Patents

Literature

219results about How to "Achieve near net shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

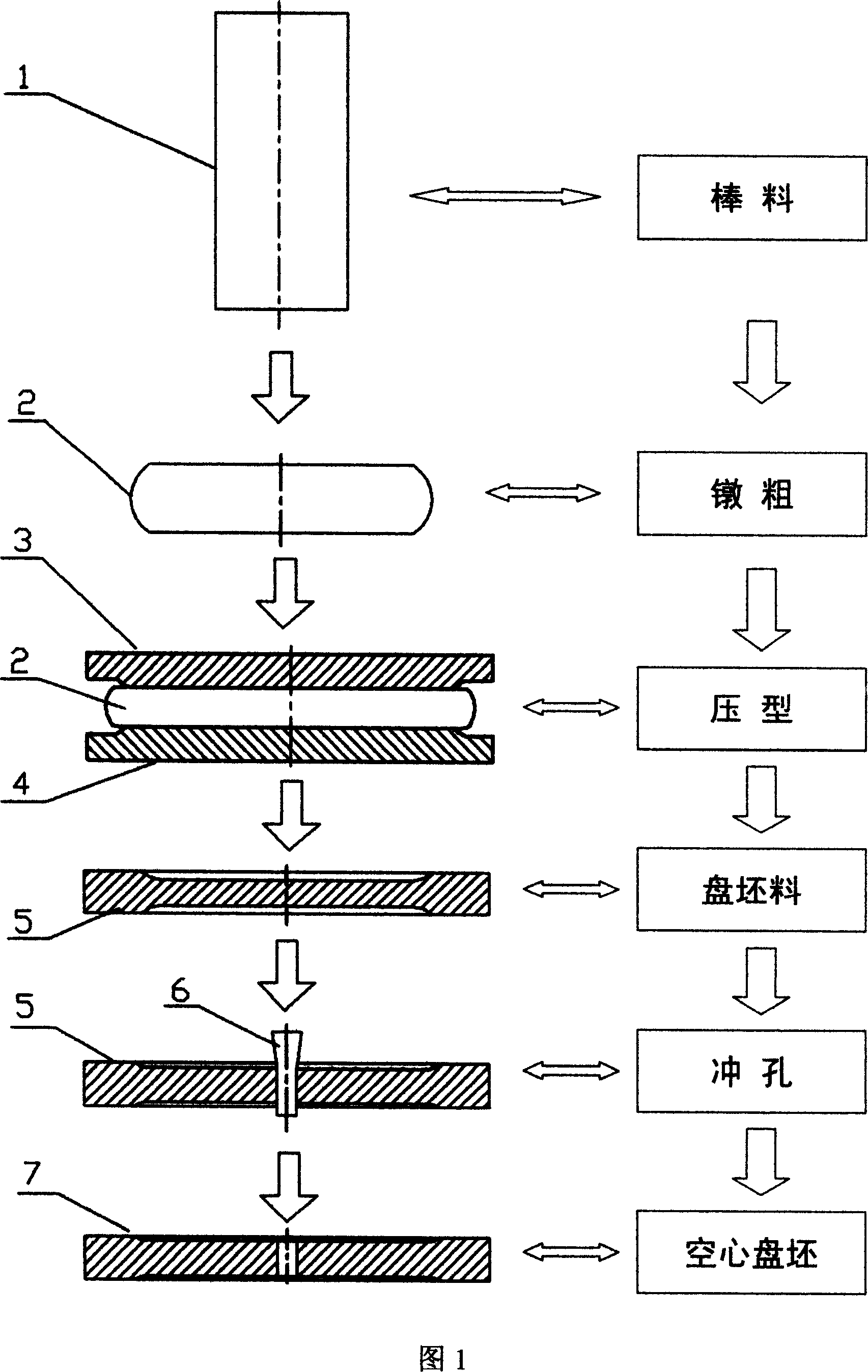

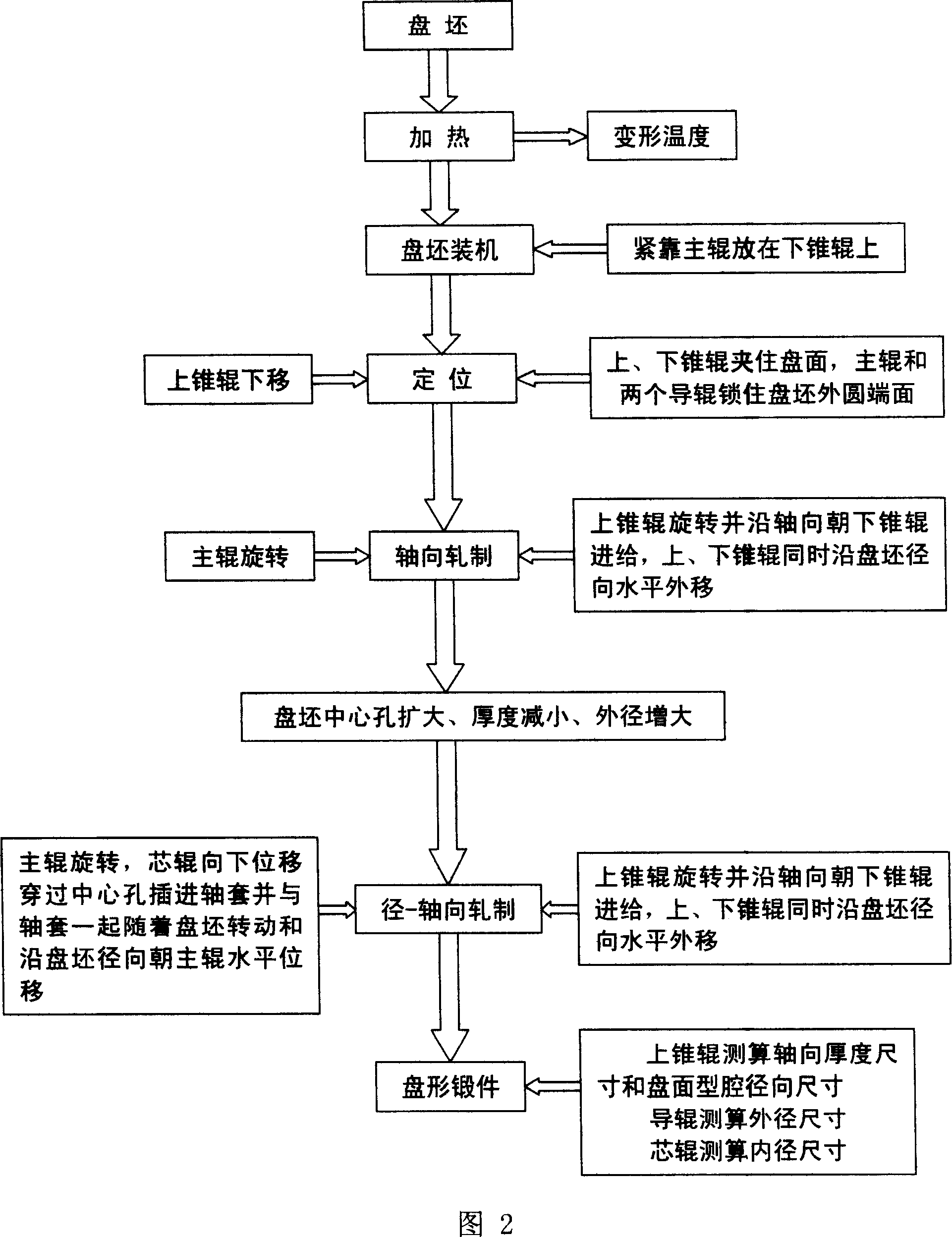

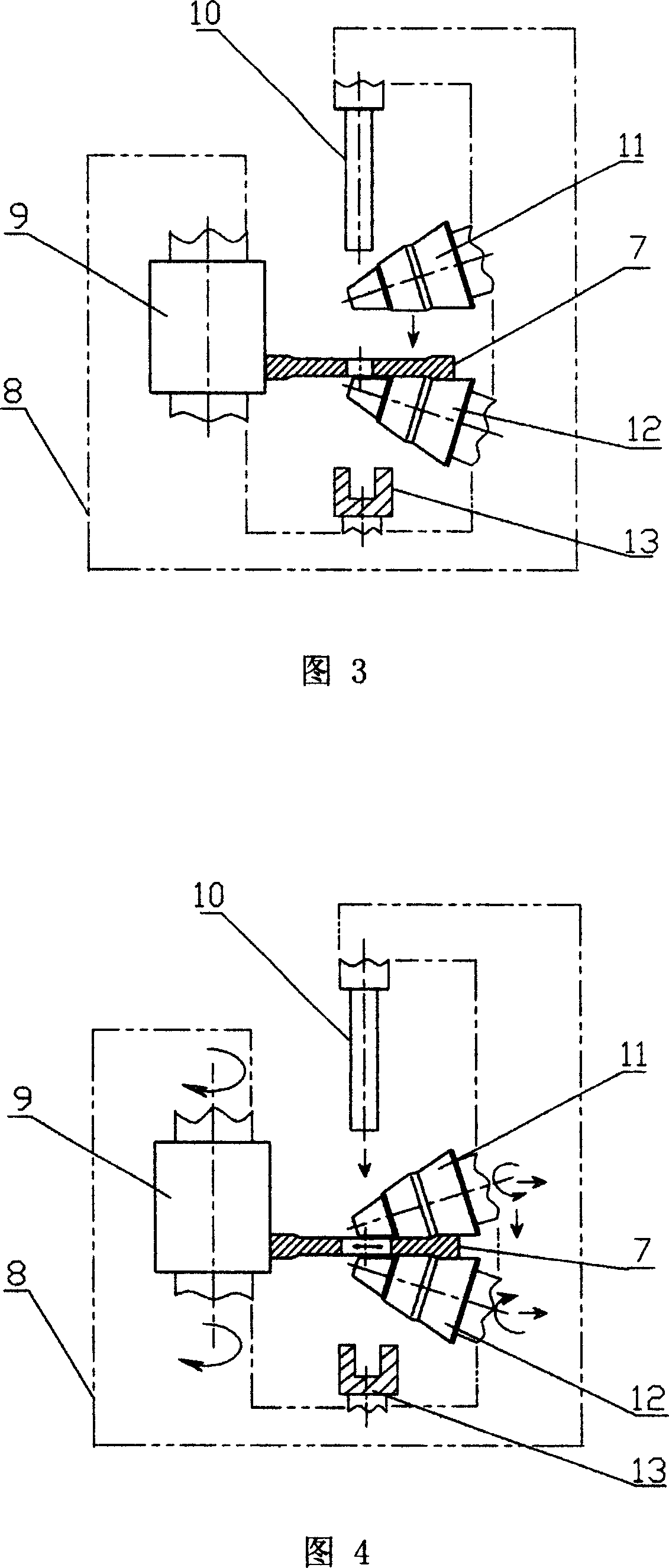

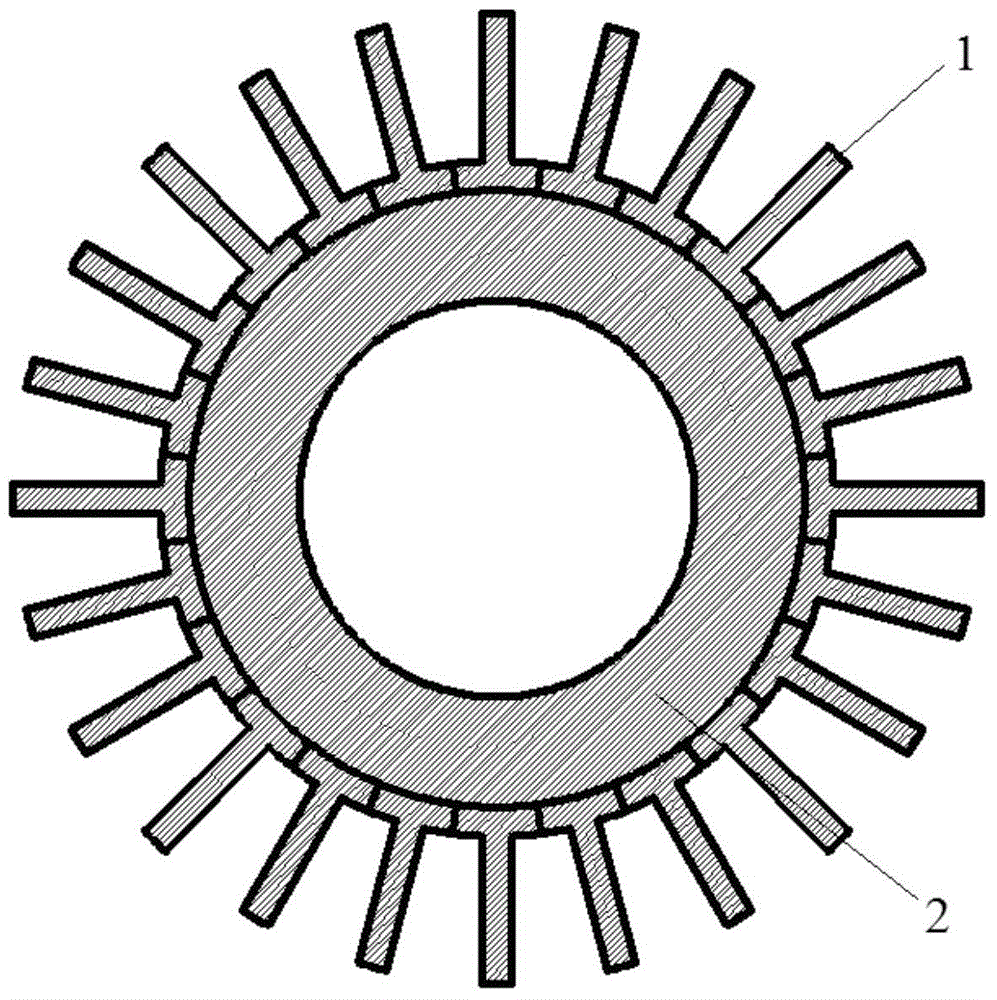

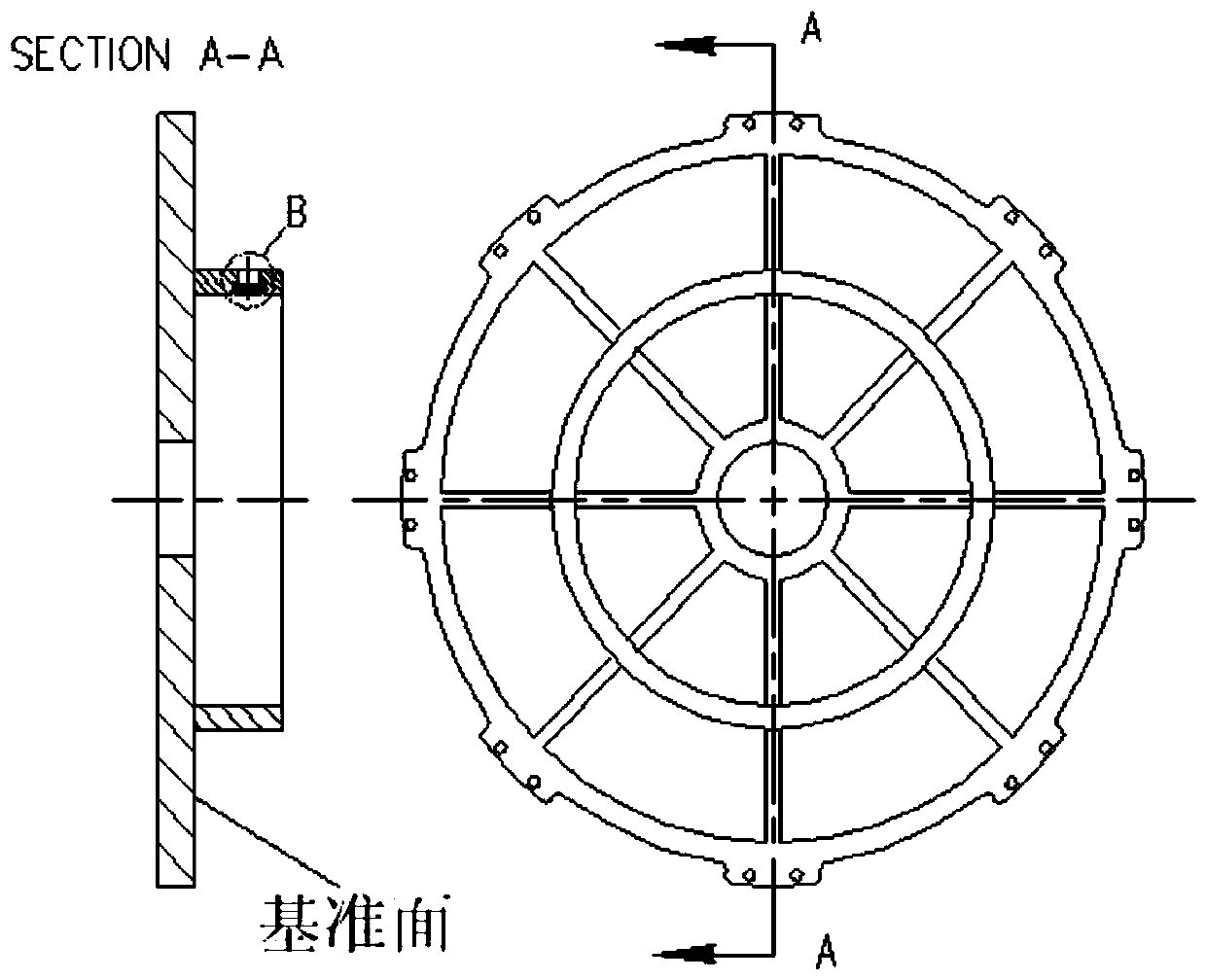

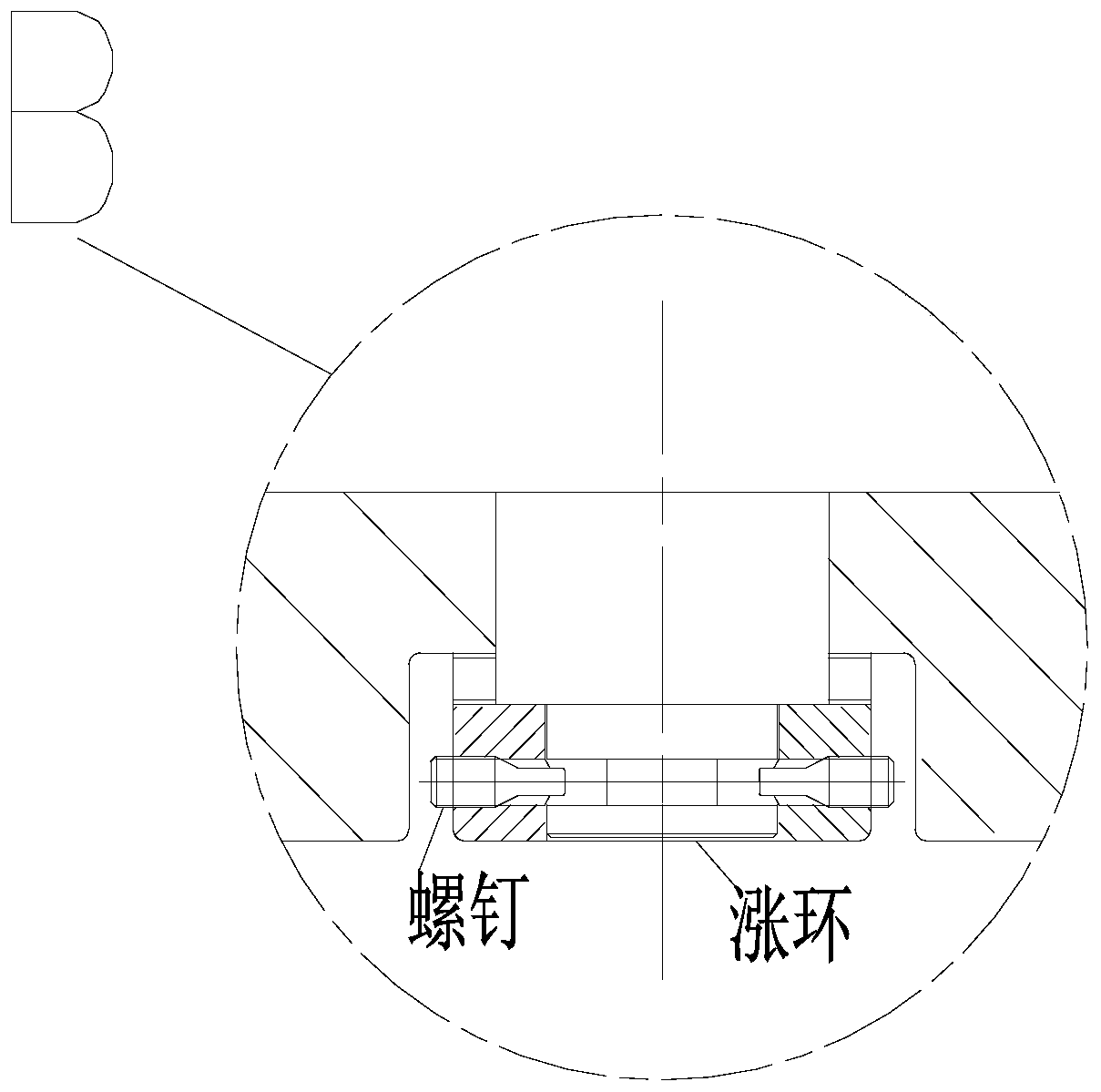

Rolling forming process for large hollow disc forging

ActiveCN101020282ARadial wall thickness reductionReduce axial thicknessRoll force/gap control deviceMeasuring devicesMaterials scienceMetal

The technological process of rolling and forming large hollow disc forging includes the steps of: deforming metal rod material, heating, upsetting to form cake blank, profiling to obtain disc blank, punching hole to obtain hollow disc blank, heating, locating, axial rolling, radial and axial rolling, and measuring size to obtain hollow disc forging. The rolling process has axial rolling force of (2-5)x10<5> kg, radial rolling force of (5-20)x10<4> kg, and broadening speed of 5-15 mm / s. The rolled disc forging has outer diameter of 800-3000 mm, inner diameter of 300-2000 mm and thickness of 30-250 mm. By means of altering the conic size and sizes of the conic roll, disc forgings of different sizes may be rolled. The present invention can form disc forging continuously and form large forging in small apparatus.

