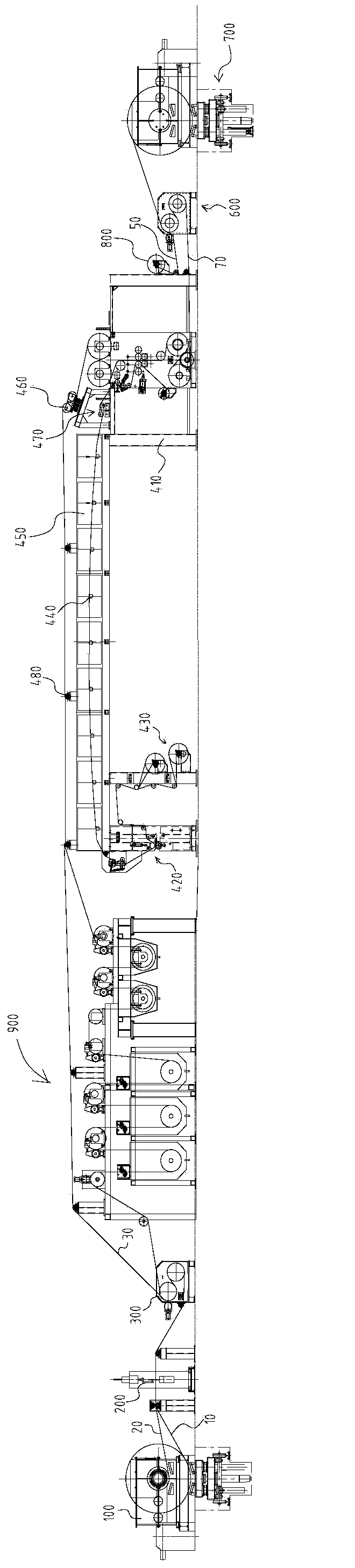

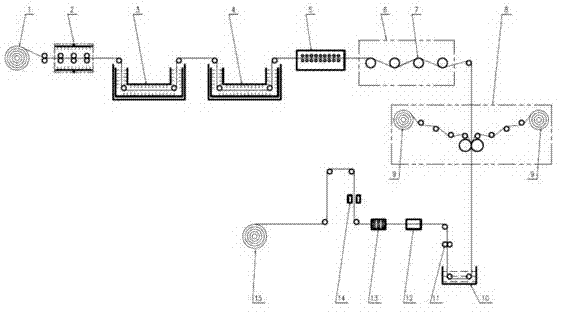

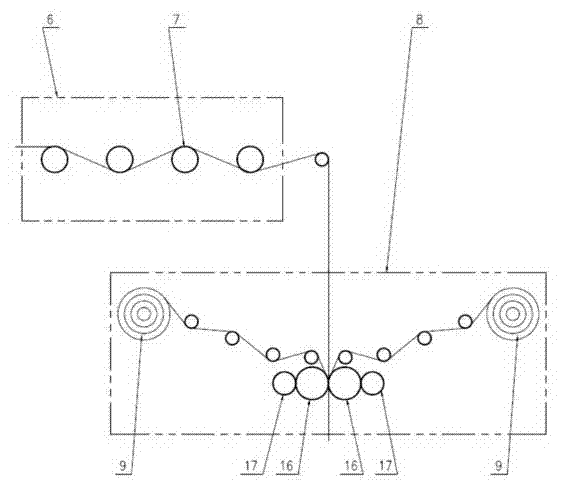

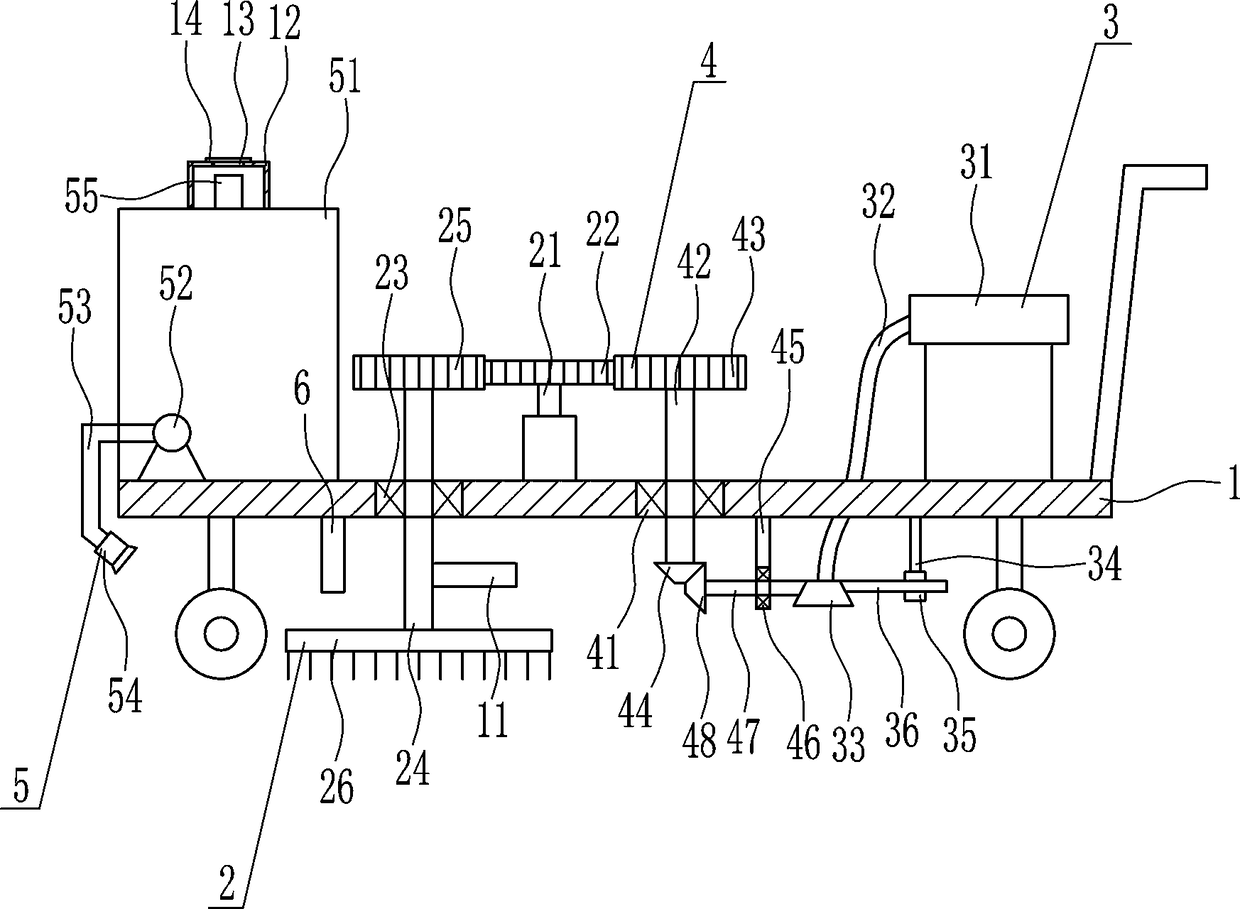

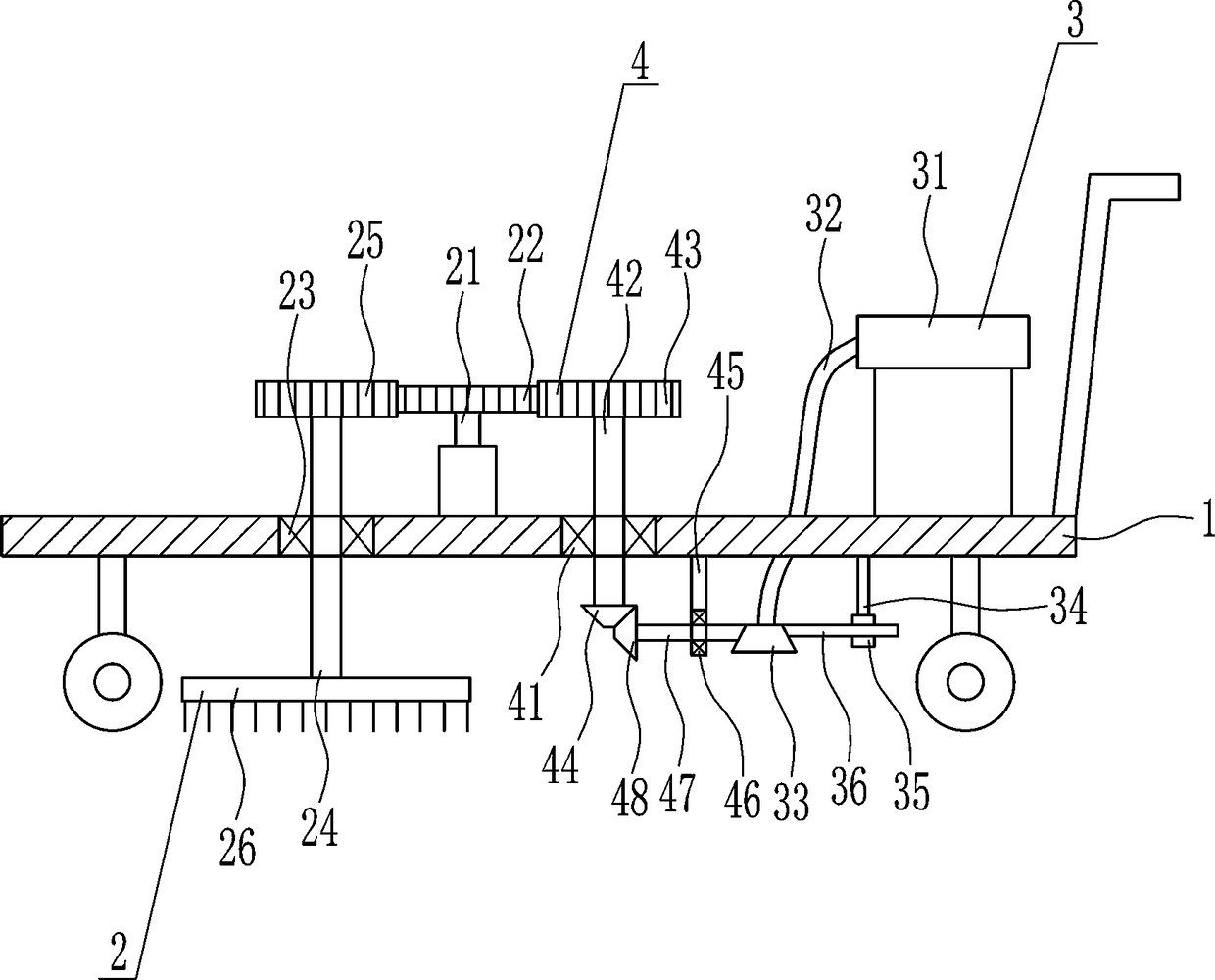

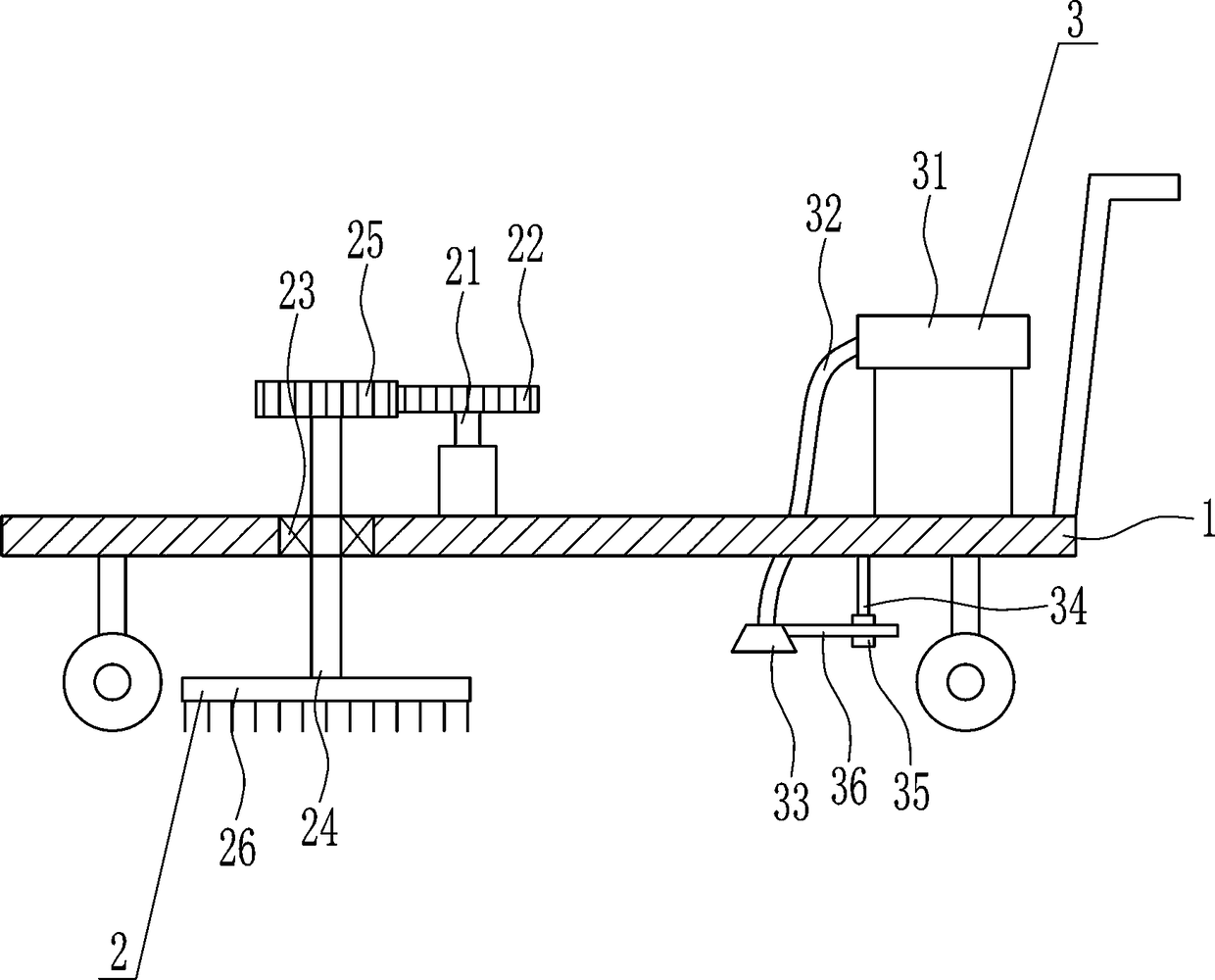

Multi-functional laminated iron production line

ActiveCN103640315AExcellent anti-rustImprove the decorative effectLamination ancillary operationsLaminationWinding machineProduction line

The invention discloses a multi-functional laminated iron production line. The multi-functional laminated steel production line comprises a cold rolled base plate unwinding device, a seam welder, two S turning roller sets, a first or / and second thin film release device, an iron sheet laminating device and a laminated iron winding machine, which are sequentially arranged in a conveying direction of metal base plates; the metal base plate from the seam welder enters the iron sheet laminating device after being tensioned and rectified, and a first thin film or / and second thin film is / are fed into an iron sheet laminating machine after rectification, so that the iron sheet laminating machine covers one surface or two surfaces of the metal base plate with the first thin film or / and the second thin film to form single-sided or double-sided laminated iron, the single-sided or double-sided laminated iron is fed into the other S turning roller set by the iron sheet laminating machine to be tensioned, and the tensioned single-sided laminated iron is wound by the laminated iron winding machine. The multi-functional laminated iron production line can produce both low-temperature bonded laminated iron and high-temperate melted laminated iron, is advanced iron laminating equipment capable of realizing efficient and continuous production, and can be well adaptive to the change of market requirement.

