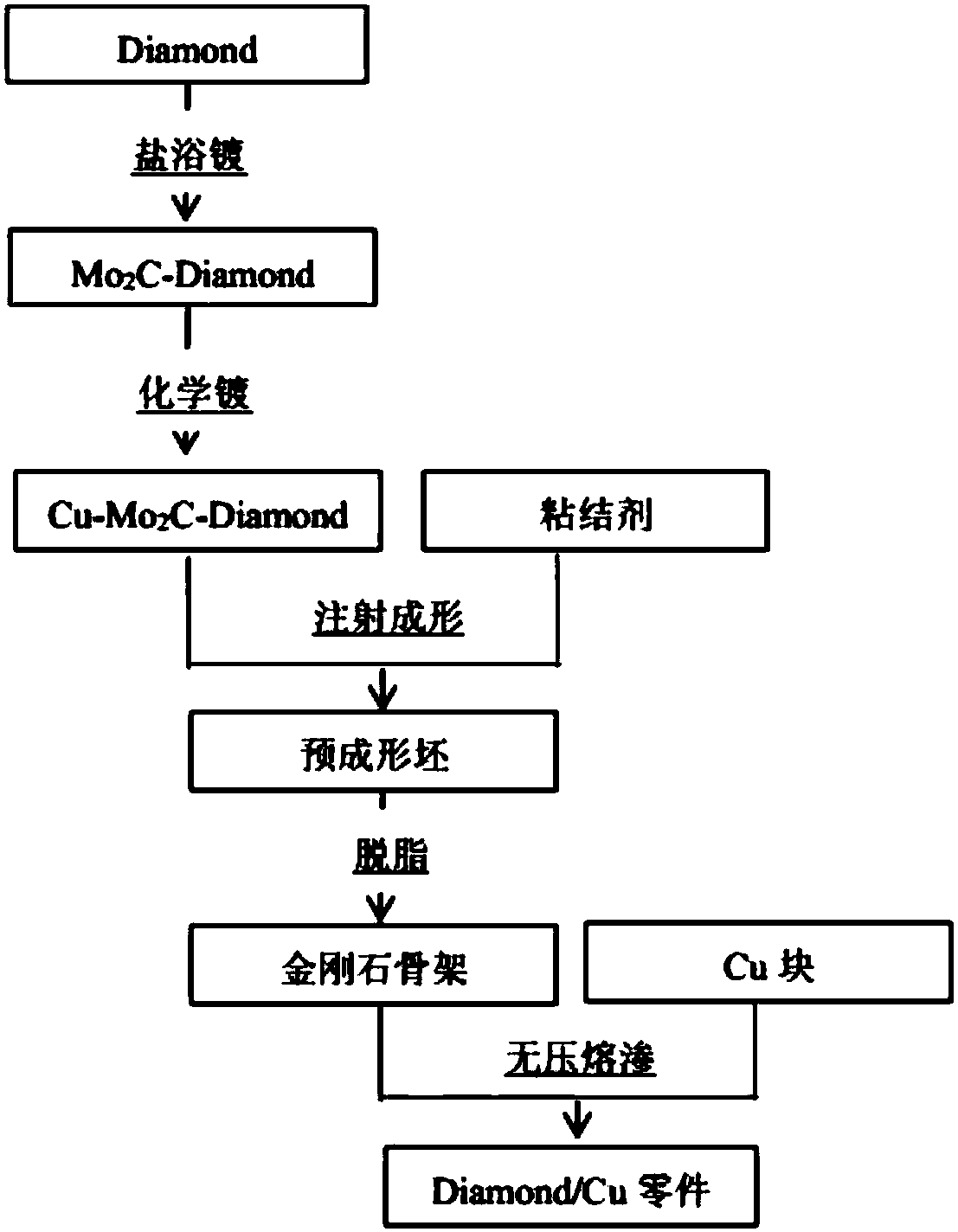

Method for preparing diamond/copper composite material by combining injection molding technology

A composite material, injection molding technology, applied in metal processing equipment, coating, transportation and packaging, etc., can solve the problems of diamond/Cu composite material machining difficulties, to overcome machining difficulties, simple production equipment, reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: the Diamond / Cu composite material part that preparation diamond volume fraction is 70%

[0015] Step 1: Weigh 10g of diamond powder, MoO 3 Powder 12g, mixed salt NaCl-KCl (molar ratio NaCl:KCl=1:1) 30g, use a powder mixer to mix evenly. The mixed powders were heated to 1000 °C for 3 h in a rapid heating tube electric furnace, during which an Ar atmosphere was introduced for protection. The reaction product is cleaned, dried, and sieved to obtain the surface-coated Mo 2 C layer of diamond powder.

[0016] Step 2: Weigh the coated Mo 2 C layer of diamond powder 8g placed in 0.4L of SnCl 2 (30g / L) deionized aqueous solution for surface sensitization, and then placed in 0.4L of PdCl 2 (0.25g / L) deionized aqueous solution for surface activation. Finally, the treated diamond powder is subjected to electroless copper plating, and 0.056L of copper sulfate plating solution is prepared, wherein the formula of copper sulfate plating solution is: CuSO 4 ·5H 2 ...

Embodiment 2

[0019] Embodiment 2: the Diamond / Cu composite material part that preparation diamond volume fraction is 60%

[0020] Step 1: Weigh 10g of diamond powder, MoO 3 Powder 24g, mixed salt NaCl-KCl (molar ratio NaCl:KCl=1:1) 40g, use a powder mixer to mix evenly. The mixed powder was heated to 1050 °C for 2 h in a rapid heating tube electric furnace, during which an Ar atmosphere was introduced for protection. The reaction product is cleaned, dried, and sieved to obtain the surface-coated Mo 2 C layer of diamond powder.

[0021] Step 2: Weigh the coated Mo 2 C layer of diamond powder 8g placed in 0.4L of SnCl 2 (30g / L) deionized aqueous solution for surface sensitization, and then placed in 0.4L of PdCl 2 (0.25g / L) deionized aqueous solution for surface activation. Finally, the treated diamond powder is subjected to electroless copper plating, and 0.280 L of copper sulfate plating solution is prepared, wherein the formula of copper sulfate plating solution is: CuSO 4 ·5H 2 O...

Embodiment 3

[0024] Embodiment 3: the Diamond / Cu composite material part that preparation diamond volume fraction is 50%

[0025] Step 1: Weigh 10g of diamond powder, MoO 3 Powder 36g, mixed salt NaCl-KCl (molar ratio NaCl:KCl=1:1) 50g, use a powder mixer to mix evenly. The mixed powder was heated to 1100 °C for 1 h in a rapid heating tube electric furnace, and an Ar atmosphere was introduced for protection during this period. The reaction product is cleaned, dried, and sieved to obtain the surface-coated Mo 2 C layer of diamond powder.

[0026] Step 2: Weigh the coated Mo 2 C layer of diamond powder 8g placed in 0.4L of SnCl 2 (30g / L) deionized aqueous solution for surface sensitization, and then placed in 0.4L of PdCl 2 (0.25g / L) deionized aqueous solution for surface activation. Finally, the treated diamond powder is subjected to electroless copper plating, and 0.592L of copper sulfate plating solution is prepared, wherein the formula of copper sulfate plating solution is: CuSO 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com