Owner:GUIZHOU ANDA AVIATION FORGING

Method for producing silicon-based ceramic core for aircraft engine blade

The invention discloses a method for producing a silicon-based ceramic core for an aircraft engine blade. The method comprises the steps of: producing the complex ceramic core through hot injection molding by utilizing three high-purity silica powders with different particle sizes as raw materials, the high-purity silica powder in large particle size as a framework, the high-purity silica powder in small particle size as sintering additives, paraffin and beewax as plasticizers, and oleic acid as a surface active agent, carrying out low-temperature dewaxing and high-temperature roasting to themolded bisque ceramic core in a padding alumina to finally obtain the silicon-based ceramic core for the aircraft engine blade.

Owner:BEIHANG UNIV

Preparation method of aluminum-alloy gas meter end cover

InactiveCN101598585AReduce weightImprove anti-corrosion performanceVolume meteringMechanical pressureAir tightness

The invention discloses a preparation method of an aluminum-alloy gas meter end cover, which is characterized by comprising the following steps: (1) respectively configurating aluminum alloy material and magnesium; (2) melting and refining; (3) pretreating and extruding cast mould; (4) extruding and moulding; (5) carrying out heat processing; and (6) carrying out post-processing. Compared with the prior art, the invention has the advantages that aluminum alloy material and advanced indirect extruding and casting process are adopted, so that the moulding material of the gas meter end cover is light in weight and good in corrosion resistance performance; the aluminum alloy melt solution is crystallized at a higher mechanical pressure, the crystal grain is refined, the organizational density is increased, and the defects of porosity, shrinkage, needle eye and the like inside the casting are eliminated, thereby significantly increasing the air tightness, hardness and tensile strength of the casting.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

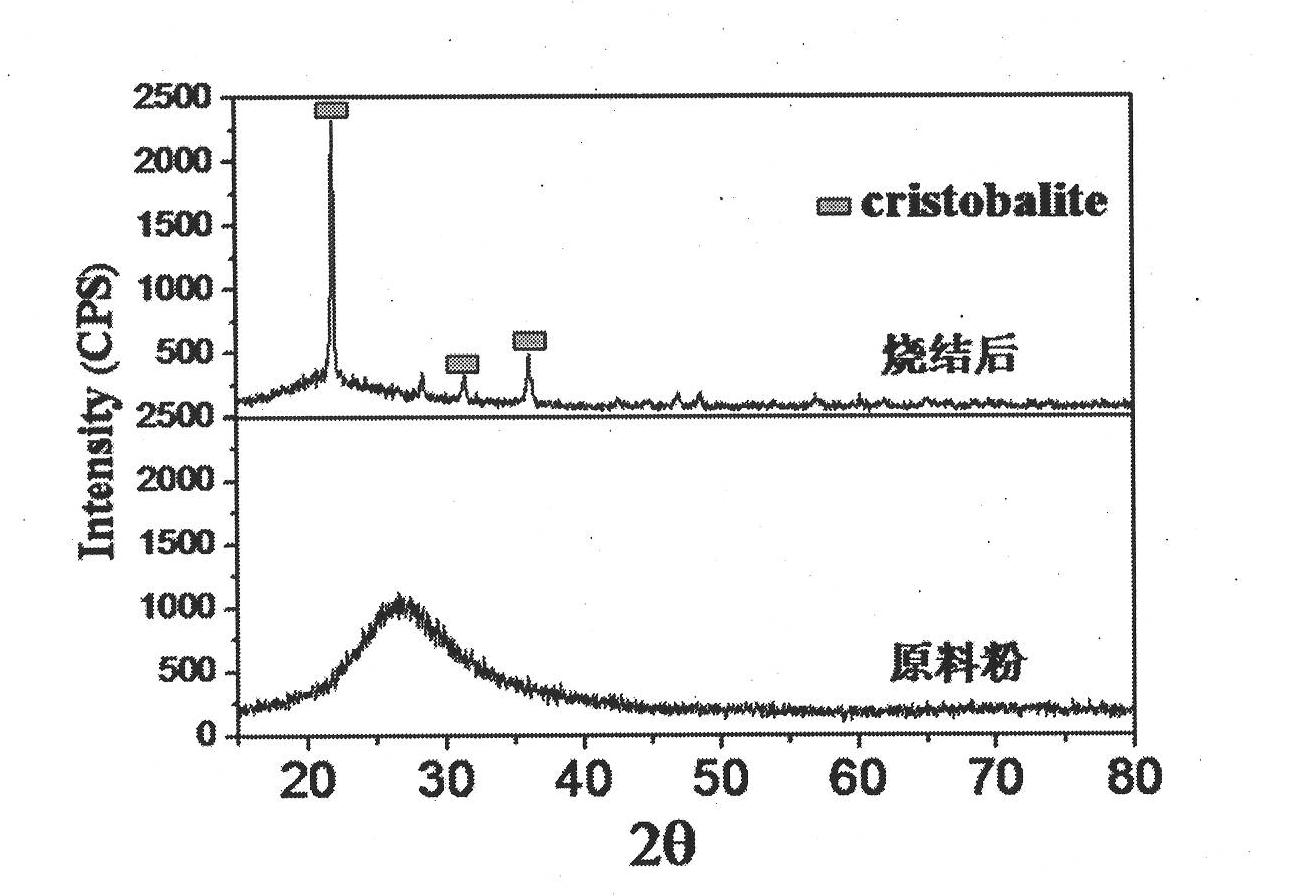

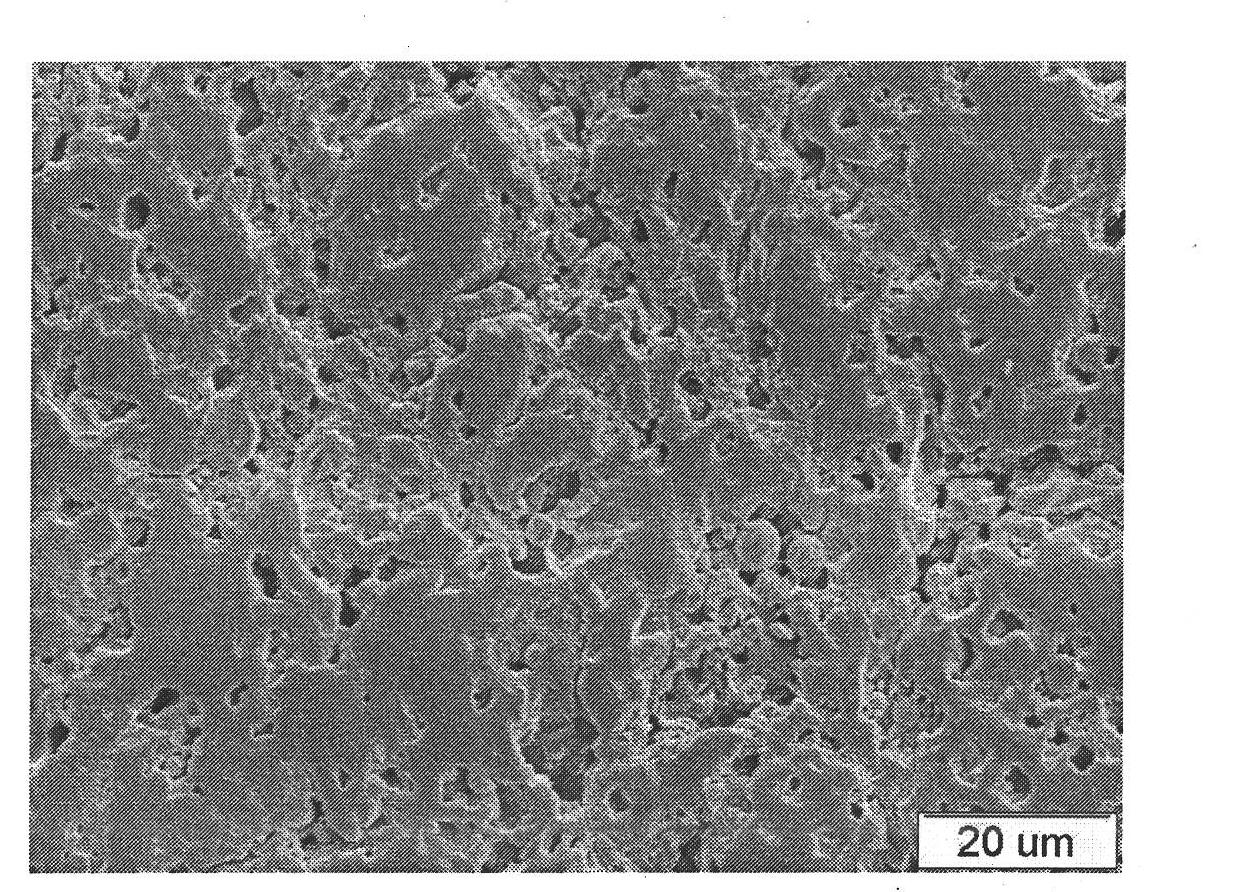

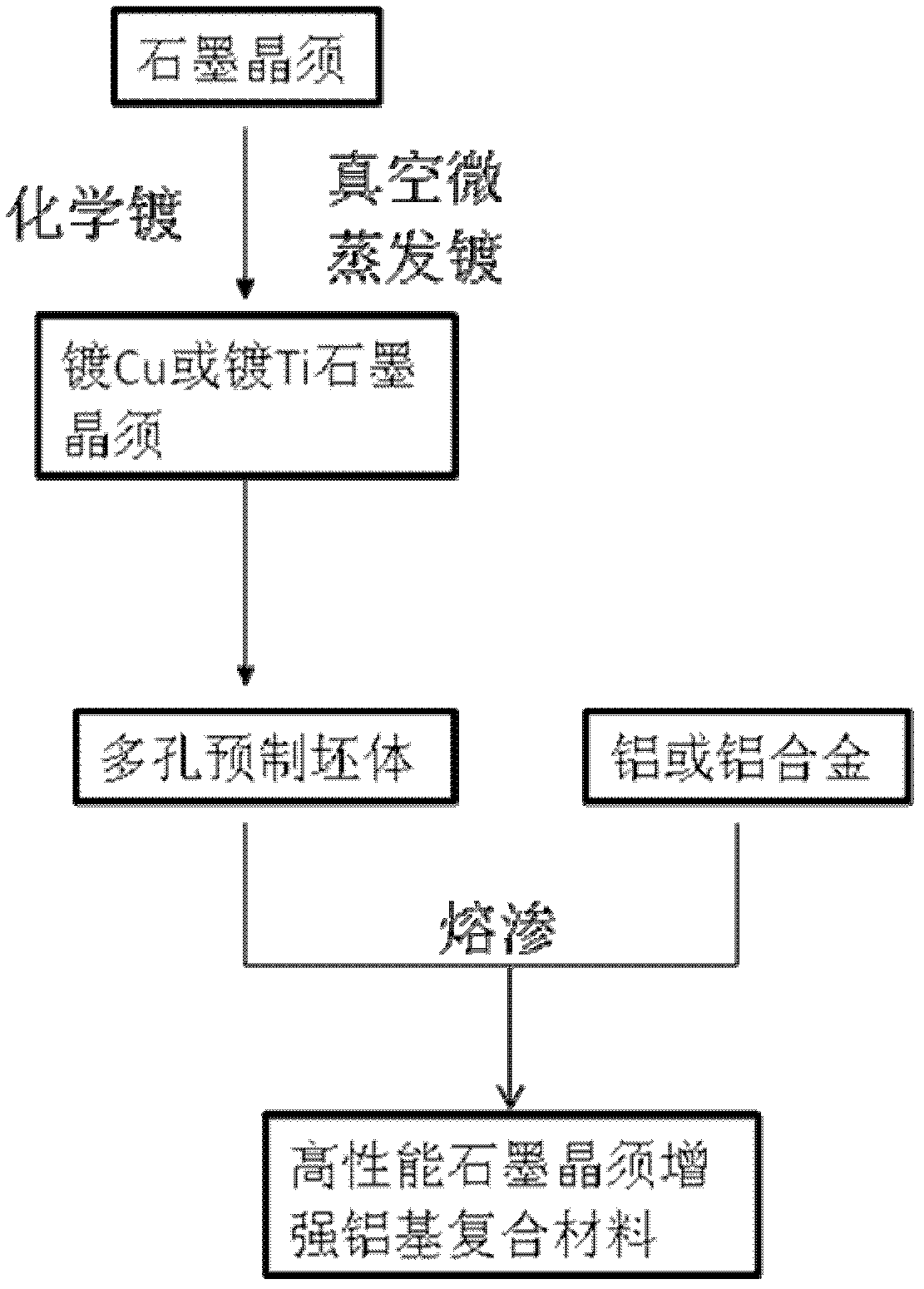

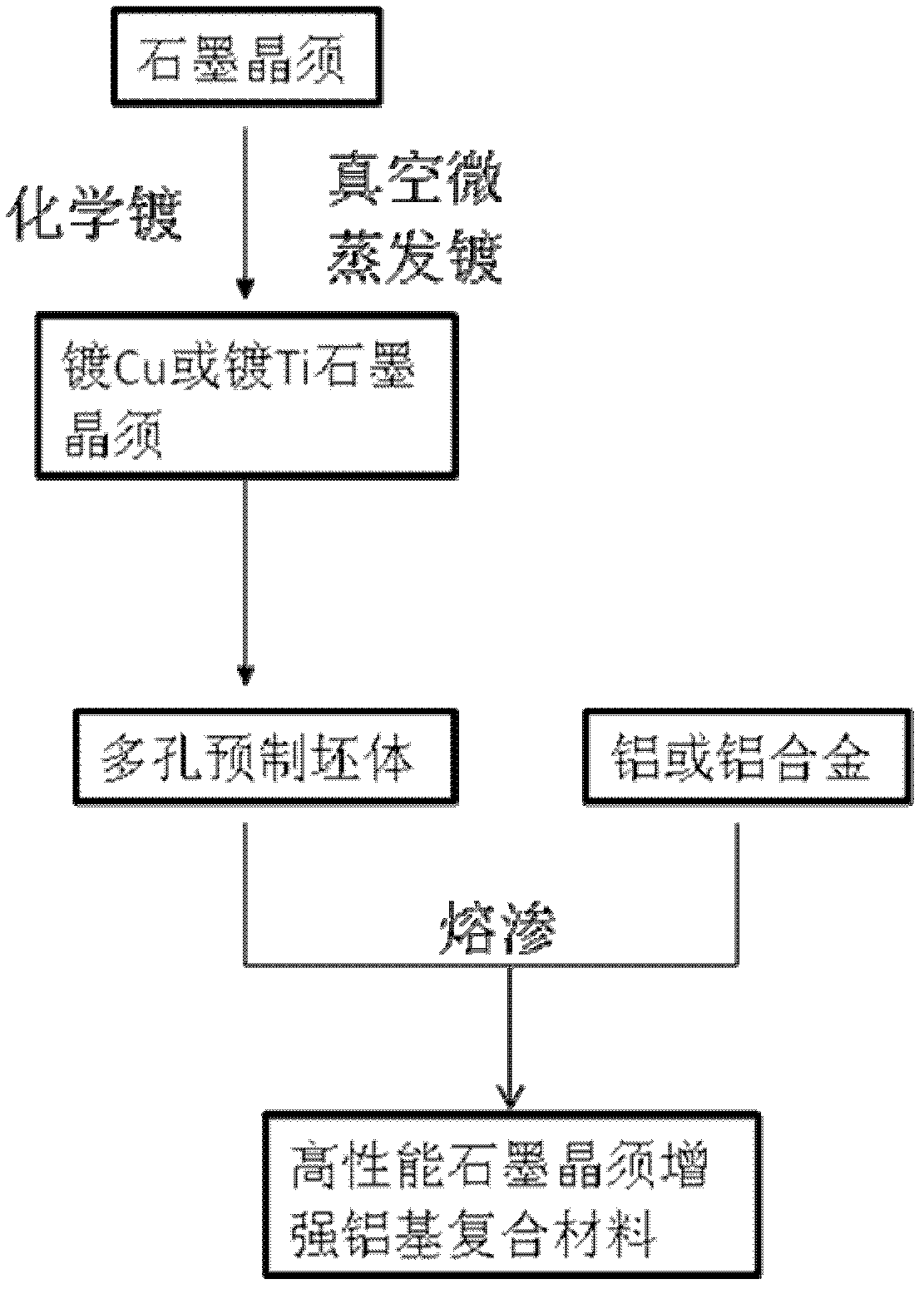

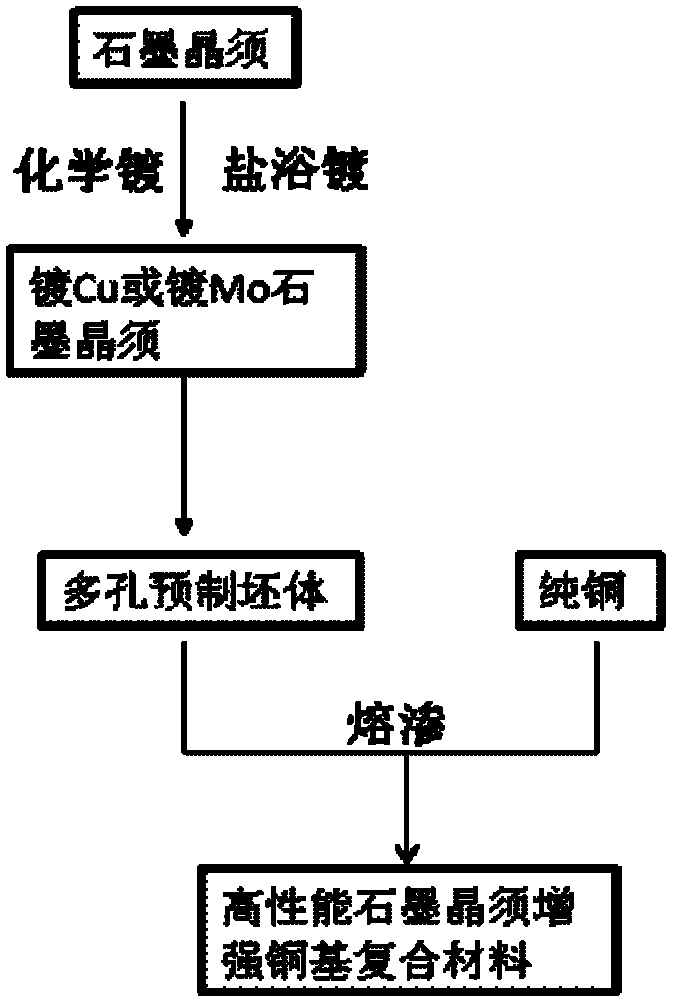

Method for preparing graphite whisker reinforced aluminum matrix composite material

InactiveCN102586703AHigh thermal conductivitySmall coefficient of thermal expansionThermal dilatationChemical plating

The invention discloses a method for preparing a graphite whisker reinforced aluminum matrix composite material. The composite material consists of plated high-reinforced-phase heat conducting graphite whiskers and matrix aluminum or aluminum alloy, wherein the volume fraction of the matrix aluminum or the aluminum alloy is 40%-65%, and the volume fraction of the plated graphite whiskers is 35%-60%. The production process comprises the steps of 1 adopting a chemical plating or vacuum salt bath plating method to plate copper or titanium on the surfaces of the graphite whiskers so as to form a plating layer with thickness of 0.1-1.5mum; 2 adding an appropriate amount of binder on the graphite whiskers with modified surfaces to perform die forming, and then adopting thermal degreasing to remove the binder and manufacture a porous prefabricated blank; and 3 stacking up the prefabricated blank and the aluminum or the aluminum alloy to perform vacuum pressure infiltration processing so as to finally obtain a graphite whisker-aluminum composite material part. The composite material prepared by means of the method has the advantages of being high in heat conductivity, low in thermal expansion coefficient, light in weight, high in densification, easy to process and the like.