Owner:SUZHOU DONGHONGRUI PACKAGE TECH

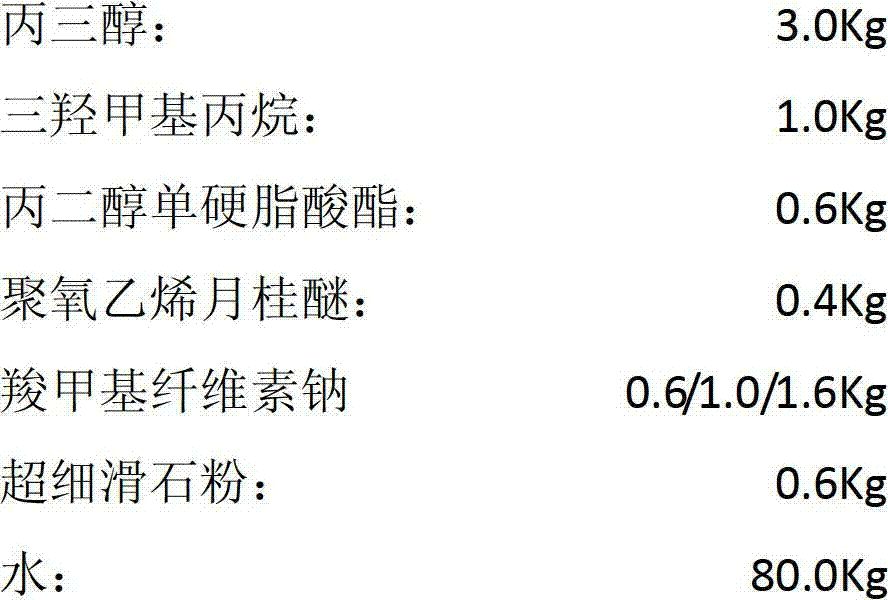

Controllable-respiration preservative film and preparation method thereof

InactiveCN102924855AAchieve free breathingImprove barrier propertiesFruit and vegetables preservationPolymer sciencePolyvinyl alcohol

The invention discloses a controllable-respiration preservative film and a preparation method thereof. The method comprises the following steps: dissolving a water-soluble polyhydroxy plasticizer in water, adding the reaction raw material, heating until the raw material is completely dissolved in water, dispersing at high speed, and cooling to 50-70 DEG C to prepare a solution for running filming; and running the solution for running filming onto a steel belt on a running production line via a die head, and drying to obtain the controllable-respiration preservative film. The controllable-respiration preservative film is prepared from the reaction raw materials in percentage by mass: 60-80% of polyvinyl alcohol, 10-30% of water-soluble polyhydroxy plasticizer, 1-5% of moisture respiration regulator, 1-3% of compatilizer, 3-10% of water retention agent and 0.5-3% of assistant. The preservative film has high barrier property for oxygen and nitrogen sources; the bidirectional permeation exchange power for moisture can be effectively regulated and controlled through the raw material formula; and thus, the preservative film can ensure free respiration and moisture exchange of fruits and vegetables in the preservation process.

Owner:SOUTH CHINA UNIV OF TECH

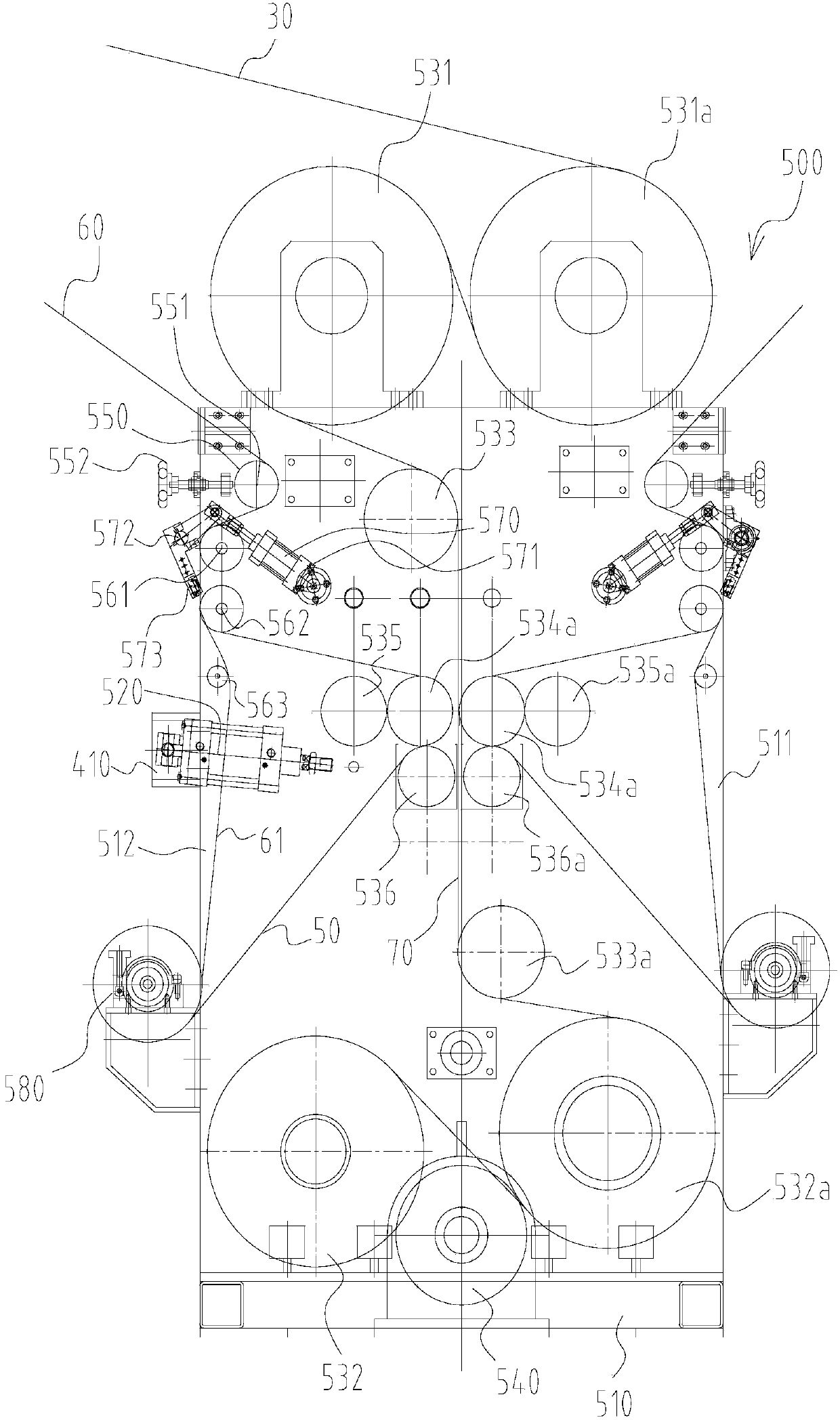

Internal air injection discharging double-roller granulator

ActiveCN103537226AWill not remainDoes not affect granulation efficiencyGranulation by pressingAir pumpEngineering

The invention discloses an internal air injection discharging double-roller granulator. A roller and a rotary shaft are hollow and are interconnected; one end of the hollow rotary shaft is connected with an air pump; a plurality of shaft air outlet holes are formed in one section, in the hollow roller, of the hollow rotary shaft; roller air outlet holes are formed in the bottom of a surface groove of the hollow roller; the roller air outlet holes are communicated with the hollow roller. Consequently, the airflow discharged by the air pump reaches the hollow roller through the hollow rotary shaft and is ejected out through the shaft outlet holes and the roller air outlet holes in turn, so that particles are separated from the groove in the surface of the roller and enter a collecting device; after granulating once by relatively squeezing the roller once, no particle remains on the surface, so that the next granulation efficiency or the next granulation quality is not affected.

Owner:WUHU 36 MACHINERY

Method for extracting cannabidiol and cannabidiol product thereof

InactiveCN107344908AReduce loss rateCreate pollutionOrganic chemistryOrganic compound preparationFiltration membraneSolvent

The invention discloses a method for extracting cannabidiol by utilizing supercritical carbon dioxide. The method comprises the following steps: pretreatment: drying flowers and leaves of cannabis at the temperature of 105-120 DEG C for 0.5-4 hours to obtain a material A with the water content of less than 7%; crushing: crushing the material A to 50-100 meshes to obtain powder B; extraction: carrying out supercritical carbon-dioxide extraction on powder C, and after extraction, obtaining liquid D and residue E; separation: by throttling expansion for the liquid D to resolve the cannabidiol, recovering a solvent F; and filtration: adopting an ultramicro filtration membrane with the cut-off molecular weight of 80-120 KD to filter separated cannabidiol. The method disclosed by the invention has the advantages that hemp seed oil in the cannabis is extracted by using the supercritical carbon dioxide, the highest extraction rate of the cannabidiol can reach 90% and the purity of the cannabidiol is more than 20%.

Owner:YUNNAN HEMPSON BIO-TECH CO LTD

60% high solid content pressure-sensitive adhesive and preparation method thereof

InactiveCN101676347AImprove bindingEasy to peel offEster polymer adhesivesTectorial membraneEmulsion polymerization

The invention relates to a 60% high solid content pressure-sensitive adhesive and a preparation method thereof, and discloses a way for obtaining environment-friendly pressure-sensitive adhesive whichis applicable to manufacturing a surface protective film of building materials, electrical and electronic products, machines, furniture and the like. The pressure-sensitive adhesive is prepared by adopting a semi-continuous seed emulsion polymerization, taking butyl acrylate, methyl methacrylate, hydroxy-ethyl acrylate and acrylic acid as monomers, synchronously adding mixed emulsifying agent formed by anionic emulsifying agent and nonionic emulsifying agent as well as mixed liquid formed by initiating agent and ammonium persulphate, and having polymerization reaction in subacid deionized water. The pressure-sensitive adhesive has no emission of noxious and harmful substances when in production and use, so as to purify the environment. Meanwhile, the protective film and base material produced by the pressure-sensitive adhesive has better combination, do not damage the surface of the protected object, and can be torn off from the surface of the protected object so as to leave no residual trace.

Owner:成都航天明江科技实业有限公司 +1

Technology and device for processing film-coated iron

ActiveCN102431269ALess surface pinholesHigh tensile strengthLamination ancillary operationsLaminationSteel platesSheet steel

The invention provides a technology for processing film-coated iron. The technology for processing film-coated iron comprises the following steps that a cold-rolled thin collared steel plate (chrome-coated iron) subjected to surface chrome coating treatment is unreeled by an unreeling machine, then is cleaned up, is dried and is put into a preheating device for preheating; and the preheated steel plate is treated by a film pressing device so that the preheated steel plate and a plastic film are compounded by heating. The invention also provides a device for processing film-coated iron. The technology and the device for processing film-coated iron have the advantages that high efficiency, environmentally friendly and low-cost steel plate surface coating is realized; a production process is environmentally friendly; a product has good impact resistance and corrosion resistance; toxic low-molecular residues are not produced; and the technology and the device accord with a modern industrial large-scale production idea of low carbon and environmental protection.

Owner:上海联净复合材料技术有限公司

Fingerprint-proof paint, product with fingerprint-proof coating and preparation method for product

InactiveCN102464923ANot easy to adsorbReduce manufacturing costSynthetic resin layered productsCoatingsNanoparticleCoupling

The invention discloses a fingerprint-proof paint, a product with a fingerprint-proof coating and a preparation method for the product. The product with a fingerprint-proof coating is prepared by coating the fingerprint-proof paint on the surface of the product. The fingerprint-proof paint is prepared by uniformly mixing a nanoparticle solution with a fluorine-containing coupling agent under agitation so as to obtain a fluorine molecule surface modified nanoparticle solution and then uniformly mixing the fluorine molecule surface modified nanoparticle solution with a paint containing fluorine polymers under agitation. According to the invention, after the fingerprint-proof paint is coated on the surface of a substrate, fluorine-containing polymers and the fluorine-containing coupling agent, which are on the surface of nanoparticles, and the substrate undergo chemical bonding, which enables a fingerprint-proof coating with a thickness of 10 to 100 nm to be formed on the surface of the product; because of low surface energy of fluorine molecules in the fingerprint-proof coating and a stereo barrier formed by the highly regularly arrayed nanoparticles, the product with the fingerprint-proof coating has a good fingerprint-proof effect, and the preparation method for the product is simple.

Owner:FUGANG ELECTRONICS DONGGUAN +1

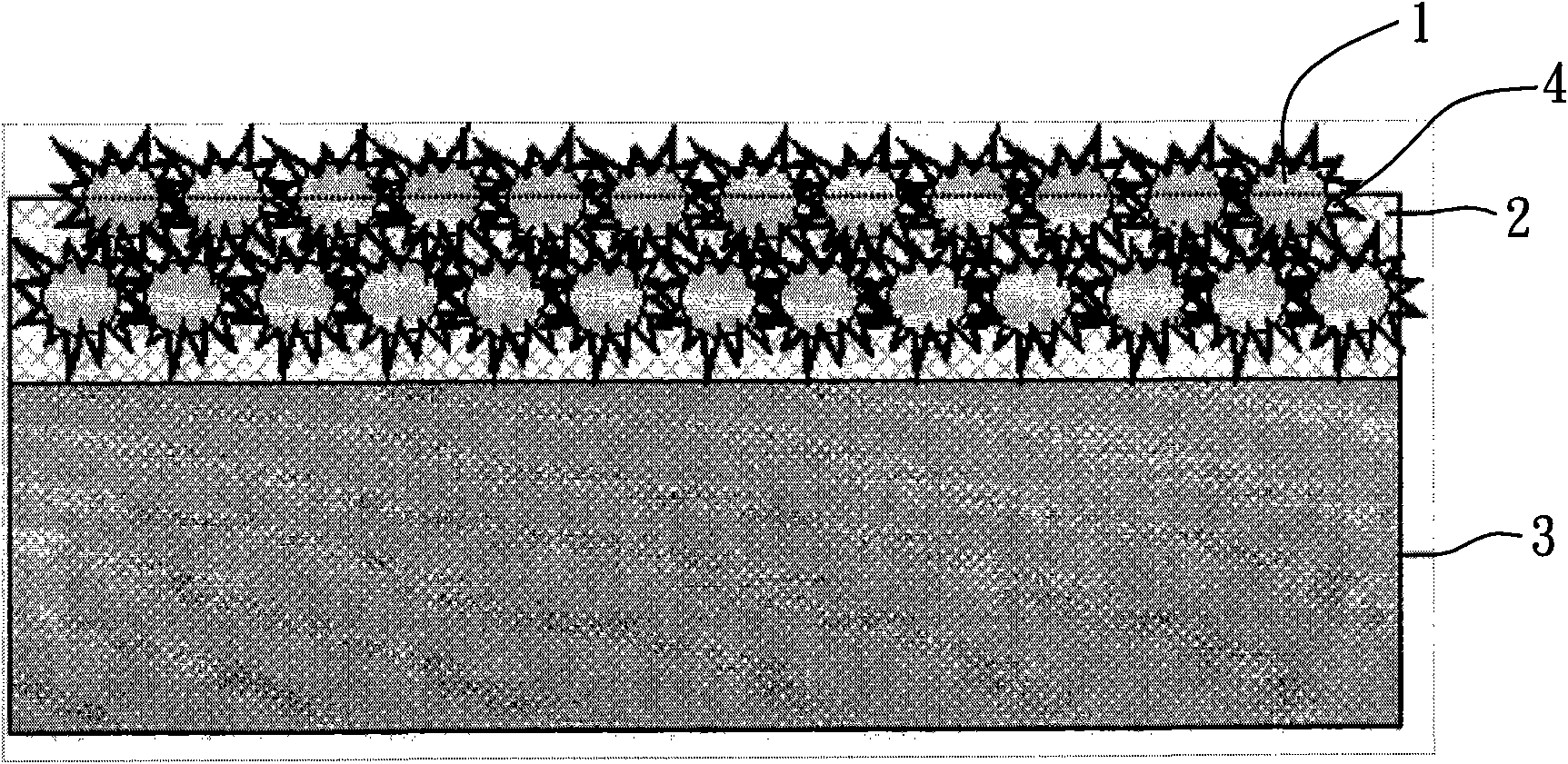

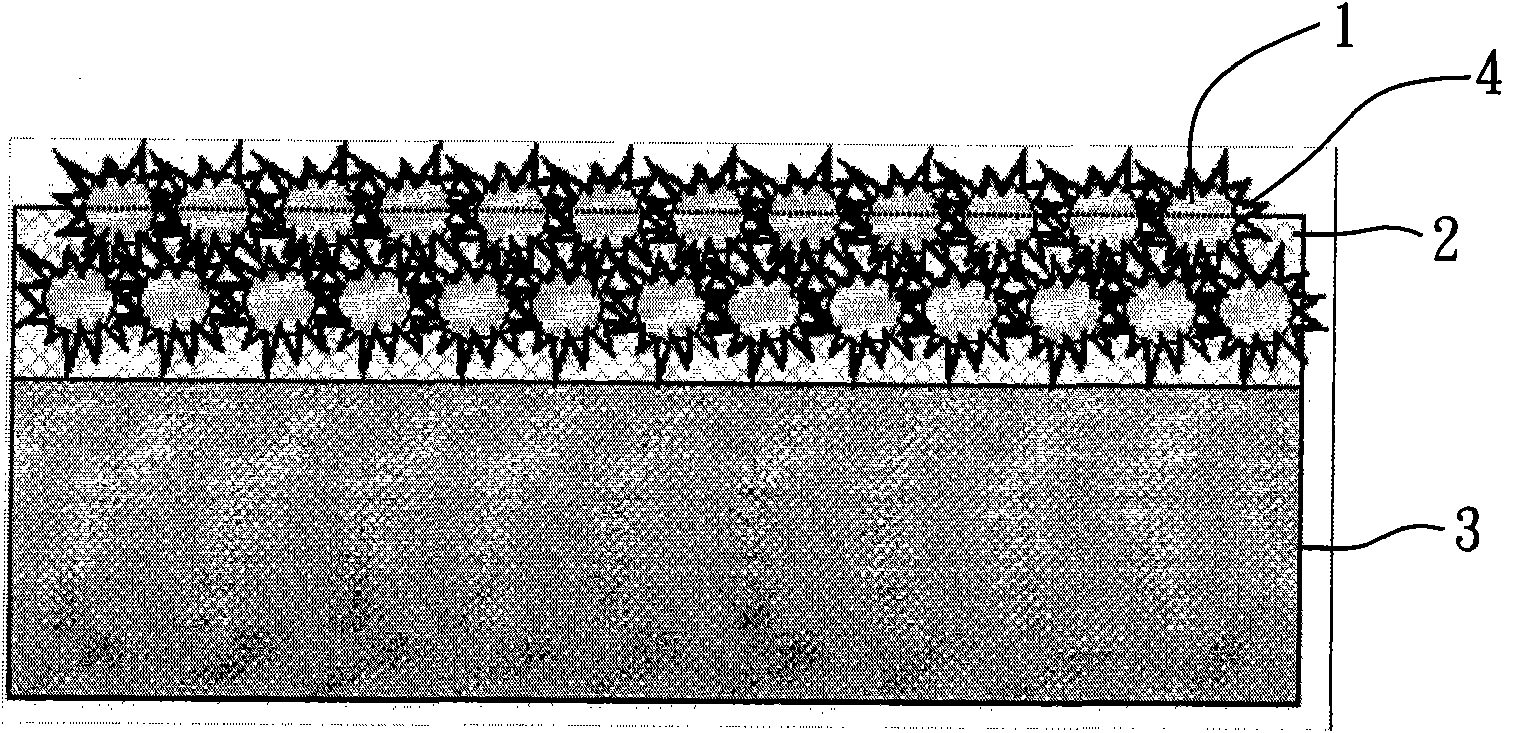

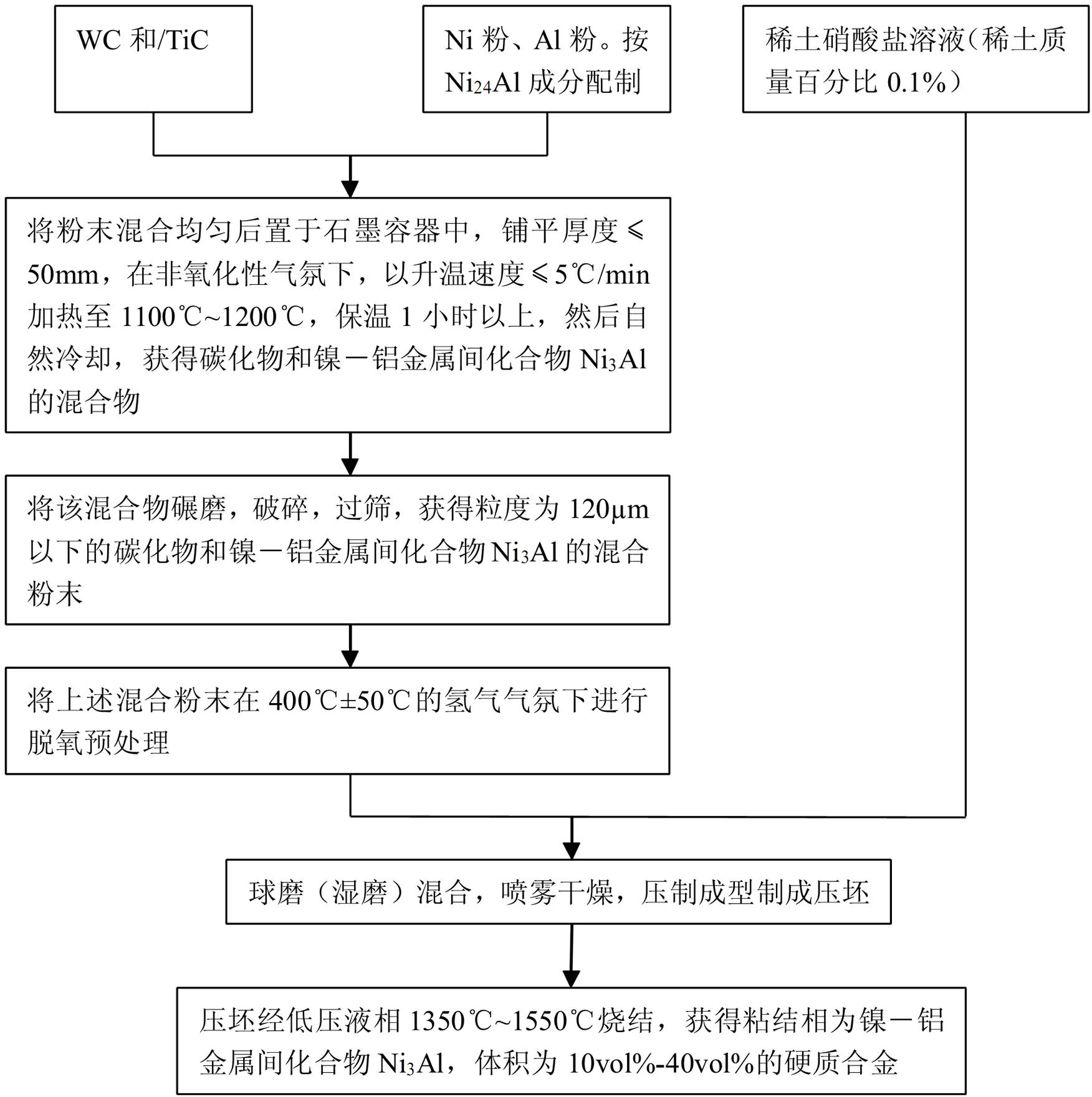

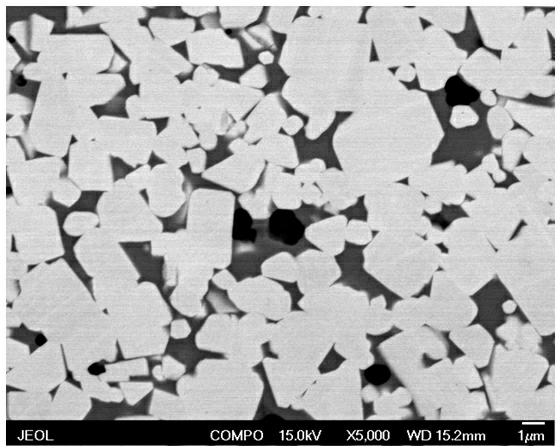

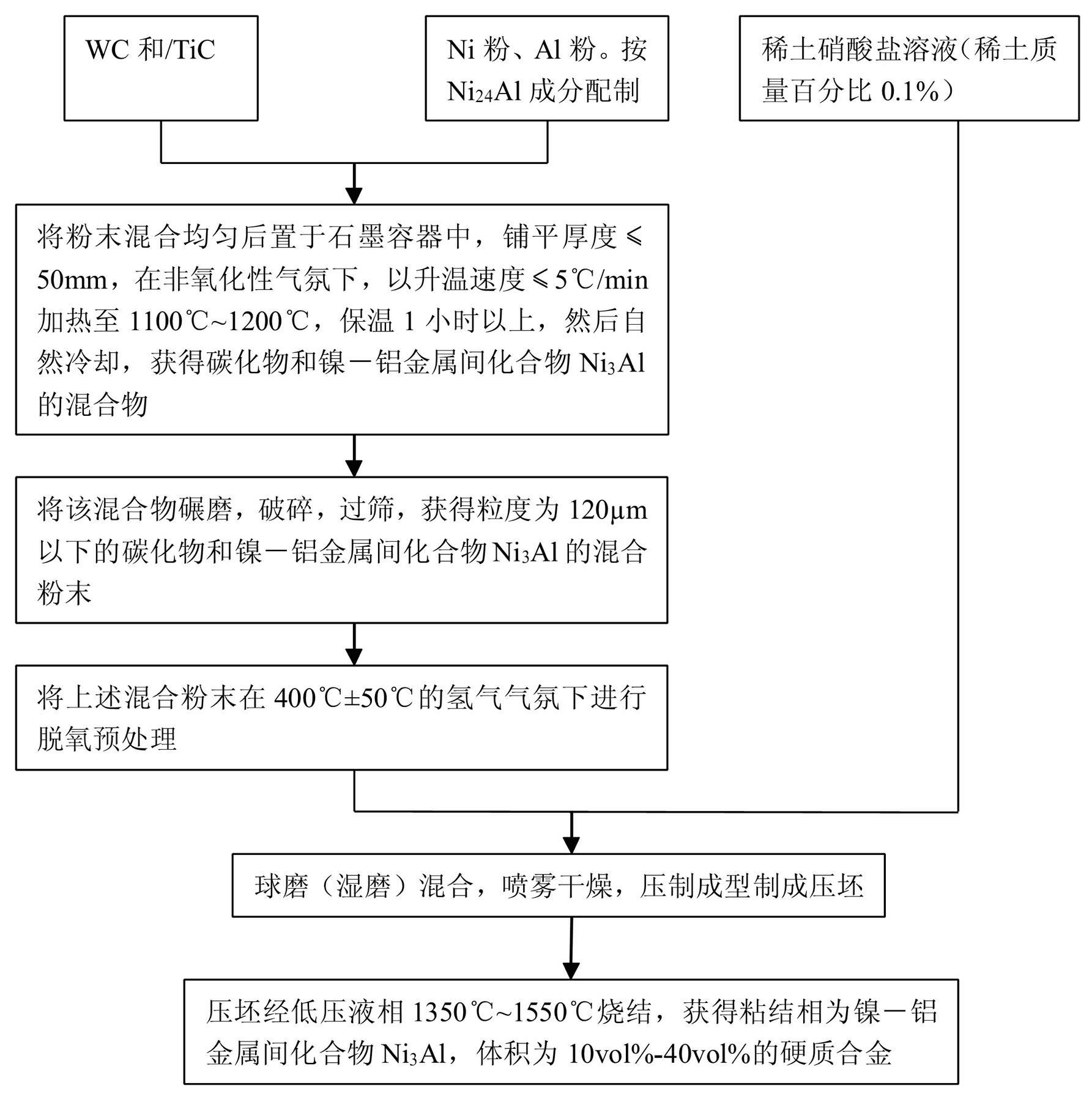

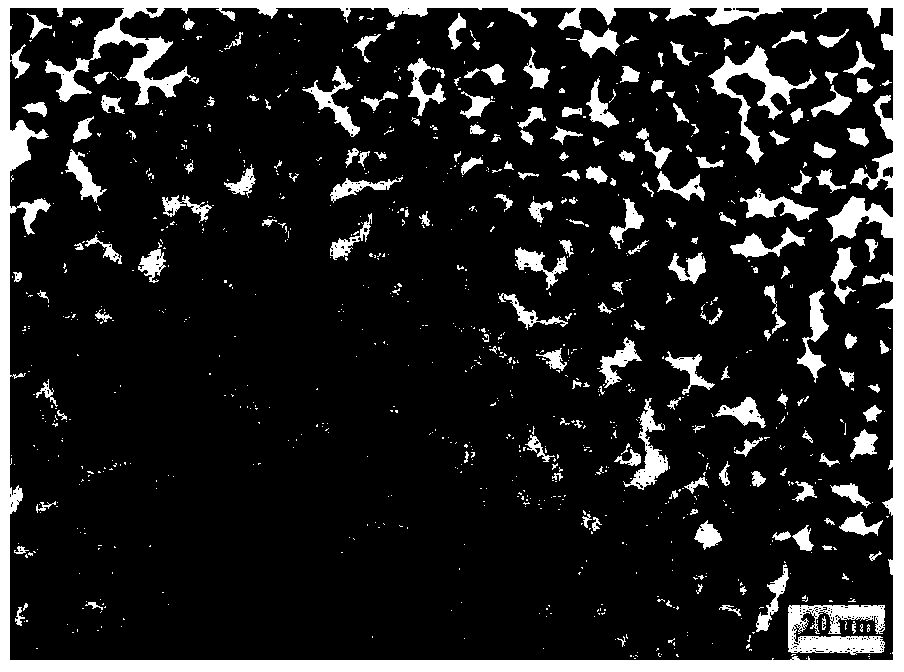

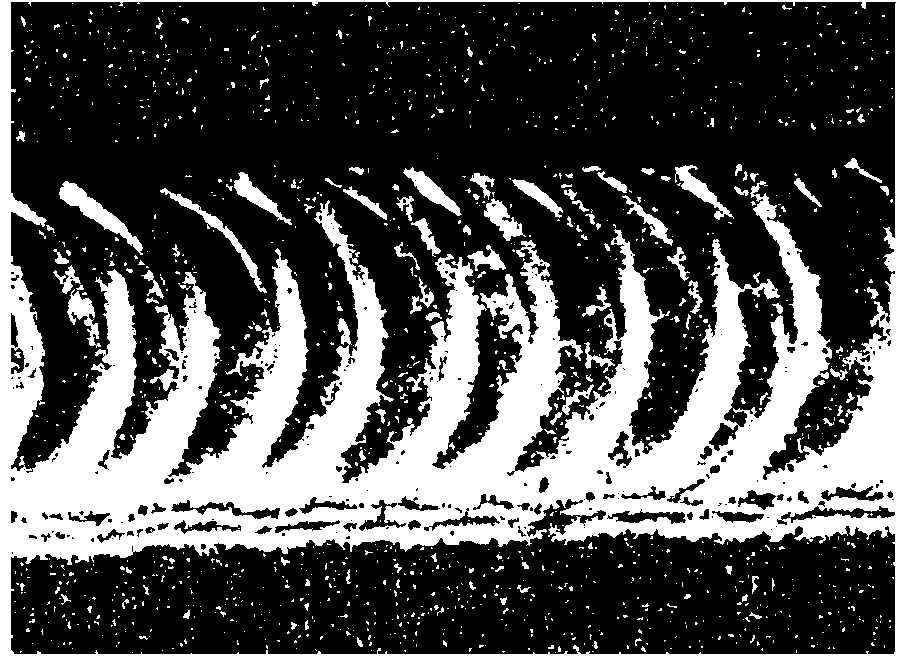

Hard alloy taking nickel-aluminium intermetallic compound Ni3Al as binding phase and preparation method