Owner:UNIV OF SCI & TECH BEIJING

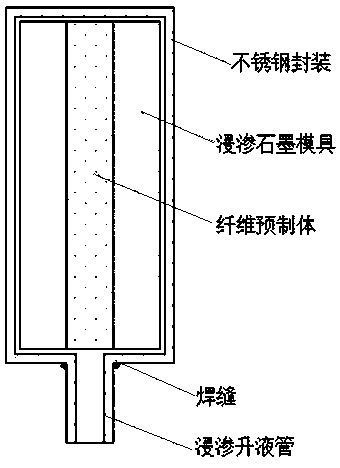

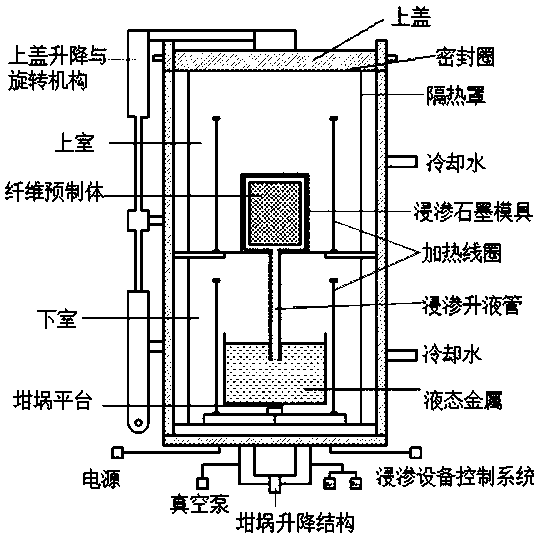

Near-net forming method of 3D braided fiber reinforced metal-based composite material

The invention discloses a near-net forming method of the 3D braided fiber reinforced metal-based composite material, and belongs to the technical field of advanced composite materials. The method is characterized in that a vacuum air pressure infiltration preparation technology based on a liquid binder is adopted to assist in accurately controlling the shape and the size of a 3D braided fiber preform structure; in the 3D weaving process of the fiber preform, a liquid binder is adopted to accurately fix and shape the 3D braided fiber preform, then the size precision of the 3D braided fiber reinforced metal-based composite material is accurately controlled through the impregnated graphite mold of the embedded fiber preform, and deformation and local fiber polarization of the 3D braided fiberpreform in the infiltration process are prevented. The prepared 3D braided fiber reinforced metal-based composite material has high dimensional accuracy and excellent mechanical properties, the near-net forming of the 3D braided fiber reinforced metal-based composite material is realized, batch industrial production can be realized, the near-net forming method has a wide application prospect in the fields of aerospace, national defense, military and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

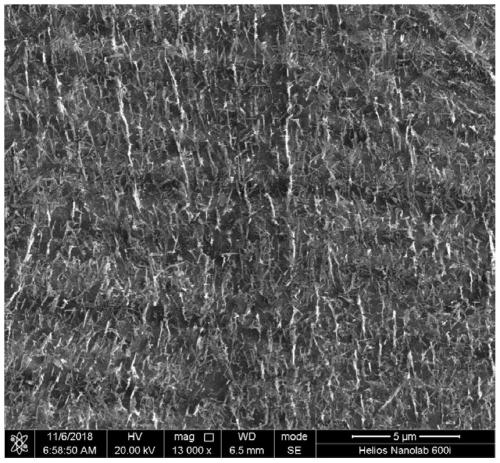

Method for preparing titanium-based nano composite material based on selective laser melting 3D printing

InactiveCN109943786ALight in massHigh thermodynamic stabilityAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingTitanium matrix composites

The invention discloses a method for preparing a titanium-based nano composite material based on selective laser melting 3D printing, relates to a method for preparing the titanium-based nano composite material, and aims at solving the problem of poor cutting processing performance of titanium and the titanium-based composite material. The method comprises the steps that preparation is conducted,wherein composite powder is prepared through ball milling, and the content of B4C powder in the composite powder is (0.5-1) wt%; selective laser melting 3D printing is utilized for shaping. The methodhas the advantages that the mass of the prepared composite material is light, the thermodynamic stability is high, the strength is high, the wearing resistance is high, fixture tools or molds are notneeded in the shaping process, 'near net shape forming' is easily achieved, the composite material can be massively prepared in a short time, and sources of raw materials are wide; substrate crystalline grains of the prepared composite material are significantly fined, in-site generated complete nano scale TiB whiskers are diffusely distributed on boarders of substrate crystalline grains, an obvious enhancing effect on the composite material is achieved, the mechanical performance is significantly improved, and the method is suitable for preparing the titanium-based nano composite material through 3D printing.

Owner:HARBIN INST OF TECH

Titanium-aluminium alloy blisk and manufacturing method thereof

InactiveCN104625629ASolve technical problemsReduce technical difficultyPump componentsPumpsTitaniumMetal

The invention provides a titanium-aluminium alloy blisk and a manufacturing method of the titanium-aluminium alloy blisk. The method includes the steps of firstly, manufacturing a disc piece and blades of the blisk; secondly, combining the disc piece and the blades according to preset positions, placing the disc piece and the blades in a coating device, and coating the outer face of the disc piece and the outer faces of the blades with metal wrapping covers according to the appearance of the disc piece and the blades so as to obtain prefabricated blanks wrapped by the wrapping covers, wherein the thicknesses of the wrapping covers preferentially each range from 1 mm to 2 mm; thirdly, conducting hot isostatic pressure machining on the prefabricated blanks wrapped by the wrapping covers so as to obtain a prefabricated blank of the blisk; fourthly, conducting postprocessing on the prefabricated blank of the blisk to obtain the titanium-aluminium alloy blisk. Due to the fact that the titanium-aluminium alloy blisk can be connected under the low-temperature condition, the influences on original structures and performance are small, the original organization structure of the obtained blisk can be more integrated, and the more excellent performance can be achieved.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

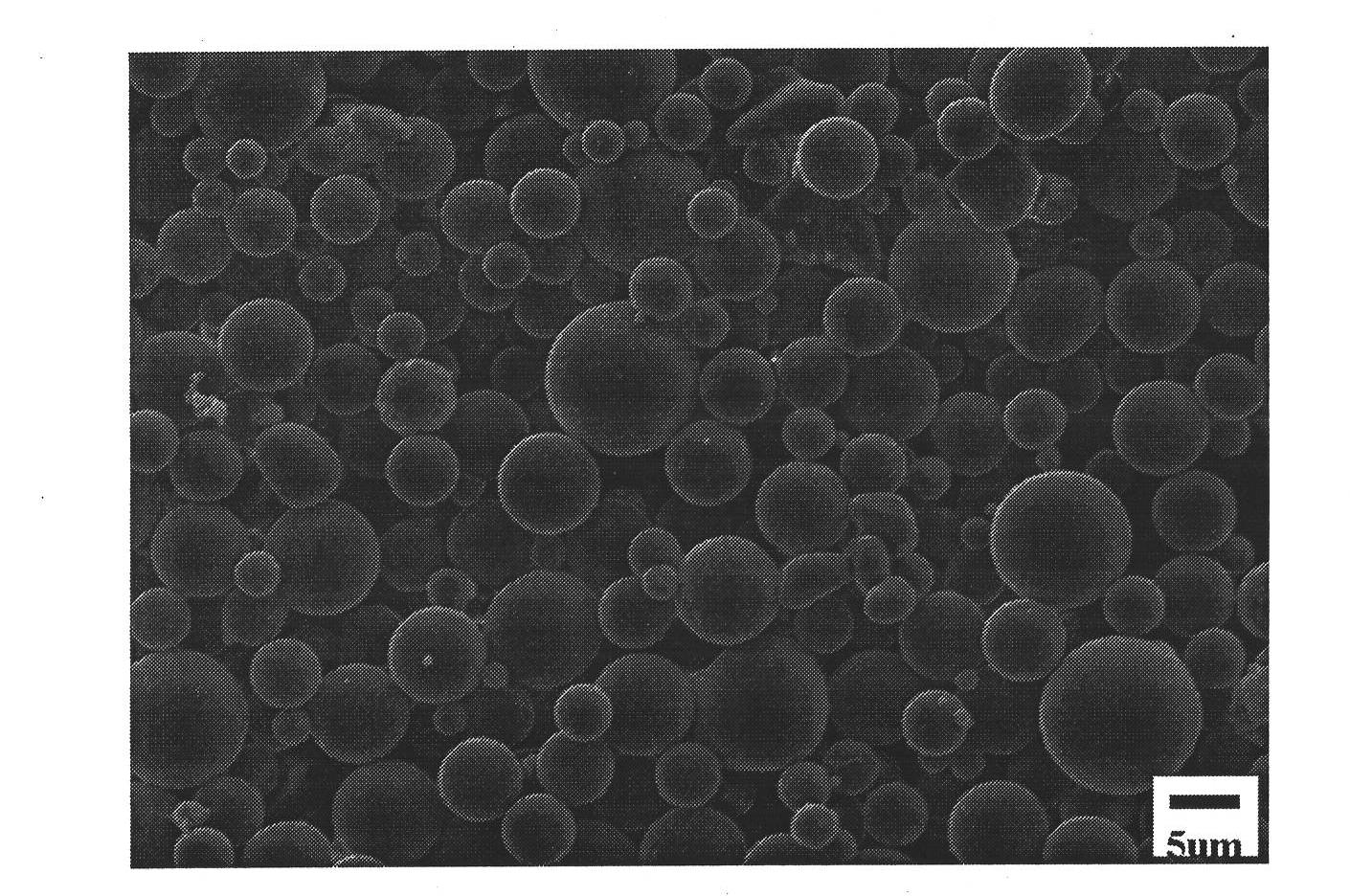

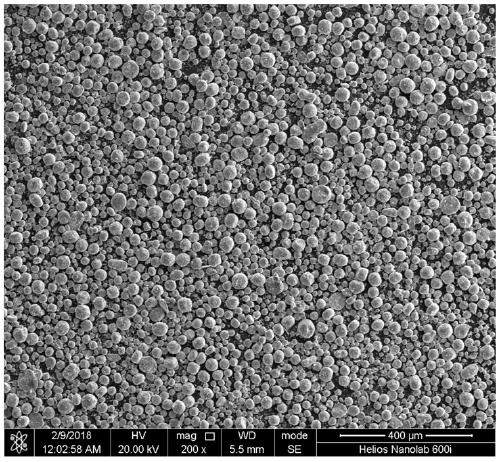

A method for preparing in situ MgSi particle reinforced metal matrix composite

InactiveCN101514409AEnhanced interface bindingImprove mechanical propertiesSlurryMetal matrix composite

A method for preparing in situ MgSi particle reinforced metal matrix composite comprises the following steps: feeding 10-60% in situ Mg2Si-Mg or Mg2Si-Al raw material, based on particle volume percentage, into the a furnace under the gas protection condition; keeping the temperature for 5-20 min between the solidus temperature and the liquidus temperature to obtain a semisolid intermediate; melting the matrix alloy under the superheat degree of being 100-300 DEG C and the gas protection condition, and then keeping the temperature for 5-20 min to maintain the matrix alloy to be in the temperature of 0-30 DEG C below the liquidus temperature; adding the semisolid intermediate while stirring for 1-20 min at the stirring speed of 100-600 rew / min, rising the temperature to the superheat degree of 10-100 DEG C, continuously stirring for 1-20 min at the stirring speed of 100-300 rew / min, and then standing for a while; rheocasting the prepared alloy flux with the superheat degree of 10-100 DEG C to obtain a semisolid composite slurry, and finally press forming. The composite primary crystal prepared by the invention is fine and in spherical shape, the Mg2Si particle as reinforcement phase is fine and uniform in distribution. Accordingly, the oxidation during the composite preparation can be effectively reduced, and the near net shape forming of the composite can be achieved.

Owner:NANCHANG UNIV

Method for preparing diamond/silicon carbide ceramic matrix composite material

The invention discloses a method for preparing a diamond / silicon carbide ceramic matrix composite material, and belongs to the field of ceramic materials. The diamond / silicon carbide ceramic matrix composite material is characterized by being prepared from the following raw materials in percentage by weight: 5 to 15 percent of adhesive, 15 to 45 percent of silicon carbide powder, and 40 to 80 percent of diamond particle. The method comprises the following steps of: wet-mixing the raw materials for 8 to 24 hours, performing die forming under the pressure of 75 to 250MPa to obtain a blank of the composite material, oxidizing the blank in the air at the temperature of 200DEG C for 6 to 10 hours, sintering under the protection of nitrogen at the temperature of between 800 and 1,200DEG C for 8 to 15 hours, and cooling together with a furnace; and performing vacuum impregnation, oxidation, sintering and cooling, and circulating for 3 to 7 times to obtain the compact diamond / silicon carbide ceramic matrix composite material, wherein the oxidation temperature is 200DEG C, the oxidation time is 6 to 10 hours, the sintering is performed at the temperature of between 800 and 1,200DEG C for 8 to 15 hours under the protection of nitrogen, and the product is cooled together with the furnace. The method has low equipment requirement, is low in cost and can prepare the complicated-shaped compact diamond / silicon carbide ceramic matrix composite material.

Owner:UNIV OF SCI & TECH BEIJING

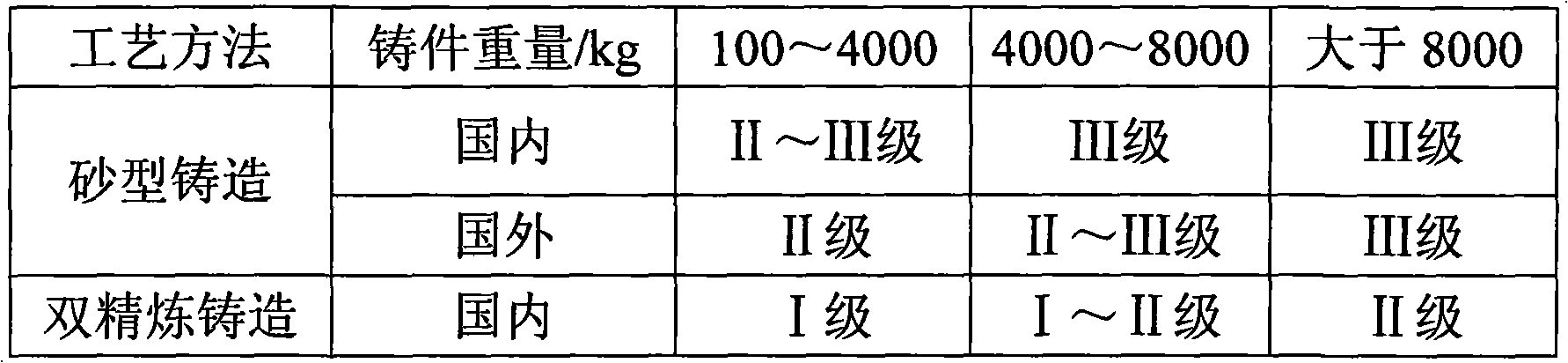

Electroslag smelting casting method of fixed blades of water turbine

The invention relates to an electroslag smelting casting method of fixed blades of a water turbine. Consumable electrodes are prepared by adopting a voltaic arc furnace refining method and the fixed blades are prepared by adopting an electroslag smelting casting process through a mould. The chemical components of the consumable electrodes are controlled as follows: C is 0.14-0.19 percent, Si is less than or equal to 0.6 percent, Mn is 1.5-1.9 percent, P is less than or equal to 0.035 percent, S is less than or equal to 0.035 percent, V is 0.02-0.15 percent, Nb is 0.015-0.06 percent, Ti is 0.15-0.25 percent, Al is more than or equal to 0.015 percent, O is less than or equal to 0.0040 percent, N is less than or equal to 0.0080 percent, H is less than or equal to 0.00035 percent, and the balance is Fe. The electroslag smelting casting system and the electroslag guide are controlled as follows: CaF2 is 60-80 percent, Al2O3 is 40-20 percent, or less MgO and CaO (the total is less than or equal to 20 percent); and the electroslag amount is usually 1.5-5 percent of the weight of a casting. The invention has less amount of oxide and sulfide, small size, even distribution, clean casting base body, high cooling speed, large crystallization temperature gradient at the front of solid and fluid, compact casting texture, high size precision and little distortion, and can greatly improve the product property of the refined casting.

Owner:SHENYANG RES INST OF FOUNDRY

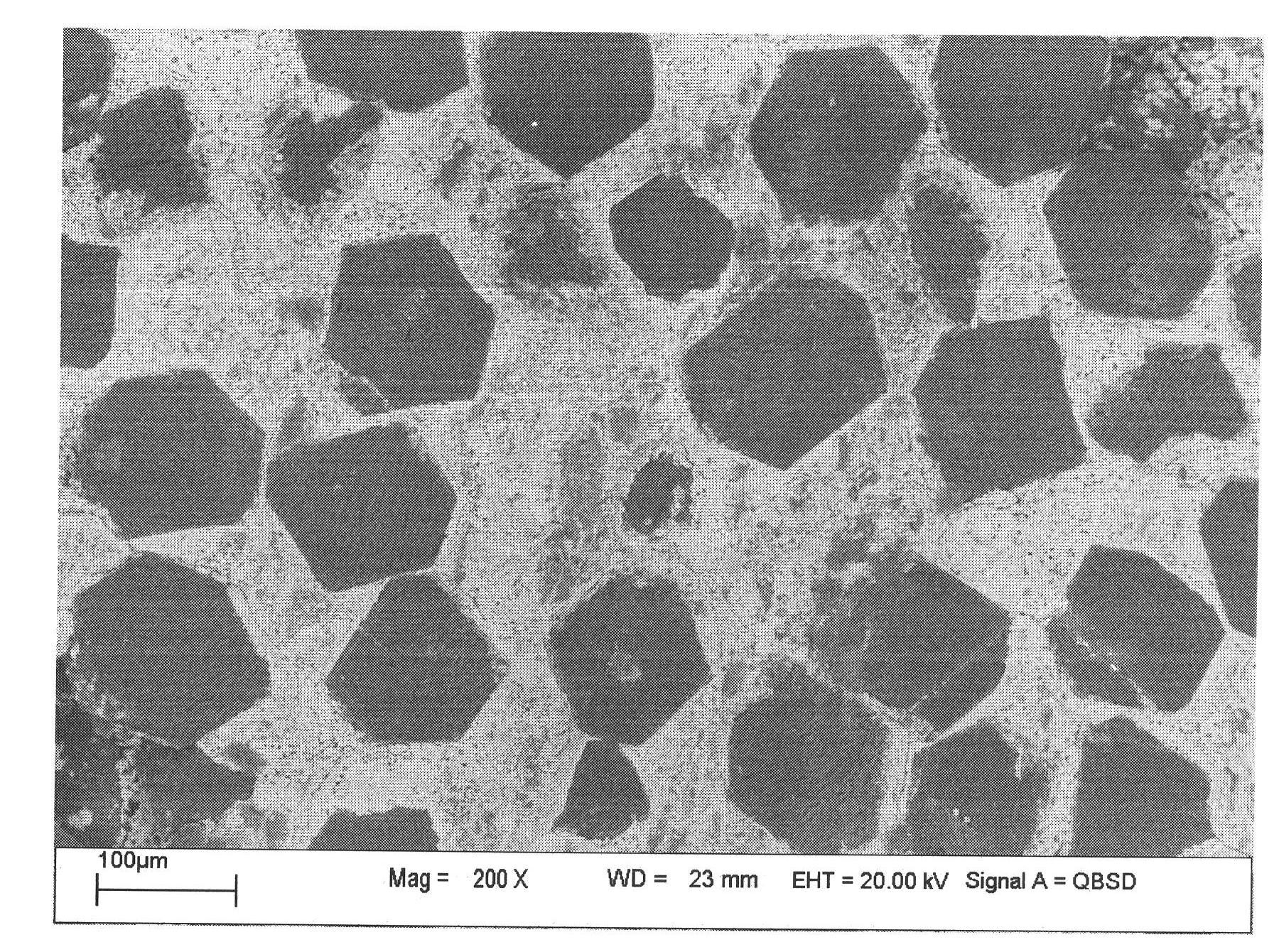

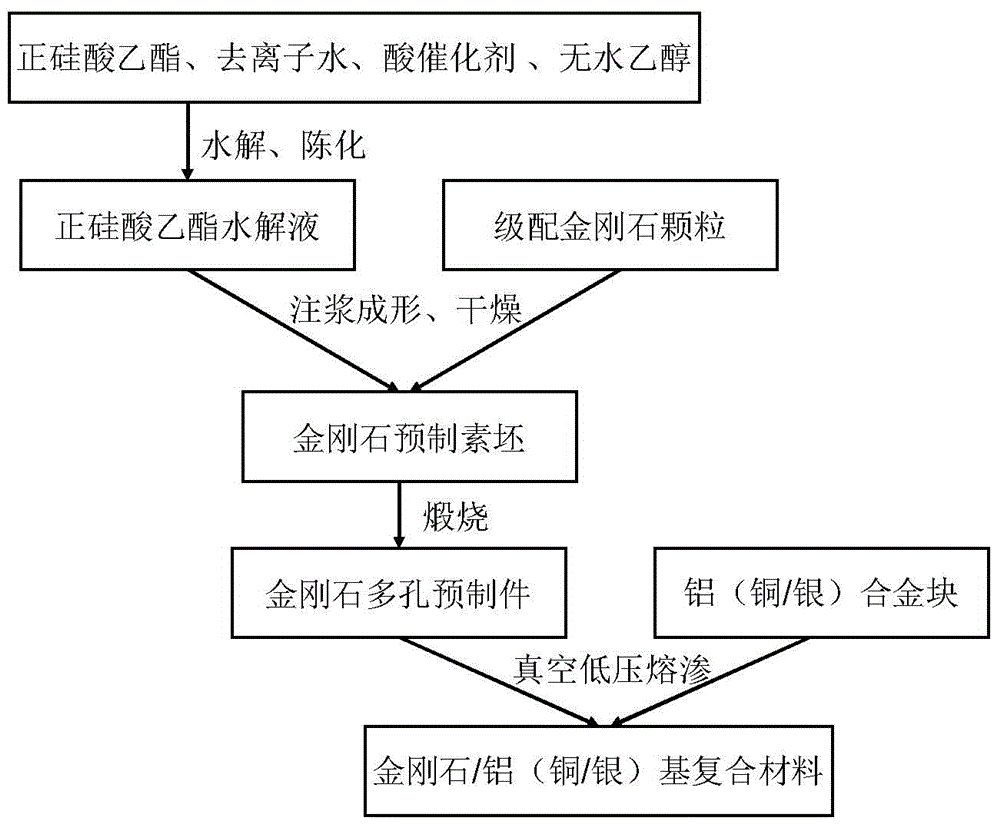

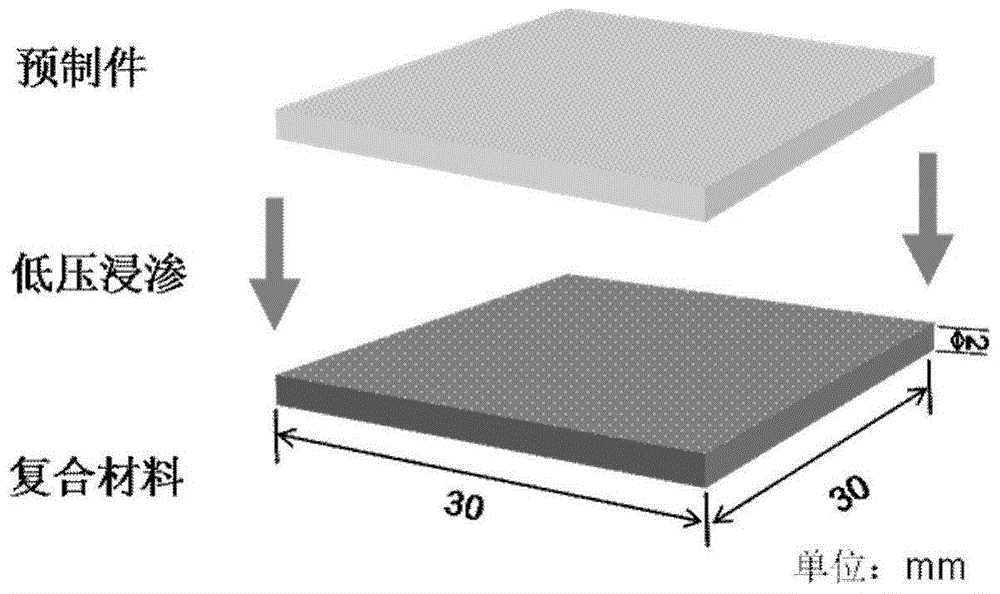

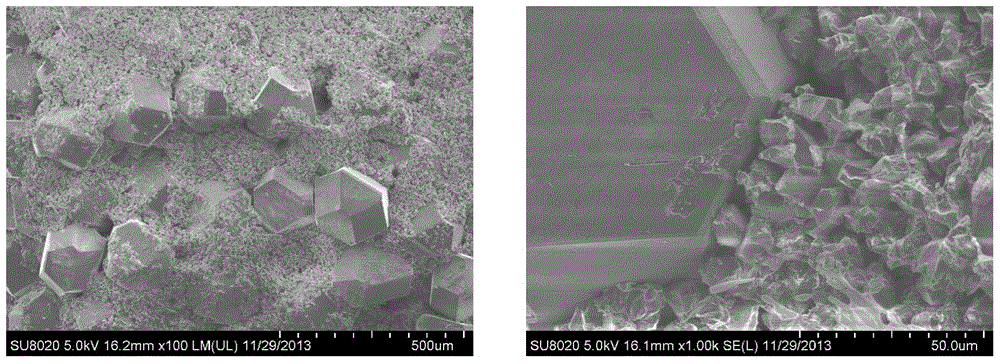

Preparation method of diamond/metal-based composite material with high volume fraction

The invention discloses a preparation method of a diamond / metal-based composite material with a high volume fraction. The preparation method comprises preparation of hydrolysate, preparation of a sizing agent, roasting of a prefabricated member, and vacuum low-pressure infiltration; and the process for each unit is as follows: firstly, preparing tetraethylortho silicate hydrolysate by taking tetraethylortho silicate as a precursor, taking absolute ethyl alcohol as a reaction solvent and taking acid as a catalyst; preparing a prefabricated blank by taking tetraethylortho silicate hydrolysate as an adhesive through a grouting and forming way, and roasting at a high temperature to obtain a diamond porous prefabricated member; and infiltrating a molten liquid into the diamond porous prefabricated member by adopting a vacuum low-pressure infiltration way to realize near net shape forming of the diamond / metal-based composite material. The prepared diamond / metal-based composite material has the advantages of being high in heat conduction, low in expansion, high in gas tightness, and the like, is simple in preparation process, low in cost and suitable for mass production.

Owner:HEFEI UNIV OF TECH

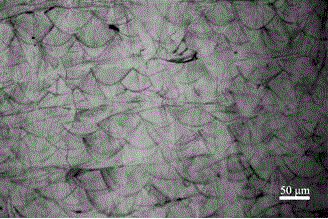

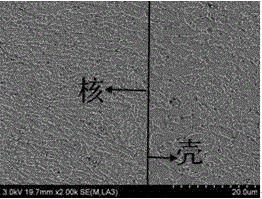

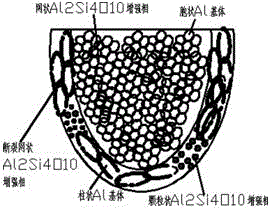

Aluminum-based in-situ composite material formed based on laser 3D printing and preparation method of aluminum-based in-situ composite material

ActiveCN105328186AGood comprehensive mechanical propertiesImprove the overall mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyLaser printingAluminium

The invention belongs to the technical field of particle-reinforced aluminum-based in-situ composite materials and discloses an aluminum-based in-situ composite material formed based on laser 3D printing and a preparation method of the aluminum-based in-situ composite material. The preparation method includes the steps that a mixture of Al-Si-Mg alloy powder and Al2O3 powder is prepared; the mixture is ball-milled through an intermittent ball-milling process; a three-dimensional CAD model established through a workpiece is subjected to layered slicing treatment; laser beams are adopted for scanning the laid powder line by line to form a two-dimensional section of the workpiece; and the steps are repeated till the workpiece is machined, and the aluminum-based in-situ composite material with an Al2Si4O10 reinforced element scattered on an Al matrix is formed. The operation method is easy and convenient to carry out, Al-Si-Mg alloy and Al2O3 generate the Al2Si4O10 reinforced phase in situ under the effect of high-energy lasers in the laser forming process, the interface wettability is improved, and then the interface strength of the composite material is enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

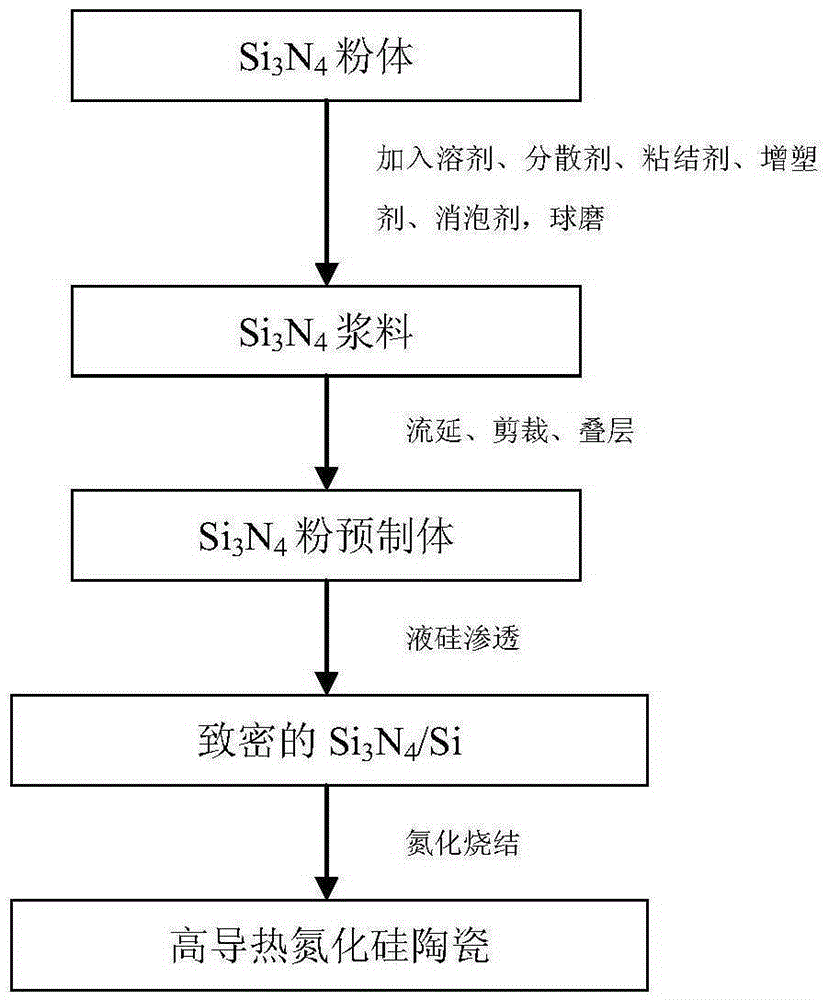

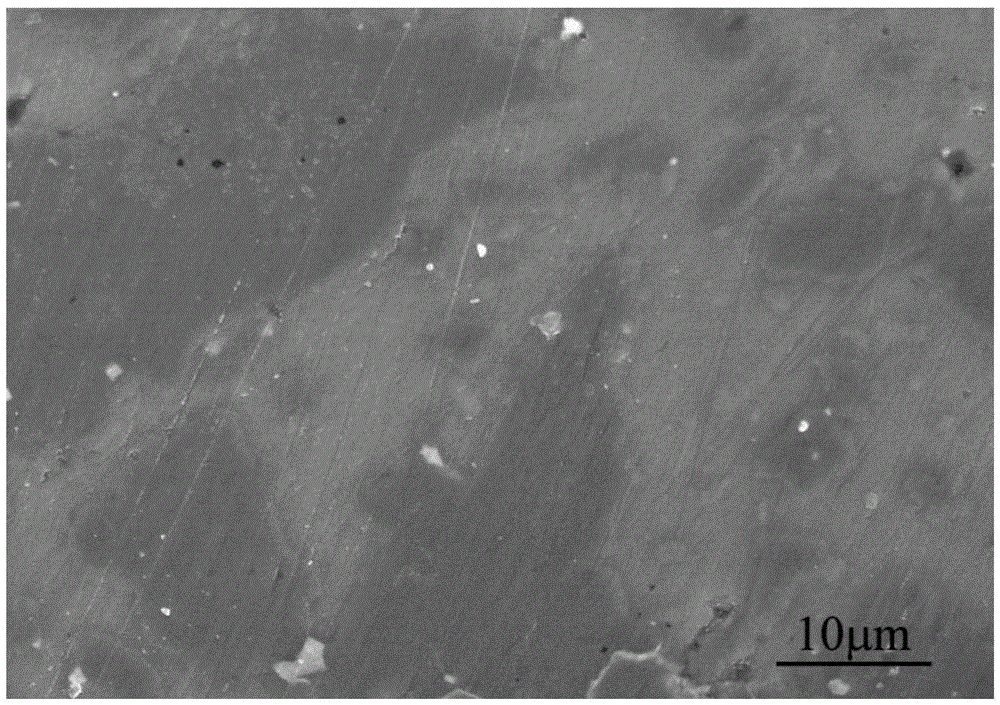

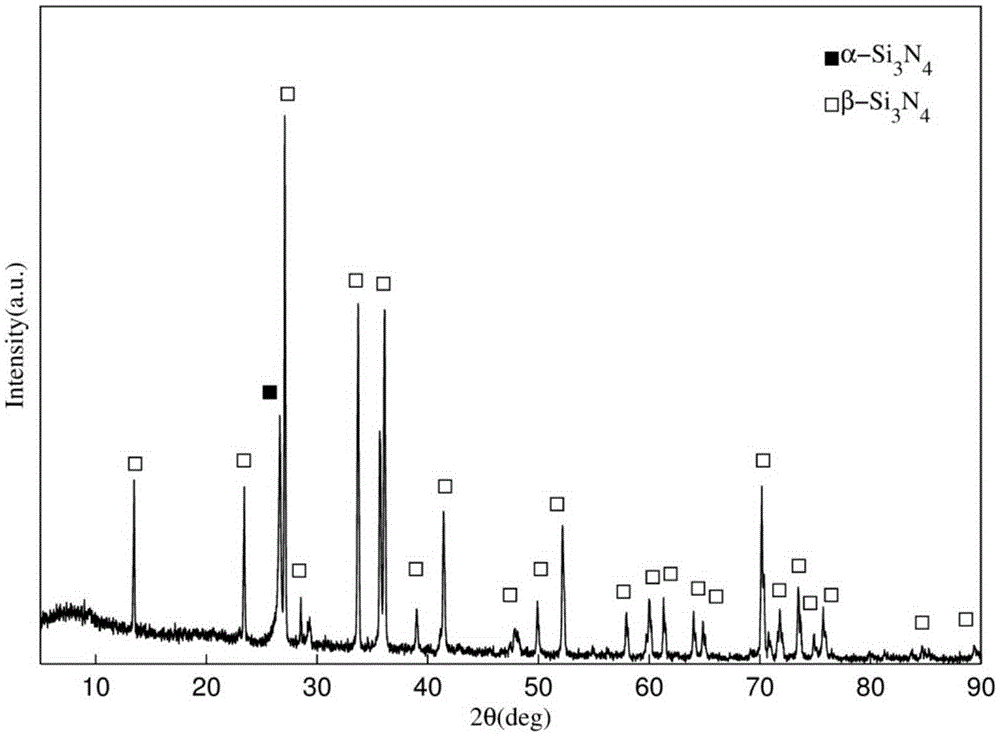

Method for preparing high-thermal-conductivity silicon nitride ceramics

InactiveCN105254306ALow preparation temperatureReduce subsequent processingThermal conductivityNitrogen treatment

The invention relates to a method for preparing high-thermal-conductivity silicon nitride ceramics. The method comprises the steps that firstly, thermal treatment and acid pickling treatment are carried out on Si3N4 powder, and then Si3N4 slurry is prepared; an Si3N4 thin layer is prepared through a casting process technology, and porous silicon nitride powder prefabricated bodies are obtained after the thin layer is cut and overlapped; the prefabricated bodies are subjected to liquid silicon penetration through high-purity silicon powder, and compact Si3N4 / Si is obtained; nitrogen treatment is carried out on Si3N4 / Si in a nitrogenation oven, so that Si in the material is subjected to a nitriding reaction to generate Si3N4. Compared with frequently-used processes for preparing the high-thermal-conductivity silicon nitride ceramics, such as isostatic pressing sintering and hot pressed sintering, a tape casting method is combined with liquid silicon penetration forming and nitriding sintering processes, no or little machining is needed, preparation temperature is low, no sintering additive needs to be added, and the influence of a grain boundary on the thermal conductivity of the material is avoided. The thermal conductivity of the prepared silicon nitride ceramics can reach 80-120 Wm<-1>K<-1>.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