The invention discloses a hard alloy taking Ni3Al as a binding phase and carbide as a hard phase, wherein Y is 0.005 to 0.050wt%, the volume percent of the binding phase is 10 to 40%; a preparation method for the hard alloy sequentially comprises the following steps of: uniformly mixing 5.04 to 50.30 wt% of nickel powder and aluminium powder and the rest of carbide powder according to a proportion of components of Ni24Al; putting and spreading out the mixture in a graphite container to lead the thickness of the mixture to be less than or equal to 50mm, heating the graphite container at a speed of less than or equal to 5 DEG C / min to a temperature of 1100 DEG C to 1200 DEG C at a non-oxidizing atmosphere, preserving heat for more than 1 hour, naturally cooling so as to obtain a mixture ofcarbide and Ni3Al; milling, crushing and sieving the mixture so as to obtain a mixture powder of carbide and Ni3Al with the thickness of below120 micrometers; carrying out deoxidization pretreatment on the mixture powder; then adding anhydrous yttrium nitrate alcoholic solution into the mixed powder pretreated through deoxidization according to 0.0050% to 0.0503% (mass percentage) of Y in the final hard alloy for wet-milling mixing for 18 to 36 hours so as to obtain a mixture; making the mixture into green compacts; and finally carrying out the low pressure liquid phase sintering on the greencompacts under a temperature of 1350 DEG C to 1550 DEG C so as to obtain the hard alloy. The hard alloy has a uniform organization structure, high compacting, high strength, good toughness and abrasive resistance and excellent high-temperature oxidation resistance and corrosion resistance; and the process is simple and has low cost.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Laser weldable aluminum based composite material and preparation method thereof

Belonging to the technical field of preparation of aluminum based composite materials, the invention especially relates to a laser weldable aluminum based composite material and a preparation method thereof. The method provided by the invention includes: mixing silicon powder and aluminum powder according to a proportion in a mixing tank uniformly to obtain a powder mixture, and subjecting the powder mixture to cold isostatic pressing, high temperature and high vacuum degassing, and hot isostatic pressing densification treatment, thus obtaining the 100% compact, and internally imporous Si / Al composite billet. The method provided by the invention has the advantages of simple and stable process and low cost, and is one of the preferred methods for preparation of preparation of high reliability and stable quality packaging materials. The Si / Al composite material prepared by the method not only has the characteristics of light weight, low expansion and high thermal conductivity, but also has high and stable mechanical properties, especially has the characteristics of good laser welding technological properties and high air tightness, thus being an advanced aluminum based composite material with an integrated functional structure. And the material can be applied as a hermetic encapsulation shell for microelectronic devices and photoelectric devices.

Owner:南京驰韵科技发展有限公司

Preparation method of amino acid modified attapulgite clay palm oil decolorizing agent

ActiveCN103357377AGood decolorization effectImprove bindingOther chemical processesFatty-oils/fats refiningImpurityPalm oil

The invention discloses a preparation method of an amino acid modified attapulgite clay palm oil decolorizing agent. The preparation method comprises: inorganic acid activating treatment of attapulgite clay, amino acid modification of the attapulgite clay, after a certain reaction time filtering and impurity removing, solid-liquid separation, drying and baking, and crushing and sieving, and obtaining of the amino acid modified attapulgite clay palm oil decolorizing agent. The amino acid modified attapulgite clay palm oil decolorizing agent prepared by the preparation method not only has good decolorizing effect, but also can prevent the palm oil oxidation deterioration during storage, and improve the storage security.