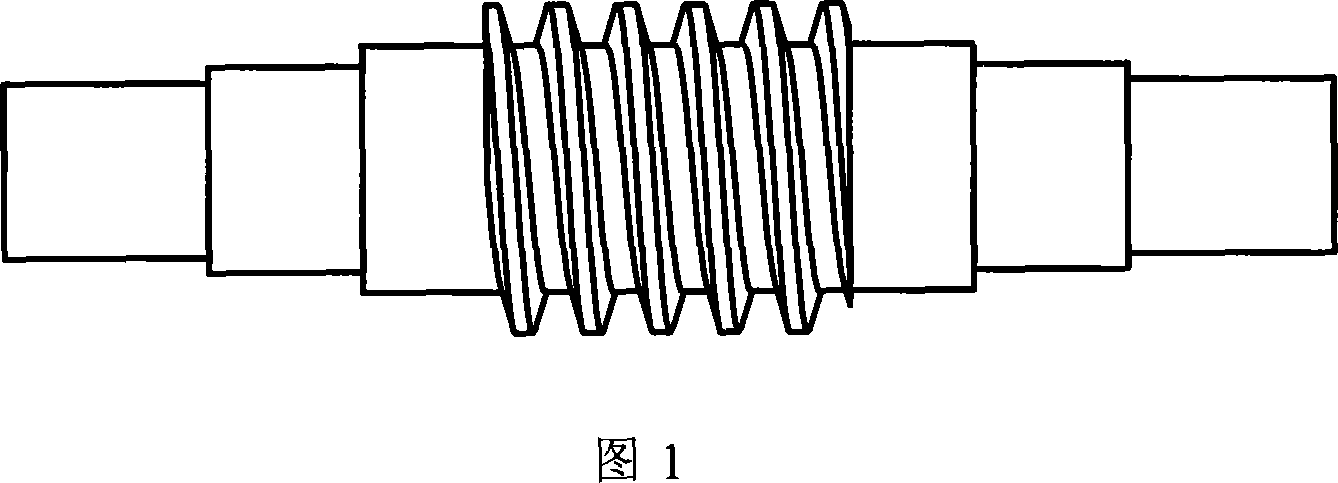

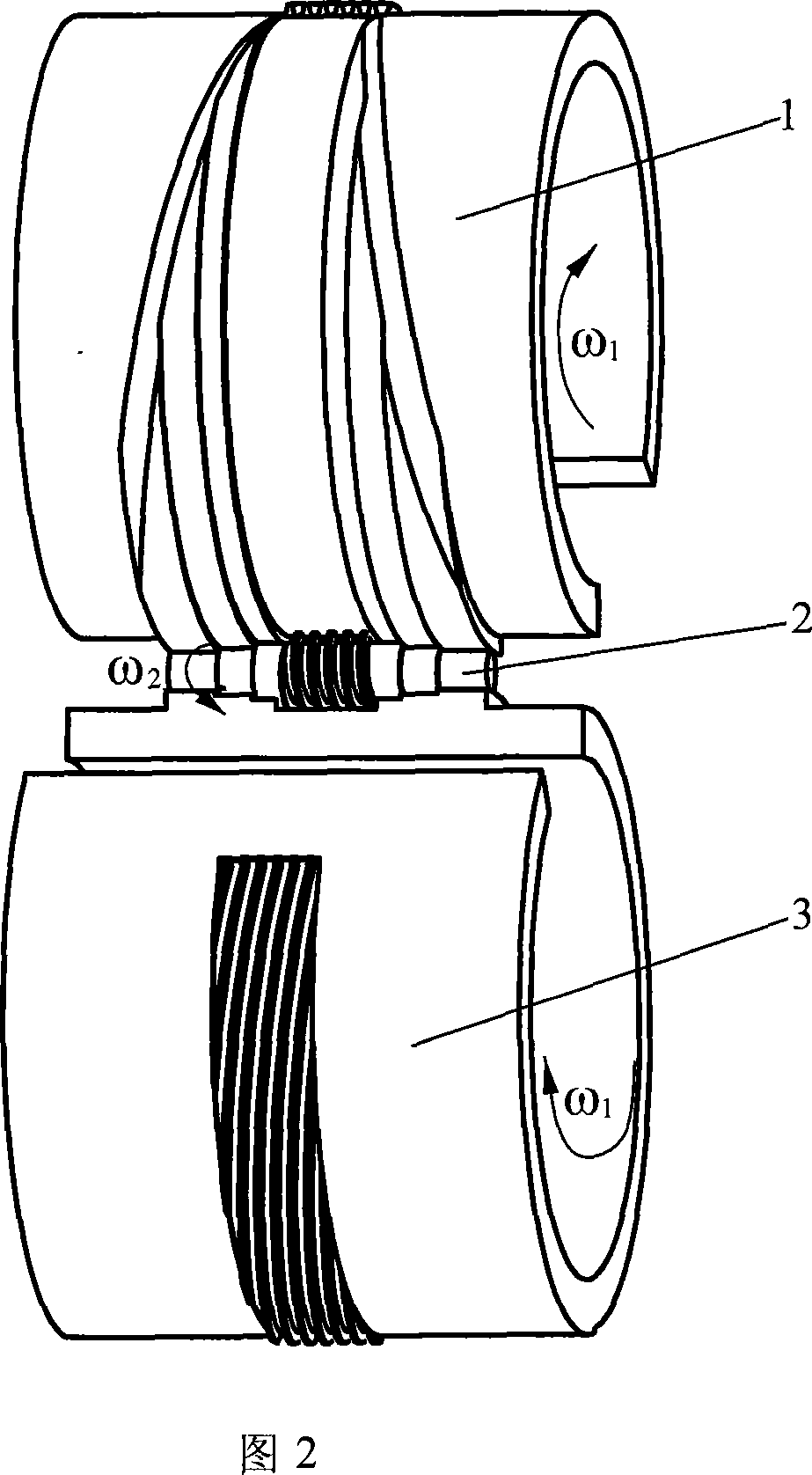

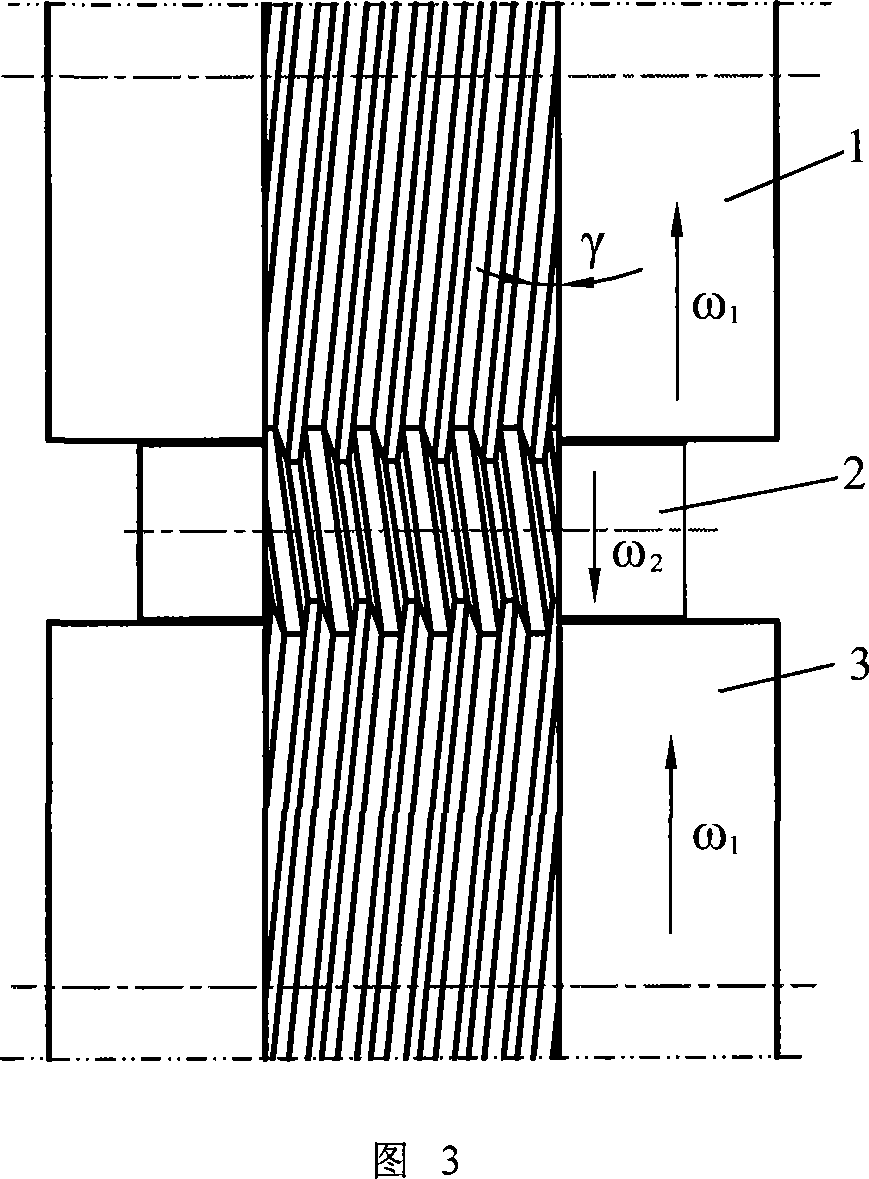

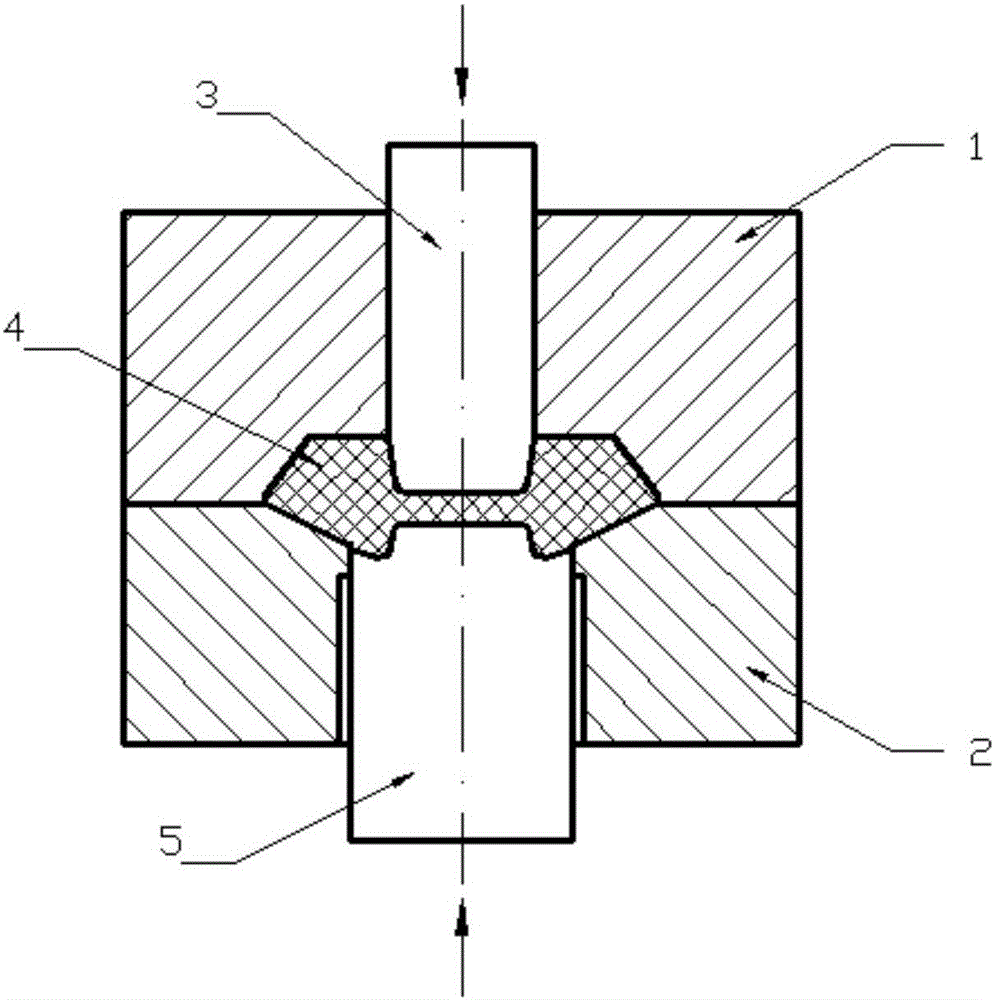

Moulds and methods for forming blanks of worm shafts rolled with roller wedge laterally

InactiveCN101073816AIncrease profitAchieve near net shapeRollsMetal rolling arrangementsDistortionRoughcast

The invention is concerned with forming mould and its method for rolling cross wedge rolling worm axis roughcast, belonging to metal plastic metal forming technology field. Set mould on the rolling cross wedge rolling and send the heated stick stuff into the cross wedge roller through feeding equipment. The upper mould and down mould with model cavity on their surface to the roller move to same direction and the heated metal round stick stuff moves to the different direction with the action of mould. This realizes continuous radial condensation and extending distortion along axis to form the each step including the shape of worm tooth. The part of spiral tooth shape of the worm axis roughcast is finished through the spiral groove tooth shape of the mould, and the part of step axis is finished through the wedge part of mould. The roller moves around to produce a roughcast of worm axis. The invention has high single machine productivity and availability with low cost, less machining process and excellent quality of production.

Owner:UNIV OF SCI & TECH BEIJING

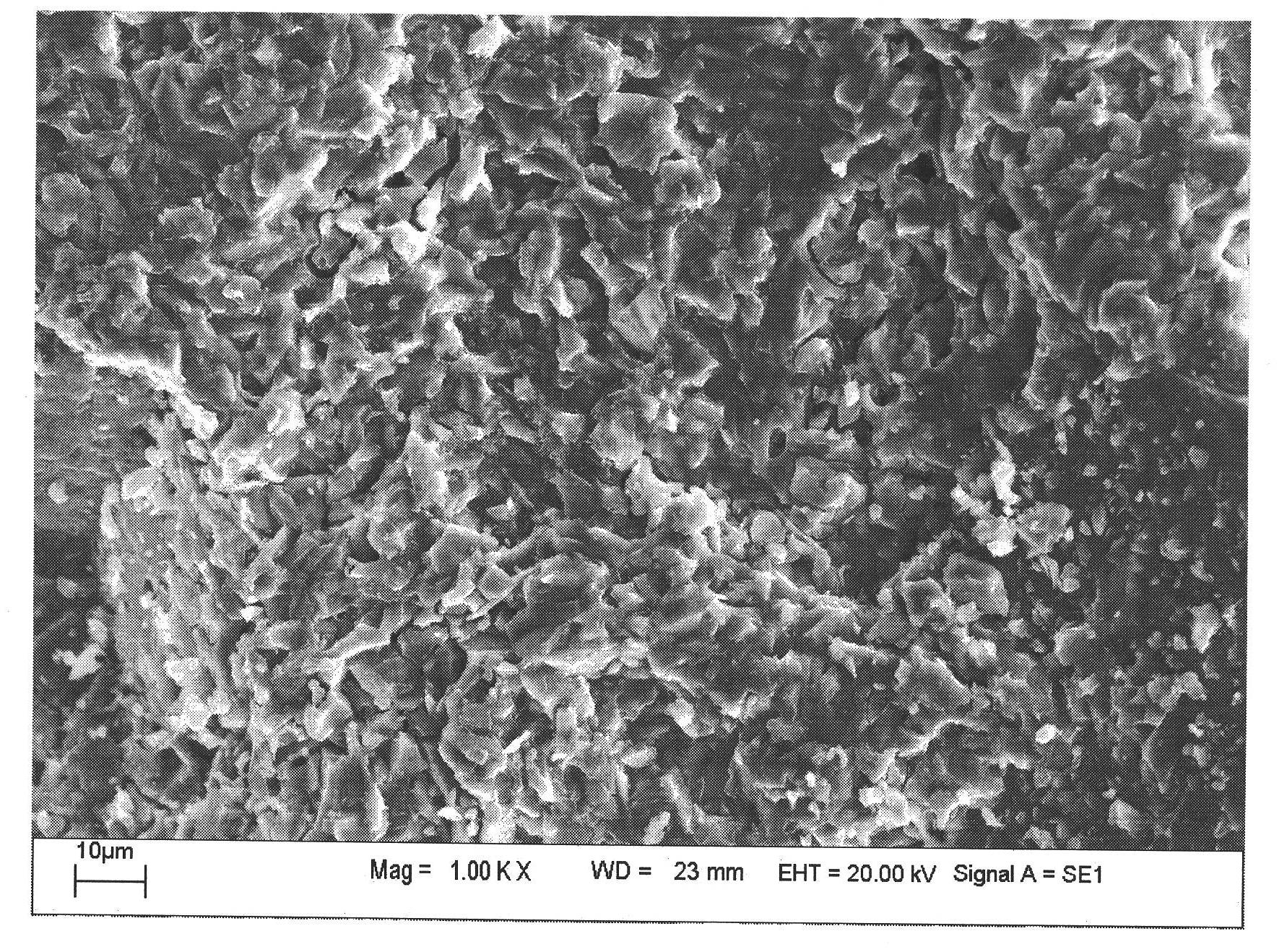

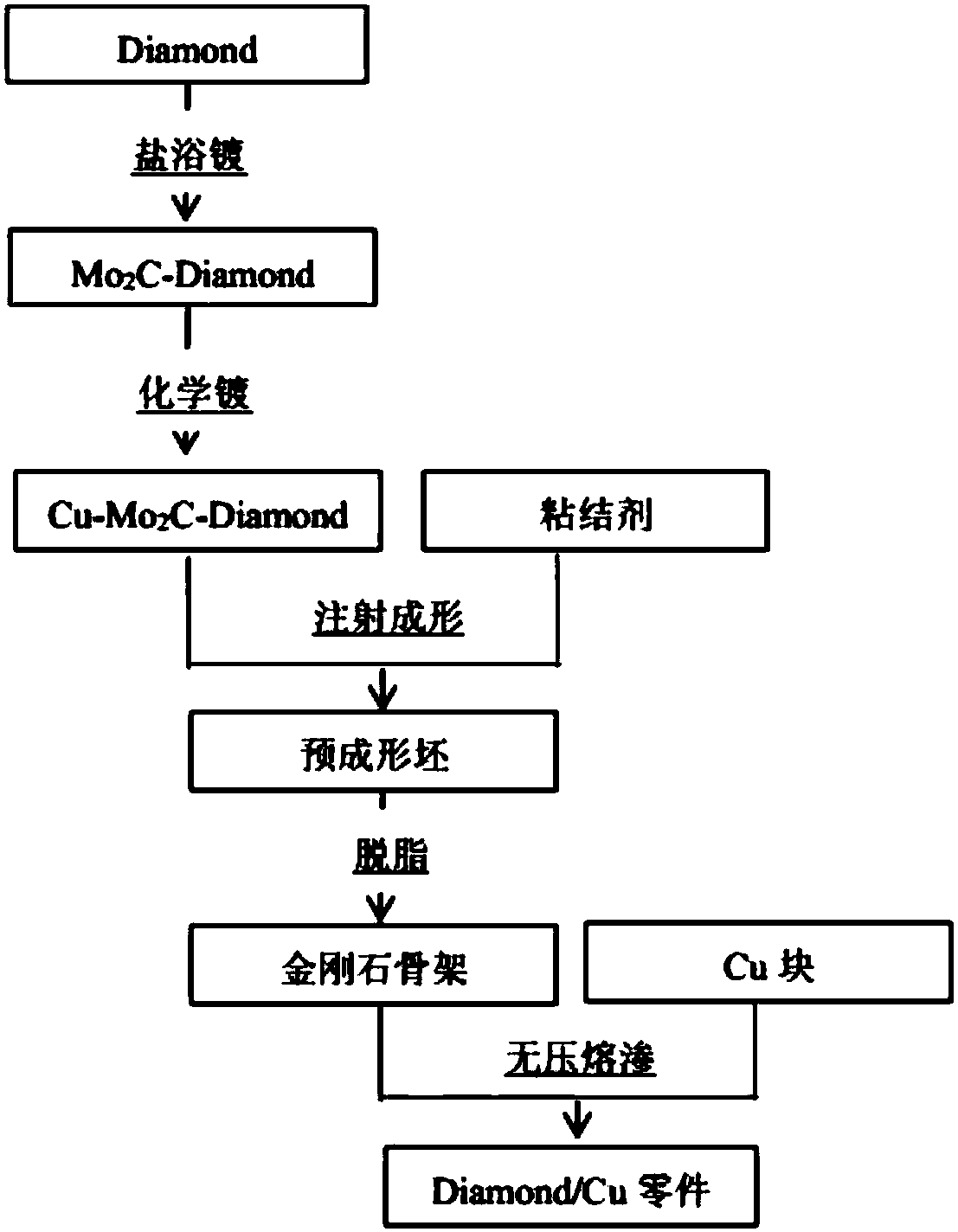

Method for preparing diamond/copper composite material by combining injection molding technology

ActiveCN107855533AHigh densityVolume fraction adjustmentTransportation and packagingMetal-working apparatusChemical platingCopper plating

The invention relates to a method for preparing a diamond / copper composite material by combining an injection molding technology. The method comprises the steps of adopting a salt-bath plating technology for plating a layer of uniform Mo2C on a diamond surface so as to improve the wettability of diamond and copper, then adopting a chemical plating method for continuously plating the copper on a surface of the Mo2C layer, and controlling the thickness of a copper plating layer by controlling the Cu2+ content in a plating solution, so that double-plating Cu-Mo2C-Diamond powder with the copper-bearing volume fraction being 1 percent to 10 percents is prepared; then mixing the quantitative Cu-Mo2C-Diamond powder and a multi-polymer component paraffin base binder to form uniform feeding; afterpelletizing, achieving injection molding on an injection molding machine; and after enabling a preformed blank to pass through a solvent and to be subjected to thermal degreasing, pre-sintering at high temperature, carrying out a vacuum pressureless infiltration technology on the obtained blank, and permeating a copper liquid into a diamond framework through a capillary action of pores, so that adiamond / copper composite material part with high volume fraction is obtained. The method provided by the invention can be used for directly preparing the Diamond / Cu composite material part in a complicated shape, the diamond is high in volume fraction and uniform and compact in texture, and the diamond / copper composite material can be produced in batch and can be low in production cost.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of high-performance ceramic

The invention relates to the field of ceramic materials and in particular relates to a preparation method of a high-performance ceramic. The preparation method of the high-performance ceramic comprises the following steps: a) preparing a ceramic part biscuit; b) dumping; c) carrying out isostatic cool pressing treatment; d) presintering; e) preparing a hot isostatic pressing sheath, concretely carrying out synchronous powder feeding and laser cladding treatment, and coating the ceramic part biscuit with the hot istostic pressing sheath; f) hot isostatic pressing sintering; and g) removing the hot isostatic pressing sheath, and precisely processing a ceramic part. The preparation method of the high-performance ceramic has the advantages that multiple technologies are combined, so that a complex ceramic part biscuit can be prepared through selective laser sintering, near-net forming of a complex ceramic part is realized, and compactness of the part biscuit subject to aftertreatment is improved; meanwhile, no vacuumizing or encapsulating needs to be carried out, and production processes are reduced; besides, technique is simple, period is short, efficiency is high, cost is low, and the obtained ceramic part is high in strength and good in performance.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

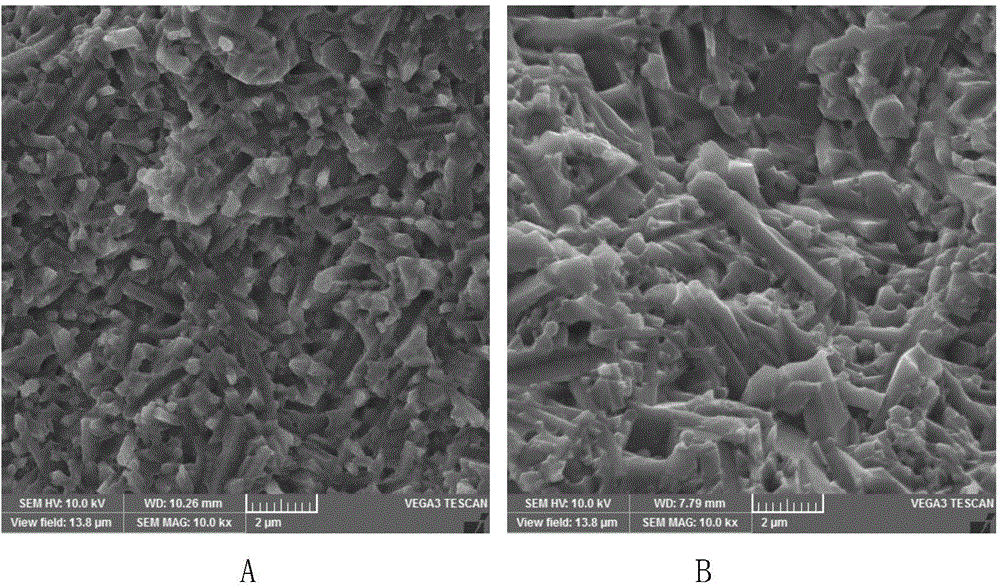

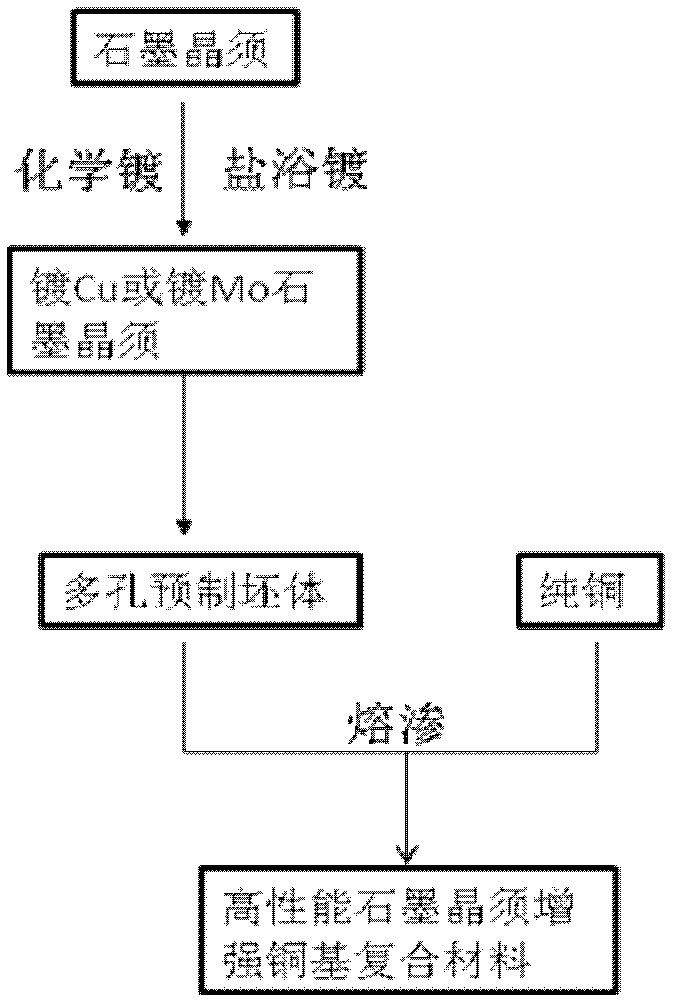

Preparation method of graphite whisker reinforced copper base composite material

InactiveCN102628149AHigh thermal conductivitySmall coefficient of thermal expansionCompression moldingChemical plating

The invention belongs to the research field of metal base composite material and relates to a high heat conductive graphite whisker reinforced copper base composite material and a preparation method thereof. The composite material comprises two parts of a matrix pure copper and a plated reinforcing phase high heat conductive graphite whiskers, wherein a volume fraction of the copper is 40%-65%, and a volume fraction of the plated graphite whisker is 35%-60%. A production process of the composite material comprises the steps of: first, plating copper or molybdenum on a surface of the graphite whisker by a chemical plating or salt bath plating method to form a 0.5-2 mum thick coating; adding a proper amount of binder into the graphite whisker treated with metal plating; carrying out compression molding; removing the binder through thermal debinding to form a porous preform; and finally stacking the preform and the pure copper and placing the two into an infiltration furnace to carry outvacuum pressure infiltration, so as to obtain the final graphite whisker reinforced copper base composite material part.

Owner:UNIV OF SCI & TECH BEIJING

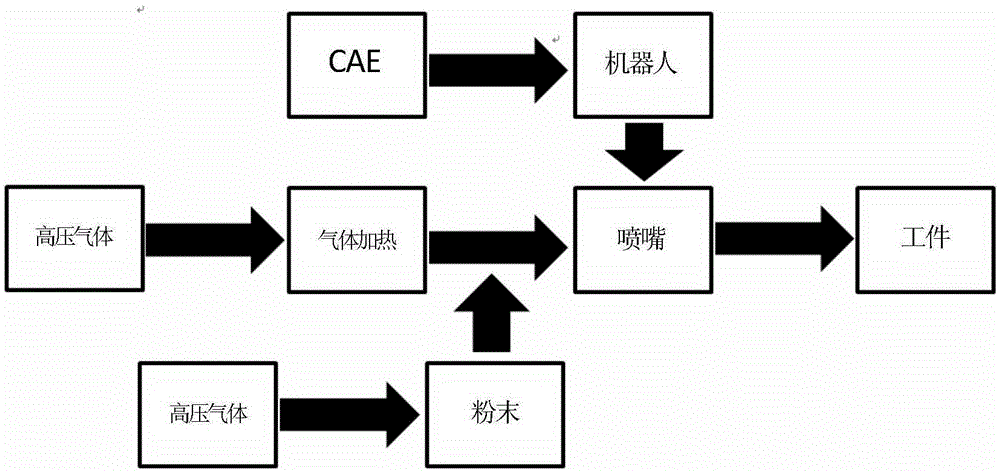

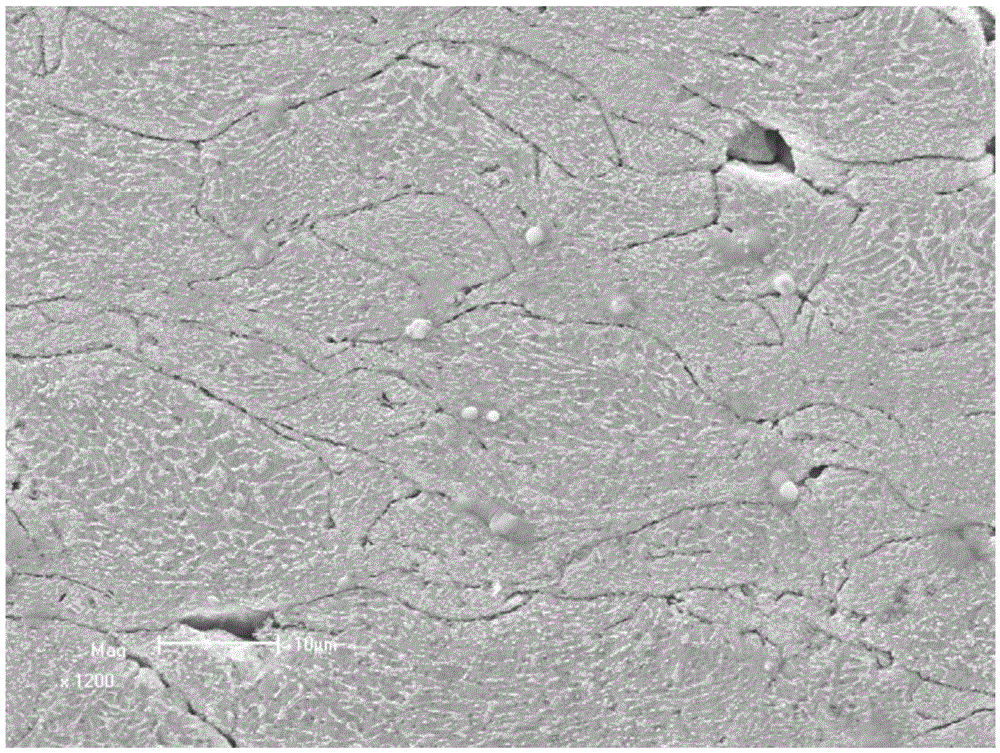

Method for realizing additive manufacturing through cold gas dynamic spray

InactiveCN106609369AGood mechanical propertiesHigh precisionPressure inorganic powder coatingSolid-stateGas dynamics

The invention relates to the technical field of additive manufacturing (AM), commonly known as 3D printing, in particular to a method for realizing additive manufacturing through cold gas dynamic spray. A cold gas dynamic spray process is adopted to be combined with computer aided manufacturing, so that a 3D printing technology is realized; different from other conventional thermal 3D printing technologies, the technology is a non-thermal input type (non-smelting) 3D printing technology. Based on the cold gas dynamic spray process, the technology enables particles to impact at a high speed under a solid state, and 3D printing additive manufacturing is realized through strong plastic deformation of the particles and deposition. Meanwhile, an advanced computer aided manufacturing technology is combined, so that complex workpieces with relatively high precision can be manufactured; and in the process, powder does not generate phenomena such as oxidization, burning loss, phase change and structural change. Therefore, the method solves the problem that materials such as alloys, amorphous materials, quasi-crystal materials and nano-crystal materials, which are liable to have phase change and are liable to volatilize at a high temperature, cannot apply the conventional thermal input type (smelting type) 3D printing technology to manufacture workpieces.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

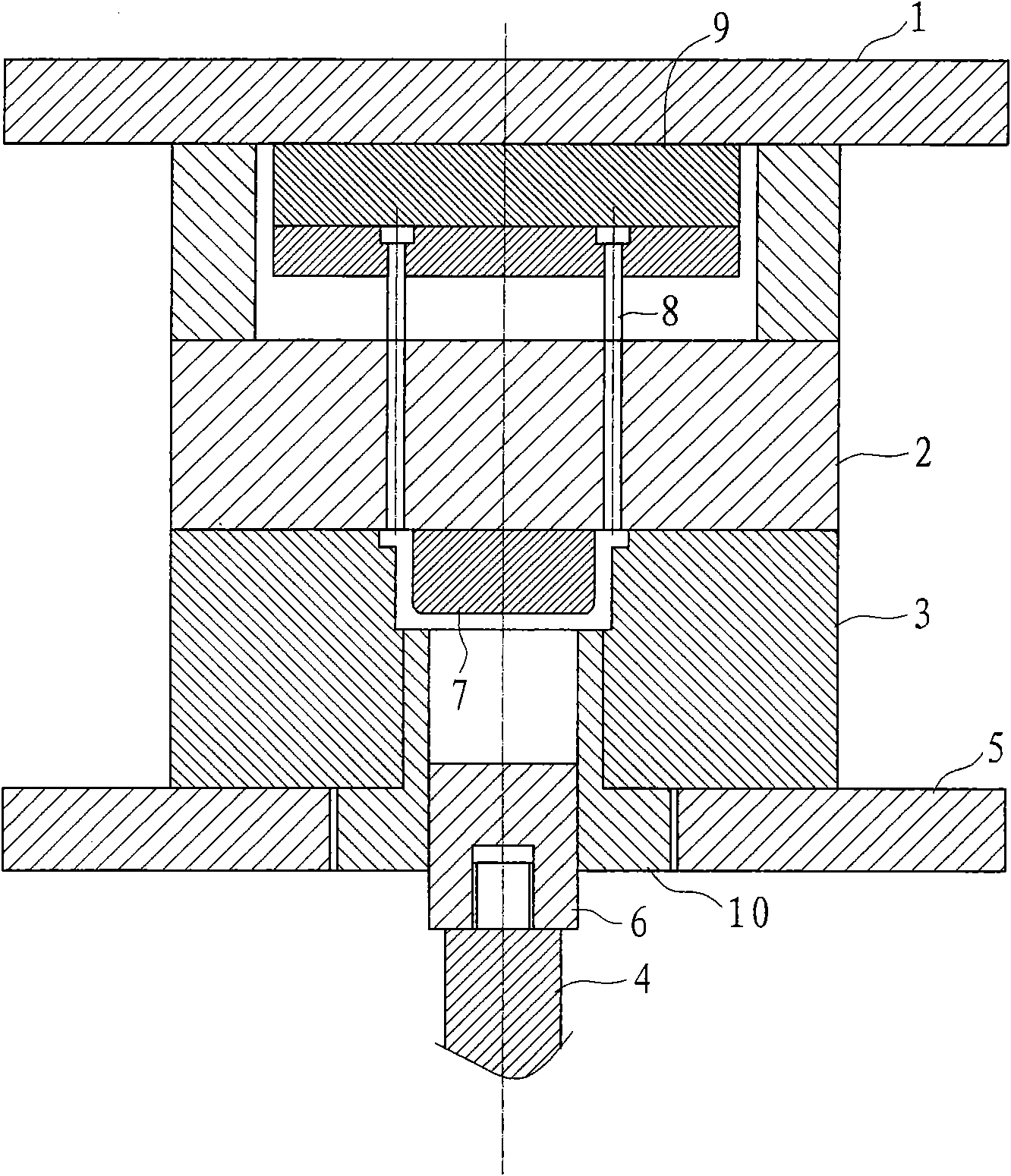

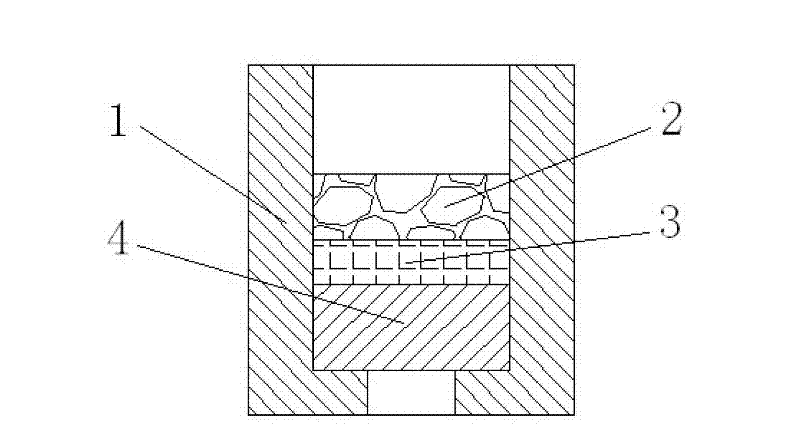

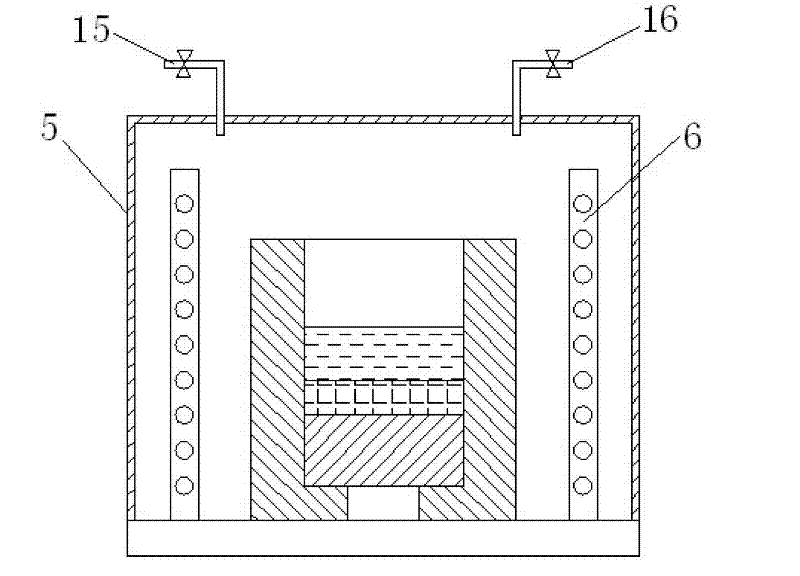

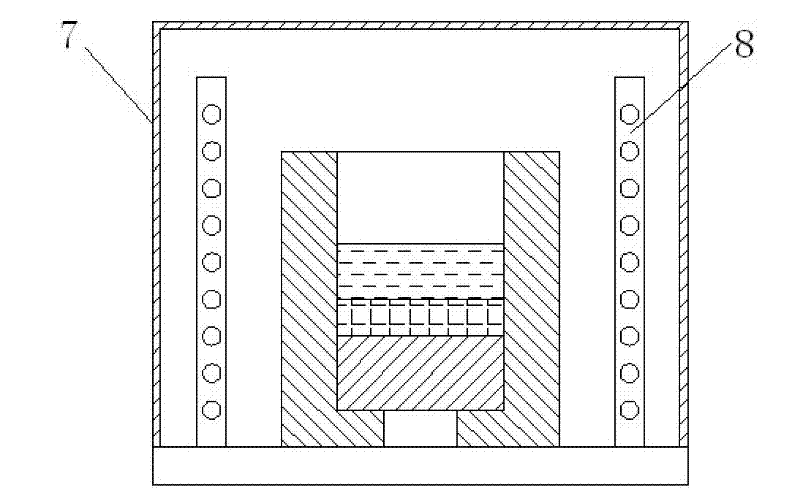

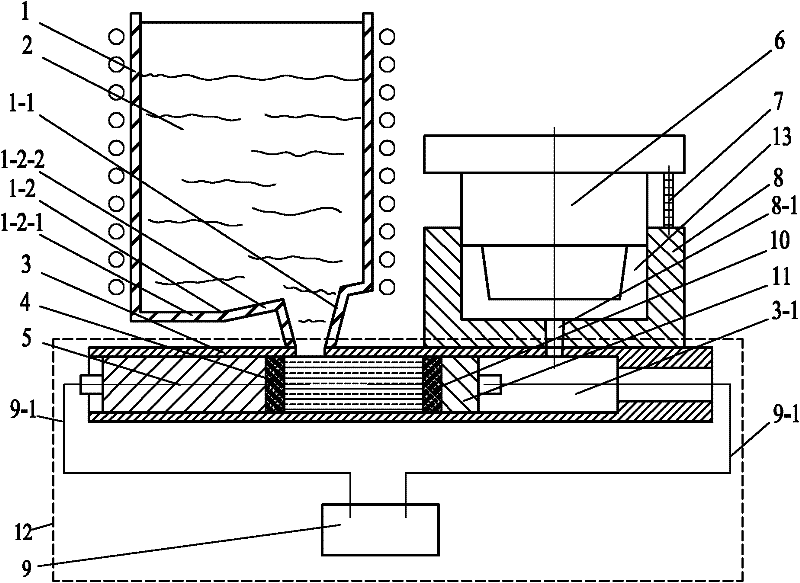

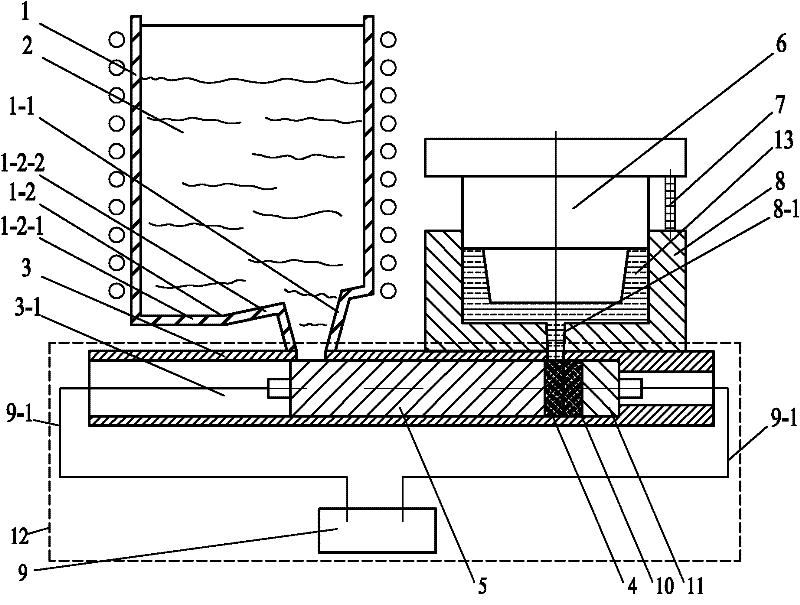

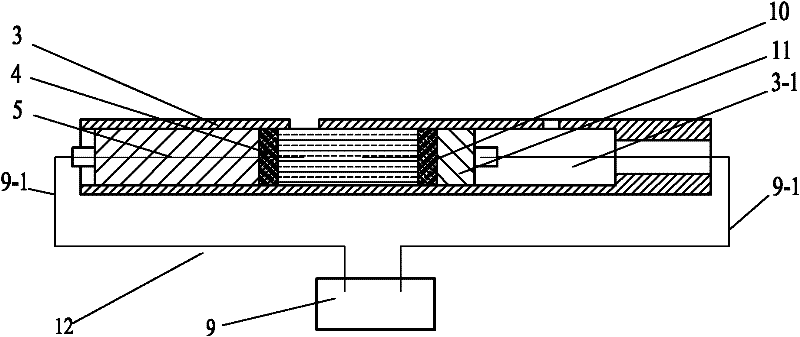

Device and method for preparing aluminum-base composite material by using vacuum impregnation andsolid-liquid direct extrusion

The invention relates to a device and a method for preparing an aluminum-base composite material by using vacuum impregnation and solid-liquid direction extrusion. A smelting furnace is installed on the upper surface of a bottom pallet, the bottom pallet and a mould outer cover are placed on the upper surface of a mould support. A top block is arranged at the bottom of an inner cavity of the smelting furnace. The upper end surface of a top rod is matched with the top block, and the lower end surface of the top rod comes into contact with a piston rod of an ejection cylinder of a four-column hydraulic press. The device accomplishes the four processes of aluminum alloy vacuum smelting, impregnation, extrusion and formation required for preparing the high-performance aluminum-base composite material by using a vacuum furnace, a resistor furnace, the four-column hydraulic press and an extruding and impregnating mould, reduces the defects of shrinkage cavities, shrinkage porosity and cavities of the composite material, increases the density and improves the performance of the aluminum-base composite material, and aluminum-base composite material pieces with different shapes and sizes formed according to the matched degrees of concave dies and convex dies. The device realizes automatic ejection of the aluminum-base composite material through an ejection structure and reduces the formation and processing procedures of parts.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

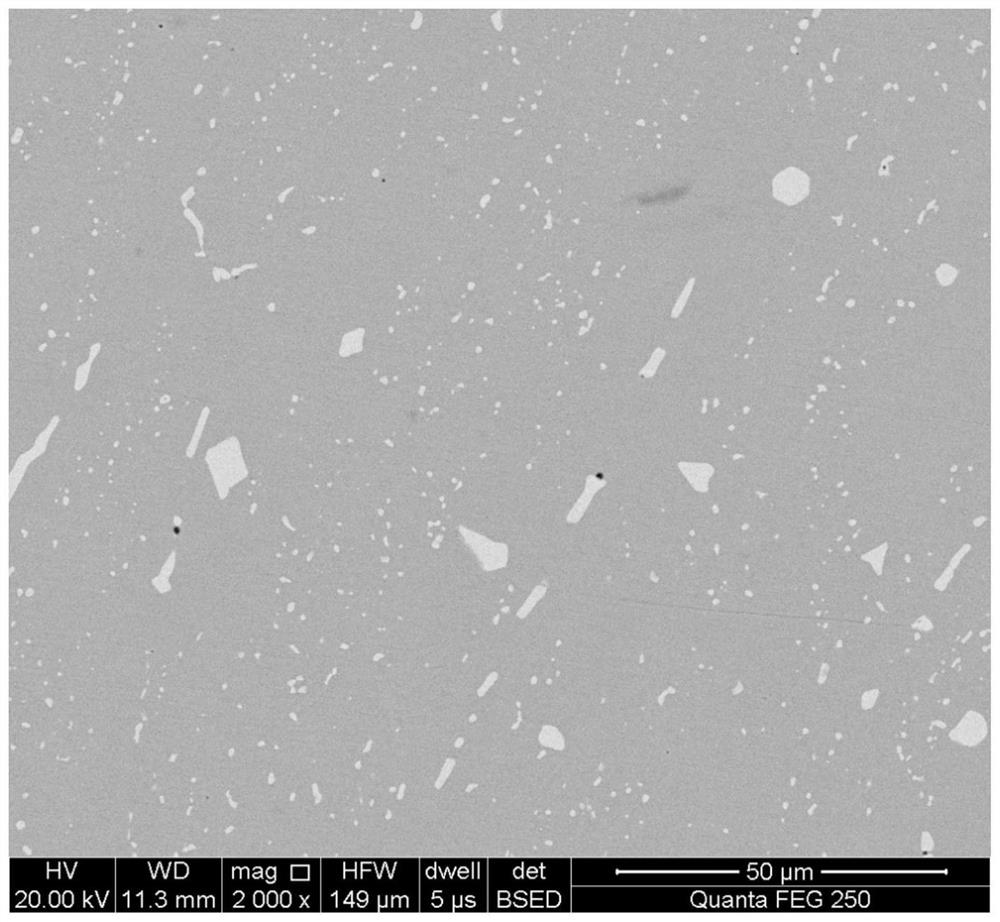

High-melting-point high-entropy alloy NbMoTaWVTi and preparation method thereof

ActiveCN105950944AUniform composition and nearly full densityOptimizing the forming processElectric arc furnaceHigh entropy alloys

The invention belongs to the technical field of high-entropy alloys and discloses a high-melting-point high-entropy alloy NbMoTaWVTi and a preparation method of the high-melting-point high-entropy alloy NbMoTaWVTi. According to the method, a forming method that a mechanical alloying technology and a spark plasma sintering technology are combined is adopted. Compared with a traditional vacuum arc furnace casting method, by the adoption of the preparation method, operation is easier and more convenient, the temperature required in forming is lowered greatly, sintering time is short, a block material which is uniform in composition and near-total dense can be obtained through one-time sintering, and near-net forming is achieved; and the microscopic structure of the obtained alloy is characterized in that granular second phases are diffused and distributed in an isometric crystal matrix. By the adoption of the preparation method, the prepared alloy is uniform in structure and tiny in grain size and has higher strength and plasticity, and the optimum mechanical performance meets the conditions that compression yield strength is 2,709.2 MPa, the maximum compressive strength is 3,114.9 MPa, and the plasticity dependent variable generated in fracture is 7.5%.