Owner:中国科学院兰州化学物理研究所盱眙凹土应用技术研发中心

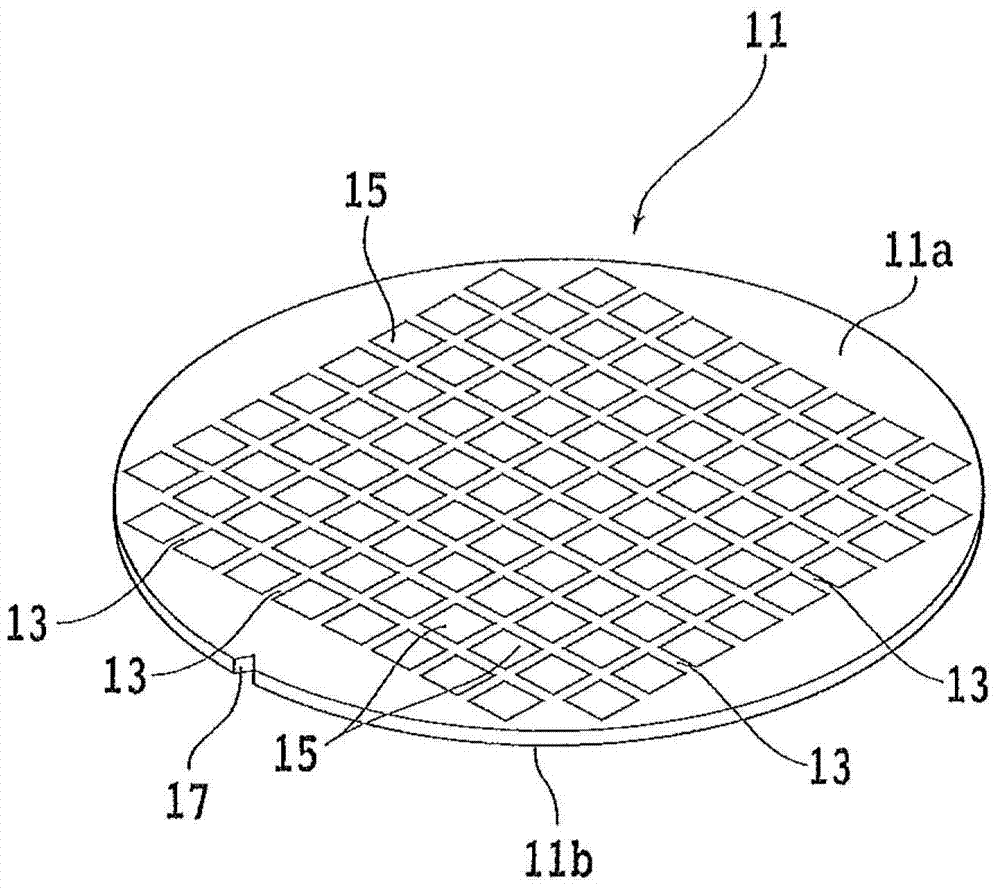

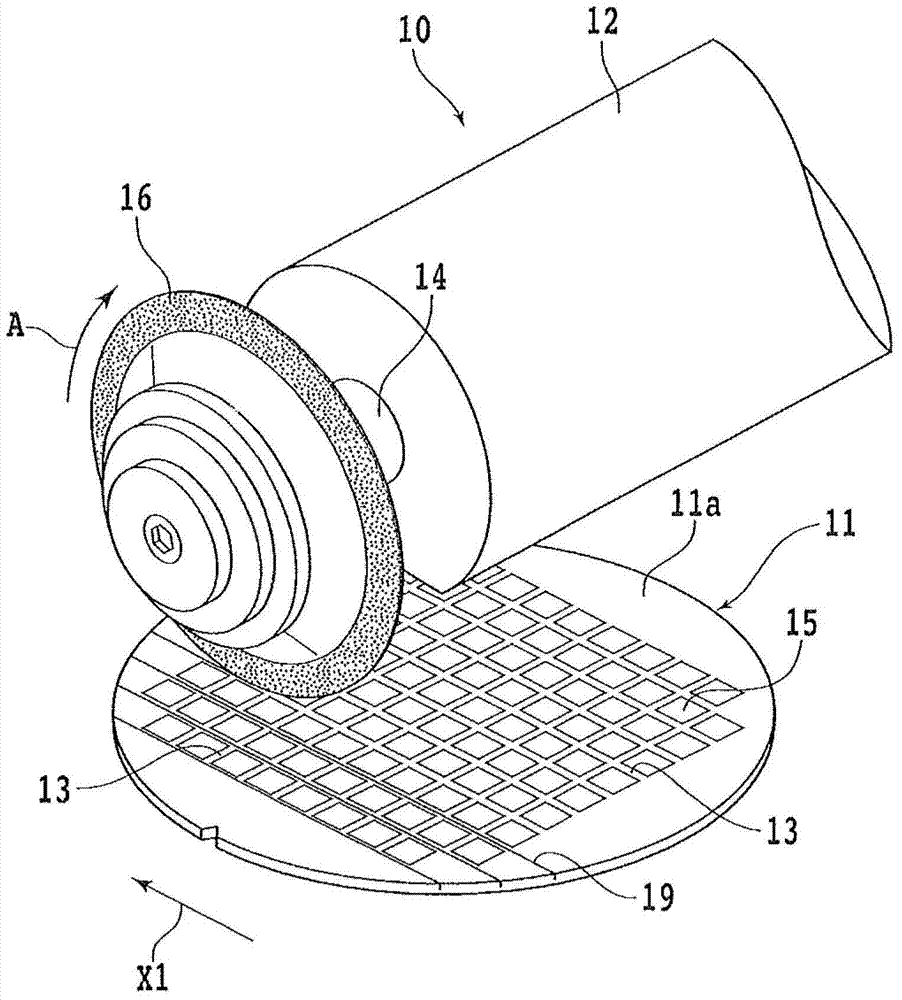

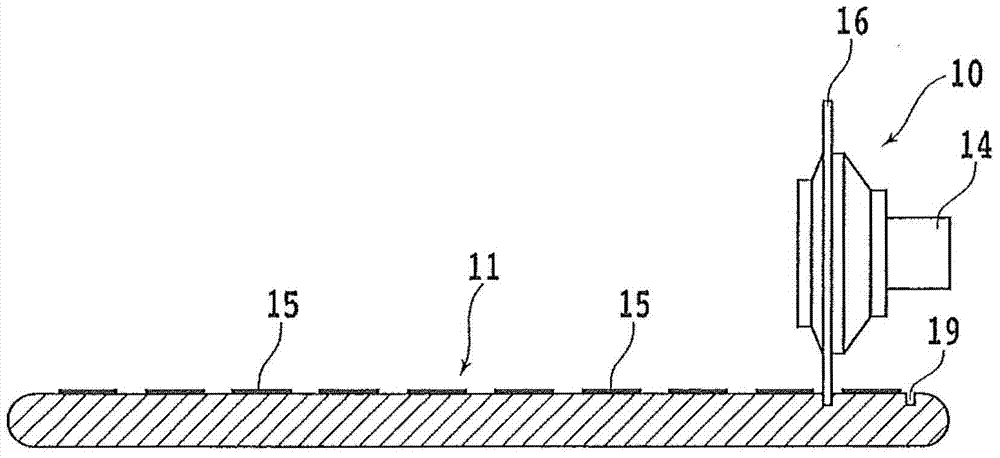

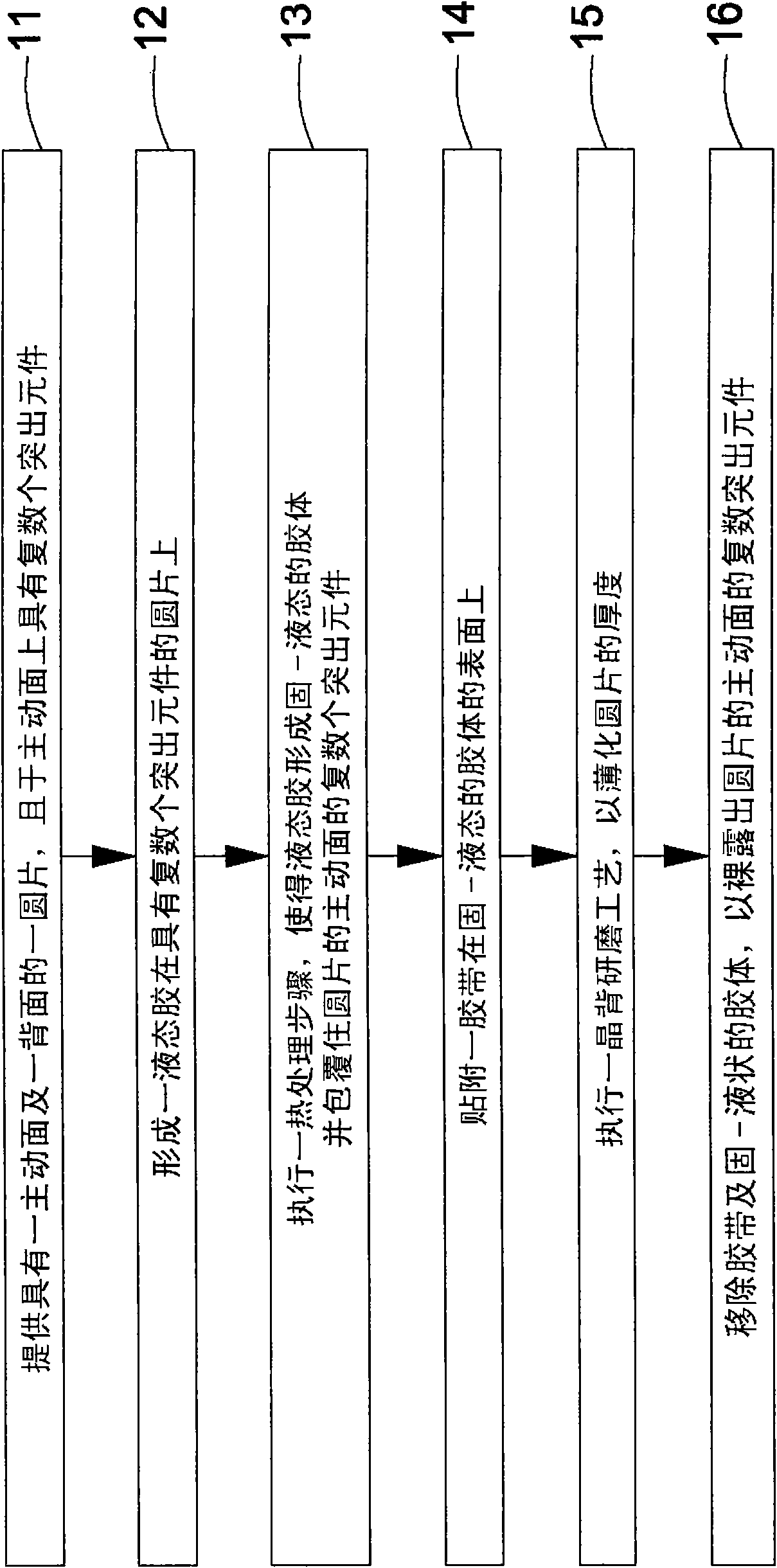

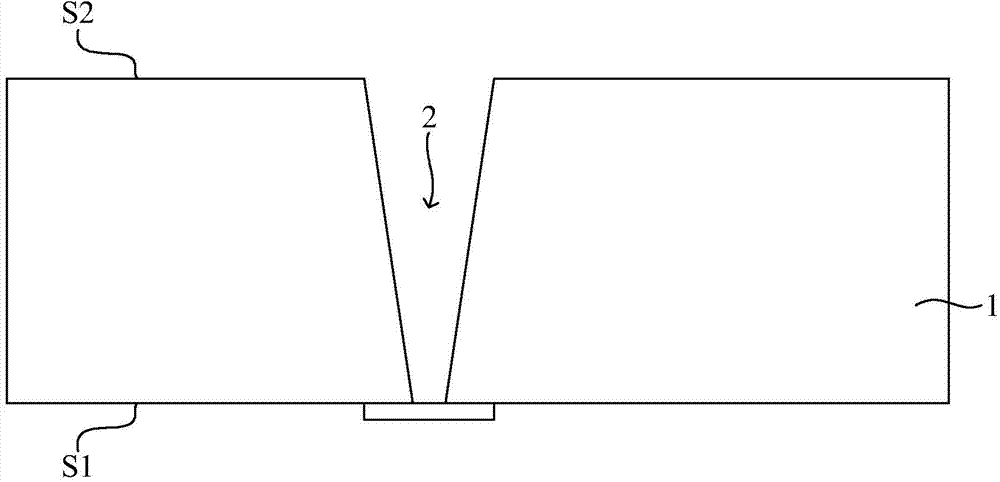

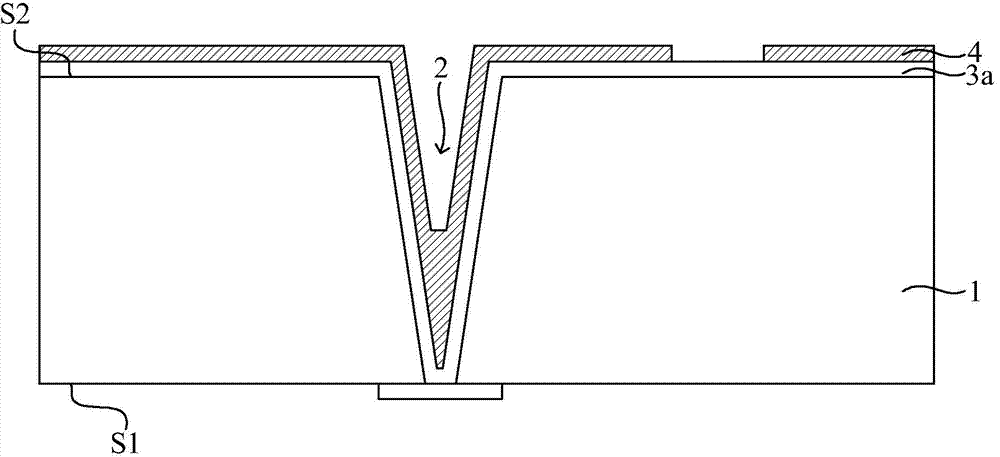

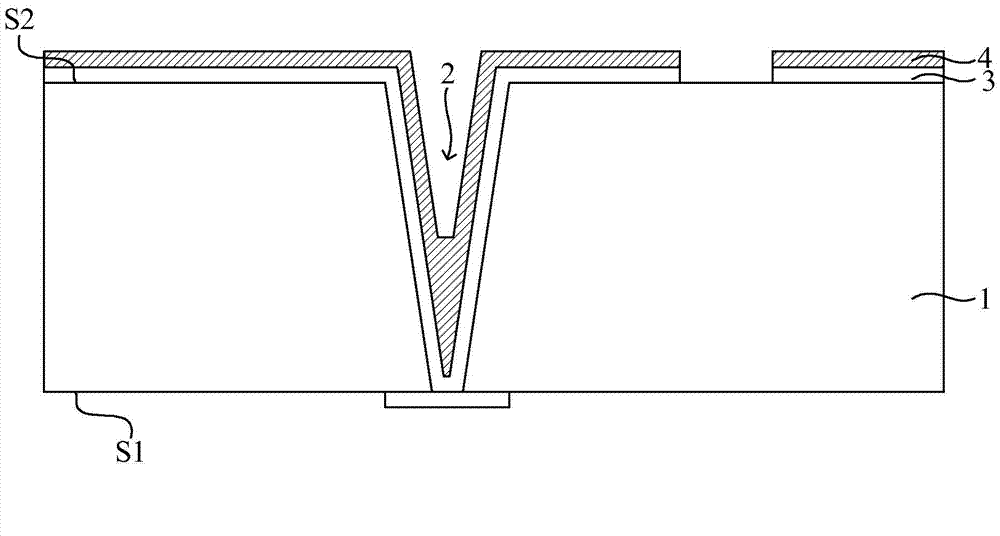

Wafer processing method

ActiveCN104779204AGuaranteed rigidityDoes not impair operabilitySemiconductor/solid-state device manufacturingFine working devicesLaser processingEngineering

The invention provides a wafer processing method. The bending strength of a chip is not reduced, and a thick chip can be formed. A wafer is provided with a plurality of crossed predetermined cutting lines. The wafer processing method is characterized by comprising a groove forming step, a protective belt pasting step, a laser processing step and a grinding step. In the groove forming step, a plurality of grooves at certain depths are formed in the front side of the wafer along the predetermined cutting lines, and the wafer does not reach the final thickness. In the protective belt pasting step, a protective belt is pasted on the front side of the wafer. In the laser processing step, the focus of a laser beam which has a certain length and can penetrate the wafer is positioned on the position, in the wafer, being closer to the back side relative to the final thickness, the laser beam irradiates the back side of the wafer along the predetermined cutting lines, a deteriorative layer along the predetermined cutting line is formed in the wafer, and a crack layer which extends from the deteriorative layer to grooves and along the predetermined cutting lines. In the grinding step, a grinding member is employed to grind the back side of the wafer, and the wafer becomes thinner and reaches the final thickness, furthermore, the deteriorative layer is removed, and the wafer is cut along the predetermined cutting lines to form chips.

Owner:DISCO CORP

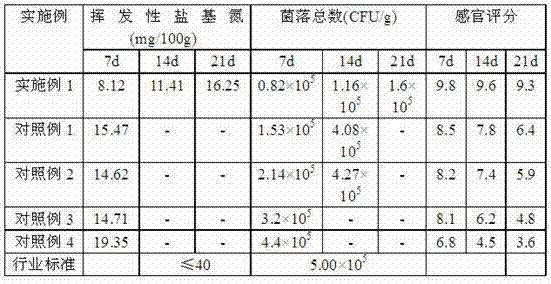

Pseudosciaena crocea ice temperature fresh-keeping method

InactiveCN102511538AImprove the bactericidal effectReduce the temperatureMeat/fish preservation by freezing/coolingFlavorIce water

The invention discloses a pseudosciaena crocea ice temperature fresh-keeping method, which comprises the steps of: ice spreading box loading, ice water cleaning, fluidized ozone ice pre-cooling, heat insulation box loading and ice temperature storage. The ozone ice and the fluidized ozone ice are sequentially adopted, the dual effects of lowering the fish body temperature and inhibiting the germ propagation are realized, further, the ice temperature storage is adopted, the freezing of the pseudosciaena crocea in the storage process is avoided, the original flavor and the fresh degree of the pseudosciaena crocea are more perfectly maintained, the quality guarantee period of the pseudosciaena crocea is greatly prolonged, and the pseudosciaena crocea is still fresh after being stored for 21 days.

Owner:福建海鑫龙水产发展有限公司

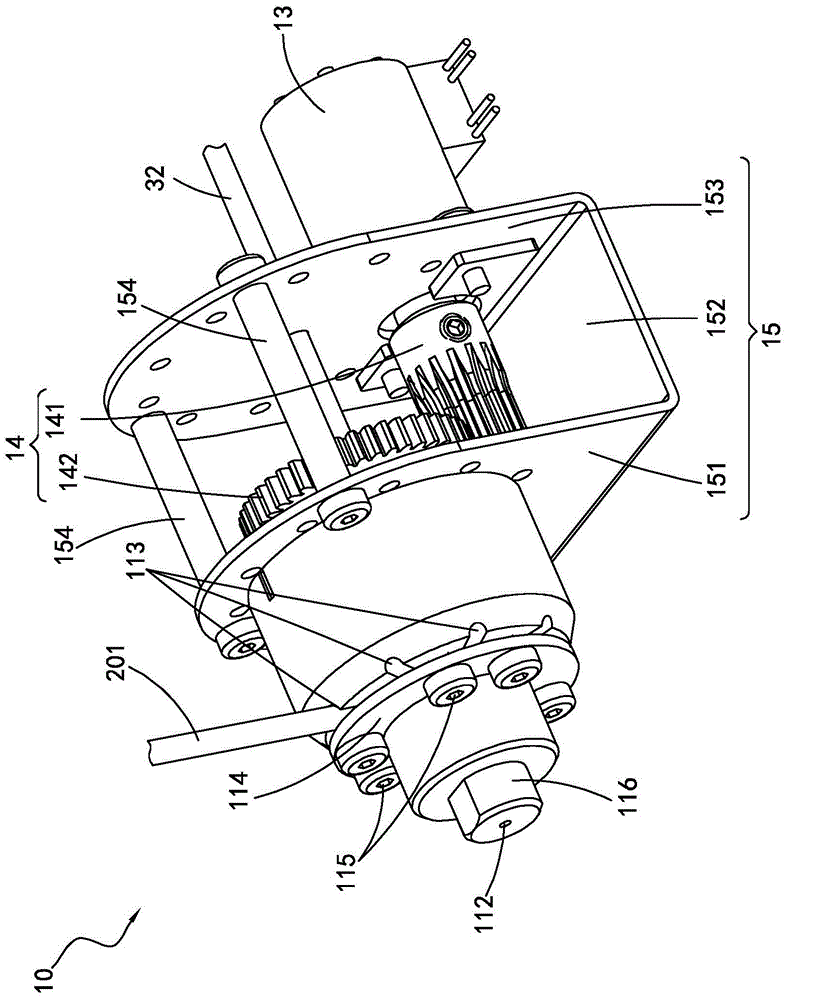

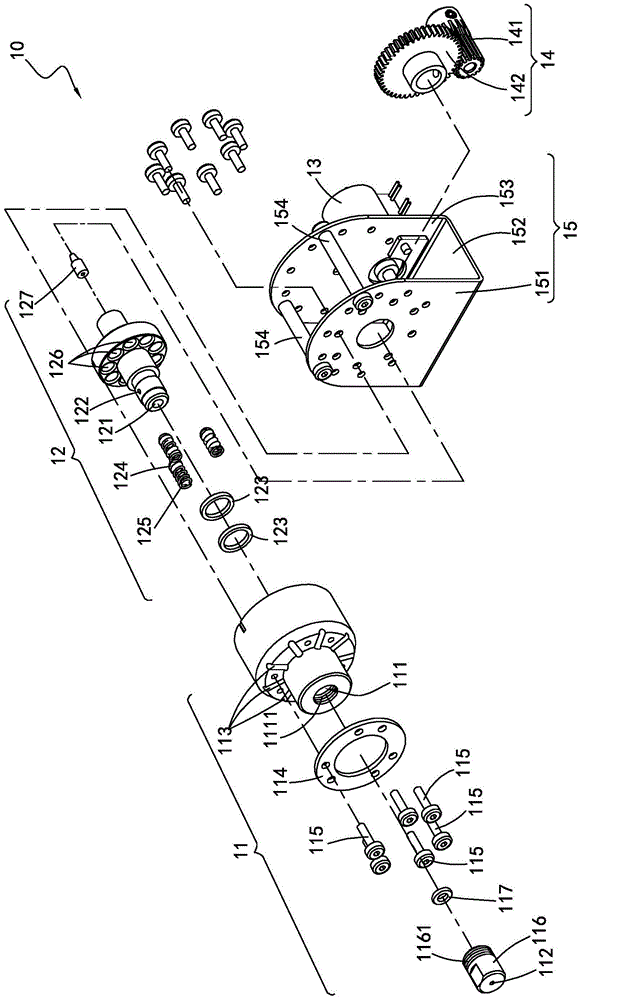

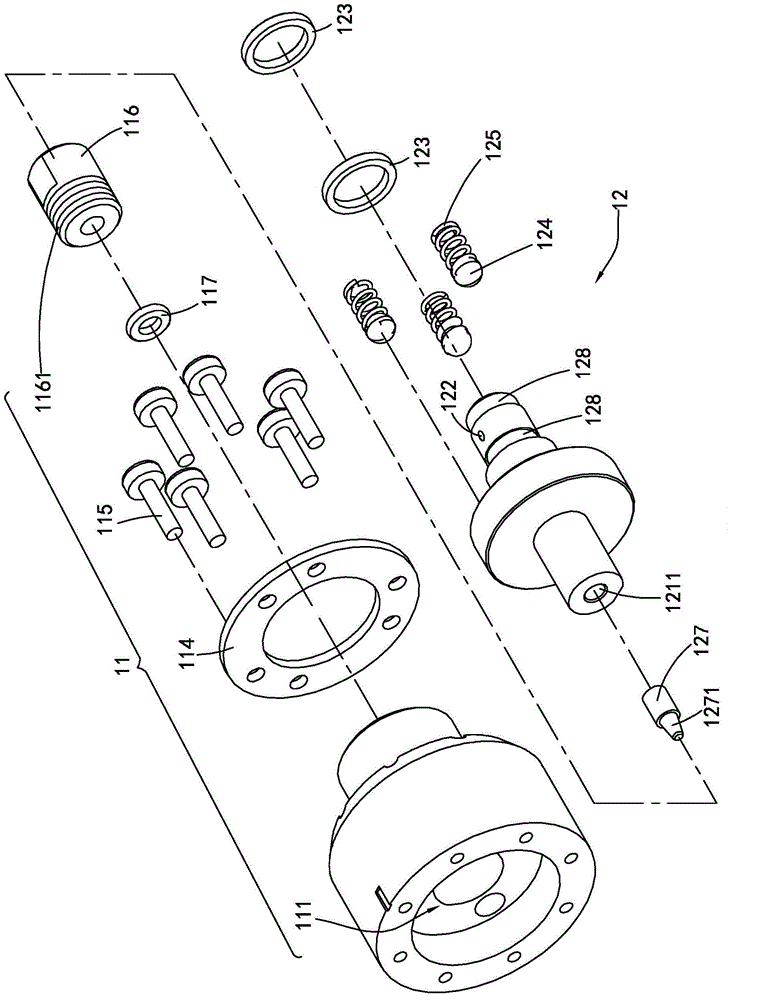

Rotatable Spray Head, Multi-material Spraying Apparatus Using Thereof, And Method For Spraying Multiple Materials

ActiveCN105750115AAvoid mixingAvoid mixing situationsLiquid surface applicatorsMovable spraying apparatusMulti materialMaterial supply

A rotatable spray head, a multiple materials spraying apparatus using thereof and a method of spraying multiple materials are provided. The multiple materials spraying apparatus includes the rotatable spray. An outer shell and an inner tube of the rotatable spray can be correspondingly rotated in order to change the material from one to another. Therefore, multiple materials can be sprayed through one nozzle of the rotatable spray. A recycling step of the method allows the sprayed material to be recycled back to a material supplying pipe or a material holder before switching to the next spraying material, thereby preventing the mixing of different spraying materials during the usage process.

Owner:ZONG JING INVESTMENT

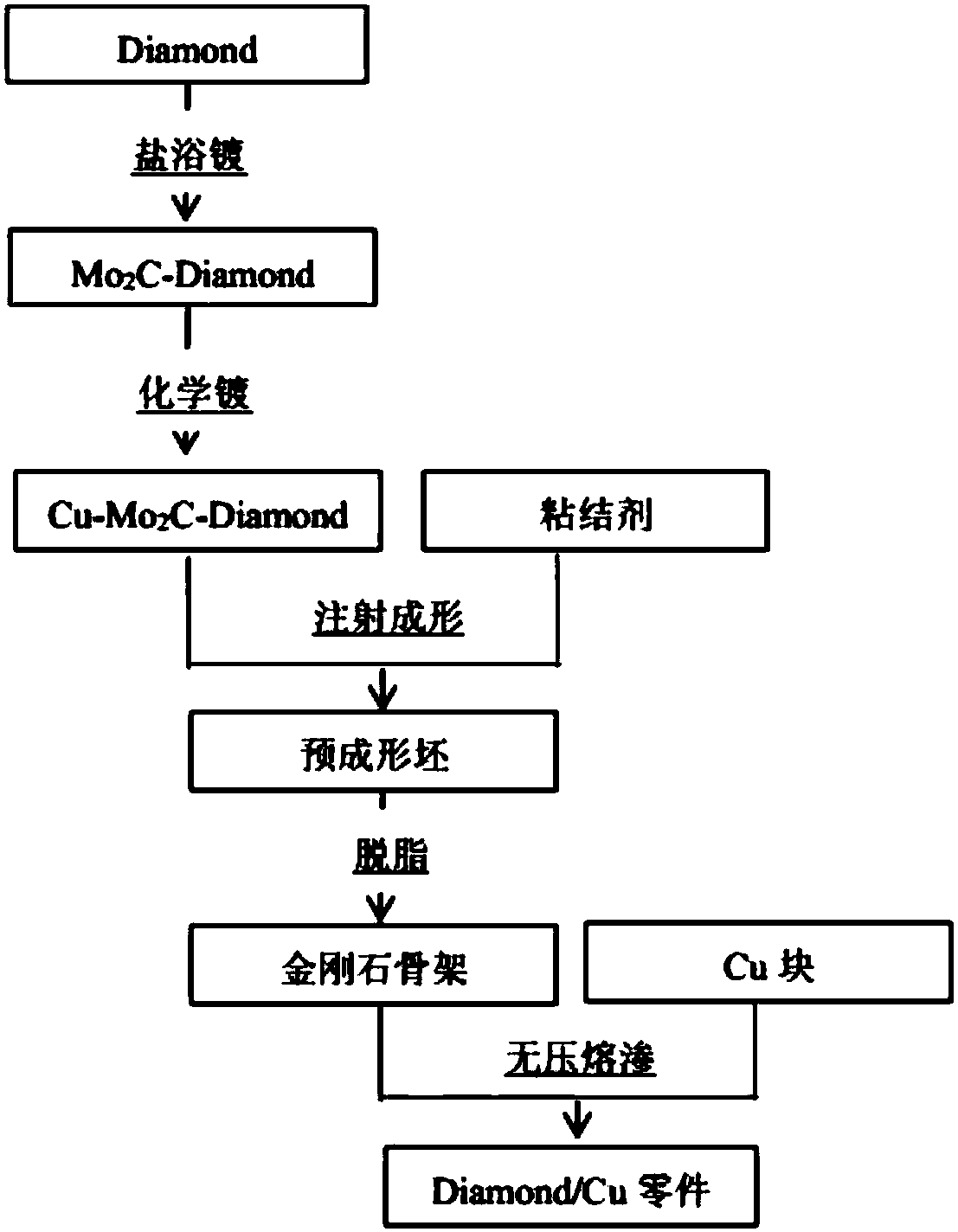

Method for preparing diamond/copper composite material by combining injection molding technology

ActiveCN107855533AHigh densityVolume fraction adjustmentTransportation and packagingMetal-working apparatusChemical platingCopper plating

The invention relates to a method for preparing a diamond / copper composite material by combining an injection molding technology. The method comprises the steps of adopting a salt-bath plating technology for plating a layer of uniform Mo2C on a diamond surface so as to improve the wettability of diamond and copper, then adopting a chemical plating method for continuously plating the copper on a surface of the Mo2C layer, and controlling the thickness of a copper plating layer by controlling the Cu2+ content in a plating solution, so that double-plating Cu-Mo2C-Diamond powder with the copper-bearing volume fraction being 1 percent to 10 percents is prepared; then mixing the quantitative Cu-Mo2C-Diamond powder and a multi-polymer component paraffin base binder to form uniform feeding; afterpelletizing, achieving injection molding on an injection molding machine; and after enabling a preformed blank to pass through a solvent and to be subjected to thermal degreasing, pre-sintering at high temperature, carrying out a vacuum pressureless infiltration technology on the obtained blank, and permeating a copper liquid into a diamond framework through a capillary action of pores, so that adiamond / copper composite material part with high volume fraction is obtained. The method provided by the invention can be used for directly preparing the Diamond / Cu composite material part in a complicated shape, the diamond is high in volume fraction and uniform and compact in texture, and the diamond / copper composite material can be produced in batch and can be low in production cost.

Owner:UNIV OF SCI & TECH BEIJING

Waterborne strippable polyurethane coating and preparation method thereof

The invention relates to a waterborne strippable polyurethane coating and a preparation method thereof. The waterborne strippable polyurethane coating is prepared from the following components and raw materials in parts by weight: 30-70 parts of waterborne polyurethane, 0.1-20 parts of silane modified polyurethane oligomer, 20-70 parts of deionized water, 0.04-1.6 parts of a defoaming agent, 0.04-1.6 parts of a wetting agent, 0-1.6 parts of a thickening agent, 0.04-1.6 parts of a leveling agent and 0.2-5 parts of a coalescing agent. Compared with the prior art, the waterborne strippable polyurethane coating provided by the invention is modified by silane, contains a polyurethane chain segment of carbamate bonds, and can be well dispersed in anionic waterborne polyurethane emulsion to ensure that the emulsion has good film forming property; and meanwhile, silane is connected to the main chain of the polyurethane chain segment by reacting with isocyanate groups, and a silane chain segment trends to be arranged on the surface of a film during film forming to ensure that a coating film has good stripping property, and when a protective film is stripped off, small molecules cannot be left on a coated surface, so that the mixed emulsion can be used for preparing a strippable film.

Owner:SHANGHAI RES INST OF CHEM IND

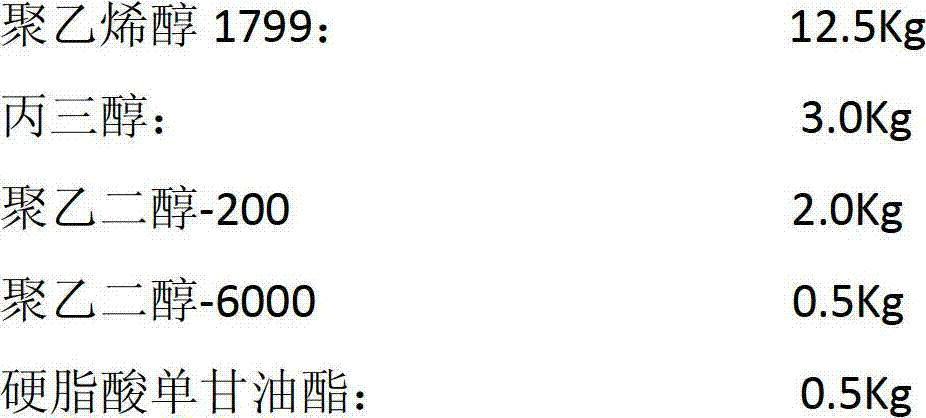

Anti-microbial and bacteriostatic preservative film and production method thereof

InactiveCN103205005AWill not remainHas antibacterial propertiesFruit and vegetables preservationBiotechnologyPolyvinyl alcohol

The invention relates to an anti-microbial and bacteriostatic preservative film and a production method thereof. The preservative film comprises, by weight, 50%-80% of polyving akohol with 500 to 2400 degrees of polymerization and 80% to 99% degrees of alcoholysis, 10% to 25% of water-solubility polyhydroxy plasticizer, 1% to 5% of polyoxyethylene, 1% to 5% of capacity-increase compatilizer and 5% to 15% of other assistants. The production method includes dissolving water-solubility polyhydroxy plasticizer in water with total weight consisted of 4 to 8 times formulation, adding polyving akohol, polyoxyethylene, capacity-increase compatilizer and other assistants, heating up above 95 DEG C to make the mixed solution completely dissolved in water, dispersing for 30 to 60 minutes at high speed, cooling to 50 DEG C to 70 DEG C, preparing a solution used for curtain coating and filming, and finally the preservative film can be prepared by a solution curtain coating method. The preservative film has good anti-microbial and bacteriostatic effects and functions to packed and fresh-keeping fruits and vegetables on the premise of no any extra anti-microbial and bacteriostatic chemical assistants.

Owner:SOUTH CHINA UNIV OF TECH

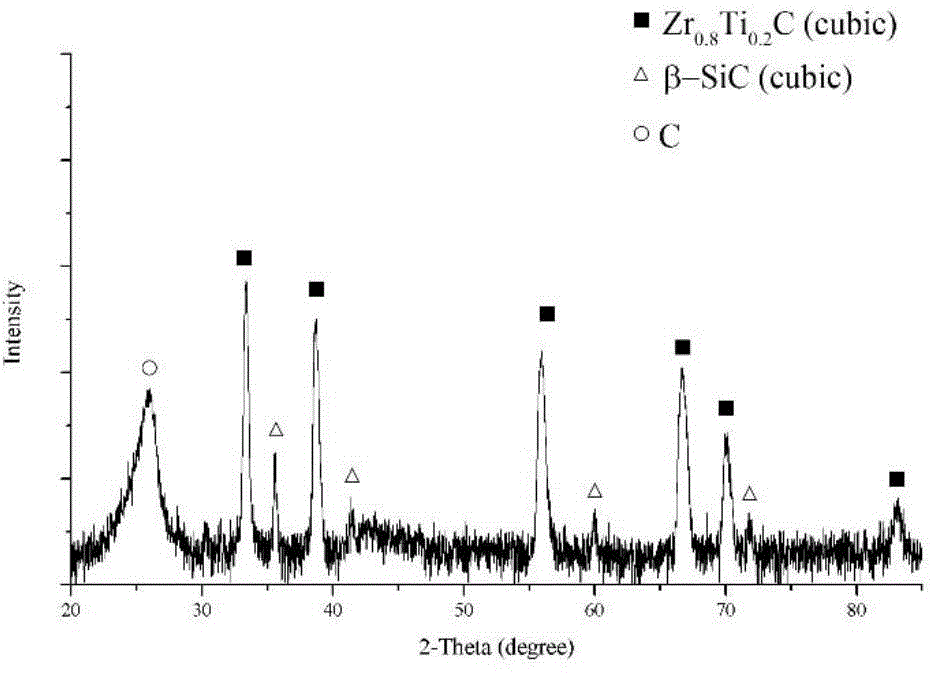

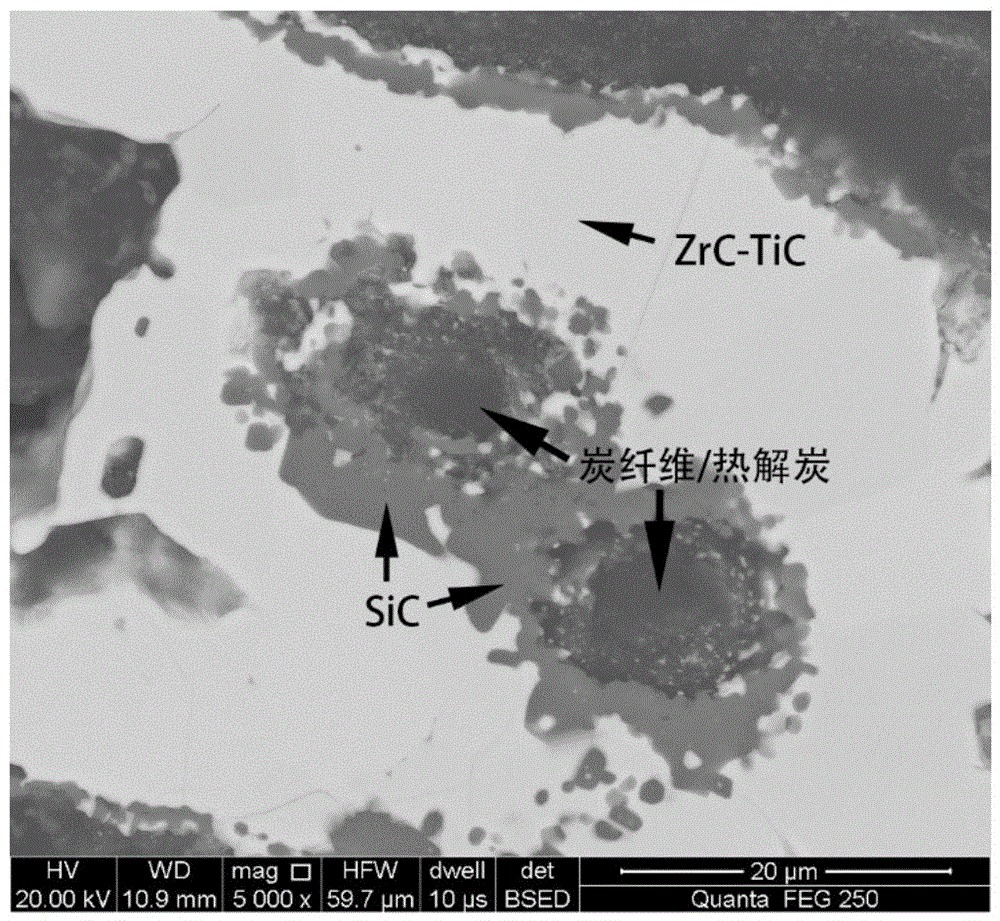

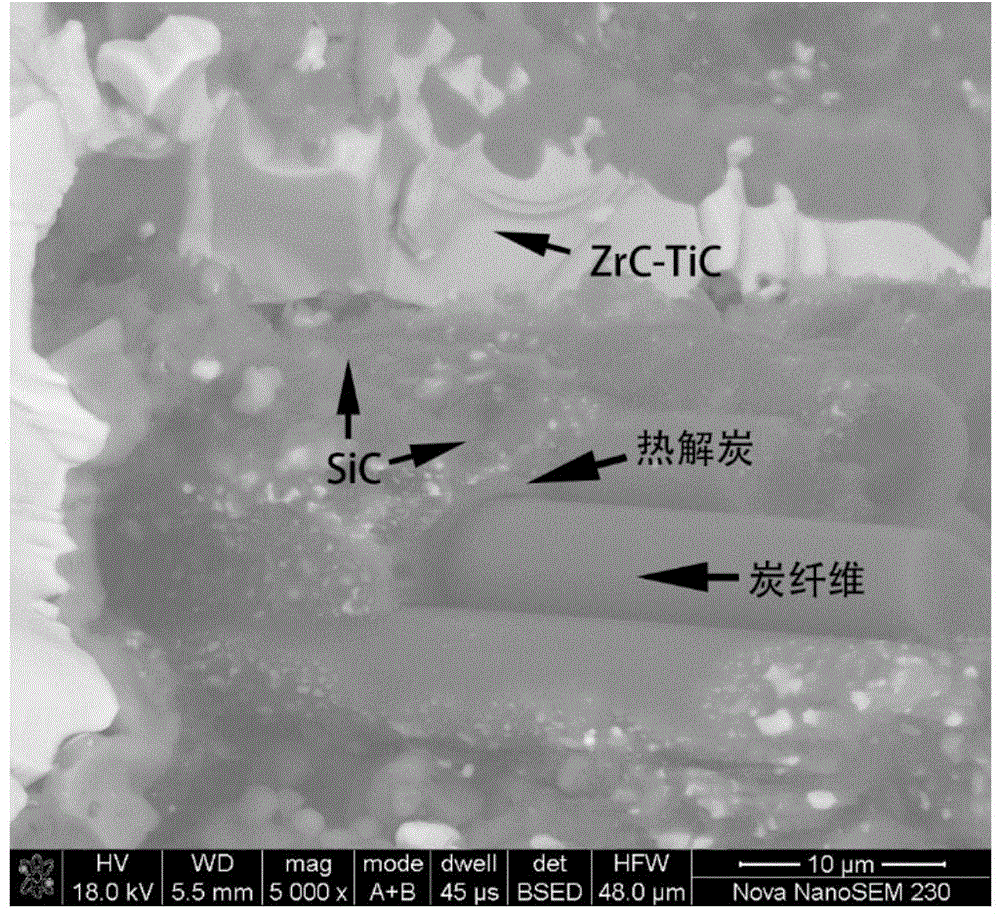

C/C-SiC-ZrC-TiC composite material and preparation method thereof

ActiveCN104671814AReduce thermal mismatchRelieve stress concentrationInterface layerPyrolytic carbon