Owner:SOUTH CHINA UNIV OF TECH

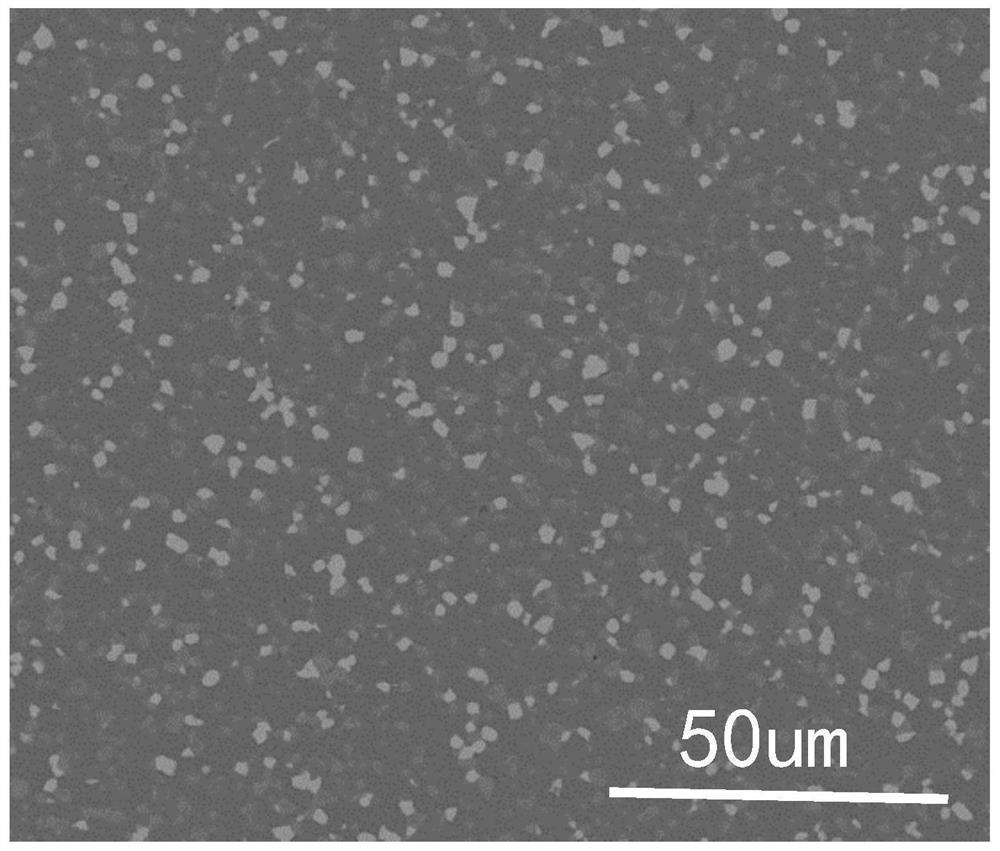

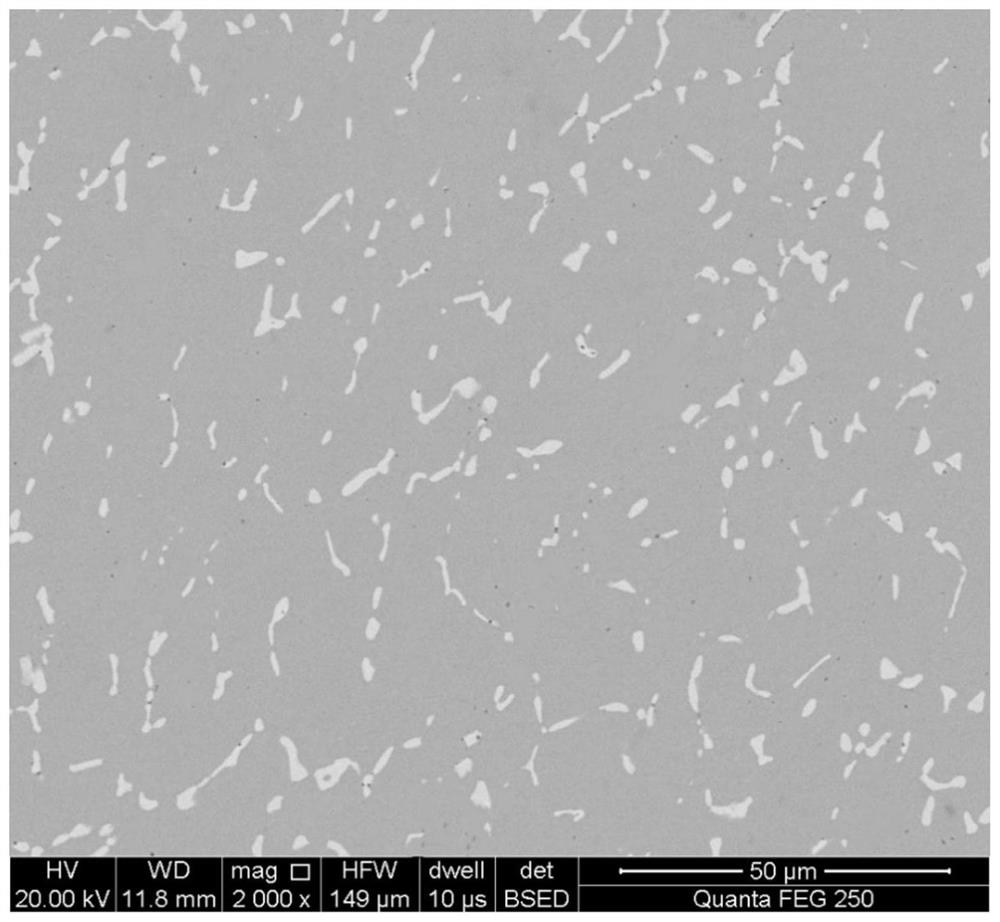

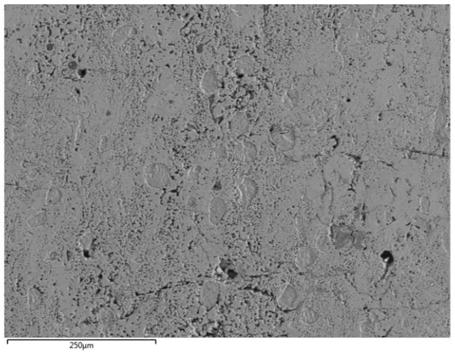

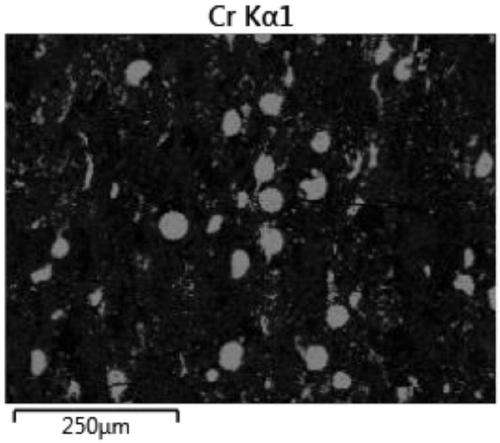

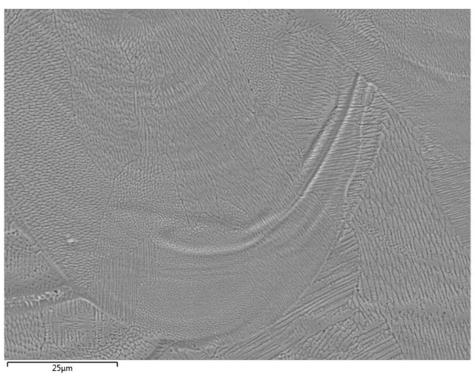

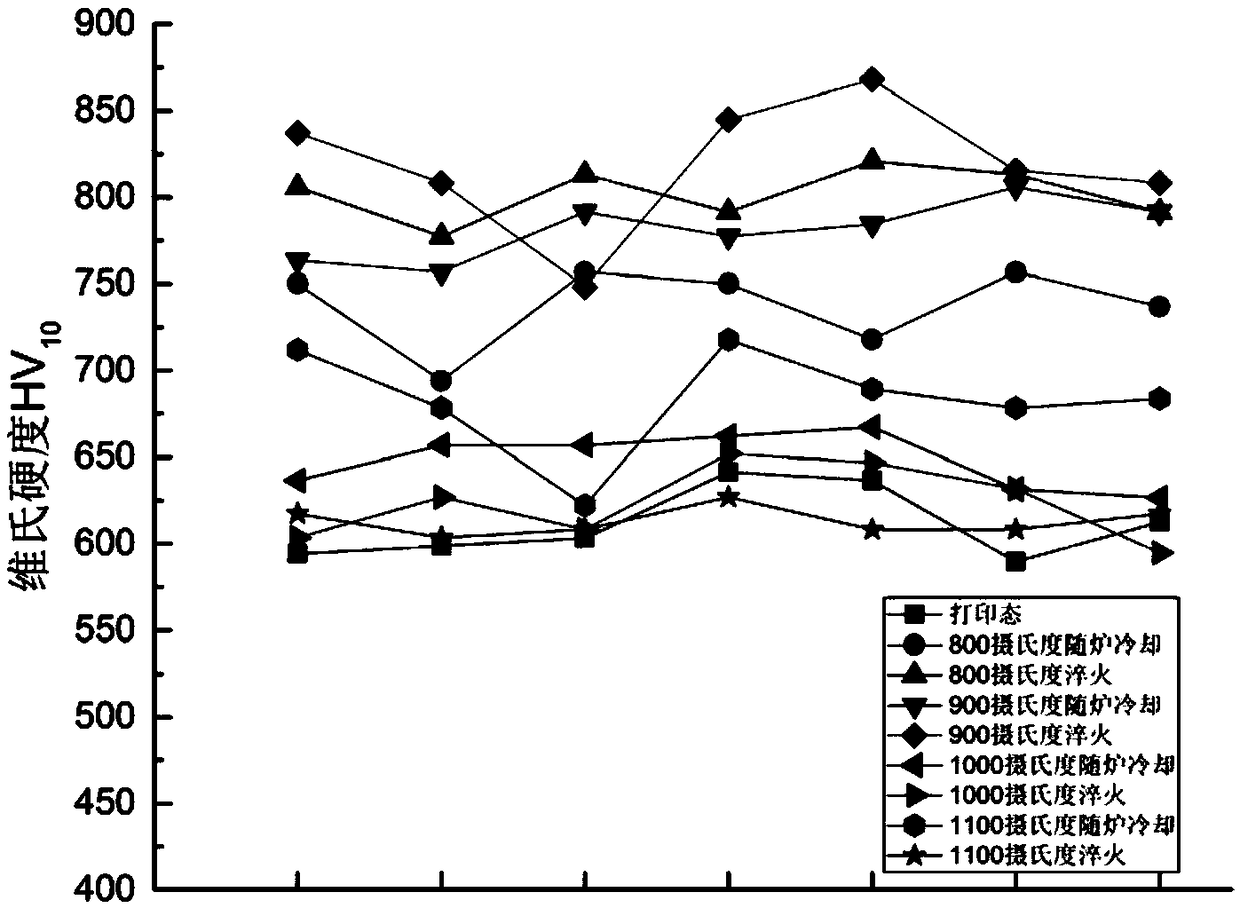

High-speed steel strengthened and hardened through combination of Laves phase and mu phase and preparation method of high-speed steel

ActiveCN111793773AHigh activation energy for diffusionSlow down the rate of aggregate growthTemperingHardness

The invention discloses high-speed steel strengthened and hardened through the combination of the Laves phase and the mu phase and a preparation method of the high-speed steel. The high-speed steel comprises a steel substrate and the strengthening and hardening phases which are dispersed in the steel substrate. The strengthening and hardening phases include the Laves phase and the mu phase. The Laves phase comprises Fe2Nb, Fe2Ti and Fe2W, and the mu phase comprises Fe7Mo6, Co7Mo6, Fe7W6 and Co7W6. According to the high-speed steel, strengthening and hardening operation is conducted through theLaves phase and the mu phase generated in an in-situ mode in the sintering process, the fine mu phase strengthens the substrate so that the substrate can have the higher hardness at high temperature,and the Laves phase with the high hardness and large particles enables the material to have the higher wear resistance. The intermetallic compound strengthening phases generated in an in-situ mode have the good interface relationship with the substrate, and are low in diffusion speed at high temperature, and therefore the material still keeps the high strength, the high toughness and the high heat conductivity coefficient as a large number of alloy elements are added to the material to achieve the high hardness, and the material has the excellent tempering resistance, the excellent high-temperature hardness and the excellent high-temperature strength and has the more excellent performance compared with traditional high-speed steel in the high-temperature and high-speed cutting operation.

Owner:CENT SOUTH UNIV

FeCoCrNi series high-entropy alloy selective laser melting in-situ additive manufacturing method and product

ActiveCN111085689AReduce manufacturing costReduce R&D costsAdditive manufacturing apparatusTransportation and packagingSelective laser meltingHigh entropy alloys

The invention provides a FeCoCrNi series high-entropy alloy selective laser melting in-situ additive manufacturing method. The method comprises the following steps: step 1, mixing mixed elemental metal powder with M-X alloy powder and / or N-Y alloy powder, wherein the mixed elemental metal powder at least comprises two of Fe, Co and Ni metal elemental powder, the M element in the M-X alloy powder is the metal element with the highest melting point in a high-entropy alloy, the N metal element in the N-Y alloy powder is the metal element with the lowest melting point in the high-entropy alloy, Xand Y are at least one metal element in the mixed elemental metal powder, and the molar number of each metal element in the mixed metal powder is the same; and step 2, carrying out laser additive manufacturing through laser 3D printing equipment to obtain the FeCoCrNi series high-entropy alloy. The product is good in forming effect and free of air holes and macroscopic cracks.

Owner:TIANJIN UNIV

High-entropy alloy in-situ preparation method and product by laser additives

ActiveCN108941581AImprove molding efficiencyReduce manufacturing costAdditive manufacturing apparatusHigh entropy alloysThree-phase

The invention overcomes the defect of the prior art and provides a high-entropy alloy in-situ preparation method and product by laser additives, FeCoCrNiTi high-entropy alloy powder preparation and in-situ laser additive fabrication are realized, microphase composition of an original sample is changed, and the hardness of the original sample is successfully improved. The method comprises the stepsof raw material mixing, additive preparing and aging treating. Materials prepared adopting the method are high in shaping efficiency and can be used for preparing parts in complex shapes. By means ofthe high-entropy alloy in-situ preparation method and product by the laser additives, near-net shaping of the materials can be realized, and the production cost of the parts is greatly lowered; the sample shaping effect is good, no pore and macroscopic cracking exist, the sample has no micropore and microcrack and has good density and relatively uniform tissue, and three phase structures coexist;and after high-temperature aging treatment is performed, precipitates are all converted from net shapes to plate strip shapes, obviously, just because of this conversion, the hardness of the sample is improved after the high-temperature aging treatment is performed, and the hardness of the sample cooled by quenching is higher than that of the sample cooled along with a furnace.

Owner:TIANJIN UNIV

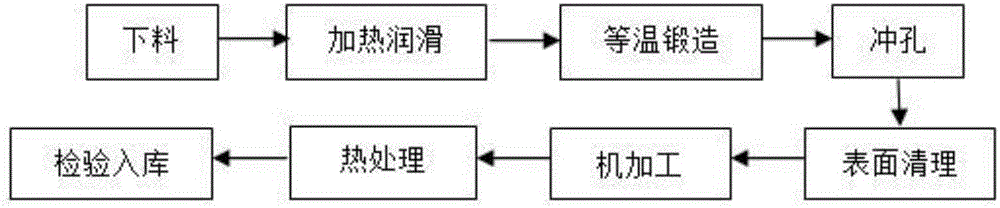

Isothermal forging method of straight bevel gear

InactiveCN105921672AAvoid chillingPromote plastic flowMetal-working apparatusWheelsGear wheelBevel gear

The invention discloses an isothermal forging method of a straight bevel gear. A blank and a mold are heated to roughly consistent temperatures respectively, then the blank is placed into the mold and is subjected to forging molding in the mold at the relatively low strain rate, and the straight bevel gear is obtained through aftertreatment, wherein the relatively low strain rate is lower than 0.1 mm / s, and the mold adopts a closed mold forging structure. According to the method, firstly, the blank and the mold are heated to the equal temperature or basically equal temperatures, so that the chilling effect produced when the temperature of the mold is lower than that of the blank is avoided, and the plastic flow of the blank is improved; secondly, the mold adopts the closed mold forging structure, the blank bears three-dimensional compressive stress in the forging process, and thus molding of the blank is facilitated; thirdly, the strain rate is lower than 0.1 mm / s, accordingly, the deformation amount of the blank in unit time is small, deformation is sufficient, and molding of the blank is more facilitated.

Owner:SHANDONG UNIV +1

Preparation method of covered metal spare parts

InactiveCN101564809ASolve for bond strengthImprove the bonding strength of the interfaceIron powderAdhesive

The invention discloses a preparation method of covered metal spare parts, comprising the steps of: mixing iron powder, nickel powder and chromium powder evenly for pelletization with adhesive; using powder co-injection formation process to form a housing layer part and a core layer part in turn by injection, wherein the feeding materials for two times of injection forming are different; and defatting and sintering the blank formed by injection to obtain the product. The invention provides the basic determination standard of the compatibility of co-sintering by measuring the difference of strain rate of sintering and provides the basic determination standard of the compatibility of co-injection by measuring the difference of viscosity of feeding materials to determine the compatibility determination standard of the covered metal spare part preparation process.

Owner:CENT SOUTH UNIV

Device and method for hydraulic injection filled type extrusion cast forming of molten aluminum magnesium alloy

The invention provides a device and a method for hydraulic injection filled type extrusion cast forming of a molten aluminum magnesium alloy, and relates to a device and a method for extrusion cast forming of an aluminum magnesium alloy, which aim to solve the problems that the conventional extrusion casting device cannot realize near net forming and liquid metal is easily oxidized in the extrusion casting process. In the device, a material pushing barrel is provided with a stepped hole; a smelting furnace and a female die are arranged in parallel on the material pushing barrel; and a first charging ram and a second charging ram are arranged in the large-diameter section of the stepped hole and are connected with a piston rod of a double piston rod hydraulic cylinder respectively. The method comprises the following steps of: arranging the smelting furnace and the female die on the material pushing barrel, forming a cavity between a male die and the female die, and introducing protective gas into the smelting furnace and the material pushing barrel; adjusting the distance between the first charging ram and the second charging ram to realize quantitative pouring; filling the liquid metal; pressurizing the male die to realize the near net forming of workpieces; and making the male die in return stroke, and taking the workpieces out. The device and the method are used for a production process of aluminum magnesium alloy workpieces.

Owner:HARBIN INST OF TECH

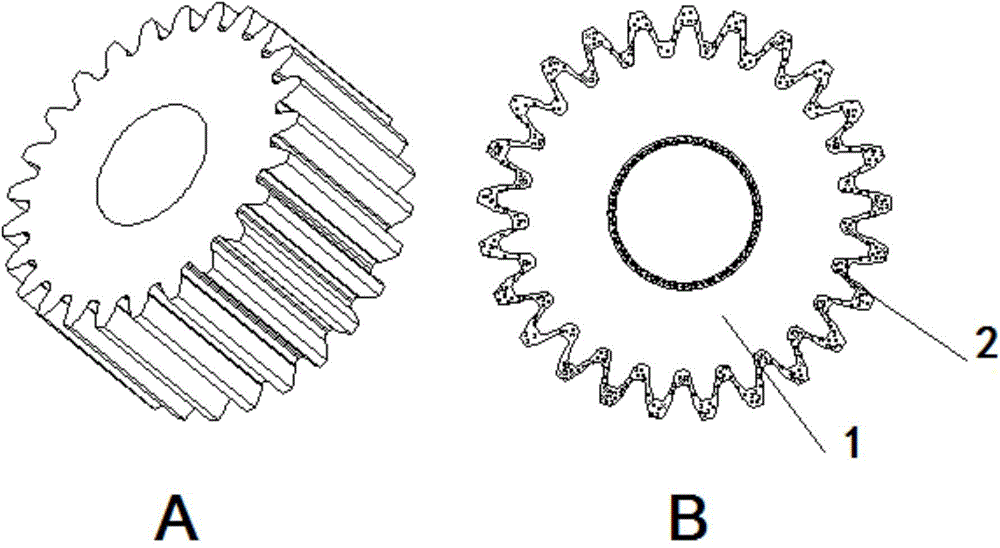

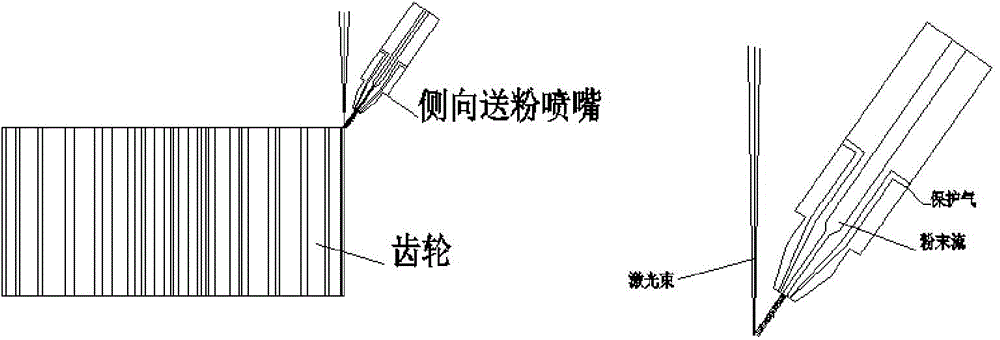

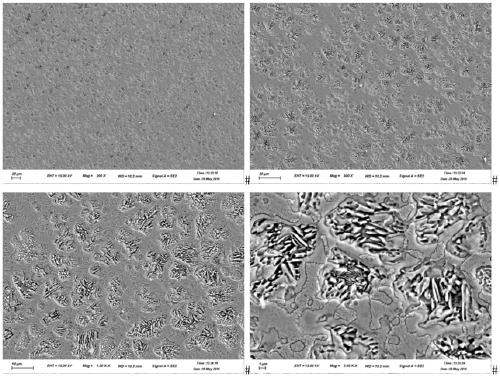

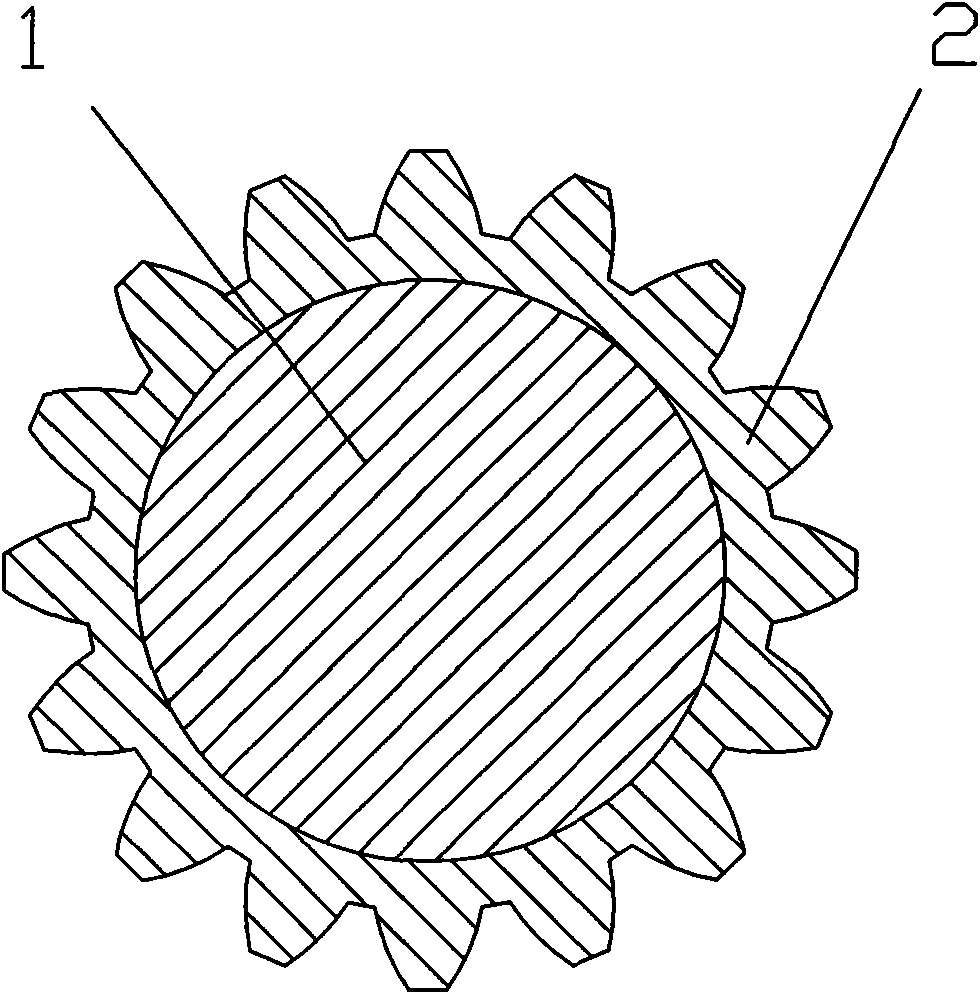

Iron-based gradient structure gear and manufacturing method thereof

ActiveCN101555937AHigh bonding strengthSpread evenlyPortable liftingGearing elementsSurface layerHigh surface

The invention discloses an iron-based gradient structure gear and a manufacturing method thereof; to realized high surface layer hardness and high core / shell layer bonding strength, Fe2Ni is adopted as a core layer and the Fe2Ni added with an alloying element Cr is adopted as a shell layer; through strengthening effect of Cr, sintering / heat treatment is adopted to facilitate surface layer hardness to exceed 40 HRC and realize the metallurgical bonding of the core layer and the shell layer; sintering time is adjusted to realized homogeneous diffusion of Cr outside the interface and core / shell layer bonding strength is higher than 280 MPa.

Owner:CENT SOUTH UNIV

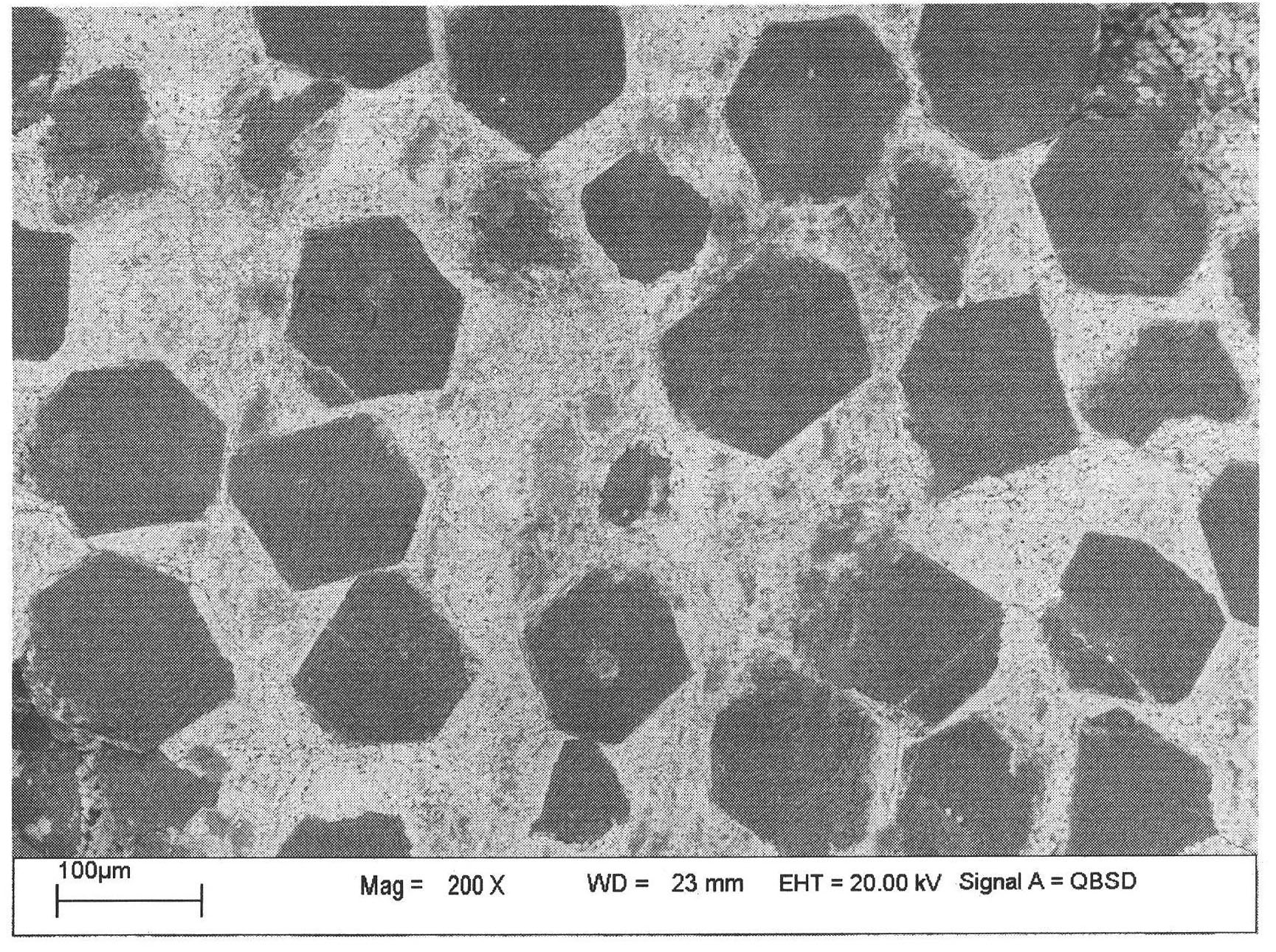

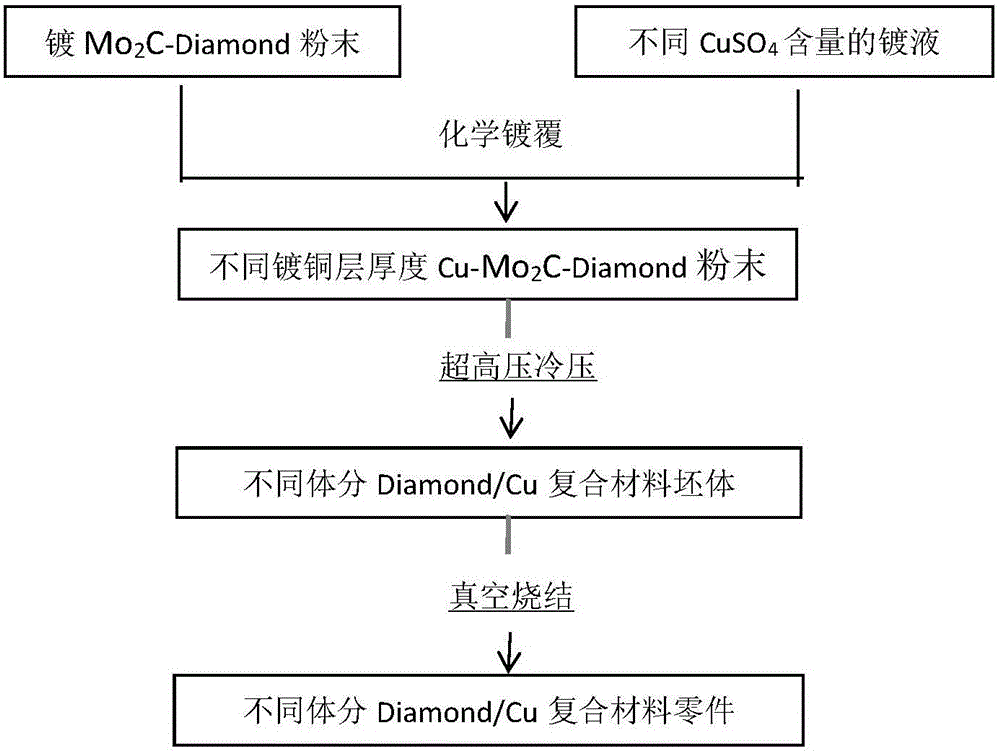

Method for preparing diamond/copper composite material parts with high volume fraction

ActiveCN106583735AVolume fraction adjustmentHigh densityLiquid/solution decomposition chemical coatingUltra high pressureChemical plating

The invention provides a method for preparing diamond / copper composite material parts with high volume fraction. The method comprises the following steps: plating the surface of diamond with a uniform Mo2C layer by using a salt-bath plating technology to improve wettability of the diamond and copper; and then continuing copperizing the surface of the Mo2C layer by using a chemical plating method, and controlling the thickness of a copperizing layer by controlling the content of Cu2+ in a plating solution so as to prepare copper-containing double-plating-layer Cu-Mo2C-Diamond powder with the volume fraction of 30-50 vol.%. The Cu-Mo2C-Diamond powder is formed by an ultra-high-pressure cold pressing method, and Diamond / Cu composite material parts are prepared by a vacuum pressureless sintering method. The method has the advantages that the Diamond / Cu composite material parts with complicated shapes and high volume fractions of (50-70 vol. %) can be directly prepared, meanwhile, composite materials are uniform in structure and high in compactness, the Diamond / Cu composite material parts can be produced in batches, and the production cost is low.

Owner:UNIV OF SCI & TECH BEIJING

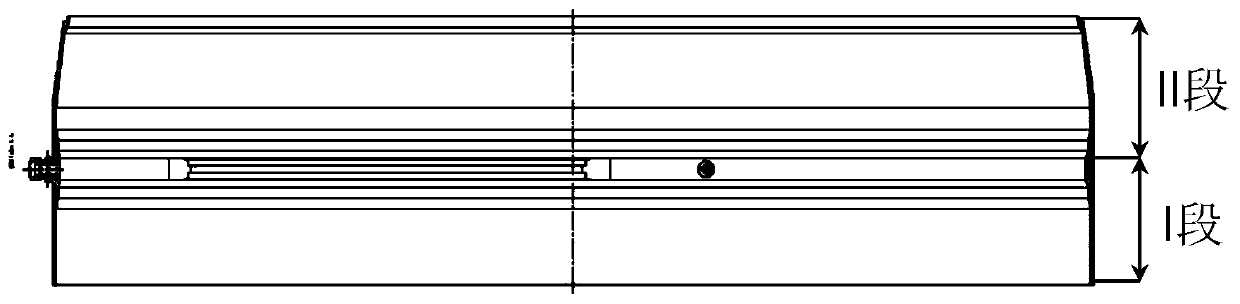

Overall manufacturing method for large-size thin-walled annular belt type oxygen-enhancing frame

ActiveCN111014668AFormed smallLess formingAdditive manufacturing apparatusFurnace typesLaser processingStress relieving

Disclosed is an overall manufacturing method for a large-size thin-walled annular belt type oxygen-enhancing frame. The overall manufacturing method comprises the following steps that a special substrate for laser melting deposition is designed; up-and-down segmentation is carried out along the wall thickness sudden changing portion of the oxygen-enhancing frame; a lower-segment part is formed byselecting a large-power large-scanning-speed laser melting deposition process parameter and a corresponding scanning strategy; laser machining program codes of all slice layers of the upper and lowersegments are obtained by utilizing slice software and are introduced into equipment to carry out laser melting deposition forming of the lower-segment portion first; stress relieving annealing is carried out after outward taking; then the lower segment end surface is taken as a substrate to complete deposition of the upper-segment portion, and heat treatment and machining are carried out to obtaina part under a final state. The overall manufacturing method solves the problems that a current forging and machining method is long in machining period, low in material utilization ratio and severein stress deformation, and the high-performance, small-deformation and small-allowance forming of the oxygen-enhancing frame part is realized.

Owner:XIAN SPACE ENGINE CO LTD

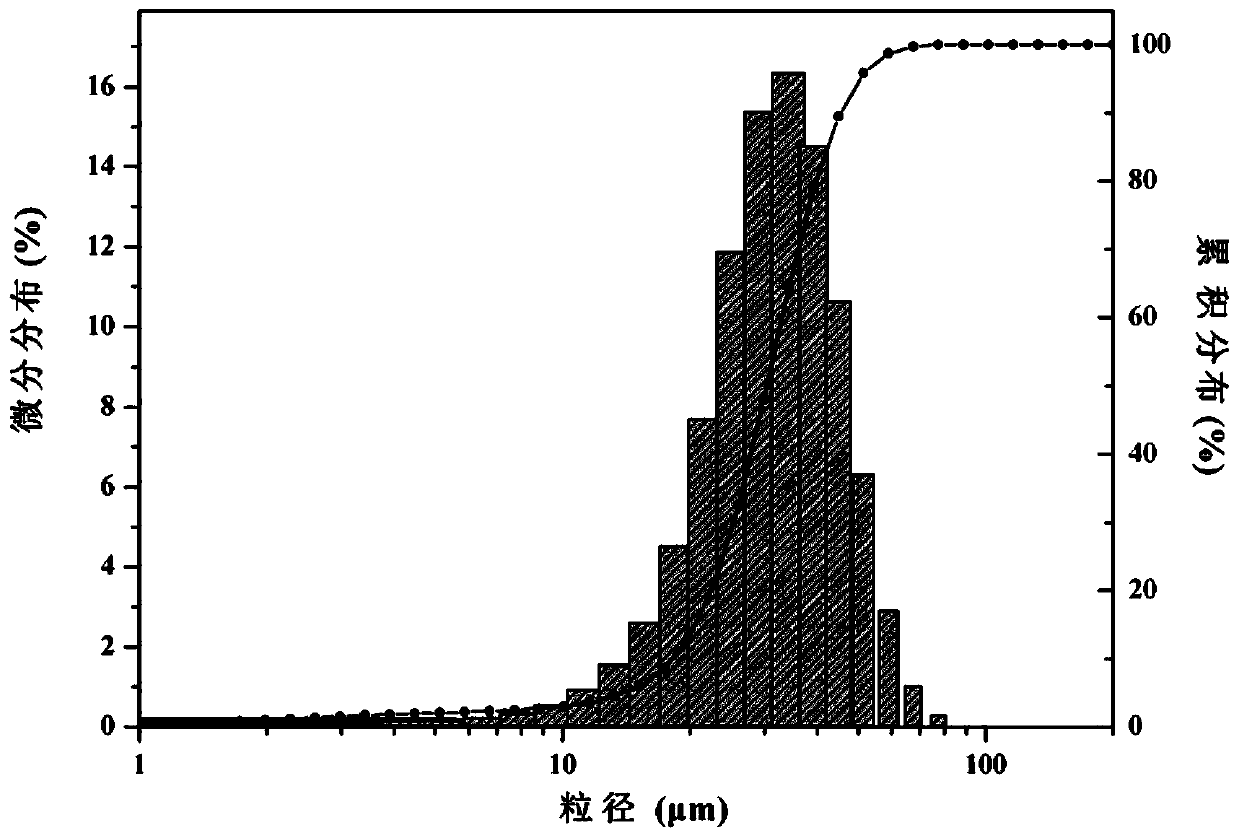

Electronic beam added material manufacturing method of molybdenum base alloy powder

ActiveCN110181048AHigh densityUniform tissueAdditive manufacturing apparatusIncreasing energy efficiencyAlloyAdditive layer manufacturing

The invention discloses an electronic beam added material manufacturing method of molybdenum base alloy powder. The particle size of the used molybdenum base alloy powder is 55-85 microns; and when powder layers are scanned by electronic beams, a twice scanning mode is adopted. The molybdenum base alloy electronic beam added material manufacturing process finds out manufacturing process parametersof added materials with the highest compactness, and adopts the twice scanning mode to solve the nodulizing and powder splashing problems in the manufacturing of the electronic beam added materials to improve the compactness of components to the casting level.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com