The invention discloses a C / C-SiC-ZrC-TiC composite material and a preparation method thereof. The composite material is composed of a carbon fibre, a pyrolytic carbon, a main matrix phase ZrC-TiC and a sub matrix phase SiC. The composite material is characterized in that the SiC is used as an interface layer for separating the pyrolytic carbon from the ZrC-TiC. The preparation method comprises the following steps: melting the mixed powder of Zr, Ti and Si, permeating into the inside of the low-density C / C composite material through a capillary action, forming a ceramic phase in a hole through an in situ reaction to obtain the C / C-SiC-ZrC-TiC composite material. The preparation method is rapid and effective and low in cost; the prepared composite material has excellent super-high temperature ablation resistance performance and simultaneously has excellent strength, breaking tenacity and thermal shock resistance.

Owner:深圳金羽先进材料有限公司

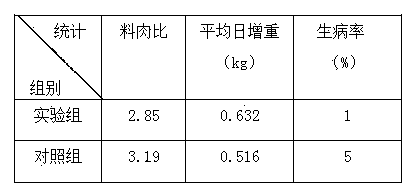

Suckling pig feed and preparation method thereof

The invention discloses a suckling pig feed. The suckling pig feed is prepared from the following raw materials in parts by weight: 80-90 parts of broken rice, 60-70 parts of bran, 50-60 parts of soybean meal, 20-30 parts of corn germ meal, 7-9 parts of peanut shell, 20-25 parts of kelp, 4-5 parts of stellaria yunnanensis, 2-3 parts of sainfoin, 2-3 parts of pear root, 1-2 parts of sepiolite powder, 4-6 parts of pumpkin seed oil, 4-5 parts of an assistant and a proper amount of water. The suckling pig feed disclosed by the invention is reasonable in matching, rich in nutrition, and good in palatability, contains a lot of protein as well as trace elements and compound vitamins necessary for animal growth, and can enhance the immunity of suckling pigs and antibacterial and disease resistant capabilities of pigs, so that the suckling pigs have small possibility of suffering from diseases such as diarrhea and edema, and can grow healthily. In addition, the suckling pig feed does not contain any chemical elements such as antibiotics, growth promoting agents or stimulants, so that bodies of grown suckling pigs cannot have residues of harmful substances, the quality and taste of pork are improved, and people can eat the pork of the pigs fed with the suckling pig feed produced by the invention at ease.

Owner:枞阳县翠平生态综合养殖场

Online particle sampling unit of minitype fluidized bed and application thereof

ActiveCN104198223ARealize the collectionRealize analysisWithdrawing sample devicesLine tubingFluidized bed

The invention relates to an online particle sampling unit of a minitype fluidized bed and application of the online particle sampling unit. The online particle sampling unit comprises a back blowing system, a reaction system, a scavenging system and a differential pressure sampling system; the back blowing system and the scavenging system, which are independent mutually, are used for back-blowing a sampling tube and scavenging a sampling bottle respectively, inert gas constantly purges the sample tube during sampling, the taken-out catalyst particles are ensured to be from a fluidized bed layer; a three-way valve adjusting part is used to control the flowing of blowback air, sampling and the back pulse jetting of the blowback air, so that particles cannot be left on the sampling tube and the sampling bottle, and the back blowing efficiency is greatly improved; and the catalysts can be quantitatively taken out by pressure control of the differential pressure sampling system and the volume control of the sampling bottle. The online particle sampling unit has the advantages that the catalysts can be quantitatively taken out, the sampling tube and the sampling bottle can be completely back-blown and scavenged, and no residual particles are left.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

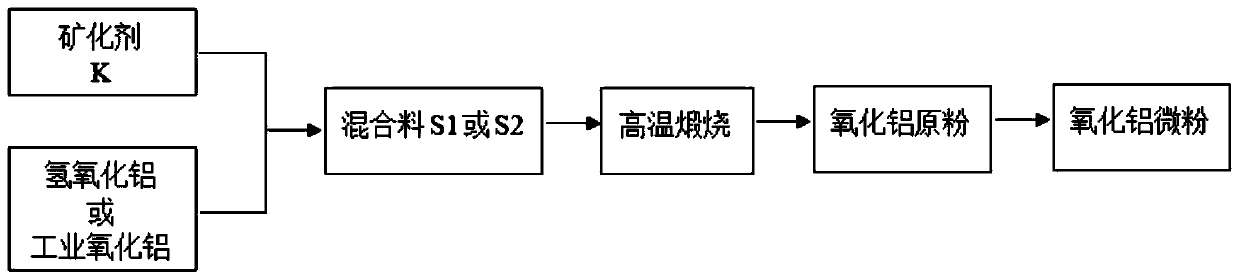

Preparation method of low-sodium and high-activity special alpha-Al2O3 micro powder

InactiveCN110342556AWide variety of sourcesHigh chemical purityAluminium compoundsAluminium hydroxideHigh activity

The invention discloses a preparation method of low-sodium and high-activity special alpha-Al2O3 micro powder. The preparation method comprises the steps that aluminum hydroxide or industrial aluminaserves as main raw materials, and ammonium chloride and aluminum fluoride serve as a mineralizer; the aluminum hydroxide or the industrial alumina and the mineralizer are mixed, a mixture is subjectedto high-temperature calcination to prepare low-sodium and high-specific-surface-area alpha-Al2O3 raw powder, the alpha-Al2O3 raw powder is placed into a ball mill for grinding, and the alpha-Al2O3 micro powder is prepared. According to the preparation method, the raw materials are wide in source, sodium removal is conducted through the ammonium chloride and aluminum fluoride composite mineralizer, the whole technology is completed through one step, neither a drying technology after acid pickling and nor silicon sand screening with silicon sodium removal is not needed, the overall cost is low,boric oxide and silicon dioxide do not remain in a final product, the alpha-Al2O3 micro powder is high in chemical purity, low in sodium oxide content, high in specific surface area and high in activity, the alpha-aluminum oxide conversion rate is greater than or equal to 96.0%, and grain size distribution is reasonable.

Owner:苏州盛曼特新材料有限公司

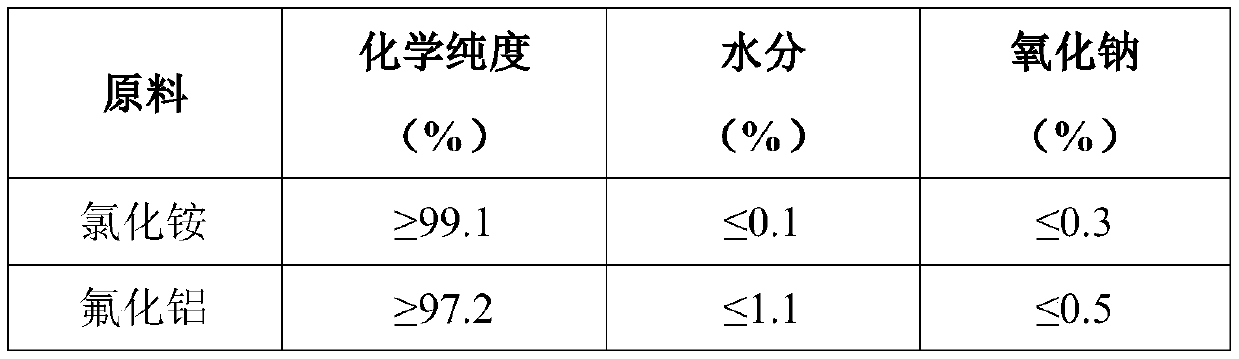

Wafer grinding process

InactiveCN101677055AProtect the active surfaceEasy to removePolishing machinesSemiconductor/solid-state device manufacturingAdhesiveColloid

The invention relates to a wafer grinding process which comprises the following steps: providing a wafer which comprises an active surface and a back surface, wherein, a plurality of protrudent components are formed on the active surface; forming a liquid adhesive for covering a plurality of protrudent components on the active surface of the wafer; pre-curing the liquid adhesive for forming a solid-liquid colloid for covering the active surface of the wafer and filling in a plurality of protrudent component; bonding an adhesive tape on the solid-liquid colloid; implementing the crystal back grinding process on the back surface of the wafer; and removing the adhesive tape and the solid-liquid colloid, thereby exposing a plurality of protrudent components on the active surface of the wafer.

Owner:高宏明

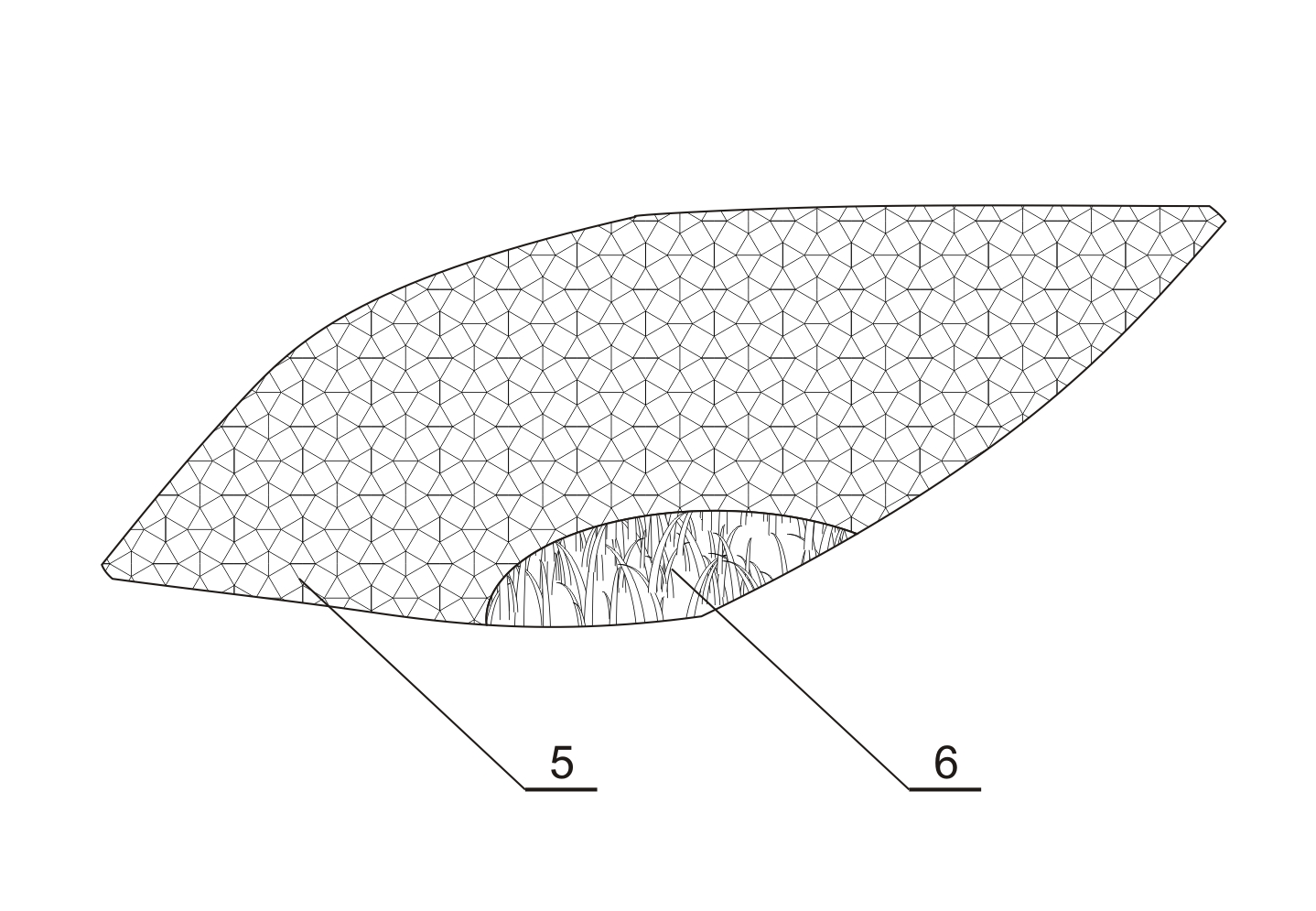

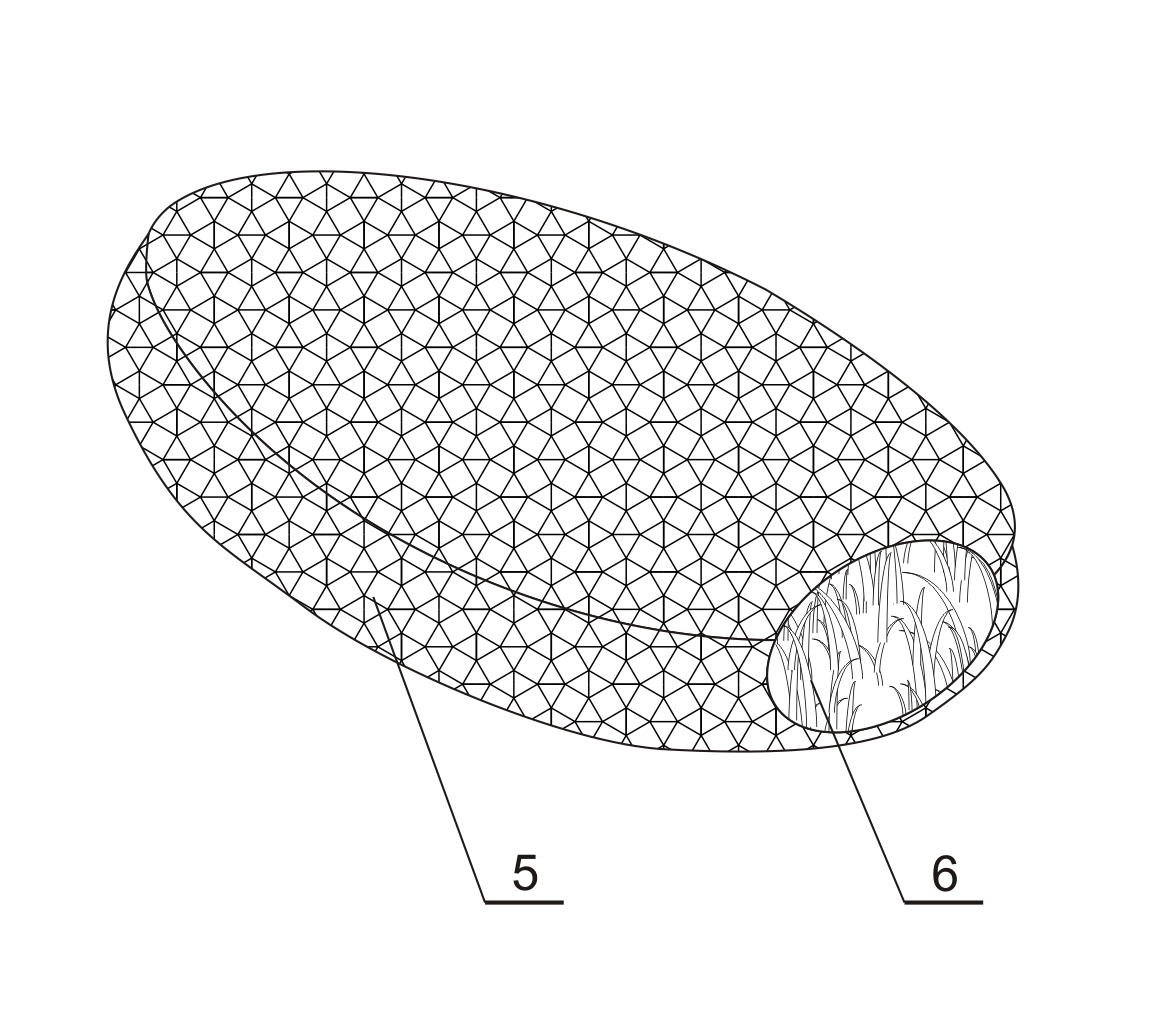

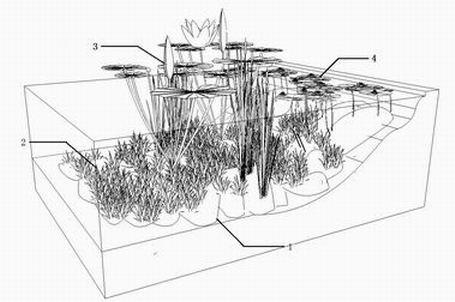

Method for planting hard artificial landscape water-body aquatic plants

InactiveCN102160522AComplete structureVitalityCultivating equipmentsSoilless cultivationLandscape designFiber

The invention discloses a method for planting hard artificial landscape water-body aquatic plants. The method comprises the following steps of: filling natural plant fibers in mesh bags which are woven by using degradable fibers to form a plant growing carrier; planting different aquatic plant seeds in the plant growing carrier according to the requirements on landscape designs; placing the plant growing carrier with the different aquatic plant seeds in water bodies with hardened underwater or poor underwater matrixes according to the requirements on the landscape designs, and the like. By the method for planting the aquatic plants, the transparency of landscape water bodies is improved, the dissolved oxygen is increased, the eutrophication degree is reduced, the landscape performance is high, and the ecological system becomes perfect gradually.

Owner:EAST CHINA NORMAL UNIV

Alley cleaning device used for garden

The invention relates to a cleaning device, in particular to an alley cleaning device used for a garden. The alley cleaning device used for the garden is high in work efficiency and clean in sweep. The alley cleaning device used for garden comprises a trolley and the like. A cleaning device is installed on the left side of the top portion of the trolley, and a dust exhaust device is installed on the right side of the top portion of the trolley. The alley cleaning device used for garden cleans an alley through the cleaning device, and exhausts the rubbishes which are cleaned out through the exhaust dust device; a swing device can be driven by the cleaning device to work; the exhaust dust device can be driven by the swing device to work; and the dust collection scope is increased ,so that the cleaning effect is improved.

Owner:台州市路桥高精模具厂

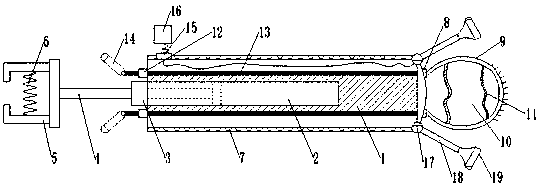

Urinary stone breaking device of urinary surgery

InactiveCN108175475AEliminate hidden dangersAvoid messy tangled situationsSurgeryUrologic surgeryVisual observation

The invention belongs to the technical field of medical instruments, and particularly relates to a urinary stone breaking device of a urinary surgery. Aiming at the problems that a larger wound is brought to a patient and stone cannot be clearly treated, a following scheme is provided. The urinary stone breaking device is characterized by comprising an access rod, wherein a round inner tube is arranged in one end of the access rod; the inner wall of the round inner tube is connected with a piston in a sliding and inserting way; the outer wall of one side of the piston is welded with a telescopic rod; a limiting nut is fixedly arranged in the middle position of the outer wall of one end of the access rod; threaded connection is formed between the limiting nut and the telescopic rod; the outer wall of one end, which is far away from the access rod, of the telescopic rod is welded with a connecting plate. The urinary stone breaking device disclosed by the invention is capable of thoroughly breaking stones of a patient, eliminating hidden dangers during a stone breaking process of the patient, enabling a treated position of the patient to have stronger visual observation performance, creating a better environment for stone breaking operation of the patient, preventing broken stone residues from remaining in a urinary system, and eliminating the follow-up hidden danger of forming stones again.

Owner:荆涛

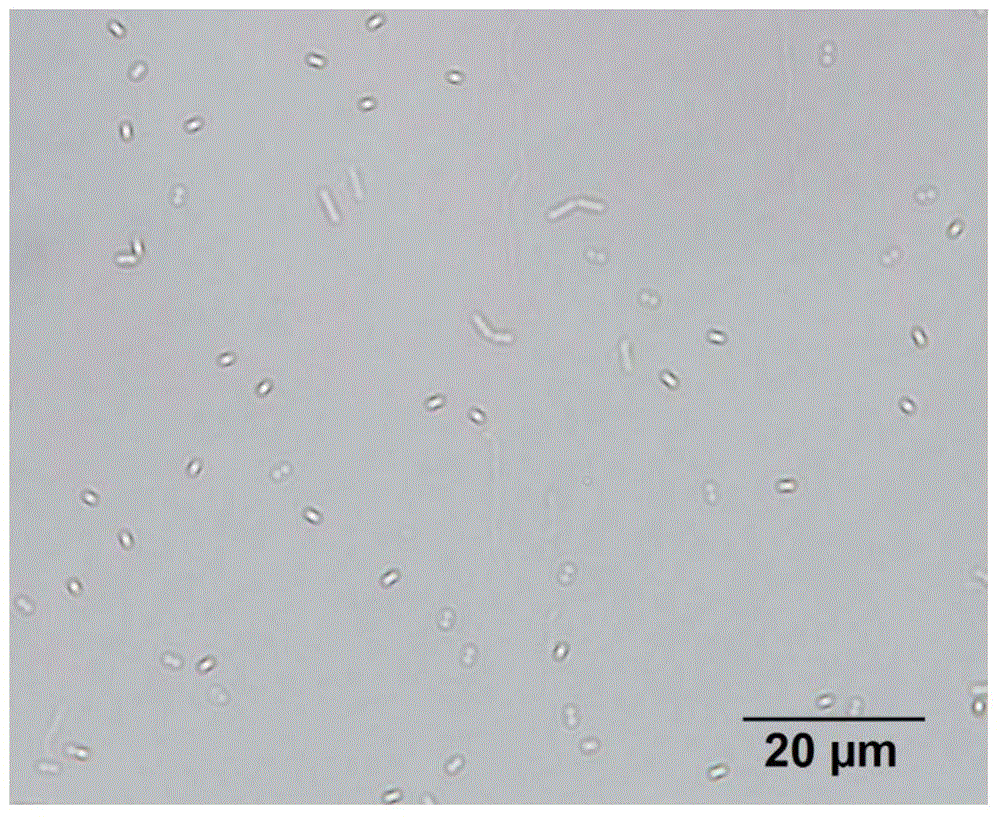

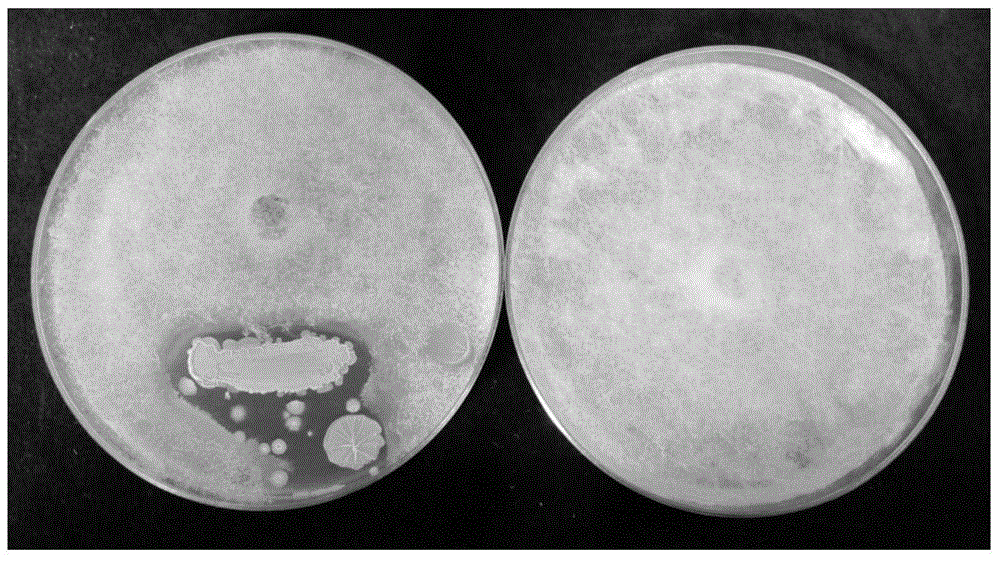

Bacillus amyloliquefaciens and application thereof

ActiveCN104371944ARealize prevention and controlWill not remainFruit and vegetables preservationBacteriaFungal diseaseBacillus amyloliquefaciens

The invention discloses Bacillus amyloliquefaciens strain, the preservation number of the strain is CGMCC NO.8040. On the other hand, the invention also provides a bacteria agent, wherein the bacteria agent contains live bacteria of the Bacillus amyloliquefaciens strain and a culture medium. On the other hand, the invention also provides the application of the Bacillus amyloliquefaciens strain and / or bacteria agent in the prevention and treatment of fungal diseases of fruits. In another aspect, the invention also provides a method for prevention and treatment of fungal diseases of fruits, and the method includes contact of the bacteria agent of the live bacteria of the Bacillus amyloliquefaciens strain with the fruits. Through the technical proposal, the Bacillus amyloliquefaciens strain can effectively realize the prevention and treatment of fungal diseases of fruits, and is free of residue of harmful chemical substances.

Owner:BEIJING LYUHUAN INT SCI & TECH

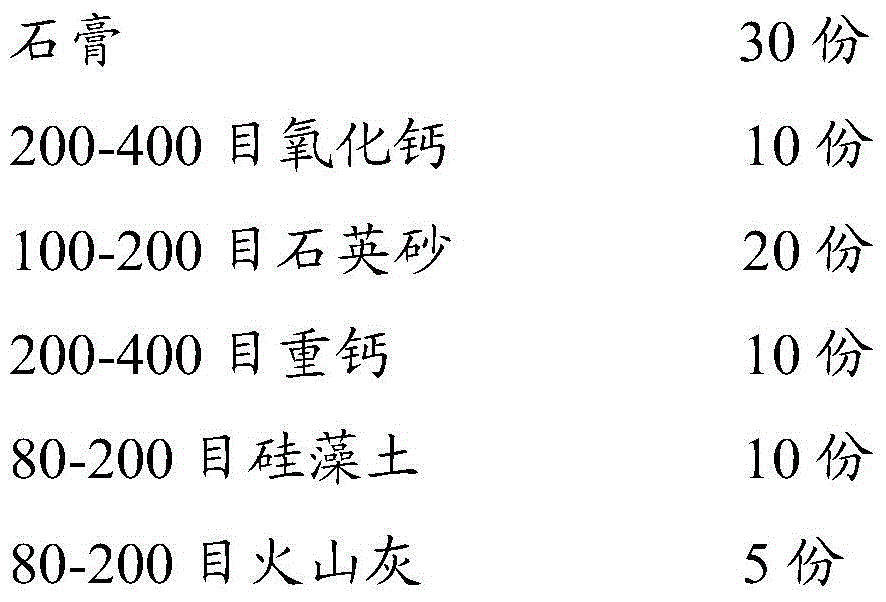

Indoor wall base bottom layer leveling mud with purification function and preparation and construction method

Belonging to the technical field of building base materials, the invention discloses an indoor wall base bottom layer leveling mud with purification function and a preparation and construction method thereof. Leveling putty comprises the following raw materials by weight: 20-50 parts of gypsum, 5-20 parts of 200-400mesh calcium oxide, 20-50 parts of 100-200mesh quartz sand, 10-30 parts of 200-400mesh heavy calcium carbonate, 10-30 parts of 80-200mesh diatomite, 5-10 parts of 80-200mesh volcanic ash, 5-20 parts of 100-200mesh non-calcined diatomite, 1-10 parts of 100-200mesh attapulgite, 1-10 parts of 200-800mesh magnesium aluminosilicate, 0.5-10 parts of 10-30nm nano-zinc oxide, and 0.5-10 parts of 10-30nm nano-titanium dioxide, etc. The leveling mud provided by the invention has the environmental protection functions of regulating humidity and preserving heat, purifying air, decomposing formaldehyde and the like.

Owner:白山和一硅藻科技股份有限公司

Patterned photoresist layer forming method and wafer-stage chip packaging method

InactiveCN104516194ALow costSimple forming processPhotomechanical apparatusSemiconductor/solid-state device manufacturingComputational physicsPhotoresist

A patterned photoresist layer forming method and a wafer-stage chip packaging method are disclosed. The wafer-stage chip packaging method comprises following steps: (1) during manufacturing of a patterned photoresist layer used for forming a re-wire arrangement, coating a substrate with a first photoresist layer in a first viscosity being less than 100cp so that the first photoresist layer is a low-viscosity photoresist layer; (2) coating the first photoresist layer with a second photoresist layer in a second viscosity being higher than the first viscosity; and (3) performing exposure and development to the first photoresist layer and the second photoresist layer. Because that adhesivity of the low-viscosity photoresist layer is weaker than that of the high-viscosity photoresist layer, the patterned photoresist layer, compared with a patterned photoresist layer in the prior art, is easier to remove, so that residue of the patterned photoresist layer in through holes is avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Formula and preparation method of human lubricant

InactiveCN104800894AMild in natureImprove lubricityOrganic active ingredientsSurgeryTremellaGlycerol

The invention belongs to the field of human lubricants, and relates to a formula and a preparation method of a human lubricant. The formula comprises the following components in parts by mass: 0.05-0.5 parts of tremella polysaccharide and 0.1-1.5 parts of preservative. The preparation method of the vaginal lubricant comprises the steps that polyacrylamide resin, glycerol, propylene glycol and 1,3-butanediol are sufficiently mixed; an aqueous medium is uniformly mixed; the preservative is added; and the human lubricant is obtained. Compounded agents used by the natural antibacterial lubricant are good in lubrication, mild in property, colorless and odorless, have no adverse effect on a human, have antibacterial and anti-inflammatory action, can be dissolved in water, are convenient to clean, and cannot remain on the surface of human skin, so that the lubricant is safe and effective.

Owner:海洁(重庆)卫生用品股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com